Page 1

FDDornetic'

GENERATOR

SET

MODEL

Kwyatt

4

&

7

SEB/ICE OFFICE

The

Dometic

Corp.

509

So.

Poplat

St

LaGrange,

lN

46761

Form No. 3102650.003

11/89

@1989

The Oomelic

Corp.

LaGrange,

lN 46761

OPERATING

INSTRUCTIONS

Please

give

this Manualto

the

Customer

along

with

the

lnstallation

Manual.

MODEL

KVNTATT

4.101

& 7.101

Page 2

Please

read this

Operator's

Manual

carefully so that

you

may enjoy

trouble-free,

safe

operation of

your generator

set.

TABLE

OFCONTENTS

External View of Generator Set

Caution Tips to Prevent Troubles

Table of

Generator Set Specifications

After-Sales Service

Pre-Work

lnspection.

Checking

Procedure

Engine Oil Level;

Deterioration & Leakage;

Governor

Oil Level

& Deterioration; Coolant Level

& Dirty

Condition; Coolant Leakage

from Cooling System;

Easiness

of Engine Starting;

Abnormal Noise from

Engine;

Exhaust

Gas Conditions; Fuel

Level; Fuel Leakage;

Cleaning

of Spark Arrester; Clogged Radiator

Core;

and Installation

Condition of Radiator

Cap.

General Service

Caution

Tips for Service; Engine

Oil Replenishment;

Engine Oil Change;

Governor Oil Replenishment;

Governor

Oil Change;

Coolant Replenishment;

Coolant Change;

Tightening of Banery

Terminals & Cleaning;

Battery

Water Replenishment,

Air Cleaner

Element Cleaning

&

Replenishment,

Oil Filter Element Replacement,

Fuel

Fiher

Replacement,

and Cleaning lnside of

Radiator

Protective

Storage

Periods

of Time

Measures

for Long

Service Data

3

4-6

B

8

Generator

Set Control System

Starting Engine

8-9

Main Switch,

Start/Stop Switch; Starting; Check

after Starting,

Stopping; Instruments and

Consuming Power; Intake

Air Switching Lever

Periodical

Maintenance Service

9-10

-tl

12-14

14-19

19

19

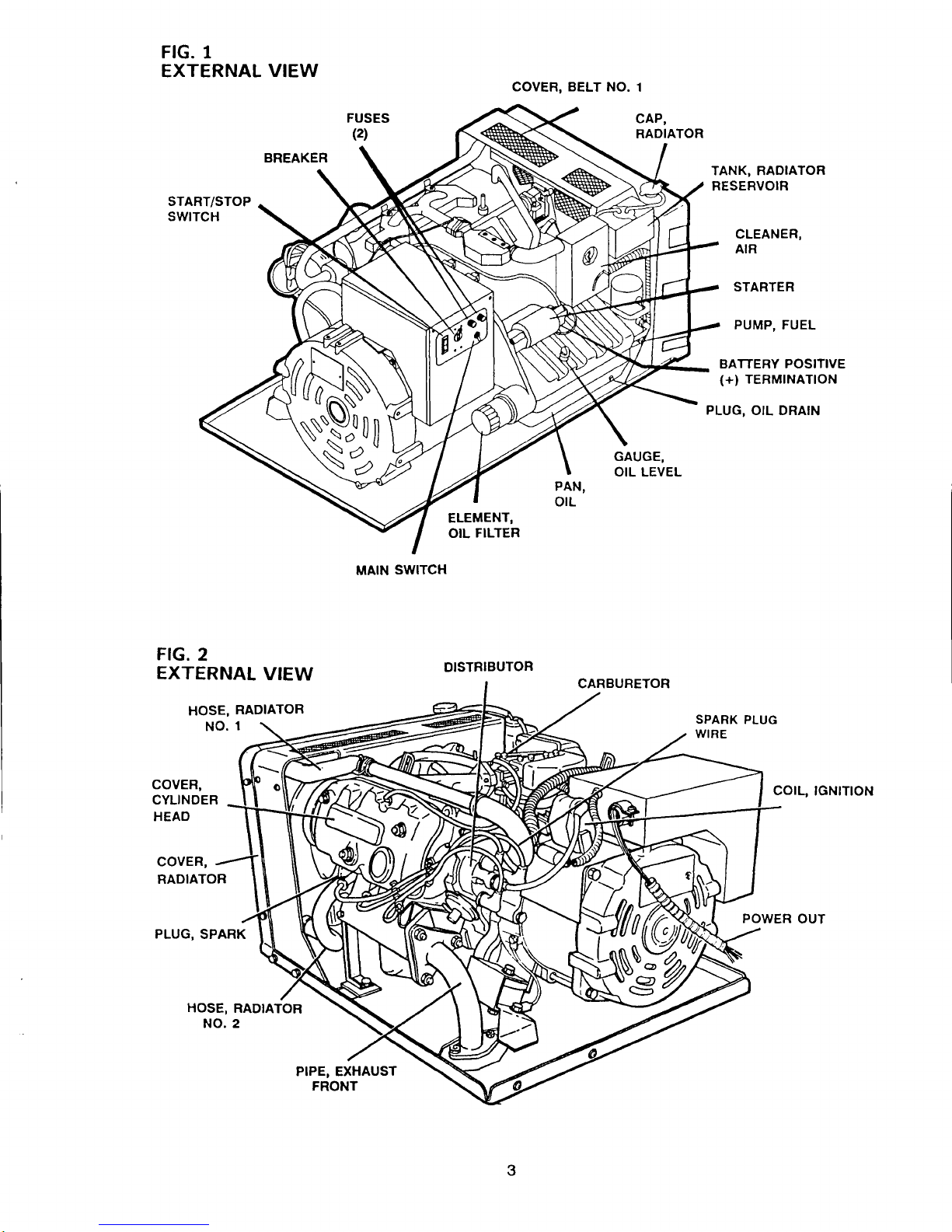

Page 3

N

Sz

COVER, BELT NO.

1

MAIN

SWITCH

FIG.

1

EXTERNAL

VIEW

START/STOP

swtTcH

FIG.

2

EXTERNAL

VIEW

HOSE,

RADIATOR

No.

1

covER,

CYLINDER

HEAD

COVER,

RADIATOR

PLUG,

SPARK

HOSE,

RADIATOR

NO.2

ELEMENT,

OIL

FILTER

DISTRIBUTOR

cAP,

RADIATOR

CARBURETOR

TANK, RADIATOR

FESERVOIR

CLEANER,

AIR

STARTER

PUMP, FUEL

BATTERY POSITIVE

(+)

TERMINATION

PLUG,

OIL DRAIN

cotL,

lGNtTloN

POWER

OUT

GAUGE,

OIL LEVEL

SPARK

PLUG

WIRE

PIPE, EXHAUST

FRONT

3

*fii

Page 4

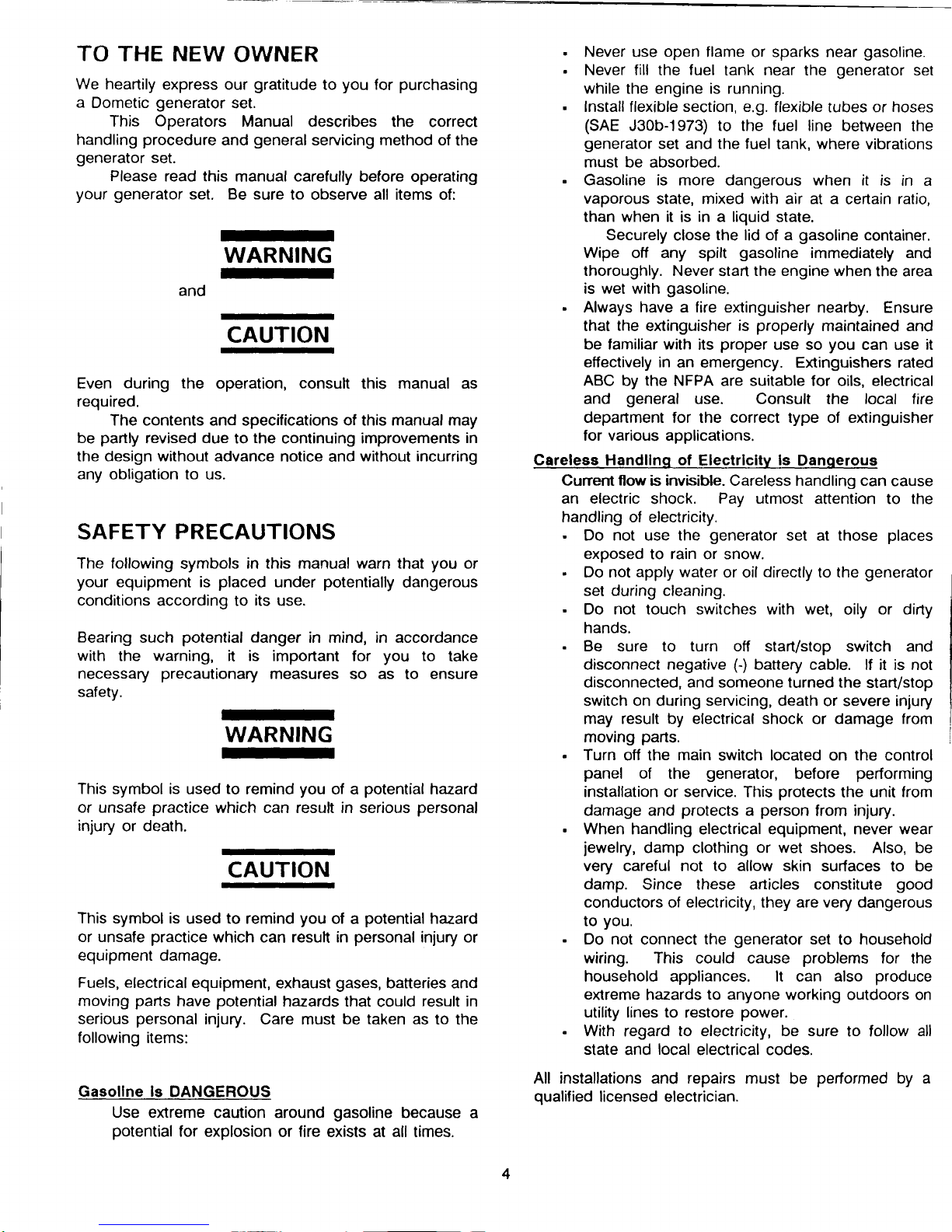

TO

THE NEW

OWNER

We heartily

express our

gratitude

to

you

for

purchasing

a

Dometic

generator

set.

This

Operators

Manual describes

the correct

handling

procedure

and

general

servicing method of

the

generator

set.

Please

read this

manual

carefully

before operating

your generator

set. Be sure

to observe all items of:

-

WARNING

-

and

CAUTION

Even

during the

operation, consult this manual as

required.

The contents and specifications of this manual may

be

partly

revised

due

to

the

continuing improvements

in

the design

without

advance

notice and

without incurring

any

obligation

to

us.

SAFETY

PRECAUTIONS

The following

symbols

in this

manual

warn that

you

or

your

equipment is

placed

under

potentially

dangerous

conditions

according to

its

use.

Bearing

such

potential

danger

in mind, in accordance

with the warning, it is important

for

you

to

take

necessary

precautionary

measures

so

as

to

ensure

safety.

'l-

WARNING

-

This

symbol is used

to

remind

you

of a

potential

hazard

or unsafe

practice

which can result in serious

personal

injury

or death.

CAUTION

This symbol is

used to remind

you

of

a

potential

hazard

or unsafe

practice

which can resuh in

personal

injury or

equipment damage.

Fuels, electrical

equipment,

exhaust

gases,

batteries and

moving

parts

have

potential

hazards that

could

result

in

serious

personal

injury. Care must

be taken

as to the

following

items:

Gasollne ls

DANGEROUS

Use extreme

caution around

gasoline

because

a

potential

for explosion

or

fire

exists at all times.

Never use

open

flame or sparks near

gasoline.

Never

fill the fuel

tank near the

generator

set

while the engine is running.

Install flexible section, e.g.

flexible tubes or hoses

(SAE

J30b-1973) to the

fuel

line

between the

generator

set and the fuel

tank, where vibrations

must be absorbed.

Gasoline is more dangerous when it

is in a

vaporous

state, mixed with air at a

certain

ratio,

than when it

is

in a liquid

state.

Securely

close

the lid of a

gasoline

container.

Wipe off any spilt

gasoline

immediately and

thoroughly. Never

start

the engine when

the area

is wet with

gasoline.

.

Always have a fire extinguisher

nearby. Ensure

that

the

extinguisher

is

properly

maintained and

be

familiar

with

its

proper

use so

you

can use it

effectively

in an emergency. E).tinguishers rated

ABC by

the

NFPA are suitable for oils, electrical

and

general

use.

Consult

the

local fire

department

for

the correct type of extinguisher

for various applications.

Careless

Handllnq

of

Electrlcitv

ls

Danoerous

Cunent flow is invisible. Careless handling can

cause

an electric

shock.

Pay utmost attention

to the

handling ot electricity.

.

Do not use the

generator

set

at

those

places

exposed

to

rain

or snow.

.

Do not

apply water

or oil

directly

to the

generator

set

during cleaning.

.

Do not touch switches

with

wet,

oily

or dirty

hands.

.

Be sure to turn off

start/stop switch and

disconnect negative

(-)

battery cable.

lf it is not

disconnected, and

someone

turned

the start/stop

switch on during servicing, death

or severe in;ury

may result

by electrical shock

or

damage from

moving

parts.

.

Turn

off the main switch located on the control

panel

of the

generator,

before

performing

installation or service.

This

protects

the unit

from

damage and

protects a person

from

injury.

.

When handling electrical equipment, never wear

jewelry,

damp clothing

or wet

shoes. Also, be

very

careful not

to

allow

skin

surfaces to be

damp. Since these articles constitute

good

conductors

of

electricity, they are very dangerous

to

you.

.

Do not

connect

the

generator

set

to household

wiring. This could cause

problems

for

the

household appliances. lt can also

produce

elilreme

hazards

to anyone

working outdoors on

utility lines to

restore

power.

.

With

regard

to electricity, be sure

to follow

all

state

and

local

electrical codes.

All installations and repairs

must be

performed

by a

qualified

licensed electrician.

Page 5

Exhaust Gasee are Toxlc

Exhaust

gases

include toxic

components such as

carbon

monoxide.

Therefore,

inhaling exhaust

gases

can lead to losing consciousness

or deatlt.

Carbon monoxide is a colorless

and

odorless

gas.

It

will cause the

following toxic symptoms to a

person

inhaling it:

Dizziness, headache,

vomiting, muscular

twitching, weakness,

sleepiness and

throbbing

in

temples.

lf

you

feel one

of

the

toxic

symptoms above,

immediately

go

out

to the fresh

air.

Stop the

generator

set. DO

NOT

operate it until

it

has been checked and necessary

repairs have

been

made.

.

Take adequate measures to

properly

discharge

exhaust

gases

to the

atmosphere.

.

Do

not

operate

the

generator

set where ventilation

is

poor,

close

to

buildings, other RV's, etc.

.

At regular intervals, check the exhaust system

tor

leaks.

.

Do

not

operate the

generator

set

with its exhaust

port

directed to

houses,

passersby,

or livestock.

Keep Flres awav from Batterv

Fire

near the

banery is

extremely dangerous.

Flammable

gases

which vaporize from

the

battery

may

be ignited

or

exploded.

.

Do

not

allow

the

battery to be shorted or sparked.

.

Do not inspect the battery electrolyte level with

open

flame of a

lighter or match. These vapors

can explode.

Do Not Touch Battery Electrolvte

.

Battery acid

contacting

skin will cause severe

burning; and

contact to clothing will

cause damage

to the clothing.

.

lf the

battery electrolyte

gets

in

your

eyes, or on

your

skin, immediately

llush

that area with lots of

water. Consuh a doctor.

Potentlal Danoer Exlsts when Enolne

ls Runnlnq

.

Be sure to operate the

generator

set

with

the

protective

cover installed correctly.

.

Do not bring

your

hands

close

to

the

rotating

parts.

Do not wear

ties,

loose-bodied

jackets,

shirts

and

sleeves during the

operation, for

they may be

caught

in the rotating

parts.

Alwavs Keep Clean

around Generator Set

.

Do

not leave tools, cloth,

etc.,

around the

generator

set.

lf they

are left around the set, they

could

be

thrown during

operation

and strike someone; or

they

could

be

caught

in the rotating

parts,

causing

unit

malfunction.

Fires

may

occur

when

flammable

objects contact

the

hot

exhaust

pipes.

.

Clearly wipe

off

deposits of

grease

and

oil, etc.

Remove all foreign materials to

help maintain a

space

necessary

for the

generator

set and keep it

dry

at all times.

Failure to observe this note

may

cause

overheating

or fires.

Never Open

the Radlator Cap

when

Water Temper-

ature ls stlll hloh.

.

Failure

to observe

the

caution

will

cause

pressurized

vapor or hot

water

to

blow up, resulting in scalding

yourself.

Other Handllnq

Instructlons

.

Never

modify the

generator

set.

.

Do not use the

generator

set for

applications except

for recreational

vehicles.

.

Do not operate

or work on the

generator

set

when

you

are

mentally or

physically

fatigued.

CAUTION

TIPS TO

PREVENT

TROUBLE

GASOLINE AS FUEL

Selectlon

of

Fuel

Gasoline comes in two kinds: unleaded

gasoline

and

leaded

gasoline.

Use wrleaded

easoline.

The use

of

leaded

gasoline

or

other

fuel

additives on

the

market

(not

specified

by the

gasoline

manufacture|

may

adversely affect

lhe

engine, causing engine malfunction

or

dropped

performance.

-

WARNING

-

When refueling, make sure to stop

the

engine. NEVER

permit

any

fire

to

be brought near the refueling site.

CAUTION

Any

luel mixed with water

or

dirt or

poor

grade

luel will

cause

engine trouble

or hard starting. Utmost care

must

be exercised when

handling fuel.

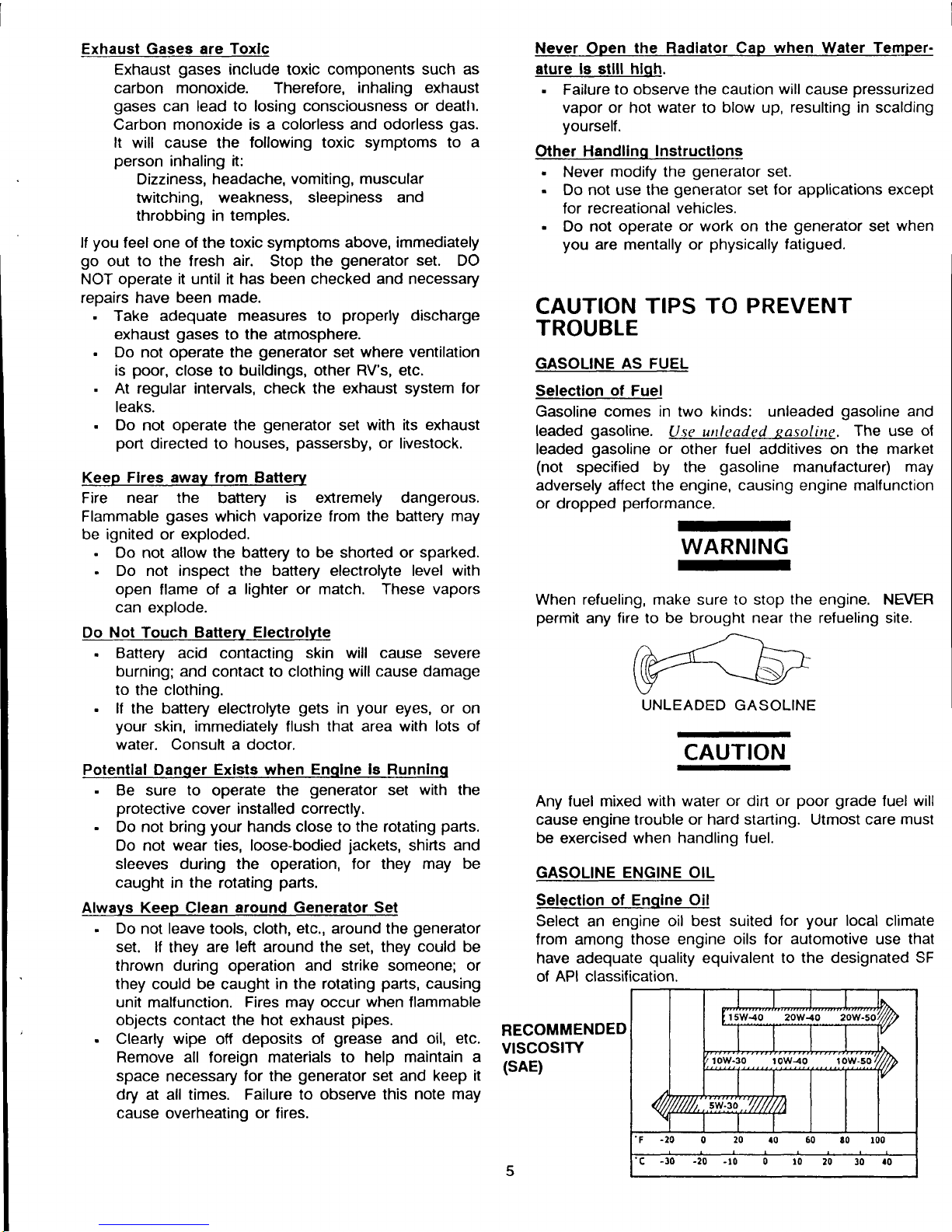

GASOLINE ENGINE OIL

Selectlon of Enqlne

Oil

Select

an

engine oil best suited

for

your

local

climate

from among those

engine oils for automotive use

that

have

adequate

quality

equivalent

to the designated

SF

of API classification.

4

b

h

10w.30

t0w{0 tow-50

n

sw-to

///,

F

-20

0

20

40

60

t0 r00

'c

-30 -20

-r0

0 r0

20 30

.0

RECOMMENOED

vtscoslrY

(sAE)

UNLEADED GASOLINE

Page 6

The

quality

of

gasoline

engine oil bears close

relationship

to

the

engine

performance

and

life.

The

use

of a

poor

grade

oil or an oil

having

viscosity not

suited

to

your

climate may cause hard

starting and/or

premature

wear due to inadequate

lubrication of

various

components,

even

leading

to engine seizure.

CAUTION

1. When the engine

is

pr.rt

into

operation for

a long

period

of

time, engine oil

properties

are bound to

deteriorate as the engine

oil

is exposed to highly

heated components,

or worn

metal

particles,

carbon, water or dust

gets

into

the

engine oil. lt is,

therefore,

necessary

to change the engine oil

at

regular

intervals,

2. Too low

oil

level not only will

quicken

oil

deterioration, btrt

will

cause

engine

seizure.

So

replenish engine oil as soon as

possible.

3.

Mixing oils of different brands might

deteriorate oil

properties.

Therefore, avoid mixing

engine oils of

different brands.

LONG LIFE

COOLANT

(Year

round

coolant) and Antlfreeze

Solutlon

Selectlon

of

Long

Llfe Coolant & Antlfreeze Solutlon

When

the

cooling water

is

frozen,

there

is

a

possibility

that

the cylinder head or cylinder block,

or

possibly

the

radiator, may

be

broken.

Long

life coolant or

antifreeze is

mixed

with

the cooling

water

to

prevent

freezing.

These solutions come

in two

kinds: Antifreeze is used

only

during a winter

season mainly

for

the

purpose

of

preventing

freezing.

Long

life coolant is used

throughout

the

year

for the

purpose

of

preventing

corrosion of

the

cooling

system, besides

the

prevention

of freezing. Select

'long

life coolant or antifreeze for

aluminum engines'. Use a mixture that is

best

suited

for

your

local

conditions

and temperature.

It

is advisable to use

long

life

coolant having

the

following

features:

1.

Long life

type coolant

in

which

special rust

prohibitive

agents, anticorrosion agents, etc. have

been added

(in

larger amounts than in antifreeze)

to a highly

pure

ethylene

glycol.

The components

of

coolant of this type will hardly

evaporate. Simple

replenishment

of

water

will

maintain the original intended

performance.

'Long

life

coolant

for

aluminum engines'can

protect

aluminum alloys that

do

not

have strong

rust/corrosion-withstanding

properties.

Also,

it can

protect

cast

iron.

Long

life

coolant

prevents

wear

of the water

pump

or water leakage.

CAUTION

Be

sure to

use

tap water to dilute long life

coolant

or antifreeze.

Keep

the concentration of long life coolant or

antifreeze at

a level matched with the lowest

temperature in

your

local

region.

3. Mixing of

long

life coolant or antifreeze

of different

brands might deteriorate its

properties.

Therefore,

avoid

mixing solutions

of

different

brands.

4. Using

100%

of undiluted solution does

not always

ensure

the

safety

of

your

engine. ln a very cold

climate,

100%

antifreeze or

long

life

coolant

can

treeze

and

cause damage.

5. The use of a

poor grade

antifreeze

may

cause

damage

to

the engine and

radiator.

The

use

of long

life coolant or antifreeze for cast iron engines may

cause

damage to aluminum, copper,

etc.

6. Long life coolant

or

antifreeze

is

poisonous.

Be sure

to

keep it in the original container and always store

it

in a

place

where

children

can

not reach.

LEAD BATTERY ELECTROLYTE

A

mixing

solution of sulfuric acid

and

distilled

water

is

used

as the battery

electrolyte.

Normally, the battery

electrolyte

is

a diluted sulfuric acid having

such

a

concentration that its specific

gravity

becomes 1.26 at

a

solution

temperature

of 20"C

(68'F)

in a fully

charged

state.

When

over-charged, the water

component

of

the

battery

electrolyte is

prone

to

evaporate.

lf the battery is operated continually with the

electrolyte

level too low, it will no longer be

possible

to store

electricity. Add water to compensate for the

evaporated

water.

-

WARNING

-

.

Never

permit

any fire to be brought

near

the battery.

CAUTION

USE DIST]LLED

WATER OR

DRINKING WATER

in

water replenlshment for lhe batlery efectrolyle.

In

each

cell,

add water up to

the

'UPPER'

level.

1.

2.

2.

3.

Page 7

Generator

Set Specifications:

Kywatl 7.1O1Kwyan 4.101

15.3

in.

(388mm)

34.4

in.

(875mm)

23.2

in.

(589mm)

313 lbs.

(1a2

Kg)

155 in.2

(0.1m,)

Negative

(-) ground

'|

2 Volts

32.2 in.

(818mm)

276 lbs.

(1

25Kg)

Weight

(without

oil, waler, muffler)

Required Air

Inlet

Opening Area

Generator

Specif

ications :

Specificallons

Kwyatt 4.101

Kwyatt 7.1O1

AC Output

UIOOO

watts 700O

watts

Voltage

12O volts

120/240 volts

Currenl

58.4

N29.2

each

leg

Frequency

60 Hz

No. of

Poles

No. of Phases

1

Power Factor

100%

Battery Charging

6 Amps @ 12VDC

DC

Voltage Control

Regulating Voltage 14.5 volts

Engine

Specifications:

Control:

Specifications Kywatl 4.101

Kwyan 7.101

Engine

Daihatsu. Model EB Daihatsu,

Model ED

TyPe 4-cycle, 3-cylinder

water cooled,

camshaft

Fuel Unleaded

Gasoline

Displacement

33.38in3

(547cc)

t1 .62 lns

(B46cc)

Bore & Stroke 2.44 x2.33

in.

(62.0

x 6O.5 mm)

2.62

x 3.19 in.

(66.6

x 81 .0 mm)

Compression Ratio 10.O : 1 9.5:1

Governed Speed

18OO rpm

Direction

of

Rotation

Clockwise

as viewed from crankshaft

pulley

side

(right)

Firing Order

1-2-3

Fuel Pump Electric, 12 volts DC, negative

ground

Lubrication

Syslem Fressurized by Oll

Pump

Oil Capacity

2.5

quarts (2.8

liters)

oil

API-SF, Use

proper

viscosity for climate

Conditions

General SAE

5W-30 or

10W-30

Oil Filter Use Dometic Part

#3102117

Only

Air Filter Use Dometic Part

#3101

191

Onlv

Coolant

Capacity

(lnclude

Reservoir)

1.11

sal.

(a.2

L) 1.27

gal.

(4.8

L)

Governor Mechanical

Governor Oil

Capacity

2.5

in3

(40cc)

Governor Oil

Starter

Use same oil as engine

lubrication

Electric, 12

volts DC, negative

ground

Spark Plug NGK, Type BP-28

Speclfications

Kwyatt 4.1O1 Kwyatl

7.101

Conlrol

Remote Slart

(Equipped

with two connectors)

and control

panel

on

generalor

sel

-7

Page 8

AFTER-SALES

SERVICE

The

Dometic Corporation has a

thoroughly

established

service

network in

all states so lhat

you

may

enjoy

a

safe,

long,

pleasant,

trouble-free operation of

your

generator

set. we

are

always ready to

meet

your

needs.

When

you

contact

The Dometic Corporation for service

or

parts,

please

supply

complete

information

regarding

the

generator

set's

model and serial numbers

(specification

number), as shown on the Dometic

nameplate, and the date

of

delivery. Thus, we can offer

correct

service

or

parts

delivery for

your

specific

generator

set.

E0

Dometlc'

b'brrd&d. h@.r.,.1

.@'

sERnlNo.

XXIOOO(

you

may replace

it

once with fuse of equal value. lf

ehher

fuse

opens a

second

time,

DO

NOT

REPI.ACE

lT

-

call

your

nearest Dometic service center for service.

Replacing Fuse:

A. Turn OFF main switch.

B. Unscrew fuse cap and remove

fuse,

C. Install new fuse rated at

'125V

-

15A into

cap.

D. Screw cap back into

fuse

holder.

E. Turn ON main

switch.

l

FU.E

H.LDE*

\ ,iifr

"o,

4f /-^

FlG.

1

fl, <:a ?-f

W

lr r

("t

,,'

/ 4,

lciruennron

ll I

tl-l

"'/'I

FUSE

I

t

Y{'l I$iT""

CIRCUIT BREAKER

FUSE

-

When excessive current flows

on

power

line,

or switch

is turned

off

manually, the breaker will

open

the

circuit.

When it closes

(switch

on),

power

is

supplied to the

appliances. NOTE: lf the breaker

opens,

you

can reset

it

once.

lf breaker

opens twice,

please

call the nearest

Dometic service center without resetting.

-

WARNING

-

Never

touch the

switches wlth wet,

olly

or dlrty

hands.

Not hlghly

purified

waler, oil

(especlally

englne oil)

or wet dust may conduct electriclty.

REMOTE CONTROL

Terminalfor remote control wiring is

provided.

lf remote

control

panel

is

provided,

remote

start/remote stop is

available.

STARTING

ENGINE

-

WARNING

-

.

Do not

operate

the

generator

when

you park

in tall,

grassy places,

bushes, etc.

There

is a

fire

hazard

in these

places.

.

Do

not operate

the

generator

set where ventilation

is

poor,

for instance close lo houses or obstructions

where the

exhaust

gases

may be hard to dissipate.

Exhaust

gzlses

may cause serirJus

personal

inlury or

(bath.

MAIN SWITCH:

(See

FlG.

1)

Turns

power

ON or OFF

to the engine control circuit.

ON

position:

Must be in

this

position

for

the engine

to

start

and

run.

OFF

position:

Used to shut

power

OFF

to control

circuit

of engine.

Always turn switch to

OFF

position

when servicing

generator

set or engine.

@:;

VOLTS

FL

AMPS.

PFOO.

NO.

MooELNo.

KWYATTX.IOl

FdR.cr..tloo.lv.hlcl.u..

rc.

60

PH s€ I

nPM 1800

KvA

}|s.ct^ss

a-ul

Ec6 AM8T. 40.C

BAIT. Ct|(l. R^nNO

a AtrpE Af r IVOC WATTS AT

pF

I .o

LTTLEADEO O

S

CO.\NEFT€OFoRLPO

E

WARNING

GENERATOR

SET CONTROL

SYSTEM

WATER TEMPERATURE CONTROL

When the cooling

water temperature rises above 107"C

(224"F)

the engine stops

automatically, thus

preventing

engine

overheating.

OIL

PRESSURE CONTROL

When the engine oil

pressure

drops below 0.3 kg/cm'

(4.25

PSI),

the

engine

stops

automatically,

thus

preventing

engine seizure.

REVOLUTION

SPEED CONTROL

When

the

engine

revolution

speed

exceeds 2500

rpm,

the engine

stops automatically,

thus

preventing

generator

set

malfunction.

CURRENT

CONTROL

1.

MAIN FUSE

(Left

Hand):

(See

FlG. 1)

When

current in excess

of 15 amps flow in wires

of

control circuit, this fuse will open.

This

prevents

the control

circuit from being

damaged. When this

fuse opens, the engine

will not run

and

the starter

will

not operate.

2. GENERATOR

FUSE

(Right

Hand):

(See

FlG. 1)

When

current in excess

of

'15

amps

flows on DC

generator

windings, this fuse will

open. This

prevents

damage

to

the

windings.

When

this

fuse

opens,

the engine will

not run, but the starter will

engage

when start/stop

switch is

pressed

to the

start

position.

NOTE:

lf

either

main or

generator

fuse

is open,

Page 9

NOTE: In

the event the engine

does not stop when

start/stop

switch is depressed,

turn main switch

to

OFF

position

to stop engine.

ASTART

srARr/sroP swlrcH

6H

sroP

START:

Position

to

be

used for starting engine. When

you

release

your

finger, the switch returns

to the

original

position.

STOP:

Position to be

used for stopping the engine.

When

you

release

your

finger,

the switch returns

to

the original

position.

STARTING

1. Before starting

the engine, be sure to turn off the

circuit breaker, or disconnect appliances

from

power

line, as far as

you

can. The

generator

may be

hard

to

start

if load is connected.

2. Press the start/stop

switch of the

generator

control

or remote control to the

ISTART]

position.

The

starter operates,

and then the engine

will start.

3. After the

engine has started, release

your

finger

from the start/stop switch.

The start/stop switch

will automatically

return to the original

position.

CAUTION

.

lf

the engine fails

to

start

in

your

first attempt,

wait for

about 30 seconds.

Then

proceed

to start the engine,

lollowing the

starting

procedure.

.

The operating duration

of the starter should

be limited

to

'10

seconds

for each cranking.

CHECK

AFTER STARTING

1. After the engine

had started, warm

up

the

engine

under unloaded

state for five

minutes. Perform the

engine warm-up

for a slightly

longer

duration

during

a cold

climate.

2. Check various

parts

of the engine

while warming

up the engine.

(Pre-work

inspection)

A. Check the

engine for abnormal

noise.

B.

Check the exhaust

gases

for improper

conditions.

CAUTION

.

Be sure to avoid

applying heavy loads

without warming

up

the engine.

.

The load

should

be limited within

the rated value

specified in the nameplate.

Overload may cause

grave problems

for the

generator

set.

STOPPING

First, disconnect loads,

and then

press

the START/STOP

switch to the

ISTOP]

position,

the engine

will stop.

Failure to follow

this

procedure

may

shorten the

generator

set life.

INSTRUMENTS

AND

POWER

CONSUMPTION

INSTRUMENT

GENERAL

TVATTAGE

Space

Heater

1000 - 1500

Air

Conditioner r400

-

2600

Converter 300

-

500

Refrigerator

600

-

1000

Coffee Percolator

500

-

700

Microwave

Oven

700

-

|

500

Ice

maker 800

-

1000

Mixer

800 - 1200

Electric

Frying Pan r000

-

r400

Electric Boiler

800 - 1500

Illumination Lamp 1000

-

2000

Electric Blanket

50

-

200

Electric Iron

600 - 1200

Hair Dryer 700

-

1400

Television

Set 100

-

500

Radio Receiver

50 - 200

INTAKE AIR SWITCHING

LEVER

This device

prevents

engine stall due

to carburetor icing.

For cold season, set the lever to WINTER

position.

For

other seasons, set the lever

to SUMMER

position.

PERIODICAL MAINTENANCE

SERVICE

The following

table informs the owner

(operator)

of

necessary maintenance service to keep

the

generator

set in

good

condition.

.

To maintain the

generator

set at

its

peaked

efficiency, it is imperative

to conduct

maintenance

service at regular

intervals and to

remedy any defect

immediately.

@

Page 10

ENGINE

MAINTENANCE

SERVICE

SCHEDULE

Mainlenance Service

hems

'See

Note

Below

Pre-Work

Inspection

Minimum

Every

25

hrs.

Every

1 25

hrs.

Every

25O hrs.

Every

5OO hrs.

Every

10OO hr.

Remarks

Engine

oil level, deterioration

&

leakage

o

o

Enqine

oil change

o

or

€very 6 months

Oil {iher change

o

or every

6 months

Governor

oil level &

deterioration

o

o

or every 6

months

Governor oil chanoe

o

or every 2 vears

Coolant

level

o

o

Coolant

leakage o o

Coolant

chanqe

o

or evsry 1

vear

Radiator cor€ clogging

*

o

or ev€ry I

y€ar

Clean radiator

interior

o

or every 2

years

Radiator cao condition

o

or

€very 6 months

Fuel level

o

as necessary

Fuel

leakage

O

o

Fuel fihor

replacement

o

or ev€ry

I

year

Air liher cleaning

o

or ev€ry 3

months

Air fiher replacemenl

o

or

every 1

year

Damaged,

worn or

loose behs

*

o

or

gvery

2

yeafs

Spark

plug

replacemenl

*

o

or ev€ry I

year

Distributor

cap condition

*

o

or ev€ry I

y€al

lgnition

timing *

o

or every

1

year

Valve clearanco

*

o

or overy 2

yoars

Battery electrolyte

level

o

Spocilic

oravitv

of batterf

elec{rolyte

*

o

or overy 1

year

Tiohtness

and corrosion

ol'batterv

iorminals

o

or svary 3 months

Easy

engine starting

*

Abnormal

engine noise

o o

Abnormal

generalor

noise

o

o

Mutfler condition

o

o

Soark arrestor cleanino

o

or

every 3 months

Exhaust

pipe

condition

o

o or every 3

months

Exhaust

gas

condition

o

o

or every

6 months

Check

generator

brush wear

*

o

or every 2

years

-

WARNING

-

For

asterisk

(t)

markod mainlenance

service ilems, NEVER DO lT BY

YOURSELF unless

you

are

an experienced, licensed service

person

and have the Dometic service manuals.

Inadequale service may incur

hazards or lroubles.

NOTE:

Aslerisk marked hema contain two cases:

l.Though service

procedures

themselves are simpl€

and easy, there

are hazards

for

personal

injury or deaih, due to accidental

fall down

or tilt of

generaior

Bot, etc.

2.Service equipment and

tools in combination with

professional

service

techniques are needed.

.

Belore

you per{orm

periodical

maintenance

service,

make sure

that

the engine lemperature

has

dropped io a

normal level

after stopPing

the engine.

.

Prior

to maintenance

sorvice lor

tho electrical

system, be

sure to

turn

otf the START/STOP

switch

and to disconnecl

the negative

(')

terminal

of th€ battery

so that no spark

or short

may occur.

This engine

maintenance

service schedule

applies

to an engine

which

will not be subjected

to elireme

operating conditions

and

which will

be

operated

approximately

5OO hours

a

year.

Hence,

if

your

engino

is operated

under more

severe

oPerating

conditions,

you

should

perform

maintenance

servico

at shorlened

intervals accordingly.

With regard

to those mainienancs

service

items

where both the

number

of operating

hours and elapsed

time

are

given,

perform

maintenance

service. whichever

comes first.

10

Page 11

I

t

PRE.WORK

INSPECTION

--

WARNING

-

Do

not

operate

or

work

on

the

generator

set

when

you

are mentally

or

physically fatigued.

The

pre-work

inspection

is

general maintenance

which

is carried

out

once

a

day

before

the engine

is operated'

To

prevent engine

trouble

because

of careless

mistakes,

e.g.

engine

stall

from

lack

of

fuel and

engine

overheating

trdm

tait<

of

cooling

water,

make

certain

to

perform

this

inspection

so

that

you may

enjoy

safe,

trouble-fee

operation.

THINGS

TO

CHECK

INSPECTION

ITEM

Check

that

engine

oil

level

is

proper.

Check

that

engine

oil

is not

dirtY.

Check

that

governor

oil

level

is

proper.

Check that

governor oil

is

not dirty'

Check

that

engine

exhibits

no

oil leakage.

Before

startlng

englne

(wlth englne

cold)

Check

that

cooling

water

level

is

proper and

not dirty'

Check

that

cooling

system

exhibits

no cooling

water

leakage'

Check

that

reservoir

tank cap

is

installed

securely'

Check

that

fuel

level

is

sufficient.

Check

that

engine

exhibits

no fuel

leakage.

Check

that

engine

starts

easily'

Check

that

engine

emits

no

abnormal

noise'

Check

that

exhaust

gases

are

in

good

condition'

After

startlng

englne

The

Engine

proper

11

Page 12

CHECKING

PROCEDURE

This section

describes the checking

procedure

for those

items of

the

pre-work

inspection and

general

maintenance

service. Be sure to see that

periodical

maintenance service

is

carried

out

without fail.

WARNING

-

Before

you perform

the

followlng servlce, make

sure

that the englne

has

cooled after

stopplng

the englne.

CAUTION

Turn off the

maln

swhch localed

on the

control

panel

of the

generator

before

performlng

Installallon or

servlce.

Thls

protects

the

unlt

from

damage and

protects a person

from

Inlury.

ENGINE

OIL

LEVEL.

DETERIORATION AND LEAKAGE

(Minlmum

of every 25 operatlng hours)

1. Ensure that the englne

oll

level ls

between the

upper llmlt and the lower llmlt on the oil level

gauge.

Check

the

oll

level

as followe: Pull

out

the oil

level

gauge.

Wlpe

otf

the oll

stlcklng

on

the

gauge

and fully Insert

the

gauge

Into

posltion.

Agaln

pull

lt out to eee

the

oil level.

CAUTION

-

The

engine

oil

level check should

be

conducted

on

level

ground,

floor, etc, before

the

engine

is

started.

-

lf

the

engine has started, stop the

engine. Wait

at

least

three minutes

before

you

check

the

oil

level.

Also,

check

the

oil

for deterioration by

touching the

oil

sticking

on the oil level

gauge

with

your

finger or

by allowing the oil to stick to cloth.

Check to see

if

engine

oil

is leaking

from the

cylinder head cover, oil

pan

and so

forth.

Check

to

be certain that

there is

no

trace

of oil leakage

beneath

the

engine or vehicle.

GOVERNOR OIL

LEVEL AND DETERIORATION

(Every

250

operating

hours or every

6 months)

1.

Ensure

that the

governor

oil level

is

between

the

upper

limit

and the

lower

limit on

the

oil level

gauge.

Lower

Limit

COOI.ANT LEVEL

AND

DIRTY

CONDITIONS

(Every

25 operating hours

minimum)

Ensure that

the

cooling water

level

of the

radiator

reservoir tank

is

between

the

upper limit

(FULL)

and

the

lower

(LOW)

limit

on the

side

of reservoir

tank.

lf no cooling

water is found

in the

reservoir tank, be sure

to fill the radiator with coolinq water.

-

WARNING

-

Never open the radiator cap when the water

temperature ls still hlgh. Failure to observe this

warnlng will

cause

pressurized

vapor

or hot water to

blow

up, resulting

in scalding

yourself.

COOI.ANT

LEAKAGE

FROM COOLING SYSTEM

(Every

25 operating hours minimum)

Check to

see

if any

water

leakage ls

present

at the

radiator, radiator hoses, water

pump

and so

forth.

Check the

ground,

floor, etc. for

trace

of

water leakage

3.

12

Page 13

EASINESS

OF

ENGINE

STARTING

1.

Check

to see

lf

the englne

can

start readlly.

Also,

check

that

the englne

runs

smoothly.

2. lf lhe englne

lalls

to slart on the flrst attempt,

walt

two or

three

mlnutes

to

allow the battery

to

recover hs functlon before

you

attempt

to start

lhe

englne agaln.

3. lf englne wlll

not

start In splte of two or three

retlres,

check

the

followlng

hems:

-

Out of

fuel

-

Low oll level

I

-

Water temperature too

high

*

(

'

Control system operates

to

prevent

starting)

ABNORMAL

NOISE FROM ENGINE

(Every

25 operating

hours

minimum)

1.

Check to see if the engine starts

smoothly

withont

emitting any abnormal noise.

2. lf

the

engine emits abnormal noise, immediately

stop

the

engine to

check

possible

causes.

EXHAUST GAS CONOITIONS

(Every

125 operating

hours or every 3 months)

1.

The engine combustion conditions can be

judged

by the color

of exhaust

gases

after the engine has

been

warmed

up.

lf

the

gases

are:

Colorless or a

light

blue

=

Good

combustion

Black

White

:

Poor

combustion

:

Oil being burned

Check to see

if exhaust

gas

is leaking

from

the

midway

point

of the

exhaust

system.

-

WARNING

-

lf the exhaust

gas

is leaking or

if

the color of

exhaust

gas

remains black or white

even

after the

engine is

running for

a little

while, stop the

engine.

DO NOT

use the

engine

until it is repaired

completely.

DO

NOT

operate

the

generator

set where ventilation

is

poor

and the

exhaust

gases

are hard to dissipate

because of recessed

ground

obstructions.

FUEL LEVEL

Before starting,

ensure

that

the fuel

level is

sufficient for

operation.

-

WARNING

-

-Never

fill

the

fuel tank near

the

generator

set.

-Make

sure

the lid of

any

gasoline

container

is

closed

tightly at

all

times. A mixture of

gasoline

vapor with air

having a

certain

ratio becomes highly

dangerous.

FUEL LEAKAGE

(Every

25

operating

hours minimum)

Check

to

see if any

fuel

leakage is

present

at the fuel

filter, carburetor, fuel hoses, etc. Be

sure

no trace

of

fuel leakage is

present

beneath the engine or vehicle.

i-

WARNING

-

-lf

any

fuel

leak

point

is

discovered,

never start

the

engine

until

it is

repaired

completely.

Call

for nearest

Dometic

service

center immediately. Also, wipe off

any

leaking

gasoline

and wait until the

engine

becomes

completely

dry.

Then

proceed

to start

the

engine.

-Under

no circumstances

should

open

fire,

such

as a lit

candle or

lighter,

be brought near

the engine

to

check

for fuel leaks.

-Have

a fire extinguisher

nearby.

CLEAN]NG

OF

SPARK

ARRESTOR

(Every

125

operallng

hours or every

3 months)

The spark

arrestor

is incorporated In

the

muffler to

prevent

llre

or burning due

to sparks. lf lt ls

reslrlcted by

carbon

deposit, the englne output

may

drop under

some

circumstances. Clean the spark

arrestor

at

regular

intervals.

Cleanlno Procedure:

After

confirming that exhaust muffler has

cooled,

remove

the 6 mm screw in the bottom of muffler.

Run set under

load for 5 minutes. lnstall screw.

13

Page 14

CLOGGED

RADIATOR

CORE

(Every

500

Operating

Hours or

Once

a Year)

lf

any mud,

paper,

dead leaves

or insects

are stuck on

the

radiator

core or

the belt

cover, ventilation

will

be

restricted

and reduced

cooling

will

result.

Deformation

or clogging

of radiator

core, or

scales,

etc., will restrict

coolant

flow.

Contact

a Domet

periodically.

INSTALLATION

CONDITION

OF

RADIATOR

CAP

(Every

250 Operatlng

Hours or Every

6 months)

'1.

When installing

the radiator

cap,

check

to see

if the

turning

effort of

the radiator

cap

is correct.

2.

Ensure

that the

negative

pressure

valve

of the

radiator

cap opens

when

it is

pulled

out by

your

fingers.

Also,

ensure

that the

valve

closes

when

you

release

your

fingers.

ic

service

.,5

{{"

GENERAL

SERVICE

When

you perform

the

pre-work

inspection

and

periodical

maintenance

service,

rt

will become

necessary

to

perform

general

service

of cleaning,

adjustment,

replacement,

etc.

This

section

describes

the

servicing

procedure

for

those

most common

items

of

general

service.

l-

WARNING

-

Before

you

perform

the

followlng

servlce:

1. Be

sure to turn

off START/STOP

switch and

to

disconnect

negative

O

banery

cable.

lf it is

not

disconnected,

and

someone

turned

the sTART/sTop

switch on

during

servicing,

death

or

severe

InJury

may result

by electrlcal

shock

or

damage

from

sudden

movement

of

parts.

2. Make

sure

that the

engine

has cooled

after stopping

the engine.

CAUTION

Turn off the

maln

swltch

located

on

lhe control

panel

of the

generator,

before

performing

Instaltatlon

or

servlce.

Thls

protects

the unlt

from

damage

and

protects

a

person

from Injury.

CAUTION

TIPS

FOB

SERVICE:

When

you perform

general

service, care

must be

taken

to follow the

points

given

below:

-First,

select a

place

which

assures

safe

operation.

-Prior

to

the service,

be

sure

to stop

the engine.

-Use

tools

best

suited

for the

parts,

-This

generator

set is

designed

in the

millimeter

systern

except

some

fittings,

i.e. oil

pump,

etc.

please

use

tools for

the

millimeter

system.

-Slart

the

operation

only

after

the engine

has

cooled.

-Be

very

careful

not to

drop

small

parts,

e.g. bolts and

nuts,

into

the

generator

set.

-When

parts

are removed,

first clean

the ad.iacent

area

thoroughly

to

remove

any mud

or dirt.

-Before

the

operation

for

the

electric

circuit

is

started,

be

certain

to disconnect

the

negative

(-)

terminal

of

the

battery.

-lt

is advisable

to use

genuine

parts,

recommended

lubricants

and recommended

antifreeze (coolant).

ENGINE

OIL

REPLENISHMENT

(Every

25 operating

hours

minimum)

lf

you

continually

operate

the

generator

set

while the

engine

oil level

is low,

it will cause

premature

wear.

3.

center

to

check

the unit

exhibits

no

Ensure

that

damage.

&

the seal

packing

section

ffi

-

WARNING

-

-

Never

open

the radiator

cap when

the water

temperature

is still

high.

14

Page 15

Engine seizure is

prevented

by

the control circuit;

please

replenish

the engine oil at an earlier

time.

'1.

Remove the oil

filler cap or the oil level

gauge

to

replenish engine oil.

After

the

engine

oil has been drained,

install the

drain

plug

securely.

Fill engine oil to the specified

level, while

checking

the oil level using

the level

gauge.

Install the oil

filler cap or the

oil level

gauge

securely.

Start

the

engine

and run it

for about five minutes.

Stop the engine and wait

at least three minutes.

Ensure that the

oil

level

is within the specified

range,

using the oil

level

gauge.

GOVERNOR OIL

REPLENISHMENT

(Every

250 operating

hours or every

6 months)

1. Remove the level

gauge.

Replenish

governor

oil.

After

the oil has been replenished,

ensure that the

oil level is

near the upper limit,

using the oil level

gauge.

CAUTION

As for the

governor

oil, use

the same oil as

the engine

oil.

GOVERNOR

OIL CHANGE

(Every

1000 Operating Hours or

Every 2

years)

1. Remove

the level

gauge

and

oil drain

plug

to drain

the

governor

oil.

2. After the oil has drained,

install the drain

plug

securely.

3. Fill oil to the

upper level, while checking

the oil level

using the level

gauge.

4. Install the level

gauge

securely.

(MMl

AttEN

3.

4.

6.

2.

After the engine

oil has

that the oil level

is

within

the oil level

gauge.

been replenished,

ensure

the specified range, using

Install

the oil

securely.

filler cap

or the oil level

gauge

CAUTION

-

Perform

the operation at

a level

place.

-

Select an engine

oil best suited

to

your

local climate

from

among those engine

oils equivalent to

designation

SF ot

API service classification

(SAE

5W-30,

10W-30,

10w-40, 10w-50,

15w-40, 20w40,

20w-50).

-

As for the oil level,

care must be taken

not to

exceed

the

upper limit.

ENGINE

OIL CHANGE

(Every

250 Operatlng

Hours or Every 6 Months)

The use of deteriorated

engine oil will cause

premature

wear,

overheating, hard starting

or even engine seizure.

Be

sure to change

the engine oil

periodically.

1. lf the

engine is cold, run the engine for about

three

minutes

so

that

the engine may drain easily. After

warming

up, stop the engine. lt

may be necessary

to

warm-up longer in a

cold climate.

2. Next, remove

the oil filler cap or the

oil level

gauge.

Remove the

oil

pan

drain

plug

to drain

the engine

oil.

2.

Wrench

15

WRENCH

Page 16

COOI.ANT

REPLENISHMENT

(Every

25 Operallng Hours

Mlnlmum)

lf

you

continually operate the

generator

set

while the

coolant level is low, it

will cause overheating or even

engine

seizure. Be

sure to replenish the tap water

(not

long life

coolant

or antifreeze).

NOTE:

lf long life coolant was

thrown away

inadvertently, the coolant system must

be filled

with long life coolant

or antifreeze of the same

concentration.

1. Remove the reservoir

tank cap. Replenish tap

water up to the

'FULL'

mark.

Normally, do not remove the radiator

cap. But if

the

reservoir tank contains no

coolant, it is

necessary to remove

the radiator cap and

to

fill

the

radiator with tap

water.

After tap

water

has

been replenished, install

the

caps securely.

-

WARNING

-

-

lf the radiator cap is opened too

early when the

coolant ternperature

is still high,

pressurized

vapor or

hot water will blow out, resulting

in

personal

injury.

After the coolant temperature

has dropped,

slowly

open the radiator cap

by wrapping the cap

with a

clolh.

-

Be careful of HOT WATER

BLOWING OUT of breather

of reservoir tank.

CAUTION

-

use tap water to dilute long life coolant or antifreeze.

-

With regard to coolant - it is advisable to use

a'long

life coolant'.

-

Long life coolant or antifreeze

must be

prepared

in a

concentration

matched with

the lowest temperature in

your

area.

-

Use

'long

life coolant or antifreeze for aluminum

engines'.

COOLANT CHANGE

(Every

500 Operatlng Hours or Once a Year)

lf

dirty coolant

is

used

continually,

rust

formation or

corrosion will be accelerated. As a resuh, it will

incur

water

leakage or

overheating. Change coolant

periodically.

Remove

the

radiator

cap. Drain coolant by opening

the drain cock.

At

the

same time. drain the coolant

from the

reservoir tank.

Close the drain cock

securely.

Loosen the

breather

plug

of the intake manifold.

Put

the

specified

amount of undiluted long

life

coolant

(or

antifreeze) in the radiator and

reservoir

tank.

When filling

radiator, do it slowly taking a

sufficient

length of

time.

(Specified

amount : See

'Service

Data:).

After confirming that

coolant has started flowing from

the breather

plug,

tighten

the breather

plug.

Fill the radiator

with tap water until the radiator

is

full. Then fill the reservoir

tank with tap water up to

'FULL'

line.

After

filling the cooling system with

tap

water,

close

the

radiator cap tightly, also install the reservoir

tank

cap securely.

8. Start the

engine. After warming up, stop the engine.

After the engine has cooled, remove the

radiator

cap. Check to see

if

the

coolant level of the radiator

drops. lf the coolant level is

low, add

tap

water.

Also, check to see it the coolant

level

of the

reservoir

tank

drops. lf the coolant level is low, add tap

water.

9. After adding

water,

tighten

the caps securely.

TIGHTENING

OF BATTERY TERMINALS

& CLEANING

(Check

Every 125 Operallng Hours)

To assure

smooth flow of electricity,

check the terminal

conditions

periodically.

1. Tighten

the terminals if they

are loose.

2.

Clean the terminals if they

are dirty or corroded.

3. lf the terminals

exhibit white

powder

due

to

corrosion, wipe off

the terminals using warm water.

4. lf the terminal

section exhibits excessive corrosion,

remove

the cable terminal by means

of a terminal

puller,

Polish the terminals using a

wire

brush

in

combination

with abrasive

paper.

5. After

cleaning and tightening, coat the terminal

section with a thin film of

grease.

1.

2.

3.

4.

5.

6.

7.

16

Page 17

-

WARNING

-

-

Be sure to stop

the engine before

the

above

operation

is

performed.

-

When disconnecting the battery terminals,

remove the

negative

(-)

cable

terminal first. Conversely, when

installing the banery cable terminal,

attach

the

positive

(+)

terminal first.

-

To avoid hazards caused by shorts,

utmost caution

must

be

taken when handling

tools

while doing the

work.

-

Never

allow any

fire to

be

brought near the battery.

Failure to follow the above instructions may resutt in

severe injury

or

dedh due to

shock

or fire.

BATTERY

WATER

REPLENISHMENT

(Check

Every 125

Operatlng

Houre

Mlnlmum)

lf the

battery is

used with

a low water

level as a resuh

of vaporizing

or

electrolyzing, water

sulfating

will take

place

on

the

plates

resulting

in

shortened battery life.

NOTE: For

inspection

intervals of

'Maintenance

Free'

batteries,

consuh a Dometic

Service

Center or

battery shop.

lf the battery electrolyte level

plug.

Replenish distilled water

is low. remove the cell

up to

the

UPPER level

for each cell.

-

WARNING

-

-

Be sure to stop the engine before

the

operation is

performed.

-

Never allow any fire to be brought near the banery.

-

The

battery electrolyte has strong corrosive

properties,

presenting potential

hazards that

could result in

dermatitis

on skin or corrosion on

metals.

Extrerne

cautbn

must be

exercised

to efie.Jre

that no bdtery

electrolyte touches skin, chhes, equiprnent,

etc.

-

lf

the banery electrolyte

gets

in

your

eyes, immediately

flush

your

eyes with

lots

of water.

Consult a doctor.

-

Carefully read the caution

plate

affixed

to the banery

so that

you

may

handle the battery correctly.

AIR CLEANER

ELEMENT CLEAN]NG &

REPI.ACEMENT

(Clean

Every

125 Operatlng Hours)

(Replace

Every

500 Operatlng

Hours)

Using a restricted air cleaner element

will

reduce engine

output, increase

fuel

consumption

or

premature

engine

wear. In dusty

conditions, clean and replace the

air

cleaner element more frequently.

1. Remove the air cleaner element by removing the

wing

nut

at the center of the

air

cleaner case

cover.

Clean the

air

cleaner element,

being very

careful not

to damage the lilter

paper

during

the cleaning.

Lighrly

rap the filter

paper

with

the handle of

a

screwdriver or

blow

out the element from the inside

of the element, using compressed

air.

Element Cleaning Intervals: Every 125 Operating

Hours or Every

3 months.

-When

replacing

the element,

thoroughly

clean the inside

of

the

case.

Element Replacement

Intervals: Every 500

Operating

Hours or once a

year.

-Replace

the

gasket

if it is damaged.

-

WARNING

-

-Be

very careful

not to inhale dirt or

dust.

/-\

IteR. \

v

\{ta&

\"

17

Page 18

CAUTION

-

Some air

cleaner

elements

sold in

the

market do

not

satisfy requirements

concerning the

engine

performance

or durability. lt is, therefore, advisable to

use reliable Dometic elements.

OIL

FILTER ELEMENT REPI.ACEMENT

(Every

250 Operatlng Hours or Every 6 Monthe)

Using a dirty oil fifter elements will weaken the

purifying

action of the engine oil

and

accelerate

engine

wear.

Beplace

the

oil fiher element

periodically.

1. Remove

the

oil fitter

element,

using a

tool.

When installing a new

oil

filter element, first apply

engine

oil to the'O'

ring.

Tighten filter with hand(s)

aboun

3/4

turn after

gasket

contacts mounting

surface

of

engine.

After installing

the

oil

filter element,

run

the engine

for 3

minutes. Ensure

that

the oil

fitter

element

installing

section exhibits no oil leakage.

4. Stop

the

engine.

After a lapse

of

at least three

minutes,

check the

oil level.

Replenish

engine

oil,

as required.

FUEL FILTER

REPI.ACEMENT

(Every

500

Operatlng Hours or once a Year)

Restricted luel

litter

will hamper

smooth flow of the fuel,

thereby causing

reduced engine output

or engine

stall.

Replace filter

periodically.

'1.

Replace

the

filter

by disconnecting

the

fuel

filter

hose. Prior to this

operation. take

precautionary

measure,

such

as

placing

a

cloth

under the filter,

so

that

the

flowing fuel from

the

fuel

fillter

may not

splash,.

lnsert

the

fuel hose

into

position.

lnstall

the

clam

p.

Start

the engine. Check to see

if

the

fuel

hose

attaching section

exhibits

any fuel leakage.

-

WARNING

-

-Pay

utmost cautlon

not

to splll

fuel

durlng

the

operatlon.

-Thoroughly

wlpe off

any

spllled fuel.

-Under

no clrcumstances should any fire be brought

near the englne.

CAUTION

-Some

fuel

filters

sold

In lhe market do not satlsty

requlrements

concernlng

the

englne

performance

or

durablllty. lt ls, therefore, advisable

to

use reliable

Dometlc fllter.

CLEANING INSIDE

OF THE RADIATOR

(Every

1000 Operatlng

Hours

or

every

2 Years)

Drain any deposition matter or

water

scale from the

radiator

periodically

to keep the cooling effect.

Remove

the radiator

cap. Drain

the coolant

by

opening

the drain

cock.

At the

same time, drain

the

coolant from the

reservoir tank.

Close

the drain

cock securely.

Loosen

the breather

plug

of the

intake manifold.

Pour

tap water

into water filling

port

of the radiator.

The water should

be

poured

slowly - taking

your

time.

After

confirming

that water has

started flowing

from

the

breather

plug,

tighten the breather

plug.

2.

2.

1.

2.

3.

4.

5.

18

Page 19

6. After filling the

radiator, fill the

reservoir

tank with

water

up to the

'FULL'

mark.

7. After filling water,

install the

radiator cap

and

reservoir

tank cap securely.

8. Start

the engine.

After warming

up, stop

the

engine.

9. Wait until the cooling

water

temperature drops.

Remove

the radiator cap

and open the

drain

cock

to

drain the cooling water.

10. Nerc,

fill

the

radiator with

tap

water

and drain the

cooling

water again. Repeat

this operation three

or

four times.

Finally, fill the

radiator with long life

coolant

or antifreeze according to

the

procedure

written

in

the

'Coolant

Change' section.

-

WARNING

-

-

Never

open the

radlator cap when the coolant

(water)

temperature ls stlll hlgh.

CAUTION

-As

for

flushlng waler,

use tap water.

-

WARNING

-

-

Exhaust

gases

are

toxic. Do not operate

the

generator

set

in

a building.

-

Before

you perform

the following service, make

sure

that the engine was

stopped

and

coolant

has cooled.

When

you

do not

operate

your

recreational

vehicle for a

long

period

of time,

perform

the

following operations to

protect generator

set

from

harmful effects of rust,

humidity and

freezing.

'1.

Start

the

engine

outdoors where ventilation is

good.

Stop

the

engine

after warming it up

thoroughly.

2.

Drain

the

old

engine oil.

Fill

with

new

engine

oil.

3.

Drain

the

oil

coolant. Fill

the

cooling

system with

new

coolant according

to the

procedure

written in

section

'coolant

Change'.

(Protection

of cooling

system against

freezing and

corrosion).

4.

To keep the

vacant

space in

the fuel

tank at

a

minimum level,

fill the fuel tank with fuel

after

stopping the

engine during a

cold

season.

(Protection

of fuel

system

against freezing

and rust

formation).

5.

Start

the

engine

outdoors where

ventilation

is

good

at regular intervals of about once

a week.

Stop the

engine

after warming it up

thoroughly

so

that each

part

may

be

lubricated by

engine oil.

CAUTION

Store

lhe

generator

set

In

a dry

bulldlng.

SERVICE DATA

ITEM

SPECIFIED VALUE

REMARKS

Engine oil

Capacity

Total oil

Capacity

2.8s - 2.96

qt.

(2.7

-

2.8

t)

Selecl an engine oil

best suited

to

your

local climate lrom among

those

engine

oils equivalent to

designation

SF

of API

service

classification

(SAE

5W-30. 10W€0,

10w-40,

10w-50, 15w40,

20w40,

and 20W-50)

Change oil

Capacity

2.54

qr.

(2.4

t)

Filling

amount of

anlilreeze

Mixing solution of

5O% long

lile

coolant

and 50%

ot

tap water is

recommended tor most

temperaturgs

and

provide

good protection

lor

corrosion

and scale. Higher

concentration

decreases cooling

effici€ncy.

Use

higher

concentration

only

when

additional

protection

against freezing

il

needed. Lower

concentration

than

40%,

under some

circumstances, may resuh

in

poor

protection

against

corrosion.

Coolant

Capacity

KWYATT 4

1.11

gal.

(4.2

t)

This

value

is

for

solution.

Also, reservoir

tank capacity

is

contained to this value

KWYATT 7

1.27

gal.

(4.8

t)

19

Loading...

Loading...