Dodge Horn 3500 2005, Horn 2500 2005, Horn 1500 2005 Service Manual

DR/DH HORN 8H - 1

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM - ELECRICAL DIAGNOSTICS..... 1 HORN SYSTEM - SERVICE INFORMATION ..... 19

HORN SYSTEM - ELECRICAL DIAGNOSTICS

TABLE OF CONTENTS

page page

HORN SYSTEM - ELECRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

HORN RELAY CONTROL CIRCUIT HIGH ....2

HORN RELAY CONTROL CIRCUIT LOW .....5

HORN RELAY CONTROL CIRCUIT OPEN ....8

*HORNS INOPERATIVE .................11

SCHEMATICS AND DIAGRAMS ............18

HORN SYSTEM - ELECRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

8H - 2 HORN SYSTEM - ELECRICAL DIAGNOSTICS DR/DH

HORN RELAY CONTROL CIRCUIT HIGH

DR/DH HORN SYSTEM - ELECRICAL DIAGNOSTICS 8H - 3

HORN RELAY CONTROL CIRCUIT HIGH (CONTINUED)

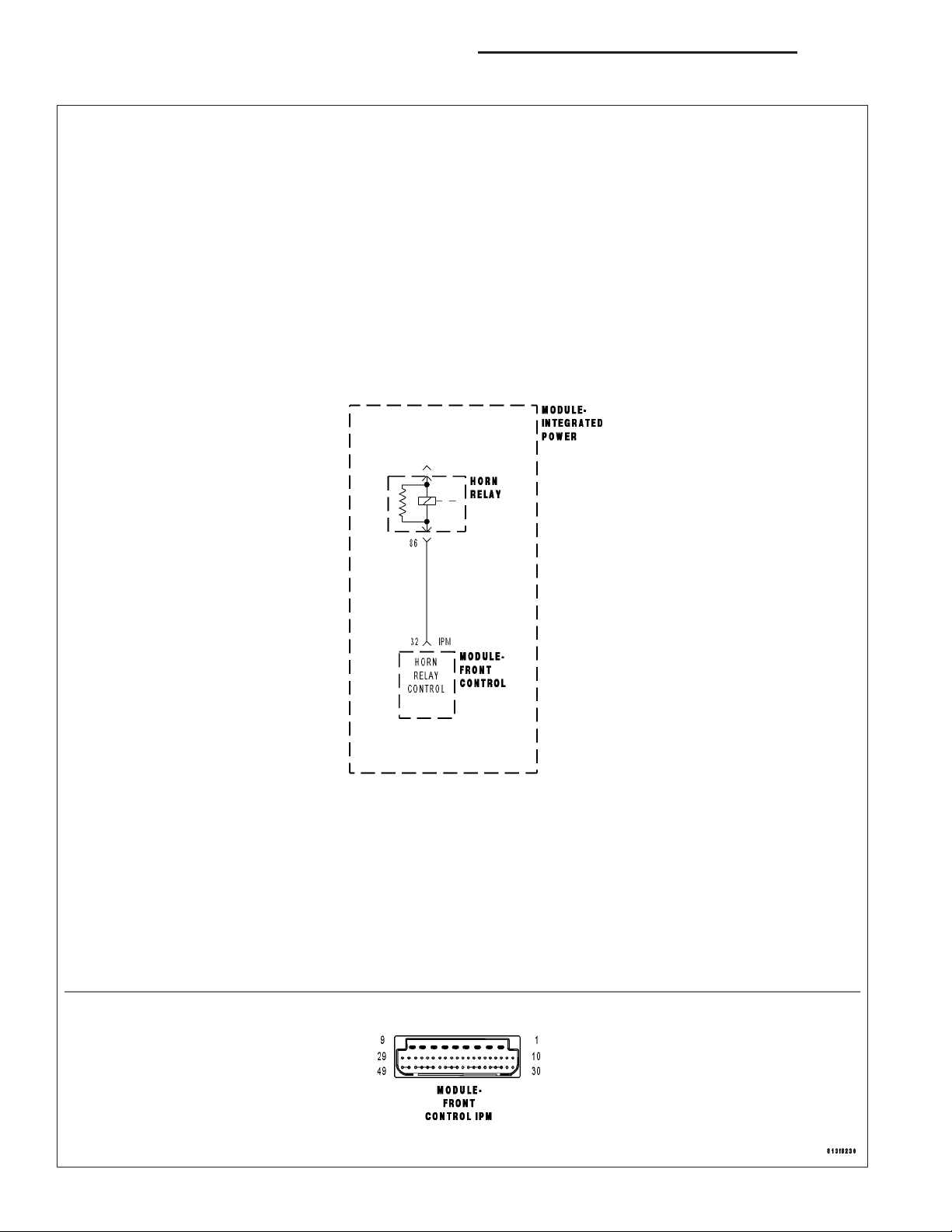

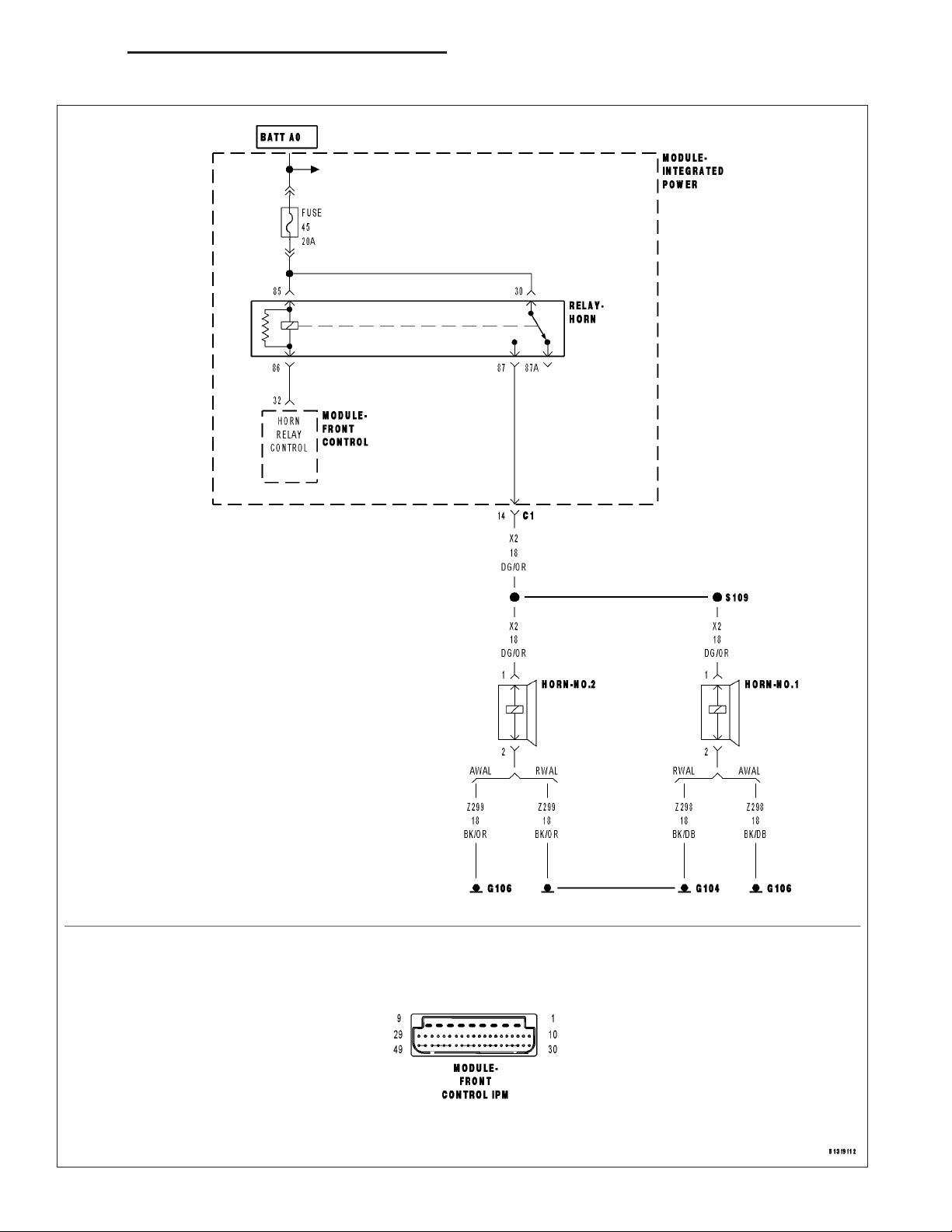

For the Horn System circuit diagram (Refer to 8 - ELECTRICAL/HORN - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition ON.

• Set Condition:

When the Front Control Module detects excessive current on the Horn Relay Control circuit.

Possible Causes

INTERMITTENT DTC

INTEGRATED POWER MODULE

FRONT CONTROL MODULE

Diagnostic Test

HORN RELAY CONTROL CIRCUIT DTC ACTIVE

1.

Turn the ignition on.

With the DRBIIIT, record and erase FCM DTC’s.

With the DRBIIIT, actuate the Horn Relay.

With the DRBIIIT, read FCM DTC’s.

Does the DRBIIIT display a HORN RELAY CONTROL CIRCUIT DTC active?

Yes >>

No >>

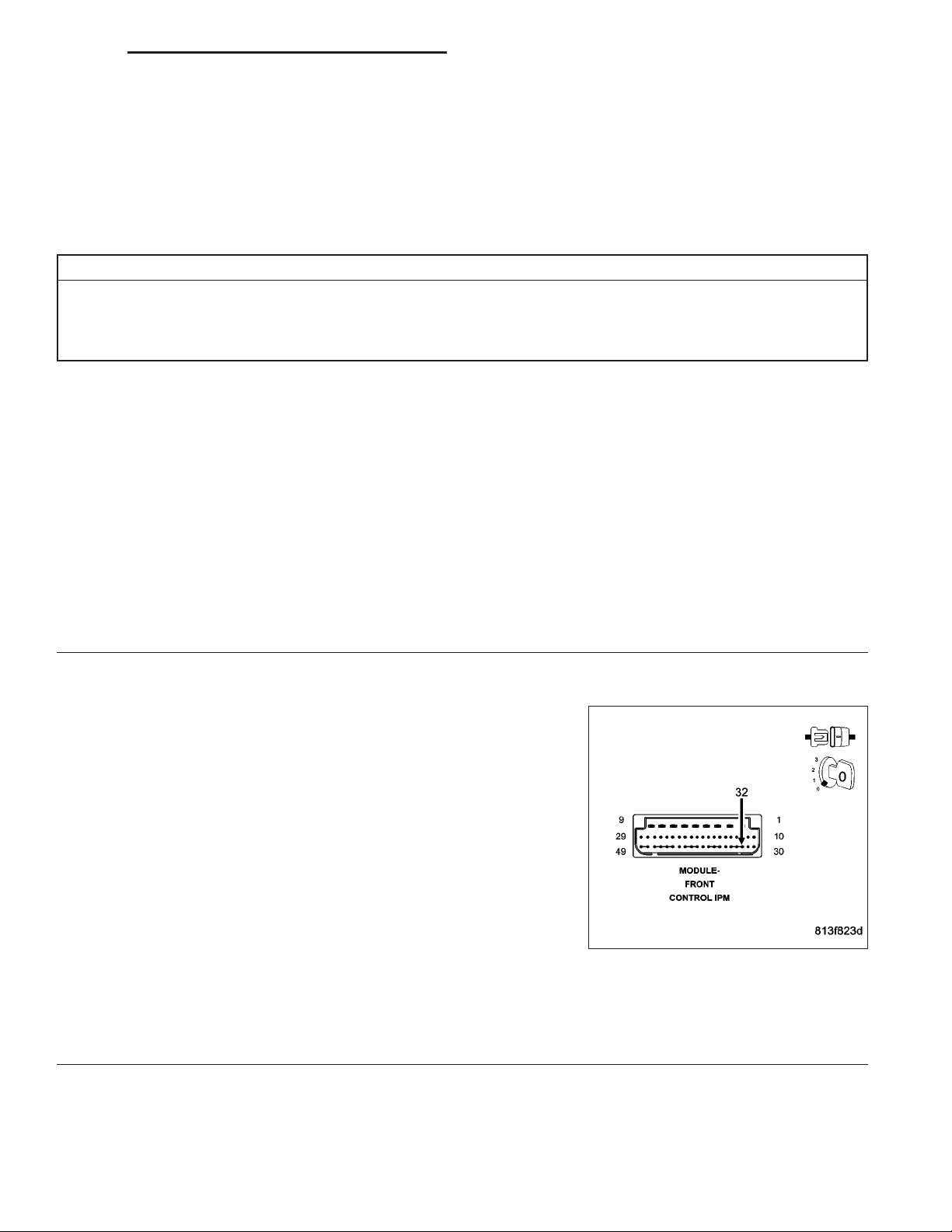

INTEGRATED POWER MODULE

2.

Turn the ignition off.

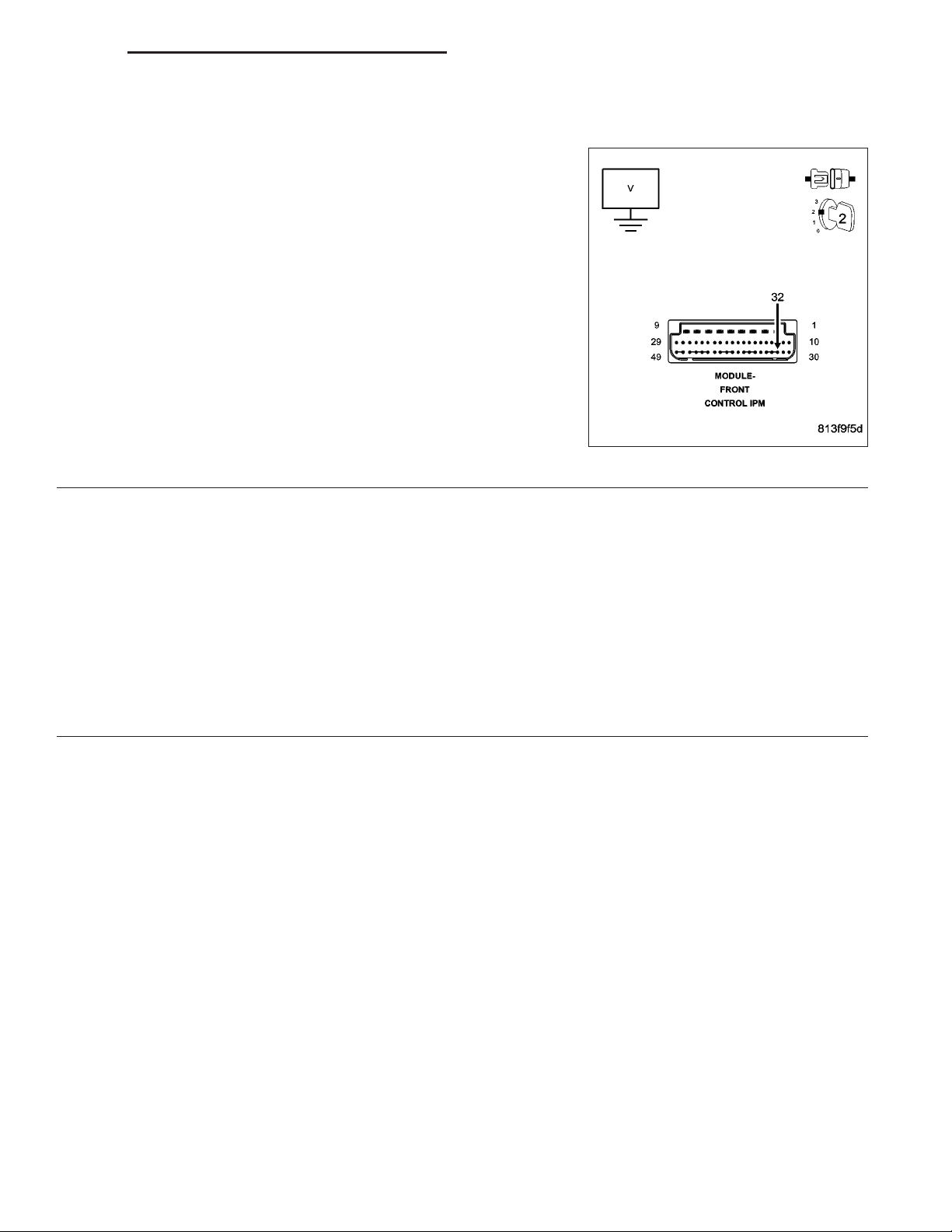

Remove the Front Control Module from the Integrated Power Module.

NOTE: NOTE: Check connectors - Clean/repair as necessary.

Use a fused jumper wire for the next step.

Momentarily jumper the Horn Relay Control circuit to ground at the

FCM connector.

Does the Horn sound?

Yes >>

No >>

Go To 2

Go To 3

Replace the Front Control Module in accordance with the

Service Information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Integrated Power Module in accordance with the Service Information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

8H - 4 HORN SYSTEM - ELECRICAL DIAGNOSTICS DR/DH

HORN RELAY CONTROL CIRCUIT HIGH (CONTINUED)

WIRING HARNESS INSPECTION

3.

Turn the ignition off.

Visually inspect the related circuit connectors. Look for broken, bent, pushed out, or corroded terminals.

Refer to any Hotline letters or Technical Service Bulletins that may apply.

Were any problems found?

Yes >>

No >>

Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Test Complete.

DR/DH HORN SYSTEM - ELECRICAL DIAGNOSTICS 8H - 5

HORN RELAY CONTROL CIRCUIT LOW

8H - 6 HORN SYSTEM - ELECRICAL DIAGNOSTICS DR/DH

HORN RELAY CONTROL CIRCUIT LOW (CONTINUED)

For the Horn System circuit diagram (Refer to 8 - ELECTRICAL/HORN - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition ON.

• Set Condition:

When the Front Control Module detects a short on the Horn Relay Control circuit.

Possible Causes

INTERMITTENT DTC

FUSE #45

INTEGRATED POWER MODULE

FRONT CONTROL MODULE

Diagnostic Test

HORN RELAY CONTROL CIRCUIT DTC ACTIVE

1.

Turn the ignition on.

With the DRBIIIT, record and erase FCM DTC’s.

With the DRBIIIT, read FCM DTC’s.

Does the DRBIIIT display a HORN RELAY CONTROL CIRCUIT DTC active?

Yes >>

No >>

CHECK FUSE #45

2.

Turn the ignition off.

Check fuse #45 in the IPM.

Is the fuse open?

Yes >>

No >>

Go To 2

Go To 4

Replace the fuse. Check for a short to ground in the Horn Relay Output circuit from the IPM to the

horns.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

DR/DH HORN SYSTEM - ELECRICAL DIAGNOSTICS 8H - 7

HORN RELAY CONTROL CIRCUIT LOW (CONTINUED)

INTEGRATED POWER MODULE

3.

Reinstall the fuse if previously removed.

Remove the Front Control Module from the Integrated Power Module.

NOTE: Check connectors - Clean/repair as necessary.

Turn the ignition on.

Measure the voltage of the Horn Relay Control circuit.

Is the voltage above 11.0 volts?

Yes >>

No >>

WIRING HARNESS INSPECTION

4.

Turn the ignition off.

Visually inspect the related circuit connectors. Look for broken, bent, pushed out, or corroded terminals.

Refer to any Hotline letters or Technical Service Bulletins that may apply.

Were any problems found?

Yes >>

No >>

Replace the Front Control Module in accordance with the

Service Information.

Perform BODY VERIFICATION TEST - VER 1.

Replace the Integrated Power Module in accordance with

the Service Information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Test Complete.

Loading...

Loading...