Page 1

REPLACEMENT INSTRUCTIONS FOR AWNING

Fabric Roller Tube

For Models 8500 & 9000

Tools Required:

The Fabric Roller Tube Assembly (FRTA) consists of a fabric,

a roller tube and torsion assemblies.

Use extreme care. Springs under tension are

dangerous. If not controlled they will unwind

quickly. Keep hands and clothing clear of top

casting, as personal injury may result.

B. REMOVAL OF THE AWNING FROM THE COACH

Vise Grips®

Socket Wrench Set

3/16" Drill Bit

1/8" Pop Rivets

End Cap Guide

A. GENERAL INSTRUCTIONS

Torsion Assembly

Screwdriver

Electric Drill

Step Ladder

3/16" Pop

RivetsPop Rivet

These instructions must be read and understood before installation, adjustment, service

or maintenance is performed. This unit must

be installed by a qualified serviceman. Modification of this product can be extremely hazardous and could result in personal injury or

property damage.

Tool

Adjustable Wrench

1/8" Drill Bit

Small File

NOTE: Awning removal from the coach is NOT necessary

when replacing a torsion assembly. Proceed to Section

C, Steps 1 & 2, Sections D, Steps 1-3, and Section L,

Steps 1-3.

1. In all instances of fabric or roller tube replacement, it will

be necessary to have a large work area to allow

complete unrolling of the awning. This work area must

be clean and smooth so the fabric will not be damaged.

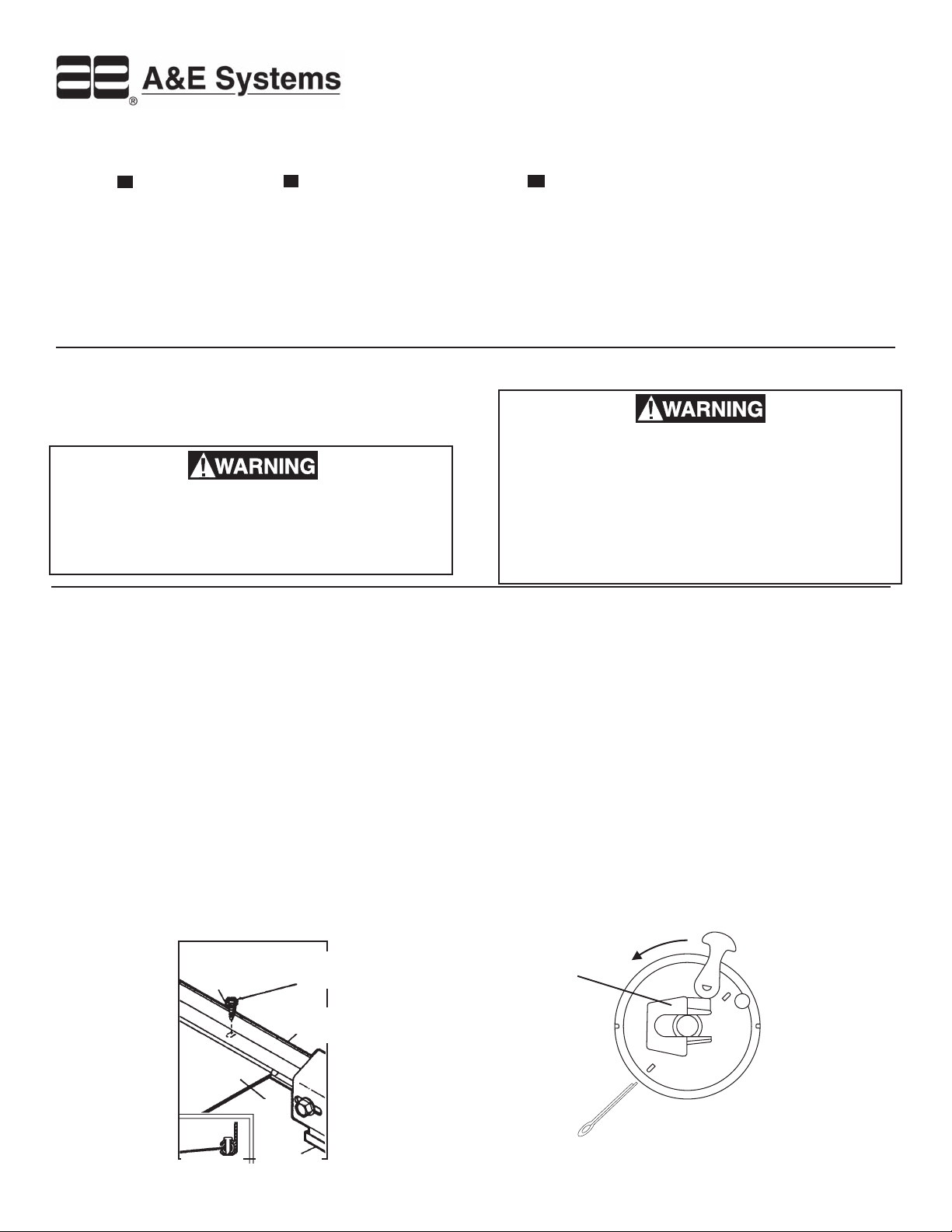

2. Remove the TEK screws securing the awning fabric or

roller cover at each end of the awning fabric. See FIG. 1.

3. Remove both top mounting brackets on the ends of the

awning rail. See FIG. 1

REMOVE FROM

BOTH SIDES

AWNING

RAIL

FIG. 1

1/2" TEK

SCREW

4. Remove both of the patio feet from their mounting

brackets and extend the adjustable arms until each patio

foot rests on the ground and lock button locks in a hole.

5. Slide the awning fabric or roller cover out of the awning

rail.

a. To keep the awnings from unwinding during this

step, be sure the cam lock lever is in the roll down

position. A 1/8" cotter pin can be inserted in each

torsion assembly for positive locking of the roller

tube. See FIG. 2.

MOVE LEVER POSITION TO

ROLL DOWN POSITION

TOP CASTING

FIG. 2

RIGHT-HAND SIDE

(VIEWED FROM FRONT)

SECTION

FABRIC

TOP

BRACKET

COTTER

PIN

1

Form No. 3107299.054 3/02

(Replaces 3107299.046)

(French 3109898.027)

©2002 Dometic Corporation

LaGrange, IN 46761

REVISION

Page 2

C. UNWINDING A TORSION ASSEMBLY SPRING

NOTE: If the awning is installed on a coach, complete the

following steps on a step ladder, with the awning fabric

unrolled two feet from the awning rail. The unwinding can also

be done while standing on the ground and the awning fully

extended and the opposite side rafter locked in place. The

torsion spring will be wound with 8/eight more turns in this

position and is extremely dangerous.

Severe injuries can result from the rapid spin-off of

the top casting. Use Vise Grips® - NEVER use bare

hands - to handle a top casting under spring tension.

TOP

CASTING

LOCK

LEVER

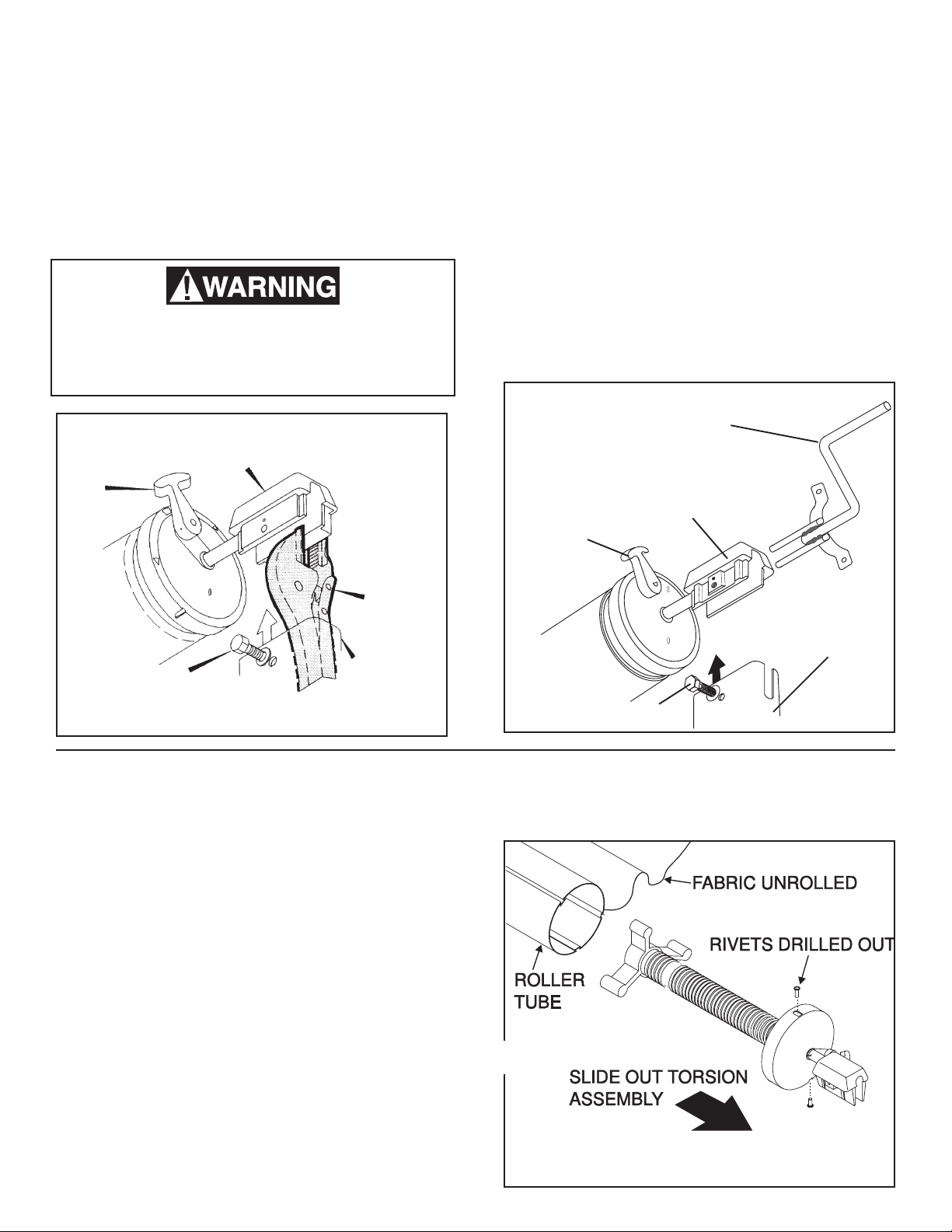

1. Clamp a Vise Grip® tightly on the top casting, or insert

the crank (3107905.006) into top casting. Remove the 1/

4-20 hex head machine screw from the top casting. See

FIG. 3 and FIG. 3A.

2. Take the top casting carefully out of the main support

arm (see NOTE below). Slowly let the torsion spring

unwind completely. Repeat Steps 1 & 2 for the opposite

end.

NOTE: If the awning's right-hand torsion assembly has been

pinned, the cotter pin must be removed from the torsion

assembly before the spring can be unwound. The cam lock

lever on the right-hand torsion assembly must be turned

clockwise to the roll up position, before the spring can be

unwound.

FIG. 3A

LOCK

LEVER

CRANK

3107905.006

TOP

CASTING

VISEGRIPS®

1/4-20 X 1/2" HEX

HD. MACH. SET SCREW

MAIN SUPPORT

ARM ASSEMBLY

FIG. 3

D. HOW TO REMOVE A TORSION ASSEMBLY

1. Make sure the torsion spring has been relieved of its

tension (see Section C.)

2. Mark or make note of the location of the fabric and the

end cap on the roller tube. This is necessary to reposition

the new torsion, fabric or roller tube exactly the same

when the new part is installed.

NOTE: Some roller tubes have notches and the end cap

has tabs, that will allow the torsion to fit only in one

position. The fabric must be positioned exactly as shown

in FIG. 5 or the lock lever will not be positioned correctly

when installed on the coach.

1/4-20 X 1/2" HEX

HD. MACH. SET SCREW

MAIN SUPPORT

ARM ASSEMBLY

3. Drill out the two rivets using a 3/16" drill bit. Remove

torsion assembly and rivet bodies from roller tube. See

FIG. 4.

2

FIG. 4

Page 3

E. HOW TO REMOVE FABRIC FROM ROLLER TUBE / COVER

1. Remove both torsions. See Section D, Steps 1-3 for

torsion removal.

2. Roll the awning completely out on a clean smooth

surface.

3. With the awning laying flat, slide the roller tube out from

fabric.

4. The metal roller cover on 8500 and 9000 models are

F. INSTALLING FABRIC ON ROLLER TUBE

crimped to the poly ropes. Use needle nose pliers and

flat blade screw dirver to spread open the channel before

removing fabric.

NOTE: Some 9000 model awning,secured the fabric to the

roller cover with 1/8" pop rivets. It is necessary to remove

the 1/8" pop rivets from both ends of the roller cover.

Once the rivets are removed, you can slide the fabric out

of the cover. See FIG. 6 & 7.

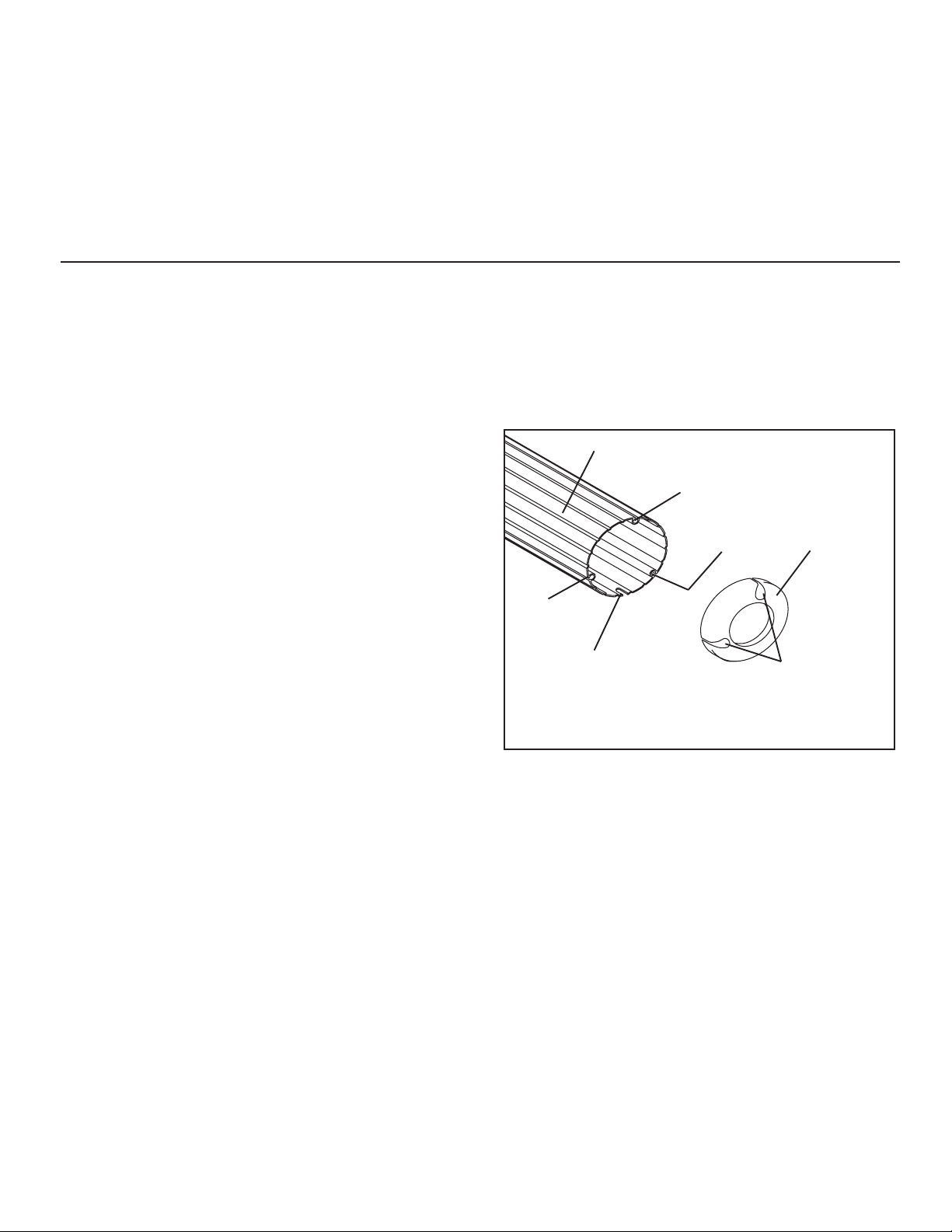

1. Unfold the new fabric and lay it on top of the existing

fabric in the exact same position. Be sure the new

fabric is the correct size and color. If roller tube is being

replaced, make sure it is the correct length and position

it with the notch located as shown in FIG. 5.

2. Dometic requires the use of the end cap guide to prevent

damages to the fabric, when replacing the fabric/roller

tube. Place the end cap guide supplied with the replacement fabric/roller tube on the end of the roller tube. Slide

the fabric and valance ropes through the end cap guide

and onto the roller tube. See figure 5.

NOTE: When changing the fabric, it is vital that the same

groove(s) be used. This eliminates the need to redrill any

holes (i.e. center support).

3. Guide the roller tube over the poly-rope(s) of the fabric.

Be careful not to damage the roller tube or the fabric.

4. Center the fabric on the roller tube and hand-roll the entire

assembly in the same direction as the original fabric.

VALANCE

ROPE

NOTCH

ROLLER

TUBE

FABRIC

GROOVE

OPEN

GROOVE

SLIDE FABRIC AND

VALANCE ROPES

THROUGH GUIDE

FIG. 5

PLACE END

CAP GUIDE

ON ROLLER

TUBE

3

Page 4

G. FABRIC REPLACEMENT ON 9000 WITH 7 SLAT ROLLER COVER

Installing a new replacement fabric on a Model 9000

roller cover with 7 slats and a vinyl strip. See FIG. 6:

1. Remove vinyl strip A (FIG. 11), and hinge slat B (FIG. 10)

from top slat C (FIG. 8). Remove two of Slat D (Fig. 9).

Discard vinyl strip A, hinge slat B and the two D slats .

2. Remove top slat C (FIG. 8) from roller cover assembly

and keep to be installed later.

Note: 9000 awning with 6 slats requires removal of one

slat D. (8500 and 9000 with 5 slats will require one slat

D to be remove and discarded if a new roller cover is being

replaced.)

3. The new replacement fabric will be installed as shown in

FIG. 7.

4. Use a small file to round the ends of the groove in the

5/16" channel of the main slat D (FIG. 9).

5. Slide the 5/16" channel of the main slat D onto the poly-

rope located approximately 12" from the top edge of the

fabric.

6. Install two pop rivets in the main slat D on both ends to

prevent the fabric from shifting in roller cover. If a new

roller cover assembly is being installed, a 1/8" hole will

need to be drilled 1-1/2" to 2" from end of the main slat

for the pop rivets. To prevent damage, be sure to remove

any burrs left by the drill.

NOTE: On 8500 models crimp the channel with pliers to

hold fabric.

7. Use a small file to round the ends of the 5/16" grooves on

the top slat C (FIG. 8) to prevent tearing of the fabric.

Slide the top slat C onto both the 1/4" channel of the fifth

main slat D and the poly-rope 1-1/2" from the edge of the

fabric.

8. Install the screws into the edge of the roller cover

assembly. See FIG. 7.

H. FABRIC REPLACEMENT ON 9000 WITH 6 SLAT ROLLER COVER

Installing a new replacement fabric on 9000 Model

awning roller cover with 6 slats. See FIG. 7.

1. Follow steps 2-8 in Section G.

I. FABRIC REPLACEMENT ON 8500 AND 9000 WITH 5 SLAT ROLLER COVER

Installing a new replacement fabric on 8500 and 9000

model awning roller cover with 5 slats. Use Section G.

J. INSTALLING NEW ROLLER COVER WITH 6 SLATS

Installing new roller cover on model 9000 with 6 slats.

See FIG. 7.

K. INSTALLING NEW ROLLER COVER WITH 5 SLATS

Installing new roller cover on 8500 model with 5 slats .

See FIG. 7.

1. Follow steps 2-8 in Section G.

1. Follow steps 1-8 in Section G.

1. Follow steps 1-8 in Section G.

4

Page 5

FIGURES 6 THROUGH 11

FIG. 6

E

C

D

D

D

D

VINYL STRIP "A"

FOR FIGS. 6–11

A - VINYL STRIP

B - HINGE SLAT

C - TOP SLAT

D - MAIN SLAT

E - AWNING RAIL

D

Trim poly rope

even and crimp

end

Drill out 1/8" pop

rivet, before

sliding out fabric

INSTALL A 1/8"

POP RIVET

EACH END

HINGE SLAT "B"

TOP SLAT "C"

VIEW RH END

FIG. 7

E

C

D

D

D

D

D

INSTALL A 1/8"

POP RIVET

EACH END

Trim poly rope

even and crimp

end

Drill out 1/8" pop

rivet, or spread

crimp before

sliding out fabric

5/16" CHANNEL

INSTALL TOWARD

CANOPY

3/8" CHANNEL

FOR VINYL

STRIP "A"

1/4" CHANNEL

FIG. 8

5/16" CHANNEL

BOTH ENDS

MAIN SLAT "D"

VIEW RH END

FIG. 9

1/4" CHANNEL

INSTALL TOWARD

AWNING RAIL

HINGE SLAT "B"

FIG. 10

VINYL STRIP "A"

5/16" ROD IN

AWNING RAIL

Note: FIG. 6 shows 9000 model with 7 slats (1 "B" hinge slat, 1 "C" top slat and 5

"D" slats).

FIG. 7 shows 9000 Model with 6 slats (1 "C" and 5 "D" slats).

5

FIG. 11

Page 6

L. REPLACING TORSION ASSEMBLIES

1. To reduce the possibility of the poly rope interfering with

the cam lock mechanism, the right-hand torsion requires

the valance rope to be cut off even with the roller tube.

a. Steel Roller Tube: The poly rope on the fabric side

must be pulled toward the valance groove and cut

off – leaving enough length to tuck it behind the

valance groove. See FIG. 12.

b. Aluminum Roller Tubes: The poly rope on the

fabric side is cut 2" longer than the roller tube.

Stretch the poly rope and pull it toward the center

of the roller tube. Make sure it is locked in the

notch of the groove in the roller tube. See FIG.12A.

2. Reinstall the torsion assembly in the roller tube. Align

the rivet slots on the end cap with the holes in the roller

tube - in the exact same position as in Section D, Step

2. If a new roller tube is being used make sure the fabric

has been installed as directed in Section "F".

3. The poly ropes on the left-hand end of the roller tube

should be trimmed in the same as the right-hand. See

Section "L" Step 1.

STEEL ROLLER TUBE

FIG. 12

NOTE: If the roller tube is new, the rivet holes are not drilled.

The torsion assemblies must be positioned as follows:

The left-hand torsion assembly position has the open

slot in the end cap aligned with the empty groove of the

roller tube.

Position the right-hand torsion assembly open hole

in the end cap in alignment with the empty groove in the

roller tube.If a new right-hand torsion assembly is being

installed and the roller tube does not have the notch

shown in FIG. 5. The two tabs inside the right-hand

torsion end cap must be broken off. See FIG. 13A.

NOTE: Placing the end caps as suggested usually

positions the lock lever in the proper position when

awning is closed. The awning should be opened and

closed several times, and checked. The cam lock lever

should be at the "11:00" position . The end cap may have

to be removed and repositioned if it is not in the proper

location. See FIG. 13.

Models 8500 and 9000 19' - 25' have been manufactured with both standard and heavy duty torsion

springs. Before reinstalling the torsion, properly

identify (Standard or Heavy Duty) the springs. This

is necessary for proper winding of the torsion. See

Spring Identification Chart on page 7.

FIG. 12A

ALUMINUM ROLLER TUBE

FABRIC

STRETCH FABRIC ROPE

TIGHT AND PULL DOWN

AND INTO THE CENTER

OF ROLLER TUBE. MAKE

SURE IT IS LOCKED IN

THE NOTCH ON THE

BOTTOM OF THE

GROOVE.

4. Secure torsion assemblies to roller using 3/16" dia. x 3/8"

long stainless steel pop rivets.

FIG. 13

FIG. 13A

BREAK OFF TWO

LOCATING

TABS

VALANCE

CUT VALANCE ROPE EVEN WITH THE

END OF THE ROLLER TUBE

6

Page 7

M. REWINDING TORSION ASSEMBLY SPRING

NOTE: If the awning is installed on a coach, complete the

following steps on a step ladder, with the awning fabric

unrolled two feet from the awning rail. The winding can also

be done while standing on the ground and the awning fully

extended and the oposite side rafter locked in place. The

torsion spring will be wound with 8/eight more turns in this

position and is extremely dangerous.

Severe injury can result from the rapid spin-off of the

top casting. Use Vise Grips® - NEVER use bare hands

- to handle a top casting under spring tension.

TORSION ASSEMBLY

TORQUE SPECIFICATIONS

Awning

Length

(Ft.)

88 –

8'6" 8 –

98 –

10 8 –

10'6" 8 –

10' 8" 8 –

11 8 –

11'6" 8 –

12 8 –

13 9 –

14 9 –

14'6" 9 –

15 10 –

15'6" 10 –

16 10 –

16'1" 10 –

16'6" 12 –

17 12 –

18 12 –

18'6" 12 –

19 12 8

19'6" 12 8

20 12 8

20'6" 12 8

20'9" 12 8

21 12 8

21'9" 12 8

22 12 8

23 12 8

24 12 8

25 12 8

Model 8500 & 9000

Standard

Number of Turns Number of Turns

Model 8500 & 9000

Heavy Duty

1. Insert the torsion winding crank (Part Number

3108896.006) or clamp a Vise Grip® tightly on the

thickest side of the top casting. See FIG. 3 and FIG. 3A

2. Rewind the torsion assembly to the number of turns

indicated by the torsion assembly Torque Chart and in

the direction shown in FIGS. 14 &15.

3. Place a 1/8" cotter pin through the hole in the end cap

and torsion rod. This will prevent the rapid spin-off of the

top casting during installation of the awning. See FIG. 2.

NOTE: If awning is installed on the coach, place the top

casting in the support arm and secure with the 1/4-20 hex

head bolt.

WIND TOP

CASTING

FIG. 14

RIGHT-HAND SIDE

(VIEW FROM FRONT)

AWNING RAIL AWNING RAIL

HEAVY DUTY

TORSION ASM.

IDENTIFIER

(GREEN DOT)

LEFT-HAND SIDE

(VIEW FROM REAR)

SPRING IDENTIFICATION CHART

Standard

Wire Dia.

RH

LH

Painted red

cap end and

no paint on

stabilizer

end.

No paint on

either end.

0.135

Painted red

cap end and

blue on

stabilizer

end.

Painted blue

cap end and

no paint on

stabilizer

end.

NOTE: Heavy duty torsions can also be identified by a green

dot on the side of the top casting or on the end of the torsion

rod. See Figures 14 and 15.

Before winding the torsion it must be identified for

heavy duty or standard springs. Incorrect winding can

result in damage and improper operation.

Heavy Duty

Painted yellow cap end,

red on stabilizer end.

Painted yellow on cap

end, no paint

on stabilizer

end.

0.148

Painted white

on cap end

and black on

stabilizer

end.

Painted black

on stabilizer

end and no

paint on cap

end.

WIND TOP

CASTING

FIG. 15

N. INSTALLING AWNING ON COACH

1. Follow installation instructions for the awning when replacing on coach.

7

Loading...

Loading...