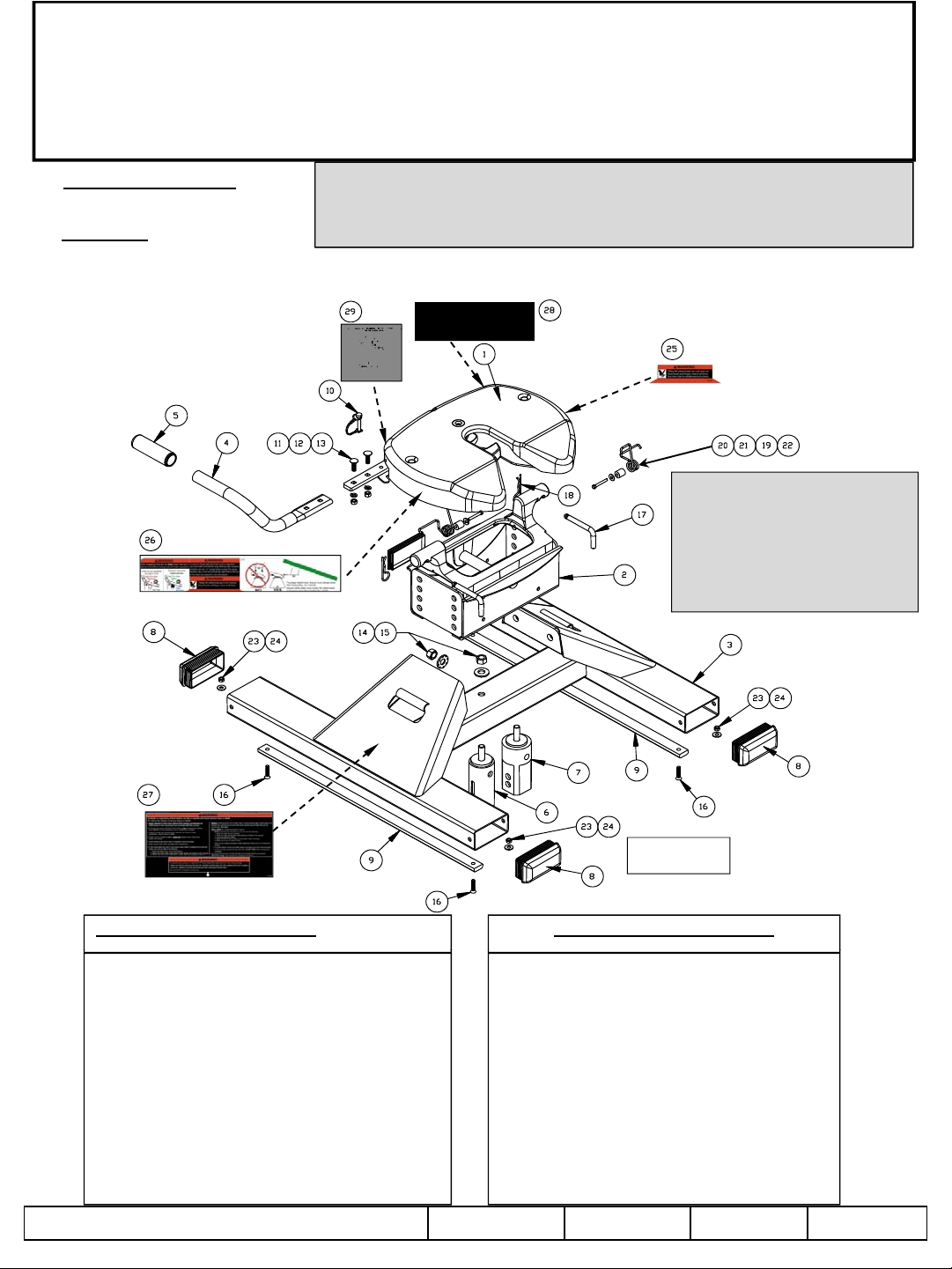

Page 1

ASSEMBLY INSTRUCTIONS

BRAND &

251LABEL, PINCH POINT

101BAIL PIN

Hi-Rise

18K 5TH WHEEL CONVERSION HITCH

DEALER/INSTALLER:

(1) Provide this Manual to end user.

This hitch is designed to work with Cequent (94XX) series gooseneck heads

utilizing the (44XX) series rails only using the round post assembly.

By using the square post assembly this hitch will also work with the

END USER:

(1) Read and follow this Manual every time you use Hitch.

(2) Save this Manual for future reference.

(3) Pass on copies of Manual to any other users or owners of the Hitch.

WEIGHT RATING

B & W gooseneck hitch.

Plastic strips supplied with

this hitch are 1/2” thick.

3/8” thick plastic strips, part

number 58438, are available

for trucks with bed

corrugations that are

shallower.

REF # QTY. DESCRIPTION REF # QTY DESCRIPTION

1 1 SKID PLATE ASSEMBLY

2 1 CENTER SECTION

3 1 BASE ASSEMBLY

4 1 HANDLE TUBE

51HANDLE GRIP

6 1 ROUND POST ASSEMBLY

7 1 SQUARE POST ASSEMBLY

84END CAP

92PLASTIC STRIP

11 2 3/8 NUT

12 2 3/8 LOCKWASHER

13 2 3/8 CARRIAGE BOLT

14 2 5/8 CONICAL TOOTHED WASHER

15 2 5/8 NYLON LOCK NUT

z 2010, 2011 Cequent Performance Products

Printed In China

Figure 1

16 4 5/16 SCREW

17 2 ½ PULL PIN 90 DEGREE

18 2 RETAINING CLIP

19 2 FLATWASHER

20 2 TORSION SPRING

21 2 TUBE SPACER

22 2 ¼-20 HEX BOLT

23 4 5/16-18 NYLON LOCK NUT

24 4 5/16 FLATWASHER

26 1 LABEL, OPERATING WARNING

27 1 LABEL, WARNING

28 1 LABEL, RATING

29 1 HANG TAG

30 1 5/8” KNURL BOLT

Sheet 1 of 12 9480N 6-22-11 Rev. C

Page 2

WARNING:

1. GUIDELINES

FOR MATCHING TOW VEHICLE AND

TRAILER

P

. 2

4

trailer). (See Fig. 2)

Vehicle T

4. Approximately 15%

25% of trailer weight should be on hitch (Pin Weight). See Fig. 3.

15-25%

Failure to follow all of these instructions may result in death or serious injury!

INDEX

2. PLASTIC BED LINER INSTRUCTIONS P. 5

3. ASSEMBLY INSTRUCTIONS P. 6-11

4. CEQUENT PERFORMANCE PRODUCTS TWO YEAR LIMITED WARRANTY P. 12

Section 1 - GUIDELINES FOR MATCHING HITCH, TRUCK, AND TRAILER

WARNING:

Failure to check and follow tow ratings could result in tow vehicle

damage or truck and trailer separation while towing.

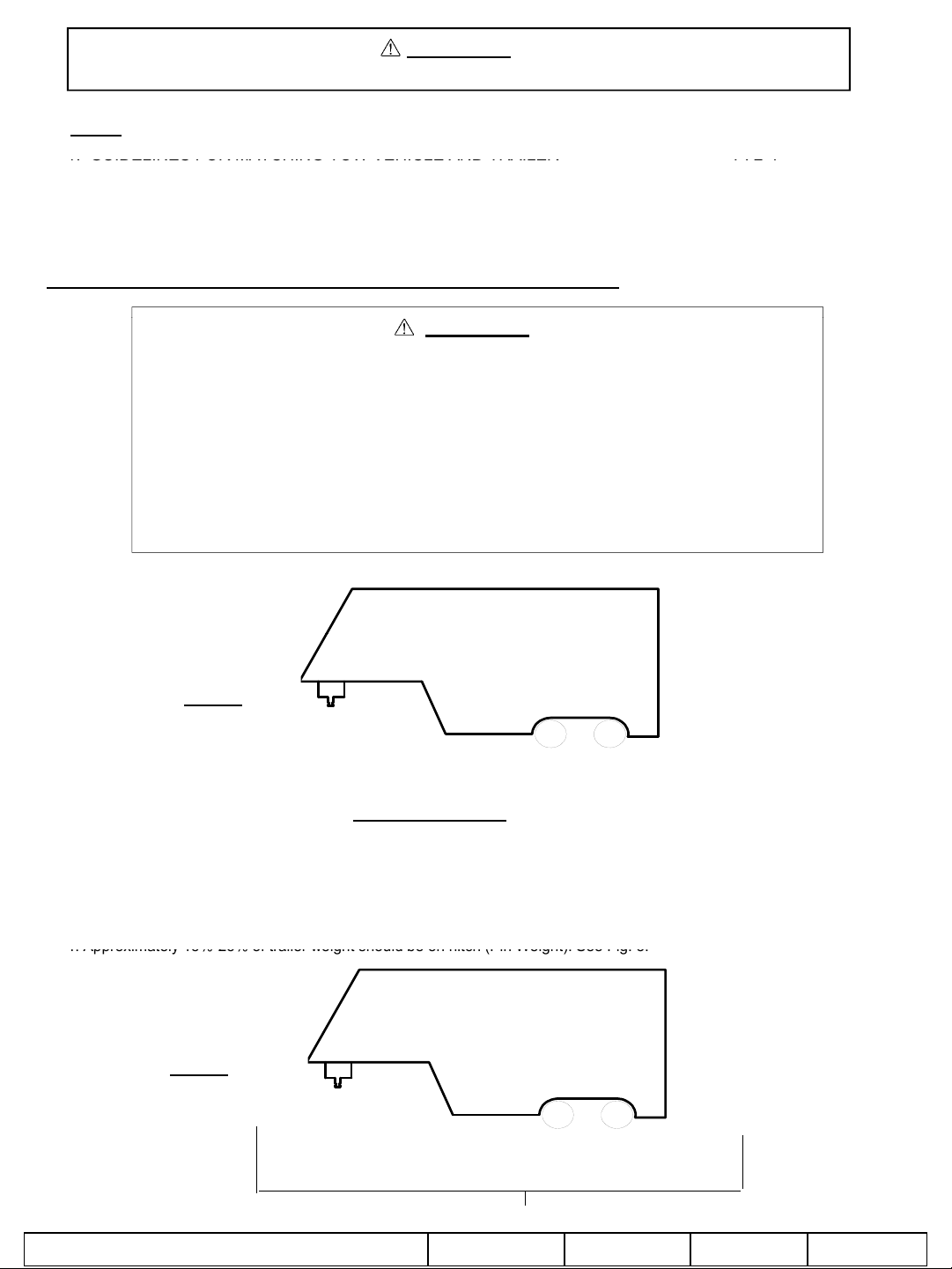

•Trailer and its contents together must not exceed truck, hitch and/or trailer tow

ratings.

•Towing vehicle must have a manufacturer’s rated towing capacity equal to or

greater than the gross trailer weight (dry weight of the trailer plus payload of the

•Gross weight of trailer must not exceed 18,000 pounds.

•King pin weight must not exceed 4,500 pounds (See Fig. 3). If in doubt have king

pin weight measured by qualified facility.

-

FACTORY TRAILER + FULL WATER

TANKS + CARGO, ETC.

= GROSS TRAILER WEIGHT

Figure 2

1. Check Tow Ratings:

ow Rating:_______________________.

Hi-Rise Hitch Rating:_______18,000 lbs.__

Gross Trailer Weight (figure 2):______________.

*Trailer weight should be the lowest of these recorded ratings for safe towing conditions.

2. Cequent Performance Products hitches are designed for use with recreational fifth wheel trailers only. Hitch applications

other than recreational fifth wheel trailers must be approved in writing by Cequent Performance Products’

Engineering Department.

3. Use only a SAE 2-inch kingpin with your Hi-Rise Fifth Wheel Conversion Hitch.

-

Figure 3

GROSS TRAILER

WEIGHT

(PIN WEIGHT)

.

75-85%

GROSS TRAILER

WEIGHT

z 2010, 2011 Cequent Performance Products

Sheet 2 of 12 9480N 6-22-11 Rev. C

Page 3

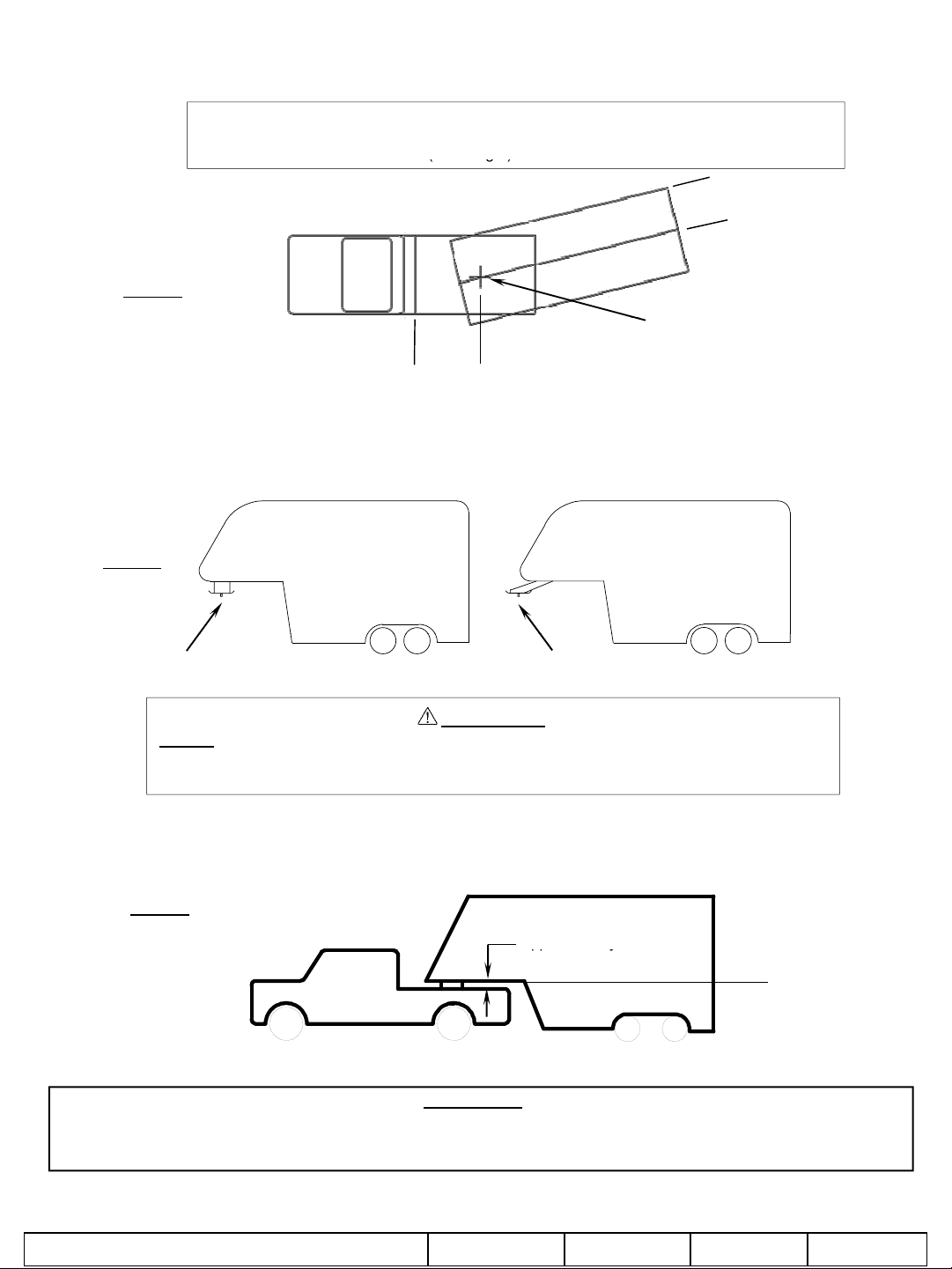

5. Trucks come in many different configurations. Cequent Performance Products hitches are designed for use in light trucks

(

)

(g)

pp y

such as the Ford F-Series, the Chevy Silverado , Dodge Ram and the Toyota Tundra. Cequent Performance Products

recommends the use of long bed (8ft) trucks for the best combination in truck - trailer turning clearance.

Rule of thumb: The distance from the back of the truck cab to the center of the rear truck

axle (“X” in Fig. 4), should be approximately 4 inches greater than one-half

the trailer width

“Y” in Fig.4

Y

RV TRAILER

Figure 4

TRUCK

KING PIN

X

6. If a short bed pickup (less than 8 ft. but longer than 6 ft.) is to be used for towing, Cequent Performance Products

recommends the trailer be equipped with a minimum 13” extended pin box to help gain additional truck - trailer turning

clearance (See trailer manufacturer for options) (See Fig. 5).

Figure 5

Conventional Pin Box

Extended Pin Box

WARNING:

Do Not install this fifth wheel hitch on or attempt to tow with a short bed pickup

truck that has a bed shorter than 6 ft.! Doing so could result in vehicle damage,

Serious injury, or Death

7. The height of the hitch and the pin box should be adjusted so the trailer is approximately level as it is towed. Allow

approximately 6 inches clearance between the top of the pickup walls and the underside of the front of the trailer for pitch and

roll of the trailer. (See Fig. 6). For off road use allow more clearance between pickup walls and trailer.

Figure 6

Approximately 6 Inches

Level Trailer

CAUTION:

The measurements above are guidelines. If your measurements are close to these numbers re-check

clearances. If vehicle and/or trailer has any added bed vicinity accessories (i.e. fairings, air dams, ground effects,

bed rails, etc.). Additional dimensioning and clearance checks have to be made.

z 2010, 2011 Cequent Performance Products

Sheet 3 of 12 9480N 6-22-11 Rev. C

Page 4

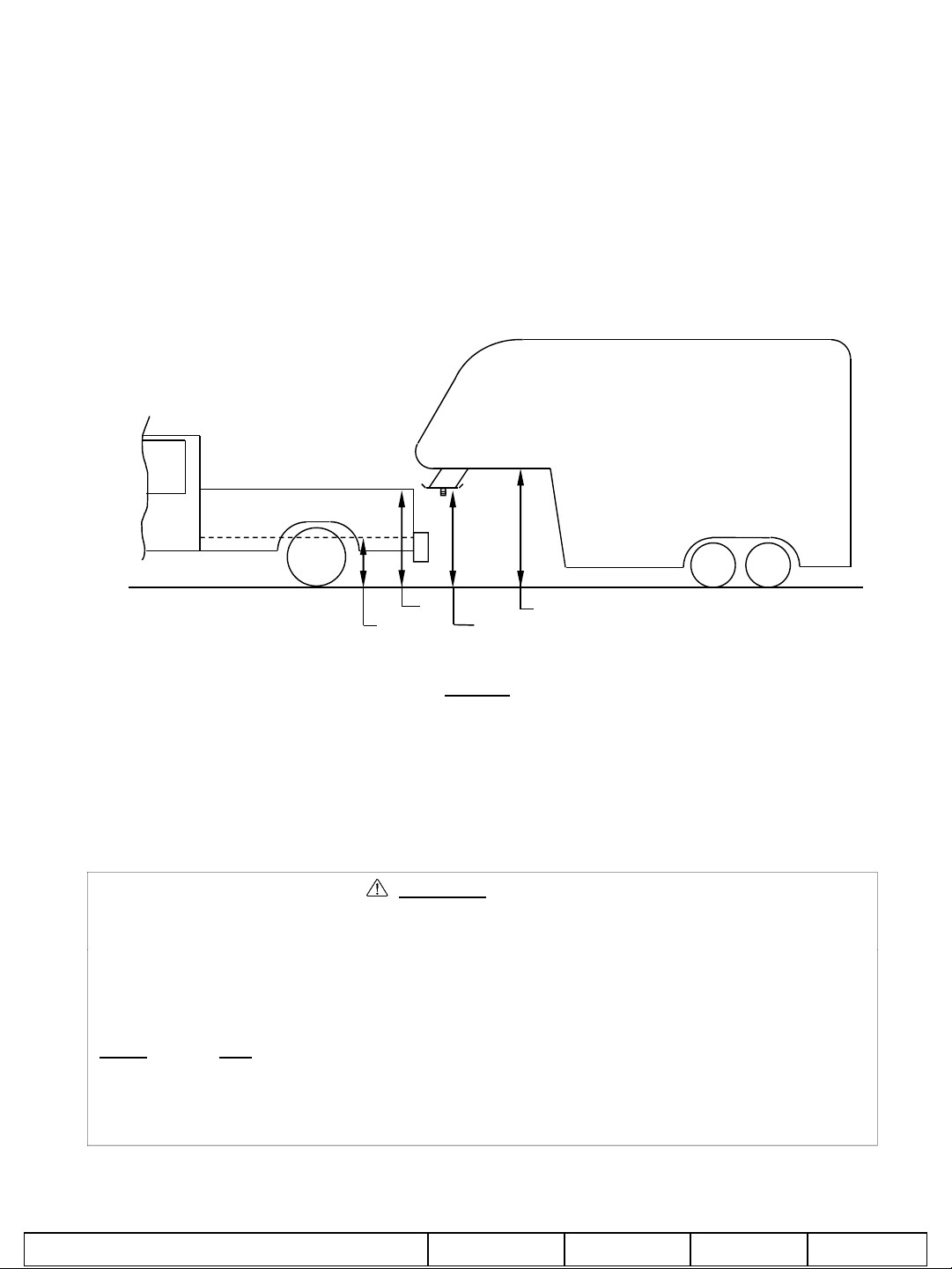

8. Hitch height determination:

A

•

Block in front of and behind all trailer tires

With trailer leveled and on level ground measure from the ground to the king pin box, “A” in Figure 7. Secondly measure

from the height of the inside of the truck bed, “B” in Figure 7. Dimensions “C” and “D” in Figure 7 can be used to determine

the amount of clearance over the side rails, as mentioned in Note 7.

The 2” value is an estimate of suspension compression due to king pin weight of the trailer. This compression could range

between 1”-5” depending on the truck being used and the trailer being towed.

Hitch Height = A – B + 2”

D – C + 2” > 6” as stated in Note 7.

C

B

D

*MEASURED WITH TRAILER LEVEL,

ON LEVEL GROUND

Figure 7

9. If a lube plate is to be used with a Hi-Rise 5thWheel Conversion Hitch, it must be at least 12” in diameter and not more

than 3/16” thick. Cequent Performance Products offers this optional lube plate as part # 83001 / 40001.

WARNING:

•Connection for trailer wiring must be located at the side of the truck bed between the driver’s

seat and the rear wheel to prevent operators from working between the truck and trailer.

•Avoid putting any part of your body under the trailer or between the truck and trailer.

Unexpected or accidental movement of the truck or the trailer can cause serious injury or death

•If you must place any part of your body under the trailer or between the truck and trailer you

MUST

perform ALL of the following steps:

•Check that the truck transmission is in park

•Check that the emergency brake is set

•Check that the trailer landing gear are resting on firm ground

z 2010, 2011 Cequent Performance Products

Printed In China

Sheet 4 of 12 9480N 6-22-11 Rev. C

Page 5

If your truck is equipped with a plastic bed liner, then cutting or removal of the plastic bed liner WILL be necessary for

remove liner and leave out.

the proper installation and operation of the 18K Hi-Rise Fifth Wheel Conversion Hitch. Refer to the “Plastic Bed

Liner Instructions” portion below for instructions on one option for cutting your plastic bed liner if required. If your truck

is not

equipped with a plastic bed liner or if it has a spray in bed liner, than you should use the instructions provided in

the mounting kit for your specific truck and skip to page 6 for the rest of the 18K Hi-Rise Fifth Wheel Conversion

Hitch instructions.

Plastic Bed Liner Instructions:

1. Note!

be removed totally as an option.

2. Follow the mounting kit instructions for your specific vehicle.

3. Measure and mark the distances provided in Figure 8 for the areas to be cut out of your plastic

bed liner. This is just one option, check with vehicle owner to discuss other ways to cut liner or

4. Remove the plastic bed liner from your truck and cut out the marked areas with a saw or cutting

device of your choice.

5. Reinstall the plastic bed liner.

6. Continue the rest of the 18K Hi-Rise Fifth Wheel Conversion Hitch instructions.

Before cutting check with vehicle owner to confirm that they want liner to be cut. Liner can

Front of Truck

Cutting

Cutting

Area

Area

Figure 8

One option for cutting of

plastic bed liner.

Check with vehicle

owner before cutting.

z 2010, 2011 Cequent Performance Products

Area in bed liner to be cut out is relative

to 3-1/2” round hole drilled in bed.

Tailgate

Sheet 5 of 12 9480N 6-22-11 Rev. C

Page 6

Hi-Rise FIFTH WHEEL ASSEMBLY

14

1/4

ASSEMBLY AND ADJUSTMENT

IS REQUIRED BEFORE INITIAL USE.

SOME USERS MAY REQUIRE MORE EXTENSIVE ADJUSTMENTS. THE TOOLS NEEDED FOR THESE

ADJUSTMENTS ARE LISTED BELOW.

POSSIBLE TOOLS NEEDED IF FURTHER ADJUSTMENT ARE REQUIRED

7/16”, 9/16” and 15/16" Socket, Open End Wrenches, Phillips Screw Driver,

200 lb-ft Torque Wrench

1. Check the box for all components listed in Figure 1 and become familiar with component terminology.

2. Determine from the Guide Lines portion of this instruction sheet (Pages 2 – 4 ) the height of the hitch that is required and

position at the correct setting. See Chart 1 on page 7 as a guide to determine which direction to attach the center section

to the base assembly. Attach the center section to the base assembly using the 5/8” Bolts and Lock washers (see Figure

9). Torque the 5/8 fasteners to 170 ft-lb. (230 N*M).

5/8” LOCK WASHER

-

15-1/2”

16-3/4”

18”

5/8” BOLT

”

CENTER SECTION

z 2010, 2011 Cequent Performance Products

FIGURE 9

Sheet 6 of 12 9480N 6-22-11 Rev. C

Page 7

Year Vehicle Fit Center-Section Offset

3A and 3B

Chart 1

See Steps

8810

GM 1500/2500/3500

including CKSeries (6’

& 8’ Beds)

Rearward

below for

spring

0410

Ford F-150 6’ & 8’

Beds

Forward

adjustment

9910

9410

Ford F-250/F-350/F450 6’ & 8’ Beds

Dodge

1500/2500/3500 6’ &

Rearward

Rearward

8’ Beds

0710

3A. To assemble the spring , use the ¼” bolts, washers, spacers and springs from the fastener kit. See Figure 10A.

Spring

Spacer

¼” Washer

¼” Bolt

Toyota Tundra 6’ & 8’

Beds

Center Section

Forward

Figure 10A

3B. The coil of the spring ( See Figure 10B) is facing the rear of the truck and wide hook sits over the center section casting as

shown in Figure 10C Assemble and tighten ¼” bolts into the thread holes in the casting.

Figure 10B

Wide Hook

Coil of Spring

Figure 10C

Center Section Casting

Rear of truck

z 2010, 2011 Cequent Performance Products

Sheet 7 of 12 9480N 6-22-11 Rev. C

Page 8

4. Assemble the plastic strips to the bottom of the legs on the base assembly, using the 5/16 X 1.50 screws, flat washers, and

FIGURE

11A

Plastic Stri

To yo ta Tundra

nylon lock nuts. The plastic strips are used to prevent rotation of the hitch and should be aligned so that they sit between

the corrugations of the bed as shown in Figure 11B.

NOTE: For the Toyota Tundra the plastic strips should be aligned so that the outer edge of the plastic strip is aligned with

the outer corrugation (see figure 11C).

Longer legs

Should be

positioned

towards the

vehicle cab

Nylok Nut

Flatwasher

p

5/16 X 1.50

Phillips Head

Machine Screw

Plastic strips supplied with

this hitch are 1/2” thick.

3/8” thick plastic strips, part

number 58438, are available

for trucks with bed

corrugations that are

shallower.

Truck Bed

Corrugations

z 2010, 2011 Cequent Performance Products

Plastic Strip

Shown In

Position

FIGURE 11B

Truck Bed

Corrugations

Sheet 8 of 12 9480N 6-22-11 Rev. C

Plastic Strip

Shown In

Position

FIGURE 11C – Toyota Tundra

Page 9

5. Insert the post assembly into the gooseneck hitch as shown in Figure 12. Fishwire the 5/8 knurl bolt through the inside of

b

the post assembly and through the horizontal hole in the post and the slot in the base assembly. Loosely tighten the 5/8”

conical toothed washers and nylon lock nuts.

6. Insert plastic end caps into the legs of the Base Assembly.

Insert End

Caps

Insert post assembly.

Fishwire 5/8 knurl bolt

through hole after

FIGURE 12

7. Slide the Post Assembly into the gooseneck hitch as shown below in figure 13. The plastic strips should fall into the

corrugations on the truck bed if adjusted correctly.

inserting the post

assembly into the

ase assembly.

FIGURE 13

8. Align the post assembly into position and close the Handle/Locking Pin mechanism on the gooseneck hitch.

Note: Before towing the 5/8 hex nuts connecting the Post Assembly to the Base Assembly should be torqued to a

minimum of 120 ft-lbs. The handle/locking Pin of the gooseneck hitch should not be able to be released when

tightened.

z 2010, 2011 Cequent Performance Products

Sheet 9 of 12 9480N 6-22-11 Rev. C

Page 10

9. Lube center section as shown in Figure 14 with lithium grease.

Figure 14

Lube 6 locations

11. Lube pins (2) shown in Figure 15 with lithium grease prior to installation/operation.

Figure 15

Lube 2 locations

z 2010, 2011 Cequent Performance Products

Sheet 10 of 12 9480N 6-22-11 Rev. C

Page 11

11. Place the skid plate assembly onto the center section assembly. Keep hands clear of pinch points while placing/removing

detachment

and

or

The

retaining

clip

can

easily

Pull Pin

15.Slide the handle grip over the handle tube

head onto/off hitch base as noted on head labels. Head will tilt rearward.

12. Insert the pull pins and retaining clips shown below. Note that the pull pins used with the Hi-Rise hitch are 90 degree bent

pins and if replacements are needed, please contact the factory.

13. Lube jaw and skid plate(If no lube plate is being used) with automotive type chassis grease. The jaw pin comes greased

from the factory. To insure smooth jaw operation, grease should be added every 6 months to grease fitting on top of head.

WARNING:

Tilting 5thWheel head can

crush and cut. Keep hands and

fingers clear from this area at

all times (including

placement/removal of head).

Grease Fitting

Sight Hole

Both Sides

Lube Skid Plate

Retaining Clip

Both Sides

(if not using a lube

plate)

Lube Jaw

WARNING:

To prevent tilting head

separation of hitch you must

make sure that the anchor

assemblies are properly

installed and pinned, and

the spring retaining clip is

properly installed onto the

½” pull pin before towing.

Figure 16

14. Attach the handle assembly to the skid plate assembly using the 3/8 carriage bolts, lock washer and hex nuts.

.

Both Sides

be seen through the sight

holes in the top of the head.

Figure 17

z 2010, 2011 Cequent Performance Products

Sheet 11 of 12 9480N 6-22-11 Rev. C

Page 12

TWO YEAR LIMITED WARRANTY

Cequent Performance Products

warrants the

Hi-Rise

5th Wheel Conversion Hitch

from date of

the address below. THIS WARRANTY IS LIMITED TO DEFECTIVE PARTS REPLACEMENT ONLY

improper installation, or any use violative of instructions furnished by us, WILL VOID THE WARRANTY

47912 Halyard

purchase against defects in material and workmanship under normal use and service, ordinary wear and

tear accepted, for 2 years of ownership to the original consumer purchaser when a Cequent

Performance Products mounting kit is used.

Cequent Performance Products will replace FREE OF CHARGE any part which proves defective in

material or workmanship when presented to any Cequent Performance Products dealer, Cequent

Performance Products warehouse or returned to factory. TRANSPORTATION CHARGES PREPAID, at

.

LABOR CHARGES AND/OR DAMAGE INCURRED IN INSTALLATION OR REPLACEMENT AS WELL

AS INCIDENTAL AND CONSEQUENTIAL DAMAGES CONNECTED THEREWITH ARE EXCLUDED.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Any damage to the 5th Wheel Conversion Hitch as a result of misuse, abuse, neglect, accident,

.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state. In the event of a problem with warranty service or performance, you may be able to go to a small

claims court, or a federal district court.

Cequent Performance Products

Plymouth, MI 48170

z 2010, 2011 Cequent Performance Products

Sheet 12 of 12 9480N 6-22-11 Rev. C

Loading...

Loading...