Dodge Horn Service Manual

DR HORN 8H - 1

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION ..........................1

OPERATION ............................1

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 1

HORN

DIAGNOSIS AND TESTING - HORN ..........1

HORN SYSTEM

DESCRIPTION

The dual-note horn system features dual electromagnetic horn units. The horn system includes the

following major components:

• Horn - The two horns are located on the left

side of the engine compartment below the Integrated

Power Module (IPM).

• Horn Switch - The horn switch is molded into

the driver airbag trim cover.

OPERATION

The horn system operates on battery current

received through a fuse in the Integrated Power

Module (IPM). The horn system circuit is designed so

that the system will remain operational, regardless

of the ignition switch position.

DIAGNOSIS AND TESTING - HORN SYSTEM

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIIt scan tool and the proper Diagnostic Procedures manual. The DRBIIIt scan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic modules are sending and receiving the proper messages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

In most cases, any problem involving continually

sounding horns can be quickly alleviated by removing

the horn fuse from the Integrated Power Module

(IPM).

REMOVAL .............................2

INSTALLATION ..........................2

HORN SWITCH

DESCRIPTION ..........................2

DIAGNOSIS AND TESTING - HORN SWITCH . . . 2

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE BEFORE PERFORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

HORN

DIAGNOSIS AND TESTING - HORN

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIIt scan tool and the proper Diagnostic Procedures manual. The DRBIIIt scan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic modules are sending and receiving the proper messages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

8H - 2 HORN DR

HORN (Continued)

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE BEFORE PERFORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

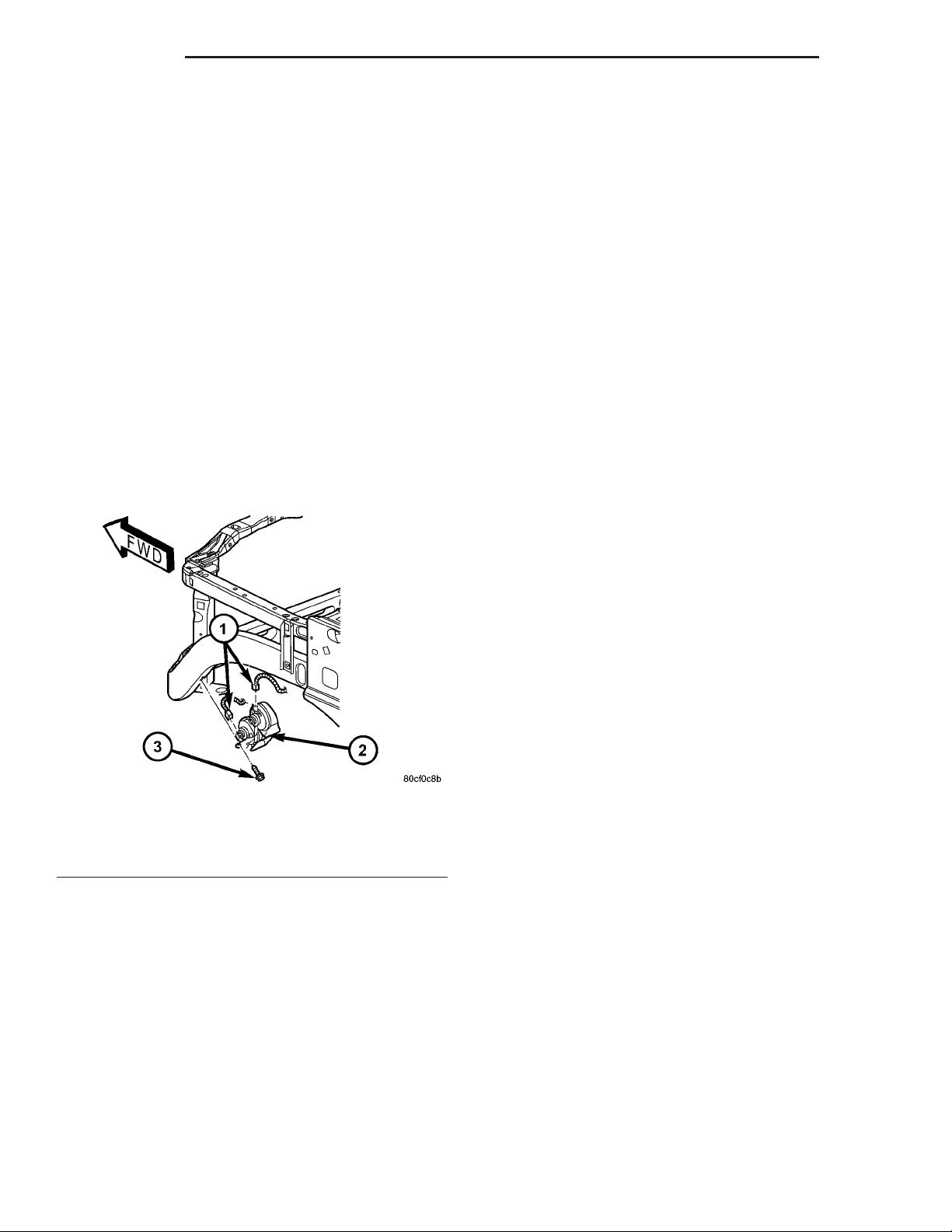

(2) Disconnect the wire harness connectors from

the horns (Fig. 1).

HORN SWITCH

DESCRIPTION

The horn switch is molded into the driver airbag.

The horn switch can not be serviced separately. For

service procedures, (Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER AIRBAG - REMOVAL).

DIAGNOSIS AND TESTING - HORN SWITCH

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIIt scan tool and the proper Diagnostic Procedures manual. The DRBIIIt scan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic modules are sending and receiving the proper messages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

For complete circuit diagrams, refer to the appropriate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connectors, splices and grounds.

Fig. 1 HORN

1 - WIRE HARNESS CONNECTORS

2 - HORNS

3 - MOUNTING BOLT

(3) Remove mounting bolt and remove horns.

INSTALLATION

(1) Position horns and install mounting bolt.

Tighten the bolt to 10 N·m (85 in. lbs.).

(2) Connect wire harness connectors.

(3) Connect battery negative cable.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE BEFORE PERFORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Loading...

Loading...