Doughpro Proluxe DP3300BZ Service Manual

Operations Manual

Rev 5

Model: DP3300BZ

Electromechanical Dough Press

formerly DOUGHPRO. New Name. Same Quality. Superior Service.

proluxe.com

Congratulations!

Your selection of the Doughpro DP3300

is a sound business decision. Doughpro

equipment is a result of the highest

quality engineering and time-tested

design. Your machine combined with

Doughpro’s reputation of innovation in

dough pressing equipment

manufacturing, insures the continuing

capability of delivering the bestdecorated product possible.

This manual describes installation,

operation, and maintenance procedures

for your new model DP3300.

Your model DP3300 machine will have

a long trouble-free life. Read this

manual carefully and keep it with your

machine; it’s your key to proper

operation and lasting service.

Installation

DOMESTIC

Use a separate 15 amp AC

circuit. Only industrial extension

cords with proper wire size

should be used; size 16/3 wire for

distance up to 25 feet, and size

14/3 for distance up to 50 feet.

INTERNATIONAL

Use a designated 16 amp AC

circuit. Only industrial extension

cords with proper wire size (2.5

sq. mm) shall be used.

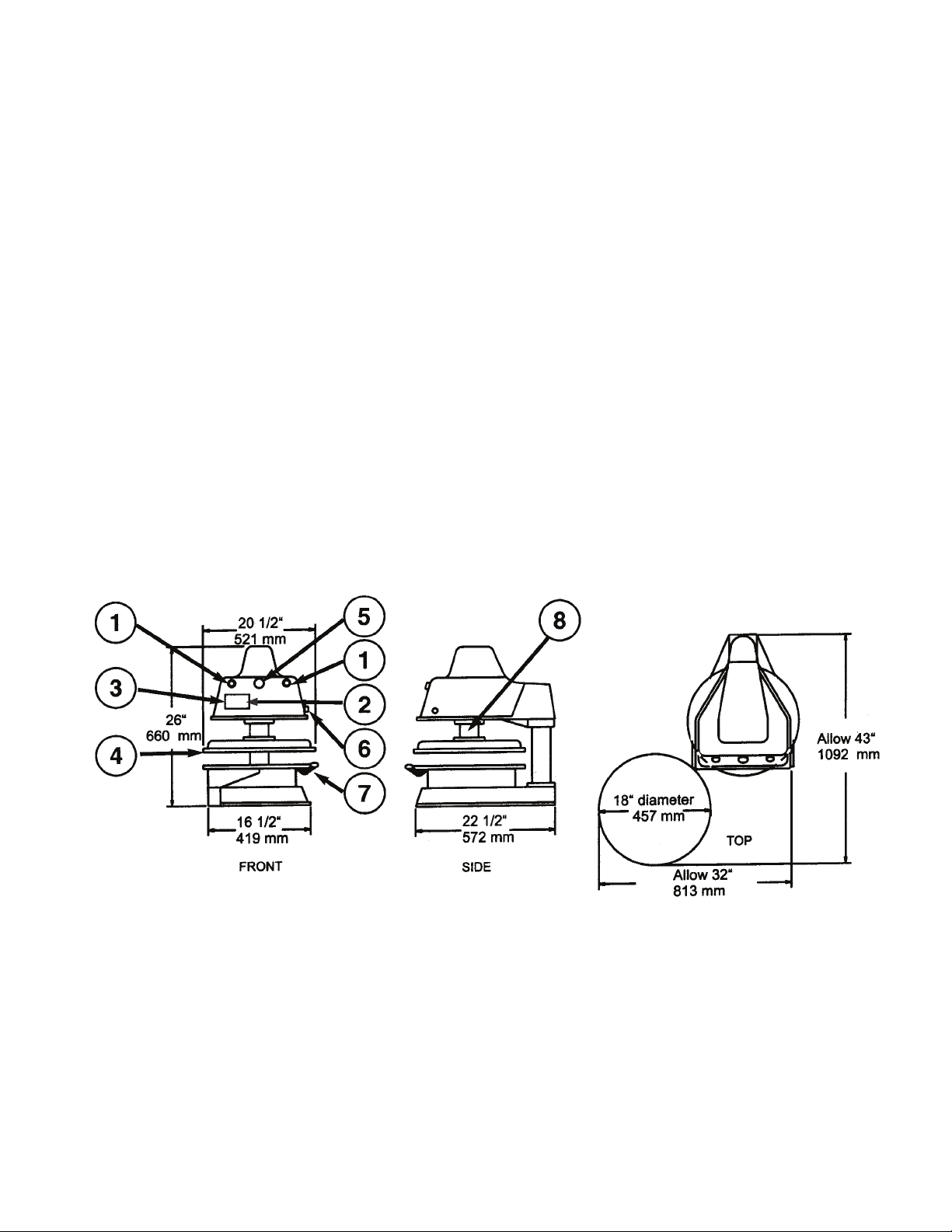

Make sure there is a proper electrical

wall outlet located within reach of the

cord and plug attached to the press.

Then place the press in an area which

allows for “swing clearance” of the

lower platen plus vertical and horizontal

clearance of the press itself.

Limited Machine Warranty

Doughpro warrants this dough press

machine, when operated under normal

conditions, to be free from

manufacturing defects in material and

workmanship for a period of one year on

parts and labor from the invoice date.

This warranty will be effective only

when Doughpro authorizes the original

purchaser to return the product to the

factory in South Gate, California freight

prepaid and only when the product, upon

examination, has proven to be defective.

This warranty does not apply to any

machine that has been subjected to

misuse, negligence or accident.

Doughpro shall not be liable for the

injury, loss or damage, direct or

consequential, arising out of the use or

the inability to use the product.

No claim of any kind shall be greater in

amount than the sale price of the product

or part to which claim is made.

This is the sole warranty given by the company, it is in

lieu of any other warranties, expressed or implied, in

law or in fact, including the warranties of

merchantability and fitness for a particular use, and is

accepted such by the purchaser in taking delivery of

this product.

Specifications

Electrical:

120V/60Hz/1450W/12.5Amps/AC

Also available; specify when ordering:

240V/50-60Hz/1450W/6.04Amps

Includes 68” cord and NEMA

approved plug.

Shipping Weight:

200lbs. (91kg)

-1- DP3300 1410/20003/40002 5/03

General Specifications

Please Note: Part Number 1101017602-Ref#

92-REPLACEMENT MOTOR BRUSH SET ACTUATOR

Must be changed annually due to wear and tear.

1. Piston Activation Buttons (2)

2. On/Off Power Switch

3. Digital Temperature & Time

Control – 0-200°F Temperature

Setting.

4. Upper Platen – Heated to help

the dough flow faster and more

evenly.

5. Disengage Switch – Releases

upper platen in case of

emergency.

6. Thickness Control Dial –

Controls the thickness of the

dough, (varies depending on size

of dough ball).

7. Lower Platen – Dough is placed

here; swings out for easy

removal of flattened dough.

8. Grease Port – Using a standard

grease gun, squeeze a food

approved, high temperature

grease into the port (once

monthly.).

Exterior Finish: Highly resistant white,

high gloss powder coat, approved for use

with food products. Molds are probrite

coated anti-stick surfaces.

-2- DP3300 1410/20003/40002 5/03

Safety Summary

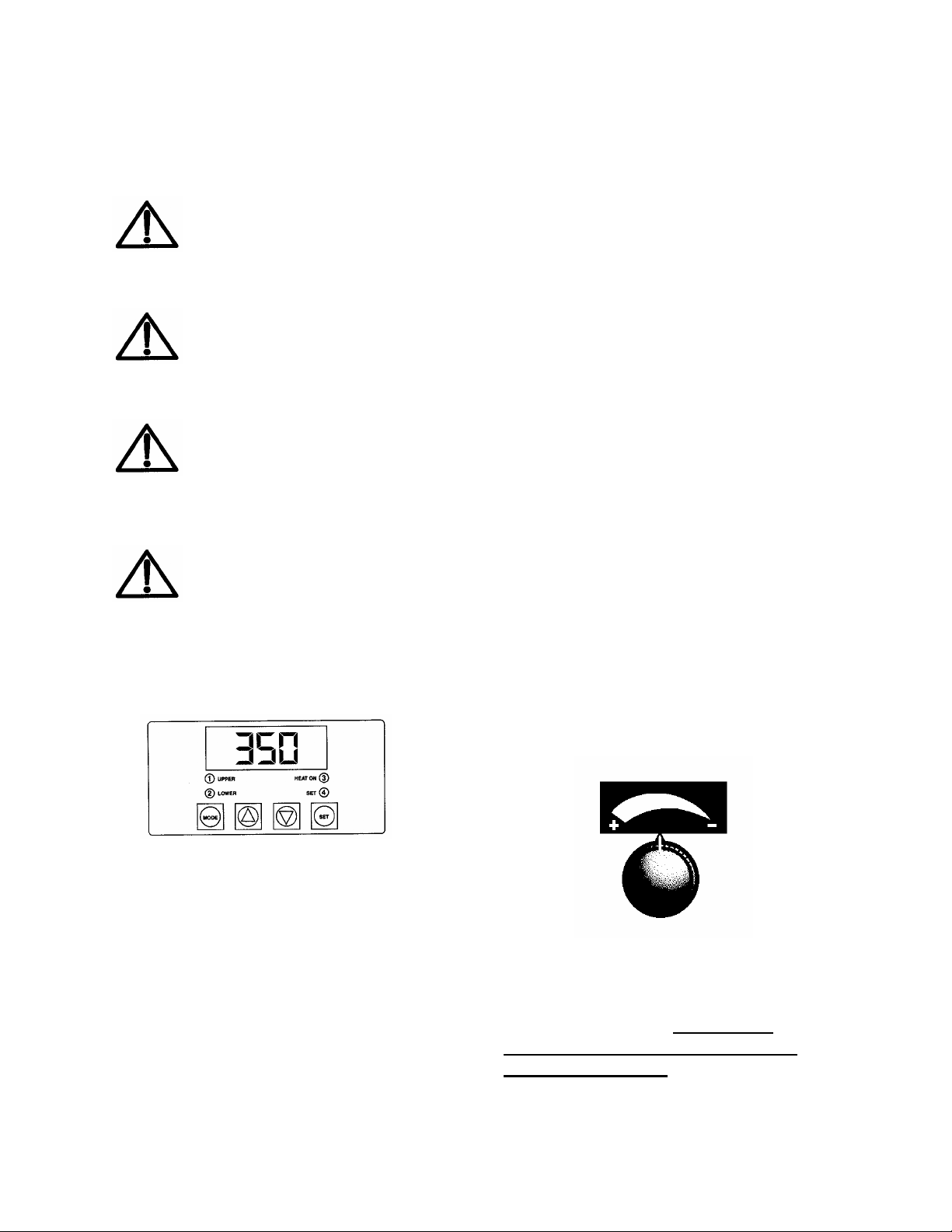

WARNING

In case of power cord damage,

do not attempt to repair or

replace the power cord. Contact

the manufacturer or the local

distributor.

WARNING

Avoid touching hot surfaces

while operating the machine.

CAUTION

During normal operation, the

base of the machine must be

installed or placed above the wall

socket.

CAUTION

When servicing or cleaning the

machine, make sure that the

power cord is removed from the

wall socket.

Operation Timer/Temperature

Control

Solid State Controller

This controller has three (3) control

features:

1. Temperature – Temperature may

be set from 100°-325°F (38°163°C)

2. Time – Time may be set from 1

second to 10 minutes.

3. Counter – Cycle counter counts

the number of applications from

1 to 9999 (see additional Notes –

Counter).

Controller Operation

1. If the temperature is not being

displayed, press the MODE

button until temperature is

displayed.

2. Push and hold SET button and

simultaneously push UP (V) or

DOWN (W) arrow buttons to the

desired temperature setting.

3. Press the MODE button until

time is displayed.

4. Push and hold SET button and

simultaneously push UP (V) or

DOWN (W) arrow button to the

desired timer setting.

Dough Pressing Operations

SETTING CRUST THICKNESS

CONTROL:

Setting crust thickness is as simple as the

twist of a dial. By means of trial and

error, rotate the dial until desired

thickness is obtained. Note: Never

force the dial past its stop position or

damage could occur.

-3- DP3300 1410/20003/40002 5/03

PRESSING DOUGH:

First allow the upper platen to reach

programmed temperature. In most

cases, 150°F (65.5°C) is ideal, but trial

and error testing will determine the best

temperature for your dough.

For best results, your dough should be

proofed before pressing, but it will also

press directly out of your refrigerator.

Flour is not required to press a crust

and should not be dusted on any part of

the machine.

Determining the proper timer setting

also requires some trial and error until

you obtain the correction thickness and

diameter of your product. Start with five

(5) seconds and go up or down from

there. Remember that the timer does

not actuate until the upper platen mates

with the lower platen and resistance is

felt.

1. Apply a quick spray of a good

water based food release on the

lower platen. Doughpro offers

its own food release spray

NATURALLY CLEAR Model

No. DPPC1. (See our catalog

and price list for information.)

Note: This spray will not affect

the taste of your crust in any

way.

2. Place your pre-portioned ball of

dough in the approximate center

of the lower platen. Add another

dash of spray to the top of the

dough ball.

3. Close the platen and, with both

hands, press the two green

buttons on the face of the press.

4. Hold the buttons in until

resistance is felt then release at

once. The timer will actuate and

when the time cycle is

completed, the upper platen will

rise automatically (timer is preset

at factory for six (6) seconds, but

this is easily changed by

following the upcoming

instructions.)

5. Remove the crust, place on disc,

screen, pan or peel, add toppings

and bake.

ADDITIONAL NOTES:

Temperature

Note

Fahrenheit/Centigrade (Celsius)

Conversion

The temperature controller can

be programmed to display either

°F or °C. To change: Press the

MODE button until the

temperature is displayed, then

push and hold the SET button for

10 seconds.

Timer

• The controller has a count down

timer that automatically activates

a buzzer at the completion of the

application.

• Timer display is minutes:

seconds. Range is 00:00 to

10:00; Colons (:) flash while

timer is running.

-4- DP3300 1410/20003/40002 5/03

Loading...

Loading...