Page 1

Catalog No. 8339

A

INSTALLATION INSTRUCTIONS

READ THOROUGHLY BEFORE BEGINNING

5

2

/16“ FOLDING BALL GOOSENECK HITCH

COVERED BY U.S. PATENT NOS. 5,738,363 & 5,893,575

Note: GM composite (NON METAL) bed will require Installation Kit #58209

IMPORTANT!

This product is intended to be used with Towing Products manufactured Rail Kits. If the Gooseneck Hitch

installation is made with Towing Products manufactured Rail Kits, the installation instructions for the

Gooseneck Hitch are included as part of the Towing Products Rail Kit installation instructions. Give this

installation instruction to vehicle owner after installation is complete.

General instructions for fabricated support structures.

IF TOWING PRODUCTS MANUFACTURED RAIL KITS ARE NOT USED, THIS PRODUCT BECOMES A

GENERAL APPLICATION PRODUCT. IT IS THE RESPONSIBILITY OF THE INSTALLER TO SELECT

STRUCTURALLY SAFE MATERIALS AND LOCATIONS FOR ATTACHMENT. INSTALLATION INFORMATION

FOLLOWS.

- MAXIMUM RATINGS -

DO NOT EXCEED LOWER OF TOWING VEHICLE MANUFACTURER'S RATINGS OR THOSE LISTED

BELOW:

25,000 LB GROSS TRAILER WEIGHT 6,250 LB VERTICAL LOAD

TOOLS REQUIRED:

Hand drill

Drill bits - 1/4”, 5/8”, 3/4”

Sockets and Wrenches - 9/16” & 15/16”

Center Punch

Torque Wrench

Saber Saw

Files - round and flat

Hammer

NOTE: CHECK HITCH FREQUENTLY, MAKING SURE ALL FASTENERS ARE PROPERLY TIGHTENED. A HITCH OR BALL WHICH HAS

BEEN DAMAGED SHOULD BE REMOVED AND REPLACED. OBSERVE SAFETY PRECAUTIONS WHEN WORKING BENEATH A VEHICLE

ND WEAR EYE PROTECTION. FOLLOW VEHICLE MANUFACTURER’S SPECIFICATIONS FOR MAXIMUM TRAILER WEIGHT. DO NOT

CUT ACCESS OR ATTACHMENT HOLES WITH A TORCH.

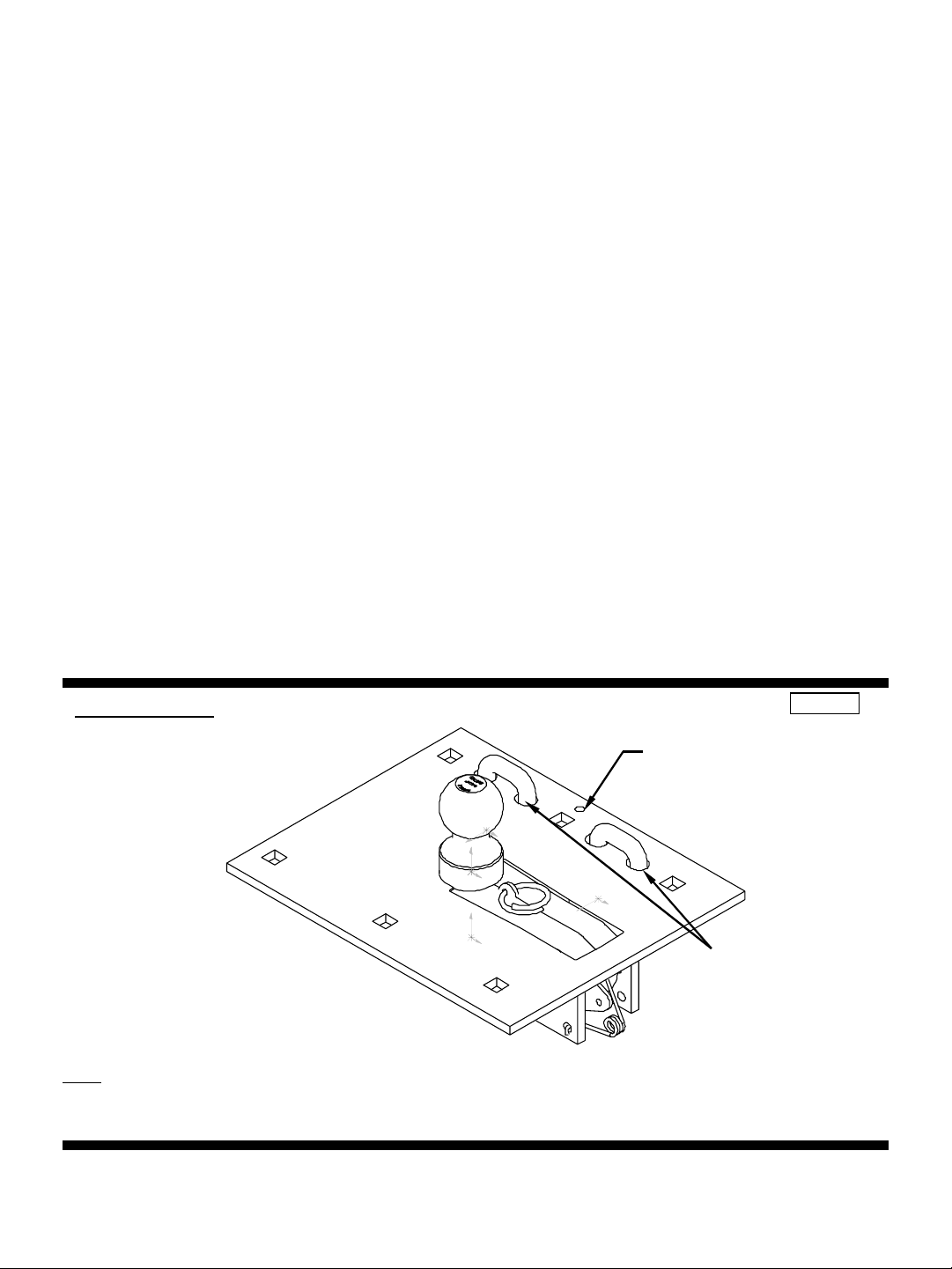

HOLE FOR BREAKAWAY

SWITCH CABLE ATTACHMENT.

(SCREW & WASHER PROVIDED)

SAFETY CHAIN ATTACHMENTS

U-BOLTS PROVIDED

Fig. 1

INSTRUCTION PART NO. N8339 1-15-07_C © 2002, 2007 CEQUENT TOWING PRODUCTS PRINTED IN U.S.A. PCN 9386

Page 2

PARTS LIST: PART BAG CONTENTS

DESCRIPTION

5/8-11 X 2.5 GRADE 5 CARRIAGE BOLTS 6

5/8-11 NUT 6

5/8 LOCKWASHER 6

5/8 U-BOLT ZINC PLATED 2

5” SPRING 4

BALL ASSEMBLY PART BAG

5/8-18 LOCKNUT 4

9/16 FLAT WASHER 8

3/8 FLAT WASHER 1

24-9 X 1” TAP SCREW 1

INSTRUCTION SHEET

Note: GM composite (NON METAL) bed will require Installation Kit #58209

INSTALLATION INSTRUCTIONS:

1. The following guidelines must be followed before installation begins:

- The hitch ball must be located along the truck’s fore/aft centerline.

- The hitch ball centerline must be located above and forward of the rear axle of the truck.

- Adequate clearance must be provided between the gooseneck trailer and the rear of the vehicle so that the gooseneck trailer does

not contact any part of the truck during turning.

- Adequate clearance must be provided between the forward corners of the gooseneck trailer and the cab of the truck.

- Determine that the ball position and under vehicle supports do not interfere with any vehicle crossmembers, brake lines, electrical

wiring, cables, fuel lines or vents.

2. With hitch ball center marked on the truck, lay template in the bed of the truck. Make sure that the template is oriented properly per

notes on the template. If truck is equipped with a bed liner a 14.5” x 12” section of the bed liner must be cut out so that the

gooseneck platform can contact the metal truck bed corrugations.

3. Center punch the holes that will be used to cut out the truck bed.

4. Drill 1/4” pilot holes (size will depend on the width of blade in saber saw).

5. Cut out truck bed. File the edges as needed.

6. Install platform into opening.

7. Use the installed platform as a guide to drill 5/8” diameter holes through the truck bed and/or under vehicle supports for the

carriage bolts and drill 3/4" diameter holes for U-bolts.

Before drilling, make sure the platform is oriented square to the truck centerline and does not interfere with

any vehicle crossmembers, brake lines, electrical wiring, cables, fuel lines or vents.

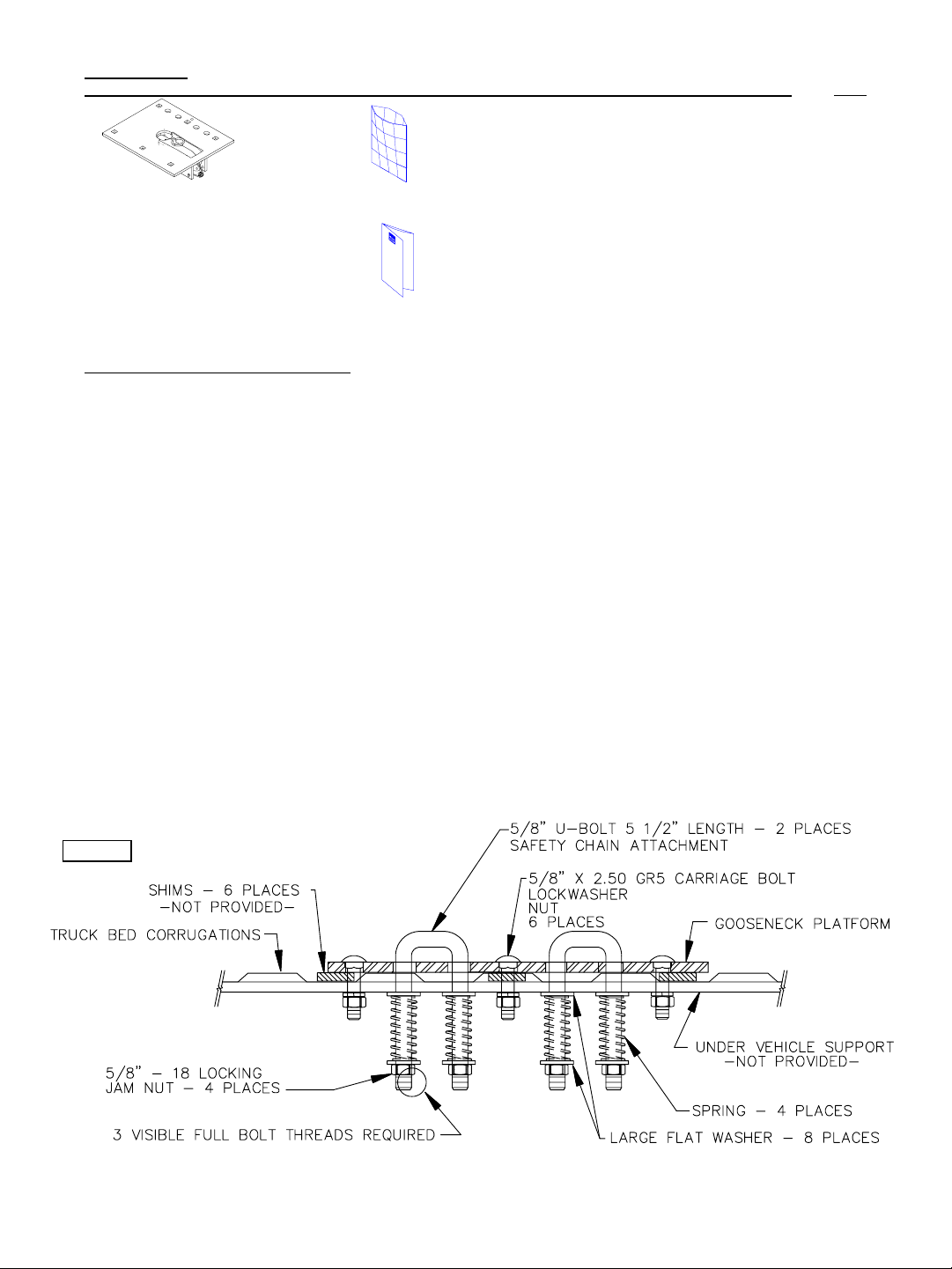

8. Before installing 5/8" carriage bolts through the platform, shims (not provided) must be placed between the platform and the bed

and between the under vehicle structure and the bottom of the bed. These shims are necessary to prevent the truck bed

corrugations from collapsing when the carriage bolts are tightened. See Fig. 2.

9. Install 5/8" x 2.50” Grade 5 carriage bolts through the platform, shims and under vehicle supports. Secure with lock washers and

nuts. Torque nuts to 150 LB-FT.

10. Install the (2) U-bolts through the platform. From under the truck install large flat washer over the U-bolt followed by a spring,

another large flat washer and secure with a thin 5/8” jam nut. Repeat for the other legs of the U-bolts. The 5/8” jam nuts are to be

tightened until 3 threads are visible past the bottom of the nut.

QTY.

Fig. 2

2

INSTRUCTION PART NO. N8339 1-15-07_C © 2002, 2007 CEQUENT TOWING PRODUCTS PRINTED IN U.S.A. PCN 9386

Page 3

OPTIONAL LAYOUT METHOD USING DIMENSIONS

CAUTION BEFORE DRILLING, CUTTING, OR SAWING CHECK BELOW BED TO ENSURE FUEL

LINES, BRAKE LINES, WIRES, ETC. WILL NOT BE DAMAGED.

Fig. 3

PLATE OUTLINE (DO NOT CUT)

1.812.08

.88

SAW LINE

5.685.68

1.81 2.08

BALL CENTER

SAW LINE

.67

.67

FRONT OF VEHICLE

6.13

4.63

3.12

2.12

2.12

3.12

4.38

12.00

1.75 2.15

5.26

14.50

7.38

7.88

CAUTION BEFORE DRILLING, CUTTING, OR SAWING CHECK BELOW BED TO ENSURE FUEL LINES,

BRAKE LINES, WIRES, ETC. WILL NOT BE DAMAGED.

3

INSTRUCTION PART NO. N8339 1-15-07_C © 2002, 2007 CEQUENT TOWING PRODUCTS PRINTED IN U.S.A. PCN 9386

Page 4

FOLDING BALL GOOSENECK OPERATION

The ball assembly offers several features with the user in mind.

-Easily accessible lift ring (Fig. B.)

-Two spring loaded safety chain mounts. (Fig. E.)

-Easily accessible grease zerk (Fig. A.)

-Ball detent lock backup to provide double coverage in preventing

ball cover from opening unintentionally.

-Spring loaded folding mechanisms to assist actuation and prevent

rattle.

-Chrome plated decorative ball.

TO RAISE BALL IN UPRIGHT POSITION

1. Grasp lift ring and raise cover until the spring holds the cover

open. Grasp ball and rock it to its vertical position. See figures A-D.

2. Lower lift ring and cover such that it locks ball in upright position.

See figure E.

3. Lift spring loaded safety chain U-bolts to attach safety chain.

To lower ball into horizontal position, repeat steps 1 then 2.

AFTER SYSTEM INSTALLATION AND BEFORE TOWING

GREASE ZERK

FIGURE A.

LIFT RING

FIGURE B.

Connect trailer to the tow vehicle following coupler manufacturer’s

operating instructions.

The coupler must be adjusted to provide about 6” of clearance

between the bottom of the trailer nose and the top of the pickup bed

sides.

Slowly back the trailer to a jackknifed position to the tow vehicle

while checking to see there is adequate clearance between the

gooseneck trailer and the rear of the vehicle. Also check to see there

is adequate clearance between the forward corners of the gooseneck

trailer and the cab of the truck. Slowly jackknife the truck and trailer

in the opposite direction and check the clearances to the end of the

truck and the cab.

FOLDING BALL GOSSENECK HITCH MAINTENANCE

-Keep ball envelope and pivoting mechanism free from dirt and debris.

-Lube ball cover pivot monthly with light weight oil or equivalent.

-Grease ball pivot at grease zerk monthly (See figure A)

-Lube ball detent regularly with light weight oil. Keep free from dirt

and debris.

-Retorque all hardware monthly.

FIGURE C.

FIGURE D.

SAFETY CHAIN

MOUNTS

FIGURE E.

4

INSTRUCTION PART NO. N8339 1-15-07_C © 2002, 2007 CEQUENT TOWING PRODUCTS PRINTED IN U.S.A. PCN 9386

Page 5

FOLDING BALL GOOSENECK HITCH SYSTEM

A

IMPORTANT INFORMATION ON TOWING

TOWING EQUIPMENT OWNERS:

towing. Save for reference. This will help you properly use and maintain your towing equipment. Refer to owner’s manuals for

your tow vehicle, trailer and other parts of your towing system. Learn the capabilities and limitations of each part. GROSS

TRAILER WEIGHT and VERTICAL LOAD are the two most important items to consider.

EXCEED THE LOWEST RATING OF ANY PART OF YOUR TOWING SYSTEM. GROSS TRAILER WEIGHT

the trailer plus cargo. Measure GROSS TRAILER WEIGHT by putting the fully loaded trailer on a vehicle scale.

is the downward force exerted on the ball by the trailer coupler. Use a vehicle scale to measure

LOAD

the fully loaded trailer on a level surface and the coupler at normal towing height.

TRAILER COUPLERS

The coupler should be smooth, clean and lightly lubricated. Adjust per coupler manufacturer’s instructions.

SAFETY CHAINS

Connect safety chains properly

loose. Leave only enough slack to permit full turning. Too much slack may prevent chains from maintaining control if other

connections separate.

TRAILER LIGHTS, TURN SIGNALS, ELECTRIC AND BREAKAWAY SWITCH CONNECTIONS

Make these safety-critical connections

brake manual control, before getting on the road.

OTHER USEFUL EQUIPMENT

IR SPRINGS, AIR SHOCKS, or HELPER SPRINGS are useful for some applications. A TRANSMISSION COOLER may be

necessary for heavy towing. Many states require TOWING MIRRORS on both sides.

TIRE INFLATION

Check often. Follow tow vehicle and trailer manufacturer’s recommendations.

CHECK YOUR EQUIPMENT/REPLACE WORN PARTS

Check ball, coupler, chains, and all other connections

Make sure all operators of your equipment read and understand this information before

EVERY TIME YOU TOW.

EVERY TIME YOU TOW,

EVERY TIME YOU TOW.

THESE WEIGHTS MUST NEVER

VERTICAL LOAD

Attach securely through the U-bolts provided so they can not bounce

no matter how short the trip. Check operation, including electric

Re-check at fuel and rest stops.

is the weight of

VERTICAL

with

NO PASSENGERS IN TRAILER!

Never allow people in the trailer while towing, under any circumstances.

TRAILER LOADING

Place heavy objects on the floor ahead of the axle. Balance the load side-to-side. Secure it to prevent shifting.

trailer rear heavy.

OF THE HITCH.

DRIVING

The additional weight of a trailer affects acceleration, braking and handling. Allow extra time for passing, stopping, and changing

lanes. A gooseneck trailer requires a large turning radius as the trailer tracks to the inside of turns. Severe bumps can damage

your towing vehicle, hitch and trailer. Drive slowly on rough roads.

PART OF YOUR TOWING SYSTEM STRIKES THE ROAD. CORRECT ANY PROBLEMS BEFORE RESUMING TRAVEL.

WARNING

DO NOT MODIFY.

instructions may result in serious personal injury or death, vehicle crash, and/or property damage.

LOAD THE TRAILER HEAVIER IN THE FRONT, BUT NOT GREATER THAN TONGUE WEIGHT RATING

STOP AND MAKE A THOROUGH INSPECTION IF ANY

Do not tow one trailer behind another, which may cause loss of control. Failure to heed warnings and follow

NEVER

load the

5

INSTRUCTION PART NO. N8339 1-15-07_C © 2002, 2007 CEQUENT TOWING PRODUCTS PRINTED IN U.S.A. PCN 9386

Loading...

Loading...