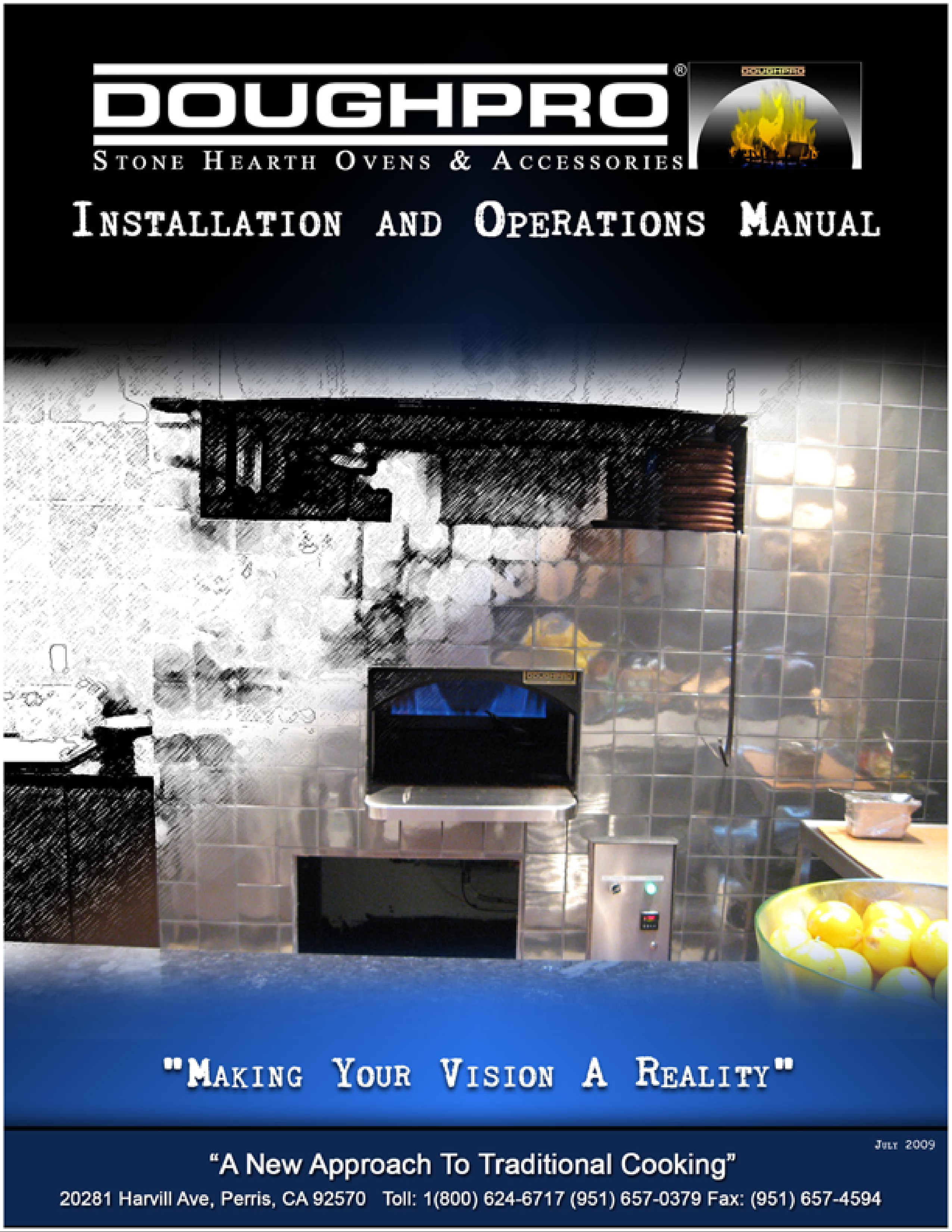

Doughpro Proluxe RECT5741 User Manual

7

(951) 657-0379

(951) 657-4594

(951) 657-0379

For 24 hour assistance please call (951) 236-7092

Note: Always follow hood manufacture cleaning and maintence procedures

2) “Never store combustible material beneath the oven, keep this are clear

at all times.”

3

4

“Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operation and maintenance

instruction thoroughly before installing or servicing this equipment.”

5) Duct: As with all commercial cooking equipment, Doughpro recommends

gas supply when pressure testing is equal or less than 1/2 PSI.”

Warning: Always disconnect power cord from electrical outlet before

servicing any electrical component in this oven.

never run the oven with doors in place.

six

This happens with wood burning ovens.

(951) 657-0379

(951) 657-0379

---------

··CAUTION··

DISCONNECT ALL

POWER SUPPLIES

BEFORE SERVICING

WARNING

This

appliance

pronA

shock

pluA

hazard

into a properlv

not

cut

or

from

this

plug.

is

for

voiur

and

Arounded

remove

equipped

protection

should

the

grounding

with a three

be

pluAAed

receptacle.

aAainst

prong

Do

WARNING

ImDroper Installation. adjustment. alteration.

or

service

Injury

oDeration and maintenance Instructions

before installing

LIGHTING

To

llcaht

lined

UD.

Aas.

Dress IAnitor button

once

lit.

Dllot. Once Dilot Is

position and

maintenance can Dropertv damage

or

death. read

the

or

servicing

installation.

this

INSTRUCTIONS

char

qrlll

tum

knob

till

red lines

Push

knob In and hold In

hold knob

for

lit.

the

char

to

lanlte flame.

30 sec

tum

the

grill

Is ready

to

knob

to

light

to

for

eqUipment.

release

the

the

on

DOUGHPRO

20281

Harvill

Ave,

Perns,

','Il,,\!,/\i

a(IU9~lpro

NY MEA# 114·08·E

MODEL

VOLTS

Tlmp.rlture

O.Type:

Burner capacity:

Disploy67~OOBTU

Food

Minimum

1

inch"

Far

install:ation

eacf1

side

Tnis

COOKing

tt"le

Standard for

Operations,

Comme(C'lal

transition

Refe,

l'eqUired

building codes. Inspect

lJ~e,

creosote

In5t:~11

trtt un:t

ContoOlct

in

your

OP07

120

60

HZ

Controller: Rid

Naturale.

High

Maln7S,oOO

Service

Equipment

Clearance

fl"om combustible

on

nun-combustible

of

oven

dOor

opening

equipment

'.,,-entallation

NFPA

96,

or

COOKing

Equipment;

to 3 Class

.A.

tIO"il) required

buildup

use

only

in

blli,Cllng

grease

and

rn:ly

accorda'"rCe

officals or tire

to

manat"C'tures installation instruction fur precaution'),

air

and

local

arE2i

1AMP

Lion

Mod.tT1624

Pr.sur-e4"WClowPressuFIMin.

BTU

""''""",,

rnaterI3\~,'

flljors

anCl

36"

is

to

be

PI"O\-~deCl

Control

and

with

the

requirements

UL

71

U . .A.lternJtively it

duct

constructed

for

Imtalla!iOn

clean

tr-II?_

o"/en

IJccur

rapiW:..'

·'i'iiU""1

installation 3nd

offic.I3l:::

CA

92570

com

SIN

Single

VAC

ULffE18C.76

M

FG:

tup

only.

E;~tend

in

fn1nt

of

door

'·"'.'IU'"I

an

exuast

Fire Protection

in

me

to

1994

of

tile

e;~'aust

ind

flue

,-",llout

restricti,:j:1S,

~

Phase

QI1l

1:.

mcne=:;

sk1es

non-combustible

opening

I,'ood

testel1

Df

Corn

mer

Standard

for

may,'

be (onnecte[1

Uniform

~,:ecr(lniC3.1

c!ear

Mod

Ensure

frequently-under

Clp~r3ting

Instructions

instsli:Jlior'i

Intertek

4001284

@

Intertek

4001284

:aM tJaiJ(

fll10ring

for

compliarce

':1.)1

COOking

Exua:;t

Hoojs

',,'Id a UL

COde

anee:;

and

compliance

cert.aln

l;ondition~

pru'-1cled

and

of

t)"IC

to

30"

ror

listed

(fIlniiTIUlri

in:peUlon

ulJen

'''''''IU"I

local

witI"J

wr

Phone (951) 657-0379

Fax (951) 657-4594

Table of Contents

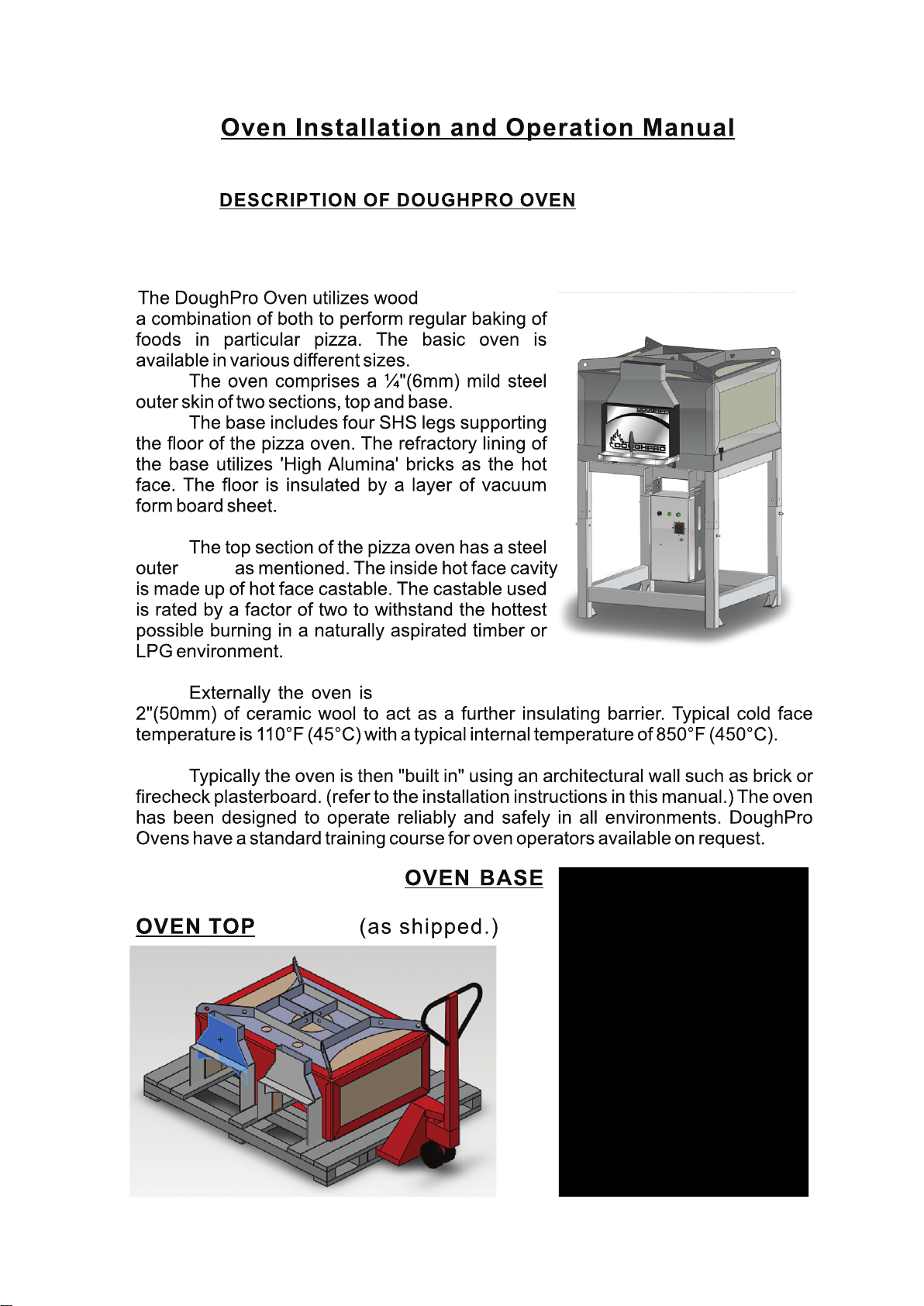

Oven Installation and Operation Manual

Section One:

Toll Free (800) 624-6717

Description of Doughpro Oven

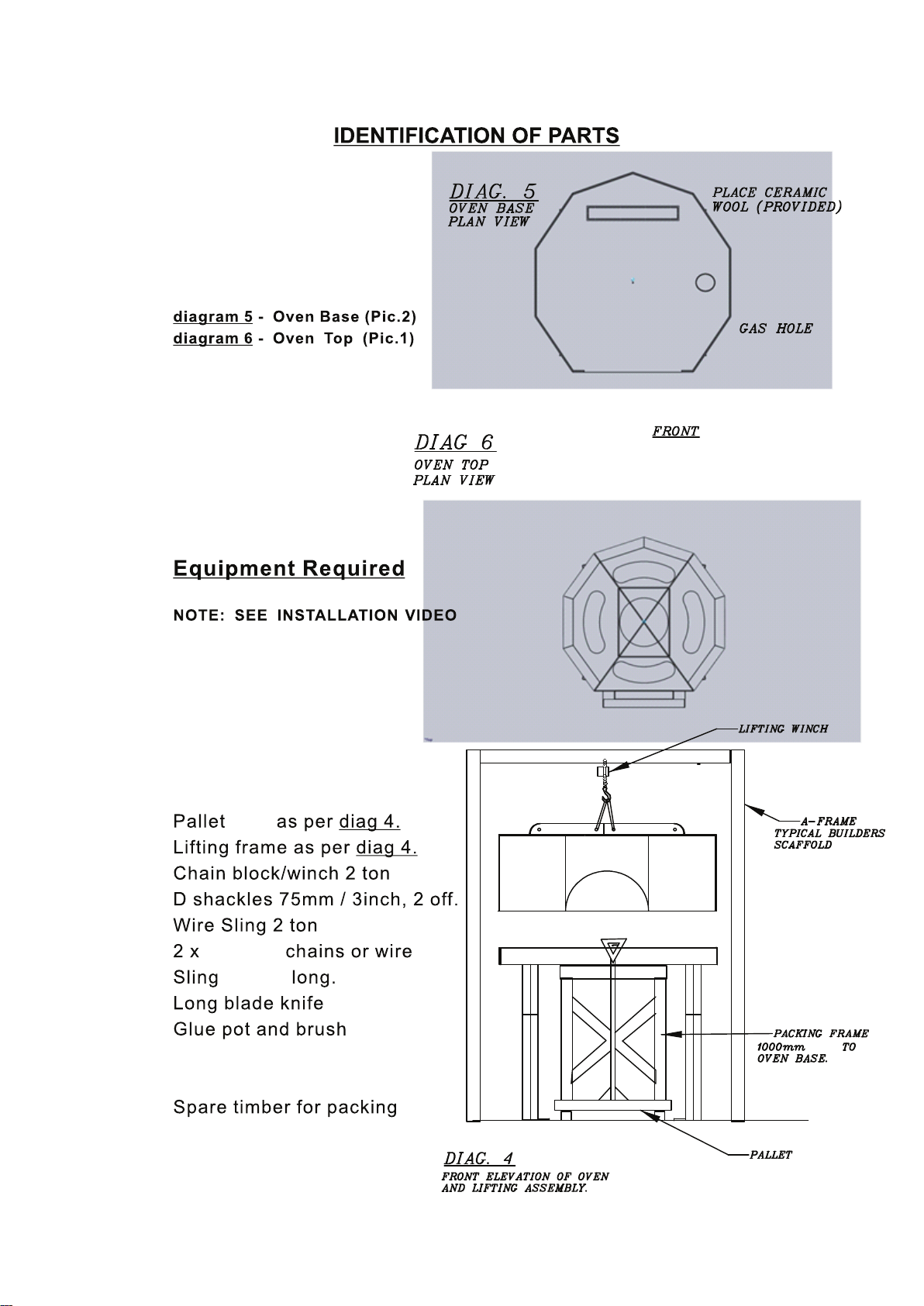

Identification of Parts

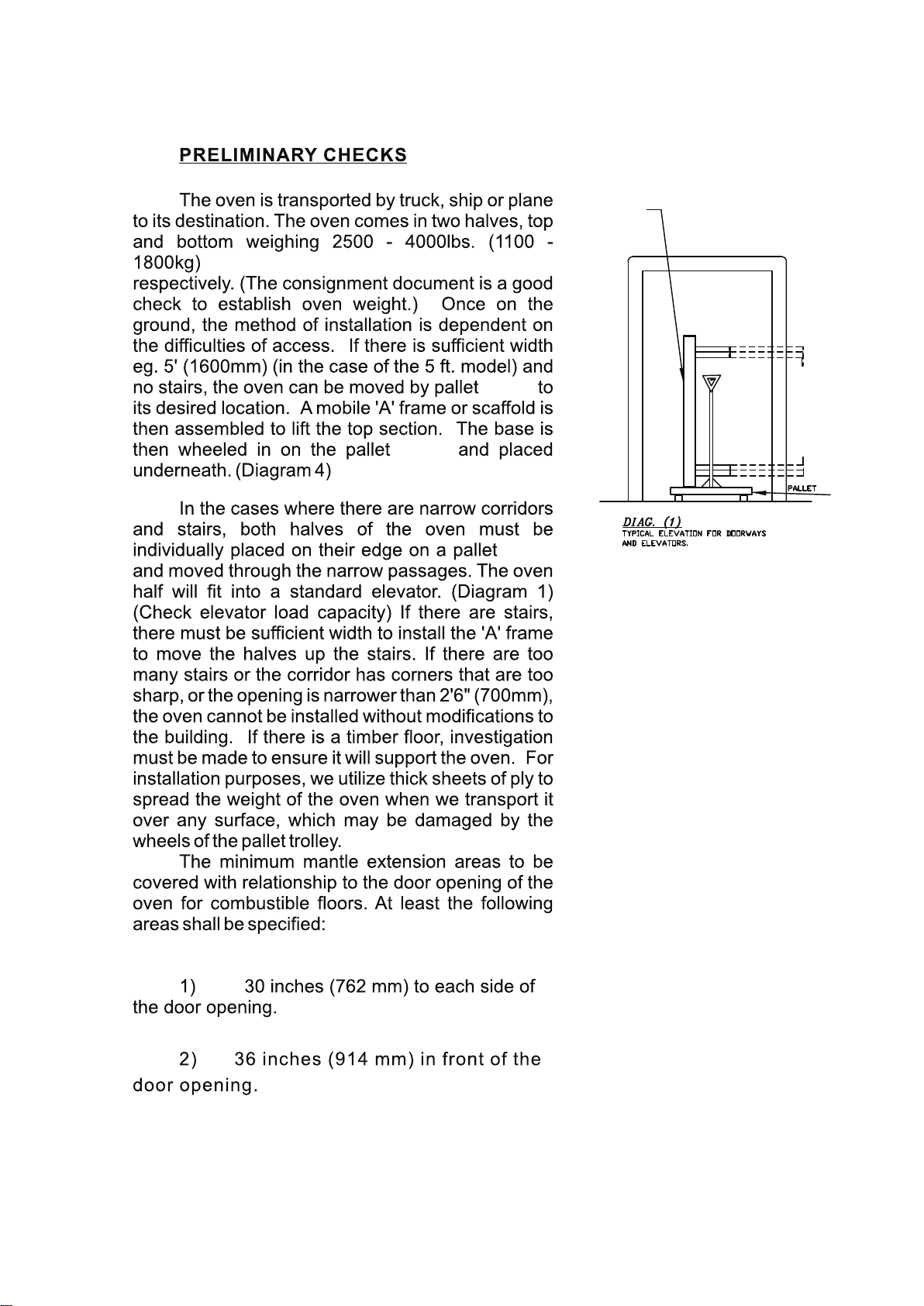

Preliminary Checks

Contactors Responsibility

Installation Procedures

•Transportation

•Assembly

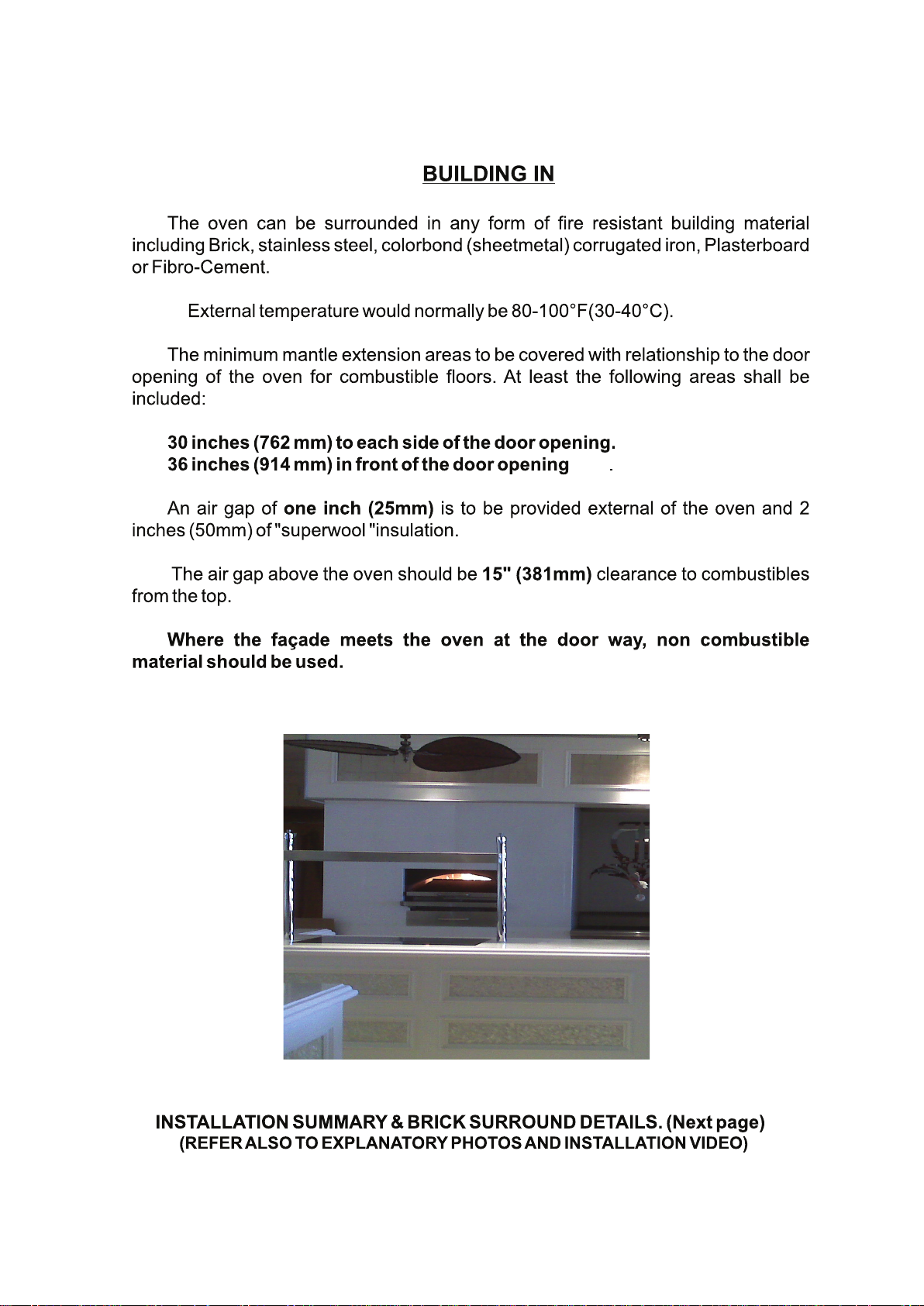

Building In

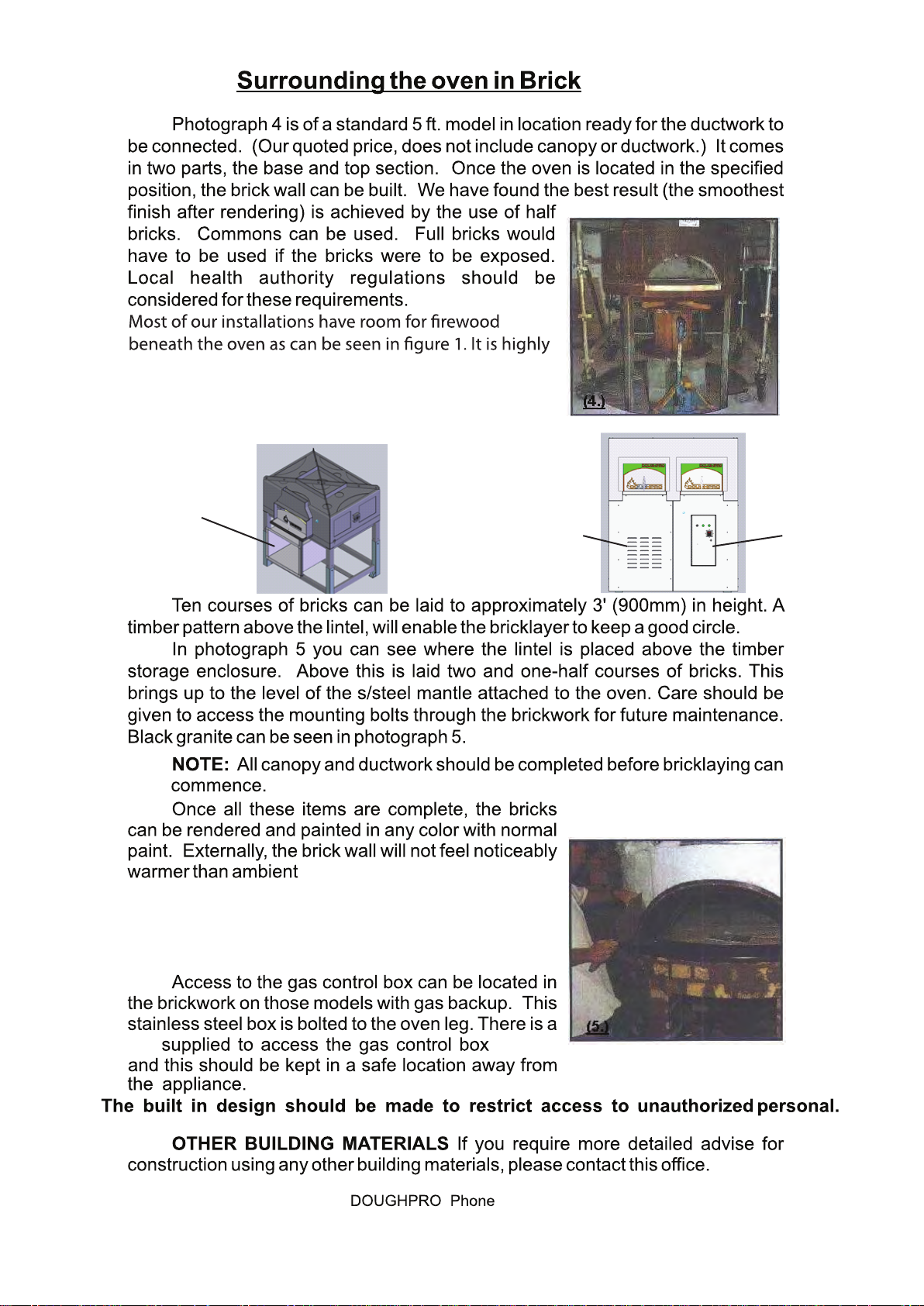

Surrounding the Oven In Brick

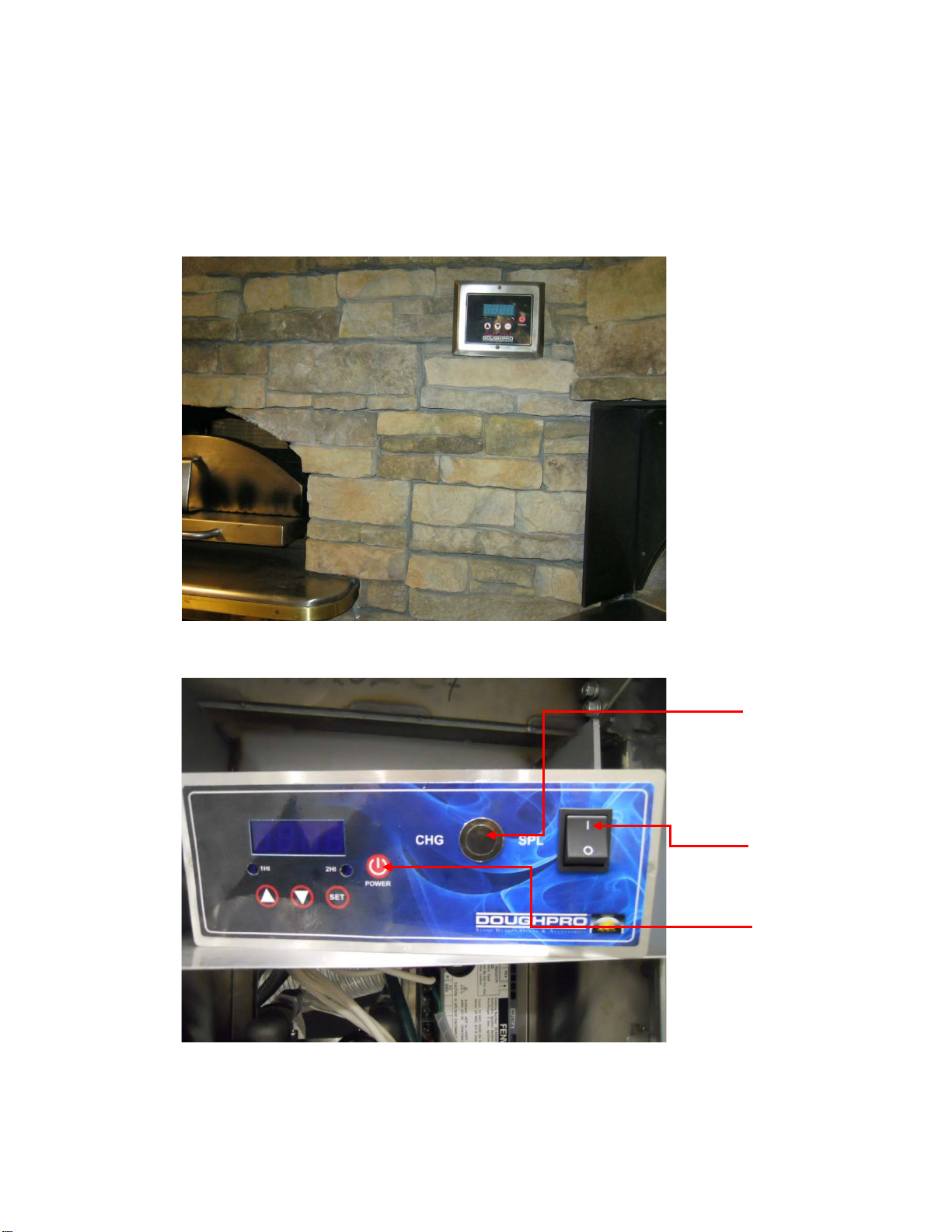

Oven Controls Installation

Gas System for Doughpro Ovens

•Connection of Gas System

•Technical Details

•Right Flame Color

Commissioning

7

8

9

10

11

13

14

18

19

20

21

22

23

26

27

Preheat / Curing of Oven

Spare Parts List

Overview of Oven Controls

Burner Removing Instructions

Technical Details

•Single Gas Box EXP and Parts

•Oven Electrical Info

•Double Gas Box EXP and Parts

28

29

30

31

39

45

46

Section Two:

Controller Configurations

Gas Ovens

•General Gas Details

•Preheating/Cooking

•Firing up to cook

Wood Ovens

•Recommended woods

•Ash Disposal

Coal Oven

•Removing ash box

•EXP drawing/Parts list

Char-grill

•Char-grill operation

•Cleaning the char-grill

•EXP and parts list

54

59

60

61

64

65

68

69

71

72

73

Care and cleaning

Oven Venting recommendations

Oven Installation clearance

Section Three:

Oven Materials

Warranty and Return Policy

76

77

84

85

91

frame

,coal or gas or

to be covered in a further

7

jack

2200 lbs

10 feet

jack

JACK

8

or shipped in one piece

jack

jack

jack

jack

9

and correct pressure is available to the gas box.

Installer is responsible to make sure oven is level to the oor

10

forklift

jack

jack

jack

jack

11

NOTE: ALWAYS FOLLOW HOOD MANUFACTURES CLEANING PROCEDURES

Captive Air...

National Accounts

Captive-Aire Systems Inc.

4641 Paragon Park

Raleigh NC 27616

800/334-9256

919/882-5204 fax#

12

Doughpro

R ND- RE C- R G O Manual

Transportation

the Oven to the site.

Take

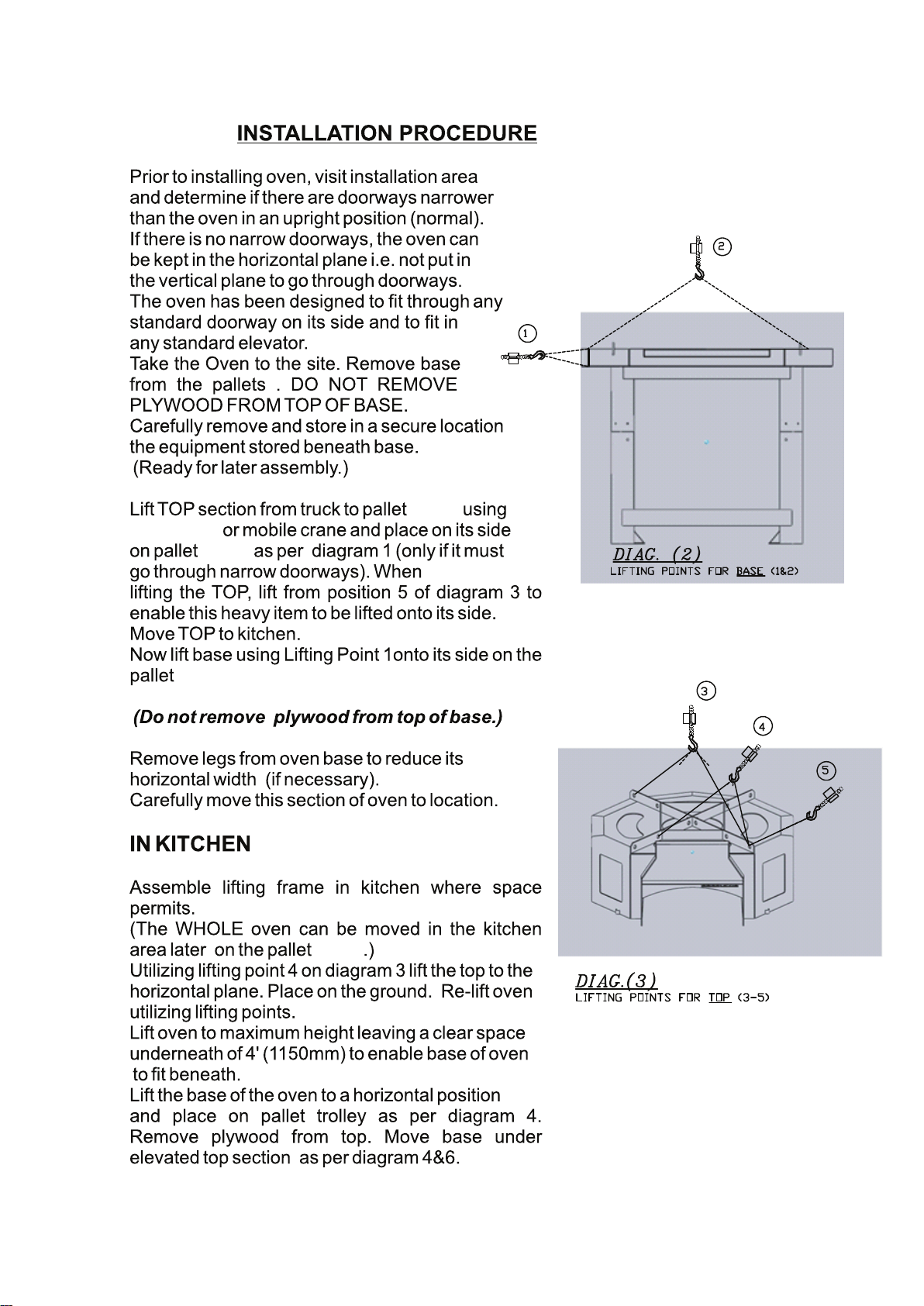

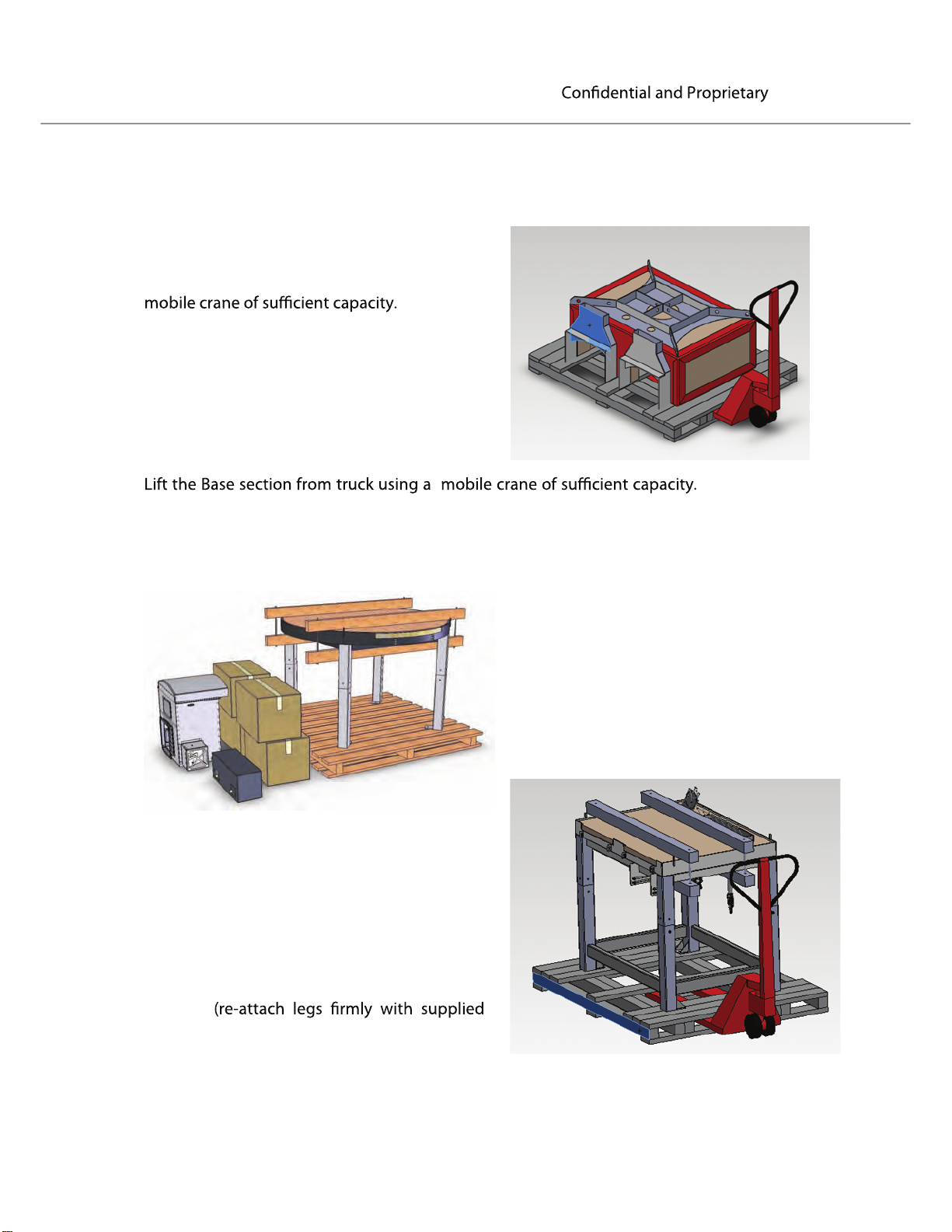

Lift the Upper section from truck using a

Move

from pallet and place on it’s side on pallet

jack if it must go through narrow doorways See previous section - Lifting Positions )

(Remove from pallet and place on its side on pallet jack if it must go through narrow

doorways - See previous section - Lifting Positions)

Do NOT remove plywood from top of Base.

the Upper section to kitchen. (Remove

Carefully remove the equipment stored

beneath the Base and store in a secure

location (ready for later assembly).

Now lift the Base onto pallet jack. (On it’s

side if it must go through narrow doorways:

See previous section - Lifting Positions)

Remove leg

width if necessary.

Carefully move this section of oven to

location

bolts if transported on its side).

s from oven base to red

uce its

13

Doughpro

RND-REC-RGO Manual

Assembly

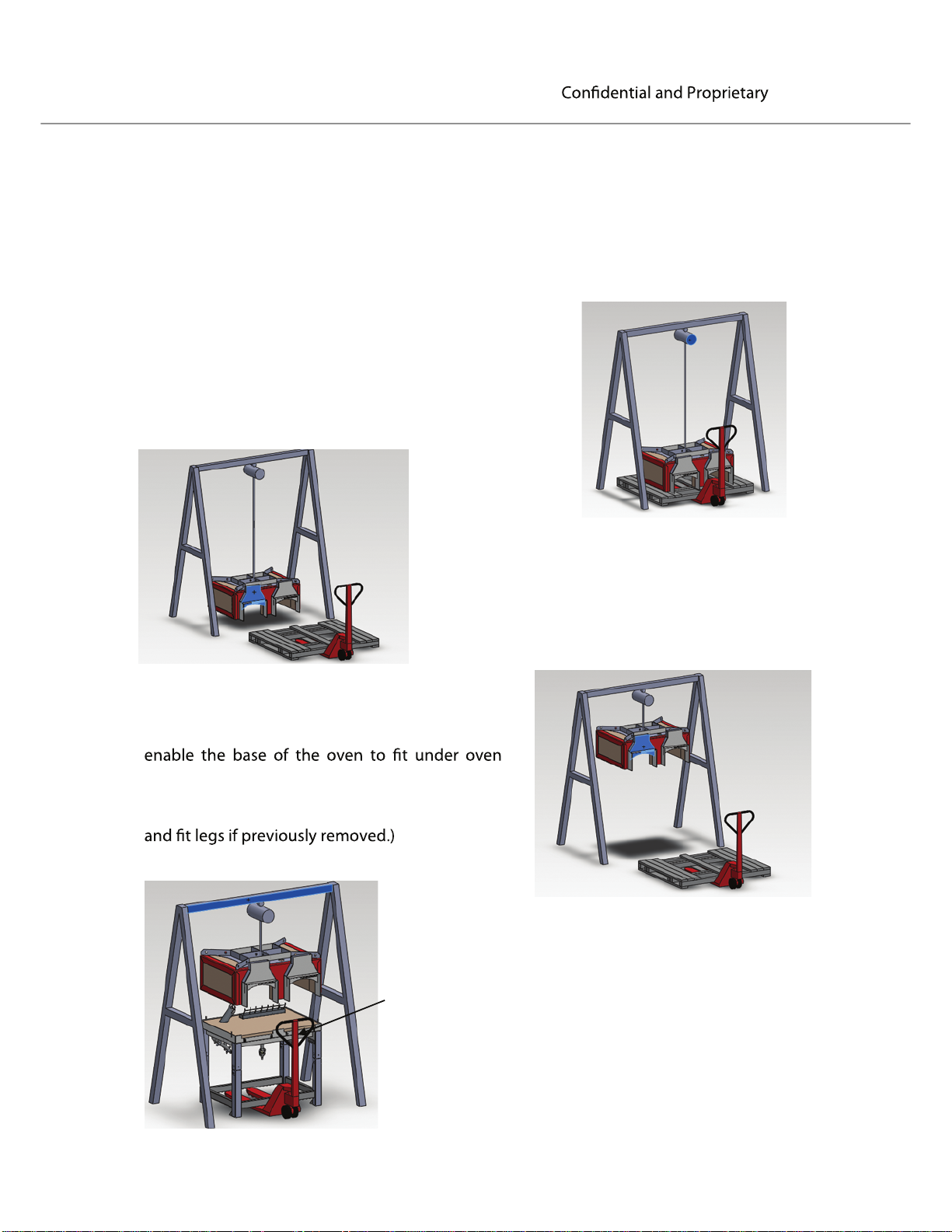

The procedure mentioned below uses an “A-Frame” lifting method for assembling the

oven. Other lifting methods may be used e.g. a fork truck or crane, however the

following principals still apply.

Assemble lifting frame in kitchen where space permits.

(The assembled oven must be able to be moved

within the kitchen area without obstruction later on the

pallet jack.)

Utilizing lifting point 3 on previous dia

top free of the pallet and place on the ground, while

moving the base

Lift the oven top to such a height to leave a

clear space underneath of minimum 46 inches to

top.

(Lift the base of the oven to a horizontal position

Move base under elevated top section using a lifting

frame or a stack of narrow pallets, being careful not to

damage any equipment under the oven; e.g.

burners, sensors, etc.

gram, lift the

into position.

You may now remove the protective plywood from the

top of the base.

14

Doughpro

RND-REC-RGO Manual

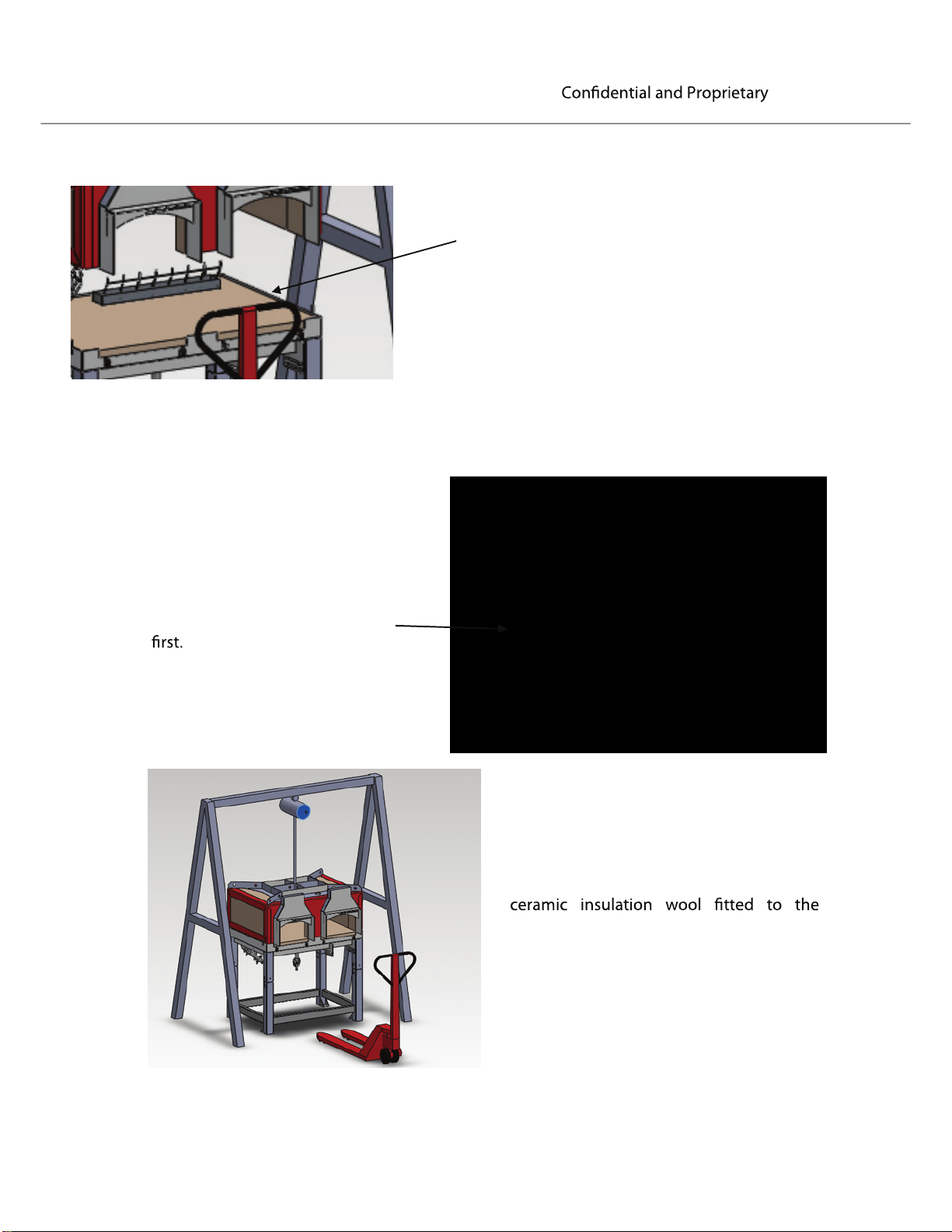

Position wool strips so that they

remain hidden when the two halves

of the oven are assembled together.

Align the top and base using

the positioning tabs welded to

the base, locating the rear tab

Ensure that the oven

mouth aligns with the cutouts in the base.

Place strips of 2 inch x 1/2 inch ceramic

insulation wool (supplied) beneath the top of

the oven where the top section touches the

base.

NOTE: No wool should come between the

steel of the top and base.

With the two halves together the oven is

now ready to have the supplied 2 inch

external surfaces.

The “A-frame” can now be dismantled

and removed.

15

Doughpro

RND-REC-RGO Manual

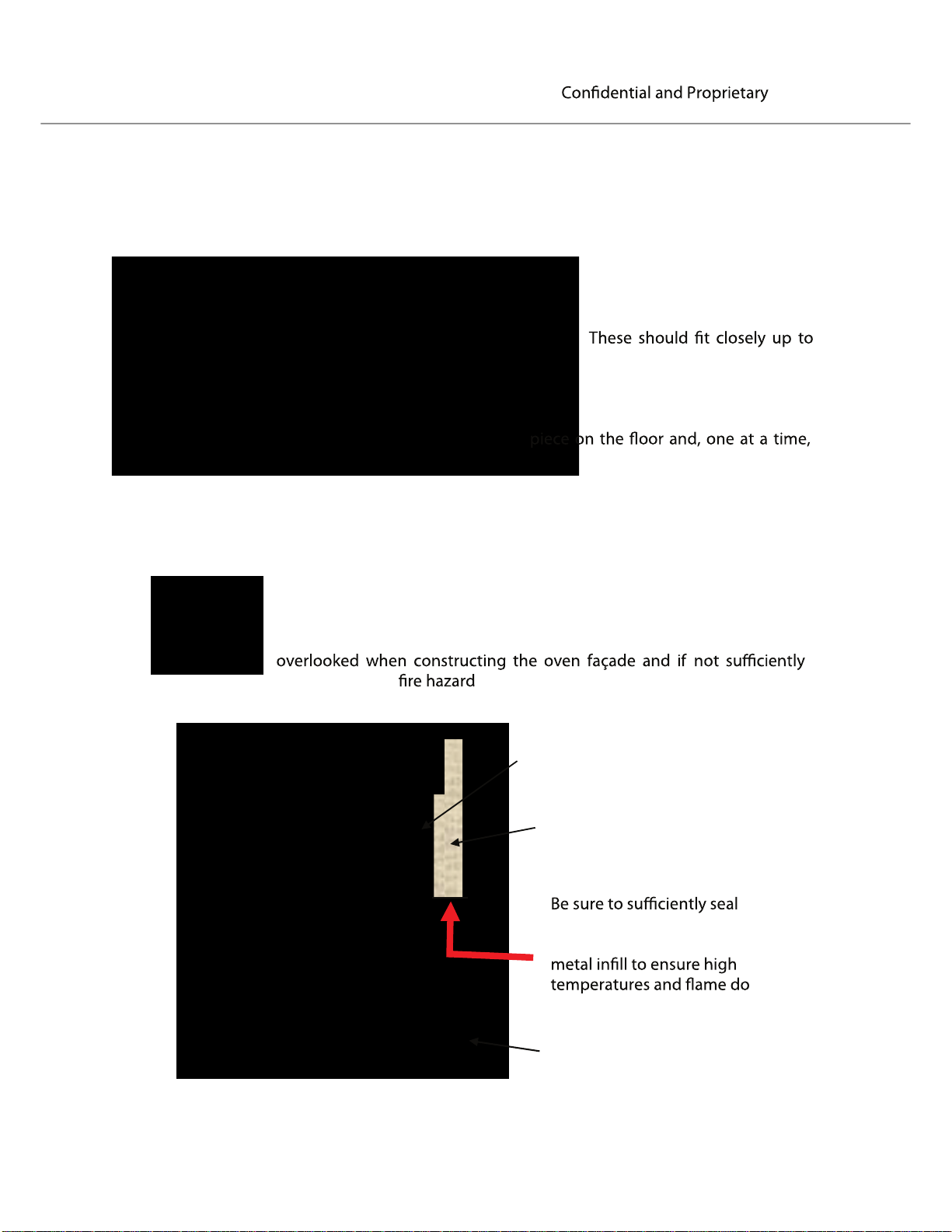

The external surfaces (sides and top) of the oven are then completely covered with

ceramic insulation wool ( 2 inch Superwool ) using the high temperature Blox Stix glue

provided.

First cut all pieces

required to cover the sides

and top using a sharp knife.

each other with no visible gaps

to allow heat to escape.

When all pieces are cut, place each

apply a generous coat of Blox Stix glue

to the wool as shown using a trowel or

similar application tool.

An important area to be aware of is directly in front of the exhaust

spigot of the oven. If the façade protrudes from the spigot there may

be an area between the spigot and the façade which is left uncovered

and vulnerable to soot and grease build up. This area is commonly

sealed creates a .

Exhaust Spigot

Insulation between spigot

and façade face

the area between the exhaust

spigot and the façade with a

not enter the façade cavity

Façade face

16

Doughpro

RND-REC-RGO Manual

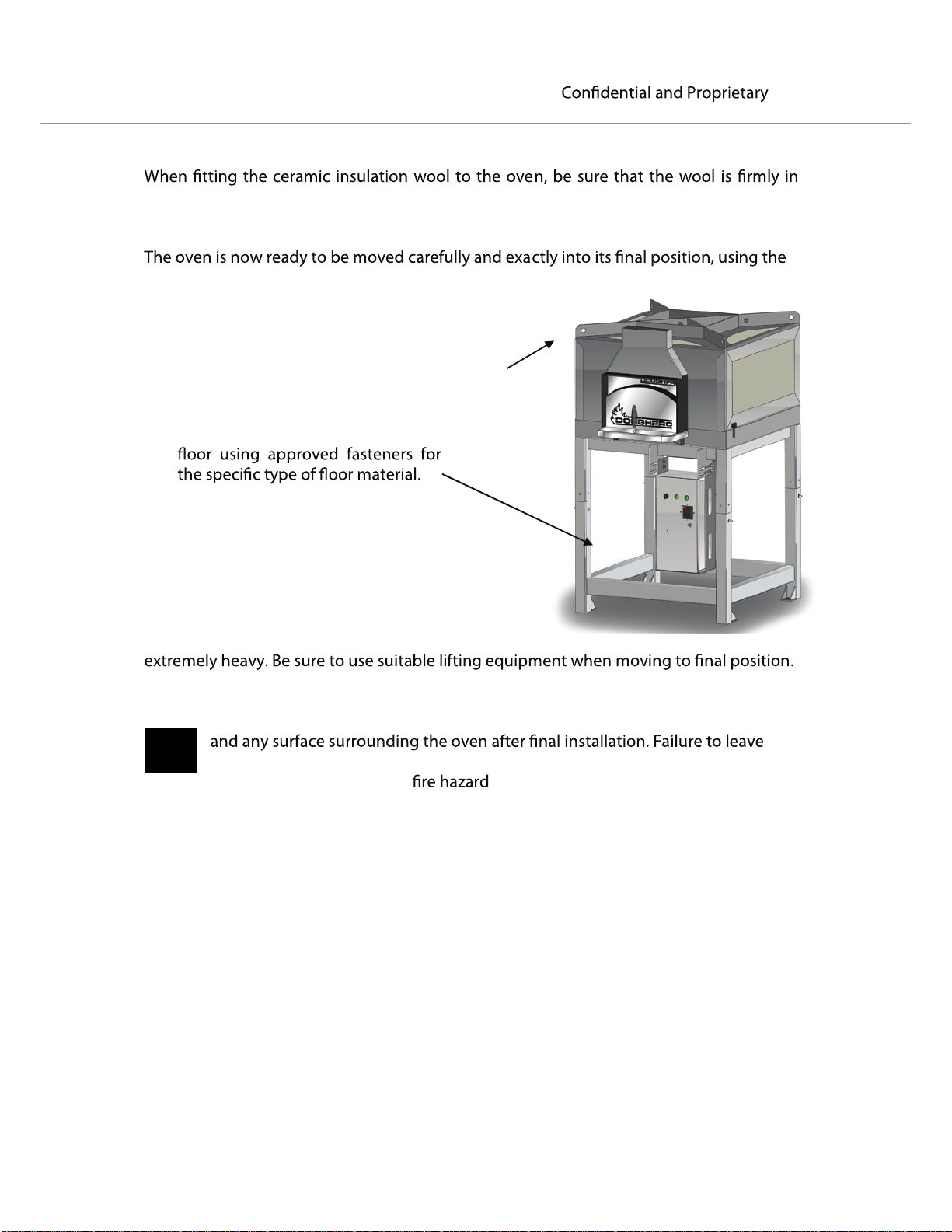

place and that all air pockets are removed. The glue will dry in approximately one (1)

hour depending on ambient conditions.

lifting frame and a pallet jack (or similar).

If required, fasten the legs to the

NOTE: Fully assembled the oven can be

1 inch Air Circulation Gap

NOTE: INSTALLER IS RESPONSIBLE TO MAKE SURE OVEN IS PROPERLY LEVEL

NOTE: A 1 inch Air Circulation Gap is to be left between the ceramic wool

this air gap will result in above normal temperatures being transferred to

exterior surfaces, causing a

.

17

18

recommended that a wood box be purchased with the

oven; Doughpro heavy duty stainless steel wood box

can help you storing the wood that is going to be used

throughout the day.

Figure 1 Figure 2

Wood box

Access panel

If the oven installed is gas red, an access area must be

left for access to the gas equipment and to enable the

ingress of air to the burners. A mesh panel of 16”x16”

minimum can be incorporated for this ventilation.

Gas box

key

(951) 657-0379

19

noitallatsnI slortnoc nevO

Install remote controller in a location no further the 6ft it is up to the customer's discretion to install

where they want

Depending on the oven configuration the control might a little bit different than the control shown

below.

It is up to the installer to make sure digital control is properly secure when installing the oven.

If digital control needs to be replace or service contact Doughpro

Install digital controller no further than 6ft from the center of the oven

Char grill igniter

button

Spot light

on/off switch

Controller

on/off button

Controller with char grill and spot light configuration

20

NOTE: GAS TECH SHOULD BRING IN A SINGLE INLET TO SUPPLY GAS SYSTEM AND CHARGRILL

Refer to page 21, 22

21

Stainless Steel

as well as granting access to the gas system.

3/4”

22

23

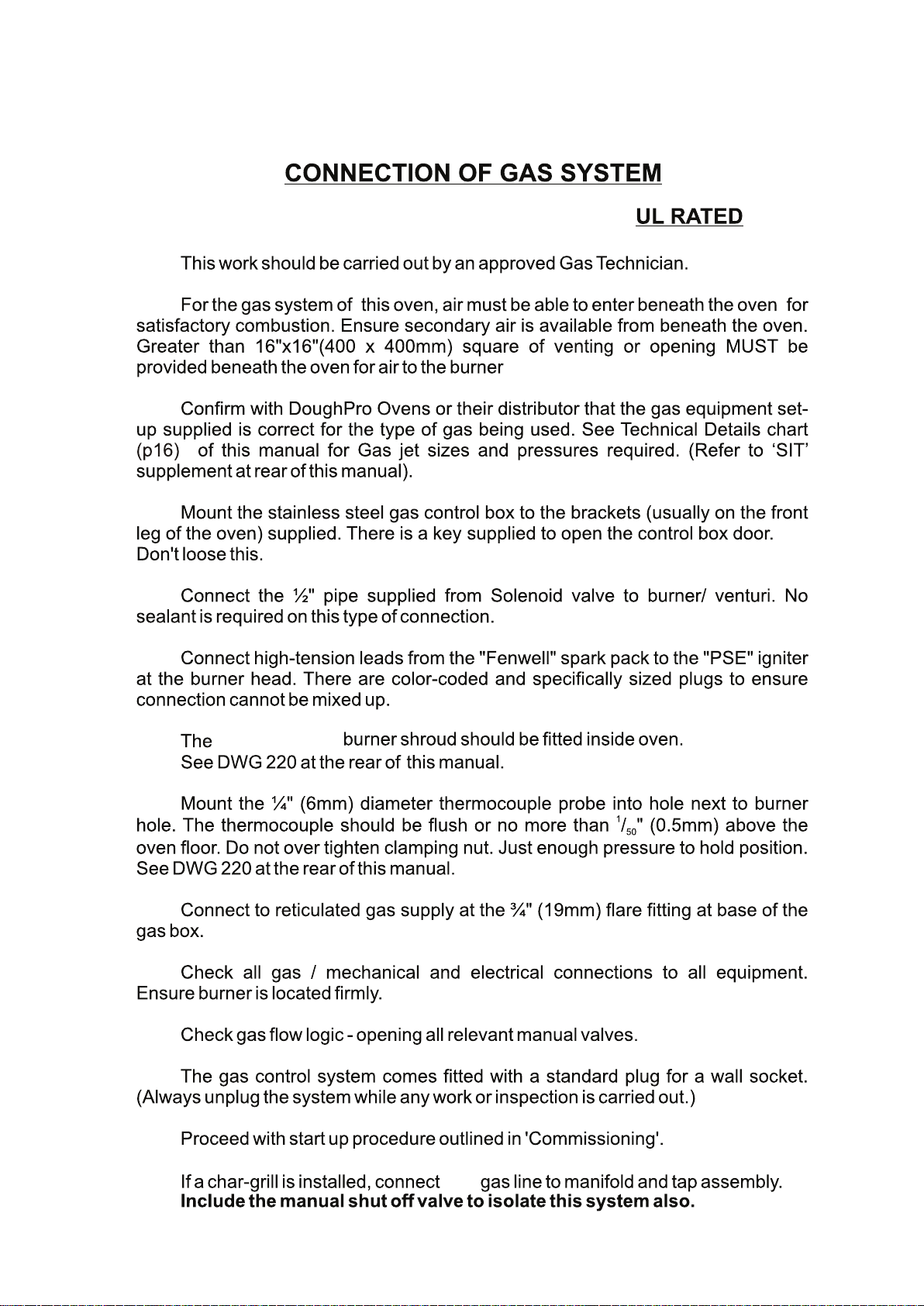

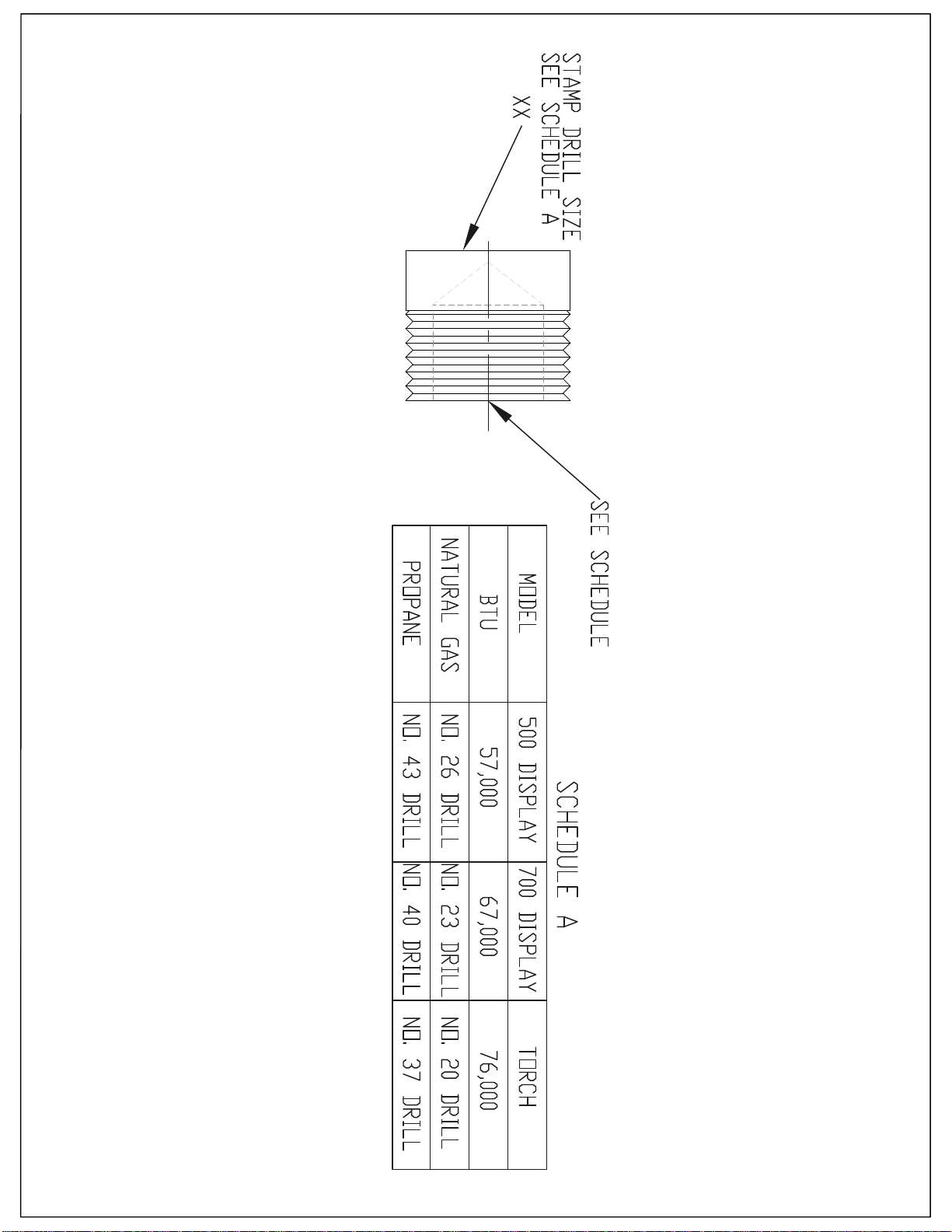

CHAR GRILL ORIFICES SIZE

DISPLAY AND TORCH BURNER ORFICES SIZE

RIGHT FLAME COLOR

air shutter

In order to have a good combustion for your oven, the mixture of air and gas has to be right, the flame

on either torch or display burner can tell you if the mixture of these two elements is been achieved.

0.400"

locking nut

A yellow flame means that there is not enough air mixing with the gas causing a poor combustion on

either burner.

A blue flame means that there is too much air in gas mixture.

Blue color and ½ inch of yellow on the tip means that there is enough air and gas mix together to obtain

a good combustion.

All ovens are calibrated to make sure there is a good combustion of oxygen and gas, a gap of .400” is

set between the venturi and

amount of air is not enough or is too much, the air shutter and hex nut have to be move up or down; by

moving the air shutter down the amount of air going through the venturi will increase, by moving the

air shutter up the amount of air will decrease, make sure locking nut is also adjusted.

the flat washer and it is properly lock by a hex nut. In cases where the

26

jack

200 °F

27

(3)

Loading...

Loading...