Page 1

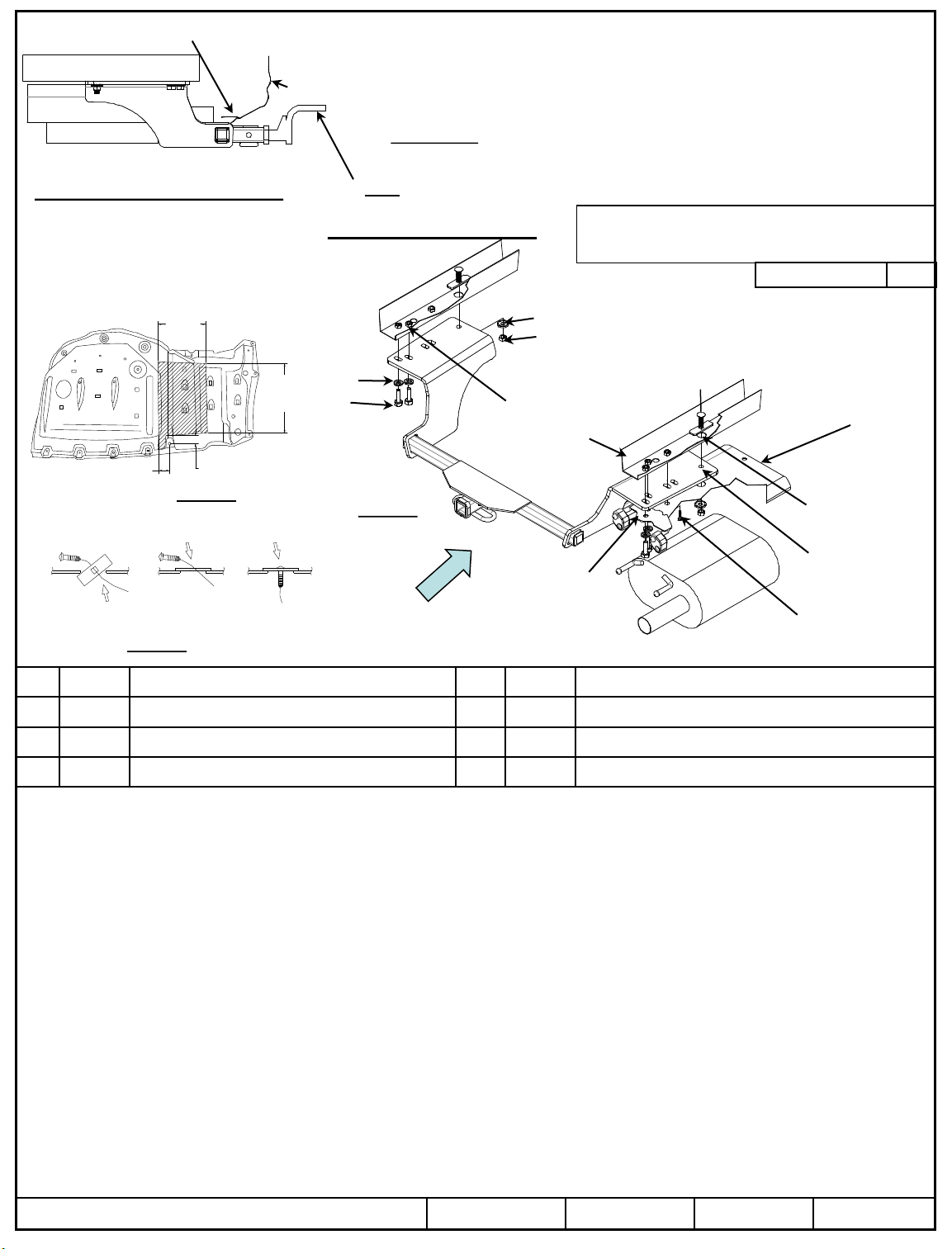

Appearance panel

Installation Instructions

Part Numbers:

Fascia

Toyota Camry shown

Hitch Shown In Proper Position

Equipment Required: Utility Knife,

Lubricant or soapy water

Fastener Kit: 36540F

Wrenches: 10mm, 12mm, 14mm,17mm, 11/16”

Drill Bits: ½”, 1”

9”

11”

2”

Appearance panel trim

1-1/2”

Figure 3

Toyota Camry page 1

Toyota Avalon page 2

Drawbar Kit:

36071

Drawbar must be used in the

RISE position only.

Toyota Camry install

k

j

Figure 1

Existing weld nuts

Frame rail

n

o

36540

90031

06160

Do Not Exceed Lower of Towing Vehicle

Manufacturer’s Rating or

3500 LB (1589 Kg) Max Gross Trailer Weight

300 LB (136 Kg) Max Tongue Weight

Accessory Rating

Wiring Access Location: PC3 & 4

l

m

Heat

shield

1” hole to be

drilled both sides

B

Battery bracket

Exhaust hanger

A. Insert bolt and

Block into frame

B. Align block

on access hole

C. Pull bolt

thru block

Forward

Figure 2

Qty. (4) Hex Bolt M10 X 1.25 X 40 CL8.8

j

Qty. (5) Conical Washer 3/8”

k

Qty. (2) Carriage Bolt 7/16-14 X 1.5 GR5

l

Qty. (2) .915 X 3.000 X 10GA Spacer

m

Note: There are different appearance panels, due to different models. Some vehicles will require no trimming of appearance panel.

1. Remove appearance panel if the panel covers the drivers side frame rails. Trim or remove panel as shown, obtain Vehicle Owner’s approval before trimming.

Note; if panel is not reinstalled there will be a ¾”-1” gap between hitch and fascia. See Figure 3.

2. Lower exhaust by removing two bolts at exhaust hanger bracket, and remove rubber isolator on the forward side of the exhaust. Spraying a lubricant or soapy

water on the metal hanger rod and the rubber isolator helps removal. Remove the rubber isolator from the muffler leaving them attached to the exhaust hanger

bracket. On vehicles with dual exhaust repeat process on both sides.

3. Remove heat shield.

4. Raise hitch into position over exhaust pipes and install M10 hex bolts. Exhaust hanger bracket not necessary at this step. (If installing on the Hybrid model,

there is a battery bracket on the passenger side of the vehicle and instead of drilling a hole in the frame simply remove the rearmost bolt from the

bracket attached to the frame and attach hitch using the supplied M8 x 40mm hex bolt. Drilling is still required on the driver’s side of the vehicle.)

5. Using the hitch as a template mark and center punch the (2) holes on both sides. Drill ½” pilot hole both sides.

6. Lower hitch and drill 1” hole in frame rail. Mark and drill heat shield for the 7/16 Carriage bolt using the frame rail as template.

7. Reinstall appearance panel.

8. Insert carriage bolt and spacer as shown leaving pull wire attached. See Figure 2.

9. Raise hitch into position threading the pullwire through the bracket. Install M10 bolts as shown on driver’s side. Remove pullwire and install conical washers

and nuts on passenger side. Install the exhaust hanger bracket on the passenger side, then remove pullwire and install conical washers and nuts on driver’s side.

See Figure 1.

10. Tighten all fasteners to the required torque specification.

11. Reinstall the heat shield/s using M6 bolt as needed.

12. Raise exhaust back into position.

Note: check hitch frequently, making sure all fasteners and ball are properly tightened. If hitch is removed, plug all holes in trunk pan or other body panels to prevent

entry of water and exhaust fumes. A hitch or ball which has been damaged should be removed and replaced. Observe safety precautions when working beneath a

vehicle and wear eye protection. Do not cut access or attachment holes with a torch.

This product complies with safety specifications and requirements for connecting devices and towing systems of the state of New York, V.E.S.C. Regulation V-5 and

SAE J684.

© 2014 Cequent Performance Products, Inc

PRINTED IN MEXICO

bracket

Note: Fasteners typical both sides of hitch.

Qty. (2) Conical Washer 7/16”

n

Qty. (2) Hex Nut 7/16-14

o

Qty. (1) Hex Bolt, M8-1.25 x 50 CL10.9

p

Qty. (2) Hex Bolt M6 X 1.0 X 40

q

Tighten all 7/16 GR5 fasteners with torque wrench to 50 Lb.-Ft. (68 N*M)

Tighten all M8 CL10.9 fasteners with torque wrench to 27 Lb.-Ft. (37 N*M)

Tighten all M10 CL8.8 fasteners with torque wrench to 38 Lb.-Ft. (52 N*M)

Sheet of 6 36540N 2/10/14 Rev. A

1

connection pointHybrid Only

q

Form F206 Rev A 5605

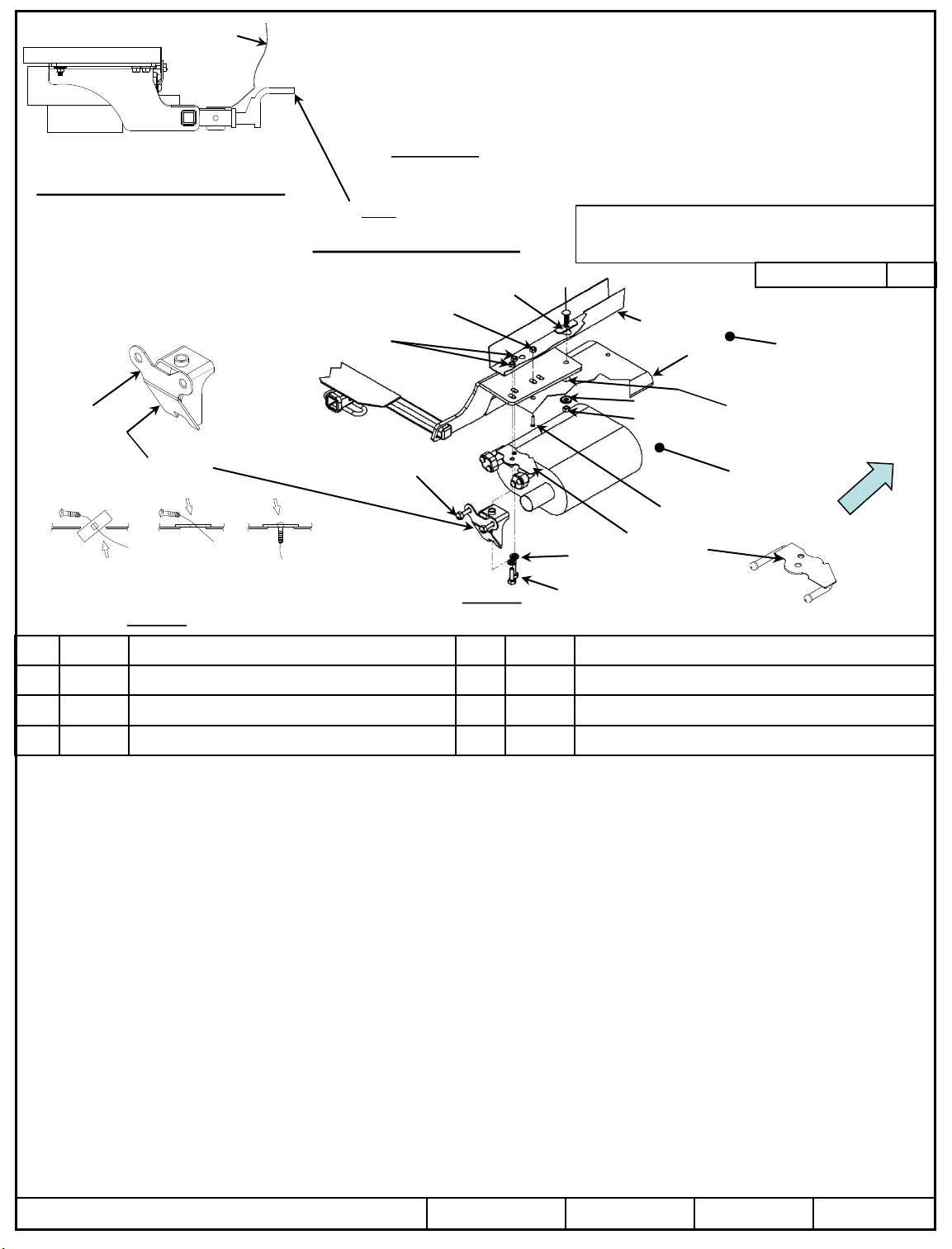

Page 2

Fascia

Installation Instructions

Part Numbers:

Toyota Avalon view

Hitch Shown In Proper Position

Equipment Required: Strap or bungee

cords to support exhaust

Fastener Kit: 36514F

Wrenches: 10mm, 12mm, 14mm,

17mm, 6” socket extension, 11/16”

Drill Bits: ¼”, 1”, ½”

Side

specific

Vehicle

support

bracket

A. Insert bolt and

Block into frame

B. Align block

on access hole

Figure 2

Toyota Avalon install

Existing M10

weld nuts

C. Pull bolt

thru block

Toyota Camry page 1

Toyota Avalon page 2

Drawbar Kit:

36071

Drawbar must be used in the

RISE position only.

1” hole to be

drilled both sides

Forward weld nut

End panel

bolts

Do Not Exceed Lower of Towing Vehicle

3500 LB (1589 Kg) Max Gross Trailer Weight

300 LB (136 Kg) Max Tongue Weight

l

m

k

Figure 1

j

36540

90031

06160

Manufacturer’s Rating or

Accessory Rating

Wiring Access Location: PC3 & 4

Frame rail

Heat

shield

n

2nd Forward rubber

isolator bracket

location

Drill ½” to ¾” hole

o

1st Forward rubber

isolator bracket

location

q

Exhaust hanger

bracket

Note: Fasteners typical both sides of hitch.

Forward

B

Qty. (4) Hex Bolt M10 X 1.25 X 40 CL8.8

j

Qty. (5) Conical Washer 3/8”

k

Qty. (2) Carriage Bolt 7/16-14 X 1.5 GR5

l

Qty. (2) .915 X 3.000 X 10GA Spacer

m

1. Remove appearance panel and return panel to owner.

2. Lower exhaust by removing two bolts at the end panel and two bolts on the frame rail exhaust hanger bracket each side. End panel bolts to be reinstalled.

3. Support the exhaust to prevent damage using straps, bungee cords or other means. Remove 1st rubber isolator bracket on the forward passenger side of the

exhaust and the next 2nd forward rubber isolator bracket.

4. Remove heat shields.

5. Raise (slide) hitch into position over exhaust pipes and temporarily install M10 hex bolts for support. Exhaust hanger bracket not necessary at this step. (If

installing on the Hybrid model, there is a battery bracket on the passenger side of the vehicle and instead of drilling a hole in the frame simply remove

the rearmost bolt from the bracket attached to the frame and attach hitch using the supplied M8 x 40mm hex bolt. Drilling is still required on the

driver’s side of the vehicle. Refer to figure on Camry page.)

6. Using the hitch as a template mark and center punch the (1) holes on both sides. Drill ¼” pilot hole both sides.

7. Lower hitch and drill 1” hole in frame rail. Mark and drill heat shield for the 7/16 carriage bolt using the frame rail as template. Set aside for later install.

8. Insert carriage bolt and spacer into the frame as shown leaving pull wire attached. See Figure 2.

9. Raise hitch into position threading the pullwire through the bracket. Install at least one M10 bolts as shown both sides.

10. Remove pullwire and install conical washers and nuts on both side. Center hitch and Torque 7/16” fasteners to required specification. Install heat shield.

11. Install the 1st & 2nd forward rubber isolator brackets.

12. Remove M10 bolts and install the exhaust hanger brackets thru the forward weld nut both sides (item 1).

13. Install vehicle support bracket re-using the existing end panel bolts

and (item 1) remaining M10 bolts.

14. Tighten all fasteners to the required torque specification.

Note: check hitch frequently, making sure all fasteners and ball are properly tightened. If hitch is removed, plug all holes in trunk pan or other body panels to prevent

entry of water and exhaust fumes. A hitch or ball which has been damaged should be removed and replaced. Observe safety precautions when working beneath a vehicle

and wear eye protection. Do not cut access or attachment holes with a torch.

This product complies with safety specifications and requirements for connecting devices and towing systems of the state of New York, V.E.S.C. Regulation V-5 and

SAE J684.

© 2014 Cequent Performance Products, Inc

PRINTED IN MEXICO

Sheet of 6 36540N 2/10/14 Rev. A

Qty. (2) Conical Washer 7/16”

n

Qty. (2) Hex Nut 7/16-14

o

Qty. (1) Hex Bolt, M8-1.25 x 50 CL10.9

p

Qty. (2) Hex Bolt M6 X 1.0 X 40

q

Tighten all 7/16 GR5 fasteners with torque wrench to 50 Lb.-Ft. (68 N*M)

Tighten all M8 CL10.9 fasteners with torque wrench to 27 Lb.-Ft. (37 N*M)

Tighten all M10 CL8.8 fasteners with torque wrench to 38 Lb.-Ft. (52 N*M)

2

Form F206 Rev A 5605

Page 3

Panneau décoratif

Carénage

Attelage montré dans la position

appropriée

Équipement requis : Lubrifiant ou

eau savonneuse

Visserie : 36514F

Clés : 10mm, 12mm, 14mm, 17mm

Mèches : ½”, 1”

9”

Installation sur Toyota Camry

11”

Instructions d’installation

Toyota Camry page 3

Toyota Avalon page 4

Ensemble de barre de remorquage :

La barre de remorquage doit

être utilisée dans la position

ÉLEVÉE seulement.

36071

Ne pas excéder les spécifications de poids

du fabricant du véhicule de remorquage, ni

3500 LB (1589 kg) Poids brut max. de la remorque

300 LB (136 kg) Poids max. au timon

n

o

k

j

Écrous à souder existants

Longeron

Numéros de pièce :

36514

90079

06139

Capacité de l'accessoire

Points d'accès au câblage : PC3, PC4

l

m

Écran thermique

B

2”

Panneau de garniture décoratif

A. Insérer un boulon

et son bloc dans le

cadre.

Qté (4)

j

Qté (5) Rondelle Conique 3/8”

k

Qté (2)

l

Qté (2)

m

Nota: Les panneaux décoratifs peuvent différer selon les modèles. Certains véhicules n'exigeront pas de découper le panneau décoratif.

1. Enlever le panneau décoratif s'il recouvre les longerons côté conducteur. Découper ou retirer le panneau comme illustré, obtenir l'autorisation du propriétaire du

véhicule avant de découper. Nota : Si le panneau n'est pas remis en place, l'espace entre l'attelage et le carénage sera de ¾ à 1 po. Voir Figure 3.

2. Abaisser l'échappement en enlevant deux (2) boulons de la ferrure du support d'échappement, puis enlever l'isolateur en caoutchouc du côté extérieur de

l'échappement. La vaporisation d’un lubrifiant ou d’eau savonneuse sur la tige du support métallique et l’isolateur en caoutchouc facilite l’enlèvement. Détacher

l'isolateur en caoutchouc du silencieux, en les laissant fixés à la ferrure du support d'échappement.

3. Enlever l’écran thermique.

4. Soulever l’attelage en position au-dessus des tuyaux d'échappement et poser les boulons hexagonaux. La ferrure de support d'échappement n'est pas nécessaire à cette

étape. (Si vous installez sur le modèle hybride, il est un support de batterie sur le côté passager du véhicule et au lieu de percer un trou dans le châssis suffit

de retirer le plus en arrière boulon du support fixé au châssis et attacher l'attelage à l'aide du M8 x 40mm fourni boulon. forage est encore nécessaire sur le

côté du conducteur du véhicule.)

5. En utilisant l’attelage comme gabarit, marquer au pointeau l’emplacement des deux (2) trous de chaque côté. Percer un trou de guidage ½ po des deux côtés.

6. Abaisser l'attelage et percer un trou de 1 po dans le longeron. En se servant du longeron comme gabarit, marquer et percer l'écran thermique pour le passage du

boulon de carrosserie 7/16.

7. Réinstaller le panneau décoratif.

8. Insérer un boulon de carrosserie et un espaceur comme illustré en les laissant liés au fil de tirage. Voir Figure 2.

9. Soulever l’attelage en position en acheminant le fil de tirage à travers le support. Poser les boulons M10 comme illustré du côté conducteur. Retirer le fil de tirage et

poser des rondelles coniques et des écrous du côté passager. Poser la ferrure de support d'échappement côté passager, puis retirer le fil de tirage et poser des rondelles

coniques et des écrous côté conducteur. Voir Figure 1.

10.Serrer toute la visserie selon les spécifications de couples de serrage.

11.Réinstaller l'écran thermique à l'aide d'un boulon M6 le cas échéant.

12.Soulever l’échappement et le remettre en place.

Nota : Vérifier l’attelage fréquemment, en s’assurant que toutes les fixations et la boule sont serrées adéquatement. Si l’attelage est enlevé, boucher tous les trous

percés dans le coffre ou la carrosserie afin de prévenir l’infiltration d’eau ou de gaz d’échappement. Un attelage ou une boule endommagés doivent être enlevés

et remplacés. Observer les mesures de sécurité appropriées en travaillant sous le véhicule et porter des lunettes de protection. Ne jamais utiliser une torche pour

découper un accès ou un trou de fixation. Ce produit est conforme aux normes V-5 et SAE J684 de la V.E.S.C. (État de New York) concernant les spécifications

en matière de sécurité des systèmes d’attelage.

Figure 2

Boulon Hexagonal M10 X 1.25 X 40 CL8.8

Boulon de Carrosserie 7/16-14 x 1.5 GR5

.915 X 3.000 X 10GA Espaceur

1-1/2”

Figure 3

B. Aligner le

bloc sur le trou

d'accès.

C. Tirer le boulon

à travers le bloc.

Avant

Figure 1

Ferrure de support

d'échappement

n

o

p

q

Trou de 1 po à

percer des deux

côtés

q

Nota : Visserie similaire des deux côtés du véhicule.

Qté (2) Rondelle Conique 7/16”

Qté (2) Écrou Hex. 7/16-14

Qté (1)

Qté (2)

Boulon Hexagonal, M8-1.25 x 50 CL10.9

Boulon Hexagonal M6 X 1.0 X 40

Serrer toute la visserie 7/16 GR5 au couple de 50 lb-pi (68 N.m)

Serrer toute la visserie M8 CL10.9 au couple de 27 lb-pi (37 N.m)

Serrer toute la visserie M10 CL8.8 au couple de 38 lb-pi (52 N.m)

© 2014 Cequent Performance Products, Inc

PRINTED IN MEXICO

Sheet of 6 36540N 2/10/14 Rev. A

3

Form F206 Rev A 5605

Page 4

Carénage

Instructions d’installation

Numéros de pièce :

Vue de la Toyota Avalon

Attelage montré dans la position

appropriée

Équipement requis : Sangles ou tendeurs

élastiques pour supporter l'échappement

Visserie : 36514F

Clés : 10mm, 12mm, 14mm,

17mm, rallonge de cliquet 6”,

11/16”

Mèches : ¼”, 1”, ½”

Adapté pour

le côté

A. Insérer un

boulon et son bloc

dans le cadre.

Ferrure de

support du

véhicule

B. Aligner le

bloc sur le trou

d'accès.

Figure 2

C. Tirer le boulon

à travers le bloc.

Toyota Camry page 3

Toyota Avalon page 4

Ensemble de barre de remorquage :

36071

La barre de remorquage

doit être utilisée dans la

position ÉLEVÉE

seulement.

Installation sur Toyota Avalon

Trou de 1 po à percer

des deux côtés

Écrou à souder avant

Écrous à souder

M10 existants

Boulons de

panneau

d'extrémité

Figure 1

Nota : Visserie similaire des deux côtés du véhicule.

Ne pas excéder les spécifications de poids du fabricant

du véhicule de remorquage, ni

3500 LB (1589 kg) Poids brut max. de la remorque

300 LB (136 kg) Poids max. au timon

l

m

Ferrure de support

d'échappement

k

j

Longeron

n

o

q

36514

90079

06139

Capacité de l'accessoire

Points d'accès au câblage : PC3 et 4

Écran

thermique

2e emplacement du support

de l'isolateur en

caoutchouc avant

Percer un trou de ½ à ¾ po

1er emplacement

du support de

l'isolateur en

caoutchouc avant

B

Avant

Qté (4)

j

Qté (5) Rondelle Conique 3/8”

k

Qté (2)

l

Qté (2)

m

1. Enlever le panneau décoratif et le remettre au propriétaire.

2. Abaisser l'échappement en enlevant deux boulons du panneau d'extrémité et deux boulons de la ferrure du support d'échappement sur le longeron, de chaque côté.

Boulons de panneau d'extrémité à réinstaller.

3. Pour prévenir les dommages, soutenir l’échappement à l'aide de sangles, de tendeurs élastiques ou d'autres moyens. Enlever le 1er support de l'isolateur en

caoutchouc du côté passager avant de l'échappement puis le 2e support de l'isolateur en caoutchouc avant.

4. Enlever les écrans thermiques.

5. Soulever (glisser) l’attelage en position au-dessus des tuyaux d'échappement et poser temporairement les boulons hexagonaux M10 à des fins de support. La

ferrure de support d'échappement n'est pas nécessaire à cette étape. (Si vous installez sur le modèle hybride, il est un support de batterie sur le côté passager

du véhicule et au lieu de percer un trou dans le châssis suffit de retirer le plus en arrière boulon du support fixé au châssis et attacher l'attelage à l'aide

du M8 x 40mm fourni boulon. forage est encore nécessaire sur le côté du conducteur du véhicule. Reportez-vous à la figure à la page de Camry.)

6. En utilisant l’attelage comme gabarit, marquer au pointeau l’emplacement des deux (1) trous de chaque côté. Percer un trou de guidage ¼ po des deux côtés.

7. Abaisser l'attelage et percer un trou de 1 po dans le longeron. En se servant du longeron comme gabarit, marquer et percer l'écran thermique pour le passage du

boulon de carrosserie 7/16. Conserver pour installation ultérieure.

8. Insérer un boulon de carrosserie et un espaceur dans le cadre comme illustré, en les laissant liés au fil de tirage. See Figure 2.

9. Soulever l’attelage en position en acheminant le fil de tirage à travers le support. Poser au moins un boulon M10 comme illustré, des deux côtés.

10. Retirer le fil de tirage et poser des rondelles coniques et des écrous des deux côtés. Centrer l'attelage et serrer la visserie 7/16 po selon les spécifications

requises. Installer l’écran thermique.

11. Poser les 1er et 2e supports d'isolateur en caoutchouc avant.

12. Enlever les boulons M10 et poser les ferrures des supports d'échappement sur l'écrou à souder avant, des deux côtés (article 1).

13. Poser la ferrure de support du véhicule en réutilisant les boulons du panneau d'extrémité existants et (article 1) les boulons M10 restants.

14. Serrer toute la visserie selon les spécifications de couples de serrage.

Nota : Vérifier l’attelage fréquemment, en s’assurant que toutes les fixations et la boule sont serrées adéquatement. Si l’attelage est enlevé, boucher tous les trous percés

dans le coffre ou la carrosserie afin de prévenir l’infiltration d’eau ou de gaz d’échappement. Un attelage ou une boule endommagés doivent être enlevés et remplacés.

Observer les mesures de sécurité appropriées en travaillant sous le véhicule et porter des lunettes de protection. Ne jamais utiliser une torche pour découper un accès ou

un trou de fixation. Ce produit est conforme aux normes V-5 et SAE J684 de la V.E.S.C. (État de New York) concernant les spécifications en matière de sécurité des

systèmes d’attelage.

© 2014 Cequent Performance Products, Inc

PRINTED IN MEXICO

Boulon Hexagonal M10 X 1.25 X 40 CL8.8

Boulon de Carrosserie 7/16-14 x 1.5 GR5

.915 X 3.000 X 10GA Espaceur

Sheet of 6 36540N 2/10/14 Rev. A

Qté (2) Rondelle Conique 7/16”

n

Qté (2) Écrou Hexagonal 7/16-14

o

p

q

Qté (1)

Qté (2)

4

Boulon Hexagonal, M8-1.25 x 50 CL10.9

Boulon Hexagonal M6 X 1.0 X 40

Serrer toute la visserie 7/16 GR5 au couple de 50 lb-pi (68 N.m)

Serrer toute la visserie M8 CL10.9 au couple de 27 lb-pi (37 N.m)

Serrer toute la visserie M10 CL8.8 au couple de 38 lb-pi (52 N.m)

Form F206 Rev A 5605

Page 5

Panel de apariencia

Instrucciones de instalación

Números de partes:

El enganche se muestra en la

posición correcta

Equipo necesario: Cuchillo utilitario,

lubricante o agua jabonosa

Kit de tornillos: 36514F

Llaves: 10mm, 12mm, 14mm, 17mm

Brocas de taladro: ½”, 1”

9".

11"

2"

Recorte del panel de

1-1/2”

Figura 3

apariencia

Placa

protectora

Kit de barra de tracción:

La barra de tracción se debe

usar en la posición levantada

únicamente.

Toyota Camry página 5

Toyota Avalon página 6

36071

Instalación en el Toyota Camry

n

o

k

j

Figura 1

Tuercas de soldar

existentes

Larguero

del

bastidor

36514

90079

06139

No supere el valor inferior entre la calificación del

fabricante del vehículo de remolque o

3500 LB (1589 Kg) Peso máximo bruto del remolque

300 LB (136 Kg) Peso máximo de la horquilla

Calificación de

accesorios

Ubicación del acceso al cableado: PC3 y 4

l

m

Protector

de calor

Orificio de 1” a

perforar en

ambos lados

B

A. Inserte el perno y

bloque en el

bastidor

Cant. (4) Perno Hexagonal M10 x 1.25 x 40 CL8.8

j

Cant. (5) Arandela Cónica 3/8"

k

Cant. (2) Perno de Carruaje, 7/16-14 X 1.5 GR5

l

Cant. (2) .915 X 3.000 X 10GA Espaciador

m

Nota: Existen diferentes paneles de apariencia para los diferentes modelos. Algunos vehículos no requieren recorte del panel de apariencia.

1. Retire el panel de apariencia si éste cubre los largueros del bastidor del lado del conductor. Recorte o retire el panel como se muestra, obtenga la aprobación del

propietario del vehículo antes de recortar. Nota; si el panel no se vuelve a instalar habrá un espacio de ¾”-1” entre el enganche y la placa protectora. Ver Figura 3.

2. Baje el escape al retirar dos pernos en el soporte del gancho del escape y retire el aislante de goma en el lado delantero del escape. Rociar un lubricante o agua

jabonosa en el vástago del gancho de metal y el aislante de goma ayuda para el desmonte. Retire el aislante de goma del silenciador dejándolo unido al soporte del

gancho del escape.

3. Retire el protector de calor.

4. Levante el enganche a su posición sobre los tubos de escape e instale los pernos hexagonales M10. El soporte del gancho del escape no es necesario en este paso. (Si

se instala en el modelo híbrido, hay un soporte de la batería en el lado del pasajero del vehículo y en lugar de la perforación de un agujero en la trama,

simplemente retire el perno más posterior del soporte fijado al bastidor y coloque el enganche mediante el suministro de M8 x 40mm perno. perforación sigue

siendo necesaria en el lado del conductor del vehículo.)

5. Usando el engancho como plantilla marque y perfore los dos (2) orificios en ambos lados. Perfore el orificio piloto de ½” en ambos lados.

6. Baje el enganche y perfore un orificio de 1” en el larguero del bastidor. Marque y perfore el protector de calor para el perno de carruaje 7/16 usando el larguero del

bastidor como plantilla.

7. Vuelva a instalar el panel de apariencia.

8. Inserte el perno de carruaje y el espaciador como se muestra dejando el cable de halar unido. Ver Figura 2.

9. Levante el enganche a su posición ensartando el cable de halar a través del soporte. Instale los pernos M10 como se muestra en el lado del conductor. Retire el cable

de halar e instale arandelas cónicas y tuercas en el lado del pasajero. Instale el soporte del gancho del escape en el lado del pasajero, luego retire el cable de halar e

instale arandelas cónicas y tuercas en el lado del conductor. Ver Figura 1.

10.Apriete todos los tornillos según las especificaciones de torsión exigidas.

11.Vuelva a instalar el protector de calor usando el perno M6 según sea necesario.

12.Levante el escape de nuevo a su posición.

Nota: Revise el enganche con frecuencia, verificando que todos los tornillos y la bola estén correctamente apretados. Si se quita el enganche tape todos los orificios en el colector del baúl u otros

paneles de la carrocería para evitar la entrada del agua y los gases del escape. Se debe retirar y reemplazar un enganche o bola que se haya dañado. Observe las precauciones de seguridad al

trabajar por debajo del vehículo y use protección visual. No corte los orificios de acceso o accesorios con soplete.

Este producto cumple con las especificaciones y requisitos de seguridad para conectar dispositivos y sistemas de remolque del estado de Nueva York, V.E.S.C. Regulación V-5 y SAE J684.

© 2014 Cequent Performance Products, Inc

PRINTED IN MEXICO

B. Alinee el

bloque en el

orificio de acceso

Figura 2

C. Hale el

perno a través

del bloque

Frente

Soporte del

gancho del

escape

n

o

p

q

Apriete todos los tornillos M8 CL10.9 con una llave de torsión a 27 Lb.-pies. (37 N*M)

Apriete todos los tornillos M10 CL8.8 con una llave de torsión a 38 Lb.-pies. (52 N*M)

Sheet of 6 36540N 2/10/14 Rev. A

Cant. (2) Arandela Cónica 7/16"

Cant. (2) Tuerca Hexagonal, 7/16-14

Cant. (1) Perno Hexagonal, M8-1.25 x 50 CL10.9

Cant. (2) Perno Hexagonal M6 1.0 x 40

Apriete todos los tornillos 7/16 GR5 con una llave de torsión a 50 Lb.-pies (68 N*M)

5

Nota: Tornillos iguales en ambos lados del enganche.

q

Form F206 Rev A 5605

Page 6

Placa protectora

Instrucciones de instalación

Números de partes:

Vista del Toyota Avalon

El enganche se muestra en la

posición correcta

Equipo necesario: Correa o cuerdas

elásticas para apoyar escape

Kit de tornillos: 36514F

Llaves: 10mm, 12mm, 14mm, 17mm,

extensión de tubo de 6”, 11/16”

Brocas de taladro: ¼”, 1”, ½”

Lado

específico

Soporte del

vehículo

A. Inserte el perno y

bloque en el

bastidor

B. Alinee el

bloque en el

orificio de

acceso

Figura 2

Toyota Camry página 5

Toyota Avalon página 6

Kit de barra de tracción:

La barra de tracción se debe

usar en la posición

LEVANTADA únicamente.

Instalación en el Toyota Avalon

Tuerca de soldar delantera

Tuercas de soldar

existentes M10

Pernos del

panel lateral

C. Hale el

perno a través

del bloque

Nota: Tornillos iguales en ambos lados del enganche.

36071

Orificio de 1” a perforar

en ambos lados

Figura 1

No supere el valor inferior entre la calificación del

fabricante del vehículo de remolque o

3500 LB (1589 Kg) Peso máximo bruto del remolque

300 LB (136 Kg) Peso máximo de la horquilla

l

m

k

j

36514

90079

06139

Calificación de

accesorios

Ubicación del acceso al cableado: PC3 y 4

Larguero del bastidor

Protector

de calor

2da ubicación del

soporte aislante de

goma delantero

n

o

Perfore orificio de ½" a ¾"

1 ra ubicación del

soporte aislante de

goma delantero

q

Soporte colgante

del escape

Frente

B

j

k

l

m

1. Quite el panel de apariencia y entregue al propietario.

2. Baje el escape quitando los dos pernos en el panel lateral y dos pernos en el soporte colgante del escape del larguero del bastidor en cada lado. Los pernos del panel

3. Apoye el escape para evitar daños usando las correas, cuerdas elásticas u otros medios. Retire el 1er soporte aislante de goma en el lado del pasajero delantero del

4. Retire los protectores de calor.

5. Levante (deslice) el enganche a su posición sobre los tubos de escape de manera temporal e instale los pernos hexagonales M10 para apoyo. El soporte del gancho

6. Usando el engancho como plantilla marque y perfore los (1) orificios en ambos lados. Perfore un orificio piloto de 1/4” en ambos lados.

7. Baje el enganche y perfore un orificio de 1” en el larguero del bastidor. Marque y perfore el protector de calor para el perno de carruaje 7/16 usando el larguero del

8. Inserte el perno de carruaje y el espaciador dentro del bastidor como se muestra dejando el cable de halar unido. Ver Figura 2.

9. Levante el enganche a su posición ensartando el cable de halar a través del soporte. Instale por lo menos un perno M10 como se muestra en ambos lados.

10. Retire el cable de halar e instale arandelas cónicas y tuercas en ambos lados. Centre el enganche y apriete a torsión los tornillos de 7/16" a la especificación

11. Instale el 1er y 2do soportes aislantes delanteros de goma.

12. Retire los pernos M10 e instale los soportes colgantes del escape a través de la tuerca de soldar delantera en ambos lados (pieza 1).

13. Instale el soporte del vehículo reutilizando los pernos del panel lateral existentes (pieza 1) y los pernos M10 restantes.

14. Apriete todos los tornillos según las especificaciones de torsión exigidas.

Nota: Revise el enganche con frecuencia, verificando que todos los tornillos y la bola estén correctamente apretados. Si se quita el enganche tape todos los orificios en el colector del baúl u otros paneles de la

carrocería para evitar la entrada del agua y los gases del escape. Se debe retirar y reemplazar un enganche o esfera que se haya dañado. Observe las precauciones de seguridad al trabajar por debajo del vehículo

y use protección visual. No corte los orificios de acceso o accesorios con soplete.

Este producto cumple con las especificaciones y requisitos de seguridad para conectar dispositivos y sistemas de remolque del estado de Nueva York, V.E.S.C. Regulación V-5 y SAE J684.

Cant. (4) Perno Hexagonal, M10 x 1.25 x 40 CL8.8

Cant. (5) Arandela Cónica, 3/8"

Cant. (2) Perno de Carruaje, 7/16-14 X 1.5 GR5

Cant. (2) .915 X 3.000 X 10GA Espaciador

lateral se vuelven a instalar.

escape y luego el 2do soporte aislante de goma delantero.

del escape no es necesario en este paso. (Si se instala en el modelo híbrido, hay un soporte de la batería en el lado del pasajero del vehículo y en lugar de la

perforación de un agujero en la trama, simplemente retire el perno más posterior del soporte fijado al bastidor y coloque el enganche mediante el

suministro de M8 x 40mm perno. perforación sigue siendo necesaria en el lado del conductor del vehículo. Consulte la figura en la página Camry.)

bastidor como plantilla. Ponga a un lado para su instalación posterior.

requerida. Instale el protector de calor.

n

o

p

q

Apriete todos los tornillos 7/16 GR5 con una llave de torsión a 50 Lb.-pies (68 N*M)

Apriete todos los tornillos M8 CL10.9 con una llave de torsión a 27 Lb.-pies. (37 N*M)

Apriete todos los tornillos M10 CL8.8 con una llave de torsión a 38 Lb.-pies. (52 N*M)

Cant. (2) Arandela Cónica, 7/16"

Cant. (2) Tuerca Hexagonal, 7/16-14

Cant. (1) Perno Hexagonal, M8-1.25 x 50 CL10.9

Cant. (2) Perno Hexagonal, M6 1.0 x 40

© 2014 Cequent Performance Products, Inc

PRINTED IN MEXICO

Sheet of 6 36540N 2/10/14 Rev. A

6

Form F206 Rev A 5605

Loading...

Loading...