Page 1

TOWING

INSTALLATION INSTRUCTIONS

BASE RAIL MOUNTING KIT

PRODUCTS

’04 & UP FORD F-150

5.5’, 6’ & 8’ BEDS

DEALER/INSTALLER:

(1) Provide this Manual to end user.

(2) Physically demonstrate procedures in this Manual to end user.

(3) Have end user demonstrate that he/she understands procedures.

END USER:

(1) Read and follow this Manual every time you use Hitch.

(2) Save this Manual for future reference.

(3) Pass on copies of Manual to any other user or owner of Hitch.

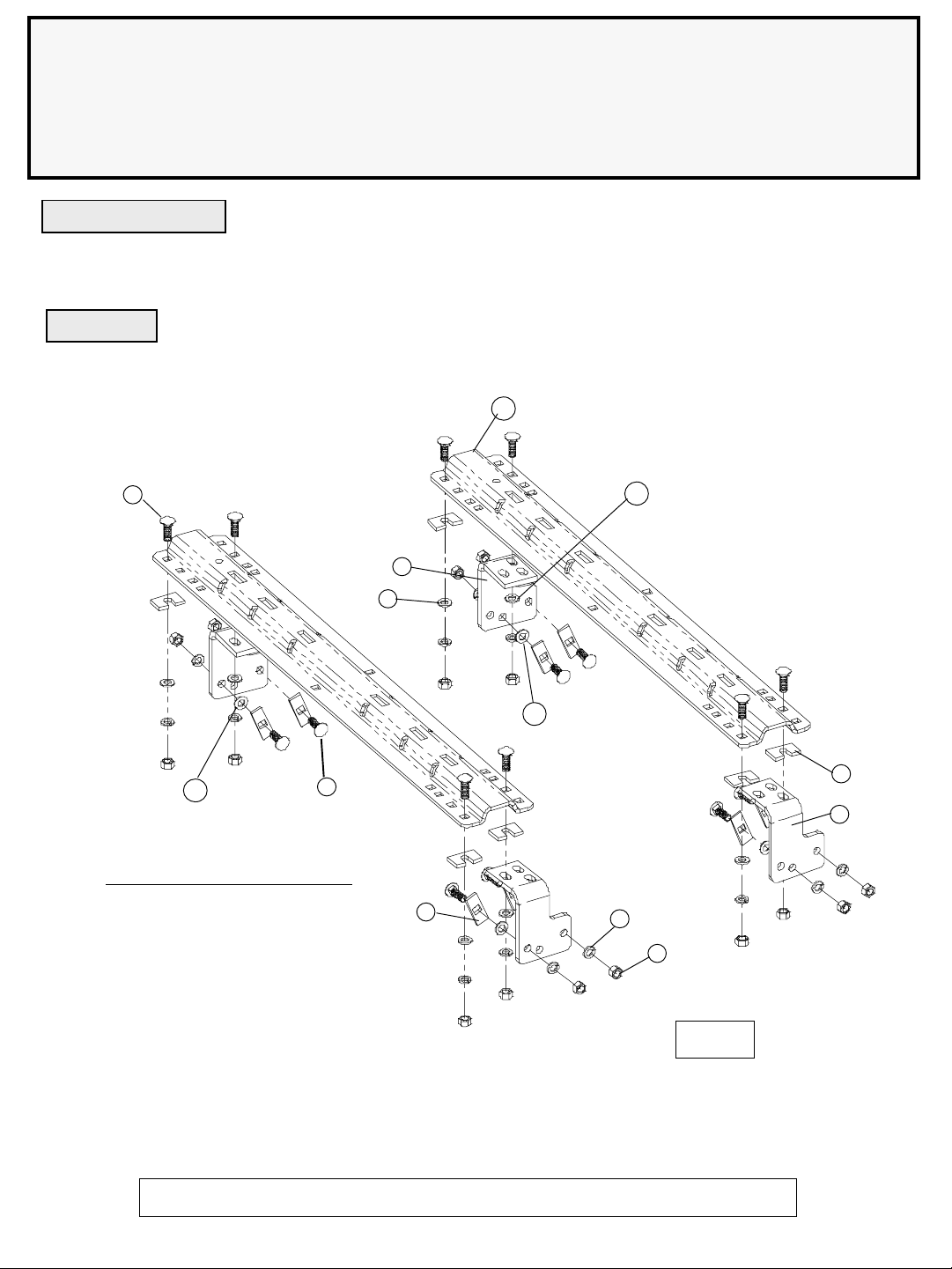

5

2

9

30080

25

10

11

BASERAILS QTY.

1. DRIVER SIDE BRACKET (2)

2. PASSENGER SIDE BRACKET (2)

3. FILLER SPACER (8)

4. BOLT PLATE (8)

5. 2” CARRIAGE BOLTS (8)

6. 1 1/2” CARRIAGE BOLTS (8)

7. 1/2” NUTS (16)

8. 1/2” LOCKWASHERS (16)

9. 1/2” SERRATED WASHERS (4)

10. 1/2” FLAT WASHERS (4)

11. 1” FILLER WASHER (2)

12. 13/16” FILLER WASHER (2)

25. BASERAILS (2)

6

For Installation Assistance or Technical Help, Call 1-888-521-0510

12

3

1

4

8

7

Fig. 1

30080IN – 8/21/08, rev B PCN11321 ©2003, 2008 CEQUENT TOWING PRODUCTS Litho in USA 1

Page 2

GENERAL INSTRUCTIONS FOR BASE RAIL INSTALLATION

TOOLS

3/16" drill 3/4" Socket & Open End Wrench

17/32" drill 100 lb-ft Torque Wrench

1” drill (Some Dodge applications only) "C" Clamps

1. The following instructions should be used to mount the 5th wheel. Care and attention to detail will ensure a quick

quality installation. Check parts against parts list to become familiar with parts in kit. (See Fig. 1)

2. Raise rear of truck high enough to allow jack stands to be placed under rear spring hanger bracket of truck. This will

provide maximum room to install the 5th wheel brackets.

WARNING:

If the truck is raised, be sure that the truck is properly blocked and restrained to prevent

the truck from falling. Failure to do so may result in the truck suddenly falling, causing

death or serious injury.

3. Do not install mounting rails over plastic bed liners. Plastic bed liners must be cut out of the way. Base rails may be

installed on spray in liner. Note: Consult installer for recommended curing time.

4. Use only CEQUENT TOWING PRODUCTS supplied bolts, nuts, and washers to install this kit. All bolts are grade 5

and nuts are grade 5 unless specified otherwise.

5. Specific instructions for most commonly used vehicles are included. If these instructions do not apply to your vehicle,

be sure that each end of each base rail is connected to the vehicle frame. Each frame bracket must be bolted to the

vehicle frame with two bolts, unless optional weld is used.

CAUTION:

These instructions are guidelines only. Actual installation is the responsibility of the

installer and the owner. Always measure truck and trailer before installing hitch to be

sure that there is clearance at the cab and at the bumper to allow for turns.

6. To prevent the trailer from hitting the cab with the trailer turned 90°, the center of the hitch should be at least 52" from

the back of the cab when using a long bed truck. (Actual distance required will depend on trailer width and king pin

location.) Short bed (Minimum 38” from back cab to axle center line) trucks require a minimum of a 13” extended pin

box or a SIDEWINDER Pinbox Coupler for regular maneuvers and do not apply. DO NOT INSTALL ON OR

ATTEMPT TO TOW WITH A TRUCK HAVING LESS THAN A 6’ BED WITHOUT A SIDEWINDER PINBOX

COUPLER INSTALLED ON THE TRAILER.

7. Measurements are given from Rear Edge of truck bed to rear edge of the base rail closest to the Rear Edge of truck

for most vehicle applications (See Fig. 2).

8. Center hitch between fender wells and make sure rails are square. Adjust position of rails until both diagonal

measurements are the same. This should allow installation of a gooseneck or other 5th wheels to these rails

(See Fig. 2).

CAUTION:

Check for obstructions before drilling. Failure to do so could result in damaged fuel or

brake lines, structural members, etc. CEQUENT TOWING PRODUCTS does its best to

communicate tow vehicle manufacturer changes; however, it is ultimately the

responsibility of the installer to prevent damage due to installation.

9. Drill 8 holes identified in Fig. 2. (Hole location will vary for individual vehicle applications.) Drill all holes with 3/16"

drill and enlarge them with a 17/32" drill. Always use sharp drill bits. A 3/16" pilot hole will greatly speed drilling larger

holes. Install 1/2” carriage bolts into holes. Install 5/16” thick slotted spacer above or below bed to fill corrugations in

bed floor.

10. Install mounting brackets onto carriage bolts with the long brackets on forward bolts and short brackets on rearward

(long and short brackets can be interchanged as needed). Secure bolts through mounting brackets with serrated

washers, lock washers, and hex nuts. Secure the other four bolts through the bed with flat washers, lock washers, and

nuts.

For Installation Assistance or Technical Help, Call 1-888-521-0510

30080IN – 8/21/08, rev B PCN11321 ©2003, 2008 CEQUENT TOWING PRODUCTS Litho in USA 2

Page 3

Note: On vehicles with heavy duty suspensions, check for interference with bolts where brackets are

mounted to frame. If interference with suspension spring results, cut bolt flush to nut outboard of frame

or use weld option.

WARNING:

DO NOT lubricate threads. It may cause bolt failure.

CAUTION:

Check for obstructions before drilling. Failure to do so could result in damaged fuel or

brake lines, structural members, etc. CEQUENT TOWING PRODUCTS does its best to

communicate tow vehicle manufacturer changes; however, it is ultimately the

responsibility of the installer to prevent damage due to installation.

CAUTION:

It is important that 17/32" drill be used for holes in chassis frame as rib neck bolts

may break if too small a hole is used and neck may not grip if too large a hole is used.

11. Torque all nuts to 75 lb-ft

12. Pull wire provided to pull bolts through frame as needed per application

Drill locations will vary. See individual installation for location

Use side bracket/hitch base assembly to position rails (not included)

ROW 2

ROW 1

ROW 3

ROW 4

Rear Edge of

Truck Bed

Measure diagonal

from same

reference point.

Measurement

should be the

same.

Front

of

Truck

Fig. 2

Choose 8 holes

identified by black dots

that correspond with

your individual

configuration.

Rear Edge of Truck bed to

Rear Edge of Base Rail

30080IN – 8/21/08, rev B PCN11321 ©2003, 2008 CEQUENT TOWING PRODUCTS Litho in USA 3

Page 4

Ford ‘04 & UP F-150, 5.5’, 6’, & 8’ BEDS

CAUTION!

Read pages 2-3 of Base Rail instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Do not drill through both walls of frame. Drill only through wall of frame to which bracket is mounted.

2. Find parallel rows of bed sill spot welds in bed of truck. No drilling should be done in the ~4” between parallel

rows of spot welds where the bed sill sits.

3. Remove jounce block from

bottom of frame on both

sides.

4. When brackets are in

place one of the front 2 holes

should line up with a hole in

the frame. A hole will need

to be drilled in the frame at

the rearward bracket hole.

5. Pull carriage bolts with bolt

plates (using supplied pull

wire) through the hole in the

bottom of frame (where the

jounce block was removed)

and through the rear hole in

each bracket. On the

forward brackets a carriage

bolt, bolt plate and a 1”

washer should be pulled

through the forward hole,

rearward brackets a carriage

bolt, bolt plate and 13/16”

washer.

Front

of

Vehicle

ROW 1

ROW 2

ROW 3

ROW 4

Rear Edge of

Truck Bed

29 5/16” Long Box,

6’ Box, & 5.5’ Box

Measure from Rear Edge

of truck bed to rear edge

of base rail.

6. Replace the jounce block.

Bracket

Washer, Filling larger

hole in frame

King Pin Center approx. 1 1/2”

Lockwasher

Nut

Carriage Bolt

Bolt Plate

Frame

Hole in Frame

forward of axle center.

Side Bracket

Drilled Hole

Driver Side Brackets

Axle Center

Bed Sill

Hole in Frame

Jounce Block

Forward

Drivers side of F150 shown

Drilled Hole

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc.

CEQUENT TOWING PRODUCTS does its best to communicate tow vehicle manufacturer changes; however, it is ultimately the

responsibility of the installer to prevent damage due to installation.

30080IN – 8/21/08, rev B PCN11321 ©2003, 2008 CEQUENT TOWING PRODUCTS Litho in USA 4

Page 5

NOTES

FIVE YEAR LIMITED WARRANTY

Hitches - Custom Receivers

Cequent Towing Products warrants its 5th Wheel Hitch Mounting Kits from date of purchase against

defects in material and workmanship under normal use and service, ordinary wear and tear excepted, for

5 years of ownership to the original consumer purchaser when a Reese mounting kit is used.

Cequent Towing Products will replace FREE OF CHARGE any part which proves defective in material or

workmanship when presented to any Reese dealer, Reese Warehouse or returned to factory.

TRANSPORTATION CHARGES PREPAID, at the address below. THIS WARRANTY IS LIMITED TO

DEFECTIVE PARTS REPLACEMENT ONLY. LABOR CHARGES AND/OR DAMAGE INCURRED IN

INSTALLATION OR REPLACEMENT AS WELL AS INCIDENTAL AND CONSEQUENTIAL DAMAGES

CONNECTED THEREWITH ARE EXCLUDED.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Any damage to the 5th Wheel Hitch as a result of misuse, abuse, neglect, accident, improper installation,

or any use violative of instructions furnished by us, WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state. In the event of a problem with warranty service or performance, you may be able to go to a small

claims court, or a federal district court.

Cequent Towing Products, Inc.

47774 Anchor Court W.

Plymouth MI 48170

30080IN – 8/21/08, rev B PCN11321 ©2003, 2008 CEQUENT TOWING PRODUCTS Litho in USA 5

Loading...

Loading...