Page 1

DR ELECTRONIC CONTROL MODULES 8E - 1

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

COMMUNICATION

DESCRIPTION ..........................1

OPERATION ............................2

CONTROLLER ANTILOCK BRAKE

DESCRIPTION ..........................3

OPERATION ............................3

REMOVAL .............................3

INSTALLATION ..........................3

DATA LINK CONNECTOR

DESCRIPTION - DATA LINK CONNECTOR .....3

OPERATION - DATA LINK CONNECTOR ......3

ENGINE CONTROL MODULE

DESCRIPTION - ECM .....................4

OPERATION - ECM ......................4

REMOVAL .............................4

INSTALLATION ..........................5

FRONT CONTROL MODULE

DESCRIPTION ..........................5

OPERATION ............................5

DIAGNOSIS AND TESTING - FRONT

CONTROL MODULE ....................6

REMOVAL .............................6

INSTALLATION ..........................6

HEATED SEAT MODULE

DESCRIPTION ..........................6

OPERATION ............................6

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE .............................7

REMOVAL .............................7

INSTALLATION ..........................7

POWERTRAIN CONTROL MODULE

DESCRIPTION

DESCRIPTION - PCM ...................8

DESCRIPTION - MODES OF OPERATION ....8

DESCRIPTION - 5 VOLT SUPPLIES .......10

DESCRIPTION - IGNITION CIRCUIT SENSE . 10

DESCRIPTION - POWER GROUNDS ......10

DESCRIPTION - SENSOR RETURN .......10

OPERATION

OPERATION - PCM ....................11

OPERATION - 5 VOLT SUPPLIES .........11

OPERATION - IGNITION CIRCUIT SENSE . . . 12

REMOVAL .............................12

INSTALLATION .........................12

SENTRY KEY IMMOBILIZER MODULE

DESCRIPTION .........................13

OPERATION ...........................13

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING ......................14

REMOVAL .............................15

INSTALLATION .........................15

TRANSFER CASE CONTROL MODULE

DESCRIPTION .........................15

OPERATION ...........................15

TRANSMISSION CONTROL MODULE

DESCRIPTION .........................19

OPERATION ...........................19

STANDARD PROCEDURE

STANDARD PROCEDURE - TCM QUICK

LEARN..............................21

STANDARD PROCEDURE - DRIVE LEARN . . 21

COMMUNICATION

DESCRIPTION

The DaimlerChrysler Programmable Communication Interface (PCI) data bus system is a single wire

multiplex system used for vehicle communications on

many DaimlerChrysler Corporation vehicles. Multi-

plexing is a system that enables the transmission of

several messages over a single channel or circuit. All

DaimlerChrysler vehicles use this principle for communication between various microprocessor-based

electronic control modules. The PCI data bus exceeds

the Society of Automotive Engineers (SAE) J1850

Standard for Class B Multiplexing.

Page 2

8E - 2 ELECTRONIC CONTROL MODULES DR

COMMUNICATION (Continued)

Many of the electronic control modules in a vehicle

require information from the same sensing device. In

the past, if information from one sensing device was

required by several controllers, a wire from each controller needed to be connected in parallel to that sensor. In addition, each controller utilizing analog

sensors required an Analog/Digital (A/D) converter in

order to 9read9 these sensor inputs. Multiplexing

reduces wire harness complexity, sensor current

loads and controller hardware because each sensing

device is connected to only one controller, which

reads and distributes the sensor information to the

other controllers over the data bus. Also, because

each controller on the data bus can access the controller sensor inputs to every other controller on the

data bus, more function and feature capabilities are

possible.

In addition to reducing wire harness complexity,

component sensor current loads and controller hardware, multiplexing offers a diagnostic advantage. A

multiplex system allows the information flowing

between controllers to be monitored using a diagnostic scan tool. The DaimlerChrysler system allows an

electronic control module to broadcast message data

out onto the bus where all other electronic control

modules can 9hear9 the messages that are being sent.

When a module hears a message on the data bus

that it requires, it relays that message to its microprocessor. Each module ignores the messages on the

data bus that are being sent to other electronic control modules.

OPERATION

Data exchange between modules is achieved by

serial transmission of encoded data over a single wire

broadcast network. The wire colors used for the PCI

data bus circuits are yellow with a violet tracer, or

violet with a yellow tracer, depending upon the application. The PCI data bus messages are carried over

the bus in the form of Variable Pulse Width Modulated (VPWM) signals. The PCI data bus speed is an

average 10.4 Kilo-bits per second (Kbps). By comparison, the prior two-wire Chrysler Collision Detection

(CCD) data bus system is designed to run at 7.8125

Kbps.

The voltage network used to transmit messages

requires biasing and termination. Each module on

the PCI data bus system provides its own biasing

and termination. Each module (also referred to as a

node) terminates the bus through a terminating

resistor and a terminating capacitor. There are two

types of nodes on the bus. The dominant node terminates the bus througha1KWresistor and a 3300 pF

capacitor. The Powertrain Control Module (PCM) is

the only dominant node for the PCI data bus system.

A standard node terminates the bus through an 11

KW resistor and a 330 pF capacitor.

The modules bias the bus when transmitting a

message. The PCI bus uses low and high voltage levels to generate signals. Low voltage is around zero

volts and the high voltage is about seven and onehalf volts. The low and high voltage levels are generated by means of variable-pulse width modulation to

form signals of varying length. The Variable Pulse

Width Modulation (VPWM) used in PCI bus messaging is a method in which both the state of the bus

and the width of the pulse are used to encode bit

information. A 9zero9 bit is defined as a short low

pulse or a long high pulse. A 9one9 bit is defined as a

long low pulse or a short high pulse. A low (passive)

state on the bus does not necessarily mean a zero bit.

It also depends upon pulse width. If the width is

short, it stands for a zero bit. If the width is long, it

stands for a one bit. Similarly, a high (active) state

does not necessarily mean a one bit. This too depends

upon pulse width. If the width is short, it stands for

a one bit. If the width is long, it stands for a zero bit.

In the case where there are successive zero or one

data bits, both the state of the bus and the width of

the pulse are changed alternately. This encoding

scheme is used for two reasons. First, this ensures

that only one symbol per transition and one transition per symbol exists. On each transition, every

transmitting module must decode the symbol on the

bus and begin timing of the next symbol. Since timing of the next symbol begins with the last transition

detected on the bus, all of the modules are re-synchronized with each symbol. This ensures that there

are no accumulated timing errors during PCI data

bus communication.

The second reason for this encoding scheme is to

guarantee that the zero bit is the dominant bit on

the bus. When two modules are transmitting simultaneously on the bus, there must be some form of

arbitration to determine which module will gain control. A data collision occurs when two modules are

transmitting different messages at the same time.

When a module is transmitting on the bus, it is reading the bus at the same time to ensure message

integrity. When a collision is detected, the module

that transmitted the one bit stops sending messages

over the bus until the bus becomes idle.

Each module is capable of transmitting and receiving data simultaneously. The typical PCI bus message has the following four components:

• Message Header - One to three bytes in length.

The header contains information identifying the message type and length, message priority, target module(s) and sending module.

• Data Byte(s) - This is the actual message that

is being sent.

Page 3

DR ELECTRONIC CONTROL MODULES 8E - 3

COMMUNICATION (Continued)

• Cyclic Redundancy Check (CRC) Byte - This

byte is used to detect errors during a message transmission.

• In-Frame Response (IFR) byte(s) -Ifa

response is required from the target module(s), it can

be sent during this frame. This function is described

in greater detail in the following paragraph.

The IFR consists of one or more bytes, which are

transmitted during a message. If the sending module

requires information to be received immediately, the

target module(s) can send data over the bus during

the original message. This allows the sending module

to receive time-critical information without having to

wait for the target module to access the bus. After

the IFR is received, the sending module broadcasts

an End of Frame (EOF) message and releases control

of the bus.

The PCI data bus can be monitored using the

DRBIIIt scan tool. It is possible, however, for the bus

to pass all DRBIIIt tests and still be faulty if the

voltage parameters are all within the specified range

and false messages are being sent.

CONTROLLER ANTILOCK

BRAKE

DESCRIPTION

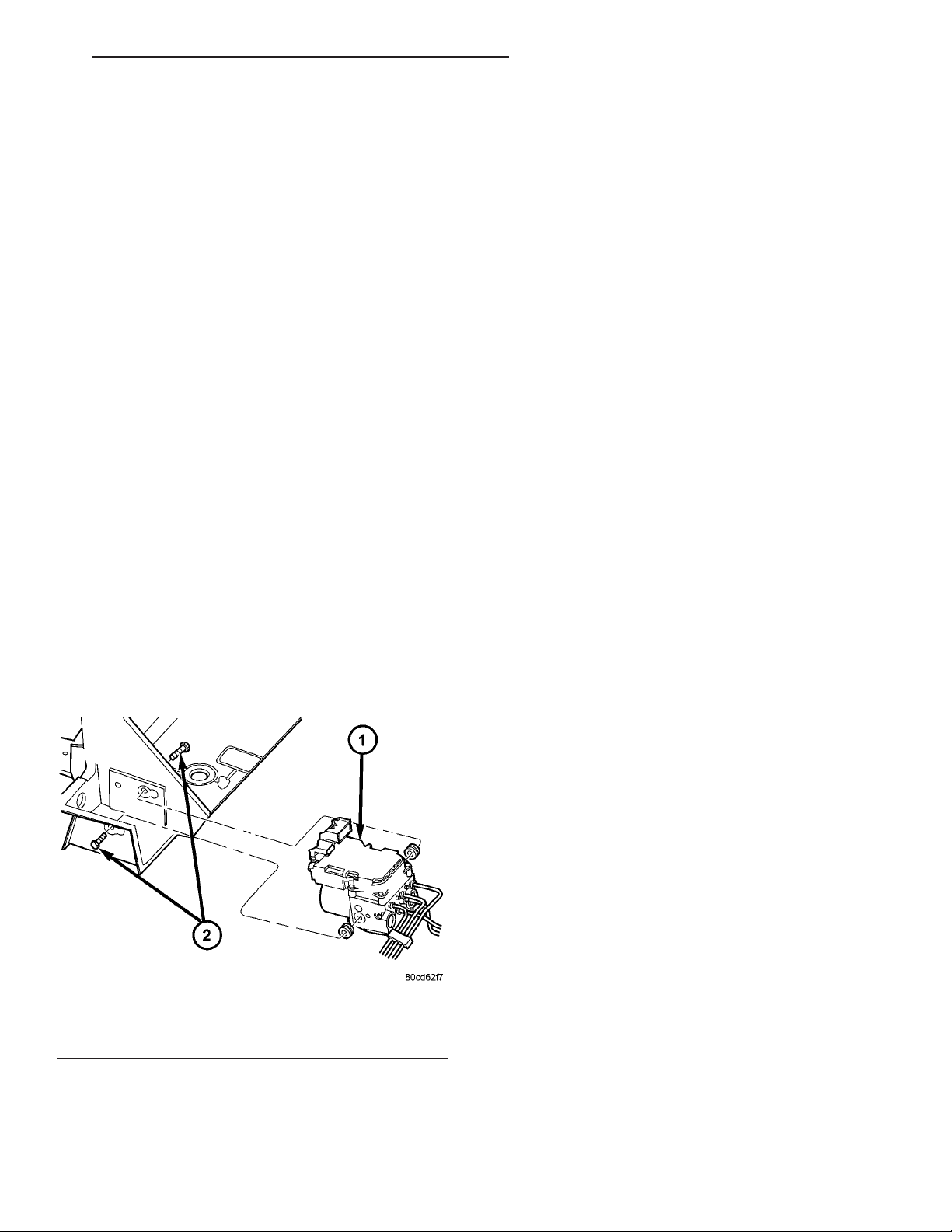

The Controler Antilock Brake (CAB) is mounted to

the Hydraulic Control Unit (HCU) and operates the

ABS system (Fig. 1).

OPERATION

The CAB voltage source is through the ignition

switch in the RUN position. The CAB contains a self

check program that illuminates the ABS warning

light when a system fault is detected. Faults are

stored in a diagnostic program memory and are

accessible with the DRB III scan tool. ABS faults

remain in memory until cleared, or until after the

vehicle is started approximately 50 times. Stored

faults are not erased if the battery is disconnected.

NOTE: If the CAB is being replaced with a new CAB

is must be reprogrammed with the use of a DRB III.

REMOVAL

(1) Remove the negative battery cable from the

battery.

(2) Pull up on the CAB harness connector release

and remove connector.

(3) Remove the CAB mounting bolts.

(4) Remove the pump connector from the CAB.

(5) Remove the CAB from the HCU.

INSTALLATION

NOTE: If the CAB is being replaced with a new CAB

is must be reprogrammed with the use of a DRB III.

(1) Install CAB to the HCU.

(2) Install the pump connector to the CAB.

(3) Install mounting bolts. Tighten to 2 N·m (16 in.

lbs.).

(4) Install the wiring harness connector to the

CAB and push down on the release to secure the connector.

(5) Install negative battery cable to the battery.

Fig. 1 HYDRAULIC CONTROL UNIT

1 - HYDRAULIC CONTROL UNIT

2 - MOUNTING BOLTS

DATA LINK CONNECTOR

DESCRIPTION - DATA LINK CONNECTOR

The Data Link Connector (DLC) is located at the

lower edge of the instrument panel near the steering

column.

OPERATION - DATA LINK CONNECTOR

The 16–way data link connector (diagnostic scan

tool connector) links the Diagnostic Readout Box

(DRB) scan tool or the Mopar Diagnostic System

(MDS) with the Powertrain Control Module (PCM).

Page 4

8E - 4 ELECTRONIC CONTROL MODULES DR

ENGINE CONTROL MODULE

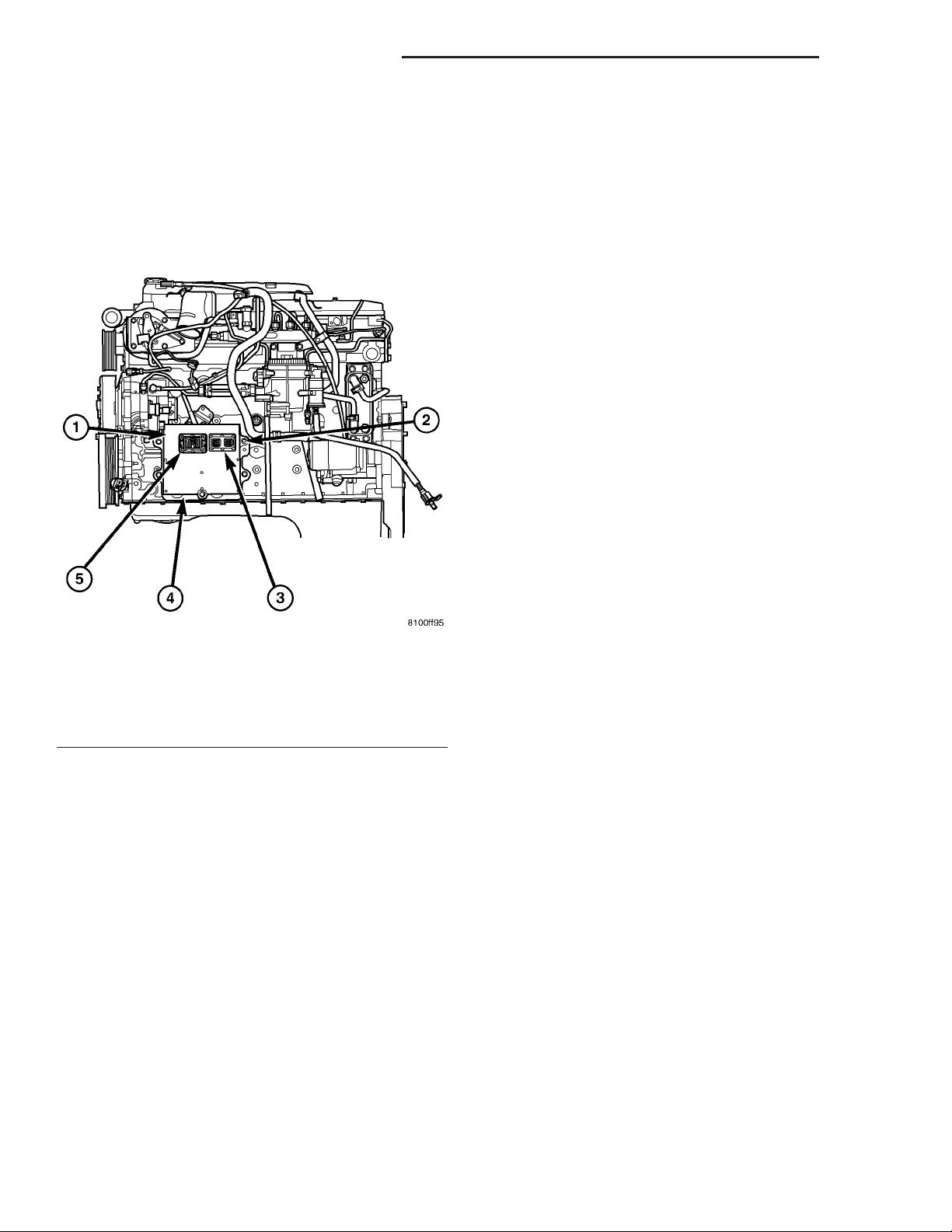

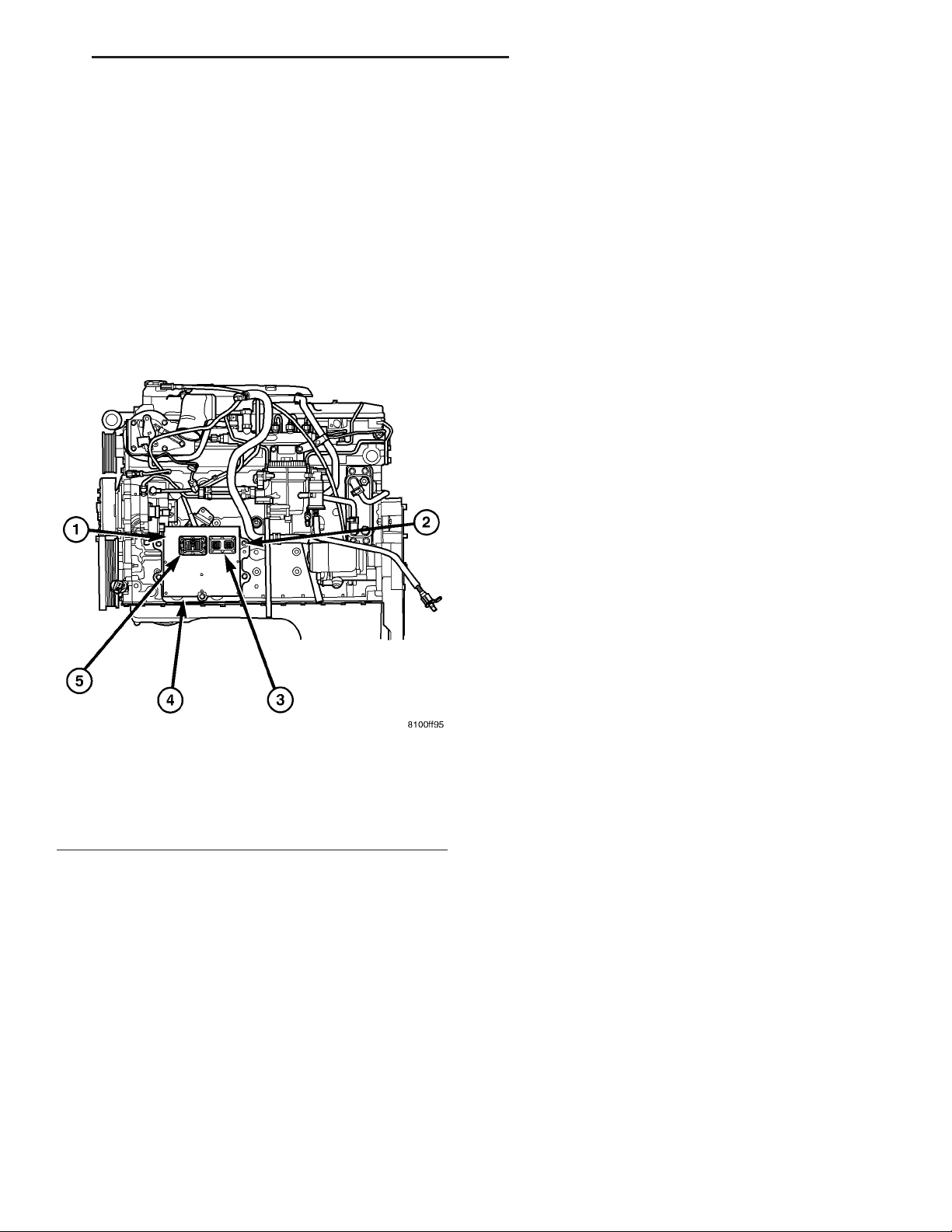

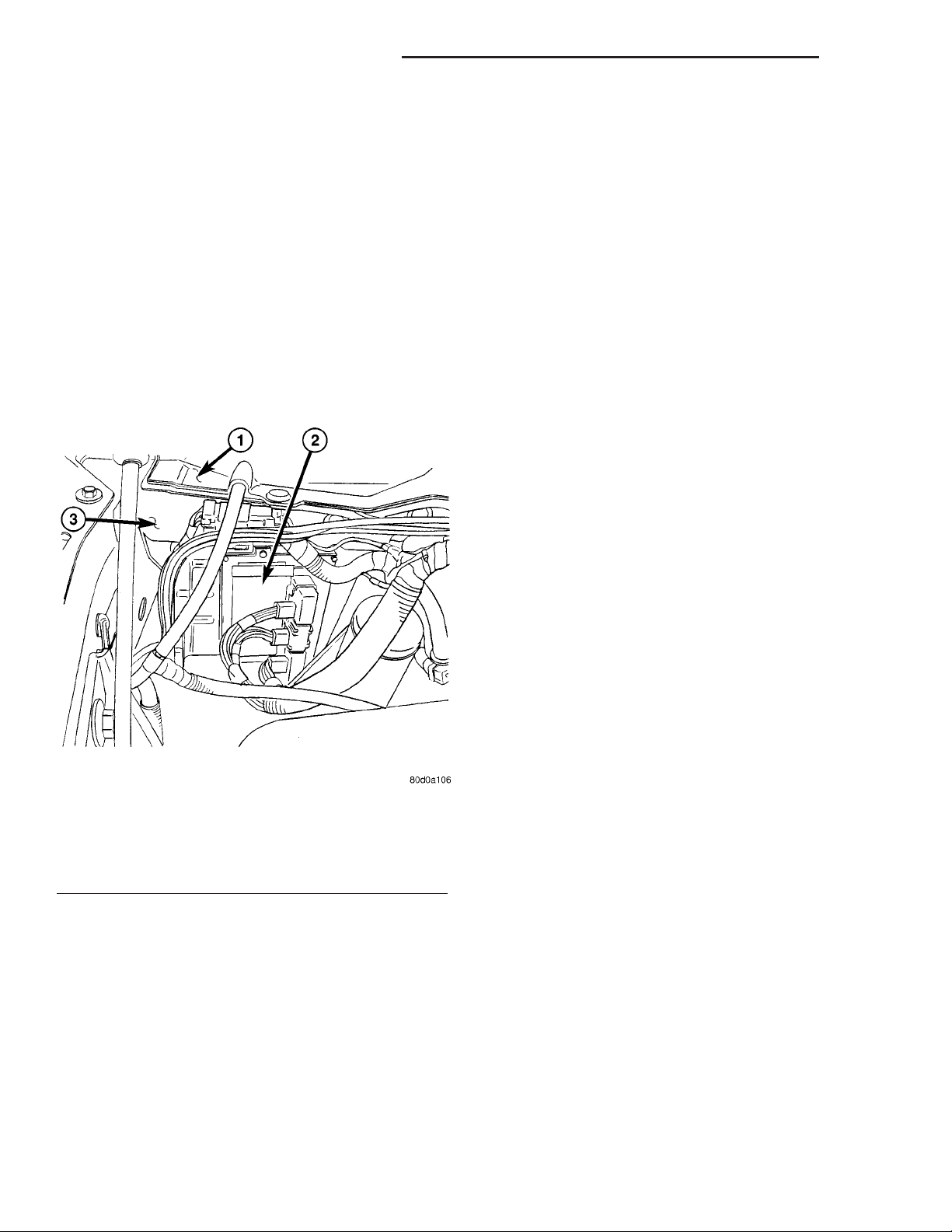

DESCRIPTION - ECM

The Engine Control Module (ECM) is bolted to the

left side of the engine below the intake manifold (Fig.

2).

NOTE: ECM Inputs:

• Accelerator Pedal Position Sensor (APPS) Volts

• APPS1 Signal — For off engine APPS

• APPS2 Signal — For off engine APPS

• APPS Idle Validation Switches #1 and #2

• Battery voltage

• Camshaft Position Sensor (CMP)

• CCD bus (+) circuits

• CCD bus (-) circuits

• Crankshaft Position Sensor (CKP)

• Data link connection for DRB scan tool

• Engine Coolant Temperature (ECT) sensor

• Ground circuits

• Fuel Pressure Sensor

• Battery Temperature

• Fan speed

• Inlet Air Temperature Sensor/Pressure Sensor

• Intake Air Temperature Sensor/MAP Sensor

• Oil Pressure SWITCH

• Power ground

• Sensor return

• Signal ground

• Water-In-Fuel (WIF) sensor

Fig. 2 DIESEL ECM

1 - ENGINE CONTROL MODULE (ECM)

2 - ECM MOUNTING BOLT

3 - 50-WAY CONNECTOR

4 - SUPPORT PLATE

5 - 60-WAY CONNECTOR

OPERATION - ECM

The main function of the Engine Control Module

(ECM) is to electrically control the fuel system. The

Powertrain Control Module (PCM) does not control

the fuel system.

The ECM can adapt its programming to meet

changing operating conditions. If the ECM has

been replaced, flashed or re-calibrated, the

ECM must learn the Accelerator Pedal Position

Sensor (APPS) idle voltage. Failure to learn

this voltage may result in unnecessary diagnostic trouble codes. Refer to ECM Removal/Installation for learning procedures.

The ECM receives input signals from various

switches and sensors. Based on these inputs, the

ECM regulates various engine and vehicle operations

through different system components. These components are referred to as ECM Outputs. The sensors

and switches that provide inputs to the ECM are

considered ECM Inputs.

NOTE: ECM Outputs:

After inputs are received by the ECM, certain sensors, switches and components are controlled or regulated by the ECM. These are considered ECM

Outputs. These outputs are for:

• CCD bus (+) circuits

• CCD bus (-) circuits

• CKP and APPS outputs to the PCM

• Data link connection for DRB scan tool

• Five volt sensor supply

• Fuel transfer (lift) pump

• Intake manifold air heater relays #1 and #2 con-

trol circuits

• Malfunction indicator lamp (Check engine lamp)

(databus)

• Oil Pressure Swith/warning lamp (databus)

• Fuel Control Actuator

• Wait-to-start warning lamp (databus)

• Fan Clutch PWM

• Water-In-Fuel (WIF) warning lamp (databus)

REMOVAL

The Engine Control Module (ECM) is bolted to a

support bracket near the fuel filter. The support

bracket mounts to the block with four capscrews and

vibration isolators. A ground wire is fastened to the

bracket. The other end of the wire is fastened to the

engine block.

(1) Record any Diagnostic Trouble Codes (DTC’s)

found in the ECM.

Page 5

DR ELECTRONIC CONTROL MODULES 8E - 5

ENGINE CONTROL MODULE (Continued)

To avoid possible voltage spike damage to either

the Engine Control Module ECM, ignition key must

be off, and negative battery cables must be disconnected before unplugging ECM connectors.

(2) Disconnect both negative battery cables at both

batteries.

(3) Remove the 50–way and 60–way connector

bolts at the ECM. Note: Tthe connector bolt is a

female allen head. As bolt is being removed, very carfully remove connectors from the ECM.

(4) Remove five ECM mounting bolts and remove

ECM form the vehicle (Fig. 3).

(6) Turn key to ON position. Without starting

engine, slowly press throttle pedal to floor and

then slowly release. This step must be done

(one time) to ensure accelerator pedal position

sensor calibration has been learned by ECM. If

not done, possible DTC’s may be set.

(7) Use DRB scan tool to erase any stored compan-

ion DTC’s from ECM.

FRONT CONTROL MODULE

DESCRIPTION

The Front Control Module (FCM) is a micro controller based module located in the left front corner

of the engine compartment. On this model the integrated power module must be positioned aside in

order to access the front control module. The front

control module mates to the power distribution center to form the Integrated Power Module (IPM). The

integrated power module connects directly to the battery and provides the primary means of circuit protection and power distribution for all vehicle

electrical systems. The front control module controls

power to some of these vehicle systems electrical and

electromechanical loads based on inputs received

from hard wired switch inputs and data received on

the PCI bus circuit (J1850).

For information on the Integrated Power Mod-

ule Refer to the Power Distribution Section of

the service manual.

Fig. 3 DIESEL ECM

1 - ENGINE CONTROL MODULE (ECM)

2 - ECM MOUNTING BOLT

3 - 50-WAY CONNECTOR

4 - SUPPORT PLATE

5 - 60-WAY CONNECTOR

INSTALLATION

Do not apply paint to ECM. Poor ground will

result.

(1) Position ECM to ECM support bracket and

install five mounting bolts. Tighten bolts to 24 N·m

(18 ft. lbs.).

(2) Check pin connectors in ECM and the 50–way

and 60–way connectors for corrosion or damage.

Repair as necessary.

(3) Clean pins in the 50–way and 60–way electrical connectors with a quick-dry electrical contact

cleaner.

(4) Very carefully install the 50–way and 60–way

connectors to ECM. Tighten connector allen bolts.

(5) Install both negative battery cables.

OPERATION

As messages are sent over the PCI bus circuit, the

front control module reads these messages and controls power to some of the vehicles electrical systems

by completing the circuit to ground (low side driver)

or completing the circuit to 12 volt power (high side

driver). The following functions are Controlled by

the Front Control Module:

• Headlamp Power with Voltage Regulation

• Windshield Wiper “ON/OFF” Relay Actuation

• Windshield Wiper “HI/LO” Relay Actuation

• Windshield Washer Pump Motor

• Fog Lamp Relay Actuation

• Park Lamp Relay Actuation

• Horn Relay Actuation

The following inputs are Received/Monitored by

the Front Control Module:

• B+ Connection Detection

• Power Ground

• Ambient Temperature Sensing

• Ignition Switch Run

• Washer Fluid Level Switch

• Windshield Wiper Park Switch

• PCI Bus Circuit

Page 6

8E - 6 ELECTRONIC CONTROL MODULES DR

FRONT CONTROL MODULE (Continued)

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Communications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diagnosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

requires the use of a DRB IIIt scan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Partially remove the integrated power module

from the engine compartment (Refer to 8 - ELECTRICAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - REMOVAL).

(3) Remove the front control module retaining

screws.

(4) Using both hands, pull the front control module

straight from the integrated power module assembly

to disconnect the 49-way electrical connector and

remove the front control module from the vehicle.

INSTALLATION

(1) Install the front control module on the integrated power module assembly by pushing the

49-way electrical connector straight in.

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Install the integrated power module (Refer to 8

- ELECTRICAL/POWER DISTRIBUTION/INTEGRATED POWER MODULE - INSTALLATION).

(4) Connect the positive and negative battery

cables.

HEATED SEAT MODULE

DESCRIPTION

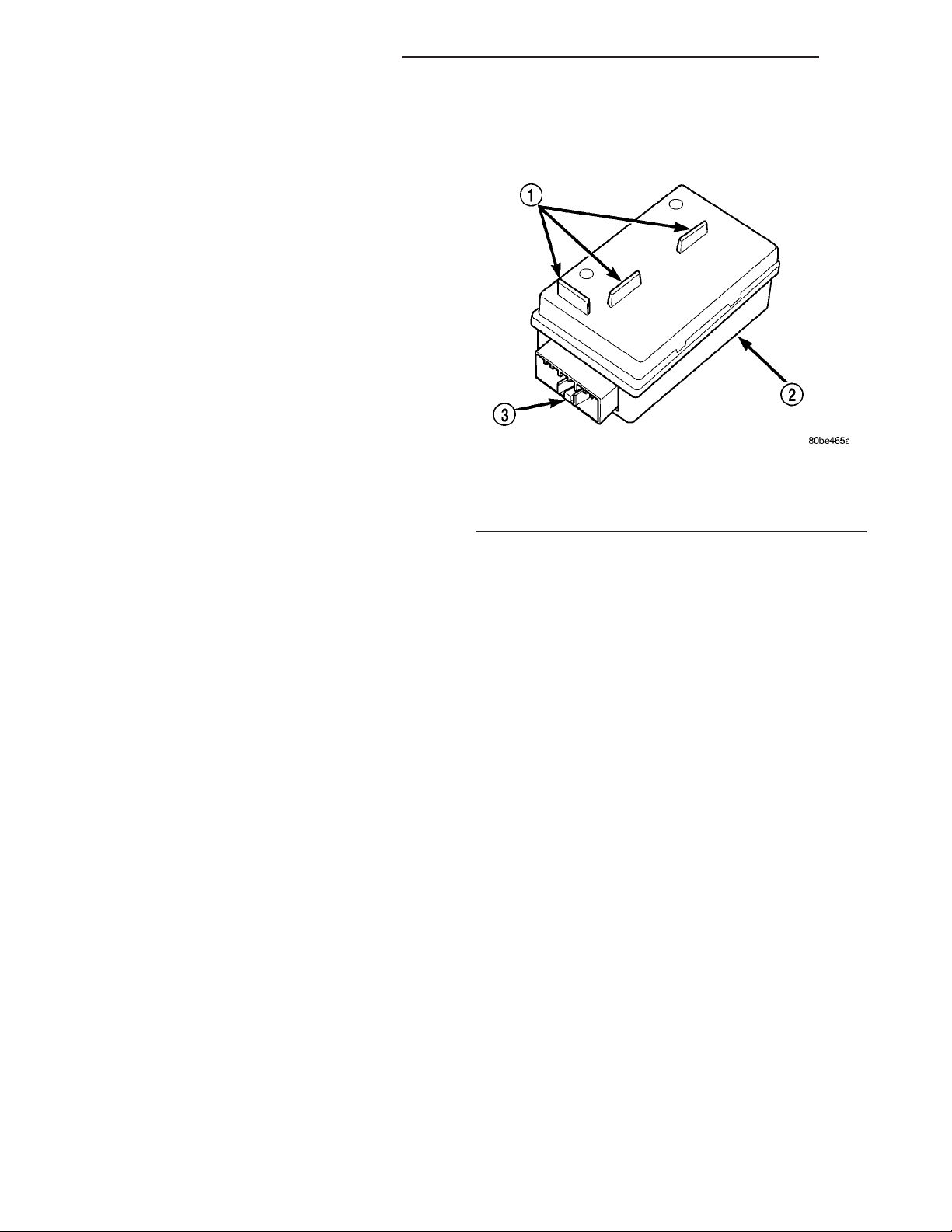

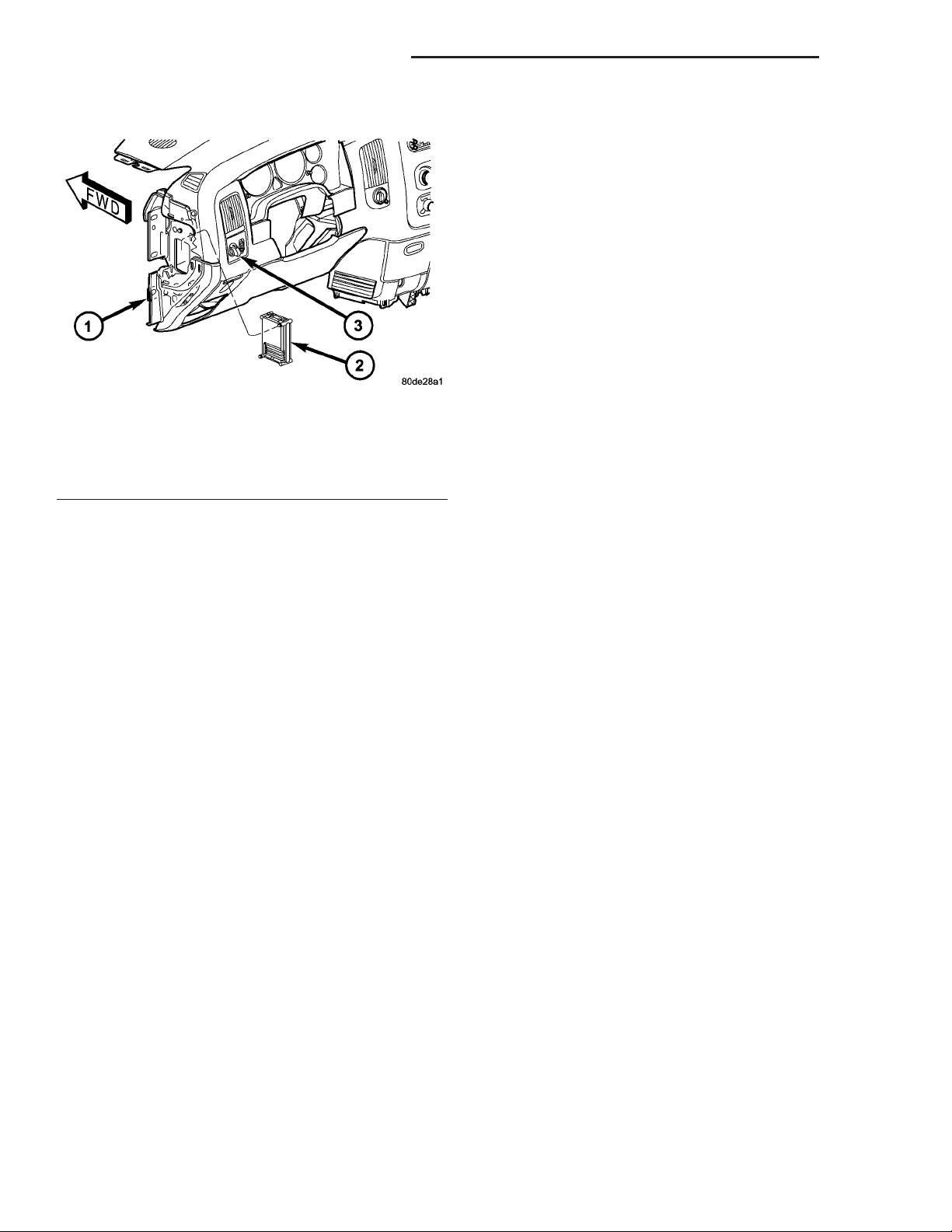

Fig. 4 Heated Seat Module

1 - MOUNTING TABS (NOT USED ON DR)

2 - HEATED SEAT MODULE

3 - ELECTRICAL CONNECTOR RECEPTACLE

The heated seat module is also known as the Seat

Heat Interface Module. The heated seat module (Fig.

4) is located under the drivers front seat cushion,

where it is secured to a mounting bracket. The

heated seat module has a single connector receptacle

that allows the module to be connected to all of the

required inputs and outputs through the seat wire

harness.

The heated seat module is an electronic microprocessor controlled device designed and programmed to

use inputs from the battery, the two heated seat

switches and the two heated seat sensors to operate

and control the heated seat elements in both front

seats and the two heated seat indicator lamp LightEmitting Diodes (LEDs) in each heated seat switch.

The heated seat module is also programmed to perform self-diagnosis of certain heated seat system

functions and provide feedback of that diagnosis

through the heated seat switch indicator lamps.

The heated seat module cannot be repaired. If the

heated seat module is damaged or faulty, the entire

module must be replaced.

OPERATION

The heated seat module operates on fused battery

current received from the integrated power module.

Inputs to the module include a resistor multiplexed

heated seat switch request circuit for each of the two

heated seat switches and the heated seat sensor

inputs from the seat cushions of each front seat. In

response to those inputs the heated seat module controls battery current feeds to the heated seat ele-

Page 7

DR ELECTRONIC CONTROL MODULES 8E - 7

HEATED SEAT MODULE (Continued)

ments and sensors, and controls the ground for the

heated seat switch indicator lamps.

When a heated seat switch (Driver or Passenger) is

depressed a signal is received by the heated seat

module, the module energizes the proper indicator

LED (Low or High) in the switch by grounding the

indicator lamp circuit to indicate that the heated seat

system is operating. At the same time, the heated

seat module energizes the selected heated seat sensor

circuit and the sensor provides the module with an

input indicating the surface temperature of the

selected seat cushion.

The Low heat set point is about 36° C (96.8° F),

and the High heat set point is about 42° C (107.6° F).

If the seat cushion surface temperature input is

below the temperature set point for the selected temperature setting, the heated seat module energizes

an N-channel Field Effect Transistor (N-FET) within

the module which energizes the heated seat elements

in the selected seat cushion and back. When the sensor input to the module indicates the correct temperature set point has been achieved, the module

de-energizes the N-FET which de-energizes the

heated seat elements. The heated seat module will

continue to cycle the N-FET as needed to maintain

the selected temperature set point.

If the heated seat module detects a heated seat

sensor value input that is out of range or a shorted

or open heated seat element circuit, it will notify the

vehicle operator or the repair technician of this condition by flashing the High and/or Low indicator

lamps in the affected heated seat switch. Refer to

Diagnosis and Testing Heated Seat System in

Heated Systems for flashing LED diagnosis and testing procedures. Refer to Diagnosis and Testing

Heated Seat Module in this section for heated seat

module diagnosis and testing procedures.

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE

If a heated seat fails to heat and one or both of the

indicator lamps on a heated seat switch flash, refer

to Diagnosis and Testing Heated Seat System in

Heated Seats for the location of flashing LED heated

seat system diagnosis and testing procedures. If a

heated seat heats but one or both indicator lamps on

the heated seat switch fail to operate, test the heated

seat switch. Refer to Diagnosis and Testing

Heated Seat Switch in Heated Seats for heated

seat switch diagnosis and testing procedures. If the

heated seat switch checks OK, proceed as follows.

(1) Check the heated seat element (Refer to 8 ELECTRICAL/HEATED SEATS/HEATED SEAT

ELEMENT - DIAGNOSIS AND TESTING).

(2) Check the heated seat sensor (Refer to 8 ELECTRICAL/HEATED SEATS/HEATED SEAT

SENSOR - DIAGNOSIS AND TESTING).

(3) Check the heated seat switch (Refer to 8 ELECTRICAL/HEATED SEATS/DRIVER HEATED

SEAT SWITCH - DIAGNOSIS AND TESTING).

NOTE: Refer to Wiring for the location of complete

heated seat system wiring diagrams and connector

pin-out information.

(4) Using a voltmeter, backprobe the appropriate

heated seat module connector, do not disconnect.

Check for voltage at the appropriate pin cavities. 12v

should be present. If OK go to Step 5, if Not, Repair

the open or shorted voltage supply circuit as

required.

(5) Using a ohmmeter, backprobe the appropriate

heated seat module connector, do not disconnect.

Check for proper continuity to ground on the ground

pin cavities. Continuity should be present. If OK

replace the heated seat module with a known good

unit and retest system, if Not OK, Repair the open or

shorted ground circuit as required.

REMOVAL

(1) Position the driver seat to the full rearward

and inclined position.

(2) Working under the driver front seat, remove

the two heated seat module retaining screws. Due to

the fact that the retaining screws are installed with

the seat cushion pan removed, a small right angle

screwdriver will be required to access and remove the

screws.

(3) Disconnect the seat wire harness connector

from the connector receptacle on the back of the

heated seat module. Depress the connector retaining

tab and pull straight apart.

(4) Remove the heated seat module from under the

front seat.

INSTALLATION

(1) Position the heated seat module under the

front seat.

(2) Connect the seat wire harness connector on the

connector receptacle on the back of the heated seat

module.

(3) Working under the driver front seat, install the

heated seat module retaining screws.

(4) Re-position the driver seat.

Page 8

8E - 8 ELECTRONIC CONTROL MODULES DR

POWERTRAIN CONTROL

MODULE

DESCRIPTION

DESCRIPTION - PCM

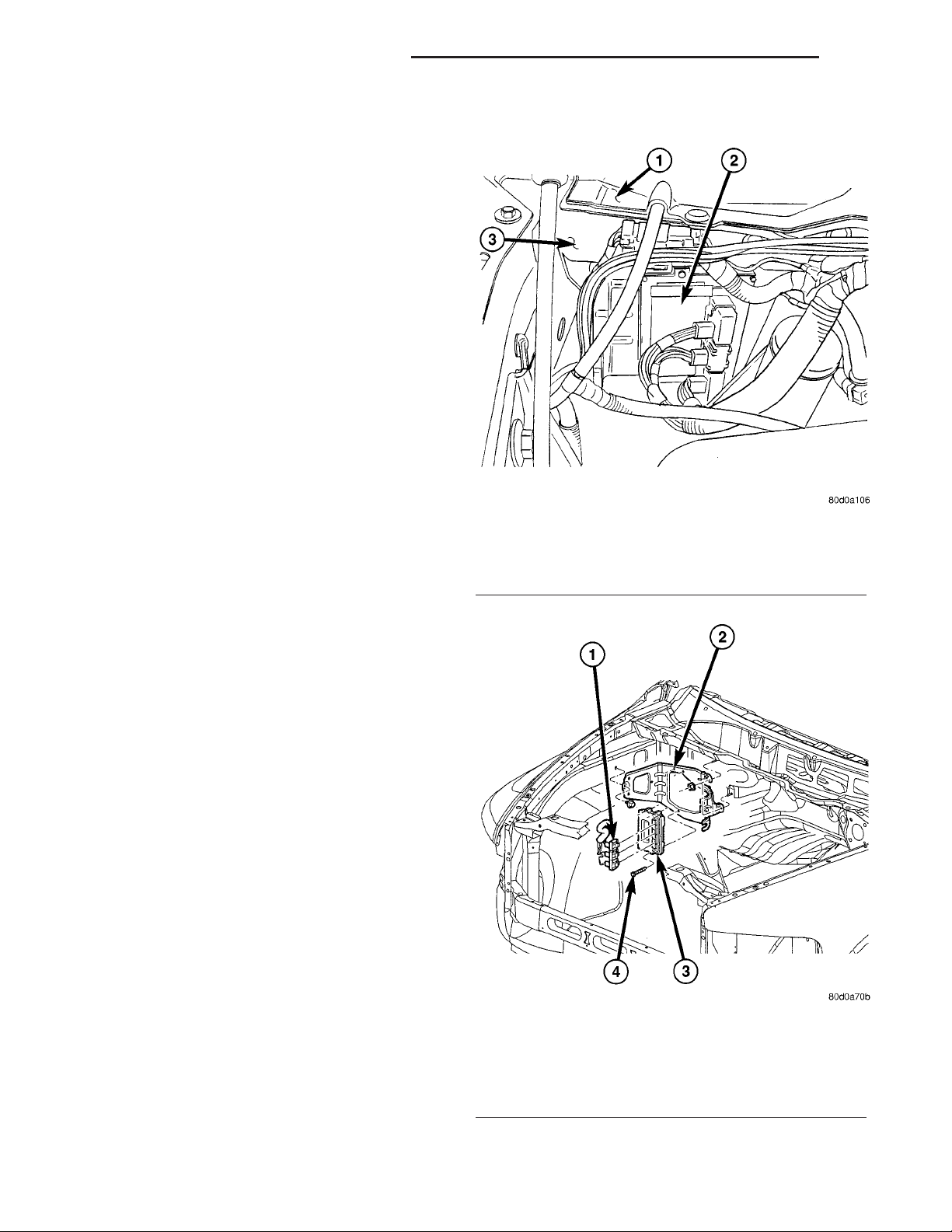

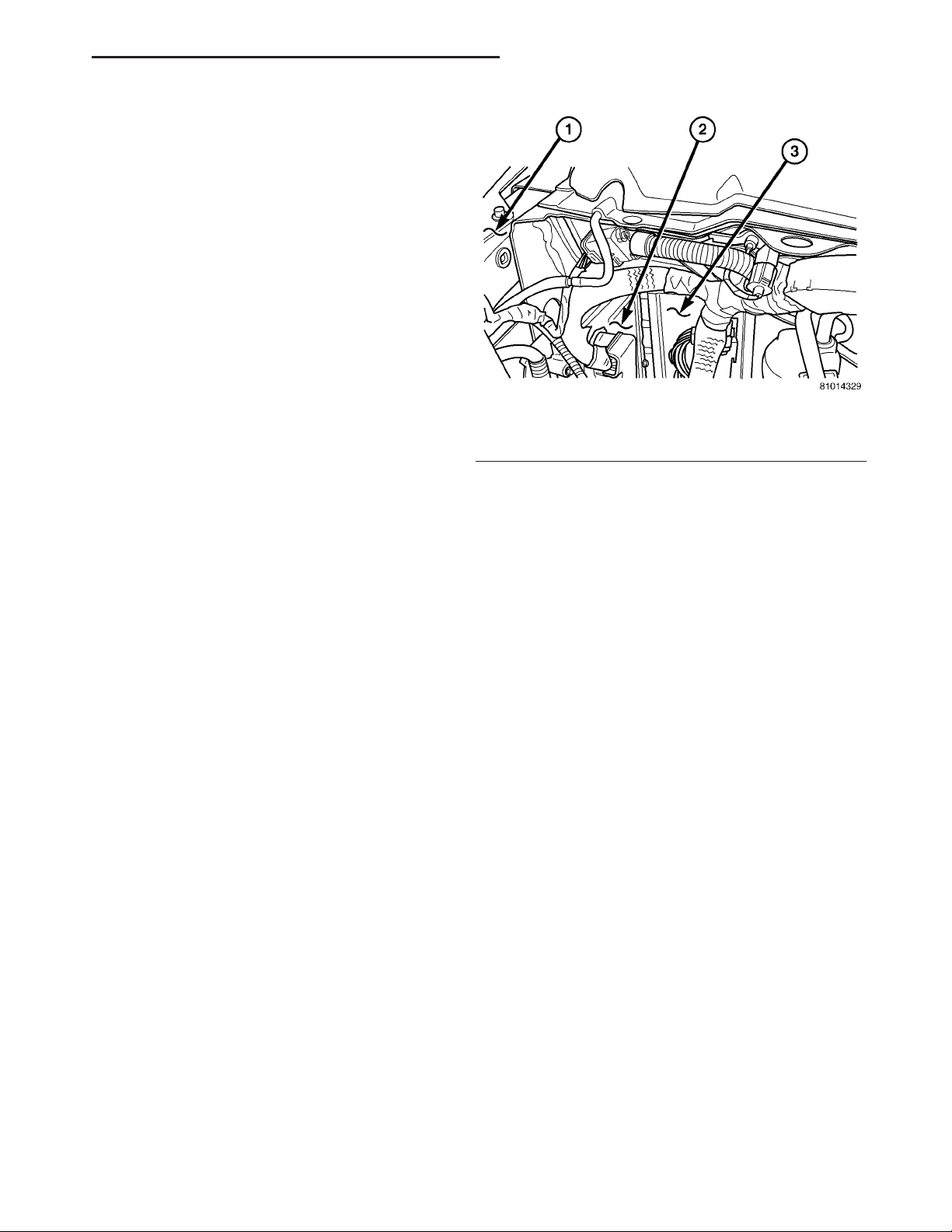

The Powertrain Control Module (PCM) is located

in the right-rear section of the engine compartment

under the cowl (Fig. 5).

Two different PCM’s are used (JTEC and

NGC). These can be easily identified. JTEC’s

use three 32–way connectors, NGC’s use four

38–way connectors

During Closed Loop modes, the PCM will monitor

the oxygen (O2S) sensors input. This input indicates

to the PCM whether or not the calculated injector

pulse width results in the ideal air-fuel ratio. This

ratio is 14.7 parts air-to-1 part fuel. By monitoring

the exhaust oxygen content through the O2S sensor,

the PCM can fine tune the injector pulse width. This

is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

• Ignition switch ON

• Engine start-up (crank)

• Engine warm-up

• Idle

• Cruise

• Acceleration

• Deceleration

• Wide open throttle (WOT)

• Ignition switch OFF

The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle

and cruise modes, (with the engine at operating temperature) are Closed Loop modes.

Fig. 5 POWERTRAIN CONTROL MODULE (PCM)

LOCATION

1 - COWL GRILL

2 - PCM

3 - COWL (RIGHT-REAR)

DESCRIPTION - MODES OF OPERATION

As input signals to the Powertrain Control Module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT).

The PCM will operate in two different modes:

Open Loop and Closed Loop.

During Open Loop modes, the PCM receives input

signals and responds only according to preset PCM

programming. Input from the oxygen (O2S) sensors

is not monitored during Open Loop modes.

IGNITION SWITCH (KEY-ON) MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following

actions occur:

• The PCM pre-positions the idle air control (IAC)

motor.

• The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

• The PCM monitors the engine coolant temperature sensor input. The PCM modifies fuel strategy

based on this input.

• Intake manifold air temperature sensor input is

monitored.

• Throttle position sensor (TPS) is monitored.

• The auto shutdown (ASD) relay is energized by

the PCM for approximately three seconds.

• The fuel pump is energized through the fuel

pump relay by the PCM. The fuel pump will operate

for approximately three seconds unless the engine is

operating or the starter motor is engaged.

• The O2S sensor heater element is energized via

the ASD or O2S heater relay. The O2S sensor input

is not used by the PCM to calibrate air-fuel ratio during this mode of operation.

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The PCM receives inputs from:

Page 9

DR ELECTRONIC CONTROL MODULES 8E - 9

POWERTRAIN CONTROL MODULE (Continued)

• Battery voltage

• Engine coolant temperature sensor

• Crankshaft position sensor

• Intake manifold air temperature sensor

• Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS)

• Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within 3 seconds of cranking the

engine, it will shut down the fuel injection system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

The PCM determines the proper ignition timing

according to input received from the crankshaft position sensor.

ENGINE WARM-UP MODE

This is an Open Loop mode. During engine warmup, the PCM receives inputs from:

• Battery voltage

• Crankshaft position sensor

• Engine coolant temperature sensor

• Intake manifold air temperature sensor

• Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS)

• Camshaft position sensor signal

• Park/neutral switch (gear indicator signal—auto.

trans. only)

• Air conditioning select signal (if equipped)

• Air conditioning request signal (if equipped)

Based on these inputs the following occurs:

• Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

• The PCM adjusts engine idle speed through the

idle air control (IAC) motor and adjusts ignition timing.

• The PCM operates the A/C compressor clutch

through the A/C compressor clutch relay. This is done

if A/C has been selected by the vehicle operator and

specified pressures are met at the high and low–pressure A/C switches. Refer to Heating and Air Conditioning for additional information.

• When engine has reached operating temperature, the PCM will begin monitoring O2S sensor

input. The system will then leave the warm-up mode

and go into closed loop operation.

IDLE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At idle speed, the PCM

receives inputs from:

• Air conditioning select signal (if equipped)

• Air conditioning request signal (if equipped)

• Battery voltage

• Crankshaft position sensor

• Engine coolant temperature sensor

• Intake manifold air temperature sensor

• Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS)

• Camshaft position sensor signal

• Battery voltage

• Park/neutral switch (gear indicator signal—auto.

trans. only)

• Oxygen sensors

Based on these inputs, the following occurs:

• Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

injection sequence and injector pulse width by turning the ground circuit to each individual injector on

and off.

• The PCM monitors the O2S sensor input and

adjusts air-fuel ratio by varying injector pulse width.

It also adjusts engine idle speed through the idle air

control (IAC) motor.

• The PCM adjusts ignition timing by increasing

and decreasing spark advance.

• The PCM operates the A/C compressor clutch

through the A/C compressor clutch relay. This is done

if A/C has been selected by the vehicle operator and

specified pressures are met at the high and low–pressure A/C switches. Refer to Heating and Air Conditioning for additional information.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the PCM

receives inputs from:

• Air conditioning select signal (if equipped)

• Air conditioning request signal (if equipped)

• Battery voltage

• Engine coolant temperature sensor

• Crankshaft position sensor

• Intake manifold air temperature sensor

• Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS)

• Camshaft position sensor signal

• Park/neutral switch (gear indicator signal—auto.

trans. only)

• Oxygen (O2S) sensors

Based on these inputs, the following occurs:

• Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then adjust

Page 10

8E - 10 ELECTRONIC CONTROL MODULES DR

POWERTRAIN CONTROL MODULE (Continued)

the injector pulse width by turning the ground circuit

to each individual injector on and off.

• The PCM monitors the O2S sensor input and

adjusts air-fuel ratio. It also adjusts engine idle

speed through the idle air control (IAC) motor.

• The PCM adjusts ignition timing by turning the

ground path to the coil(s) on and off.

• The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

ACCELERATION MODE

This is an Open Loop mode. The PCM recognizes

an abrupt increase in throttle position or MAP pressure as a demand for increased engine output and

vehicle acceleration. The PCM increases injector

pulse width in response to increased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

PCM receives the following inputs.

• Air conditioning select signal (if equipped)

• Air conditioning request signal (if equipped)

• Battery voltage

• Engine coolant temperature sensor

• Crankshaft position sensor

• Intake manifold air temperature sensor

• Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS)

• Camshaft position sensor signal

• Park/neutral switch (gear indicator signal—auto.

trans. only)

• Vehicle speed

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not

supply a ground to the injectors. If a hard deceleration does not exist, the PCM will determine the

proper injector pulse width and continue injection.

Based on the above inputs, the PCM will adjust

engine idle speed through the idle air control (IAC)

motor.

The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

WIDE OPEN THROTTLE MODE

This is an Open Loop mode. During wide open

throttle operation, the PCM receives the following

inputs.

• Battery voltage

• Crankshaft position sensor

• Engine coolant temperature sensor

• Intake manifold air temperature sensor

• Manifold absolute pressure (MAP) sensor

• Throttle position sensor (TPS)

• Camshaft position sensor signal

During wide open throttle conditions, the following

occurs:

• Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off. The PCM ignores the oxygen sensor input

signal and provides a predetermined amount of additional fuel. This is done by adjusting injector pulse

width.

• The PCM adjusts ignition timing by turning the

ground path to the coil(s) on and off.

IGNITION SWITCH OFF MODE

When ignition switch is turned to OFF position,

the PCM stops operating the injectors, ignition coil,

ASD relay and fuel pump relay.

DESCRIPTION - 5 VOLT SUPPLIES

Two different Powertrain Control Module (PCM)

five volt supply circuits are used; primary and secondary.

DESCRIPTION - IGNITION CIRCUIT SENSE

This circuit ties the ignition switch to the Powertrain Control Module (PCM).

DESCRIPTION - POWER GROUNDS

The Powertrain Control Module (PCM) has 2 main

grounds. Both of these grounds are referred to as

power grounds. All of the high-current, noisy, electrical devices are connected to these grounds as well as

all of the sensor returns. The sensor return comes

into the sensor return circuit, passes through noise

suppression, and is then connected to the power

ground.

The power ground is used to control ground circuits for the following PCM loads:

• Generator field winding

• Fuel injectors

• Ignition coil(s)

• Certain relays/solenoids

• Certain sensors

DESCRIPTION - SENSOR RETURN

The Sensor Return circuits are internal to the Powertrain Control Module (PCM).

Sensor Return provides a low–noise ground reference for all engine control system sensors. Refer to

Power Grounds for more information.

Page 11

DR ELECTRONIC CONTROL MODULES 8E - 11

POWERTRAIN CONTROL MODULE (Continued)

OPERATION

OPERATION - PCM

The PCM operates the fuel system. The PCM is a

pre-programmed, triple microprocessor digital computer. It regulates ignition timing, air-fuel ratio,

emission control devices, charging system, certain

transmission features, speed control, air conditioning

compressor clutch engagement and idle speed. The

PCM can adapt its programming to meet changing

operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These components are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that provide inputs to the PCM are considered Powertrain

Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon

inputs it receives from sensors that react to: engine

rpm, manifold absolute pressure, engine coolant temperature, throttle position, transmission gear selection (automatic transmission), vehicle speed, power

steering pump pressure, and the brake switch.

The PCM adjusts idle speed based on inputs it

receives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine

coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.

Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the generator charge rate through control of the generator

field and provides speed control operation.

NOTE: PCM Inputs:

• ABS module (if equipped)

• A/C request (if equipped with factory A/C)

• A/C select (if equipped with factory A/C)

• A/C pressure transducer

• Auto shutdown (ASD) sense

• Battery temperature sensor

• Battery voltage

• Brake switch

• J1850 bus (+) circuits

• J1850 bus (-) circuits

• Camshaft position sensor signal

• Crankshaft position sensor

• Data link connection for DRB scan tool

• EATX module (if equipped)

• Engine coolant temperature sensor

• Fuel level (through J1850 circuitry)

• Generator (battery voltage) output

• Ignition circuit sense (ignition switch in on/off/

crank/run position)

• Intake manifold air temperature sensor

• Knock sensors (2 on 3.7L engine)

• Leak detection pump (switch) sense (if equipped)

• Manifold absolute pressure (MAP) sensor

• Oil pressure

• Oxygen sensors

• Park/neutral switch (auto. trans. only)

• Power ground

• Power steering pressure switch (if equipped)

• Sensor return

• Signal ground

• Speed control multiplexed single wire input

• Throttle position sensor

• Transfer case switch (4WD range position)

• Vehicle speed signal

NOTE: PCM Outputs:

• A/C clutch relay

• Auto shutdown (ASD) relay

• J1850 bus (+/-) circuits for: speedometer, voltme-

ter, fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

• Data link connection for DRB scan tool

• EGR valve control solenoid (if equipped)

• EVAP canister purge solenoid

• Five volt sensor supply (primary)

• Five volt sensor supply (secondary)

• Fuel injectors

• Fuel pump relay

• Generator field driver (-)

• Generator field driver (+)

• Idle air control (IAC) motor

• Ignition coil(s)

• Leak detection pump (if equipped)

• Malfunction indicator lamp (Check engine lamp).

Driven through J1850 circuits.

• Oxygen sensor heater relays

• Oxygen sensors (pulse width modulated)

• Radiator cooling fan relay (pulse width modu-

lated)

• Speed control vacuum solenoid

• Speed control vent solenoid

• Tachometer (if equipped). Driven through J1850

circuits.

• Transmission convertor clutch circuit. Driven

through J1850 circuits.

OPERATION - 5 VOLT SUPPLIES

Primary 5–volt supply:

• supplies the required 5 volt power source to the

Crankshaft Position (CKP) sensor.

• supplies the required 5 volt power source to the

Camshaft Position (CMP) sensor.

• supplies a reference voltage for the Manifold

Absolute Pressure (MAP) sensor.

Page 12

8E - 12 ELECTRONIC CONTROL MODULES DR

POWERTRAIN CONTROL MODULE (Continued)

• supplies a reference voltage for the Throttle

Position Sensor (TPS) sensor.

Secondary 5–volt supply:

• supplies the required 5 volt power source to the

oil pressure sensor.

• supplies the required 5 volt power source for the

Vehicle Speed Sensor (VSS) (if equipped).

• supplies the 5 volt power source to the transmission pressure sensor (certain automatic transmissions).

OPERATION - IGNITION CIRCUIT SENSE

The ignition circuit sense input tells the PCM the

ignition switch has energized the ignition circuit.

Battery voltage is also supplied to the PCM

through the ignition switch when the ignition is in

the RUN or START position. This is referred to as

the 9ignition sense9 circuit and is used to 9wake up9

the PCM. Voltage on the ignition input can be as low

as 6 volts and the PCM will still function. Voltage is

supplied to this circuit to power the PCM’s 8-volt regulator and to allow the PCM to perform fuel, ignition

and emissions control functions.

REMOVAL

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW POWERTRAIN CONTROL MODULE

(PCM) WITH THE VEHICLES ORIGINAL IDENTIFICATION NUMBER (VIN) AND THE VEHICLES ORIGINAL MILEAGE. IF THIS STEP IS

NOT DONE, A DIAGNOSTIC TROUBLE CODE

(DTC) MAY BE SET.

The PCM is located in the engine compartment

attached to the dash panel (Fig. 6).

To avoid possible voltage spike damage to the

PCM, ignition key must be off, and negative battery

cable must be disconnected before unplugging PCM

connectors.

(1) Disconnect negative battery cable at battery.

(2) Remove cover over electrical connectors. Cover

snaps onto PCM.

(3) Carefully unplug the three 32–way connectors

(four 38–way connectors if equipped with NGC) from

PCM (Fig. 7).

(4) Remove three PCM mounting bolts (Fig. 7) and

remove PCM from vehicle.

1 - COWL GRILL

2 - PCM

3 - COWL (RIGHT-REAR)

Fig. 6 PCM LOCATION

INSTALLATION

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW POWERTRAIN CONTROL MODULE

(PCM) WITH THE VEHICLES ORIGINAL IDENTIFICATION NUMBER (VIN) AND THE VEHICLES ORIGINAL MILEAGE. IF THIS STEP IS

NOT DONE, A DIAGNOSTIC TROUBLE CODE

(DTC) MAY BE SET.

(1) Install PCM and 3 mounting bolts to vehicle.

Fig. 7 PCM REMOVAL / INSTALLATION

1 - THREE 32-WAY CONNECTORS WITH JTEC (FOUR 38-WAY

CONNECTORS WITH NGC)

2 - PCM MOUNTING BRACKET

3 - PCM

4 - PCM MOUNTING SCREWS (3)

Page 13

DR ELECTRONIC CONTROL MODULES 8E - 13

POWERTRAIN CONTROL MODULE (Continued)

(2) Tighten bolts. Refer to torque specifications.

(3) Check pin connectors in the PCM and the three

32–way connectors (four 38–way connectors if

equipped with NGC) for corrosion or damage. Also,

the pin heights in connectors should all be same.

Repair as necessary before installing connectors.

(4) Install three 32–way connectors (four 38–way

connectors if equipped with NGC).

(5) Install cover over electrical connectors. Cover

snaps onto PCM.

(6) Install negative battery cable.

(7) Use the DRB scan tool to reprogram new PCM

with vehicles original Vehicle Identification Number

(VIN) and original vehicle mileage.

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) contains a Radio Frequency (RF) transceiver and a central processing unit, which includes the Sentry Key

Immobilizer System (SKIS) program logic. The SKIS

programming enables the SKIM to program and

retain in memory the codes of at least two, but no

more than eight electronically coded Sentry Key

transponders. The SKIS programming also enables

the SKIM to communicate over the Programmable

Communication Interface (PCI) bus network with the

Powertrain Control Module (PCM), and/or the

DRBIIIt scan tool.

OPERATION

The SKIM transmits and receives RF signals

through a tuned antenna enclosed within a molded

plastic ring that is integral to the SKIM housing.

When the SKIM is properly installed on the steering

column, the antenna ring is oriented around the ignition lock cylinder housing. This antenna ring must be

located within eight millimeters (0.31 inches) of the

Sentry Key in order to ensure proper RF communication between the SKIM and the Sentry Key transponder.

For added system security, each SKIM is programmed with a unique “Secret Key” code and a

security code. The SKIM keeps the “Secret Key” code

in memory. The SKIM also sends the “Secret Key”

code to each of the programmed Sentry Key transponders. The security code is used by the assembly

plant to access the SKIS for initialization, or by the

dealer technician to access the system for service.

The SKIM also stores in its memory the Vehicle

Identification Number (VIN), which it learns through

a PCI bus message from the PCM during initialization.

The SKIM and the PCM both use software that

includes a rolling code algorithm strategy, which

helps to reduce the possibility of unauthorized SKIS

disarming. The rolling code algorithm ensures security by preventing an override of the SKIS through

the unauthorized substitution of the SKIM or the

PCM. However, the use of this strategy also means

that replacement of either the SKIM or the PCM

units will require a system initialization procedure to

restore system operation.

When the ignition switch is turned to the ON or

START positions, the SKIM transmits an RF signal

to excite the Sentry Key transponder. The SKIM then

listens for a return RF signal from the transponder

of the Sentry Key that is inserted in the ignition lock

cylinder. If the SKIM receives an RF signal with

valid “Secret Key” and transponder identification

codes, the SKIM sends a “valid key” message to the

PCM over the PCI bus. If the SKIM receives an

invalid RF signal or no response, it sends “invalid

key” messages to the PCM. The PCM will enable or

disable engine operation based upon the status of the

SKIM messages.

The SKIM also sends messages to the Instrument

Cluster which controls the VTSS indicator LED. The

SKIM sends messages to the Instrument Cluster to

turn the LED on for about three seconds when the

ignition switch is turned to the ON position as a bulb

test. After completion of the bulb test, the SKIM

sends bus messages to keep the LED off for a duration of about one second. Then the SKIM sends messages to turn the LED on or off based upon the

results of the SKIS self-tests. If the VTSS indicator

LED comes on and stays on after the bulb test, it

indicates that the SKIM has detected a system malfunction and/or that the SKIS has become inoperative.

If the SKIM detects an invalid key when the ignition switch is turned to the ON position, it sends

messages to flash the VTSS indicator LED. The

SKIM can also send messages to flash the LED as an

indication to the customer that the SKIS has been

placed in it’s “Customer Learn” programming mode.

See Sentry Key Immobilizer System Transponder

Programming in this section for more information on

the “Customer Learn” programming mode.

For diagnosis or initialization of the SKIM and the

PCM, a DRBIIIt scan tool and the proper Powertrain

Diagnostic Procedures manual are required. The

SKIM cannot be repaired and, if faulty or damaged,

the unit must be replaced.

Page 14

8E - 14 ELECTRONIC CONTROL MODULES DR

SENTRY KEY IMMOBILIZER MODULE (Continued)

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING

NOTE: There are two procedures for transfering the

secret key to the SKIM:

• When ONLY the SKIM module is replaced, the

secret key is transfered from the PCM to the SKIM.

The ORGINAL KEYS may then be programmed to

the SKIM.

• When ONLY the PCM is replaced, then the

secret key is transfered from the SKIM to the PCM.

The ORGINAL KEYS may be used.

• When BOTH the SKIM and the PCM are

replaced the secret key is transferred from the

SKIM to the PCM, and NEW KEYS must be programmed.

NOTE: Before replacing the Powertrain Control

Module (PCM) for a failed driver, control circuit, or

ground circuit, be sure to check the related component/circuit integrity for failures not detected due to

a double fault in the circuit. Most PCM driver/control circuit failures are caused by internal component failures (i.e. relay and solenoids) and shorted

circuits (i.e. pull-ups, drivers and switched circuits).

These failures are difficult to detect when a double

fault has occurred and only one Diagnostic Trouble

Code (DTC) has set.

When a PCM (SBEC) and the Sentry Key Immobilizer Module (SKIM) are replaced at the same time

perform the following steps in order:

(1) Program the new PCM (SBEC).

(2) Program the new SKIM.

(3) Replace all ignition keys and program them to

the new SKIM.

PROGRAMMING THE PCM (SBEC)

The Sentry Key Immobilizer System (SKIS) Secret

Key is an ID code that is unique to each SKIM. This

code is programmed and stored in the SKIM, PCM

and transponder chip (ignition keys). When replacing

the PCM it is necessary to program the secret key

into the new PCM using the DRBIIIt scan tool. Perform the following steps to program the secret key

into the PCM.

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRBIIIt scan tool and select THEFT

ALARM, SKIM then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

(5) Select ENTER to update PCM VIN.

NOTE: If three attempts are made to enter secure

access mode using an incorrect PIN, secured

access mode will be locked out for one hour. To

exit this lockout mode, turn the ignition to the RUN

position for one hour then enter the correct PIN.

(Ensure all accessories are turned OFF. Also monitor the battery state and connect a battery charger

if necessary).

(6) Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

(7) Press Page Back to get to the Select System

menu and select ENGINE, MISCELLANEOUS, and

SRI MEMORY CHECK.

(8) The DRBIIIt scan tool will ask, Is odometer

reading between XX and XX? Select the YES or NO

button on the DRB IIIt scan tool. If NO is selected,

the DRBIIIt scan tool will read, Enter odometer

Reading<From I.P. odometer>. Enter the odometer

reading from the instrument cluster and press

ENTER.

PROGRAMMING THE SKIM

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRBIIIt scan tool and select THEFT

ALARM, SKIM then MISCELLANEOUS.

(3) Select SKIM REPLACED (GAS ENGINE).

(4) Program the vehicle four-digit PIN into SKIM.

(5) Select COUNTRY CODE and enter the correct

country.

NOTE: Be sure to enter the correct country code. If

the incorrect country code is programmed into the

SKIM, the SKIM must be replaced.

(6) Select YES to update the VIN (the SKIM will

learn the VIN from the PCM).

(7) Press ENTER to transfer the secret key (the

PCM will send the secret key information to the

SKIM).

(8) Program ignition keys to the SKIM.

NOTE: If the PCM and the SKIM are replaced at the

same time, all vehicle keys will need to be replaced

and programmed to the new SKIM.

PROGRAMMING IGNITION KEYS TO THE SKIM

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRBIIIt scan tool and select THEFT

ALARM, SKIM then MISCELLANEOUS.

(3) Select PROGRAM IGNITION KEY’S.

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

Page 15

DR ELECTRONIC CONTROL MODULES 8E - 15

SENTRY KEY IMMOBILIZER MODULE (Continued)

NOTE: A maximum of eight keys can be learned to

each SKIM. Once a key is learned to a SKIM, it (the

key) cannot be transferred to another vehicle.

(5) If ignition key programming is unsuccessful,

the DRBIIIt scan tool will display one of the following messages:

(a) Programming Not Attempted - The DRBIIIt

scan tool attempts to read the programmed key

status and there are no keys programmed into

SKIM memory.

(b) Programming Key Failed (Possible Used Key

From Wrong Vehicle) - SKIM is unable to program

key due to one of the following:

• Faulty ignition key transponder.

• Ignition key is programmed to another vehicle.

(c) 8 Keys Already Learned, Programming Not

Done - SKIM transponder ID memory is full.

(6) Obtain ignition keys to be programmed from

customer (8 keys maximum).

(7) Using the DRBIIIt scan tool, erase all ignition

keys by selecting MISCELLANEOUS and ERASE

ALL CURRENT IGN. KEYS.

(8) Program all ignition keys.

Learned Key In Ignition - Ignition key transponder

ID is currently programmed in SKIM memory.

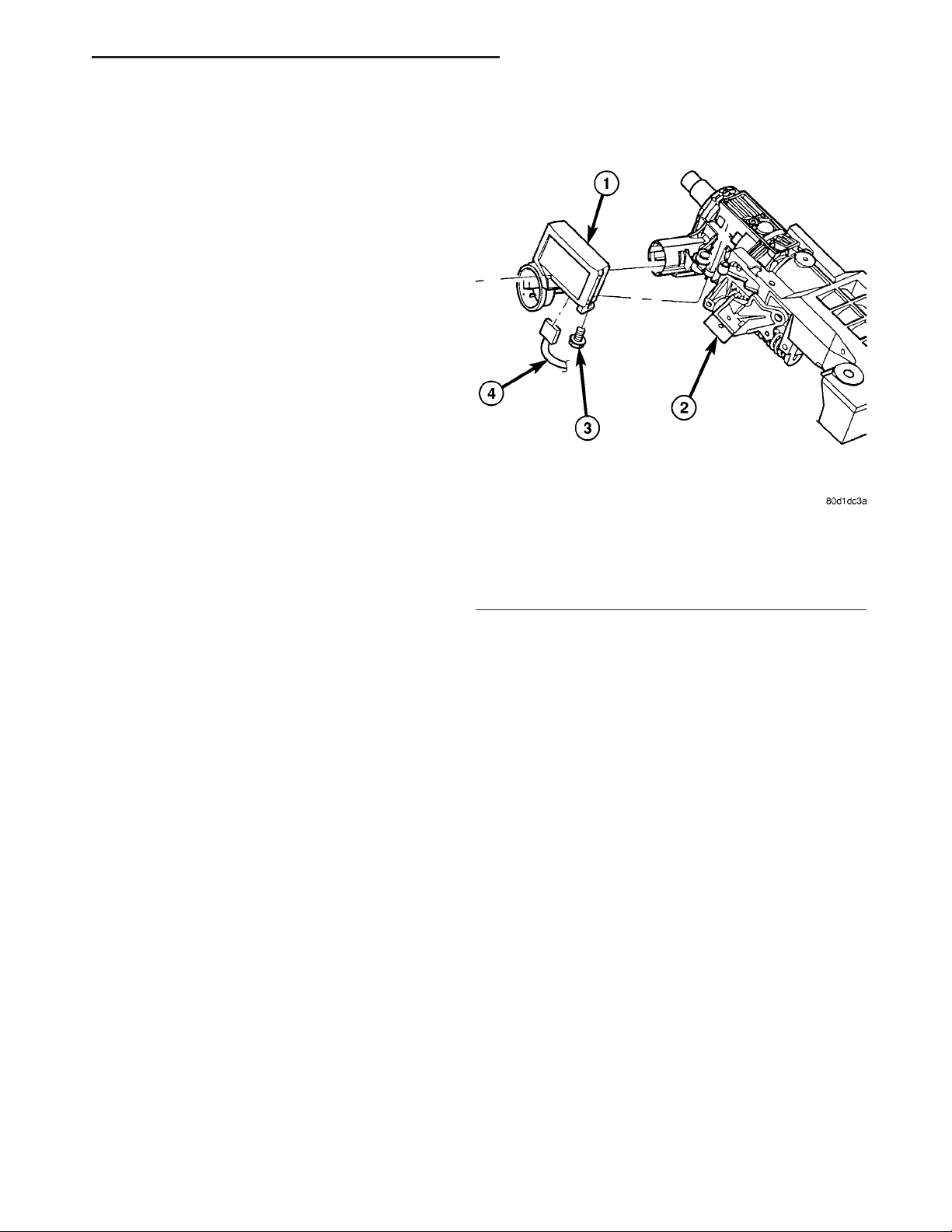

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column upper and lower

shrouds. Refer to Steering, Column, Shroud,

Removal.

(3) Disconnect the steering column wire harness

connector from the Sentry Key Immobilizer Module

(SKIM)

(4) Remove the screw securing the SKIM module

to the steering column (Fig. 8).

(5) Release the SKIM antenna ring retaining clips

from around the ignition switch lock cylinder housing

and remove the SKIM.

INSTALLATION

NOTE: If the SKIM is replaced with a new unit, a

DRBIIIT scan tool MUST be used to initialize the

new SKIM and to program at least two Sentry Key

transponders. (Refer to 8 - ELECTRICAL/VEHICLE

THEFT SECURITY - STANDARD PROCEDURE).

Fig. 8 SENTRY KEY IMMOBILIZER MODULE (SKIM)

1 - SENTRY KEY IMMOBILIZER MODULE (SKIM)

2 - STEERING COLUMN

3 - SCREW

4 - WIRING HARNES

(4) Install the steering column upper and lower

shrouds. Refer to Steering, Column, Shroud, Installation.

(5) Connect the battery negative cable.

TRANSFER CASE CONTROL

MODULE

DESCRIPTION

The Transfer Case Control Module (TCCM) (Fig. 9)

is a microprocessor-based assembly, controlling the

4X4 transfer case shift functions via the actuation of

a shift motor and utilizing the feedback of a mode

sensor assembly. Communication is via the PCI serial

bus. Inputs include user selectable 4X4 modes that

include 2WD, 4HI, 4LO, and Neutral. The logic and

driver circuitry is contained in a molded plastic housing with an embedded heat-sink and is located

behind the left side of the lower instrument panel.

OPERATION

(1) Slide the SKIM antenna ring around the ignition switch lock cylinder housing and clip in place

(Fig. 8).

(2) Install the retaining screw.

(3) Connect the steering column wire harness connector to the Sentry Key Immobilizer Module

(SKIM).

The Transfer Case Control Module (TCCM) utilizes

the input from the transfer case mounted mode sensor, the instrument panel mounted selector switch,

and the following information from the vehicle’s PCI

serial bus to determine if a shift is allowed.

• Engine RPM and Vehicle Speed

Page 16

8E - 16 ELECTRONIC CONTROL MODULES DR

TRANSFER CASE CONTROL MODULE (Continued)

module must receive one ignition message that

denotes that the ignition is in the RUN position.

• Sleep Mode will be entered, from the Reduced

Power Mode, when no PCI traffic has been sensed for

20 ±1 seconds. If during Sleep Mode the module

detects PCI bus traffic, it will revert to the Reduced

Power mode while monitoring for ignition messages.

It will remain in this state as long as there is traffic

other than run or start messages, and will return to

Sleep mode if the bus goes without traffic for 20 ±1

seconds.

SHIFT REQUIREMENTS

If the TCCM is in full power mode and at functionality level zero, it uses the following criteria to determine if a shift is allowed.

Fig. 9 Transfer Case Control Module (TCCM)

Location

1 - INSTRUMENT PANEL

2 - TRANSFER CASE CONTROL MODULE (TCCM)

3 - TRANSFER CASE SELECTOR SWITCH

• Diagnostic Requests

• Manual Transmission and Brake Applied

• PRNDL

• Ignition Status

• ABS Messages

Once the TCCM determines that a requested shift

is allowed, it actuates the bi-directional shift motor

as necessary to achieve the desired transfer case

operating mode. The TCCM also monitors the mode

sensor while controlling the shift motor to determine

the status of the shift attempt.

Several items can cause the requested shift not to

be completed. If the TCCM has recognized a fault

(DTC) of some variety, it will begin operation in one

of four Functionality Levels. These levels are:

• Level Zero - Normal Operation.

• Level One - Only Mode Shifts Are Allowed.

• Level Two - Only Mode Shifts and Shifts Into

LOW Are Allowed (No Neutral Shifts Are Allowed).

• Level Three - No Shifts Are Allowed

The TCCM can also be operating in one of three

possible power modes. These power modes are:

• Full Power Mode is the normal operational

mode of the module. This mode is achieved by normal

PCI bus traffic being present and the ignition being

in the RUN position.

• Reduced Power Mode will be entered when

the ignition has been powered off. In this state, the

module will shut down power supplied to external

devices, and to electronic interface inputs and outputs. From this state the module can enter either

Sleep Mode or Full Power Mode. To enter this mode,

the module must receive an ignition message denoting that the ignition is off, or not receive any messages for 5 ±0.5 seconds. To exit this mode, the

If any of the driver controllable conditions are not

met once the shift request is recognized, the TCCM

will solidly illuminate the source position’s LED and

flash the desired position’s LED for all shifts except

NEUTRAL. The NEUTRAL shift LED strategy will

be discussed later.

Mode shifts will be allowed regardless of transmission gear or vehicle speed, whenever the following

conditions are met:

• Front and rear wheel speed are within 21 km/hr

(13 mph).

• A change in the Selector switch state indicates

that a mode shift has been requested.

• A valid mode sensor signal is being sensed by

the TCCM.

• Proper transmit/receive messages are occurring

on the PCI bus.

• Ignition key switch is in the RUN position.

Range shifts will be allowed only if all of the following conditions are met:

• Front and rear wheel speed are within 21 km/hr

(13 mph).

• A change in the Selector Switch state indicating

a range shift has been requested.

• Transmission in NEUTRAL signal must be recognized for at least 1.5 seconds ±100 msec. (Automatic transmissions only)

• Proper transmit/receive messages are occurring

on the PCI bus.

• Clutch signal is recognized for 500 msec ± 50

msec (Manual transmissions only).

• Vehicle speed is less than or equal to 4.8 km/hr

(3 miles per hour).

• Ignition key switch is in the RUN position.

• A valid mode sensor signal is being sensed by

the TCCM.

A shift into transfer case Neutral will be

allowed only if all of the following conditions are met:

• Front and rear wheel speed are within 21 km/hr

(13 mph).

Page 17

DR ELECTRONIC CONTROL MODULES 8E - 17

TRANSFER CASE CONTROL MODULE (Continued)

• The recessed Neutral Selection switch has been

depressed continuously for 4.0 seconds ±100 msec

while all shift conditions have been continuously met.

• Transmission in NEUTRAL signal recognized

from the bus. (Automatic transmissions only)

• Clutch signal is recognized from the bus (Manual transmissions only).

• Proper message transmissions/receptions are

occurring on the PCI bus.

• Vehicle speed is less than or equal to 4.8 km/hr

(3 miles per hour).

• Ignition key switch is in the RUN position,

engine off.

• Foot Brake is applied.

• A valid mode sensor signal is being sensed by

the TCCM.

A shift out of transfer case Neutral will be

allowed only if all of the following conditions are met:

• Front and rear wheel speed are within 21 km/hr

(13 mph).

• The recessed Neutral Selection switch has been

depressed continuously for 1.0 seconds ±100 msec

while all shift conditions have been continuously met.

• Transmission in NEUTRAL signal recognized

from the bus.(Automatic transmissions only)

• Clutch signal is recognized from the bus (Manual transmissions only).

• Proper message transmissions/receptions are

occurring on the PCI bus.

• Vehicle speed is less than or equal to 4.8 km/hr

(3 miles per hour).

• Ignition key switch is in the RUN position.

• Foot Brake is applied.

• A valid mode sensor signal is being sensed by

the TCCM.

SHIFT SEQUENCES

Once all the driver controllable conditions for the

requested shift have been met, the TCCM begins a

shift timer with a maximum duration of 1 second per

’D’ channel transition. If the shift timer expires

before the TCCM recognizes to correct mode sensor

code, the shift is considered to have been blocked.

The blocked shift will increment the blocked shift

counter by one. The TCCM strategy for handling

blocked shifts will be described later. The process the

TCCM performs for the various shifts will be

described first.

RANGE AND MODE SHIFTS

The process for performing all the range and mode

shifts are the same. The following steps describe the

process.

• Allow time for Selector Switch debounce; 250

msec ±50 msec.

• Extinguish the source gear’s LED while flashing

desired transfer case position’s LED.

• Engage the shift motor for a maximum of 1 second ±100 msec per ’D’ channel transition in the destination gear’s direction while monitoring the mode

sensor channel transitions.

• Disengage the shift motor when the correct

mode sensor code is recognized.

• Solidly illuminate the selected gear’s LED.

• Transmit a bus message that the transfer case

shift is complete.

• If the desired mode sensor code is not received

after the shift timer expires (ie. a blocked or other

condition exists), stop driving the motor and wait for

200 msec ±50 msec. The shift motor is then reversed

in the direction back toward the source gear for up to

1.0 seconds ±100 msec. per ’D’ channel. The TCCM

waits for 2.0 seconds ±50 msec. and repeats the

attempt to shift to the desired position.

The exception to the preceding sequence is when a

shift from 4L to 2WD/AWD is requested. If 2WD/

AWD is requested from the 4L position, the transfer

case is first driven to the 4H position. If the 4H position is reached, the transfer case is then driven back

to the 2WD/AWD position and the shift is considered

complete. If the transfer case does not reach any the

4H position, but is in the 2WD/AWD ’D’ channel, or

the 2WD/AWD between gear position on the 4H side

of 2WD/AWD, the shift is also considered complete.

SHIFT OUT OF NEUTRAL

• Extinguish the Neutral LED.

• Engage the shift motor for a maximum of 1 sec-

ond ±100 msec toward the transfer case 4H mode

position while monitoring the mode sensor channel

transitions.

• Disengage the shift motor when the correct

mode sensor code is recognized.

• Extinguish the Neutral LED.

• Transmit a bus message that the transfer case

shift is complete.

• If the desired mode sensor code is not received

after the shift timer expires (ie. a blocked or other

condition exists), stop driving the motor and wait for

200 msec ±50 msec. The shift motor is then reversed

in the direction back toward the source gear for up to

1.0 seconds 100 msec. The TCCM waits for 2.0 seconds ±50 msec. and repeats the attempt to shift to

the desired position.

• When the Neutral button is released, if the 4H

position is the desired position, the shift is complete.

Illuminate the 4H LED.

• Otherwise when the Neutral button is released,

if all of the shift requirements are being met then

engage the shift motor towards the desired position

for 1 second ±100 msec per ’D’ channel. (if require-

Page 18

8E - 18 ELECTRONIC CONTROL MODULES DR

TRANSFER CASE CONTROL MODULE (Continued)

ments for shifting are not met, illuminate the 4H

LED and flash the destination LED as an indication

to the driver that all of the driver controllable shift

conditions are not being met). If this requires

another range or mode shift, begin the range/mode

shift process.

• If the desired mode sensor code is not received

after the shift timer expires (i.e. a blocked or other

condition exists), refer to the section on Blocked Shift

Strategy.

BLOCKED SHIFT STRATEGY

When a shift is commanded, the shift motor will be

driven towards its destination position, except in the

case of shifting out of Neutral if 4L was selected (the

transfer case will shift to the 4H position first, before

proceeding to 4L). If the shift is blocked on the way

to the destination, the TCCM may attempt to drive

the motor back to the original position. This process

will be allowed to occur 5 times. If the transfer case

has reached a non-NEUTRAL ’D’ channel during the

shift re-attempts, the LED for the achieved gear position is illuminated and the shift attempts are

stopped. To re-attempt the desired shift, the selector

switch will need to be rotated to the current position

until the switch debounce timer expires then a shift

will need to be requested again.

At the end of the 5th blocked attempt, the shift

motor is driven towards the last known ’D’ channel

position. If this motor drive allows the transfer case

to reach the 2WD/AWD ’D’ channel, or the 2WD/AWD

between gear position on the 4H side of 2WD/AWD,

the shift is considered complete and the shift

attempts are ended.

If the mode sensor is in the NEUTRAL region at

the expiration of the shift timer, the TCCM will continue to make the shift attempts according to the

blocked shift strategy independent of whether or not

the driver controlled conditions are met.

For shifts from NEUTRAL, if all 5 attempts fail to

reach the desired position (which by default is 4H),

the motor will be driven to stall in the direction of

4H or 4L, depending on the achieved position. If the

transfer case has reached the 2WD/AWD or 4L

between gear position nearest the NEUTRAL positions and the shift conditions are no longer being

met, the transfer case will be driven toward the corresponding ’D’ channel. Otherwise, the transfer case

will be driven in the direction opposite the last

attempt with the desired target being 4H or 4L.

If the transfer case reaches the 2WD/AWD ’D’

channel when being driven in the 4H direction, then

one final 1.0 second drive toward 4H is attempted. If

the transfer case then reaches any of the 4H positions, the shift is considered complete and the 4H

LED is illuminated. If the transfer case is still the

2WD/AWD position, the shift is considered complete

and the 2WD/AWD LED is illuminated.

NOTE: If after the 5th blocked shift and reversal

attempt, if the transfer case position is in the NEUTRAL region, shift attempts will continue until a

non-NEUTRAL ’D’ channel is reached.

SHIFT REVERSAL TARGETS

If the shift timer expires (1 second per ’D’ channel)

and the transfer case has not reached the desired

position, all shifts will attempt to return to their

original position with the exceptions of:

• If the intended shift is going to the High rail

from Low and can’t make it, but it can make the

2WD/AWD position, the motor stops at that position.

The TCCM will not attempt to cross back over NEUTRAL if it does not have to. This means that there

was a block on the first attempt to go to 4H and the

transfer case has made it through NEUTRAL to a

known good position, then the motor will go back

only to the 2WD/4WD position and execute the

remainder of the attempts from there.

• For shifts out of NEUTRAL, any time a shift is

commanded out of NEUTRAL, the system needs to

get out. The TCCM should never go to NEUTRAL

unless the driver is commanding it and all required

conditions are being met

ENCODER DRIFT CORRECTION

Whenever a shift is completed, the TCCM stores

the position in memory as the transfer case’s

intended position. The TCCM continuously monitors

the mode sensor and if the mode sensor drifts toward

into a NEUTRAL region sensor position for 2.0 seconds, the TCCM will perform a motor drive to correct

the drift. The transfer case will be driven toward the

intended position for 1.0 seconds 100 msec. The

TCCM will wait for 2.0 seconds ±50 msec. and repeat

the attempt to shift to the desired position. This will

continue until the intended position is reached.

SHIFT MOTOR BRAKING

Two modes of shift motor braking are employed to

improve shift performance, static and dynamic. Static

shift motor braking is utilized under the following

conditions:

• Whenever the transfer case is in the 2WD/AWD

or 4L ’D’ channel position.

• Whenever an invalid mode sensor code is

present.

Static motor braking is achieved by applying +12V

on both shift motor wires.

NOTE: Static Shift Motor Braking is independent of

ignition key position.

Page 19

DR ELECTRONIC CONTROL MODULES 8E - 19

TRANSFER CASE CONTROL MODULE (Continued)

SHIFT ATTEMPT LIMIT

To protect the transfer case system, the TCCM will

impose a limit on the number of shifts that can occur

over a calibrated time period. The system will monitor

the number of ’D’ channel segment transitions that

occur in any 30 second time period. If the number of

segment transitions is 30 or greater, the system will go

into a default mode. The default mode of operation for

shifting is that the number of allowed ’D’ channel transitions permitted to occur will be 3 over each 15 second

±100 msec calibrated window of time. After 5 minutes

±100 msec, the motor can be assumed to have cooled

down and the system will revert to normal operation.

The following rules also apply to the shift limit:

• The attempt limit will not prevent shifts coming

out of NEUTRAL, they will be allowed regardless of

the counter/timer.

• Any shift that is in progress when the counter

reaches a maximum count in time will be allowed to

complete before the default mode is entered. D-channel transitions during this period will not be counted

towards the default mode limit.