Page 1

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

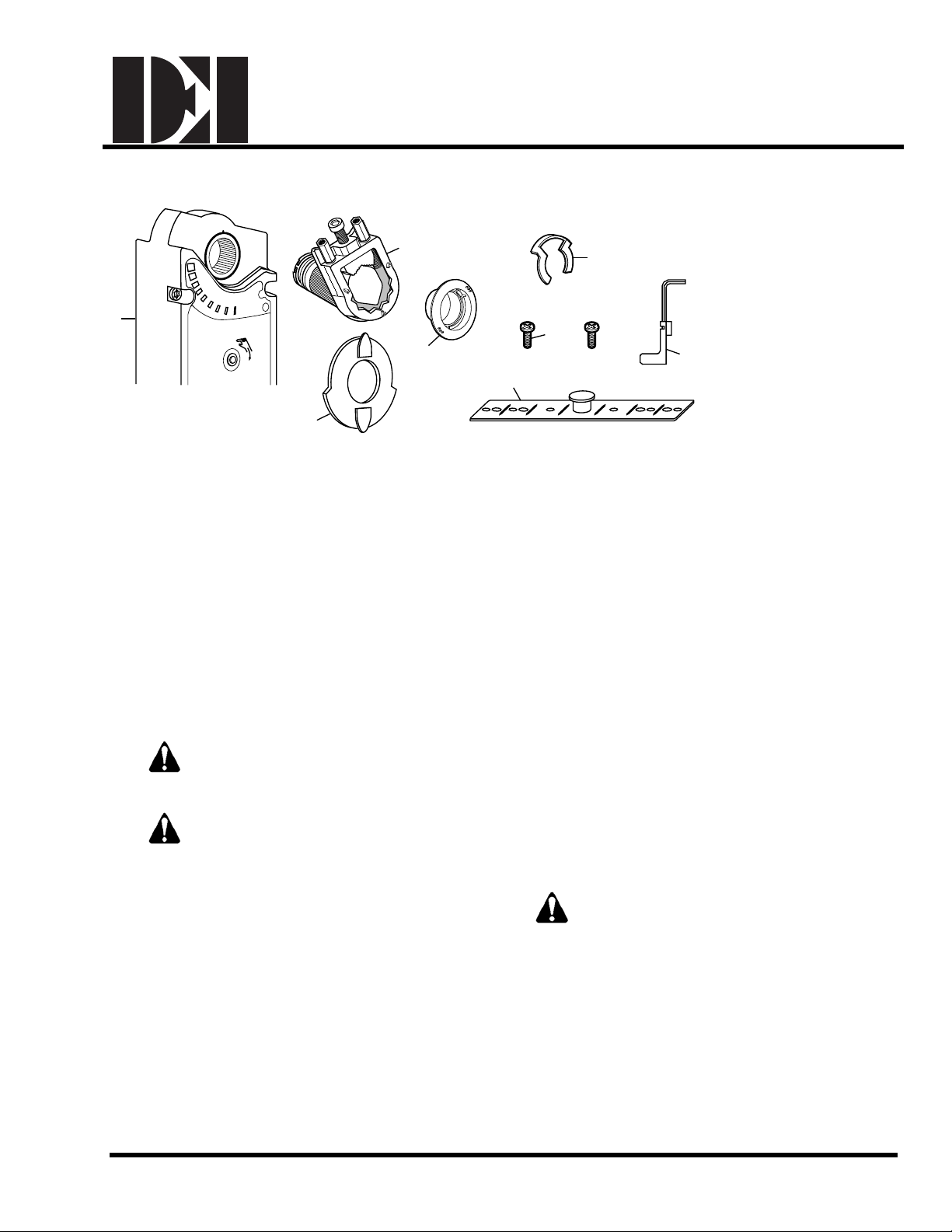

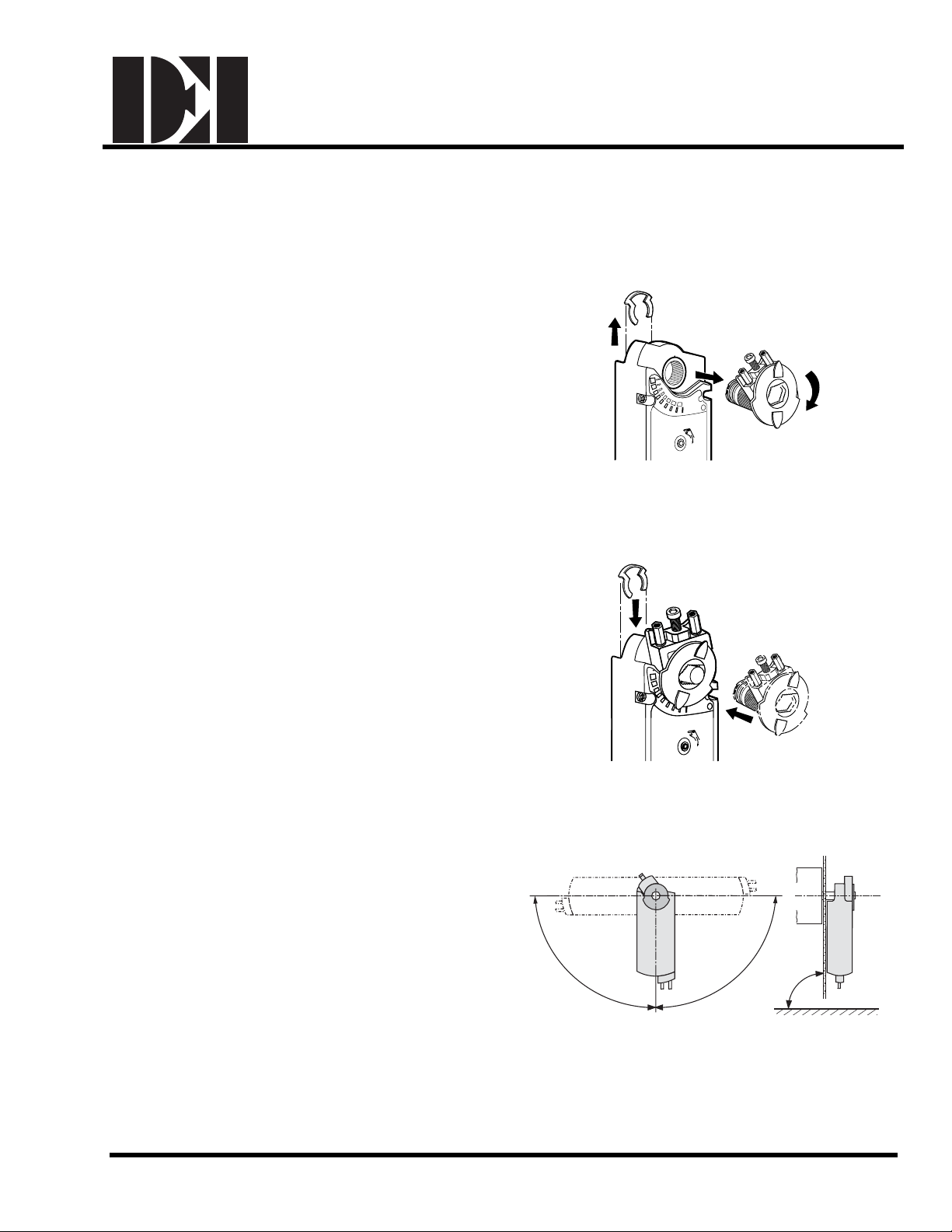

ES142 Spring Return Electronic Actuators

b

a

e

EA0655R1

c

Figure 1. Parts of the ES142 Actuator.

Product Description

This installation instruction describes the steps for

direct-coupled mounting the ES142 series spring

return electronic actuator.

Product Numbers

ES142 (all versions)

Installation

a. Actuator

b. Shaft adapter

d

g

f

c. Position indicator

d. Shaft adapter locking

clip

e. Position indicator

adapter

h

f. Mounting bracket

(for dampers)

g. Mounting screws

h. 3 mm hex wrench

Required Tools

• 10 mm (13/32 in. open end wrench or ratchet

• Drill

• 4 mm (5/32 in.) drill bit

• 3 mm hex wrench (provided)

• Phillips screwdriver

• Marker or pencil

Installation Conventions

Warning

Caution

Personal injury or loss of life may

occur if you do not perform a

procedure as specified.

Equipment damage or loss of data

may occur if you do not follow a

procedure as specified.

Expected Installation Time

30 minutes

Prerequisites

NOTE: The actuator is shipped from the factory

with a 5° preload on the spring. The

position of the indicator points to the 0°

position. When power is applied to the

actuator, the preload is released.

WARNING:

Do not open the actuator.

129-270 EAI/ES-1 DEI, Inc.

Page 2

Installation

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

1

Installation

Manual

Overide

90¡

EA1119R1

90¡

2

Manual

Overide

2

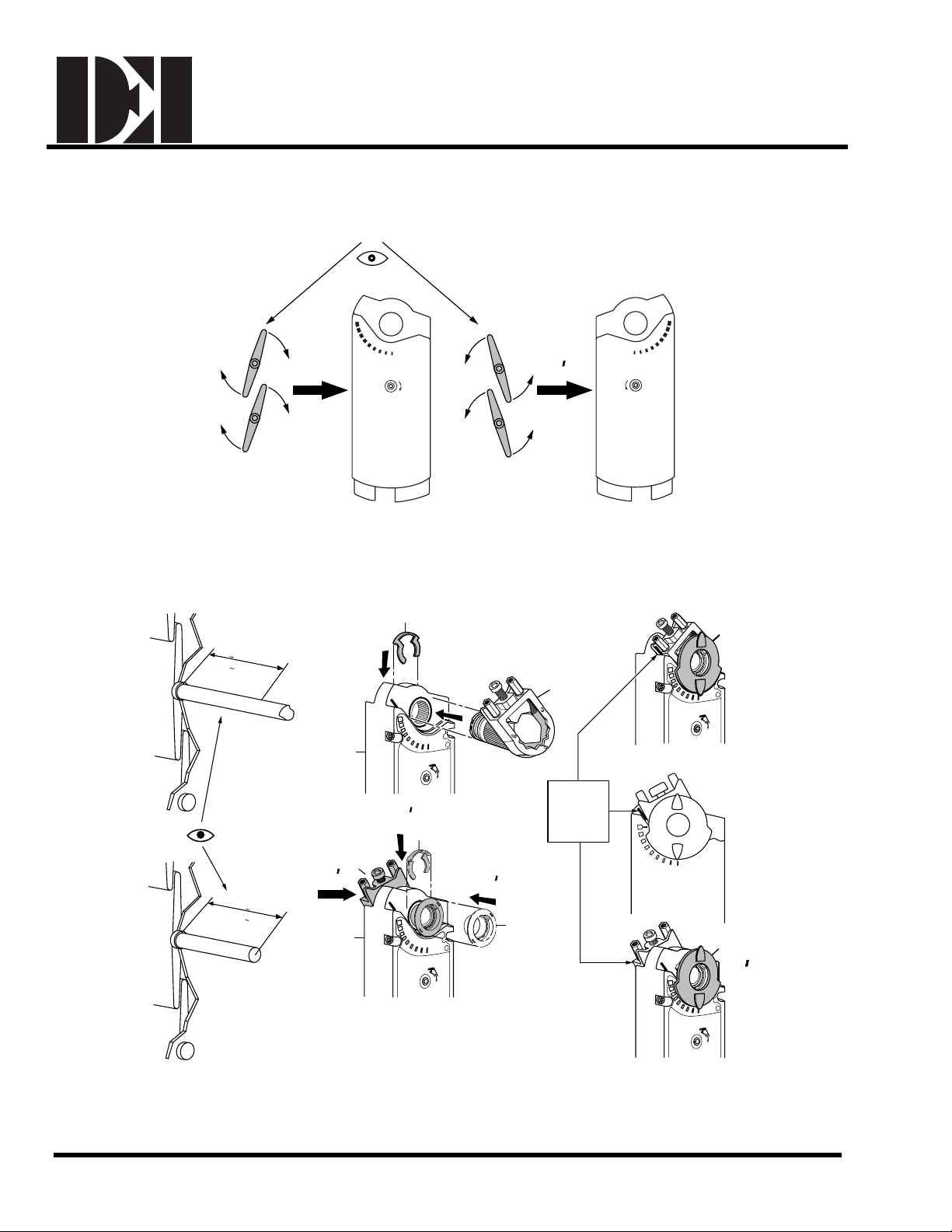

NOTE: The actuator can be mounted for clockwise or counterclockwise rotation of the damper shaft.

Figure 2. Actuator Mounting Orientation.

d

>

77 mm

>3 in

5

4

a

b

cc

c

c

6

6

SHAFT

3

EA0656R1

>20 mm

>3/4 in

<

77 mm

<3 in

4

ADAPTER

5

d

b

ALIGNMENT

MARK

6

a

e

90

cc

7

7

NOTE: The shaft coupling and position indicator can be mounted on either side of the actuator.

Place the shaft adapter right next to the alignment mark keeping the mark visible.

Figure 3. Shaft Length and Proper Shaft Adapter Location.

129-270 EAI/ES-2 DEI, Inc.

Page 3

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

OR

1

4

3

3

4

2

EA0289R2

OVERRIDE

MANUAL

OVERRIDE

MANUAL

EA0288R1

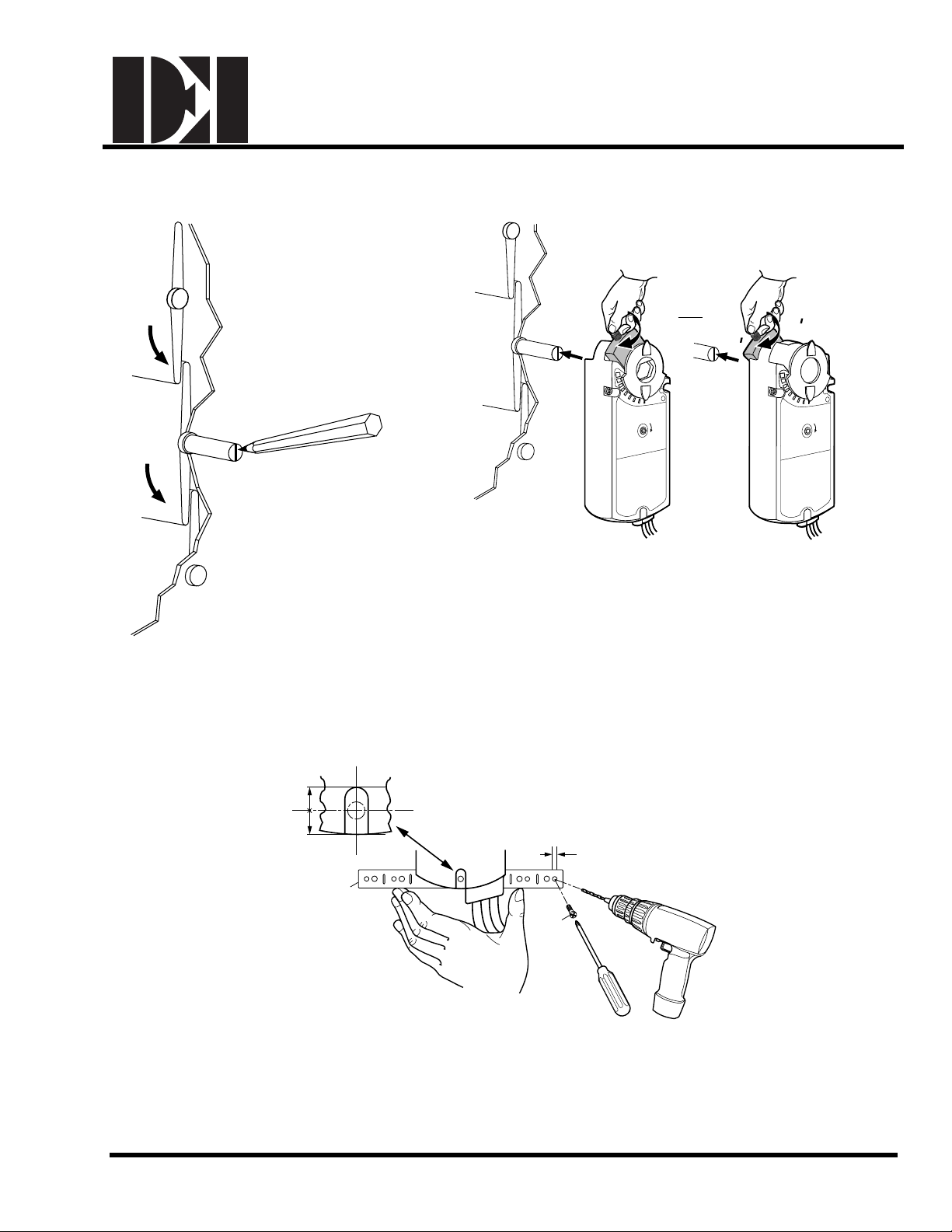

Place the actuator on the shaft with the damper blades in the desired 0 position.

Tighten the middle screw so that the shaft is in the center of the shaft adapter opening.

Figure 4. Actuator Mounting.

1/2

1/2

5

f

4 mm

5/32 in.

2 PLACES

g

EA0357R2

6

Anti-rotation tab should be approximately in the center of the actuator anti-rotation slot.

Figure 5. Fasten the Mounting Bracket.

129-270 EAI/ES-3 DEI, Inc.

Page 4

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

EA0697R1

10 mm HEX

SOCKET

88 lb. - in.

(10Nm) TORQUE

10 mm HEX

SOCKET

88 lb. - in.

(10Nm) TORQUE

NOTE: Keep the shaft in the center of the shaft adapter opening. Apply 7.5 lb-ft (10 Nm) torque maximum.

Figure 6. Fasten the Shaft Adapter to the Damper Shaft.

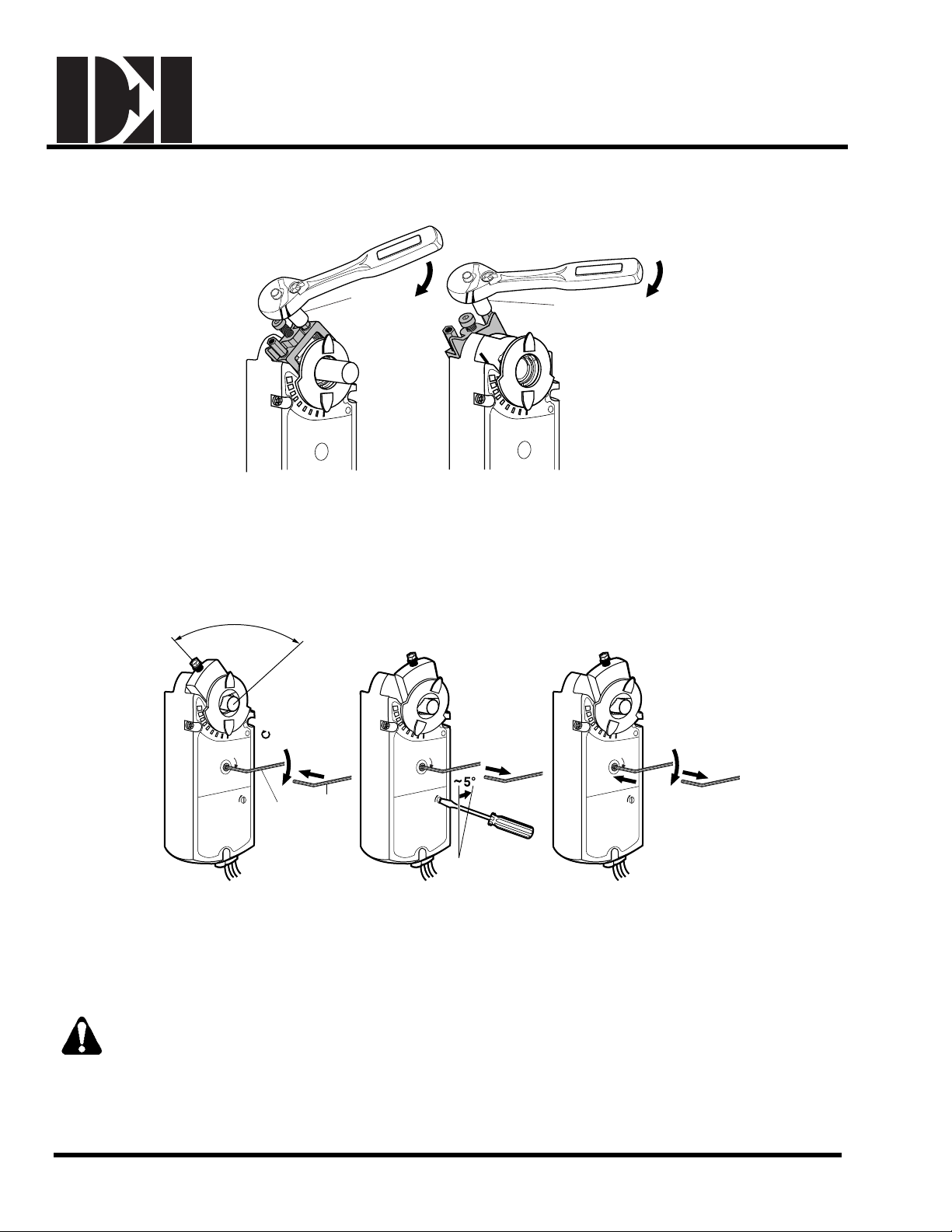

Manual Override

90˚

90˚

Manual

Override

GEAR TRAIN

LOCK PIN

x 7-3/4 = 90˚

2

1

h

3 mm

Manual

Override

GEAR TRAIN

LOCK PIN

3

HOLD

5

90˚

7

Manual

Override

GEAR TRAIN

LOCK PIN

6

8

EA0374R3

4

Rotating

Turn the key in the direction of

the arrow on the hand symbol.

CAUTION:

When you lock the gear train lock pin, be careful to turn only about 5 degrees until you hear a light

click or meet slight resistance. Turning too far will strip the head of the lock pin. Once power is

restored, the actuator returns to automated control, without having to rotate the gear train lock pin.

129-270 EAI/ES-4 DEI, Inc.

Locking in place

Rotate the gear train

lock pin.

Releasing when power is absent

Turn the key in the direction of the

arrow.

Figure 7. Manual Override.

Page 5

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

Mechanical Range Adjustment –

Limiting Rotation (0 through 90°)

Make sure the actuator is in the zero position when

making this adjustment. If making the adjustment

before the actuator is in service, take into account the

5° preload. To release the preload, insert the 3 mm hex

key in the override opening and turn the key in the

direction of the arrow.

To line up the actuator at the desired angle of rotation,

begin by removing the clamp from actuator.

Rotate adapter and insert at desired angle of rotation.

Return clamp to secure the adapter. Test rotation by

applying signal.

If necessary, re-adjust adapter and restart.

Installation

1

2

3

EA0701R1

Figure 8.

The Angular Rotation is Adjustable between

0° and 90° at 5-degree Intervals.

5

Mounting for NEMA 2

See Figure 10 for acceptable NEMA 2 mounting

positions.

90

4

EA0660R1

Figure 9.

NEMA 2

<

90

˚

EA0692R1

Figure 10. Acceptable NEMA 2 Mounting Positions.

˚

90

<

˚

90

129-270 EAI/ES-5 DEI, Inc.

Page 6

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

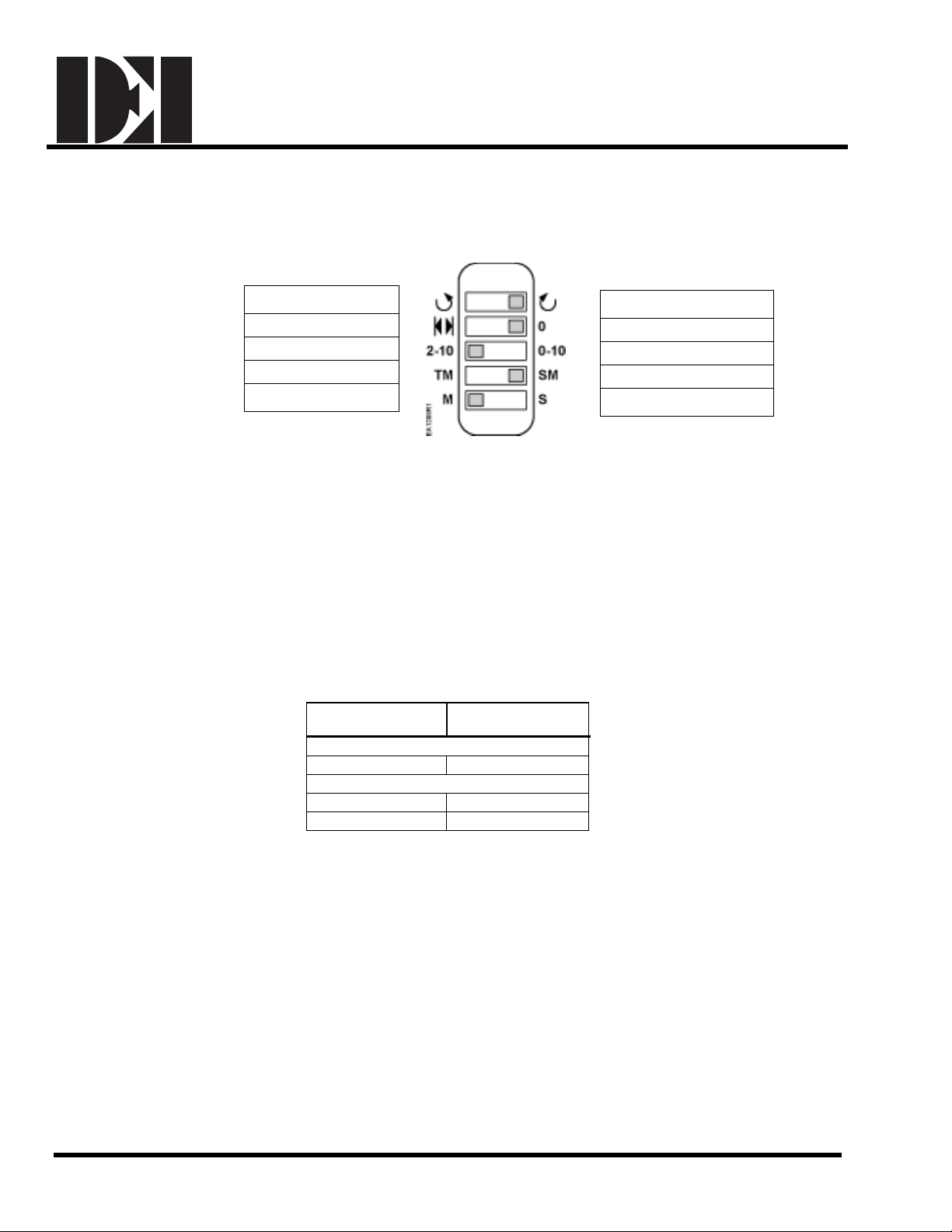

DIP Switch Features

(ES142-M2 and ES142-M2-S Only)

Installation

Counterclockwise

Self-adapt feature

2 to 10 Vdc

Tandem Mount

Master

Figure 11. DIP Switch Settings.

• After setting the 4th DIP switch for TM (tandem mount) on all actuators used in the

tandem application, one actuator must be identified as the Master by selecting the

"M" on the 5th DIP switch.

• The rest of the actuators used in the application should have the "S" (slave) set on

the 5th DIP switch.

• Connect all the 2 (black) Neutral wires and connect them to the power supply.

• Connect all the 1 (red) Supply wires and connect them to the power supply.

• The Output Signal 9 (pink) wire identified as the Master actuator, needs to be

connected to all the Control Signal Wires 8 (gray) of the slave actuators used in the

tandem application.

Operating

Voltage

Modulating Control

24 Vac/dc 9 VA/7W

2-Position and 3-Position Control

24 Vac/dc 8 VA/6W

120 Vac 9 VA

Power

Consumption

Clockwise

Self-Adapt Off

0 to 10 Vdc

Single Mount

Slave

129-270 EAI/ES-6 DEI, Inc.

Page 7

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

Dual Auxiliary Switch (-S option)

Installation

-5° 0° 10° 20° 30° 70° 80° 90°

0° 10° 20° 30° 70° 80° 90°

EA0413R2

A

Figure 12.

B

Factory setting:

Switch A 5°

Switch B 85°

To change the settings of A and B:

• Make sure the actuator is in the 0 position. The

scale is valid only in the 0 position.

• Use a flat-blade screwdriver to turn the switch

adjustment dials to the desired setting at which a

signal is to be given.

Actuator rotary range with the shaft adapter mounted at

position 0.

Setting range for Switches A and B: 0 – 90°

Setting interval: 5°

Switching hysteresis: 2°

10

20

A

AUX

SWITCH

ADJ

B

40

30

40

70

20

90

80

70

50

60

Manual

Override

EA0277R3

Figure 13. Dual Auxiliary Switch Dials.

129-270 EAI/ES-7 DEI, Inc.

Page 8

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

Zero Span Control Signal Adjustment (-ZS option)

The offset (start point) and

span of the control signal

can be adjusted. The offset,

U0, can be adjusted between

0 to 5 VDC. The span, ∆U,

can be adjusted between 2

to 30 VDC.

Y

(%)

S

100

0

2 5 10 35

EA0411R1

U

O

U (max. 30 V)

Δ

Ys Mechanical positioning range

(100% = angle of rotation 90°)

Yu Control signal

U0 Offset (start point)

∆U Span

Installation

2)1) 3)

Control

Signals

Span, U

5

2

10

15

20

30

25

Y

(v)

U

Offset, Uo

1

0

5

4

Uo

2

3

U

Examples above:

Ex. 1. U0 = 0V, ∆U = 2V The minimum working

range for Ys = 100%.

Ex. 2. U0 = 5V, ∆U = 30V The maximum working

range for Ys = 100%

Ex. 3. U0 = 0V, ∆U = 10V Factory setting

Figure 14. The Minimum and Maximum Control Signal

Adjustment.

Figure 15. Setting for

Example:

Open the actuator from 0% to 50% (45°) using a control signal of Umin = 2V to Umax = 10V.

Calculating the value of ∆U:

50

2)(10 x 100

−

V16

Y

(%)

S

100

50

0

21810

U

o

ΔU (16 V)

min) Umax (U %] [ 100

U =

=Δ

−

=

% in rotation of angle Working

Settings:

Offset U0 = 2, Span: ∆U = 16V

Umin = minimum control signal

Umax = maximum control signal

EA0287R1

10V Span, 0 Offset.

Y

(v)

U

U

min

U

EA0412R1

max

Figure 16. Example.

129-270 EAI/ES-8 DEI, Inc.

Page 9

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

Wiring

24 VAC or 120 VAC

All wiring must conform to NEC and local codes and regulations.

24 VAC

Use earth ground isolating step-down Class 2 transformers. Do not use auto transformers. Determine the supply

transformer rating by summing the total VA of all actuators used. The maximum rating for a Class 2 step-down

transformer is 100 VA. The ES142 (24 VAC) actuators require 8 to 9 VA; therefore it is recommended that up to

10 actuators (between 80 and 90% of transformer VA) can be powered by one transformer. Operating more than

10 actuators requires additional transformers or separate 100 VA power trunks.

WARNING:

Mixed switch operation is not permitted. To the switching outputs of both auxiliary switches (A and B),

only apply:

• Standard cable (250 Vac/24 Vdc)

− UL/cUL: line voltage, or

− UL/cUL: Class 2 voltage.

NOTE: Either all six outputs of the dual auxiliary switches must be connected to line voltage or all six

outputs must be connected to Class 2 voltage.

• Plenum cable (24V)

− UL/cUL: Class 2 voltage.

Wiring Diagrams

Three-Position Control (24 VAC/DC)

NEUT

7 (ORANGE)

24

Vac

ISOLATING CLASS 2

TRANSFORMER FOR

2 (BLACK)

6 (VIOLET)

1 (RED)

EARTH GROUND

24 Vac POWER

EA0868R1

Figure 17. Three-Position Control.

120 Vac

129-270 EAI/ES-9 DEI, Inc.

Page 10

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

Two-Position Control (24 VAC/DC)

1

M

EA0281R1

2

Figure. 18

Table 1. Two-position Control 24 VAC/DC.

Standard

Symbol

1

2 Com Black

S1 Switch A Common Gray/red

S2 Switch A N.C. Gray/blue

S3 Switch A N.O. Gray/pink

S4 Switch B Common Black/red

S5 Switch B N.C. Black/blue

S6 Switch B N.O. Black/pink

Function

(+)

S1

A

S2 S3 S5 S6

Red

S4

B

Color

Plenum

Two-Position Control (120 VAC)

3

M

PL0026R1

4

Figure 19.

Table 2. Two-position Control 120 VAC.

Standard

Symbol

3 Line (120 VAC) Black

4 Neutral (120 VAC) White

S1 Switch A Common Gray/red

S2 Switch A N.C. Gray/blue

S3 Switch A N.O. Gray/pink

S4 Switch B Common Black/red

S5 Switch B N.C. Black/blue

S6 Switch B N.O. Black/pink

Function

S1

A

S4

B

S2 S3 S5 S6

Color

Standard

129-270 EAI/ES-10 DEI, Inc.

Page 11

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

Three-Position Control (24 VAC/DC) Modulating Position Control

CONTROL SIGNAL

CW6CCW

7

(24 VAC/DC)

8

9

S1

Installation

S4

M

2

1

SUPPLY

PL0154R1

NEUTRAL

Figure 20.

Table 3. Three-position Control 24 VAC/DC.

Standard

Symbol

1

(+)

Function

Color

Plenum

Red

2 Com Black

6 Control signal clockwise Violet

7

Control signal

Orange

counterclockwise

(0 to 10 Vdc or 2 to 10 Vdc) for Tandem

Application (Master/Slave)

Supply (+)

Controller

Control Signal

0 to 10 Vdc

or 2 to 10 Vdc

Neutral

9

8

2

81

Supply

Actuator 2

Input 0 to 10 Vdc

or 2 to 10 Vdc

1

Supply

8

Input 0 to 10 Vdc

Actuator 1

Output (Feedback)

Neutral

Neutral

2

EA0284R1

M

2

1

A

S2 S3 S5 S6

B

Figure 21.

Table 4. Modulating Control 24 VAC/DC.

Standard

Symbol

1

(+)

Function

Color

Plenum

Red

2 Com Black

8

0 to 10 VDC/

Gray

2 to 10 Vdc input signal

Output for 0 to 10 VDC

9

Pink

position indication

S1 Switch A Common Gray/red

S2 Switch A N.C. Gray/blue

S3 Switch A N.O. Gray/pink

S4 Switch B Common Black/red

S5 Switch B N.C. Black/blue

S6 Switch B N.O. Black/pink

Input 0 to 10 Vdc

Actuator 3

or 2 to 10 Vdc

Neutral

Neutral (-)

2

EA1217R1

1

Supply

129-270 EAI/ES-11 DEI, Inc.

Page 12

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

Start-Up/Commissioning

Two-Position Control, 24 VAC/DC

1. Check that the wires are connected correctly.

2. Connect wires 1 (red) and 2 (black) to a Digital Multimeter (DMM) with the dial set at VAC to verify that the

operating voltage is within range.

3. Check operation:

a. Connect wires 1 (red) and 2 (black) to 24 VAC/DC signal.

b. Allow the actuator shaft coupling to rotate from 0 to 90°.

c. Disconnect wire 1 (red) and the actuator shaft coupling returns to the 0 position.

4. Check spring return:

a. Connect wires 1 (red) and 2 (black) to the 24 VAC/DC signal.

b. Allow the actuator shaft coupling to rotate half-way.

c. Disconnect wire 1 (red).

d. The spring returns the actuator shaft coupling to the fail 0 position.

e. Connect wire 1 (red) and the actuator shaft coupling begins to move.

5. Check the auxiliary switch A (-S option):

a. Set the DMM dial to OHMS (resistance) or continuity check.

b. Connect wires S1 and S3 to the DMM. The DMM should indicate an open circuit or no resistance.

c. Apply a 24 VAC signal to wire 1 (red).

d. The DMM should indicate contact closure as the actuator shaft coupling reaches the setting of switch A.

e. Connect wires S1 and S2 to the DMM. The DMM should indicate an open circuit or no resistance.

f. Disconnect wire 1 (red).

g. The DMM should indicate contact closure as the actuator shaft coupling reaches the setting of switch A.

6. Check the auxiliary switch B (-S option):

a. Set the DMM dial to OHMS (resistance) or continuity check.

b. Connect wires S4 and S6 to the DMM. The DMM should indicate an open circuit or no resistance.

c. Apply a 24 VAC signal to wire 1 (red).

d. The DMM should indicate contact closure as the actuator shaft coupling reaches the setting of switch B.

e. Connect wires S4 and S5 to the DMM. The DMM should indicate an open circuit or no resistance.

f. Disconnect wire 1 (red).

g. The DMM should indicate contact closure as the actuator shaft coupling reaches the setting of switch B.

Service

WARNING:

Do not open the actuator. If the actuator is inoperative, replace the unit.

129-270 EAI/ES-12 DEI, Inc.

Page 13

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

Two-Position Control, 120 VAC

1. Check that the wires are connected correctly.

2. Connect wires to a Digital Multimeter (DMM) with the dial set at VAC to verify that the operating voltage is

within range.

3. Check operation:

a. Connect wires 3 (black) and 4 (white) to 120 VAC signal.

b. Allow the actuator shaft coupling to rotate from 0 to 90°.

c. Disconnect wire 3 (black) and the actuator shaft coupling returns to the 0 position.

4. Check spring return:

a. Connect wires 3 (black) and 4 (white) to the 120 VAC signal.

b. Allow the actuator shaft coupling to rotate half-way.

c. Disconnect wire 3 (black).

d. The spring returns the actuator shaft coupling to the fail 0 position.

e. Connect wire 3 (black) and the actuator shaft coupling begins to move.

5. Check the auxiliary switch A (-S option):

a. Set the DMM dial to OHMS (resistance) or continuity check.

b. Connect wires S1 and S3 to the DMM. The DMM should indicate an open circuit or no resistance.

c. Apply a 120 VAC across wires 3 (black) and 4 (white).

d. The DMM should indicate contact closure as the actuator shaft coupling reaches the setting of switch A.

e. Connect wires S1 and S2 to the DMM. The DMM should indicate an open circuit or no resistance.

f. Disconnect wire 3 (black).

g. The DMM should indicate contact closure as the actuator shaft coupling reaches the setting of switch A.

6. Check the auxiliary switch B (-S option):

a. Set the DMM dial to OHMS (resistance) or continuity check.

b. Connect wires S4 and S6 to the DMM. The DMM should indicate an open circuit or no resistance.

c. Apply a 120 VAC across wires 3 (black) and 4 (white).

d. The DMM should indicate contact closure as the actuator shaft coupling reaches the setting of switch B.

e. Connect wires S4 and S5 to the DMM. The DMM should indicate an open circuit or no resistance.

f. Disconnect wire 3 (black).

g. The DMM should indicate contact closure as the actuator shaft coupling reaches the setting of switch B.

Service

WARNING:

Do not open the actuator. If the actuator is inoperative, replace the unit.

129-270 EAI/ES-13 DEI, Inc.

Page 14

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

Three-Position Control, 24 VAC/DC

1. Check that the wires are connected correctly.

2. Connect wires 1 (red) and 2 (black) to a Digital Multimeter (DMM) with the dial set at VAC to verify that the

operating voltage is within range.

3. Check operation:

a. Connect wires 1 (red) and 2 (black) to the actuator.

b. Apply a control signal (24 VAC/DC) to wire 6 (violet).

c. Allow the actuator shaft coupling to rotate from 0 to 90°.

d. Stop applying a control signal to wire 6 (violet).

e. Apply a control signal (24 VAC/DC) to wire 7 (orange).

f. Allow the actuator shaft coupling to rotate from 90 to 0°.

4. Check spring return:

a. Apply a control signal (24 VAC/DC) to wire 6 (violet).

b. Allow the actuator shaft coupling to rotate half-way.

c. Disconnect wire 1 (red).

d. The spring returns the actuator shaft coupling to the fail 0 position.

Service

WARNING:

Do not open the actuator. If the actuator is inoperative, replace the unit.

129-270 EAI/ES-14 DEI, Inc.

Page 15

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

Modulating Control, 24 VAC/DC

1. Check that the wires are connected correctly.

2. Check that the offset (start point) and span are set correctly, if used.

3. Connect wires 1 (red) and 2 (black) to a Digital Multimeter (DMM) with the dial set at VAC to verify that the

operating voltage is within range.

4. Check operation:

a. Connect wires 1 (red) and 2 (black) to the actuator.

b. Set the DMM dial to VDC for the actuator input signal as required for voltage.

c. Connect wires 2 (black) and 8 (gray) to DMM.

d. Apply a full scale input signal (10 VDC) to wire 8 (gray).

e. Allow the actuator shaft coupling to rotate from 0 to 90°.

f. Disconnect wire 1 (red) and the shaft coupling returns to the 0 position.

5. Check spring return:

a. Set the DMM dial to VDC.

b. Connect wires 2 (black) and 8 (gray) to DMM.

c. Apply an input signal (5 VDC) to wire 8 (gray).

d. Allow the actuator shaft coupling to rotate half-way.

e. Disconnect wire 1 (red). The spring returns the actuator shaft coupling to the fail 0 position.

f. Connect wire 1 (red) and the actuator moves.

6. Check feedback:

a. Set the DMM dial to VDC.

b. Attach wires 2 (black) and 9 (pink) to the DMM.

c. Apply a full scale input signal to wire 8 (gray). The reading at the DMM should increase.

d. Remove the signal from wire 8 (gray) and the reading at the DMM should decrease and the actuator

shaft coupling returns to the fail 0 position.

7. Check the auxiliary switch A (-S option):

a. Set the DMM dial to OHMS (resistance) or continuity check.

b. Connect wires S1 and S3 to the DMM. The DMM should indicate an open circuit or no resistance.

c. Apply a full scale input signal to wire 8 (gray). The DMM should indicate contact closure as the actuator

shaft coupling reaches the setting of switch A.

d. Connect wires S1 and S2 to the DMM. The DMM should indicate an open circuit or no resistance.

e. Stop the signal to wire 8 (gray).

f. The DMM should indicate contact closure as the actuator shaft coupling reaches the setting of switch A.

8. Check the auxiliary switch B (-S option):

a. Set the DMM dial to OHMS (resistance) or continuity check.

b. Connect wires S4 and S6 to the DMM. The DMM should indicate an open circuit or no resistance.

c. Apply a full scale input signal to wire 8 (gray). The DMM should indicate contact closure as the actuator

shaft coupling reaches the setting of switch B.

d. Connect wires S4 and S5 to the DMM. The DMM should indicate an open circuit or no resistance.

e. Stop the signal to wire 8 (gray).

f. The DMM should indicate contact closure as the actuator shaft coupling reaches the setting of switch B.

Service

WARNING:

Do not open the actuator. If the actuator is inoperative, replace the unit.

129-270 EAI/ES-15 DEI, Inc.

Page 16

Dimensions

min. 4 in.

100 mm

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

1-1/8 in.

28 mm

Installation

0

5

1

˚

O

P

T

I

O

N

A

L

9

5

˚

min. 1/4 in.

7 mm

PL0117R1

1-11/32

34 mm

3-3/8 in.

86 mm

3-15/16 in.

100 mm

1.1 in.

28.5 mm

OPENING

FOR 3/8"

FLEX CONDUIT

(3 PLS)

11/32 in.

10 mm

1-23/32 in.

30 mm

1-19/32

37 mm

min. 8 in.

200 mm

min.

2-1/2 in.

60 mm

11 in.

279 mm

7-3/4 in.

197 mm

Figure 22. Dimensions of the ES142 Actuator and Mounting Bracket.

230 mm

EA0249R2

25/32 in

9 in

20 mm

129-270 EAI/ES-16 DEI, Inc.

Page 17

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

Sizing Actuators for Damper Applications

The number of actuators required depends on several factors. To determine the quantity of actuators required for

the installation:

1. Obtain damper torque ratings (ft-lb/ft

2. Determine the area of the damper.

3. Calculate the total torque required to move the damper:

Total Torque = Torque Rating x Damper Area

4. Select the total quantity of actuators, required:

Number of Actuators =

Total Damper Torque required

SF

(see note

below)

2

or Nm/m2) from the damper manufacturer.

x

Actuator T orque

(refer to

specifications)

NOTE: When calculating the number of actuators required, a safety factor (SF) should be included for

unaccountable variables such as slight misalignments, aging of the damper, etc. A suggested

safety factor is 0.80 (or 80% of the rated torque).

Mechanical coupling of the actuator is allowed if:

• The same type of actuator is used.

• The operating voltage is within the tolerance.

129-270 EAI/ES-17 DEI, Inc.

Page 18

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

ACCESSORIES

NOTE: The auxiliary switches and/or the control signal adjustment cannot be added in the field. Order the

product number that includes the option(s), if required.

ASK71.1U This kit allows foot mounting of the ES142

actuator. This kit should be used for

in-the-airstream applications, and generally, anywhere

a foot-mounted actuator can be mounted.

This kit contains a crank arm that changes the angular

rotation into a linear stroke, a support bearing ring to

minimize side loading on the actuator’s output bearing,

a mounting bracket, and required mounting fasteners.

EA0477R2

(4 each)

Figure 1. Floor Mount Kit.

EA0476R2

Figure 2. Frame Mount Kit.

EA0495R1

Figure 3. Crank Arm Kit.

EA0494R1

Figure 4. Crank Arm Kit with Mounting Bracket.

ASK71.2U This kit allows mounting of the ES142

actuator directly to a damper frame. This kit should be

used with louvers and vents, and in applications where

use of the floor mount kit is not possible.

This kit contains a crank arm that changes the angular

rotation into a linear stroke, a support bearing ring to

minimize side loading on the actuator’s output bearing,

a mounting bracket, and required mounting fasteners.

ASK71.3 This kit allows a direct coupled actuator to

provide an auxiliary linear drive. This crank arm kit can

be used to simultaneously drive a set of opposing or

adjacent dampers with a single actuator.

This kit includes a crank arm that attaches to the

splined hub of the shaft adapter, and other required

mounting fasteners.

ASK71.4 This kit allows economical mounting of an

actuator to a variety of surfaces. This kit should be

used in applications where the actuator can be rigidly

surface mounted and a linear stroke output is required.

This kit includes a crank arm that attaches to the

splined hub of the shaft adapter, a mounting bracket,

and other required mounting fasteners.

129-270 EAI/ES-18 DEI, Inc.

Page 19

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

ASK73.1 This bracket provides an extended anti-

rotation pin that allows two ES142 actuators to directly

drive a single damper shaft. For use with two and

three–position actuators.

EA0496R1

Figure 5. Tandem Mount Bracket.

ASK73.2U This bracket provides an extended anti-

rotation pin that allows two modulating actuators to

directly drive a single damper shaft. (Applicable for

standard models and models with dual auxiliary

switches; not applicable for zero span control signal

EA0740R1

adjustment models.)

Figure 6. Tandem Mount Bracket.

EA0498R1

Figure 7. Self-centering Shaft Adapter.

Service Parts

EA0499R1

985-003

Position indicators (package of 10).

EA0497R1

ASK74.1U

Special shaft adapter.

985-004 The self-centering shaft adapter will attach to

a shaft up to 1.00 inch (25.4 mm) in diameter. (The

special shaft adapter will attach to a 1.05-inch

(26.6-mm) diameter shaft.) This shaft adapter is

13/16-inches (20 mm) taller than the height of the

special shaft adapter.

EA0500R1

985-006

Anti-rotation (mounting) bracket.

Figure 8. Orderable Parts.

129-270 EAI/ES-19 DEI, Inc.

Page 20

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875

ES142 Spring Return Electronic Actuator

Installation Guide

General Installation ..................................................................................................EAI/ES – 1

Mounting...................................................................................................................EAI/ES – 1-4

Manual Override .......................................................................................................EAI/ES – 4

Mechanical Range Adjustment.................................................................................EAI/ES – 5

Mounting for NEMA 2 ...............................................................................................EAI/ES – 5

DIP Switch Features.................................................................................................EAI/ES – 6

Dual Auxiliary Switch (-S option) ..............................................................................EAI/ES – 6

Zero Span Control Signal Adjustment (-ZS option)..................................................EAI/ES – 7

Wiring........................................................................................................................EAI/ES – 8

General ..............................................................................................................EAI/ES – 8

Transformer........................................................................................................EAI/ES – 8

Three-Position Control (24 VAC/DC) .................................................................EAI/ES – 8

Two-Position Control (24 VAC/DC)....................................................................EAI/ES – 9

Two-Position Control (120 VAC)........................................................................EAI/ES – 9

Three-Position (Floating) Control (24 VAC/DC).................................................EAI/ES – 10

Modulating Control (24 VAC/DC).......................................................................EAI/ES – 10

Start-up/Commissioning ...........................................................................................EAI/ES – 11

Two-Position Control (24 VAC/DC)....................................................................EAI/ES – 11

Two-Position Control (120 VAC)........................................................................EAI/ES – 12

Three-Position (Floating) Control (24 VAC/DC).................................................EAI/ES – 13

Modulating Control (24 VAC/DC).......................................................................EAI/ES – 14

Actuator Dimensions ................................................................................................EAI/ES – 15

Actuator Sizing for Dampers.....................................................................................EAI/ES – 16

Accessories ..............................................................................................................EAI/ES – 17-18

Item Number 129-270-08, Rev. BA

196 Riverneck Road, Chelmsford, MA 01824 Tel: (978)-244-1200 Fax: (978) 244-1422

Loading...

Loading...