Page 1

BLUTEC 40d

Operation, maintenance and installation manual

Libretto istruzioni per l’uso, la manutenzione e l’installazione

Betriebs-, Wartungs- und Installationsanleitung

Manuel d’utilisation, d’entretien et d’installation

Bedienings-, onderhouds- en installatiehandleiding

Manual de instrucciones para el uso, mantenimiento e instalación

Manual de instruções de uso, manutenção e instalação

Användning, underhåll och installation

Käyttö-, huolto- ja asennusohje

Bruks-, vedlikeholds- og installasjonsanvisning

Betjenings-, vedligeholdelses- og installationsvejledning

Kullanım, bakım ve kurulum talimatları kitapçığı

Οδηγίες χρήσης, συντήρησης και εγκατάστασης

Page 2

ENGLISH

With Dometic you are at home, everywhere. Thank you for having

chosen one of our products. This Dometic product has been

specifically designed for your vessel. With over 75 years experience,

Dometic satisfies your mobile leisure needs thanks to state-of-the-art

technology and top quality materials, combined with great care for the

environment.

ITALIANO

Con Dometic come a casa, ovunque. Vi ringraziamo per averci scelto.

Questo prodotto Dometic è stato espressamente concepito per la

Vostra imbarcazione. Dometic, con un'esperienza di oltre 75 anni,

soddisfa completamente le esigenze del tempo libero in movimento,

utilizza le tecnologie più avanzate e materiali di prima qualità con

estrema attenzione per l'ambiente.

DEUTSCH

Mit Dometic wie zuhause - überall. Wir bedanken und freuen uns, dass

Sie sich für ein Produkt unserer Marke entschieden haben. Dieses

Dometic-Produkt wurde von uns speziell für Ihre Yacht entworfen. Alle

Dometic-Produkte basieren auf mehr als 75 Jahren Erfahrung in der

Ausstattung von Freizeityachten, modernster Technologie,

erstklassigen Materialien und zeichnen sich durch ihre

Umweltfreundlichkeit aus.

FRANÇAIS

Avec Dometic, partout comme à la maison. Nous vous remercions de

votre préférence. Ce produit Dometic a été conçu spécifiquement pour

votre embarcation. Grâce à son expérience de plus de 75 ans, Dometic

répondra pleinement à vos exigences liées au temps libre en

mouvement, car elle adopte les technologies les plus avancées et des

matériaux de première qualité, avec une attention particulière pour

l'environnement.

NEDERLANDS

Met Dometic voelt u zich thuis, overal. We danken u ervoor dat u ons

heeft gekozen. De producten van Dometic zijn speciaal ontworpen

voor uw vaartuig en spelen volledig in op de behoeften van uw vrije tijd.

Door onze ervaring van meer dan 75 jaar kunnen wij u de meest

geavanceerde technologie, eersteklas materialen, een fantastische

technische ondersteuning en functionele design aanbieden. Ook met

het milieu is zorgvuldig rekening gehouden.

ESPAÑOL

Con Dometic como en casa, allí donde esté. Gracias por elegir un

producto Dometic diseñado específicamente para su embarcación.

Gracias a una experiencia de más de 75 años, Dometic es capaz de

satisfacer todas las exigencias del tiempo libre en movimiento y utiliza

tecnología avanzada y materiales de primera calidad respetuosos con

el medio ambiente.

PORTUGUÊS

Com Dometic como em casa, em qualquer lugar. Agradecemos a sua

preferência. Este produto Dometic foi expressamente concebido para

a sua embarcação. A Dometic, com uma experiência de mais de 75

anos, satisfaz completamente as exigências do tempo livre em

movimento, utiliza as tecnologias mais avançadas e materiais de

primeira qualidade com extrema atenção ao meio ambiente.

SVENSKA

Med Dometic känner du dig som hemma var du än befinner dig. Tack

för att du har valt en av våra produkter. Företaget har mer än 75 års

erfarenhet i branschen och produktframtagningen grundar sig på

mycket avancerade teknologier, förstaklassiga material och extrem

omsorg om miljön, vilket gör att Dometic kan tillgodose alla dina behov

av bekvämlighetsprodukter för fritidsbåtar.

SUOMI

Dometic-generaattorin ansiosta olet kuin kotonasi, missä tahansa

oletkin. Onnittelut valinnastasi. Tämä Dometicin tuote on suunniteltu

erityisesti vesialuksia varten. Dometicin 75 vuoden kokemukseen

perustuen pystymme täyttämään täydellisesti vapaa-ajan liikkumiseen

liittyvät vaatimukset hyödyntäen huipputeknologiaa ja korkealaatuisia

materiaaleja ja kiinnittäen erityistä huomiota ympäristönäkökohtiin.

NORSK

Dometic overalt, akkurat som hjemme. Takk for at du valgte oss. Dette

produktet har blitt uttrykkelig designet med tanke på fartøyet ditt.

Dometic, med mer enn 75 års erfaring, tilfredsstiller alt du trenger til en

fritid i bevegelse og de benytter det siste innen teknologien og

førsteklasses materialer med ekstra hensyn til miljøet.

DANSK

Med Dometic som derhjemme, overalt. Vi takker, fordi I har valgt os.

Dette Dometic produkt er netop udformet til jeres båd; Med mere end

75 års erfaring opfylder Dometic fuldt ud behovet i fritiden i bevægelse

og bruger de mest avancerede teknologier og første klasses materialer

med stor miljøbevidsthed.

TÜRKÇE

Dometic ile her yerde evinizde gibi. Bizi seçtiğiniz için teşekkür

ederiz. Bu Dometic ürünü, tekneniz için etkileyici bir tasarıma

sahiptir. Dometic, 75 yılı aşkın bir tecrübe ile seyahat esnasında

duyulan boş zaman değerlendirme gereksinimlerini karşılar,

çevreye karşı son derece dikkatli bir şekilde, en ileri teknolojiyi ve

nıf kalitede malzemeler kullanır.

birinci sı

ΕΛΛΗNIKA

Με την Dometic σαν στο σπίτι σας, παντού. Σας ευχαριστούµε για

την προτίµησή σας. Το παρόν προϊόν της Dometic έχει µελετηθεί

ειδικά για το σκάφος σας. Με την εµπειρία των 75 και πλέον ετών

που διαθέτει η Dometic, µπορεί να ικανοποιεί πλήρως τις

απαιτήσεις για τον ελεύθερο χρόνο εν κινήσει και χρησιµοποιεί τις

πιο προηγµένες τεχνολογίες και υλικά πρώτης ποιότητας µε

απόλυτο σεβασµό προς το περιβάλλον.

Page 3

Operation, Maintenance and

Installation manual

Marine generator

Libretto istruzioni per l’uso, la

manutenzione e l’installazione

Generatore marino

Bedienungs- und

Wartungsanleitung

Bordgenerator

Mise en route, entretien

et installation

Générateur marin

Bedienings-, onderhouds- en

installatiehandleiding

Nautische generator

Manual de instrucciones para el

uso, mantenimiento e instalación

Generador marino

Manual de instruções de uso,

manutenção e instalação

Gerador marítimo

Användning, underhåll och

installation

Maringenerator

Käyttö-, huolto- ja

asennusohje

Laivageneraattori

Bruks-, vedlikeholds- og

installasjonsanvisning

Båtgenerator

Betjenings-, vedligeholdelses- og

installationsvejledning

Marinegenerator

Kullanım, bakım ve kurulum talimatları

kitapçığı

Deniz jeneratörü

C140200701.fm

Οδηγίες χρήσης, συντήρησης και

εγκατάστασης

Γεννήτρια θαλάσσης

English

Italiano

Deutsch

Français

Nederlands

Español

Português

Svenska

Suomi

Norsk

Dansk

Türkçe

ΕΛΛΗNIKA

GB

I

D

F

NL

E

P

S

FIN

N

DK

TR

GR

Page 4

© DOMETIC - 2006 All rights reserved - Printed in Italy Made by IDM

No part of this manual may be duplicated, copied or published in

any form without written authorization from DOMETIC

The figures, descriptions, references and technical data contained

in this manual are merely guidelines and are not binding

DOMETIC reserves the right to make all the modifications it may

deem fit, at any time and without notice, in a constant effort to

improve quality and safety, without undertaking to update this

manual every time.

© 2006 - Texts by: IDM experts in technical communication - Forlì

- The text may be reproduced , either partially or in full, provided the

author is duly cited.

Keep this document for future reference.

Page 5

CONTENTS

GENERAL INFORMATION................................. 6

TECHNICAL INFORMATION.............................. 8

SAFETY INFORMATION .................................. 11

INFORMATION ON MOVEMENT AND

INSTALLATION ................................................15

INFORMATION ON ADJUSTMENTS ............... 23

TABLE OF CONTENTS

A

Adjustment method

C

Changing engine oil

Changing the fuel filter (28)

Changing the sacrificial anode (28)

Changing the water pump rotor (31)

Check oil level (26)

Connecting the battery (21)

Connecting the battery charger (21)

Connecting the fuel indicator (21)

Connection to the exhaust (22)

Connection to the external power supply (34)

Connection to the power supply (20)

Cooling water connection (22)

D

Decommissioning the unit

Description of controls (23)

E

Electrical connection to the external network

F

Finding malfunctions

Fuel connection (22)

G

General description of the appliance

General rules (11)

Glossary and terms (7)

I

Improper use

Installing the unit (16)

L

Loading and transport

(23)

(27)

(32)

(21)

(29)

(8)

(10)

(15)

INFORMATION ON USE .................................. 23

MAINTENANCE INFORMATION ..................... 25

TROUBLESHOOTING INFORMATION ........... 29

INFORMATION ON SPARE PARTS................ 31

WIRING DIAGRAM........................................... 33

M

Main components

Manufacturer and appliance identification (6)

Movement and lifting (16)

P

Packing and unpacking

Prolonged inactivity of the unit (24)

R

Recommendations for maintenance

Recommendations for movement and installation (15)

Recommendations for use and operation (23)

Recommendations when changing parts (31)

Recommended lubricants (26)

Requesting assistance (7)

Rules for adjustment and maintenance (12)

Rules for movement and installation (11)

Rules for operation and use (12)

Rules for safety from environmental impact (13)

S

Safety and information signs

Safety devices (10)

Safety for the disposal of Waste from Electrical and

Electronic Equipment (WEEE Directive 2002/96)

Scope of the manual (6)

Starting and stopping the unit (24)

Storage (16)

T

Table of alarm signals

Table of maintenance operations (25)

Technical data (9)

Testing the unit (22)

W

Wiring diagram

(8)

(15)

(25)

(14)

(13)

(30)

(33)

GB

C140200701.fm

- 5 -

User manual

Page 6

GENERAL INFORMATION

SCOPE OF THE MANUAL

This manual, which is an integral part of the

equipment, has been drawn up by the manufacturer to provide the information required

GB

by those trained and authorised to work on

and with it during its working life.

This information is supplied by the Manufacturer in the original language (Italian) and

may be translated into other languages to

satisfy legal and/or commercial requirements.

Those to whom this information is addressed

must not only use the appliance in a proper

manner, but must read the information carefully and apply all instructions strictly.

Spending a short time reading this information will allow you to avoid risks that might result in a health or safety hazard and in

economic damage.

Should this manual contain information that

is additional to the actual set-up of the appliance, this additional information will have no

influence on the rest.

Keep this manual in a safe, known and easily

accessible place for the entire working life of

the appliance, so that it is always to hand

when required.

The manufacturer reserves the right to make

all modifications it may deem fit, without undertaking to give any prior notice.

To highlight certain sections of text that are

particularly important or to indicate certain

important specifications, various symbols

have been used. These are described below.

Danger - Attention

Indicates states of severe danger that, if ignored, may seriously endanger the health

and safety of persons.

Warning - Caution

Indicates that it is necessary to take suitable precautions in order to avoid endangering the health and safety of persons

and causing economic damage.

Important

Indicates technical information of particular importance that must not be ignored.

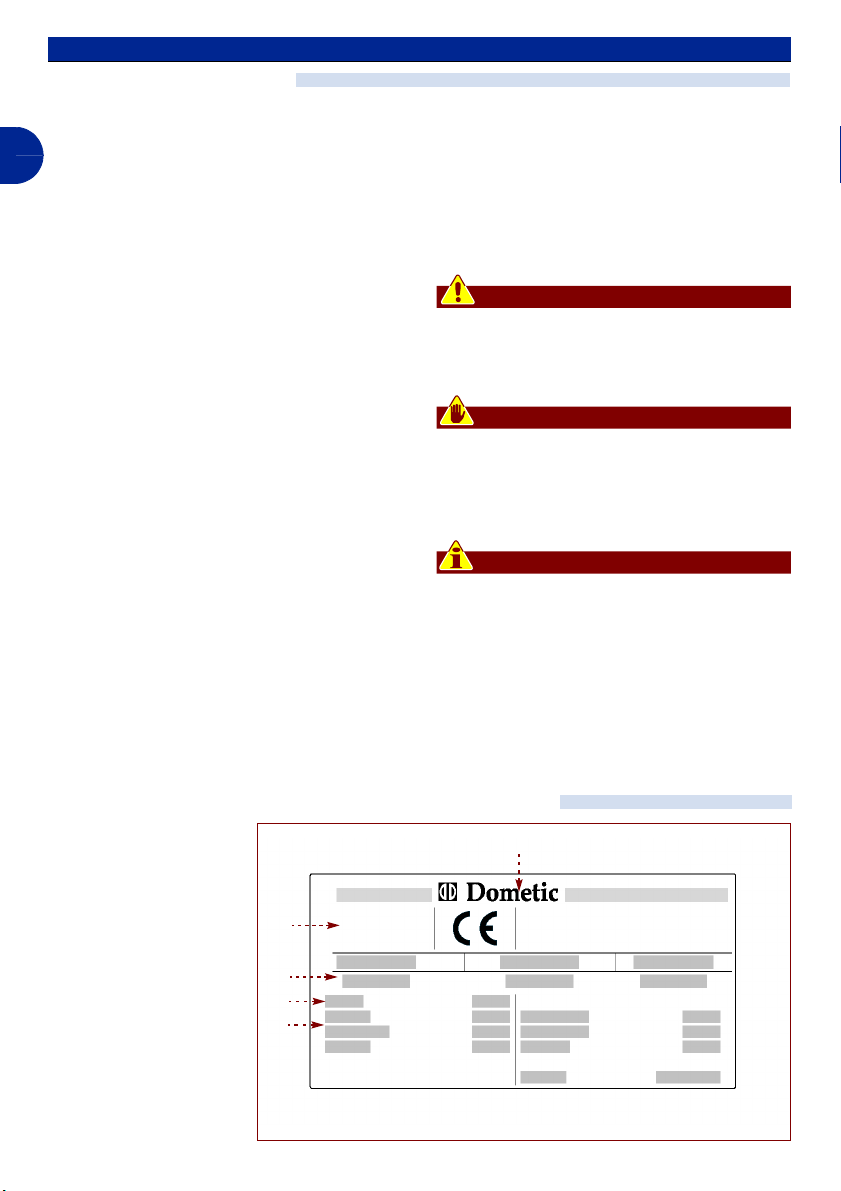

MANUFACTURER AND APPLIANCE IDENTIFICATION

The identification plate

shown here is affixed directly to the appliance.

A) Manufacturer identifi-

cation

B) Conformity markings

C) Model/Serial number

D) Year of manufacture

E) Technical data

B

C

D

E

A

- 6 -

C140200701.fm

IDM - 40200700100.tif

User manual

Page 7

GLOSSARY AND TERMS

Certain terms that are used frequently in the

manual are described, so as to give the fullest possible view of their meaning.

Installation technician: a technician selected and authorised by the Manufacturer or his

agent, from among those with the necessary

qualifications to carry out installation and

testing of the appliance.

Ordinary maintenance: series of operations

necessary to keep the appliance in a state of

proper efficiency and operation. These operations are normally planned by the Manufacturer, who sets down the qualifications

required to carry them out and the intervention method.

REQUESTING ASSISTANCE

For any assistance, please contact the Manufacturer's Service Department.

When requesting technical assistance,

please indicate the information provided on

the identification plate, the approximate

number of working hours and the type of

problem encountered.

Special maintenance: series of operations

necessary to keep the appliance in a state of

proper efficiency and operation. These operations are not planned by the Manufacturer

and must be carried out by the maintenance

technician.

Senior maintenance technician: a technician selected and authorised by the Manufacturer from among those with the

necessary qualifications, experience and information to carry out special maintenance

and repairs on the appliance.

GB

C140200701.fm

- 7 -

User manual

Page 8

TECHNICAL INFORMATION

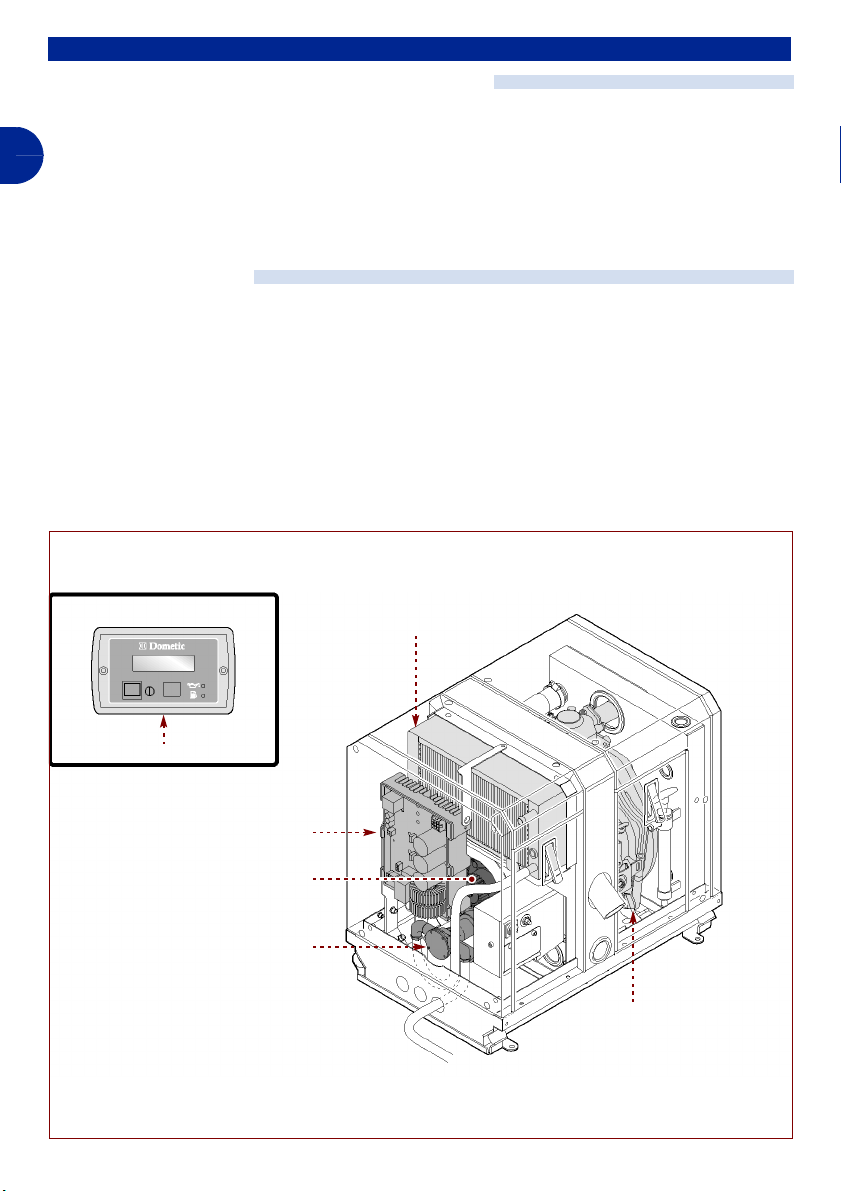

GENERAL DESCRIPTION OF THE APPLIANCE

The generator unit for vessels "BLUTEC 40

D", is an appliance designed and built to be

installed on board vessels of all types.

GB

It is used in the professional and civil shipping sector to generate current on sea-going

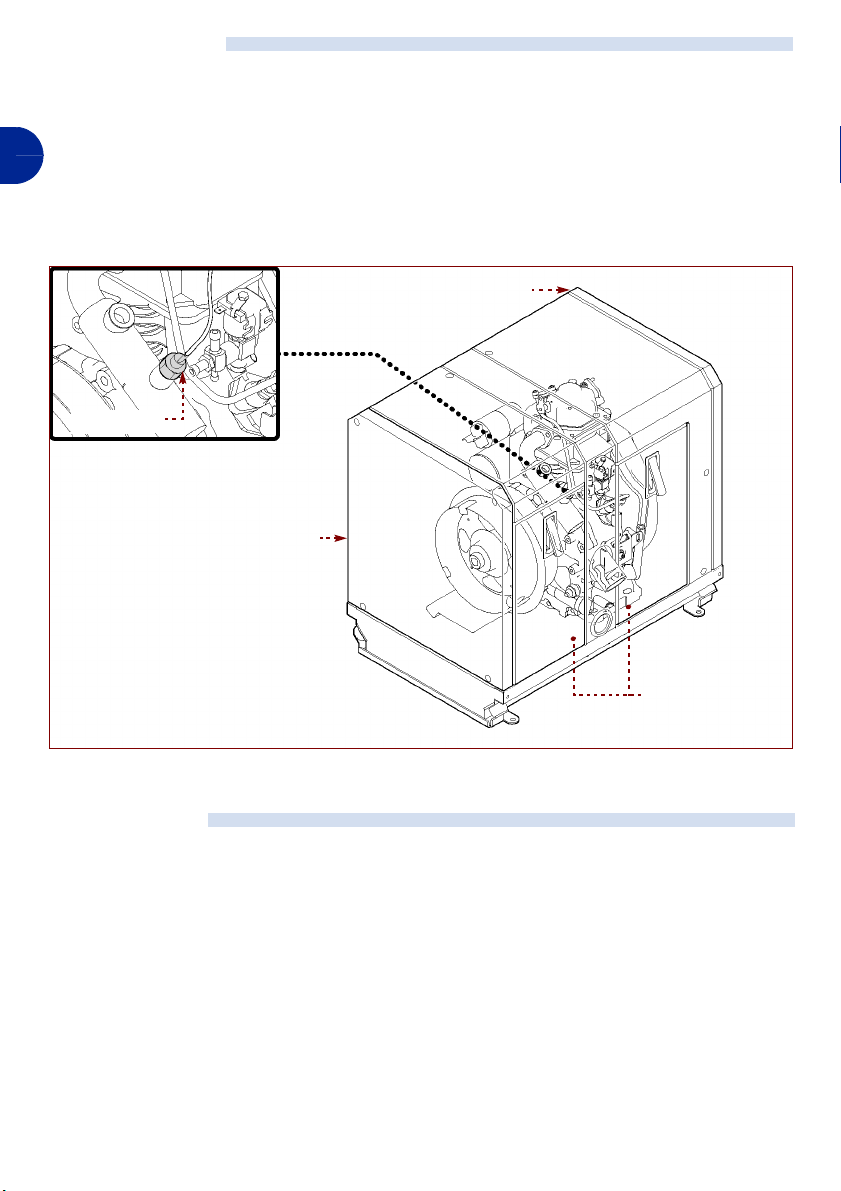

MAIN COMPONENTS

– Endothermic motor (A): to power all the

main components.

– Alternator (B): transofms the mechanical

energy of the motor into alternat current

electrical energy.

– Heat exchanger (C): cools the air inside

the unit through heat exchange with the

sea water.

heat exchanger (C)

vessels.

The appliance is fitted with a control panel,

from which it is possible to controll all working

functions.

– Water pump (D): feeds the sea water

cooling circuit

– Inverter (E): converts the supply voltage

into a perfectly stable, high quality voltage

of 230V/50Hz.

– Control panel (F): comprises the devices

used to operate and control all functions.

control panel (F)

inverter (E)

alternator (B)

water pump (D)

- 8 -

C140200701.fm

endothermic motor (A)

IDM - 40200700200.tif

User manual

Page 9

TECHNICAL DATA

GB

IDM - 40200700300.tif

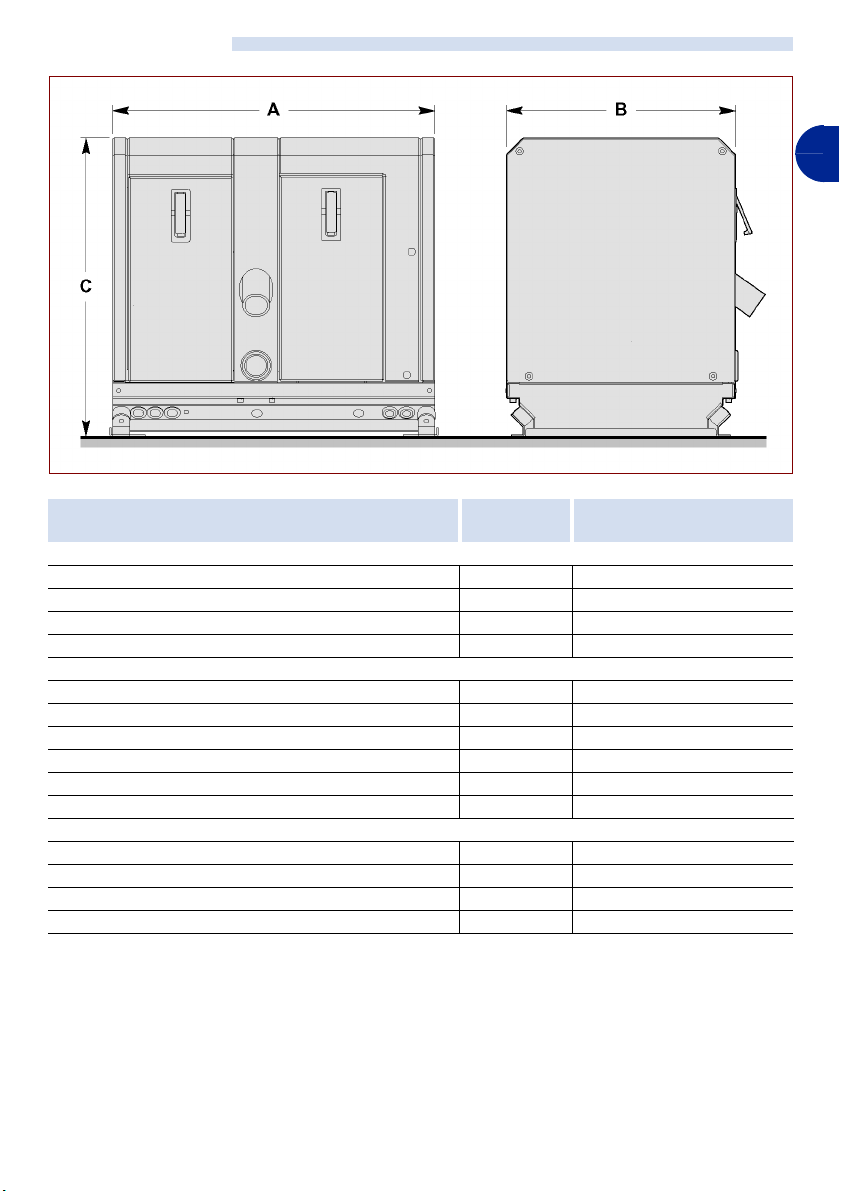

Appliance model

Dimensions

A mm 570

B mm 406

C mm 528

Weight kg 85

Motor technical data

Model YANMAR L 70 N / 320cc

Maximum power HP 6,1

maximum running speed giri/min 3300

Fuel consumption lt 1,3

Oil sump capacity lt 1,1

Inclinazioni consentite ± 20°

Generator technical data

Maximum output (continuous) W 3500

Output voltage V 230±10%

Frequency Hz 50

Insulation Class H

C140200701.fm

Unit of

measurement

BLUTEC 40D

- 9 -

User manual

Page 10

SAFETY DEVICES

The illustration shows the position of the devices.

– Fixed guard (A): prevents access to mov-

GB

ing parts of the unit. It can only be opened

by a voluntary action and with the aid of a

tool.

– Mobile guard (B): prevents access to the

interior of the unit.

sensor (C)

fixed guard (A)

– Temperature probe (C): disables the unit

if the exhaust gas reaches an excessively

high temperature.

fixed guard (A)

IMPROPER USE

Any form of use other than that authorised is

to be considered IMPROPER USE.

mobile guard (B)

Under no circumstances must this unit be

used in explosive environments or when

exposed to the elements.

- 10 -

IDM - 40200700400.tif

C140200701.fm

User manual

Page 11

SAFETY INFORMATION

GENERAL RULES

– When designing and building this unit, the

manufacturer has paid particular attention

to all aspects that might result in a risk to

the health and safety of those working with

the unit itself. As well as complying with

current legal requirements, all "rules of

good manufacturing practice" have been

followed. The aim of this information is to

notify users of the need to pay particular attention, in order to prevent any type of risk.

The need for prudence can never be sufficiently stressed. Safety also depends on

the operators working with the unit.

– Please read the instructions provided in

this manual carefully, and also read the instructions affixed directly to the unit, in particular those relating to safety. Dedicating a

short time to reading this information will

help avoid unnecessary accidents; it is always too late to remember what you should

have done when you have already done it.

– Pay particular attention to the meaning of

the symbols on the unit; their shape and

colour are significant for the purposes of

safety. Make sure they remain legible, and

follow the instructions given.

– Do not tamper with, elude, eliminate or by-

pass the safety devices fitted. Failure to

comply with this requirement may result in

severe risks for the health and safety of

persons.

– Staff carrying out any type of operation on

the unit throughout its working life must

have specific technical qualifications, abilities and experience that has been acquired

in and is recognised by the specific sector.

If these requirements are lacking, damage

to the health and safety of persons may result.

– When working, only use the clothing and/or

personal protection devices indicated in the

instructions for use supplied by the manufacturer, or those foreseen by local laws on

safety in the workplace.

– During normal use or for whatever opera-

tion, always ensure there is sufficient access space to use the comands in

conditions that are not liable to result in a

risk for the health and safety of persons.

– Every operation, unless expressly indicat-

ed, must be carried out with the motor

turned off and after allowing sufficient time

for it to cool down, so as to avoid the risk of

scalding.

GB

RULES FOR MOVEMENT AND INSTALLATION

– Lift and move the unit as described by the

manufacturer and indicated on the packaging, on the unit itself and in the user manual.

– The staff loading, unloading and moving

the unit, must have experience and abilities

gaiend and recognised in the sector in

C140200701.fm

question, and must be familiar with the lifting equipment to be used.

– Loading and transport must be carried out

using means of adequate capacity, anchoring the unit at the points foreseen by the

manufacturer. Those authorised to carry out

– All phases of installation must be consid-

- 11 -

these operations must have specific experience and abilities, so as to safeguard themselves and any other persons involved.

ered, from the time the general plan was

drawn up. Before starting these phases, as

well as defining the installation area, the

person authorised to carry out these operations must, if necessary, implement a "safety plan" to safeguard the persons directly

involved from harm, and must scrupulously

follow all laws, with particular reference to

those regarding mobile work sites.

User manual

Page 12

– It is necessary to ensure that the installa-

tion area has been provided with all the

suction, power supply and drainage connections required.

– During installation, respect the perimeter

GB

areas indicated by the manufacturer, also

bearing in mind all the other operations in

the surrounding areas. This requirement

must be implemented in such a way as to

comply with current laws on safety at work.

RULES FOR OPERATION AND USE

– As well as being suitably trained and in-

formed regarding use of the unit, the operator

must have the abilities and knowledge required for the type of work to be carried out.

– Even after adequate documentation, simu-

late a few test operations on first use, if necessary, so as to identify the various controla

and their main functions, in particular those

relating to start-up and stoppage.

– Only use the unit for the purposes foreseen

by the manufacturer. Improper use of the unit

may result in risks for the health and safety of

persons, and in damage to property.

– Installation and connection must be carried

out according to the manufacturer's instructions. The person in charge must also take

into account all legal requirements and

rules, and must carry out all installation and

connection operations in a workmanlike

manner. When installation has been completed, before use, he must carry out a general check to ensure these requirements

have been met.

– The appliance has been designed and built to

satisfy all the working conditions indicated by

the manufacturer. Tampering with any of the

devices in order to achieve performance levels other than the ones foreseen may result in

risks for the health and safety of persons, and

in damage to property.

– Do not use the unit if the safety devices are

not properly installed and operating correctly.

Failure to comply with this requirement may

result in severe risks for the health and safety

of persons.

RULES FOR ADJUSTMENT AND MAINTENANCE

– Keep the appliance in a state of maximum ef-

ficiency, by carrying out the planned maintenance operations foreseen by the

manufacturer. If these are properly carried

out, they will ensure the appliance provides

optimum performance, a longer working life

and constant compliance with the safety requirements.

– Before carrying out any maintenance or ad-

justments, activate all the safety devices provided and evaluate the need to inform the

persons working on the machine and any

persons in the vicinity. In particular, make

sure that the surrounding areas are adequately marked and prevent access to any of

the devices that might, if active, result in unexpected dangers and risks to the health and

safety of persons.

– Maintenance and adjustment operations

must only be carried out by persons authorised to do so, who must ensure that all the

necessary safety precautions are taken and

that the procedures indicated here are complied with.

– All maintenance operations that require spe-

cific technical knowledge or special abilities

must only be carried out by qualified technicians, who have esperience in the specific

sector of operation.

– To carry out maintenance operations in areas

that are not easily accessible or dangerouse,

ensure that suitable safety precautions are

taken for yourselves and others, in full compliance with current laws on safety at work.

- 12 -

C140200701.fm

User manual

Page 13

– Replace worn components with original

spare parts. Use the oils and greases indicated in the manual. All this will ensure that the

machine retains the functions and safety levels foreseen.

– Do not discard pollutants into the environ-

ment. They must be disposed of according to

current laws.

RULES FOR SAFETY FROM ENVIRONMENTAL IMPACT

Each organisation has the job of applying

certain procedures to identify, evaluate and

control the influence that its own activities

(products, services, etc.) have on the environment.

The procedures to be followed to identify significant impacts on the environment must

take the following factors into account:

– Emissions into the atmosphere

– Discharge of liquids

– Waste management

– Contamination of the ground

– Use of raw materials and natural resources

– Local problems relating to environmental

impact

In order to minimise environmental impact,

the manufacturer provides, below, a series of

indications that should be taken into account

by all those who, for whatever reason, work

with the appliance during its expected working life.

– All packaging components must be dis-

posed of according to current laws in force

in the country in which said disposal takes

place.

– During installation, ensure that the location

is suitably ventilated, so as to avoid any

concentration of air that might be unhealthy

for operators.

– During use and maintenance, do not dis-

perse pollutants into the environment (oils,

greases, etc.) and make sure they are disposed of separately according to the composition of the various materials and in

compliance with current laws in that regard.

Electrical and electronic components

should be disposed of as special waste.

– Keep noise levels down to reduce noise

pollution.

– When decommissioning, select all the com-

ponents according to their chemical characteristics and dispose of them according

to type.

GB

SAFETY FOR THE DISPOSAL OF WASTE FROM ELECTRICAL AND

ELECTRONIC EQUIPMENT (WEEE DIRECTIVE 2002/96)

– Waste from Electrical and Electronic Equip-

ment may contain dangerous substances

that are potentially harmful for the environment and for public health. They must always be disposed of properly.

– When decommissioning, select all the com-

C140200701.fm

ponents according to their chemical characteristics and dispose of them according

to type, in compliance with current laws.

– With reference to the WEEE directive

(Waste from Electrical and Electronic

Equipment), the user, when decommissioning, must separate the electrical and

electronic components and dispose of

them in special authorised collection centres, or return them, still installed, to the

dealer on making a new purchase.

– All the components that must be removed

and disposed of separately are marked by

a special indication.

– Unlawful disposal of Waste from Electronic

and Electrical Equipment (WEEE) is punishable under the laws in force in the country in which any infringement is found.

- 13 -

User manual

Page 14

– For example, to implement European direc-

tives (2002/95/CE, 2002/96/CE, 2003/108/

CE) within Italy, a Decree Law (No. 151 of

GB

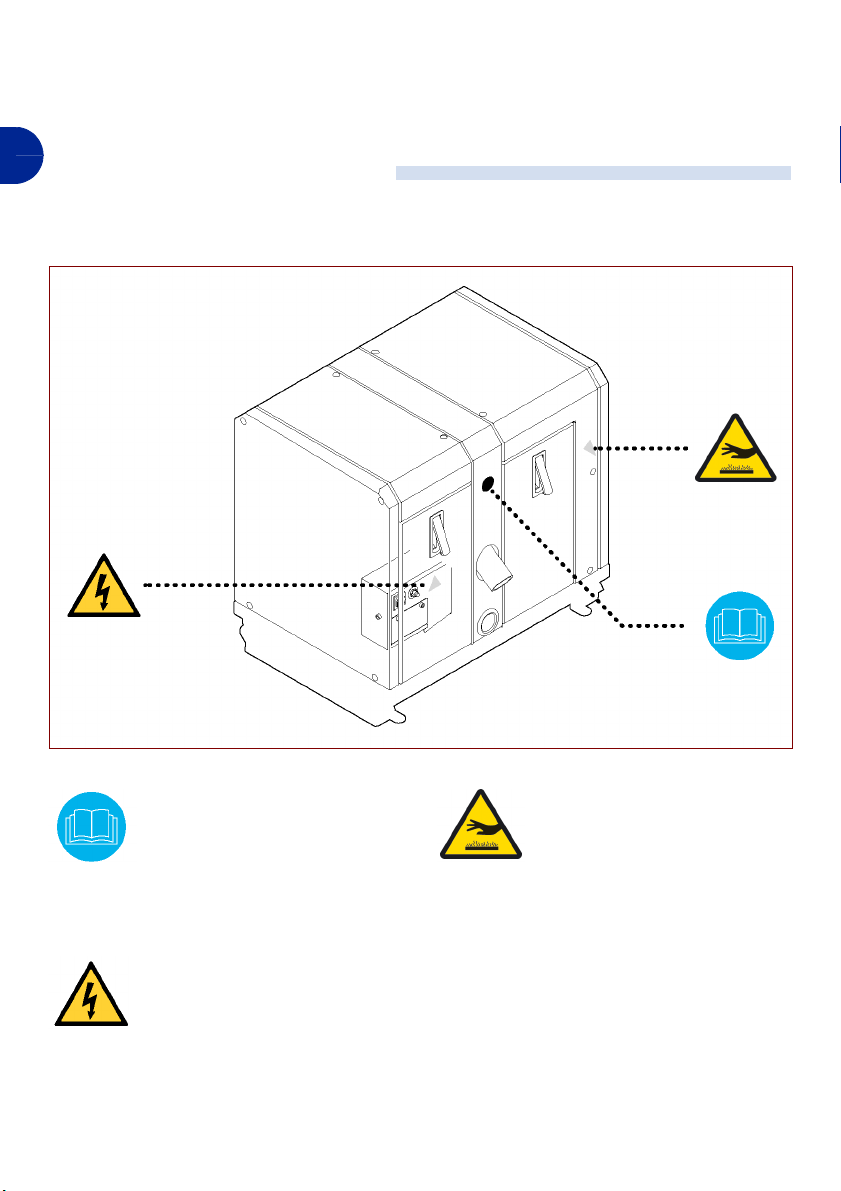

SAFETY AND INFORMATION SIGNS

The illustration indicates the position of the

signs affixed to the appliance.

25 July 2005) has been issued, foreseeing

a fine of 2000÷5000 €.

Read the user manual: the operator must read and fully understand the whole contents of

the document to understand the

commands and functions of the

machine. Keep the document

within easy access.

Danger of electrocution: never

access areas that contain live

elements.

- 14 -

IDM - 40200702400.tif

Danger of scalding: beware of

hot surfaces.

C140200701.fm

User manual

Page 15

INFORMATION ON MOVEMENT AND INSTALLATION

RECOMMENDATIONS FOR MOVEMENT AND INSTALLATION

When moving and installing the appliance,

follow the indications provided by the manufacturer and marked on the packaging and in

the instructions for use. Those authorised to

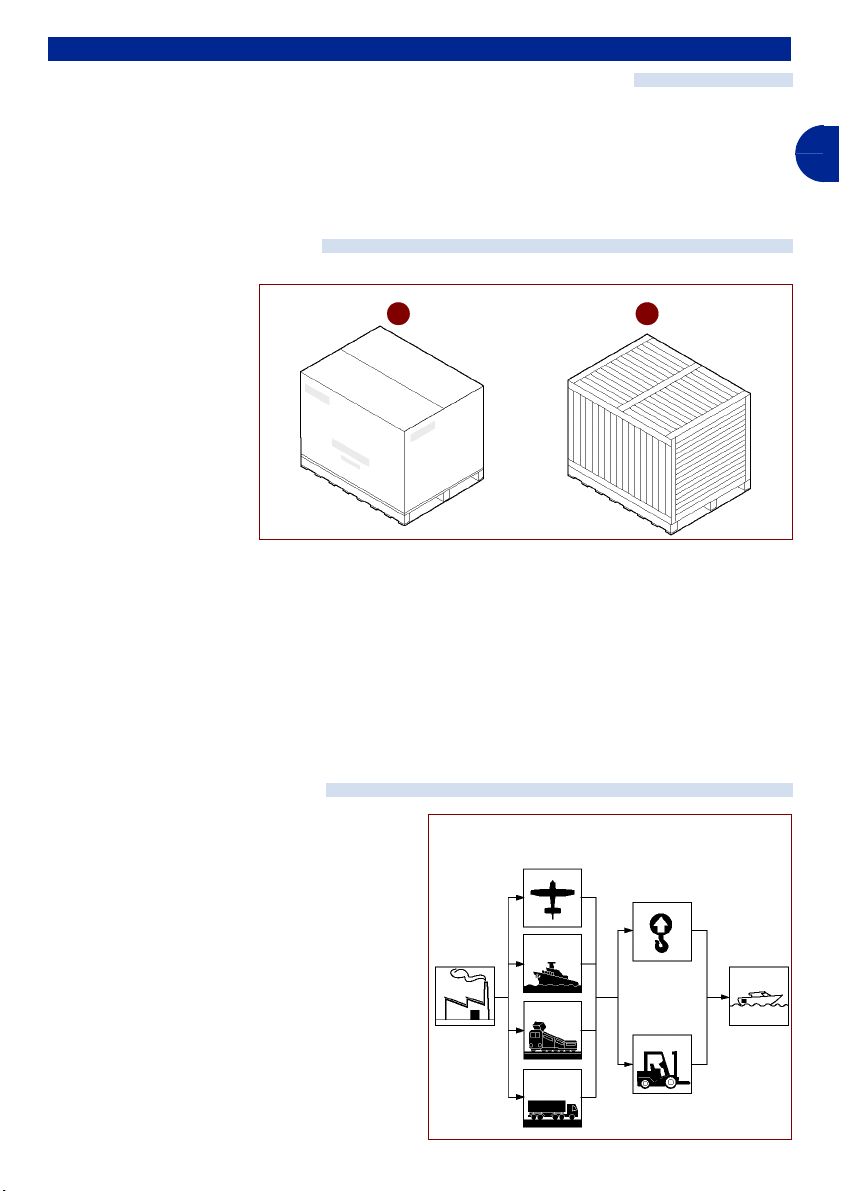

PACKING AND UNPACKING

The packaging, to reduce

working dimensions, may

vary according to the type

of transport being used.

To facilitate transport, the

appliance may be

shipped with some of its

components dismantled

and suitably protected

and wrapped.

Certain parts, particularly

electrical components,

are protected with damp-proof nylon.

All the information required to carry out loading and unloading is indicated on the packaging.

During unloading, check that the components are undamaged and that all the components are present.

carry out these operations must, if necessary, organise a "safety plan" to safeguard

the persons directly involved.

A B

The packing materials must be disposed of in

compliance with current laws.

The packaging may be:

A) on a pallet in a cardboard box

B) in a crate (for overland or air cargo ship-

ping)

GB

IDM - 40200700400.tif

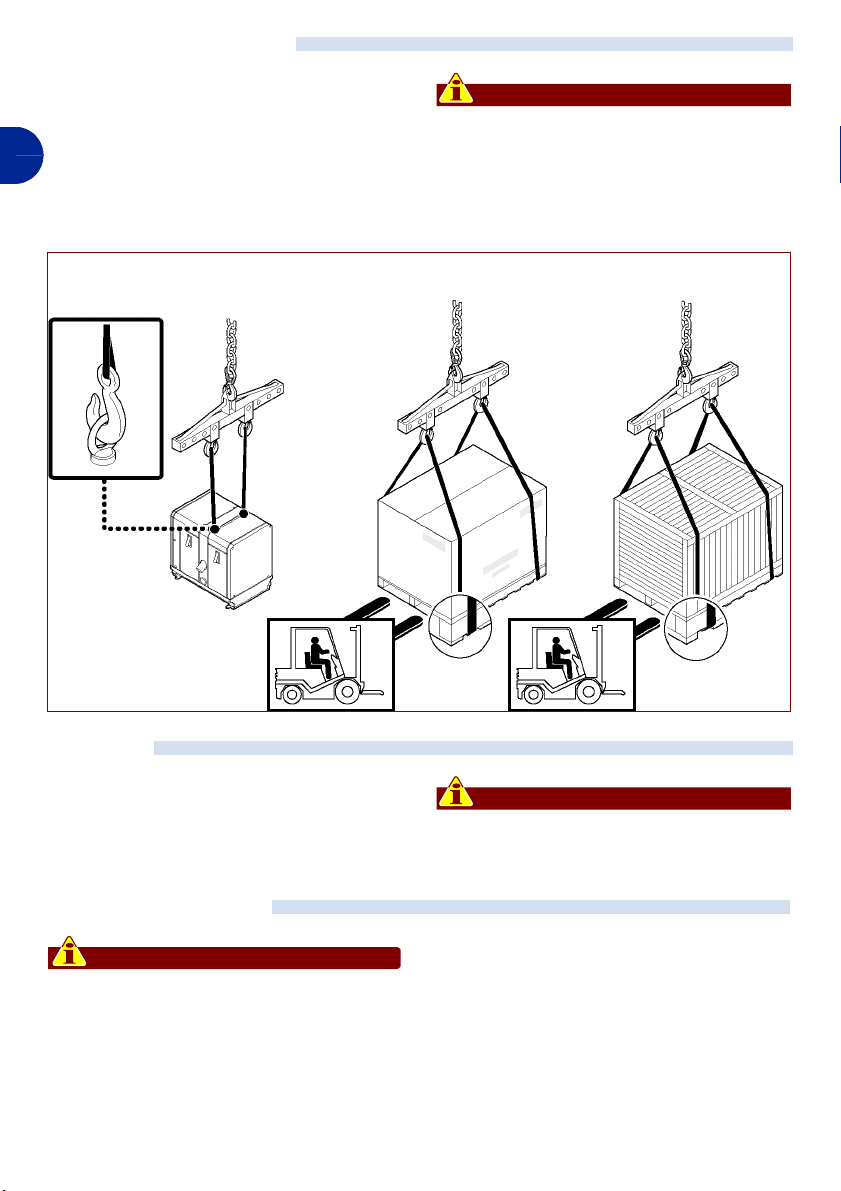

LOADING AND TRANSPORT

Loading and transport, according to the place

of destination, may take place using different

means.

The following diagram illustrates the most

common solutions.

During transport, in order to avoid sudden

movements, make sure the load is adequate-

C140200701.fm

ly fastened to the vehicle.

- 15 -

means of

transport

lifting

equipment

IDM - 40200700400.tif

User manual

Page 16

MOVEMENT AND LIFTING

The unit can be moved using a fork lift truck

or hoist of suitable capacity.

To lift and move the unit with an overhead

hoist, use the U-bolts provided.

GB

Important

Before lifting, check that the load is properly centred. Move the load with care, so

as to avoid sudden and dangerous swinging.

WITHOUT PACKING

MATERIALS

CARDBOARD BOX

STORAGE

In the event of prolonged inactivity, check the

conditions of the storage area, the type of

packaging and check that the conditions are

such as to ensure proper maintenance of the

unit.

PACKING WITH

Important

PACKING IN A CRATE

Avoid storing in environments that are

damp or exposed to the weather.

IDM - 40200700700.tif

INSTALLING THE UNIT

Important

All phases of installation must be considered, from the time the general plan was

drawn up. Before starting these phases,

as well as defining the installation area,

the installation technicial who will be carrying out these operations must, if neces-

sary, implement a "safety plan" to

safeguard the persons directly involved

from harm, and must scrupulously follow

all laws, with particular reference to those

regarding mobile work sites.

- 16 -

C140200701.fm

User manual

Page 17

The installation area must have suitable environmental conditions (light, ventilation, etc.).

The floor, as well as having a load capacity

capable of bearing the weight and vibration of

the unit, must be stable and level to guarantee proper support.

The installation area must have all the supply

and drainage connections required.

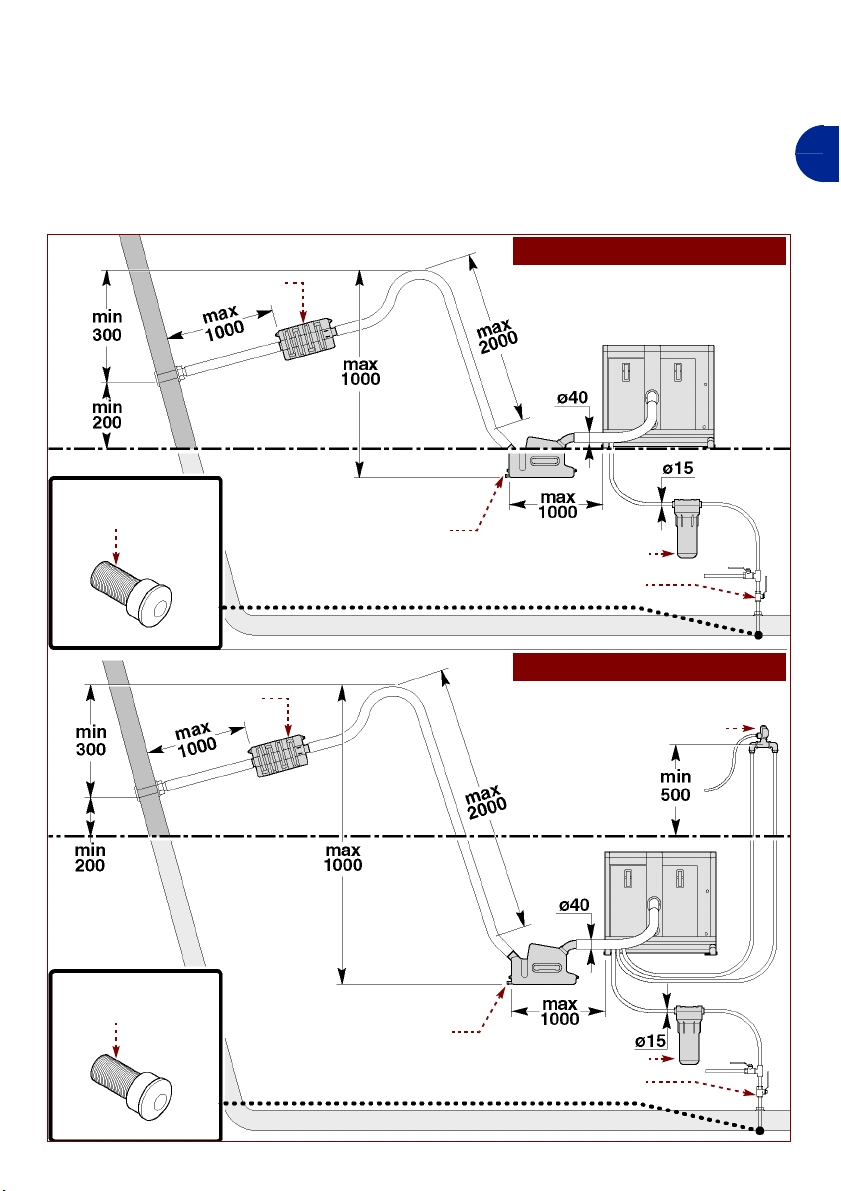

The applicance can be installed in a number

of ways (see figure)

– installation above the water line

– installation below the water line

GB

sea water intake

silencer

water line

silencer

exhaust pipe

INSTALLATION ABOVE THE WATER

sea water filter

non-return valve

INSTALLATION BELOW THE WATER

anti-siphon valve

LINE

LINE

C140200701.fm

sea water intake

water line

exhaust pipe

- 17 -

sea water filter

non-return valve

IDM - 40200702300.tif

User manual

Page 18

If the anti-siphon valve has to be fitted, install

it as shown in the figure.

GB

Important

Take care that water

does not stagnate in

the drainage pipe.

anti-siphon valve

IDM - 40200702500.tif

- 18 -

IDM - 40200702600.tif

User manual

C140200701.fm

Page 19

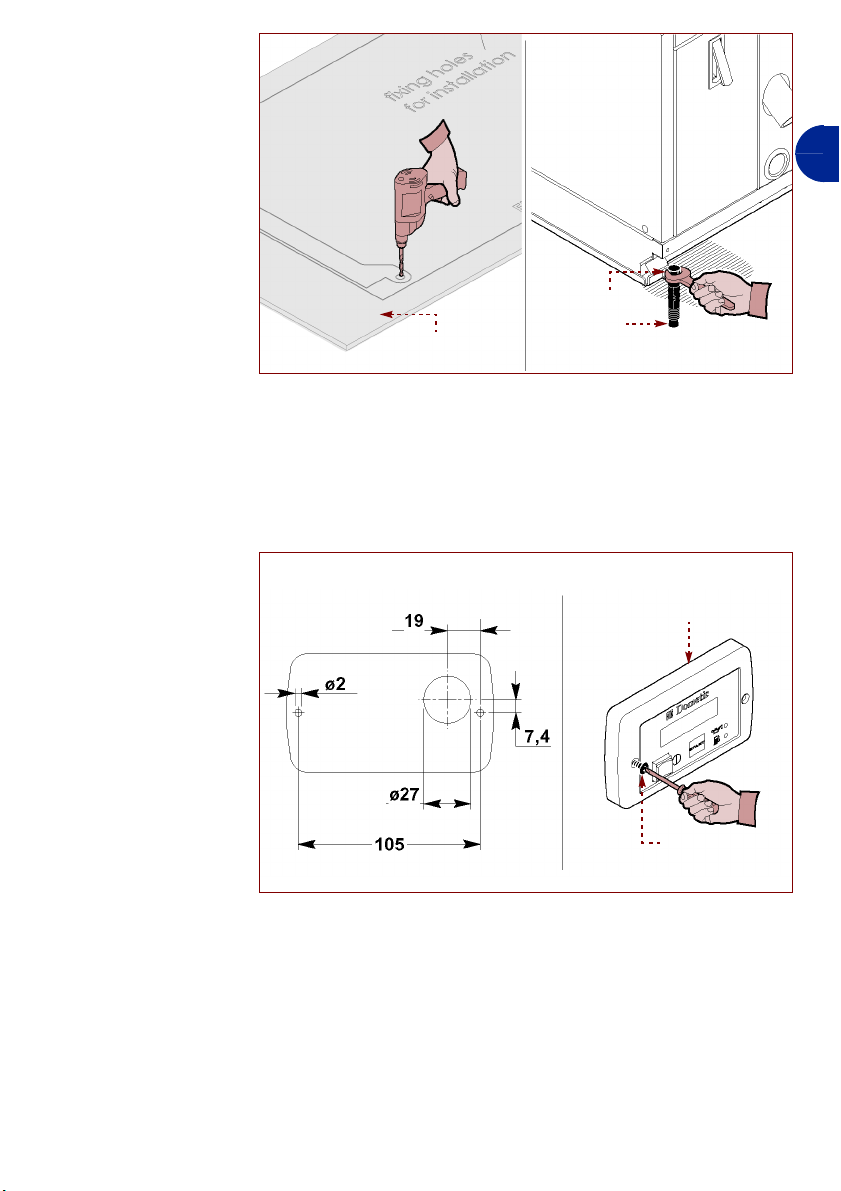

Proceed as indicated.

1 -Identify the exact po-

sition using the boring

template (A), supplied in the pack, and

drill the holes.

2 -Insert the plugs (B)

provided.

3 -Position the unit in the

set area.

4 -Fix the unit to the floor

using appropriate

screws (B).

5 -Identify the exact po-

sition and, if necessary, trace the

coordinates so as to

position the control

panel properly (C)

(see figure).

6 -Fix the control panel

(C) using the screws

(D) provided.

drilling

template (A)

GB

screw (C)

block (B)

IDM - 40200700800.tif

control panel (C)

screw (D)

IDM - 40200700900.tif

C140200701.fm

- 19 -

User manual

Page 20

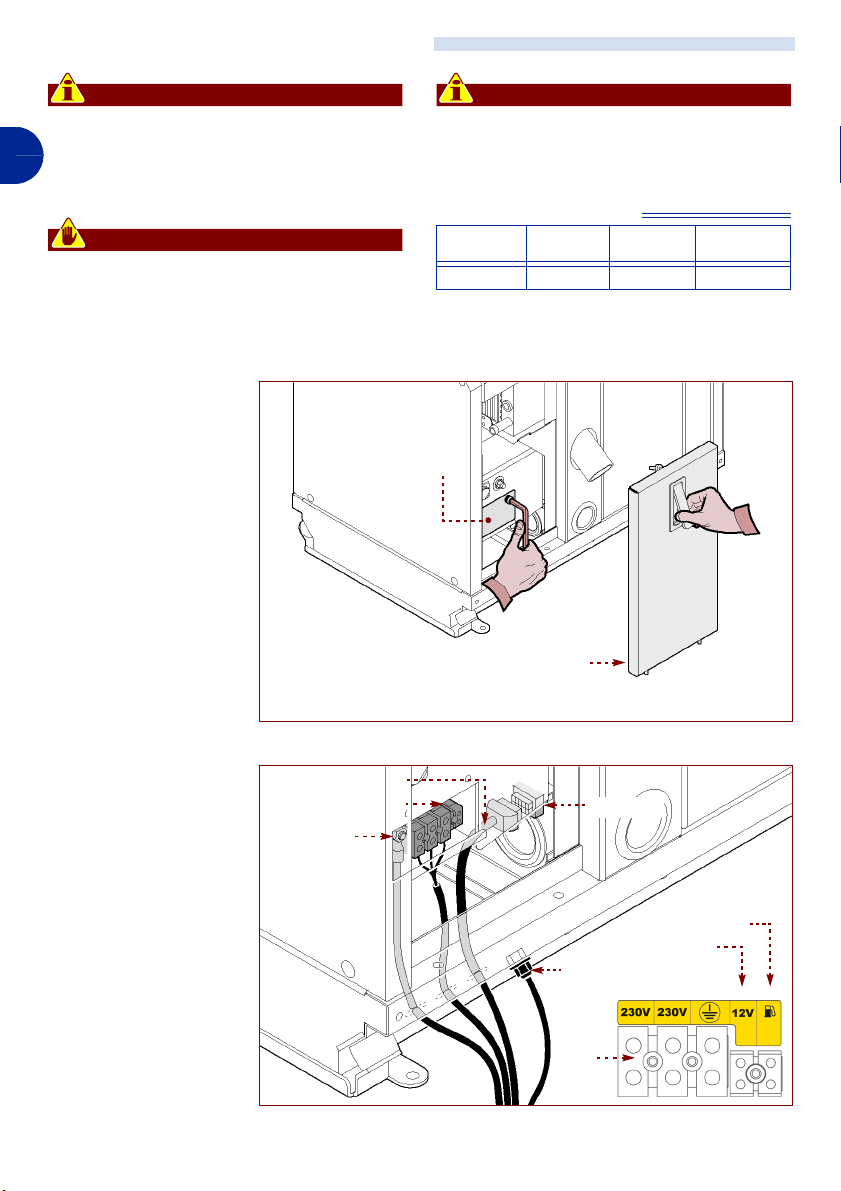

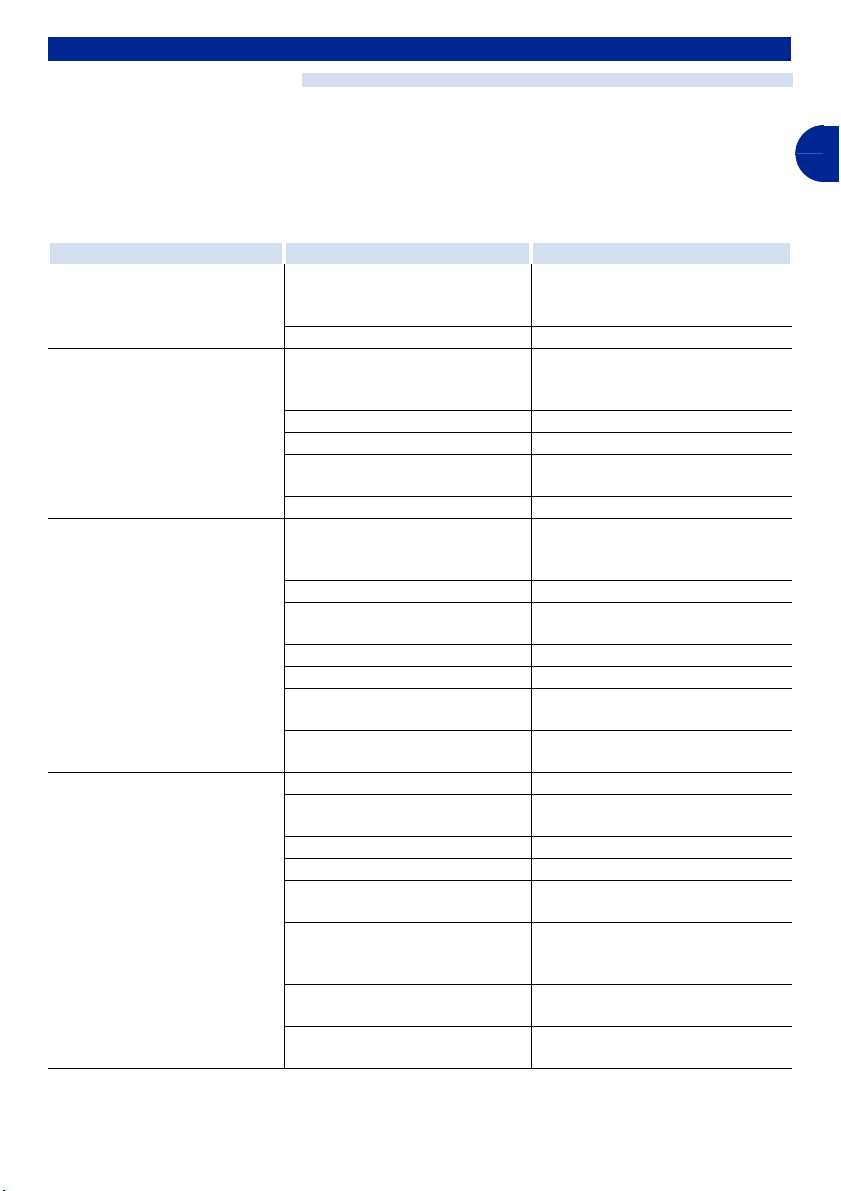

CONNECTION TO THE POWER SUPPLY

Important

The connection must be carried out by a

qualified, authorised technician, in com-

GB

pliance with current laws and using appropriate, prescribed materials.

Warning - Caution

Before carrying out any operation, turn the

main power supply off.

Proceed as indicated.

1 -Open the door (E).

2 -Unfasten the screws

to dismantle the casing (F).

3 -Use cables of the cor-

rect diameter (see

"Table of Cable Sections").

Important

Only connect the battery after having

made all the electrical connections.

Table of Cable Sections

L

12

(BATTERY

CHARGER)

door (E)

V

ENGTH UP TO 6 M

BATTERY CON-

(

NECTION)

casing (F)

230V

(POWER CABLES)

4 mm2 2.5 mm2 16 mm2 25 mm2

L

ENGTH OVER 6 M

BATTERY CONNEC-

(

TION)

4 -Connect the cable to

terminals (G) (230V

live and earth) on the

panelboard.

5 -Connect cable (H)

powering the control

panel to the socket (L).

6 -Connect the battery as

indicated in the following paragraphs.

7 -Replace the casing (F)

and fasten the screws.

8 -Close the door (E)

when the operation

has been completed.

terminals (G)

+ battery

cable (H)

- 20 -

intake (L)

fuel reserve indicator

battery charger

- battery

terminals

(G)

IDM - 40200701000.tif

C140200701.fm

User manual

Page 21

CONNECTING THE BATTERY CHARGER

The unit is set up to provide for automatic

battery recharging. If this function is to be

used, proceed as follows.

Use a cable of the section indicated in the table, and connect it to the relevant terminal on

the generator and to the positive terminal of

CONNECTING THE FUEL INDICATOR

Only use the indicator connection if there is a

fuel level probe in the tank used for the generator.

CONNECTING THE BATTERY

To start the generator it is necessary to use a

12VDC battery, with a minimum capacity of

60Ah.

Use regulation, sheathed cables, with the

section indicated in the table, and follow the

working order given below:

First connect the positive cable (+ ) of the battery to the terminal marked with the symbol

"+ " on the generator.

the battery to be charged.

If the battery to be charged is not the one

used to start the generator, the negative terminal of that battery must be connected to

the generator mass point.

Connect the proble cable (e.g. float) to the

relevant terminal (see figure above).

Then connect the negative cable (-) of the

battery to the terminal marked with the symbol "-" on the generator.

Protect the connections with specific grease.

It is advisable to use a 100A fuse, series fit-

ted in the vicinity of the starter battery positive terminal, so as to protect the unit system.

GB

ELECTRICAL CONNECTION TO THE EXTERNAL NETWORK

Important

To use electric power from the external

network, follow the instructions given below with care.

The on board electrical system must be fitted

with a relay or switch (e.g. Dometic switch

cod. AG113, available on request) to prevent

damage to the generator when the external

power supply network is connected; in this

case, it is suggested that the generator be

connected in such a way as to give it priority

with respect to the external network.

C140200701.fm

The electrical connection must be made in

compliance with current laws in the country of

use.

For proper installation by the end user, it is

recommended that you request the technical

assistance of the dealer or a specialist technician.

For the 230 V, use an approved cable with

the section indicated in the table. For connection of the Dometic switch cod. AG113 refer

to the instructions and diagram on the following pages.

- 21 -

User manual

Page 22

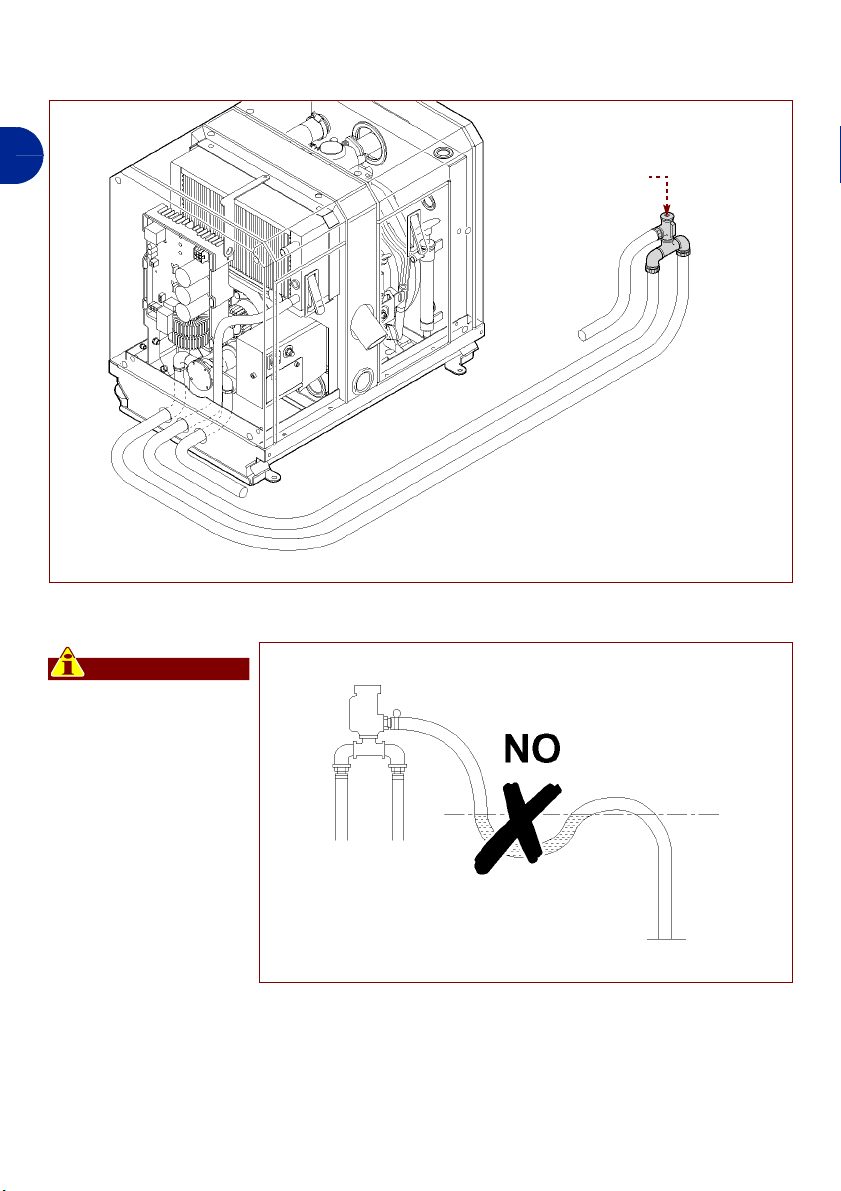

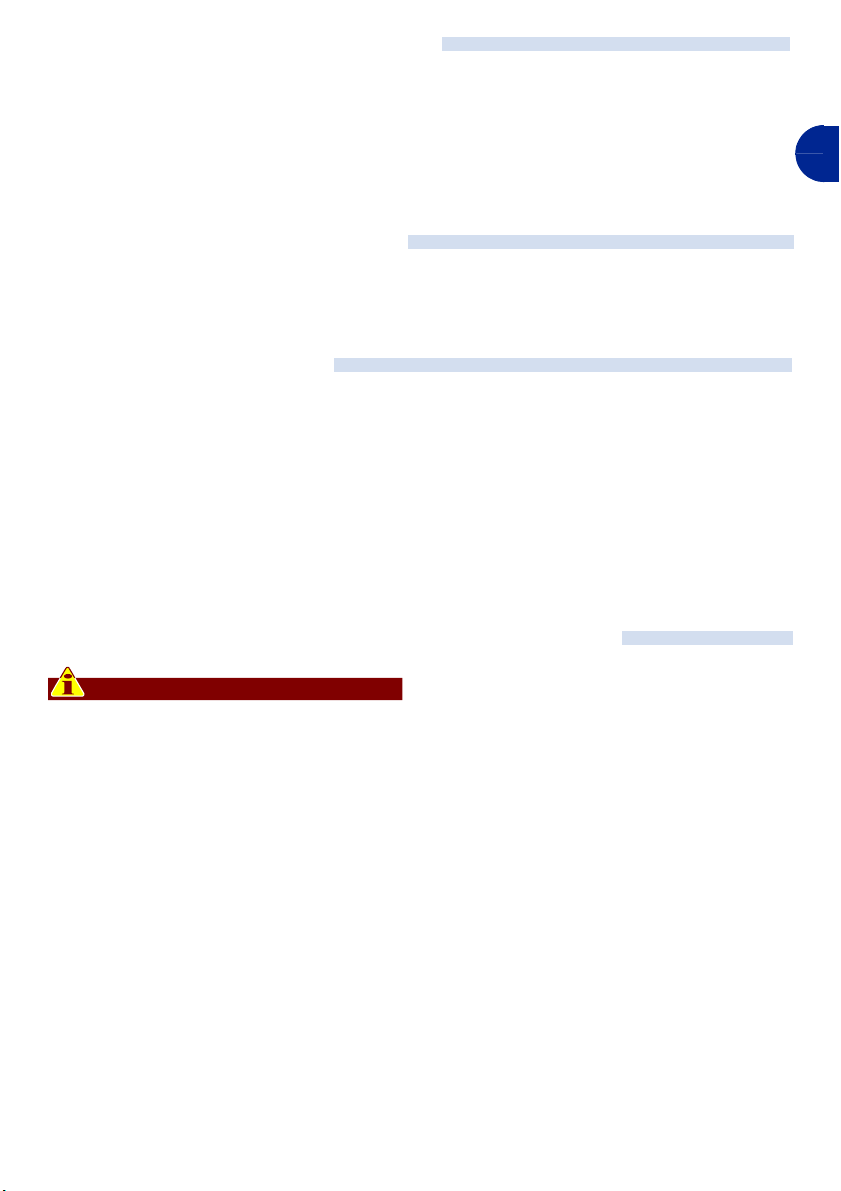

CONNECTION TO THE EXHAUST

Connect the exhaust pipe

(M) and lock it with an appropriate hose clamp.

GB

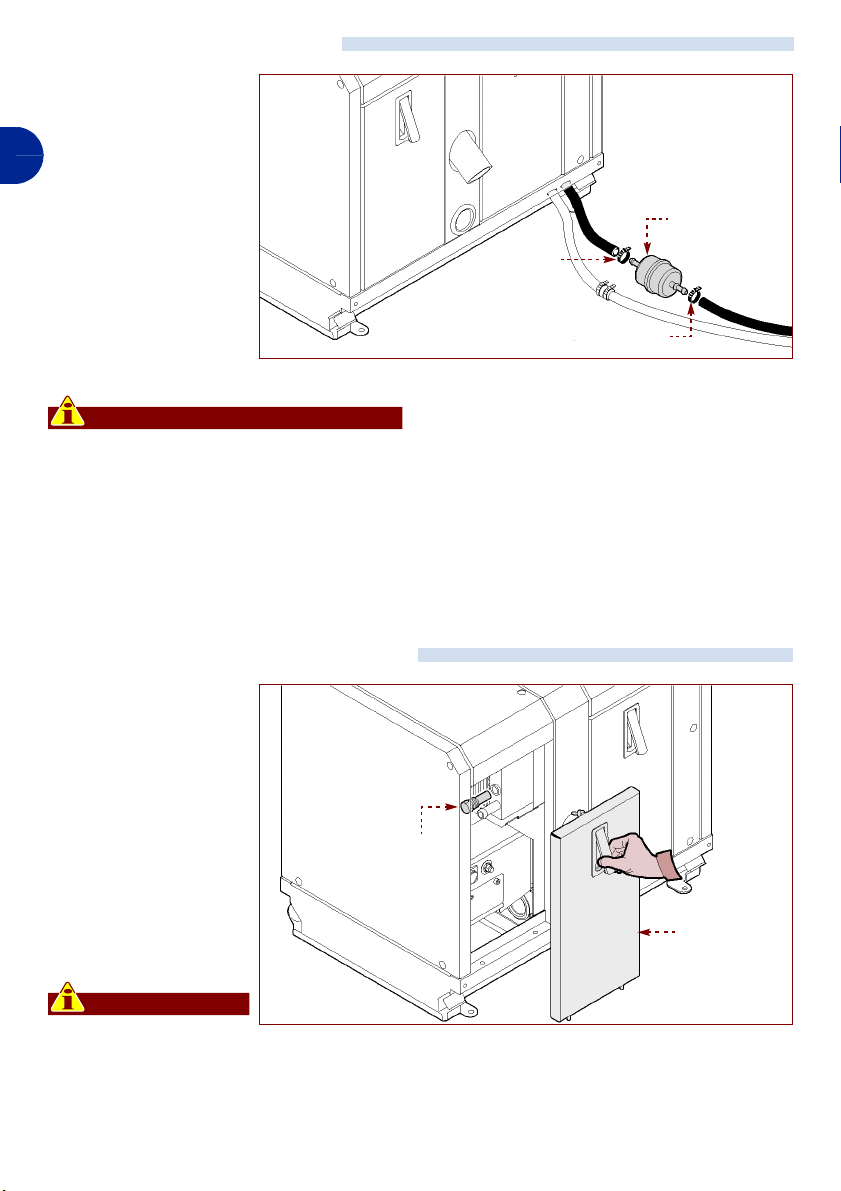

FUEL CONNECTION

1 -Connect the fuel sup-

ply pipe (N) to the filter (P) and lock it in

position with appropriate hose clamps.

2 -Connect the fuel dis-

charge pipe (Q) to the

connector (R) and

lock it in position with

appropriate hose

clamps.

pipe (Q)

connector (R)

pipe (M)

pipe (Q)

IDM - 40200701200.tif

pipe (N)

fuel filter (P)

pipe (N)

IDM - 40200701300.tif

COOLING WATER CONNECTION

Connect the water supply

pipes (S) using a connector (T) and lock them in

position with appropriate

hose clamps.

TESTING THE UNIT

The unit is tested in advance by the Manufacturer, and no particular operations need to be

carried out by the operator.

- 22 -

pipe (S)

connector

pipe (S)

IDM - 40200701400.tif

User manual

C140200701.fm

Page 23

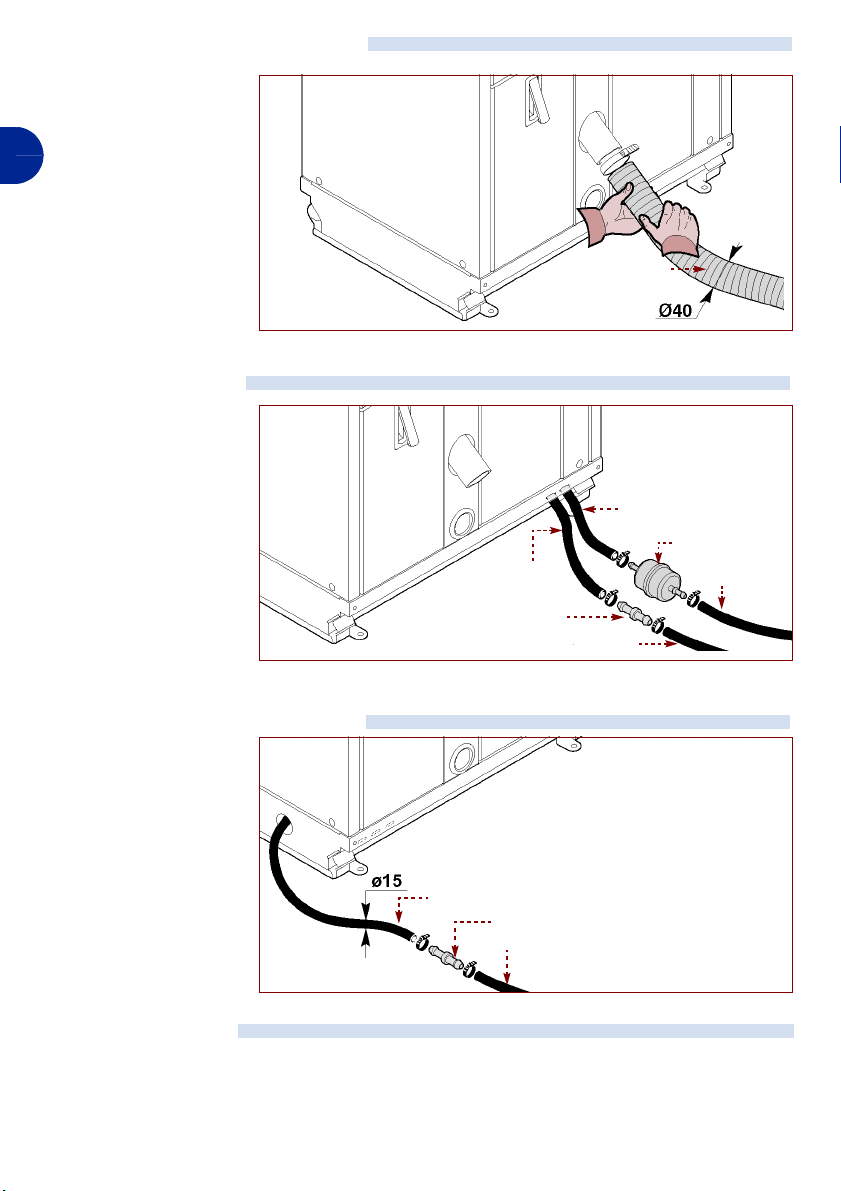

INFORMATION ON ADJUSTMENTS

ADJUSTMENT METHOD

The main functions of the unit do not require

particular adjustments by specialist techni-

cians, with the exception of working adjustments carried out by the user.

INFORMATION ON USE

RECOMMENDATIONS FOR USE AND OPERATION

The appliance has been designed and built to

satisfy all the working conditions indicated by

the manufacturer. Tampering with any of the

devices in order to achieve performance lev-

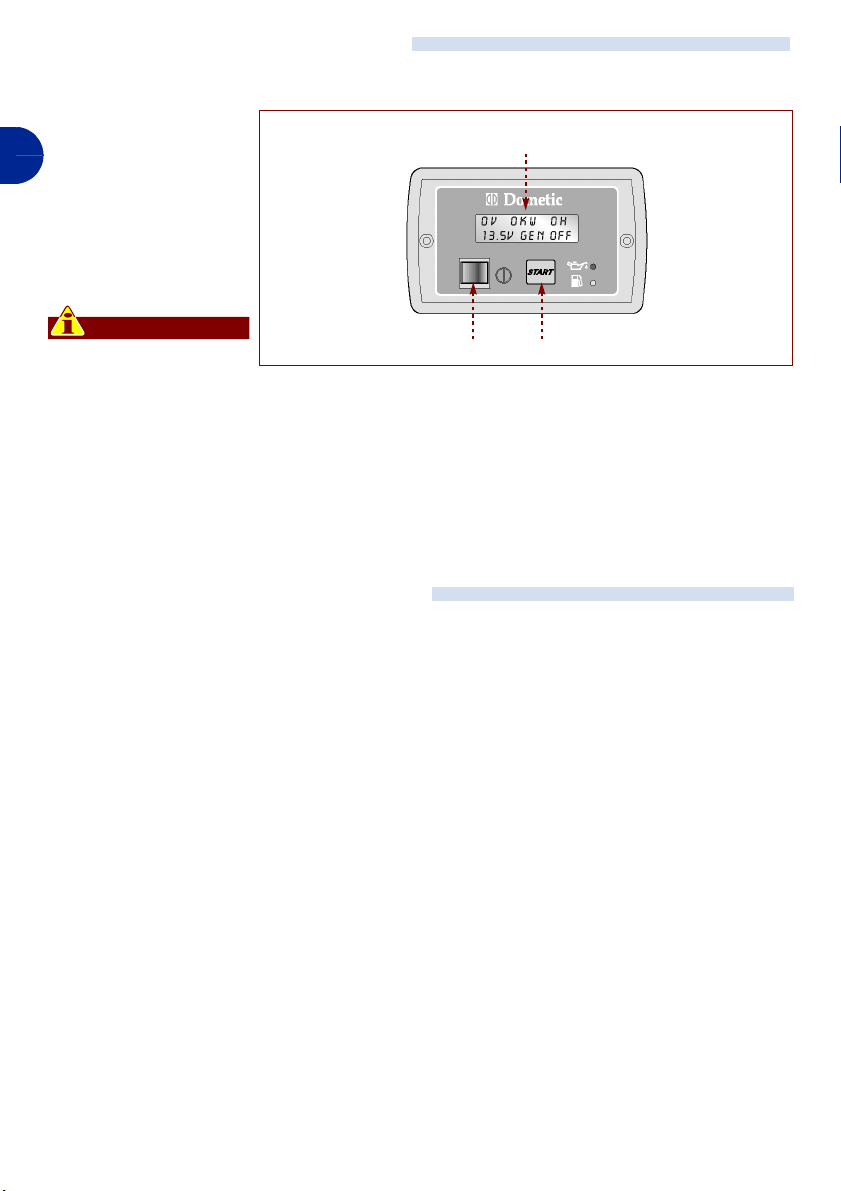

DESCRIPTION OF CONTROLS

A) Safety switch: Prepares the unit for

start-up or stops operation.

1) Position 1: the unit is powered by the battery

and is ready for start-up.

2) Position 0

B) Thermal micro-circuit breaker (12Vdc):

serves to restore power to the electrical

commands after the safety circuit has

been triggered.

Press button to restore power to the electrical controls.

: Shuts off all power to the unit.

els other than the ones foreseen may result

in risks for the health and safety of persons,

and in damage to property.

C) Starter switch: serves to enable and dis-

able the control panel and to turn the generator off.

D) Starter button: serves to turn the unit on.

E) Indicator (red light): indicates insuffi-

cient engine oil pressure

F) Indicator (orange light): Indicates that

the fuel level is low

G) Digital display: displays the working pa-

rameters and alarm messages.

GB

B

G

C140200701.fm

E

F

CD

- 23 -

A

A

IDM - 40200701500.tif

User manual

Page 24

STARTING AND STOPPING THE UNIT

Proceed as indicated.

Starting

1 -Press the switch (C)

GB

to enable the power

supply to the controls.

2 -When the display (G)

indicates "GEN OFF",

press the button (D)

to start the unit.

Important

When the unit starts up

for the first time the water pump is empty. Keep on carrying out

the start-up operation for 4/5 seconds until the water pump starts to take in sea water (priming).

Stopping

1 -Press the switch (C) to turn the unit off.

PROLONGED INACTIVITY OF THE UNIT

In the event of prolonged inactivity of the unit,

a series of operations must be carried out to

guarantee proper operation when it is used

again.

– Drain the water circuit completely.

– Disconnect the battery.

– Turn the safety switch to the "0" (OFF) po-

sition

G

CD

IDM - 40200701600.tif

To restore the unit to operation after a period

of prolonged inactivity it is recommended that

you:

– Change the engine oil (see "Changing en-

gine oil" ).

– Change the fuel filter (see "Changing the

fuel filter").

– Change the sacrificial anode (see "Chang-

ing the sacrificial anode").

- 24 -

C140200701.fm

User manual

Page 25

MAINTENANCE INFORMATION

RECOMMENDATIONS FOR MAINTENANCE

Before carrying out any type of maintenance

operation, activate all the safety devices provided and evaluate whether or not those

working on the unit and those in the vicinity of

the unit should be informed. In particular,

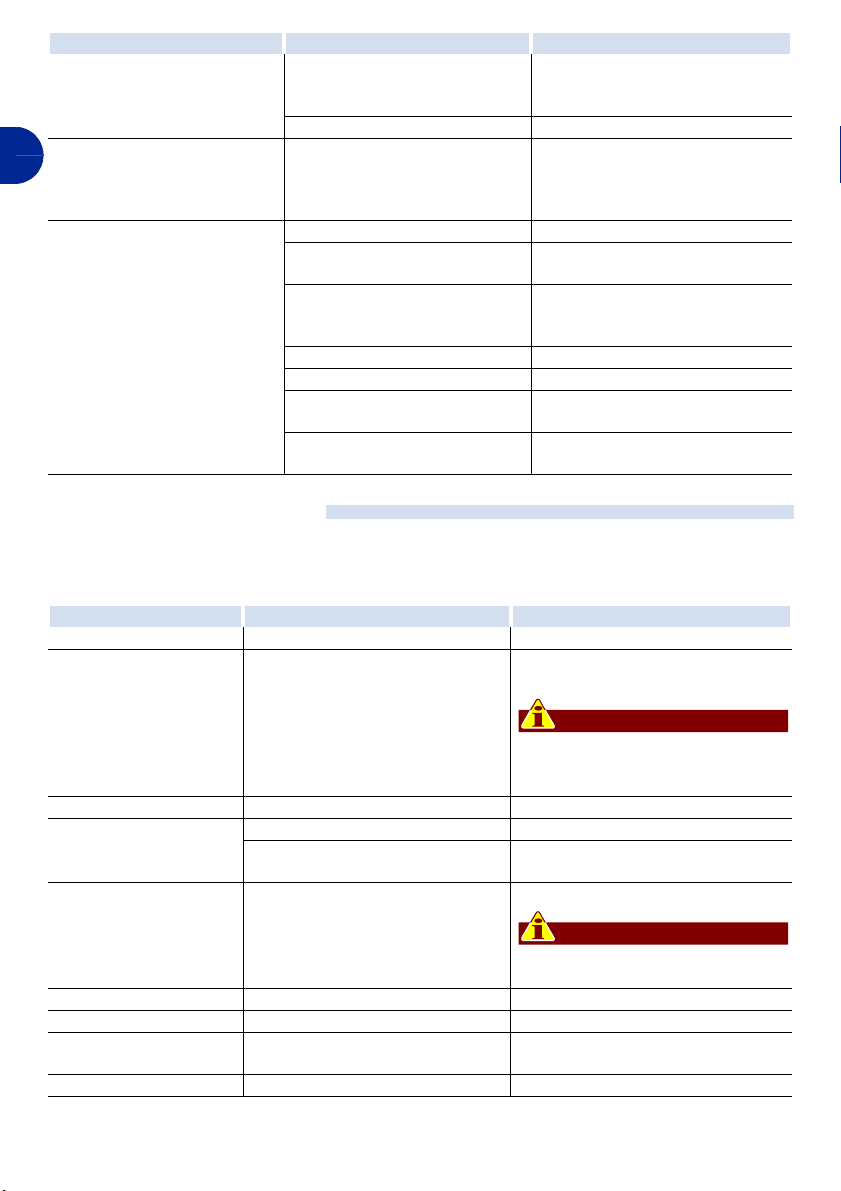

TABLE OF MAINTENANCE OPERATIONS

Important

Keep the appliance in a state of maximum

efficiency, by carrying out the planned

maintenance operations foreseen by the

manufacturer. If these are properly car-

Action Daily

check the fuel and top up

clean the fuel filter

change the fuel filter

check that there are no leaks

check the state of the injector

check the fuel injector phases

check the fuel injection pump

check the lubricant level in the oil sump

change the lubricant oil

clean the oil filter

check that there are no oil leaks

adjust play in the inlet and outlet valves

check that delivery connector is tight

check pump rotor

clean and deoxidise metal parts

change the zinc anode

change the piston rings

X* = must be carried out by an authorised YANMAR dea ler or by qualified Dometic personnel..

C140200701.fm

X

X

after use

X

before use

X

after use

make sure that the surrounding area is clearly signed and prevent access to all the devices that might, if activated, result in

unexpected dangers or endanger the health

and safety of persons.

ried out, they will ensure the appliance

provides optimum performance, a longer

working life and constant compliance

with the safety requirements.

1st month

FIRST 50

hours

the first time

the first time

X

X*

every 3

months or

200 hours

X

X

2nd time and following

X

every 6

months or

400 hours

X

X*

X*

X*

2nd time and following

X*

X

yearly or

1000 hours

X*

X

X

X

GB

- 25 -

User manual

Page 26

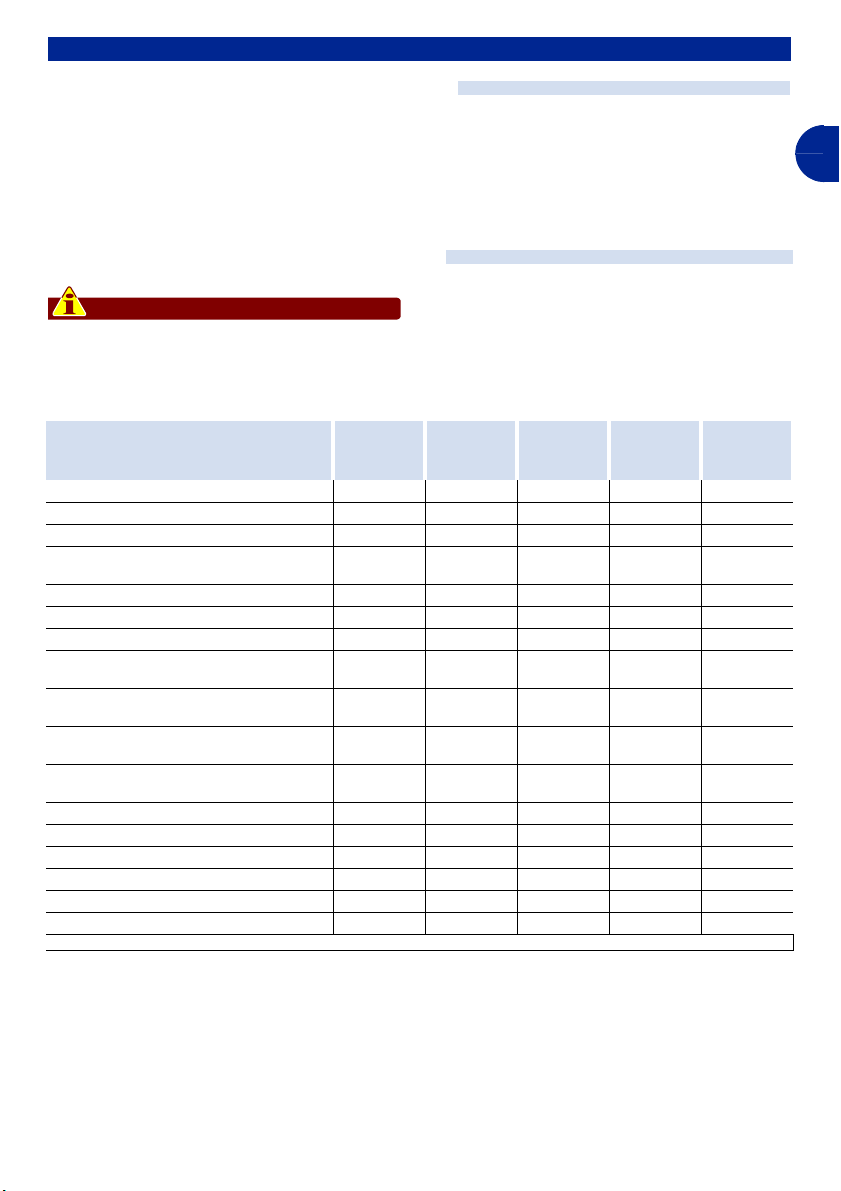

RECOMMENDED LUBRICANTS

Use oils and lubricants with characteristics

the same as those indicated in the table.

GB

IDM - 40200702700.tif

CHECK OIL LEVEL

Proceed as indicated.

1 -Turn the unit on and

allow it to warm up for

a few minutes.

2 -Turn the unit off.

3 -Wait for a few min-

utes to allow all the oil

to flow into the sump.

4 -Open the door (A).

5 -Extract the dipstick

(B) and check the oil

level; top up if neces-

sary. For the amounts

of oil, see "Technical data".

Important

The oil level must be between the minimum and maximum marks.

Do not mix oils with different characteristics or from different manufacturers.

rod (B)

door (A)

6 -Close the door (A) when the operation

has been completed.

- 26 -

IDM - 40200701700.tif

User manual

C140200701.fm

Page 27

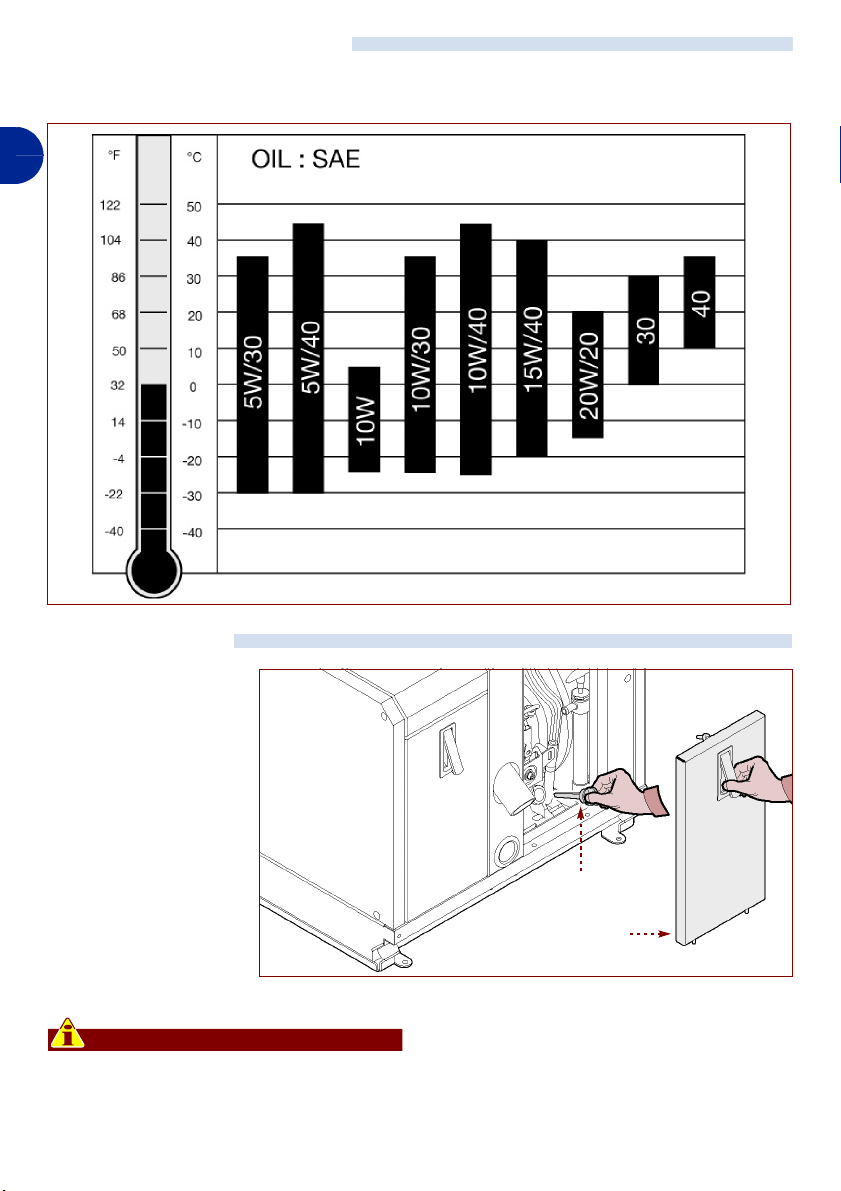

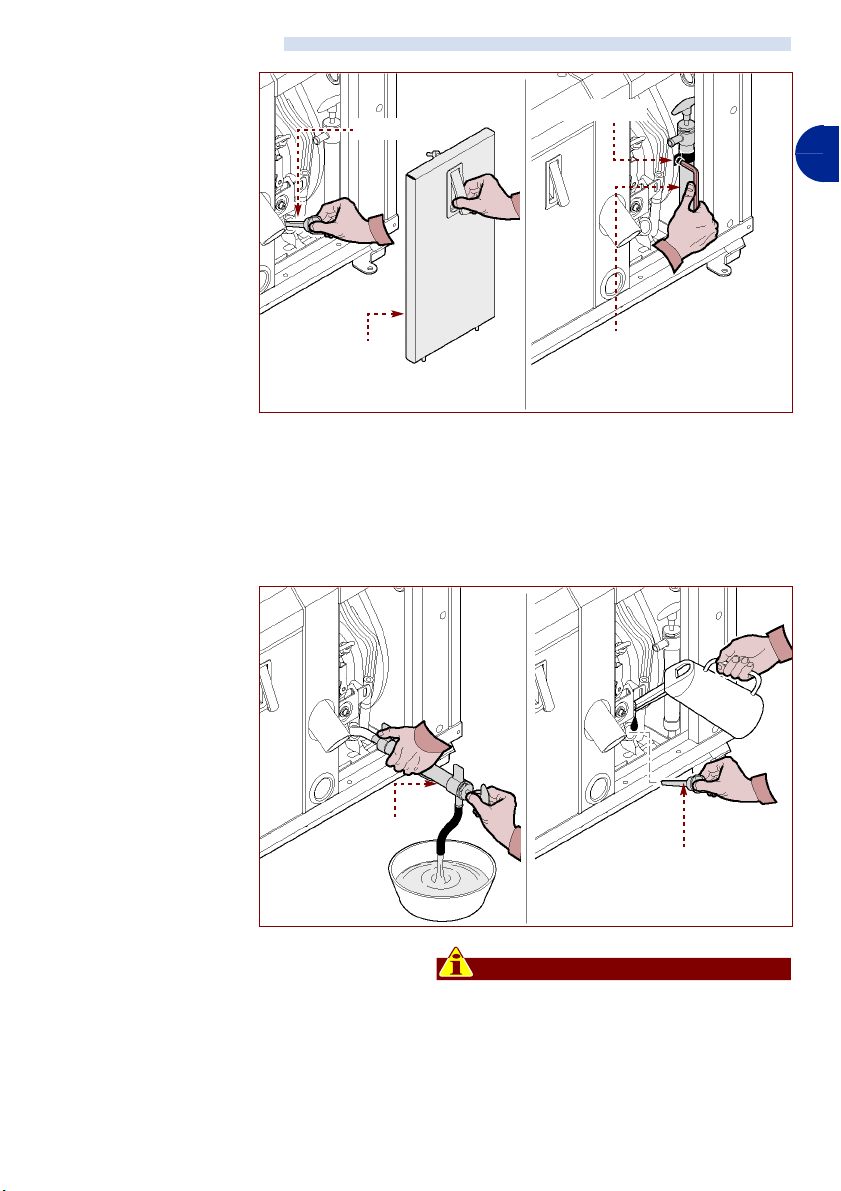

CHANGING ENGINE OIL

Proceed as indicated.

1 -Turn the unit off.

2 -Leave the unit to cool

down sufficiently, to

avoid the risk of burn-

ing.

3 -Open the door (A).

4 -Provide a container of

sufficient capacity.

For the amounts of

oil, see "Technical da-

ta".

5 -Extract the dipstick

(B).

6 -Unfasten the screw

(C) to extract the pump (D).

7 -Adjust the pump man-

ually to drain all the oil

into the container.

8 -Replace the pump (D)

in its housing and fix it

with the screw (C).

9 -Pour in the new oil until

reaching the correct

level on the dipstick

(B) (see "Check oil

level").

10 -Replace the dipstick

(B).

11 -Close the door (A)

when the operation

has been completed.

C140200701.fm

12 -Turn the unit on and allow it to warm up

for a few minutes.

13 -Turn the unit off and check the oil level

(see "Check oil level").

rod (B)

door (A)

pump (D)

screw (C)

GB

pump (D)

IDM - 40200701800.tif

rod (B)

IDM - 40200701900.tif

Important

Do not discard used oil, but hand it over to

an authorised disposal organisation in

compliance with current local laws.

Use oils and lubricants of the types recommended by the manufacturer.

- 27 -

User manual

Page 28

CHANGING THE FUEL FILTER

Proceed as indicated.

1 -Switch the appliance

off and leave it to

GB

cool.

2 -Provide a container to

catch any leaks.

3 -Loosen the hose

clamps (E).

4 -Remove the filter (F)

and replace it.

5 -Lock the hose clamps

(E) when you have

done this.

Important

Do not discard pollutants into the environment. They must be disposed of according to current laws.

tie (E)

tie (E)

fuel filter (F)

IDM - 40200702000.tif

CHANGING THE SACRIFICIAL ANODE

Proceed as indicated.

1 -Switch the appliance

off and leave it to

cool.

2 -Open the door (A).

3 -Unscrew the sacrifi-

cial anode (M) and re-

place it with a new

anode (M)

one.

4 -Close the door (A)

when the operation

has been completed.

Important

Do not discard pollutants into the environment. They must be

disposed of according to current laws.

- 28 -

door (A)

C140200701.fm

IDM - 40200702800.tif

User manual

Page 29

TROUBLESHOOTING INFORMATION

FINDING MALFUNCTIONS

The aim of the following information is to help

identify and correct any malfunctions and

problems that might occur during use. Some

of these problems may be solved by the user,

while for all the others specific technical

Problem Cause Remedy

When the starter button is

pressed the control panel does

not light up

When the starter button is

pressed the unit does not start

The starter motor turns, but the

unit does not start

The unit tends to shut down

C140200701.fm

The power cables are

disconnected or they do not

provide a continuous supply

Battery low Change the battery

The power cables are

disconnected or they do not

provide a continuous supply

The inverter is broken Contact the service department

The starter motor does not turn Contact the service department

electrical power disconnected

Battery low Change the battery

The power cables are

disconnected or they do not

provide a continuous supply

The inverter is broken Contact the service department

Malfunction in the pump power

supply

Engine malfunction Contact the service department

Injectors dirty or faulty Contact the service department

Cooling air/water pipe blocked

Sea water pump rotor worn

The inverter is broken Contact the service department

Malfunction in the pump power

supply

Injectors dirty or faulty Contact the service department

Air filter blocked Clean the air filter

Cooling air/water pipe blocked

Oil level too high

Sea water pump rotor worn

Voltage required higher than 3,5

kW

knowledge or abilities are required, so that

they must only be carried out by qualified

technicians of proven experience in the specific field of operation.

Contact the service department

Contact the service department

Press the restore button to

reconnect the electrical power.

Contact the service department

Contact the service department

Check the cooling air/water pipe

and clean it if necessary

Replace the rotor (see “Changing

the water pump rotor”)

Contact the service department

Check the cooling air/water pipe

and clean it if necessary

Check the oil level, and remove

excess oil if necessary (see “Check

oil level”)

Replace the rotor (see “Changing

the water pump rotor”)

Decrease the required voltage load

GB

- 29 -

User manual

Page 30

Problem Cause Remedy

The power cables are

The unit is not delivering power

The unit starts and accelerates

GB

strongly, then stops and the

message "generator alert" is

displayed

The power supplied is not

constant

disconnected or they do not

provide a continuous supply

The inverter is broken Contact the service department

The inverter is broken Contact the service department

The inverter is broken Contact the service department

Malfunction in the pump power

supply

The power cables are

disconnected or they do not

provide a continuous supply

Injectors dirty or faulty Contact the service department

Air filter blocked Clean the air filter

Cooling air/water pipe blocked

Voltage required higher than 3,5

kW

TABLE OF ALARM SIGNALS

If the problem or malfunction encountered is

not listed in the table, you should check the

Alarm Problem Remedy

LOW BATTERY Battery low Change the battery

OIL CHANGE

NO FUEL Fuel level too low Fill up with fuel

OIL TEMP PRESS

Indicates that it is necessary to

change the engine oil

Insufficient oil in engine Top up with oil of the same type

Exhaust gas temperature too high

"Alarm signals" table given below.

Change the engine oil (see “Changing

engine oil”)

On restarting the unit, keep the start

switch pressed for a long time to

reset the hour counter.

Check the cooling air/water pipe and

clean it if necessary

See “Finding malfunctions”

Contact the service department

Contact the service department

Contact the service department

Check the cooling air/water pipe

and clean it if necessary

Decrease the required voltage load

Important

GENERATOR ALERT! General alarm

OVERLOAD! Voltage required higher than 3,5 kW Decrease the required load

SHORT CIRCUIT Output cable short-ircuit Eliminate the short-circuit

OVER TEMPERATURE Inverter overheating

LOW POWER ENGINE Engine revs too low Decrease the required load

Important

If the problem persists, contact the

service department

Switch the appliance off and leave it to

cool.

- 30 -

C140200701.fm

User manual

Page 31

Alarm Problem Remedy

RESTART GEN? Unit overheating

GEN CAL

GEN WAIT The unit is paused before starting

GEN ON Unit running

GEN OFF Unit off or ready for START

The unit is performing automatic setup prior to starting

Switch the appliance off and leave it to

cool.

Wait until the operation has ended

then start the unit

Wait until the operation has ended

then start the unit

INFORMATION ON SPARE PARTS

RECOMMENDATIONS WHEN CHANGING PARTS

Before replacing any parts, activate all the

safety devices provided and evaluate the

need to inform the persons working on the

machine and any persons in the vicinity.

In particular, make sure that the surrounding

areas are adequately marked and prevent

access to any of the devices that might, if active, result in unexpected dangers and risks

to the health and safety of persons. Should it

be necessary to change worn components,

only use original spare parts.

The manufacturer will not be liable for any

damage to persons or components deriving

from the use of non-original spare parts and

from repairs carried out without the authorisation of the manufacturer.

GB

CHANGING THE WATER PUMP ROTOR

Proceed as indicated.

1 -Switch the appliance

off and leave it to

cool.

2 -Unfasten the screws

to dismantle the cas-

ing (M).

3 -Unfasten the screws

to remove the cover

C140200701.fm

(N).

4 -Extract and replace

the rotor (P).

5 -Fit the cover (N) and

fix it with the screws.

6 -Fit the casing (M) and fix it with the

casing (M)

- 31 -

rotor (P)

cover (N)

IDM - 40200702200.tif

screws when this operation has been

completed.

User manual

Page 32

DECOMMISSIONING THE UNIT

When decommissioning, leave the unit, disconnected from the power supply, in a suitable area so that it will not get in the way and

will not be within easy access of unauthor-

GB

ised persons.

The unit must be disposed of by experienced

operators, in compliance with current regula-

tions regarding safety at work.

When decommissioning, the various types of

material, such as electrical and electronic

components, must be separated and disposed of according to law.

- 32 -

C140200701.fm

User manual

Page 33

WIRING DIAGRAM

GB

DESCRIPTION

1 THREE PHASE COIL

2 AUXILIARY COIL

3 AUXILIARY COIL

4 INVERTER MODULE

5 9 PIN CONNECTOR

6 12V REGULATOR

7 EMERGENCY SWITCH 0/1

8 PRESSURE SWITCH

9 STARTER RELAY

10 STARTER MOTOR

11 9 PIN CONNECTOR

12 INTERNAL CONTROL PANEL

13 THERMAL CUTOUT

14 INTERFACE MODULE

15 ELECTROSTOP

16 12 PIN CONNECTOR

17 TEMPERATURE PROBE

18 2 PIN CONNECTOR

19 CABIN CONTROL PANEL

20 12 PIN CONNECTOR

21 AUXILIARY COIL

22 CYLINDRICAL COUPLING CONNECTOR

23 PUMP RELAY

24 ENGINE STARTER RELAY

25 4 PIN CONNECTOR

26 6 PIN CONNECTOR

C140200701.fm

- 33 -

User manual

Page 34

GB

CONNECTION TO THE EXTERNAL POWER SUPPLY

AG113 switching accessory (available on demand)

1) Use cables of suitable section (see table in paragraph "electrical connection")

2) Fix the AG113 switch in a position that facilitates connection.

3) Break the cable connecting the mains input with the cut-out on the control

panel, so that it is possible to make the connections as shown in the wiring

diagram.

4) Connect the cables to the switch, it is necessary to insert a jumper between

terminal 1 and R1 and between terminal 3 and R3.

5) In positions R2 and R4, connect the cables from the generator 230 V terminal

board.

User

External

socket

Battery

- 34 -

AG113 switch

Generator

C140200701.fm

User manual

Page 35

Page 36

© DOMETIC - 2006 Tutti i diritti riservati - Stampato in Italia Realizzato da IDM

Nessuna parte di questo manuale può essere riprodotta, copiata o

divulgata con qualsiasi mezzo senza l'autorizzazione scritta della

DOMETIC

Le figure, le descrizioni, i riferimenti ed i dati tecnici contenuti nel

presente manuale sono indicativi e non impegnativi.

La DOMETIC si riserva il diritto di apportare in qualsiasi momento

e senza preavviso tutte le modifiche che riterrà opportuno, nella

costante ricerca di migliorare la qualità e la sicurezza, senza

impegnarsi ad aggiornare di volta in volta questo manuale.

© 2006 - Autore dei testi: IDM esperti in comunicazione tecnica Forlì - I testi possono essere riprodotti, integralmente o

parzialmente, purché venga citato l’autore.

Conservare questo documento per futuri riferimenti.

Page 37

SOMMARIO

INFORMAZIONI GENERALI...............................6

INFORMAZIONI TECNICHE ............................... 8

INFORMAZIONI SULLA SICUREZZA..............11

INFORMAZIONI SULLA MOVIMENTAZIONE

E INSTALLAZIONE .......................................... 15

INFORMAZIONI SULLE REGOLAZIONI.......... 23

INFORMAZIONI SULL'USO............................. 23

INFORMAZIONI SULLA MANUTENZIONE ..... 25

INFORMAZIONI SUI GUASTI .......................... 29

INFORMAZIONI SULLE SOSTITUZIONI ......... 31

SCHEMA ELETTRICO ..................................... 33

INDICE ANALITICO

A

Accensione e spegnimento apparecchiatura

Acqua di raffreddamento, allacciamento (22)

Allacciamento acqua di raffreddamento (22)

Allacciamento elettrico (20)

Allacciamento gasolio (22)

Allacciamento scarico fumi (22)

Anodo sacrificale, cambio (28)

Apparecchiatura e costruttore, identificazione (6)

Apparecchiatura, collaudo (22)

Apparecchiatura, descrizione generale (8)

Apparecchiatura, dismissione (32)

Apparecchiatura, inattività prolungata (24)

Apparecchiatura, installazione (16)

Assistenza, modalità di richiesta (7)

C

Cambio anodo sacrificale

Cambio filtro combustibile (28)

Cambio olio motore (27)

Carico e trasporto (15)

Collaudo apparecchiatura (22)

Comandi, descrizione (23)

Controllo livello olio (26)

Costruttore e apparecchiatura, identificazione (6)

D

Dati tecnici

Deposito, modalità di (16)

Descrizione comandi (23)

Descrizione generale apparecchiatura (8)

Disimballo e imballo (15)

Dismissione apparecchiatura (32)

Dispositivi di sicurezza (10)

F

Filtro combustibile, cambio

Funzionamento e l’uso, norme per (12)

Funzionamento e uso, raccomandazioni (23)

G

Glossario e terminologie

Guasti, ricerca (29)

I

Identificazione costruttore e apparecchiatura

Imballo e disimballo (15)

Inattività prolungata dell'apparecchiatura (24)

Informazione e sicurezza, segnali di (14)

C140200701.fm

Installazione apparecchiatura (16)

Installazione e movimentazione, raccomandazioni per

la

Intervalli di manutenzione, tabella (25)

L

Livello olio, controllo

Lubrificanti consigliati (26)

M

Manuale, scopo del

(9)

(15)

(28)

(28)

(7)

(26)

(6)

(24)

(6)

Manutenzione, raccomandazioni per la (25)

Manutenzione, tabella intervalli di (25)

Modalità di deposito (16)

Modalità di richiesta assistenza (7)

Modalità per le regolazioni (23)

Movimentazione e installazione, raccomandazioni per

(15)

la

Movimentazione e l’installazione, norme per (11)

Movimentazione e sollevamento (16)

N

Norme generali

Norme per il funzionamento e l’uso (12)

Norme per la movimentazione e l’installazione (11)

Norme per la sicurezza sull’impatto ambientale (13), (21)

Norme per le regolazioni e la manutenzione (12)

O

Olio motore, cambio

Organi principali (8)

P

Pompa acqua, sostituzione girante

R

Raccomandazioni per l'uso e funzionamento

Raccomandazioni per la manutenzione (25)

Raccomandazioni per la movimentazione e

installazione

Raccomandazioni per la sostituzione parti (31)

Regolazioni e la manutenzione, norme per (12)

Ricerca guasti (29)

Richiesta assistenza, modalità di (7)

S

Scarico fumi, allacciamento

Scopo del manuale (6)

Segnali di sicurezza e informazione (14)

Sicurezza e informazione, segnali di (14)

Sicurezza per lo smaltimento di Rifiuti di Apparecchiature

Elettriche ed Elettroniche (Direttiva RAEE 2002/96)

(21)

Sicurezza sull’impatto ambientale, norme per (13), (21)

Sicurezza, dispositivi di (10)

Smaltimento di Rifiuti di Apparecchiature Elettriche ed

Elettroniche (Direttiva RAEE 2002/96), sicurezza

Sollevamento e movimentazione (16)

Sostituzione girante pompa acqua (31)

Sostituzione parti, raccomandazioni per la (31)

Spegnimento e accensione apparecchiatura (24)

T

Tabella intervalli di manutenzione

Tabella segnalazione allarmi (30)

Terminologie e glossario (7)

Trasporto e carico (15)

U

Usi impropri

Uso e funzionamento, raccomandazioni (23)

- 5 -

(11)

(27)

(31)

(15)

(22)

(25)

(10)

Manuale d’uso

I

(23)

(13),

(13), (21)

Page 38

INFORMAZIONI GENERALI

SCOPO DEL MANUALE

Questo manuale, che è parte integrante

dell'apparecchiatura, è stato realizzato dal

costruttore per fornire le informazioni necessarie a coloro che sono addestrati e autorizzati ad interagire con essa nell'arco della sua

vita prevista.

I

Queste informazioni sono fornite dal Costruttore nella propria lingua originale (italiano) e

possono essere tradotte in altre lingue per

soddisfare le esigenze legislative e/o commerciali.

Oltre ad adottare una buona tecnica di utilizzo, i destinatari delle informazioni devono

leggerle attentamente ed applicarle in modo

rigoroso.

Un po' di tempo dedicato alla lettura di tali informazioni permetterà di evitare rischi alla

salute e alla sicurezza delle persone e danni

economici.

Nel caso in cui, in questo manuale, vi siano

delle informazioni supplementari rispetto

all'effettivo allestimento dell'apparecchiatura,

esse non interferiscono con la lettura.

Conservare questo manuale per tutta la durata di vita dell'apparecchiatura in un luogo

noto e facilmente accessibile, per averlo

sempre a disposizione nel momento in cui è

necessario consultarlo.

Il costruttore si riserva il diritto di apportare

modifiche senza l'obbligo di fornire preventivamente alcuna comunicazione.

Per evidenziare alcune parti di testo di rilevante importanza o per indicare alcune specifiche importanti, sono stati adottati alcuni

simboli il cui significato viene di seguito descritto.

Pericolo - Attenzione

Indica situazioni di grave pericolo che, se

trascurate, possono mettere seriamente a

rischio la salute e la sicurezza delle persone.

Cautela - Avvertenza

Indica che è necessario adottare comportamenti adeguati per non mettere a rischio

la salute e la sicurezza delle persone e non

provocare danni economici.

Importante

Indica informazioni tecniche di particolare importanza da non trascurare.

IDENTIFICAZIONE COSTRUTTORE E APPARECCHIATURA

La targhetta di identificazione raffigurata è appli-

A

cata direttamente

sull'apparecchiatura.

A) Identificazione co-

B

struttore

B) Marcature di confor-

mità

C) Modello/Numero di

matricola

C

D

E

D) Anno di costruzione

E) Dati tecnici

- 6 -

C140200701.fm

IDM - 40200700100.tif

Manuale d’uso

Page 39

GLOSSARIO E TERMINOLOGIE

Vengono descritti alcuni termini ricorrenti

all'interno del manuale in modo da fornire

una visione più completa del loro significato.

Installatore: tecnico scelto e autorizzato dal

Costruttore o dal suo mandatario, fra coloro

che hanno i requisiti per eseguire l'installazione ed il collaudo dell'apparecchiatura.

Manutenzione ordinaria: insieme delle operazioni necessarie a conservare la conveniente funzionalità ed efficienza

dell'apparecchiatura. Normalmente queste

operazioni vengono programmate dal Costruttore che definisce le competenze necessarie e le modalità di intervento.

MODALITÀ DI RICHIESTA ASSISTENZA

Per qualsiasi esigenza rivolgersi al Servizio

Assistenza del costruttore.

Manutenzione straordinaria: insieme delle

operazioni necessarie a conservare la conveniente funzionalità ed efficienza dell'apparecchiatura. Queste operazioni non sono

programmate dal Costruttore e devono essere eseguite dal manutentore.

Manutentore esperto: tecnico scelto ed autorizzato dal costruttore fra coloro che hanno

i requisiti, le competenze e le informazioni

per eseguire interventi di riparazione e manutenzione straordinaria sull'apparecchiatura.

Per ogni richiesta di assistenza tecnica, indicare i dati riportati sulla targhetta di identificazione, le ore approssimative di utilizzo e il

tipo di difetto riscontrato.

I

C140200701.fm

- 7 -

Manuale d’uso

Page 40

INFORMAZIONI TECNICHE

DESCRIZIONE GENERALE APPARECCHIATURA

Il gruppo elettrogeno per imbarcazioni “BLUTEC 40 D”, è un'apparecchiatura progettata

e costruita per essere installata entrobordo

su natanti.

Viene impiegata nel settore della nautica pro-

fessionale e civile per generare corrente sulle

imbarcazioni da diporto.

L'apparecchiatura è dotata di un quadro comandi da dove è possibile controllare tutte le

funzioni operative.

I

ORGANI PRINCIPALI

– Motore endotermico (A): per fornire

energia a tutti gli organi principali.

– Alternatore (B): trasforma l'energia mec-

canica del motore in energia elettrica a

corrente alternata.

– Scambiatore di calore (C): raffredda

l'aria all'interno dell'apparecchiatura attraverso lo scambio termico con l'acqua marina.

scambiatore di calore (C)

– Pompa acqua (D): alimenta il circuito di

– Inverter (E): converte la tensione che lo

– Quadro comandi (F): comprende i dispo-

raffreddamento acqua marina

alimenta in una tensione di qualità superiore di 230V/50Hz perfettamente stabile.

sitivi per attivare e controllare tutte le funzioni operative

quadro comandi (F)

alternatore (B)

pompa acqua (D)

inverter (E)

- 8 -

C140200701.fm

motore endotermico (A)

IDM - 40200700200.tif

Manuale d’uso

Page 41

DATI TECNICI

IDM - 40200700300.tif

Modello apparecchiatura Unità di misura BLUTEC 40D

Dimensioni

A mm 570

B mm 406

C mm 528

Peso kg 85

Dati tecnici motore

Modello YANMAR L 70 N / 320cc

Potenza massima HP 6,1

Regime massimo di esercizio giri/min 3300

Consumo combustibile lt 1,3

Capacità coppa olio lt 1,1

Inclinazioni consentite ± 20°

Dati tecnici generatore

Potenza elettrica massima in uscita (continua) W 3500

Tensione in uscita V 230±10%

Frequenza Hz 50

Classe di isolamento H

I

C140200701.fm

- 9 -

Manuale d’uso

Page 42

DISPOSITIVI DI SICUREZZA

L'illustrazione indica la posizione dei dispositivi.

– Riparo fisso (A): impedisce l'accesso agli

organi in movimento dell'apparecchiatura.

Può essere aperto solo con un'azione volontaria e con l'ausilio di un utensile.

I

sensore (C)

riparo fisso (A)

– Riparo mobile (B): impedisce l'accesso

all'interno dell'apparecchiatura.

– Sensore temperatura (C): disattiva l'ap-

parecchiatura in caso di temperatura troppo elevata dei gas di scarico.

riparo fisso (A)

USI IMPROPRI

Qualsiasi utilizzo diverso da quello autorizzato è da considerarsi USO IMPROPRIO.

riparo mobile (B)

È assolutamente vietato l'uso di questa

apparecchiatura in ambienti esplosivi o

esposti agli agenti atmosferici.

- 10 -

Manuale d’uso

IDM - 40200700400.tif

C140200701.fm

Page 43

INFORMAZIONI SULLA SICUREZZA

NORME GENERALI

– Il costruttore, in fase di progettazione e co-

struzione, ha posto particolare attenzione

agli aspetti che possono provocare rischi

alla sicurezza e alla salute delle persone che

interagiscono con l'apparecchiatura. Oltre al

rispetto delle leggi vigenti in materia, egli ha

adottato tutte le “regole della buona tecnica

di costruzione”. Scopo di queste informazioni è quello di sensibilizzare gli utenti a porre

particolare attenzione per prevenire qualsiasi rischio. La prudenza è comunque insostituibile. La sicurezza è anche nelle mani di

tutti gli operatori che interagiscono con l'apparecchiatura.

– Leggere attentamente le istruzioni riportate

nel manuale in dotazione e quelle applicate

direttamente, in particolare rispettare quelle riguardanti la sicurezza. Un po' di tempo

dedicato alla lettura risparmierà spiacevoli

incidenti; è sempre troppo tardi ricordarsi di

quello che si sarebbe dovuto fare quando

ciò è già accaduto.

– Prestare attenzione al significato dei sim-

boli delle targhette applicate; la loro forma

e colore sono significativi ai fini della sicurezza. Mantenerle leggibili e rispettare le informazioni indicate.

– Non manomettere, non eludere, non elimi-

nare o bypassare i dispositivi di sicurezza

installati. Il mancato rispetto di questo requisito può recare rischi gravi per la sicurezza e la salute delle persone.

– Il personale che effettua qualsiasi tipo di in-

tervento in tutto l'arco di vita dell'apparecchiatura, deve possedere precise

competenze tecniche, particolari capacità

ed esperienze acquisite e riconosciute nel

settore specifico. La mancanza di questi requisiti può causare danni alla sicurezza e

alla salute delle persone.

– In fase d'esercizio utilizzare solo gli indu-

menti e/o i dispositivi di protezione individuali indicati nelle istruzioni per l'uso fornite

dal costruttore e quelli previsti dalle leggi vigenti in materia di sicurezza sul lavoro.

– Durante il normale uso o per qualsiasi inter-

vento, mantenere gli spazi perimetrali, in

particolare quelli d'accesso ai comandi, in

condizioni adeguate per non causare rischi

alla sicurezza e alla salute delle persone.

– Ogni intervento, salvo quando espressa-

mente indicato, va eseguito a motore spento e adeguatamente raffreddato per evitare

rischi di scottature.

I

NORME PER LA MOVIMENTAZIONE E L'INSTALLAZIONE

– Eseguire il sollevamento e la movimenta-

zione nel rispetto delle informazioni fornite

dal costruttore e riportate direttamente

sull'imballo, sull'apparecchiatura e nelle

istruzioni per l'uso.

– Il personale che effettua il carico, lo scarico

e la movimentazione dell'apparecchiatura,

C140200701.fm

deve possedere capacità ed esperienza

acquisita e riconosciuta nel settore specifico e deve avere la padronanza dei mezzi di

sollevamento da utilizzare.

– Il carico ed il trasporto devono essere ese-

guiti con mezzi di portata adeguata, mediante l'ancoraggio dell'apparecchiatura

nei punti previsti dal costruttore. Chi è autorizzato ad effettuare tali operazioni dovrà

possedere specifiche capacità ed esperienza, al fine di salvaguardare la propria sicurezza e quella delle persone coinvolte.

– Tutte le fasi di installazione devono essere

considerate, sin dalla realizzazione del progetto generale. Prima di iniziare tali fasi, oltre alla definizione della zona di

installazione, colui che è autorizzato ad

eseguire queste operazioni dovrà, se necessario, attuare un “piano di sicurezza”

per salvaguardare l'incolumità delle persone direttamente coinvolte ed applicare in

- 11 -

Manuale d’uso

Page 44

modo rigoroso tutte le leggi, con particolare

riferimento a quelle sui cantieri mobili.

– È necessario accertarsi che la zona di installa-

zione sia predisposta per tutti gli allacciamenti

di aspirazione, alimentazione e scarico.

– In fase di installazione, rispettare gli spazi

perimetrali indicati dal costruttore, anche in

considerazione di tutte le attività lavorative

I

circostanti. L'attuazione di questo requisito

va effettuata anche nel rispetto delle leggi

vigenti in materia di sicurezza sul lavoro.

NORME PER IL FUNZIONAMENTO E L'USO

– L'operatore, oltre ad essere opportuna-

mente addestrato e documentato sull'uso

dell'apparecchiatura, deve possedere capacità e competenze adeguate al tipo di attività lavorativa da svolgere.

– Anche dopo essersi documentati opportu-

namente, al primo uso, se necessario, simulare alcune manovre di prova per

individuare i comandi e le loro funzioni principali, in particolare quelle relative all'avviamento ed all'arresto.

– Utilizzare l'apparecchiatura solo per gli usi

previsti dal fabbricante. L'impiego dell'apparecchiatura per usi impropri può recare

– L'installazione e gli allacciamenti vanno

eseguiti secondo le indicazioni fornite dal

costruttore. Il responsabile dovrà tener

conto anche di tutti i requisiti normativi e legislativi ed eseguire tutte le operazioni di installazione ed allacciamento a regola

d'arte. Ad installazione completata, prima

delle fasi d'uso, egli dovrà verificare, attraverso un controllo generale, se tali requisiti

sono stati rispettati.

rischi per la sicurezza e la salute delle persone e danni economici.

– L'apparecchiatura è stata progettata e co-

struita per soddisfare tutte le condizioni

operative indicate dal costruttore. Manomettere qualsiasi dispositivo per ottenere

prestazioni diverse da quelle previste può

comportare rischi per la sicurezza e la salute delle persone e danni economici.

– Non utilizzare l'apparecchiatura con i disposi-

tivi di sicurezza non perfettamente installati

ed efficienti. Il mancato rispetto di questo requisito può comportare rischi gravi per la sicurezza e la salute delle persone.

NORME PER LE REGOLAZIONI E LA MANUTENZIONE

– Mantenere l'apparecchiatura in condizioni di

massima efficienza, grazie alle operazioni di

manutenzione programmata previste dal costruttore. Se ben effettuata, essa consentirà

di ottenere le migliori prestazioni, una più lunga durata di esercizio ed un mantenimento

costante dei requisiti di sicurezza.

– Prima di effettuare qualsiasi intervento di

manutenzione e regolazione, attivare tutti i

dispositivi di sicurezza previsti e valutare la

necessità di informare il personale che opera e quello nelle vicinanze. In particolare,

segnalare adeguatamente le zone limitrofe

ed impedire l'accesso a tutti i dispositivi che

potrebbero, se attivati, provocare condizioni di pericolo inatteso e di rischio per la sicurezza e la salute delle persone.

– Gli interventi di manutenzione e regolazio-

ne devono essere eseguiti da persone autorizzate che dovranno predisporre tutte le