Page 1

DR EMISSIONS CONTROL 25 - 1

EMISSIONS CONTROL

TABLE OF CONTENTS

page page

EMISSIONS CONTROL

DESCRIPTION

STATE DISPLAY TEST MODE .................2

CIRCUIT ACTUATION TEST MODE ............2

DIAGNOSTIC TROUBLE CODES ..............2

TASK MANAGER .............................2

MONITORED SYSTEMS ......................2

TRIP DEFINITION ............................5

COMPONENT MONITORS ....................6

OPERATION

OPERATION .................................6

TASK MANAGER .............................7

NON-MONITORED CIRCUITS ................10

EVAPORATIVE EMISSIONS ................12

EXHAUST GAS RECIRCULATION ...........51

Page 2

25 - 2 EMISSIONS CONTROL DR

EMISSIONS CONTROL

DESCRIPTION

STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Module (PCM) have two recognized states; HIGH and LOW. For this

reason, the PCM cannot recognize the difference between a selected switch position versus an open circuit, a short

circuit, or a defective switch. If the State Display screen shows the change from HIGH to LOW or LOW to HIGH,

assume the entire switch circuit to the PCM functions properly. Connect the DRB scan tool to the data link connector and access the state display screen. Then access either State Display Inputs and Outputs or State Display

Sensors.

CIRCUIT ACTUATION TEST MODE

The Circuit Actuation Test Mode checks for proper operation of output circuits or devices the Powertrain Control

Module (PCM) may not internally recognize. The PCM attempts to activate these outputs and allow an observer to

verify proper operation. Most of the tests provide an audible or visual indication of device operation (click of relay

contacts, fuel spray, etc.). Except for intermittent conditions, if a device functions properly during testing, assume the

device, its associated wiring, and driver circuit work correctly. Connect the DRB scan tool to the data link connector

and access the Actuators screen.

DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the PCM has recognized an abnormal condition in the system.

Remember that DTC’s are the results of a system or circuit failure, but do not directly identify the failed

component or components.

BULB CHECK

Each time the ignition key is turned to the ON position, the malfunction indicator (check engine) lamp on the instrument panel should illuminate for approximately 2 seconds then go out. This is done for a bulb check.

OBTAINING DTC’S USING DRB SCAN TOOL

1. Obtain the applicable Powertrain Diagnostic Manual.

2. Obtain the DRB Scan Tool.

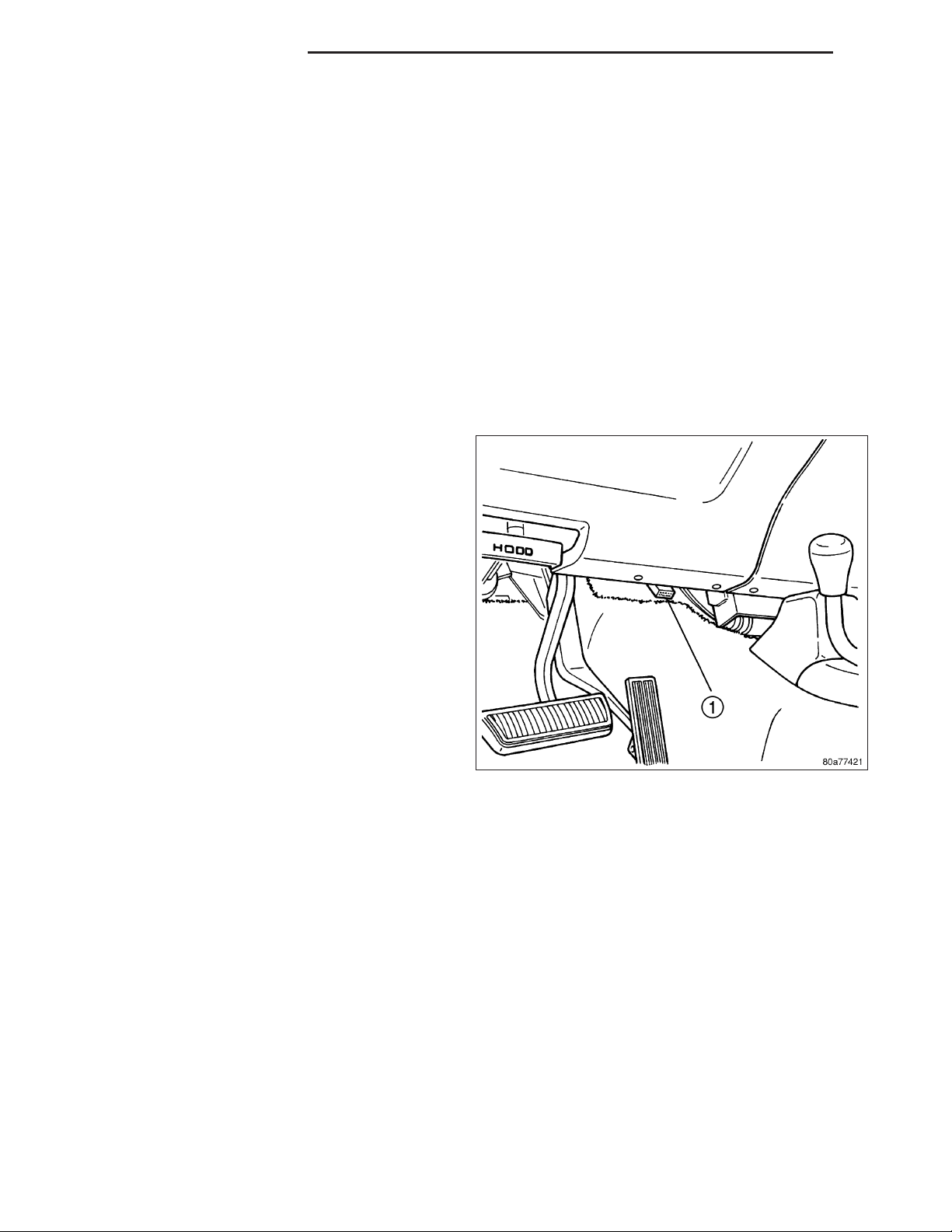

3. Connect the DRB Scan Tool to the data link (diagnostic) connector. This connector is located in the passenger

compartment at the lower edge of instrument panel, and near the steering column.

4. Turn the ignition switch on and access the “Read Fault” screen.

5. Record all the DTC’s and “freeze frame” information shown on the DRB scan tool.

6. To erase DTC’s, use the “Erase Trouble Code” data screen on the DRB scan tool. Do not erase any DTC’s

until problems have been investigated and repairs have been performed.

TASK MANAGER

The PCM is responsible for efficiently coordinating the operation of all the emissions-related components. The PCM

is also responsible for determining if the diagnostic systems are operating properly. The software designed to carry

out these responsibilities is called the ’Task Manager’.

MONITORED SYSTEMS

There are new electronic circuit monitors that check fuel, emission, engine and ignition performance. These monitors use information from various sensor circuits to indicate the overall operation of the fuel, engine, ignition and

emission systems and thus the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems monitors do not indicate a specific component problem. They do

indicate that there is an implied problem within one of the systems and that a specific problem must be diagnosed.

If any of these monitors detect a problem affecting vehicle emissions, the Malfunction Indicator Lamp (MIL) will be

illuminated. These monitors generate Diagnostic Trouble Codes that can be displayed with the MIL or a scan tool.

Page 3

DR EMISSIONS CONTROL 25 - 3

The following is a list of the system monitors:

• Misfire Monitor

• Fuel System Monitor

• Oxygen Sensor Monitor

• Oxygen Sensor Heater Monitor

• Catalyst Monitor

• Leak Detection Pump Monitor (if equipped)

All these system monitors require two consecutive trips with the malfunction present to set a fault.

Refer to the appropriate Powertrain Diagnostics Procedures manual for diagnostic procedures.

The following is an operation and description of each system monitor:

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved by an oxygen feedback system. The most important element of

the feedback system is the O2S. The O2S is located in the exhaust path. Once it reaches operating temperature

300° to 350°C (572° to 662°F), the sensor generates a voltage that is inversely proportional to the amount of oxygen in the exhaust. The information obtained by the sensor is used to calculate the fuel injector pulse width. This

maintains a 14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio, the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from the exhaust.

The O2S is also the main sensing element for the Catalyst and Fuel Monitors.

The O2S can fail in any or all of the following manners:

• slow response rate

• reduced output voltage

• dynamic shift

• shorted or open circuits

Response rate is the time required for the sensor to switch from lean to rich once it is exposed to a richer than

optimum A/F mixture or vice versa. As the sensor starts malfunctioning, it could take longer to detect the changes

in the oxygen content of the exhaust gas.

The output voltage of the O2S ranges from 0 to 1 volt. A good sensor can easily generate any output voltage in this

range as it is exposed to different concentrations of oxygen. To detect a shift in the A/F mixture (lean or rich), the

output voltage has to change beyond a threshold value. A malfunctioning sensor could have difficulty changing

beyond the threshold value.

OXYGEN SENSOR HEATER MONITOR

If there is an oxygen sensor (O2S) shorted to voltage DTC, as well as a O2S heater DTC, the O2S fault MUST be

repaired first. Before checking the O2S fault, verify that the heater circuit is operating correctly.

Effective control of exhaust emissions is achieved by an oxygen feedback system. The most important element of

the feedback system is the O2S. The O2S is located in the exhaust path. Once it reaches operating temperature

300°C to 350°C (572°F to 662°F), the sensor generates a voltage that is inversely proportional to the amount of

oxygen in the exhaust. The information obtained by the sensor is used to calculate the fuel injector pulse width. This

maintains a 14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio, the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from the exhaust.

The voltage readings taken from the O2S sensor are very temperature sensitive. The readings are not accurate

below 572°F (300°C). Heating of the O2S sensor is done to allow the engine controller to shift to closed loop control

as soon as possible. The heating element used to heat the O2S sensor must be tested to ensure that it is heating

the sensor properly.

The O2S sensor circuit is monitored for a drop in voltage. The sensor output is used to test the heater by isolating

the effect of the heater element on the O2S sensor output voltage from the other effects.

LEAK DETECTION PUMP MONITOR (IF EQUIPPED)

The leak detection assembly incorporates two primary functions: it must detect a leak in the evaporative system and

seal the evaporative system so the leak detection test can be run.

Page 4

25 - 4 EMISSIONS CONTROL DR

The primary components within the assembly are: A three port solenoid that activates both of the functions listed

above; a pump which contains a switch, two check valves and a spring/diaphragm, a canister vent valve (CVV) seal

which contains a spring loaded vent seal valve.

Immediately after a cold start, between predetermined temperature thresholds limits, the three port solenoid is briefly

energized. This initializes the pump by drawing air into the pump cavity and also closes the vent seal. During non

test conditions the vent seal is held open by the pump diaphragm assembly which pushes it open at the full travel

position. The vent seal will remain closed while the pump is cycling due to the reed switch triggering of the three

port solenoid that prevents the diaphragm assembly from reaching full travel. After the brief initialization period, the

solenoid is de-energized allowing atmospheric pressure to enter the pump cavity, thus permitting the spring to drive

the diaphragm which forces air out of the pump cavity and into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow in typical diaphragm pump fashion. The pump is controlled in

2 modes:

Pump Mode: The pump is cycled at a fixed rate to achieve a rapid pressure build in order to shorten the overall test

length.

Test Mode: The solenoid is energized with a fixed duration pulse. Subsequent fixed pulses occur when the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system will achieve an equalized pressure of about 7.5” H20. The cycle

rate of pump strokes is quite rapid as the system begins to pump up to this pressure. As the pressure increases, the

cycle rate starts to drop off. If there is no leak in the system, the pump would eventually stop pumping at the equalized pressure. If there is a leak, it will continue to pump at a rate representative of the flow characteristic of the size

of the leak. From this information we can determine if the leak is larger than the required detection limit (currently

set at .040” orifice by CARB). If a leak is revealed during the leak test portion of the test, the test is terminated at

the end of the test mode and no further system checks will be performed.

After passing the leak detection phase of the test, system pressure is maintained by turning on the LDP’s solenoid

until the purge system is activated. Purge activation in effect creates a leak. The cycle rate is again interrogated and

when it increases due to the flow through the purge system, the leak check portion of the diagnostic is complete.

The canister vent valve will unseal the system after completion of the test sequence as the pump diaphragm assembly moves to the full travel position.

Evaporative system functionality will be verified by using the stricter evap purge flow monitor. At an appropriate

warm idle the LDP will be energized to seal the canister vent. The purge flow will be clocked up from some small

value in an attempt to see a shift in the 02 control system. If fuel vapor, indicated by a shift in the 02 control, is

present the test is passed. If not, it is assumed that the purge system is not functioning in some respect. The LDP

is again turned off and the test is ended.

MISFIRE MONITOR

Excessive engine misfire results in increased catalyst temperature and causes an increase in HC emissions. Severe

misfires could cause catalyst damage. To prevent catalytic convertor damage, the PCM monitors engine misfire.

The Powertrain Control Module (PCM) monitors for misfire during most engine operating conditions (positive torque)

by looking at changes in the crankshaft speed. If a misfire occurs the speed of the crankshaft will vary more than

normal.

FUEL SYSTEM MONITOR

To comply with clean air regulations, vehicles are equipped with catalytic converters. These converters reduce the

emission of hydrocarbons, oxides of nitrogen and carbon monoxide. The catalyst works best when the Air Fuel (A/F)

ratio is at or near the optimum of 14.7 to 1.

The PCM is programmed to maintain the optimum air/fuel ratio of 14.7 to 1. This is done by making short term

corrections in the fuel injector pulse width based on the O2S sensor output. The programmed memory acts as a self

calibration tool that the engine controller uses to compensate for variations in engine specifications, sensor tolerances and engine fatigue over the life span of the engine. By monitoring the actual fuel-air ratio with the O2S sensor (short term) and multiplying that with the program long-term (adaptive) memory and comparing that to the limit,

it can be determined whether it will pass an emissions test. If a malfunction occurs such that the PCM cannot maintain the optimum A/F ratio, then the MIL will be illuminated.

Page 5

DR EMISSIONS CONTROL 25 - 5

CATALYST MONITOR

To comply with clean air regulations, vehicles are equipped with catalytic converters. These converters reduce the

emission of hydrocarbons, oxides of nitrogen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a catalyst to decay. This can increase vehicle emissions and

deteriorate engine performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors (O2S’s) to monitor the efficiency of the converter. The dual O2S’s

sensor strategy is based on the fact that as a catalyst deteriorates, its oxygen storage capacity and its efficiency are

both reduced. By monitoring the oxygen storage capacity of a catalyst, its efficiency can be indirectly calculated. The

upstream O2S is used to detect the amount of oxygen in the exhaust gas before the gas enters the catalytic converter. The PCM calculates the A/F mixture from the output of the O2S. A low voltage indicates high oxygen content

(lean mixture). A high voltage indicates a low content of oxygen (rich mixture).

When the upstream O2S detects a lean condition, there is an abundance of oxygen in the exhaust gas. A functioning converter would store this oxygen so it can use it for the oxidation of HC and CO. As the converter absorbs the

oxygen, there will be a lack of oxygen downstream of the converter. The output of the downstream O2S will indicate

limited activity in this condition.

As the converter loses the ability to store oxygen, the condition can be detected from the behavior of the downstream O2S. When the efficiency drops, no chemical reaction takes place. This means the concentration of oxygen

will be the same downstream as upstream. The output voltage of the downstream O2S copies the voltage of the

upstream sensor. The only difference is a time lag (seen by the PCM) between the switching of the O2S’s.

To monitor the system, the number of lean-to-rich switches of upstream and downstream O2S’s is counted. The

ratio of downstream switches to upstream switches is used to determine whether the catalyst is operating properly.

An effective catalyst will have fewer downstream switches than it has upstream switches i.e., a ratio closer to zero.

For a totally ineffective catalyst, this ratio will be one-to-one, indicating that no oxidation occurs in the device.

The system must be monitored so that when catalyst efficiency deteriorates and exhaust emissions increase to over

the legal limit, the MIL will be illuminated.

TRIP DEFINITION

The term “Trip” has different meanings depending on what the circumstances are. If the MIL (Malfunction Indicator

Lamp) is OFF, a Trip is defined as when the Oxygen Sensor Monitor and the Catalyst Monitor have been completed

in the same drive cycle.

When any Emission DTC is set, the MIL on the dash is turned ON. When the MIL is ON, it takes 3 good trips to turn

the MIL OFF. In this case, it depends on what type of DTC is set to know what a “Trip” is.

For the Fuel Monitor or Mis-Fire Monitor (continuous monitor), the vehicle must be operated in the “Similar Condition

Window” for a specified amount of time to be considered a Good Trip.

If a Non-Continuous OBDII Monitor fails twice in a row and turns ON the MIL, re-running that monitor which previously failed, on the next start-up and passing the monitor, is considered to be a Good Trip. These will include the

following:

• Oxygen Sensor

• Catalyst Monitor

• Purge Flow Monitor

• Leak Detection Pump Monitor (if equipped)

• EGR Monitor (if equipped)

• Oxygen Sensor Heater Monitor

If any other Emission DTC is set (not an OBDII Monitor), a Good Trip is considered to be when the Oxygen Sensor

Monitor and Catalyst Monitor have been completed; or 2 Minutes of engine run time if the Oxygen Sensor Monitor

or Catalyst Monitor have been stopped from running.

It can take up to 2 Failures in a row to turn on the MIL. After the MIL is ON, it takes 3 Good Trips to turn the MIL

OFF. After the MIL is OFF, the PCM will self-erase the DTC after 40 Warm-up cycles. A Warm-up cycle is counted

when the ECT (Engine Coolant Temperature Sensor) has crossed 160°F (71.1C) and has risen by at least 40°F

(4.4°C) since the engine has been started.

Page 6

25 - 6 EMISSIONS CONTROL DR

COMPONENT MONITORS

There are several components that will affect vehicle emissions if they malfunction. If one of these components

malfunctions the Malfunction Indicator Lamp (MIL) will illuminate.

Some of the component monitors are checking for proper operation of the part. Electrically operated components

now have input (rationality) and output (functionality) checks. Previously, a component like the Throttle Position sensor (TPS) was checked by the PCM for an open or shorted circuit. If one of these conditions occurred, a DTC was

set. Now there is a check to ensure that the component is working. This is done by watching for a TPS indication

of a greater or lesser throttle opening than MAP and engine rpm indicate. In the case of the TPS, if engine vacuum

is high and engine rpm is 1600 or greater, and the TPS indicates a large throttle opening, a DTC will be set. The

same applies to low vacuum if the TPS indicates a small throttle opening.

All open/short circuit checks, or any component that has an associated limp-in, will set a fault after 1 trip with the

malfunction present. Components without an associated limp-in will take two trips to illuminate the MIL.

OPERATION

OPERATION

The Powertrain Control Module (PCM) monitors many

different circuits in the fuel injection, ignition, emission

and engine systems. If the PCM senses a problem

with a monitored circuit often enough to indicate an

actual problem, it stores a Diagnostic Trouble Code

(DTC) in the PCM’s memory. If the problem is repaired

or ceases to exist, the PCM cancels the code after 40

warm-up cycles. Diagnostic trouble codes that affect

vehicle emissions illuminate the Malfunction Indicator

Lamp (MIL). The MIL is displayed as an engine icon

(graphic) on the instrument panel. Refer to Malfunction

Indicator Lamp in this section.

Certain criteria must be met before the PCM stores a

DTC in memory. The criteria may be a specific range

of engine RPM, engine temperature, and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met. For example, assume the diagnostic trouble code criteria requires the PCM to monitor the

circuit only when the engine operates between 750 and 2000 RPM. Suppose the sensor’s output circuit shorts to

ground when engine operates above 2400 RPM (resulting in 0 volt input to the PCM). Because the condition happens at an engine speed above the maximum threshold (2000 rpm), the PCM will not store a DTC.

There are several operating conditions for which the PCM monitors and sets DTC’s. Refer to Monitored Systems,

Components, and Non-Monitored Circuits in this section.

Technicians must retrieve stored DTC’s by connecting the DRB scan tool (or an equivalent scan tool) to the 16–way

data link connector. The connector is located on the bottom edge of the instrument panel near the steering column.

NOTE: Various diagnostic procedures may actually cause a diagnostic monitor to set a DTC. For instance,

pulling a spark plug wire to perform a spark test may set the misfire code. When a repair is completed and

verified, connect the DRB scan tool to the 16–way data link connector (1) to erase all DTC’s and extinguish

the MIL.

Page 7

DR EMISSIONS CONTROL 25 - 7

TASK MANAGER

The Task Manager determines which tests happen when and which functions occur when. Many of the diagnostic

steps required by OBD II must be performed under specific operating conditions. The Task Manager software organizes and prioritizes the diagnostic procedures. The job of the Task Manager is to determine if conditions are appropriate for tests to be run, monitor the parameters for a trip for each test, and record the results of the test. Following

are the responsibilities of the Task Manager software:

• Test Sequence

• MIL Illumination

• Diagnostic Trouble Codes (DTCs)

• Trip Indicator

• Freeze Frame Data Storage

• Similar Conditions Window

Test Sequence

In many instances, emissions systems must fail diagnostic tests more than once before the PCM illuminates the

MIL. These tests are know as ’two trip monitors.’ Other tests that turn the MIL lamp on after a single failure are

known as ’one trip monitors.’ A trip is defined as ’start the vehicle and operate it to meet the criteria necessary to

run the given monitor.’

Many of the diagnostic tests must be performed under certain operating conditions. However, there are times when

tests cannot be run because another test is in progress (conflict), another test has failed (pending) or the Task

Manager has set a fault that may cause a failure of the test (suspend).

• Pending

Under some situations the Task Manager will not run a monitor if the MIL is illuminated and a fault is stored

from another monitor. In these situations, the Task Manager postpones monitors pending resolution of the

original fault. The Task Manager does not run the test until the problem is remedied.

For example, when the MIL is illuminated for an Oxygen Sensor fault, the Task Manager does not run the

Catalyst Monitor until the Oxygen Sensor fault is remedied. Since the Catalyst Monitor is based on signals

from the Oxygen Sensor, running the test would produce inaccurate results.

• Conflict

There are situations when the Task Manager does not run a test if another monitor is in progress. In these

situations, the effects of another monitor running could result in an erroneous failure. If this conflict is present,

the monitor is not run until the conflicting condition passes. Most likely the monitor will run later after the conflicting monitor has passed.

For example, if the Fuel System Monitor is in progress, the Task Manager does not run the EGR Monitor.

Since both tests monitor changes in air/fuel ratio and adaptive fuel compensation, the monitors will conflict with

each other.

• Suspend

Occasionally the Task Manager may not allow a two trip fault to mature. The Task Manager will suspend the

maturing of a fault if a condition exists that may induce an erroneous failure. This prevents illuminating the MIL

for the wrong fault and allows more precis diagnosis.

For example, if the PCM is storing a one trip fault for the Oxygen Sensor and the EGR monitor, the Task

Manager may still run the EGR Monitor but will suspend the results until the Oxygen Sensor Monitor either

passes or fails. At that point the Task Manager can determine if the EGR system is actually failing or if an

Oxygen Sensor is failing.

MIL Illumination

The PCM Task Manager carries out the illumination of the MIL. The Task Manager triggers MIL illumination upon

test failure, depending on monitor failure criteria.

The Task Manager Screen shows both a Requested MIL state and an Actual MIL state. When the MIL is illuminated

upon completion of a test for a third trip, the Requested MIL state changes to OFF. However, the MIL remains

illuminated until the next key cycle. (On some vehicles, the MIL will actually turn OFF during the third key cycle)

During the key cycle for the third good trip, the Requested MIL state is OFF, while the Actual MIL state is ON. After

the next key cycle, the MIL is not illuminated and both MIL states read OFF.

Page 8

25 - 8 EMISSIONS CONTROL DR

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different priorities according to regulations. As a result, the priorities determine MIL illumination and DTC erasure. DTCs are entered according to individual priority. DTCs with a higher priority overwrite lower priority DTCs.

Priorities

• Priority 0 —Non-emissions related trouble codes

• Priority 1 — One trip failure of a two trip fault for non-fuel system and non-misfire.

• Priority 2 — One trip failure of a two trip fault for fuel system (rich/lean) or misfire.

• Priority 3 — Two trip failure for a non-fuel system and non-misfire or matured one trip comprehensive com-

ponent fault.

• Priority 4 — Two trip failure or matured fault for fuel system (rich/lean) and misfire or one trip catalyst damaging misfire.

Non-emissions related failures have no priority. One trip failures of two trip faults have low priority. Two trip failures

or matured faults have higher priority. One and two trip failures of fuel system and misfire monitor take precedence

over non-fuel system and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure in two consecutive trips for MIL illumination. Upon failure of the

first test, the Task Manager enters a maturing code. If the component fails the test for a second time the code

matures and a DTC is set.

After three good trips the MIL is extinguished and the Task Manager automatically switches the trip counter to a

warm-up cycle counter. DTCs are automatically erased following 40 warm-up cycles if the component does not fail

again.

For misfire and fuel system monitors, the component must pass the test under a Similar Conditions Window in order

to record a good trip. A Similar Conditions Window is when engine RPM is within ±375 RPM and load is within

±10% of when the fault occurred.

NOTE: It is important to understand that a component does not have to fail under a similar window of operation to mature. It must pass the test under a Similar Conditions Window when it failed to record a Good

Trip for DTC erasure for misfire and fuel system monitors.

DTCs can be erased anytime with a DRB III. Erasing the DTC with the DRB III erases all OBD II information. The

DRB III automatically displays a warning that erasing the DTC will also erase all OBD II monitor data. This includes

all counter information for warm-up cycles, trips and Freeze Frame.

Trip Indicator

The Trip is essential for running monitors and extinguishing the MIL. In OBD II terms, a trip is a set of vehicle

operating conditions that must be met for a specific monitor to run. All trips begin with a key cycle.

Good Trip

The Good Trip counters are as follows:

• Specific Good Trip

• Fuel System Good Trip

• Misfire Good Trip

• Alternate Good Trip (appears as a Global Good Trip on DRB III)

• Comprehensive Components

• Major Monitor

• Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings depending on the circumstances:

• If the MIL is OFF, a trip is defined as when the Oxygen Sensor Monitor and the Catalyst Monitor have been

completed in the same drive cycle.

Page 9

DR EMISSIONS CONTROL 25 - 9

• If the MIL is ON and a DTC was set by the Fuel Monitor or Misfire Monitor (both continuous monitors), the

vehicle must be operated in the Similar Condition Window for a specified amount of time.

• If the MIL is ON and a DTC was set by a Task Manager commanded once-per-trip monitor (such as the Oxygen Sensor Monitor, Catalyst Monitor, Purge Flow Monitor, Leak Detection Pump Monitor, EGR Monitor or

Oxygen Sensor Heater Monitor), a good trip is when the monitor is passed on the next start-up.

• If the MIL is ON and any other emissions DTC was set (not an OBD II monitor), a good trip occurs when the

Oxygen Sensor Monitor and Catalyst Monitor have been completed, or two minutes of engine run time if the

Oxygen Sensor Monitor and Catalyst Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off the MIL, the following conditions must occur:

• Engine in closed loop

• Operating in Similar Conditions Window

• Short Term multiplied by Long Term less than threshold

• Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will count a good trip (three required) and turn off the MIL.

Misfire Good Trip

If the following conditions are met the PCM will count one good trip (three required) in order to turn off the MIL:

• Operating in Similar Condition Window

• 1000 engine revolutions with no misfire

Warm-Up Cycles

Once the MIL has been extinguished by the Good Trip Counter, the PCM automatically switches to a Warm-Up

Cycle Counter that can be viewed on the DRB III. Warm-Up Cycles are used to erase DTCs and Freeze Frames.

Forty Warm-Up cycles must occur in order for the PCM to self-erase a DTC and Freeze Frame. A Warm-Up Cycle

is defined as follows:

• Engine coolant temperature must start below and rise above 160° F (71.1°C).

• Engine coolant temperature must rise by 40° F (4.4°C)

• No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records several engine operating conditions and stores it in a Freeze

Frame. The Freeze Frame is considered one frame of information taken by an on-board data recorder. When a fault

occurs, the PCM stores the input data from various sensors so that technicians can determine under what vehicle

operating conditions the failure occurred.

The data stored in Freeze Frame is usually recorded when a system fails the first time for two trip faults. Freeze

Frame data will only be overwritten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays information about engine operation during a monitor. Absolute MAP (engine

load) and Engine RPM are stored in this window when a failure occurs. There are two different Similar conditions

Windows: Fuel System and Misfire.

FUEL SYSTEM

• Fuel System Similar Conditions Window — An indicator that ’Absolute MAP When Fuel Sys Fail’ and ’RPM

When Fuel Sys Failed’ are all in the same range when the failure occurred. Indicated by switching from ’NO’

to ’YES’.

• Absolute MAP When Fuel Sys Fail — The stored MAP reading at the time of failure. Informs the user at

what engine load the failure occurred.

• Absolute MAP — A live reading of engine load to aid the user in accessing the Similar Conditions Window.

• RPM When Fuel Sys Fail — The stored RPM reading at the time of failure. Informs the user at what engine

RPM the failure occurred.

Page 10

25 - 10 EMISSIONS CONTROL DR

• Engine RPM — A live reading of engine RPM to aid the user in accessing the Similar Conditions Window.

• Adaptive Memory Factor — The PCM utilizes both Short Term Compensation and Long Term Adaptive to

calculate the Adaptive Memory Factor for total fuel correction.

• Upstream O2S Volts — A live reading of the Oxygen Sensor to indicate its performance. For example, stuck

lean, stuck rich, etc.

• SCW Time in Window (Similar Conditions Window Time in Window) — A timer used by the PCM that

indicates that, after all Similar Conditions have been met, if there has been enough good engine running time

in the SCW without failure detected. This timer is used to increment a Good Trip.

• Fuel System Good Trip Counter — A Trip Counter used to turn OFF the MIL for Fuel System DTCs. To

increment a Fuel System Good Trip, the engine must be in the Similar Conditions Window, Adaptive Memory

Factor must be less than calibrated threshold and the Adaptive Memory Factor must stay below that threshold

for a calibrated amount of time.

• Test Done This Trip — Indicates that the monitor has already been run and completed during the current trip.

MISFIRE

• Same Misfire Warm-Up State — Indicates if the misfire occurred when the engine was warmed up above

160° F (71.1°C).

• In Similar Misfire Window — An indicator that ’Absolute MAP When Misfire Occurred’ and ’RPM When Mis-

fire Occurred’ are all in the same range when the failure occurred. Indicated by switching from ’NO’ to ’YES’.

• Absolute MAP When Misfire Occurred — The stored MAP reading at the time of failure. Informs the user at

what engine load the failure occurred.

• Absolute MAP — A live reading of engine load to aid the user in accessing the Similar Conditions Window.

• RPM When Misfire Occurred — The stored RPM reading at the time of failure. Informs the user at what

engine RPM the failure occurred.

• Engine RPM — A live reading of engine RPM to aid the user in accessing the Similar Conditions Window.

• Adaptive Memory Factor — The PCM utilizes both Short Term Compensation and Long Term Adaptive to

calculate the Adaptive Memory Factor for total fuel correction.

• 200 Rev Counter — Counts 0–100 720 degree cycles.

• SCW Cat 200 Rev Counter — Counts when in similar conditions.

• SCW FTP 1000 Rev Counter — Counts 0–4 when in similar conditions.

• Misfire Good Trip Counter — Counts up to three to turn OFF the MIL.

• Misfire Data— Data collected during test.

• Test Done This Trip— Indicates YES when the test is done.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits, systems and conditions that could have malfunctions causing

driveability problems. The PCM might not store diagnostic trouble codes for these conditions. However, problems

with these systems may cause the PCM to store diagnostic trouble codes for other systems or components. EXAM-

PLE: a fuel pressure problem will not register a fault directly, but could cause a rich/lean condition or misfire. This

could cause the PCM to store an oxygen sensor or misfire diagnostic trouble code

FUEL PRESSURE

The fuel pressure regulator controls fuel system pressure. The PCM cannot detect a clogged fuel pump inlet filter,

clogged in-line fuel filter, or a pinched fuel supply or return line. However, these could result in a rich or lean condition causing the PCM to store an oxygen sensor or fuel system diagnostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil, fouled or worn spark plugs, ignition cross firing, or open spark

plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine cylinder compression.

Page 11

DR EMISSIONS CONTROL 25 - 11

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or leaking exhaust system, although it may set a fuel system fault.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is clogged, the needle is sticking or if the wrong injector is installed.

However, these could result in a rich or lean condition causing the PCM to store a diagnostic trouble code for either

misfire, an oxygen sensor, or the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen content when the system is in closed loop, it cannot determine

excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the vacuum circuits of vacuum assisted engine control system

devices. However, these could cause the PCM to store a MAP sensor diagnostic trouble code and cause a high idle

condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground. However, one or more diagnostic trouble codes may be generated as a result of this condition. The module should be mounted to the body at all times, also during diagnostic.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or damaged connector pins. However, it might store diagnostic

trouble codes as a result of spread connector pins.

Page 12

25 - 12 EVAPORATIVE EMISSIONS DR

EVAPORATIVE EMISSIONS

TABLE OF CONTENTS

page page

EVAPORATIVE EMISSIONS

DESCRIPTION - EVAP SYSTEM ................13

SPECIFICATIONS

TORQUE ...................................13

SOLENOID-EVAP/PURGE

DESCRIPTION ................................14

OPERATION ..................................14

REMOVAL ....................................14

INSTALLATION ...............................14

CAP - FUEL FILLER

DESCRIPTION ................................15

OPERATION ..................................15

REMOVAL

REMOVAL/INSTALLATION ...................15

PUMP-LEAK DETECTION

DESCRIPTION ................................16

OPERATION ..................................16

REMOVAL ....................................19

INSTALLATION ...............................20

ORVR

DESCRIPTION ................................21

OPERATION ..................................21

PUMP-NATURAL VAC LEAK DETECTION

DESCRIPTION ................................22

OPERATION ..................................22

REMOVAL ....................................23

INSTALLATION ...............................26

VALVE - PCV

DESCRIPTION ................................30

OPERATION ..................................32

DIAGNOSIS AND TESTING

PCV VALVE - 3.7L V-6/ 4.7L V-8 ..............33

REMOVAL ....................................35

INSTALLATION ...............................36

LINES - VACUUM

DESCRIPTION ................................37

CANISTER - VAPOR

DESCRIPTION ................................38

OPERATION ..................................40

REMOVAL ....................................40

INSTALLATION ...............................46

Page 13

DR EVAPORATIVE EMISSIONS 25 - 13

EVAPORATIVE EMISSIONS

DESCRIPTION - EVAP SYSTEM

The evaporation control system prevents the emission of fuel tank vapors into the atmosphere. When fuel evaporates in the fuel tank, the vapors pass through vent hoses or tubes into the two charcoal filled evaporative canisters.

The canisters temporarily hold the vapors. The Powertrain Control Module (PCM) allows intake manifold vacuum to

draw vapors into the combustion chambers during certain operating conditions.

All gasoline powered engines use a duty cycle purge system. The PCM controls vapor flow by operating the duty

cycle EVAP purge solenoid. Refer to Duty Cycle EVAP Canister Purge Solenoid for additional information.

When equipped with certain emissions packages, a Leak Detection Pump (LDP) will be used as part of the evaporative system. This pump is used as a part of OBD II requirements. Refer to Leak Detection Pump for additional

information. Other emissions packages will use a Natural Vacuum Leak Detection (NVLD) system in place of the

LDP. Refer to NVLD for additional information.

NOTE: The hoses used in this system are specially manufactured. If replacement becomes necessary, it is

important to use only fuel resistant hose.

SPECIFICATIONS

TORQUE

DESCRIPTION N·m Ft. Lbs. In. Lbs.

EVAP Canister Mounting

Nuts

EVAP Canister Mounting

Bracket-to-Frame Bolts

Leak Detection Pump

Mounting Bolts

Breathers (PCV system) 12 - 106

Leak Detection Pump

Filter Mounting Bolt

11 -

14 10

11 - 95

11 - 95

95

125

Page 14

25 - 14 EVAPORATIVE EMISSIONS DR

SOLENOID-EVAP/PURGE

DESCRIPTION

The duty cycle EVAP canister purge solenoid is located in the engine compartment. It is attached to the side of the

Power Distribution Center (PDC).

OPERATION

The Powertrain Control Module (PCM) operates the solenoid.

During the cold start warm-up period and the hot start time delay, the PCM does not energize the solenoid. When

de-energized, no vapors are purged. The PCM de-energizes the solenoid during open loop operation.

The engine enters closed loop operation after it reaches a specified temperature and the time delay ends. During

closed loop operation, the PCM energizes and de-energizes the solenoid 5 or 10 times per second, depending upon

operating conditions. The PCM varies the vapor flow rate by changing solenoid pulse width. Pulse width is the

amount of time the solenoid energizes. The PCM adjusts solenoid pulse width based on engine operating condition.

REMOVAL

The duty cycle EVAP canister purge solenoid (3) is

located in the engine compartment. It is attached to

the side of the Power Distribution Center (PDC).

1. Disconnect electrical wiring connector at solenoid.

2. Disconnect vacuum harness (2) at solenoid.

3. Remove solenoid from mounting bracket.

INSTALLATION

1. Install solenoid assembly to mounting bracket.

2. Connect vacuum harness.

3. Connect electrical connector.

Page 15

DR EVAPORATIVE EMISSIONS 25 - 15

CAP - FUEL FILLER

DESCRIPTION

The plastic fuel tank filler tube cap is threaded onto the end of the fuel fill tube. Certain models are equipped with

a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube is prevented by the use of a pressure-vacuum fuel fill cap. Relief

valves inside the cap will release fuel tank pressure at predetermined pressures. Fuel tank vacuum will also be

released at predetermined values. This cap must be replaced by a similar unit if replacement is necessary. This is

in order for the system to remain effective.

CAUTION: Remove fill cap before servicing any fuel system component to relieve tank pressure. If equipped

with a Leak Detection Pump (LDP), or NVLD system, the cap must be tightened securely. If cap is left loose,

a Diagnostic Trouble Code (DTC) may be set.

REMOVAL

REMOVAL/INSTALLATION

If replacement of the 1/4 turn fuel tank filler tube cap is necessary, it must be replaced with an identical cap to be

sure of correct system operation.

CAUTION: Remove the fuel tank filler tube cap to relieve fuel tank pressure. The cap must be removed prior

to disconnecting any fuel system component or before draining the fuel tank.

Page 16

25 - 16 EVAPORATIVE EMISSIONS DR

PUMP-LEAK DETECTION

DESCRIPTION

Vehicles equipped with JTEC engine control modules use a leak detection pump. Vehicles equipped with NGC

engine control modules use an NVLD pump. Refer to Natural Vacuum - Leak Detection (NVLD) for additional information.

The evaporative emission system is designed to prevent the escape of fuel vapors from the fuel system. Leaks in

the system, even small ones, can allow fuel vapors to escape into the atmosphere. Government regulations require

onboard testing to make sure that the evaporative (EVAP) system is functioning properly. The leak detection system

tests for EVAP system leaks and blockage. It also performs self-diagnostics. During self-diagnostics, the Powertrain

Control Module (PCM) first checks the Leak Detection Pump (LDP) for electrical and mechanical faults. If the first

checks pass, the PCM then uses the LDP to seal the vent valve and pump air into the system to pressurize it. If a

leak is present, the PCM will continue pumping the LDP to replace the air that leaks out. The PCM determines the

size of the leak based on how fast/long it must pump the LDP as it tries to maintain pressure in the system.

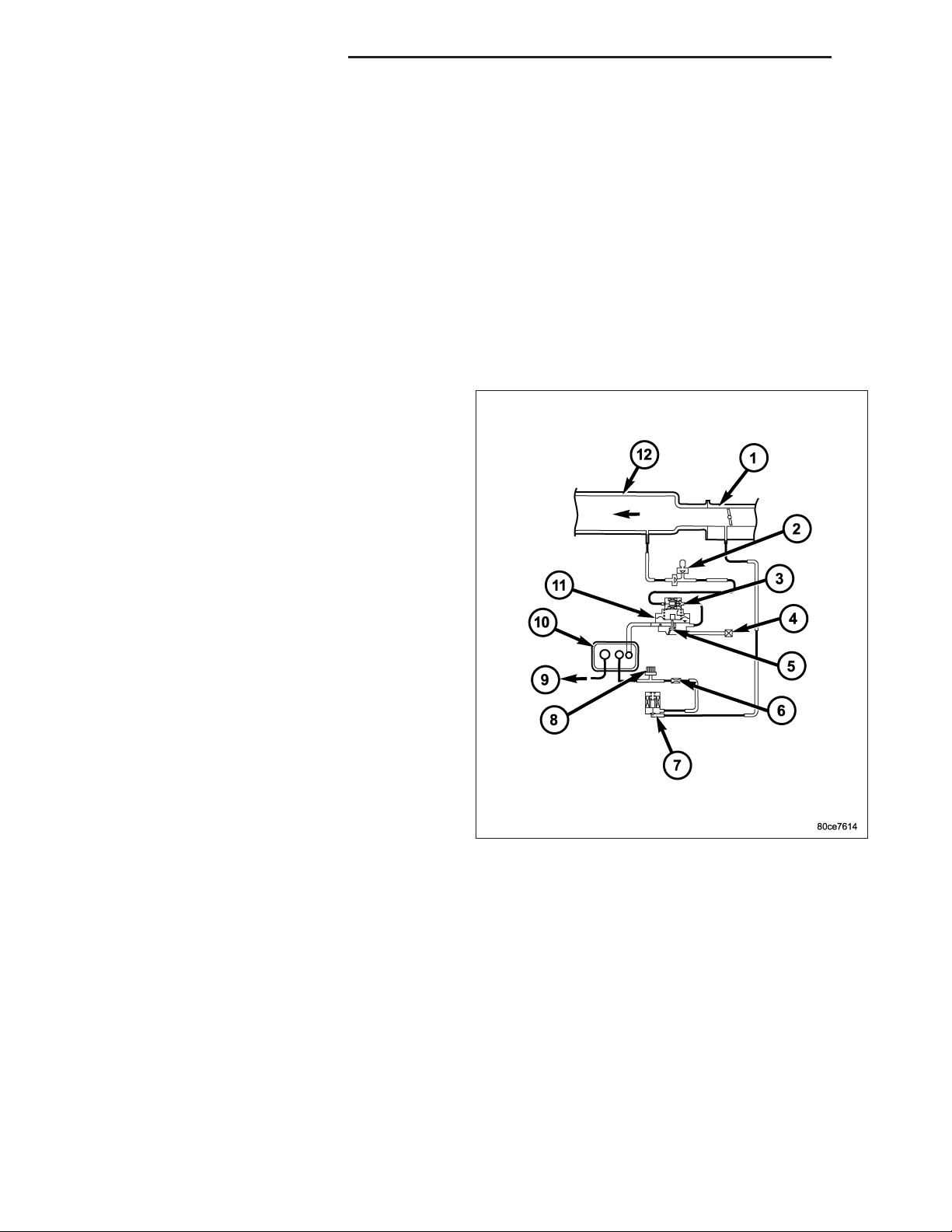

EVAP LEAK DETECTION SYSTEM

COMPONENTS

Service Port: Used with special tools like the Miller

Evaporative Emissions Leak Detector (EELD) to test

for leaks in the system.

EVAP Purge Solenoid: The PCM uses the EVAP

purge solenoid to control purging of excess fuel

vapors stored in the EVAP canister. It remains closed

during leak testing to prevent loss of pressure.

EVAP Canister: The EVAP canister stores fuel vapors

from the fuel tank for purging.

EVAP Purge Orifice: Limits purge volume.

EVAP System Air Filter: Provides air to the LDP for

pressurizing the system. It filters out dirt while allowing

a vent to atmosphere for the EVAP system.

OPERATION

The main purpose of the LDP is to pressurize the fuel system for leak checking. It closes the EVAP system vent to

atmospheric pressure so the system can be pressurized for leak testing. The diaphragm is powered by engine vacuum. It pumps air into the EVAP system to develop a pressure of about 7.59 H2O (1/4) psi. A reed switch in the LDP

allows the PCM to monitor the position of the LDP diaphragm. The PCM uses the reed switch input to monitor how

fast the LDP is pumping air into the EVAP system. This allows detection of leaks and blockage. The LDP assembly

consists of several parts. The solenoid is controlled by the PCM, and it connects the upper pump cavity to either

engine vacuum or atmospheric pressure. A vent valve closes the EVAP system to atmosphere, sealing the system

during leak testing. The pump section of the LDP consists of a diaphragm that moves up and down to bring air in

through the air filter and inlet check valve, and pump it out through an outlet check valve into the EVAP system. The

diaphragm is pulled up by engine vacuum, and pushed down by spring pressure, as the LDP solenoid turns on and

off. The LDP also has a magnetic reed switch to signal diaphragm position to the PCM. When the diaphragm is

down, the switch is closed, which sends a 12 V (system voltage) signal to the PCM. When the diaphragm is up, the

switch is open, and there is no voltage sent to the PCM. This allows the PCM to monitor LDP pumping action as it

turns the LDP solenoid on and off.

Page 17

DR EVAPORATIVE EMISSIONS 25 - 17

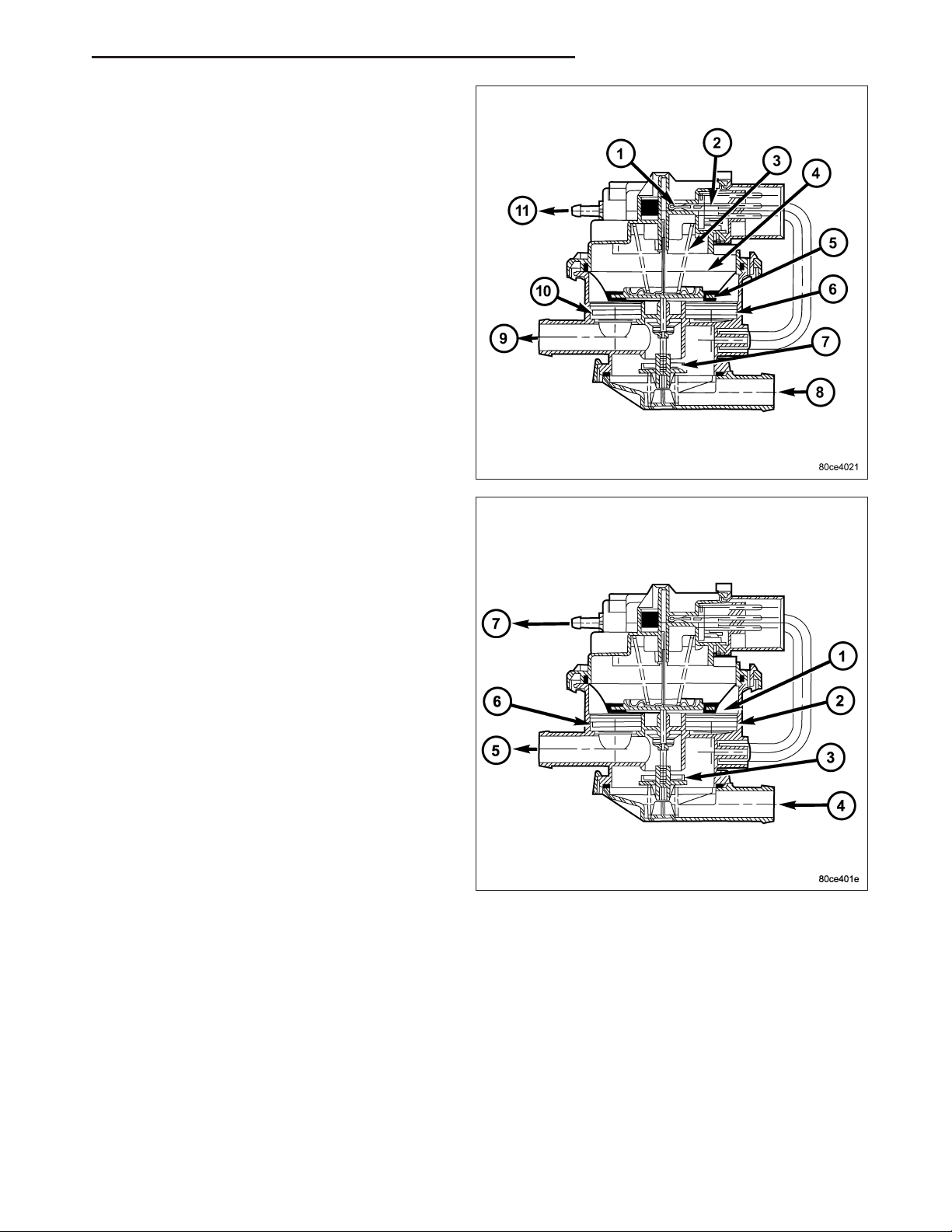

LDP AT REST (NOT POWERED)

When the LDP is at rest (no electrical/vacuum) the

diaphragm is allowed to drop down if the internal

(EVAP system) pressure is not greater than the return

spring. The LDP solenoid blocks the engine vacuum

port and opens the atmospheric pressure port connected through the EVAP system air filter. The vent

valve is held open by the diaphragm. This allows the

canister to see atmospheric pressure.

DIAPHRAGM UPWARD MOVEMENT

When the PCM energizes the LDP solenoid, the solenoid blocks the atmospheric port leading through the

EVAP air filter and at the same time opens the engine

vacuum port to the pump cavity above the diaphragm.

The diaphragm moves upward when vacuum above

the diaphragm exceeds spring force. This upward

movement closes the vent valve. It also causes low

pressure below the diaphragm, unseating the inlet

check valve and allowing air in from the EVAP air filter. When the diaphragm completes its upward movement, the LDP reed switch turns from closed to open.

Page 18

25 - 18 EVAPORATIVE EMISSIONS DR

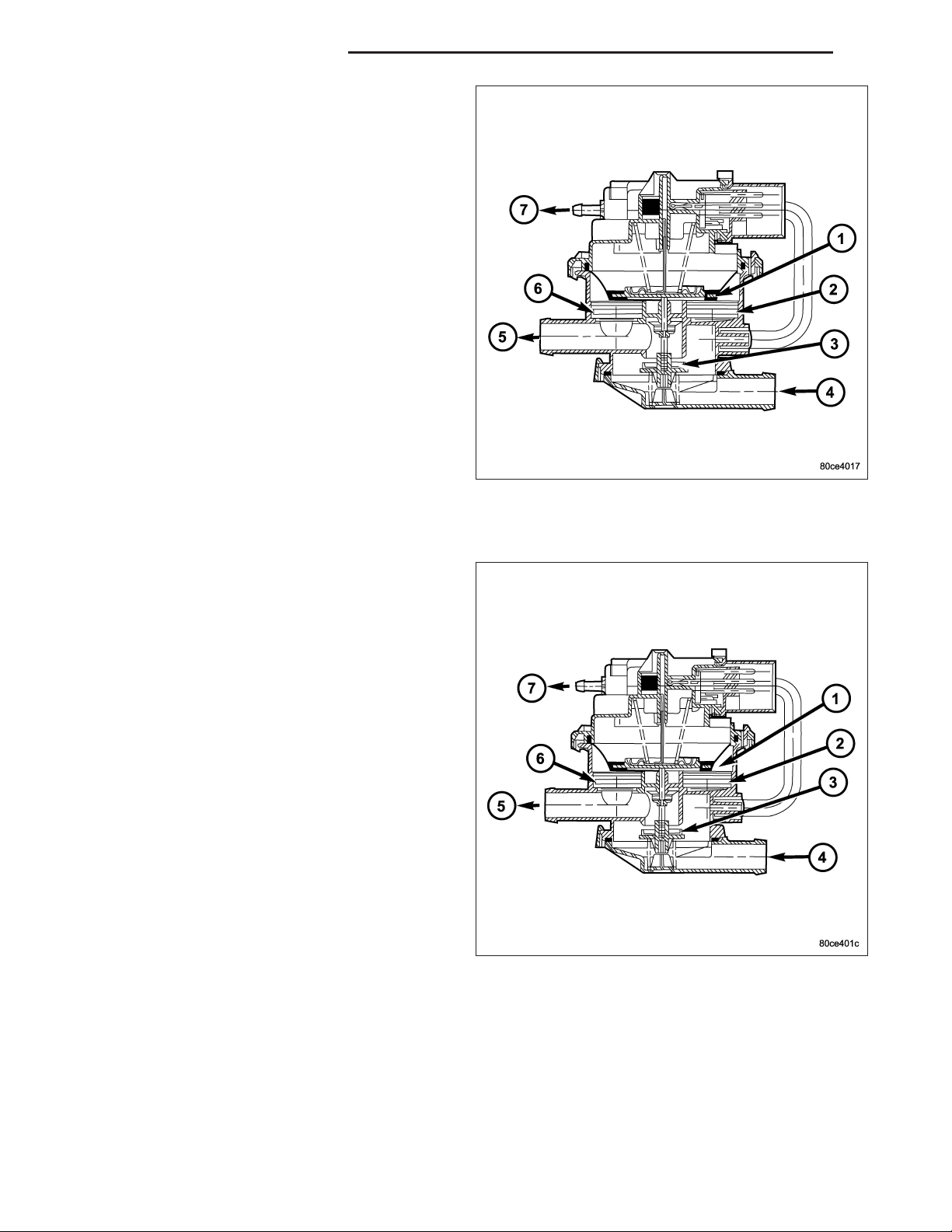

DIAPHRAGM DOWNWARD MOVEMENT

Based on reed switch input, the PCM de-energizes

the LDP solenoid, causing it to block the vacuum port,

and open the atmospheric port. This connects the

upper pump cavity to atmosphere through the EVAP

air filter. The spring is now able to push the diaphragm

down. The downward movement of the diaphragm

closes the inlet check valve and opens the outlet

check valve pumping air into the evaporative system.

The LDP reed switch turns from open to closed, allowing the PCM to monitor LDP pumping (diaphragm

up/down) activity. During the pumping mode, the diaphragm will not move down far enough to open the

vent valve. The pumping cycle is repeated as the solenoid is turned on and off. When the evaporative system begins to pressurize, the pressure on the bottom

of the diaphragm will begin to oppose the spring pressure, slowing the pumping action. The PCM watches

the time from when the solenoid is de-energized, until

the diaphragm drops down far enough for the reed

switch to change from opened to closed. If the reed

switch changes too quickly, a leak may be indicated.

The longer it takes the reed switch to change state, the tighter the evaporative system is sealed. If the system

pressurizes too quickly, a restriction somewhere in the EVAP system may be indicated.

PUMPING ACTION

Action : During portions of this test, the PCM uses the

reed switch to monitor diaphragm movement. The

solenoid is only turned on by the PCM after the reed

switch changes from open to closed, indicating that

the diaphragm has moved down. At other times during

the test, the PCM will rapidly cycle the LDP solenoid

on and off to quickly pressurize the system. During

rapid cycling, the diaphragm will not move enough to

change the reed switch state. In the state of rapid

cycling, the PCM will use a fixed time interval to cycle

the solenoid. If the system does not pass the EVAP

Leak Detection Test, the following DTCs may be set:

• P0442 - EVAP LEAK MONITOR 0.0409 LEAK

DETECTED

• P0455 - EVAP LEAK MONITOR LARGE LEAK

DETECTED

• P0456 - EVAP LEAK MONITOR 0.0209 LEAK

DETECTED

• P1486 - EVAP LEAK MON PINCHED HOSE

FOUND

• P1494 - LEAK DETECTION PUMP SW OR MECH FAULT

• P1495 - LEAK DETECTION PUMP SOLENOID CIRCUIT

Page 19

DR EVAPORATIVE EMISSIONS 25 - 19

REMOVAL

The Leak Detection Pump (LDP) (4) and LDP filter are attached to the front of the EVAP canister mounting bracket.

This is located near the front of the fuel tank. The LDP and LDP filter are replaced (serviced) as one unit.

1. Raise and support vehicle.

2. Certain models, equipped with a certain fuel tank size, may require the removal of the fuel tank skid plate and/or

the transfer case skid plate to gain access to the leak pump. Remove necessary skid plates.

3. Carefully remove hose at LDP filter.

4. Remove LDP filter mounting bolt and remove from vehicle.

5. Carefully remove vapor/vacuum lines at LDP.

6. Disconnect electrical connector at LDP.

7. Remove LDP mounting bolt and remove LDP from vehicle.

Page 20

25 - 20 EVAPORATIVE EMISSIONS DR

INSTALLATION

The LDP (4) and LDP filter are attached to the front of the EVAP canister mounting bracket. The LDP and LDP filter

are replaced (serviced) as one unit.

1. Install LDP to mounting bracket. Tighten to 95 in. lbs. (11 N·m).

2. Install LDP filter to mounting bracket. Tighten to 95 in. lbs. (11 N·m).

3. Carefully install vapor/vacuum lines to LDP, and install hose to LDP filter. The vapor/vacuum lines and hoses

must be firmly connected. Check the vapor/vacuum lines at the LDP, LDP filter and EVAP canister purge

solenoid for damage or leaks. If a leak is present, a Diagnostic Trouble Code (DTC) may be set.

4. Connect electrical connector to LDP.

5. If necessary, install skid plate(s).

Page 21

DR EVAPORATIVE EMISSIONS 25 - 21

ORVR

DESCRIPTION

The ORVR (On-Board Refueling Vapor Recovery) system consists of a unique fuel tank, flow management valve,

fluid control valve, one-way check valve and vapor canister.

OPERATION

The ORVR (On-Board Refueling Vapor Recovery) system is used to remove excess fuel tank vapors. This is done

while the vehicle is being refueled.

Fuel flowing into the fuel filler tube (approx. 1” I.D.) creates an aspiration effect drawing air into the fuel fill tube.

During refueling, the fuel tank is vented to the EVAP canister to capture escaping vapors. With air flowing into the

filler tube, there are no fuel vapors escaping to the atmosphere. Once the refueling vapors are captured by the

EVAP canister, the vehicle’s computer controlled purge system draws vapor out of the canister for the engine to

burn. The vapor flow is metered by the purge solenoid so that there is no, or minimal impact on driveability or

tailpipe emissions.

As fuel starts to flow through the fuel fill tube, it opens the normally closed check valve and enters the fuel tank.

Vapor or air is expelled from the tank through the control valve and on to the vapor canister. Vapor is absorbed in

the EVAP canister until vapor flow in the lines stops. This stoppage occurs following fuel shut-off, or by having the

fuel level in the tank rise high enough to close the control valve. This control valve contains a float that rises to seal

the large diameter vent path to the EVAP canister. At this point in the refueling process, fuel tank pressure

increases, the check valve closes (preventing liquid fuel from spiting back at the operator), and fuel then rises up

the fuel filler tube to shut off the dispensing nozzle.

Page 22

25 - 22 EVAPORATIVE EMISSIONS DR

PUMP-NATURAL VAC LEAK DETECTION

DESCRIPTION

Vehicles equipped with an NGC Powertrain Control Module (PCM) use a Natural Vacuum Leak Detection (NVLD)

pump and system. Vehicles equipped with a JTEC PCM use an LDP (Leak Detection Pump). Refer to Leak Detection Pump (LDP) for additional information.

The NVLD pump is located in the same area as the leak detection pump. Refer to NVLD Removal / Installation for

additional information.

OPERATION

The Natural Vacuum Leak Detection (NVLD) system is the next generation evaporative leak detection system that

will first be used on vehicles equipped with the Next Generation Controller (NGC). This new system replaces the

leak detection pump as the method of evaporative system leak detection. This is to detect a leak equivalent to a

0.0209 (0.5 mm) hole. This system has the capability to detect holes of this size very dependably.

The basic leak detection theory employed with NVLD is the 9Gas Law9. This is to say that the pressure in a sealed

vessel will change if the temperature of the gas in the vessel changes. The vessel will only see this effect if it is

indeed sealed. Even small leaks will allow the pressure in the vessel to come to equilibrium with the ambient pressure. In addition to the detection of very small leaks, this system has the capability of detecting medium as well as

large evaporative system leaks.

A vent valve seals the canister vent during engine off conditions. If the vapor system has a leak of less than the

failure threshold, the evaporative system will be pulled into a vacuum, either due to the cool down from operating

temperature or diurnal ambient temperature cycling. The diurnal effect is considered one of the primary contributors

to the leak determination by this diagnostic. When the vacuum in the system exceeds about 19 H2O (0.25 KPA), a

vacuum switch closes. The switch closure sends a signal to the NGC. The NGC, via appropriate logic strategies,

utilizes the switch signal, or lack thereof, to make a determination of whether a leak is present.

The NVLD device is designed with a normally open vacuum switch, a normally closed solenoid, and a seal, which

is actuated by both the solenoid and a diaphragm. The NVLD is located on the atmospheric vent side of the canister. The NVLD assembly may be mounted on top of the canister outlet, or in-line between the canister and atmospheric vent filter. The normally open vacuum switch will close with about 19 H2O (0.25 KPA) vacuum in the

evaporative system. The diaphragm actuates the switch. This is above the opening point of the fuel inlet check valve

in the fill tube so cap off leaks can be detected. Submerged fill systems must have recirculation lines that do not

have the in-line normally closed check valve that protects the system from failed nozzle liquid ingestion, in order to

detect cap off conditions.

The normally closed valve in the NVLD is intended to maintain the seal on the evaporative system during the engine

off condition. If vacuum in the evaporative system exceeds 39 to 69 H2O (0.75 to 1.5 KPA), the valve will be pulled

off the seat, opening the seal. This will protect the system from excessive vacuum as well as allowing sufficient

purge flow in the event that the solenoid was to become inoperative.

The solenoid actuates the valve to unseal the canister vent while the engine is running. It also will be used to close

the vent during the medium and large leak tests and during the purge flow check. This solenoid requires an initial

1.5 amps of current to pull the valve open, but after 100 mili-seconds, will be duty cycled down to an average of

about 150 mA for the remainder of the drive cycle.

Another feature in the device is a diaphragm that will open the seal in the NVLD with pressure in the evaporative

system. The device will 9blow off9 at about 0.59 H2O (0.12 KPA) pressure to permit the venting of vapors during

refueling. An added benefit to this is that it will also allow the tank to 9breathe9 during increasing temperatures, thus

limiting the pressure in the tank to this low level. This is beneficial because the induced vacuum during a subsequent declining temperature will achieve the switch closed (pass threshold) sooner than if the tank had to decay

from a built up pressure.

The device itself has 3 wires: Switch sense, solenoid driver and ground. It also includes a resistor to protect the

switch from a short to battery or a short to ground. The NGC utilizes a high-side driver to energize and duty-cycle

the solenoid.

Page 23

DR EVAPORATIVE EMISSIONS 25 - 23

REMOVAL

If Equipped With Horizontally Mounted EVAP Canisters

The NVLD pump (4) is attached to the EVAP canister.

1. Raise and support vehicle.

2. Certain models, equipped with a certain fuel tank size, may require the removal of the fuel tank skid plate and/or

the transfer case skid plate to gain access to the leak pump. Remove necessary skid plates.

3. Disconnect electrical connector at NVLD assembly.

Page 24

25 - 24 EVAPORATIVE EMISSIONS DR

4. Carefully disconnect vapor lines from NVLD assembly.

5. Lift tab on NVLD assembly and twist assembly

counterclockwise.

6. Pull NVLD pump out to remove from EVAP

canister.

Page 25

DR EVAPORATIVE EMISSIONS 25 - 25

7. Remove O-ring from EVAP canister.

If Equipped With Vertically Mounted EVAP Canisters

The NVLD pump (4) is located at the front of fuel tank.

1. Raise and support vehicle.

2. Certain models, equipped with a certain fuel tank size, may require the removal of the fuel tank skid plate and/or

the transfer case skid plate to gain access to the leak pump. Remove necessary skid plates.

3. Disconnect electrical connector at pump.

4. Carefully remove vapor/vacuum hoses at pump.

Page 26

25 - 26 EVAPORATIVE EMISSIONS DR

5. The NVLD pump snaps into the EVAP canister.

Press on release tab (2) while rotating pump from

canister.

INSTALLATION

If Equipped With Horizontally Mounted EVAP Canisters

Page 27

DR EVAPORATIVE EMISSIONS 25 - 27

The NVLD pump (4) is attached to the EVAP canister.

1. Install new O-ring to EVAP canister.

Page 28

25 - 28 EVAPORATIVE EMISSIONS DR

2. Align NVLD assembly into EVAP canister.

3. Rotate NVLD assembly until alignment tab drops

into slot.

4. Connect electrical connector to NVLD assembly.

5. Carefully install vapor/vacuum lines to NVLD pump.

The vapor/vacuum lines and hoses must be

firmly connected. Check the vapor/vacuum

lines at the NVLD pump, filter and EVAP canister purge solenoid for damage or leaks. If a leak

is present, a Diagnostic Trouble Code (DTC)

may be set.

6. If necessary, install skid plate(s).

Page 29

DR EVAPORATIVE EMISSIONS 25 - 29

If Equipped With Vertically Mounted EVAP Canisters

The NVLD pump (4) is located at the front of fuel tank.

1. Snap NVLD pump (1) to EVAP canister until tab (2)

engages.

2. Connect electrical connector to NVLD pump.

3. Carefully install vapor/vacuum lines to NVLD pump.

The vapor/vacuum lines and hoses must be

firmly connected. Check the vapor/vacuum

lines at the NVLD pump, filter and EVAP canister purge solenoid for damage or leaks. If a leak

is present, a Diagnostic Trouble Code (DTC)

may be set.

4. If equipped, install skid plate(s).

Page 30

25 - 30 EVAPORATIVE EMISSIONS DR

VALVE - PCV

DESCRIPTION

3.7L V-6 / 4.7L V-8

The 3.7L V-6 and 4.7L V-8 engines are equipped with

a closed crankcase ventilation system and a Positive

Crankcase Ventilation (PCV) valve (6).

This system consists of:

• a PCV valve mounted to the oil filler housing.

The PCV valve is sealed to the oil filler housing

with an o-ring.

• the air cleaner housing

• two interconnected breathers (1) threaded into

the rear of each cylinder head.

• tubes and hoses to connect the system

components.

Page 31

DR EVAPORATIVE EMISSIONS 25 - 31

5.7L V-8

The 5.7L V-8 engine is equipped with a closed crankcase ventilation system and a Positive Crankcase

Ventilation (PCV) valve (4).

This system consists of:

• a PCV valve mounted into the top of the intake

manifold, located to the right / rear of the throttle

body. The PCV valve (1) is sealed to the intake

manifold with 2 o-rings (2).

• passages in the intake manifold.

• tubes and hoses to connect the system

components.

Page 32

25 - 32 EVAPORATIVE EMISSIONS DR

OPERATION

A typical enclosed crankcase ventilation system is

shown in the graphic.

The PCV system operates by engine intake manifold

vacuum. Filtered air is routed into the crankcase

through the air cleaner hose. The metered air, along

with crankcase vapors, are drawn through the PCV

valve (4) and into a passage in the intake manifold.

The PCV system manages crankcase pressure and

meters blow by gases to the intake system, reducing

engine sludge formation.

The PCV valve contains a spring loaded plunger. This

plunger meters the amount of crankcase vapors

routed into the combustion chamber based on intake

manifold vacuum.

When the engine is not operating or during an engine

pop-back, the spring forces the plunger back against

the seat. This will prevent vapors from flowing through

the valve.

During periods of high manifold vacuum, such as idle

or cruising speeds, vacuum is sufficient to completely

compress spring. It will then pull the plunger to the top

of the valve. In this position there is minimal vapor

flow through the valve.

Page 33

DR EVAPORATIVE EMISSIONS 25 - 33

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve.

DIAGNOSIS AND TESTING

PCV VALVE - 3.7L V-6/ 4.7L V-8

1. Disconnect PCV line/hose (5) by disconnecting rubber connecting hose at PCV valve fitting.

2. Remove PCV valve at oil filler tube by rotating PCV

valve downward until locating tabs (2) have been

freed at cam lock (3). After tabs have cleared, pull

valve straight out from filler tube. To prevent dam-

age to PCV valve locating tabs, valve must be

pointed downward for removal. Do not force

valve from oil filler tube.

3. After valve is removed, check condition of valve

O-ring (1). Also, PCV valve should rattle when

shaken.

4. Reconnect PCV valve to its connecting line/hose.

5. Start engine and bring to idle speed.

6. If valve is not plugged, a hissing noise will be

heard as air passes through valve. Also, a strong

vacuum should be felt with a finger placed at valve

inlet.

7. If vacuum is not felt at valve inlet, check line/hose

for kinks or for obstruction. If necessary, clean out

intake manifold fitting at rear of manifold. Do this

by turning a 1/4 inch drill (by hand) through the fitting to dislodge any solid particles. Blow out the fitting with

shop air. If necessary, use a smaller drill to avoid removing any metal from the fitting.

8. Do not attempt to clean the old PCV valve.

9. Return PCV valve back to oil filler tube by placing valve locating tabs (2) into cam lock (3). Press PCV valve in

and rotate valve upward. A slight click will be felt when tabs have engaged cam lock. Valve should be pointed

towards rear of vehicle.

10. Connect PCV line/hose (5) and connecting rubber hose to PCV valve.

11. Disconnect rubber hose from fresh air fitting at air cleaner resonator box. Start engine and bring to idle speed.

Hold a piece of stiff paper (such as a parts tag) loosely over the opening of the disconnected rubber hose.

Page 34

25 - 34 EVAPORATIVE EMISSIONS DR

12. The paper should be drawn against the hose opening with noticeable force. This will be after allowing approx-

imately one minute for crankcase pressure to reduce.

13. If vacuum is not present, disconnect each PCV

system hose at top of each crankcase breather

(1). Check for obstructions or restrictions.

14. If vacuum is still not present, remove each PCV

system crankcase breather (1) from each cylinder

head. Check for obstructions or restrictions. If

plugged, replace breather. Tighten breather to 12

N·m (106 in. lbs.) torque. Do not attempt to clean

breather.

15. If vacuum is still not present, disconnect each

PCV system hose (1) at each fitting, and at each

check valve (2). Check for obstructions or

restrictions.

Page 35

DR EVAPORATIVE EMISSIONS 25 - 35

REMOVAL

3.7L V-6 / 4.7L V-8

The PCV valve (6) is located on the oil filler tube (4).

Two locating tabs are located on the side of the valve

(2). These 2 tabs fit into a cam lock (3) in the oil filler

tube. An O-ring (1) seals the valve to the filler tube.

1. Disconnect PCV line/hose (5) by disconnecting rubber hose at PCV valve fitting.

2. Remove PCV valve at oil filler tube by rotating PCV

valve downward (counter-clockwise) until locating

tabs (2) have been freed at cam lock (3). After tabs

have cleared, pull valve straight out from filler tube.

To prevent damage to PCV valve locating tabs,

valve must be pointed downward for removal.

Do not force valve from oil filler tube.

3. After valve is removed, check condition of valve

O-ring (1).

5.7L V-8

The PCV valve (4) is mounted into the top of the

intake manifold (1). This is located to the right / rear of

the throttle body (2).

Page 36

25 - 36 EVAPORATIVE EMISSIONS DR

1. The PCV valve is sealed to the intake manifold

with 2 O-rings (2).

2. Remove PCV valve by rotating counter-clockwise

90 degrees until locating tabs (3) have been freed.

After tabs have cleared, pull valve straight up from

intake manifold.

3. After valve is removed, check condition of 2 valve

O-rings (2).

INSTALLATION

3.7L V6 / 4.7L V-8

The PCV valve is located on the oil filler tube. Two locating tabs are located on the side of the valve. These 2 tabs

fit into a cam lock in the oil filler tube. An O-ring seals the valve to the filler tube.

1. Return PCV valve back to oil filler tube by placing valve locating tabs into cam lock. Press PCV valve in and

rotate valve upward. A slight click will be felt when tabs have engaged cam lock. Valve should be pointed

towards rear of vehicle.

2. Connect PCV line/hose and rubber hose to PCV valve.

5.7L V-8

1. Clean out intake manifold opening.

2. Check condition of 2 O-rings on PCV valve.

3. Apply engine oil to 2 O-rings.

4. Place PCV valve into intake manifold and rotate 90 degrees clockwise for installation.

Page 37

DR EVAPORATIVE EMISSIONS 25 - 37

LINES - VACUUM

DESCRIPTION

A vacuum schematic for emission related items can be found on the vehicles VECI label. Refer to Vehicle Emission

Control Information (VECI) Label for label location.

Page 38

25 - 38 EVAPORATIVE EMISSIONS DR

CANISTER - VAPOR

DESCRIPTION

Page 39

DR EVAPORATIVE EMISSIONS 25 - 39

Two EVAP canisters are used. Depending on vehicle model and fuel tank size, the canisters may be mounted either

vertically or horizontally. These maintenance free, EVAP canisters (5) are located near the front of the fuel tank.

Page 40

25 - 40 EVAPORATIVE EMISSIONS DR

OPERATION

Two EVAP canisters are used. Depending on vehicle model and fuel tank size, the canisters may be mounted either

vertically or horizontally.

The EVAP canisters are filled with granules of an activated carbon mixture. Fuel vapors entering the EVAP canisters

are absorbed by the charcoal granules.

Fuel tank pressure vents into the EVAP canisters. Fuel vapors are temporarily held in the canisters until they can be

drawn into the intake manifold. The duty cycle EVAP canister purge solenoid allows the EVAP canisters to be

purged at predetermined times and at certain engine operating conditions.

REMOVAL

Page 41

DR EVAPORATIVE EMISSIONS 25 - 41

Page 42

25 - 42 EVAPORATIVE EMISSIONS DR

Two EVAP canisters are used. Depending on vehicle model and fuel tank size, the canisters may be mounted either

vertically or horizontally. These maintenance free, EVAP canisters (5) are located near the front of the fuel tank.

Type 1 Canisters

Use the following procedure for vertically mounted canisters.

Page 43

DR EVAPORATIVE EMISSIONS 25 - 43

1 - CANISTER MOUNTING NUTS

2 - CONNECTING HOSE

3 - UPPER SUPPORT BRACKET

4 - LOWER SUPPORT BRACKET

5 - OUTER CANISTER

6 - INNER CANISTER

1. Raise and support vehicle.

2. Certain models, equipped with a certain fuel tank size, may require the removal of the fuel tank skid plate and/or

the transfer case skid plate to gain access to the EVAP canister(s). Remove necessary skid plates.

3. Remove fuel tubes/lines at each EVAP canister. Note location of tubes/lines before removal for easier installation.

4. Remove lower support bracket (4).

5. Remove mounting nuts (1) at top of each canister.

6. Remove each canister from upper support bracket.

Type 2 Canisters

Use the following procedure for horizontally mounted canisters.

1. Raise and support vehicle.

2. Certain models, equipped with a certain fuel tank size, may require the removal of the fuel tank skid plate and/or

the transfer case skid plate to gain access to the EVAP canister(s). Remove necessary skid plates.

Page 44

25 - 44 EVAPORATIVE EMISSIONS DR

3. Remove fuel tubes/lines (1) at each EVAP canister.

Note location of tubes/lines before removal for easier installation. Remove bolts (6).

4. Remove nut (1) and remove NVLD filter (2).

Page 45

DR EVAPORATIVE EMISSIONS 25 - 45

5. Remove nuts (4) and remove NVLD filter support

bracket (2). Remove upper canister.

6. Remove nuts (5) and remove lower canister (6).

Slip lower canister pins (7) from rubber grommets.

Page 46

25 - 46 EVAPORATIVE EMISSIONS DR

INSTALLATION

Page 47

DR EVAPORATIVE EMISSIONS 25 - 47

Two EVAP canisters are used. Depending on vehicle model and fuel tank size, the canisters may be mounted either

vertically or horizontally. These maintenance free, EVAP canisters (5) are located near the front of the fuel tank.

Type 1 Canisters

Use the following procedure for vertically mounted canisters.

Page 48

25 - 48 EVAPORATIVE EMISSIONS DR

1 - CANISTER MOUNTING NUTS

2 - CONNECTING HOSE

3 - UPPER SUPPORT BRACKET

4 - LOWER SUPPORT BRACKET

5 - OUTER CANISTER

6 - INNER CANISTER

1. Place each canister (5) and (6) into upper support bracket and install nuts. Tighten nuts to 95 in.lbs. (11 N·m).

2. Install lower support bracket (4). Tighten nuts to 125 in.lbs. (14 N·m).

3. Carefully install vapor/vacuum lines. The vapor/vacuum lines and hoses must be firmly connected. Also

check the vapor/vacuum lines at the NVLD Pump, LDP, LDP filter and EVAP canister purge solenoid for

damage or leaks. If a leak is present, a Diagnostic Trouble Code (DTC) may be set.

4. If necessary, install skid plate(s).

Type 2 Canisters

Use the following procedure for horizontally mounted canisters.

Page 49

DR EVAPORATIVE EMISSIONS 25 - 49

1. Slip lower canister pins (7) into rubber grommets.

Install lower canister (6) and nuts (5).

2. Install upper canister (1). Install NVLD filter support

bracket (2) and install nuts (4).

Page 50

25 - 50 EVAPORATIVE EMISSIONS DR

3. Install NVLD filter (2) and nut (1).

4. Carefully install vapor/vacuum lines, and fuel tubes/

lines (1) to each EVAP canister. Install bolts (6).

5. The vapor/vacuum lines and hoses must be

firmly connected. Also check the vapor/vacuum

lines at the NVLD Pump, LDP, LDP filter and

EVAP canister purge solenoid for damage or

leaks. If a leak is present, a Diagnostic Trouble

Code (DTC) may be set.

6. If necessary, install skid plate(s).

Page 51

DR EXHAUST GAS RECIRCULATION 25 - 51

EXHAUST GAS RECIRCULATION

TABLE OF CONTENTS

page page

VALVE-EGR

DESCRIPTION ................................52

OPERATION ..................................52

REMOVAL

4.7L .......................................53

5.7L .......................................54

INSTALLATION

4.7L .......................................55

5.7L .......................................57

Page 52

25 - 52 EXHAUST GAS RECIRCULATION DR

VALVE-EGR

DESCRIPTION

4.7L Engine

The electronic EGR valve and solenoid assembly (3)

is attached to the rear of the left cylinder head. An

exhaust gas routing tube (1) connects the EGR valve

to the intake manifold.

5.7L Engine

The electronic EGR valve and solenoid assembly (2)

is attached to the front of the right cylinder head. An

exhaust gas routing tube (4) connects the EGR valve

to the intake manifold.

OPERATION

Exhaust gas recirculation flow is determined by the Powertrain Control Module (PCM) and is controlled by an electronic EGR valve assembly. For a given set of conditions, the PCM knows the ideal exhaust gas recirculation flow

to optimize NOx and fuel economy as a function of the pintle position. Pintle position is obtained from the position

sensor. The PCM adjusts the duty cycle of 128 Hz power supplied to the solenoid coil to obtain the correct position.

The electronic EGR valve assembly consists of a pintle, valve seat, and housing which contains and regulates

exhaust gas flow. An armature, return spring, and solenoid coil provide the operating force to regulate exhaust gas

Page 53

DR EXHAUST GAS RECIRCULATION 25 - 53

flow by changing the pintle position. The solenoid coil assembly is wired in parallel with a diode that connects two

internal connectors.

REMOVAL

4.7L

The electronic EGR valve and solenoid assembly (4)

is attached to the rear of the left cylinder head. An

exhaust gas routing tube (3) connects the EGR valve

to the intake manifold.

1. Remove electrical connector (5) at top of EGR

valve solenoid.

2. Remove tube mounting bolt (1) at intake manifold.

3. Remove two bolts (4) connecting EGR tube (1) to

valve assembly.

4. Remove gasket located between EGR tube flange

and EGR valve assembly.