Page 1

Installation Instructions

High-Performance Sway Control

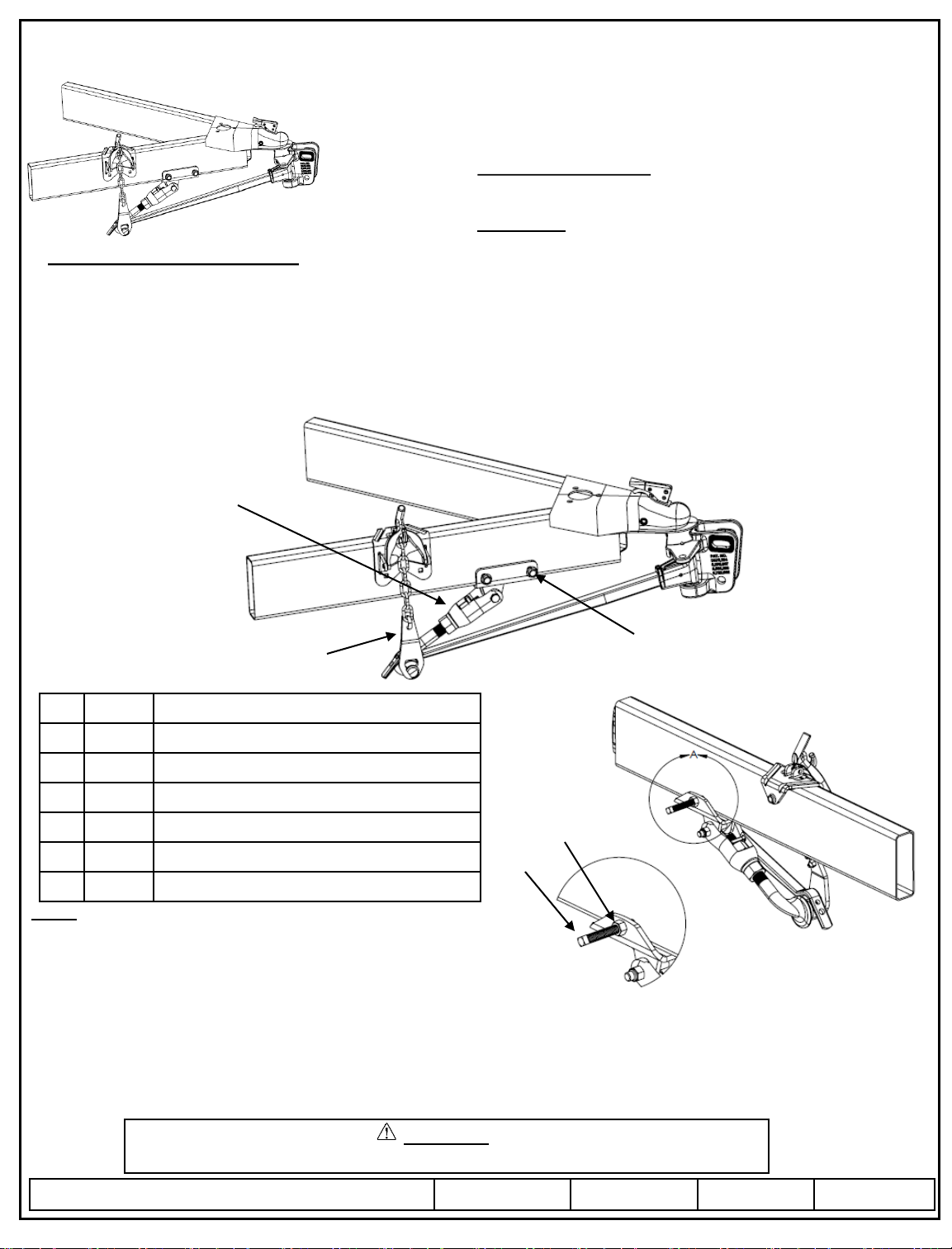

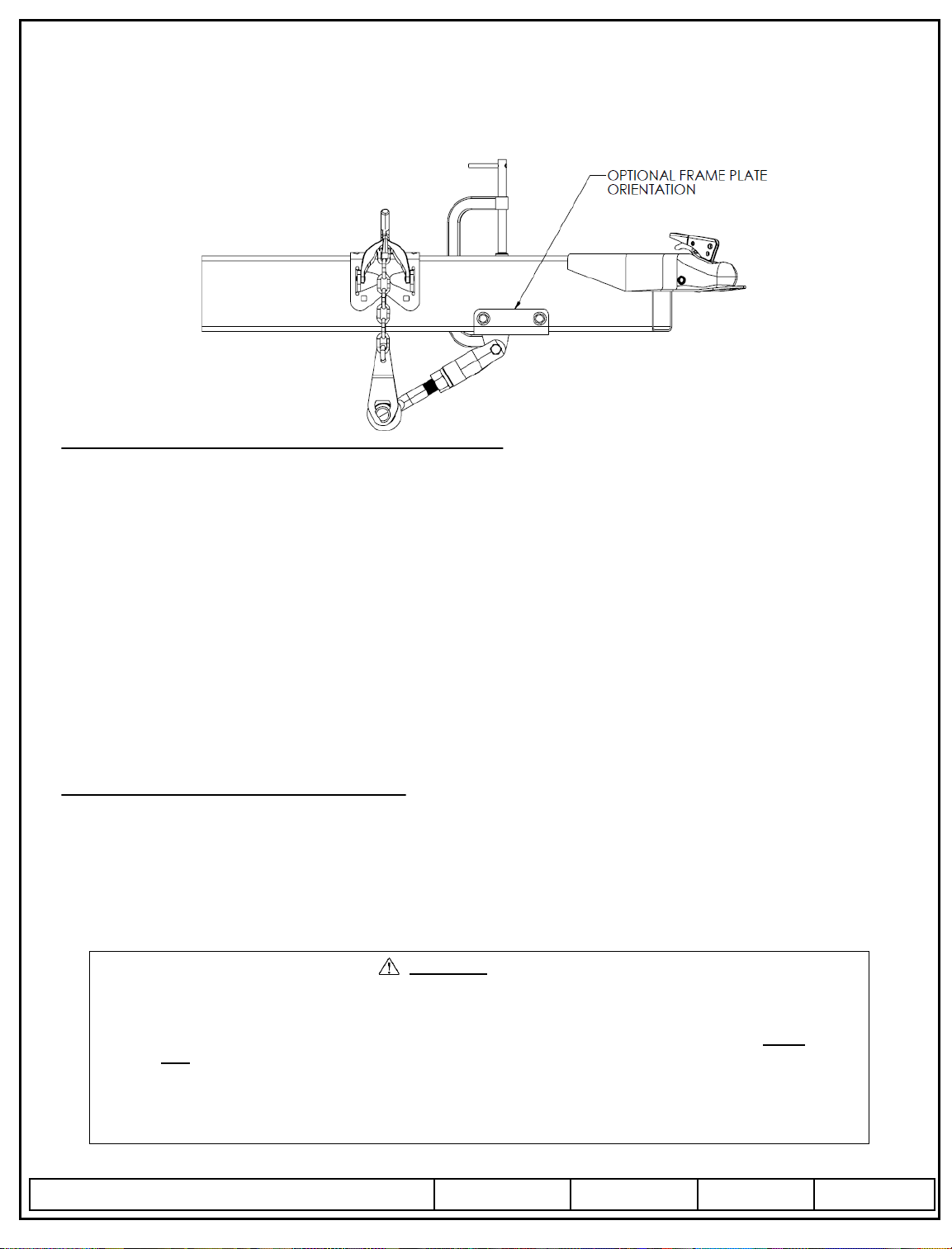

DUAL CAM HP ASSEMBLED

Equipment Required:

Fastener Kit: 100126

Wrenches: 1-1/2” Open End, ¾” Open End

½” Open End, ¾” Socket & Ratchet

Drill Bits: 7/16”, 17/32” & Center Drill (Pilot Drill)

Other: 8 – 10” C-Clamp, Tape Measure, Light Penetrant Oil

j

Part Numbers:

26102

Dual Cam HP

DEALER/INSTALLER:

(1) Provide this Manual to end user

END USER:

(1) Read and follow this Manual every time you use Dual Cam HP.

(2) Save this Manual for Future Reference.

(3) Pass on copies of Manual to any other users or owner.

Do Not Exceed Lower of Towing Vehicle Manufacturer’s Rating, or

Trailer Manufacturer’s Rating

Figure 1

*For Tubular Style Frame Attachment

**Not Shown, For C-Channel Style Frame Attachment

Qty. (2) Dual Cam HP Cam Arm Assembly

j

Qty. (2) Hanger Bracket

k

Qty. (6) ½ - 13 Thread Forming Screw*

l

Qty. (2) ½-13 X 3 ½” Square Head Bolt*

m

Qty. (6) ½-13 Hex Nut*

n

o

Qty. (2)

p

Qty. (4)

INDEX

1. INSTALLATION & ASSEMBLY P. 2-4

2. PRE-INSTALLATION (TOW VEHICLE MAY NOT BE PRESENT) P. 4

2. INSTALLATION WITH TOW VEHICLE PRESENT P.4-5

3. TUBULAR FRAME DUAL CAM HP FRAME PLATE INSTALLATION P. 5-6

4. C-CHANNEL FRAME DUAL CAM HP FRAME PLATE INSTALLATION P. 6

5. CAM ARM ADJUSTMENT P. 7

6. BEFORE EACH TRIP & MAINTENANCE P. 7

7. NOTES P. 8

8. LIMITED LIFETIME WARRANTY P. 8

½” Lock Washer**

½-13 X 1 ½” Grade 5 Bolt**

For Installation or Operation Support contact CPP Technical Service: 1-888-521-0510.

k

m*

l*

n*

Figure 2 – Inside View of Trailer Frame

Failure to follow all of these instructions may result in death or serious injury!

© 2010 Cequent Performance Products, Inc.

WARNING:

Sheet 1 of 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 2

Installation Instructions

Dual Cam HP

High-Performance Sway Control

INSTALLATION

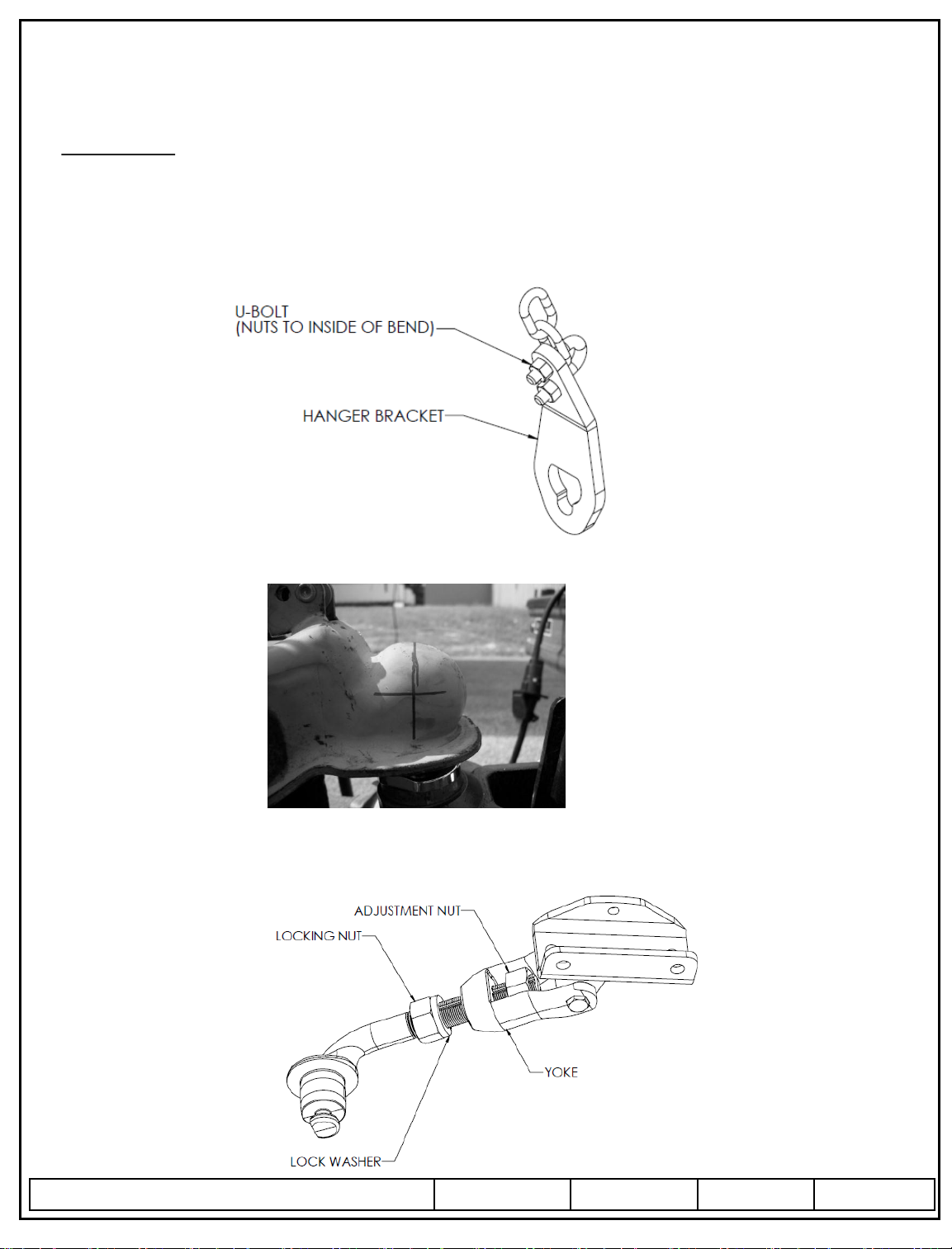

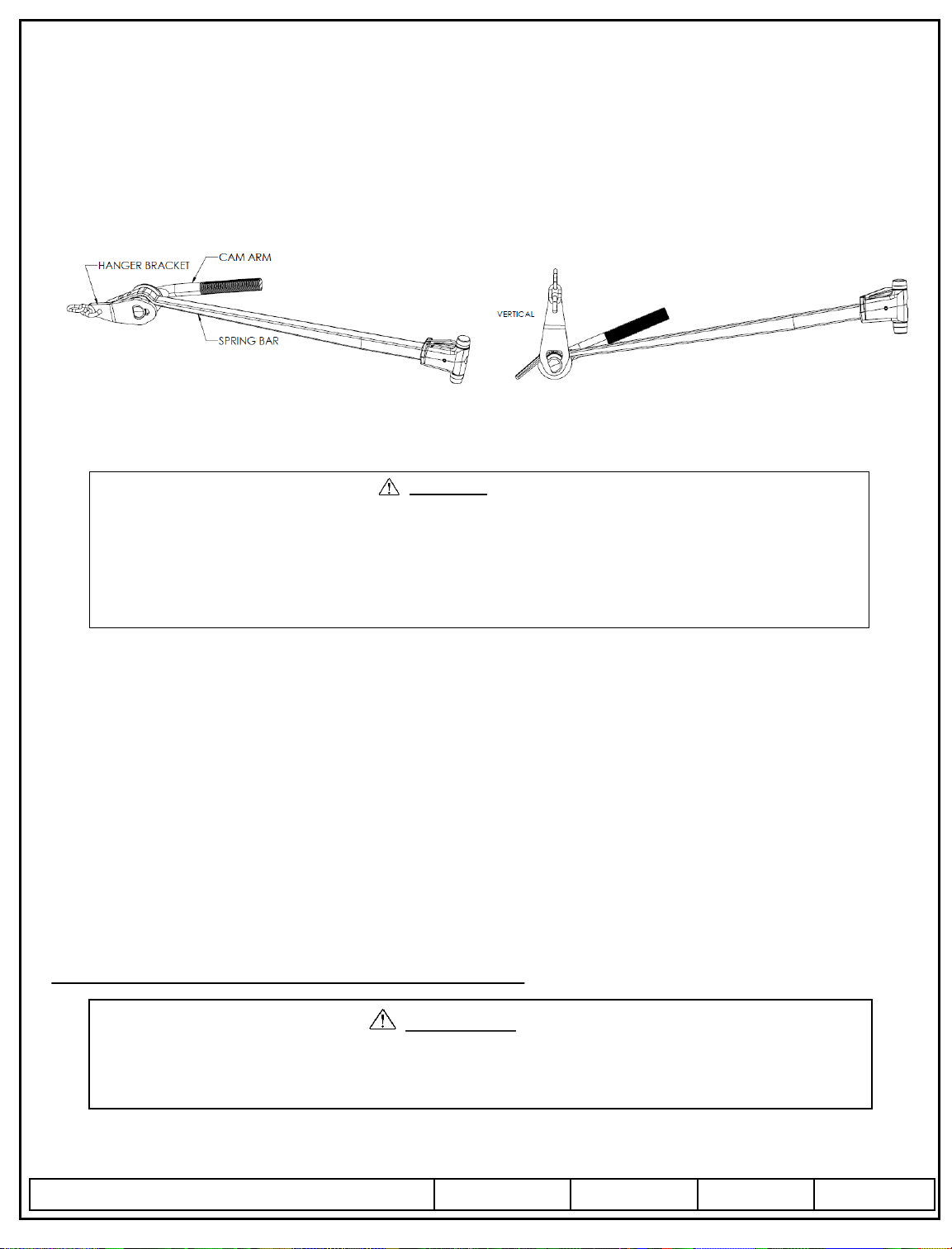

1. Locate both hanger brackets included in the kit (item 2, figure 1). Install U-bolt and chain from your Weight Distribution Kit

on each hanger bracket as shown in figure 3 (if installing Dual Cam HP on an existing weight distribution kit, the U-bolts and

chains will need to be removed from each spring bar before they can be installed on the hanger brackets).

The U-bolts must be installed in the ends of the chains (last link) as shown in figure 3.

2. Install 2 lock nuts per U-bolt, tighten u-bolt nuts. Make sure at least 2 threads are showing past the ends of the nuts.

Figure 3

3. Using a grease pencil or suitable marking device such as a marker and a straight edge locate and mark the center of the hitch

ball on the coupler both horizontally and vertically as shown in figure 4 . This reference point will be used to locate the cam

arm assembly position. Mark both sides of the coupler.

Figure 4

4. Position the adjustment nut and locking nut to the outermost positions as shown in figure 5. If the

adjustment is difficult, as the adjustment nut must be turned by hand, apply a small amount of light penetrating oil such as

WD40 or PB Blast to the threads of the cam arm. Work the adjustment nut back or forward to get the penetrating oil into the

threads until the adjustment nut moves freely to the desired position.

© 2010 Cequent Performance Products, Inc.

Figure 5

Sheet 2 of 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 3

Installation Instructions

Dual Cam HP

High-Performance Sway Control

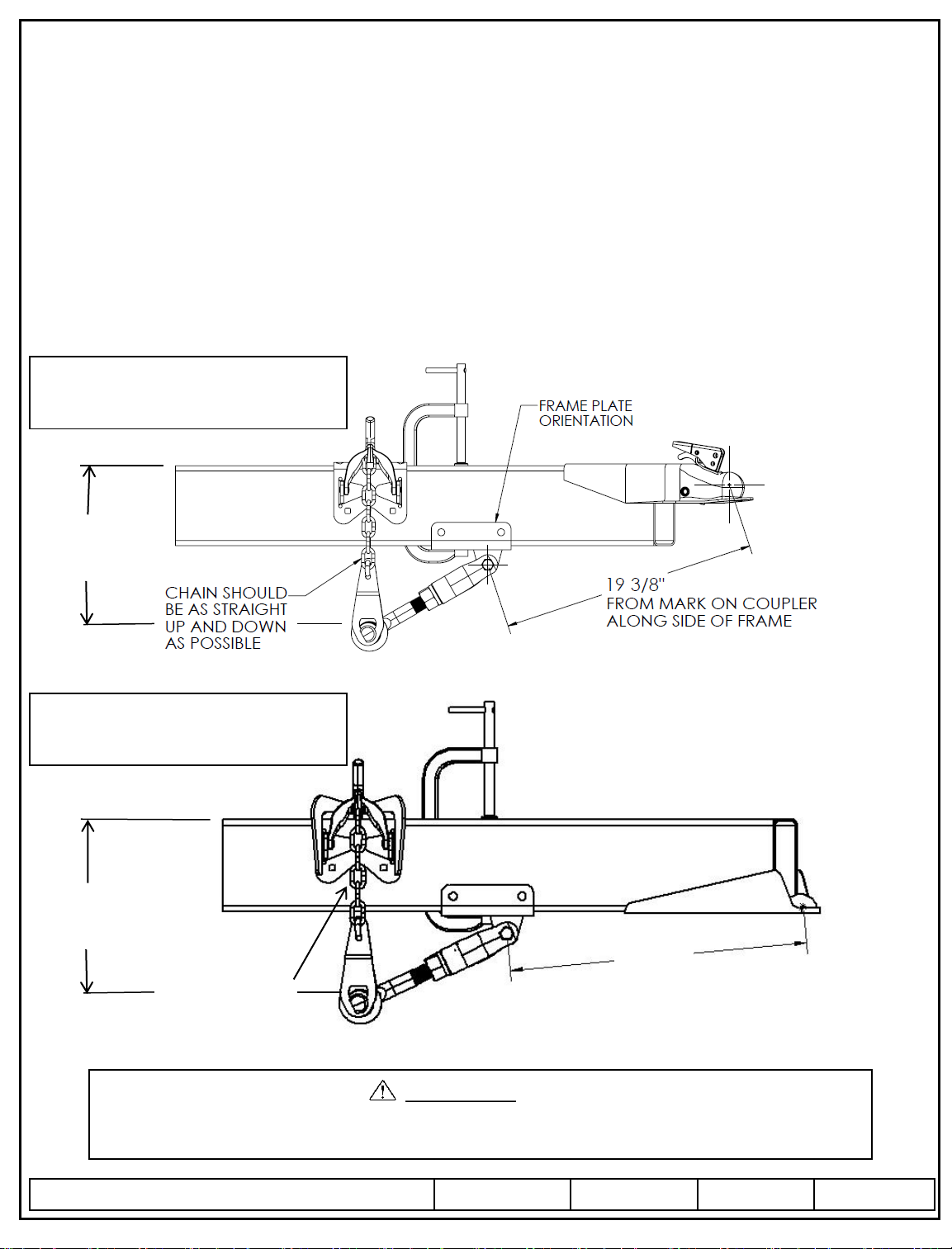

5. Using a C-clamp suitable to accommodate your trailer frame height and the Dual Cam HP frame plate, temporarily clamp the

Dual Cam HP cam arm assembly to the trailer frame and Dual Cam HP frame plate as shown in figure 6 for Trunnion style

Weight Distribution kits, for Round Bar style Weight Distribution Kits, follow the dimensions in figure 7.

6. Position the Frame Plate at the dimension shown for your type Weight Distribution Kit (Trunnion Style or Round Bar.

Standard coupler or bottom mounted).

Measure from the mark on the ball coupler to the center of the cam arm pivot bolt as shown in figure 6 or figure 7 on the next

page. If the frame plate interferes with any part of the trailer frame, the orientation can be changed by switching sides, see

figure 8 for optional Frame plate orientation – maintain the same coupler center to cam arm pivot dimension regardless of frame

plate orientation.

7. Position the Chain Hanger temporarily above the cam arm. (Upon hook-up, the Hanger position must

be adjusted to be sure the chain is vertical before towing). Tighten the Chain Hanger bolt shown in figure 2 against the frame.

Trunnion Style Set Up Locations

(Standard Coupler)

Approximate desired

working range on a 6” tall

frame.

12”-13”

Figure 6 – Cam Arm Approximate Locations for Trunnion Style Weight Distribution kits

Trunnion Style Set Up Locations

(Bottom Mount Coupler)

Approximate desired

working range on a 6” tall

frame.

12”-13”

CHAIN SHOULD

BE AS STRAIGHT

UP AND DOWN

AS POSSIBLE

8. If you have a bottom mounted coupler it may be necessary

for you to tilt the ball mount as far forward towards the front

of the tow vehicle as possible.

20-1/2

FROM MARK ON COUPLER

ALONG SIDE FRAME

Figure 6A – Cam Arm Approximate Locations for Trunnion Style Weight Distribution kits

The Measurements in figures 6, 6A, 7 & 7A are guidelines, adjustment of the cam arm length via the adjustment nut (Figure 5)

may be required after hookup in later instructions of this manual Cequent Performance Products, Inc. is not responsible for

damage incurred due to disregarding any part of this manual.

© 2010 Cequent Performance Products, Inc.

CAUTION:

Sheet 3 of 30 26012IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 4

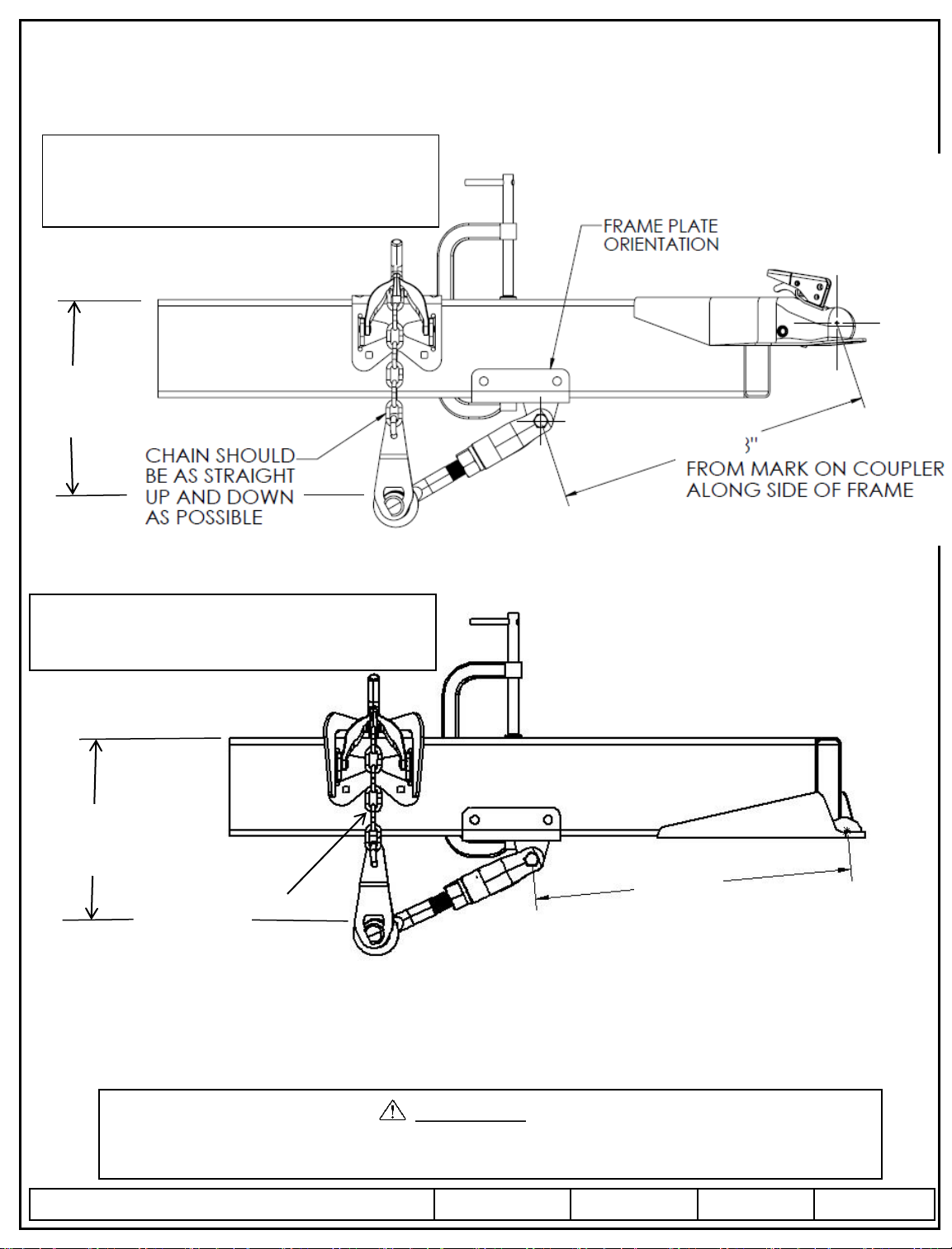

Round Bar Set Up Locations

(Standard Coupler)

Approximate desired

working range on a 6”

tall frame.

12”-13”

Installation Instructions

REESE Dual Cam HP

High-Performance Sway Control

18”

Figure 7 – Cam Arm Approximate Location for Round Bar Weight Distribution kits

Round Bar Set up Locations

(Bottom Mounted Coupler)

Approximate desired

working range on a 6”

tall frame.

12”-13”

If you have a bottom mounted coupler it may be necessary for you to tilt the ball mount as far forward

towards the front of the tow vehicle as possible.

CHAIN SHOULD

BE AS STRAIGHT

UP AND DOWN

AS POSSIBLE

Figure 7A – Cam Arm Approximate Location for Round Bar Weight Distribution kits

19-1/8”

FROM MARK ON COUPLER

ALONG SIDE OF FRAME

The Measurements in figures 6, 6A, 7 & 7A are guidelines, adjustment of the cam arm length via the adjustment nut (Figure 5)

may be required after hookup in later instructions of this manual Cequent Performance Products, Inc. is not responsible for

damage incurred due to disregarding any part of this manual.

© 2010 Cequent Performance Products, Inc.

CAUTION:

Sheet 4 of 30 26102IN 05/14/12 Rev. G

Page 5

Installation Instructions

Dual Cam HP

High-Performance Sway Control

FOLLOW THE SAME MEASUREMENTS FOR THIS

ORIENTATION AS SHOWN IN FIGURE 6 OR 7.

Figure 8

PRE-INSTALLATION (TOW VEHICLE MAY NOT BE PRESENT)

1. If the tow vehicle is not available at the time of installation of the Dual Cam HP system, position the yolk centered on the

threads of the cam arm (Approximately 2” from either end of the threaded portion of the cam arm. Run the adjustment nut

down to meet the yolk. Tighten the locking nut until the lock washer is fully compressed and continue to the Frame Plate

Installation portion of this manual for your specific frame style; Tubular Frame or C-Channel Frame.

2. Pass this manual along to the customer/end user of this product and inform them that minor adjustments to their cam arm

length may be required depending on head tilt of the WD system, number of chains used for proper weight distribution, tow

vehicle variance and/or; changes in tongue weight of their trailer as all of these variables will slightly affect the proper position

of the cam with respect to proper seating in the detent of the cam arm.

3. Direct the customer to the INSTALLATION WITH TOW VEHICLE PRESENT portion of this manual for hook-up procedure,

and fully explain proper seating of the cam within the spring bar detent. Refer them to their specific Weight Distributing Hitch

Instruction manual and be sure they follow the INITIAL HOOKUP section of their Weight Distribution Kit Manual for first

time hook-up and/or any changes in the variables listed in item 2. of this section occur.

4. BE SURE to pass along the Towing Information Packet (P/N: 110400) to the customer/end user and BE SURE they

understand the material within the Towing Information Packet for safe towing.

INSTALLATION WITH TOW VEHICLE PRESENT

NOTE: Set-up and adjust weight distribution hitch per the installation instructions for your Weight Distribution Hitch.

1. Connect the trailer to the tow vehicle. Tow vehicle and trailer should be on level ground and in a straight line. Raise the

tongue and rear of the vehicle enough to install the spring bars onto the dual cam arm with the trailer tongue jack

(approximately 6”-12” or until the spring bar can be lifted with the supplied lifting handle with very little effort, this will vary

depending on spring bar rating and head tilt adjustment).

Avoid putting any part of your body under the trailer or between the truck and trailer. Unexpected or

accidental movement of the truck or the trailer can cause serious injury or death

If you must place any part of your body under the trailer or between the truck and trailer you MUST

perform ALL of the following steps:

Check that the truck transmission is in park

Check that the emergency brake is set

Block in front of and behind all trailer tires

Check that the trailer jack foot is resting on firm ground

© 2010 Cequent Performance Products, Inc.

WARNING:

Sheet 5 of 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 6

Installation Instructions

Dual Cam HP

High-Performance Sway Control

2. Install the spring bars into the ball mount head. Position the spring bar over the cam portion of the cam arm.

3. Install the Hanger Bracket (with the ends of the u-bolts facing inward) and Chain onto the cam by slipping the keyed slot of the

hanger bracket over the button end of the cam arm (figure 9). Rotate Hanger bracket to the vertical position and pull chain

vertical to the chain attachment point on the snap-up bracket (Figure 10).

Figure 9 Figure 10

4. Raise the chains until they meet the hook of the snap-up bracket, using the chain link furthest down the chain that allows you to

close the snap-up bracket by hand (without the supplied lifting tube – this is generally the 2nd or 3rd link from the free end of the

chain for most installation). Use the same link # for both sides of the trailer. Lift both spring bars with the snap-up brackets

and install the keeper pin in the snap-up bracket. Be sure that the hanger bracket is fully engaged in the slot of the cam arm.

When lifting/lowering Snap-Up Bracket, Avoid putting any part of your body in the path of the lifting handle

and under the cam arm and spring bars. Components of this system are loaded with substantial force and

could shift position or drop suddenly causing serious injury or death.

Never Raise or Lower Snap-Up Brackets without raising the trailer tongue jack to remove the load from the

spring bars and cam arms. Failure to do so could cause serious injury.

5. Lower the trailer tongue jack.

6. Check that the cam is properly seated properly in the detent of the spring bar (figure 14). If the cam arm assembly dose not

automatically seat in the detent of the spring bar, rap the end of the cam arm with a

mallet or hammer until it seats into the spring bar detent as shown in figure 14.

7. Once the cam arms are properly positioned in the detent of the spring bar. Check the ride height of the tow vehicle per your

Weight Distributing Hitch Kit; specifically the Initial Hookup section of that manual. It may be necessary to adjust the number

of links engaged or the ball mount tilt for proper weight distribution for your tow vehicle and trailer. Re-seating of the

Cam Arm Assemblies in the spring bar detent may be necessary until the Initial Hookup requirements are met.

Run the adjustment nut shown in figure 5 down to meet the yolk. Tighten the locking nut shown in figure 5 until the locking

washer is fully compressed. This process needs to be done for both cam assemblies, i.e. both sides of the trailer frame.

8. The Cam Arm Assemblies are now ready to be permanently mounted to the trailer frame. Follow the proper instruction for

frame plate installation of this manual for your particular frame type.

TUBULAR FRAME DUAL CAM HP FRAME PLATE INSTALLATION

WARNING:

CAUTION:

Before drilling, make sure there are no obstructions in the trailer frame where the intended bolt holes are to be drilled, such as

trailer wiring and or electric brake beak-away switch.

DO NOT drill through the opposite wall of the frame tube.

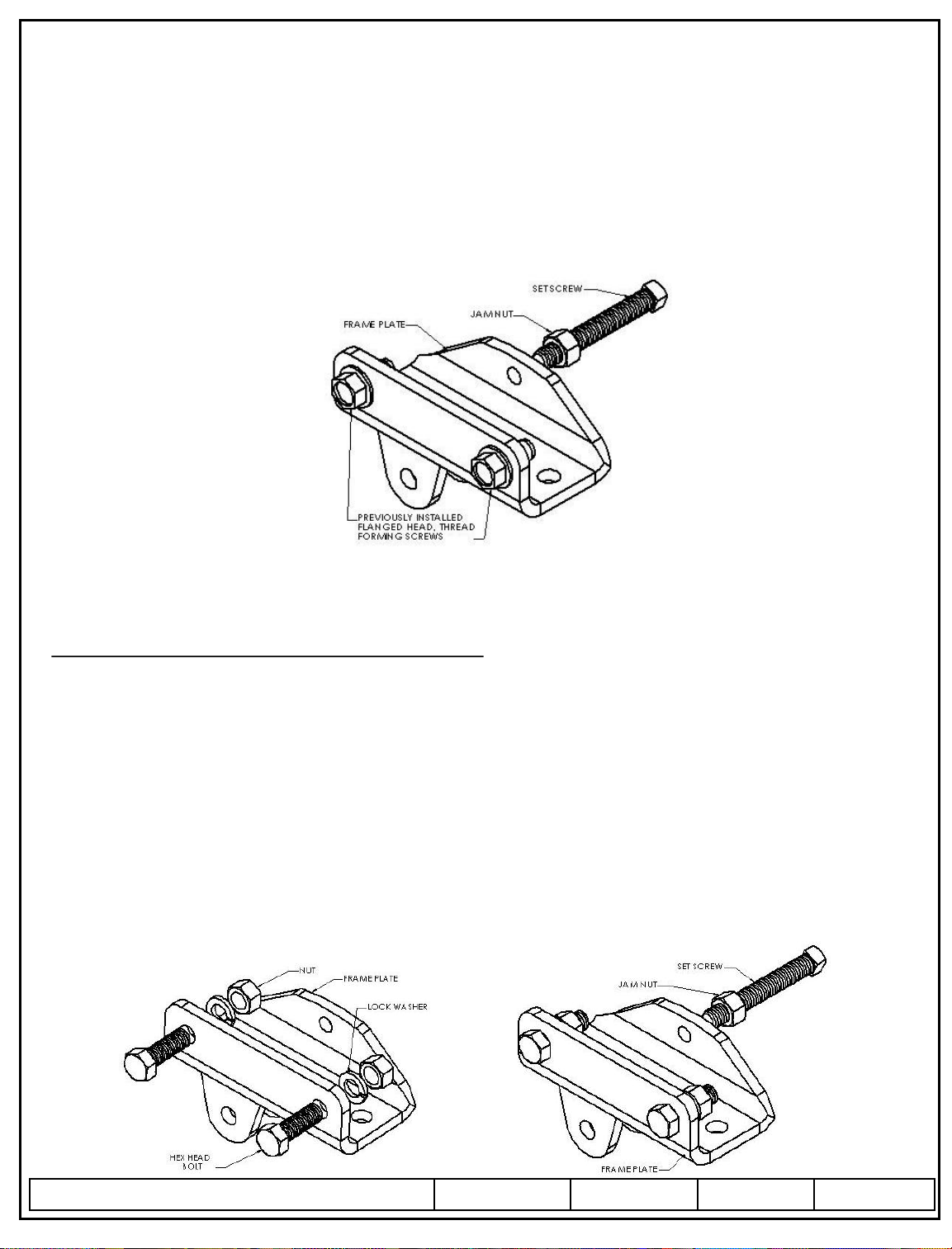

1. With the C-clamps still in place, center punch (2) holes in the frame for each bracket..

© 2010 Cequent Performance Products, Inc.

Sheet 6 of 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 7

Installation Instructions

Dual Cam HP

High-Performance Sway Control

2. Drill (2) 7/16” holes in each side of the frame where the punched center marks were made. The use of a center drill or small

pilot hole may be very helpful prior to final drilling.

3. Install (2) supplied ½-13 Thread Forming Screws (Item 3, figure 1).

Repeat for opposite side and torque (4) ½-13 Thread Forming Screws to 50 ft-lb.

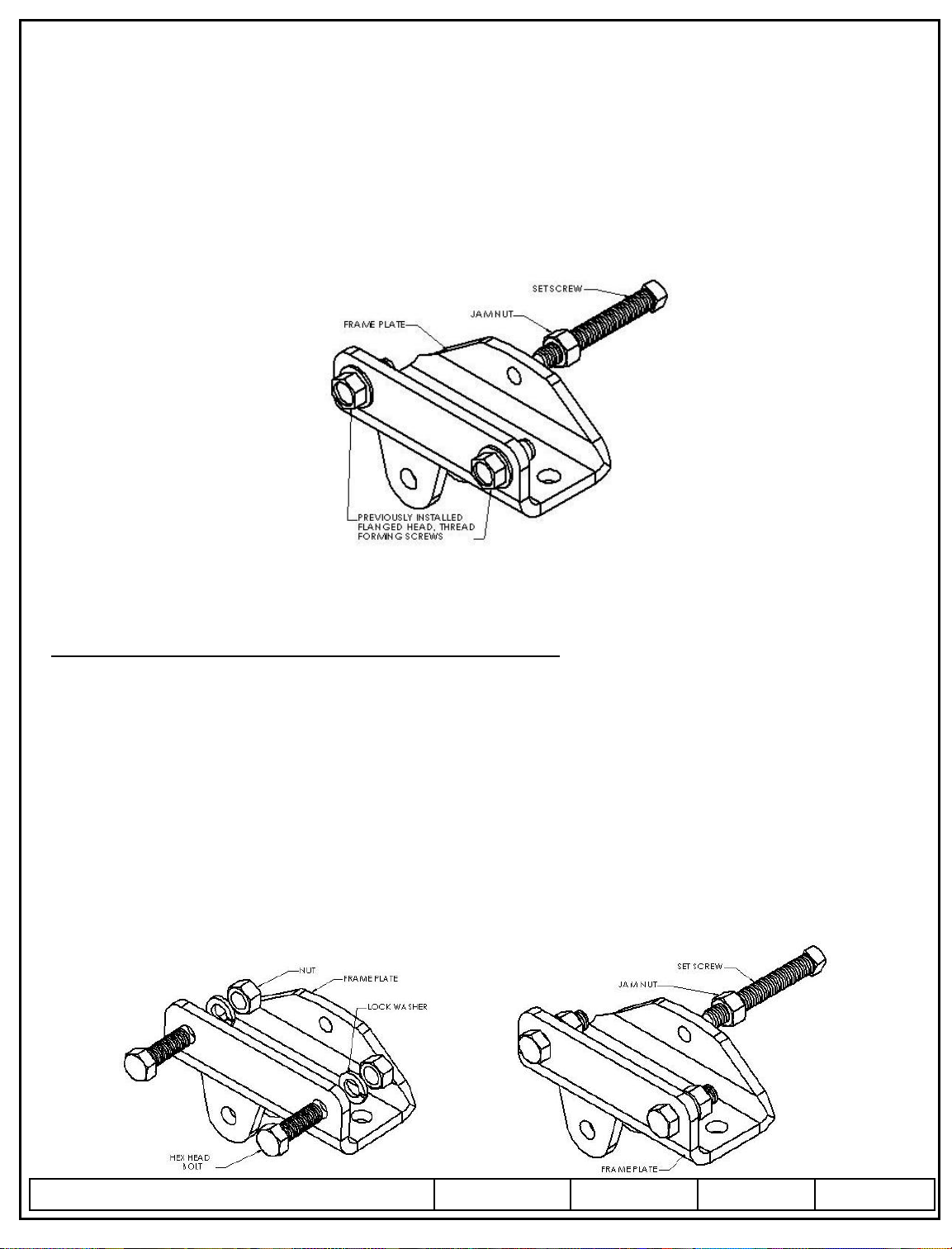

4. Install ½-13 Hex Nut (Jam Nut) onto the ½-13 X 3 ½” Square Head Bolts and Install into the frame brackets as shown in figure 11.

5. Tighten the Set Screw until it contacts the trailer frame. Then proceed to tighten ¼ to ½ turn (DO NOT OVERTIGHTEN SET

SCREW). Tighten the Jam Nut preventing the set screw from backing out while in use. Repeat for other side of trailer frame.

6. Remove C-Clamps from frame.

C-CHANNEL DUAL CAM HP FRAME PLATE INSTALLATION

NOTE: Some C-Channel frames may have square outside corners that do not allow the frame plate to contact the

bottom of the frame. For these type of frames a ½” flat washer (Not Supplied) is required between the outside of the

trailer frame and the frame plate. The bottom of the frame plate MUST contact the bottom of the trailer frame.

1. With the C-clamps still in place, center punch (2) holes in the frame for each bracket.

2. Drill (2) 17/32” holes in each side of the frame where the punched center marks were made. The use of a center drill or small

pilot hole may be very helpful prior to final drilling.

3. Install the (2) supplied ½-13 x 1 ½” Bolts, ½” Lock Washers & ½” Nuts (1tems 5,6 & 7) figure 13.

Repeat for opposite side and torque (4) ½-13 Bolts to 85 ft-lb.

4. Install ½-13 Hex Bolts onto the ½-13 X 3 ½” Square Head Bolts and Install into the frame brackets as shown in figure 13.

5. Tighten the Set Screw until it contacts the trailer frame. Then proceed to tighten ¼ to ½ turn (DO NOT OVERTIGHTEN SET

SCREW). Tighten the Jam Nut preventing the set screw from backing out while in use. Repeat for other side of trailer frame.

6. Remove C-Clamps from frame.

Figure 11

Figure 12

© 2010 Cequent Performance Products, Inc.

Figure 13

Sheet 7 of 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 8

Installation Instructions

Dual Cam HP

High-Performance Sway Control

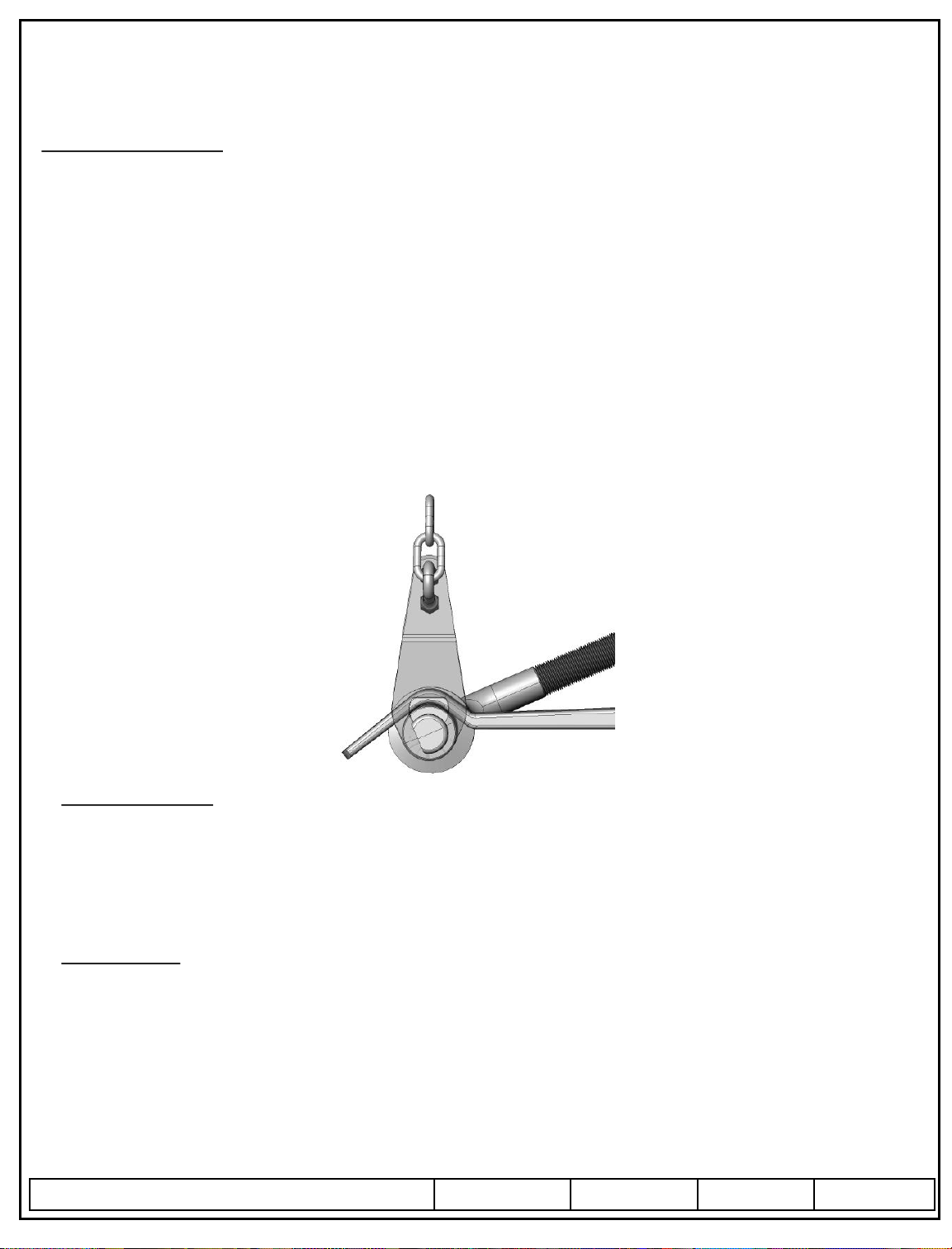

CAM ARM ADJUSTMENT

1. Be sure that the truck and trailer are adjusted properly per the instructions for your Weight Distribution Hitch, pull forward far

enough to be sure the truck and trailer are in a straight line. (Picking a point at a distance away from the vehicle (about 100

yards) drive forward toward that point keeping the steering perfectly straight until the truck and trailer are perfectly in a straight

line.)

2. Go to each cam arm and check to see that the cam is perfectly centered in the detent of the spring bar. Make adjustments to

the cam arm length as required, it is important to have the cam arm/spring bar detent exactly as shown in figure 14.

3. Before adjustments to the cam arm length can be made, raise the trailer tongue jack and lower the snap-up brackets. Loosen the

Locking nut (figure 5) and move the adjustment nut (figure 5) until the cam is centered into the detent of the spring bar (figure

14). After making adjustments, lift both snap-up brackets and install retainer clips; lower the trailer tongue jack. Repeat step 2

of this section

3. Adjust the position of the snap-up brackets as needed, the chain should be perfectly vertical while in use to avoid damage to the

snap up bracket itself.

* From time to time, with changing towing/loading conditions, it may be necessary to use a different chain link to properly level

the tow vehicle (See your Weight Distribution Kit Installation Instructions). Anytime a different link is used, the cam arm

must be readjusted.

BEFORE EACH TRIP:

1. CHECK YOUR EQUIPMENT: Check that condition of all of your towing equipment and keep it in top condition.

2. Check that the torque of all fasteners are in accordance to this manual.

3. Re-Check spring bar detent and cam alignment, and periodically while towing for the best performance.

4. Check for any excessive wear to any of the components of this system.

MAINTENANCE:

1. DO NOT – use grease on the cams or cam arms.

2. If noise of the system is offensive, a very light coating of lubricant such as Vaseline may be used on the portion of the

cam where the spring bar rides on the cam.

Tongue weights in excess of 1,200 lbs. may require the use of such a lubricant to prevent excessive wear.

3. Keep all painted parts painted to prevent rust and maintain a good appearance. (Do Not paint over labels)

© 2010 Cequent Performance Products, Inc.

Figure 14

Sheet 8 of 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 9

Installation Instructions

1/2" x 1.00" SELF TAPPING SCREW

INSTRUCTION SHEET

TOOLS NEEDED:

Drill Bits: 7/16”, 9/16” & ¼”

Failure to follow all of these instructions may result in death or serious injury!

2-1/4”

Snap Up Bracket

WARNING:

Read all instructions before installing the additional bolt.

•Installation of an additional bolt into the snap up bracket when using

a Jayco RV with a coupler mounted to the bottom of the frame.

•If a hole does not already exist, mark the location of the hole to be

drilled into the snap up bracket. Center the hole from left to right and

place it 2-1/4” above the arc in the bracket. See the picture at left.

•Before the bracket is placed on the frame, drill a 9/16” hole in the

bracket

•Place the bracket in the correct place on the frame as directed in the

product instructions or replace it where it was if it had already been

installed.

•Using the hole in the bracket as a guide, drill a ¼” pilot hole. Be sure

to stay centered in the bracket hole.

• One method to stay centered is to use the 9/16” drill first. Just put a

small dimple into the frame with the 9/16” bit. Then finish drilling

with the ¼” drill bit and then a 7/16” drill bit to get the final hole. See

pilot hole to the left.

For Installation or Operation Support contact CPP Technical Service: 1-888-521-0510.

© 2010 Cequent Performance Products, Inc.

•Install the ½” self tapping screw into the hole in the bracket and

frame. Tighten it to 50 ft/lbs.

•Re-tighten the ½” set screw on the inside of the frame. Turn only

¼ to ½ of a turn after making contact with the frame.

PARTS LIST

QTY DESCRIPTION

2

1

Cequent Performance Products, Inc.

47912 Halyard Dr. Suite 100

Plymouth, MI 48170

Sheet 9 of 30 26102IN 05/14/12 Rev. G

Page 10

NOTES:

Installation Instructions

Dual Cam HP

High-Performance Sway Control

LIMITED LIFETIMEWARRANTY

1. Limited Warranty. Cequent Performance Products, Inc. (“We” or “Us”) warrants to the original consumer purchaser only

(“You”) that the product will be free from material defects in both material and workmanship for lifetime of the product, ordinary

wear and tear excepted; provided that installation and use of the product is in accordance with product instructions. There are no

other warranties, express or implied, including the warranty of merchantability or fitness for a particular purpose. If the

product does not comply with this limited lifetime warranty, Your sole and exclusive remedy is that We will replace the product

without charge to You and within a reasonable time or, at our option, refund the purchase price. This warranty is not

transferable.

2. Limitations on the Warranty. This limited warranty does not cover: (a) normal wear and tear; (b) damage through abuse,

neglect, misuse, or as a result of any accident or in any other manner; (c) damage from misapplication, overloading, or improper

installation, including welds; (d) improper maintenance and repair; and (e) product alteration in any manner by anyone other than

Us, with the sole exception of alterations made pursuant to product instructions and in a workmanlike manner.

3. Obligations of Purchaser. To make a warranty claim, contact Us at 47774 Anchor Court West, Plymouth, MI, 48170, 1-888-521 0510, identify the product by model number, and follow the claim instructions that will be provided. Any returned product that is

replaced or refunded by Us becomes our property. You will be responsible for return shipping costs. Please retain your purchase

receipt to verify date of purchase and that You are the original consumer purchaser. The product and the purchase receipt must be

provided to Us in order to process Your warranty claim.

4. Remedy Limits. Repair or replacement is Your sole remedy under this limited warranty or any other warranty related to the

product. We shall not be liable for service or labor charges incurred in removing or replacing a product or any incidental or

consequential damages of any kind.

5. Assumption of Risk. You acknowledge and agree that any use of the product for any purpose other than the specified use(s)

stated in the product instructions is at Your own risk.

6. Governing Law. This limited warranty gives You specific legal rights, and You also may have other rights which vary from state

to state. This limited warranty is governed by the laws of the State of Michigan, without regard to rules pertaining to conflicts of

law. The state courts located in Oakland County, Michigan shall have exclusive jurisdiction for any disputes relating to this

warranty.

Cequent Performance Products, Inc.

47912 HALYARD DR. SUITE 100

PLYMOUTH, MI. 48170

© 2010 Cequent Performance Products

Sheet 10 of 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 11

Instructions d’installation

Dual Cam HP

Stabilisateur haute performance

DUAL CAM HP ASSEMBLÉ

Équipement requis :

Trousse de visserie : 100126

Clés : Clés ouvertes 1-1/2” et ¾”

Clé ouverte ½”, cliquet et douille ¾”

Mèches : 7/16”, 17/32” et foret à centrer (foret-pilote)

Autres : 8 brides en C de 10”, ruban à mesurer, huile légère pénétrante

j

Numéro de pièce :

26102

CONCESSIONNAIRE/INSTALLATEUR :

(1) Remettre ce Manuel à l'utilisateur final.

UTILISATEUR FINAL :

(1) Lire et observer les instructions de ce Manuel à chaque utilisation

du Dual Cam HP.

(2) Conserver ce manuel pour consultation ultérieure.

(3) Remettre des copies du Manuel à tout autre utilisateur ou

propriétaire.

Ne pas excéder les spécifications de charge du fabricant

du véhicule de remorquage et du fabricant de la remorque.

Figure 1

*Pour fixation de cadre de type tubulaire

**Non illustré, pour fixation de cadre de type profilé en C

Qté (2) Bras de came du DUAL CAM HP

j

Qté (2) Ferrure du support

k

Qté (6)

l

Qté (2) Vis à tête carrée ½-13 X 3 ½”*

m

Qté (6) Écrou hexagonal ½-13*

n

o

Qté (2)

p

Qté (4)

SOMMAIRE

1. INSTALLATION ET ASSEMBLAGE P. 2-4

2. PRÉ-INSTALLATION (VÉHICULE PEUT ÊTRE ABSENT) P. 4

2. INSTALLATION AVEC PRÉSENCE DU VÉHICULE P.4-5

3. INSTALLATION DE LA PLAQUE DE CADRE (TUBULAIRE) P. 5-6

4. INSTALLATION DE LA PLAQUE DE CADRE (PROFILÉ EN C) P. 6

5. RÉGLAGE DU BRAS DE CAME P. 7

6. INSPECTION ET ENTRETIEN P. 7

7. NOTES P. 8

8. GARANTIE À VIE LIMITÉE P. 8

Vis à formage de filet ½ - 13*

Rondelle frein ½” **

Boulon Grade 5 ½-13 X 1 ½” **

Pour de l'assistance concernant l'installation ou le fonctionnement, contacter le service technique CPP : 1-888-521-0510.

k

l*

n*

m*

Figure 2 – Vue intérieure du cadre

de remorque

L'omission d'observer toutes les instructions peut causer des blessures sévères, voire la mort !

© 2010 Cequent Performance Products, Inc.

AVERTISSEMENT :

Feuille 11 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 12

Instructions d’installation

Dual Cam HP

Stabilisateur haute performance

INSTALLATION

1. Repérer les deux ferrures de support incluses dans l'ensemble (article 2, figure 1). Poser le boulon en U et la chaîne fournis

dans votre nécessaire de répartition de charge sur chaque ferrure de support, comme illustré à la figure 3 (si l'on installe le Dual

Cam HP avec un nécessaire de répartition de charge existant, les boulons en U et les chaînes devront être enlevés de chaque

barre stabilisatrice avant qu'ils puissent être installés sur les ferrures de support).

Les boulons en U doivent être posés dans les extrémités des chaînes (dernier maillon), comme illustré à la figure 3.

2. Poser deux (2) contre-écrous par boulon en U et serrer. Au moins deux (2) filets doivent dépasser de l'extrémité des écrous.

Boulon en U

(écrous à l’intérieur de la courbe

Ferrure de support

Figure 3

3. À l'aide d'un crayon gras ou d'un marqueur et d'une règle, indiquer le centre de la boule d'attelage sur le coupleur en traçant une

croix, comme illustré à la figure 4 . Ce point de référence sera utilisé pour positionner le bras de came. Marquer de cette

manière les deux côtés du coupleur.

Figure 4

4. Positionner l’écrou de réglage et l’écrou de blocage aux positions les plus externes, comme illustré à la figure 5. Si le réglage

est difficile à obtenir, puisqu’il faut serrer manuellement l’écrou de réglage, appliquer une petite quantité d’huile pénétrante

légère (WD40 ou PB Blast) sur les filets du bras de came. Tourner l’écrou dans les deux sens pour que l’huile pénétrante

s’infiltre sur les filets jusqu’à ce que l’écrou de réglage bouge librement vers la position désirée.

Écrou de réglage

Écrou de blocage

Rondelle frein

© 2010 Cequent Performance Products, Inc.

Fourche

Figure 5

Feuille 12 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 13

Instructions d’installation

REESE Dual Cam HP

Dispositif de stabilisation du roulis haute performance

5. À l'aide d'une bride en C proportionnée à la hauteur du cadre de remorque et à la plaque de cadre du Dual Cam HP, fixer temporairement le

bras de came Dual Cam HP au cadre de remorque et à la plaque de cadre Dual Cam HP, comme illustré à la figure 6 (ensemble de

répartition de charge de type à tourillons) ou à la figure 7 (ensemble de répartition de charge à barres rondes).

6. Placer la plaque de cadre selon la dimension indiquée pour le type de répartition de charge (à tourillons ou à barres rondes). (Coupleur

standard ou monté dans le bas).

Mesurer à partir de la marque sur le coupleur à boule jusqu'au centre du boulon de pivot du bras de came comme illustré à la figure 6 ou 7

de la page suivante. Si la plaque de cadre fait obstacle à une pièce quelconque du cadre de remorque, l'orientation peut être modifiée en

changeant de côté (voir la figure 8 pour une orientation différente de la plaque) ; maintenir la même distance entre le centre du coupleur et

le pivot du bras de came quelle que soit l'orientation.

7. Placer temporairement le support de chaîne au-dessus du bras de came. (Lors de l'accouplement, la position du support doit être ajustée de

façon que la chaîne se trouve à la verticale avant le remorquage). Serrer le boulon du support de chaîne illustré à la figure 2 contre le cadre.

Positionnement pour le type à tourillons

(coupleur standard)

Orientation de la

plaque de cadre

En haut et en bas, la

chaîne doit être la

plus droite possible.

Figure 6 – Positionnement approximatif du bras de came pour le dispositif de répartition de charge à tourillons

Positionnement pour le type à tourillons

(coupleur monté dans le bas)

En haut et en bas, la

chaîne doit être aussi

droite que possible.

Figure 6A – Positionnement approximatif du bras de came pour le dispositif de répartition de charge à tourillons

Depuis la marque sur le

coupleur, le long du cadre

8. S'il s'agit d'un coupleur monté dans le bas, il peut s'avérer

nécessaire d'incliner le montage sur boule le plus vers l'avant

du véhicule qu'il est possible.

20-1/2

Depuis la marque sur le coupleur, le long du cadre.

ATTENTION :

Les mesures des figures 6, 6A, 7 et 7A sont à titre indicatif, un ajustement de la longueur du bras de came par l'écrou d'ajustement

(Figure 5) peut s'avérer nécessaire après l'accrochage, dans les instructions à venir de ce manuel. Cequent Performance Products,

Inc. n'est pas responsable des dommages résultant de la non observation d'une partie quelconque de ce manuel.

©2010 Cequent Performance Products, Inc.

Feuille 13 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 14

Instructions d’installation

REESE Dual Cam HP

Dispositif de stabilisation du roulis haute performance

Positionnement pour

le type à barres rondes

(Coupleur standard)

Orientation de la

plaque de cadre

En haut et en bas, la

chaîne doit être la

plus droite possible.

Figure 7 – Positionnement approximatif du bras de came pour le dispositif de répartition de charge à barres rondes

Positionnement pour

le type à barres rondes

(Coupleur monté dans le bas)

En haut et en bas, la

chaîne doit être aussi

droite que possible.

Depuis la marque sur le

coupleur, le long du cadre

19-1/8”

Depuis la marque sur le coupleur,

le long du cadre.

Figure 7A – Positionnement approximatif du bras de came pour le dispositif de répartition de charge à barres rondes

S'il s'agit d'un coupleur monté dans le bas, il peut s'avérer nécessaire d'incliner

le montage sur boule le plus vers l'avant du véhicule qu'il est possible.

Les mesures des figures 6, 6A, 7 et 7A sont à titre indicatif, un ajustement de la longueur du bras de came par l'écrou d'ajustement

(Figure 5) peut s'avérer nécessaire après l'accrochage, dans les instructions à venir de ce manuel. Cequent Performance Products,

Inc. n'est pas responsable des dommages résultant de la non observation d'une partie quelconque de ce manuel.

©2010 Cequent Performance Products, Inc.

ATTENTION :

Feuille 14 de 30 26102IN 05/14/12 Rev. G

Page 15

Instructions d’installation

Dual Cam HP

Stabilisateur haute performance

Orientation facultative de la

RESPECTER POUR CETTE ORIENTATION LES

MÊMES MESURES QUE CELLES INDIQUÉES À LA

FIGURE 6 OU 7.

PRÉ-INSTALLATION (VÉHICULE PEUT ÊTRE ABSENT)

1. Si le véhicule de remorquage n’est pas disponible au moment de l’installation du système Dual Cam HP, centrer la fourche sur

les filets du bras de came (environ 5 cm [2 po] de l’une des parties filetées du bras de came. Tourner l’écrou de réglagle vers le

bas à la rencontre de la fourche. Serrer l’écrou de blocage jusqu’à ce que la rondelle frein soit entièrement comprimée et

continuer jusqu’à la partie de l’installation de la plaque de cadre selon votre style précis de cadre indiqué dans le présent

manuel; cadre tubulaire ou à profilé en C.

2. Remettre ce manuel au client ou à l'utilisateur final de ce produit et l'informer qu'il peut s'avérer nécessaire d'ajuster légèrement

la longueur du bras de came. Cet ajustement pourra dépendre de plusieurs facteurs: inclinaison de la tête du système WD,

nombre de chaînes utilisées pour répartir la charge adéquatement, différences entre les véhicules de remorquage, modification

du poids du timon de la remorque. Toutes ces variables vont affecter légèrement la position de la came par rapport à son assise

dans la détente du bras de came.

3. Diriger le client vers la section du manuel intitulée INSTALLATION AVEC PRÉSENCE DU VÉHICULE pour la procédure

d'attelage, et lui expliquer en détail le positionnement de la came à l'intérieur de la détente de la barre stabilisatrice. Référer

aussi le client au manuel d'instructions de l'attelage à répartition de charge et s'assurer qu'il observera la section ATTELAGE

INITIAL de ce manuel lorsqu'il procédera à son premier attelage et/ou s'il survient une modification quelconque aux variables

énumérées au point 2 de cette section.

4. NE PAS OUBLIER de remettre au client/à l'utilisateur final la trousse d'information sur le remorquage (P/N : 110400) et

FAIRE EN SORTE qu'il comprenne bien l'information qui s'y trouve afin de procéder à un remorquage sécuritaire.

INSTALLATION AVEC PRÉSENCE DU VÉHICULE

plaque de cadre

Figure 8

NOTA : Installer et ajuster l'attelage selon les instructions d'installation de votre attelage à répartition de charge.

1. Atteler la remorque au véhicule de remorquage. Le véhicule et la remorque doivent se trouver en ligne droite et sur une surface

de niveau. Soulever le timon et l'arrière du véhicule suffisamment pour installer les barres stabilisatrices sur le bras de came

double, à l'aide du vérin du timon de la remorque (environ 6 à 12 po, ou jusqu'à ce que la barre stabilisatrice puisse être

soulevée à l'aide de la poignée de levage fournie sans trop d'effort ; cela variera selon la capacité de charge nominale de la barre

stabilisatrice et l'ajustement de l'inclinaison de la tête).

Éviter de placer une partie du corps sous la caravane ou entre la camionnette et la caravane. Un

mouvement imprévu ou accidentel de la camionnette ou de la caravane peut causer des blessures sévères,

voire la mort.

Si l'on place une partie du corps sous la remorque ou entre le véhicule et la remorque, il FAUT exécuter

TOUTES les étapes suivantes :

S'assurer que la transmission de la camionnette est en position de stationnement

S'assurer que le frein de secours est appliqué

Placer des cales à l'avant et l'arrière des pneus de la caravane

S'assurer que la béquille de la caravane repose sur un sol ferme

© 2010 Cequent Performance Products, Inc.

AVERTISSEMENT :

Feuille 15 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 16

Instructions d’installation

Dual Cam HP

Stabilisateur haute performance

2. Installer les barres stabilisatrices dans la tête du montage de boule. Placer la barre stabilisatrice au-dessus de la partie "came"

du bras de came.

3. Poser la ferrure de support (avec les extrémités des boulons en U orientés vers l'intérieur) et la chaîne sur la came en faisant

glisser la fente en forme de poire de la ferrure au-dessus de l'extrémité à boutons du bras de came (figure 9). Faire pivoter la

ferrure de support en position verticale et tirer la chaîne de façon qu'elle soit à la verticale vis-à-vis du point d'accrochage de la

chaîne sur la ferrure (Figure 10).

Ferrure de support

Figure 9 Figure 10

4. Soulever les chaînes jusqu'à ce qu'elles rencontrent le crochet de la ferrure, en utilisant le maillon le plus bas de la chaîne

permettant de fermer la ferrure à la main (sans le tube de levage fourni – dans la plupart des installations, il s'agit généralement

du 2e ou 3e maillon à partir de l'extrémité libre de la chaîne). Utiliser le même nombre de maillons des deux côtés de la

remorque. Soulever les deux barres stabilisatrices à l'aide des supports à enclenchement rapide et poser la cheville-arrêt dans le

support à enclenchement rapide. S'assurer que la ferrure de support est engagée à fond dans la fente du bras de came.

Lors du soulèvement ou de l'abaissement du support d'enclenchement rapide, éviter de placer une partie

quelconque du corps dans la trajectoire de la poignée de levage ainsi que sous le bras de came et les

barres stabilisatrices. Les composants de ce système sont chargés d'une force substantielle et leur

déplacement ou chute soudains risquent de causer des blessures sévères voire la mort.

Ne jamais soulever ou abaisser les supports d'enclenchement rapide sans monter le vérin de timon de

remorque afin d'enlever la charge des barres stabilisatrices et des bras de came. Le défaut d’observer

cette consigne de sécurité peut causer des blessures sévères.

5. Baisser le vérin du timon de remorque.

6. Vérifier que la came est correctement assise dans la détente de la barre stabilisatrice (figure 14). Si l’assemblage du bras de

came ne s’assoit pas correctement dans la détente de la barre stabilisatrice, frapper l’extrémité du bras de came avec un maillet

ou un marteau jusqu’à ce que l’assise avec la détente de la barre stabilisatrice corresponde à la figure 14.

7. Dès que les bras de came sont correctement assis dans la détente de la barre stabilisatrice, vérifier la hauteur droite du véhicule

de remorquage et comparer avec la trousse de répartition de poids; plus particulièrement le chapitre traitant de l’attelage de ce

manuel. Il peut s’avérer nécessaire d’ajuster le nombre de maillons engagés ou l’inclinaison du montage de la boule pour

assurer une répartition correcte de la charge pour le véhicule de remorquage et la remorque. Le repositionnement des

assemblages à l’intérieur de la détente de la barre stabilisatrice peut être nécessaire pour répondre aux exigences de l’attelage

initial.

8. Les assemblages de bras de came sont maintenant prêts à être montés en permanence sur le cadre du véhicule. Suivre les

instructions appropriées de ce manuel pour l'installation de la plaque de cadre, en fonction du type de cadre de la remorque.

INSTALLATION DE LA PLAQUE DE CADRE (CADRE TUBULAIRE)

Bras de came

Barre stabilisatrice

AVERTISSEMENT :

ATTENTION :

Avant de percer, s'assurer que le cadre de remorque ne comporte aucune obstruction dans la zone où les trous de boulons

doivent être percés, par exemple le câblage de la remorque ou le dispositif de freinage automatique.

NE PAS percer la paroi opposée du cadre tubulaire.

1. Avec les brides en C toujours en place, marquer au pointeau dans le cadre le centre de deux (2) trous pour chaque support.

© 2010 Cequent Performance Products, Inc.

Feuille 16 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 17

Instructions d’installation

Dual Cam HP

Stabilisateur haute performance

2. Percer deux (2) trous 7/16 po dans chaque côté du cadre où les trous ont été marqués. L'utilisation d'un foret à centrer ou d'un petit

trou pilote peut s'avérer très utile avant le perçage final.

3. Poser deux (2) vis à formage de filet ½-13 fournies (article 3, figure 1).

Répéter du côté opposé et serrer les quatre (4) vis à formage de filet ½-13 au couple de 50 lb-pi.

4. Enfiler un écrou hexagonal ½-13 (écrou de blocage) sur les boulons à tête carrée ½-13 X 3 ½” et poser les fixations dans les

supports de cadre comme illustré à la figure 11.

5. Serrer la vis de pression jusqu'à son contact avec le cadre de remorque. Serrer ensuite sur ¼ à ½ de tour (NE PAS TROP

SERRER LA VIS DE PRESSION). Serrer l’écrou de blocage pour empêcher la vis de pression de reculer pendant l'utilisation.

Répéter de l’autre côté du cadre de remorque.

6. Retirer les brides en C du cadre.

INSTALLATION DE LA PLAQUE DE CADRE (CADRE EN PROFILÉ EN C)

NOTA : Certains cadres à profilés en C peuvent comporter des coins extérieurs carrés ne permettant pas à la plaque de

cadre de toucher le bas du cadre. Pour ces types de cadre, une rondelle plate ½” (non fournie) est requise entre

l'extérieur du cadre de remorque et la plaque de cadre. Le bas de la plaque de cadre DOIT toucher le bas du cadre de

remorque.

1. Avec les brides en C toujours en place, marquer au pointeau dans le cadre le centre de deux (2) trous pour chaque support.

2. Percer deux (2) trous 17/32 po dans chaque côté du cadre où les trous ont été marqués. L'utilisation d'un foret à centrer ou d'un

petit trou pilote peut s'avérer très utile avant le perçage final.

3. Poser deux (2) boulons ½-13 x 1 ½ po avec leurs rondelles freins ½ po et leurs écrous ½ po (articles 5, 6 et 7), figure 13.

Répéter du côté opposé et serrer les quatre (4) boulons ½-13 au couple de 85 lb-pi.

4. Enfiler les écrous hex. ½-13 sur les boulons à tête carrée ½-13 X 3 ½” et les poser dans les supports de cadre comme illustré à

la figure 13.

5. Serrer la vis de pression jusqu'à son contact avec le cadre de remorque. Serrer ensuite sur ¼ à ½ de tour (NE PAS TROP

SERRER LA VIS DE PRESSION). Serrer le contre-écrou pour empêcher la vis de pression de reculer pendant l'utilisation.

Répéter de l’autre côté du cadre de remorque.

6. Retirer les brides en C du cadre.

Tête à embase déjà installée,

vis à formage de filet

Plaque de cadre

Écrou

Plaque de cadre

Rondelle frein

Écrou de blocage

Vis de pression

Figure 11

Vis de pression

Écrou de blocage

Boulon à tête hex.

Figure 12

© 2010 Cequent Performance Products, Inc.

Plaque de cadre

Feuille 17 de 30 26102IN 05/14/12 Rev. G

Figure 13

Form: F205 Rev A 5-6-05

Page 18

Instructions d’installation

Dual Cam HP

Stabilisateur haute performance

AJUSTEMENT DU BRAS DE CAME

1. S'assurer que le véhicule et la remorque sont réglés correctement d'après les instructions de l'attelage à répartition de charge,

tirer suffisamment vers l'avant pour que véhicule et remorque se trouvent en ligne droite. (En repérant un point à une certaine

distance du véhicule (environ 100 mètres), conduire en avançant vers ce point en gardant la direction parfaitement droite jusqu'à

obtenir le parfait alignement du véhicule et de la remorque.)

2. Aller à chaque bras de came et vérifier que la came est parfaitement centrée dans la détente de la barre stabilisatrice. Ajuster la

longueur des bras de came selon les instructions, il est important que le bras de came/la détente de la barre stabilisatrice se

trouvent exactement tel qu'illustré à la figure 14.

3. Avant d'ajuster la longueur du bras de came, monter le vérin du timon de remorque et abaisser les supports à enclenchement

rapide. Desserrer le contre-écrou (figure 5) et déplacer l'écrou d'ajustement (figure 5) jusqu'à ce que la came soit centrée dans la

détente de la barre stabilisatrice (figure 14). Une fois les ajustements effectués, soulever les deux supports à enclenchement

rapide et poser les agrafes de retenue ; abaisser le vérin du timon de remorque. Répéter l'étape 2 de cette section.

4. Ajuster la position des supports à enclenchement rapide au besoin, la chaîne devrait être parfaitement verticale lors de

l'utilisation afin de prévenir les dommages aux supports à enclenchement rapide.

* De temps à autre, au gré des changements de conditions de remorquage ou de charge, il peut s'avérer nécessaire d'utiliser un

maillon de chaîne différent pour obtenir le niveau approprié du véhicule de remorquage (voir les instructions d'installation du

dispositif de répartition de charge). Il faut rajuster le bras de came à chaque fois qu'un maillon différent est utilisé.

AVANT CHAQUE DÉPLACEMENT :

1. VÉRIFIER L'ÉQUIPEMENT : Inspecter la condition de l'ensemble de l'équipement de remorquage et garder celui-ci en

parfaite condition.

2. Vérifier que les couples de serrage de toute la visserie correspond aux spécifications de ce manuel.

3. Revérifier l'alignement de la détente de la barre stabilisatrice et de la came, et répéter la vérification pendant le

remorquage pour obtenir le meilleur rendement.

4. Rechercher les signes d'usure excessive sur tous les composants du système.

ENTRETIEN :

1. NE PAS appliquer de la graisse sur les cames ou les bras de came.

2. Si le bruit du dispositif constitue un problème, une petite quantité de lubrifiant tel que Vaseline peut être appliquée sur la

partie où les barres stabilisatrices entrent en contact avec la came.

Les charges au timon excédant 1200 lb peuvent nécessiter l'application de lubrifiant afin de prévenir l'usure excessive.

3. Maintenir la peinture en bon état afin de prévenir la rouille et conserver une apparence agréable. (Ne PAS peindre les

étiquettes)

© 2010 Cequent Performance Products, Inc.

Figure 14

Feuille 18 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 19

Instructions d’installation

Vis autotaraudeuse 1/2" x 1.00"

Feuillet d’instructions

OUTILS REQUIS :

Mèches : 7/16”, 9/16” et ¼”

Veuillez lire toutes les instructions avant de poser un boulon supplémentaire.

L'omission d'observer toutes les instructions peut causer des blessures sévères, voire la mort !

2-1/4”

Support encliquetable

AVERTISSEMENT :

•Pose d'un boulon supplémentaire dans le support encliquetable.

•Marquer l'emplacement du trou à percer dans le support

encliquetable. Centrer le trou sur l'axe gauche-droite et le positionner

2-1/4 po au-dessus de l'arc du support. Voir la photo à gauche.

•Avant de placer le support sur le cadre, percer un trou de 9/16 po

dans le support.

•Placer le support à l'endroit approprié sur le cadre tel qu'indiqué dans

le manuel du produit, ou le remettre à sa position initiale s'il a déjà été

installé.

•En se servant du trou du support comme guide, percer un trou de

départ de ¼ po. S'assurer de rester bien centré dans le trou du support.

• Pour ce faire, on peut utiliser la mèche 9/16 po en premier. Laisser

simplement une petite marque sur le cadre à l'aide de la mèche 9/16

po. Puis terminer le perçage à l'aide de la mèche ¼ po puis celle de

7/16 po pour le trou final. Voir le trou de départ à gauche.

Pour de l'assistance concernant l'installation ou le fonctionnement, contacter le service technique CPP : 1-888-521-0510.

© 2010 Cequent Performance Products, Inc.

•Poser la vis autotaraudeuse de ½ po dans le trou du support et du

cadre. Serrer à un couple de 50 lb-pi.

•Resserrer la vis de blocage ½ po sur l'intérieur du cadre. Visser

de ¼ à ½ tour seulement après le contact avec le cadre.

NOMENCLATURE DES PIÈCES

QTÉ DESCRIPTION

2

1

Cequent Performance Products, Inc.

47912 Halyard Dr. Suite 100

Plymouth, MI 48170

Feuille 19 de 30 26102IN 05/14/12 Rev. G

Page 20

REMARQUES :

Instructions d’installation

Dual Cam HP

Stabilisateur haute performance

GARANTIE À VIE LIMITÉE

1. Garantie limitée. Cequent Trailer Products, Inc. (“Nous”) garantit à l’acheteur initial seulement (“Vous”) que le produit sera

exempt de vices de matériaux et de fabrication pendant la durée de vie du produit, exception faite de l’usure normale, dans la

mesure où l’installation et l’utilisation du produit sont conformes aux instructions accompagnant celui-ci. Aucune autre

garantie, expresse ou implicite, ne s’applique, y compris les garanties relatives à la qualité marchande ou à l'adéquation à un

usage particulier. Si le produit présente un vice couvert par cette garantie à vie limitée, Votre seul et unique recours consiste

dans le fait que Nous remplacerons le produit gratuitement dans un délai raisonnable ou, à notre discrétion, rembourserons le

prix d’achat. Cette garantie n’est pas transférable.

2. Limites de la garantie. Cette garantie limitée ne couvre pas : (a) l’usure normale; (b) les dommages causés par l’abus, la

négligence, une mauvaise utilisation, ou résultant de tout accident survenu de quelque manière que ce soit; (c) les dommages

causés par une application inappropriée, une charge excessive ou une installation inadéquate, y compris les soudures; (d) un

entretien ou une réparation inadéquate; (e) un produit modifié de quelque manière que ce soit par quiconque d’autre que Nous,

à l’exception des modifications stipulées dans les instructions accompagnant le produit et réalisées selon les règles de l’art.

3. Obligations de l’acheteur. Pour effectuer une réclamation, communiquez avec nous au 47774 Anchor Court West, Plymouth, MI

48170, 1-888-521-0510, et veuillez identifier le produit d'après le numéro de modèle et suivre les directives qui vous seront

fournies. Tout produit retourné qui est remplacé ou remboursé devient notre propriété. Vous serez tenu d’assumer les frais

d’expédition de retour. Veuillez conserver votre reçu d’achat afin que nous puissions en vérifier la date et confirmer que

Vous êtes l'acheteur initial. Le produit et le reçu d’achat doivent Nous être fournis afin que nous puissions traiter Votre

réclamation.

4. Limites des recours. La réparation ou le remplacement sont Vos seuls recours en vertu de cette garantie limitée ou d'une

quelconque autre garantie relative au produit. Nous ne sommes pas responsables des frais de service ou de main-d’oeuvre

encourus pour l’enlèvement ou la réinstallation d’un produit, ni des dommages accessoires ou indirects, quels qu’ils soient.

5. Acceptation des risques. Vous reconnaissez et acceptez que toute utilisation du produit à des fins autres que celle(s) stipulée(s)

dans les instructions relatives au produit est faite à vos propres risques.

6. Loi applicable. Cette garantie Vous confère des droits légaux spécifiques, et il se peut que Vous possédiez d’autres droits qui

peuvent varier d’une province ou d’un État à l’autre. Cette garantie limitée est régie par les lois de l’État du Michigan,

abstraction faite des règles relatives aux conflits de lois. Les cours de l’État situées dans le comté d’Oakland, Michigan,

constituent les autorités judiciaires exclusives relativement à cette garantie.

© 2010 Cequent Performance Products, Inc.

Cequent Performance Products, Inc.

47912 HALYARD DR. SUITE 100

PLYMOUTH, MI. 48170

Feuille 20 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 21

Instrucciones de instalación

Sistema Doble Leva HP

Control de oscilación de Alto Desempeño

SISTEMA DOBLE LEVA HP

Equipo necesario:

Kit de tornillos: 100126

ENSAMBLADO

Llaves: Extremo abierto 1-1/2", extremo abierto

3/4"

Brocas de taladro: 7/16”, 17/32” y taladro central (taladro piloto)

Otros: Abrazadera en C 8 – 10”, cinta de medir, aceite ligero penetrante

Extremo abierto ½”, tubo y trinquete 3/4"

j

Números de partes:

26102

CONCESIONARIO/INSTALADOR:

(1) Entregue este manual al usuario final.

USUARIO FINAL:

(1) Lea y siga este manual todas las veces que use su sistema Doble

Leva HP.

(2) Guarde este Manual para referencia futura.

(3) Distribuya copias de este manual a cualquier otro usuario o propietario.

No supere el valor inferior entre la calificación del fabricante del

vehículo de remolque o la calificación del fabricante del remolque

Figura 1

* Para unión al bastidor estilo tubular

**No se muestra, para unión al bastidor estilo Canal en C

Cant. (2) Ensamble del brazo doble leva HP

j

Cant. (2) Soporte colgante

k

Cant. (6) Tornillo formante de rosca ½ - 13*

l

Cant. (2) Perno de cabeza cuadrada,½-13 X 3 ½"*

m

Cant. (6) Tuerca hexagonal ½-13*

n

o

Cant. (2)

p

Cant. (4)

ÍNDICE

1 INSTALACIÓN Y ENSAMBLE P . 2-4

2 PRE-INSTALACIÓN (SIN VEHÍCULO DE REMOLQUE ) P. 4

2 INSTALACIÓN CON VEHÍCULO DE REMOLQUE PRESENTE P.4-5

3 INST. DE PLACA DEL BASTIDOR DE SIST.DBL. LEVA HP EN BAST. TUBULAR P. 5-6

4 INST.DE PLACA DEL BASTIDOR DE SIST. DBL. LEVA HP EN BAST. CANAL EN C P. 6

5 AJUSTE DEL BRAZO DE LEVA P. 7

6 ANTES DE CADA VIAJE: Y MANTENIMIENTO P. 7

7 NOTAS P. 8

8 GARANTÍA LIMITADA DE POR VIDA P. 8

Arandela de bloqueo ½”**

Perno Grado 5,½-13 X 1 ½"**

Para instalación u operación contacte al Servicio Técnico de CPP: 1-888-521-0510.

k

k

n*

m*

l*

Figura 2 – Vista interior del bastidor del

remolque

¡No seguir estas instrucciones puede resultar en la muerte o en lesiones serias!

© 2010 Cequent Performance Products, Inc.

ADVERTENCIA:

Hoja 21 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 22

Instrucciones de instalación

Sistema Doble Leva HP

Control de oscilación de Alto Desempeño

INSTALACIÓN

1. Localice ambos soportes colgantes que se incluyen en el kit (pieza 2, figura 1). Instale el perno en U y la cadena de su Kit de

Distribución de Peso en cada soporte colgante como se muestra en la figura 3 (si se instala el sistema Doble Leva HP en un kit

de distribución de peso existente, los pernos en U y las cadenas deben quitarse de cada barra de resorte antes de que se puedan

instalar en los soportes colgantes).

Los pernos en U se deben instalar en los extremos de las cadenas (último eslabón) como se muestra en la Figura 3.

2. Instale 2 tuercas de bloqueo por perno en U, apriete las tuercas en U. Verifique que al menos 2 roscas son visibles más allá de

los extremos de las tuercas.

PERNO EN U

(TUERCAS AL INTERIOR DEL CODO)

SOPORTE COLGANTE

Figura 3

3. Con un lápiz de grasa o aparato adecuado para marcar como un marcador y un borde recto localice y marque el centro de la bola

del enganche en el acoplador tanto horizontal como verticalmente como se muestra en la Figura 4 . Este punto de referencia se usará para

localizar la posición del ensamble del brazo de leva. Marque ambos lados del acoplador.

Figura 4

4. Coloque la tuerca de ajuste y tuerca de bloqueo en la posición más externa como se muestra en la figura 5. Si el ajuste es difícil, ya que la

tuerca de ajuste se de girar a mano, aplique una pequeña cantidad de aceite liviano penetrante como el WD40 o PB Blast a las roscas del

brazo de leva. Manipule la tuerca de ajuste hacia atrás o hacia adelante para que el aceite penetrante entre en las roscas hasta que la tuerca

de ajuste se mueva libremente a la posición deseada.

Tuerca de ajuste

Tuerca de bloqueo

Arandela de bloqueo

© 2010 Cequent Performance Products, Inc.

Horquillla

Figura 5

Hoja 22 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 23

Instrucciones de instalación

Sistema REESE Doble Leva HP

Control de oscilación de Alto Desempeño

5. Con una abrazadera en C adecuada para acomodar su altura del bastidor del remolque y la placa del bastidor del sistema Doble Leva HP, sujete

temporalmente el ensamble del brazo Doble Leva HP al bastidor del remolque y placa del bastidor del sistema Doble Leva HP como se muestra

en la figura 6 para los kits de distribución de peso estilo Trunnion, para kits de distribución de peso estilo barra redonda, siga las

dimensiones en la figura 7.

6. Coloque la placa del bastidor en la dimensión que se muestra para su tipo de kit de distribución de peso (estilo Trunnion o barra redonda).

Acoplador estándar o instalado en la parte inferior). Mida desde la marca en el acoplador esférico hasta el centro del perno de pivote del brazo

de leva como se muestra en la figura 6 ó 7 en la siguiente página. Si la placa del bastidor interfiere con cualquier parte del bastidor del

remolque, la orientación se puede cambiar al alternar los lados, vea la figura 8 para la orientación opcional de la placa del bastidor. Mantenga el

mismo acoplador centrado en el pivote del brazo de leva sin importar la orientación de la placa del bastidor.

7. Coloque el gancho de cadena temporalmente por encima del brazo de leva. (En el momento de la instalación, la posición del gancho se debe

ajustar para verificar que la cadena esté vertical antes de remolcar). Apriete el perno del gancho de cadena como se muestra en la figura 2 contra

el bastidor.

Puntos de instalación estilo Trunnion

(Acoplador estándar)

ORIENTACIÓN

DE LA PLACA

DEL BASTIDOR

LA CADENA DEBE

ESTAR LO MÁS

RECTA POSIBLE

Figura 6 – Ubicaciones aproximadas del brazo de leva para kits de distribución de peso estilo

Trunnion

Puntos de instalación estilo Trunnion

(Acoplador de montaje inferior)

LA CADENA DEBE

ESTAR LO MÁS

RECTA

POSIBLE HACIA

ARRIBA Y HACIA

ABAJO

Figura 6A- Ubicaciones aproximadas del brazo de leva para kits de distribución de peso estilo Trunnion

DESDE LA MARCA EN EL

ACOPLADOR A LO LARGO DEL

COSTADO DEL DEL BASTIDOR

8. Si usted tiene un acoplador instalado en la parte inferior

podría ser necesario que incline el montaje esférico lo más

que pueda hacia el frente del vehículo de remolque.

20-1/2

DESDE LA MARCA EN EL ACOPLADOR

A LO LARGO DEL COSTADO DEL

BASTIDOR

Las mediciones en las figuras 6A y 7A son pautas, el ajuste de la longitud del brazo de leva mediante la tuerca de ajuste

(Figura 5) podría ser necesario después de la instalación en instrucciones posteriores de este manual. Cequent Performance

Products, Inc. no es responsable por daños incurridos por ignorar alguna parte de este manual.

© 2010 Cequent Performance Products, Inc.

PRECAUCIÓN:

Hoja 23 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 24

Instrucciones de instalación

Sistema REESE Doble Leva HP

Control de oscilación de Alto Desempeño

Puntos de instalación estilo Barra Redonda

(Acoplador estándar)

LA CADENA

DEBE ESTAR LO

MÁS RECTA

POSIBLE

Figura 7 – Ubicaciones aproximadas del brazo de leva para kits de distribución de peso estilo Barra Redonda

Puntos de instalación de Barra Redonda

(Acoplador de montaje inferior)

ORIENTACIÓN

DE LA PLACA

DEL BASTIDOR

DESDE LA MARCA EN EL

ACOPLADOR A LO LARGO DEL

COSTADO DEL DEL BASTIDOR

LA CADENA DEBE

ESTAR LO MÁS

RECTA

POSIBLE HACIA

ARRIBA Y HACIA

ABAJO

Figura 7A – Ubicaciones aproximadas del brazo de leva para kits de distribución de peso de Barra Redonda

19-1/8”

DESDE LA MARCA EN EL

ACOPLADOR

A LO LARGO DEL COSTADO

DEL BASTIDOR

Si usted tiene un acoplador instalado en la parte inferior podría ser necesario que incline el montaje esférico

lo más que pueda hacia el frente del vehículo de remolque.

PRECAUCIÓN:

Las mediciones en las figuras 6A y 7A son pautas, el ajuste de la longitud del brazo de leva mediante la tuerca de ajuste

(Figura 5) podría ser necesario después de la instalación en instrucciones posteriores de este manual. Cequent Performance

Products, Inc. no es responsable por daños incurridos por ignorar alguna parte de este manual.

© 2010 Cequent Performance Products, Inc.

Hoja 24 de 30 26102IN 05/14/12 Rev. G

Page 25

Instrucciones de instalación

Sistema Doble Leva HP

Control de oscilación de Alto Desempeño

SIGA LAS MISMAS MEDIDAS PARA ESTA

Orientación opcional de la placa del bastidor

ORIENTACIÓN COMO SE MUESTRA EN LA FIGURA

6 Ó 7.

Figura 8

PRE-INSTALACIÓN (VEHÍCULO DE REMOLQUE PODRÍA NO ESTAR PRESENTE)

1. Si el vehículo de remolque no está presente en el momento de la instalación del sistema Doble Leva HP, posicione la horquilla centrada

en las roscas del brazo de leva (aproximadamente a 2” de cualquier extremo de la porción roscada del brazo de leva. Corra la tuerca de

ajuste hasta encontrarse con la horquilla. Apriete la tuerca de bloqueo hasta que la arandela de bloqueo esté completamente comprimida

y continúe con la porción de la instalación de la placa del bastidor de este manual para su estilo de bastidor específico, Bastidor Tubular

o Bastidor con Canal en C.

2. Pase este manual al cliente/usuario final de este producto e infórmeles que podría ser necesario realizar ajustes menores a su

longitud del brazo de leva dependiendo de la inclinación de la cabeza del sistema de distribución de peso, el número de cadenas usadas

para la distribución de peso correcta, la variación del vehículo de remolque y/o cambios en el peso de la horquilla de su remolque ya que

todas estas variables afectarán ligeramente la posición correcta del sistema de leva con respecto a la ubicación correcta del retenedor del

brazo de leva.

3. Dirija al cliente a la porción INSTALACIÓN CON EL VEHÍCULO PRESENTE de este manual para el procedimiento de instalación,

y explique completamente la ubicación de sistema de leva dentro del retenedor de la barra de resorte. Remítalos al manual de

instrucciones del enganche de distribución de peso que tengan y verifique que sigan la sección de INSTALACIÓN INICIAL del

manual de Distribución de Peso para instalación por primera vez y/o cambios que ocurran en las variables que se enumeran en el punto

2 de esta sección.

4. CERCIÓRESE de pasar el paquete de Información de remolque (P/N: 110400) al cliente/usuario final y VERIFIQUE que

entienden el material que se encuentra en el paquete de información de remolque para un remolque seguro.

INSTALACIÓN CON VEHÍCULO DE REMOLQUE PRESENTE

NOTA: Instale y ajuste el enganche de distribución de peso según las instrucciones de instalación para su enganche de

distribución de peso.

1. Conecte el remolque al vehículo de remolque. El vehículo de remolque y el remolque deben estar en terreno nivelado y en l

ínea recta. Levante la horquilla y parte posterior del vehículo lo suficiente para instalar las barras de resorte sobre el brazo de

leva doble con el gato de la horquilla del remolque (aproximadamente 6”-12” o hasta que la barra de resorte se pueda levantar

con la manija de elevación que se suministra con muy poco esfuerzo, esto variará dependiendo de la calificación de la barra de

resorte y del ajuste de la inclinación de la cabeza).

Evite colocar cualquier parte de su cuerpo debajo del remolque o entre el vehículo y el remolque. El

movimiento no esperado o accidental del vehículo o el remolque puede causar lesiones serias o muerte

Si debe colocar cualquier parte de su cuerpo debajo del remolque o entre el vehículo y el remolque,

DEBE realizar TODOS los pasos siguientes:

Revise que la transmisión del vehículo esté en posición de estacionamiento

Revise que el freno de emergencia esté activado

Coloque bloques al frente y detrás de todas las llantas del remolque

Revise que la base del gato del remolque esté apoyada en terreno firme

ADVERTENCIA:

© 2010 Cequent Performance Products, Inc.

Hoja 25 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 26

Instrucciones de instalación

Sistema Doble Leva HP

Control de oscilación de Alto Desempeño

2 Instale las barras de resorte dentro de la cabeza de montaje esférico. Coloque la barra de resorte sobre la porción de leva del brazo de leva.

3. Instale el soporte colgante (con los extremos de los pernos en U orientados al interior) y la cadena sobre el sistema de leva deslizando la

ranura con chaveta del soporte colgante sobre el extremo inferior del brazo de leva (figura 9). Rote el soporte colgante hacia la posición

vertical y hale la cadena vertical hacia el punto de unión de la cadena en el soporte a presión (Figura 10).

SOPORTE COLGANTE

BRAZO DE LEVA

Figura 9 Figura 10

4. Levante las cadenas hasta que encuentren el gancho del soporte a presión, usando el eslabón de cadena más bajo de la cadena que le

permita cerrar el soporte a presión a mano (sin el tubo de elevación suministrado – por lo general este es el 2do o 3er eslabón del extremo

libre de la cadena para la mayoría de las instalaciones). Use el mismo número de eslabón para ambos lados del remolque. Levante

ambas barras de resorte con los soportes a presión e instale el pasador sujetador en el soporte a presión. Verifique que el soporte

colgante esté completamente enganchado en la ranura del brazo de leva.

Al levantar/bajar el soporte a presión, evite colocar cualquier parte del cuerpo en la ruta de la manija de elevación

y debajo del brazo de leva y barras de resorte. Los componentes de este sistema se cargan con fuerza

sustancial y podrían cambiar de posición o caer repentinamente causando severa lesión o muerte.

Nunca levante o baje los soportes a presión sin levantar el gato de la horquilla del remolque para quitar la carga

de las barras de resorte y brazos de leva. No seguir estas instrucciones podría causar graves lesiones.

5. Baje el gato de la horquilla del remolque.

6. Revise que el sistema de leva esté correctamente instalado en el retenedor de la barra de resorte (figura 14). Si el ensamble del brazo de

leva no se acomoda automáticamente en el retenedor de la barra de resorte, golpee el extremo del brazo de leva con un mazo o martillo

hasta que se acomode dentro de retenedor de la barra de resorte como se muestra en la figura 14.

7. Una vez que los brazos de leva estén correctamente posicionados en el retenedor de la barra de resorte, revise la altura de conducción

del vehículo de remolque según su kit de enganche de distribución de peso, específicamente la sección de instalación inicial de ese

manual. Podría ser necesario ajustar el número de eslabones enganchados o la inclinación del montaje esférico para una distribución de

peso correcta para su remolque y vehículo de remolque. Podría ser necesario re-posicionar los ensambles del brazo de leva hasta que se

cumplan los requisitos de instalación iniciales.

Corra la tuerca de ajuste que se muestra en la figura 5 para encontrarse con la horquilla. Apriete la tuerca de bloqueo que se muestra

en la figura 5 hasta que la arandela de bloqueo esté completamente apretada. Este proceso debe hacer para ambos ensambles de la

leva, es decir, ambos lados del bastidor del remolque.

8. Los ensambles del brazo de leva están ahora listos para instalarse de manera permanente en el bastidor del remolque. Siga las

instrucciones correctas para la instalación de la placa del bastidor de este manual para su tipo de bastidor en particular.

INSTALACIÓN DE PLACA DEL BASTIDOR DEL SISTEMA DOBLE LEVA HP EN BASTIDOR TUBULAR

BARRA DE RESORTE

ADVERTENCIA:

PRECAUCIÓN:

Antes de perforar, verifique que no haya obstrucciones en el bastidor del remolque cuando se perforen los orificios, como son

los cables del remolque, o el interruptor eléctrico de liberación.

NO perfore a través de la pared opuesta del tubo del bastidor.

1. Con las abrazaderas en C en su lugar, perfore (2) orificios en el bastidor para cada soporte.

© 2010 Cequent Performance Products, Inc.

Hoja 26 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 27

Instrucciones de instalación

Sistema Doble Leva HP

Control de oscilación de Alto Desempeño

2. Perfore (2) orificios de 7/16” en cada lado del bastidor donde se hicieron las marcas de perforación. Podría ser de utilidad usar un

taladro central o pequeño orificio piloto antes de la perforación final.

3. Instale (2) tornillos de rosca formante de ½-13 que se suministran (pieza 3, figura 1). Repita para el lado opuesto y apriete a torsión (4)

tornillos de rosca formante de ½-13 a 50 pies-lbs.

4. Instale la tuerca hexagonal de ½-13 (tuerca de bloqueo) en los pernos de cabeza cuadrada de ½-13 X 3 ½” e instale en los soportes del

bastidor como se muestra en la figura 11.

PLACA DEL

BASTIDOR

TUERCA DE

BLOQUEO

TORNILLOS

FORMANTES DE

ROSCA, CABEZA

MARIPOSA

ANTERIORMENTE

INSTALADOS

5. Apriete el tornillo de fijación hasta que haga contacto con el bastidor del remolque. Luego proceda a apretar ¼ a ½ giro (NO

APRIETE EN EXCESO EL TORNILLO DE FIJACIÓN). Apriete la tuerca de bloqueo evitando que el tornillo de fijación se salga

mientras está en uso. Repita para el otro lado del bastidor del remolque.

6. Retire las abrazaderas en C del bastidor.

INSTALACIÓN DE PLACA DEL BASTIDOR DEL SISTEMA DOBLE LEVA HP EN CANAL EN C

NOTA: Algunos bastidores con canal en C pueden tener esquinas exteriores cuadradas que no permiten que la placa

del bastidor haga contacto con la base del bastidor. Para este tipo de bastidores, se requiere una arandela plana de ½”

(no se suministra) entre el exterior del bastidor del remolque y la placa del bastidor. La base de la placa del bastidor

DEBE hacer contacto con la base del bastidor del remolque.

1. Con las abrazaderas en C todavía en su lugar, perfore (2) orificios en el bastidor para cada soporte.

2. Perfore (2) orificios de 17/32” en cada lado del bastidor donde se hicieron las marcas de perforación. Podría ser de utilidad usar un

taladro central o pequeño orificio piloto antes de la perforación final.

3. Instale los (2) pernos de ½-13 x 1 ½” suministrados, arandelas de bloqueo y tuercas de 1/2" (piezas 5, 6 y 7), figura 13. Repita para el

lado opuesto y apriete a torsión (4) pernos de ½-13 a 85 pies-lbs.

4. Instale tuercas hexagonales de ½-13 en los pernos de cabeza cuadrada de ½-13 X 3 ½” e instale en los soportes del bastidor como se

muestra en la figura 13.

5. Apriete el tornillo de fijación hasta que haga contacto con el bastidor del remolque. Luego proceda a apretar ¼ a ½ giro (NO APRIETE

EN EXCESO EL TORNILLO DE FIJACIÓN). Apriete la tuerca de bloqueo evitando que el tornillo de fijación se salga mientras está

en uso. Repita para el otro lado del bastidor del remolque.

6. Retire las abrazaderas en C del bastidor.

TUERCA

PLACA DEL

BASTIDOR

TORNILLO DE

FIJACIÓN

ARANDELA

DE BLOQUEO

Figura 11

TUERCA DE

BLOQUEO

TORNILLO DE

FIJACIÓN

PERNO CABEZA

HEXAGONAL

Figura 12

© 2010 Cequent Performance Products, Inc.

PLACA DEL

BASTIDOR

Hoja 27 de 30 26102IN 05/14/12 Rev. G

Figura 13

Form: F205 Rev A 5-6-05

Page 28

Instrucciones de instalación

Sistema Doble Leva HP

Control de oscilación de Alto Desempeño

AJUSTE DEL BRAZO DE LEVA

1. Verifique que el vehículo y el remolque se ajusten correctamente según las instrucciones para su enganche de distribución de peso,

empuje hacia el frente lo suficiente para verificar que el vehículo y el remolque estén en línea recta. (Seleccionando un punto a una

distancia del vehículo (unas 100 yardas) conduzca hacia el frente hacia ese punto manteniendo la dirección recta hasta que el vehículo y

el remolque estén en perfecta línea recta.)

2. Vaya a cada brazo de leva y revise que el sistema de leva esté perfectamente centrado en el retenedor de la barra de resorte. Haga

ajustes a la longitud del brazo de leva según sea necesario, es importante tener el brazo de leva/retenedor de barra de resorte

exactamente como se muestra en la figura 14.

3. Antes de poder hacer los ajustes a la longitud del brazo de leva, levante el gato de la horquilla del remolque y baje los soportes a

presión. Afloje la tuerca de bloqueo (figura 5) y mueva la tuerca de ajuste (figura 5) hasta que el sistema de leva esté centrado en el

retenedor de la barra de resorte (figura 14). Después de hacer los ajustes, levante ambos soportes a presión e instale ganchos

retenedores; baje el gato de la horquilla del remolque. Repita el paso 2 de esta sección

3. Ajuste la posición de los soportes a presión según sea necesario, la cadena debe estar completamente vertical mientras esté en uso para

evitar daños al soporte a presión mismo.

* Ocasionalmente, con las condiciones cambiantes de remolque/cargas, podría ser necesario usar un eslabón diferente de la cadena para

nivelar correctamente al vehículo de remolque (Consulte sus instrucciones de instalación del kit de Distribución de Peso). Cada vez que se

use un eslabón diferente, se debe reajustar el brazo de leva.

ANTES DE CADA VIAJE:

1. REVISE SU EQUIPO: Revise que todo su equipo de remolque esté en condiciones óptimas.

2. Revise que la torsión de todos los tornillos sea de acuerdo a este manual.

3. Vuelva a revisar el retenedor de la barra de resorte y alineación del sistema de leva y periódicamente mientras remolca

para obtener el mejor desempeño.

4. Revise cualquier desgaste excesivo de los componentes de este sistema.

Mantenimiento:

1. NO use grasa en el sistema de leva o brazos de leva.

2. Si el ruido del sistema es molesto, una ligera cubierta de lubricante podría usarse en la porción del sistema de

leva donde la barra de resorte se apoya sobre el sistema de leva.

Las horquillas de peso superior a 1,200 lbs. podrían requerir el uso de lubricante para evitar el desgaste excesivo.

3. Mantenga todas las partes pintadas para evitar el óxido y mantener un buen aspecto. (No pinte sobre las etiquetas)

© 2010 Cequent Performance Products, Inc.

Figura 14

Hoja 28 de 30 26102IN 05/14/12 Rev. G

Form: F205 Rev A 5-6-05

Page 29

Instrucciones de instalación

TORNILLO DE AUTO

1.00”

HOJA DE INSTRUCCIONES

HERRAMIENTAS NECESARIAS:

Brocas: 7/16”, 9/16” y ¼”

Lea todas las instrucciones antes de instalar el perno adicional.

¡No seguir estas instrucciones podría resultar en la muerte o lesión de gravedad!

2-1/4”

Soporte de agarre

ADVERTENCIA:

•Instalación de un perno adicional en el soporte de agarre.

•Marque la localización del orificio a perforar dentro del soporte de

agarre. Centre el orificio de izquierda a derecha y colóquelo 2-1/4”

por encima del arco en el soporte. Vea la foto de la izquierda.

•Antes de colocar el soporte en el bastidor, perfore un orificio de

9/16” en el soporte.

•Coloque el soporte en el lugar correcto en el bastidor de la manera

indicada en las instrucciones del producto o vuelva a colocarlo donde

estaba si ya se había instalado.

•Usando el orificio del soporte como guía, perfore un orificio piloto

de ¼”. Cerciórese de que quede centrado en el orificio del soporte.

• Un método para permanecer centrado es usar el taladro 9/16”

primero. Simplemente haga un pequeño orificio en el bastidor con la

broca 9/16”. Luego termine de taladrar con una broca de ¼” y luego

con una broca de 7/16” para obtener el orificio final. Vea el orificio

piloto a la izquierda.

Para apoyo con la instalación u operación, póngase en contacto con el Servicio Técnico de CPP: 1-888-521-0510.

© 2010 Cequent Performance Products, Inc.

•Instale el tornillo de auto-enroscado de ½” dentro del orificio en

el soporte y bastidor. Apriete a 50 pies/lbs.

•Vuelva a apretar el tornillo de fijación de ½” en el interior del

bastidor. Gire únicamente un ¼ a ½ de giro después de hacer

contacto con el bastidor.

LISTA DE PARTES

CANT. DESCRIPCIÓN

2

1

Cequent Performance Products, Inc.

47912 Halyard Dr. Suite 100

Plymouth, MI 48170

Hoja 29 de 30 26102IN 05/14/12 Rev. G

-ENROSCADO 1/2" x

Page 30

NOTAS:

Instrucciones de instalación

Sistema Doble Leva HP