Page 1

DODGE CALIBER

BODY REPAIR MANUAL

Page 2

SAFETY NOTICE

CAUTION

ALL SERVICE AND REBUILDING INSTRUCTIONS CONTAINED HEREIN ARE APPLICABLE TO, AND FOR THE

CONVENIENCE OF, THE AUTOMOTIVE TRADE ONLY. All test and repair procedures on components or assemblies

in non-automotive applications should be repaired in accordance with instructions supplied by the manufacturer of the

total product.

Proper service and repair is important to the safe, reliable operation of all motor vehicles. The service produces

recommended and described in this publication were developed for professional service personnel, and are effective

methods for performing vehicle repair. Following these procedures will help ensure efficient economical vehicle performance and service reliability. Some service procedures require the use of special tools designed for specific procedures. These special tools should be used as recommended throughout this publication.

Special attention should be exercised when working with spring-or tension-loaded fasteners and devices such as EClips, Circlips, Snap rings, etc., since careless removal may cause personal injury. Always wear safety goggles when

working on vehicles or vehicle components.

It is important to note that this publication contains various Cautions and Warnings. These should be read carefully in

order to minimize risk of personal injury or the possibility that improper service methods may damage the vehicle or

render it unsafe. It is important to note that these Cautions and Warnings cover only the situations and procedures

DaimlerChrysler Corporation has encountered and recommended. DaimlerChrysler Corporation cannot possibly know,

evaluate, and advise the service trade of all conceivable ways in which service may be performed, or of the possible

hazards of each. Consequently, DaimlerChrysler has not undertaken any such broad service review. Accordingly, anyone uses a service procedure or tool that is not recommended in this publication must be certain that neither

personal safety, nor vehicle safety, will be jeopardized by the service methods they select.

Back to Index

Page 3

MANUFACTURER ADVERTISEMENTS

(CLICK ON LINKS )

• PPG INDUSTRIES

• TECH AUTHORITY

• DAIMLERCHRYSLER PAINT CONDITION DECK,

SEALER SOUND DEADENER REPAIR GUIDE

• MOPAR PARTS

• DAIMLERCHRYSLER PLASTIC REPAIR GUIDE,

WELDING & WELD BONDING MANUAL

• HEMI.COM

• TEAM PSE FACILITY PLANNING SERVICES

Copies of the following Body Repair Manuals are available by calling 1-800-890-4038

• Chrysler 300 (81-316-0531CD) • Jeep Grand Cherokee (81-316-0635-CD)

• Dakota (81-316-0634CD) • Pacifica (81-316-0530-CD)

• Durango (81-316-0430CD) • PT Convertible (81-316-0531-CD)

• Jeep Commander (81-316-0636-CD) • Sprinter Van (81-316-0533-CD)

Back to Index

Page 4

INTRODUCTION

Dodge Caliber

This manual has been prepared for use by all body technicians involved in the repair of the Dodge Caliber.

This manual shows:

- Typical unibody panels contained in these vehicles - The types of welds for the panel

- The weld locations for these panels - Proper sealer types and correct locations

Body Construction Characteristics.............................................................

History of Collision Repair..........................................................................

Corrosion Protection ..................................................................................

Vehicle Identification Number Information.................................................

Paint Codes Information ............................................................................

Welded Panel Replacement.......................................................................

Sealer Locations ........................................................................................

Structural Adhesive Locations ...................................................................

NVH/Structural Foam Locations ................................................................

Sound Deadener Locations .......................................................................

Frame/Body Dimensions ............................................................................

Front Frame Rail Sectioning Procedure ....................................................

Additional Support/Information ...................................................................

DaimlerChrysler Motors Corporation reserves the right to make improvements in design or to change specifications to

these vehicles without incurring any obligation upon itself.

Page 5

BODY CONSTRUCTION CHARACTERISTICS

Definitions of Steels used in the Jeep Compass:

MS 66 - Represents an uncoated Hot Rolled Steel Sheet used mainly for interior braces and reinforcements.

MS

67 - Represents an uncoated Cold Rolled Sheet structural steel used in areas where structural integrity is critical.

EG., the type of steel used for the “A” pillar

.

MS

264 -

Represents an uncoated high strength low alloy (HSLA) steel used in applications where structural integrity is critical.

MS 6000-44A - Low carbon, hot dipped galvanneal (or EGA) with 45 g/m² minimum coating weight on both sides.

- Most common Sheet Steel product used by Chrysler.

MS 6000-44VA - 50 ksi min. yield strength, HSLA, killed steel, with 44 g/m² minimum coating weight on both sides.

- Most common high strength coated steel product used by Chrysler.

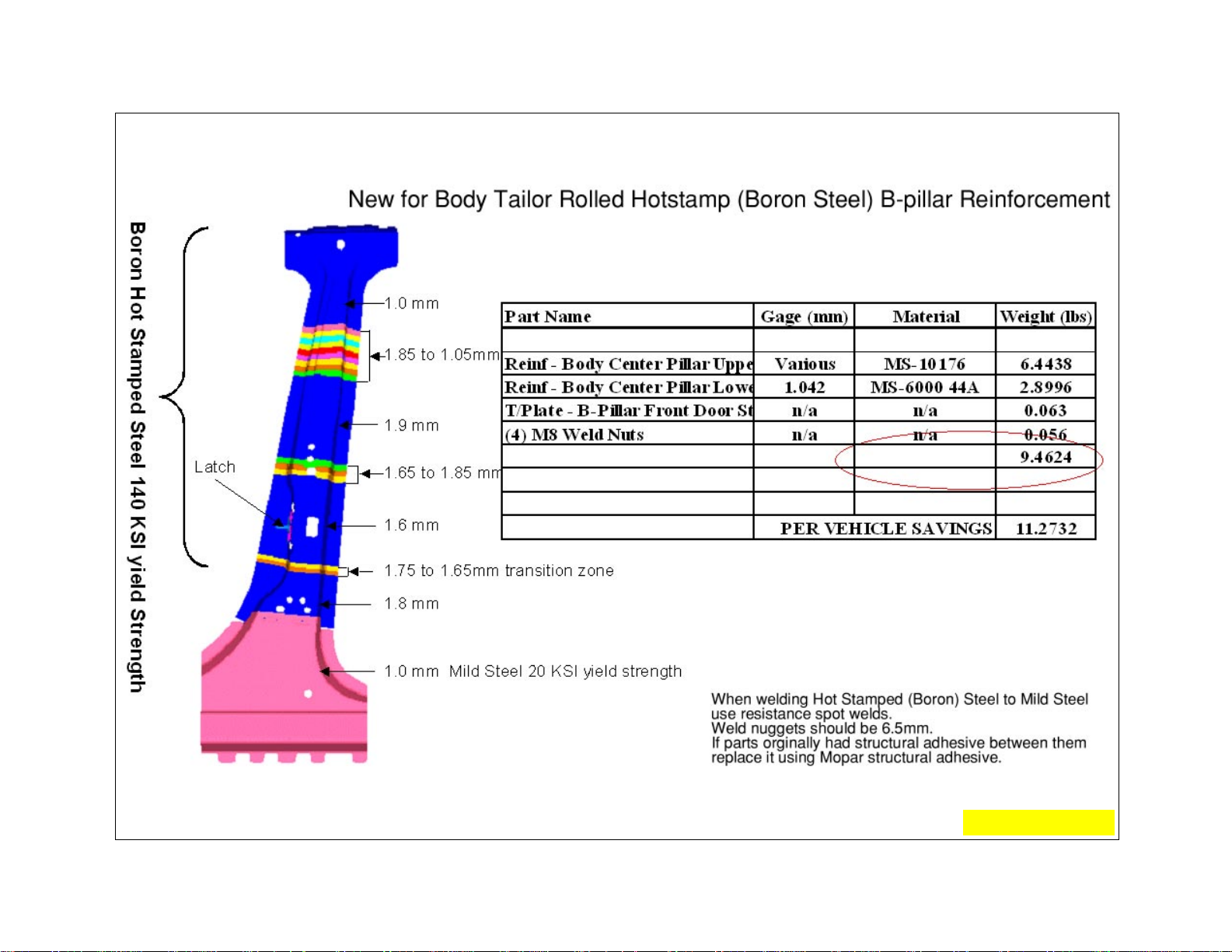

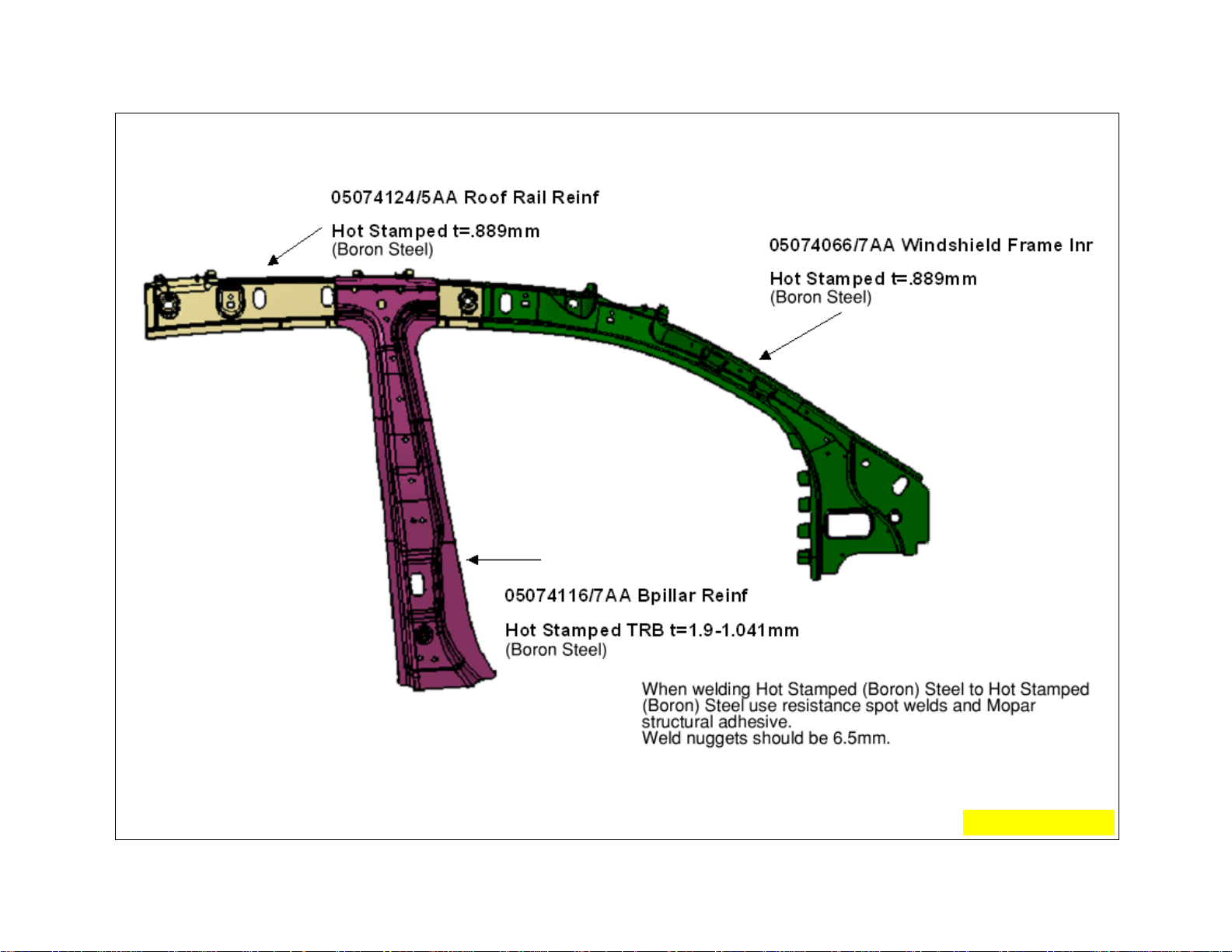

MS 10176 - Boron-alloyed steels ate analogy with 22MnB5 which are matched to the hardening process die. Sheet

blanks are heat treated in the furnace on an inert gas or air atmosphere and then formed in the press die and hardened at the same time. The boron is produced in two configurations one for use in upper body and one that has hotdip aluminizated coating for corrosion protection.

MS82-1228 - Represent a coated high strength low alloy (HSLA) hot or cold rolled sheet steel used in applictions where structural

integrity is critical.

PARTIAL LIST OF STEEL APPLICATIONS

Galvannealed Steel

Body Side Aperture Rear Door - Inner Panel

Cowl Plenum Panel Rear Door - Outer Panel

Cowl Side Panel Rear Floor Pan

Dash Panel Rear Floor Pan Front Crossmember

Front Door - Inner Panel Rear Floor Pan Side Rail

Front Door - Outer Panel Rear Suspension Crossmember

Front Fender Rear Quarter Panel - Inner

Front Floor Pan Rear Quarter Panel - Outer

Front Hinge Pillar Rear Wheelhouse - Inner

Front Rail Roof Panel

Front Strut Mounting Tower UpperLoad Path Beam

Front Wheelhouse (Front and Rear) Upper Radiator Crossmember

Lower Radiator Crossmember

Back to Index

Page 6

BODY CONSTRUCTION CHARACTERISTICS

The following measures have been implemented in order to provide maximum corrosion prevention and protection.

1. The use of galvannealed coatings throughout the body structure.

2. Ecoat is used on the complete body in all instances.

3. Body sealing.

4. Stone-chipping resistant primer application.

5. Underbody corrosion prevention.

Back to Index

Page 7

Back to Index

Page 8

Back to Index

Page 9

Back to Index

Page 10

Back to Index

Page 11

HISTORY OF COLLISION REPAIR

Time was, if you had an accident, the call went out to the insurance company - to the collision shop - or several shops get the lowest bid and in no time at all, the vehicle was repaired.

The facilities, training, and equipment were simple. Use a torch to cut, shape, and bend. Use something substantial as

an anchoring point - maybe a tree and then just pull.

Use plenty of solder or body putty to make it look good. With the frame and body vehicle, the job was easy; first

straighten the frame - then fix the mechanical components and the body work was cosmetic. This was all well and good

until the mid - '70s.

Then, the designers, engineers, and manufacturers had to find ways to make the vehicles energy efficient - and that

meant unibody cars. The unibody concept wasn't new - back in the '30s the Chrysler Air Flow had it - race cars have it and now the driving public worldwide has it.

The change came quickly. Manufacturers devoted time, money, and talent to develop the unibody car.

The public was ready to buy and did!

But then came the problem! The collision repair industry wasn't given the luxury of taking their time to train people in the

new technology - or take time to plan for new equipment.

The collision happened and the vehicle had to be fixed. Cars that were repairable were being totalled.

Cars that were repaired were not repaired correctly. Everybody was in a quandary - auto manufacturer - insurance

company - repair equipment people - body shops - and repair technicians.

The problem started in the early '70s and body shops are still catching up today. Yesterday's "ding" is today's "crash". It

takes trained technicians and sophisticated equipment to do the repair today.

That's why DaimlerChrysler is taking the time and effort to get the right information into the hands of the people that

handle the repair job.

Back to Index

Page 12

Corrosion Protection

Factory Applied Corrosion Protection

During the manufacturing of the unibody car, the manufacturer applies "corrosion protection" using specialized

manufacturing processes. This system is not duplicated in the collision repair body shop. However, the body shop still

has a responsibility to apply corrosion protection to the unibody vehicle. So, the collision repair shop must use

alternative materials to do the corrosion protection job after the repair.

This corrosion protection is required regardless of the environment and weather conditions the vehicle will be operated

in. Corrosion protection is as important in the desert as it is at the seaside. Corrosion damage can literally destroy the

structural integrity of a unibody vehicle from within. Many corrosion protection systems are destroyed during collision

repair operations. Metal finishing, metal working and fatigue can cause the breakdown of many of the corrosion barriers

installed at the factory. The use of heat for stress relief and welding also destroys factory installed corrosion barriers.

These corrosion barriers and corrosion protection systems must be replaced after collision repair to ensure that the

structural integrity of the unibody will remain intact throughout its life. In the past, only vehicles with aftermarket or after

delivery corrosion protection systems installed were serviced after collision repair to restore the corrosion protection

system.

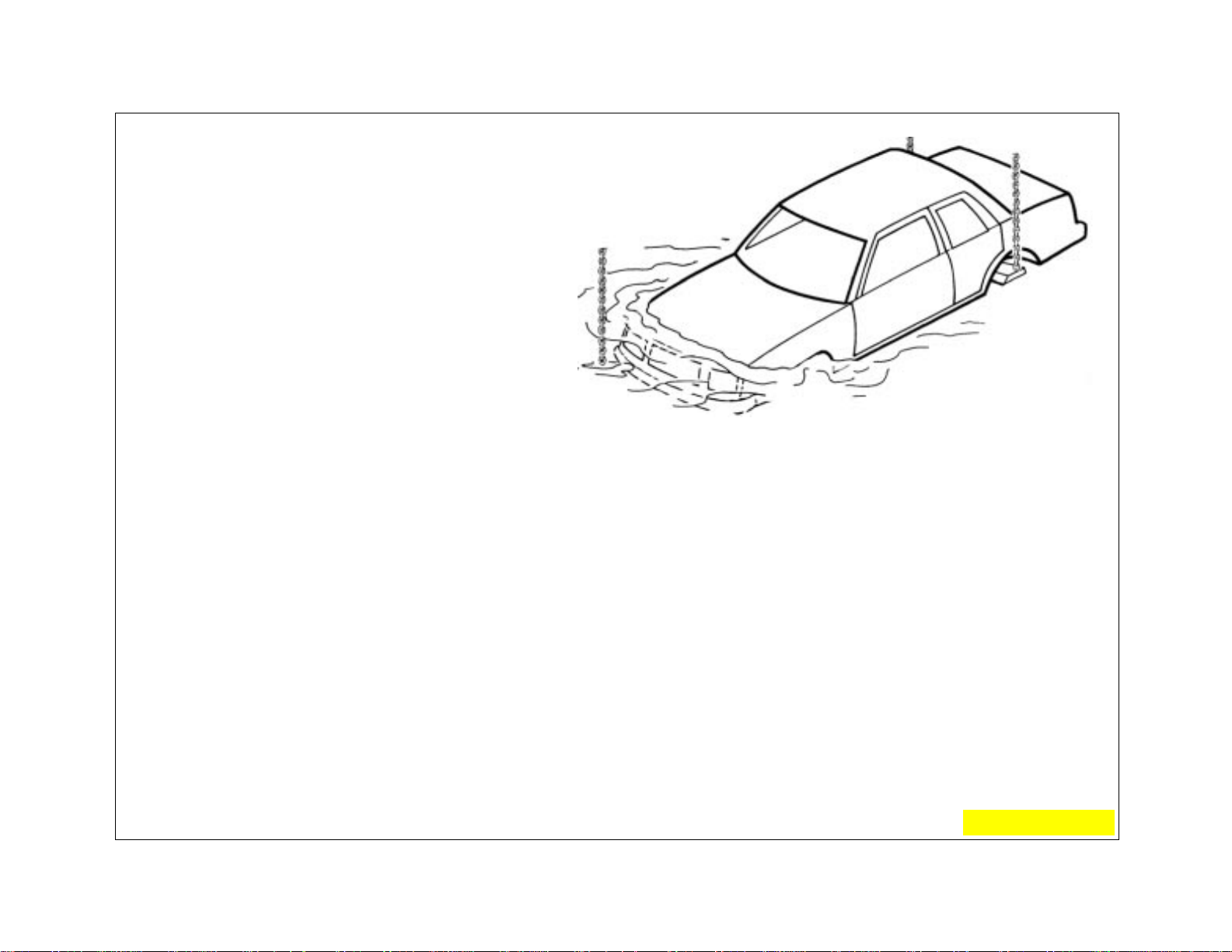

An understanding of the types of corrosion which affect the unibody vehicles will assist in understanding why the factory

protection systems are important, how the factory protection systems consist of and how the systems' protection is

replaced after collision and electrolytic corrosion. Some of the more common types of corrosion are crevice corrosion,

pitting, galvanic corrosion, stress corrosion, cracking, fretting, and erosion corrosion.

Back to Index

Page 13

Corrosion Protection

Crevice corrosion is a form of localized attack that occurs in areas on metal surfaces exposed to the elements.

Examples include spot weld lap joints, threaded or riveted connections, gasket fittings, porous welds, valve seats.

Pitting is the corrosion of a metal surface at points or small areas which look like a small hole in the metal.

Galvanic corrosion is the type that occurs when dissimilar metals are in electrical contact while immersed in an

electrolyte.

Back to Index

Page 14

Corrosion Protection

The penetration of corrosive solutions into these small areas, with widths that are typically a few thousandths of an inch,

can result in various types of failures: the metal surface may become rusty in appearance, operating components may seize

when protective coatings may have been removed from the metal surface. The coating of zinc on steel, known as galvanized, is an example of sacrificial cathodic protection.

An example of galvanic corrosion on the automobile is a stainless steel trim molding on a painted mild steel. When the paint

becomes damaged, a galvanic corrosion cell is formed between the passive stainless steel (cathode) and the steel (anode).

The corrosion leads to what would look like a rust stain. Methods of reducing galvanic corrosion include the use of

compatible materials, minimizing of cathode-to-anode areas, the insulation of dissimilar metal contacts and the use of thick,

replaceable sections.

Stress corrosion, cracking, fretting, and erosion corrosion.

Corrosion cracking is the early cracking of metals produced by the combined action of tensile stress and a corrosive

atmosphere.

Corrosion fatigue is cracking due to the action of stresses and corrosion. Methods of reducing corrosion fatigue include the

reduction in stress and the use of coatings.

Fretting is the deterioration of a metal at contact surfaces due to the presence of a corrosive and relative motion between

the surfaces. The two metal surfaces initially are covered with an oxide film that becomes abraded during vibration. The

results are oxide particles that become corroded. During the collision repair process, the factory protection materials

become damaged from working the metals, or from the use of heat in the repair operations. If these factory protection materials are not replaced with some similar protection material after repair, a corrosion hot spot is formed. A corrosion hot spot

is a small unprotected area surrounded by a protected area throughout the rest of the vehicle. the hot spot effect causes

rapid deterioration of the unprotected area. This deterioration takes place at a much faster rate, sometimes 10-12 times

faster than if the entire car were unprotected. The hot spot effect is created because all the corrosive factors are channeled

to the unprotected area much the same way all material flowing through a funnel is concentrated in a small area. This hot

spot effect means that corrosion failures to the unibody structure could occur in a short period of time even in an

atmosphere normally not subject to corrosion. The hot spot effect can cause rapid deterioration of unibody structures from

corrosion damage in a desert as well as seaside.

Back to Index

Page 15

Corrosion Protection

The types of materials used in rustproofing application include oil based materials, wax base materials, primers and

color coats. The most important properties of rustproofing materials are adhesion, toughness, and the resistance to the

environment. The best coating in the world is not effective unless it is present in the right place at the right time.

Corrosion Protection Information

When making the collision repair, refer to the manufacturer's information on where corrosion protection and sealants

are applied. Be sure to follow the recommendations. The application process is usually included with the material

manufacturer's information so be sure to read and understand it before proceeding with the repair.

Collision Repair Corrosion Protection Materials

The materials must provide good electrolyte barriers. The material must also be able to penetrate tiny crevices and

prevent abrasive corrosion. The material must be compatible with paint systems as many areas of the car must be

treated before paint is applied.

Materials containing silicones will cause paint conditions such as fish eyes if they are applied before the repaired

vehicle is painted. So no silicone containing material is to be used. As many of the repair areas are more accessible

before final assembly and painting, the non-silicone type materials are a must for this type of application.

When protecting an enclosed area, fog type properties for the corrosion protection material are a plus. The fog

properties make the material much less susceptible to operator error or misapplication. With a fog type material, once

the material is introduced inside of an enclosure, the fog spreads rapidly and evenly into all areas including tiny

crevices. The fog type materials do not require direct spray application to be effective. Fog type materials are also very

effective in coating over any existing rusted or corrosion damaged areas and preventing further corrosion of these

areas. This is especially important on repairs of older vehicles.

Back to Index

Page 16

Corrosion Protection

Spray Accessibility to the Repair

Being able to achieve fog spray penetration into enclosed cavities as well as open areas requires application

equipment, which includes an assortment of wands of various lengths and design.

Some areas are more effectively treated by brush application of corrosion protection material before they are

assembled. A good example of this is an inner and outer engine compartment side rail area. Brush application to the

inside of these areas as individual pieces is easy before assembly and can be followed by a light fog application to the

weld areas and the crevices formed during assembly after the rails are assembled. Brush application keeps the foreign

material from getting between welded joints during assembly yet gives good coverage to general areas with easy

application. The material selected in addition to paint compatibility features and fog application features is also an

excellent brush application material. Repaired areas, boxed in or closed in are more easily treated during assembly

using fog and brush on techniques. Care must be taken to keep the corrosion materials away from the welding areas

as welding contamination might take place. Brush-on applications are used before welding and fog in applications are

used after welding assemblies together.

Back to Index

Page 17

Back to Index

Corrosion Protection

Desired Characteristics of Corrosion Protection Material

1. Corrosion prevention material- The material must displace water to prevent corrosion. This can be tested by

spraying water on an open panel on the floor, then spraying the corrosion preventative material over the watered panel

and observing if the material displaces the water.

2. Creepage of material- To insure thorough and complete protection coverage, the material should have a "creep"

capability, approximately 1/4 inch per minute while drying. This assures protective penetration of pinch welds, cracks, etc.

3. Safe material- Material should be non-combustible when dried and when wet unable to support a fire after ignition.

4. Clean-up- The material should be of a viscosity which inhibits runs or drips. Overspray on a vehicle's painted surface

should wipe off easily without solvent when wet, with solvent when dry. The material should also dry clean off clothing.

5. Guarantee/Warranty- The corrosion protection has to be done to maintain factory corrosion warranty.

Manufacturer's recommendations must be followed.

Glossary:

Abrasion Corrosion - Rubbing or hitting of one material by another

Corrosion Protection - Material applied to deter corrosion (oxidation)

Crevice Corrosion - Oxidation when two metals are joined

Electrolytic Corrosion - Electrical action taking place between two materials in the presence of an electrolyte (liquid)

Fogging - Applying material in a mist form

Fretting - Deterioration of metal at contact surfaces due to motion and corrosive elements

Galvanic Corrosion - Electrical action (electrolysis) between two dissimilar metals in the presence of electrolyte (liquid)

Hot Spot - An unprotected area subject to corrosion

Pitting Corrosion - Corrosion on a surface the results in a small "specks" or "pinholes"

Stress of Fatigue, Cracking Corrosion - Cracking due to stress and atmospheric elements

Page 18

Back to Index

Page 19

DODGE CALIBER VEHICLE IDENTIFICATION NUMBER DESCRIPTION

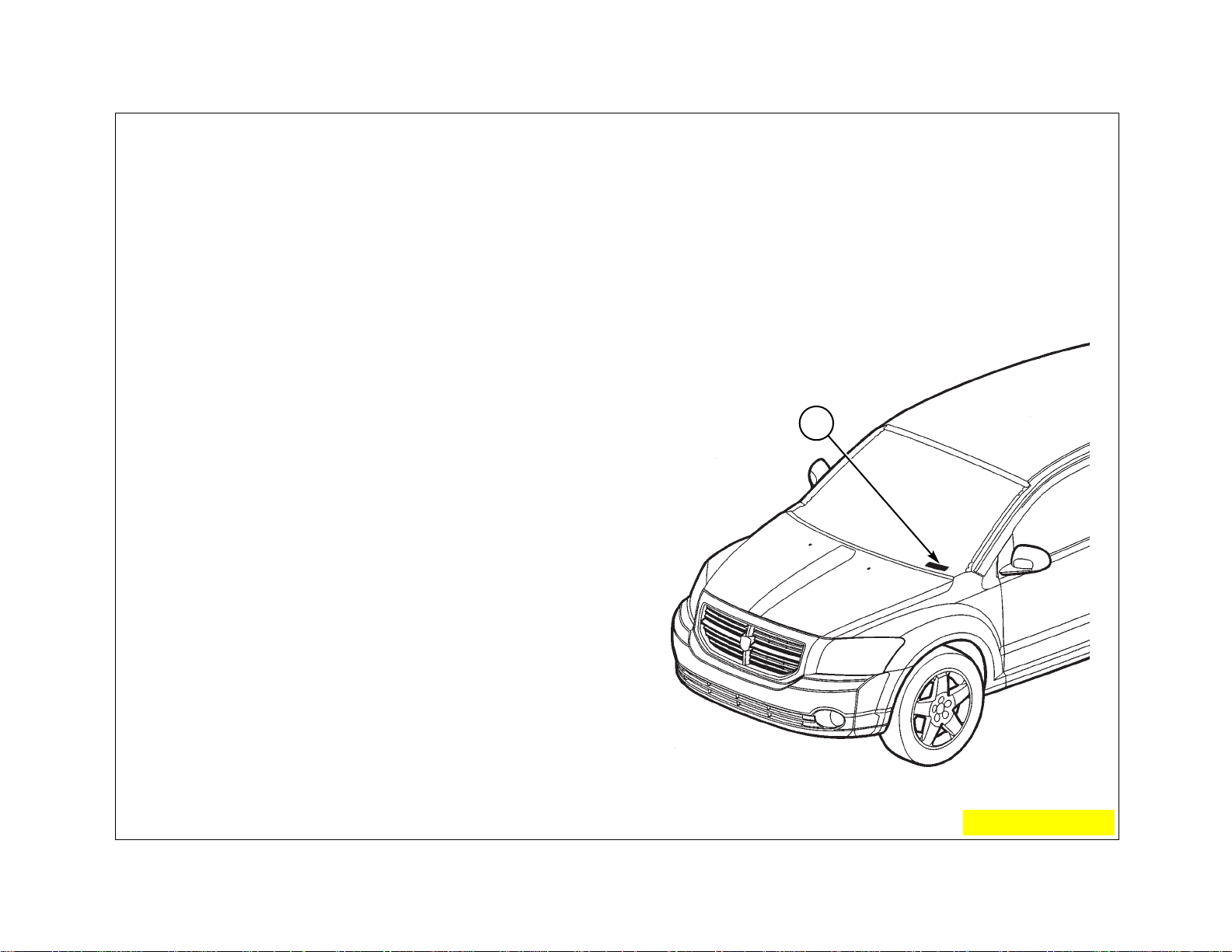

The Vehicle Identification Number (VIN) can be viewed through the windshield at the upper left corner of the instrument

panel, near the left windshield pillar. The VIN consists of 17 characters in a combination of letters and numbers that

provide specific information about the vehicle. Refer to VIN Code Breakdown Chart for decoding information. To protect

the consumer from theft and possible fraud the manufacturer is required to include a Check Digit at the ninth position of

the vehicle identification number. The check digit is used by the manufacturer and government agencies to verify the

authenticity of the vehicle and official documentation. The formula to use the check digit is not released to the general

public.

VEHICLE IDENTIFICATION NUMBER (VIN)

1 - VEHICLE IDENTIFICATION NUMBER (VIN)

1

Back to Index

Page 20

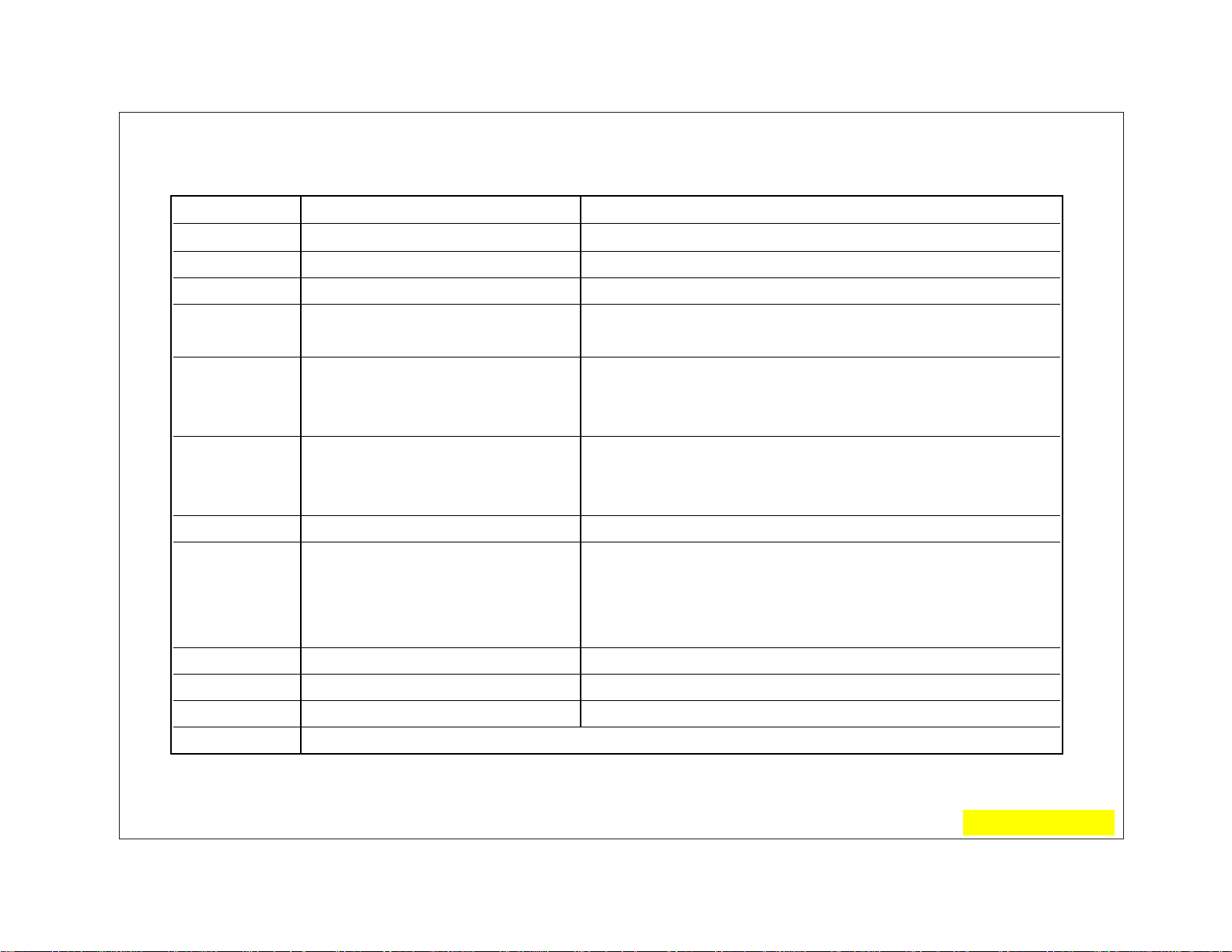

VEHICLE IDENTIFICATION NUMBER DECODING CHART

POSITION INTERPRETATION CODE = DESCRIPTION

1 Country of Origin 1 = Manufactured by Daimler Chrysler Corporation

2 Make B = Dodge

3 Vehicle Type 3 = Passenger Car

4 Restraint System J = Without Side Air Bags

H = With Side Air Bags

5 Vehicle Line (PM) 3 = Caliber Right Hand Drive (FWD)

B = Caliber Left Hand Drive (FWD)

E = Caliber Left Hand Drive (AWD)

6 Series 2 = Caliber

4 = Caliber SXT

7 = Caliber R/T

7 Body Style 8 = Hatchback 4 Door

8 Engine C = 1.8L 4 Cyl. 16V DOHC Dual VVT GAsoline

A = 2.0L 4 Cyl. 16V DOHC Diesel

B = 2.0L 4 Cyl. 16V DOHC 5MPI Gasoline

K = 2.4L 4 Cyl. 16V Dual VVT Gasoline

9 Check Digit 0 through 9 or X

10 Model Year 7 = 2007

11 Assembly Plant D = Belvidere Assembly

12 through 17 Vehicle Build Sequence

Back to Index

Page 21

MFD BY

DAIMLER CHRYSLER

CORPORATION

DATE OF MFR GVWR

1-96 C 2268 KG (05000 LB)

GAWR FRONT

1203 KG (2850 LB)

GAWR REAR

1225 KG (2700 LB)

WITH TIRES

P185/75R14

WITH TIRES

P195/75R14

RIMS AT

14 X 5.5

RIMS AT

14 X 5.5

COLD

380 KPA(35 PSI)

COLD

380 KPA(35 PSI)

THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFETY

STANDARDS IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE.

VIN: XXXXXXXXXXXXXXXXX TYPE: SINGLE X DUAL

MDH:

010615 021

PAINT:POP VEHICLE MADE IN CANADA TRIM:

C503

4848505

8086df7b

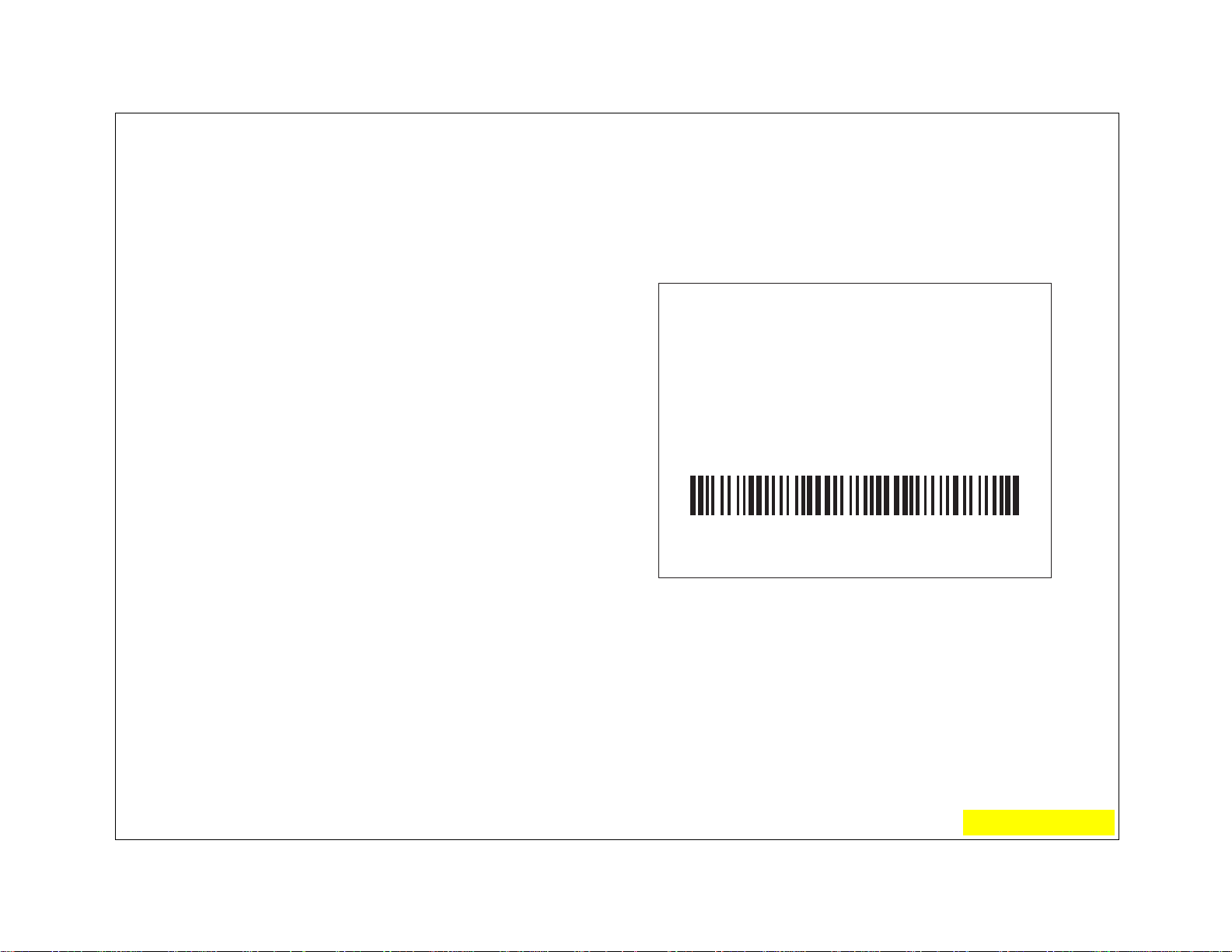

VEHICLE CERTIFICATION LABEL

DESCRIPTION

A vehicle certification label is attached to every

DaimlerChrysler Corporation vehicle. The label certifies

that the vehicle conforms to all applicable Federal

Motor Vehicle Standards. The label also lists:

• Month and year of vehicle manufacture.

• Gross Vehicle Weight Rating (GVWR). The gross

front and rear axle weight ratings (GAWR’s) are

based on a minimum rim size and maximum cold

tire inflation pressure.

• Vehicle Identification Number (VIN).

• Type of vehicle.

• Type of rear wheels.

• Bar code.

• Month, Day and Hour (MDH) of final assembly.

• Paint and Trim codes.

• Country of origin.

The label is located on the driver-side door shut-face.

Back to Index

Page 22

DODGE CALIBER PAINT CODES

EXTERIOR

CODE COLOR

ARH Inferno Red Crystal Pearl Coat

VYH Solar Yellow Clear Coat

DV6 Sunburst Orange Pearl Coat

CB6 Marine Blue Pearl Coat

DBM Steel Blue Metallic Pearl Coat

WS2 Bright Silver Metallic Clear Coat

DX8 Black Clear Coat

SW1 Stone White Clear Coat

INTERIOR

CODE COLOR

S Pastel Slate Gray (DA)

B Pastel Pebble Beidge/Medium Pebble Beidge (KA)

Back to Index

Page 23

Back to Index

DODGE CALIBER PAINT CODE LOCATION

The vehicle certification label identifies the paint code. This label is located on the driver’s door shut face.

VEHICLE

CERTIFICATION

LABEL

Page 24

Back to Index

Page 25

WELD PANEL

REPLACEMENT

Dodge Caliber

The basic parts of the body structure are the welded panels. This section contains a brief description of the placement

of some of the panels and their weld locations.

Note: To ensure the strongest, most durable and cleanest welds possible, perform testing before and during all weld

procedures. Always follow American Weld Society specifications and procedures.

Note: Diagrams do not show all of the parts.

Explanation of Manual Contents......................................... Liftgate...................................................................................

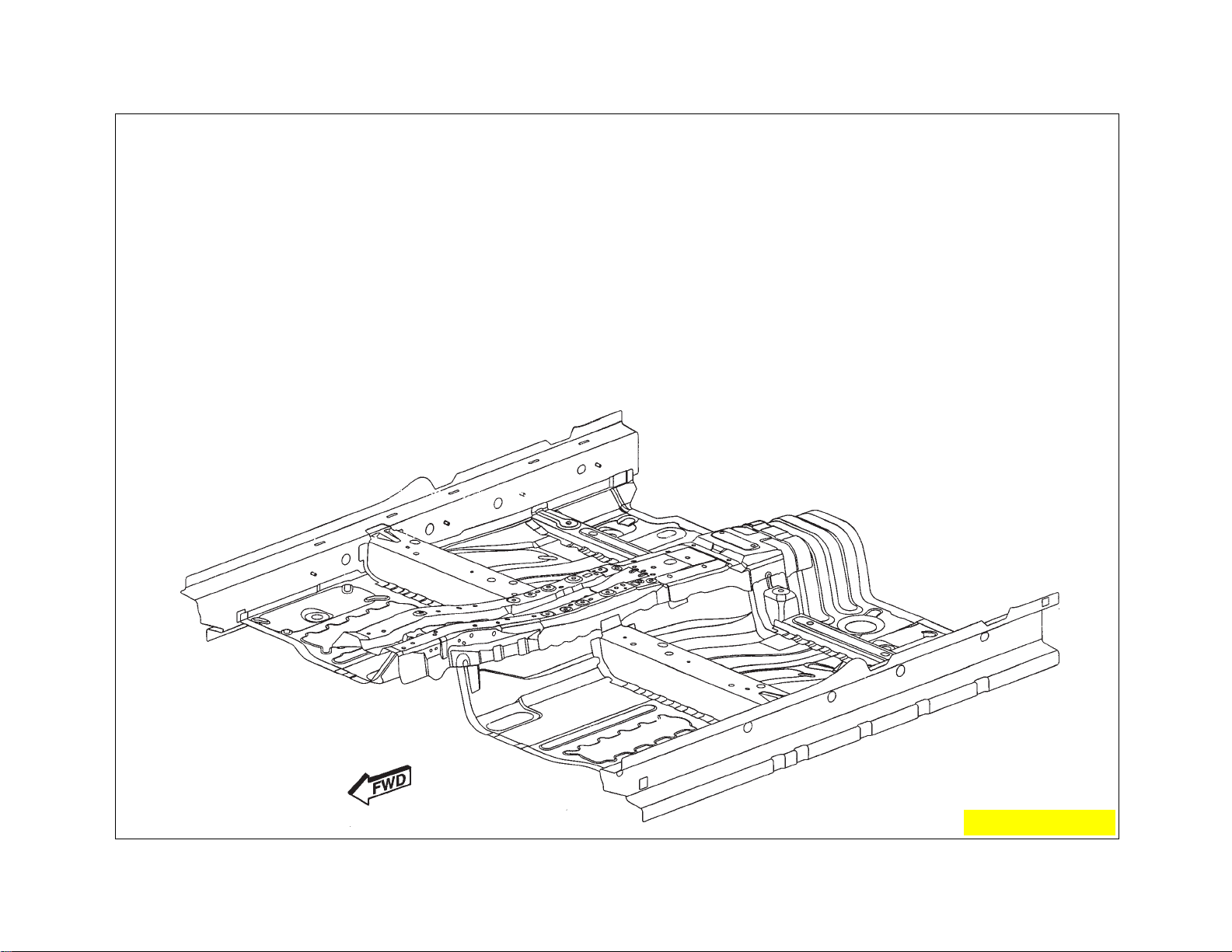

Front Floor ........................................................................... Engine Box Assembly ...........................................................

Sidemember........................................................................ Plenum/Dash.........................................................................

Rear Floor ........................................................................... Engine Box Complete............................................................

Front Rails........................................................................... Front Floor Complete ............................................................

Plenum................................................................................ Rear Floor Complete.............................................................

Dash.................................................................................... Underbody Complete.............................................................

Engine Box.......................................................................... Body Side Aperture Inner......................................................

Body Side Aperture............................................................. Body Side Aperture Outer .....................................................

Hood and Front Fenders..................................................... Body Side Aperture Complete...............................................

Front Door........................................................................... Roof without Sunroof.............................................................

Rear Door ............................................................................ Body in White Complete ...........................

Back to Index

Page 26

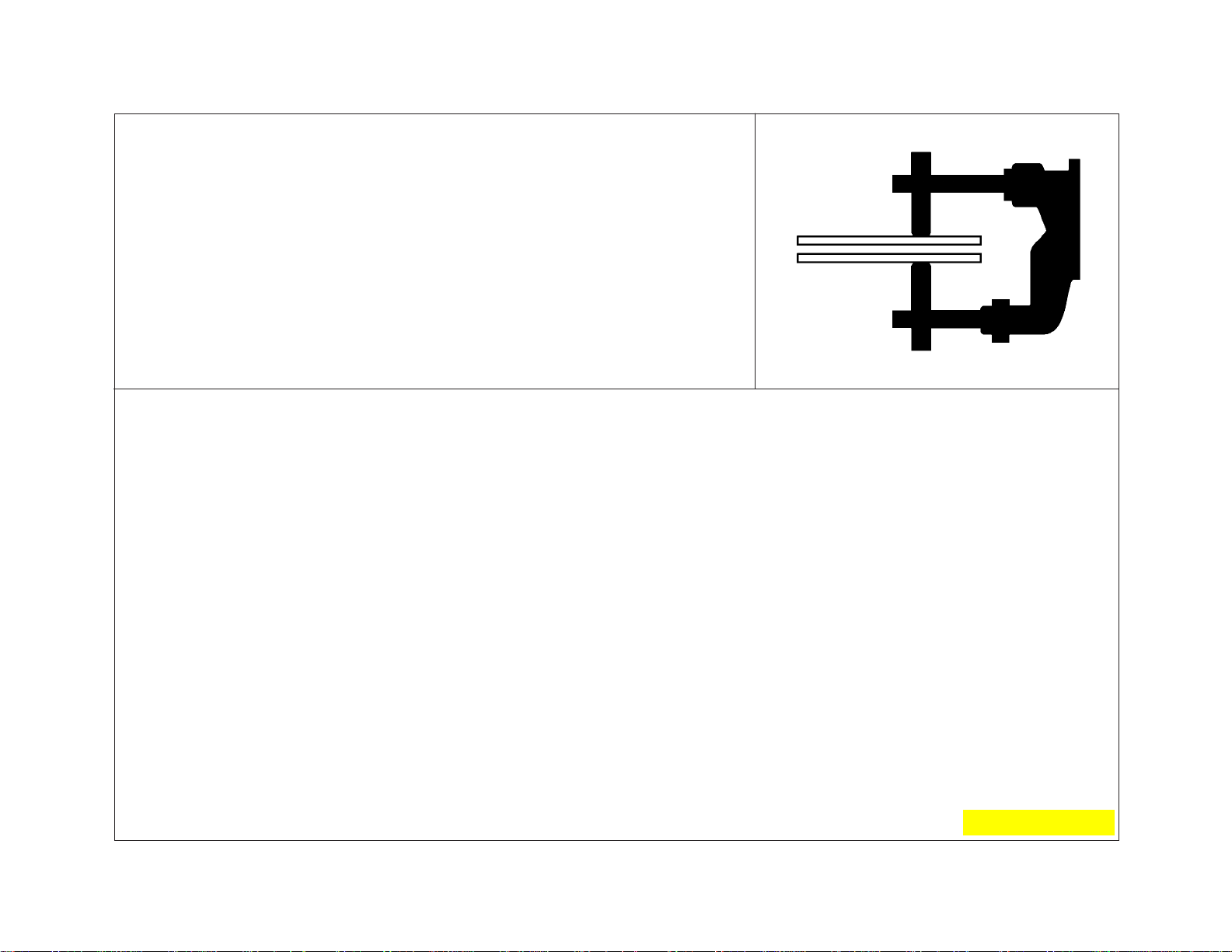

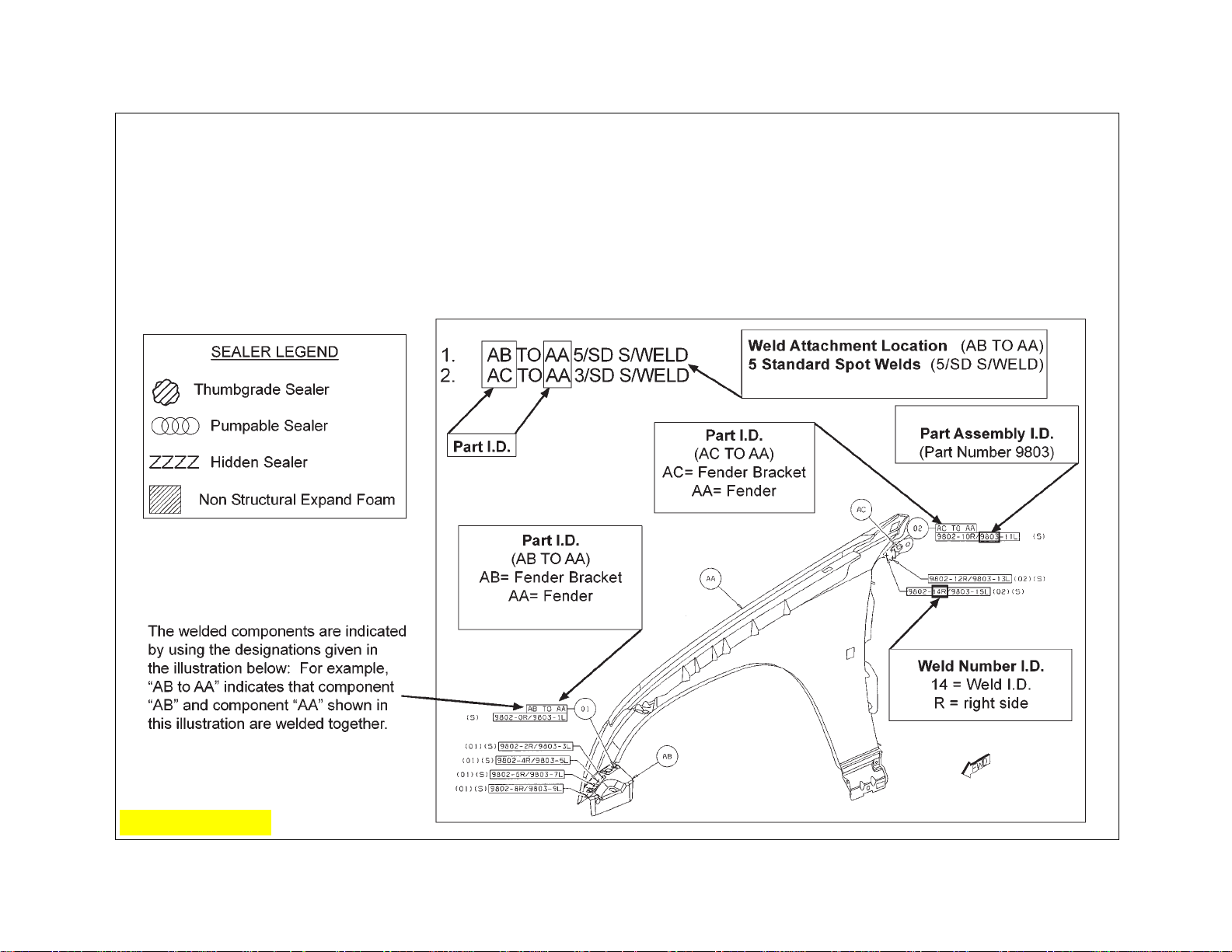

Explanation of Welding/Sealer Information

The major construction of a unibody vehicle consists of welded panels that create the supporting structure for all components and assemblies of the vehicle. Here are some examples for replacement of these parts.

Certain body components must use sealers to ensure proper assembly. Be sure to check the Body Sealing

Locations and Structural Adhesive Sections for location and sealer type.

Back to Index

Page 27

Explanation of Welding Abbreviations

Definitions

Weld Type

(ORD)=Ordinary Weld or Standard

(CRT)=Critical Weld or Diamond

(SAF)=Safety Weld

PROJ=Projection Weld

FCAW=Flex Core Arc Weld

MFG=Manufacturing Weld

S/WELD=Spot Welds

/SD=Per Side

Examples

AA TO AB 5/SD S/WELDS (ORD)=

PART AA WELDED TO PART AB 5 PER SIDE (5 RIGHT/5 LEFT) SPOT WELDS STANDARD

AA TO AB 12 PROJ WELDS (CRT)=

PART AA WELDED TO PART AB 12 PROJECTION WELDS CRITICAL OR DIAMOND

Adhesives

STRUCT ADH (ORD) = Ordinary Structural Adhesive

ADH (ORD) = Ordinary Adhesive

Back to Index

Page 28

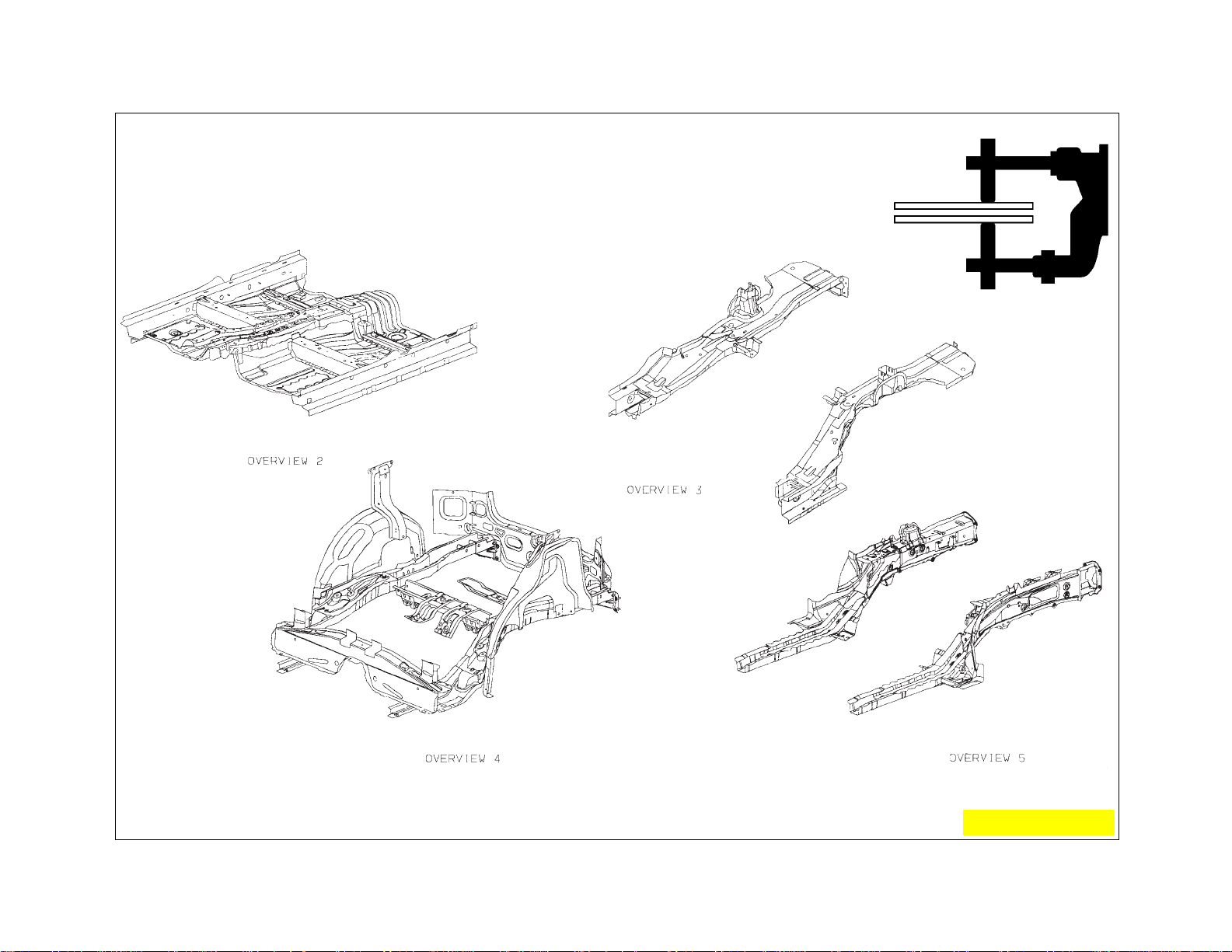

WELD LOCATION OVERVIEW ZONES

Back to Index

Page 29

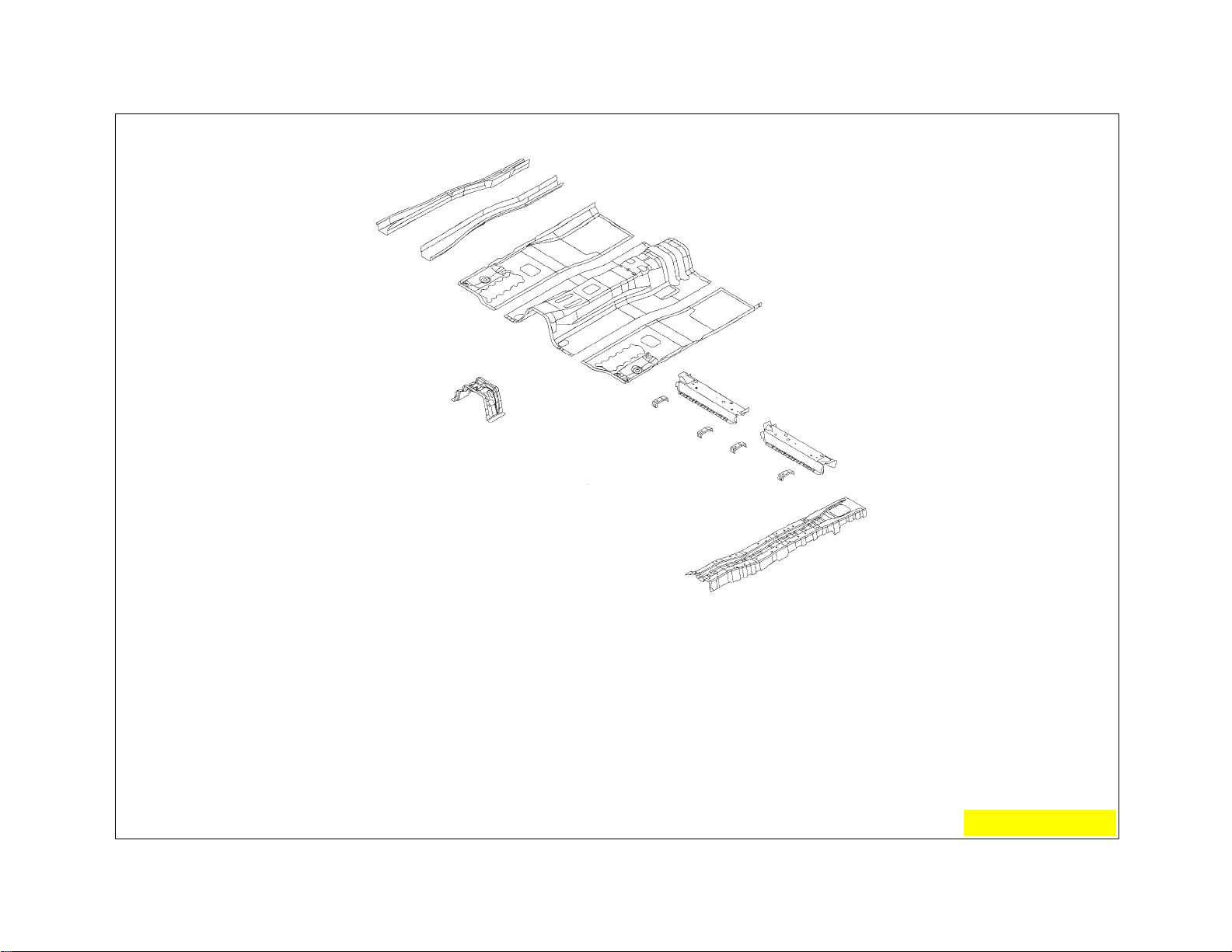

DODGE CALIBER FRONT FLOOR SECTION

AA REINF – TUNNEL –

AB REINF – HAND BRAKE MTG –

AC CROSSMEMBER – FRT FLOOR PAN FRT RT –

AC CROSSMEMBER – FRT FLOOR PAN FRT LT –

AD 05115421

AE CROSSMEMBER – TUNNEL FRT –

AF NUT/WELD.HEX – NIBS.NO.FIN. – DRIVE

SHAFT TO CROSSMEMBER

AG HOOK – MUFLER HANGER BRACKET –

AH BRACKET – CONSOLE –

AJ NUT/WELD.HEX – NIBS.NO.FIN.PILET.PT –

ESP MODULE TO TUNNEL REINF

AK STUD.WELD/INTERNAL – HEADER.PT.NIBS.NO.

FIN – PARK BRAKE LEVER TO TUNNEL REINF

AL NUT/WELD.HEX – NIB.NO.FIN.PILET. PT – FUEL

TUBE TO RAIL EXT

AM STUD.WELD/EXTERNAL – HEADER.PT.PNT.

CUTTER.SPECIAL – WIRING TO SILL INR RT

AM STUD.WELD/EXTERNAL – HEADER.PT.PNT.

CUTTER.SPECIAL – WIRING TO SILL INR LT

AN SILL – FRT FLOOR –

AN SILL – FRT FLOOR –

AP RAIL – TUNNEL FRT RT –

AP RAIL – TUNNEL FRT LT –

Back to Index

Page 30

PARTS IDENTIFICATION LEGEND, OVERVIEW 2

Back to Index

AA REINF – TUNNEL –

AB REINF – HAND BRAKE MTG –

AC CROSSMEMBER – FRT FLOOR PAN FRT RT –

AC CROSSMEMBER – FRT FLOOR PAN FRT LT –

AD 05115421

AE CROSSMEMBER – TUNNEL FRT –

AF NUT/WELD.HEX – NIBS.NO.FIN. – DRIVE

SHAFT TO CROSSMEMBER

AG HOOK – MUFLER HANGER BRACKET –

AH BRACKET – CONSOLE –

AJ NUT/WELD.HEX – NIBS.NO.FIN.PILET.PT –

ESP MODULE TO TUNNEL REINF

AK STUD.WELD/INTERNAL – HEADER.PT.NIBS.NO.

FIN – PARK BRAKE LEVER TO TUNNEL REINF

AL NUT/WELD.HEX – NIB.NO.FIN.PILET. PT – FUEL

TUBE TO RAIL EXT

AM STUD.WELD/EXTERNAL – HEADER.PT.PNT.

CUTTER.SPECIAL – WIRING TO SILL INR RT

AM STUD.WELD/EXTERNAL – HEADER.PT.PNT.

CUTTER.SPECIAL – WIRING TO SILL INR LT

AN SILL – FRT FLOOR –

AN SILL – FRT FLOOR –

AP RAIL – TUNNEL FRT RT –

AP RAIL – TUNNEL FRT LT –

Page 31

WELD LAYOUT LOCATION GUIDE

Back to Index

Page 32

01 AB TO AA 10 S/WELDS (ORD)

Back to Index

Page 33

02 AD TO AC 24 S/WELDS (ORD)

03 AF TO AE 1 PROJ WELD (ORD)

04 AG TO AE 2 ARC WELDS (ORD)

Back to Index

Page 34

05 AH TO AA 13 S/WELDS (ORD)

06 AJ TO AA 4 PROJ WELDS (ORD)

07 AL TO AA 2 PROJ WELDS (ORD)

08 AK TO AB 2 PROJ WELDS (ORD)

Back to Index

Page 35

09 AM TO AN 8 PROJ WELDS (ORD)

10 AF TO AD 1 PROJ WELD (ORD)

Back to Index

Page 36

11 AR TO AP 8/SD S/WELDS (ORD)

12 AS TO AP 2 S/WELDS (ORD)

13 AT TO TP 1 PROJ WELD (ORD)

Back to Index

Page 37

DODGE CALIBER SIDEMEMBER SECTION

AA SIDEMEMBER – RR FLOOR UPR RT –

AA SIDEMEMBER – RR FLOOR UPR LT –

AB EXTENSION – RR FLOOR PAN RT –

AB EXTENSION – RR FLOOR PAN LT –

AC SIDEMEMBER – RR FLOOR LWR RT –

AC SIDEMEMBER – RR FLOOR LWR LT–

AD 05115200AA/05115201AA – EXTENSION – RR

FLOOR SIDEMEMBER – RT/LT

AE SILL – RR FLOOR SIDEMEMBER RT –

AE SILL – RR FLOOR SIDEMEMBER LT –

AF REINF – RR SPRING –

AF REINF – RR SPRING –

AG BRACKET – RR SPRING –

AG BRACKET – RR SPRING –

AH PANEL – RR SPRING –

AH PANEL – RR SPRING –

AJ 05115204AA/05115205AA – SUPPORT ASSY –

RR BUMPER RT/LT

AK EXTENSION – RR FLOOR CROSSMEMBER

FRT RT –

AK EXTENSION – RR FLOOR CROSSMEMBER

FRT LT –

AL BRACKET – TRAILING ARM RT –

AL BRACKET – TRAILING ARM LT –

AM BULKHEAD – RR FLOOR SIDEMEMBER RT –

AM BULKHEAD – RR FLOOR SIDEMEMBER LT –

AN EXTENSION – RR FLOOR SIDEMEMBER RT –

AN EXTENSION – RR FLOOR SIDEMEMBER LT –

AP REINF – RR FLOOR SIDEMEMBER EXTENSION

RT –

AP REINF – RR FLOOR SIDEMEMBER EXTENSION

LT –

AR BULKHEAD – RR FLOOR SIDEMEMBER

EXTENSION RT –

AR BULKHEAD – RR FLOOR SIDEMEMBER

EXTENSION LT –

Back to Index

AS REINF – MUFFLER HANGER BRACKET –

AT BRACKET – PARKING BRAKE CABLE RR RT –

AT BRACKET – PARKING BRAKE CABLE RR LT –

AU BRACKET – RR BRAKE HOSE –

AU BRACKET – RR BRAKE HOSE –

AV BULKHEAD – RR FLOOR SIDEMEMBER RT –

CENTER

AV BULKHEAD – RR FLOOR SIDEMEMBER LT –

CENTER

AW BRACKET – RR SUSPENSION FRT –

AX BRACKET – RR SUSPENSION RR RT –

AX BRACKET – RR SUSPENSION RR LT –

AY REINF – RR FLOOR SIDEMEMBER RT –

AY REINF – RR FLOOR SIDEMEMBER LT –

AZ BULKHEAD – RR FLOOR SIDEMEMBER RT –

AZ BULKHEAD – RR FLOOR SIDEMEMBER LT –

BA NUT– PIPE – RR SUSPENSION TO BODY

BA NUT– PIPE – RR SUSPENSION TO BODY

Page 38

PARTS IDENTIFICATION LEGEND, OVERVIEW 3

Back to Index

AA SIDEMEMBER – RR FLOOR UPR RT –

AA SIDEMEMBER – RR FLOOR UPR LT –

AB EXTENSION – RR FLOOR PAN RT –

AB EXTENSION – RR FLOOR PAN LT –

AC SIDEMEMBER – RR FLOOR LWR RT –

AC SIDEMEMBER – RR FLOOR LWR LT–

AD 05115200AA/05115201AA – EXTENSION – RR

FLOOR SIDEMEMBER – RT/LT

AE SILL – RR FLOOR SIDEMEMBER RT –

AE SILL – RR FLOOR SIDEMEMBER LT –

AF REINF – RR SPRING –

AF REINF – RR SPRING –

AG BRACKET – RR SPRING –

AG BRACKET – RR SPRING –

AH PANEL – RR SPRING –

AH PANEL – RR SPRING –

AJ 05115204AA/05115205AA – SUPPORT ASSY –

RR BUMPER RT/LT

AK EXTENSION – RR FLOOR CROSSMEMBER

FRT RT –

AK EXTENSION – RR FLOOR CROSSMEMBER

FRT LT –

AL BRACKET – TRAILING ARM RT –

AL BRACKET – TRAILING ARM LT –

AM BULKHEAD – RR FLOOR SIDEMEMBER RT –

AM BULKHEAD – RR FLOOR SIDEMEMBER LT –

AN EXTENSION – RR FLOOR SIDEMEMBER RT –

AN EXTENSION – RR FLOOR SIDEMEMBER LT –

AP REINF – RR FLOOR SIDEMEMBER EXTENSION

RT –

AP REINF – RR FLOOR SIDEMEMBER EXTENSION

LT –

AR BULKHEAD – RR FLOOR SIDEMEMBER

EXTENSION RT –

AR BULKHEAD – RR FLOOR SIDEMEMBER

EXTENSION LT –

AS REINF – MUFFLER HANGER BRACKET –

AT BRACKET – PARKING BRAKE CABLE RR RT –

AT BRACKET – PARKING BRAKE CABLE RR LT –

AU BRACKET – RR BRAKE HOSE –

AU BRACKET – RR BRAKE HOSE –

AV BULKHEAD – RR FLOOR SIDEMEMBER RT –

CENTER

AV BULKHEAD – RR FLOOR SIDEMEMBER LT –

CENTER

AW BRACKET – RR SUSPENSION FRT –

AX BRACKET – RR SUSPENSION RR RT –

AX BRACKET – RR SUSPENSION RR LT –

AY REINF – RR FLOOR SIDEMEMBER RT –

AY REINF – RR FLOOR SIDEMEMBER LT –

AZ BULKHEAD – RR FLOOR SIDEMEMBER RT –

AZ BULKHEAD – RR FLOOR SIDEMEMBER LT –

BA NUT– PIPE – RR SUSPENSION TO BODY

BA NUT– PIPE – RR SUSPENSION TO BODY

Page 39

WELD LAYOUT LOCATION GUIDE

Back to Index

Page 40

01 AH TO AG 5/SD S/WELD (CRT)

02 AH TO AF 2/SD S/WELD (CRT)

03 AH TO AG TO AF 2/SD S/WELD (CRT)

04 AG TO AF 2/SD S/WELD (ORD)

05 AJ TO AD 6 S/WELD (ORD)

06 AF TO AD 9 SD S/WELD (ORD)

Back to Index

Page 41

07 AP TO AD 7/SD S/WELD (ORD)

08 AR TO AJ TO AD 6 S/WELD (CRT)

09 AS TO AD 4 S/WELD (ORD)

10 AE TO AC 12/SD S/WELD (ORD)

Back to Index

Page 42

11 AT TO AC 1 S/WELD (ORD)

12 AL TO AC 12 S/WELD (ORD)

13 AU TO AC 1 S/WELD (ORD)

14 AT TO AL TO AC 1 S/WELD (ORD)

15 AU TO AL TO AC 1 S/WELD (ORD)

16 AC TO AG 7/SD S/WELD (CRT)

Back to Index

Page 43

17 AV TO AC 2 S/WELD (ORD)

18 AW TO AC 13 S/WELD (CRT)

Back to Index

Page 44

19 AK TO AC 6R S/WELD (ORD)

20 AZ TO AC 3R S/WELD (ORD)

21 AX TO AG TO AC 2R S/WELD (CRT)

22 AX TO AC 5R S/WELD (CRT)

23 AZ TO AC TO AG 3R S/WELD (CRT)

Back to Index

Page 45

24 AY TO AC 5R S/WELD (CRT)

25 AY TO AL 2R S/WELD (CRT)

26 AY TO AE TO AC 2R S/WELD (CRT)

27 AN TO AC 10R S/WELD (ORD)

Back to Index

Page 46

28 AK TO AC TO AR 2R S/WELD (ORD)

29 AY TO AC TO AA 13R S/WELD (CRT)

30 AM TO AE 3R S/WELD (ORD)

31 AY TO AE TO AA 6R S/WELD (CRT)

32 AE TO AC TO AA 1R S/WELD (ORD)

33 AD TO AC 10R S/WELD (ORD)

Back to Index

Page 47

34 AD TO AA 11R S/WELD (ORD)

35 AD TO AC TO AA 4R S/WELD (CRT)

36 AC TO AA 5R S/WELD (ORD)

37 AC TO AA 1R S/WELD (CRT)

38 AY TO AC TO AA 6R S/WELD (CRT)

Back to Index

Page 48

39 AD TO AB 7R S/WELD (ORD)

40 AD TO AB TO AA 2R S/WELD (ORD)

41 AG TO AA 2R S/WELD (CRT)

42 AG TO AF TO AC 2R S/WELD (CRT)

43 AG TO AC TO AA 2R S/WELD (CRT)

44 AH TO AG TO AA 2R S/WELD (CRT)

45 AB TO AA 4R S/WELD (ORD)

Back to Index

Page 49

46 AJ TO AD 6L S/WELD (ORD)

47 AP TO AD 6L S/WELD (ORD)

48 AD TO AA 11L S/WELD (ORD)

49 AR TO AJ TO AD 6L S/WELD (CRT)

Back to Index

Page 50

50 AL TO AC 13L S/WELD (CRT)

51 AU TO AC 1L S/WELD (CRT)

52 AU TO AC TO AL 1L S/WELD (CRT)

53 AT TO AC 2L S/WELD (CRT)

54 AV TO AC TO AK 4L S/WELD (ORD)

55 AV TO AC 2L S/WELD (ORD)

Back to Index

Page 51

56 AK TO AC 2L S/WELD (ORD)

57 AG TO AF TO AC 2L S/WELD (CRT)

58 AZ TO AC TO AG 3L S/WELD (CRT)

59 AZ TO AC 3L S/WELD (ORD)

60 AD TO AC 6L S/WELD (ORD)

Back to Index

Page 52

61 AY TO AC 5L S/WELD (CRT)

62 AY TO AL 2L S/WELD (CRT)

63 AN TO AC 9L S/WELD (ORD)

64 AX TO AC 5L S/WELD (CRT)

65 AX TO AG TO AC 2L S/WELD (CRT)

66 AM TO AE 1L S/WELD (ORD)

Back to Index

Page 53

67 AD TO AC TO AA 4L S/WELD (CRT)

68 AK TO AC TO AA 2L S/WELD (ORD)

69 AY TO AC TO AA 19L S/WELD (CRT)

Back to Index

Page 54

70 AB TO AA 4L S/WELD (ORD)

71 AY TO AE TO AC 2L S/WELD (CRT)

72 AE TO AC TO AA 1L S/WELD (CRT)

73 AY TO AE TO AA 6L S/WELD (CRT)

74 AD TO AB 7L S/WELD (ORD)

75 AD TO AB TO AA 2L S/WELD (ORD)

Back to Index

Page 55

76 AG TO AA 4L S/WELD (CRT)

77 AH TO AG TO AA 2L S/WELD (CRT)

78 AG TO AC TO AA 2L S/WELD (CRT)

79 AC TO AA 5L S/WELD (CRT)

Back to Index

Page 56

80 AE TO AC 1/SD FCAW (ORD)

81 AY TO AE 1/SD ADH BESAD (ORD)

82 AX TO AC 1/SD FCAW (CRT)

83 AX TO AC 1/SD FCAW (CRT)

84 BA TO AX 2/SD FCAW (CRT)

Back to Index

Page 57

85 AG TO AC TO AA 1/SD ADH BEAD 9ORD)

86 AB TO AA 1/SD ADH BEAD (ORD)

87 AY TO AE TO AA 1/SD ADH BEAD (ORD)

Back to Index

Page 58

88 BA TO AC 1/SD FCAW (CRT)

89 BA TO AC 1/SD FCAW (CRT)

90 AG TO AF TO AC 1/SD ADH BEAD (ORD)

Back to Index

Page 59

BD REINF – SPARE TIRE HOLD-DOWN –

BE TAPPING PLATE –

BF EXTENSION – RR FLOOR –

BG BRACKET – RR FLOOR EXTENSION SIDE RT –

BG BRACKET – RR FLOOR EXTENSION SIDE LT –

BH BRACKET – RR FLOOR EXTENSION CTR RT –

BH BRACKET – RR FLOOR EXTENSION CTR LT –

BJ CROSSMEMBER – RR SEAT –

BK EXTENSION – SIDEMEMBER FRT FLOOR RT –

BK BULKHEAD – CROSSMEMBER RR SEAT LT –

BL STUD.WELD/INTERNAL – HEADER.PT.NIBS.NO.

FIN – BRAKE LINE TO RH WHEELHOUSE ASSY

BM BULKHEAD – CROSSMEMBER RR SEAT RT –

BN NUT/WELD.HEX – NIBS.NO.FIN – FUEL TANK

TO RR SEAT X-MBR –

BP REINF – RR CLOSURE – RR END REINF

BR PANEL – RR CLOSURE – RR END CLOSURE

BS REINF – LIFTGATE STRIKER –

AA SIDEMEMBER – RR FLOOR LWR RT –

AA SIDEMEMBER – RR FLOOR LWR LT –

AB NUT – PIPE

AC EXTENSION – RR FLOOR –

AC EXTENSION – RR FLOOR SIDEMEMBER LT

AD SUPPORT – RR BUMPER RT –

AD SUPPORT – RR BUMPER LT –

AE 06104968AA

AF

SPACER – RR FLOOR SIDEMEMBER EXTENSION –

AG REINF – RR FLOOR SIDEMEMBER RT –

AG REINF – RR FLOOR SIDEMEMBER LT –

AH STUD.WELD/INTERNAL – HEADER.PT.NIBS.

NO.FIN – RR SEAT TO RAIL COVER

AJ NUT WELD HEX – NIBS.NO.FIN – RR SEAT TO

RAIL COVER

AK NUT – PIPE – TRAILING ARM TO RAIL

AL BRACKET – TRAILING ARM RT –

AL BRACKET – TRAILING ARM LT –

AM BRACKET – PARKING BRAKE CABLE RR RT –

AM BRACKET – PARKING BRAKE CABLE RR LT –

AN NUT/WELD.HEX – NIBS.NO.FIN.PIOLT.PT –

AP PANEL – RR WHEELHOUSE INR RT –

AP PANEL – RR WHEELHOUSE INR LT –

AR REINF – RR WHEELHOUSE RT –

AR REINF – RR WHEELHOUSE LT –

AS BRACKET – FILLER –

AT PLATE – SIDE SILL RT –

AT PLATE – SIDE SILL LT –

AU CROSSMEMBER – RR FLOOR FRT –

AV BRACKET – FUEL TANK RR –

AW BRACKET – RR SEAT –

AX SHIELD – FUEL TANK –

AY BRACKET – RR BRAKE HOSE –

AZ BRACKET – RR SUSPENSION FRT –

BA REINF – RR SEAT BELT –

BB BULKHEAD – FRR FLOOR CROSSMEMBER

FRT RT –

BC CROSSMEMBER – RR FLOOR RR –

DODGE CALIBER REAR FLOOR SECTION

Back to Index

Page 60

PARTS IDENTIFICATION LEGEND, OVERVIEW 4

Back to Index

BC CROSSMEMBER – RR FLOOR RR –

BD REINF – SPARE TIRE HOLD-DOWN –

BE TAPPING PLATE –

BF EXTENSION – RR FLOOR –

BG BRACKET – RR FLOOR EXTENSION SIDE RT –

BG BRACKET – RR FLOOR EXTENSION SIDE LT –

BH BRACKET – RR FLOOR EXTENSION CTR RT –

BH BRACKET – RR FLOOR EXTENSION CTR LT –

BJ CROSSMEMBER – RR SEAT –

BK EXTENSION – SIDEMEMBER FRT FLOOR RT –

BK BULKHEAD – CROSSMEMBER RR SEAT LT –

BL STUD.WELD/INTERNAL – HEADER.PT.NIBS.NO.

FIN – BRAKE LINE TO RH WHEELHOUSE ASSY

BM BULKHEAD – CROSSMEMBER RR SEAT RT –

BN NUT/WELD.HEX – NIBS.NO.FIN – FUEL TANK

TO RR SEAT X-MBR –

BP REINF – RR CLOSURE – RR END REINF

BR PANEL – RR CLOSURE – RR END CLOSURE

BS REINF – LIFTGATE STRIKER –

AA SIDEMEMBER – RR FLOOR LWR RT –

AA SIDEMEMBER – RR FLOOR LWR LT –

AB NUT – PIPE

AC EXTENSION – RR FLOOR –

AC EXTENSION – RR FLOOR SIDEMEMBER LT

AD SUPPORT – RR BUMPER RT –

AD SUPPORT – RR BUMPER LT –

AE 06104968AA

AF

SPACER – RR FLOOR SIDEMEMBER EXTENSION –

AG REINF – RR FLOOR SIDEMEMBER RT –

AG REINF – RR FLOOR SIDEMEMBER LT –

AH STUD.WELD/INTERNAL – HEADER.PT.NIBS.

NO.FIN – RR SEAT TO RAIL COVER

AJ NUT WELD HEX – NIBS.NO.FIN – RR SEAT TO

RAIL COVER

AK NUT – PIPE – TRAILING ARM TO RAIL

AL BRACKET – TRAILING ARM RT –

AL BRACKET – TRAILING ARM LT –

AM BRACKET – PARKING BRAKE CABLE RR RT –

AM BRACKET – PARKING BRAKE CABLE RR LT –

AN NUT/WELD.HEX – NIBS.NO.FIN.PIOLT.PT –

AP PANEL – RR WHEELHOUSE INR RT –

AP PANEL – RR WHEELHOUSE INR LT –

AR REINF – RR WHEELHOUSE RT –

AR REINF – RR WHEELHOUSE LT –

AS BRACKET – FILLER –

AT PLATE – SIDE SILL RT –

AT PLATE – SIDE SILL LT –

AU CROSSMEMBER – RR FLOOR FRT –

AV BRACKET – FUEL TANK RR –

AW BRACKET – RR SEAT –

AX SHIELD – FUEL TANK –

AY BRACKET – RR BRAKE HOSE –

AZ BRACKET – RR SUSPENSION FRT –

BA REINF – RR SEAT BELT –

BB BULKHEAD – FRR FLOOR CROSSMEMBER

FRT RT –

Page 61

WELD LAYOUT LOCATION GUIDE

Back to Index

Page 62

01 AB TO AA 1/SD PROJ WELD (ORD)

02 AF TO AC 4/SD ARC WELDS (CRT)

03 AE TO AD 4/SD PROJ WELDS (ORD)

04 AH TO AG 1/SD PROJ WELDS (ORD)

05 AJ TO AG 2/SD PROJ WELDS (ORD)

06 AK TO AL 4/SD ARC WELDS (SAF)

07 AN TO AM 1/SD PROJ WELD (ORD)

Back to Index

Page 63

08 AR TO AP 8R/15L S/WELDS (CRT)

09 AT TO AP 8/SD S/WELDS (ORD)

10 AS TO AP 2L S/WELDS (ORD)

Back to Index

Page 64

Back to Index

11 AN TO AY 1L PROJ WELD (ORD)

12 AB TO AZ 1L PROJ WELD (ORD)

13 AX TO BA 1 PROJ WELD (SAF)

14 AJ TO AW 1 PROJ WELD (ORD)

15 AH TO BA 1 PROJ WELD (ORD)

16 AN TO AA 1L PROJ WELD (ORD)

17 AJ TO BA 1 PROJ WELD (ORD)

18 BG TO BF 4 S/WELDS (ORD)

19 BG TO BH 4 S/WELDS (SAF)

Page 65

20 AV TO AU 7/SD S/WELDS (SAF)

21 BB TO AU 12 S/WELDS (ORD)

Back to Index

Page 66

22 BK TO BJ 3/SD ARC WELDS (SAF)

23 BJ TO BK 8/SD S/WELDS (SAF)

24 BL TO BJ 12 S/WELDS (SAF)

Back to Index

Page 67

25 BN TO BM 1/SD PROJ WELD (ORD)

26 BM TO BJ 3/SD S/WELDS (CRT)

27 BM TO BK TO BJ 1/SD S/WELDS (CRT)

28 BK TO BJ 3/SD S/WELDS (ORD)

29 BK TO BK 4/SD S/WELDS (ORD)

30 BN TO BJ 1/SD PROJ WELD (ORD)

Back to Index

Page 68

31 BS TO BR 12 S/WELDS (ORD)

Back to Index

Page 69

32 BP TO BS TO BR 6 S/WELDS (ORD)

33 BP TP BR 30 S/WELDS (ORD)

Back to Index

Page 70

AA PANEL – FRT SIDE RAIL INR RT –

AA PANEL – FRT SIDE RAIL INR LT –

AB PANEL – SIDE FRT RAIL QTR RT –

AB PANEL – SIDE FRT RAIL QTR LT –

AC BULKHEAD – FRT SUSPENSION CROSSMEMBER RT –

AC BULKHEAD – FRT SUSPENSION CROSSMEMBER LT –

AD BRACKET – FRONT ENGINE MOUNT –

AD BRACKET – TRANS MOUNTING LT–

AF BRACKET – FRT SUSP RT –

AF BRACKET – FRT SUSP LT –

AG PANEL – EXTENSION FRT RAIL INR RT –

AG PANEL – EXTENSION FRT RAIL INR LT –

AH BRACE – TORQUE BOX RT –

AH BRACE – TORQUE BOX LT –

AJ BRACE – FRT SIDE FRT RT –

AJ BRACE – FRT SIDE FRT LT –

AK NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT – SPEED

SENSOR TO RAIL QTR RT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

ACCUM TO FRT RAIL QTR RT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

SPEED SENSOR TO RAIL QTR LT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

DIESEL INT TO RAIL QTR LT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

POWER STEERING LINE TO RAIL INR RT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

RAIL ASSY TO BATTERY BRKT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

RAIL ASSY TO BATTERY TRAY

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

LHD ABS UNIT TO RAIL INR RT

AL REINF – FRT RAIL INR RT –

AM

NUT/WELD.HEX – NIBS.NO.FIN. – ENGINE MOUNT

TO RAIL ASSY FRT RT

AM

NUT/WELD.HEX – NIBS.NO.FIN. – TRANS MOUNT

TO RAIL ASSY

AN BRACKET – BATTERY HOLD-DOWN –

AP 06104961AA – NUT/WELD.HEX –

HEADER.PT.NILES.NO.FIN QTY.1

AR NUT – PIPE – FRT SUSPENSION TO BODY

AR NUT – PIPE – FRT SUSPENSION TO BODY

AR NUT – PIPE – FRT SUSPENSION TO BODY

AR NUT – PIPE – FRT SUSPENSION TO BODY

AS REINF – FRT SIDE RAIL BUMPER

MOUNTING RT –

AS REINF – FRT SIDE RAIL BUMPER

MOUNTING LT –

AT BRACKET – BRAKE HOSE FRT –

AT BRACKET – BRAKE HOSE FRT –

AU REINF – TIE DOWN MTG –

AU REINF – TIE DOWN MTG –

AV REINF – EXTENSION FRT RAIL INR RT –

AV REINF – EXTENSION FRT RAIL INR LT –

AW BULKHEAD – EXTENSION FRT RAIL INR LT –

AX EXTENSION – DASH LWR –

AX EXTENSION – DASH LWR –

AY BRACKET – FRT SUSPENSION CROSS

MEMBER LWR RT –

AY BRACKET – FRT SUSPENSION CROSS

MEMBER LWR LT –

Back to Index

DODGE CALIBER FRONT RAILS SECTION

Page 71

PARTS IDENTIFICATION LEGEND, OVERVIEW 5

Back to Index

AA PANEL – FRT SIDE RAIL INR RT –

AA PANEL – FRT SIDE RAIL INR LT –

AB PANEL – SIDE FRT RAIL QTR RT –

AB PANEL – SIDE FRT RAIL QTR LT –

AC BULKHEAD – FRT SUSPENSION CROSSMEMBER RT –

AC BULKHEAD – FRT SUSPENSION CROSSMEMBER LT –

AD BRACKET – FRONT ENGINE MOUNT –

AD BRACKET – TRANS MOUNTING LT–

AF BRACKET – FRT SUSP RT –

AF BRACKET – FRT SUSP LT –

AG PANEL – EXTENSION FRT RAIL INR RT –

AG PANEL – EXTENSION FRT RAIL INR LT –

AH BRACE – TORQUE BOX RT –

AH BRACE – TORQUE BOX LT –

AJ BRACE – FRT SIDE FRT RT –

AJ BRACE – FRT SIDE FRT LT –

AK NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT – SPEED

SENSOR TO RAIL QTR RT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

ACCUM TO FRT RAIL QTR RT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

SPEED SENSOR TO RAIL QTR LT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

DIESEL INT TO RAIL QTR LT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

POWER STEERING LINE TO RAIL INR RT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

RAIL ASSY TO BATTERY BRKT

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

RAIL ASSY TO BATTERY TRAY

AK

NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

LHD ABS UNIT TO RAIL INR RT

AL REINF – FRT RAIL INR RT –

AM

NUT/WELD.HEX – NIBS.NO.FIN. – ENGINE MOUNT

TO RAIL ASSY FRT RT

AM

NUT/WELD.HEX – NIBS.NO.FIN. – TRANS MOUNT

TO RAIL ASSY

AN BRACKET – BATTERY HOLD-DOWN –

AP 06104961AA – NUT/WELD.HEX –

HEADER.PT.NILES.NO.FIN QTY.1

AR NUT – PIPE – FRT SUSPENSION TO BODY

AR NUT – PIPE – FRT SUSPENSION TO BODY

AR NUT – PIPE – FRT SUSPENSION TO BODY

AR NUT – PIPE – FRT SUSPENSION TO BODY

AS REINF – FRT SIDE RAIL BUMPER

MOUNTING RT –

AS REINF – FRT SIDE RAIL BUMPER

MOUNTING LT –

AT BRACKET – BRAKE HOSE FRT –

AT BRACKET – BRAKE HOSE FRT –

AU REINF – TIE DOWN MTG –

AU REINF – TIE DOWN MTG –

AV REINF – EXTENSION FRT RAIL INR RT –

AV REINF – EXTENSION FRT RAIL INR LT –

AW BULKHEAD – EXTENSION FRT RAIL INR LT –

AX EXTENSION – DASH LWR –

AX EXTENSION – DASH LWR –

AY BRACKET – FRT SUSPENSION CROSS

MEMBER LWR RT –

AY BRACKET – FRT SUSPENSION CROSS

MEMBER LWR LT –

Page 72

WELD LAYOUT LOCATION GUIDE

Back to Index

Page 73

01 AD TO AB TO AA 4R S/WELDS (ORD)

02 AC TO AB TO 2R FCAW (ORD)

03 AC TO AB TO AA 3R S/WELDS (ORD)

04 AB TO AA 16R S/WELDS (ORD)

05 AB TO AA 2R FCAW (ORD)

06 AE TO AB TO AA 5R S/WELDS (ORD)

07 AF TO AB 1R FCAW (ORD)

Back to Index

Page 74

08 AC TO AB TO AA 3L S/WELDS (ORD)

09 AC TO AB 2L FCAW (ORD)

10 AD TO AB TO AA 2L S/WELDS (ORD)

11 AE TO AB TO AA 5L S/WELDS (ORD)

12 AB TO AA 2L FCAW (ORD)

13 AB TO AA 16L S/WELDS (ORD)

14 AF TO AB 1L FCAW (ORD)

Back to Index

Page 75

15 AJ TO AB TO AA 1R S/WELD (ORD)

16 AJ TO AB 1R S/WELD (ORD)

17 AH TO AB TO AA 2R S/WELDS (ORD)

18 AH TO AB 2R S/WELDS (ORD)

19 AH TO AG TO AB 4R S/WELDS (ORD)

Back to Index

20 AG TO AB 1R FCAW (ORD)

21 AJ TO AG TO AA 1R S/WELD (ORD)

22 AH TO AG TO AA 4R S/WELDS (ORD)

23 AG TO AA 8R S/WELDS (ORD)

Page 76

24 AG TO AA 8L S/WELDS (ORD)

25 AH TO AG TO AA 4L S/WELDS (ORD)

26 AH TO AB 3L S/WELDS (ORD)

27 AH TO AB TO AA 2L S/WELDS (ORD)

28 AJ TO AB 1L S/WELD (ORD)

Back to Index

29 AJ TO AB TO AA 1L S/WELD (ORD)

30 AJ TO AG TO AA 1L S/WELD (ORD)

31 AG TO AB 1L FCAW (ORD)

32 AH TO AG TO AB 4L S/WELDS (ORD)

Page 77

Back to Index

33 AK TO AA 1R PROJ WELD (ORD)

34 AL TO AD TO AA 2R S/WELDS (ORD)

35 AE TO AD TO AA 4R S/WELDS (ORD)

36 AD TO AA 2R S/WELDS (ORD)

37 AC TO AJ TO AA 4R S/WELDS (ORD)

38 AJ TO AA 3R S/WELDS (ORD)

39 AE TO AA 3R S/WELDS (ORD)

40 AL TO AA 1R S/WELDS (ORD)

Page 78

Back to Index

41 AK TO AA 3L PROJ WELDS (ORD)

42 AP TO AA 1L PROJ WELD (ORD)

43 AN TO AA 4L FCAW (ORD)

44 AM TO AA 2L PROJ WELDS (ORD)

45 AJ TO AA 3L S/WELDS 9ORD)

46 AC TO AJ TO AA 4L S/WELDS (ORD)

47 AE TO AA 3L S/WELDS (ORD)

48 AE TO AD TO AA 4L S/WELDS (ORD)

Page 79

49 AF TO AC TO AA S/WELDS (CRT)

50 AC TO AA 7/SD S/WELDS (ORD)

51 AS TO AA 4/SD S/WELDS (ORD)

52 AR TO AC 2/SD FCAW (CRT)

Back to Index

Page 80

53 AK TO AJ 2R PROJ WELDS (ORD)

54 AM TO AD 2R/2L PROJ WELDS (ORD)

55 AF TO AF 6/SD S/WELDS (ORD)

56 AR TO AF 1/SD PROJ WELDS (SAF)

Back to Index

Page 81

57 AT TO AB 2/SD S/WELDS (ORD)

58 AK TO AB 5R/4L PROJ WELDS (ORD)

Back to Index

Page 82

59 AR TO AH 1R/1L PROJ WELDS (SAF)

60 AU TO AH 8R/8L S/WELDS (ORD)

61 AK TO AS 4/SD PROJ WELDS (ORD)

Back to Index

Page 83

62 AW TO AV 2/SD FCAW (ORD)

63 AX TO AV TO AG 2/SD S/WELDS (ORD)

64 AH TO AG 1/SD S/WELDS (ORD)

65 AH TO AV TO AG 1/SD S/WELDS (ORD)

66 AV TO AG 27/SD S/WELDS (ORD)

Back to Index

Page 84

67 AX TO AW TO AG 2/SD A/WELDS (ORD)

68 AY TO AH TO AG 2/SD S/WELDS (CRT)

69 AH TO AG 1/SD S/WELDS (CRT)

70 AW TO AH TO AG 1/SD S/WELDS (ORD)

71 AX TO AG 3/SD S/WELDS (ORD)

72 AW TO AG 4/SD S/WELDS (ORD)

Back to Index

Page 85

73 AY TO AH TO AG 2/SD S/WELDS (ORD)

74 AW TO AG 3/SD S/WELDS (ORD)

75 AH TO AG 4/SD S/WELDS (ORD)

76 AW TO AH TO AG 2/SD S/WELDS (ORD)

77 AR TO AY 1/SD FCAW (CRT)

78 AY TO AG 3/SD FCAW (ORD)

Back to Index

Page 86

Back to Index

Page 87

Back to Index

WELD LOCATION OVERVIEW ZONES

Page 88

DODGE CALIBER PLENUM ASSEMBLY SECTION

Back to Index

AA PANEL – COWL TOP INNER – COWL TOP, INR

AB PANEL – COWL SIDE UPPER – COWL TOP, UPR

AC BRACKET – VIN PLATE ATTACH –

AD REINF – BRAKE PEDAL –

AE 05074690AA – BULKHEAD – FRAME

AF PANEL – COWL TOP LOWER – COWL TOP, LWR

AG BRACKET – WINDSHIELD –

AH BRACKET – WIPER –

AJ BRACKET – COWL PLENUM –

AK BULKHEAD – COWL CTR – UPR FRAME RR

AL BRACKET – WIPER – WIPER, CTR

Page 89

PARTS IDENTIFICATION LEGEND, OVERVIEW 6

Back to Index

AA PANEL – COWL TOP INNER – COWL TOP, INR

AB PANEL – COWL SIDE UPPER – COWL TOP, UPR

AC BRACKET – VIN PLATE ATTACH –

AD REINF – BRAKE PEDAL –

AE 05074690AA – BULKHEAD – FRAME

AF PANEL – COWL TOP LOWER – COWL TOP, LWR

AG BRACKET – WINDSHIELD –

AH BRACKET – WIPER –

AJ BRACKET – COWL PLENUM –

AK BULKHEAD – COWL CTR – UPR FRAME RR

AL BRACKET – WIPER – WIPER, CTR

Page 90

WELD LAYOUT LOCATION GUIDE

Back to Index

Page 91

01 AC TO AB 2 S/WELDS (ORD)

02 AD TO AD 2 S/WELDS (ORD)

03 AD TO AA 2 S/WELDS (ORD)

Back to Index

Page 92

04 AE TO AB 6 S/WELDS (ORD)

05 AE TO AB TO AA 3 S/WELDS (ORD)

06 AB TO AA 4 S/WELDS (ORD)

Back to Index

Page 93

07 AF TO AB 4 S/WELDS (ORD)

08 AG TO AB 4 S/WELDS (ORD)

09 AH TO AB 3 S/WELDS (ORD)

10 AF TO AB TO AA 23 S/WELDS (ORD)

Back to Index

Page 94

11 AJ TO AF 2 S/WELDS (ORD)

12 AK TO AB 3 S/WELDS (ORD)

13 AL TO AF 5 S/WELDS (ORD)

14 AJ TO AK TO AB 2 S/WELDS (ORD)

15 AK TO AA 1 STRUC ADH (ORD)

16 AK TO AA 1 STRUC ADH (ORD)

17 AK TO AA 1 STRUC ADH (ORD)

18 AK TO AA 1 STRUC ADH (ORD)

19 AK TO AA 2 STRUC ADH (ORD)

Back to Index

Page 95

DODGE CALIBER DASH ASSEMBLY SECTION

Back to Index

AA PANEL – DASH –

AB CROSSMEMBER – DASH –

AC REINF – DASH PANEL –

AD STUD.WELD/INTERNAL – HEADER.PT.NIBS.NO.FIN

– CLUTCH & CVT MOD TO DASH

AE SPACER – WELD –

AF CROSSMEMBER – DASH –

Page 96

PARTS IDENTIFICATION LEGEND, OVERVIEW 7

Back to Index

AA PANEL – DASH –

AB CROSSMEMBER – DASH –

AC REINF – DASH PANEL –

AD STUD.WELD/INTERNAL – HEADER.PT.NIBS.NO.FIN

– CLUTCH & CVT MOD TO DASH

AE SPACER – WELD –

AF CROSSMEMBER – DASH –

Page 97

WELD LAYOUT LOCATION GUIDE

Back to Index

Page 98

01 AB TO AA 10 S/WELDS (ORD)

02 AC TO AA 11 S/WELDS (ORD)

Back to Index

Page 99

03 AE TO AC 4 PROJ WELDS (ORD)

04 AD TO AA 7 PROJ WELDS (ORD)

05 AF TO AA 10 S/WELDS (ORD)

Back to Index

Page 100

DODGE CALIBER ENGINE BOX ASSEMBLY SECTION

AA BAR – HEADLAMP RT –

AA BAR – HEADLAMP LT –

AB BRACKET – FRT FENDER OTR LT –

AB BRACKET – FRT FENDER OTR RT –

AC GUSSET – PANEL RT –

AC GUSSET – PANEL LT –

AD GUSSET – CROSSMEMBER – FRT LWR –

AE CROSSMEMBER – FRT UPR –

AF CROSSMEMBER – FRT LWR –

AG REINF – CROSSMEMBER –

AH NUT – PIPE – F/A MEMBER MOUNTING

AJ BRACKET – RADIATOR SUPPORT LWR –

AJ BRACKET – RADIATOR SUPPORT LWR –

AL PANEL – SHOCK TOWER MOUNTING FRT RT –

AL PANEL – SHOCK TOWER MOUNTING FRT LT –

AM PANEL – FRT FENDER SHIELD RT –

AM SHIELD – FRT FENDER SIDE SHIELD LT –

AN GUSSET – FRT SUSPENSION ISOLATOR

STRUT MOUNTING LT –

AP REINF – FRT SUSPENSION ISOLATOR STRUT

MOUNTING RT –

Back to Index

BF BRACKET – BRAKE LINE –

BG CROSSMEMBER – DASH –

BH CROSSMEMBER – DASH –

BJ EXTENSION – RAIL FRT RT –

BK EXTENSION – RAIL FRT LT –

BL BULKHEAD – CROSSMEMBER –

BM NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

BATTERY HOLD DOWN

BN BRACKET – BATTERY HOLD DOWN –

BP BRACKET ASSY – ACCELERATOR PEDAL –

BQ NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

CANISTER TO DASH

BR NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

I/P TO COWL SIDE REINF

BS REINF – I/P –

BT NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT –

FRT WIPER MODULE TO PLENUM ASSY

BU BRACKET – COWL PLENUM –

AP REINF – FRT SUSPENSION ISOLATOR STRUT

MOUNTING LT –

AR REINF – SHOCK TOWER MOUNTING FRT RT –

AR REINF – SHOCK TOWER MOUNTING FRT LT –

AT GUSSET – ENGINE MOUNT –

AU BRACKET – FRT ENGINE MOUNT ATTACH –

AV GUSSET – TRANSMISSION –

AW REINF – SHIPPING TIE DOWN FRT –

AX BRACKET – SHIPPING TIE DOWN FRT –

AY NUT/WELD.HEX – NIBS.NO.FIN.PILOT.PT – FRT

WIPER MODULE TO PLENUM ASSY

AZ BRACKET – WIPER –

BA SILL – FRT FLOOR –

BB STUD.WELD/EXTERNAL – HEADER.PT.PNT.CUTTER.

SPECIAL – FRT FLR PAN FRT H/SHLD TO FLR PAN

BB STUD.WELD/EXTERNAL – HEADER.PT.PNT.CUTTER.

SPECIAL – WIRING TO SILL INR RT

BC SPACER – WELD –

BD REINF – DASH PANEL –

BE EXTENSION – DASH –

Loading...

Loading...