Page 1

DR ELECTRONIC CONTROL MODULES 8E - 1

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ELECTRONIC CONTROL MODULES -

ELECTRICAL DIAGNOSTICS................. 1

ELECTRONIC CONTROL MODULES - ELECTRICAL

DIAGNOSTICS

TABLE OF CONTENTS

ELECTRONIC CONTROL MODULES -

ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

B210D-BATTERY VOLTAGE LOW ..............4

B210E-BATTERY VOLTAGE HIGH .............5

B222C-VEHICLE CONFIGURATION NOT

PROGRAMMED..............................6

B2206-CURRENT VIN MISSING/MISMATCH ....7

B2215-FRONT CONTROL MODULE

INTERNAL (TOTALLY INTEGRATED

POWER MODULE)...........................8

C2100–BATTERY VOLTAGE LOW (FDCM) ......9

C2101–BATTERY VOLTAGE HIGH (FDCM) ....11

C2201-FDCM ECU INTERNAL (FDCM) ........13

U0001-CAN C BUS CIRCUIT .................14

U0021-CAN B BUS (+) CIRCUIT OPEN ........19

U0022-CAN B BUS (+) CIRCUIT LOW .........22

U0023-CAN B BUS (+) CIRCUIT HIGH ........25

U0024-CAN B BUS (-) CIRCUIT OPEN ........28

U0025-CAN B BUS (-) CIRCUIT LOW .........31

U0026-CAN B BUS (-) CIRCUIT HIGH .........35

U0027-CAN B BUS (-) SHORTED TO BUS

(+).........................................38

U0100-LOST COMMUNICATION WITH

ECM/PCM..................................41

U0101-LOST COMMUNICATION WITH TCM . . . 44

U0114-LOST COMMUNICATION WITH FINAL

DRIVE CONTROL MODULE..................47

U0121-LOST COMMUNICATION WITH

ANTI-LOCK BRAKE MODULE................50

U0141–LOST COMMUNICATION WITH

FRONT CONTROL MODULE (TOTALLY

INTEGRATED POWER MODULE).............53

ELECTRONIC CONTROL MODULES - SERVICE

INFORMATION......................... 178

page page

U0151–LOST COMMUNICATION WITH

OCCUPANT RESTRAINT CONTROLLER

(ORC)......................................56

U0155-LOST COMMUNICATION WITH

CLUSTER/CCN.............................59

U0156–LOST COMMUNICATION WITH EOM .. 62

U0164-LOST COMMUNICATION WITH HVAC

CONTROL MODULE.........................65

U0168-LOST COMMUNICATION WITH

VEHICLE SECURITY CONTROL MODULE

(SKREEM/WCM)............................68

U0169-LOST COMMUNICATION WITH

SUNROOF CONTROL MODULE..............71

U0184-LOST COMMUNICATION WITH

RADIO.....................................74

U0186-LOST COMMUNICATION WITH

AUDIO AMPLIFIER..........................77

U0195-LOST COMMUNICATION WITH

SDARS.....................................80

U0196-LOST COMMUNICATION WITH

VEHICLE ENTERTAINMENT CONTROL

MODULE...................................83

U0197-LOST COMMUNICATION WITH

HANDS FREE PHONE MODULE..............86

U1108-ADDITIONAL CAN B ECU DETECTED . . 89

*STORED LOST COMMUNICATION DTCS ....91

*CAN C DIAGNOSTIC (+) AND/OR CAN C

DIAGNOSTIC (-) CIRCUITS HIGH.............94

*CAN C DIAGNOSTIC (+) SHORTED TO

CAN C DIAGNOSTIC (-).....................96

*CAN C DIAGNOSTIC (+) CIRCUIT LOW ......98

*CAN C DIAGNOSTIC (-) CIRCUIT LOW .....100

*CAN C DIAGNOSTIC (+) CIRCUIT OPEN ....102

*CAN C DIAGNOSTIC (-) CIRCUIT OPEN ....104

Page 2

8E - 2 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

*BOTH CAN C DIAGNOSTIC (+) AND CAN C

DIAGNOSTIC (-) CIRCUITS OPEN...........106

*NO RESPONSE FROM ABS (ANTILOCK

BRAKE MODULE)..........................109

*NO RESPONSE FROM AMP (AMPLIFIER) . . . 113

*NO RESPONSE FROM CCN (CLUSTER) ....116

*NO RESPONSE FROM ECM (ENGINE

CONTROL MODULE) - DIESEL..............120

*NO RESPONSE FROM EOM (ELECTRONIC

OVERHEAD MODULE).....................123

*NO RESPONSE FROM FDCM (FINAL

DRIVE CONTROL MODULE) (POWER

WAGON ONLY)............................126

*NO RESPONSE FROM GATEWAY MODULE

- (SRT10 ONLY)............................130

*NO RESPONSE FROM HFM (HANDS FREE

MODULE).................................135

*NO RESPONSE FROM HVAC (A/C HEATER

CONTROL)................................138

*NO RESPONSE FROM ORC (OCCUPANT

RESTRAINT CONTROLLER)................141

*NO RESPONSE FROM PCM

(POWERTRAIN CONTROL MODULE)

(NGC).....................................145

*NO RESPONSE FROM PCM (PCI BUS) -

(SRT10 ONLY).............................149

*NO RESPONSE FROM PCM (SCI ONLY) -

(SRT10 ONLY).............................152

*NO RESPONSE FROM RADIO .............156

*NO RESPONSE FROM SDAR (SATELLITE

RECEIVER)................................159

*NO RESPONSE FROM SUNR (SUNROOF

MOTOR/MODULE).........................162

*NO RESPONSE FROM TCM

(POWERTRAIN CONTROL MODULE) -

NGC......................................165

*NO RESPONSE FROM TIPM (TOTALLY

INTEGRATED POWER MODULE)............167

*NO RESPONSE FROM VES (MONITOR/

DVD MEDIA SYSTEM)......................170

*NO RESPONSE FROM WCM (SENTRY KEY

REMOTE ENTRY MODULE).................173

STANDARD PROCEDURE

BODY VERIFICATION TEST - VER 1 ........177

Page 3

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 3

ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

Page 4

8E - 4 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

B210D-BATTERY VOLTAGE LOW

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on.

• Set Condition:

Battery voltage less than 9 volts for more than 15 seconds.

Possible Causes

RESISTANCE IN THE (A1) BATTERY POSITIVE CIRCUIT

RESISTANCE IN THE GENERATOR CASE GROUND

GENERATOR OPERATION

GENERATOR FIELD CONTROL CIRCUIT OPEN

GENERATOR FIELD CONTROL CIRCUIT SHORTED TO GROUND

GROUND CIRCUIT OPEN

PCM/ECM

Diagnostic Test

CHECK FOR ANY POWERTRAIN/ENGINE CONTROL MODULES DTCS

1.

NOTE: Make sure the Battery is in good condition. Using the Midtronics Battery Tester, test the Battery

before continuing.

NOTE: Inspect the vehicle for after market accessories that may exceed the Generator System output.

NOTE: Make sure the generator drive belt is in good operating condition.

NOTE: Inspect the fuses in the TIPM. If an open fuse is found, use the wire diagram/schematic as a guide,

inspect the wiring and connectors for damage.

Turn the ignition on.

With the scan tool, read active PCM/ECM DTC’s.

Does the scan tool display any active DTC’s?

Yes >>

No >>

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING) for the diagnostic test procedure.

Check the above conditions that can cause a low voltage condition. Repair as necessary.

Page 5

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 5

B210E-BATTERY VOLTAGE HIGH

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on.

• Set Condition:

Battery voltage greater than 16 volts for more than 15 seconds.

Possible Causes

GENERATOR FIELD CONTROL CIRCUIT SHORTED TO BATTERY VOLTAGE

GENERATOR

PCM/ECM

Diagnostic Test

CHECK FOR ANY POWERTRAIN/ENGINE CONTROL MODULES DTCS

1.

NOTE: Make sure the Battery is in good condition. Using the Midtronics Battery Tester, test the Battery

before continuing.

NOTE: Inspect the vehicle for after market accessories that may exceed the Generator System output.

NOTE: Make sure the generator drive belt is in good operating condition.

NOTE: Inspect the fuses in the TIPM. If an open fuse is found, use the wire diagram/schematic as a guide,

inspect the wiring and connectors for damage.

Turn the ignition on.

With the scan tool, read active PCM/ECM DTC’s.

Does the scan tool display any active DTC’s?

Yes >>

No >>

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING) for the diagnostic test procedure.

Check the above conditions that can cause a high voltage condition. Repair as necessary.

Page 6

8E - 6 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

B222C-VEHICLE CONFIGURATION NOT PROGRAMMED

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on.

• Set Condition:

The Totally Integrated Power Module is not configured correctly to the vehicle.

Possible Causes

TOTALLY INTEGRATED POWER MODULE NOT CONFIGURED CORRECTLY

TOTALLY INTEGRATED POWER MODULE

Diagnostic Test

CHECK FOR ACTIVE DTC

1.

With the scan tool, read the active DTC’s.

Cycle the ignition switch from off to on at least 5 times, leaving the ignition on for a minimum of 90 seconds per

cycle.

With the scan tool, read the active DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

CONFIGURE THE TIPM TO THE VEHICLE

2.

With the scan tool enter program network configuration and program the TIPM to the vehicle configuration.

With the scan tool, erase TIPM DTC’s.

Cycle the ignition switch from off to on at least 5 times, leaving the ignition on for a minimum of 90 seconds per

cycle.

With the scan tool, read the active DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

Go To 2

If the DTC is stored, check for an intermittent condition. Visually inspect the related wiring harness con-

nectors. Look for broken, bent, pushed out, or corroded terminals.

Inspect the wiring and connectors for damage or shorted circuits. If ok, replace and program the Totally

Integrated Power Module in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Repair is complete.

Page 7

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 7

B2206-CURRENT VIN MISSING/MISMATCH

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on.

• Set Condition:

The Totally Integrated Power Module (TIPM) will receive and monitor the VIN message from the PCM and

record the VIN if different from the last VIN.

Possible Causes

INCORRECT VIN PROGRAMMED IN PCM

TOTALLY INTEGRATED POWER MODULE

Diagnostic Test

CHECK FOR ACTIVE DTC

1.

With the scan tool, read the active DTC’s.

Cycle the ignition switch from off to on at least 5 times, leaving the ignition on for a minimum of 90 seconds per

cycle.

With the scan tool, read the active DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

CHECK VIN IN PCM

2.

With the scan tool compare the VIN that is programmed into the PCM to the VIN on the vehicle.

Does the VIN programmed into the PCM match the vehicles VIN?

Yes >>

No >>

Go To 2

If the DTC is stored, check for an intermittent condition. Visually inspect the related wiring harness con-

nectors. Look for broken, bent, pushed out, or corroded terminals.

Inspect the wiring and connectors for damage or shorted circuits. If ok, replace and program the Totally

Integrated Power Module in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Program the correct VIN in the PCM and retest.

Page 8

8E - 8 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

B2215-FRONT CONTROL MODULE INTERNAL (TOTALLY INTEGRATED POWER

MODULE)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Continuously.

• Set Condition:

The Totally Integrated Power Module detects an internal fault.

Possible Causes

TOTALLY INTEGRATED POWER MODULE (TIPM)

Diagnostic Test

REPLACE THE TOTALLY INTEGRATED POWER MODULE IF DTC IS ACTIVE

1.

With the scan tool, read the active DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

Replace and program the Totally Integrated Power Module in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

If the DTC is stored, check for an intermittent condition. Visually inspect the related wiring harness con-

nectors. Look for broken, bent, pushed out, or corroded terminals.

Page 9

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 9

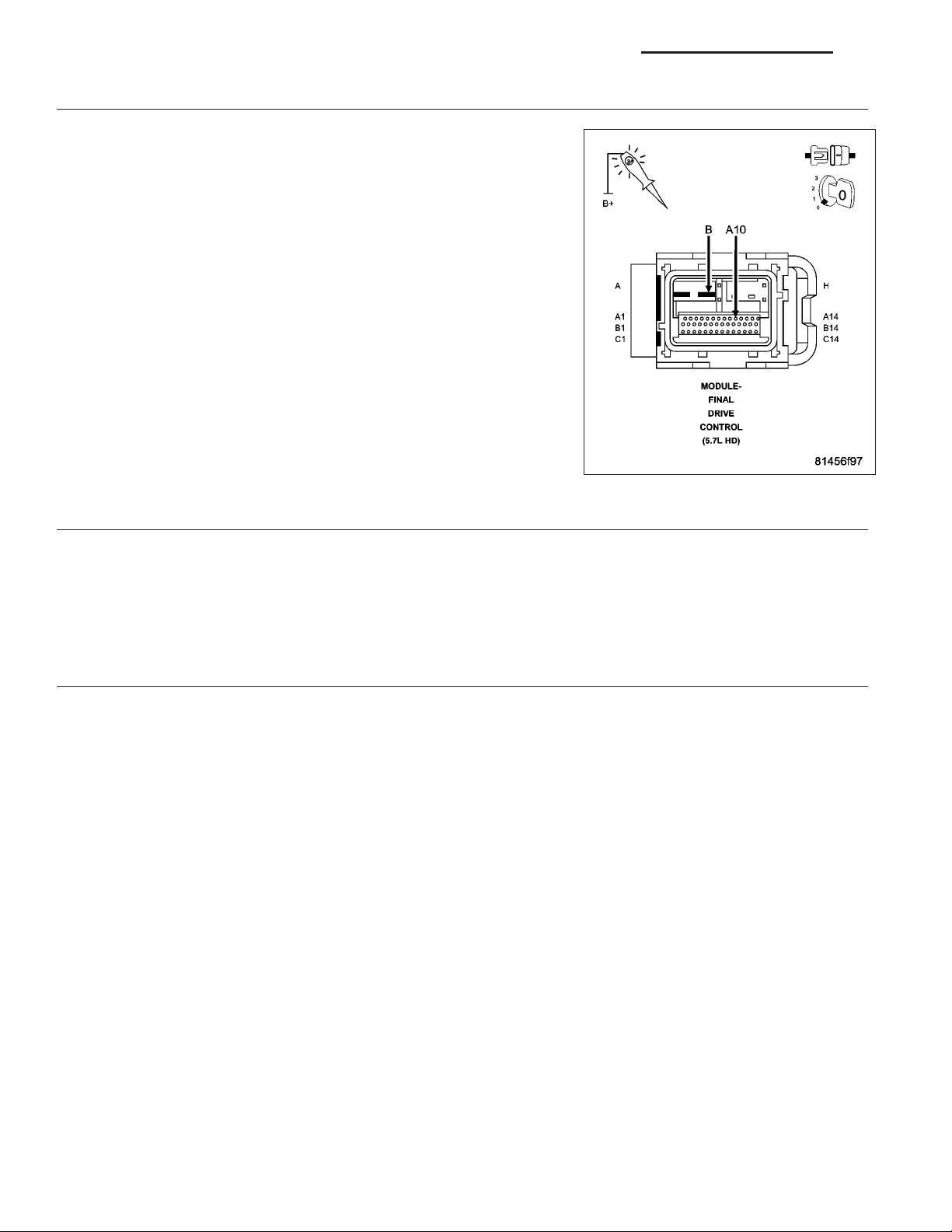

C2100–BATTERY VOLTAGE LOW (FDCM)

For a complete wiring diagram Refer to Section 8W

• When Monitored:

Continuously.

• Set Condition:

The Final Drive Control Module detects that system voltage is below 9.0 volts for 60 seconds.

Possible Causes

INTERMITTENT BATTERY VOLTAGE LOW

CHARGING SYSTEM DTCS PRESENT

FINAL DRIVE CONTROL MODULE POWER CIRCUITS OPEN OR HIGH RESISTANCE

FINAL DRIVE CONTROL MODULE

Diagnostic Test

CHARGING SYSTEM DTCS PRESENT

1.

Ignition on.

With the scan tool, select View DTCs in the Powertrain Control Module.

Are there any Charging System or related voltage DTCs present?

Yes >>

No >>

DTC IS ACTIVE

2.

With the scan tool, select View DTCs in the Final Drive Control Module.

Is the status Active for this DTC?

Yes >>

No >>

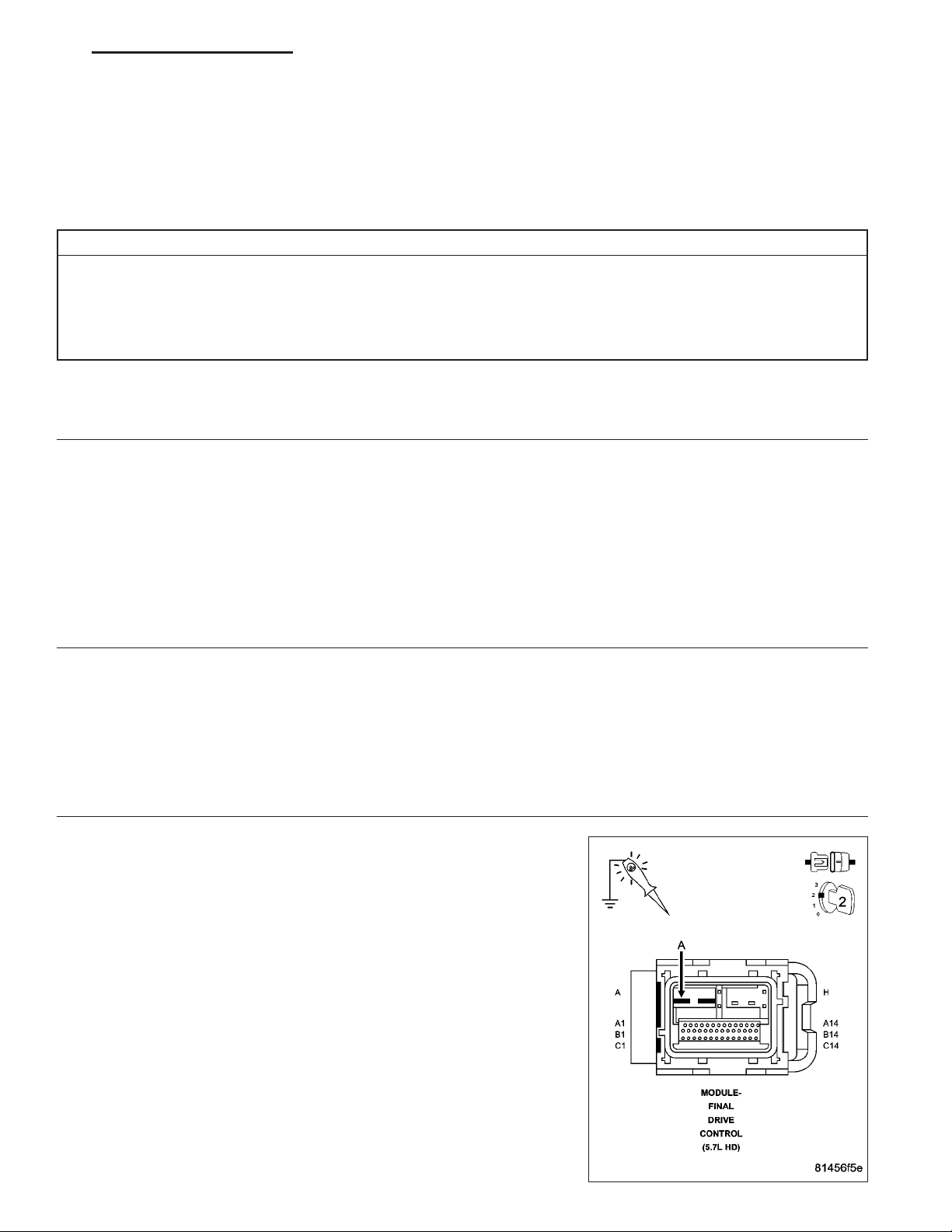

(A34) FUSED B+ CIRCUIT OPEN OR HIGH RESISTANCE

3.

Turn the ignition off.

Disconnect the Final Drive Control Module harness connector.

Turn the ignition on.

With a 12–volt test light connected to ground, check the (A34) Fused

B+ circuit in the Final Drive Control Module harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Refer to the symptom list and perform any Charging System DTC diagnostic procedures before continuing with this test.

Go to 2

Go to 3

Go to 5

Yes >>

No >>

Go to 4

Repair the (A34) Fused B+ circuit for an open circuit or high

resistance.

Perform the FDCM VERIFICATION TEST. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE - STANDARD PROCEDURE)

Page 10

8E - 10 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

FINAL DRIVE CONTROL MODULE

4.

View repair.

Repair

Replace the Final Drive Control Module in accordance with the Service information.

Perform the FDCM VERIFICATION TEST. (Refer to 3 - DIFFERENTIAL & DRIVELINE - STANDARD

PROCEDURE)

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Yes >>

No >>

Repair as necessary.

Perform the FDCM VERIFICATION TEST. (Refer to 3 - DIFFERENTIAL & DRIVELINE - STANDARD

PROCEDURE)

Test complete.

Page 11

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 11

C2101–BATTERY VOLTAGE HIGH (FDCM)

For a complete wiring diagram Refer to Section 8W

• When Monitored:

Continuously.

• Set Condition:

The Final Drive Control Module detects that system voltage is above 16.0 volts for 10 seconds with engine

RPM greater than 350.

Possible Causes

INTERMITTENT BATTERY VOLTAGE HIGH

CHARGING SYSTEM DTCS PRESENT

FINAL DRIVE CONTROL MODULE GROUND CIRCUITS OPEN OR HIGH RESISTANCE

FINAL DRIVE CONTROL MODULE

Diagnostic Test

CHARGING SYSTEM DTCS PRESENT

1.

Ignition on.

With the scan tool, select View DTCs in the Powertrain Control Module.

Are there any Charging System or related voltage DTCs present?

Yes >>

No >>

DTC IS ACTIVE

2.

With the scan tool, select View DTCs in the Final Drive Control Module.

Is the status Active for this DTC?

Yes >>

No >>

Refer to the symptom list and perform any Charging System DTC diagnostic procedures before continuing with this test.

Go to 2

Go to 3

Go to 5

Page 12

8E - 12 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

FINAL DRIVE CONTROL MODULE GROUND CIRCUITS OPEN OR HIGH RESISTANCE

3.

Turn the ignition off.

Disconnect the Final Drive Control Module harness connector.

Turn the ignition on.

With a 12–volt test light connected to B+, check the Ground circuits in

the Final Drive Control Module harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly for each of the Ground

circuits?

Yes >>

No >>

FINAL DRIVE CONTROL MODULE

4.

View repair.

Repair

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Go to 4

Repair the Ground circuit(s) for an open circuit or high

resistance.

Perform the FDCM VERIFICATION TEST. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE - STANDARD PROCEDURE)

Replace the Final Drive Control Module in accordance with the Service information.

Perform the FDCM VERIFICATION TEST. (Refer to 3 - DIFFERENTIAL & DRIVELINE - STANDARD

PROCEDURE)

Yes >>

No >>

Repair as necessary.

Perform the FDCM VERIFICATION TEST. (Refer to 3 - DIFFERENTIAL & DRIVELINE - STANDARD

PROCEDURE)

Test complete.

Page 13

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 13

C2201-FDCM ECU INTERNAL (FDCM)

For a complete wiring diagram Refer to Section 8W

• When Monitored:

With the ignition on.

• Set Condition:

The Final Drive Control Module has detected a failure internal to the controller.

Possible Causes

FINAL DRIVE CONTROL MODULE

FINAL DRIVE CONTROL MODULE

1.

The Final Drive Control Module has detected an internal failure.

View repair

Repair

Replace the Final Drive Control Module in accordance with the Service Information.

Perform the FDCM VERIFICATION TEST. (Refer to 3 - DIFFERENTIAL & DRIVELINE - STANDARD

PROCEDURE)

Page 14

8E - 14 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

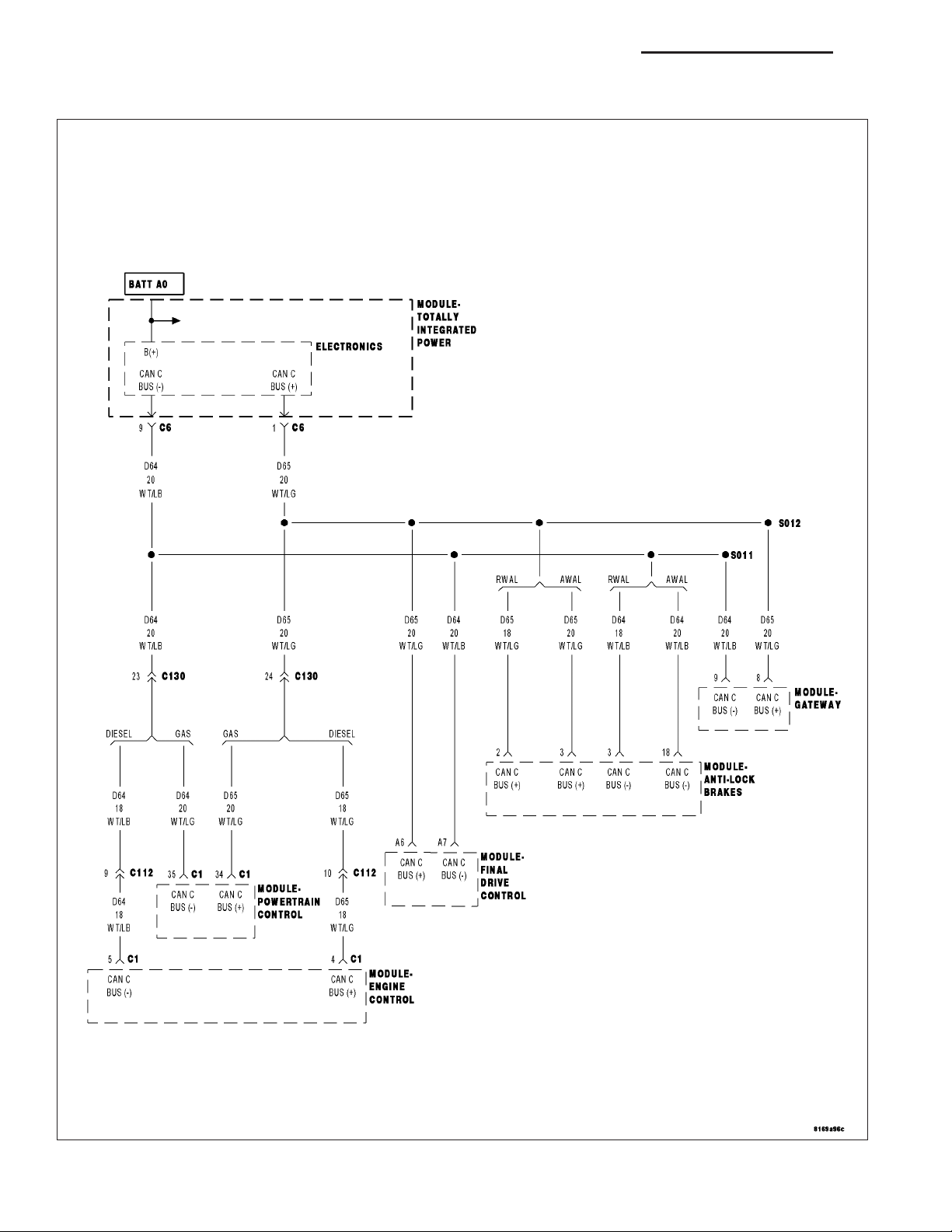

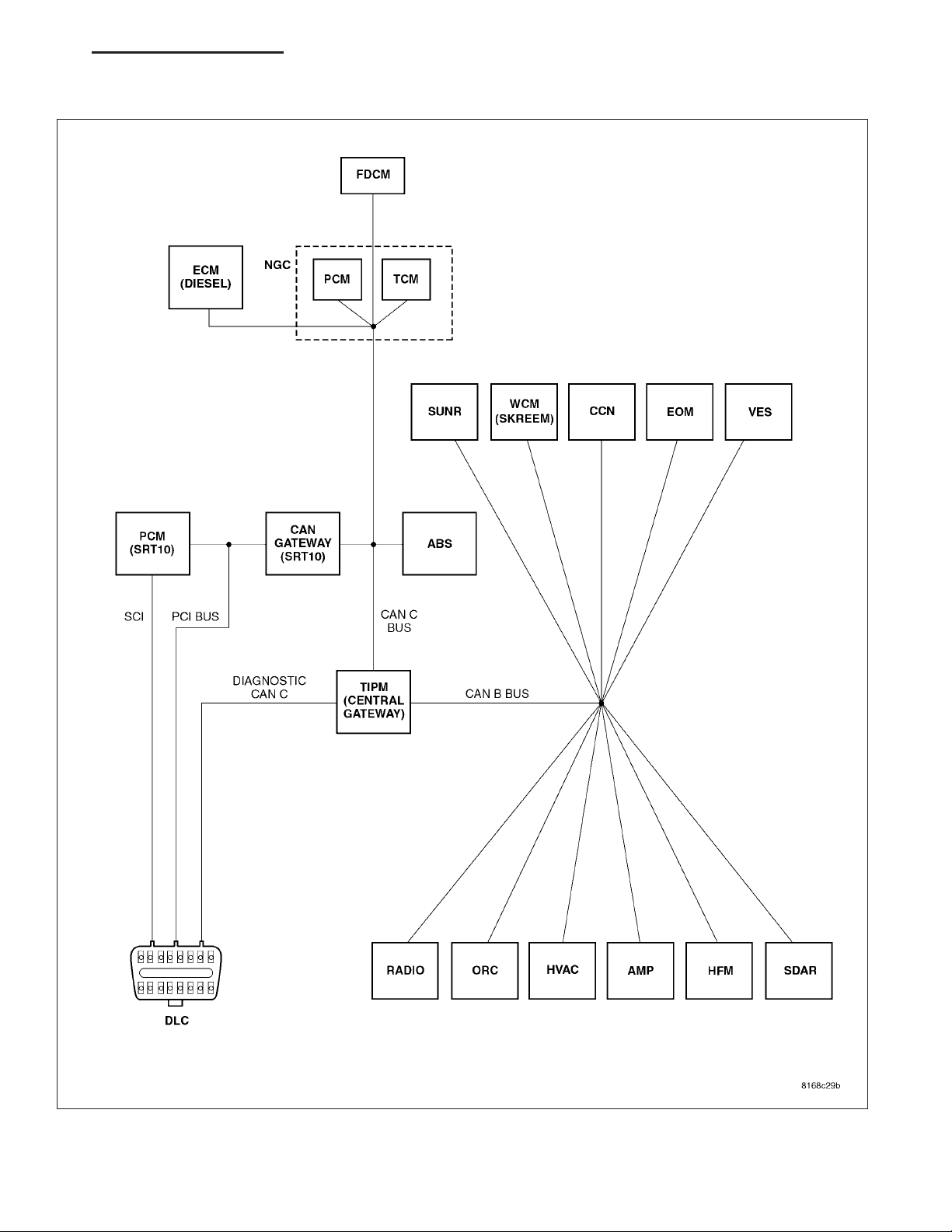

U0001-CAN C BUS CIRCUIT

For a complete wiring diagram Refer to Section 8W.

Page 15

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 15

• When Monitored:

With the ignition on.

• Set Condition:

The TIPM detects a short in either CAN C Bus circuit.

Possible Causes

(D65) CAN C BUS (+) CIRCUIT SHORTED TO GROUND

(D64) CAN C BUS (-) CIRCUIT SHORTED TO GROUND

(D65) CAN C BUS (+) CIRCUIT SHORTED TO VOLTAGE

(D64) CAN C BUS (-) CIRCUIT SHORTED TO VOLTAGE

(D65) CAN C BUS (+) CIRCUIT SHORTED TO (D64) CAN C BUS (-) CIRCUIT

ANTILOCK BRAKE MODULE

POWERTRAIN CONTROL MODULE

ENGINE CONTROL MODULE (DIESEL ONLY)

GATEWAY MODULE (SRT10 ONLY)

FINAL DRIVE CONTROL MODULE

TOTALLY INTEGRATED POWER MODULE

Diagnostic Test

TEST FOR INTERMITTENT CONDITION

1.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display U0001–CAN C BUS CIRCUIT as active?

Yes >>

No >>

ANTILOCK BRAKE MODULE — INTERNAL SHORT

2.

Turn the ignition off.

Disconnect the Antilock Brake Module harness connector.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display U0001–CAN C BUS CIRCUIT as active?

Go To 2

The conditions that caused this code to set are not present at this time. Using the wiring diagram/sche-

matic as a guide, inspect the wiring and connectors.

Yes >>

No >>

Go To 3

Inspect the wiring and connectors for damage or shorted circuits. If ok, replace the Antilock Brake Mod-

ule in accordance with the service information.

Perform the ABS VERIFICATION TEST — VER 1.

Page 16

8E - 16 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

POWERTRAIN CONTROL MODULE — INTERNAL SHORT

3.

Turn the ignition off.

Disconnect the Powertrain Control Module C1 harness connector.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display U0001–CAN C BUS CIRCUIT as active?

Yes >>

No >>

GATEWAY MODULE (SRT10 ONLY) — INTERNAL SHORT

4.

Turn the ignition off.

NOTE: If vehicle is not equipped with this module, answer yes to the question.

Disconnect the Gateway Module harness connector.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display U0001–CAN C BUS CIRCUIT as active?

Yes >>

No >>

Go To 4

Inspect the wiring and connectors for damage or shorted circuits. If ok, replace and program the Pow-

ertrain Control Module in accordance with the service information.

Perform the POWERTRAIN VERIFICATION TEST

Go To 5

Inspect the wiring and connectors for damage or shorted circuits. If ok, replace the Gateway Module in

accordance with the service information.

Perform the BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES - STANDARD PROCEDURE)

ENGINE CONTROL MODULE (DIESEL ONLY) — INTERNAL SHORT

5.

Turn the ignition off.

NOTE: If vehicle is not equipped with this module, answer yes to the question.

Disconnect the Engine Control Module C1 harness connector.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display U0001–CAN C BUS CIRCUIT as active?

Yes >>

No >>

Go To 6

Inspect the wiring and connectors for damage or shorted circuits. If ok, replace and program the Engine

Control Module in accordance with the service information.

Perform the POWERTRAIN VERIFICATION TEST VER - 5 (DIESEL).

Page 17

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 17

FINAL DRIVE CONTROL MODULE (POWER WAGON ONLY) — INTERNAL SHORT

6.

Turn the ignition off.

NOTE: If vehicle is not equipped with this module, answer yes to the question.

Disconnect the Final Drive Control Module harness connectors.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display U0001–CAN C BUS CIRCUIT as active?

Yes >>

No >>

(D65) CAN C BUS (+) CIRCUIT SHORTED TO VOLTAGE

7.

Turn the ignition off.

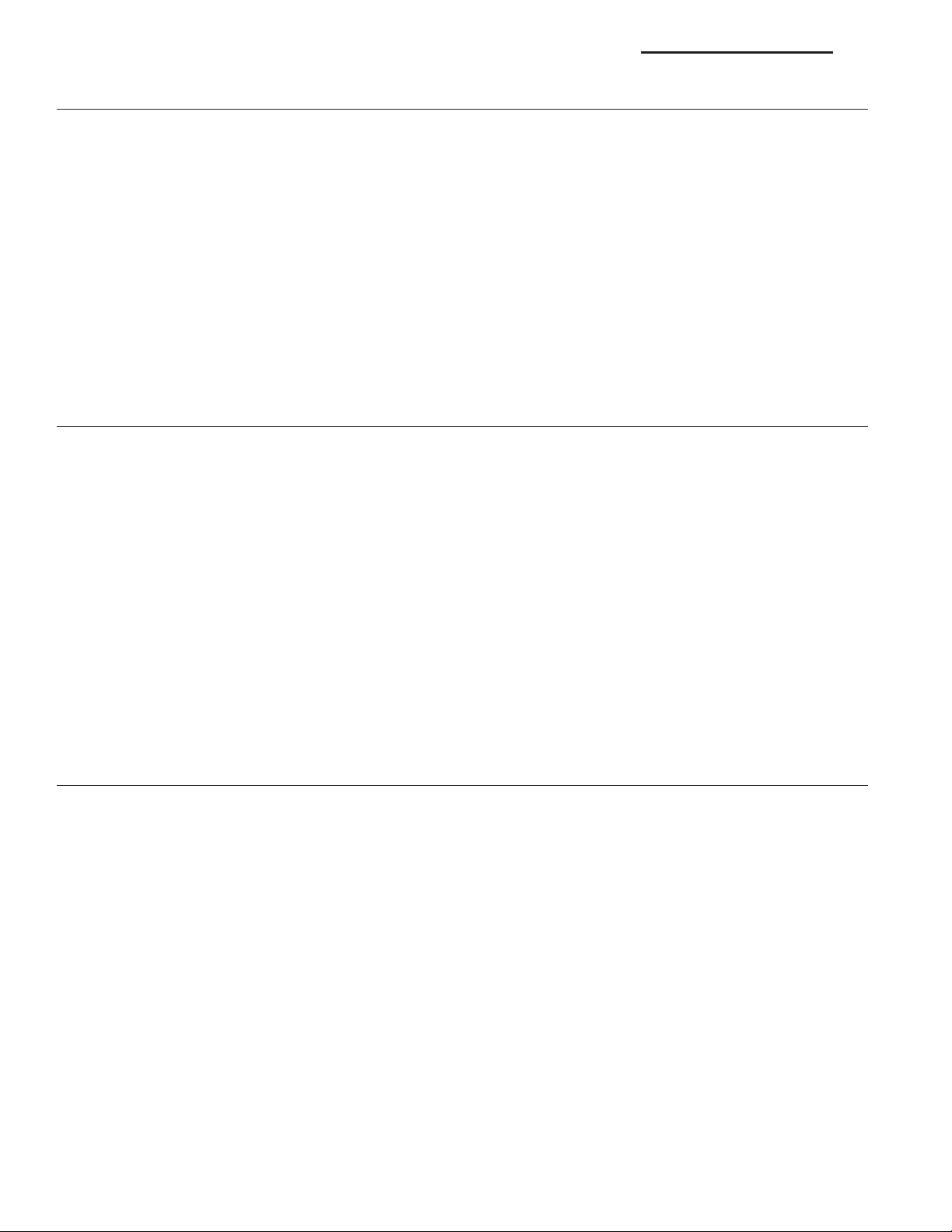

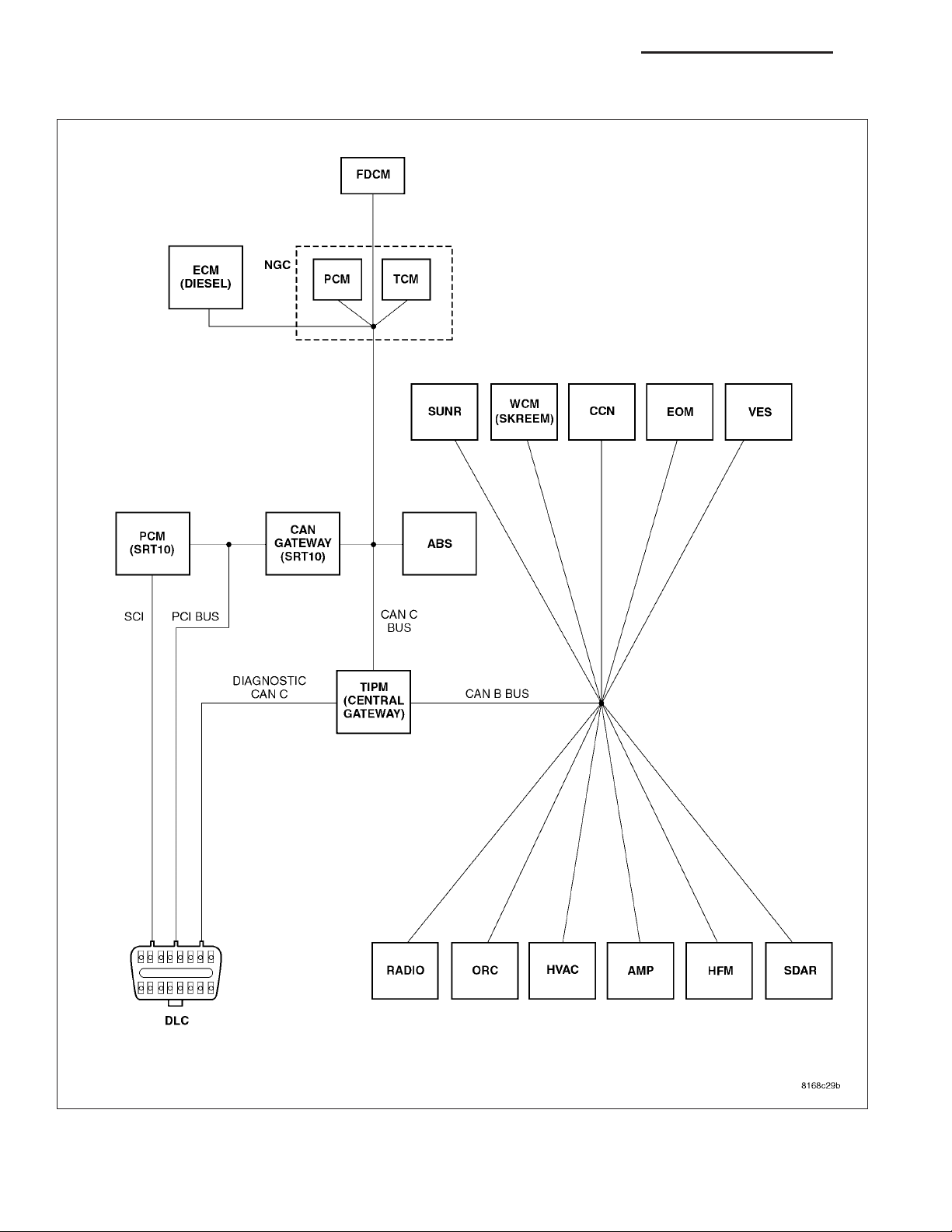

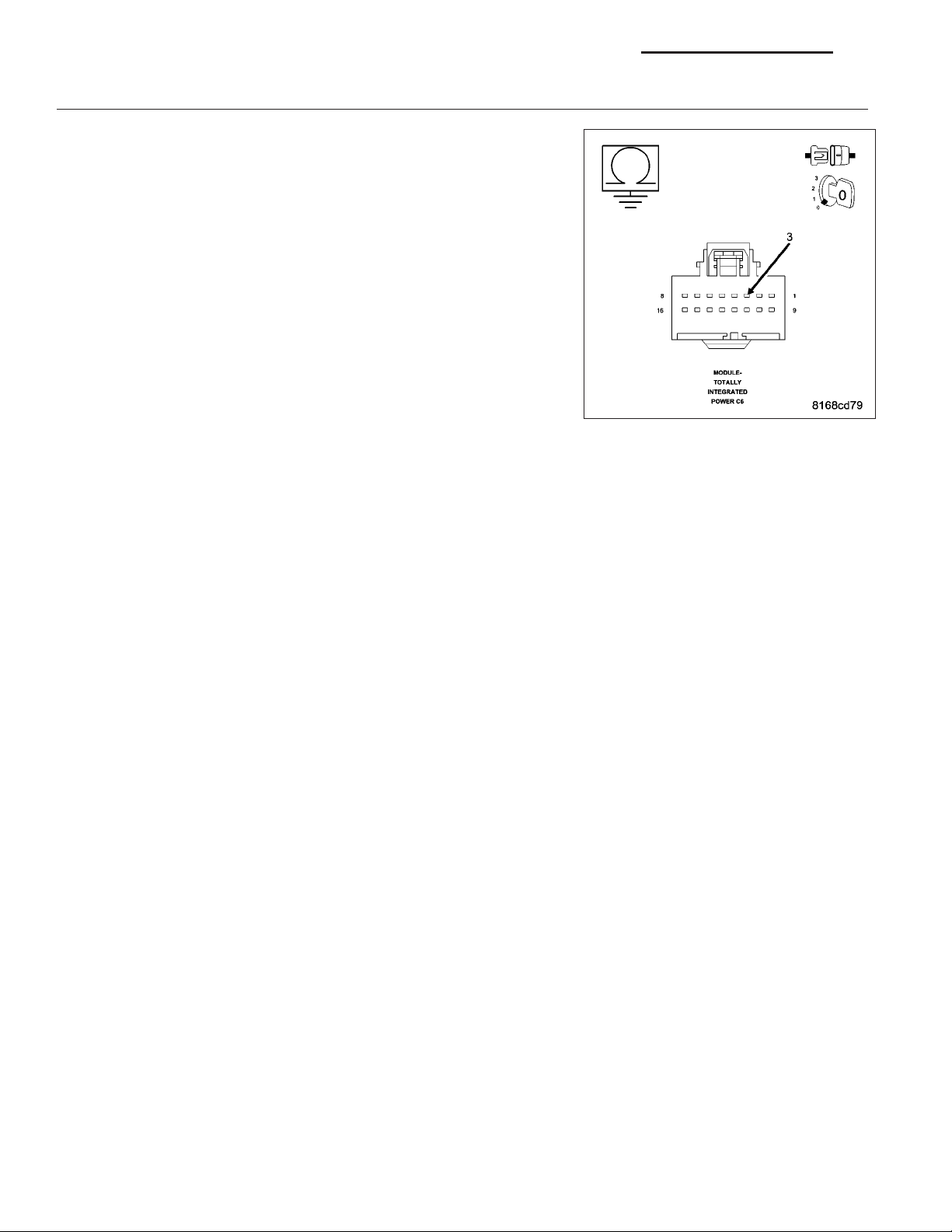

Disconnect the Totally Integrated Power Module C6 harness connector.

Turn the ignition on.

Measure the voltage between the (D65) CAN C Bus (+) circuit and

ground.

Is there any voltage present?

Yes >>

No >>

Go To 7

Inspect the wiring and connectors for damage or shorted circuits. If ok, replace and program the Final

Drive Control Module in accordance with the service information.

Perform the FDCM VERIFICATION TEST.

Repair the (D65) CAN C Bus (+) circuit for a short to voltage.

Perform the BODY VERIFICATION TEST – VER 1. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE)

Go To 8

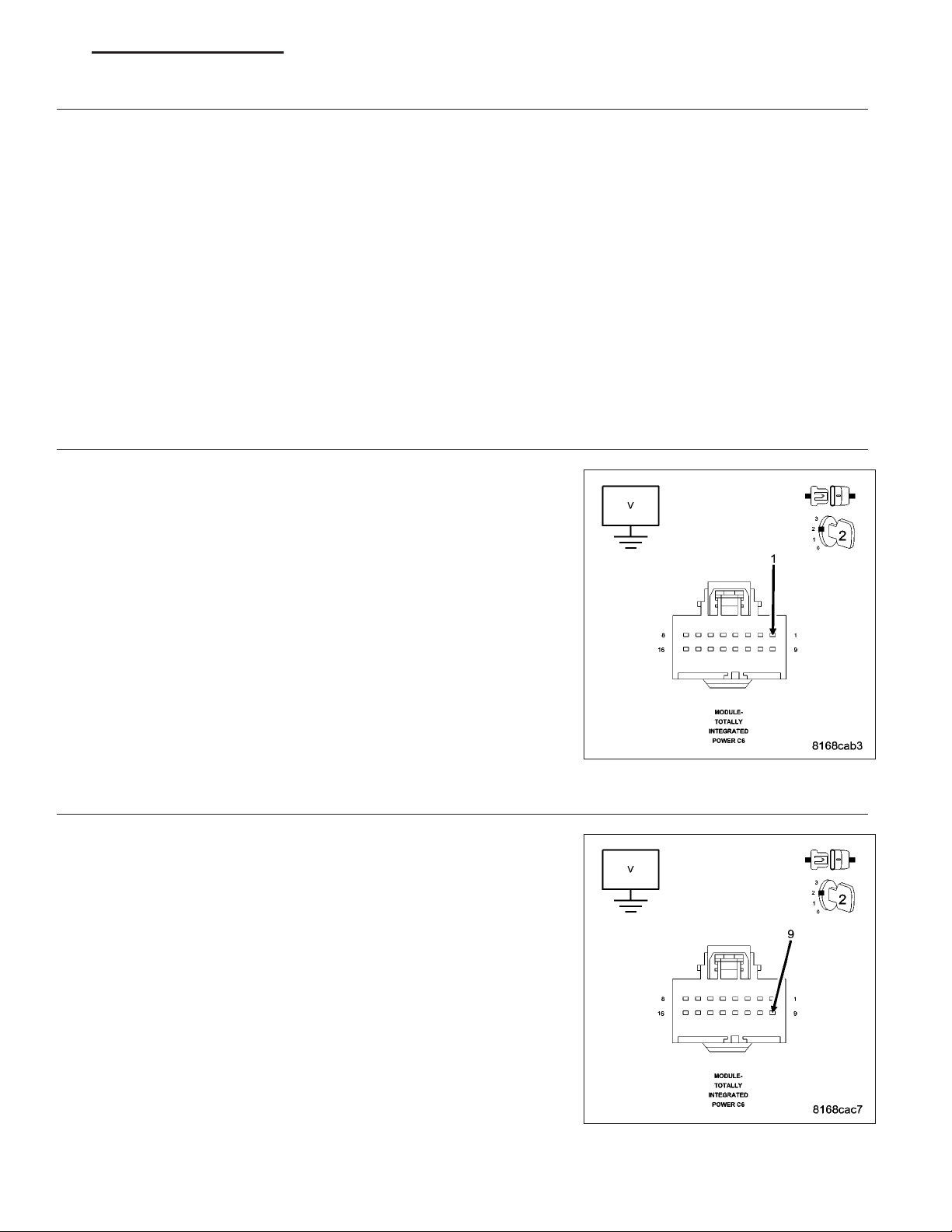

(D64) CAN C BUS (-) CIRCUIT SHORTED TO VOLTAGE

8.

Measure the voltage between the (D64) CAN C Bus (-) circuit and

ground.

Is there any voltage present?

Yes >>

No >>

Repair the (D64) CAN C Bus (-) circuit for a short to voltage.

Perform the BODY VERIFICATION TEST – VER 1. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Go To 9

Page 18

8E - 18 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

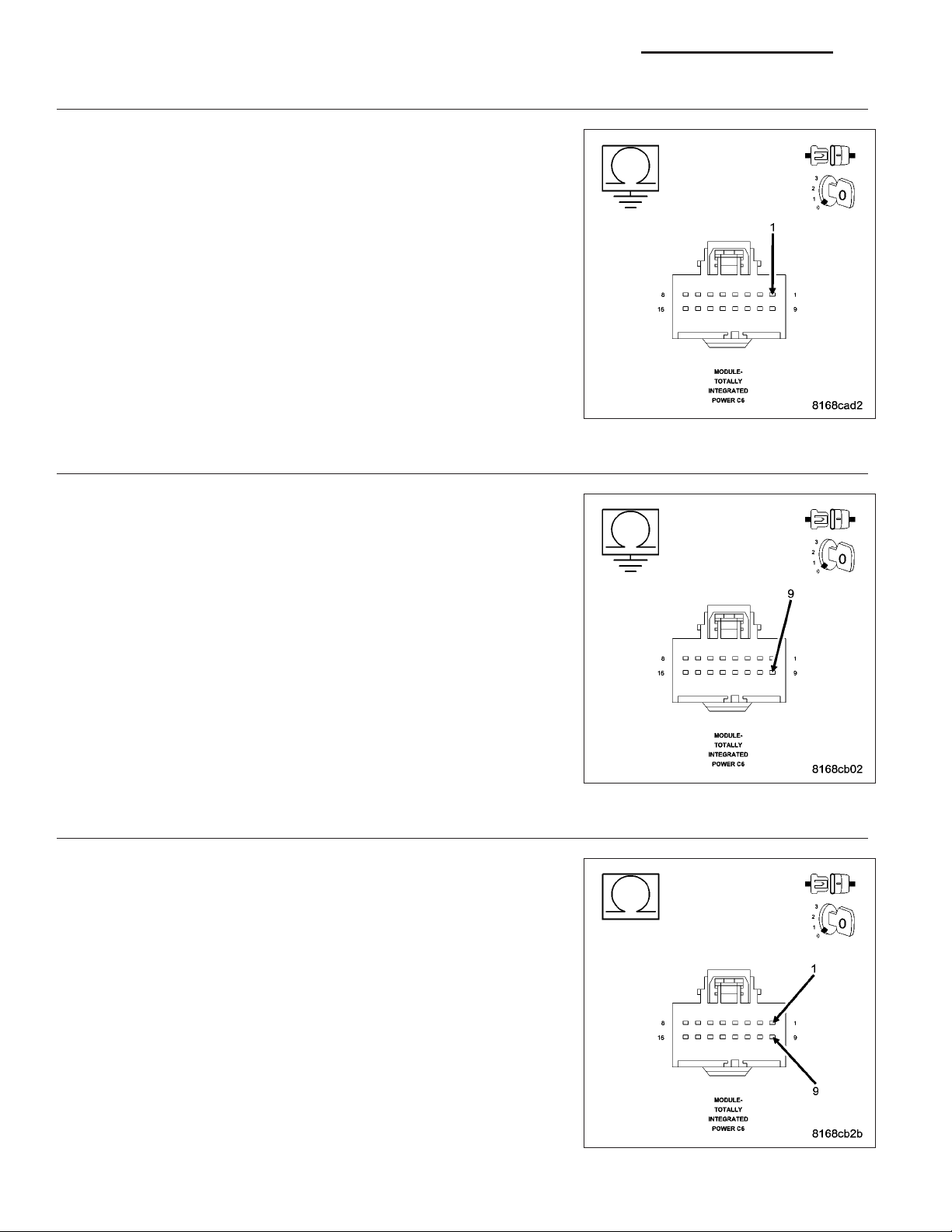

(D65) CAN C BUS (+) CIRCUIT SHORTED TO GROUND

9.

Turn the ignition off.

Measure the resistance between ground and the (D65) CAN C Bus (+)

circuit.

Is any resistance present?

Yes >>

No >>

10.

Measure the resistance between ground and the (D64) CAN C Bus (-)

circuit.

Is any resistance present?

Yes >>

No >>

Repair the (D65) CAN C Bus (+) circuit for a short to

ground.

Perform the BODY VERIFICATION TEST – VER 1. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Go To 10

(D64) CAN C BUS (-) CIRCUIT SHORTED TO GROUND

Repair the (D64) CAN C Bus (-) circuit for a short to

ground.

Perform the BODY VERIFICATION TEST – VER 1. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Go To 11

(D65) CAN C BUS (+) CIRCUIT SHORTED TO (D64) CAN C BUS (-) CIRCUIT

11.

Measure the resistance between the (D65) CAN C Bus (+) circuit and

the (D64) CAN C Bus (-) circuit.

Is any resistance present?

Yes >>

No >>

Repair the (D65) CAN C Bus (+) circuit for a short to the

(D64) CAN C Bus (-) circuit.

Perform the BODY VERIFICATION TEST – VER 1. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Inspect the wiring and connectors for damage or shorted

circuits. If ok, replace and program the Totally Integrated

Power Module in accordance with the service information.

Perform the BODY VERIFICATION TEST – VER 1. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Page 19

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 19

U0021-CAN B BUS (+) CIRCUIT OPEN

For a complete wiring diagram Refer to Section 8W.

Page 20

8E - 20 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

With the ignition on and battery voltage between 10 and 16 volts.

• Set Condition:

The TIPM detects the (D55) CAN B Bus (+) circuit is open.

Possible Causes

CAN B BUS TERMINAL PUSH OUT

SPREAD CAN B BUS TERMINAL

(D55) CAN B BUS (+) CIRCUIT OPEN

INTERNAL OPEN IN A CAN B BUS MODULE

Diagnostic Test

TEST FOR INTERMITTENT CONDITION

1.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

ATTEMPT TO ISOLATE THE OPEN CONDITION

2.

Turn the ignition on.

Verify that all CAN B Bus modules are communicating with the scan

tool.

NOTE: A red X will be next to the module that is not communicating, indicating that the module is not active on the Bus network. A

green check indicates that the module is active on the Bus network.

NOTE: If any module is not communicating, perform the appropriate no response test procedure before proceeding.

Turn the ignition off.

Gain access to the Totally Integrated Power Module C6 harness con-

nector, but do not disconnect.

Using a fused jumper wire, connect one end to ground and with the

other end backprobe the (D54) CAN B Bus (-) circuit at the TIPM C6

harness connector.

Turn the ignition on.

With the scan tool monitor the network status screen and document all modules that display a red X.

Are there any red X’s displayed next to the modules?

Go To 2

The conditions that caused this code to set are not present at this time. Using the wiring diagram/sche-

matic as a guide, inspect the wiring and connectors.

Yes >>

No >>

Go To 3

Check backprobe connection to ground, make sure it is proper. The CAN B Bus open DTC may no

longer be active, it may be stored. Check all module connections.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 21

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 21

ATTEMPT TO ISOLATE THE OPEN CONDITION — MULTIPLE RED X’S

3.

With the scan tool continue monitoring the network status screen.

Are there multiple red X’s displayed next to the modules?

Yes >>

No >>

(D55) CAN B BUS (+) CIRCUIT OPEN — SINGLE RED X

4.

Turn the ignition off.

Disconnect the module that has the red X displayed next to it.

Turn the ignition on.

Measure the voltage between the (D55) CAN B Bus (+) circuit and ground.

Is there any voltage present?

Yes >>

No >>

The most likely cause of this condition is an open CAN B Bus (+) circuit between a common CAN B

Bus splice and the modules that display the red X next to them. Using the wiring diagrams will help you

determine where open condition exists.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Go To 4

Inspect the connector and terminal for damage, inspect for spread terminals, or push out terminals. If

ok, replace the module that displayed the red X next to it in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Repair the (D55) CAN B Bus (+) circuit for an open between the next common splice and the module

that has the red X displayed next to it. Using the wiring diagrams will help you determine where open

condition exists.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 22

8E - 22 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

U0022-CAN B BUS (+) CIRCUIT LOW

For a complete wiring diagram Refer to Section 8W.

Page 23

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 23

• When Monitored:

Continuously.

• Set Condition:

The TIPM detects the (D55) CAN B Bus (+) circuit is shorted to ground.

Possible Causes

(D55) CAN B BUS (+) CIRCUIT SHORTED TO GROUND

ANY CAN B BUS MODULE

TOTALLY INTEGRATED POWER MODULE

Diagnostic Test

TEST FOR INTERMITTENT CONDITION

1.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

CHECK THE (D55) CAN B BUS (+) CIRCUIT FOR A SHORT TO GROUND

2.

Turn the ignition off.

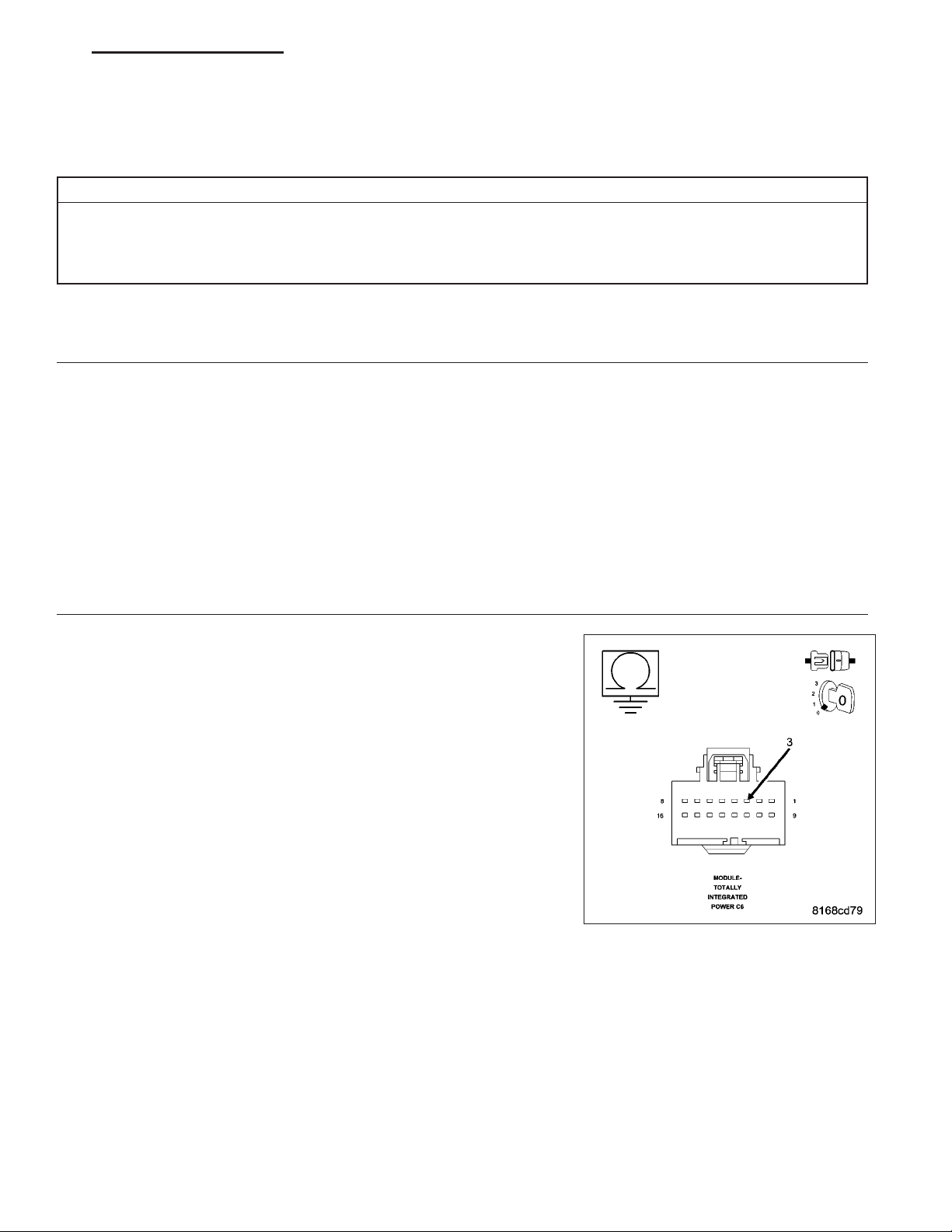

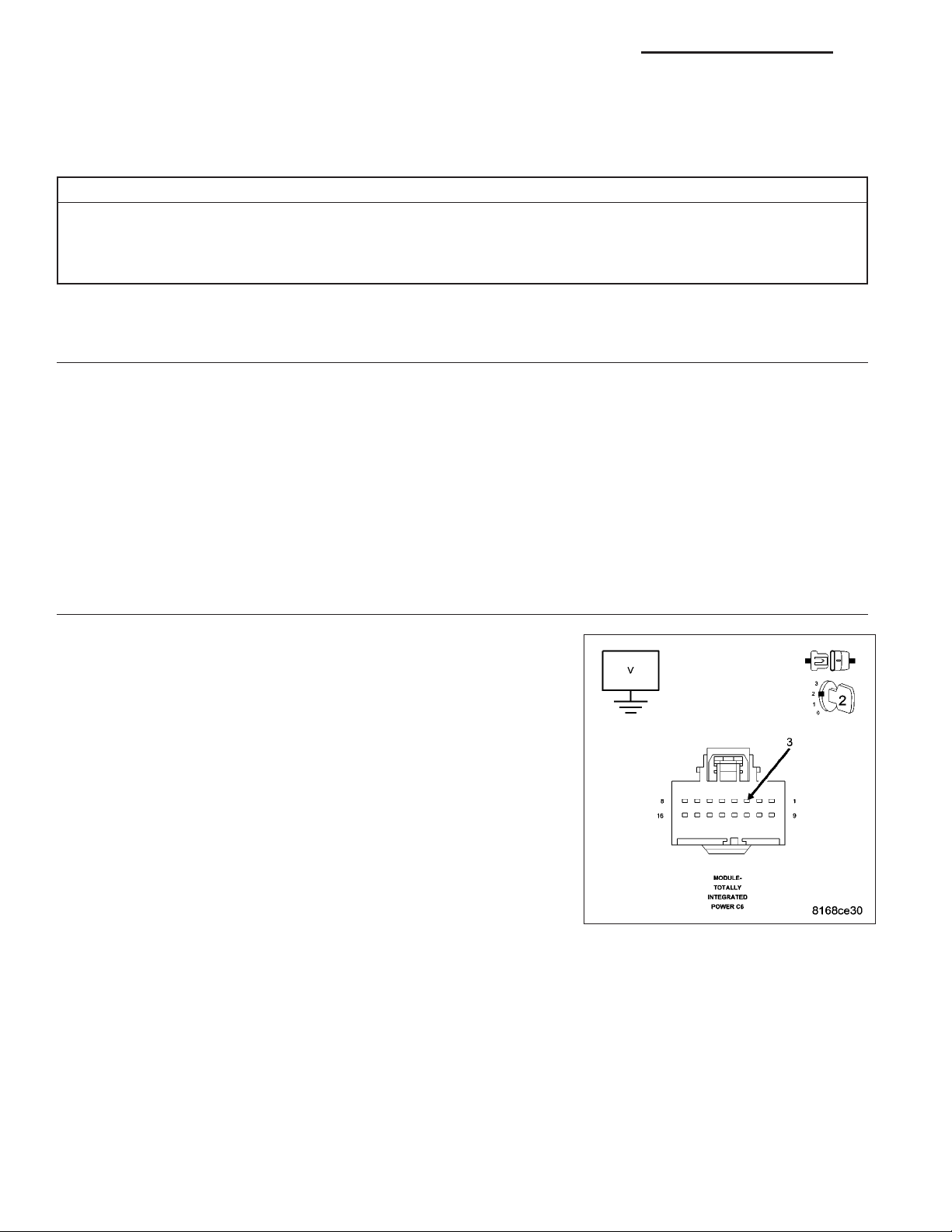

Disconnect the Totally Integrated Power Module C6 harness connector.

Measure the resistance between ground and the (D55) CAN B Bus (+)

circuit.

Is resistance below 1000.0 ohms?

Yes >>

No >>

Go To 2

The conditions that caused this code to set are not present at this time. Using the wiring diagram/sche-

matic as a guide, inspect the wiring and connectors.

Go To 3

Inspect the wiring and connectors for damage or shorted

circuits. If ok, replace the Totally Integrated Power Module

in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Page 24

8E - 24 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

(D55) CAN B BUS (+) CIRCUIT SHORTED TO GROUND

3.

Measure the resistance between ground and the (D55) CAN B Bus (+)

circuit.

While monitoring the ohmmeter, disconnect each CAN B Bus module

one at a time.

NOTE: This is to determine if the short to ground is internal within

a module or if the circuit is shorted.

NOTE: Disconnecting an in-line connector can eliminate a module

or group of modules from the list of possible causes for this fault.

Refer to the wiring diagrams to assist in diagnosis.

Is resistance below 1000.0 ohms with all the CAN B Bus modules disconnected?

Yes >>

No >>

Repair the (D55) CAN B Bus (+) circuit for a short to

ground.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Replace the module that when disconnected the short to ground was eliminated, in accordance with the

service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 25

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 25

U0023-CAN B BUS (+) CIRCUIT HIGH

For a complete wiring diagram Refer to Section 8W.

Page 26

8E - 26 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Continuously

• Set Condition:

The TIPM detects the (D55) CAN B Bus (+) circuit is shorted to voltage.

Possible Causes

(D55) CAN B BUS (+) CIRCUIT SHORTED TO VOLTAGE

ANY CAN B BUS MODULE

TOTALLY INTEGRATED POWER MODULE

Diagnostic Test

TEST FOR INTERMITTENT CONDITION

1.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

CHECK THE (D55) CAN B BUS (+) CIRCUIT FOR A SHORT TO VOLTAGE

2.

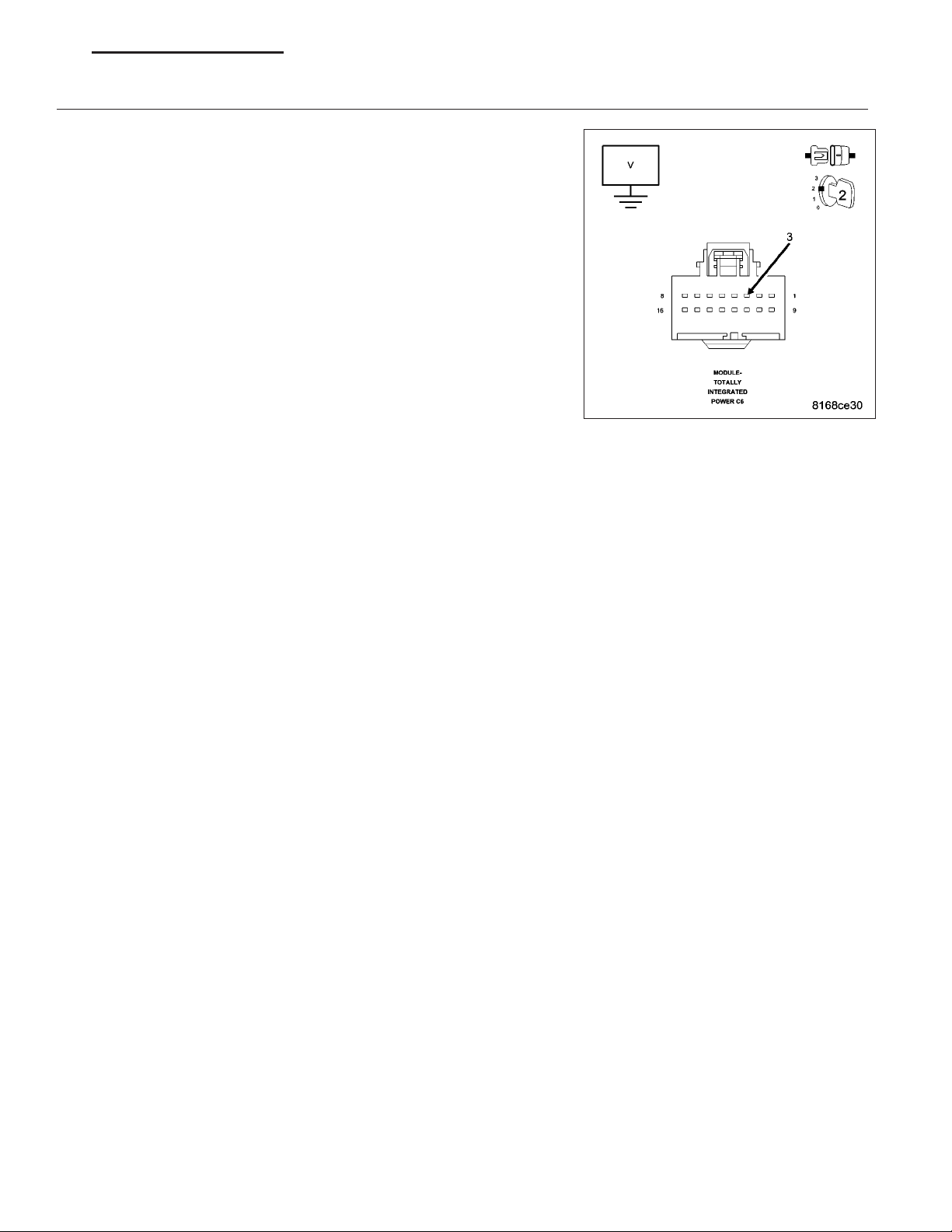

Turn the ignition off.

Disconnect the Totally Integrated Power Module C6 harness connector.

Turn the ignition on.

Measure the voltage between the (D55) CAN B Bus (+) circuit and

ground.

Is voltage above 10.0 volts?

Yes >>

No >>

Go To 2

The conditions that caused this code to set are not present at this time. Using the wiring diagram/sche-

matic as a guide, inspect the wiring and connectors.

Go To 3

Inspect the wiring and connectors for damage or shorted

circuits. If ok, replace the Totally Integrated Power Module

in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Page 27

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 27

(D55) CAN B BUS (+) CIRCUIT SHORTED TO VOLTAGE

3.

Measure the voltage between the (D55) CAN B Bus (+) circuit and

ground.

While monitoring the voltmeter, disconnect each CAN B Bus module

one at a time.

NOTE: When performing the above step, turn the ignition off (wait

one minute) before disconnecting any module. When the module is

disconnected turn the ignition on to check for a short to voltage.

NOTE: This is to determine if the short to voltage is internal within

a module or if the circuit is shorted.

NOTE: Disconnecting an in-line connector can eliminate a module

or group of modules from the list of possible causes for this fault.

Refer to the wiring diagrams to assist in diagnosis.

Is the voltage above 10.0 volts with all the CAN B Bus modules disconnected?

Yes >>

No >>

Repair the (D55) CAN B Bus (+) circuit for a short to voltage.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Replace the module that when disconnected the short to voltage was eliminated, in accordance with the

service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 28

8E - 28 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

U0024-CAN B BUS (-) CIRCUIT OPEN

For a complete wiring diagram Refer to Section 8W.

Page 29

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 29

• When Monitored:

With the ignition on and battery voltage between 10 and 16 volts.

• Set Condition:

The TIPM detects the (D54) CAN B Bus (-) circuit is open.

Possible Causes

CAN B BUS TERMINAL PUSH OUT

SPREAD CAN B BUS TERMINAL

(D54) CAN B BUS (-) CIRCUIT OPEN

INTERNAL OPEN IN A CAN B BUS MODULE

Diagnostic Test

TEST FOR INTERMITTENT CONDITION

1.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

ATTEMPT TO ISOLATE THE OPEN CONDITION

2.

Turn the ignition on.

Verify that all CAN B Bus modules are communicating with the scan

tool.

NOTE: A red X will be next to the module that is not communicating, indicating that the module is not active on the Bus network. A

green check indicates that the module is active on the Bus network.

NOTE: If any module is not communicating, perform the appropriate no response test procedure before proceeding.

Turn the ignition off.

Gain access to the Totally Integrated Power Module C6 harness con-

nector, but do not disconnect.

Using a fused jumper wire, connect one end to ground and with the

other end backprobe the CAN B Bus (+) circuit at the TIPM C6 harness

connector.

Turn the ignition on.

With the scan tool monitor the network status screen and document all modules that display a red X.

Are there any red X’s displayed next to the modules?

Go To 2

The conditions that caused this code to set are not present at this time. Using the wiring diagram/sche-

matic as a guide, inspect the wiring and connectors.

Yes >>

No >>

Go To 3

Check backprobe connection to ground, make sure it is proper. The CAN B Bus open DTC may no

longer be active, it may be stored. Check all module connections

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 30

8E - 30 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

ATTEMPT TO ISOLATE THE OPEN CONDITION — MULTIPLE RED X’S

3.

With the scan tool continue monitoring the network status screen.

Are there multiple red X’s displayed next to the modules?

Yes >>

No >>

(D54) CAN B BUS (-) CIRCUIT OPEN — SINGLE RED X

4.

Turn the ignition off.

Disconnect the module that has the red X displayed next to it.

Turn the ignition on.

Measure the voltage between the (D54) CAN B Bus (-) circuit and ground.

Is there any voltage present?

Yes >>

No >>

The most likely cause of this condition is an open CAN B Bus (-) circuit between a common CAN B Bus

splice and the modules that display the red X next to them. Using the wiring diagrams will help you

determine where open condition exists.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Go To 4

Inspect the connector and terminal for damage, inspect for spread terminals, or push out terminals. If

ok, replace the module that displayed the red X next to it in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Repair the (D54) CAN B Bus (-) circuit for an open between the next common splice and the module

that has the red X displayed next to it. Using the wiring diagrams will help you determine where open

condition exists.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 31

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 31

U0025-CAN B BUS (-) CIRCUIT LOW

For a complete wiring diagram Refer to Section 8W.

Page 32

8E - 32 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Continuously

• Set Condition:

The TIPM detects the (D54) CAN B Bus (-) circuit is shorted to ground.

Possible Causes

(D54) CAN B BUS (-) CIRCUIT SHORTED TO GROUND OR TO (D55) CAN B BUS (+) CIRCUIT

ANY CAN B BUS MODULE

TOTALLY INTEGRATED POWER MODULE

Diagnostic Test

TEST FOR INTERMITTENT CONDITION

1.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

CHECK THE (D54) CAN B BUS (-) CIRCUIT FOR A SHORT TO GROUND

2.

Turn the ignition off.

Disconnect the Totally Integrated Power Module C6 harness connector.

Measure the resistance between ground and the (D54) CAN B Bus (-)

circuit.

Is resistance below 1000.0 ohms?

Yes >>

No >>

Go To 2

The conditions that caused this code to set are not present at this time. Using the wiring diagram/sche-

matic as a guide, inspect the wiring and connectors.

Go To 3

Go To 4

Page 33

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 33

(D54) CAN B BUS (-) CIRCUIT SHORTED TO GROUND

3.

Measure the resistance between ground and the (D54) CAN B Bus (-)

circuit.

While monitoring the ohmmeter, disconnect each CAN B Bus module

one at a time.

NOTE: This is to determine if the short to ground is internal within

a module or if the circuit is shorted.

NOTE: Disconnecting an in-line connector can eliminate a module

or group of modules from the list of possible causes for this fault.

Refer to the wiring diagrams to assist in diagnosis.

Is resistance below 1000.0 ohms with all the CAN B Bus modules disconnected?

Yes >>

No >>

CHECK THE (D55) CAN B BUS (+) CIRCUIT FOR A SHORT TO THE (D54) CAN B BUS (-) CIRCUIT

4.

Measure the resistance between the (D55) CAN B Bus (+) circuit and

(D54) CAN B Bus (-) circuit.

Is resistance below 1000.0 ohms?

Yes >>

No >>

Repair the (D54) CAN B Bus (-) circuit for a short to

ground.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Replace the module that when disconnected the short to ground was eliminated, in accordance with the

service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Go To 5

Inspect the wiring and connectors for damage or shorted

circuits. If ok, replace the Totally Integrated Power Module

in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Page 34

8E - 34 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

(D55) CAN B BUS (+) CIRCUIT SHORTED TO THE (D54) CAN B BUS (-) CIRCUIT

5.

Measure the resistance between the (D55) CAN B Bus (+) circuit and

(D54) CAN B Bus (-) circuit.

While monitoring the ohmmeter, disconnect each CAN B Bus module

one at a time.

NOTE: This is to determine if the short together is internal within a

module or if the circuits are shorted together.

NOTE: Disconnecting an in-line connector can eliminate a module

or group of modules from the list of possible causes for this fault.

Refer to the wiring diagrams to assist in diagnosis.

Is resistance below 1000.0 ohms with all the CAN B Bus modules disconnected?

Yes >>

No >>

Repair the (D55) CAN B Bus (+) circuit for a short to the

(D54) CAN B Bus (-) circuit.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Replace the module that when disconnected the short together was eliminated, in accordance with the

service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 35

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 35

U0026-CAN B BUS (-) CIRCUIT HIGH

For a complete wiring diagram Refer to Section 8W.

Page 36

8E - 36 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

Continuously

• Set Condition:

The TIPM detects the (D54) CAN B Bus (-) circuit is shorted to voltage.

Possible Causes

(D54) CAN B BUS (-) CIRCUIT SHORTED TO VOLTAGE

ANY CAN B BUS MODULE

TOTALLY INTEGRATED POWER MODULE

Diagnostic Test

TEST FOR INTERMITTENT CONDITION

1.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

CHECK THE (D54) CAN B BUS (-) CIRCUIT FOR A SHORT TO VOLTAGE

2.

Turn the ignition off.

Disconnect the Totally Integrated Power Module C6 harness connector.

Turn the ignition on.

Measure the voltage between the (D54) CAN B Bus (-) circuit and

ground.

Is voltage above 10.0 volts?

Yes >>

No >>

Go To 2

The conditions that caused this code to set are not present at this time. Using the wiring diagram/sche-

matic as a guide, inspect the wiring and connectors.

Go To 3

Inspect the wiring and connectors for damage or shorted

circuits. If ok, replace the Totally Integrated Power Module

in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Page 37

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 37

(D54) CAN B BUS (-) CIRCUIT SHORTED TO VOLTAGE

3.

Measure the voltage between the (D54) CAN B Bus (-) circuit and

ground.

While monitoring the voltmeter, disconnect each CAN B Bus module

one at a time.

NOTE: When performing the above step, turn the ignition off (wait

one minute) before disconnecting any module. When the module is

disconnected turn the ignition on to check for a short to voltage.

NOTE: This is to determine if the short to voltage is internal within

a module or if the circuit is shorted.

NOTE: Disconnecting an in-line connector can eliminate a module

or group of modules from the list of possible causes for this fault.

Refer to the wiring diagrams to assist in diagnosis.

Is the voltage above 10.0 volts with all the CAN B Bus modules disconnected?

Yes >>

No >>

Repair the (D54) CAN B Bus (-) circuit for a short to voltage.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Replace the module that when disconnected the short to voltage was eliminated, in accordance with the

service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 38

8E - 38 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

U0027-CAN B BUS (-) SHORTED TO BUS (+)

For a complete wiring diagram Refer to Section 8W.

Page 39

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 39

• When Monitored:

Continuously

• Set Condition:

The TIPM detects the (D55) CAN B Bus (+) circuit is shorted to the (D54) CAN B Bus (-) circuit.

Possible Causes

(D55) CAN B BUS (+) CIRCUIT SHORTED TO THE (D54) CAN B BUS (-) CIRCUIT

ANY CAN B BUS MODULE

TOTALLY INTEGRATED POWER MODULE

Diagnostic Test

TEST FOR INTERMITTENT CONDITION

1.

Turn the ignition on.

With the scan tool, record and erase TIPM DTC’s.

Cycle the ignition from on to off 3 times.

Turn the ignition on.

With the scan tool, read active TIPM DTC’s.

Does the scan tool display this DTC as active?

Yes >>

No >>

CHECK THE (D55) CAN B BUS (+) CIRCUIT FOR A SHORT TO THE (D54) CAN B BUS (-) CIRCUIT

2.

Turn the ignition off.

Disconnect the Totally Integrated Power Module C6 harness connector.

Measure the resistance between the (D55) CAN B Bus (+) circuit and

(D54) CAN B Bus (-) circuit.

Is resistance below 1000.0 ohms?

Yes >>

No >>

Go To 2

The conditions that caused this code to set are not present at this time. Using the wiring diagram/sche-

matic as a guide, inspect the wiring and connectors.

Go To 3

Inspect the wiring and connectors for damage or shorted

circuits. If ok, replace the Totally Integrated Power Module

in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Page 40

8E - 40 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

(D55) CAN B BUS (+) CIRCUIT SHORTED TO THE (D54) CAN B BUS (-) CIRCUIT

3.

Measure the resistance between the (D55) CAN B Bus (+) circuit and

(D54) CAN B Bus (-) circuit.

While monitoring the ohmmeter, disconnect each CAN B Bus module

one at a time.

NOTE: This is to determine if the short together is internal within a

module or if the circuits are shorted together.

NOTE: Disconnecting an in-line connector can eliminate a module

or group of modules from the list of possible causes for this fault.

Refer to the wiring diagrams to assist in diagnosis.

Is resistance below 1000.0 ohms with all the CAN B Bus modules disconnected?

Yes >>

No >>

Repair the (D55) CAN B Bus (+) circuit for a short to the

(D54) CAN B Bus (-) circuit.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES STANDARD PROCEDURE).

Replace the module that when disconnected the short together was eliminated, in accordance with the

service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 41

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 41

U0100-LOST COMMUNICATION WITH ECM/PCM

For a complete wiring diagram Refer to Section 8W.

Page 42

8E - 42 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

• With the ignition on

• Battery voltage between 10 and 16 volts

• IOD fuse installed

• TIPM is configured correctly

• Set Condition:

Bus messages not received from the ECM/PCM for approximately 2 to 5 seconds.

Possible Causes

CAN B OR CAN C BUS CIRCUITS OPEN OR SHORTED

DTCS RELATED TO BATTERY VOLTAGE, IGNITION, OR VIN MESSAGES

TIPM NOT CONFIGURED CORRECTLY

ECM/PCM POWER AND GROUND

ECM/PCM

MODULE THAT SET THIS DTC

Diagnostic Test

VERIFY DTC IS ACTIVE

1.

NOTE: Ensure the IOD fuse is installed and battery voltage is between 10 and 16 volts before proceeding.

With the scan tool, read active DTCs.

Is this DTC active?

Yes >>

No >>

CHECK FOR ANY OF THE FOLLOWING ACTIVE DTCS

2.

With the scan tool, read all active DTCs from all modules.

NOTE: Check for TIPM configuration, CAN B or C hardware electrical, VIN Missing/Mismatch, battery or ignition related DTCs.

Does the scan tool display any active DTCs to the conditions listed above?

Yes >>

No >>

VERIFY THAT THE ECM/PCM IS ACTIVE ON THE BUS

3.

Turn the ignition on.

With the scan tool, select Network Diagnostics.

Verify that the ECM/PCM is active on the bus.

Is the ECM/PCM active on the bus?

Go To 2

Refer to the Stored Lost Communication test procedure. Refer to the table of contents in this section.

Diagnose and repair the DTC. Refer to the Index for a complete list of the symptoms.

Go To 3

Yes >>

No >>

Go To 4

Refer to the No Response test procedure. Refer to the table of contents in this section.

Page 43

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 43

CHECK FOR ADDITIONAL COMMUNICATION RELATED DTCS

4.

With the scan tool, select Network Diagnostics.

Is there more than one module with active DTCs “Logged Against” the ECM/PCM?

Yes >>

No >>

Replace/update the ECM/PCM in accordance with the service information.

Perform the appropriate VERIFICATION TEST.

Replace/update the module that set this DTC in accordance with the service information.

Perform the appropriate VERIFICATION TEST.

Page 44

8E - 44 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

U0101-LOST COMMUNICATION WITH TCM

For a complete wiring diagram Refer to Section 8W.

Page 45

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 45

• When Monitored:

• With the ignition on

• Battery voltage between 10 and 16 volts

• IOD fuse installed

• TIPM is configured correctly

• Set Condition:

Bus messages not received from the TCM for approximately 2 to 5 seconds.

Possible Causes

CAN B OR CAN C BUS CIRCUITS OPEN OR SHORTED

DTCS RELATED TO BATTERY VOLTAGE, IGNITION, OR VIN MESSAGES

TIPM NOT CONFIGURED CORRECTLY

TCM POWER AND GROUND

TCM (PCM)

MODULE THAT SET THIS DTC

Diagnostic Test

VERIFY DTC IS ACTIVE

1.

NOTE: Ensure the IOD fuse is installed and battery voltage is between 10 and 16 volts before proceeding.

With the scan tool, read active DTCs.

Is this DTC active?

Yes >>

No >>

CHECK FOR ANY OF THE FOLLOWING ACTIVE DTCS

2.

With the scan tool, read all active DTCs from all modules.

NOTE: Check for TIPM configuration, CAN B or C hardware electrical, VIN Missing/Mismatch, battery or ignition related DTCs.

Does the scan tool display any active DTCs to the conditions listed above?

Yes >>

No >>

VERIFY THAT THE TCM IS ACTIVE ON THE BUS

3.

Turn the ignition on.

With the scan tool, select Network Diagnostics.

Verify that the TCM is active on the bus.

Is the TCM active on the bus?

Go To 2

Refer to the Stored Lost Communication test procedure. Refer to the table of contents in this section.

Diagnose and repair the DTC. Refer to the Index for a complete list of the symptoms.

Go To 3

Yes >>

No >>

Go To 4

Refer to the No Response test procedure. Refer to the table of contents in this section.

Page 46

8E - 46 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

CHECK FOR ADDITIONAL COMMUNICATION RELATED DTCS

4.

With the scan tool, select Network Diagnostics.

Is there more than one module with active DTCs “Logged Against” the TCM?

Yes >>

No >>

Replace/update the TCM (PCM) in accordance with the service information.

Perform the appropriate VERIFICATION TEST.

Replace/update the module that set this DTC in accordance with the service information.

Perform the appropriate VERIFICATION TEST.

Page 47

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 47

U0114-LOST COMMUNICATION WITH FINAL DRIVE CONTROL MODULE

For a complete wiring diagram Refer to Section 8W.

Page 48

8E - 48 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

• With the ignition on

• Battery voltage between 10 and 16 volts

• IOD fuse installed

• TIPM is configured correctly

• Set Condition:

Bus messages not received from the Final Drive Control Module (FDCM) for approximately 2 to 5 seconds.

Possible Causes

CAN B OR CAN C BUS CIRCUITS OPEN OR SHORTED

DTCS RELATED TO BATTERY VOLTAGE, IGNITION, OR VIN MESSAGES

TIPM NOT CONFIGURED CORRECTLY

FINAL DRIVE CONTROL MODULE POWER AND GROUND

FINAL DRIVE CONTROL MODULE

MODULE THAT SET THIS DTC

Diagnostic Test

VERIFY DTC IS ACTIVE

1.

NOTE: Ensure the IOD fuse is installed and battery voltage is between 10 and 16 volts before proceeding.

With the scan tool, read active DTCs.

Is this DTC active?

Yes >>

No >>

CHECK FOR ANY OF THE FOLLOWING ACTIVE DTCS

2.

With the scan tool, read all active DTCs from all modules.

NOTE: Check for TIPM configuration, CAN B or C hardware electrical, VIN Missing/Mismatch, battery or ignition related DTCs.

Does the scan tool display any active DTCs to the conditions listed above?

Yes >>

No >>

VERIFY THAT THE FDCM IS ACTIVE ON THE BUS

3.

Turn the ignition on.

With the scan tool, select Network Diagnostics.

Verify that the FDCM is active on the bus.

Is the FDCM active on the bus?

Go To 2

Refer to the Stored Lost Communication test procedure. Refer to the table of contents in this section.

Diagnose and repair the DTC. Refer to the Index for a complete list of the symptoms.

Go To 3

Yes >>

No >>

Go To 4

Refer to the No Response test procedure. Refer to the table of contents in this section.

Page 49

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 49

CHECK FOR ADDITIONAL COMMUNICATION RELATED DTCS

4.

With the scan tool, select Network Diagnostics.

Is there more than one module with active DTCs “Logged Against” the FDCM?

Yes >>

No >>

Replace/update the Final Drive Control Module in accordance with the service information.

Perform the appropriate VERIFICATION TEST.

Replace/update the module that set this DTC in accordance with the service information.

Perform the appropriate VERIFICATION TEST.

Page 50

8E - 50 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

U0121-LOST COMMUNICATION WITH ANTI-LOCK BRAKE MODULE

For a complete wiring diagram Refer to Section 8W.

Page 51

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 51

• When Monitored:

• With the ignition on

• Battery voltage between 10 and 16 volts

• IOD fuse installed

• TIPM is configured correctly

• Set Condition:

Bus messages not received from the Antilock Brake Module for approximately 2 to 5 seconds.

Possible Causes

CAN B OR CAN C BUS CIRCUITS OPEN OR SHORTED

DTCS RELATED TO BATTERY VOLTAGE, IGNITION, OR VIN MESSAGES

TIPM NOT CONFIGURED CORRECTLY

ANTILOCK BRAKE MODULE POWER AND GROUND

ANTILOCK BRAKE MODULE

MODULE THAT SET THIS DTC

Diagnostic Test

VERIFY DTC IS ACTIVE

1.

NOTE: Ensure the IOD fuse is installed and battery voltage is between 10 and 16 volts before proceeding.

With the scan tool, read active DTCs.

Is this DTC active?

Yes >>

No >>

CHECK FOR ANY OF THE FOLLOWING ACTIVE DTCS

2.

With the scan tool, read all active DTCs from all modules.

NOTE: Check for TIPM configuration, CAN B or C hardware electrical, VIN Missing/Mismatch, battery or ignition related DTCs.

Does the scan tool display any active DTCs to the conditions listed above?

Yes >>

No >>

VERIFY THAT THE ABS IS ACTIVE ON THE BUS

3.

Turn the ignition on.

With the scan tool, select Network Diagnostics.

Verify that the ABS is active on the bus.

Is the ABS active on the bus?

Go To 2

Refer to the Stored Lost Communication test procedure. Refer to the table of contents in this section.

Diagnose and repair the DTC. Refer to the Index for a complete list of the symptoms.

Go To 3

Yes >>

No >>

Go To 4

Refer to the No Response test procedure. Refer to the table of contents in this section.

Page 52

8E - 52 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

CHECK FOR ADDITIONAL COMMUNICATION RELATED DTCS

4.

With the scan tool, select Network Diagnostics.

Is there more than one module with active DTCs “Logged Against” the ABS?

Yes >>

No >>

Replace/update the Antilock Brake Module in accordance with the service information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES - DIAGNOSIS AND TESTING)

Replace/update the module that set this DTC in accordance with the service information

Perform the appropriate VERIFICATION TEST.

Page 53

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 53

U0141–LOST COMMUNICATION WITH FRONT CONTROL MODULE (TOTALLY

INTEGRATED POWER MODULE)

For a complete wiring diagram Refer to Section 8W.

Page 54

8E - 54 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

• With the ignition on

• Battery voltage between 10 and 16 volts

• IOD fuse installed

• TIPM is configured correctly

• Set Condition:

Bus messages not received from the Front Control Module (on this vehicle, it is the Totally Integrated Power

Module or TIPM) for approximately 2 to 5 seconds.

Possible Causes

CAN B BUS CIRCUITS OPEN OR SHORTED

DTCS RELATED TO BATTERY VOLTAGE, IGNITION, OR VIN MESSAGES

TIPM NOT CONFIGURED CORRECTLY

TOTALLY INTEGRATED POWER MODULE POWER AND GROUND

TOTALLY INTEGRATED POWER MODULE

MODULE THAT SET THIS DTC

Diagnostic Test

VERIFY DTC IS ACTIVE

1.

NOTE: Ensure the IOD fuse is installed and battery voltage is between 10 and 16 volts before proceeding.

With the scan tool, read active DTCs.

Is this DTC active?

Yes >>

No >>

CHECK FOR ANY OF THE FOLLOWING ACTIVE DTCS

2.

With the scan tool, read all active DTCs from all modules.

NOTE: Check for TIPM configuration, CAN B or C hardware electrical, VIN Missing/Mismatch, battery or ignition related DTCs.

Does the scan tool display any active DTCs to the conditions listed above?

Yes >>

No >>

VERIFY THAT THE TIPM IS ACTIVE ON THE BUS

3.

Turn the ignition on.

With the scan tool, select Network Diagnostics.

Verify that the TIPM is active on the bus.

Is the TIPM active on the bus?

Go To 2

Refer to the Stored Lost Communication test procedure. Refer to the table of contents in this section.

Diagnose and repair the DTC. Refer to the Index for a complete list of the symptoms.

Go To 3

Yes >>

No >>

Go To 4

Refer to the No Response test procedure. Refer to the table of contents in this section.

Page 55

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 55

CHECK FOR ADDITIONAL COMMUNICATION RELATED DTCS

4.

With the scan tool, select Network Diagnostics.

Is there more than one module with active DTCs “Logged Against” the TIPM?

Yes >>

No >>

Replace/update the Totally Integrated Power Module (TIPM) in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Replace/update the module that set this DTC in accordance with the service information

Perform the appropriate VERIFICATION TEST.

Page 56

8E - 56 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

U0151–LOST COMMUNICATION WITH OCCUPANT RESTRAINT CONTROLLER

(ORC)

For a complete wiring diagram Refer to Section 8W.

Page 57

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 57

• When Monitored:

• With the ignition on

• Battery voltage between 10 and 16 volts

• IOD fuse installed

• TIPM is configured correctly

• Set Condition:

Bus messages not received from the Occupant Restraint Controller for approximately 2 to 5 seconds.

Possible Causes

CAN B BUS CIRCUITS OPEN OR SHORTED

DTCS RELATED TO BATTERY VOLTAGE, IGNITION, OR VIN MESSAGES

TIPM NOT CONFIGURED CORRECTLY

OCCUPANT RESTRAINT CONTROLLER POWER AND GROUND

OCCUPANT RESTRAINT CONTROLLER

MODULE THAT SET THIS DTC

Diagnostic Test

VERIFY DTC IS ACTIVE

1.

NOTE: Ensure the IOD fuse is installed and battery voltage is between 10 and 16 volts before proceeding.

With the scan tool, read active DTCs.

Is this DTC active?

Yes >>

No >>

CHECK FOR ANY OF THE FOLLOWING ACTIVE DTCS

2.

With the scan tool, read all active DTCs from all modules.

NOTE: Check for TIPM configuration, CAN B or C hardware electrical, VIN Missing/Mismatch, battery or ignition related DTCs.

Does the scan tool display any active DTCs to the conditions listed above?

Yes >>

No >>

VERIFY THAT THE ORC IS ACTIVE ON THE BUS

3.

Turn the ignition on.

With the scan tool, select Network Diagnostics.

Verify that the ORC is active on the bus.

Is the ORC active on the bus?

Go To 2

Refer to the Stored Lost Communication test procedure. Refer to the table of contents in this section.

Diagnose and repair the DTC. Refer to the Index for a complete list of the symptoms.

Go To 3

Yes >>

No >>

Go To 4

Refer to the No Response test procedure. Refer to the table of contents in this section.

Page 58

8E - 58 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

CHECK FOR ADDITIONAL COMMUNICATION RELATED DTCS

4.

With the scan tool, select Network Diagnostics.

Is there more than one module with active DTCs “Logged Against” the ORC?

Yes >>

No >>

Replace/update the Occupant Restraint Controller in accordance with the service information.

Perform AIRBAG VERIFICATION TEST – VER 1.

Replace/update the module that set this DTC in accordance with the service information

Perform the appropriate VERIFICATION TEST.

Page 59

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 59

U0155-LOST COMMUNICATION WITH CLUSTER/CCN

For a complete wiring diagram Refer to Section 8W.

Page 60

8E - 60 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

• With the ignition on

• Battery voltage between 10 and 16 volts

• IOD fuse installed

• TIPM is configured correctly

• Set Condition:

Bus messages not received from the Cluster/CCN for approximately 2 to 5 seconds.

Possible Causes

CAN B BUS CIRCUITS OPEN OR SHORTED

DTCS RELATED TO BATTERY VOLTAGE, IGNITION, OR VIN MESSAGES

TIPM NOT CONFIGURED CORRECTLY

CLUSTER/CCN POWER AND GROUND

CLUSTER/CCN

MODULE THAT SET THE DTC

Diagnostic Test

VERIFY DTC IS ACTIVE

1.

NOTE: Ensure the IOD fuse is installed and battery voltage is between 10 and 16 volts before proceeding.

With the scan tool, read active DTCs.

Is this DTC active?

Yes >>

No >>

CHECK FOR ANY OF THE FOLLOWING ACTIVE DTCS

2.

With the scan tool, read active DTCs from all modules.

NOTE: Check for TIPM configuration, CAN B or C hardware electrical, VIN Missing/Mismatch, battery or ignition related DTCs.

Does the scan tool display any active DTCs to the conditions listed above?

Yes >>

No >>

VERIFY THAT THE CCN IS ACTIVE ON THE BUS

3.

Turn the ignition on.

With the scan tool, select Network Diagnostics.

Verify that the CCN is active on the bus.

Is the CCN active on the bus?

Go To 2

Refer to the Stored Lost Communication test procedure. Refer to the table of contents in this section.

Diagnose and repair the DTC. Refer to the Index for a complete list of the symptoms.

Go To 3

Yes >>

No >>

Go To 4

Refer to the No Response test procedure. Refer to the table of contents in this section.

Page 61

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 61

CHECK FOR ADDITIONAL COMMUNICATION RELATED DTCS

4.

With the scan tool, select Network Diagnostics.

Is there more than one module with active DTCs “Logged Against” the CCN?

Yes >>

No >>

Replace/update the Cluster (CCN) in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Replace/update the module that set this DTC in accordance with the service information.

Perform the appropriate VERIFICATION TEST.

Page 62

8E - 62 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

U0156–LOST COMMUNICATION WITH EOM

For a complete wiring diagram Refer to Section 8W.

Page 63

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 63

• When Monitored:

• With the ignition on

• Battery voltage between 10 and 16 volts

• IOD fuse installed

• TIPM is configured correctly

• Set Condition:

Bus messages not received from the Electronic Overhead Module (EOM) for approximately 2 to 5 seconds.

Possible Causes

CAN B BUS CIRCUITS OPEN OR SHORTED

DTCS RELATED TO BATTERY VOLTAGE, IGNITION, OR VIN MESSAGES

TIPM NOT CONFIGURED CORRECTLY

ELECTRONIC OVERHEAD MODULE POWER OR GROUND

ELECTRONIC OVERHEAD MODULE

MODULE THAT SET THIS DTC

Diagnostic Test

VERIFY DTC IS ACTIVE

1.

NOTE: Ensure the IOD fuse is installed and battery voltage is between 10 and 16 volts before proceeding.

With the scan tool, read active DTCs.

Is this DTC active?

Yes >>

No >>

CHECK FOR ANY OF THE FOLLOWING ACTIVE DTCS

2.

With the scan tool, read all active DTCs from all modules.

NOTE: Check for TIPM configuration, CAN B or C hardware electrical, VIN Missing/Mismatch, battery or ignition related DTCs.

Does the scan tool display any active DTCs to the conditions listed above?

Yes >>

No >>

VERIFY THAT THE EOM IS ACTIVE ON THE BUS

3.

Turn the ignition on.

With the scan tool, select Network Diagnostics.

Verify that the EOM is active on the bus.

Is the EOM active on the bus?

Go To 2

Refer to the Stored Lost Communication test procedure. Refer to the table of contents in this section.

Diagnose and repair the DTC. Refer to the Index for a complete list of the symptoms.

Go To 3

Yes >>

No >>

Go To 4

Refer to the No Response test procedure. Refer to the table of contents in this section.

Page 64

8E - 64 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

CHECK FOR ADDITIONAL COMMUNICATION RELATED DTCS

4.

With the scan tool, select Network Diagnostics.

Is there more than one module with active DTCs “Logged Against” the EOM?

Yes >>

No >>

Replace/update the Electronic Overhead Module (EOM) in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Replace/update the module that set this DTC in accordance with the service information

Perform the appropriate VERIFICATION TEST.

Page 65

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 65

U0164-LOST COMMUNICATION WITH HVAC CONTROL MODULE

For a complete wiring diagram Refer to Section 8W.

Page 66

8E - 66 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

• When Monitored:

• With the ignition on

• Battery voltage between 10 and 16 volts

• IOD fuse installed

• TIPM is configured correctly

• Set Condition:

Bus messages not received from the A/C Heater Control (HVAC) for approximately 2 to 5 seconds.

Possible Causes

CAN B BUS CIRCUITS OPEN OR SHORTED

DTCS RELATED TO BATTERY VOLTAGE, IGNITION, OR VIN MESSAGES

TIPM NOT CONFIGURED CORRECTLY

A/C HEATER CONTROL POWER AND GROUND

A/C HEATER CONTROL

MODULE THAT SET THIS DTC

Diagnostic Test

VERIFY DTC IS ACTIVE

1.

NOTE: Ensure the IOD fuse is installed and battery voltage is between 10 and 16 volts before proceeding.

With the scan tool, read active DTCs.

Is this DTC active?

Yes >>

No >>

CHECK FOR ANY OF THE FOLLOWING ACTIVE DTCS

2.

With the scan tool, read active DTCs from all modules.

NOTE: Check for TIPM configuration, CAN B or C hardware electrical, VIN Missing/Mismatch, battery or ignition related DTCs.

Does the scan tool display any active DTCs to the conditions listed above?

Yes >>

No >>

VERIFY THAT THE HVAC IS ACTIVE ON THE BUS

3.

Turn the ignition on.

With the scan tool, select Network Diagnostics.

Verify that the HVAC is active on the bus.

Is the HVAC active on the bus?

Go To 2

Refer to the Stored Lost Communication test procedure. Refer to the table of contents in this section.

Diagnose and repair the DTC. Refer to the Index for a complete list of the symptoms.

Go To 3

Yes >>

No >>

Go To 4

Refer to the No Response test procedure. Refer to the table of contents in this section.

Page 67

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 67

CHECK FOR ADDITIONAL COMMUNICATION RELATED DTCS

4.

With the scan tool, select Network Diagnostics.

Is there more than one module with active DTCs “Logged Against” the HVAC?

Yes >>

No >>

Replace/update the A/C Heater Control in accordance with the service information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Replace/update the module that set the DTC in accordance with the service information

Perform the appropriate VERIFICATION TEST.

Page 68

8E - 68 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR

U0168-LOST COMMUNICATION WITH VEHICLE SECURITY CONTROL MODULE

(SKREEM/WCM)

For a complete wiring diagram Refer to Section 8W.

Page 69

DR ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 69

• When Monitored:

• With the ignition on

• Battery voltage between 10 and 16 volts

• IOD fuse installed

• TIPM is configured correctly

• Set Condition:

Bus messages not received from the Sentry Key Remote Entry Module (WCM) for approximately 2 to 5 seconds.

Possible Causes

CAN B BUS CIRCUITS OPEN OR SHORTED

DTCS RELATED TO BATTERY VOLTAGE, IGNITION, OR VIN MESSAGES

TIPM NOT CONFIGURED CORRECTLY

SENTRY KEY REMOTE ENTRY MODULE POWER AND GROUND

SENTRY KEY REMOTE ENTRY MODULE

MODULE THAT SET THIS DTC

Diagnostic Test

VERIFY DTC IS ACTIVE

1.

NOTE: Ensure the IOD fuse is installed and battery voltage is between 10 and 16 volts before proceeding.

With the scan tool, read active DTCs.

Is this DTC active?

Yes >>

No >>

CHECK FOR ANY OF THE FOLLOWING ACTIVE DTCS

2.

With the scan tool, read active DTCs from all modules.

NOTE: Check for TIPM configuration, CAN B or C hardware electrical, VIN Missing/Mismatch, battery or ignition related DTCs.

Does the scan tool display any active DTCs to the conditions listed above?

Yes >>

No >>

VERIFY THAT THE WCM IS ACTIVE ON THE BUS

3.

Turn the ignition on.

With the scan tool, select Network Diagnostics.

Verify that the WCM is active on the bus.

Is the WCM active on the bus?

Go To 2

Refer to the Stored Lost Communication test procedure. Refer to the table of contents in this section.

Diagnose and repair the DTC. Refer to the Index for a complete list of the symptoms.

Go To 3

Yes >>

No >>

Go To 4

Refer to the No Response test procedure. Refer to the table of contents in this section.

Page 70