Page 1

INSTALLATION INSTRUCTIONS

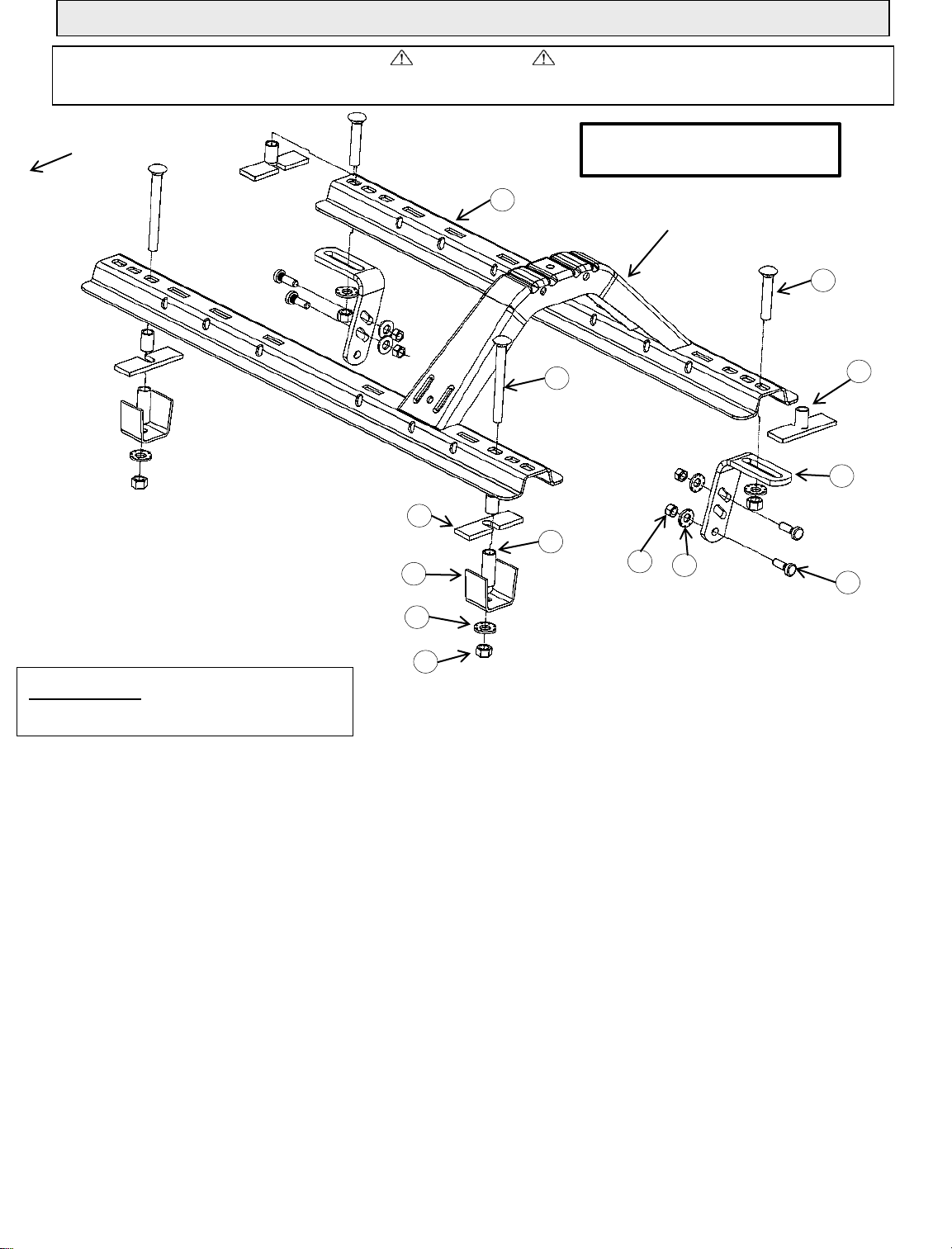

30095 BASE RAIL MOUNTING KIT

For updated instructions see

DEALER/INSTALLER:

(1) Provide this Manual to end user.

(2) Physically demonstrate procedures in this Manual to end user.

(3) Have end user demonstrate that he/she understands procedures.

END USER:

(1) Read and follow this Manual every time you use Hitch.

(2) Save this Manual for future reference.

(3) Pass on copies of Manual to any other user or owner of Hitch.

* FOR EASE OF INSTALLATION:

5/8” x 3-1/2” HEX BOLT MAY BE USED ALONG WITH A

FLAT WASHER ABOVE THE RAIL IN PLACE OF THE

5/8” x 3-1/2” CARRIAGE BOLT (GRADE 5 OR HIGHER).

HEX BOLT AND WASHER NOT SUPPLIED.

www.ReeseProducts.com or www.Draw-Tite.com

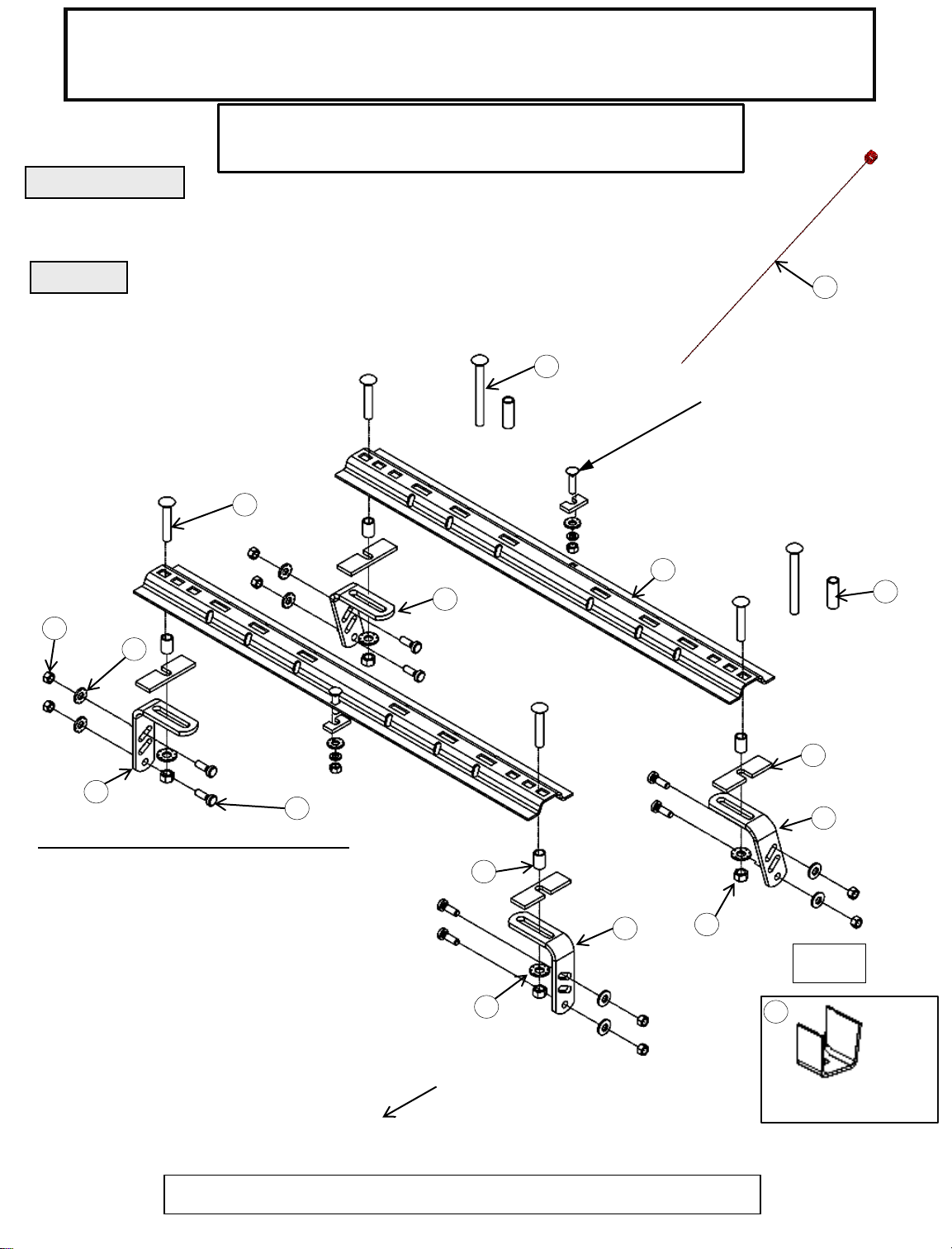

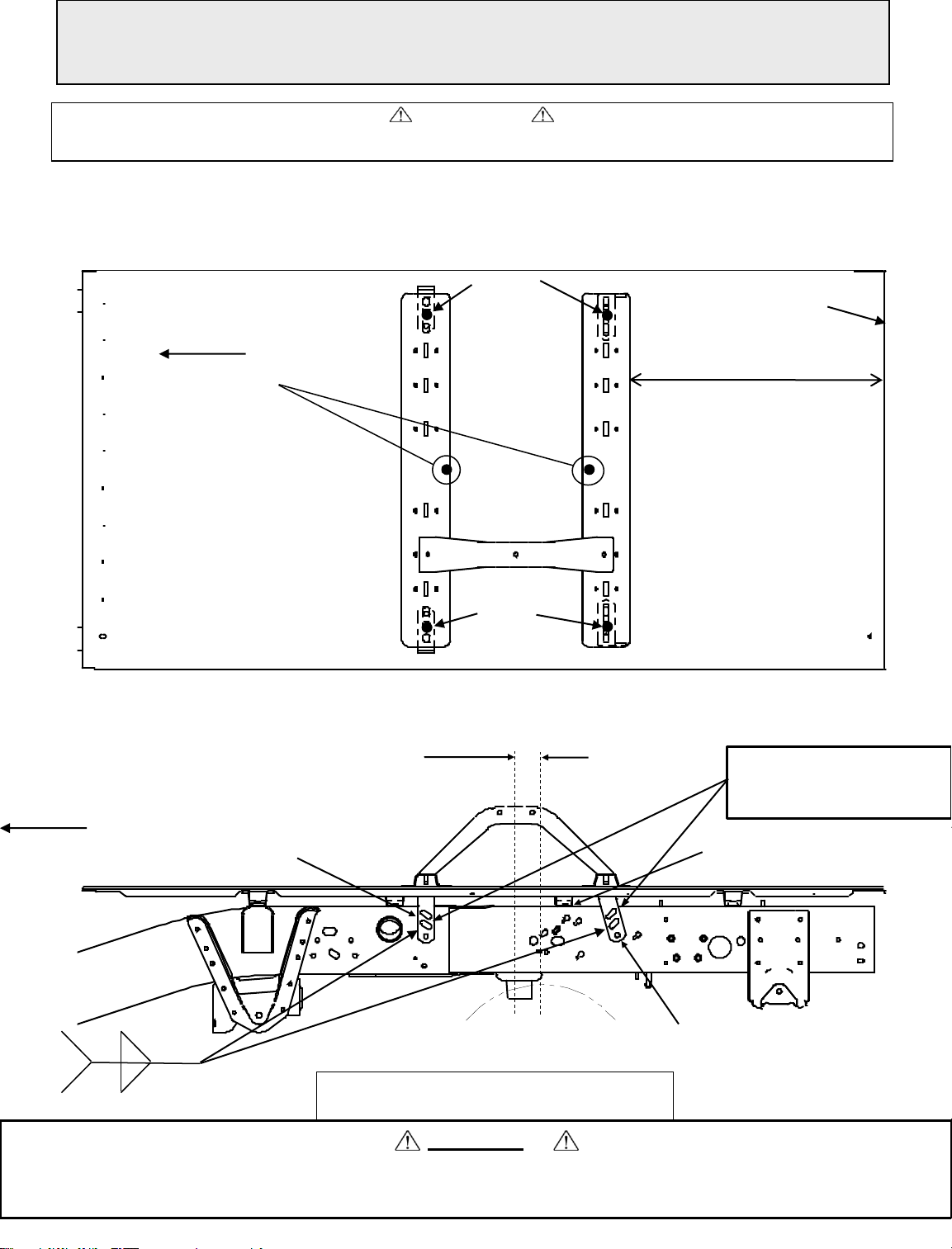

5*

9

15

Center bolts and hardware

are supplied with Fifth

wheel or gooseneck

hitches that are rated

over 18k.

7

8

1

6

BASE RAIL KIT QTY.

1. STRAIGHT FRAME BRACKET (2)

2. ANGLED FRAME BRACKET (RH) (1)

3. ANGLED FRAME BRACKET (LH) (1)

4. FILLER SPACER – 5/16” THICK (4)

5. 5/8” x 3-1/2” CARRIAGE BOLTS GR 5 (4)

6. ½” x 1-1/2” KNURLED BOLTS GR 5 (8)

7. 1/2” NUTS (8)

8. 1/2” SERRATED WASHERS (8)

9. 5/8” x 6” CARRIAGE BOLT GR 5 (2)

10. TUBE SPACER - 1-1/4” LONG (4)

11. BASE RAILS (2)

12. TUBE SPACER – 2-3/8” LONG (2)

13. 5/8” SERRATED WASHERS (4)

14. 5/8” NUTS (4)

15. ½” PULL WIRE (4)

16. U-SHAPED BRACKET (2)

11

3

10

1

13

14

Front of Vehicle

NOTE: ALL HARDWARE WILL NOT BE USED ON ALL INSTALLATIONS

12

4

2

Fig. 1

16

NOTE: SEE PG. 9 FOR USE OF

U-SHAPED BRACKETS

For Installation Assistance or Technical Help, Call 1-888-521-0510

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

Page 2

GENERAL INSTRUCTIONS FOR 30095 BASE RAIL INSTALLATION

TOOLS

1/8" drill 3/4" Socket & Open End Wrench 15/16” Socket

17/32" drill 100 lb-ft Torque Wrench 21/32" drill

1 1/4” Hole Saw (Some Dodge applications only) "C" Clamps 10 mm Socket (Some applications)

1. The following instructions should be used to mount the Fifth wheel. Care and attention to detail will ensure a quick quality installation.

Check parts against parts list to become familiar with parts in kit. (See Fig. 1)

2. Raise rear of truck high enough to allow jack stands to be placed under rear spring hanger bracket of truck. This will provide maximum

room to install the Fifth wheel brackets.

If the truck is raised, be sure that the truck is properly blocked and restrained to prevent the truck

from falling. Failure to do so may result in the truck suddenly falling, causing death or serious injury.

3. Do not install mounting rails over plastic bed liners. Plastic bed liners must be cut out of the way. Base rails may be

installed on spray in liner. Note: Consult installer for recommended curing time.

4. Use only Cequent Performance Products, Inc. supplied bolts, nuts, and washers to install this kit (Unless instructed otherwise). All bolts

are Grade 5 and nuts are Grade 5 unless specified otherwise.

5. Specific instructions for most commonly used vehicles are included. Each frame bracket must be bolted to the vehicle frame with two

bolts, unless optional weld is used.

These instructions are guidelines only. Actual installation is the responsibility of the installer and the owner. Always measure

truck and trailer before installing hitch to be sure that there is clearance at the cab and at the bumper to allow for turns.

To prevent the trailer from hitting the cab with the trailer turned 90°, the center of the hitch should be at least 52" from the back of the

cab when using a long bed truck. (Actual distance required will depend on trailer width and king pin location.) Short bed trucks (Minimum

38” from back cab to axle center line) require a minimum of a 13” extended pin box with a Kwik slide or a SIDEWINDER Pinbox for regular

maneuvers. DO NOT INSTALL ON OR ATTEMPT TO TOW WITH A TRUCK HAVING LESS THAN A 6’ BED WITHOUT A SIDEWINDER PINBOX

INSTALLED ON THE TRAILER.

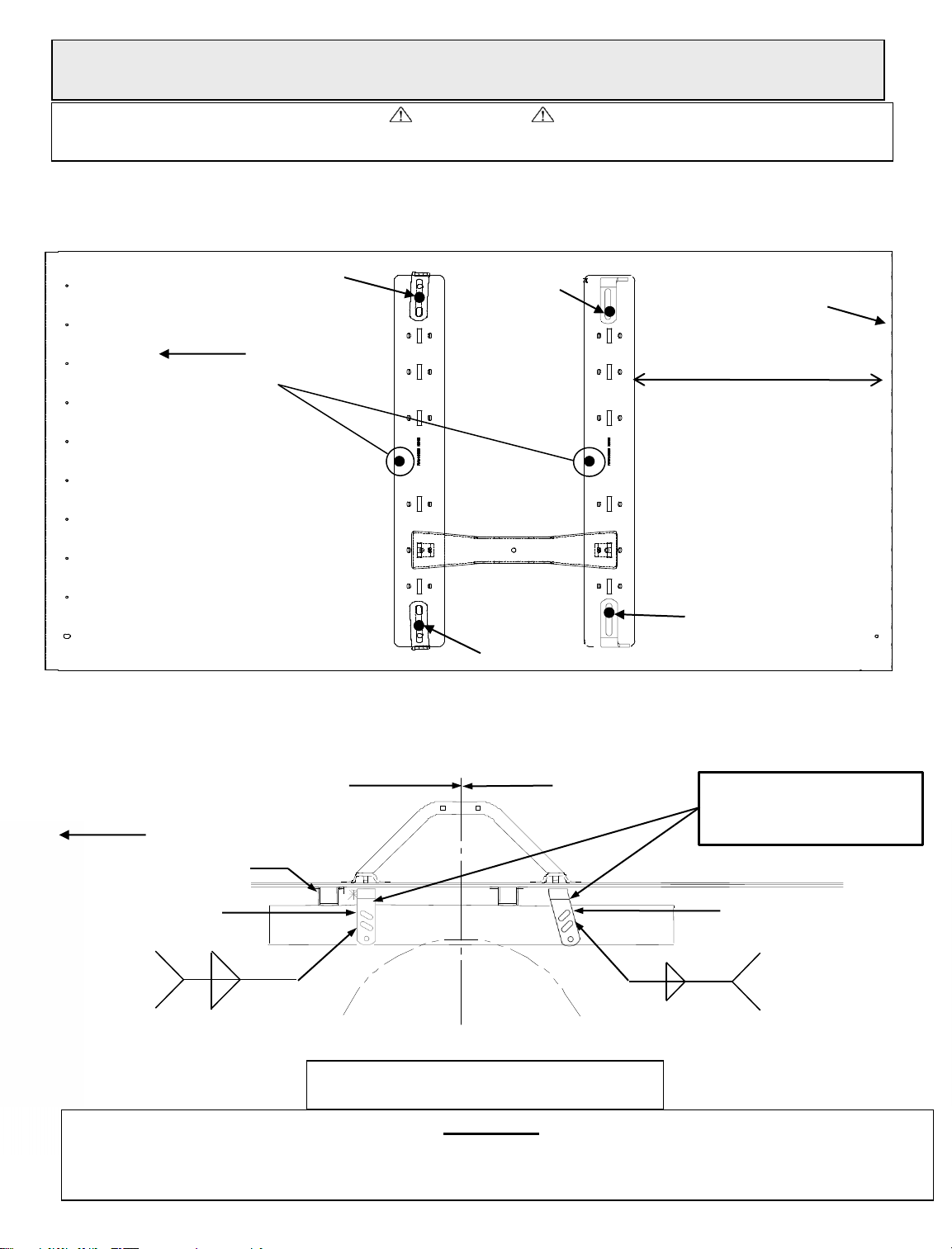

6. Measurements for rail placement are given from rear edge of truck bed to rear edge of the base rail closest to the rear edge of truck for

most vehicle applications.

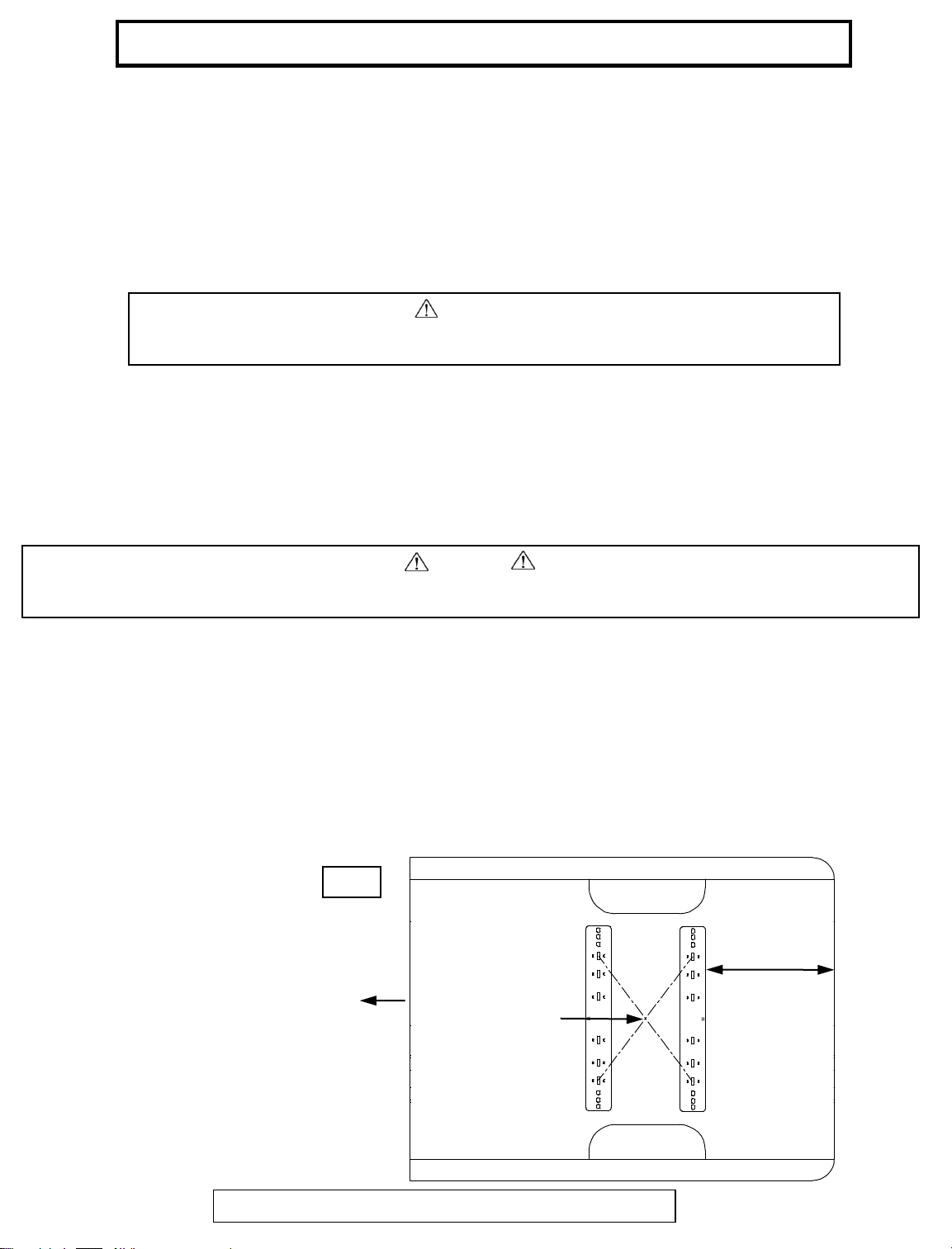

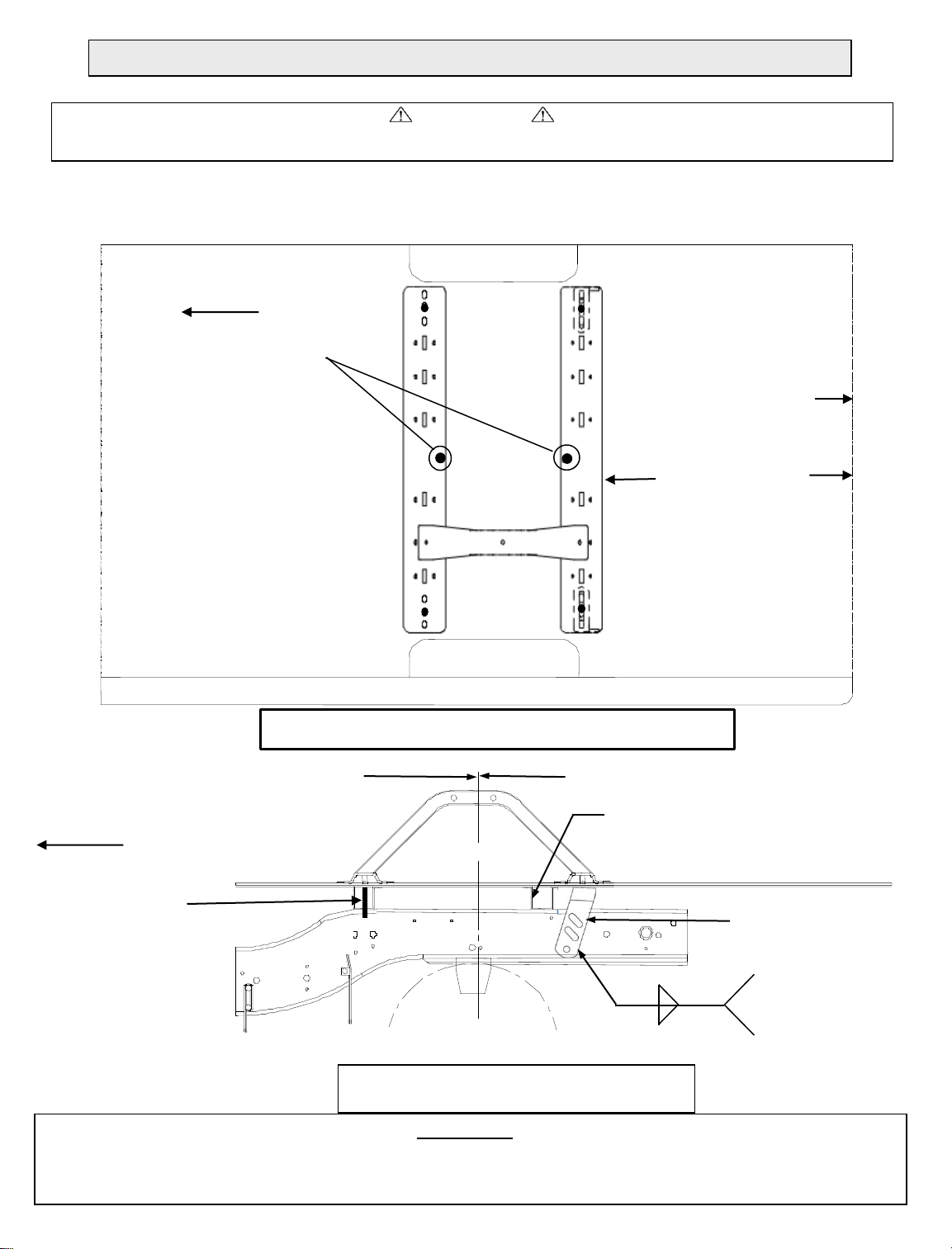

7. Center hitch between fender wells and make sure rails are square. Adjust position of rails until both diagonal measurements are the

same. This should allow installation of a gooseneck or other Fifth wheels to these rails.

NOTE: For ease of installation, place the

unassembled fifth wheel support

arches/slider/goose into the already

installed rear mounting rail. Position the

forward mounting rail with the support

arches/slider/goose by inserting

the tabs into the mounting rail and

pushing the mounting rail tight towards

the other mounting rail. Ensure that the

mounting rail is centered on the bed of the

vehicle. This will position the rail in the correct

location and ensure that the fifth wheel will

have a snug fit to the truck.

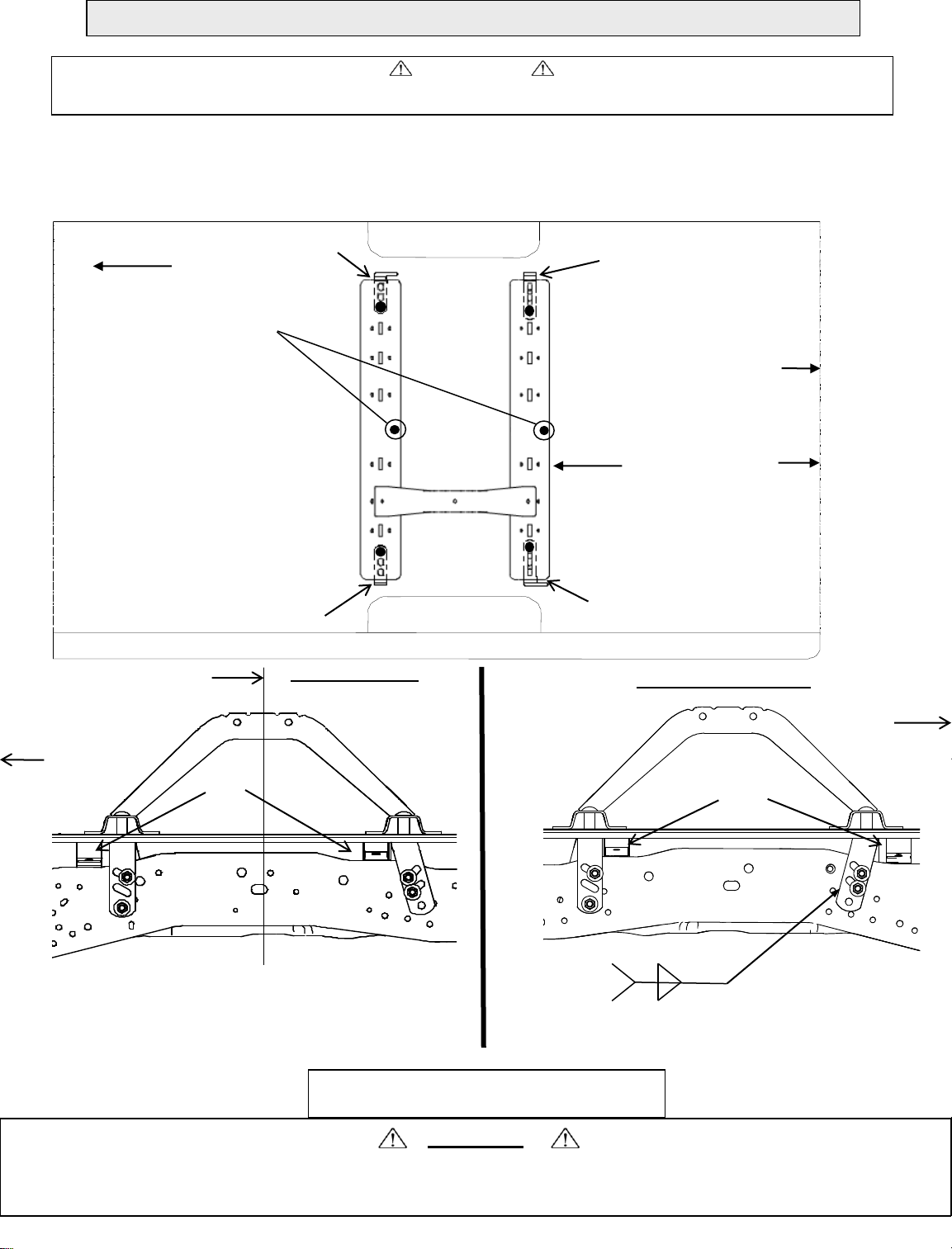

Fig. 2

FRONT

30095N 1/30/12 REV. H

For Installation Assistance or Technical Help, Call 1-888-521-0510

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

WARNING:

CAUTION:

Rear rail to rear

edge of bed

measurement

Measure diagonally

from same reference

point. Measurement

should be the same.

2

Page 3

1/4" 2.00"

1/4" 2.00"

1/4" 2.00"

1/4" 2.00"

CAUTION:

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural

members, etc. Cequent Performance Products, Inc. does its best to communicate tow vehicle manufacturer

changes; however, it is ultimately the responsibility of the installer to prevent damage due to installation.

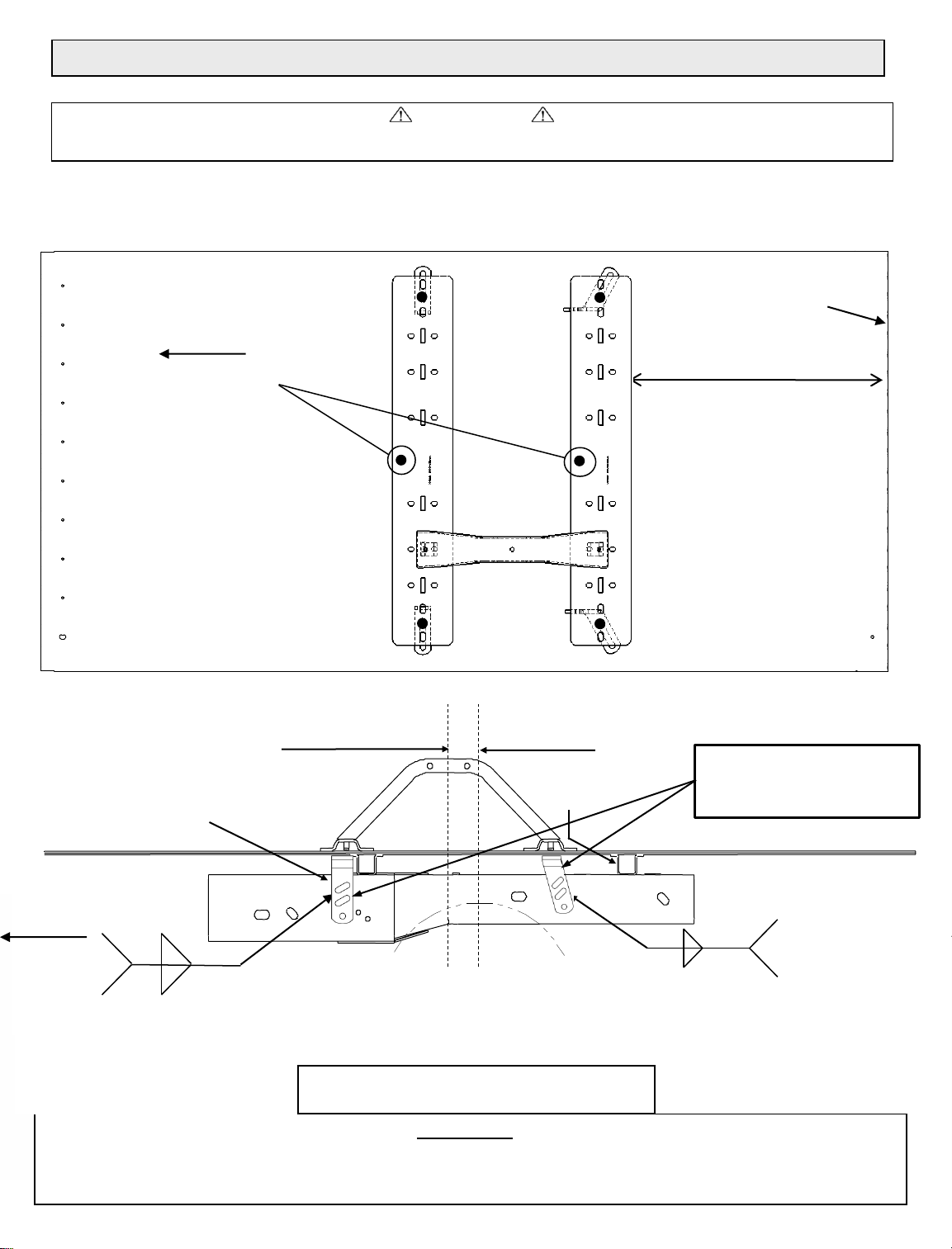

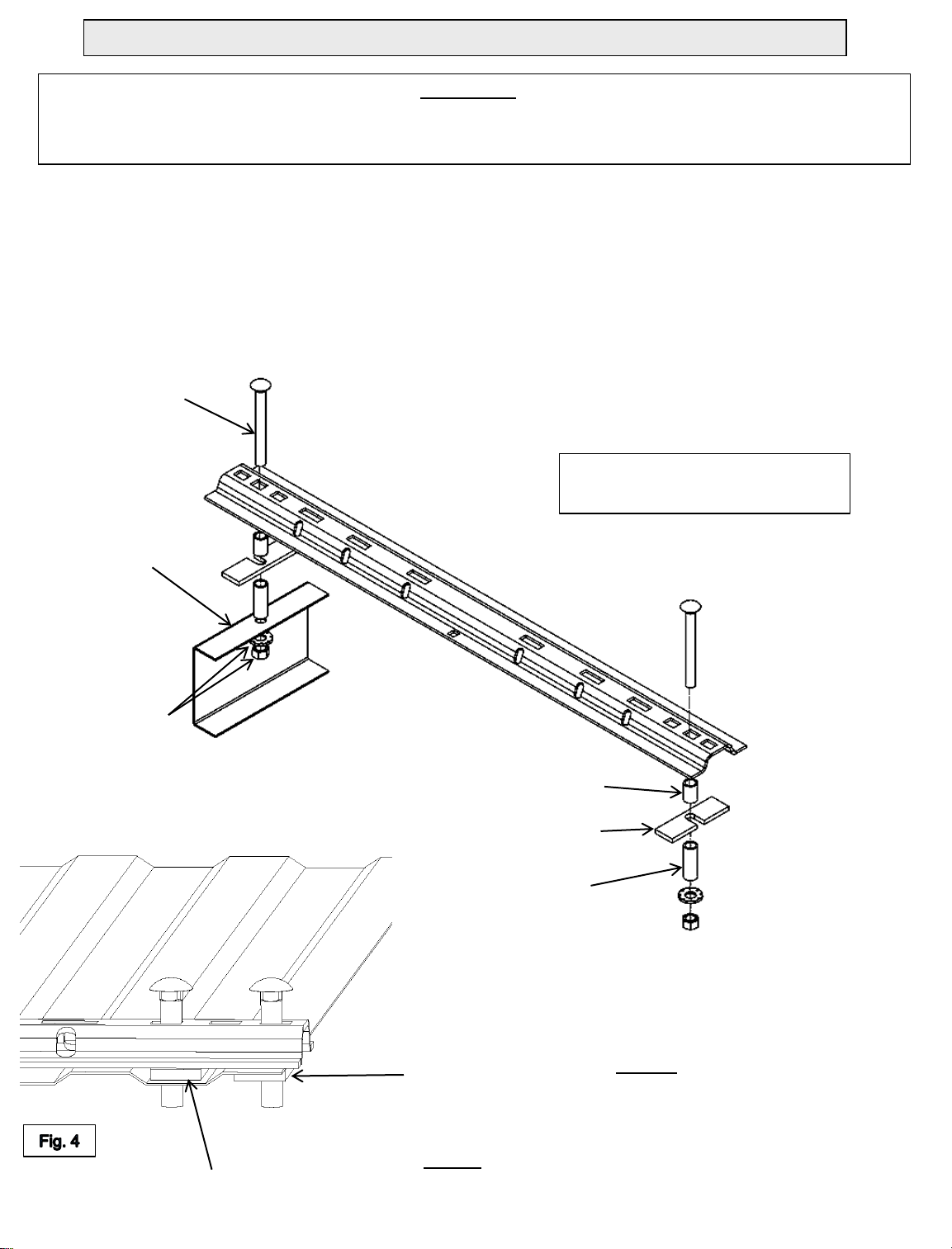

8. Mark 4 holes to be drilled through the truck bed (see the illustrations for your truck). Measure carefully to determine if the frame

bracket is under the hole in the rail you have chosen. (Hole location will vary for individual vehicle applications.) Drill 4 holes with 1/8"

drill. Be sure that the frame brackets will align with the 1/8” holes that were just drilled. If they don’t, move either the frame brackets or

the rails slightly. Drill another 1/8” hole and check again. Then enlarge the 1/8” drilled holes with a 21/32" drill. Always use sharp drill bits.

Install tube spacer between rail and bed, install 5/8” carriage bolts into holes. Install filler spacer above or below bed to fill corrugations in

bed floor. SEE FIG. 4 on page 11. This is done to fill any space between the Frame bracket and the rail. This will keep the bed corrugation

from crushing when the bolts are tightened.

9. Install mounting brackets onto carriage bolts. Use the left and right angled frame brackets at locations where frame obstruction will not

allow the straight frame brackets to be positioned. Secure bolts through mounting brackets with serrated washers and hex nuts.

10. Drill two 17/32” holes in truck frame for each frame bracket. Select the holes which will give the greatest spread between bolts.

Install eight 1/2”-13x1-3/8” ribbed neck bolts, (threads pointing out), serrated washers, and hex nuts. Tighten nuts until bolt heads seat.

Lubrication of knurls of all rib neck bolts is recommended. But only the knurled area. (See figure below for weld option)

Note: On vehicles with heavy duty suspensions, check for interference with bolts where brackets are mounted to

frame. If interference with suspension spring results, cut bolt flush to nut outboard of frame or use weld option.

WARNING:

DO NOT lubricate threads. It may cause bolt failure.

CAUTION:

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines,

structural members, etc. Cequent Performance Products, Inc. does its best to communicate tow

vehicle manufacturer changes; however, it is ultimately the responsibility of the installer to prevent

damage due to installation.

CAUTION:

It is important that 17/32" drill be used for holes in chassis frame as rib neck bolts

may break if too small a hole is used and neck may not grip if too large a hole is used.

11. Torque all 1/2” nuts to 75 lb-ft and all 5/8” nuts to 130 lb-ft.

12. Pull wire provided to pull rib neck bolts through frame as needed per application. See figure 1.

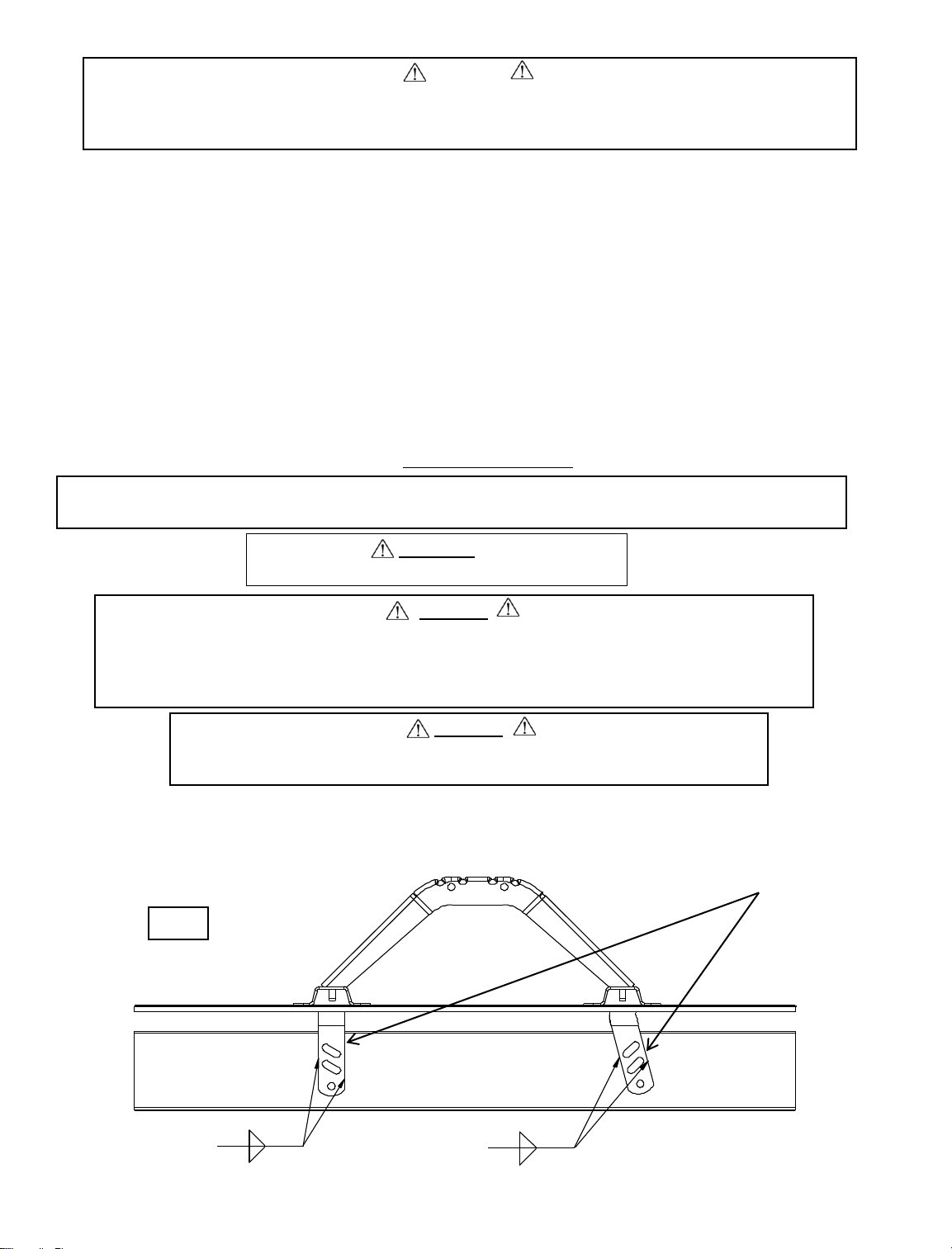

OPTIONAL WELD ON APPLICATION

CAN BE USED ON ALL TRUCKS

FRONT & REAR BRACKETS CAN BE

SWITCHED TO GET A BETTER FIT

Fig. 3

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

3

Page 4

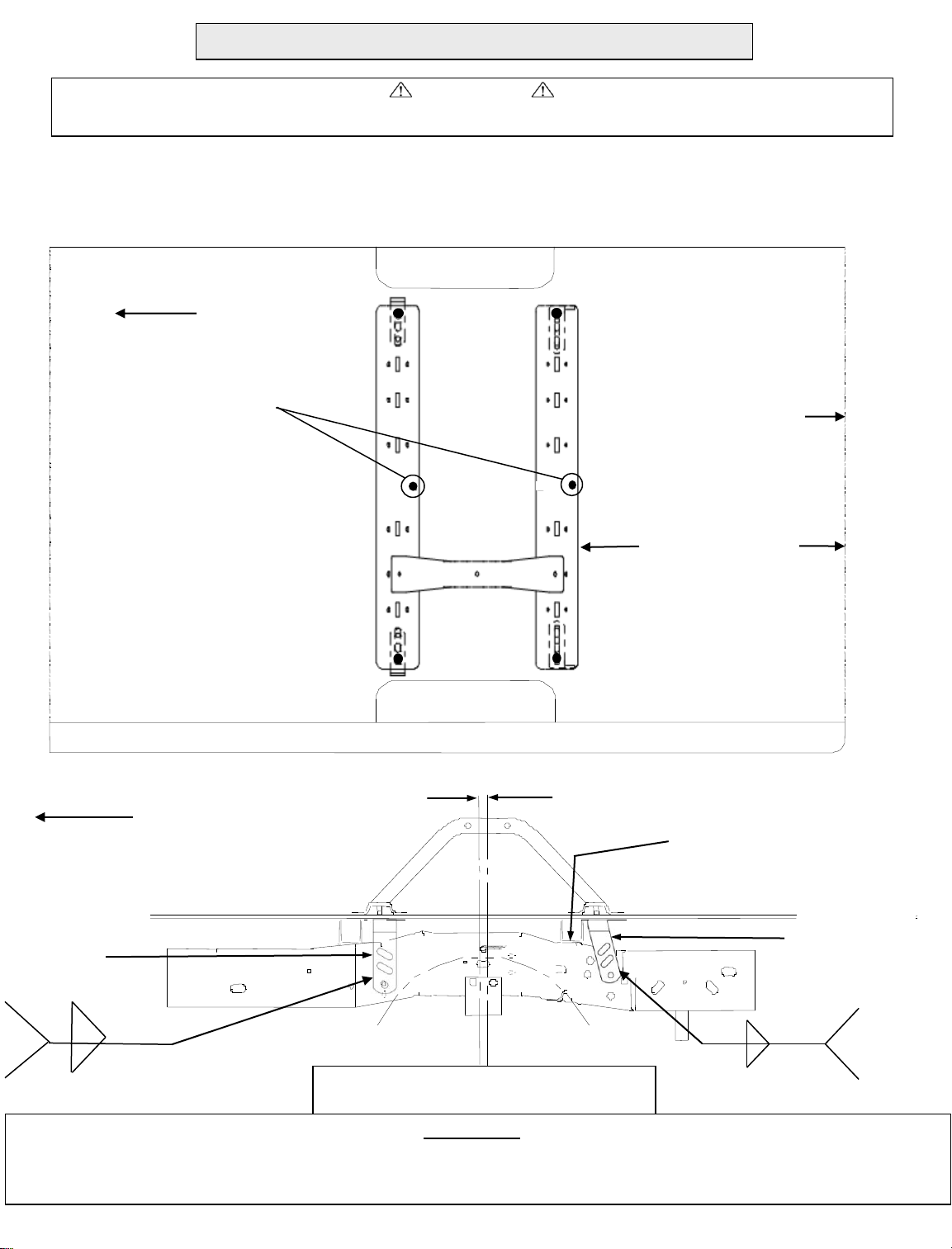

Chevy and GM 2011 & 2012 2500 HD & 3500 HD Silverado and Sierra

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Find parallel rows of bed sill spot welds in bed of truck. No drilling should be done in the approximately 4” between

parallel rows of spot welds where the bed sill sets.

Rear Edge of

Truck Bed

Front of

Vehicle

Long Bed = 29 11/16”

Short Bed =25 3/16”

Fifth wheel hitches over 18k

must have a center bolt in the

center hole in both rails.

Note: Place center bolt in the

hole that does not interfere

with the bed sill. If needed, flip

the rail around.

Center bolts and hardware

are supplied with Fifth wheel

or gooseneck hitches that are

rated over 18k.

Measure from rear edge of

truck bed to rear edge of

base rail

Front of

Vehicle

1/4 1.5-3

*

1/4 2

Short Bed Sills

Straight frame

bracket

Long Bed Sills

Note: Pull wire provided, will be needed to install

hardware in brackets through frame.

King pin

Axle center

* Optional weld

pattern

Drivers side of 3/4 ton HD shown

1/4 2

1/4 2

Angled bracket

On inside of frame

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc.

Cequent Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately

the responsibility of the installer to prevent damage due to installation.

*

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

4

Page 5

GM ‘99 Silverado, Sierra (not Sierra Classic) models

Chevy & GMC ‘00 to 10 Silverado, Sierra including HD models, and ’04 & up 1500 Crew

Cab with 5’8” bed (Reese

™

Sidewinder® Pinbox required for 5’8” bed)

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Find parallel rows of bed sill spot welds in bed of truck. No drilling should be done in the approximately 4” between

parallel rows of spot welds where the bed sill sets.

Front of

Vehicle

Fifth wheel hitches over

18k must have a center

bolt in the center hole in

both rails.

Note: Place center bolt in

the hole that does not

interfere with the bed sill. If

needed, flip the rail around.

Center bolts and hardware

are supplied with Fifth

wheel or gooseneck

hitches that are rated over

18k.

* Optional weld

pattern

King Pin Center approx.. 3-1/2”

Front of

forward of Axle Center

Vehicle

Center

Hole

Center

Hole

Long Bed =31”

Short Bed =23 1/2”

Measure from rear edge of

truck bed to rear edge of

base rail

Axle Center

Rear Edge of

Truck Bed

Left, right angle and frame

brackets may be placed

wherever brackets fits best.

1/4 1.5-3

*

1/4 2

Straight Bracket

Bed Sill

Angled Bracket

Note: Pull wire provided, will be needed to install

hardware in brackets through frame.

Drivers side of 3/4 ton

Chevy Long Box Shown

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc. Cequent

Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately the responsibility of the

installer to prevent damage due to installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

5

Page 6

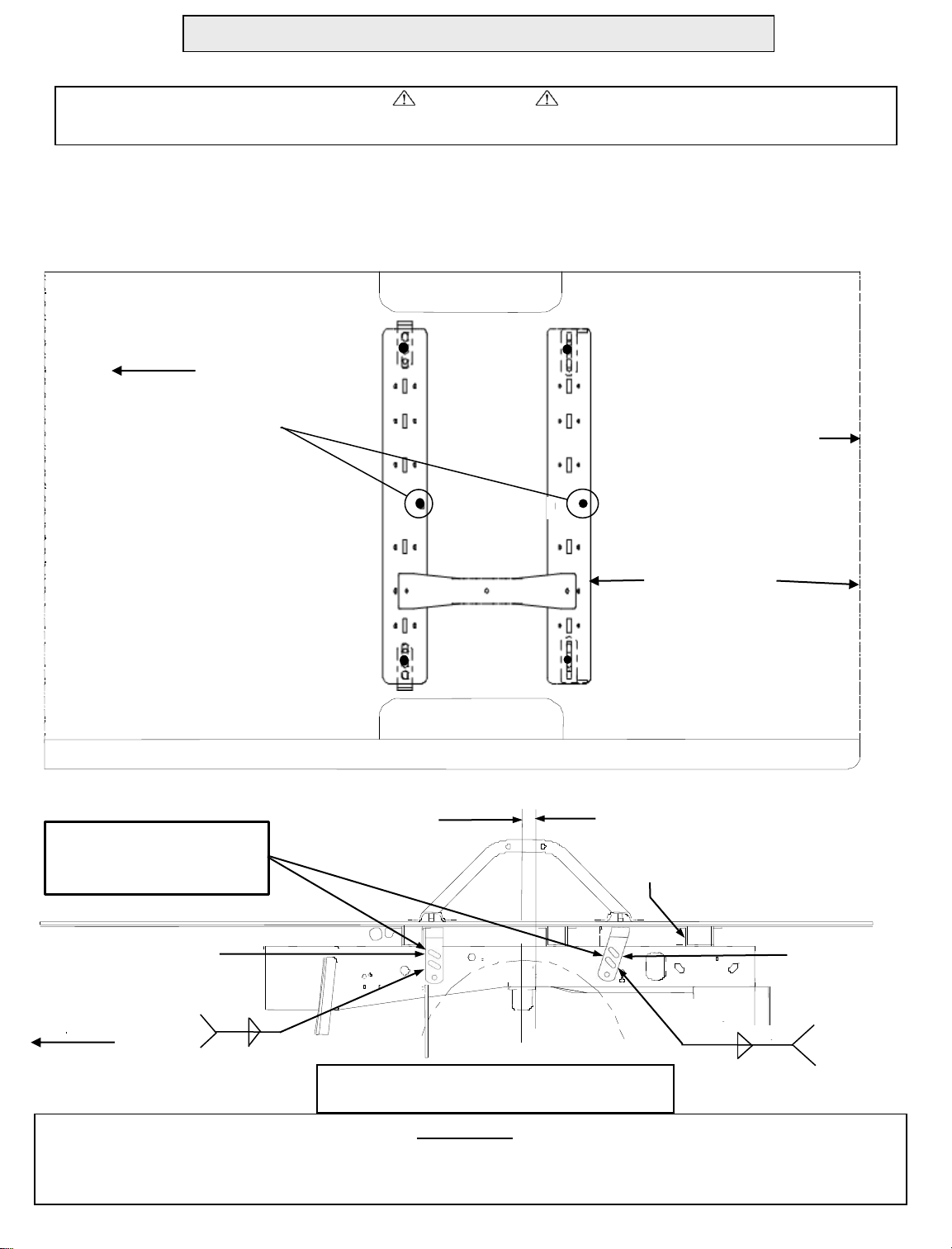

CHEVROLET/GMC 88-98 & 92-98 4-DOOR & 99 SILVERADO

SIERRA CLASSIC (WITH TAPERED FRAME) (RED TURN SIGNALS)

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Find parallel rows of bed sill spot welds in bed of truck. No drilling should be done in the approximately 4” between

parallel rows of spot welds where the bed sill sets.

Center Hole

Front of

Vehicle

Fifth wheel hitches over

18k must have a center

bolt in the center hole in

both rails.

Note: Place center bolt in

the hole that does not

interfere with the bed sill. If

needed, flip the rail around.

Center bolts and hardware

are supplied with Fifth

wheel or gooseneck

hitches that are rated over

18k.

Inside Hole

Center Hole

Rear Edge of

Truck Bed

Long Bed = 29 7/16”

Short Bed =23 15/16”

Measure from rear edge of

truck bed to rear edge of

base rail

Inside Hole

Front of

Vehicle

Straight bracket

*

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc.

Cequent Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately

30095N 1/30/12 REV. H

King Pin Center

over Axle Center

Bed Sill

1/4 1.5-3

1/4 2

the responsibility of the installer to prevent damage due to installation.

Axle Center

Drivers side 1/2 ton Long Box shown

1/4 2

1/4 2

Left, right angle and frame

brackets maybe place where

ever brackets fits best.

Angle bracket

*

* Optional weld

Note: Pull wire provided, will be needed to install

hardware in brackets through frame.

pattern

CAUTION!

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

6

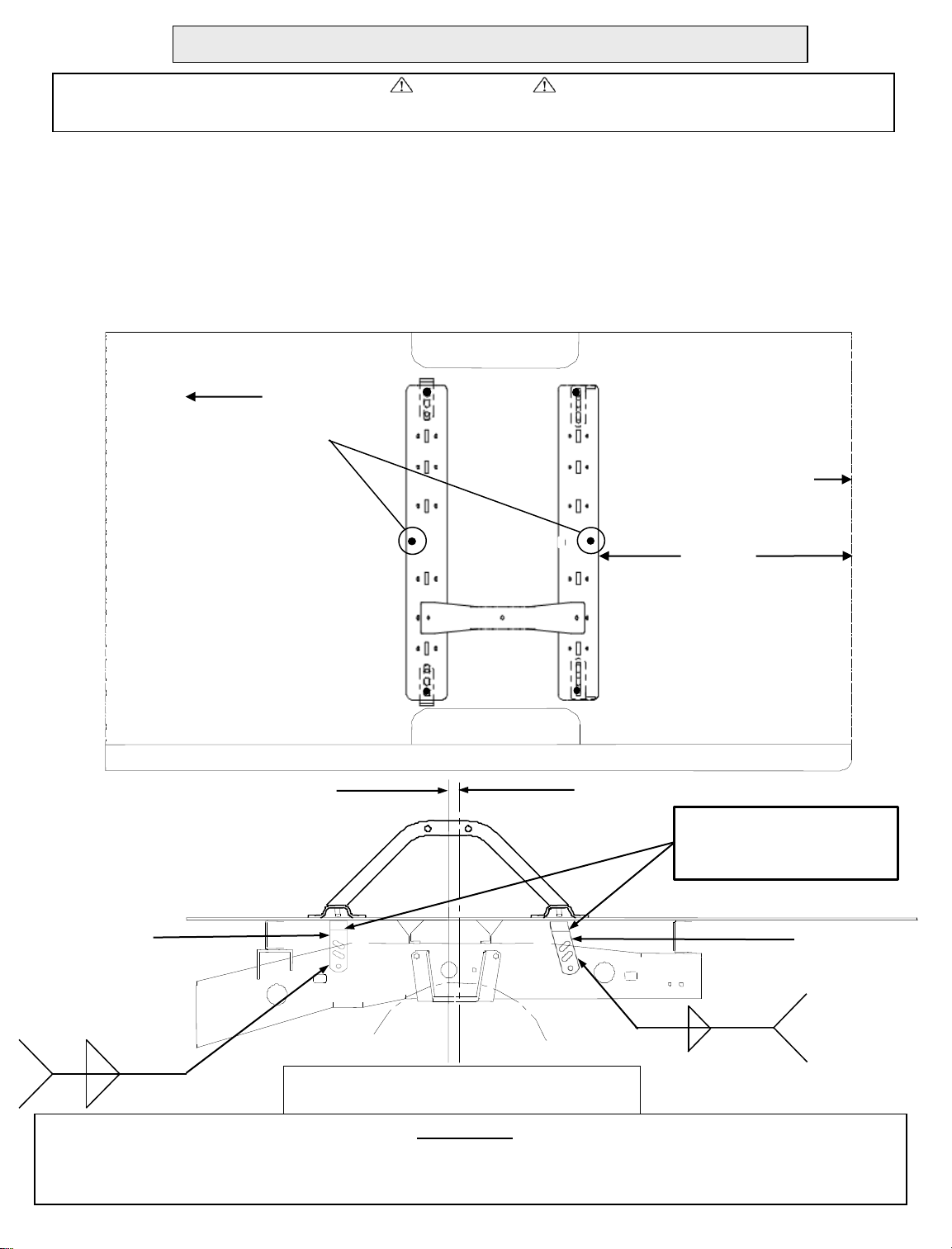

Page 7

Chevrolet & GMC 73 to 87 & 73 to 92 4-door (34” Straight, with Inside Shock Absorbers)

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Find parallel rows of bed sill spot welds in bed of truck. No drilling should be done in the approximately 4” between

parallel rows of spot welds where the bed sill sets.

Front of

Vehicle

Fifth wheel hitches over

18k must have a center

bolt in the center hole in

both rails.

Note: Place center bolt in

the hole that does not

interfere with the bed sill. If

needed, flip the rail around.

Center bolts and hardware

are supplied with Fifth

wheel or gooseneck

hitches that are rated over

18k.

King Pin Center approx.

Long bed 3 1/2” & short

bed over the Axle Center

Straight Bracket

Center

Hole

Center

Hole

Bed Sill

Rear Edge of

Truck Bed

Long Bed =33 3/16”

Short Bed =23 3/16”

Measure from rear edge of

truck bed to rear edge of

base rail

Axle Center

Drivers side of 1/2 ton Chevy Long Box Shown

Left, right angle and frame

brackets maybe place where

ever brackets fits best.

Front of

Vehicle

1/4 2

1/4 1.5-3

*

1/4 2

1/4 2

Angled Bracket

Note: Pull wire provided, will be needed to install

hardware in brackets through frame.

*

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc.

Cequent Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately

the responsibility of the installer to prevent damage due to installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

* Optional weld

pattern

7

Page 8

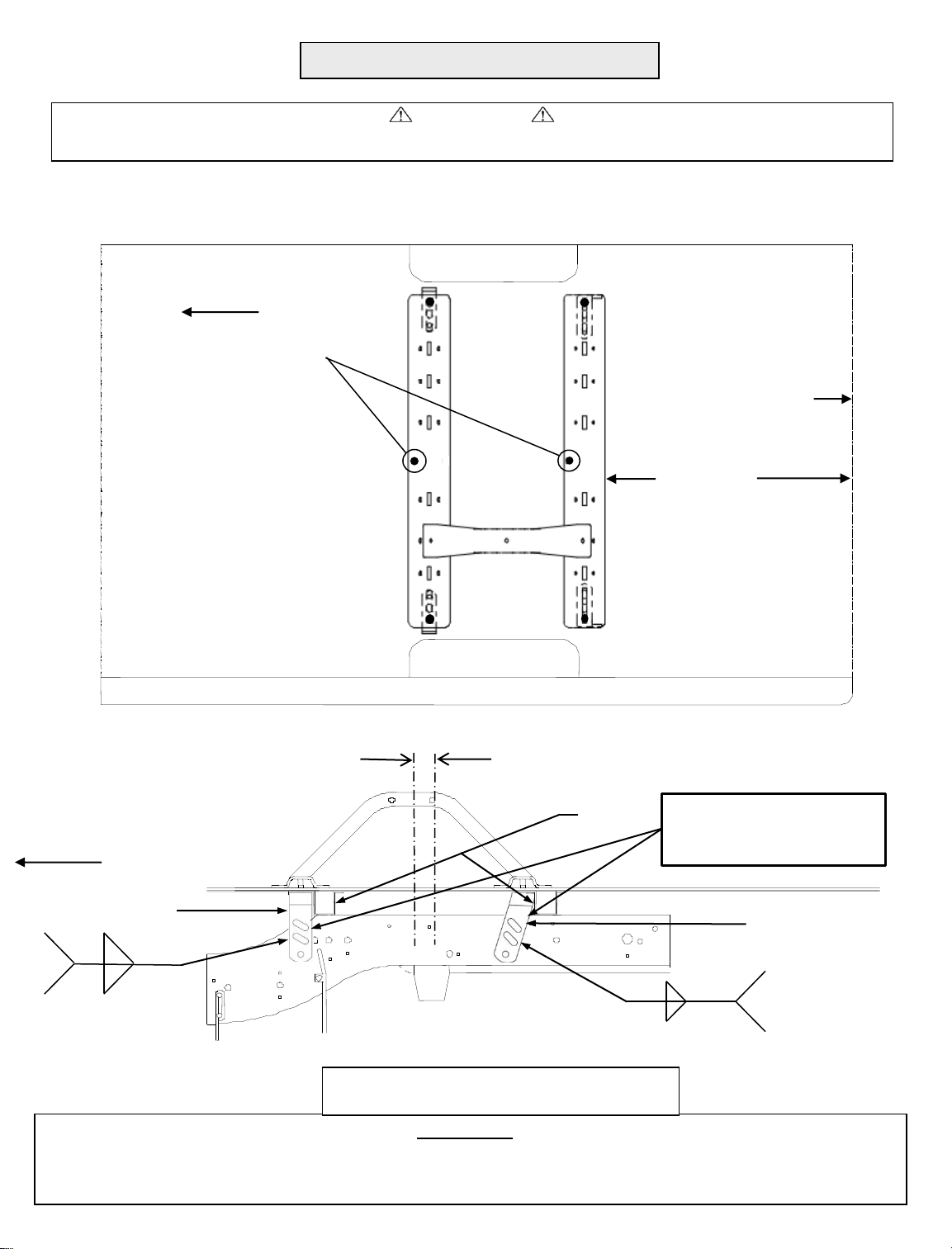

*** NOTE: 2009-CURRENT DODGE 1500 LONG BED & SHORT BED – REQUIRES ADAPTER KIT 58433

SEE 58433 INSTRUCTION FOR INSTALLATION

02-08 DODGE 1500

2002 – PRESENT DODGE 2500 – 3500 LONG BED & SHORT BED

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

Front of Vehicle

Fifth wheel hitches over 18k

must have a center bolt in the

center hole in both rails.

Note: Place center bolt in the

hole that does not interfere with

the bed sill. If needed, flip the

rail around.

Center bolts and hardware are

supplied with Fifth wheel or

gooseneck hitches that are rated

over 18k.

Measure from Rear Edge of

truck bed to rear edge of base

rail.

Rear Edge of

Truck Bed

27 7/8” Long Bed

25 7/8” Short Bed

U- Shaped Bracket.

Placed around bed

sill.

Front of

Vehicle

KING PIN CENTERED

APPROX OVER AXLE

CENTER

Bed sill

See the following page for more detailed information.

Note: Pull wire provided, will be needed to install

hardware in brackets through frame.

5th Wheel Leg

Angled bracket

(Inside of Frame)

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc.

Cequent Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately

the responsibility of the installer to prevent damage due to installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

1/4 2

8

Page 9

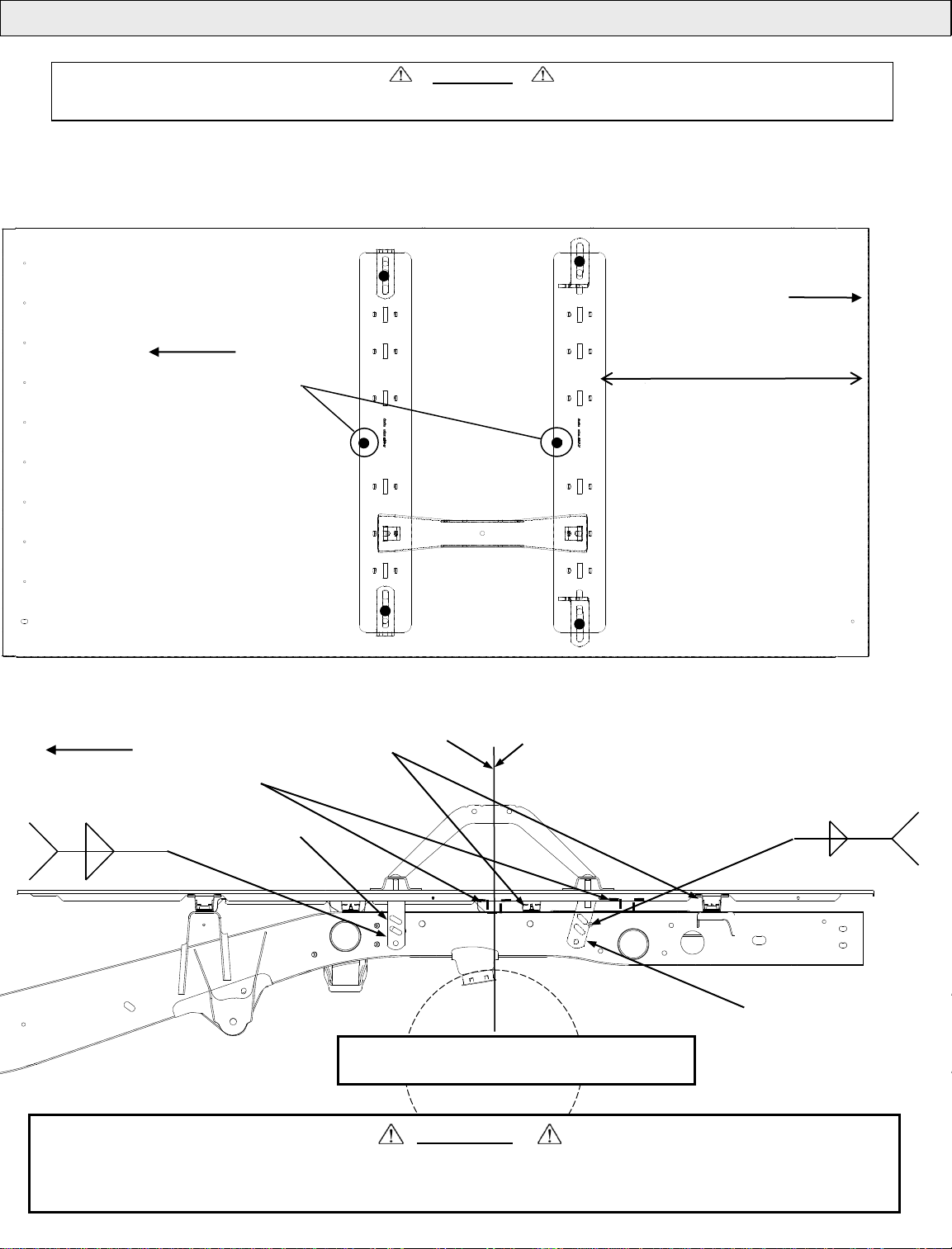

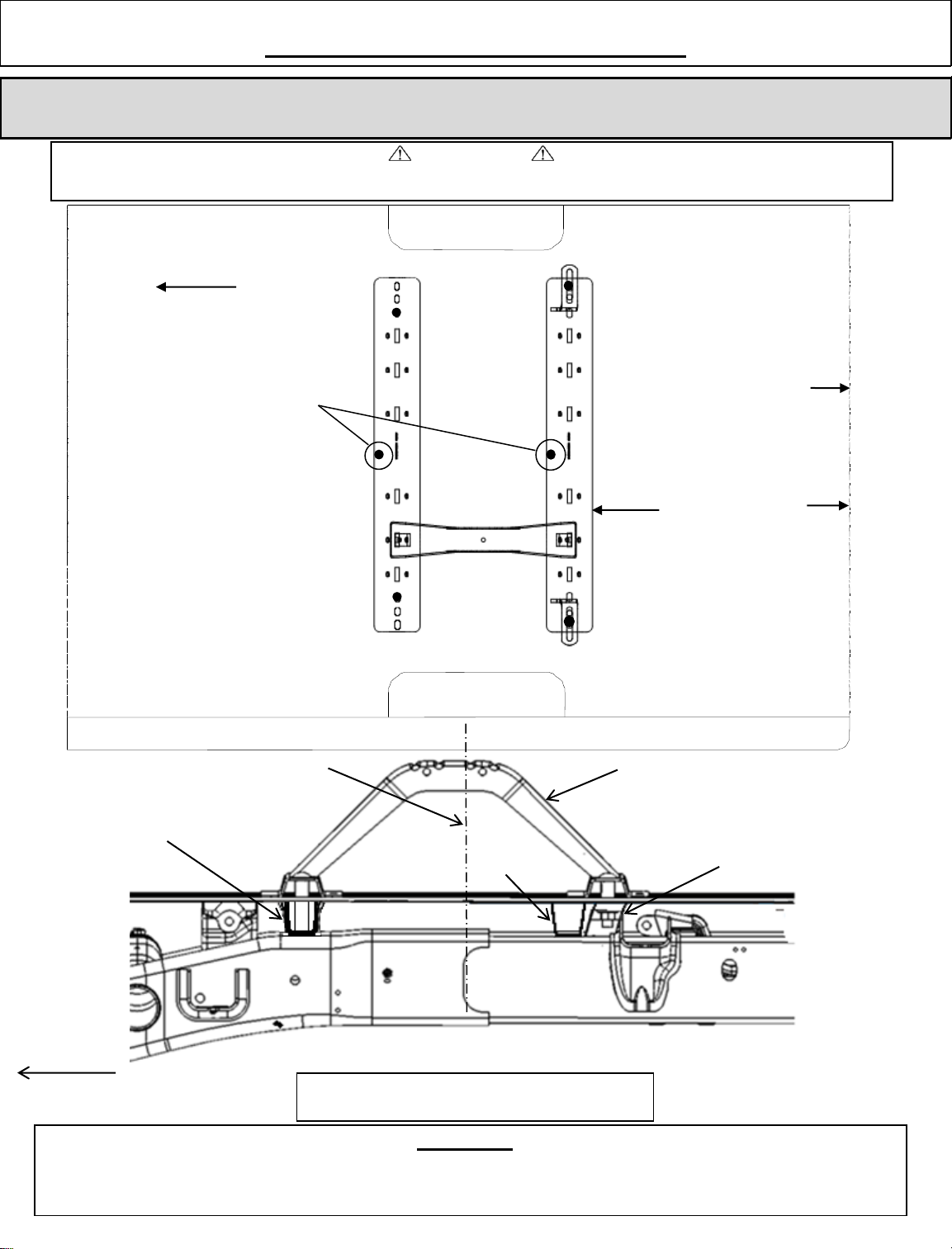

Continued from previous page.

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

Front of Vehicle

16

4

11

9

12

This sheet used for same vehicles

from previous PAGE.

ONLY ONE LEG SHOWN FOR CLARITY

7

8

5

10

2

6

13

14

PARTS LIST.

View Pg. 1 for complete list of parts

3. Place the long tube spacer(12) into the bed sill. Place the filler spacer(4) into the bed corrugation either above the bed, if

the hole is in the bottom of the corrugation or below the bed if the hole is in the top of the corrugation. Place the short tube

spacer(10) on the filler spacer(4). Set the rail in position. Install the 6” long carriage bolt(9) through the top of the rail and

out through the bottom of the bed sill.

4. Place the U-shaped bracket(16) over the bolt. Install the 5/8” serrated washer(13) and the 5/8” nut(14) on the bolt(9). Hand

tighten the nuts.

5. With the 5th wheel legs installed in the rails, mark the locations in the rear rail to be drilled. Drill an 1/8” pilot hole. See the

diagram on the previous page for hole location. Be sure that the angled bracket will align with the 1/8” pilot hole. See the

diagram above. The angle brackets are to be installed from the inside of the frame. Left and right angled brackets may be

interchanged if it helps to get the bracket installed on the frame. Drill the pilot hole out to 21/32”.

6. Place the filler spacer(4) in the bottom of the bed corrugation if the hole is in the bottom. Place the filler spacer(4) under the

bed corrugation if the hole is in the top of the corrugation. Place the short tube spacer(10) over the hole. Set the rear rail

over the tube spacer(10).

7. Insert the short carriage bolt(5) down through the rail and the spacer. Install the angled brackets on the carriage bolt (5).

Fasten with 5/8” serrated washer(13) and nut(14). Hand tighten.

8. Follow steps 10-12 on page 3. you will only be installing 4 knurled bolts(6) instead of the 8 called for in step 10. Remove the

heat shield around the spare tire if there is one and if it will give better access to the frame. Replace heat shield when done.

1. After placing the rear rail in position as shown on the previous page,

position the front rail with the 5th wheel legs in place. This will properly

locate the front rail. Drill an 1/8” hole in the bed using the holes shown in

the diagram shown above. Check to be sure the hole is in the center of the

bed sill.

2. Using the 1/8” pilot hole as a guide, drill the hole out with an 1-1/4” hole

saw. Using the pilot bit of the hole saw, dimple the bottom of the bed sill.

Drill this out to 21/32”.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

9

Page 10

94-01 DODGE 1500 & 94-02 DODGE 2500, 3500 LONG BED AND SHORT BED

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Find parallel rows of bed sill spot welds in bed of truck.

Front of Vehicle

Fifth wheel hitches over

18k must have a center

bolt the center hole in both

rails.

Note: Place center bolt in

the hole that does not

interfere with the bed sill. If

needed, flip the rail around.

Center bolts and hardware

are supplied with Fifth

wheel or gooseneck

hitches that are rated over

18k.

Measure from Rear Edge of

truck bed to rear edge of

base rail.

Rear Edge of

Truck Bed

28-7/16” Long Bed

24-5/16” Short Bed

Instructions continued on the next page.

Front

Axle Center

of

Vehicle

See following page

for carriage bolt (9)

installation

instructions.

Note: Pull wire provided, may be needed to install

hardware in brackets through frame.

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc.

Cequent Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately

the responsibility of the installer to prevent damage due to installation.

King Pin Center approx.

Over Axle Center

Bed Sill

Drivers side Ram 1500 Shown

Angled

bracket

1/4 2

1/4 2

*

* Optional

weld

pattern

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

10

Page 11

94-01 DODGE 1500 & 94-02 DODGE 2500, 3500 LONG BED AND SHORT BED

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc.

Cequent Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately

the responsibility of the installer to prevent damage due to installation.

1. Using the center mounting hole shown on the previous page, and below, for the front rail mounting holes, drill an 1-1/4”

hole through the truck bed.

2. Let the pilot bit of the hole saw dimple the top of the truck frame. Check to be sure you are above the truck frame.

Check to see that the inside of the frame at this location is clear of any wiring or brake lines. Drill a 21/32” hole through

the top flange of the truck frame.

3. Insert the long spacer(12), in the hole in the bed. Install the filler spacer(4) as shown in fig. 4 below. Install the short

spacer the(10) as shown below. Set the rail over the spacers and insert the long carriage bolt(9) through the holes.

4. Install 5/8” serrated washers(13) and 5/8” nuts(14) on the bolts.

5. Torque all ½” nuts to 75 ft-lb and all 5/8” nuts to 130 ft-lb.

CARRIAGE BOLT(9)

Instructions continued from

previous page.

TRUCK FRAME

WASHER(13) AND

NUT(14) BELOW

FRAME FLANGE

TRUCK BED

SHORT SPACER(10)

FILLER SPACER(4))

LONG SPACER(12)

30095N 1/30/12 REV. H

FILLER SPACER SHOWN BELOW BED WITH

BOLT IN THIS POSITION

FILLER SPACER SHOWN ABOVE BED WITH

BOLT IN THIS POSITION

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

11

Page 12

DODGE THROUGH 93 (FULL SIZE)

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Find parallel rows of bed sill spot welds in bed of truck. No drilling should be done in the approximately 4” between

parallel rows of spot welds where the bed sill sets.

Front of Vehicle

Fifth wheel hitches over

18k must have a center

bolt in the center hole in

both rails.

Note: Place center bolt in

the hole that does not

interfere with the bed sill. If

needed, flip the rail around.

Center bolts and hardware

are supplied with Fifth

wheel or gooseneck

hitches that are rated over

18k.

Measure from Rear Edge of

truck bed to rear edge of

base rail.

Rear Edge of

Truck Bed

Long bed &

Short bed

32”

Hitch center approximately 3” ahead

of axle center.

Front of

Vehicle

Straight bracket

1/4 1.5-3

*

1/4 2

Note: Pull wire provided, will be needed to install

hardware in brackets through frame.

Axle center

Bed Sill

Left, right angle and frame

brackets maybe place where

ever brackets fits best.

Drivers side of 1/2 ton Ram Shown

Angled bracket

* Optional weld

pattern

1/4 2

1/4 2

*

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc.

Cequent Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately

the responsibility of the installer to prevent damage due to installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

12

Page 13

2005-CURRENT FORD F-250, F-350 & F-450 SUPER DUTY (NOT CAB-CHASSIS)

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Find parallel rows of bed sill spot welds in bed of truck. No drilling should be done in the approximately 4” between

parallel rows of spot welds where the bed sill sets.

2. It may be necessary to move the brake cable hanger bracket into another hole just rearward from its present

location.

Front of Vehicle

Fifth wheel hitches over

18k must have a center

bolt in the center hole in

both rails.

Note: Place center bolt in

the hole that does not

interfere with the bed sill. If

needed, flip the rail around.

Center bolts and hardware

are supplied with Fifth

wheel or gooseneck

hitches that are rated over

18k.

Straight Bracket

Angled Bracket

Straight Bracket

Rear Edge of

Truck Bed

30 3/16” Long Bed

& Short Bed

Measure from Rear Edge of

truck bed to rear edge of base

rail.

Angled Bracket

Hitch center approximately

Over the axle center.

Front of

Vehicle

Bed sill

* Optional weld pattern. Typical for all 4

brackets.

DRIVERS SIDE

Note: Pull wire provided, will be needed to install

hardware in brackets through frame.

PASSENGERS SIDE

Bed sill

1/4 2

*

1/4 2

F-350 super Duty long bed

frame shown

Front of

Vehicle

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc. Cequent

Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately the responsibility of the

installer to prevent damage due to installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

13

Page 14

1992-2004 FORD F-250 & F-350 SHORT & LONG BED

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Find parallel rows of bed sill spot welds in bed of truck. No drilling should be done in the approximately 4” between parallel

rows of spot welds where the bed sill sets.

Measure from Rear Edge of

Front of Vehicle

truck bed to rear edge of base

rail.

Fifth wheel hitches over

18k must have a center

bolt in the center hole in

both rails.

Note: Place center bolt in

the hole that does not

interfere with the bed sill. If

needed, flip the rail around.

Center bolts and hardware

are supplied with Fifth

wheel or gooseneck

hitches that are rated over

18k.

Front of

Vehicle

Axle Center

Rear Edge of

Truck Bed

30 3/16” Long Bed

and Short Bed

King Pin Center approx. 1/2” rearward of

Axle Center

Bed Sill

Drivers side of F350 Super Duty

long bed Shown

Angled bracket

STRAIGHT

BRACKET

1/4 2

*

1/4 2

Note: Pull wire provided, will be needed to install

hardware in brackets through frame.

1/4 2

1/4 2

*

* Optional weld pattern

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc. Cequent

Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately the responsibility of the

installer to prevent damage due to installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

14

Page 15

97-2003 FORD F-150 & F-250 LD & 2004 HERITAGE MODEL

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Find parallel rows of bed sill spot welds in bed of truck. No drilling should be done in the approximately 4” between

parallel rows of spot welds where the bed sill sets.

Measure from Rear Edge of

Front of Vehicle

truck bed to rear edge of base

rail.

Fifth wheel hitches over

18k must have a center

bolt in the center hole in

both rails.

Note: Place center bolt in

the hole that does not

interfere with the bed sill. If

needed, flip the rail around.

Center bolts and hardware

are supplied with Fifth

wheel or gooseneck

hitches that are rated over

18k.

Left, right angle and frame

brackets maybe place where

ever brackets fits best.

Axle

Center

Rear Edge of

Truck Bed

26-5/16” Long Bed

and Short Bed

King Pin Center approx.. 1-1/2”

rearward of axle center.

Bed Sill

Drivers side of F150 shown

STRAIGHT

BRACKET

Front of

Vehicle

*

1/4 2

1/4 2

1/4 2

1/4 2

Note: Pull wire provided, will be needed to install

hardware in brackets through frame.

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc.

Cequent Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately

the responsibility of the installer to prevent damage due to installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

ANGLED

BRACKET

*

15

Page 16

2000-06, TOYOTA TUNDRA (STANDARD CAB LONG BED ONLY)

CAUTION!

Read pages 1-3 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

IMPORTANT NOTES FOR THIS INSTALLATION:

1. Find parallel rows of bed sill spot welds in bed of truck. No drilling should be done in the approximately 4” between

parallel rows of spot welds where the bed sill sets.

2000-06, TOYOTA TUNDRA long: (Approx. over the axle)

With Fifth wheel assembly in the bed of the truck. Position the rear rail 30 7/16” from rear edge of truck bed. Attach the left and right

angled frame brackets to the rear Fifth wheel rail. Note: The left and right angle bracket can be mounted on either side of the truck if

needed. Then attach the frame bracket to the front Fifth wheel rail.

Front of Vehicle

Fifth wheel hitches over

18k must have a center

bolt in the center hole in

both rails.

Note: Place center bolt in

the hole that does not

interfere with the bed sill. If

needed, flip the rail around.

Center bolts and hardware

are supplied with Fifth

wheel or gooseneck

hitches that are rated over

18k.

Measure from Rear Edge of

truck bed to rear edge of

base rail.

Rear Edge of

Truck Bed

30 7/16”

King Pin Centered approx. 1-1/4”

forward of Axle Center

Straight bracket

1/4 1.5-3

*

1/4 2

Note: Pull wire provided, will be needed to install

hardware in brackets through frame.

Axle Center

Left, right angle and frame

brackets maybe place where

ever brackets fits best.

Drivers side shown

1/4 2

1/4 2

* Optional weld pattern

CAUTION!

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural members, etc.

Cequent Performance Products, Inc. does its best to communicate tow vehicle manufacturer changes; however, it is ultimately

the responsibility of the installer to prevent damage due to installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

Angled bracket

*

16

Page 17

THREE YEAR LIMITED WARRANTY

Cequent Performance Products, Inc. warrants its Fifth Wheel Hitch Mounting Kits from date of purchase against defects in material and

workmanship under normal use and service, ordinary wear and tear excepted, for 3 years of ownership to the original consumer

purchaser when a Cequent Performance Products, Inc. mounting kit is used.

Cequent Performance Products, Inc. will replace FREE OF CHARGE any part which proves defective in material or workmanship when

presented to any Cequent Performance Products, Inc. dealer Cequent Performance Products, Inc. Warehouse or returned to the factory.

TRANSPORTATION CHARGES PREPAID. THIS WARRANTY IS LIMITED TO DEFECTIVE PARTS REPLACEMENT ONLY. LABOR CHARGES

AND/OR DAMAGE INCURRED IN INSTALLATION OR REPLACEMENT AS WELL AS INCIDENTAL AND CONSEQUENTIAL DAMAGES

CONNECTED THEREWITH ARE EXCLUDED.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not

apply to you.

Any damage to the Fifth Wheel Hitch as a result of misuse, abuse, neglect, accident, improper installation, or any use violative of

instructions furnished by us, WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. In the event of a problem

with warranty service or performance, you may be able to go to a small claims court, or a federal district court.

Cequent Performance Products, Inc.

47912 Halyard Dr. Suite 100

Plymouth, MI. 48170

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

17

Page 18

INSTRUCTIONS D’INSTALLATION

ENSEMBLE DE TRAVERSES DE MONTAGE 30095

Pour mise à jour des instructions voir

CONCESSIONNAIRE/INSTALLATEUR:

(1) Remettre ce manuel à l’utilisateur final.

(2) Démontrer physiquement à l’utilisateur les procédures d’attelage et de dételage décrites dans ce manuel.

(3) Demander à l’utilisateur de démontrer qu’il comprend bien ces procédures.

UTILISATEUR FINAL :

(1) Lire ce manuel et suivres les instructins à chaque utilisation de l’attelage.

(2) Conserver ce manuel pour toute référence future.

(3) Remettre des copies du manuel à tout autre utilisateur ou propriétaire.

*Pour faciliter l’installation: Un boulon à

tête hexagonale (5/8” x 3-1/2”) peut être

utilisé avec une rondelle plate au-dessus du

rail à la place du boulon à voiture (5/8” x 31/2”). Grade 5 ou supérieur. Boulon à tête

hexagonale et rondelle non inclus.

5*

www.ReeseProducts.com ou www.Draw-Tite.com

9

Les boulons et la ferronnerie

du centre sont fournies avec

les attelages à sellette ou à

col de cygne dont la charge

nominale est supérieure à

18 000 livres.

15

7

8

1

6

ENSEMBLE DE TRAVERSES DE MONTAGE ___ _ QTÉ

1. SUPPORT DE CADRE RECTILIGNE (2)

2. SUPPORT DE CADRE ANGULAIRE (D) (1)

3. SUPPORT DE CADRE ANGULAIRE (G) (1)

4. ESPACEUR DE REMPLISSAGE – 5/16” ÉPAISS. (4)

5. BOULONS DE CARROSSERIE 5/8” x 3-1/2” GR5 (4)

6. BOULONS MOLETÉS ½” x 1-1/2” GR 5 (8)

7. ÉCROUS 1/2” (8)

8. RONDELLES STRIÉES 1/2” (8)

9. BOULON DE CARROSSERIE 5/8” x 6” GR5 (2)

10. ESPACEUR TUBULAIRE, 1-1/4" LONG. (4)

11. TRAVERSES DE MONTAGE (2)

12. ESPACEUR TUBULAIRE, 2-3/8" LONG. (2)

13. RONDELLES STRIÉES 5/8” (4)

14. ÉCROUS 5/8” (4)

15. FIL DE TIRAGE ½” (4)

3

10

13

1

11

12

4

2

14

Fig. 1

REMARQUE : LA FERRONNERIE NE SERA PAS NÉCESSAIREMENT UTILISÉE EN ENTIER DANS TOUTES LES INSTALLATIONS.

Pour obtenir de l'assistance pour l'installation ou un autre aspect technique, composer le 1-888-521-0510

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

Page 19

INSTRUCTIONS GÉNÉRALES POUR L'INSTALLATION DES TRAVERSES 30035

OUTILS

Mèche 1/8" Clé ouverte et douille 3/4" Douille 15/16”

Mèche 17/32" Clé dynamométrique 100 lb-pi Perceuse 21/32"

Cloche-scie 1 1/4” Brides en "C" Douilles 10 mm

(Certaines applic. Dodge seul.) (Certaines applications)

1. Les instructions suivantes doivent être suivies pour le montage de la sellette. Un travail soigné et une attention aux détails procurera une

installation rapide de qualité. Comparez les pièces avec celles qui sont énumérées dans la liste pour vous familiariser avec les éléments du

montage. (Voir la Fig. 1)

2. Soulevez l'arrière de la camionnette à une hauteur suffisante pour placer les vérins sous le support de la main de ressort arrière de la

camionnette. Vous disposerez ainsi du maximum d'espace pour installer les supports de sellette.

3. N'installez pas les rails sur la doublure de caisse en plastique. La doublure de caisse en plastique doit être découpée pour libérer l'accès.

Les traverses peuvent être installées sur une doublure pulvérisée en place. Nota : Consultez l'installateur pour connaître le temps de

durcissement recommandé.

4. Utiliser seulement les boulons, écrous et rondelles fournis par Cequent Performance Products, Inc. pour installer ce produit. Tous les

boulons et les écrous sont de classe 5 sauf indication contraire.

5. Des instructions particulières pour la plupart des véhicules usagés sont incluses. Chaque support de cadre doit être boulonné au cadre du

véhicule à l'aide de deux boulons, sauf si la soudure facultative est préférée.

Pour éviter que la cabine ne soit heurtée par la remorque lorsque celle-ci se trouve à un angle de 90°, le centre de l'attelage doit être à une

distance d'au moins 52" (132 cm) de l'arrière de la cabine s'il s'agit d'une camionnette à plateforme longue.

Ces instructions servent à vous guider seulement. L'installation relève de la responsabilité de l’installateur et

du propriétaire. Mesurez toujours la camionnette et la remorque avant d'installer l'attelage pour vous assurer

(La distance réelle requise dépendra de la largeur de la remorque et de l'emplacement du pivot d'attelage.) Les camionnettes à plateforme

courte (minimum de 38 po / 97 cm entre l'arrière de cabine et la ligne de centre de l'essieu) exigent un boîtier de pivot allongé d'un minimum

de 13 po / 33 cm, avec curseur Kwik-Slide ou un coupleur pour boîtier de pivot SIDEWINDER, pour les manoeuvres régulières. NE TENTEZ

PAS D'INSTALLER OU DE REMORQUER AVEC UNE CAMIONNETTE DONT LA PLATEFORME FAIT MOINS DE 6 PI (1,83 M) SI UN

CARTER DE PIVOT SIDEWINDER N'EST PAS INSTALLÉ SUR LA REMORQUE.

6. Les mesures pour le positionnement des traverses consistent en la distance entre le bord arrière de la plateforme de la camionnette et le

bord arrière de la traverse la plus proche du bord arrière de la camionnette, et ce pour la plupart des modèles.

7. Centrez l'attelage entre les compartiments d'aile et assurez-vous que les traverses sont d'équerre. Réglez la position des traverses jusqu'à

ce que les diagonales mesurées soient identiques. Ceci devrait permettre l'installation d'un attelage col de cygne ou à sellette sur ces

traverses.

Si la camionnette est soulevée, assurez-vous qu'elle est adéquatement bloquée et retenue

pour prévenir sa chute. L’omission de procéder ainsi peut entraîner la chute de la

camionnette et causer des blessures sévères, voire la mort.

que le dégagement à la cabine et au pare-chocs est suffisant pour permettre les virages.

Fig. 2

AVERTISSEMENT :

ATTENTION :

AVANT

Pour obtenir de l'assistance pour l'installation ou un autre aspect technique, composer le 1-888-521-0510

30095N 1/30/12 REV. H

Mesure entre

Mesurer la

diagonale à partir

du même point de

référence. Les

la traverse

arrière et le

bord arrière de

la plateforme

mesures doivent

être identiques.

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

19

Page 20

1/4" 2.00"

1/4" 2.00"

1/4" 2.00"

1/4" 2.00"

ATTENTION :

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut

causer l'endommagement des conduites de carburant ou de frein, des éléments structuraux, etc.

Cequent Performance Products, Inc. fait de son mieux pour communiquer les modifications des

constructeurs des véhicules de remorquage; cependant, il est ultimement de la responsabilité de

l'installateur de prévenir les dommages associés à l'installation.

8. Marquer 4 trous à percer dans la plateforme (voir les illustrations pour votre modèle). Mesurer attentivement pour déterminer si le support

de cadre se trouve sous le trou de la traverse que vous avez choisie. (L'emplacement du trou variera selon le modèle de véhicule.) Percez

quatre (4) trous à l'aide de la perceuse 1/8 po. S'assurer que les supports de cadre s'aligneront sur les trous 1/8 po tout juste percés. Si ce

n'est pas le cas, déplacer légèrement soit les supports de cadre, soit les traverses. Percer un autre trou de 1/8 po et vérifier à nouveau. Puis

à l'aide d'une perceuse 21/32 po, agrandir les trous 1/8 po percés. Utilisez toujours des forets de perceuse affûtés. Posez l'espaceur

tubulaire entre la traverse et la plateforme, posez les boulons de carrosserie 5/8 po dans les trous. Posez l'espaceur de remplissage audessus ou au-dessous de la plateforme pour remplir les ondulations du plancher. Voir la FIG. 4 à la page 11. Cette manoeuvre vise à

remplir tout espace entre le support de cadre et la traverse. Cela empêchera les ondulations de la plateforme de s'écraser une fois les

boulons serrés.

9. Posez les supports de montage sur les boulons de carrosserie. Utilisez les supports de cadre angulaires gauche et droit aux endroits où

des obstacles au cadre empêcheront le positionnement des supports de cadre rectilignes. Fixez les boulons dans les supports de montage à

l'aide des rondelles striées et des écrous hexagonaux.

10. Percez deux trous de 17/32 po dans le cadre de camionnette pour chaque support de cadre. Choisissez les trous qui donneront le plus

grand écart entre les boulons. Posez huit boulons à collet dentelé 1/2-13 x 1-3/8 po (filetage pointant vers l'extérieur), avec rondelles striées

et écrous hexagonaux. Serrez les écrous jusqu'à appuyer les têtes de boulon. La lubrification du collet dentelé des boulons de ce type est

recommandée. Mais seulement la partie dentelée. (Voir la figure ci-dessous pour l'option soudure)

Nota : Sur les véhicules à suspension pour usage intensif, vérifiez si les boulons constituent un obstacle là où les

supports sont montés sur le cadre. S'ils présentent une obstruction pour les ressorts de suspension, coupez les

boulons au niveau dde l'écrou du côté extérieur du cadre, ou optez pour un montage soudé.

NE PAS lubrifier les filets. Cela peut causer la défaillance des boulons.

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut causer

l'endommagement des conduites de carburant ou de frein, des éléments structuraux, etc. Cequent

Performance Products, Inc. fait de son mieux pour communiquer les modifications des constructeurs des

véhicules de remorquage; cependant, il est ultimement de la responsabilité de l'installateur de prévenir les

dommages associés à l'installation.

Il est important que la perceuse 17/32 po soit utilisée pour les trous dans le cadre de

châssis, puisque les boulons à collet dentelé risquent de se rompre si le trou est trop

petit et le collet risque de ne pas s'agripper si le trou est trop grand.

11. Serrez tous les écrous 1/2 po au couple de 75 lb-pi et tous les écrous 5/8 po au couple de 130 lb-pi.

12. Les fils de tirage sont fournis pour acheminer les boulons à collet dentelé à travers le cadre, selon les

besoins de votre modèle particulier. Voir la figure 1.

L'OPTION SOUDURE PEUT S'UTILISER

SUR TOUTES LES CAMIONNETTES

Fig. 3

AVERTISSEMENT :

ATTENTION :

ATTENTION :

LES SUPPORTS AVANT ET ARRIÈRE

PEUVENT ÊTRE INTERVERTIS POUR

UN MEILLEUR AJUSTEMENT

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

20

Page 21

Chevy et GM 2011 2500 HD et 3500 HD Silverado et Sierra

MISE EN GARDE !

Lire attentivement les pages 1 à 3 de ces instructions avant de commencer l’installation.

Le défaut d’observer ce conseil peut causer des dommages importants au véhicule !

NOTES IMPORTANTES CONCERNANT CETTE INSTALLATION :

1. Repérer les rangées parallèles de soudures par points au niveau de la pièce d'appui de la plateforme. Aucun

perçage ne doit être effectué dans les rangées parallèles (d'environ 4 po) de soudures par points à l'endroit où est

fixée la pièce d'appui de la plateforme.

Bord arrière de

la plateforme

Avant du

véhicule

Platef. longue = 29 11/16”

Platef. courte = 25 3/16”

Le boulon du centre des

attelages à sellette de plus de

18 000 livres de capacité doit se

trouver dans le trou central des

deux traverses de montage.

Nota : Placer le boulon du centre

dans le trou qui ne gêne pas la

pièce d'appui de la plateforme.

En cas de nécessité, retourner la

traverse.

Les boulons et la ferronnerie du

centre sont fournies avec les

attelages à sellette ou à col de

cygne dont la charge nominale

est supérieure à 18 000 livres.

Mesurer à partir du bord

arrière de la plateforme

jusqu'au bord arrière de la

traverse.

Avant du véhicule

Pièces d’appui courtes

1/4 1.5-3

*

1/4 2

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut

causer l'endommagement des conduites de carburant ou de frein, des éléments structuraux, etc.

Cequent Performance Products, Inc. fait de son mieux pour communiquer les modifications des

constructeurs des véhicules de remorquage; cependant, il est ultimement de la responsabilité de

Pièces d’appui longues

Support de cadre

rectiligne

l'installateur de prévenir les dommages associés à l'installation.

Pivot d’attelage

Nota : Fil de tirage fourni, nécessaire pour poser

la visserie dans les supports à travers le cadre.

Centre de l’essieu

Côté conducteur du modèle 3/4 tonne HD illustré

MISE EN GARDE !

* Patron de soudure facultatif

1/4 2

1/4 2

Support angulaire

sur l’intérieur

du cadre

*

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

21

Page 22

Modèle GM ‘99 Silverado, Sierra (et non Sierra Classic)

Chevy et GMC ‘00 à 10 Silverado, Sierra y compris modèles HD, et ’04 et plus récent 1500 Crew

Cab avec plateforme 5’8” (carter de pivot Reese™ Sidewinder® Pinbox requis pour plateforme 5’8”)

MISE EN GARDE !

Lire attentivement les pages 1 à 3 de ces instructions avant de commencer l’installation.

Le défaut d’observer ce conseil peut causer des dommages importants au véhicule !

NOTES IMPORTANTES CONCERNANT CETTE INSTALLATION :

1. Repérer les rangées parallèles de soudures par points au niveau de la pièce d'appui de la plateforme. Aucun

perçage ne doit être effectué dans les rangées parallèles (d'environ 4 po) de soudures par points à l'endroit où est

fixée la pièce d'appui de la plateforme.

Avant du

véhicule

Le boulon du centre des

attelages à sellette de plus de

18 000 livres de capacité doit

se trouver dans le trou central

des deux traverses de

montage.

Nota : Placer le boulon du

centre dans le trou qui ne

gêne pas la pièce d'appui de

la plateforme. En cas de

nécessité, retourner la

traverse.

Les boulons et la ferronnerie

du centre sont fournies avec

les attelages à sellette ou à

col de cygne dont la charge

nominale est supérieure à

18 000 livres.

Trou

central

Trou

central

Bord arrière de

la plateforme

Platef. longue =31”

Platef. courte =23 1/2”

Mesurer à partir du bord

arrière de la plateforme

jusqu'au bord arrière de la

traverse.

Les supports angulaires

gauche et droit et les

supports de cadre peuvent

être placés là où ils

s'adaptent le mieux.

Pièce d’appui

Côté conducteur du modèle

3/4 tonne Chevy Long Box illustré

Support angulaire

* Patron de soudure facultatif

Avant du

Centre du pivot d’attelage approx.

3-1/2” à l’avant du centre de l’essieu

Centre de l’essieu

véhicule

Support rectiligne

1/4 1.5-3

*

1/4 2

Nota : Fil de tirage fourni, nécessaire pour poser

la visserie dans les supports à travers le cadre.

MISE EN GARDE !

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut causer l'endommagement des

conduites de carburant ou de frein, des éléments structuraux, etc. Cequent Performance Products, Inc. fait de son mieux pour

communiquer les modifications des constructeurs des véhicules de remorquage; cependant, il est ultimement de la responsabilité

de l'installateur de prévenir les dommages associés à l'installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

22

Page 23

CHEVROLET/GMC 88-98 et 92-98 4 portes et 99 SILVERADO

SIERRA CLASSIC (avec cadre rétréci) (feux de direction rouges)

MISE EN GARDE !

Lire attentivement les pages 1 à 3 de ces instructions avant de commencer l’installation.

Le défaut d’observer ce conseil peut causer des dommages importants au véhicule !

NOTES IMPORTANTES CONCERNANT CETTE INSTALLATION :

1. Repérer les rangées parallèles de soudures par points au niveau de la pièce d'appui de la plateforme. Aucun

perçage ne doit être effectué dans les rangées parallèles (d'environ 4 po) de soudures par points à l'endroit où est

fixée la pièce d'appui de la plateforme.

Avant du

Trou central

véhicule

Le boulon du centre des

attelages à sellette de plus de

18 000 livres de capacité doit

se trouver dans le trou central

des deux traverses de

montage.

Nota : Placer le boulon du

centre dans le trou qui ne

gêne pas la pièce d'appui de

la plateforme. En cas de

nécessité, retourner la

traverse.

Les boulons et la ferronnerie

du centre sont fournies avec

les attelages à sellette ou à

col de cygne dont la charge

nominale est supérieure à

18 000 livres.

Centre du pivot d'attelage au-dessus

du centre de l'essieu

Avant du

véhicule

Trou intérieur

Trou central

Centre de

l’essieu

Bord arrière de

la plateforme

Platef. longue = 29 7/16”

Platef. courte =23 15/16”

Mesurer à partir du bord

arrière de la plateforme

jusqu'au bord arrière de la

traverse.

Trou intérieur

* Patron de soudure facultatif

Les supports angulaires

gauche et droit et les

supports de cadre peuvent

être placés là où ils

s'adaptent le mieux.

Pièce d'appui

Support rectiligne

*

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut causer

l'endommagement des conduites de carburant ou de frein, des éléments structuraux, etc. Cequent Performance

Products, Inc. fait de son mieux pour communiquer les modifications des constructeurs des véhicules de remorquage;

cependant, il est ultimement de la responsabilité de l'installateur de prévenir les dommages associés à l'installation.

30095N 1/30/12 REV. H

1/4 1.5-3

1/4 2

Côté conducteur 1/2 tonne Long Box illustré

Support angulaire

1/4 2

1/4 2

Nota : Fil de tirage fourni, nécessaire pour poser

la visserie dans les supports à travers le cadre.

MISE EN GARDE !

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

* Patron de soudure

*

facultatif

23

Page 24

Chevrolet et GMC 73 à 87 et 73 à 92 4 portes (34” droit, avec amortisseurs intérieurs)

MISE EN GARDE !

Lire attentivement les pages 1 à 3 de ces instructions avant de commencer l’installation.

Le défaut d’observer ce conseil peut causer des dommages importants au véhicule !

NOTES IMPORTANTES CONCERNANT CETTE INSTALLATION :

1. Repérer les rangées parallèles de soudures par points au niveau de la pièce d'appui de la plateforme. Aucun

perçage ne doit être effectué dans les rangées parallèles (d'environ 4 po) de soudures par points à l'endroit où est

fixée la pièce d'appui de la plateforme.

Avant du

véhicule

Le boulon du centre des

attelages à sellette de plus de

18 000 livres de capacité doit

se trouver dans le trou central

des deux traverses de

montage.

Nota : Placer le boulon du

centre dans le trou qui ne

gêne pas la pièce d'appui de

la plateforme. En cas de

nécessité, retourner la

traverse.

Les boulons et la ferronnerie

du centre sont fournies avec

les attelages à sellette ou à

col de cygne dont la charge

nominale est supérieure à

18 000 livres.

Centre du pivot d’attelage

approx. 3 1/2” (platef. longue)

et plateforme courte au-dessus

du centre de l’essieu

Support rectiligne

Trou

central

Trou

central

Pièce

d'appui

Platef. longue =33 3/16”

Platef. courte =23 3/16”

Centre de

l’essieu

Côté conducteur du modèle 1/2 tonne

Chevy Long Box illustré

Bord arrière de

la plateforme

Mesurer à partir du bord

arrière de la plateforme

jusqu'au bord arrière de la

traverse.

Les supports angulaires

gauche et droit et les

supports de cadre peuvent

être placés là où ils

s'adaptent le mieux.

Avant du

véhicule

1/4 1.5-3

*

1/4 2

Nota : Fil de tirage fourni, nécessaire pour poser

la visserie dans les supports à travers le cadre.

MISE EN GARDE !

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut causer

l'endommagement des conduites de carburant ou de frein, des éléments structuraux, etc. Cequent Performance

Products, Inc. fait de son mieux pour communiquer les modifications des constructeurs des véhicules de remorquage;

cependant, il est ultimement de la responsabilité de l'installateur de prévenir les dommages associés à l'installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

Support

angulaire

* Patron de soudure

facultatif

24

Page 25

2009-PRÉSENT DODGE 1500 PLATEFORMES LONGUE ET COURTE – DEMANDE ENSEMBLE ADAPTATEUR 58433

VOIR INSTRUCTIONS DE 58433 POUR INSTALLATION

02-08 DODGE 1500

2002 – PRÉSENT DODGE 2500 – 3500 PLATEFORMES LONGUE ET COURTE

MISE EN GARDE !

Lire attentivement les pages 1 à 3 de ces instructions avant de commencer l’installation.

Le défaut d’observer ce conseil peut causer des dommages importants au véhicule !

Avant du véhicule

Le boulon du centre des

attelages à sellette de plus de

18 000 livres de capacité doit se

trouver dans le trou central des

deux traverses de montage.

Nota : Placer le boulon du centre

dans le trou qui ne gêne pas la

pièce d'appui de la plateforme.

En cas de nécessité, retourner

la traverse.

Les boulons et la ferronnerie du

centre sont fournies avec les

attelages à sellette ou à col de

cygne dont la charge nominale

est supérieure à 18 000 livres.

Platef. longue 27 7/8”

Platef. courte 25 7/8”

Mesurer à partir du bord

arrière de la plateforme

jusqu'au bord arrière de la

traverse.

Bord arrière de la

plateforme

PIVOT D'ATTELAGE CENTRÉ

APPROX. AU-DESSUS DU

Support en U.

Placé autour de

la pièce d’appui.

Avant du

véhicule

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut causer

l'endommagement des conduites de carburant ou de frein, des éléments structuraux, etc. Cequent Performance

Products, Inc. fait de son mieux pour communiquer les modifications des constructeurs des véhicules de remorquage;

cependant, il est ultimement de la responsabilité de l'installateur de prévenir les dommages associés à l'installation.

30095N 1/30/12 REV. H

CENTRE DE L’ESSIEU

Pièce

d'appui

Voir la page suivante pour de l’information détaillée.

Nota : Fil de tirage fourni, nécessaire pour poser

la visserie dans les supports à travers le cadre.

MISE EN GARDE !

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

Patte de

sellette

Support angulaire

(intérieur du cadre)

1/4 2

25

Page 26

2002 – PRÉSENT DODGE 2500 – 3500 PLATEFORMES LONGUE ET COURTE

Lire attentivement les pages 1 à 3 de ces instructions avant de commencer l’installation.

Le défaut d’observer ce conseil peut causer des dommages importants au véhicule !

Avant du véhicule

MISE EN GARDE !

16

Suite de la page précédente.

UNE SEULE PATTE MONTRÉE

15

PAR SOUCI DE CLARTÉ

4

LISTE DES PIÈCES QTY

1. SUPPORT DE CADRE ANGULAIRE (D) (1)

2. SUPPORT DE CADRE ANGULAIRE (G) (1)

3. ESPACEUR DE REMPL. – 5/16” ÉPAIS (4)

4. BOULONS CARROSS. 5/8” x 3-1/2” GR 5 (4)

5. BOULONS MOLETÉS ½” x 1-1/2” GR 5 (8)

6. ÉCROUS 1/2” (8)

7. RONDELLES STRIÉES 1/2” (8)

8. BOULONS CARROSS. 5/8” x 6” GR 5 (2)

9. ESPACEUR TUBULAIRE - 1-1/4” LONG (4)

10. TRAVERSES DE MONTAGE (2)

11. ESPACEUR TUBULAIRE – 2-3/8” LONG (2)

12. RONDELLES STRIÉES 5/8” (4)

13. ÉCROUS 5/8” (4)

14. SUPPORT EN U (2)

15. PATTE DE SELLETTE (2)

16. TRAVERSE DE MONTAGE (2)

8

9

2

3

11

6

14

7

5

12

13

1. Après avoir positionné la traverse arrière comme illustré à la page précédente,

positionner la traverse avant avec les pattes de sellette en place. Cela aura pour

effet de bien positionner la traverse avant. Percer un trou de 1/8” dans la

plateforme en utilisant les trous indiqués dans le diagramme ci-dessus. S’assurer

que le trou se trouve au centre de la pièce d'appui de la plateforme.

2. En se servant du trou 1/8” comme guide, percer un trou plus grand avec une scie-

cloche de 1-1/4”. À l'aide de la mèche-pilote de la scie-cloche, creuser légèrement

le bas de la pièce d'appui. Puis percer cet endroit à 21/32 po.

3. Placer l'espaceur tubulaire long (11) dans la pièce d'appui de la plateforme. Placer l'espaceur de remplissage (3) dans une ondulation

de la plateforme, soit au-dessus de celle-ci si le trou est dans le fond de l'ondulation, soit sous la plateforme si le trou est sur le sommet

de l'ondulation. Placer l'espaceur tubulaire court (art. 9) sur l'espaceur de remplissage (3). Placer la traverse en position. Poser le

boulon long 6” (8) à travers le dessus de la traverse puis le faire ressortir dans le bas de la pièce d'appui.

4. Placer le support en forme de U (14) au-dessus du boulon. Poser une rondelle striée 5/8 po (12) et un écrou 5/8 po (13) sur le boulon

(8). Visser les écrous à la main.

5. Pattes de sellette installées dans les traverses, marquer les endroits à percer dans la traverse arrière. Percer un trou-pilote de 1/8”. Voir

le diagramme de la page précédente pour la position du trou. S'assurer que le support angulaire s'alignera sur le trou-pilote 1/8 po. Voir

le schéma ci-dessus. Les supports angulaires doivent être installés depuis l'intérieur du cadre. Les supports angulaires gauche et droit

peuvent être intervertis si cela facilite la pose du support sur le cadre. Percer le trou-pilote à 21/32 po.

6. Placer l'espaceur de remplissage (3) dans le bas de l'ondulation de la plateforme si le trou est dans le bas. Placer l'espaceur de

remplissage (3) en-dessous de l'ondulation de la plateforme si le trou est dans le haut de l'ondulation. Placer l'espaceur tubulaire court

(9) au-dessus du trou. Placer la traverse arrière au-dessus de l'espaceur tubulaire (9).

7. Insérer le boulon de carrosserie court (4) vers le bas à travers la traverse et l'espaceur. Positionner les supports angulaires sur le boulon

de carrosserie (4). Fixer à l'aide d'une rondelle striée 5/8” (12) et d'un écrou (13). Serrer à la main.

8. Suivre les étapes 10 à 12 de la page 3. On ne posera que quatre boulons moletés (5) au lieu des huit de l'étape 10. Enlever l'écran

thermique autour du pneu de secours s'il est présent et si l'accès au cadre est amélioré. Replacer l'écran thermique une fois terminé.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

26

Page 27

94-01 DODGE 1500 et 94-02 DODGE 2500, 3500 PLATEFORMES COURTE ET LONGUE

MISE EN GARDE !

Lire attentivement les pages 1 à 3 de ces instructions avant de commencer l’installation.

Le défaut d’observer ce conseil peut causer des dommages importants au véhicule !

NOTES IMPORTANTES CONCERNANT CETTE INSTALLATION :

1. Repérer les rangées parallèles de soudures par points au niveau de la pièce d'appui de la plateforme. Aucun

perçage ne doit être effectué dans les rangées parallèles (d'environ 4 po) de soudures par points à l'endroit où est

fixée la pièce d'appui de la plateforme.

Avant du véhicule

Le boulon du centre des

attelages à sellette de plus de

18 000 livres de capacité doit

se trouver dans le trou central

des deux traverses de

montage.

Nota : Placer le boulon du

centre dans le trou qui ne

gêne pas la pièce d'appui de

la plateforme. En cas de

nécessité, retourner la

traverse.

Les boulons et la ferronnerie

du centre sont fournies avec

les attelages à sellette ou à

col de cygne dont la charge

nominale est supérieure à

18 000 livres.

Mesurer à partir du bord

arrière de la plateforme

jusqu'au bord arrière de la

traverse.

Bord arrière de

la plateforme

Platef. longue 28-7/16”

Platef. courte 24-5/16”

Suite des instructions à la page suivante.

Centre de

l’essieu

Avant du véhicule

Voir page suivante pour

la pose du boulon de

carrosserie (9).

Nota : Fil de tirage fourni, nécessaire pour poser

la visserie dans les supports à travers le cadre.

MISE EN GARDE !

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut causer

l'endommagement des conduites de carburant ou de frein, des éléments structuraux, etc. Cequent Performance

Products, Inc. fait de son mieux pour communiquer les modifications des constructeurs des véhicules de remorquage;

cependant, il est ultimement de la responsabilité de l'installateur de prévenir les dommages associés à l'installation.

Centre du pivot d'attelage approx.

au-dessus du centre de l'essieu.

Pièce

d'appui

Côté conducteur Ram 1500 illustré

Support

angulaire

1/4 2

1/4 2

* Patron de soudure

*

facultatif

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

27

Page 28

94-01 DODGE 1500 et 94-02 DODGE 2500, 3500 PLATEFORMES COURTE ET LONGUE

MISE EN GARDE !

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut causer

l'endommagement des conduites de carburant ou de frein, des éléments structuraux, etc. Cequent Performance

Products, Inc. fait de son mieux pour communiquer les modifications des constructeurs des véhicules de remorquage;

cependant, il est ultimement de la responsabilité de l'installateur de prévenir les dommages associés à l'installation.

1. En utilisant le trou de montage central indiqué à la page précédente, et ci-dessous, pour les trous de montage de la

traverse avant, percer un trou 1-1/4” dans la plateforme.

2. À l'aide de la mèche-pilote de la scie-cloche, creuser légèrement le dessus du cadre de camionnette. Assurez-vous d'être

au-dessus du cadre de camionnette. Vérifier que l'intérieur du cadre à cet endroit est libre de tout câblage ou conduite de

frein. Percer un trou de 21/32 po dans le rebord supérieur du cadre de camionnette.

3. Insérer l'espaceur long (12) dans le trou de la plateforme. Poser l'espaceur de remplissage (4) comme illustré à la fig. 4 cidessous. Poser l'espaceur tubulaire court (10) comme illustré ci-dessous. Placer la traverse au-dessus des espaceurs et

insérer un boulon de carrosserie long (9) dans les trous.

4. Poser des rondelles striées 5/8 po (13) et des écrous 5/8 po (14) sur les boulons.

5. Serrez tous les écrous 1/2 po au couple de 75 lb-pi et tous les écrous 5/8 po au couple de 130 lb-pi.

BOULON DE

CARROSSERIE (9)

Suite des instructions de la

page précédente.

CADRE DE

CAMIONNETTE

RONDELLE (13) ET

ÉCROU (14) SOUS LE

REBORD DU CADRE

PLATEFORME DE CAMIONNETTE

ESPACEUR COURT (10)

ESPACEUR DE

REMPLISSAGE (4)

ESPACEUR LONG (12)

30095N 1/30/12 REV. H

ESPACEUR DE REMPLISSAGE MONTRÉ

SOUS LA PLATEFORME AVEC BOULON

DANS CETTE POSITION

ESPACEUR DE REMPLISSAGE MONTRÉ

AU-DESSUS DE LA PLATEFORME AVEC

BOULON DANS CETTE POSITION

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

28

Page 29

DODGE JUSQU’À 93 (PLEINE GRANDEUR)

MISE EN GARDE !

Lire attentivement les pages 1 à 3 de ces instructions avant de commencer l’installation.

Le défaut d’observer ce conseil peut causer des dommages importants au véhicule !

NOTES IMPORTANTES CONCERNANT CETTE INSTALLATION :

1. Repérer les rangées parallèles de soudures par points au niveau de la pièce d'appui de la plateforme. Aucun

perçage ne doit être effectué dans les rangées parallèles (d'environ 4 po) de soudures par points à l'endroit où est

fixée la pièce d'appui de la plateforme.

Avant du véhicule

Le boulon du centre des

attelages à sellette de plus de

18 000 livres de capacité doit

se trouver dans le trou central

des deux traverses de

montage.

Nota : Placer le boulon du

centre dans le trou qui ne

gêne pas la pièce d'appui de

la plateforme. En cas de

nécessité, retourner la

traverse.

Les boulons et la ferronnerie

du centre sont fournies avec

les attelages à sellette ou à

col de cygne dont la charge

nominale est supérieure à

18 000 livres.

Mesurer à partir du bord

arrière de la plateforme

jusqu'au bord arrière de la

traverse.

Bord arrière de

la plateforme

Plateformes courte

et longue 32”

Centre de l’attelage approx. 3” à

l’avant du centre de l’essieur axle.

Avant du

véhicule

Centre de l’essieu

Pièce

d'appui

Côté conducteur du modèle 1/2 tonne Ram illustré

Les supports angulaires

gauche et droit et les

supports de cadre peuvent

être placés là où ils

s'adaptent le mieux.

Support rectiligne

Support angulaire

1/4 1.5-3

*

1/4 2

1/4 2

1/4 2

Nota : Fil de tirage fourni, nécessaire pour poser

la visserie dans les supports à travers le cadre.

MISE EN GARDE !

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut causer

l'endommagement des conduites de carburant ou de frein, des éléments structuraux, etc. Cequent Performance

Products, Inc. fait de son mieux pour communiquer les modifications des constructeurs des véhicules de remorquage;

cependant, il est ultimement de la responsabilité de l'installateur de prévenir les dommages associés à l'installation.

30095N 1/30/12 REV. H

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

* Patron de soudure

facultatif

*

29

Page 30

2005-PRÉSENT FORD F-250, F-350 et F-450 SUPER DUTY (mais non CHÂSSIS-CABINE)

MISE EN GARDE !

Lire attentivement les pages 1 à 3 de ces instructions avant de commencer l’installation.

Le défaut d’observer ce conseil peut causer des dommages importants au véhicule !

NOTES IMPORTANTES CONCERNANT CETTE INSTALLATION :

1. Repérer les rangées parallèles de soudures par points au niveau de la pièce d'appui de la plateforme. Aucun

perçage ne doit être effectué dans les rangées parallèles (d'environ 4 po) de soudures par points à l'endroit où est

fixée la pièce d'appui de la plateforme.

2. Il peut être nécessaire de déplacer le support du câble de frein vers un autre trou immédiatement à l'arrière de son

emplacement actuel.

Avant du véhicule

Le boulon du centre des

attelages à sellette de plus de

18 000 livres de capacité doit

se trouver dans le trou central

des deux traverses de

montage.

Nota : Placer le boulon du

centre dans le trou qui ne

gêne pas la pièce d'appui de

la plateforme. En cas de

nécessité, retourner la

traverse.

Les boulons et la ferronnerie

du centre sont fournies avec

les attelages à sellette ou à

col de cygne dont la charge

nominale est supérieure à

18 000 livres.

Support

angulaire

Support rectiligne

Support rectiligne

Bord arrière de

la plateforme

Plateformes longue

et courte 30 3/16”

Mesurer à partir du bord

arrière de la plateforme

jusqu'au bord arrière de

la traverse.

Support angulaire

Centre d’attelage approx.

Côté conducteur

CÔTÉ PASSAGER

au-dessus du centre de

l’essieu.

Avant du

véhicule

Avant du

véhicule

* Patron de soudure facultatif. Typique pour

les 4 supports.

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut causer l'endommagement des

conduites de carburant ou de frein, des éléments structuraux, etc. Cequent Performance Products, Inc. fait de son mieux pour

communiquer les modifications des constructeurs des véhicules de remorquage; cependant, il est ultimement de la responsabilité

30095N 1/30/12 REV. H

Pièce

d'appui

*

Nota : Fil de tirage fourni, nécessaire pour poser

la visserie dans les supports à travers le cadre.

MISE EN GARDE !

de l'installateur de prévenir les dommages associés à l'installation.

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

Pièce

d'appui

1/4 2

1/4 2

Côté conducteur du modèle F-350

super Duty plateforme longue illustré

30

Page 31

1992-2004 FORD F-250 et F-350 PLATEFORMES COURTE ET LONGUE

MISE EN GARDE !

Lire attentivement les pages 1 à 3 de ces instructions avant de commencer l’installation.

Le défaut d’observer ce conseil peut causer des dommages importants au véhicule !

NOTES IMPORTANTES CONCERNANT CETTE INSTALLATION :

1. Repérer les rangées parallèles de soudures par points au niveau de la pièce d'appui de la plateforme. Aucun perçage ne

doit être effectué dans les rangées parallèles (d'environ 4 po) de soudures par points à l'endroit où est fixée la pièce d'appui de

la plateforme.

Mesurer à partir du bord

Avant du véhicule

Le boulon du centre des

attelages à sellette de plus de

18 000 livres de capacité doit

se trouver dans le trou central

des deux traverses de

montage.

Nota : Placer le boulon du

centre dans le trou qui ne

gêne pas la pièce d'appui de

la plateforme. En cas de

nécessité, retourner la

traverse.

Les boulons et la ferronnerie

du centre sont fournies avec

les attelages à sellette ou à

col de cygne dont la charge

nominale est supérieure à

18 000 livres.

arrière de la plateforme

jusqu'au bord arrière de la

traverse.

Bord arrière de la

plateforme

Plateformes longue

et courte 30 3/16”

Centre du pivot d’attelage approx.

Centre de

l’essieu

Support rectiligne

Avant du

véhicule

Avant de percer, assurez-vous qu'il n'y a pas d'obstacles. L’omission d’observer ce conseil peut causer l'endommagement des

conduites de carburant ou de frein, des éléments structuraux, etc. Cequent Performance Products, Inc. fait de son mieux pour

communiquer les modifications des constructeurs des véhicules de remorquage; cependant, il est ultimement de la

30095N 1/30/12 REV. H

¼ 2

*

¼ 2

Nota : Fil de tirage fourni, nécessaire pour poser la

visserie dans les supports à travers le cadre.

Utiliser un des plus gros trous du cadre pour ce faire.

MISE EN GARDE !

responsabilité de l'installateur de prévenir les dommages associés à l'installation.

©2012 Cequent Performance Products, Inc. PRINTED IN XXX

1/2” à l’arrière du centre de l’essieu

Pièce

d'appui

Côté conducteur du modèle F350

Super Duty long bed illustré

Support angulaire

1/4 2

1/4 2