Doosan G70WJD-2A-T3, G145WJD-2A-T3, G25WMI-2A-T2, G185WJD-2A-T3, G240WJD-2B-T3 Installation, Operation & Maintenance Manual

...

OPERATION, MAINTENANCE

MANUAL

G10WMI-2D-T2 (B63)

G25WMI-2A-T2 (B54)

G40WMI-2A-T2 (B50)

G60WJD-2A-T2 (B55)

G70WJD-2A-T3 (D63)

G80

G90WJD-2A-T3 (C24)

G125

G145WJD-2A-T3 (C27)

G185WJD-2A-T3 (C28)

G240WJD-2B-T3 (C31)

G240WCU-2C-T3 (D97)

G290WCU-3B-T3 (C38)

G290WCU-3C-T3 (D77)

G450WCU-2B-T2 (C34)

G450WCU-2C-T2 (D96)

G570WCU-2B-T2 (C37)

G570WCU-2C-T2 (D78)

GENERATOR MODELS

This manual contains important safety information.

Do not destroy this manual.

This manual must be available to the personnel who operate and maintain this machine.

Doosan Infracore Portable Power

1293 Glenway Drive

Statesville, N.C. 28625

www.doosanportablepower.com

Book: 22637300 (8-2-2010) Rev H

2

TABLE OF CONTENTS

Operation & Maintenance Manual

TITLE PAGE

DRAWBAR NOTICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HAZARDOUS SUBSTANCE PRECAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

GENERAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Unit Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unit Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Unit Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Consumables Service Parts:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Consumable Service Parts:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Expendable Service Parts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

BEFORE TOWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

TOWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SETTING UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DISCONNECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

BEFORE STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

STARTING (AUTOSTART MODELS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

STOPPING (AUTOSTART MODELS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

REMOTE STARTING AND STOPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DIAGNOSTICS/AUTO SHUTDOWN (AUTOSTART MODELS). . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

ENGINE CONTROLS and INSTRUMENTS (AUTOSTART MODELS) . . . . . . . . . . . . . . . . . . . . . . 35

CUSTOMER - DIAGNOSTIC GAUGE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

STARTING (KEY START MODELS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

STOPPING (KEYSTART MODELS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DIAGNOSTICS and AUTO SHUTDOWN (KEYSTART MODELS). . . . . . . . . . . . . . . . . . . . . . . . . . 40

ENGINE CONTROLS and INSTRUMENTS (Keystart Models) . . . . . . . . . . . . . . . . . . . . . . . . . 41

GENERATOR SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

MONITOR SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

CIRCUIT BREAKERS - Flip to Reset (if equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

RECEPTACLES (if equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

PROTECTION/REGULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

VOLTAGE SELECTION/ADJUSTMENTS G25 thru G185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

SWITCH POSITION - 120/208V 3 Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SWITCH POSITION - 277/480V 3 Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SWITCH POSITION - 120/240 1Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

VOLTAGE SELECTION/ADJUSTMENTS G240 thru G570 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

120/208V 3 Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

277/480V 3 Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

BASIC DIGITAL CONTROLS OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3

TABLE OF CONTENTS

Operation & Maintenance Manual

TITLE PAGE

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

ADJUSTMENT INSTRUCTIONS and TESTING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ACCESSING COMPARTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

VOLTAGE REGULATOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

OVERCURRENT RELAY ADJUSTMENT (Set Dial on the OCR Relay) . . . . . . . . . . . . . . . . . . . . . 72

POWER BYPASS SWITCH FOR ENGINE ECU SERVICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

PACKAGE PREVENTIVE MAINTENANCE SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

ALTERNATOR INSTALLATION AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . 75

SAFETY MEASURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

INSTALLATION - COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

SERVICING-MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

TECHNICAL CHARACTERISTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4

Drawbar Notice

22637300 5

Operation & Maintenance Manual Drawbar Notice

Drawbar Notice

This machine may have been shipped from the factory with the drawbar positioned upright. To

convert from shipping position to towing position, the following tools are required:

Tool Required:

Ratchet, 24mm socket and an 18mm socket to fit ratchet

Torque wrench set to 166 ft-lbs (226 Nm) and 67 ft-lbs. (91 Nm)

24mm socket and an 18mm socket to fit torque wrench

Hardware included: (1) 16mm nut, (2) Washers, (2) Safety Chains

1. Remove hardware box from generator.

2. Open box and remove the bag containing hardware, safety chains and assembly

instructions.

3. Using the jack, raise the front of the unit so that the end of the drawbar is

approximately 1 inch above the ground.

4. While holding the drawbar, carefully remove the temporary retaining bolt that holds

the drawbar to the top of the enclosure (See Fig. 1).

5. Carefully lower drawbar to the Level Position.

6. Install the bolt (that was removed in Step 4) with the washers and nut from the

included hardware to secure the end of the drawbar underneath the unit and torque to

166 ft-lbs (226 Nm). Also torque the drawbar pivot bolt to 166 ft-lbs. (226 Nm). See

Figure 2).

7. Install safety chains by first removing the longest bolt used to attach the hitch then

insert the last link of one chain onto the bolt. Slide one spa cer back on the bo lt and pu t

the assembly back into the hitch. Slide the other spacer onto th e bolt, th en the last link

of the other safety chain washer. Tighten the nut to 67 ft-lbs (91 Nm).

6 22637300

Safety Symbols

22637300 7

Operation & Maintenance Manual Safety Symbols

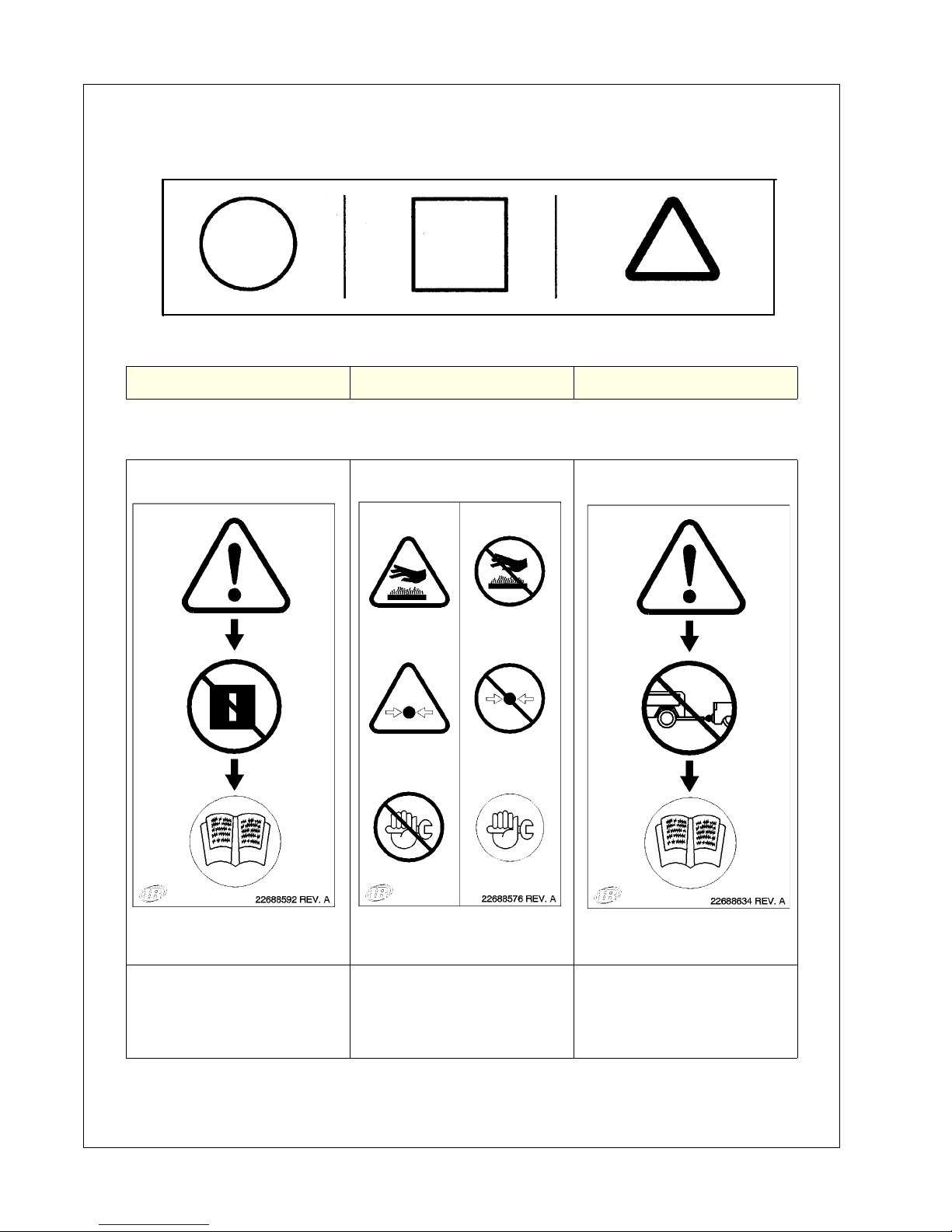

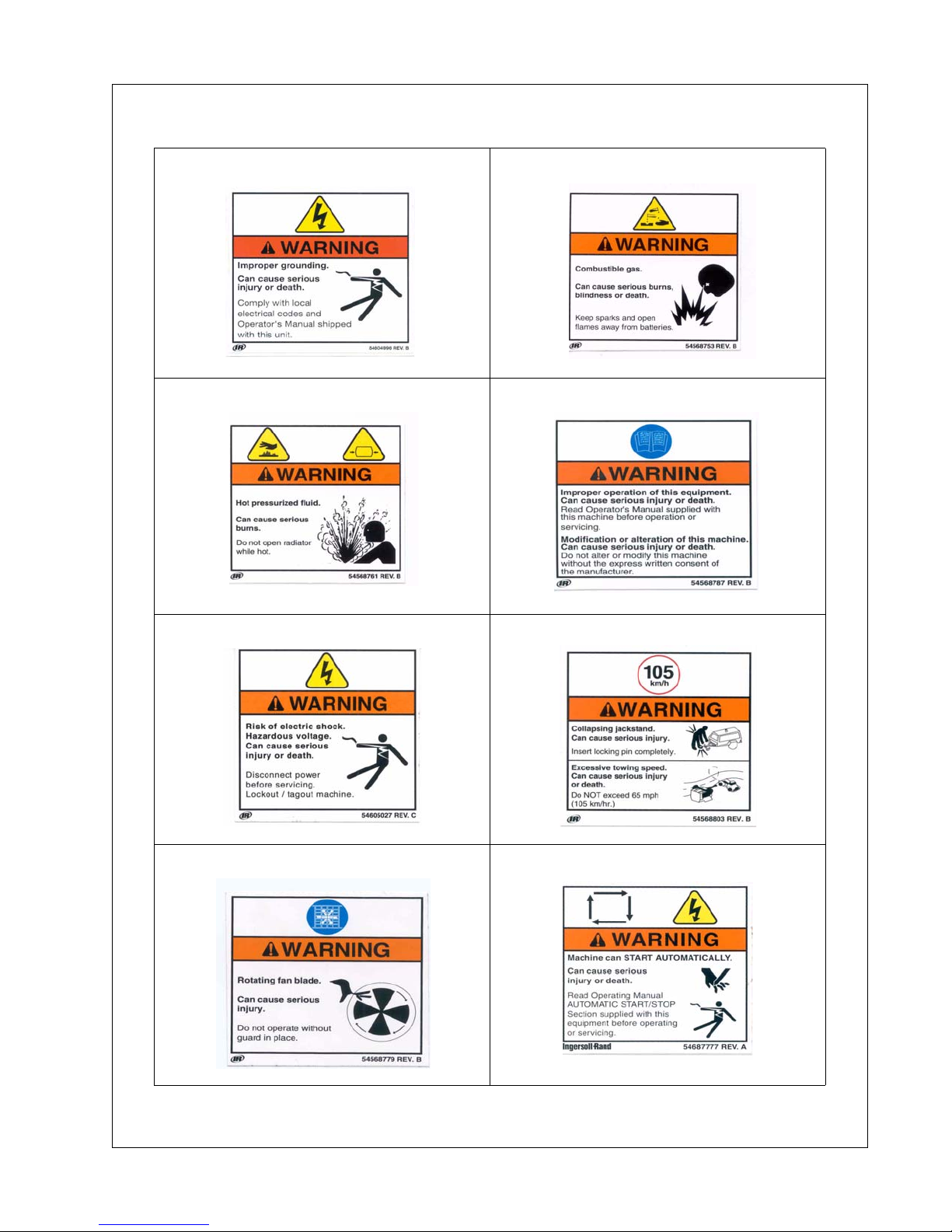

Symbols below point out potential safety hazards and provide important information about this

machine. Read and understand. Heed warnings and follow instructions. If you do not

understand, inform your supervisor.

Prohibition/ Mandatory Information/Instructions WARNING

WARNING - Read the

operator’s manual before

operating this machine.

WARNING - Do not open

radiator until radiator is

cool and pressure is

WARNING - Read the

operator’s manual before

towing machine.

relieved.

8 22637300

Safety Symbols Operation & Maintenance Manual

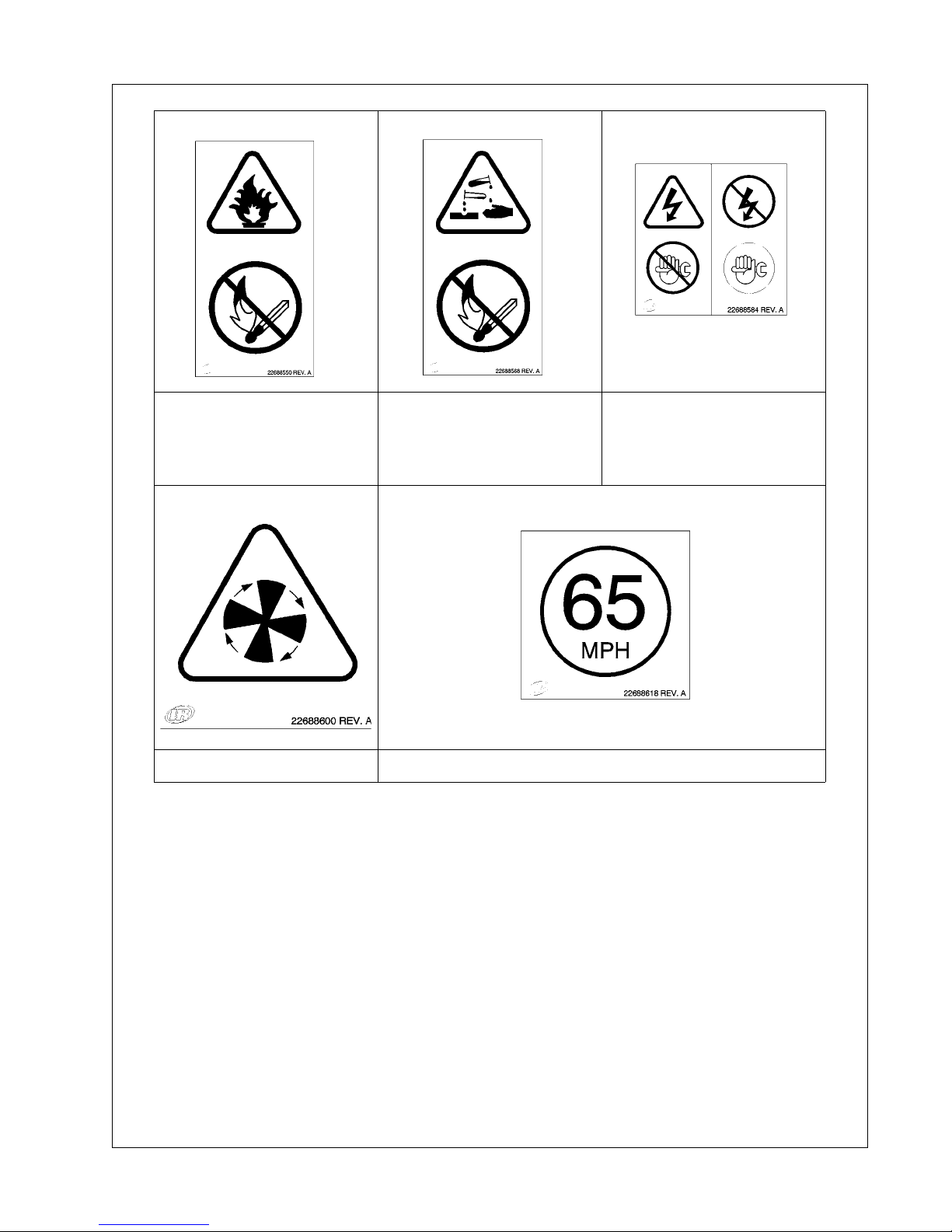

WARNING - Diesel fuel is

flammable. No open

flames or sparks.

WARNING - Battery

contains acid. Gases are

flammable. No open

flames or sparks.

WARNING - Do not

perform maintenance until

all electrical power has

been disconnected.

WARNING - Rotating fan. 65 MPH maximum towing speed.

22637300 9

Operation & Maintenance Manual Safety Symbols

Safety Symbols

Look for these signs on machines manufactured in North America, which point out

potential hazards to the safety of you and others. Read and understand thoroughly.

Heed warnings and follow instructions. If you do not understand, inform your

supervisor.

Safety Decals area available free of charge.

Safety decals are identified by the decal heading:

DANGER, WARNING or CAUTION

Decal part numbers are on the bottom of each decal and are listed

in the parts manual. Help promote product safety! Assure that

decals are present on the machines. Replace decals that are not

legible.

10 22637300

Safety Symbols Operation & Maintenance Manual

22637300 11

Always use genuine replacement parts!

12 22637300

Safety

22637300 13

Operation & Maintenance Manual Safety

Safety

!

DANGER

This machine is not designed for operating life-sustaining equipment. It

is equipped with a safety shutdown system that will cause the machine to

stop operating whenever a shutdown condition is present.

!

DANGER

Never operate the engine of this machine inside a building without

adequate ventilation. Avoid breathing exhaust fumes when working on

on near the machine.

!

WARNING

A battery contains sulfuric acid and can give off gases which are

corrosive and potentially explosive. Avoid contact with skin, eyes, and

clothing. In case of contact, flush area immediately with water.

!

WARNING

Improper operation of this equipment can cause severe injury or death.

Read Operator’s Manual supplied with this machine before operation or

service.

Modification or alteration of this machine CAN result in severe injury or

death. Do not alter or modify this machine without the express written

consent of the manufacturer.

14 22637300

Safety Operation & Maintenance Manual

!

CAUTION

Exercise extreme caution when using booster battery. To jump battery,

connect ends of one booster cable to the positive (+) terminal of each

battery. Connect one end of other cable to the negative (-) terminal of the

bosster battery and other end to a ground connection away from dead

battery (to avoid a spark occurring near any explosive gases that may be

present). After starting unit, always disconnect cables in reverse order.

!

WARNING

Never inspect or service unit without first disconnecting battery cable(s)

to prevent accidental starting.

Wear eye protection while cleaning unit with compressed air, to prevent

debris from injuring eyes.

!

WARNING

HOT PRESSURIZED FLUID - Remove cap slowly to relieve PRESSURE

from HOT radiator. Protect skin and eyes. HOT water or steam and

chemical additives can cause serious personal injury.

22637300 15

Operation & Maintenance Manual Safety

!

WARNING

Flammable Fuels - Do not fill tank when engine is running.

Do not smoke or use an open flame in the vicinity of the generator set or

fuel tank.

Do not permit smoking, open flame, or sparks to occur near the battery,

fuel, cleaning solvents or other flammable substances and explosive

gases.

Do not operate Genset if fuel has been spilled inside or near the unit.

!

WARNING

Electrical Shock -

Do not operate electrical equipment while standing in water, on wet

ground or with wet hands or shoes.

Use extreme caution when working on electrical components. Battery

voltage (12V/24V DC) is present unless the battery cables have been

disconnected. Higher voltage (potentially 480V) is possibly present at all

times.

Always treat electrical circuits as if they were energized.

Disable Start Control before attempting any repair service, disconnect all

leads to electrical power requirements and disconnect battery to prevent

start up.

GROUNDING

!

WARNING

Depending upon your application, it may be MANDATORY to ground this unit to earth or to

NOT ground this unit to earth. Comply with local electrical codes and Operation Manual.

16 22637300

Safety Operation & Maintenance Manual

!

WARNING

The Generator Set can produce high voltages, which can cause severe

injury or death to personnel and damage to equipment. The Generator Set

should have proper internal and external ground when required by the

National Electric Code.

The Generator Set is internally grounded neutral to the frame of the

Generator Set. This internal ground connection is essential for proper

Generator Set performance and personal protection.

External grounding consists of connecting the generator neutral to a

solid earth ground, and is the responsibility of the operator, when

grounding is required by National Electrical Code, Article 250, and other

local codes as applicable. Several methods are employed to externally

ground portable generator sets, depending on the intended use and code

requirements. In all cases, a continuous length of splice-free copper

cable, no smaller than AWG#8, shall be used for the external ground

conductor, when grounding is required.

A qualified, licensed electrical contractor, knowledgeable in local codes,

should be consulted.

The Generator Set has two main applications:

(1) If the Generator Set is supplying electrical power to portable equipment, the vehicle frame

shall NOT be grounded to earth per National Electrical Code, Article 250-34(b). All other

provisions of the Article shall be complied with.

(2) If the Generator Set is connected to a temporary or fixed distribution system (such as a

building), grounding of the vehicle frame is required at the service entrance to the building, per

National Electrical Code, Article 250-20 (b).

If the Generator Set is supplying power to more than one temporary or fixed wiring system, a

separate ground cable must be connected from the generator neutral to each distribution

systems ground as detailed above.

!

WARNING

Failure to properly ground the Generator Set can result in severe injury

or death.

IF USED AS ALTERNATE POWER SUPPLY

Connect only after the main service entrance switch has been DISCONNECTED and

LOCKED OPEN. In addition, circuit overload protection must be provided in accord ance with

National Electrical Codes and local regulations.

22637300 17

Operation & Maintenance Manual Safety

!

WARNING

TOWING -

Do not tow this unit in excess of 65 mph (104 km/hr).

Do not tow this unit with a vehicle whose towing capacity is less than the

gross vehicle weight.

Steps for determining correct load limit -

1. Locate the statement “The weight of cargo should never exceed

xxx kg or xxx lbs” on your vehicle’s placard.

2. This figure equals the available amount of cargo and luggage l oad

capacity.

3. Determine the combined weight of luggage and cargo being loaded

on the vehicle. That weight may not safely exceed the available cargo

and luggage load capacity.

Always make sure the wheels, tires and towbar connectors are in safe

operating condition and tow bar is properly connected before towing.

Chock the wheels of the unit when it is not connected to the tow vehicle.

Do not store or transport material or equipment in or on the unit.

!

WARNING

Drawbar/Hitch Hookup -

Safety chains must be crossed under drawbar and attached to towing

vehicle to prevent drawbar from dropping to ground in event of coupling

failure.

18 22637300

Safety Operation & Maintenance Manual

!

WARNING

If the drawbar is removed from this machine, use new OEM fasteners,

thread locking compound and torque per the tables included in this

manual, when re-installing the drawbar.

!

WARNING

Voltage Selection - Do not turn Voltage Selector Switch while engine is

running. Voltage selection, adjustment and electrical connections shall

be performed only by qualified personnel.

!

CAUTION

Welding -

Prior to any welding, disconnect alternator relays, diagnostic circuit

board, voltage regulator circuit board, meters, circuit breakers and

battery cables. Open all circuit breakers, and remove any external

connections (except grounding rod). Connect the welding ground as

close as possible to the area being welded.

!

WARNING

Electrical Loading -

Never make electrical connections with the unit running.

Before placing the unit in operation, verify the electrical rating of the

Generator Set and do not exceed generator set ratings.

22637300 19

Operation & Maintenance Manual Safety

!

CAUTION

Use extreme care to avoid contacting hot surfaces (engine exhaust

manifold and piping).

HAZARDOUS SUBSTANCE PRECAUTION

Ensure that adequate ventilation of the cooling system and exhaust gases is maintained at all

times.

The following substances are used in the manufacture of this machine and may be hazardous

to health if used incorrectly.

Avoid ingestion, skin contact and breathing fumes for the following substances: Antifreeze,

Engine Lubricating Oil, Preservative Grease, Rust Preventative, Diesel Fuel and Battery

Electrolyte.

The following substances may be produced during the operation of this machine and may be

hazardous to health:

• Avoid build-up of engine exhaust fumes in confined spaces.

• Avoid breathing exhaust fumes.

• Avoid breathing brake lining dust during maintenance.

• Always operate in a well ventilated area.

20 22637300

General Data

22637300 21

Operation & Maintenance Manual General Data

General Data

Unit Model:

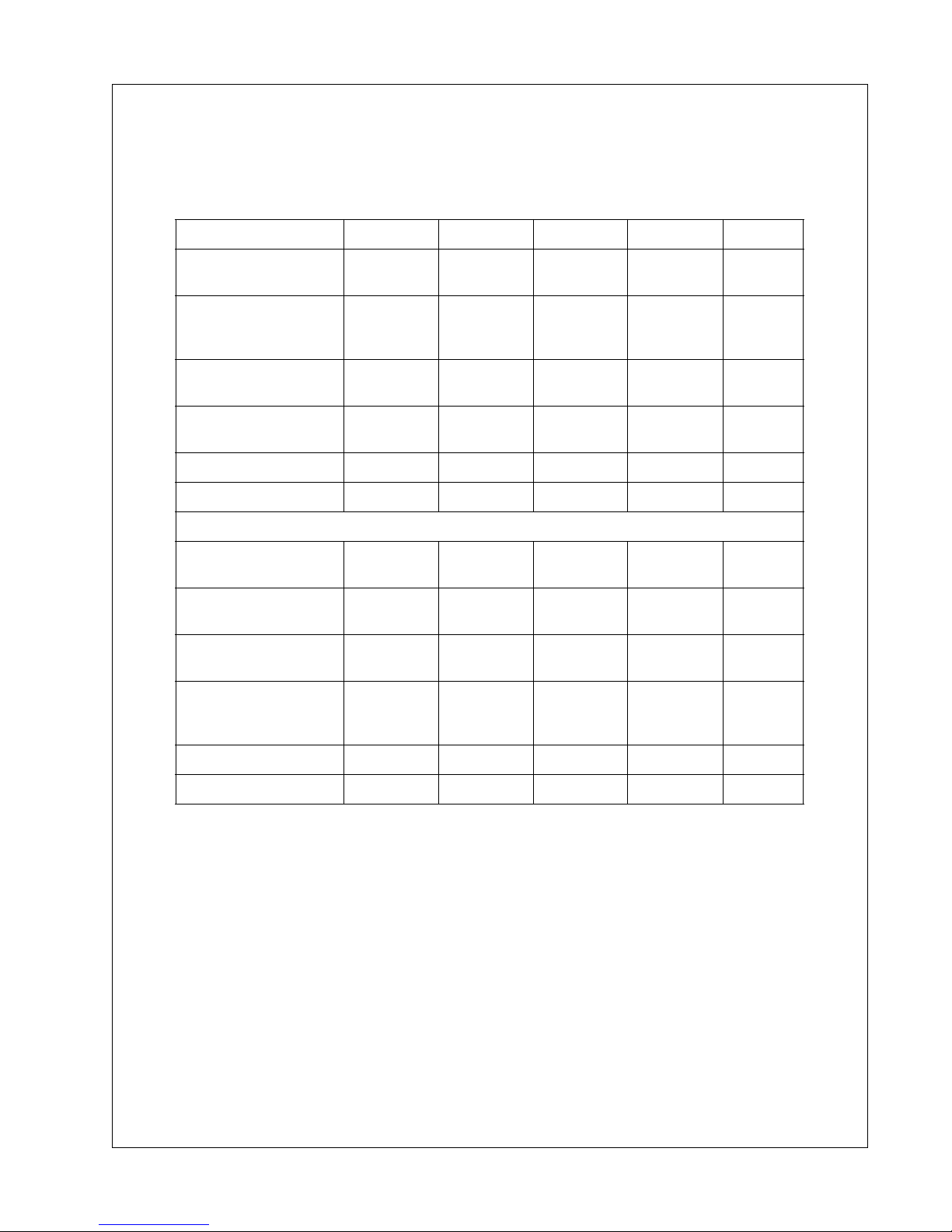

UNIT MODEL G10A G25B, G25C G40B, G40C G60

Engine Speed - RPM 1800 1800 1800 1800

ENGINE Diesel Diesel Diesel Diesel

Manufacturer IR IR IR JD

Model 3IRL2N 4IRQ2N 4IRS2N 5030TF270

FLUID CAPACITIES

Engine Crankcase Lubricant .98 1.7 gal 2.64 gal 2.96 gal

Fuel Tank 21 36 gal 47 gal 103 gal

Radiator & Engine Coolant 2.0 4 gal 5 gal 6 gal

Electrical System 12VDC 12VDC 12VDC 12VDC

RUNNING GEAR

Tire Size ST175/80D13 ST205/75D15 ST205/75D15 ST205/75D15

Inflation Pressure (Cold) 50 psi 50 psi 50 psi 50 psi

Towing Speed (Maximum) 65 mph 65 mph 65 mph 65 mph

UNIT MEASUREMENTS/ WEIGHTS (w/running gear)

Overall length (inches) 121 131 143 156

Overall width (inches) 56 60 66 69

Overall height (inches) 43 67 72 85

Track width (inches) 48 50 56 60

Weight (with fuel) 1708 lbs 2588 lbs 3508 lbs 4658 lbs

Weight (less fuel) 1529 lbs 2420 lbs 3078 lbs 3895 lbs

22 22637300

General Data Operation & Maintenance Manual

Unit Model:

UNIT MODEL G70A G80A G90A G125 G145B G185

Engine Speed - RPM 1800 1800 1800 1800 1800 1800

ENGINE Diesel Diesel Diesel Diesel Diesel Diesel

Manufacturer JD JD JD JD JD JD

Model 4045

TF285E

FLUID CAPACITIES

Engine Crankcase Lubricant 3.57 gal 3.57 gal 3.57 gal 3.57 gal 3.57 gal 8.59 gal

Fuel Tank 103 gal 103 gal 190 gal 145 gal 190 gal 255.3 gal

Engine Coolant Only 6 gal 6 gal 3.1 gal 5.3 gal 3.1 gal 3.1 gal

Electrical System 12VDC 12VDC 12VDC 12VDC 12VDC 12VDC

RUNNING GEAR

Tire Size ST205/

75D15

Inflation Pressure (Cold) 50 PSI 50 PSI 50 PSI 50 psi 50 psi 50 psi

Towing Speed (Maximum) 65 mph 65 mph 65 mph 65 mph 65 mph 65 mph

UNIT MEASUREMENTS/ WEIGHTS (w/running gear)

Overall length (inches) 156 156 165 166 166 204

Overall width (inches) 69 69 71 72 72 76

Overall height (inches) 85 85 84 80 84 95

Track width (inches) 60 60 63 64 63 61.7

4045

TF275

ST205/

75D15

4045

HF285

ST205/

75D15

6068

TF275-123

ST205

75D15

4045

HF485

ST205

75D15

6068

HF285

9.50-16.5

LT/E

Weight (with fuel) 5105 lbs 5174 lbs 6466 lbs 5632 lbs 7220 lbs 9166 lbs

Weight (less fuel) 4435 lbs 4478 lbs 5004 lbs 4518 lbs 5758 lbs 7205 lbs

22637300 23

Operation & Maintenance Manual General Data

Unit Model:

UNIT MODEL G240 G290 G450 G570

Engine Speed - RPM 1800 1800 1800 1800

ENGINE Diesel Diesel

Manufacturer JD Cummins Cummins Cummins

Model 6068HF485 QSL9G3 QSX15 QSX15

FLUID CAPACITIES

Engine Crankcase Lubricant

(gal)

Fuel Tank (gal) 255.3 gal 389.5 gal 652 652

Engine Coolant Only (gal) 3.1 gal 2.91 gal 15 15

Electrical System VDC 12VDC 24VDC 24VDC 24VDC

RUNNING GEAR

Tire Size 9.50-16.5 LT/E 9.50-16.5 LT/E 9.50 -16.5 LT/E 9.50 -16.5 LT/E

Inflation Pressure (Cold) psi 50 PSI 50 PSI 75 75

Towing Speed (Maximum) 65 mph 65 mph 65 mph 65 mph

UNIT MEASUREMENTS/ WEIGHTS

Overall length (in/mm) 204 221 261/6626 261/6626

Overall width (in/mm) 76 78 86/2181 86/2181

Overall height (in/mm) 95 111 120/3042 120/3042

Track width (in/mm) 65 68.5 74/ 74/

Weight (with fuel) lbs 9678 lbs 11,957 lbs 18271 18573

Weight (less fuel) lbs 7717 lbs 8989 lbs 13868 14170

8.59 gal 7 gal 24 24

24 22637300

General Data Operation & Maintenance Manual

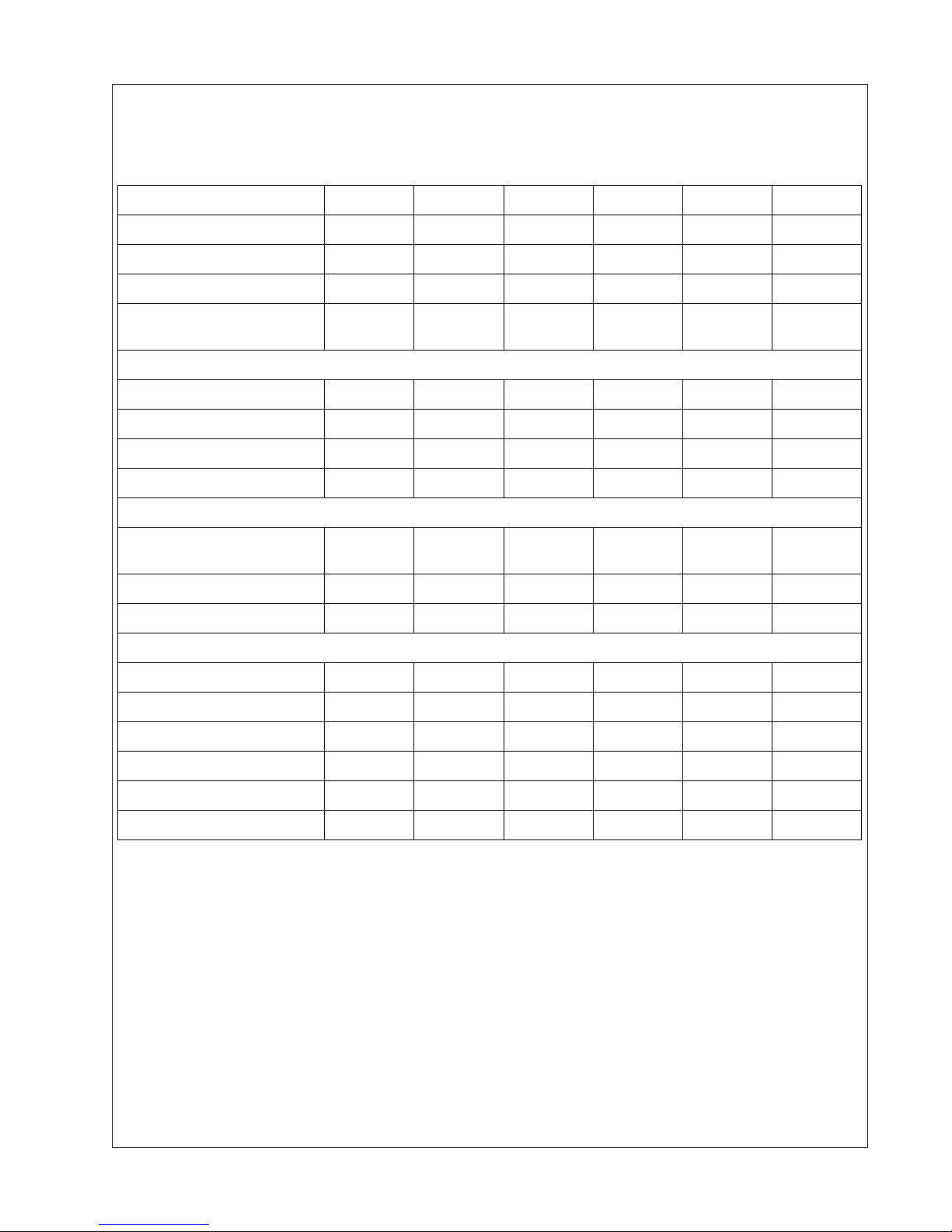

Consumables Service Parts:

For Models: G10A G25B G40B G60 G 70A G80A G125

Air Cleaner Element

(Engine) primary

Air Cleaner Element

(Engine) secondary optional

Engine Oil Filter

Element

Fuel Water Separator

Element

Engine Fuel Element 85426815 85426823 22712475 22556138 22969257 22206197 22206197

Inline Fuel Filter NA NA NA NA NA NA NA

MAINTENANCE KITS

250 hour Maintenance

Kit (without fluids)

250 hour Maintenance

Kit (& engine fluids)

500 hour Maintenance

Kit (without fluids)

500 hour Maintenance

Kit (& Engine fluids

fluids)

36890135 35393685 35393685 54471834 54471834 54471834 54717145

NA NA NA NA 54471842 NA 54717152

85426849 85426856 22712467 22545867 22206148 22206148 22206148

54525530 54525530 54525530 54525530 22969265 54525530 54468178

44003929 44003945 44000404 44003960 44029098 44003986 44003986

44003648 44003663 44000388 44003705 44029072 44003721 44003747

44003937 44003952 44000412 44003978 44029106 44003994 44004000

44003655 44003671 44000396 44003713 44029080 44003739 44003754

Protec Eng Fluid - 5 gal 54480918 54480918 54480918 54480918 54480918 54480918 54480918

Protec Eng Fluid -1 gal 36875938 36875938 36875938 36875938 36875938 36875938 36875938

22637300 25

Operation & Maintenance Manual General Data

Consumable Service Parts:

For Models: G450 G570

Air Cleaner Element

(Engine) primary

Air Cleaner Element

(Engine) secondary optional

Engine Oil Filter

Element

Fuel Water Separator

Element

Engine Fuel Element 54662036 54662036

MAINTENANCE KITS

250 hour Maintenance

Kit (without fluids)

250 hour Maintenance

Kit (& engine fluids)

500 hour Maintenance

Kit (without fluids)

500 hour Maintenance

Kit (& Engine fluids

fluids)

36864361 36864361

36864379 36864379

54662028 54662028

22201396 22201396

44020279 44020295

44020212 44020238

44020287 44020303

44020220 44020246

Protec Eng Fluid - 5 gal 54480918 54480918

Protec Eng Fluid -1 gal 36875938 36875938

26 22637300

General Data Operation & Maintenance Manual

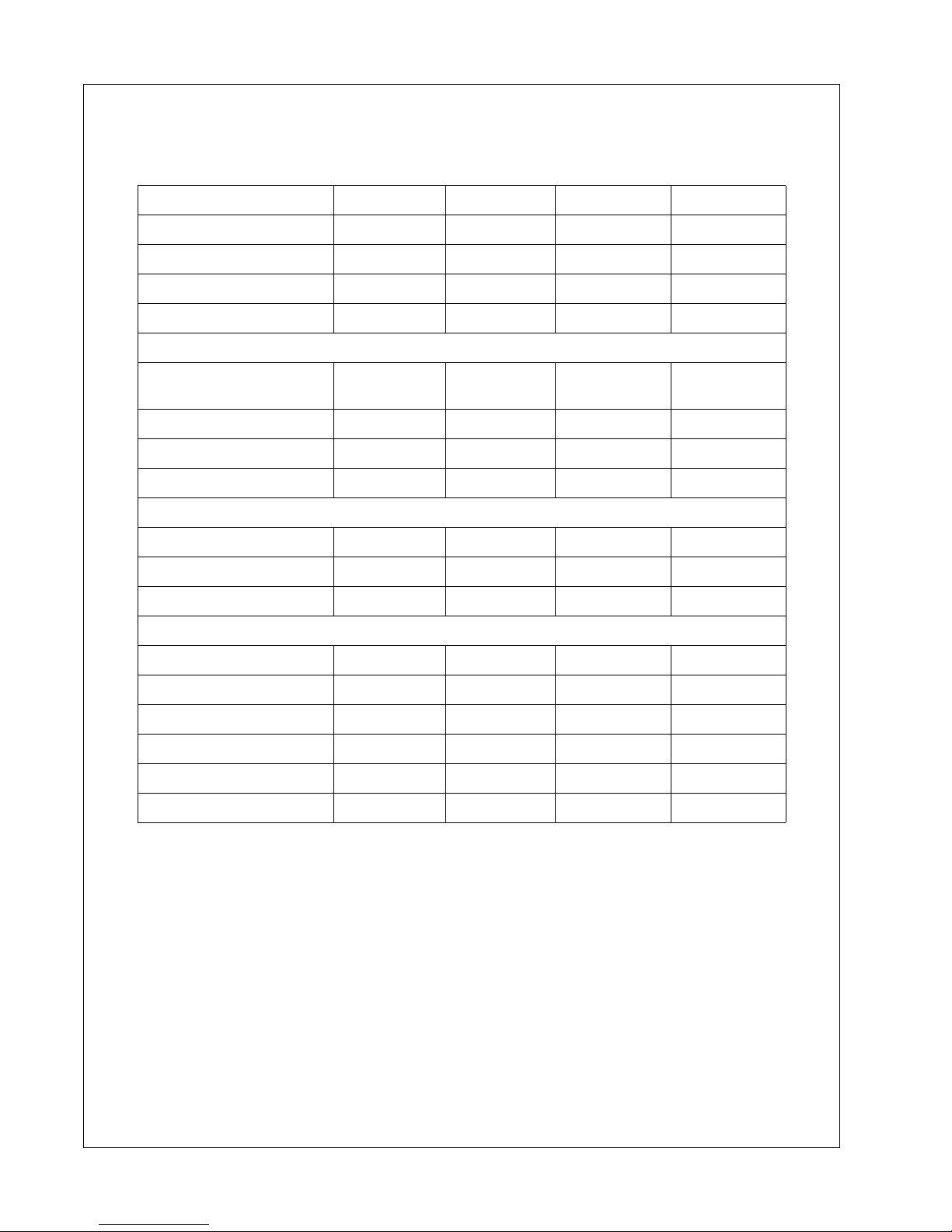

Expendable Service Parts:

For Models: G90A G145B G185 G240 G290

Air Cleaner Element

(Engine) primary

Air Cleaner Element

(Engine) secondary optional

Engine Oil Filter

Element

Fuel Water Separator

Element

Engine Fuel Element 22206197 22 969257 22969257 22969257 22765325

MAINTENANCE KITS

250 hour Maintenance

Kit (without fluids)

250 hour Maintenance

Kit (& engine fluids)

500 hour Maintenance

Kit (without fluids)

500 hour Maintenance

Kit (& Engine fluids

fluids)

54471834 54717145 54717145 22119168 89288971

NA 54717152 54717152 22119176 89288989

22206148 22206148 22206148 22206148 22177737

54525530 22969265 22969265 22969265 22637904

TBD 44016038 44016038 44016038 44020253

TBD 44016004 44016004 44016004 44020196

TBD 44016046 44016046 44016020 44020261

TBD 44016012 44016012 44016053 44020204

Protec Eng Fluid - 5 gal TBD 54480918 54480918 54480918 54480918

Protec Eng Fluid -1 gal TBD 36875938 36875938 36875938 36875938

22637300 27

28 22637300

Operating Instructions

22637300 29

Operation & Maintenance Manual Operating Instructions

Operating Instructions

Never operate unit without first observing all safety warnings and carefully reading the

operation and maintenance manual shipped from the factory with this machine.

BEFORE TOWING

!

WARNING

Failure to follow these instructions can cause severe injury or death.

!

CAUTION

- Position the tow vehicle to align its hitch with the pintle eye or coupler.

- Engage the parking brake and chock the wheels of the tow vehicle.

- Stand to the side and ensure pin is FULLY inserted (secure) in tube of

jack.

- Crank jack to lower pintle eye coupler onto the hitch and to raise foot off

the ground. Pull pin from tube of jack. Fold jack handle down and forward.

Swing up jack tube and FULLY insert pin in tube.

- Connect machine towing lights to tow vehicle.

- Remove chocks from tow vehicle wheels.

Steps for determining correct load limit -

1. Locate the statement “The weight of cargo should never exceed xxx kg or xxx lbs” on

your vehicle’s placard.

2. This figure equals the available amount of cargo and luggage load capacity.

3. Determine the combined weight of luggage and cargo being loaded on the vehicle.

That weight may not safely exceed the available cargo and luggage load capacity.

30 22637300

Operating Instructions Operation & Maintenance Manual

TOWING

!

WARNING

Failure to follow these instructions can cause severe injury or death.

— Ensure that tires, wheels and running gear are in good condition and secure.

— Ensure that tires are inflated to 50 psi.

— Do not tow this unit in excess of 65 mph (104 km/hr).

— Use a tow vehicle whose towing capacity is greater than the gross weight of this unit.

— Adjust hitch to assure machine is level for towing.

SETTING UP

Place the unit in an open, well ventilated area. Position as level as possible. The design of

these units permits a 15 degree limit on out-of-level operation.

When the unit is to be operated out-of-level, it is important to keep the engine crankcase oil

level near the high level mark (with the unit level).

DISCONNECT

— Set the vehicle parking brake. Chock wheels of unit.

— Disconnect machine towing lights from tow vehicle.

— Standing to the side, remove pin from tube of jack. As jack tube swings down, FULLY

insert pin in the tube.

— Disconnect safety chains. Crank jack to raise eye or coupler from hitch. Tow vehicle

can be moved.

22637300 31

Operation & Maintenance Manual Operating Instructions

BEFORE STARTING

1. Ensure load wiring connections are tight.

2. Check for fluid leaks.

3. Check for fluid level in container base.

4. Check engine oil and coolant level.

5. Check proper grounding circuit. Refer to Safety-Grounding.

6. Check for frayed or loose fan belts, hoses or wiring insulation.

7. Check for leaves, paper, debris in air vents.

8. Check Fuel Level. Add CLEAN diesel fuel.

!

WARNING

Do not remove the cap from a HOT engine radiator. The sudden release

of pressure from a heated cooling system can cause severe injury or

death.

32 22637300

Operating Instructions Operation & Maintenance Manual

STARTING (AUTOSTART MODELS)

!

CAUTION

Use the EMERGENCY STOP button ONLY in the event of an emergency.

NEVER use it for normal shut-down.

Verify the following:

1. All external electrical power loads are turned “OFF”.

2. Main Breaker is “OFF”.

3. Battery Disconnect Switch is “ON”.

4. Ensure that both the VOLTAGE SELECTOR (if equipped) and DIRECT HOOKUP Doors are closed:

5. Reset (pull to unlatch) Emergency Stop Button.

6. Push the Engine “START” Button.

7. Wait for preheating if enabled.

!

CAUTION

Do NOT use engine starting fluids.

!

DANGER

POWER is present upon cranking the engine.

!

CAUTION

Allow starter to cool for one minute between start attempts. If engine

does not start after a few attempts, refer to Trouble Shooting Section.

If engine shuts down, diagnostic lamps will indicate the problem. Correct

the problem before continuing.

22637300 33

Operation & Maintenance Manual Operating Instructions

8. Allow the engine to warm-up for 3 to 5 minutes. If the engine stops

unexpectedly, refer to Trouble Shooting Section.

9. Check the CONTROL Panel for proper voltages. No RED diagnostic lamps

should be glowing. Otherwise, shut down the unit and refer to Trouble

Shooting.

10. With main breaker “ON” power is present and available for use.

11. Close side doors for optimum cooling of the unit while running.

STOPPING (AUTOSTART MODELS)

1. Turn off all external electrical power loads.

2. Turn Main Breaker “OFF”.

3. Allow 5 minute cool down.

4. Push Engine “STOP” Button.

5. Wait at least 15 seconds before restarting.

6. Fill fuel tank at end of working day to prevent condensate.

REMOTE STARTING AND STOPPING

1. Connect the remote start contacts (located in the Generator System direct

hookup compartment) to a customer-supplied contact that closes to initiate a

genset start.

2. Push the Autostart Mode Switch to illuminate the Autostart Mode LED on

control panel.

3. When the customer contact closes, a 10-second alarm will sound prior to each

crank cycle until the engine starts. Preheating will also occur if enabled.

4. The engine will stop when the customer-supplied contact opens, and the

controller will return to the Auto Start Mode.

34 22637300

Operating Instructions Operation & Maintenance Manual

DIAGNOSTICS/AUTO SHUTDOWN (AUTOSTART MODELS)

The operating controls and instruments are arranged on the control panel as shown. A

description of each panel device is as follows:

1. High Engine Temperature - Indicates engine shutdown due to high coolant

temperature or low coolant level.

2. Low Engine Oil Pressure - Indicates engine shutdown due to low engine oil

pressure.

3. Low Fuel Level - Indicates engine shutdown due to low fuel level.

4. High Containment Fluid Level - Indicates high level of fluids in the

containment base.

5. Over Crank - Indicates engine did not start after 3 cranks.

6. Battery Not Charging - Indicates battery voltage is low or not being charged.

7. Engine Speed - Indicates engine overspeed.

8. Engine Operating - Indicates engine is cranking or operating.

9. Preheat - Indicates preheating is on.

10. Engine Communication - Indicates the controller has commu nication with the

engine ECU. (N/A for G20-G40).

11. Engine Fault - Indicates that engine service is required. (N/A for G25-G40).

ENGINE CONTROLS and INSTRUMENTS (AUTOSTART MODELS)

12. Engine Start Switch

13. Engine Stop/Reset Switch - Stops engine and resets diagnostics. Also,

awakens controller from sleep mode. Wait 15 seconds for reset to complete

before attempting start.

14. Autostart Mode Switch - Puts engine in Autostart Mode.

15. Autostart Mode - Indicates genset is in Autostart Mode. Note: the controller

will enter low power sleep mode after a short time and all other LED’s will go off.

16. Emergency Stop Switch - Disables running, cranking, and trips main breaker.

17. Alarm Horn - Sounds prior to a start when in Auto Start Mode (not visible)

18. Diagnostic Trouble Code (DTC) Display - Displays engine shutdown and

warning codes, and text messages on electronic ECU engines.

19. Autostart/Stop Controller

20. Hourmeter - Indicates engine run hours.

21. Battery Volts

22. Fuel Level

22637300 35

Operation & Maintenance Manual Operating Instructions

(19)

(20)

(21)

(22)

(18)

36 22637300

Operating Instructions Operation & Maintenance Manual

CUSTOMER - DIAGNOSTIC GAUGE OPERATION

AUTO Mode Any active engine SPN codes are automatically deployed for 3

seconds each.

Auto mode is default on power up.

Press “SPN” for 3 seconds to return to AUTO mode from

MANUAL mode.

“MEM” indicator is on if engine ECU contains stored codes - Go

to “MAN” mode to see codes.

MANUAL Mode Used to see both active and stored engine codes, and to see

additional SPN data (FMI, OC, SRC).

Press “i” or “SPN” for MANUAL mode if in AUTO.

Press “SPN” to advance to the next SPN code.

Press “i” to get additional data on any displayed SPN.

If the “MEM” indicator is lit, then the displayed SPN is a stored

(not active) code.

Unit will return to AUTO mode in 30 seconds.

22637300 37

Operation & Maintenance Manual Operating Instructions

STARTING (KEY START MODELS)

!

CAUTION

Use the EMERGENCY STOP button ONLY in the event of an emergency.

NEVER use it for normal shut-down.

Verify the following:

1. All external electrical power requirements are turned “OFF”.

2. Main Breaker is “OFF”.

3. Battery Disconnect Switch “ON”

4. Ensure both the VOLTAGE SELECTOR (if equipped) and DIRECT HOOK-UP

terminal doors are closed.

5. Reset (pull to unlatch) Emergency Stop Button.

6. Turn the ENGINE START SWITCH to “PREHEAT” for maximum of 10 seconds

for cold weather starts.

7. Turn ENGINE START switch to “START”. Release after engine starts.

!

CAUTION

Do NOT use engine starting fluids.

!

DANGER

POWER is present upon cranking the engine.

38 22637300

Operating Instructions Operation & Maintenance Manual

!

CAUTION

Allow starter to cool for one minute between start attempts. If engine

does not start after a few attempts, refer to Trouble Shooting Section.

If engine shuts down when ENGINE START switch in in the “ON” position,

diagnostic lamps will indicate the problem. Correct the problem before

continuing.

22637300 39

Operation & Maintenance Manual Operating Instructions

1.

1. Allow the engine to warm-up for 3 to 5 minutes. If the engine stops

unexpectedly, refer to Trouble Shooting Section.

2. Check the CONTROL Panel for proper voltages. No RED diagnostic lamps

should be glowing. Otherwise, shut down the unit and refer to Trouble Shooting

Section.

3. With main breaker “ON” power is present and available for use.

4. Close side doors for optimum cooling of the unit while running.

STOPPING (KEYSTART MODELS)

1. Turn off all external electrical power loads.

2. Turn Main Breaker “OFF”.

3. Allow 5 minute cool down.

4. Turn the Engine Start Switch to “OFF”.

5. Fill fuel tank at end of working day to prevent condensate.

DIAGNOSTICS and AUTO SHUTDOWN (KEYSTART MODELS)

On some models, the operating controls and instruments are arranged on the control panel as

shown. A description of each panel device is as follows:

1. High Engine Temperature - Indicates engine shutdown due to high engine

coolant temperature.

2. Low Engine Oil Pressure - Indicates engine shutdown due to low engine oil

pressure.

3. Low Fuel Level - Indicates engine shutdown due to low fuel level.

4. High Containment Fluid Level - Indicates high fluid level in the containment

base.

40 22637300

Operating Instructions Operation & Maintenance Manual

ENGINE CONTROLS and INSTRUMENTS (Keystart Models)

5. Engine Start Switch Positions - PREHEAT, OFF, RUN, START.

6. Emergency Stop- Disables running, cranking, and trips main breaker.

7. Hourmeter - Records operating time.

8. Fuel Level - Indicates fuel level in fuel tank.

9. Voltmeter - Indicates battery charging voltage.

(8)

(7)

22637300 41

Operation & Maintenance Manual Operating Instructions

GENERATOR SYSTEM

METERS

1. AC Volts - Indicates the generator output voltage corresponding to VOLTAGE

OUTPUT MONITOR switch position.

2. AC Amperes - Indicates the generator load in amperes corresponding to

AMPERAGE OUTPUT MONITOR switch position.

3. Hertz - Indicates frequency of generator output.

4. Panel Lamp - Illumination Only.

MONITOR SWITCHES

5. Voltage Output - Selects the line to line (phase) or line to neutral (phase to

neutral) generator voltage to be displayed on the AC Voltmeter.

6. Amperage Output - Selects the line (phase) amperage to be displayed on the

AC Ammeter.

7. Voltage Adjust Rheostat (VAR) - Turn to adjust generator output voltage.

8. Trip Reset Button - Push to reset the overcurrent relay that trips the main

breaker.

42 22637300

Operating Instructions Operation & Maintenance Manual

CIRCUIT BREAKERS - Flip to Reset (if equipped)

9. 20 AMP/120 Volt - (two)

10. 50 AMP/120V/240 Volt (one, two or three)

RECEPTACLES (if equipped)

11. 125 Volt 1 Phase - GFI, straight blade, duplex.

12. 125/250 VOLT 1 Phase - Special “Tempower” Twist Lock, CS-6369.

PROTECTION/REGULATION

13. 3 Phase Direct Hookup Connections - LO, L1, L2, L3,

14. Fuse Holders- Fuses for voltage output selector switch and meter. (not shown)

15. Overcurrent Protection Relay - (not shown) but is located behind reset

button,8.

16. Main Circuit Breaker

17. Alarm Horn - (not shown) but is located on back of control box.

22637300 43

VOLTAGE SELECTION/ADJUSTMENTS G25 thru G185

!

DANGER

This set up procedure shall be performed only by knowledgeable qualifed

persons. Ensure all external electrical connections are disconnected.

Use extreme CAUTION when working on electrical components. Battery

voltage (12V or 24V) is present unless the battery cables are

disconnected. Higher voltage (potentially 480V) is present at all times

when the engine is running.

This Generator Set may be equipped with both panel convenience

receptacles (120 and 240 volts, 1-phase) and direct wiring hook-ups. Any

of the voltages listed below are obtainable by connection to the direct

hook-up terminal block.

NOTICE

Do not hook-up electrical loads until following adjustments have been

completed, otherwise damage to the equipment may result.

SET-UP PROCEDURE

Before starting and making electrical connections:

1. Open the VOLTAGE SELECTOR switch door.

2. Position the VOLTAGE SELECTOR switch to the desired voltage.

3. Close and latch the VOLTAGE SELECTOR switch door.

4. Start the unit per the Operating Section instructions.

!

DANGER

Electric power is present at all times when the Generator Set Engine is

running.

5. Fine tuning of the VOLTAGE ADJUSTMENTS are as follows:

44 22637300

Operating Instructions Operation & Maintenance Manual

SWITCH POSITION - 120/208V 3 Phase

1. Turn Voltage Output Monitor to L1-L2 position.

2. Turn Voltage Adjust Rheostat (VAR) Shaft to read 208V on AC Voltmeter.

3. Turn Voltage Output Monitor to L

4. Turn Voltage Output Monitor to L

5. Power is available on all panel receptacles.

6. Turn Voltage Output Monitor to L

7. Shutdown unit.

8. Make 120/208V connections at the direct hook-up terminal blocks.

9. At start-up, 120/208V will be present.

position and verify 208V ± 5%.

2-L3

position and verify 208V ± 5%.

3-L1

position and verify 120V ± 5%.

1-L0

SWITCH POSITION - 277/480V 3 Phase

1. Turn Voltage Output Monitor to L1-L0 position.

2. Turn Voltage Adjust Rheostat (VAR) Shaft to read 277V on AC Voltmeter.

3. Turn Voltage Output Monitor to L

4. Turn Voltage Output Monitor to L

5. One of the 120V 15A or 20A panel receptacles now has power. The right

duplex receptacle is “not active in 480V mode.”

position and verify 277V ± 5%.

2-L0

position and verify 277V ± 5%.

3-L0

6. Turn Voltage Output Monitor to L

7. Shutdown unit.

8. Make 277/480V connections at the direct hook-up terminal blocks.

9. At start-up, 277/480V will be available at the direct hook-up terminal blocks.

position and verify 480V ± 5%.

1-L2

NOTICE

Applying single-phase loads or receptacle loads when in 3-phase switch

positions can cause unbalanced loading of windings in excess of the

maximum recommended, which may shorten alternator life.

22637300 45

Operation & Maintenance Manual Operating Instructions

SWITCH POSITION - 120/240 1Phase

1. Turn Voltage Output Monitor to L1-L2 position.

2. Turn Voltage Adjust Shaft to read 240V on AC Voltmeter.

!

CAUTION

Do not use L3-L0 due to the likelihood of equipment damage.

3. Turn Voltage Output Monitor to L

4. Turn Voltage Output Monitor to L

5. Power is available on all panel receptacles.

6. Shut down unit.

7. Make 120/240V connections at either the panel receptacles or the direct hookup terminal blocks.

8. At start-up, 120/240V will be present.

It may be necessary to check the voltage at the end of long drop cord and increase the voltage

to compensate for losses.

Voltages required other than those specified above may be adjustable within the following

ranges. Follow the National Electrical Code and Local Codes. DO NOT exceed recommended

voltages output to equipment.

Selector Switch Position Line-Neutral Line - Line

position and verify 120V ± 5%.

1-L0

position and verify 120V ± 5%.

2-L0

Voltage Adjustment Range

L

1-L0

L1-L

2

120/208 110V-140V 190V-240V

277/480 220V-290V 380V-500V

120/240 100V-120V 190V-240V

46 22637300

Operating Instructions Operation & Maintenance Manual

VOLTAGE SELECTION/ADJUSTMENTS G240 thru G570

!

DANGER

This set up procedure shall be performed only by knowledgeable qualifed

persons. Ensure all external electrical connections are disconnected.

Use extreme CAUTION when working on electrical components. Battery

voltage (12V or 24V) is present unless the battery cables are

disconnected. Higher voltage (potentially 480V) is present at all times

when the engine is running.

This Generator Set is equipped with direct wiring hook-ups. Any of the

voltages listed below are obtainable by connection to the direct hook-up

terminal block.

NOTICE

Do not hook-up electrical loads until following adjustments have been

completed, otherwise damage to the equipment may result.

SET-UP PROCEDURE

Before starting and making electrical connections:

1. Remove the top cover on junction box (located on the AC Alternator).

2. Remove all nuts and washers from all the studs in the junction box and position

the copper bars on the studs as seen in figure A for 120/208V AC or figure B

for 277/480V AC.

3. Once bars are in position for the voltage you will need, reinstall nuts and

washers and tighten to 50 ft lbs. and replace cover. Note:

properly installed for either 480V or 208V, it automatically activates the control circuit

Automatic Reconnect Switch located under the busbar.

4. Start the unit per the Operating Section instructions.

When the busbar is

22637300 47

Operation & Maintenance Manual Operating Instructions

Figure A: Connection Chart

Desired Output Voltage 208/240 Output

Busbar Links

T1-T7, T2-T8, T3-T9, T4 to T10, T5 to T11, T6 to T12

T10 to T11 to T12

Figure B:

!

DANGER

Electric power is present at all times when the Generator Set Engine is

running.

5. Fine tuning of the VOLTAGE ADJUSTMENTS are as follows:

48 22637300

Operating Instructions Operation & Maintenance Manual

120/208V 3 Phase

1. Turn Voltage Output Monitor to L1-L2 position.

2. Turn Voltage Adjust Rheostat (VAR) Shaft to read 208V on AC Voltmeter.

3. Turn Voltage Output Monitor to L

4. Turn Voltage Output Monitor to L

5. Turn Voltage Output Monitor to L

position and verify 208V ± 5%.

2-L3

position and verify 208V ± 5%.

3-L1

position and verify 120V ± 5%.

1-L0

6. Shutdown unit.

7. Make 120/208V connections at the direct hook-up terminal blocks.

8. At start-up, 120/208V will be present.

277/480V 3 Phase

1. Turn Voltage Output Monitor to L1-L0 position.

2. Turn Voltage Adjust Rheostat (VAR) Shaft to read 277V on AC Voltmeter.

3. Turn Voltage Output Monitor to L

4. Turn Voltage Output Monitor to L

5. Turn Voltage Output Monitor to L

6. Shutdown unit.

7. Make 277/480V connections at the direct hook-up terminal blocks.

position and verify 277V ± 5%.

2-L0

position and verify 277V ± 5%.

3-L0

position and verify 480V ± 5%.

1-L2

8. At start-up, 277/480V will be available at the direct hook-up terminal blocks.

22637300 49

Operation & Maintenance Manual Operating Instructions

BASIC DIGITAL CONTROLS OPERATION

Overview

Ingersoll Rand's Digital Controller is a comprehensive generator set controlle r that is used as

the primary interface between the operator and the generator set. It provides a high degree of

engine and generator protection. Multiple real-time parameters can also be viewed. The

parameters include, but are not limited to kW, KVA, kVAr, power factor, oil pressure, coolant

temperature, engine speed, and diagnostic history.

50 22637300

Operating Instructions Operation & Maintenance Manual

IDENTIFYING KEYPAD BUTTONS AND INDICATORS

OPERATION BUTTONS

22637300 51

Operation & Maintenance Manual Operating Instructions

Status LED’s

Shutdown - Indicates the generator set has shutdown due to a fault.

Not in Auto - Indicates that the generator set operation mode is not in the automatic position.

Running - Indicates that the generator set is running.

Warning - Indicates that the generator set is operating in a condition outside its normal

operational parameters.

Ready/Auto - Indicates the generator set is ready and is in automatic mode.

Supplying Load - Indicates that the generator set is under load.

52 22637300

Operating Instructions Operation & Maintenance Manual

VIEWING REAL-TIME DATA - ACCESSING THE SCREENS

22637300 53

Operation & Maintenance Manual Operating Instructions

54 22637300

Operating Instructions Operation & Maintenance Manual

22637300 55

Operation & Maintenance Manual Operating Instructions

CHECKING SOFTWARE VERSION/LAMP TEST

To check the software version and to test the operation of the LED's on the control panel,

simultaneously press

ADJUSTING THE CONTRAST ON THE LCD

To adjust the contrast on the LCD display, simultaneously press

56 22637300

Operating Instructions Operation & Maintenance Manual

PARAMETER ADJUSTMENTS VIA KEYPAD

22637300 57

Operation & Maintenance Manual Operating Instructions

SETPOINTS DESCRIPTIONS

BASIC SETTINGS

Gen-Set Name

User defined name, used for the CONTROLLER identification at remote phone or mobile

connection. The Gen-set name is max 14 characters long and has to be entered using Lite

Edit software.

Nomin Power (3ph)

Nominal power of the generator in three phase HI-WYE series connection.

Nomin Current

Nominal current of the generator in three phase LOW-WYE parallel connection.

CT Ratio

The generator set current transformer ratio.

PT Ratio

The generator set potential transformers ratio. PT's are not needed on 480 Volt systems and

below.

Nominal Voltage 1

Line to neutral voltage in LOW-WYE, Parallel connection.

Nominal Voltage 2

Line to neutral voltage in HI-WYE, series connection.

Gear Teeth

Number of teeth on the engine gear for the pick-up. Set to zero, if no pick-up is used. Engine

speed is counted from the generator frequency. Electronic engines get the speed signal from

the engine controller.

Alternator Frequency

Frequency of the battery alternator when the controller stops cranking.

Nominal RPM

The nominal engine speed of the generator set.

Mode [OFF, MAN, AUT]

This is the equivalent of controller "Mode" buttons.

Fault Reset Go to Manual

Enables or Disables return to MAN mode when reset is pushed.

Display Backlight Timeout

The time limit in minutes for the backlight to go off.

58 22637300

Operating Instructions Operation & Maintenance Manual

IL Power OFF

The time limit in minutes for the controller to go to Sleep Mode. The control power is restored

by pushing the Control Power Button for 5 seconds.

Controller ADDR

The setting of the controller address.

RS232 Mode

The communication protocol selection.

Standard = Lite Edit

Modbus = Modbus Protocol

Cummins MB = Cummins Modbus Protocol

ENGINE PARAMETERS

Start RPM

"Firing" speed when controller stops cranking (starter goes OFF).

Starting POil

When reached, controller stops cranking (starter goes OFF). There are three conditions for

stop cranking: Starting RPM, Starting POil and D+ (when enabled). The starter goes off when

any of these conditions are valid.

PreHeat Time

The time delay for preheating after the unit gets the start command. The unit begins to start

after preheating. Select No Preheat with a setting = O. Factory default setting = 10 seconds.

MaxCrank time

Maximum time limit of cranking.

Crank Fail Pause

Pause time between crank attempts.

Crank Attempts

Maximum number of crank attempts.

Idle Time

Idle time delay starts when RPM exceeds Start RPM. Start fail is detected when during idle

state RPM decrease below 2.

22637300 59

Operation & Maintenance Manual Operating Instructions

Min Stability Time

Generator nominal voltage starts being detected after starter is switched off, idle time elapses,

and this time has elapsed.

Max Stability Time

If generator nominal voltage is not stable within the time after starter is OFF and idle time

elapes, then the genset will shutdown. Stability means that voltage and frequency are within

warning setting limits.

Cooling Speed

This function is not used. Reserved for future applications. Factory default setting = NOMINAL.

Cooling Time

Runtime of the unloaded generator set to cool the engine before stop.

After Cool Time

This function is not used. Factory default setting = 0.

Stop Time

When genset stop sequence is initiated, fuel solenoid output cannot activate during this time.

Fuel Solenoid

Determines behavior of the Binary output FUEL SOLENOID.

DIESEL: Output closes together with Binary output STARTER.

The output opens if Emergency stop comes or Cooled generator set is stopped or in pause

between repeated starts.

GAS: Output closes together with Binary output IGNITION if RPM is over the 30 RPM (Fix

value). Output opens after stop command or in pause between repeated start.

Fuel Pull Coil

Time duration that output Fuel Pull Coil is active. This output is used for momentary activation

of a fuel solenoid pull coil.

60 22637300

Operating Instructions Operation & Maintenance Manual

D+ Function

ENABLED: The D+ terminal is used for both functions - "running engine" detection and charge

fail detection.

CHRGFAIL: The D+ terminal is used for charge fail detection only.

DISABLED: The D+ terminal is not used, but still provides flash voltage to battery alternator.

ECU Freq Select

This function is not used. Factory Setting = DEFAULT.

ECU Speed Adjust

This function is not used. Factory Default Setting = O

ENGINE PROTECTION

Eng prot del [s]

During the start of the generator set, some engine protections have to be blocked (e.g. Oil

Pressure). The protections are unblocked after the protection del time. The time starts after

reaching START RPM.

Alarm Horn

Three selections possible:

NONE = Horn only sounds for 10 seconds prior to a start in Auto Mode.

SHUTDOWN = Horn sounds for any shutdown and also for an Autostart.

SD+ WARNING = Horn sounds for any alarm or shutdown and also for an Autostart.

Overspeed

Threshold for overspeed protection.

Wrn Oil Press

Warning threshold for low oil pressure.

Sd Oil Press

Shutdown threshold level low oil pressure.

Oil Press Del

Delay for oil pressure warning/shutdown.

Sd Engine Temp

Shutdown threshold level for high engine coolant temperature.

Wrn Engine Temp

Warning threshold level for high engine coolant temperature.

Wrn Eng Temp Low

Warning threshold level for low engine coolant temperature.

22637300 61

Operation & Maintenance Manual Operating Instructions

Engine Temp Del

Delay for high/low engine coolant temperatures.

Wrn Fuel Level

Warning threshold level for low fuel level.

Sd Fuel Level

Shutdown threshold level for low fuel level.

Fuel Level Del

Delay for low fuel level.

Batt Overvolt

Warning threshold for high battery voltage.

Batt Undervolt

Warning threshold for low battery voltage.

Battvolt del

Delay for low battery voltage alarm.

NextServTime [h]

Counts down when engine running. If reaches zero, an alarm appears.

ALTERNATOR PROTECTION

Overload

Threshold for generator overload (in % of nominal power)

Overload Wrn

Threshold for generator overload warning (in % of nominal power)

Overload del

Delay for generator overload alarm.

Ishort

Shutdown occurs when lshort circuit limit is reached.

Ishort del

Delay for lshort Alarm.

2Inom del

IDMT is "very inverse" generator over current protection. 2Inom del is Reaction time of IDMT

protection for 200% overcurrent Igen = 2* Nominal current.

Curr unbal del

Delay for generator current asymmetry.

62 22637300

Operating Instructions Operation & Maintenance Manual

Gen >V Sd

Shutdown level for generator over voltage. All three phases are checked. Maximum out of

three is used.

Gen >V Wrn

Warning level for generator over voltage. All three phases are checked. Maximum out of three

is used.

Gen <V Sd

Shutdown level for generator under voltage. All three phases are checked. Minimum out of

three is used.

Gen <V Wrn

Warning level for generator under voltage. All three phases are checked. Minimum o ut of three

is used.

Gen V del

Delay for generator under voltage and over voltage alarm.

Volt unbal

Threshold for generator voltage unbalance alarm.

Volt unbal del

Delay for generator voltage unbalance alarm.

Gen >f SD

Shutdown level for generator over frequency.

Gen>f Wrn

Warning level for generator over frequency.

Gen <f Wrn

Warning level for generator under frequency.

Gen <f SD

Shutdown level for generator under frequency.

Gen f del

Delay for generator under frequency and over frequency alarm.

22637300 63

Operation & Maintenance Manual Operating Instructions

DATE/TIME

Time Stamp Per

Fixed time interval when history of all parameters is recorded. Factory Default Setting = 0.

Summer Time Mod

Automatic time adjustment for daylight savings time.

Time

Time of day setting.

Date

Date setting

Timer 1 Repeat

Selection of day/days when exercise Timer 1 will run.

Timer 1 on Time

Selection of time of day when Timer 1 will start the genset.

Timer 1 Duration

Selection of length of run time.

Timer 2 Repeat

Selection of day/days when exercise Timer 2 will run.

Timer 2 on Time

Selection of time of day when Timer 2 will start the genset.

Timer 2 Duration

Selection of length of run time.

64 22637300

Maintenance

22637300 65

Operation & Maintenance Manual Maintenance

Maintenance

!

CAUTION

Any unauthorized modification or failure to maintain this equipment may

make it unsafe and out of factory warranty.

!

WARNING

Before attempting any repair service, disconnect engine battery cables

and all leads to electrical power requirements. Failure to do so can result

in severe personal injury, death or damage to the equipment.

General

In addition to periodic inspections, many of the components in this unit requires periodic

servicing to provide maximum output and performance. Servicing may consist of pre-operation

and post-operation procedures to be performed by the operating or maintenance personnel.

The primary function of preventive maintenance is to prevent failure and consequently, the

need for repair. Preventive maintenance is the easiest and the least expensive type of

maintenance. Maintaining your unit and keeping it clean at all times will facilitate servicing.

Scheduled Maintenance

The maintenance schedule is based on normal operation of the unit. In the event unusual

environmental operating conditions exist, the schedule should be adjusted accordingly.

Wiring Routing Clamps

Daily check for loose wire routing clamps. Clamps must be secure and properly mounted. Also

check wiring for wear, deterioration and vibration abrasion.

Electrical Terminals

Check daily for evidence of arcing around electrical terminals.

Grounding Circuit

Daily check that the grounding circuit is in accordance with the National Electrical Code Article

250-122 and the local code requirements. As a minimum, the copper wire size should be

American Wire Gauge 8 (AWG#8) from the grounding terminal, frame, generator and engine

block.

66 22637300

Maintenance Operation & Maintenance Manual

Hoses

Each month it is recommended that the intake hoses from the air cleaner and all flexible hoses

used for water and fuel be inspected for the following:

1. All rubber hose joints and the screw type hose clamps must be tight and the

hoses showing no signs of wear, abrasion or deterioration.

2. All flexible hoses must be free of wear, deterioration and vibration abrasion.

Routing clamps must be secure and properly mounted.

Wiring Insulation

Daily check for loose, or frayed wiring insulation or sleeving.

Fuel/Water Separator

Daily check for water in the fuel filter/water separator unit. Some engines have a translucent

bowl for visual indication, and others have a drain valve below the primary element.

Every six months or 500 hours, or less if fuel is of poor quality or contaminated, replace the

bowl elements(s).

Air Vents

Daily clean the air vents of any obstruction or debris.

Air Cleaner

Proper maintenance of the air cleaner provides maximum protection against airborne dust.

Squeeze the rubber valve (precleaner dirt dump periodically to ensure that it is not clogged).

To service the air cleaners, proceed as follows:

1. Remove filter element.

2. Inspect air cleaner housing for any condition that might cause a leak and

correct as necessary.

3. Wipe inside of air cleaner housing with a clean, damp cloth to remove any dirt

accumulation. This will permit better seal for gasket on filter element.

4. Install element.

The air cleaner assembly (housing) should be inspected every 3 months or 500 hours for any

leakage paths.

Note: Make sure the inlet is free from obstruction.

Make sure the air cleaner mounting bolts and clamps are tight and the air cleaner is mounted

securely. Check the air cleaner housing for dents or damage to the cleaner, which could le ad

to a leak.

22637300 67

Operation & Maintenance Manual Maintenance

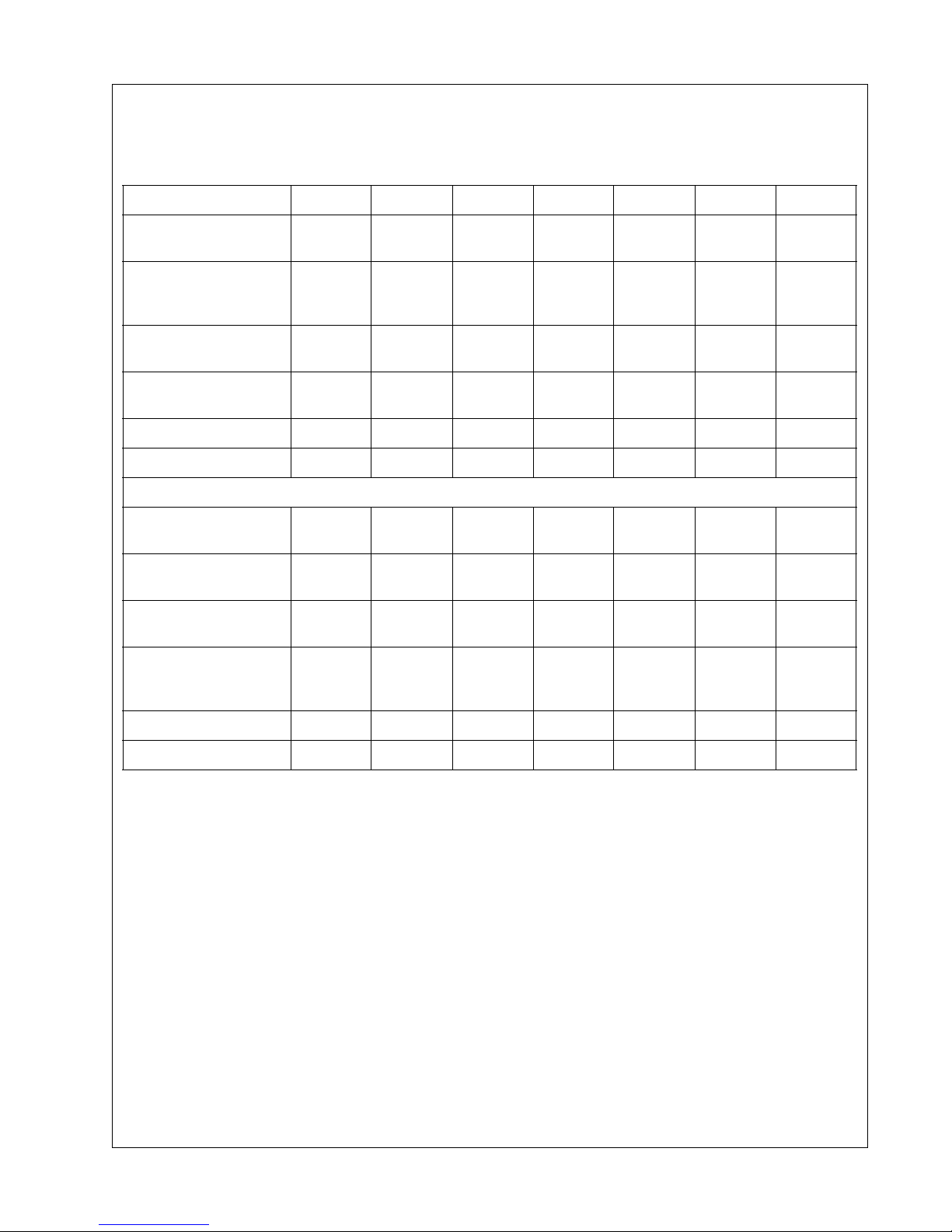

Fasteners

(See following inch torque chart, metric torque chart and wheel torque chart). All fasteners

should be torqued in accordance to size and grade.

Torque Chart

68 22637300

Maintenance Operation & Maintenance Manual

Wheel Torque Chart

M12 Bolts Torque (Ft-Lbs)

13” wheel 60-70

1/2" lug nuts

13” wheel 80-90

15” wheel 105-115

16” wheel 105-115

16.5 wheel 105-115

5/8" lug nuts

16” wheel 190-210

17.5 wheel 190-210

Tires

Weekly check the condition of the tires, and gauge the air pressure. Tires that have cuts or

cracks or little tread should be repaired or replaced.

Engine Radiator

Check the coolant level in the radiator. The coolant must cover the tubes in the top tank

(approximately 1 inch high on a clean measuring rod, stuck down filler neck).

!

WARNING

Remove cap slowly to relieve pressure from HOT radiator. Protect skin

and eyes. Hot water or steam and chemical additives can cause serious

personal injury.

The engine coolant system is normally filled with a 50/50 mixture of water and ethylene glycol.

This permanent type anti-freeze contains rust inhibitors and provides protection to -35°F (37°C). The use of such a mixture is recommended for both summer and winter operation.

When using water alone, be sure to add a reputable bra nd of rust inhibitor to prevent internal

corrosion.

It is recommended to test the freezing protection of the coolant every six months or prior to

freezing temperatures. Replenish with a fresh mixture every twelve months.

Each month, inspect the radiator exterior for obstructions, dirt and debris. If present, blow

water or compressed air containing a non-flammable solvent between the fins in a direction

opposite the normal air flow. Should the radiator be clogged internally, reverse flushing, using

a commercial product and the supplier’s recommended procedure, may correct the problem.

22637300 69

Operation & Maintenance Manual Maintenance

Diagnostic Lamps

On Keystart models, each month the diagnostic lamps should be tested. With unit shutdown

and emergency stop pushed, turn the Engine Start Switch to “START”, or pull the ESTOP to

apply power to the controller. All diagnostic lamps should glow; If not, refer to troubleshooting.

Diagnostic Trouble Code (DTC) Display

On models with Electronic (ECU) engines, each month, the DTC display should be tested.

When unit is started, the DTC Display should show dashes (----) or a trouble code if there is a

fault condition.

Emergency Stop Switch

Each month, check the operation of the emergency stop switch. Running with no electrical

loads and the main breaker “ON”, press the EMERGENCY STOP SWITCH. The unit should

shutdown immediately and the main breaker should trip with cranking disabled. Emergency

Stop Switch must be reset (pull to unlatch) for operation.

Voltage Selector Door Interlock Switch

Every three months or 250 operating hours, the interlock switch should be checked. Runnin g

with no electric load, open the VOLTAGE SELECTOR door. This will shutdown the engine and

trip the main breaker. To reset, close the door.

Engine Protection Shutdown System

The operation of the engine protection shutdown system should be checked, whenever it

appears not to be operating properly. The three devices involved in this protective shutdown

system are the engine coolant high temperature switch/sensor, the engine oil pressure switch/

sensor and the low fuel switch.

The engine oil pressure switch/sensor prevents the engine from operating with low oil

pressure. Once a month, remove a wire from the engine oil pressure switch/sensor to check

the shutdown system for proper operation. Do the same for the wire on the engin e temperature

switch/sensor.

High Containment Fluid Alarm System

The operation of the high containment fluid alarm system should be checked every 3 months

or whenever it appears not to be operating properly.

The level switch is located at the lower end of a pipe at the bottom of the containment tank.

Test the switch by unfastening the u-bolts holding the pipe, and then inverting the pipe to allow

the switch float to fall.

The “High Containment Level” LED should illuminate. Replace any defective switch.

Drain the containment area using the drain plug at either end of the containment basin.

70 22637300

Maintenance Operation & Maintenance Manual

ADJUSTMENT INSTRUCTIONS and TESTING PROCEDURES

ACCESSING COMPARTMENT

1. Disconnect all electrical loads to the unit.

!

DANGER

High Voltage is present in alternator and control compartments when

engine is running. Battery voltage is present whenever battery is

connected.

2. With engine stopped, remove the plate on the left side or front of the alternator

junction box.

VOLTAGE REGULATOR ADJUSTMENT

Refer to ACCESSING COMPARTMENT Section and Figure 8-1 for locations.

1. With all electric loads disconnected, engine stopped and main breaker turned

on, turn VOLTAGE SELECTOR Switch to 277/480V position, and close and

latch the VSS door.

2. Adjust “Voltage” POT(P2) on regulator to full counterclockwise position.

3. Adjust “Voltage” POT on control panel

4. Start unit.

5. Verify generator frequency to 62-63 Hz at no load on G10 - G40, 60-60.5 Hz on

G60 - G570.

6. Set the VOLTAGE OUTPUT MONITOR switch on the control panel to L

position.

7. Adjust “VOLTAGE” POT(P2) on the regulator to read 500V on AC voltmeter.

8. Adjust “Stability” POT(P3) counter clockwise until the AC volts within ± 1 volt.

Then turn the adjusting “Stability” POT (P3) some 5-10 degrees clockwise.

9. Adjust “Voltage” POT on control panel to read 480V on AC voltmeter.

10. Stop Generator Set.

to full clockwise position.

1-L2

11. Check the range in each VOLTAGE SELECTOR switch position (120/208, 120/

240 and 277/480).

22637300 71

Operation & Maintenance Manual Maintenance

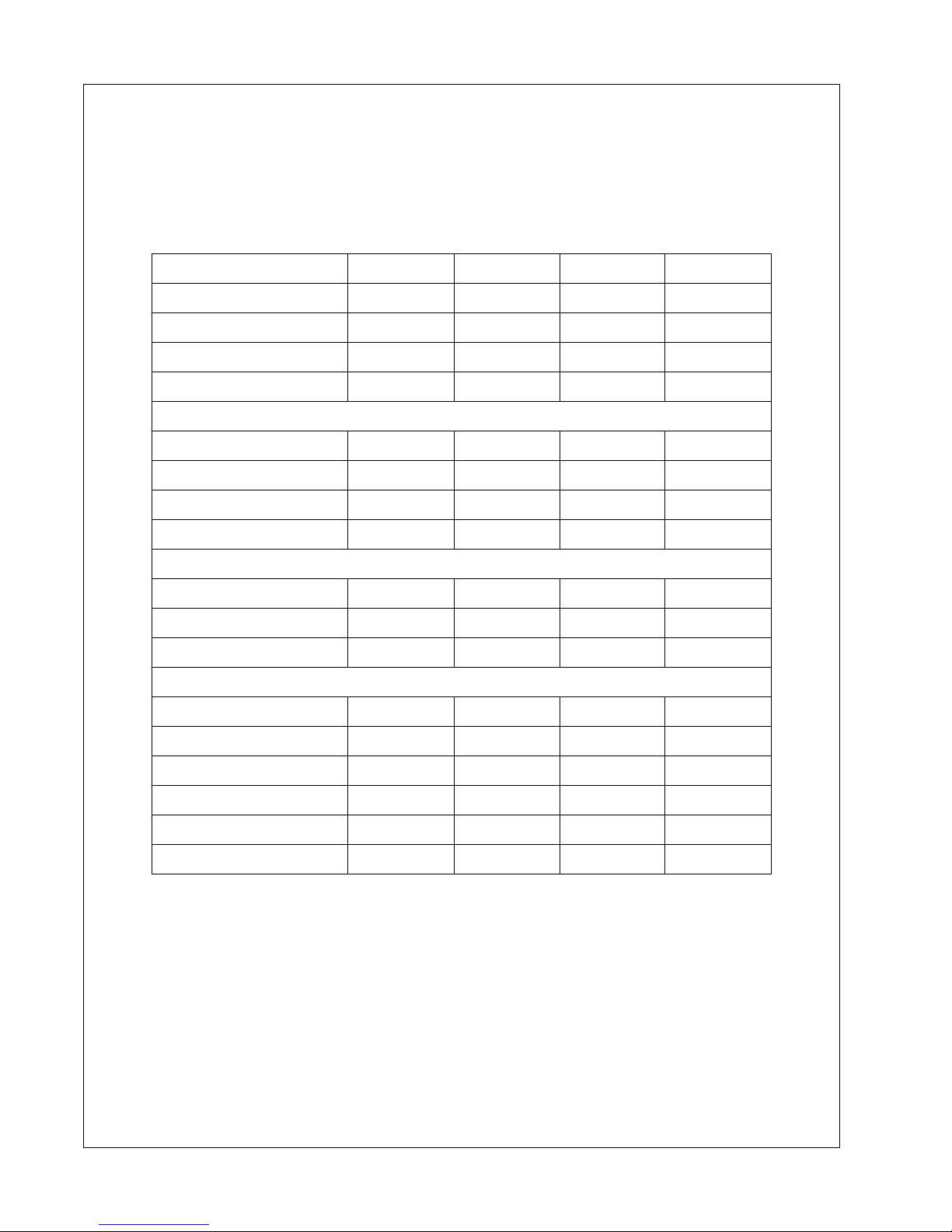

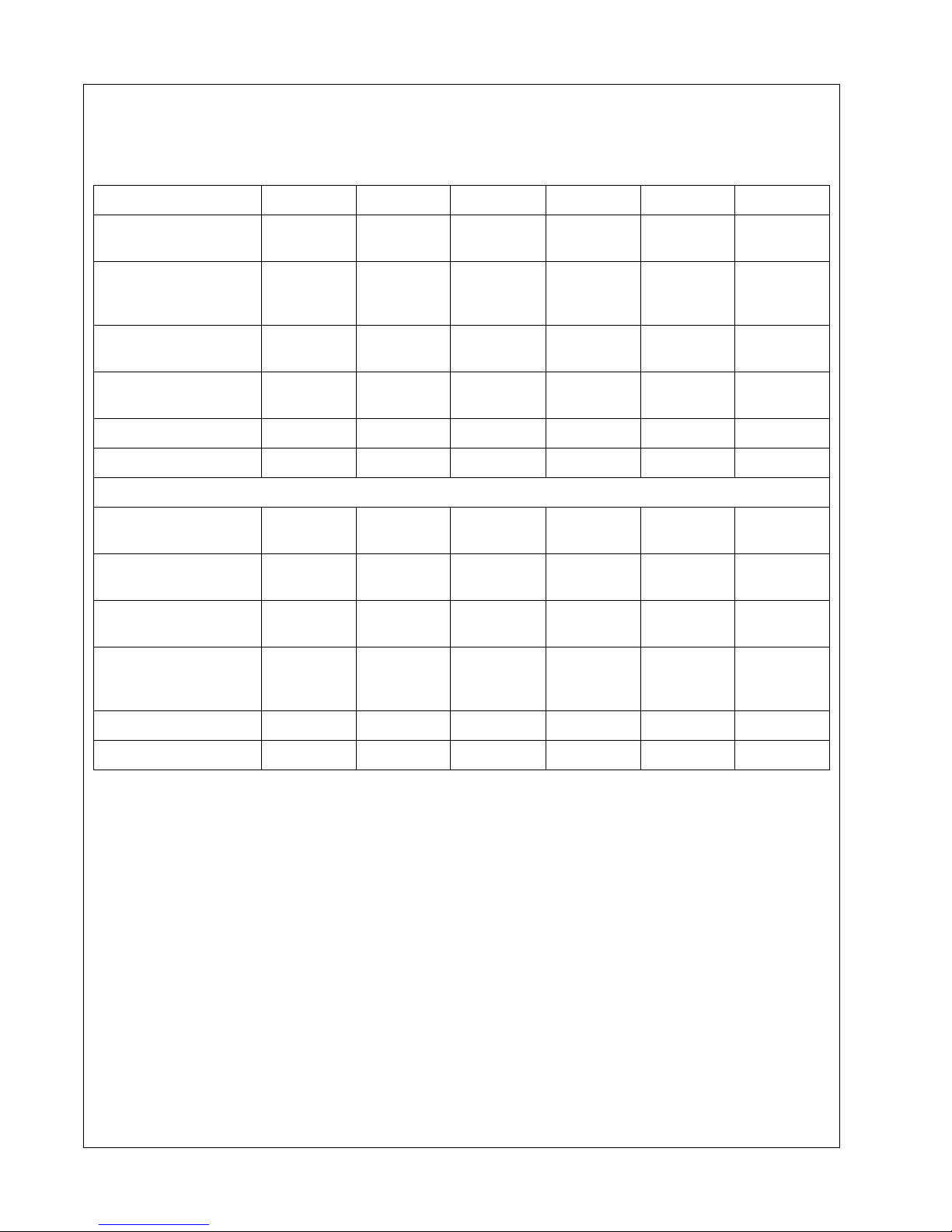

OVERCURRENT RELAY ADJUSTMENT (Set Dial on the OCR Relay)

Overcurrent Relay Adjustment

KVa

25 2.1 34

40 2.3 47

60 1.9 77

70 1.9 96

80 2.2 109

90 2.4 124

125 2.1 165

145 2.4 190

185 2.0 242

240 2.0 314

290 1.9 384

315 2.1 415

450 2.0 603

Setting ±

0.1

AMPS

570 2.4 754

72 22637300

Maintenance Operation & Maintenance Manual

POWER BYPASS SWITCH FOR ENGINE ECU SERVICE

Push the Power Bypass Switch to temporarily apply power to the engine ECU during engine

computer diagnostics on a stopped engine. The switch is located on the side of the engine next

to the Can Bus diagnostic connector.

22637300 73

PACKAGE PREVENTIVE MAINTENANCE SCHEDULE

Daily Weekly Mon.

Evidence of Arcing around electrical terminals C

Loose Wire Routing Clamps C

Engine Oil and Coolant Level C

Proper Grounding Circuit C

Instruments C

Frayed/Loose Fan belts, hoses, wiring insulation C

Fuel/Water Separator drain

Precleaner Dumps C

Tires C

Battery Connections C

Engine Radiator (exterior) C

Air Intake Hoses and Flexible Hoses C

Fasteners (tighten) C

Emergency Stop Switch Operation C

Engine Protection Shutdown System C

Diagnostic Lamps C

Voltage Selector/Interlock Switches C

3 Mon.

250 hrs

6 Mon.

500 hrs

12 Mon.

1000 hrs

High Containment Fluid Alarm System C

Air Cleaner Housing C

Control Compartment (Interior) C

Fuel Tank (fill at end of each day) drain

Fuel/Water Separator Element R

Wheel Bearings & Grease Seals repack

Engine Shutdown System Switches (setting) C

Exterior Finish As needed

Engine Refer to Engine Operation Section

Decals Replace decals if removed, damaged or missing

C = Check (and adjust or replace if necessary)

WI = OR when indicated

R = Replace

Unit: Hours:

Date: Serviceman:

74 22637300

Alternator Inst allation and

Maintenance

22637300 75

Operation & Maintenance Manual Alternator Installation and Maintenance

Leroy Somer Alternator LSA 42.2/43.2/44.2/46.2/47.2

- 4 POLE

This section concerns the alternator used in the generator set, which you have ju st purchased.

We wish to draw your attention to the contents of this maintenance section. By following

certain important points during installation, use and servicing of your alternator, you can look

forward to many years of trouble-free operation.

Our alternators comply with most international standards and are compatible with:

• The recommendations of the International Electrotechnical Commission IEC 34-1,

(EN60034).

• The recommendation of the International Standards Organization ISO 8528.

• The European Community directive on Electromagnetic Compatibility (EMC) 89/336/

EEC).

• The European Community directives 73/23/EEC and 93/68/EEC (Low Voltage

Directive).

The are CE marked with regard to the LVD (Low Voltage Directive) in the ir role as a machine

component. A declaration of incorporation can be supplied on request.

SAFETY MEASURES

Before using your machine for the first time, it is important to read the whole of this installation

and maintenance manual.

All necessary operations and interventions on this machine must be performed by a qualified

technician.

Our technical support service will be pleased to provide any additional infomation you may

require.

The various operations described in this manual are accompanied by recommendations or

symbols to alert the user to potential risk of accident. It is vital that you understand and take

notice of the different warning symbols used.

!

CAUTION

Warning symbol for an operation capable of damaging or destroying the

machine or surrounding equipment.

76 22637300

Alternator Installation and Maintenance Operation & Maintenance Manual

!

WARNING

Safety symbol for an operation capable of damaging or destroying the

machine or surrounding equipment or danger to personnel.

Safety symbol for electrical danger to personnel.

Identification

The alternator is identified by means of a nameplate glued to the frame. Make sure that the

nameplate on the machine conforms to your order. The machine name is defined according

to various criteria (see below).

Example of description: LSA 43.2 M45 J6/4

• LSA: Name used in the PARTNER range

•M: Marine

• C: Cogeneration

• T: Telecommunications

• 43.2: Machine Type

• M45: Model

• J: Excitation System (C: AREP/J: SHUNT or PMG/E: COMPOUND)

• 6/4: Winding number/number of poles

22637300 77

Operation & Maintenance Manual Alternator Installation and Maintenance

Nameplate

So that you can identify your machine quickly and accurately, we suggest you fill in its

specifications on the nameplate below.

Voltage Regulation - AREP System with R438 AVR (42.2, 43.2, 44.2), R448 (46.2, 47.2)

AREP Excitation System

With AREP excitation, the R438 electronic AVR is

powered by two auxiliary windings which are

independent of the voltage sensing circuit. The

first winding has a voltage in proportion to that of

the alternator (shunt characteristic), the second

has a voltage in proportion to the stator current

(compound characteristic: booster effect). The

power supply voltage is rectified and filtered

before being used by the AVR monitoring

transistor. This principle ensures that regulation is

not affected by distortions generated by the load.

78 22637300

Alternator Installation and Maintenance Operation & Maintenance Manual

R 438 or R448 Regulator

• Short-circuit current = 3 x IN for 10 seconds

• Standard power supply; 2 auxiliary windings

• Shunt power supply; max 150V -50/60 Hz

• Rated overload current: 8A-10S (R448: 10A-10S)

• Electronic protection (overload, short-circuit opening on voltage detection): excitation

ceiling current for 10 seconds then return to approx. 1A

The alternator must be stopped (or the power switched off) in order to reset the

protection.

• Fuse F1 on input side (X1, X2)

• Voltage detection: 5 VA isolated via transformer. 0-110V terminals = 95 to 140V, 0220V terminals = 170 to 260V, 0-380V terminals = 340 to 520V

• Voltage regulation ± 1% (R448: ± 0.5%)

• Rapid or normal response time via strap ST2

• Voltage adjustment via potentiometer P2. Other voltages via step down transformer.

• Current detection: (parallel operation): C.T. 2.5VA cl1, secondary 1A (Option)

• Quadrature droop adjustment via potentiometer P1