Dodge Electronic Control Modules 3500 2005, Electronic Control Modules 2500 2005, Electronic Control Modules 1500 2005 Service Manual

Page 1

DR/DH ELECTRONIC CONTROL MODULES 8E - 1

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ELECTRONIC CONTROL MODULES -

ELECTRICAL DIAGNOSTICS................. 1

ELECTRONIC CONTROL MODULES - ELECTRICAL

DIAGNOSTICS

TABLE OF CONTENTS

ELECTRONIC CONTROL MODULES -

ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

BATTERY VOLTAGE OPEN (FCM) ..........3

BATTERY 1 VOLTAGE OPEN (FCM) ........5

BATTERY 2 VOLTAGE OPEN (FCM) ........8

BUS SHORTED TO BATTERY (FCM) .......11

BUS SHORTED TO GROUND (FCM) .......12

EEPROM CHECKSUM FAILURE (FCM) .....13

INTERNAL BOOTLOADER CHECKSUM

FAILURE (FCM) .......................14

INTERNAL FLASH MEMORY CHECKSUM

FAILURE (FCM) .......................15

MIC MESSAGES NOT RECEIVED (FCM) ....16

PCI BUS INTERNAL - LOOPBACK FAILURE

(FCM) ..............................17

PCM MESSAGES NOT RECEIVED (FCM) . . . 18

VIN NOT LEARNED CORRECTLY (FCM) ....20

*NO RESPONSE FROM ANTILOCK BRAKE

MODULE ............................21

*NO RESPONSE FROM AMPLIFIER .......24

*NO RESPONSE FROM CLUSTER ........27

*NO RESPONSE FROM ENGINE CONTROL

MODULE (PCI BUS) - DIESEL ............31

*NO RESPONSE FROM ENGINE CONTROL

MODULE (SCI ONLY) - DIESEL ...........34

*NO RESPONSE FROM FRONT CONTROL

MODULE ............................38

*NO RESPONSE FROM FINAL DRIVE

CONTROL MODULE ...................41

ELECTRONIC CONTROL MODULES - SERVICE

INFORMATION......................... 100

page page

*NO RESPONSE FROM HANDS FREE

MODULE ............................45

*NO RESPONSE FROM HVAC ...........49

*NO RESPONSE FROM OCCUPANT

RESTRAINT CONTROL MODULE .........52

*NO RESPONSE FROM OVERHEAD

CONSOLE ...........................55

*NO RESPONSE FROM PCM (PCI BUS) -

JTEC ...............................59

*NO RESPONSE FROM PCM (SCI ONLY) -

JTEC ...............................62

*NO RESPONSE FROM PCM (PCI BUS) -

NGC ...............................66

*NO RESPONSE FROM PCM (PCM SCI

ONLY)-NGC.........................69

*NO RESPONSE FROM RADIO ...........73

*NO RESPONSE FROM SATELLITE

RECEIVER...........................77

*NO RESPONSE FROM SENTRY KEY

IMMOBILIZER MODULE (SKIM) ...........80

*NO RESPONSE FROM TRANSFER CASE

CONTROL MODULE ...................84

*NO RESPONSE FROM TRANSMISSION

CONTROL MODULE - NGC ..............87

*PCI BUS COMMUNICATION FAILURE .....91

C2100–BATTERY VOLTAGE LOW (FDCM) . . . 95

C2101–BATTERY VOLTAGE HIGH (FDCM) . . 97

C2201-FDCM ECU INTERNAL (FDCM) .....99

Page 2

8E - 2 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

Page 3

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 3

BATTERY VOLTAGE OPEN (FCM)

Page 4

8E - 4 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

BATTERY VOLTAGE OPEN (FCM) (CONTINUED)

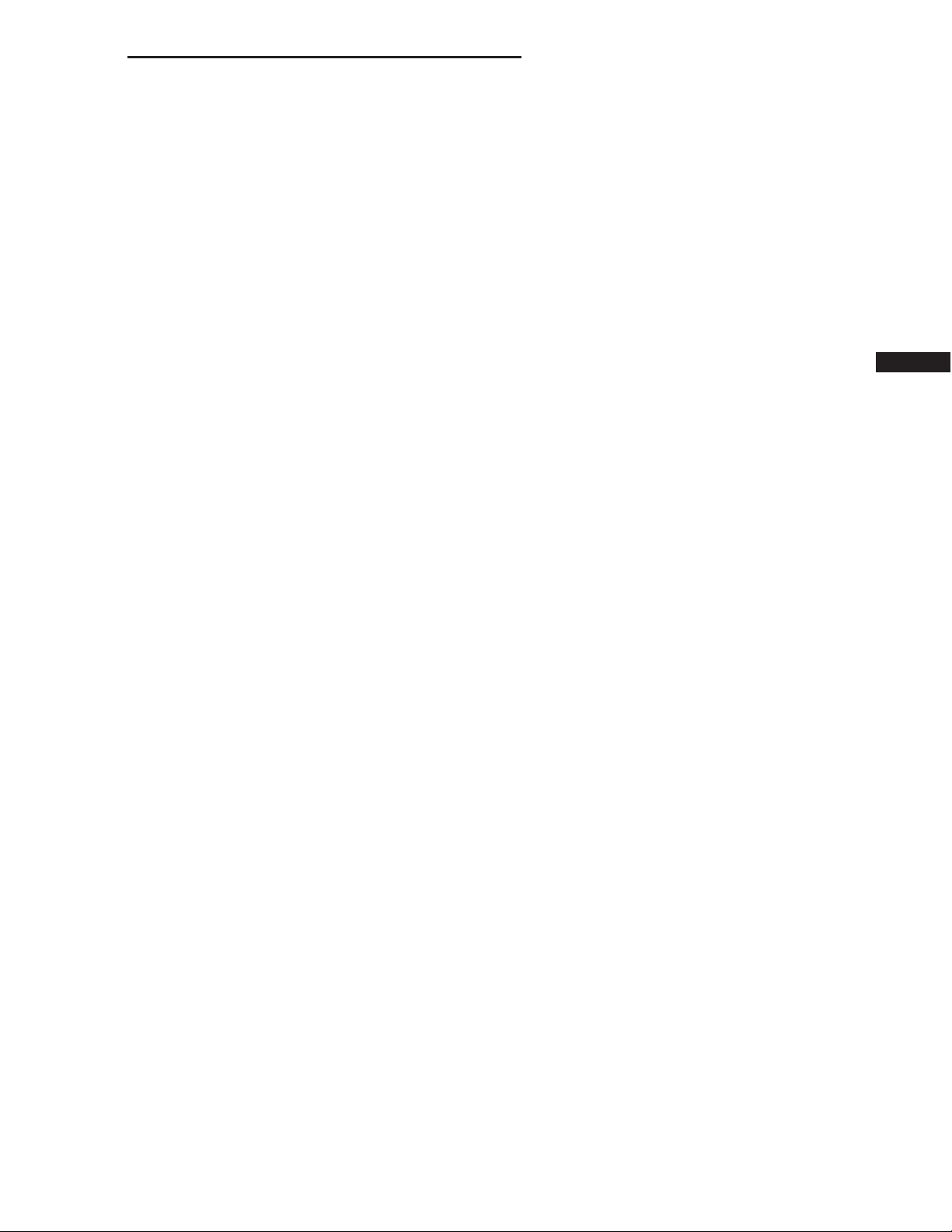

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on.

• Set Condition:

The FCM detects a low voltage condition.

Possible Causes

POWER DISTRIBUTION CENTER

FRONT CONTROL MODULE

Diagnostic Test

CHECK FOR AN ACTIVE DTC

1.

Turn the ignition on.

With the DRB, erase the FCM DTC’s.

Turn the ignition off then turn the ignition on and wait approximately 1 minute.

With the DRB, read the FCM DTC’s.

Did this DTC reset?

Yes >>

No >>

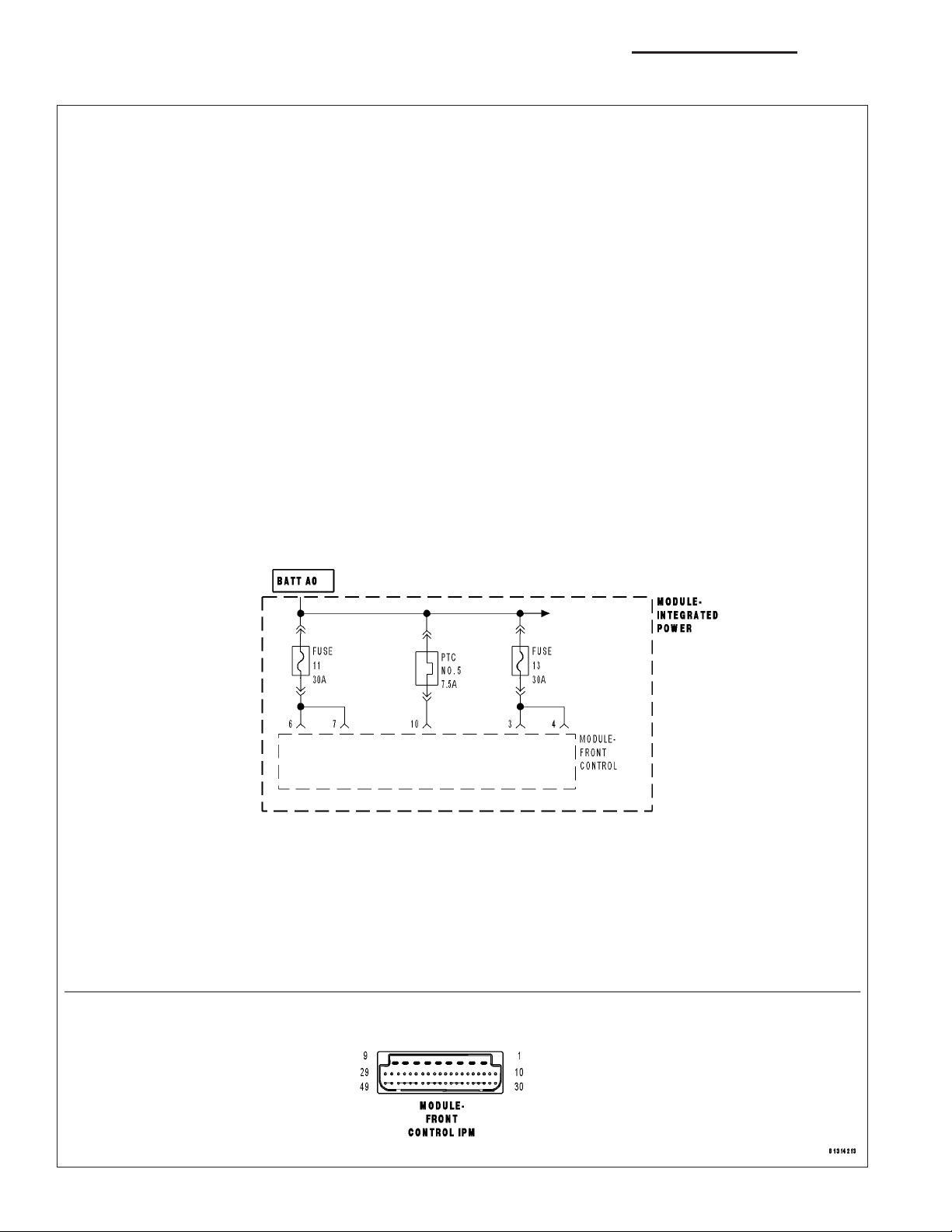

CHECK THE FUSED B+ CIRCUIT

2.

Turn the ignition off.

Remove the FCM from the IPM.

Using a 12-volt test light connected to ground, probe the Fused B+ cir-

cuit (cavity 10).

Is the test light illuminated?

Yes >>

No >>

Go To 2

The condition that set this DTC is no longer present. Using the wiring diagram/schematic as a guide,

inspect the wiring for chafed, pierced, pinched, and partially broken wires and the wiring harness connectors for broken, bent, pushed out, and corroded terminals.

Replace the Front Control Module in accordance with the

service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Replace the Power Distribution Center in accordance with

the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 5

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 5

BATTERY 1 VOLTAGE OPEN (FCM)

Page 6

8E - 6 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

BATTERY 1 VOLTAGE OPEN (FCM) (CONTINUED)

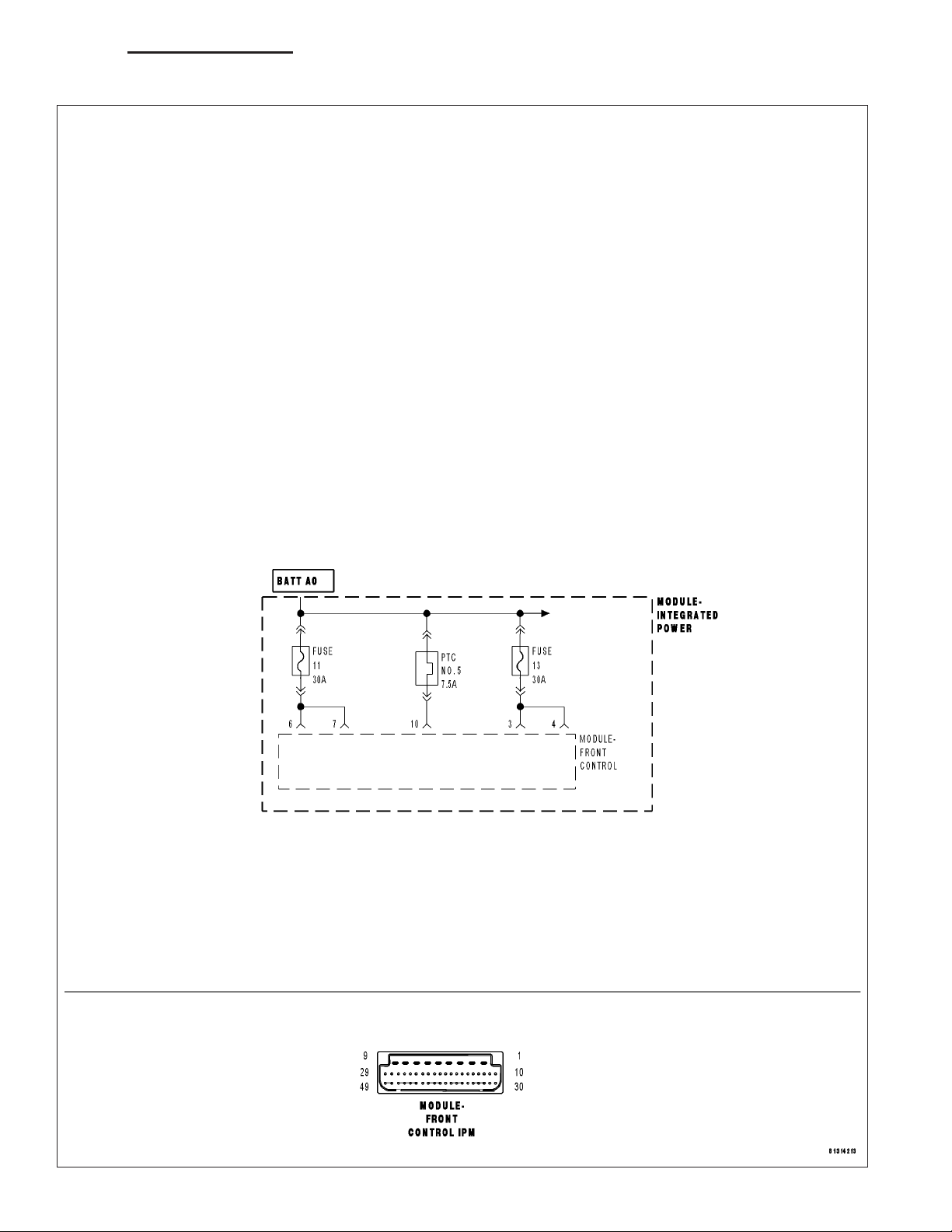

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on.

• Set Condition:

The FCM detects low voltage on battery input 1.

Possible Causes

FUSE #13

POWER DISTRIBUTION CENTER

FRONT CONTROL MODULE

Diagnostic Test

CHECK FOR AN ACTIVE DTC

1.

Turn the ignition on.

With the DRB, erase the FCM DTC’s.

Turn the ignition off then turn the ignition on and wait approximately 1 minute.

With the DRB, read the FCM DTC’s.

Did this DTC reset?

Yes >>

No >>

CHECK FUSE #13

2.

Turn the ignition off.

Check fuse #13 in the IPM.

Is the fuse open?

Yes >>

No >>

Go To 2

The condition that set this DTC is no longer present. Using the wiring diagram/schematic as a guide,

inspect the wiring for chafed, pierced, pinched, and partially broken wires and the wiring harness connectors for broken, bent, pushed out, and corroded terminals.

Replace the fuse and check for a possible intermittent short to ground condition.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Go To 3

Page 7

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 7

BATTERY 1 VOLTAGE OPEN (FCM) (CONTINUED)

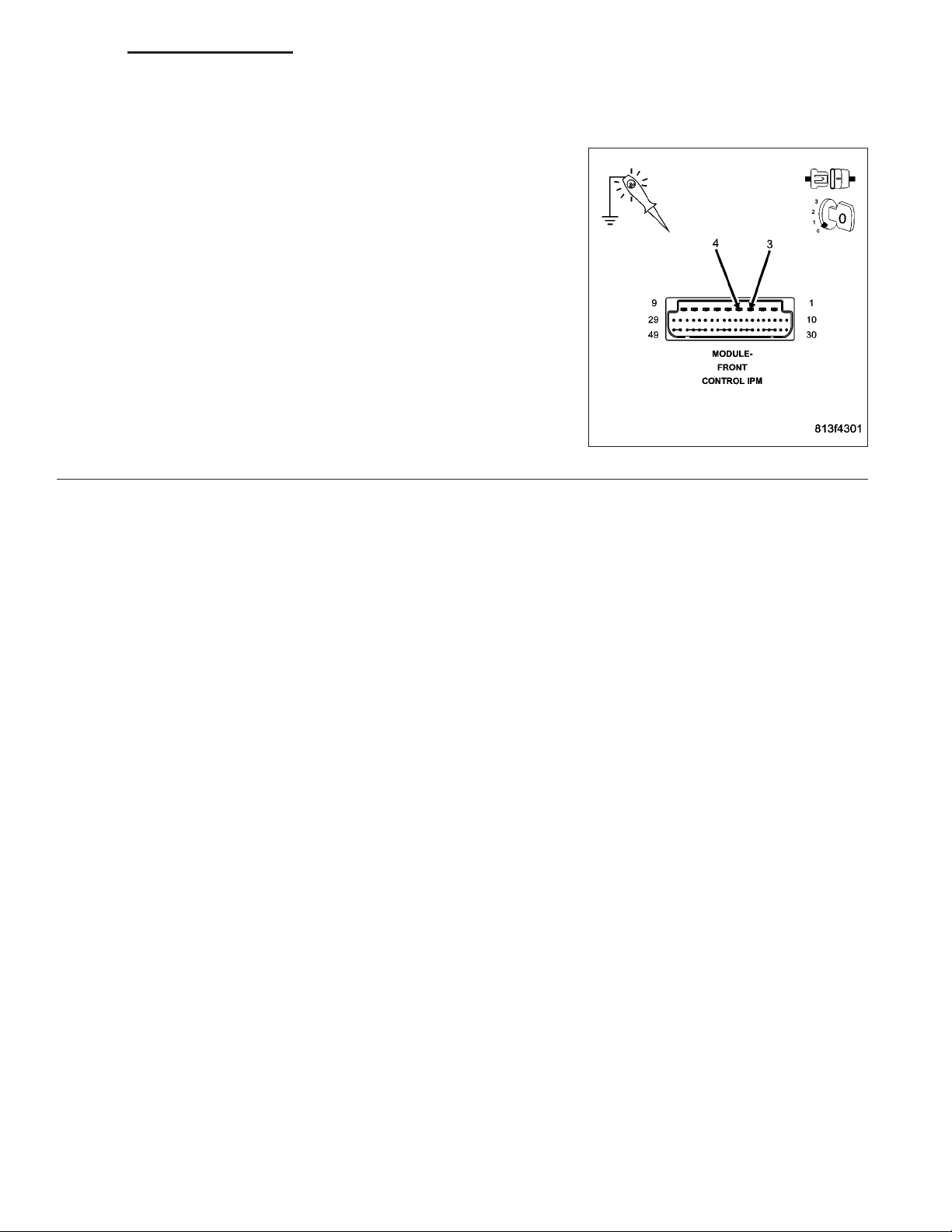

CHECK THE FUSED B+ CIRCUITS

3.

Remove the FCM from the IPM.

NOTE: Ensure fuse #13 is installed in the IPM.

Using a 12-volt test light connected to ground, probe both Fused B+

circuits (cavities 3 and 4).

Is the test light illuminated for both circuits?

Yes >>

No >>

Replace the Front Control Module in accordance with the

service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Replace the Power Distribution Center in accordance with

the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 8

8E - 8 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

BATTERY 2 VOLTAGE OPEN (FCM)

Page 9

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 9

BATTERY 2 VOLTAGE OPEN (FCM) (CONTINUED)

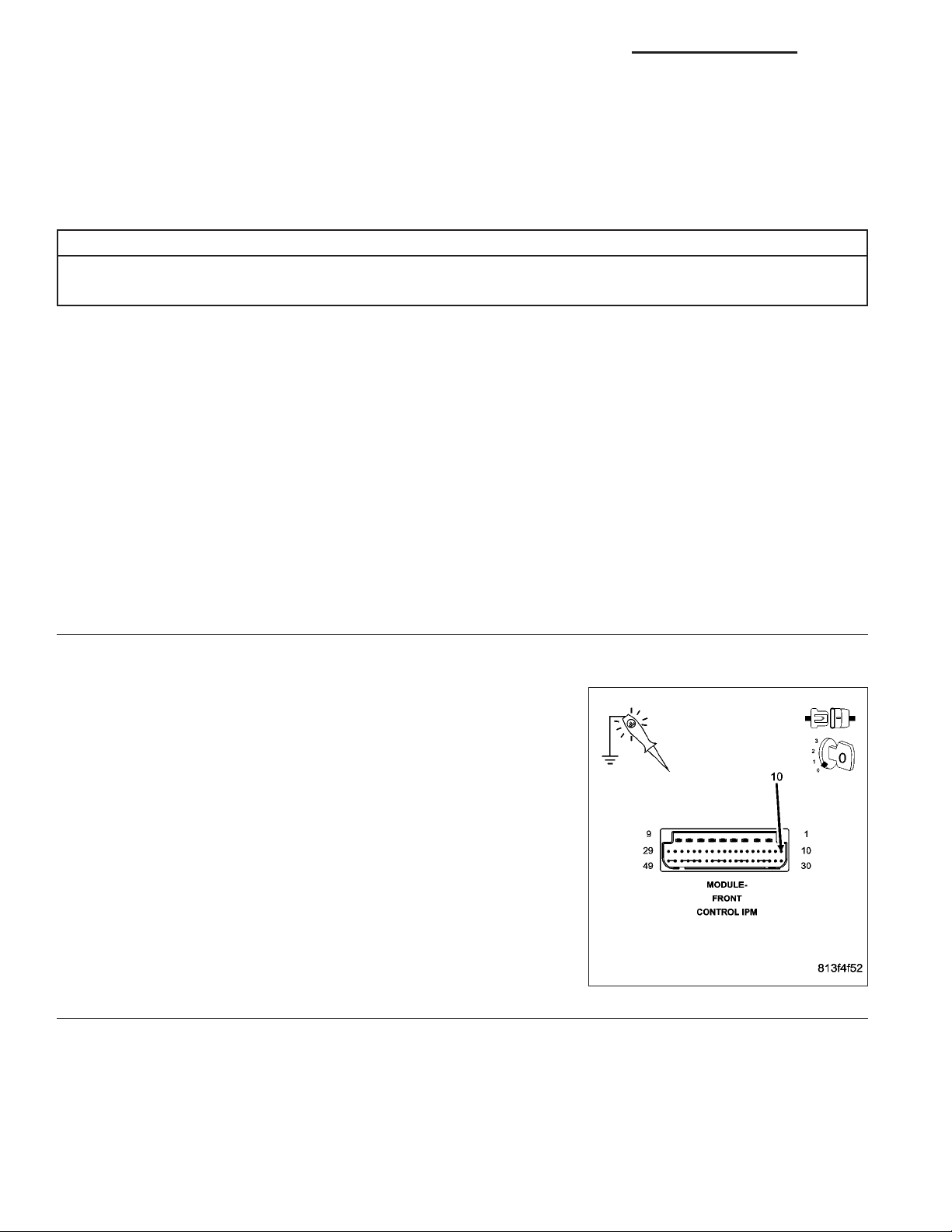

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on.

• Set Condition:

The FCM detects low voltage on battery input 2.

Possible Causes

FUSE #11

POWER DISTRIBUTION CENTER

FRONT CONTROL MODULE

Diagnostic Test

CHECK FOR AN ACTIVE DTC

1.

Turn the ignition on.

With the DRB, erase the FCM DTC’s.

Turn the ignition off then turn the ignition on and wait approximately 1 minute.

With the DRB, read the FCM DTC’s.

Did this DTC reset?

Yes >>

No >>

CHECK FUSE #11

2.

Turn the ignition off.

Check fuse #11 in the IPM.

Is the fuse open?

Yes >>

No >>

Go To 2

The condition that set this DTC is no longer present. Using the wiring diagram/schematic as a guide,

inspect the wiring for chafed, pierced, pinched, and partially broken wires and the wiring harness connectors for broken, bent, pushed out, and corroded terminals.

Replace the fuse and check for a possible intermittent short to ground condition.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Go To 3

Page 10

8E - 10 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

BATTERY 2 VOLTAGE OPEN (FCM) (CONTINUED)

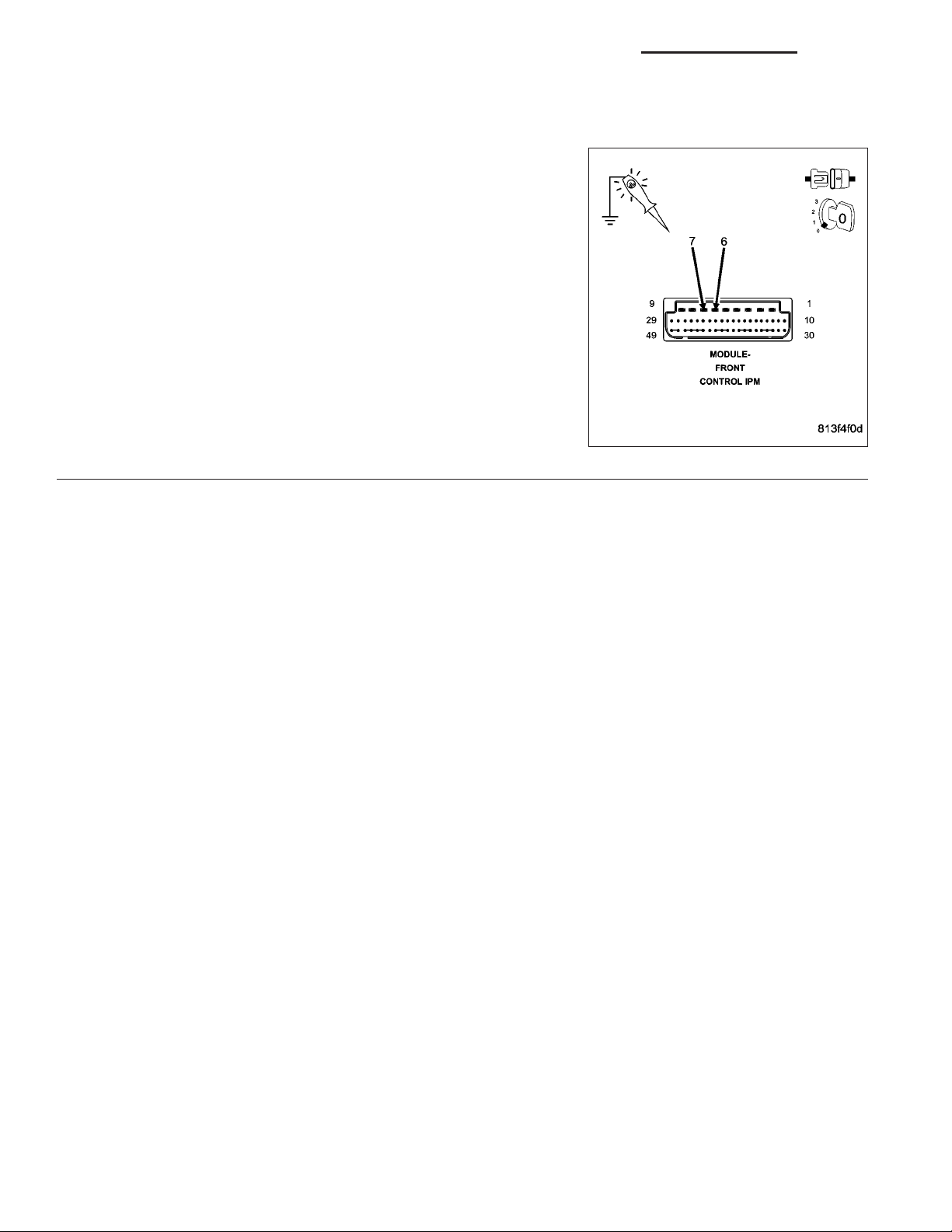

CHECK THE FUSED B+ CIRCUITS

3.

Remove the FCM from the IPM.

NOTE: Ensure fuse #11 is installed in the IPM.

Using a 12-volt test light connected to ground, probe both Fused B+

circuits (cavities 6 and 7).

Is the test light illuminated for both circuits?

Yes >>

No >>

Replace the Front Control Module in accordance with the

service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Replace the Power Distribution Center in accordance with

the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 11

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 11

BUS SHORTED TO BATTERY (FCM)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Continuously

• Set Condition:

Anytime the FCM detects a short to battery on the PCI Bus circuit.

Possible Causes

INTERMITTENT SHORT TO BATTERY ON THE (D25) PCI BUS CIRCUIT

Diagnostic Test

INTERMITTENT CONDITION

1.

NOTE: For this code to be active, the DRB will not be able to communicate with any modules on the vehicle

(except the PCM/ECM).

NOTE: Clear the code. If this code continues to set and the DRB can still communicate with the FCM, it will

be necessary to replace the FCM.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A DIRECT LINE WITH THE FAN. DO NOT

PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, wiggle the wiring harnesses. This is to try and duplicate

the complete bus failure condition.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Were any of the above conditions present?

Yes >>

No >>

Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Test Complete.

Page 12

8E - 12 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

BUS SHORTED TO GROUND (FCM)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Continuously

• Set Condition:

Anytime the FCM detects a short to ground on the PCI Bus circuit.

Possible Causes

INTERMITTENT SHORT TO GROUND ON THE (D25) PCI BUS CIRCUIT

Diagnostic Test

INTERMITTENT CONDITION

1.

NOTE: For this code to be active, the DRB will not be able to communicate with any modules on the vehicle

(except the PCM/ECM).

NOTE: Clear the code. If this code continues to set and the DRB can still communicate with the FCM, it will

be necessary to replace the FCM.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A DIRECT LINE WITH THE FAN. DO NOT

PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, wiggle the wiring harnesses. This is to try and duplicate

the complete bus failure condition.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Were any of the above conditions present?

Yes >>

No >>

Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Test Complete.

Page 13

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 13

EEPROM CHECKSUM FAILURE (FCM)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Continuously

• Set Condition:

When the EEPROM memory checksum is determined to be incorrect.

Possible Causes

FRONT CONTROL MODULE

Diagnostic Test

ACTIVE DTC

1.

Turn the ignition on.

With the DRB, erase the FCM DTC’s.

Turn the ignition off then turn the ignition on and wait approximately 1 minute.

With the DRB, read the FCM DTC’s.

Did this DTC reset?

Yes >>

No >>

Replace the Front Control Module in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Test Complete.

Page 14

8E - 14 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

INTERNAL BOOTLOADER CHECKSUM FAILURE (FCM)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Continuously

• Set Condition:

When the bootloader checksum is determined to be incorrect.

Possible Causes

FRONT CONTROL MODULE

Diagnostic Test

ACTIVE DTC

1.

Turn the ignition on.

With the DRB, erase the FCM DTC’s.

Turn the ignition off then turn the ignition on and wait approximately 1 minute.

With the DRB, read the FCM DTC’s.

Did this DTC reset?

Yes >>

No >>

Replace the Front Control Module in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Test Complete.

Page 15

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 15

INTERNAL FLASH MEMORY CHECKSUM FAILURE (FCM)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Continuously

• Set Condition:

When the flash memory checksum is determined to be incorrect.

Possible Causes

FRONT CONTROL MODULE

Diagnostic Test

ACTIVE DTC

1.

Turn the ignition on.

With the DRB, erase the FCM DTC’s.

Turn the ignition off then turn the ignition on and wait approximately 1 minute.

With the DRB, read the FCM DTC’s.

Did this DTC reset?

Yes >>

No >>

Replace the Front Control Module in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Test Complete.

Page 16

8E - 16 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

MIC MESSAGES NOT RECEIVED (FCM)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on.

• Set Condition:

The FCM does not receive any messages from the MIC for at least 5 seconds.

Possible Causes

(D25) PCI BUS CIRCUIT OPEN

INSTRUMENT CLUSTER POWER AND GROUND

FRONT CONTROL MODULE

Diagnostic Test

ATTEMPT TO COMMUNICATE WITH THE INSTRUMENT CLUSTER (MIC)

1.

Turn the ignition on.

With the DRB, enter Body then Electro/Mech Cluster.

Was the DRB able to I/D or communicate with the Instrument Cluster (MIC)?

Yes >>

No >>

FRONT CONTROL MODULE

2.

With the DRB, erase DTC’s.

Turn the ignition on and wait approximately 1 minute.

With the DRB, read DTC’s.

Did this DTC reset?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Replace the Front Control Module in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

The condition that set this DTC is no longer present. Using the wiring diagram/schematic as a guide,

inspect the wiring for chafed, pierced, pinched, and partially broken wires and the wiring harness connectors for broken, bent, pushed out, and corroded terminals.

Page 17

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 17

PCI BUS INTERNAL - LOOPBACK FAILURE (FCM)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Continuously

• Set Condition:

When the loopback test has failed.

Possible Causes

FRONT CONTROL MODULE

Diagnostic Test

ACTIVE DTC

1.

Turn the ignition on.

With the DRB, erase the FCM DTC’s.

Turn the ignition off then turn the ignition on and wait approximately 1 minute.

With the DRB, read the FCM DTC’s.

Did this DTC reset?

Yes >>

No >>

Replace the Front Control Module in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Test Complete.

Page 18

8E - 18 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

PCM MESSAGES NOT RECEIVED (FCM)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on.

• Set Condition:

The FCM does not receive any messages from the PCM for at least 5 seconds.

Possible Causes

(D25) PCI BUS CIRCUIT OPEN

POWERTRAIN CONTROL MODULE POWER AND GROUND

FRONT CONTROL MODULE

Diagnostic Test

CHECK THE STATUS OF THE PCM ON THE PCI BUS NETWORK

1.

Turn the ignition on.

With the DRB, enter System Monitors then J1850 Module Scan.

Is the PCM active on the bus?

Yes >>

No >>

ATTEMPT TO COMMUNICATE WITH THE PCM

2.

With the DRB, attempt to communicate with the PCM.

Was the DRB able to communicate with the PCM?

Yes >>

No >>

Erase the DTC, if the DTC resets replace the Front Control Module in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Go To 2

Go To 3

Refer to the table of contents and perform the related symptom.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Page 19

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 19

PCM MESSAGES NOT RECEIVED (FCM) (CONTINUED)

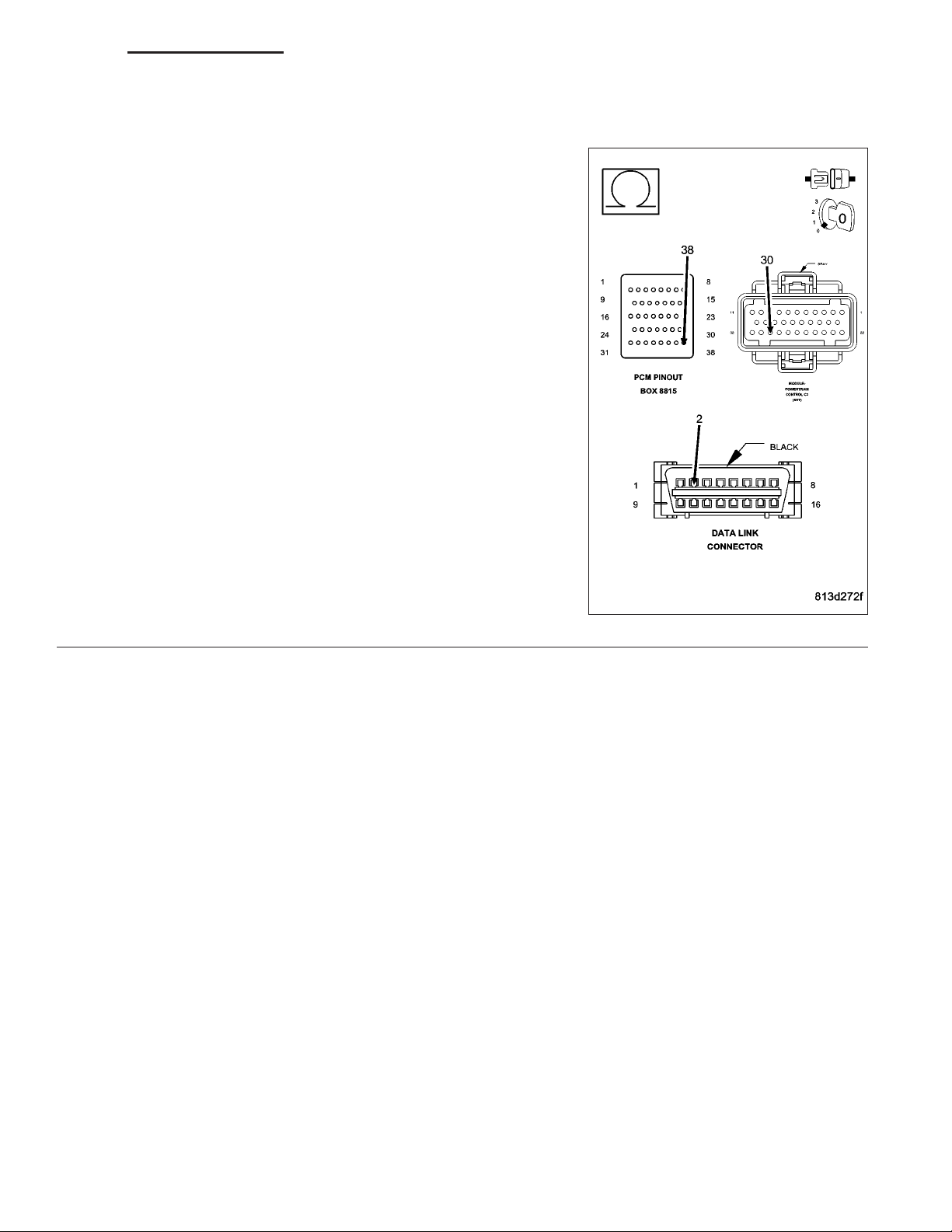

CHECK THE (D25) PCI BUS CIRCUIT FOR AN OPEN

3.

Turn the ignition off.

Disconnect the PCM harness connector.

CAUTION: If the vehicle is equipped with an NGC controller, do

not probe the PCM harness connectors. Probing the PCM harness connectors will damage the PCM terminals resulting in poor

terminal to pin connection. Install miller special tool #8815 to perform diagnosis.

Disconnect the DRB from the DLC.

Measure the resistance of the PCI Bus circuit between the PCM con-

nector (from special tool #8815 if NGC) and the DLC.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Replace and program the PCM in accordance with the

service information.

Perform the appropriate VERIFICATION TEST.

Repair the PCI Bus circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 20

8E - 20 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

VIN NOT LEARNED CORRECTLY (FCM)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on.

• Set Condition:

The VIN is programmed into the FCM via a PCI bus message from the PCM/ECM. When learning the VIN, the

FCM computes a check digit to verify that the VIN learned was valid. If not valid, the DTC will set and the VIN

will not be learned.

Possible Causes

FRONT CONTROL MODULE

Diagnostic Test

ACTIVE DTC

1.

Turn the ignition on.

With the DRB, erase the FCM DTC’s.

Turn the ignition off then turn the ignition on and wait approximately 1 minute.

With the DRB, read the FCM DTC’s.

Did this DTC reset?

Yes >>

No >>

Replace the Front Control Module in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Test Complete.

Page 21

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 21

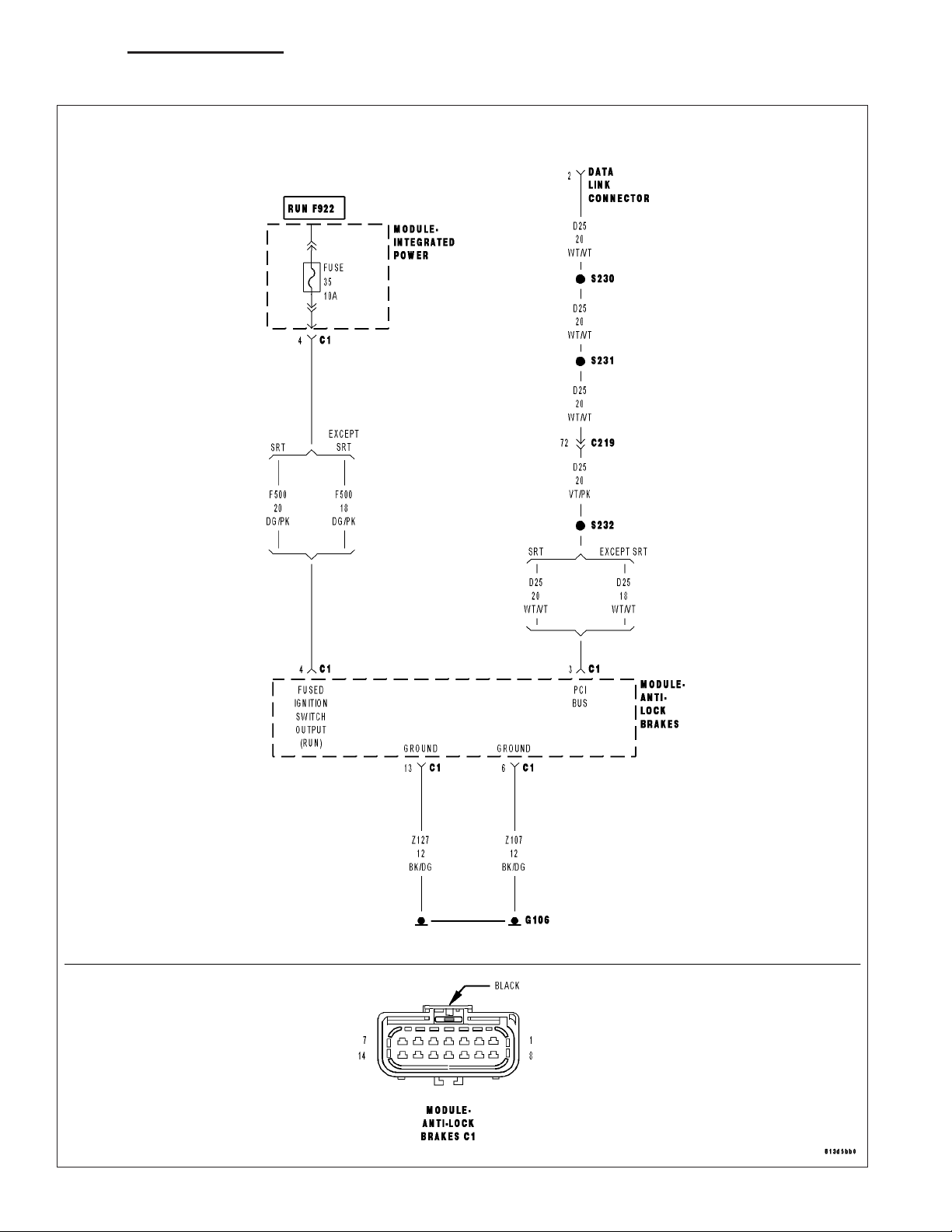

*NO RESPONSE FROM ANTILOCK BRAKE MODULE

Page 22

8E - 22 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM ANTILOCK BRAKE MODULE (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(Z107) (Z127) GROUND CIRCUIT OPEN

(F500) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

(D25) PCI BUS CIRCUIT OPEN

ANTILOCK BRAKE MODULE

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH OTHER PCI BUS MODULES

1.

Turn the ignition on.

NOTE: As soon as one or more modules communicates with the DRB, answer the question.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communi-

cation Failure symptom and repair as necessary.

With the DRB, attempt to communicate with the ORC.

With the DRB, attempt to communicate with the Instrument Cluster.

Was the DRB able to I/D or communicate with either of the modules?

Yes >>

No >>

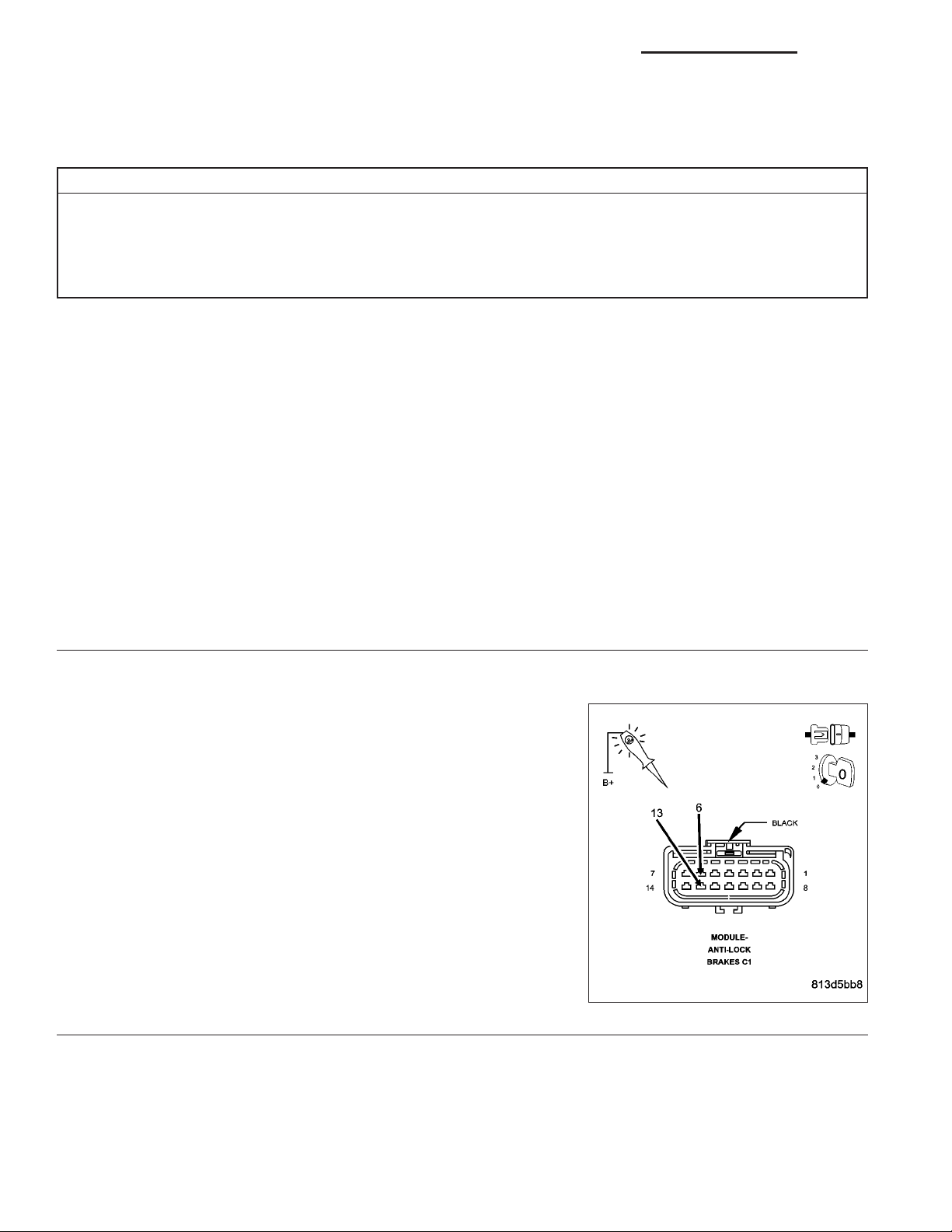

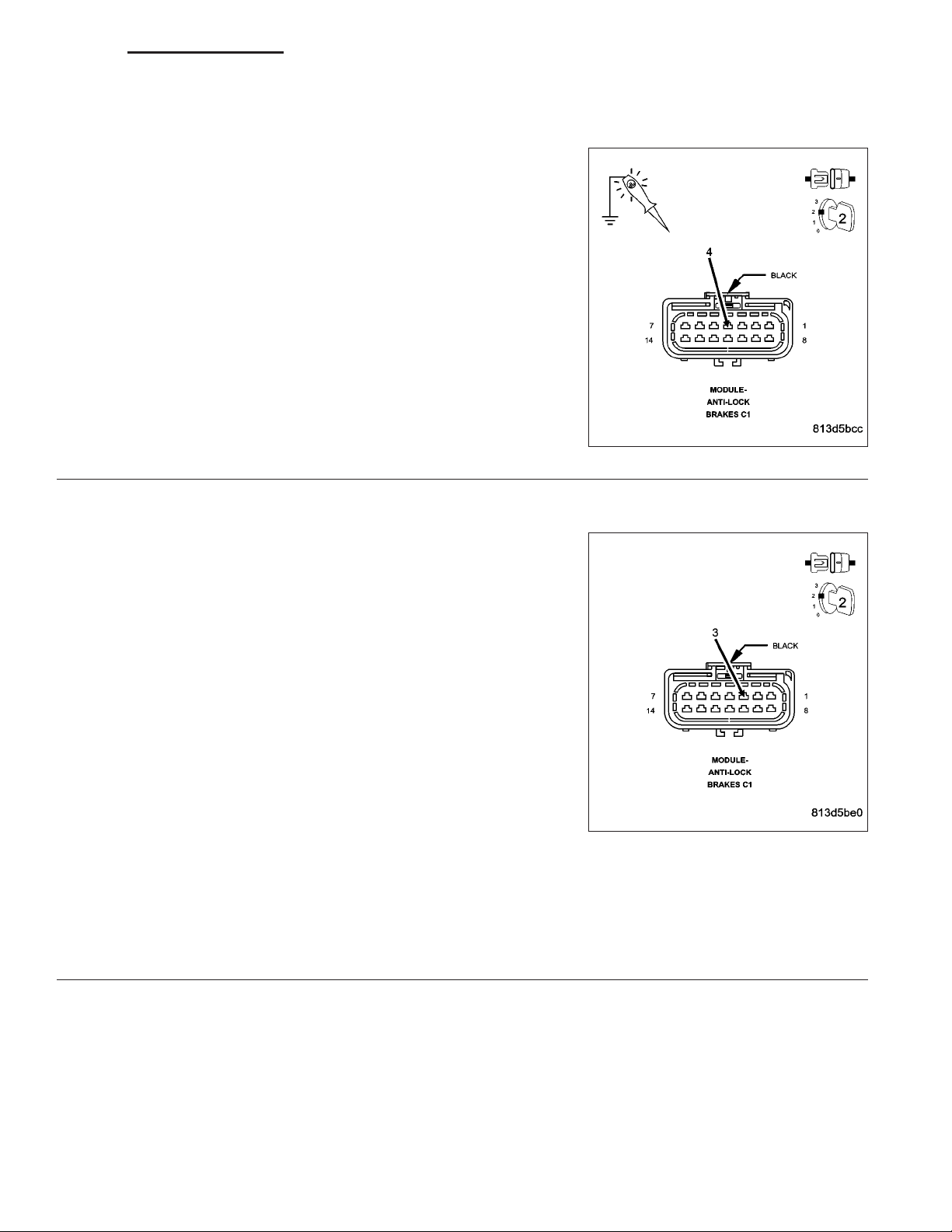

(Z107) (Z127) GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Disconnect the Antilock Brake Module C1 harness connector.

Using a 12-volt test light connected to 12-volts, probe each (Z107)

(Z127, if equipped) ground circuit.

Is the test light illuminated for each circuit?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform ABS VERIFICATION TEST - VER 1.

Go To 3

Repair the (Z107) or (Z127) Ground circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

Page 23

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 23

*NO RESPONSE FROM ANTILOCK BRAKE MODULE (CONTINUED)

(F500) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

3.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the (F500) Fused

Ignition Switch Output circuit.

Is the test light illuminated?

Yes >>

No >>

(D25) PCI BUS CIRCUIT OPEN

4.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts.

Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead

to the PCI Bus circuit in the Antilock Brake Module connector.

Observe the voltage display on the DRB Lab Scope.

Go To 4

Repair the (F500) Fused Ignition Switch Output circuit for

an open.

Perform ABS VERIFICATION TEST - VER 1.

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Antilock Brake Module in accordance with the service information.

Perform ABS VERIFICATION TEST - VER 1.

Repair the (D25) PCI Bus circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

Page 24

8E - 24 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

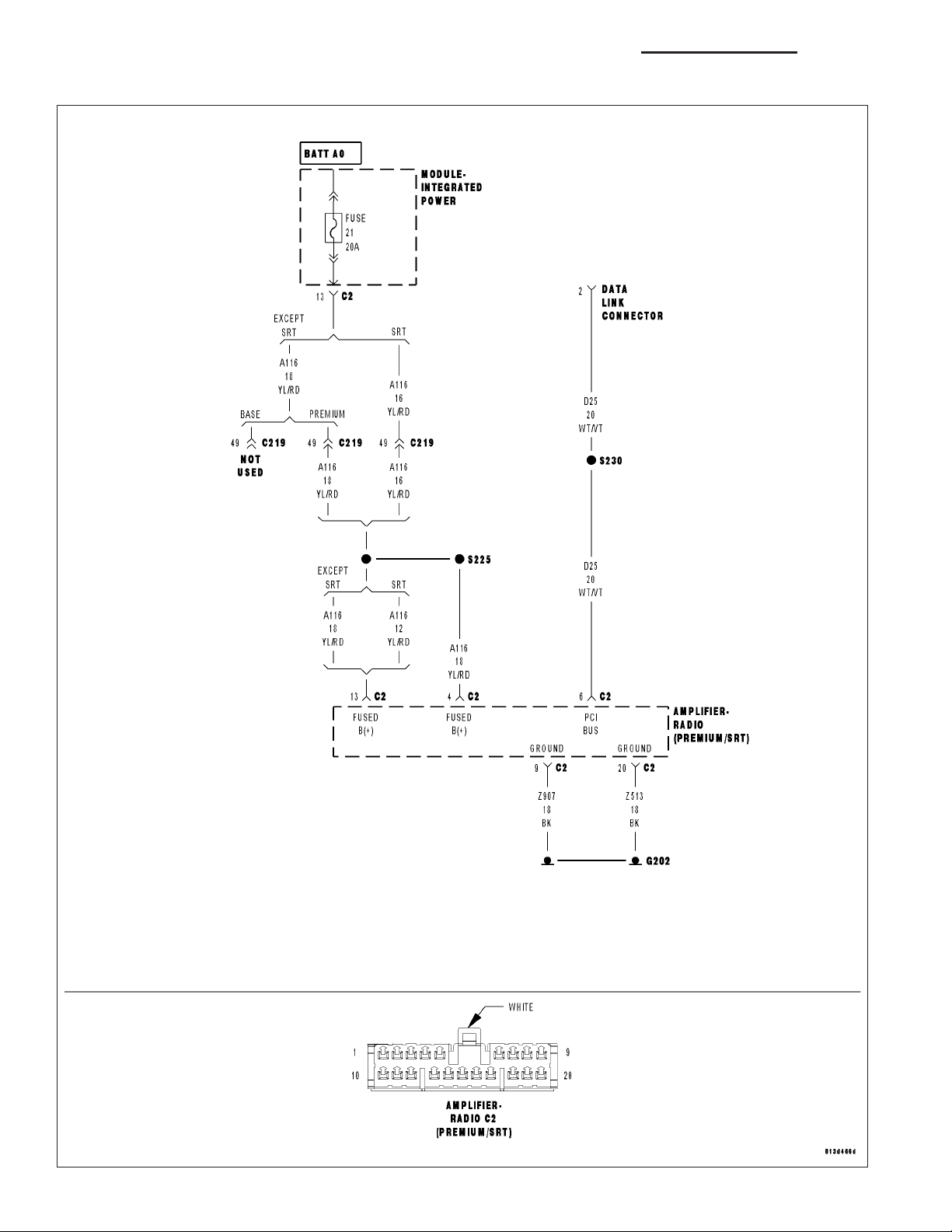

*NO RESPONSE FROM AMPLIFIER

Page 25

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 25

*NO RESPONSE FROM AMPLIFIER (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(Z513) (Z907) GROUND CIRCUIT OPEN

(A116) FUSED B+ CIRCUIT OPEN

(D25) PCI BUS CIRCUIT OPEN

AMPLIFIER

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH THE RADIO

1.

Turn the ignition on.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communication Failure symptom and repair as necessary.

NOTE: The radio must be turned on for the DRB to get a response from the amplifier.

With the DRB, attempt to communicate with the radio.

Was the DRB able to I/D or communicate with the radio?

Yes >>

No >>

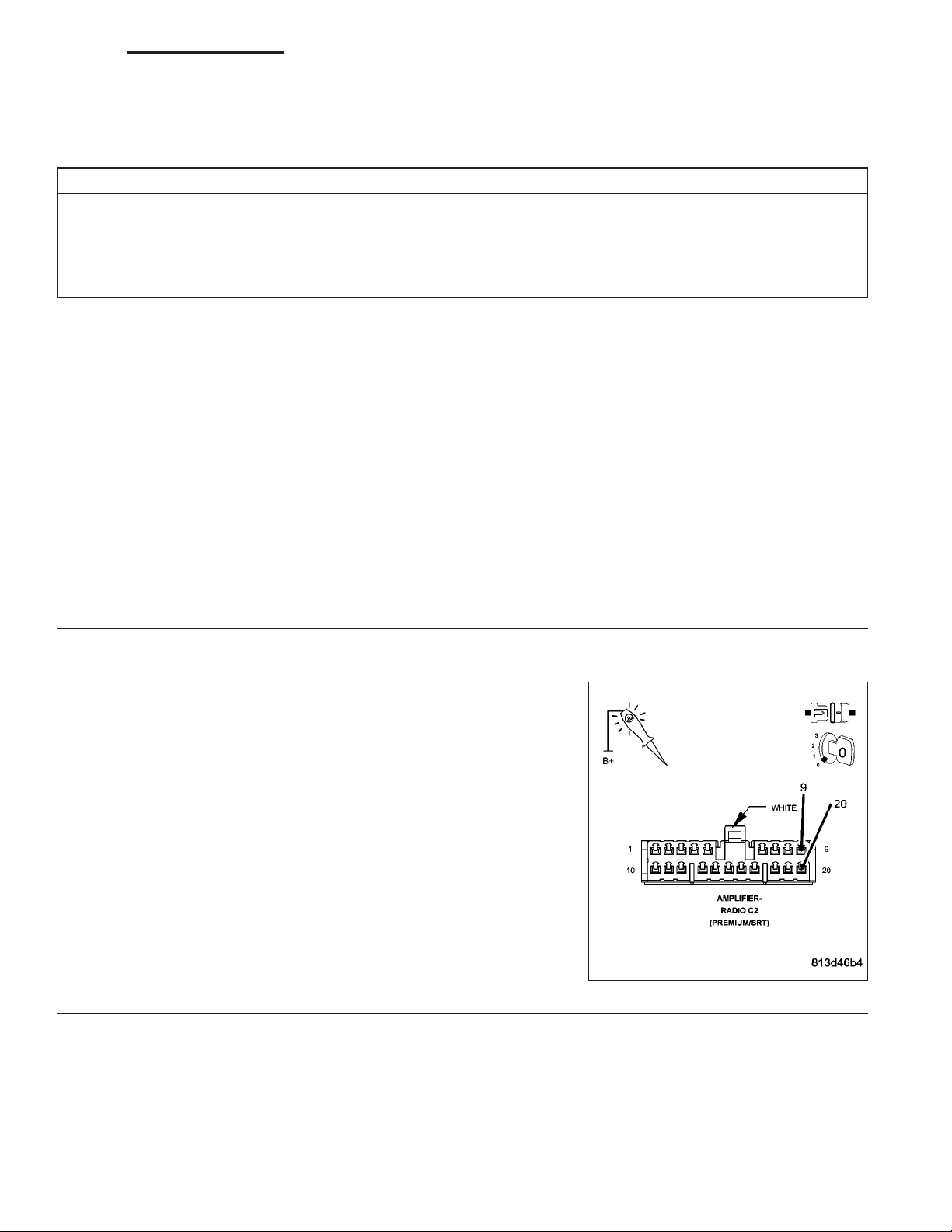

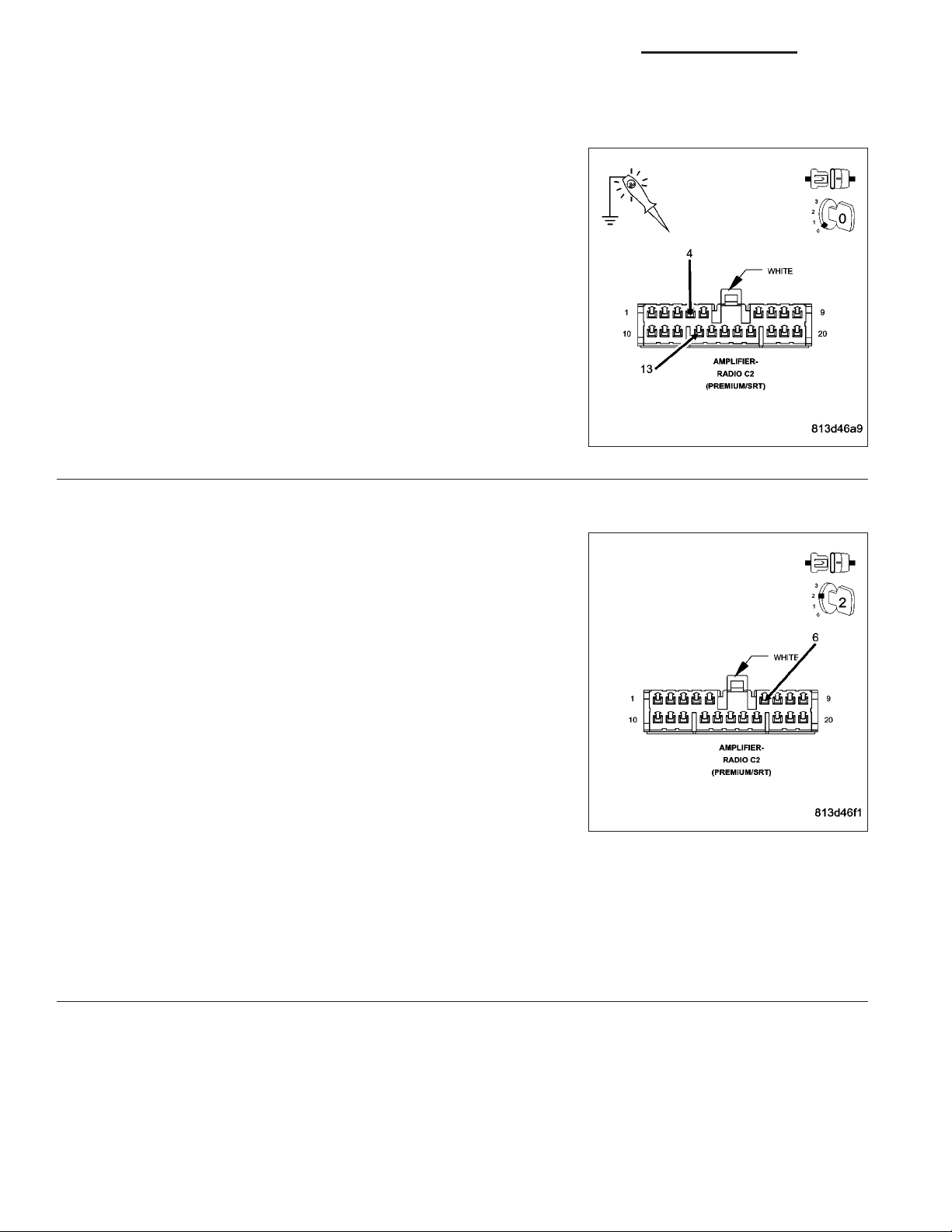

(Z513) (Z907) GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Disconnect the Amplifier C2 harness connector.

Using a 12-volt test light connected to 12-volts, probe each (Z513)

(Z907) ground circuit.

Is the test light illuminated for each circuit?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Go To 3

Repair the (Z513) or (Z907) Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 26

8E - 26 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM AMPLIFIER (CONTINUED)

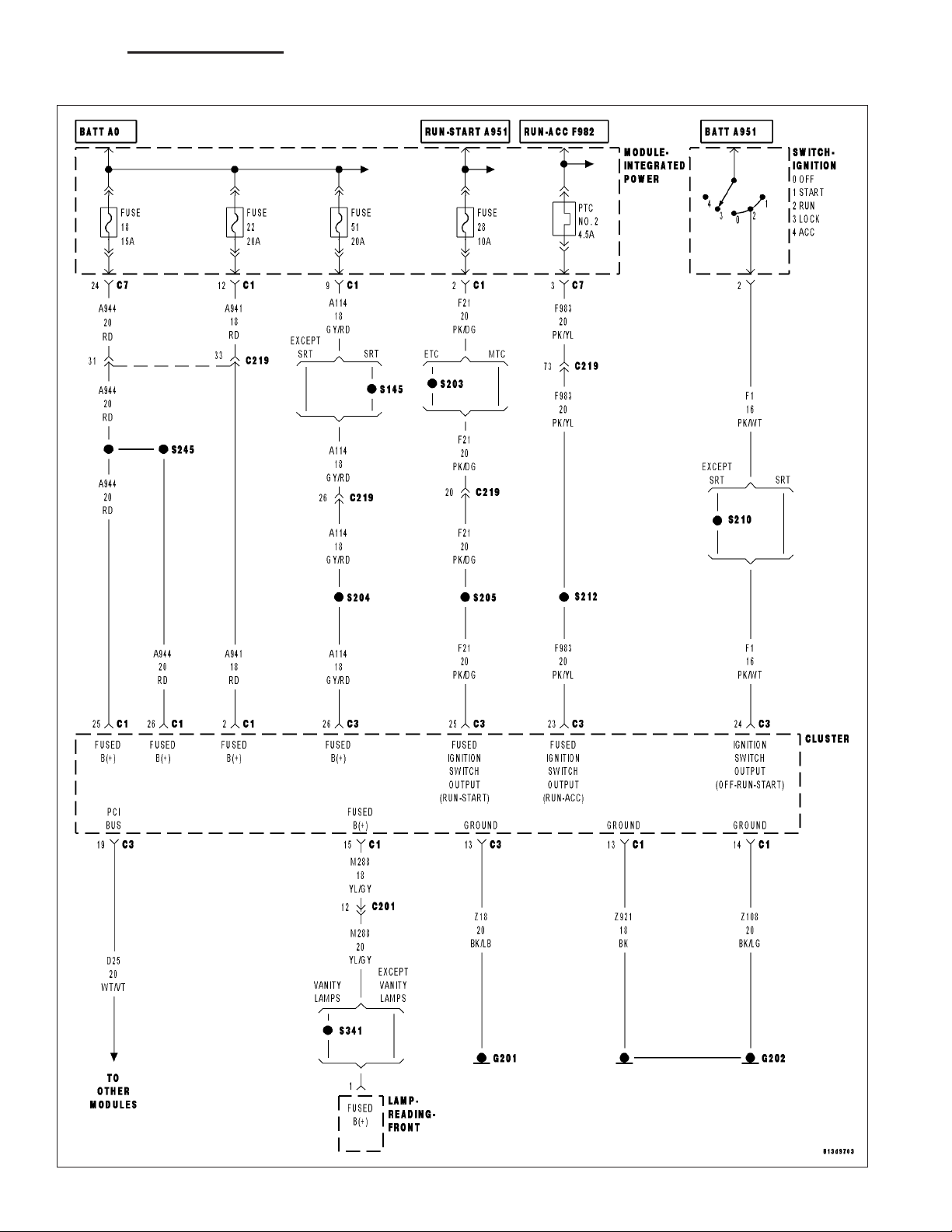

(A116) FUSED B+ CIRCUIT OPEN

3.

Using a 12-volt test light connected to ground, probe each (A116)

Fused B+ circuit.

Is the test light illuminated for each circuit?

Yes >>

No >>

(D25) PCI BUS CIRCUIT OPEN

4.

Turn the ignition on.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts.

Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead

to the PCI Bus circuit in the Amplifier connector.

Observe the voltage display on the DRB Lab Scope.

Go To 4

Repair the (A116) Fused B+ circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Amplifier in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Repair the (D25) PCI Bus circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Page 27

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 27

*NO RESPONSE FROM CLUSTER

Page 28

8E - 28 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM CLUSTER (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(Z921) (Z108) (Z18) GROUND CIRCUIT OPEN

(A944) (M288) (A941) (A114) FUSED B+ CIRCUIT OPEN

(F21) (F1) (F983) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

(D25) PCI BUS CIRCUIT OPEN

CLUSTER

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH OTHER PCI BUS MODULES

1.

Turn the ignition on.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communication Failure symptom and repair as necessary.

With the DRB, attempt to communicate with the ORC.

With the DRB, attempt to communicate with the ABS.

Was the DRB able to I/D or communicate with either module?

Yes >>

No >>

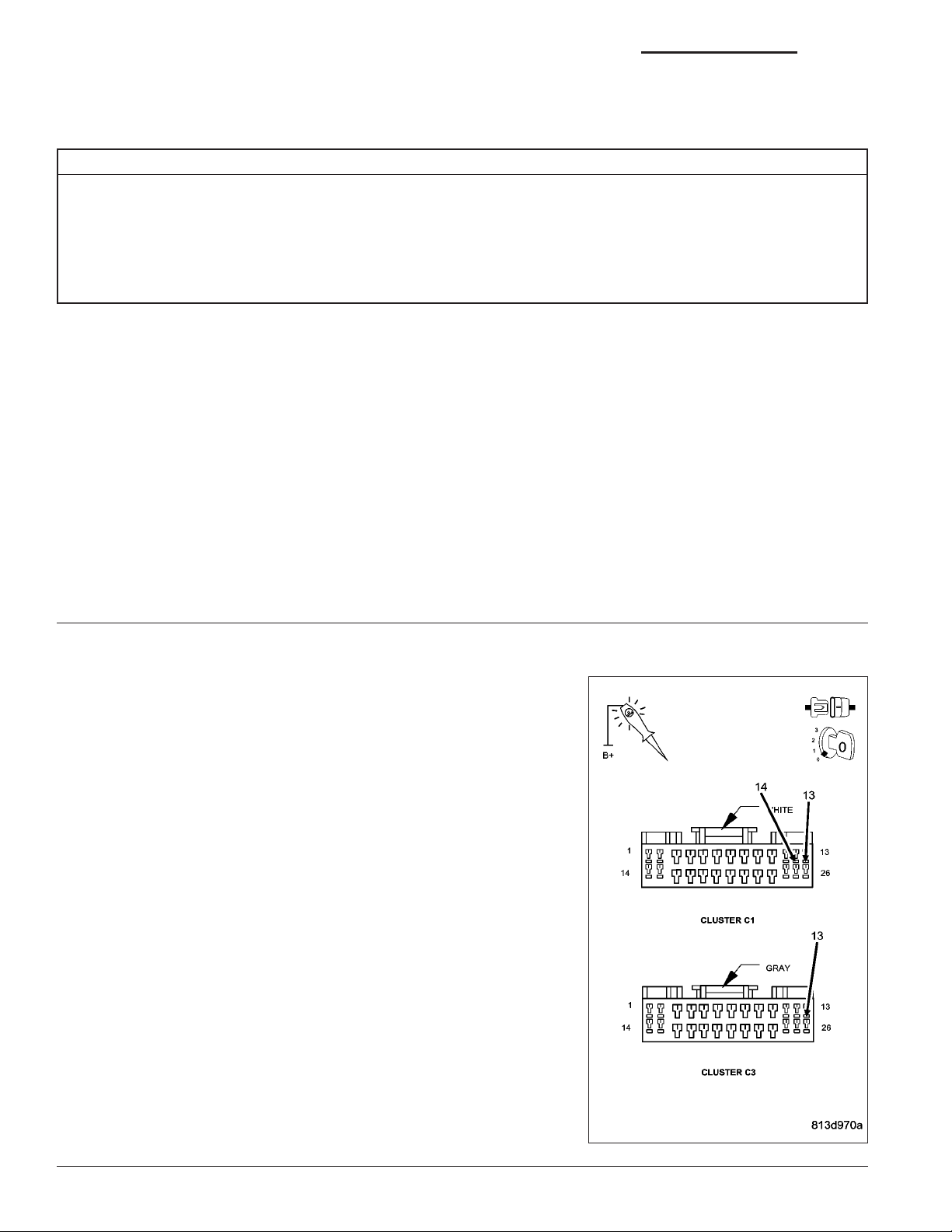

(Z921) (Z108) (Z18) GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Disconnect the Cluster harness connectors.

Using a 12-volt test light connected to 12-volts, probe each (Z921)

(Z108) (Z18) ground circuit.

Is the test light illuminated for each circuit?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Go To 3

Repair the (Z921) (Z108) (Z18) Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 29

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 29

*NO RESPONSE FROM CLUSTER (CONTINUED)

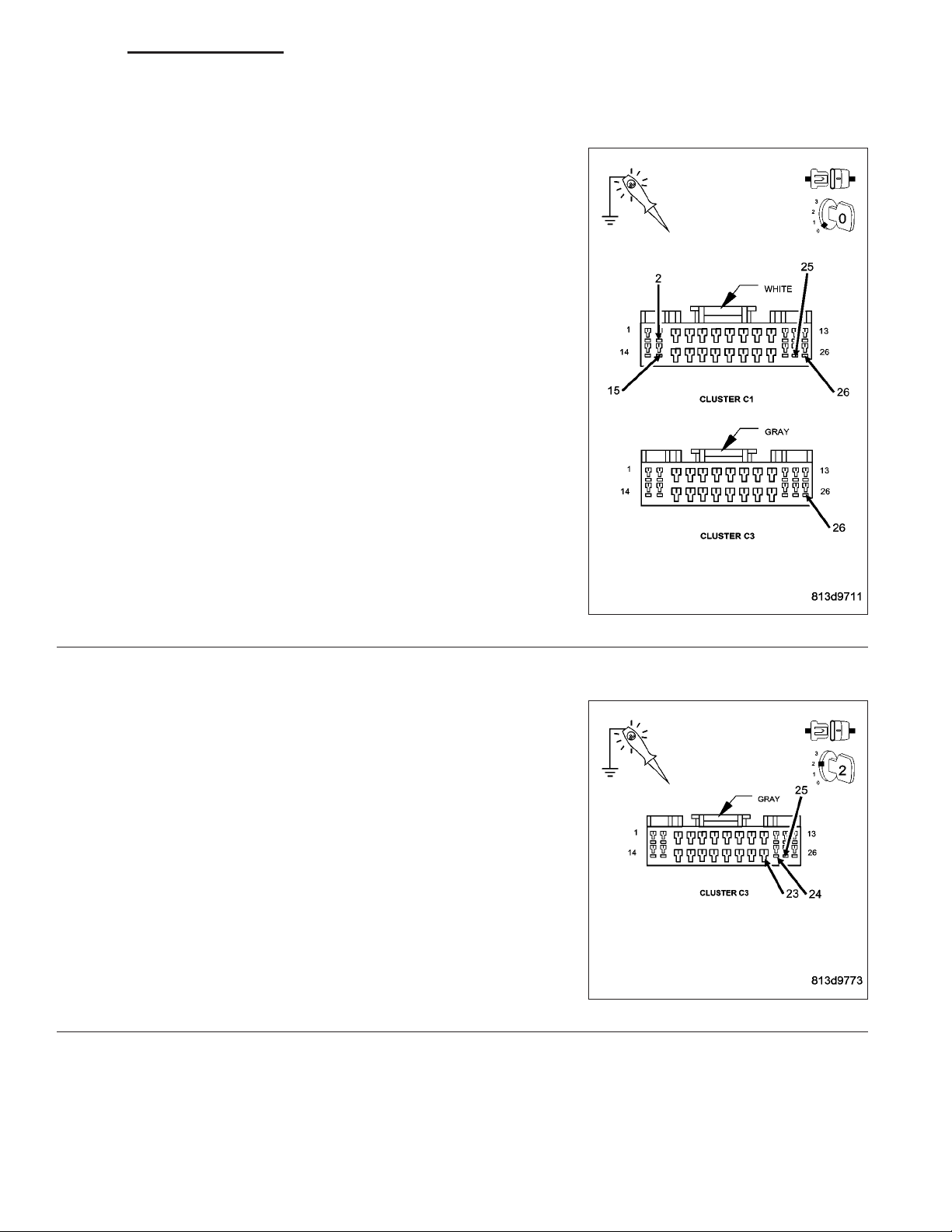

(A944) (M288) (A941) (A114) FUSED B+ CIRCUIT OPEN

3.

Using a 12-volt test light connected to ground, probe each (A944)

(M288) (A941) (A114) Fused B+ circuit.

Is the test light illuminated for each circuit?

Yes >>

No >>

(F21) (F1) (F983) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

4.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe each (F21) (F1)

(F983) Fused Ignition Switch Output circuit.

Go To 4

Repair the (A944) (M288) (A941) (A114) Fused B+ circuit

for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Is the test light illuminated?

Yes >>

No >>

Go To 5

Repair the (F21) (F1) (F983) Fused Ignition Switch Output

circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 30

8E - 30 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM CLUSTER (CONTINUED)

(D25) PCI BUS CIRCUIT OPEN

5.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts.

Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead

to the PCI Bus circuit in the Cluster connector.

Observe the voltage display on the DRB Lab Scope.

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Cluster in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Repair the (D25) PCI Bus circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Page 31

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 31

*NO RESPONSE FROM ENGINE CONTROL MODULE (PCI BUS) - DIESEL

Page 32

8E - 32 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM ENGINE CONTROL MODULE (PCI BUS) - DIESEL (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

ENGINE CONTROL MODULE POWER AND GROUND

(D25) PCI BUS CIRCUIT OPEN

ENGINE CONTROL MODULE

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH OTHER PCI BUS MODULES

1.

Turn the ignition on.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communication Failure symptom and repair as necessary.

NOTE: As soon as one or more modules communicates with the DRB, answer the question.

With the DRB, attempt to communicate with the ORC.

With the DRB, attempt to communicate with the Instrument Cluster.

Was the DRB able to I/D or communicate with either of the modules?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform POWERTRAIN VERIFICATION TEST - VER 1 (DIESEL).

Page 33

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 33

*NO RESPONSE FROM ENGINE CONTROL MODULE (PCI BUS) - DIESEL (CONTINUED)

(D25) PCI BUS CIRCUIT OPEN

2.

With the DRB, read Engine Control Module DTC’s. This is to ensure

power and ground to the ECM are operational.

NOTE: If the DRB will not read ECM DTC’s, follow the NO

RESPONSE TO ECM (SCI ONLY) symptom.

NOTE: If the vehicle will not start and the DRB displays a no

response message, refer to the appropriate symptom in the

Engine Electrical Diagnostics - Diesel category.

Turn the ignition off.

Disconnect the Engine Control Module C2 harness connector.

Turn the ignition on.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts. Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead to the PCI Bus circuit in the Engine Control

Module connector.

Observe the voltage display on the DRB Lab Scope.

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Engine Control Module in accordance with the service information.

Perform POWERTRAIN VERIFICATION TEST - VER 1 (DIESEL).

Repair the (D25) PCI Bus circuit for an open.

Perform POWERTRAIN VERIFICATION TEST - VER 1 (DIESEL).

Page 34

8E - 34 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM ENGINE CONTROL MODULE (SCI ONLY) - DIESEL

Page 35

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 35

*NO RESPONSE FROM ENGINE CONTROL MODULE (SCI ONLY) - DIESEL (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(D21) SCI TRANSMIT CIRCUIT SHORTED TO GROUND

(D20) SCI RECEIVE CIRCUIT SHORTED TO GROUND

(D21) SCI TRANSMIT CIRCUIT SHORTED TO VOLTAGE

(D20) SCI RECEIVE CIRCUIT SHORTED TO VOLTAGE

(D21) SCI TRANSMIT CIRCUIT OPEN

(D20) SCI RECEIVE CIRCUIT OPEN

(D21) SCI TRANSMIT CIRCUIT SHORTED TO THE (D20) SCI RECEIVE CIRCUIT

ENGINE CONTROL MODULE

Diagnostic Test

CHECK ENGINE CONTROL MODULE POWER AND GROUND

1.

Refer to the Engine Electrical Diagnostics - Diesel and perform the symptom Checking ECM Power and Ground

Circuits.

Did the vehicle pass this test?

Yes >>

No >>

SCI CIRCUITS SHORTED TO GROUND

2.

Turn the ignition off.

Disconnect the DRB from the DLC.

Disconnect the Engine Control Module C2 harness connector.

Measure the resistance between ground and the (D21) SCI Transmit

circuit.

Measure the resistance between ground and the (D20) SCI Receive

circuit.

Is the resistance below 10.0 ohms for either circuit?

Yes >>

No >>

Go To 2

Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST - VER 1 (DIESEL).

Repair the SCI Circuit that measured below 10.0 ohms for

a short to ground.

Perform POWERTRAIN VERIFICATION TEST - VER 1

(DIESEL).

Go To 3

Page 36

8E - 36 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM ENGINE CONTROL MODULE (SCI ONLY) - DIESEL (CONTINUED)

SCI CIRCUITS SHORTED TO VOLTAGE

3.

Turn the ignition on.

Measure the voltage of the (D21) SCI Transmit circuit.

Measure the voltage of the (D20) SCI Receive circuit.

Is the voltage above 1.0 volt for either circuit?

Yes >>

No >>

(D21) SCI TRANSMIT CIRCUIT OPEN

4.

Turn the ignition off.

Measure the resistance of the (D21) SCI Transmit circuit between the

ECM harness connector and the DLC.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Repair the SCI Circuit that measured above 1.0 volt for a

short to voltage.

Perform POWERTRAIN VERIFICATION TEST - VER 1

(DIESEL).

Go To 4

Go To 5

Repair the (D21) SCI Transmit circuit for an open.

Perform POWERTRAIN VERIFICATION TEST - VER 1

(DIESEL).

Page 37

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 37

*NO RESPONSE FROM ENGINE CONTROL MODULE (SCI ONLY) - DIESEL (CONTINUED)

(D20) SCI RECEIVE CIRCUIT OPEN

5.

Measure the resistance of the (D20) SCI Receive circuit between the

ECM harness connector and the DLC.

Is the resistance below 5.0 ohms?

Yes >>

No >>

(D21) SCI TRANSMIT CIRCUIT SHORTED TO THE (D20) SCI RECEIVE CIRCUIT

6.

Measure the resistance between the (D21) SCI Transmit and the

(D20) SCI Receive circuits.

Go To 6

Repair the (D20) SCI Receive circuit for an open.

Perform POWERTRAIN VERIFICATION TEST - VER 1

(DIESEL).

Is the resistance below 5.0 ohms?

Yes >>

No >>

Repair the (D21) SCI Transmit circuit for a short to the

(D20) SCI Receive circuit.

Perform POWERTRAIN VERIFICATION TEST - VER 1

(DIESEL).

Replace the Engine Control Module in accordance with the

service information.

Perform POWERTRAIN VERIFICATION TEST - VER 1

(DIESEL).

Page 38

8E - 38 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM FRONT CONTROL MODULE

Page 39

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 39

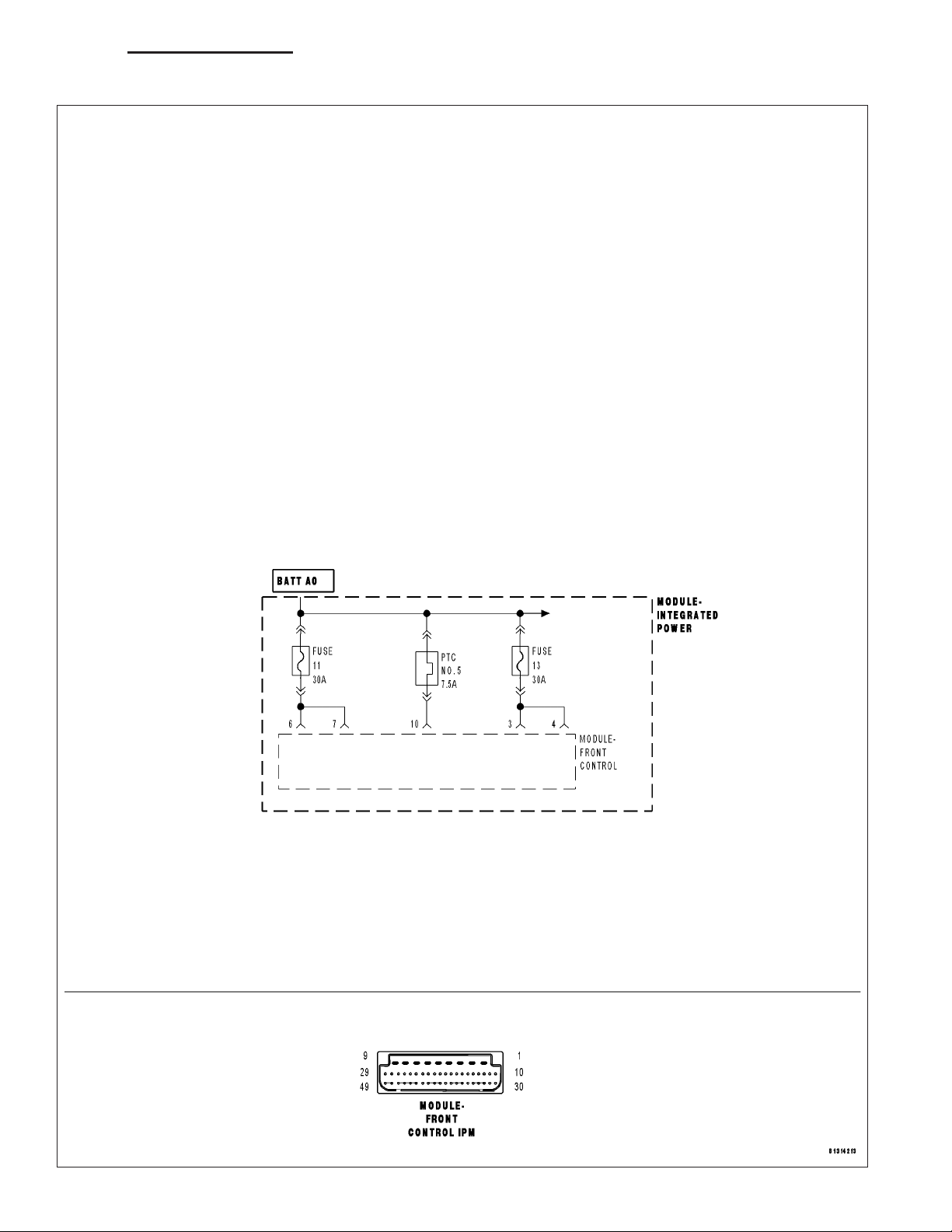

*NO RESPONSE FROM FRONT CONTROL MODULE (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(Z117) (Z118) GROUND CIRCUIT OPEN

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

(D25) PCI BUS CIRCUIT OPEN

FRONT CONTROL MODULE

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH OTHER PCI BUS MODULES

1.

Turn the ignition on.

NOTE: Check all fuses before beginning.

NOTE: As soon as one or more modules communicates with the DRB, answer the question.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communi-

cation Failure symptom and repair as necessary.

With the DRB, attempt to communicate with the ORC.

With the DRB, attempt to communicate with the Instrument Cluster.

Was the DRB able to I/D or communicate with either of the modules?

Yes >>

No >>

(Z117) (Z118) GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Remove the Front Control Module from the IPM.

Using a 12-volt test light connected to 12-volts, probe each (Z117) and

(Z118) ground circuits.

Is the test light illuminated for each circuit?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Go To 3

Repair the (Z117) or (Z118) Ground circuit for an open

between the IPM connector and the grounding point. If

OK, replace the power distribution center in accordance

with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 40

8E - 40 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM FRONT CONTROL MODULE (CONTINUED)

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

3.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Fused Igni-

tion Switch Output circuit.

Is the test light illuminated?

Yes >>

No >>

(D25) PCI BUS CIRCUIT OPEN

4.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts.

Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead

to the PCI Bus circuit in the IPM FCM connector.

Observe the voltage display on the DRB Lab Scope.

Go To 4

Check all IPM fuses. If OK, replace the power distribution

center in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Front Control Module in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Repair the (D25) PCI Bus circuit for an open. If OK, replace the power distribution center in accordance

with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Page 41

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 41

*NO RESPONSE FROM FINAL DRIVE CONTROL MODULE

Page 42

8E - 42 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM FINAL DRIVE CONTROL MODULE (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(Z935) (Z937) GROUND CIRCUIT OPEN

(A34) FUSED B+ CIRCUIT OPEN

(F202) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

(D25) PCI BUS CIRCUIT OPEN

FINAL DRIVE CONTROL MODULE

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH THE INSTRUMENT CLUSTER (MIC)

1.

Turn the ignition on.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communication Failure symptom and repair as necessary.

With the DRB, attempt to communicate with the MIC.

Was the DRB able to I/D or communicate with the MIC?

Yes >>

No >>

(Z935) (Z937) GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Disconnect the Final Drive Control Module harness connector.

Using a 12-volt test light connected to 12-volts, probe each (Z935) and

(Z937) ground circuit.

Is the test light illuminated for each circuit?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform FDCM VERIFICATION TEST

Go To 3

Repair the (Z935) or (Z937) Ground circuit for an open.

Perform FDCM VERIFICATION TEST

Page 43

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 43

*NO RESPONSE FROM FINAL DRIVE CONTROL MODULE (CONTINUED)

(A34) FUSED B+ CIRCUIT OPEN

3.

Using a 12-volt test light connected to ground, probe the (A34) Fused

B+ circuit.

Is the test light illuminated?

Yes >>

No >>

(F202) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

4.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the (F202) Fused

Ignition Switch Output circuit.

Is the test light illuminated?

Yes >>

No >>

Go To 4

Repair the (A34) Fused B+ circuit for an open.

Perform FDCM VERIFICATION TEST

Go To 5

Repair the (F202) Fused Ignition Switch Output circuit for

an open.

Perform FDCM VERIFICATION TEST

Page 44

8E - 44 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM FINAL DRIVE CONTROL MODULE (CONTINUED)

(D25) PCI BUS CIRCUIT OPEN

5.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts.

Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead

to the PCI Bus circuit in the FDCM connector.

Observe the voltage display on the DRB Lab Scope.

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Final Drive Control Module in accordance with the service information.

Perform FDCM VERIFICATION TEST

Repair the (D25) PCI Bus circuit for an open.

Perform FDCM VERIFICATION TEST

Page 45

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 45

*NO RESPONSE FROM HANDS FREE MODULE

Page 46

8E - 46 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM HANDS FREE MODULE (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(Z970) GROUND CIRCUIT OPEN

(A114) FUSED B+ CIRCUIT OPEN

(F983) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

(D25) PCI BUS CIRCUIT OPEN

HANDS FREE MODULE

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH THE INSTRUMENT CLUSTER (MIC)

1.

Turn the ignition on.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communication Failure symptom and repair as necessary.

With the DRB, attempt to communicate with the MIC.

Was the DRB able to I/D or communicate with the MIC?

Yes >>

No >>

(Z970) GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Disconnect the Hands Free Module C1 harness connector.

Using a 12-volt test light connected to 12-volts, probe the (Z970)

ground circuit.

Is the test light illuminated?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Go To 3

Repair the (Z970) Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 47

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 47

*NO RESPONSE FROM HANDS FREE MODULE (CONTINUED)

(A114) FUSED B+ CIRCUIT OPEN

3.

Using a 12-volt test light connected to ground, probe the (A114) Fused

B+ circuit.

Is the test light illuminated?

Yes >>

No >>

(F983) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

4.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the (F983) Fused

Ignition Switch Output circuit.

Is the test light illuminated?

Yes >>

No >>

Go To 4

Repair the (A114) Fused B+ circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Go To 5

Repair the (F983) Fused Ignition Switch Output circuit for

an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 48

8E - 48 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM HANDS FREE MODULE (CONTINUED)

(D25) PCI BUS CIRCUIT OPEN

5.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts.

Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead

to the PCI Bus circuit in the HFM connector.

Observe the voltage display on the DRB Lab Scope.

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Hands Free Module in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Repair the (D25) PCI Bus circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Page 49

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 49

*NO RESPONSE FROM HVAC

Page 50

8E - 50 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM HVAC (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(Z24) GROUND CIRCUIT OPEN

(F504) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

(D25) PCI BUS CIRCUIT OPEN

A/C HEATER CONTROL

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH OTHER PCI BUS MODULES

1.

Turn the ignition on.

NOTE: As soon as one or more modules communicates with the DRB, answer the question.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communi-

cation Failure symptom and repair as necessary.

With the DRB, attempt to communicate with the ORC.

With the DRB, attempt to communicate with the Instrument Cluster.

Was the DRB able to I/D or communicate with either of the modules?

Yes >>

No >>

(Z24) GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Disconnect the A/C Heater Control C1 harness connector.

Using a 12-volt test light connected to 12-volts, probe the (Z24)

ground circuit.

Is the test light illuminated?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Go To 3

Repair the (Z24) Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 51

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 51

*NO RESPONSE FROM HVAC (CONTINUED)

(F504) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

3.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the (F504) Fused

Ignition Switch Output circuit.

Is the test light illuminated?

Yes >>

No >>

(D25) PCI BUS CIRCUIT OPEN

4.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts.

Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead

to the PCI Bus circuit in the A/C Heater Control connector.

Observe the voltage display on the DRB Lab Scope.

Go To 4

Repair the (F504) Fused Ignition Switch Output circuit for

an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the A/C Heater Control in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Repair the (D25) PCI Bus circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Page 52

8E - 52 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM OCCUPANT RESTRAINT CONTROL MODULE

Page 53

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 53

*NO RESPONSE FROM OCCUPANT RESTRAINT CONTROL MODULE (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(F201) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT OPEN

(F100) FUSED IGNITION SWITCH OUTPUT (RUN) CIRCUIT OPEN

(Z104) GROUND CIRCUIT OPEN

(D25) PCI BUS CIRCUIT OPEN

OCCUPANT RESTRAINT CONTROL MODULE

Diagnostic Test

CHECKING FOR VOLTAGE AT ORC

1.

NOTE: Ensure that the battery is fully charged.

NOTE: Ensure there is PCI bus communication with other mod-

ules. If not, refer to the PCI Bus Communication Failure symptom

and repair as necessary.

WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE

IGNITION OFF, DISCONNECT THE BATTERY AND WAIT TWO MINUTES BEFORE PROCEEDING.

Disconnect the ORC harness connectors.

Connect the appropriate Load Tool ORC Adapter to the ORC connec-

tor.

Turn the ignition on and then reconnect the Battery.

Using a 12-volt test light connected to ground, probe the (F100) Fused

Ignition Switch Output (Run) Circuit and the (F201) Fused Ignition

Switch Output (Run-Start) Circuit.

NOTE: One open circuit will not cause a NO RESPONSE condition.

Is the test light illuminated on both circuits?

Yes >>

No >>

Go To 2

Repair the (F100) Fused Ignition Switch Output (Run) and (F201) Fused Ignition Switch Output (Run/

Start) circuits for an open.

Perform AIRBAG VERIFICATION TEST - VER 1.

Page 54

8E - 54 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM OCCUPANT RESTRAINT CONTROL MODULE (CONTINUED)

(Z104) GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Using a 12-volt test light connected to 12-volts, probe the (Z104)

ground circuit.

Is the test light illuminated?

Yes >>

No >>

(D25) PCI BUS CIRCUIT OPEN

3.

Turn the ignition on.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts.

Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead

to the PCI Bus circuit in the ORC connector.

Observe the voltage display on the DRB Lab Scope.

Go To 3

Repair the (Z104) Ground circuit for an open.

Perform AIRBAG VERIFICATION TEST - VER 1.

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Occupant Restraint Control Module in accordance with the service information.

Perform AIRBAG VERIFICATION TEST - VER 1.

Repair the (D25) PCI Bus circuit for an open.

Perform AIRBAG VERIFICATION TEST - VER 1.

Page 55

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 55

*NO RESPONSE FROM OVERHEAD CONSOLE

Page 56

8E - 56 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM OVERHEAD CONSOLE (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(Z13) GROUND CIRCUIT OPEN

(A919) FUSED B+ CIRCUIT OPEN

(F21) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

(D25) PCI BUS CIRCUIT OPEN

ELECTRONIC OVERHEAD MODULE

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH THE INSTRUMENT CLUSTER (MIC)

1.

Turn the ignition on.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communication Failure symptom and repair as necessary.

With the DRB, attempt to communicate with the MIC.

Was the DRB able to I/D or communicate with the MIC?

Yes >>

No >>

(Z13) GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Disconnect the Electronic Overhead Module harness connector.

Using a 12-volt test light connected to 12-volts, probe the (Z13)

ground circuit.

Is the test light illuminated?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Go To 3

Repair the (Z13) Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 57

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 57

*NO RESPONSE FROM OVERHEAD CONSOLE (CONTINUED)

(A919) FUSED B+ CIRCUIT OPEN

3.

Using a 12-volt test light connected to ground, probe the (A919) Fused

B+ circuit.

Is the test light illuminated?

Yes >>

No >>

(F21) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

4.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the (F21) Fused

Ignition Switch Output circuit.

Is the test light illuminated?

Yes >>

No >>

Go To 4

Repair the (A919) Fused B+ circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Go To 5

Repair the (F21) Fused Ignition Switch Output circuit for

an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 58

8E - 58 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM OVERHEAD CONSOLE (CONTINUED)

(D25) PCI BUS CIRCUIT OPEN

5.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts.

Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead

to the PCI Bus circuit in the Electronic Overhead Module connector.

Observe the voltage display on the DRB Lab Scope.

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Electronic Overhead Module in accordance with the service information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Repair the (D25) PCI Bus circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Page 59

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 59

*NO RESPONSE FROM PCM (PCI BUS) - JTEC

Page 60

8E - 60 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM PCM (PCI BUS) - JTEC (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

POWERTRAIN CONTROL MODULE POWER AND GROUND

(D25) PCI BUS CIRCUIT OPEN

POWERTRAIN CONTROL MODULE

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH OTHER PCI BUS MODULES

1.

Turn the ignition on.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communication Failure symptom and repair as necessary.

NOTE: As soon as one or more modules communicates with the DRB, answer the question.

With the DRB, attempt to communicate with the ORC.

With the DRB, attempt to communicate with the Instrument Cluster.

Was the DRB able to I/D or communicate with either of the modules?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform POWERTRAIN VERIFICATION TEST - VER 1.

Page 61

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 61

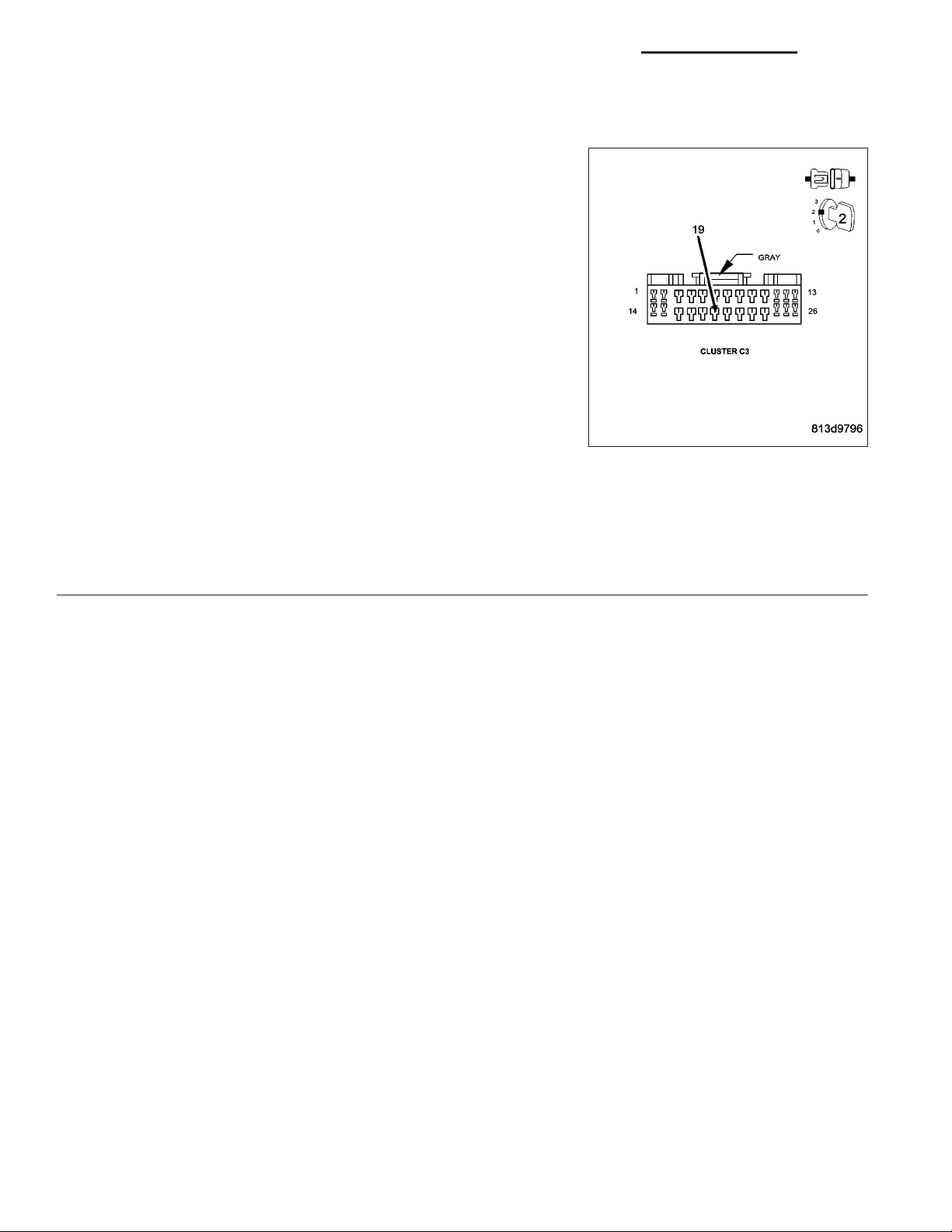

*NO RESPONSE FROM PCM (PCI BUS) - JTEC (CONTINUED)

(D25) PCI BUS CIRCUIT OPEN

2.

With the DRB, read PCM DTC’s. This is to ensure power and ground

to the PCM are operational.

NOTE: If the DRB will not read PCM DTC’s, follow the NO

RESPONSE TO PCM (SCI ONLY) - JTEC symptom.

NOTE: If the vehicle will not start and the DRB displays a no

response message, refer to the appropriate symptom in the

Engine Electrical Diagnostics category.

Turn the ignition off.

Disconnect the PCM C3 harness connector.

Turn the ignition on.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts. Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead to the PCI Bus circuit in the PCM connector.

Observe the voltage display on the DRB Lab Scope.

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Powertrain Control Module in accordance with the service information.

Perform POWERTRAIN VERIFICATION TEST - VER 1.

Repair the (D25) PCI Bus circuit for an open.

Perform POWERTRAIN VERIFICATION TEST - VER 1.

Page 62

8E - 62 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM PCM (SCI ONLY) - JTEC

Page 63

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 63

*NO RESPONSE FROM PCM (SCI ONLY) - JTEC (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(D21) SCI TRANSMIT (PCM) CIRCUIT SHORTED TO GROUND

(D20) SCI RECEIVE (PCM) CIRCUIT SHORTED TO GROUND

(D21) SCI TRANSMIT (PCM) CIRCUIT SHORTED TO VOLTAGE

(D20) SCI RECEIVE (PCM) CIRCUIT SHORTED TO VOLTAGE

(D21) SCI TRANSMIT (PCM) CIRCUIT OPEN

(D20) SCI RECEIVE (PCM) CIRCUIT OPEN

(D21) SCI TRANSMIT (PCM) CIRCUIT SHORTED TO THE (D20) SCI RECEIVE (PCM) CIRCUIT

POWERTRAIN CONTROL MODULE

Diagnostic Test

CHECK POWERTRAIN CONTROL MODULE POWER AND GROUND

1.

Refer to the Engine Electrical Diagnostics and perform the symptom Checking PCM Power and Ground Circuits.

NOTE: With the DRB in the generic scan tool mode, attempt to communicate with the PCM. If the DRB can

communicate with the PCM in the generic scan tool mode, it may not be necessary to perform this step.

Did the vehicle pass this test?

Yes >>

No >>

SCI CIRCUITS SHORTED TO GROUND

2.

Turn the ignition off.

Disconnect the DRB from the DLC.

Disconnect the Powertrain Control Module C3 harness connector.

Measure the resistance between ground and the (D21) SCI Transmit

(PCM) circuit.

Measure the resistance between ground and the (D20) SCI Receive

(PCM) circuit.

Is the resistance below 10.0 ohms for either circuit?

Yes >>

No >>

Go To 2

Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST - VER 1.

Repair the SCI Circuit that measured below 10.0 ohms for

a short to ground.

Perform POWERTRAIN VERIFICATION TEST - VER 1.

Go To 3

Page 64

8E - 64 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM PCM (SCI ONLY) - JTEC (CONTINUED)

SCI CIRCUITS SHORTED TO VOLTAGE

3.

Turn the ignition on.

Measure the voltage of the (D21) SCI Transmit (PCM) circuit.

Measure the voltage of the (D20) SCI Receive (PCM) circuit.

Is the voltage above 1.0 volt for either circuit?

Yes >>

No >>

(D21) SCI TRANSMIT (PCM) CIRCUIT OPEN

4.

Turn the ignition off.

Measure the resistance of the (D21) SCI Transmit (PCM) circuit

between the DLC and the PCM connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Repair the SCI Circuit that measured above 1.0 volt for a

short to voltage.

Perform POWERTRAIN VERIFICATION TEST - VER 1.

Go To 4

Go To 5

Repair the (D21) SCI Transmit (PCM) circuit for an open.

Perform POWERTRAIN VERIFICATION TEST - VER 1.

Page 65

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 65

*NO RESPONSE FROM PCM (SCI ONLY) - JTEC (CONTINUED)

(D20) SCI RECEIVE (PCM) CIRCUIT OPEN

5.

Measure the resistance of the (D20) SCI Receive (PCM) circuit

between the DLC and the PCM connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

(D21) SCI TRANSMIT (PCM) CIRCUIT SHORTED TO THE (D20) SCI RECEIVE (PCM) CIRCUIT

6.

Measure the resistance between the (D21) SCI Transmit (PCM) and

the (D20) SCI Receive (PCM) circuits.

Go To 6

Repair the (D20) SCI Receive (PCM) circuit for an open.

Perform POWERTRAIN VERIFICATION TEST - VER 1.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Repair the (D21) SCI Transmit (PCM) circuit for a short to

the (D20) SCI Receive (PCM) circuit.

Perform POWERTRAIN VERIFICATION TEST - VER 1.

Replace the Powertrain Control Module in accordance with

the service information.

Perform POWERTRAIN VERIFICATION TEST - VER 1.

Page 66

8E - 66 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM PCM (PCI BUS) - NGC

Page 67

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 67

*NO RESPONSE FROM PCM (PCI BUS) - NGC (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

POWERTRAIN CONTROL MODULE POWER AND GROUND

(D25) PCI BUS CIRCUIT OPEN

POWERTRAIN CONTROL MODULE

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH OTHER PCI BUS MODULES

1.

Turn the ignition on.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communication Failure symptom and repair as necessary.

NOTE: As soon as one or more modules communicates with the DRB, answer the question.

With the DRB, attempt to communicate with the ORC.

With the DRB, attempt to communicate with the Instrument Cluster.

Was the DRB able to I/D or communicate with either of the modules?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform (NGC) POWERTRAIN VERIFICATION TEST - VER 1.

Page 68

8E - 68 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM PCM (PCI BUS) - NGC (CONTINUED)

(D25) PCI BUS CIRCUIT OPEN

2.

With the DRB, read PCM DTC’s. This is to ensure power and ground

to the PCM are operational.

NOTE: If the DRB will not read PCM DTC’s, follow the NO

RESPONSE TO PCM (SCI ONLY) - NGC symptom.

NOTE: If the vehicle will not start and the DRB displays a no

response message, refer to the appropriate symptom in the

Engine Electrical Diagnostics category.

Turn the ignition off.

Disconnect the PCM C1 harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing

the PCM harness connectors will damage the PCM terminals

resulting in poor terminal to pin connection. Install Miller Special

Tool #8815 to perform diagnosis.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts. Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead to the PCI Bus circuit in the appropriate ter-

minal of special tool #8815.

Turn the ignition on.

Observe the voltage display on the DRB Lab Scope.

Does the voltage pulse from 0 to approximately 7.5 volts?

Yes >>

No >>

Replace the Powertrain Control Module in accordance with the service information.

Perform (NGC) POWERTRAIN VERIFICATION TEST - VER 1.

Repair the (D25) PCI Bus circuit for an open.

Perform (NGC) POWERTRAIN VERIFICATION TEST - VER 1.

Page 69

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 69

*NO RESPONSE FROM PCM (PCM SCI ONLY) - NGC

Page 70

8E - 70 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM PCM (PCM SCI ONLY) - NGC (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(D21) SCI TRANSMIT (PCM) CIRCUIT SHORTED TO GROUND

(D20) SCI RECEIVE (PCM) CIRCUIT SHORTED TO GROUND

(D21) SCI TRANSMIT (PCM) CIRCUIT SHORTED TO VOLTAGE

(D20) SCI RECEIVE (PCM) CIRCUIT SHORTED TO VOLTAGE

(D21) SCI TRANSMIT (PCM) CIRCUIT OPEN

(D20) SCI RECEIVE (PCM) CIRCUIT OPEN

(D21) SCI TRANSMIT (PCM) CIRCUIT SHORTED TO THE (D20) SCI RECEIVE (PCM) CIRCUIT

POWERTRAIN CONTROL MODULE

Diagnostic Test

CHECK POWERTRAIN CONTROL MODULE POWER AND GROUND

1.

Refer to the Engine Electrical Diagnostics and perform the symptom Checking PCM Power and Ground Circuits.

NOTE: With the DRB in the generic scan tool mode, attempt to communicate with the PCM. If the DRB can

communicate with the PCM in the generic scan tool mode, it may not be necessary to perform this step.

Did the vehicle pass this test?

Yes >>

No >>

SCI CIRCUITS SHORTED TO GROUND

2.

Turn the ignition off.

Disconnect the DRB from the DLC.

Disconnect the Powertrain Control Module C1 harness connector.

Measure the resistance between ground and the (D21) SCI Transmit

(PCM) circuit.

Measure the resistance between ground and the (D20) SCI Receive

(PCM) circuit.

Is the resistance below 10.0 ohms for either circuit?

Yes >>

No >>

Go To 2

Repair as necessary.

Perform (NGC) POWERTRAIN VERIFICATION TEST - VER 1.

Repair the SCI Circuit that measured below 10.0 ohms for

a short to ground.

Perform (NGC) POWERTRAIN VERIFICATION TEST VER 1.

Go To 3

Page 71

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 71

*NO RESPONSE FROM PCM (PCM SCI ONLY) - NGC (CONTINUED)

SCI CIRCUITS SHORTED TO VOLTAGE

3.

Turn the ignition on.

Measure the voltage of the (D21) SCI Transmit (PCM) circuit.

Measure the voltage of the (D20) SCI Receive (PCM) circuit.

Is the voltage above 1.0 volt for either circuit?

Yes >>

No >>

(D21) SCI TRANSMIT (PCM) CIRCUIT OPEN

4.

Turn the ignition off.

CAUTION: Do not probe the PCM harness connectors. Probing

the PCM harness connectors will damage the PCM terminals

resulting in poor terminal to pin connection. Install Miller Special

Tool #8815 to perform diagnosis.

Measure the resistance of the (D21) SCI Transmit (PCM) circuit

between the DLC and the appropriate terminal of special tool #8815.

Repair the SCI Circuit that measured above 1.0 volt for a

short to voltage.

Perform (NGC) POWERTRAIN VERIFICATION TEST VER 1.

Go To 4

Is the resistance below 5.0 ohms?

Yes >>

No >>

Go To 5

Repair the (D21) SCI Transmit (PCM) circuit for an open.

Perform (NGC) POWERTRAIN VERIFICATION TEST VER 1.

Page 72

8E - 72 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM PCM (PCM SCI ONLY) - NGC (CONTINUED)

(D20) SCI RECEIVE (PCM) CIRCUIT OPEN

5.

CAUTION: Do not probe the PCM harness connectors. Probing

the PCM harness connectors will damage the PCM terminals

resulting in poor terminal to pin connection. Install Miller Special

Tool #8815 to perform diagnosis.

Measure the resistance of the (D20) SCI Receive (PCM) circuit

between the DLC and the appropriate terminal of special tool #8815.

Is the resistance below 5.0 ohms?

Yes >>

No >>

(D21) SCI TRANSMIT (PCM) CIRCUIT SHORTED TO THE (D20) SCI RECEIVE (PCM) CIRCUIT

6.

Measure the resistance between the (D21) SCI Transmit (PCM) and

the (D20) SCI Receive (PCM) circuits.

Is the resistance below 5.0 ohms?

Go To 6

Repair the (D20) SCI Receive (PCM) circuit for an open.

Perform (NGC) POWERTRAIN VERIFICATION TEST VER 1.

Yes >>

No >>

Repair the (D21) SCI Transmit (PCM) circuit for a short to

the (D20) SCI Receive (PCM) circuit.

Perform (NGC) POWERTRAIN VERIFICATION TEST VER 1.

Replace the Powertrain Control Module in accordance with

the service information.

Perform (NGC) POWERTRAIN VERIFICATION TEST VER 1.

Page 73

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 73

*NO RESPONSE FROM RADIO

Page 74

8E - 74 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM RADIO (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

(Z514) (Z515) GROUND CIRCUIT OPEN

(A114) FUSED B+ CIRCUIT OPEN

(F983) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

(D25) PCI BUS CIRCUIT OPEN

RADIO

Diagnostic Test

ESTABLISH COMMUNICATIONS WITH THE INSTRUMENT CLUSTER (MIC)

1.

Turn the ignition on.

NOTE: Ensure there is PCI bus communication with other modules. If not, refer to the PCI Bus Communication Failure symptom and repair as necessary.

With the DRB, attempt to communicate with the MIC.

Was the DRB able to I/D or communicate with the MIC?

Yes >>

No >>

(Z514) (Z515) GROUND CIRCUIT OPEN

2.

Turn the ignition off.

Disconnect the Radio C1 harness connector.

Using a 12-volt test light connected to 12-volts, probe each (Z514)

(Z515) ground circuit.

Is the test light illuminated for each circuit?

Yes >>

No >>

Go To 2

Refer to the table of contents and perform the related symptom.

Perform BODY VERIFICATION TEST - VER 1. (Refer to BODY VERIFICATION TEST - VER 1.)

Go To 3

Repair the (Z514) (Z515) Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 75

DR/DH ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS 8E - 75

*NO RESPONSE FROM RADIO (CONTINUED)

(A114) FUSED B+ CIRCUIT OPEN

3.

Using a 12-volt test light connected to ground, probe each (A114)

Fused B+ circuit.

Is the test light illuminated for each circuit?

Yes >>

No >>

(F983) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

4.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the (F983) Fused

Ignition Switch Output circuit.

Is the test light illuminated?

Yes >>

No >>

Go To 4

Repair the (A114) Fused B+ circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Go To 5

Repair the (F983) Fused Ignition Switch Output circuit for

an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to

BODY VERIFICATION TEST - VER 1.)

Page 76

8E - 76 ELECTRONIC CONTROL MODULES - ELECTRICAL DIAGNOSTICS DR/DH

*NO RESPONSE FROM RADIO (CONTINUED)

(D25) PCI BUS CIRCUIT OPEN

5.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and

the red and black test probes.

Connect the scope input cable to the channel one connector on the

DRB. Attach the red and black leads and the cable to probe adapter to

the scope input cable.

With the DRBIIIT select Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts.

Press F2 again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead

to the PCI Bus circuit in the Radio connector.

Observe the voltage display on the DRB Lab Scope.