1st Printing

WWW.ALL-TRANS.BY

August, 2011

INTRODUCTION

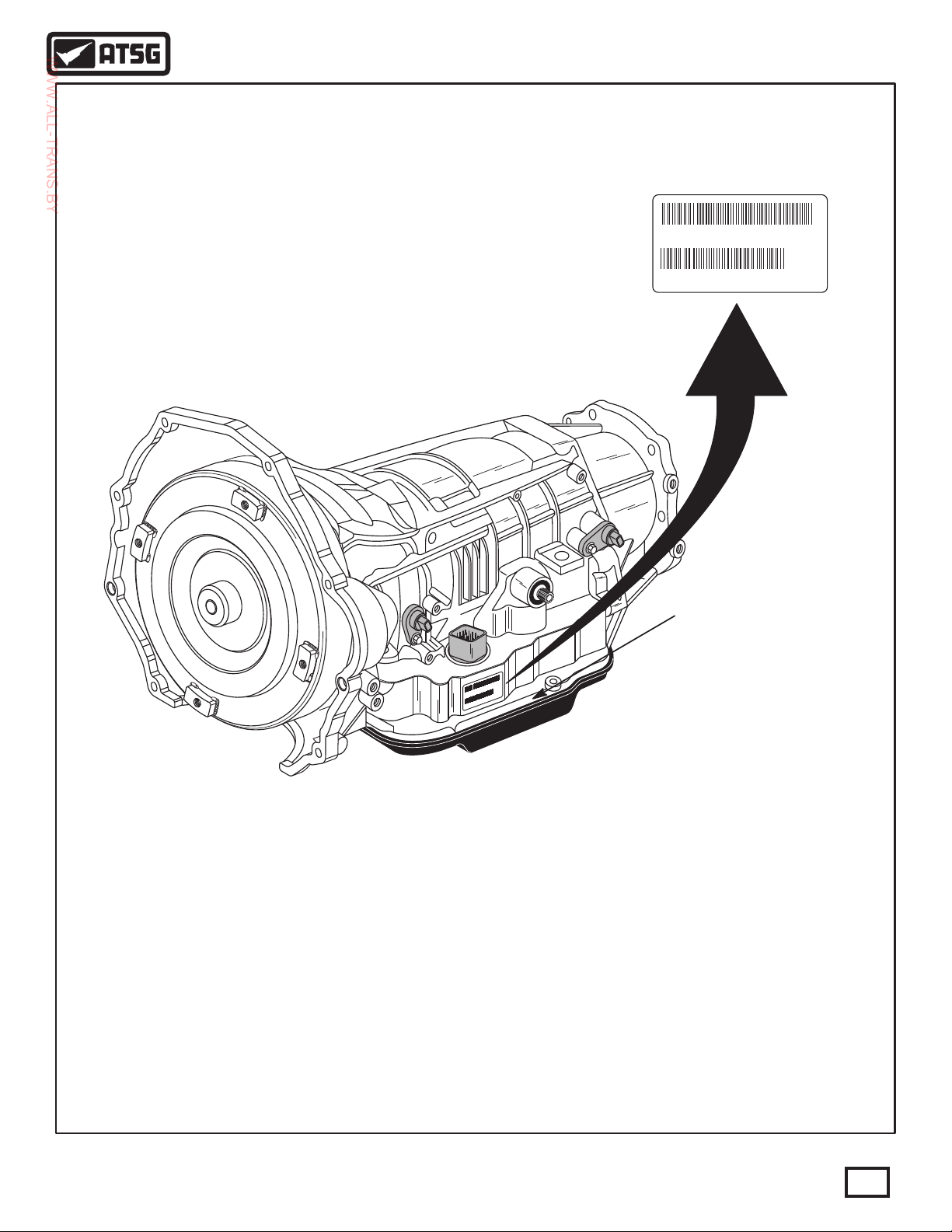

DODGE RAM 68RFE

Beginning at the start of production for the 2006 model year Chrysler Corporation has introduced a new version

of the 5/45RFE transmission and is found in Dodge Ram trucks. The new 68RFE designation tells us that this

new unit has 6 forward speeds, a relative torque rating of 8, is for Rear drive vehicles and is Fully Electronic

controlled. Refer to Figure 1. The 68RFE transmission is a sophisticated, multi-range, electronically controlled

transmission which combines optimized gear ratios for responsive performance, improved efficiency features,

and low NVH (Noise, Vibration, Harshness). Other features include driver adaptive shifting and three, 6 pinion,

planetary gear sets to provide wide ratio capability with precise ratio steps for optimum drivability. There have

been several engineering changes in the geartrain to improve durability and reliability.

The primary mechanical components consist of the following:

Larger Bell Housing, different bolt pattern and a cutout to accommodate diesel applications.

Three multiple disc driving clutch packs.

Three multiple disc brake clutch packs.

Three 6 pinion planetary gear sets (Totally New Design).

Dual stage hydraulic oil pump.

Valve Body and TRS/Solenoid pack.

No part of any ATSG publication may be reproduced, stored in any retrieval system or transmitted in any form or

by any means, including but not limited to electronic, mechanical, photocopying, recording or otherwise,

without written permission of Automatic Transmission Service Group. This includes all text illustrations,

tables and charts.

The information and part numbers contained in this booklet have

been carefully compiled from industry sources known for their

reliability, but ATSG does not guarantee its accuracy.

Copyright © ATSG 2011

WAYNE COLONNA

PRESIDENT

DALE ENGLAND

FIELD SERVICE CONSULTANT

PETER LUBAN

TECHNICAL CONSULTANT

JON GLATSTEIN

TECHNICAL CONSULTANT

GERALD CAMPBELL

TECHNICAL CONSULTANT

TECHNICAL CONSULTANT

TECHNICAL CONSULTANT

GREGORY LIPNICK

TECHNICAL CONSULTANT

TECHNICAL CONSULTANT

JIM DIAL

ED KRUSE

DAVID CHALKER

GREG CATANZARO

TECHNICAL CONSULTANT

AUTOMATIC TRANSMISSION SERVICE GROUP

18635 S.W. 107 AVENUE

CUTLER BAY, FLORIDA 33157

(305) 670-4161

1

DO DG E R AM 6 8R F E

WWW.ALL-TRANS.BY

INDEX

IDENTIFICATION TAG INFORMATION & FLUID REQUIREMENTS ....... ..................................................

COMPONENT LOCATIONS AND CLUTCH APPLICATION CHART ..............................................................

SOLENOID OPERATION AND APPLICATION CHART ....................................................................................

ELECTRICAL AND LIMP-IN MODE OPERATION ...........................................................................................

SOLENOID DESCRIPTION ...................................................................................................................................

WIRE SCHEMATIC ................................................................................................................................................

CASE CONNECTOR TERMINAL IDENTIFICATION .......................................................................................

CONTROLLER LOCATION ...................................................................................................................................

CONTROLLER CONNECTOR TERMINAL IDENTIFICATION .......................................................................

CLUTCH VOLUME INDEX INFORMATION ......................................................................................................

AIR PRESSURE TESTS ..........................................................................................................................................

EXTERNAL SENSOR LOCATIONS ......................................................................................................................

TRANSMISSION RANGE SENSOR/SOLENOID BODY .....................................................................................

DIAGNOSTIC TROUBLE CODES ........................................................................................................................

CHECKBALL LOCATIONS ....................................................................................................................................

PRESSURE TAP LOCATIONS AND TEST PROCEDURES ...............................................................................

ACCELERATOR PEDAL POSITION SENSOR INFORMATION, 6.7L DIESEL ..............................................

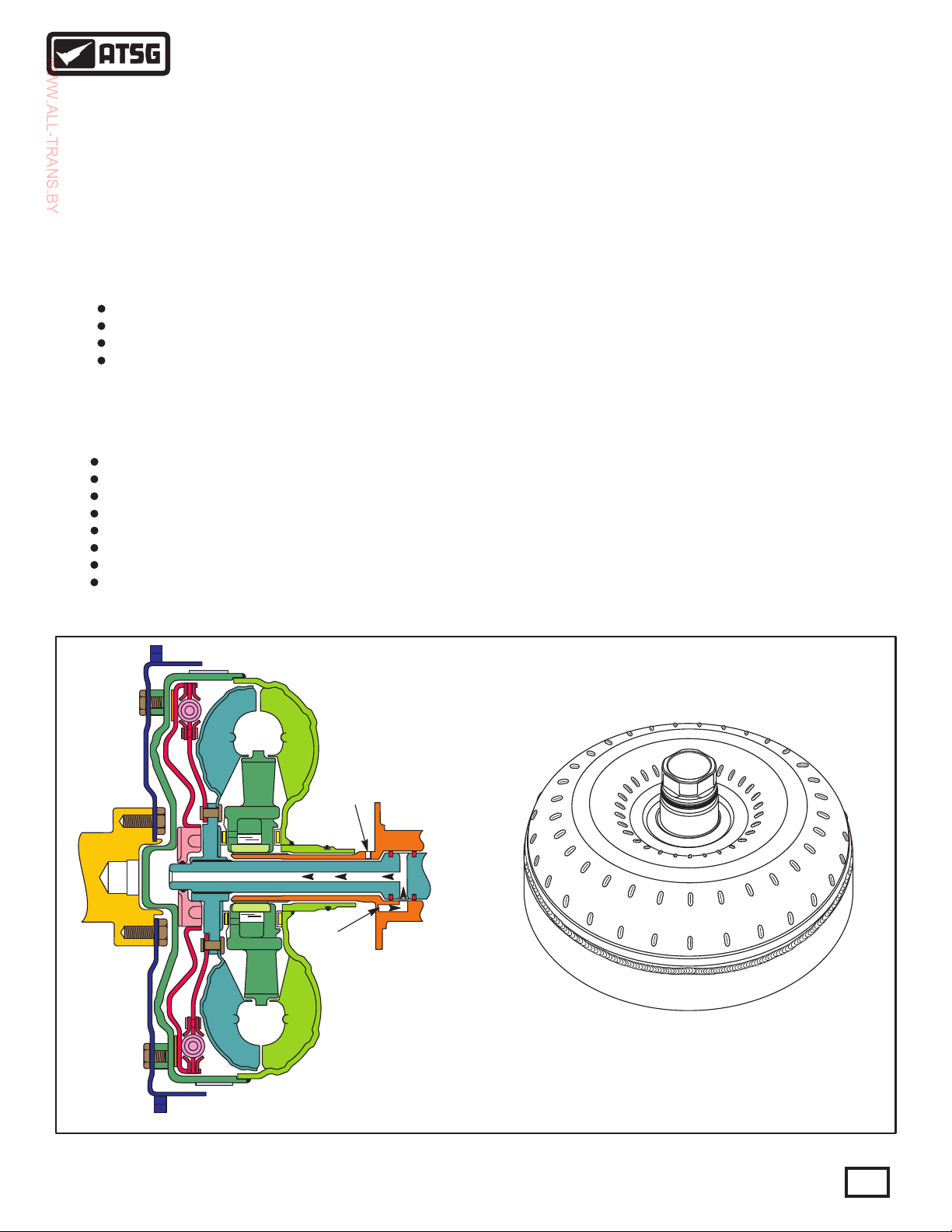

CONVERTER CLUTCH OPERATION ..................................................................................................................

CASE & OIL PUMP PASSAGE IDENTIFICATION ............................................................................................

TRANSMISSION DISASSEMBLY .........................................................................................................................

COMPONENT REBUILD SECTION

EXTENSION HOUSING ..................................................................................................................................

TRANSMISSION CASE ASSEMBLY .............................................................................................................

LOW/REVERSE CLUTCH HOUSING ASSEMBLY ......................................................................................

2-4 CLUTCH RETAINER ASSEMBLY ...........................................................................................................

GEARTRAIN ASSEMBLY ...............................................................................................................................

INPUT CLUTCH HOUSING ASSEMBLY .....................................................................................................

OIL PUMP ASSEMBLY ...................................................................................................................................

VALVE BODY ASSEMBLY ..............................................................................................................................

TRANSMISSION FINAL ASSEMBLY ..................................................................................................................

SETTING REAR TRANSMISSION END-PLAY ...................................................................................................

SETTING FRONT TRANSMISSION END-PLAY ................................................................................................

CLEARANCE SPECIFICATIONS AND BOLT IDENTIFICATION ...................................................................

THRUST BEARING IDENTIFICATION ..............................................................................................................

TORQUE SPECIFICATIONS .................................................................................................................................

SPECIAL TOOLS ....................................................................................................................................................

HEAVY DUTY LOW ROLLER CLUTCH ..............................................................................................................

3

4

5

6

7

11

12

13

14

16

18

19

20

22

25

26

28

29

30

32

44

44

46

53

56

60

72

78

90

95

97

105

106

108

109

112

2

CAUTION: ATSG service manuals are intended for use by professional,

qualified technicians. Attempting repairs or service without the proper

training, tools and equipment could cause injury to you or others and damage

to the vehicle that may cause it not to operate properly.

AUTOMATIC TRANSMISSION SERVICE GROUP

18635 S.W. 107 AVENUE

CUTLER BAY, FLORIDA 33157

(305) 670-4161

Copyright © ATSG 2011

Technical Service Information

WWW.ALL-TRANS.BY

DODGE RAM TRUCKS 68RFE TRANSMISSION

FOUND BEHIND 5.9L (L6) and 6.7L Diesel Engines

Bar Code Label

TITTJ177720548 14:10:44

704

P52119704AB RFE

ID Numbers Also Etched Into

Case Pan Rail Here

1777 20548 P52119704AB

{

Build

:

41 : 4

8 1 0 4

4

0

70

7

7 5

7 2

T 1 4

T

I

T J

FEP 1 4

5

A

0 B

7 R

9

1

2

2

7 05

1 7

A

4

9 0

1 71

2

5

P B7

48

Date

{

Serial

Number

Number

Part

{

6 = Six Forward Speeds

8 = Relative Torque Capacity

R = Rear Wheel Drive

FE = Fully Electronic

Fluid Requirements

"Mopar® ATF+4"

Figure 1

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

3

SELECTOR

WWW.ALL-TRANS.BY

POSITION

PARK ON

REVERSE

NEUTRAL

OD-1ST

OD-2ND

OD-3RD

OD-4TH

OD-5TH

OD-6TH

OD-LIMP

Technical Service Information

CLUTCH APPLICATION CHART

LO/REV

CLUTCHUDCLUTCH

ON ON 4.44:1

ON

ON

*

ON

ON

ON ON

ON

SECOND

CLUTCHODCLUTCH

ON

ONON

ON

ONON

ON

FOURTH

CLUTCH

ON

REVERSE

CLUTCH

LOW SPRAG

CLUTCH

HOLD

GEAR

RATIO

3.23:1

1.83:1

1.41:1

1.00:1

0.81:1

0.62:1

1.00:1

(2)-1ST

(2)-2ND

(2)-LIMP

(1)-1ST

L/R Clutch is on only with the output shaft speed below 150 RPM.

*

ON

ON

*

ON

ON

ON

ON

ON

ON

COMPONENT LOCATIONS

Underdrive

Clutch

Overdrive

Clutch

Reverse

Clutch

Fourth

Clutch

Second

Clutch

HOLD

HOLD

Low/Reverse

Clutch

3.23:1

1.83:1

1.83:1

3.23:1

Low Sprag

Clutch

4

Copyright © 2011 ATSG

Figure 2

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

WWW.ALL-TRANS.BY

MECHANICAL OPERATION

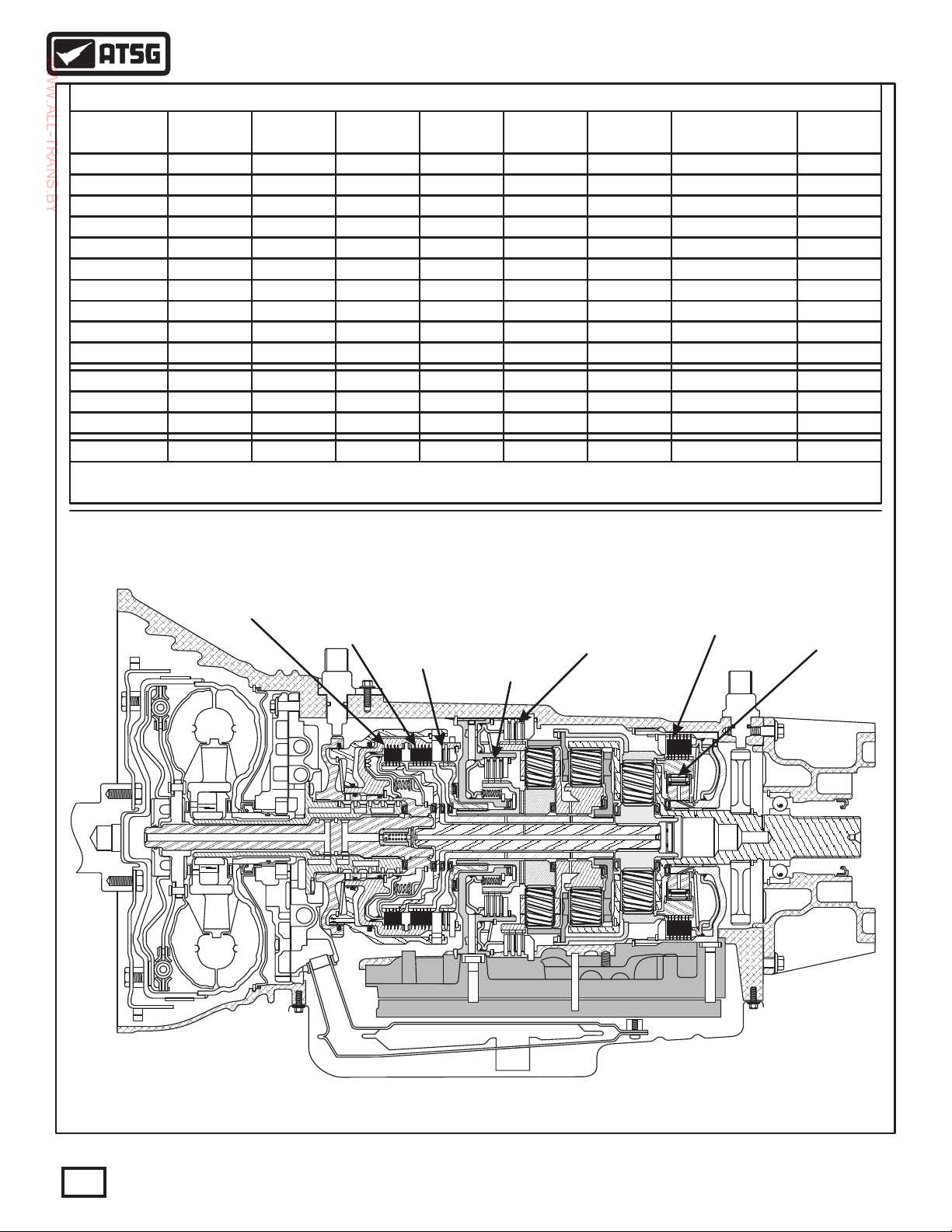

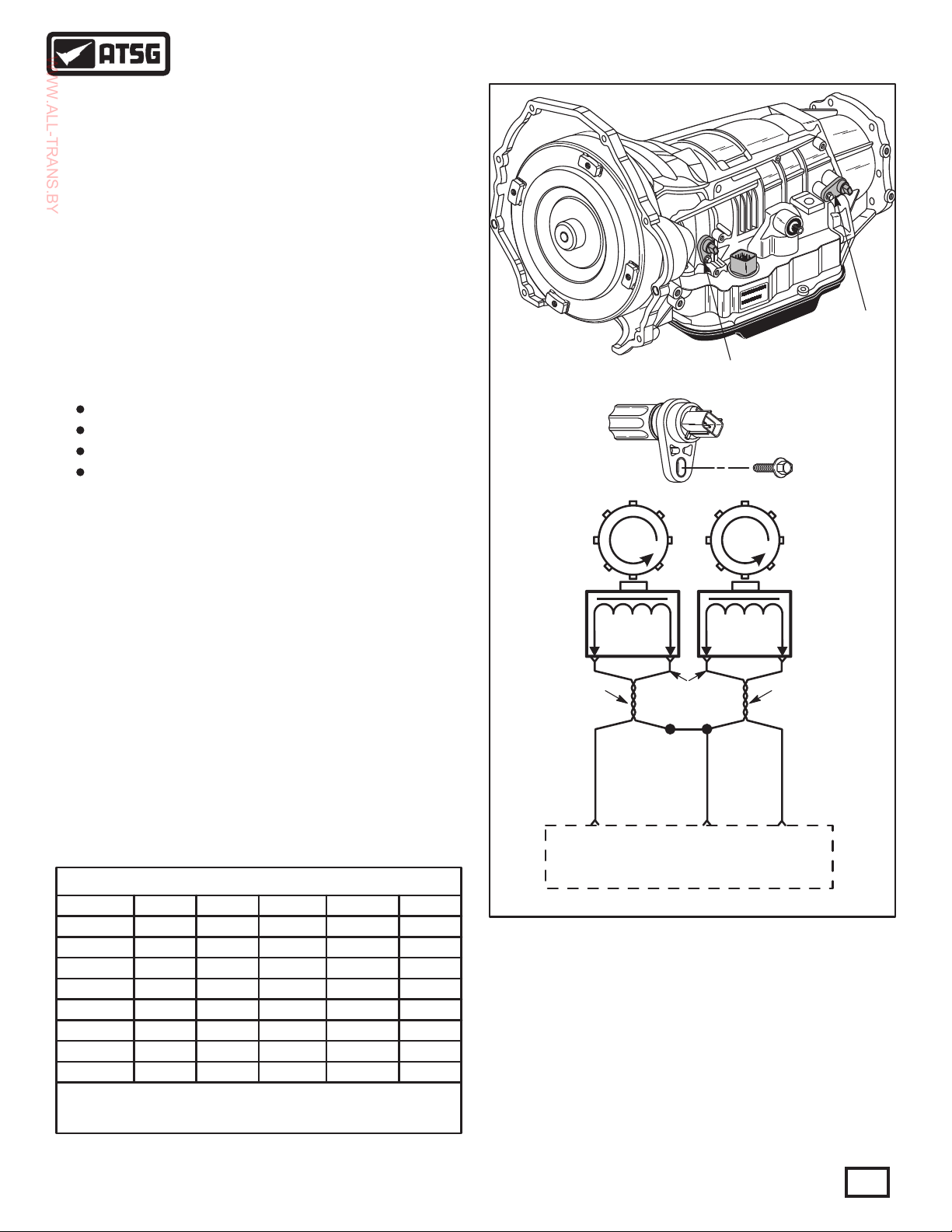

The operation of the 68RFE is very similar to the Chrysler 45RFE. Drive range provides reduction 1st, 2nd,

and 3rd gear, direct 4th gear and overdrive 5th and 6th gears. The shift into 5th and 6th gear occurs only after the

transmission has completed the shift into 4th gear. Upshifts into 5th and 6th gear will be delayed when the fluid

temperature is below 4.5°C (40°F) or above 115°C (240°F). The Input Clutch Housing retains the "singlesided" underdrive clutch, "single-sided" overdrive clutch and the reverse clutch. It is set up almost identical to

the 41TE transaxle, except much larger. The 68RFE also contains seperate holding clutches, such as the 2nd

clutch, 4th clutch and the "single-sided" low/reverse clutch. This unit also uses one freewheel device called the

low sprag.

To achieve its different gear ratios, the 68RFE applies different combinations of two clutch packs at a time, as

shown in Figure 2. In Park and Neutral, only the low/reverse clutch is applied. Refer to the chart in Figure 2 for

the clutches that are applied for each shift lever (gear) position.

Another feature of the 68RFE is the three planetary gear sets, as shown in Figure 2, that are all equipped with 6

pinion carriers to accommodate the Diesel engine. These planetary gear sets also provide a deeper 1st and

reverse ratio. All gear ratios are also shown in the chart in Figure 2.

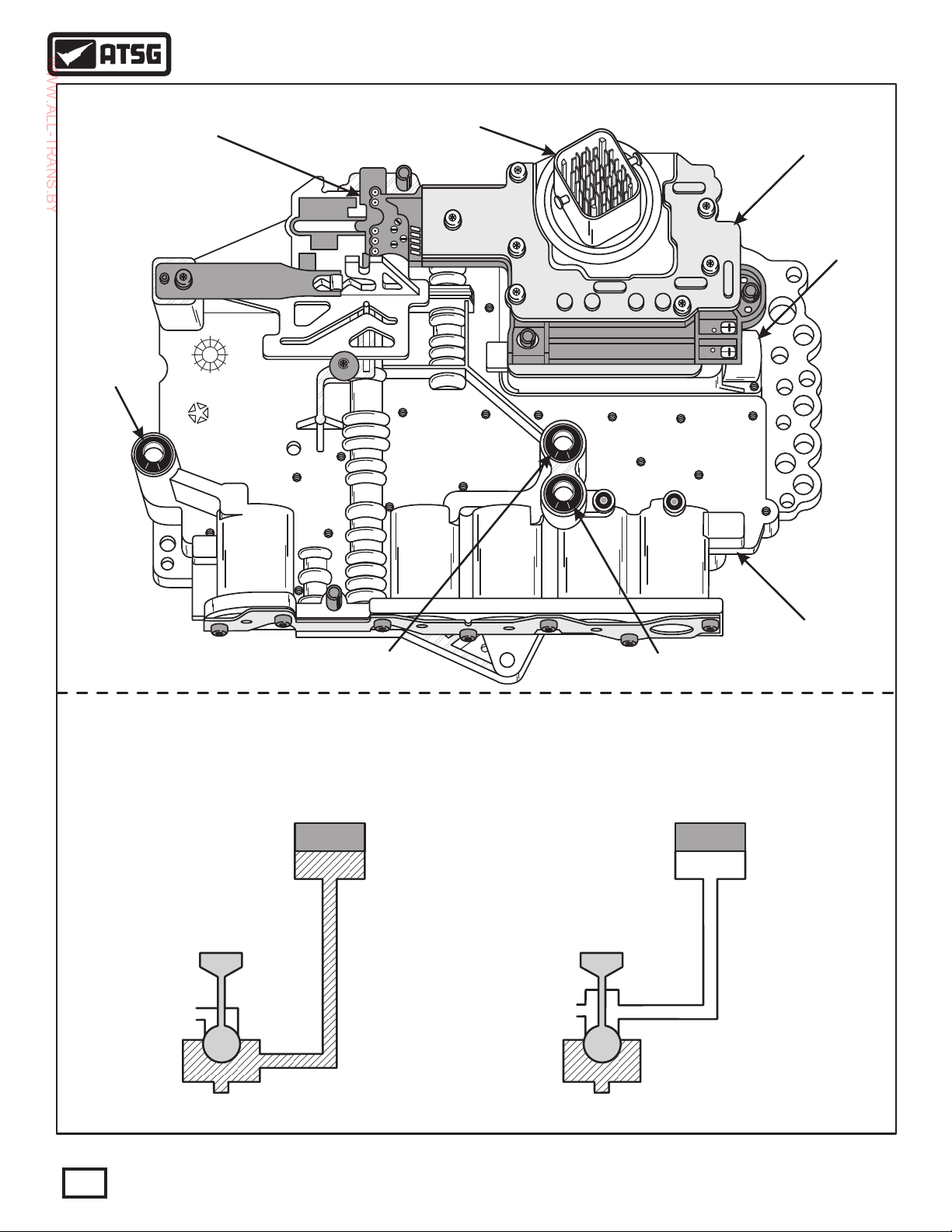

SOLENOID OPERATION

Solenoids are used to control the L/R, 2C, 4C, UD and OD friction elements. The Reverse clutch is controlled

by the manual valve in the valve body and line pressure. The Multi-Select solenoid is used primarily to provide

3rd gear and reverse "limp-in" operation. The TCM energizes or operates the solenoids individually by

grounding the return wire of the solenoid as necessary. When a solenoid is energized, a fluid passage is opened

or closed (vented or applied), depending on its default operating state. The result is an apply or release of a

friction element. Refer to the chart in Figure 3.

SELECTOR

POSITION

Park/

Neutral

Park/

Neutral

REVERSE

OD-1ST

OD-2ND

OD-3RD

OD-4TH

OD-5TH

OD-6TH

(1)-1ST Or

Autostick

FAILSAFE

* L/R Clutch is on only with the output shaft speed below 150 RPM.

**Modulating (EMCC) if the Converter Clutch has been signaled.

***Off Below 8 MPH, On Above 8 MPH.

SOLENOID APPLICATION CHART

N.V. N.V. N.V. N.V. N.V.N.A. N.A.

LR/CC

SOLENOIDUDSOLENOIDODSOLENOID

ON

ON

ON

*ON

**

**

**

**

**

ON ON

OFF OFF OFF OFF OFF OFF OFF

ON

ON

ON ON ON

ON

ON OFF

ON ON OFF

ON ON ON

2nd CLUT

SOLENOID

ON

4th CLUT

SOLENOID

N.V. = Normally Vented

N.A. = Normally Applied

Multi-Select

SOLENOID

***OFF

ON

ON

ON

ON

ON

Line Pressure

SOLENOID

Modulating

Modulating

Modulating

Modulating

Modulating

Modulating

Modulating

Modulating

Modulating

Modulating

Figure 3

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

5

Technical Service Information

WWW.ALL-TRANS.BY

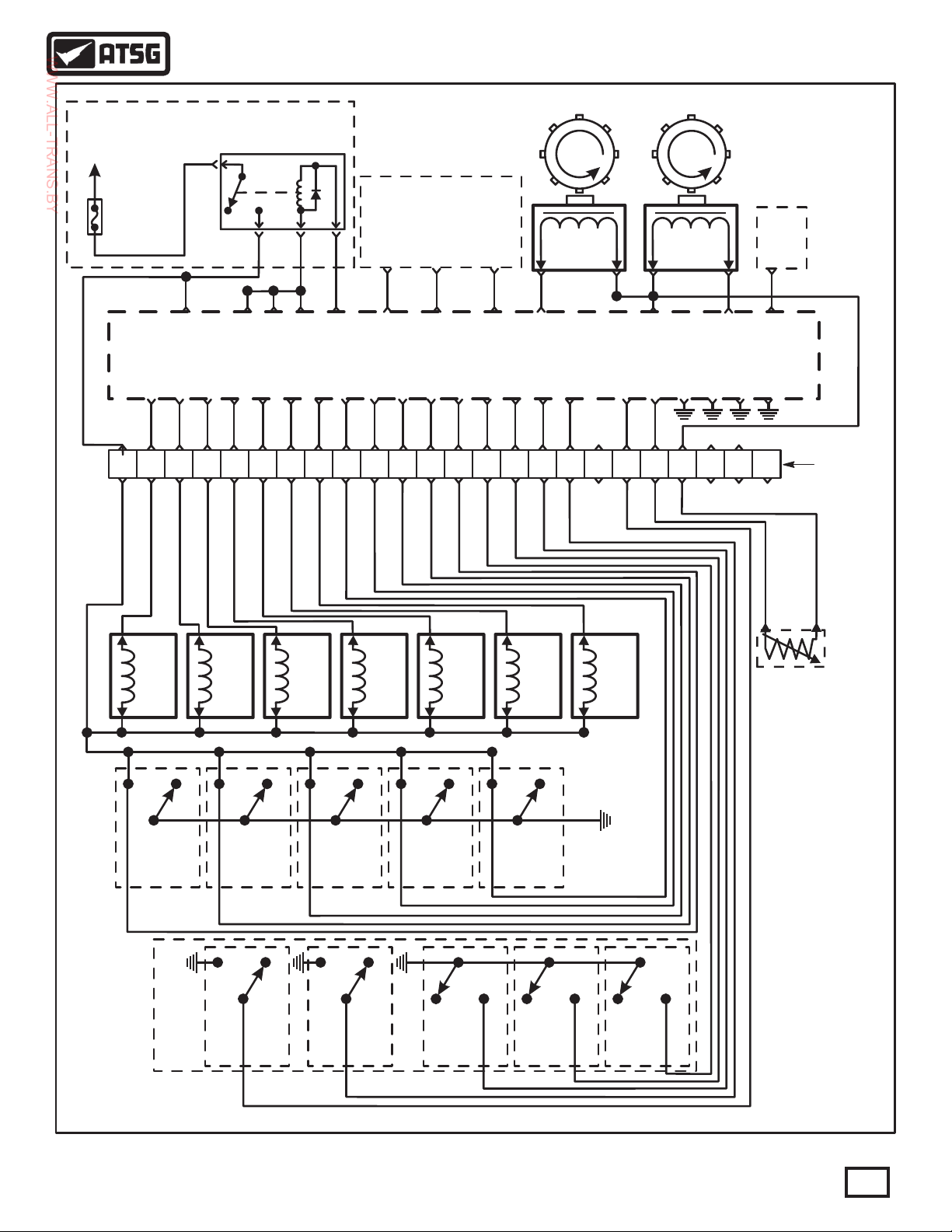

ELECTRICAL OPERATION

Transmission Control Module (TCM)

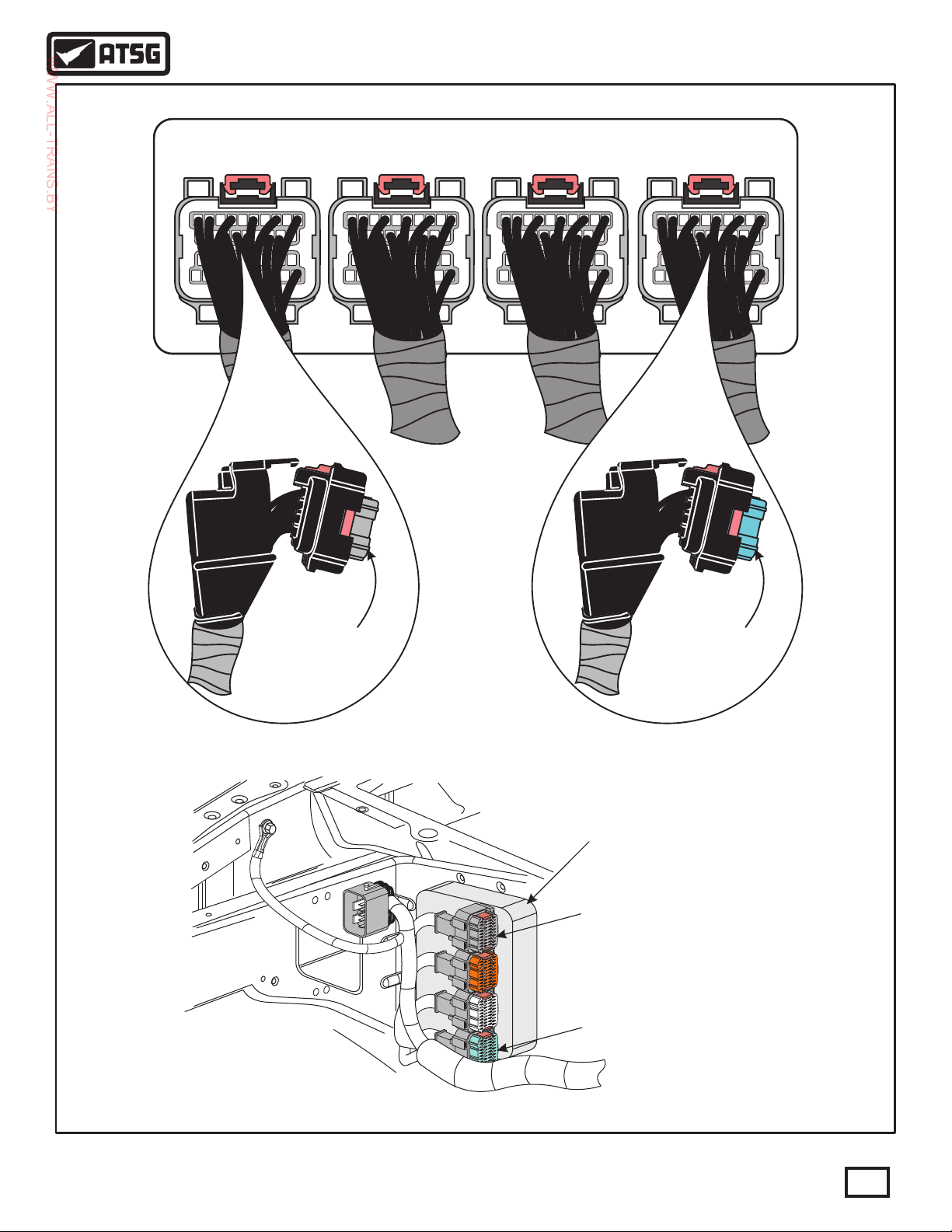

Vehicles equipped with the 68RFE and a 6.7L Diesel engine use a Transmission Control Module (TCM) housed in

the New Generation Controller (NGC) utilizing only the C1 and C4 connectors. The TCM controls all of the

transmission functions. The controller is located at the rear of the engine compartment, near the right inner fender, as

shown in Figure 12. The Powertrain Control Module (PCM) does not control the transmission. The electronic

components of the 68RFE transmission consist of various sensors and switches as input information to the TCM,

that the TCM uses to determine the appropriate gear ratio and shift schedule points. There is also the associated

wiring, fuses, relays, connectors, splices and grounds for the transmission to function as designed. A complete

transmission wiring schematic has been provided for you in Figure 10.

The final output from the TCM is to the six shift solenoids and the line pressure control solenoid located in the

Solenoid Body/Transmission Range Sensor assembly and bolted on the valve body as shown in Figure 9. The

solenoids in this transmission are unique in that some are normally vented and some are normally applied and this is

also illustrated in Figure 9. The TCM also communicates with other control modules, such as the PCM, and the

New Generation Controller (NGC) modules currently use PCI or CAN C bus.

The TCM recieves power from two sources, fused battery power to pin 18 (C4 connector) and fused ignition switch

input to pin 30 (C1 connector). The TCM also has several grounds to complete its electrical circuit, as shown in

Figure 10.

ADAPTIVE LEARNING

The 68RFE transmission uses an "Adaptive Learning" feature which allows the TCM to modify the clutch apply

rate to maintain consistant shift quality. This is done based on the amount of wear on the friction elements. The

TCM then adjusts the duty cycle of the shift solenoids to achieve the smoothest possible upshifts and downshifts.

The TCM adjusts the "Clutch Volume Index" when a shift change takes place to optimize clutch to clutch timing.

Clutch Volume Index is described on Page 16, along with proper clutch volumes and clutch clearances for the

68RFE transmission shown in Figure 15.

LIMP-IN MODE OPERATION

The TCM has the ability to monitor all transmission related electrical components and if it detects a problem, takes

appropriate action, and most of the time results in the TCM setting a Diagnostic Trouble Code (DTC). Whether this

results in MIL illumination, or Limp-in Mode operation, depends on the type of DTC that was set.

If the TCM determines that transmission damage may result from the DTC type that was set, the TCM will shut off

the ground signal to the transmission control relay which will shut off all power to the transmission and the vehicle

will be in Limp-in Mode Operation.

When in Limp-in Mode Operation, with the shift lever in the "Drive" position the transmission will be in 4th gear,

and if the shift lever is moved to "2" or "L" position the transmission will be in 2nd gear. This will allow the driver to

manually shift the transmission to Limp home.

Note: Vehicles equipped with Electronic Range Select (ERS) do not provide 2nd gear limp-in, because the shift

lever has no "2" or "1" shift lever positions.

The hydraulic control system design, without any electronic assist, provides the 68RFE transmission with PARK,

REVERSE, NEUTRAL, and FOURTH gears based solely on driver selection. This design allows the vehicle to be

driven in "limp-in" mode (4th gear) in the event of a total electronic control system failure, or a situation that the

TCM recognizes as potentially damaging to the transmission (DTC Stored).

Copyright © 2011 ATSG

6

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

WWW.ALL-TRANS.BY

INPUTS TO THE TCM

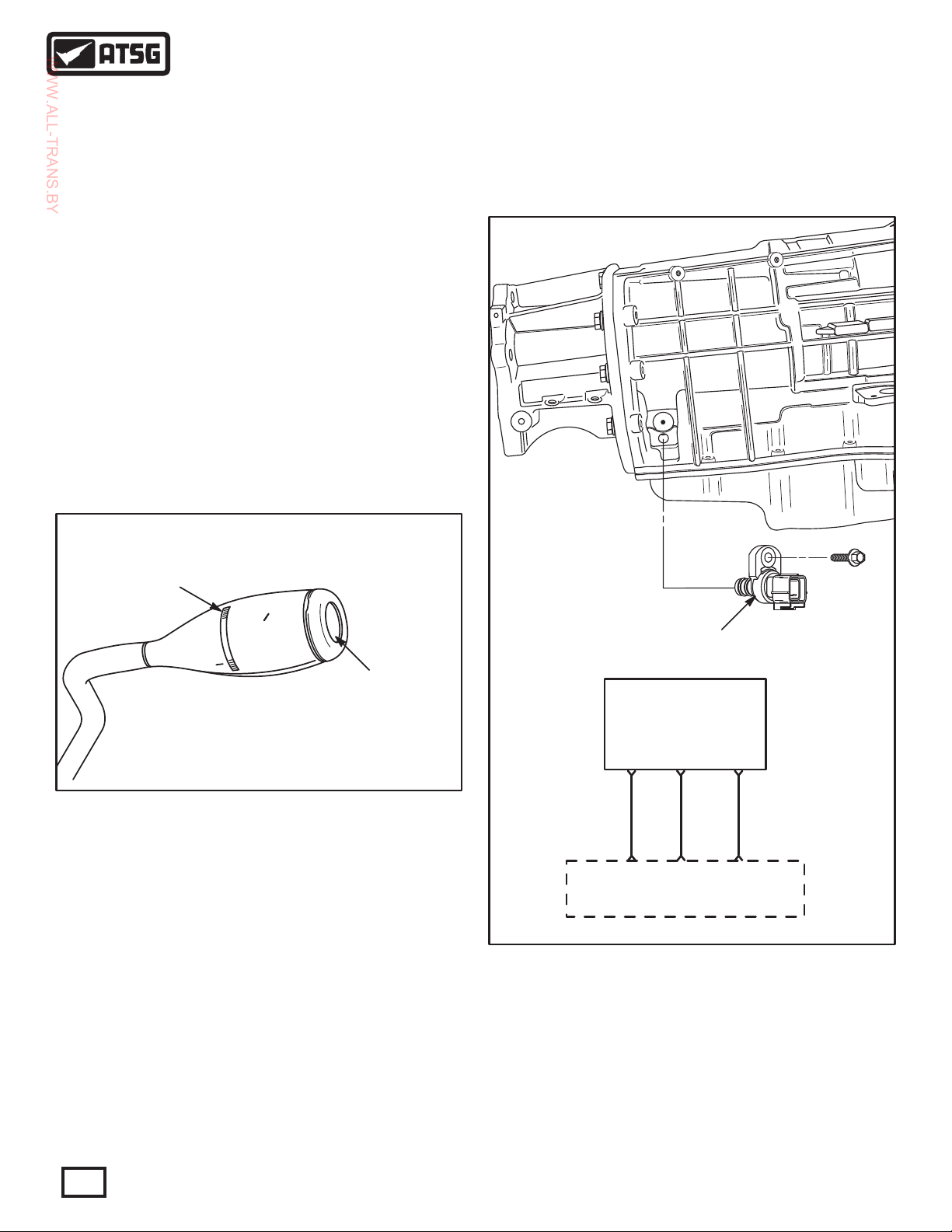

Input and Output Shaft Speed Sensors - are located

on the left side of the transmission and are illustrated in

Figure 5. The input shaft speed sensor reads input shaft

speed off of a tone wheel on the input clutch housing.

As the teeth of the tone wheel pass the sensor coil, an

AC voltage is generated and sent to the TCM. The

TCM interprets this information as input shaft rpm.

The output speed sensor generates an AC signal in a

similar fashion, though its coil is excited by rotation of

the parking gear teeth. The TCM interprets this

information as output shaft rpm.

The TCM compares the input and output speed signals

to determine the following:

Transmission gear ratio.

Speed ratio error detection.

Clutch Volume Index calulation.

Torque Converter Clutch slippage.

Both speed sensors are the same and will interchange.

New speed sensors, when checked for resistance, read

535 ohms at room temperature.

2

7

7

1

J7 0

T

T

0

97

1

5

P 2

2 B05

777

1

INPUT SPEED

SENSOR

4

:

1 4

4T

1I

8 0

4 :

5

4

0

7

E

F

R

1

B

A

4

4

0 A

7

1

1 9

2

5

P

8

4

OUTPUT SPEED

SENSOR

Pressure Switches - are located inside the solenoid and

pressure switch assembly and are only serviced by

replacing the complete solenoid/TRS assembly. The

TCM relies on five pressure switches to monitor

pressure in the Low/Rev, 2nd Clutch, 4th Clutch,

Underdrive, and Overdrive hydraulic circuits. The

primary function of these switches is to help the TCM

detect when clutch circuit hydraulic failures occur. The

switches close at 23 psi and open at 11 psi, and indicate

whether or not pressure exists. The switches are

continuously monitored by the TCM for the proper

states (Open or Closed) in each gear, shown in the chart

in Figure 4.

68RFE PRESSURE SWITCH CHART

Low/Rev

Park/Neut

Reverse

First

Second

Third

Fourth

Fifth

Sixth

* L/R is closed if output speed is below 150 RPM in Drive and Manual 2.

L/R is open in Manual 1.

Closed

Open

Closed*

Open

Open

Open

Open

Open Open

2nd Clut 4th Clut Underdrive Overdrive

Open Open

Open

Open

Closed

Open

Open

Open

Open

Open

Open

Closed

Open

Closed

Open

Open

Closed

Closed

Closed

Open

Open

Open

Open

Open

Closed Closed

Open

Closed

Closed Closed Closed

Copyright © 2011 ATSG

Input

Speed

Sensor

Twisted

Pair

Dk Green/Orange

Dk Green/Violet

C4

33

TCM

Figure 5

Inputs To The TCM

Continued on Page 8

Output

Speed

Sensor

Twisted

Pair

Dk Green/Violet

C4

34

Dk Green/Brown

C4

32

Copyright © 2011 ATSG

Figure 4

AUTOMATIC TRANSMISSION SERVICE GROUP

7

Technical Service Information

WWW.ALL-TRANS.BY

INPUTS TO THE TCM (Cont'd)

Tow/Haul & Auto-6 Electronic Range Select (ERS)

Switches - are located in the manual shift lever, as

shown in Figure 6. The switches are momentary

contact devices that signal the TCM to toggle current

status of the Tow/Haul function and adjust the ERS

maximum allowed gear range. At key on, normal

operation is provided. Pressing the switch enables

Tow/Haul mode and the Tow/Haul lamp will be

illuminated. In Tow/Haul mode, 4-5 upshifts are

delayed. Shifts into 5th and 6th gear are still allowed

under steady cruise conditions. Pressing the switch a

second time restores normal operation.

The Electronic Range Select (ERS), if equipped,

allows the selection of the desired top gear, when the

selector lever is in the D (Drive) position. For example,

if ERS 4th is selected, the transmission will never shift

above 4th gear, but can down shift into 3rd, 2nd or 1st

when needed.

TOW/HAUL AND AUTO-6

ELECTRONIC RANGE SELECT (ERS) SWITCH

Line Pressure Sensor - is located on the right rear of

transmission, as shown in Figure 7, and supplies the

TCM with line pressure information. The line pressure

sensor operates much like a throttle position sensor.

ERS

SWITCH

Transmission Range Sensor (TRS) - communicates

the manual shift lever position to the TCM with a

combination of open and closed switches. Each manual

shift lever position has an assigned combination of

switch states (open/closed) that the TCM recieves from

four sense circuits. The TCM interprets this

information and determines the appropriate

transmission gear position and shift schedule.

Transmission Range Sensor is an integral part of

Solenoid Pack/TRS body and serviced only as an

assembly. Checking the TRS for proper operation is

shown on Page 20 and 21.

AUTO-6

+

T HOW

Figure 6

AUL

TOW/HAUL

SWITCH

Copyright © 2011 ATSG

LINE PRESSURE

SENSOR

Pressure Sensor

Line

Pressure

Yellow/Pink

27

Sensor

Signal

Yellow/Brown

C4

31

Ground

Supply

Dk Green/White

(C1)19(C1)

5 Volt

TCM

Copyright © 2011 ATSG

Figure 7

Transmission Fluid Temp Sensor - is located in the

Solenoid Pack/Transmission Range Sensor and is a

thermister that the TCM uses to moniter transmission

fluid temperature. The TFT is an integral part of

Solenoid Pack/TRS body and serviced only as an

assembly.

8

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

WWW.ALL-TRANS.BY

OUTPUTS FROM THE TCM

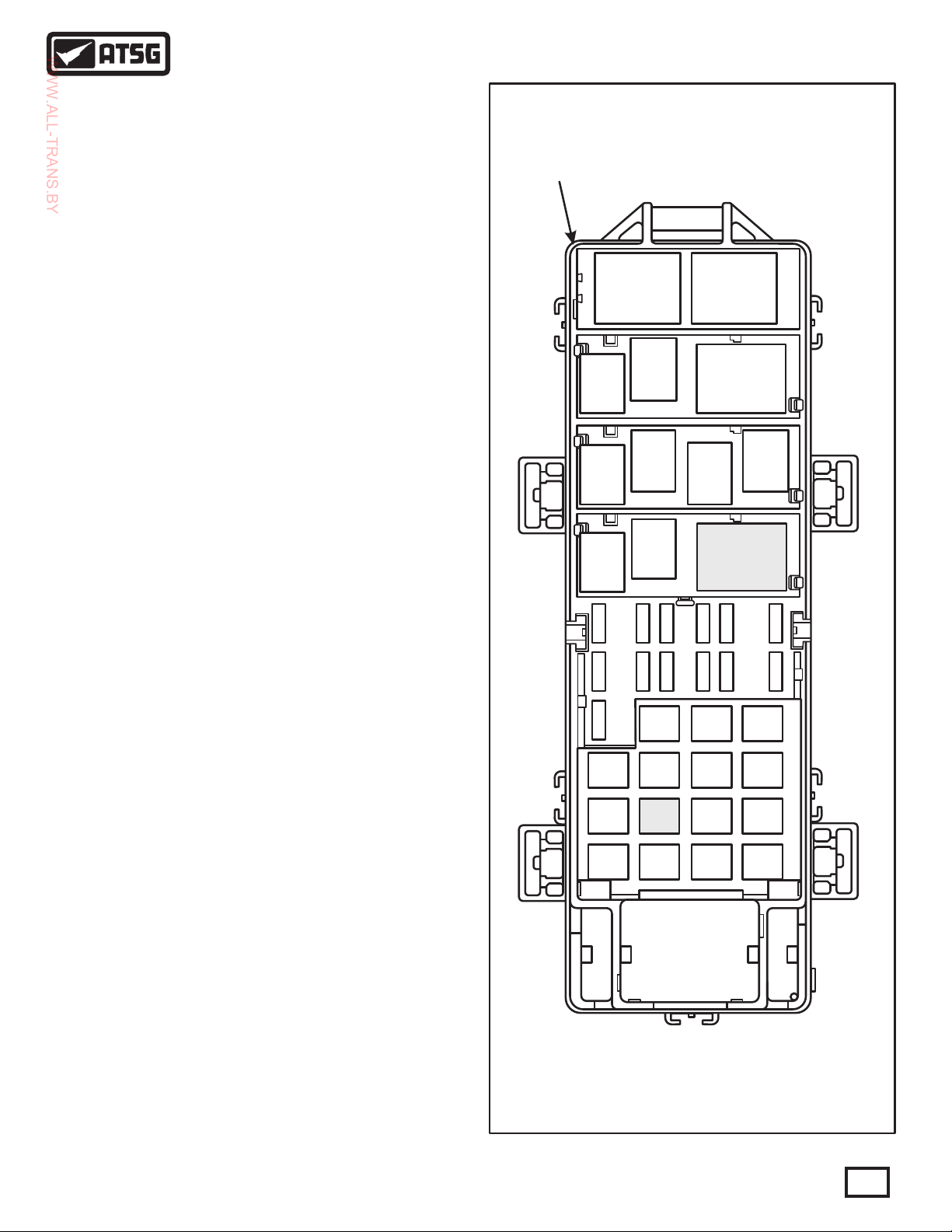

Transmission Control Relay - is located in the

Integrated Power Distribution Module (IPDM), as

shown in Figure 8, and recieves a ground signal from

terminal (C1) 18 at the TCM to close the relay. Refer to

the wiring schematic in Figure 10.

Underdrive Solenoid - is normally applied and

controls oil to the Underdrive Clutch in 1st, 2nd, 3rd,

and 4th gears of the transmission.

Overdrive Solenoid - is normally vented and controls

oil to the Overdrive Clutch in 4th, 5th, and 6th gears in

the transmission.

4th Clutch Solenoid - is normally vented and controls

oil to the 4th clutch in 3rd and 5th gears in the

transmission.

2nd Clutch Solenoid - is normally vented and controls

oil to the 2nd clutch in 2nd and 6th gears in the

transmission.

Low/Reverse Solenoid - is normally vented and is

used to apply the Low/Reverse clutch in 1st gear from

Park or Neutral, or a coast down to 1st gear. This

solenoid also controls oil pressure for the converter

clutch engagement based on switch valve position.

TRANSMISSION CONTROL RELAY LOCATION

Integrated Power

Distribution Module

(IPDM)

Spare

Relay

Horn

AC

Clutch

Relay

Wiper

On/Off

Relay

Fuel

Pump

Relay

Relay

Wiper

Hi/Lo

Relay

Starter

Relay

In the IPDM Cover To Identify

Heater

DownStream

Model Sensitive

All Models Have Schematic

Locations

Spare

Relay

Automatic

Shutdown

Relay

Heater

Relay

Relay

Up-

Stream

Transmission

Control

Relay

Multi-Select Solenoid - is normally applied and

controls the Overdrive Clutch in 4th gear Limp-in, and

the Low/Reverse clutch for reverse block. This

solenoid is Off below 8 MPH, On above 8 MPH.

Line Pressure Solenoid - is normally vented and is

used to controll all oil pressures in the transmission.

Note: Refer to Page 20 for a solenoid resistance chart

for all solenoids.

DIAGNOSIS AND SERVICE INFORMATION

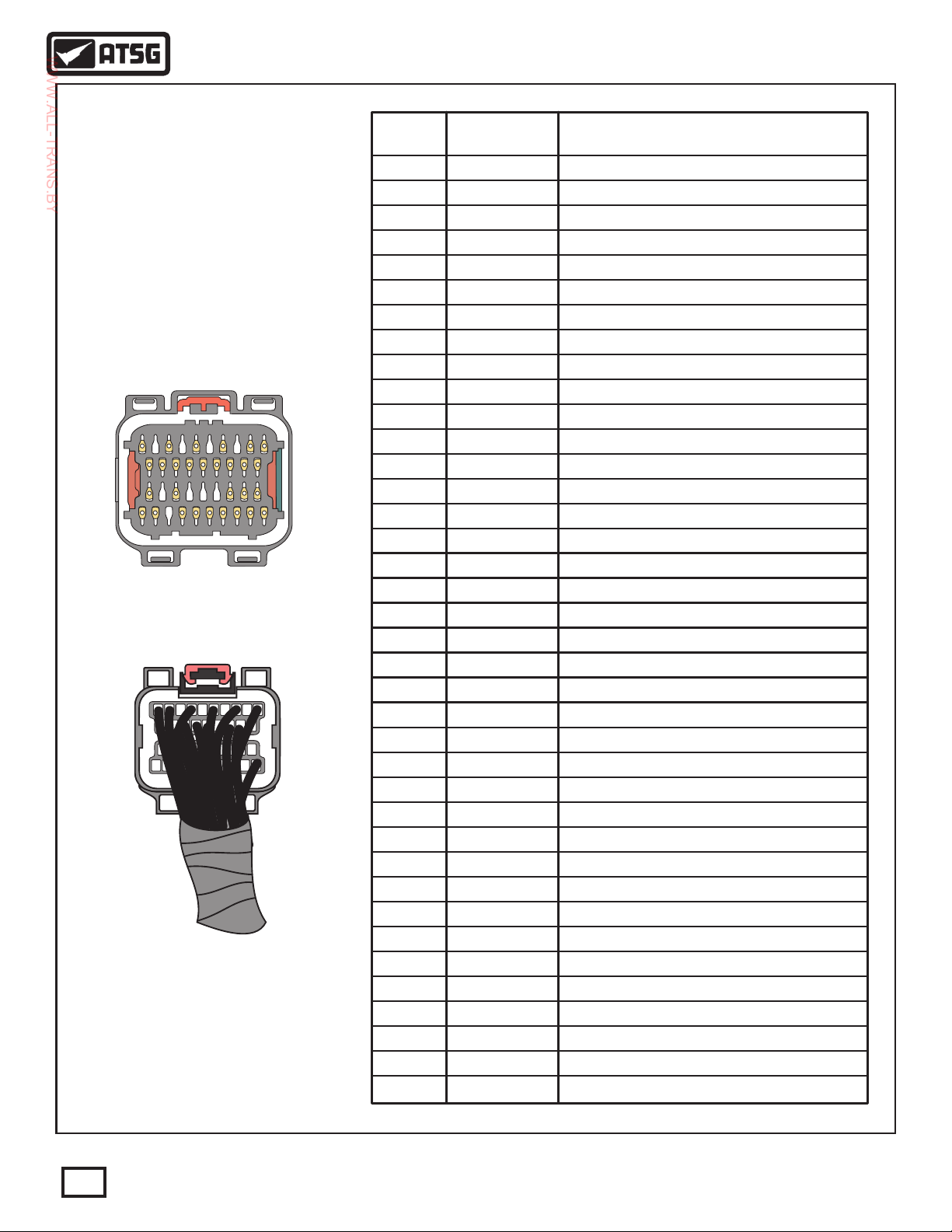

You have been provided with the 23-way case

connector pin cavity identification and pin function in

Figure 11. The 38-way Diesel NGC/TCM connector

pin cavity identification and pin function is shown in

Figure 13 and 14. A complete transmission wiring

schematic is provided in Figure 10, and transmission

control relay location in the power distribution center is

shown in Figure 9.

Special tools that might be needed are illustrated on

Page 26 and 27, along with the identification of the

pressure taps that are available on the main valve body.

Air pressure test passage identification is provided for

you in Figure 17.

Fuse

(30A)

Located In Engine Compartment

On Left Fender Well

Figure 8

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

9

Technical Service Information

WWW.ALL-TRANS.BY

TRANSMISSION

RANGE SENSOR

L/R Clutch

Seal

97

4799591

23-WAY

CONNECTOR

SOLENOID

PACK

PRESSURE

CONTROL

SOLENOID

2nd Clutch

TWO DIFFERENT TYPES OF SHIFT SOLENOIDS

Underdrive Solenoid

Multi-Select Solenoid

"Solenoid Off"

"Normally Applied"

Seal

VALVE BODY

4th Clutch

Seal

Overdrive Solenoid

4th Clutch Solenoid

2nd Clutch Solenoid

Low/Reverse Solenoid

Line Pressure Solenoid

"Solenoid Off"

"Normally Vented"

Copyright © 2011 ATSG

10

Figure 9

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

WWW.ALL-TRANS.BY

INTEGRATED POWER DISTRIBUTION MODULE

FUSE

30A

C4

18

TRANSMISSION

CONTROL RELAY

C4

C4

C4

38

19

28

(C1)

18

TRANSMISSION CONTROL MODULE/NEW GENERATION CONTROLLER

C4

C4

8

4

C4

C4

2

6

1

11

10

C4

C4

C4

10 1217 721 23 2220 19 18 16 15 14 138 9 4 3 5 1 6112

6.7L DIESEL WIRE SCHEMATIC

Pressure Sensor

Line

Pressure

Sensor

Signal

C4

29

(T3)

C4

16

C4

31

(T2)

C4

26

27

C4

21

Ground

(C1)19(C1)

C4

C4

22

20

5 Volt

Supply

C4

30

C4

33

(T1)

C4

15

Input

Speed

Sensor

(T41)

C4

27

(T42)

C4

37

Output

Sensor

C4

34

C4

35

See Figure 11, 12, 13, 14

For Connector ID

See Page 28 For

APPS Information

Ignition

Speed

C414C413C4

Switch

12V

C432(C1)

30

(C1)

12

9

Term 1, 3, 6

Not Used

Multi-Select

Pressure

Solenoid

L/R

Switch

Solenoid

Underdrive

2nd Clut

Pressure

Switch

TRS

(C2)

T42

Signal

Solenoid

Overdrive

Pressure

Switch

OD

TRS

(C1)

Signal

2nd Clutch

T41

Solenoid

4th Clut

Pressure

Switch

TRS

(C4)

T1

Signal

Solenoid

4th Clutch

LR/TCC

UD

Pressure

Switch

TRS

(C5)

T2

Signal

Solenoid

Control

Pressure

Solenoid

TRS

(C3)

T3

Signal

TFT

Sensor

Copyright © 2011 ATSG

Figure 10

AUTOMATIC TRANSMISSION SERVICE GROUP

11

Technical Service Information

WWW.ALL-TRANS.BY

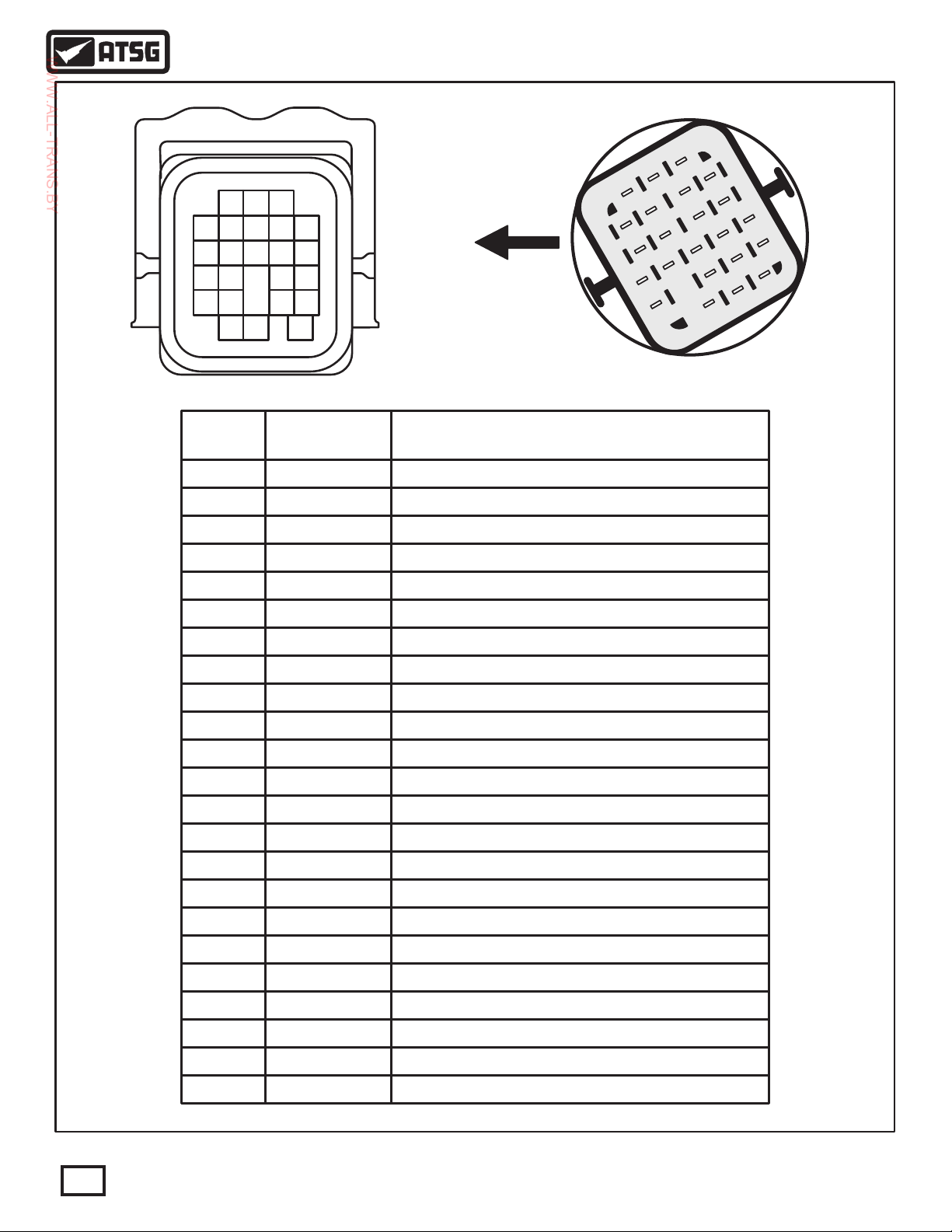

23-WAY CASE CONNECTOR PIN CAVITY IDENTIFICATION AND FUNCTION

123

4

567

89101112

13

141516

17181920

212223

Vehicle Harness Connector

"Front"

212223

17

8

1

19

20

15

16

11

12

7

13

14

9

01

6

3

Transmission

Case Connector

8

4

5

1

2

PIN

CAVITY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

WIRE

COLOR

Dk Green/White

Yellow/Dk Blue

Dk Green/Yellow

Yellow/Gray

Dk Green/Dk Blue

Dk Green/Lt Blue

Yellow/Orange

Brown/Yellow

Dk Green

Dk Green/Red

Dk Green/Pink

Yellow/Tan

FUNCTION

(Not Used)

LR/TC Clutch Solenoid Control

(Not Used)

Transmission Range Sensor T41 (C1) Signal (P/N)

Transmission Range Sensor T42 (C2) Signal

(Not Used)

Overdrive Clutch Solenoid Control

Transmission Range Sensor T3 (C3) Signal

Transmission Range Sensor T1 (C4) Signal

Transmission Control Relay Output

4th Clutch Pressure Switch Signal

Line Pressure Control Solenoid Control

Transmission Range Sensor T2 (C5) Signal

Low/Reverse Clutch Pressure Switch Signal

2nd Clutch Pressure Switch Signal

Wire Colors

May Vary

12

16

17

18

19

20

21

22

23

Dk Green/Tan

Yellow/Lt Blue

Yellow/White

Yellow/Dk Green

Yellow/Lt Green

Yellow/Gray

Dk. Blue/Dk Green

Dk Green/Orange

Overdrive Clutch Pressure Switch Signal

Underdrive Clutch Solenoid Control

Underdrive Clutch Pressure Switch Signal

4th Clutch Solenoid Control

2nd Clutch Solenoid Control

Multi-Select Solenoid Control

Speed Sensor Ground

Transmission Oil Temperature Sensor Signal

Figure 11

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

Technical Service Information

WWW.ALL-TRANS.BY

68RFE NGC CONNECTOR IDENTIFICATION

Black C1

Connector Face

1 10

11 19

20 28

29 38

Orange C2

Connector Face

1 10

11 19

20 28

29 38

All Connectors

are not used for

All Models

White C3

Connector Face

1 10

11 19

20 28

29 38

Green C4

Connector Face

1 10

11 19

20 28

29 38

Black

Connector

Face

C1, C4 Connectors

are used for Trans

Circuits

"6.7L Diesel"

Transmission

Control Module

"C1" 38 Way

Connector

"C4" 38 Way

Connector

Green

Connector

Face

Right Rear Of

{

Engine Compartment

Figure 12

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

13

10

WWW.ALL-TRANS.BY

19

28

38

C1 Connector

Face View (Black)

C1 Connector

Wire Side View

1 10

11 19

20 28

29 38

Technical Service Information

68RFE NGC "C1" CONNECTOR TERMINAL I.D.

1

11

20

29

PIN

CAVITY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

WIRE

COLOR

Black/Brown

Pink/White

Pink/White

Black/Dk Green

Dk Green/White

Dk Green/Yellow

Yellow/Pink

Red

Yellow

FUNCTION

Ground

Fused Ignition Switch Output (Run/Start)

Fused Ignition Switch Output (Run/Start)

Ground For Transmission Control Relay

Line Pressure Sensor Ground

Electric Range Select (ERS)-Tow/Haul Signal

5 Volt Supply

Fused Battery (+)

Ignition Start

14

Wire Colors

May Vary

34

35

36

37

38

White/Lt Green

White/Lt Blue

CAN C Bus (+)

CAN C Bus (-)

Figure 13

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

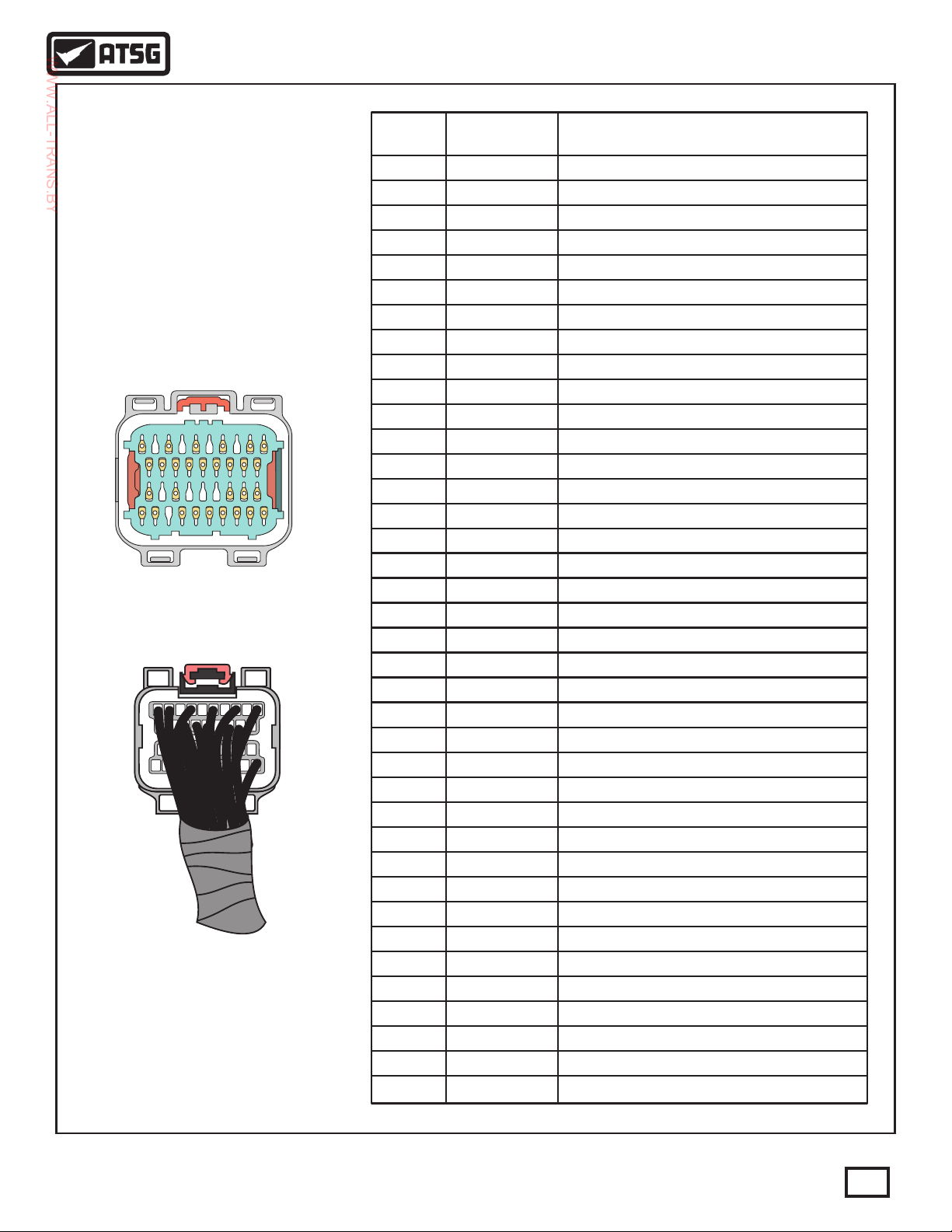

C4 Connector

WWW.ALL-TRANS.BY

Face View (Green)

10

19

28

38

C4 Connector

Wire Side View

1 10

11 19

20 28

29 38

Wire Colors

May Vary

Technical Service Information

68RFE NGC "C4" CONNECTOR TERMINAL I.D.

1

11

20

29

PIN

CAVITY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

WIRE

COLOR

Yellow/Gray

Yellow/Dk Green

Dk Green

Yellow/Lt Green

Yellow/Lt Blue

Dk Green/White

Yellow/Gray

Black

Black

Black

Dk Green/Lt Blue

Dk Green/Dk Blue

Dk Green

Yellow/Dk Blue

Yellow/Orange

Brown/Yellow

Yellow/White

Dk Green/Tan

Dk Green/Lt Blue

Yellow/Dk Blue

Yellow/Orange

Yellow/Tan

Dk Green/Yellow

Yellow/Brown

Dk Green/Brown

Dk Green/Orange

Dk Green/Violet

Dk Green/Orange

Dk Green/Yellow

Yellow/Orange

FUNCTION

Overdrive Clutch Solenoid Control

4th Clutch Solenoid Control

Multi-Select Solenoid Control

2nd Clutch Solenoid Control

Underdrive Clutch Solenoid Control

LR/TC Clutch Solenoid Control

Line Pressure Control Solenoid Control

Ground

Ground

Ground

Transmission Range Sensor T1 (C4) Signal

Transmission Range Sensor T3 (C3) Signal

Towhaul Overdrive Off Switch Sense

Transmission Control Relay Control

Transmission Control Relay Output

4th Clutch Pressure Switch Signal

Underdrive Clutch Pressure Switch Signal

Overdrive Clutch Pressure Switch Signal

Transmission Range Sensor T2 (C5) Signal

Transmission Range Sensor T41 (C1) Signal

Transmission Control Relay Output

Low/Reverse Clutch Pressure Switch Signal

2nd Clutch Pressure Switch Signal

Line Pressure Sensor Signal

Output Speed Sensor Signal

Input Speed Sensor Signal

Speed Sensor Ground

Transmission Oil Temperature Sensor Signal

Transmission Range Sensor T42 (C2) Signal

Transmission Control Relay Output

Figure 14

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

15

Technical Service Information

WWW.ALL-TRANS.BY

CLUTCH VOLUME INDEXES

An important function of the TCM is to monitor Clutch Volume Indexes (CVI). CVIs represent the volume of fluid

needed to compress a clutch pack properly.

The TCM monitors gear ratio changes by monitoring the Input and Output Speed Sensors. The Input Speed Sensor

sends an AC voltage signal to the TCM that represents input shaft rpm. The Output Speed Sensor provides the TCM

with output shaft speed information.

By comparing these two inputs, the TCM can determine actual gear ratio. This is important to the CVI calculation

because the TCM determines CVIs by monitoring how long it takes for a gear change to occur.

Gear ratios can be determined by using the DRB Scan Tool and reading the Input/Output Speed Sensor values in the

"Monitors" display. Gear ratio can be obtained by dividing the Input Speed Sensor value by the Output Speed

Sensor value.

For example, if the input shaft is turning at 1000 rpm and the output shaft is turning at 500 rpm, the TCM can

determine that the gear ratio is 2:1. In 3rd gear the gear ratio changes to 1:1. The gear ratio changes as clutches are

applied and released. By monitoring the length of time it takes for a gear ratio to change following a shift request,

the TCM can determine the volume of fluid used to apply or release a friction element.

The volume of transmission fluid needed to apply the friction elements are continuously updated for the adaptive

controls. As friction material wears, the volume of fluid needed to apply the friction element increases.

Certain mechanical problems within the transmission assembly such as broken return springs, out of position snap

rings, excessive clutch pack clearance, or improper assembly can cause inadequate or out-of-range CVI readings.

The chart in Figure 15 identifies the proper CVIs, when they are monitored and updated, and the proper clutch pack

clearances.

CLUTCH WHEN UPDATED PROPER VOLUME CLUTCH CLEARANCE

Low/Reverse

2nd Clutch

2nd Clutch

Overdrive

4th Clutch

4th Clutch

Underdrive

Reverse

OIL PUMP OPERATION

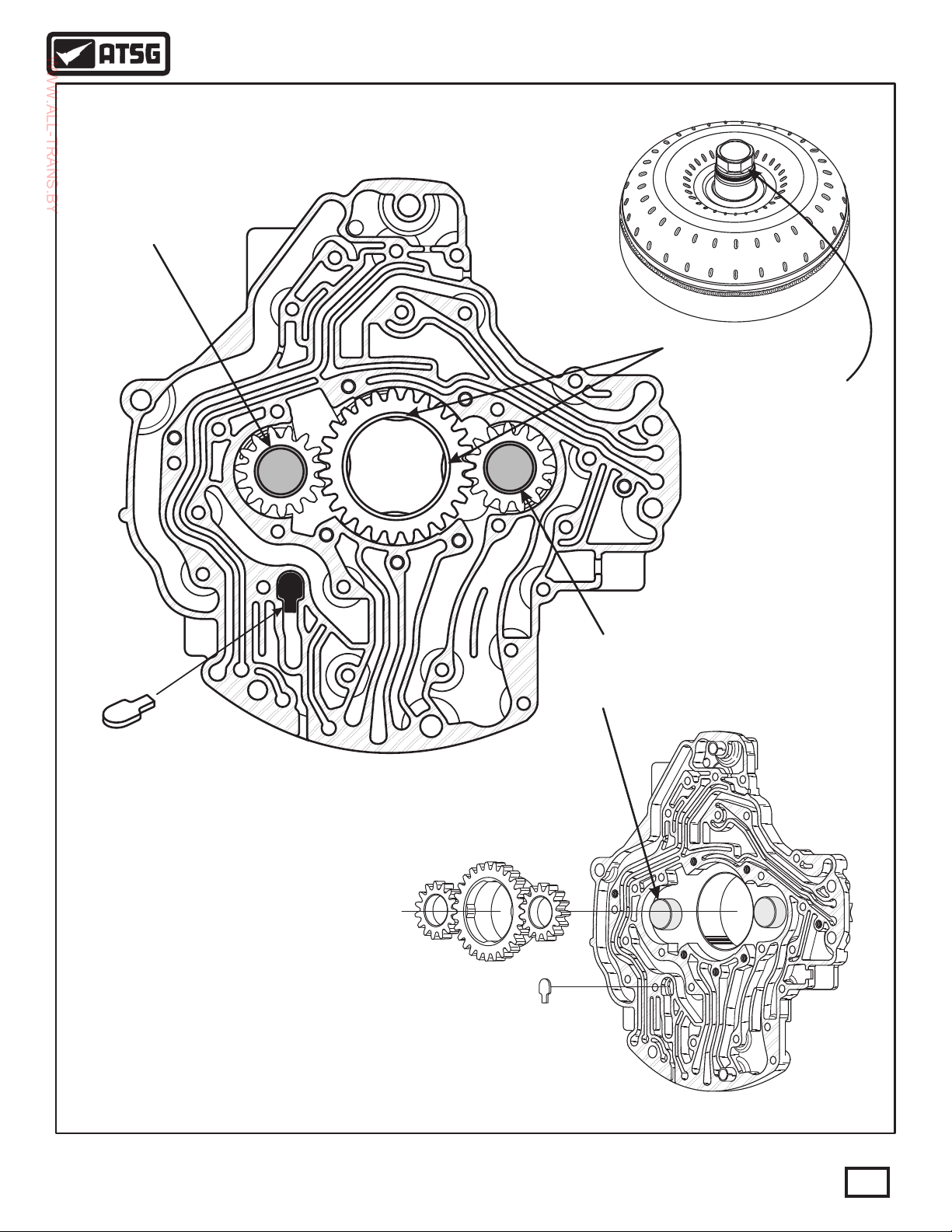

A dual stage oil pump is also used for the 68RFE. The pump has three gears, one drive gear and two driven gears as

shown in Figure 16. Both stages of the pump supply fluid during idle and at low engine speeds. Under these

conditions there is not enough pressure from the primary stage to close the shuttle valve. As engine speed increases,

so does the output from the primary stage. Once the pressure from the primary stage builds up, the shuttle valve is

forced closed and in this condition the secondary stage has no effect and the primary side supplies all of the pressure

needed for proper transmission operation. The 68RFE pump has four lugs on the drive gear instead of the previous

two and the driven gears now rotate on a permanent shaft that is part of the oil pump body, as shown in Figure 16.

The oil pump body also no longer contains a pocket for the converter hub seal, as the seal is in front cover. These

features make the oil pumps non-interchangeable.

CLUTCH VOLUMES AND CLEARANCES

2-1, 3-1 or 4-1 Downshift 45 to 134 1.18-2.09mm (.046"-.082")

4-3 or3-2 Downshift

5-6 Upshift

3-4 Upshift

4-5 Upshift

4-5 Upshift

5-4 or 6-4 Kickdown shift

Not Monitored Not Monitored

Figure 15

25 to 85

25 to 85

30 to 100

30 to 85

30 to 85

30 to 100

0.99-1.65mm (.039"-.065")

0.99-1.65mm (.039"-.065")

0.75-1.61mm (.030"-.063")

0.77-1.39mm (.030"-.055")

0.77-1.39mm (.030"-.055")

1.02-1.72mm (.040"-.068")

0.58-1.47mm (.023"-.058")

Copyright © 2011 ATSG

16

AUTOMATIC TRANSMISSION SERVICE GROUP

Driven Gears Now

WWW.ALL-TRANS.BY

Rotate On Permanent

Shafts In Punp Body

Technical Service Information

68RFE OIL PUMP BODY AND GEARS

Four Drive Lugs On

Drive Gear And Four

Flats On Converter

Shuttle Valve

Driven Gears Now

Rotate On Permanent

Shafts In Punp Body

Figure 16

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

17

Technical Service Information

WWW.ALL-TRANS.BY

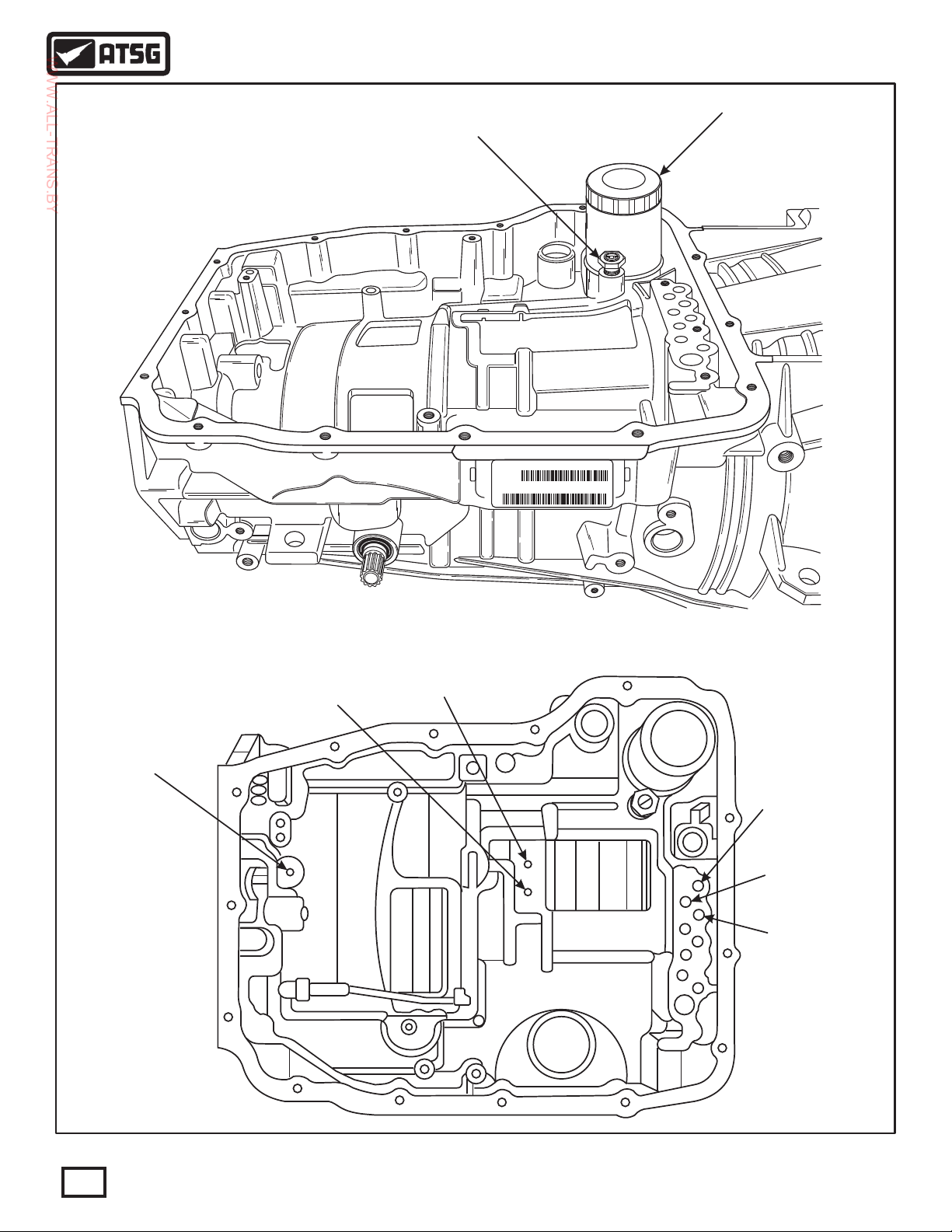

COOLER FILTER

BYPASS VALVE

704

COOLER FILTER

177720548P52119704AB

P52119704AB RFE

TITTJ177720548 14:10:44

Low/Reverse

Clutch

2nd Clutch

AIR PRESSURE TESTS

4th Clutch

Overdrive

Clutch

Underdrive

Clutch

Reverse

Clutch

18

Copyright © 2011 ATSG

Figure 17

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

WWW.ALL-TRANS.BY

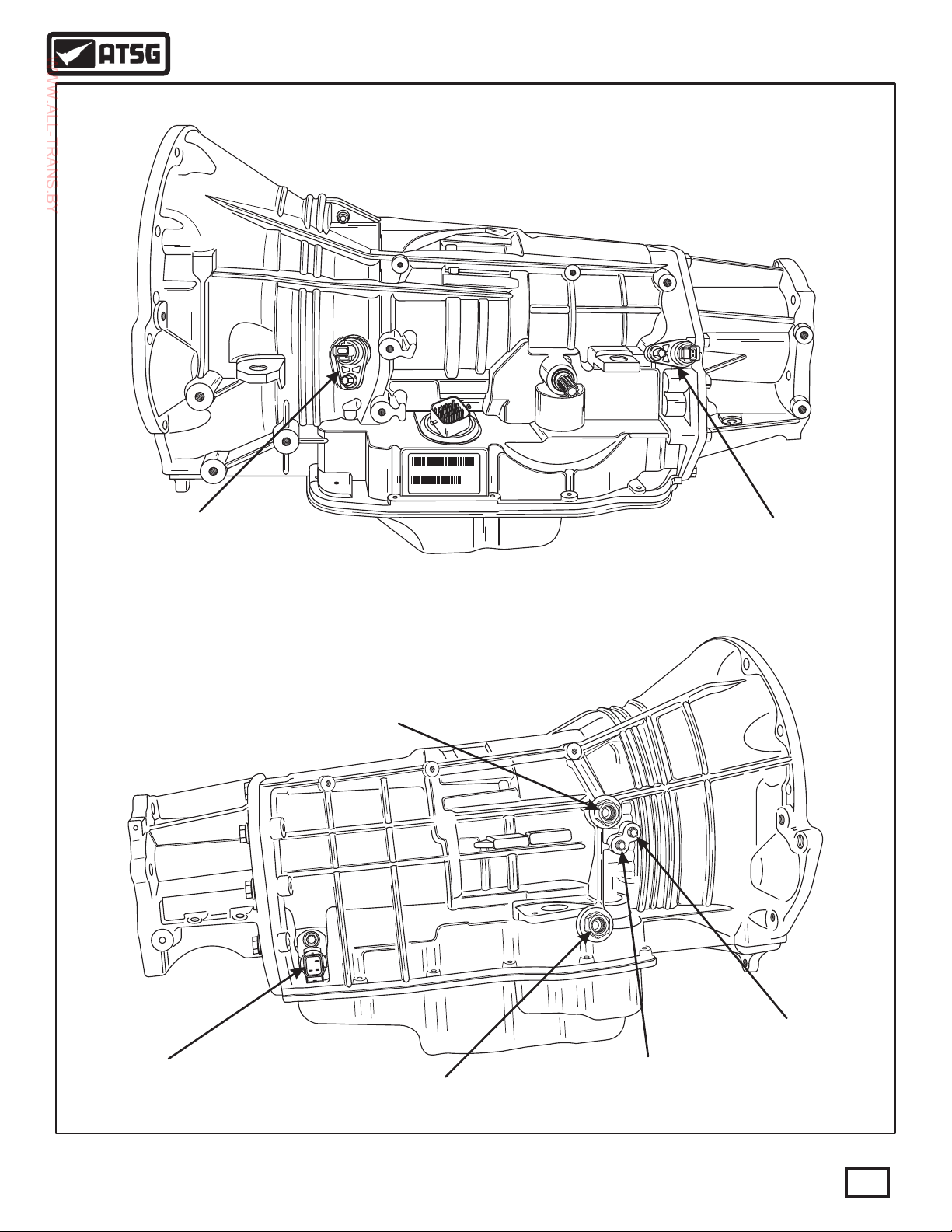

EXTERNAL SENSOR LOCATIONS AND COOLER LINE IDENTIFICATION

INPUT SPEED

SENSOR

TITTJ177720548 14:10:44

P52119704AB RFE

177720548P52119704AB

"TO" COOLER

704

OUTPUT SPEED

SENSOR

LINE PRESSURE

SENSOR

LOCK-UP "ON"

"FROM" COOLER

PRESSURE

Figure 18

AUTOMATIC TRANSMISSION SERVICE GROUP

LOCK-UP "OFF"

PRESSURE

Copyright © 2011 ATSG

19

T41 (C1)

WWW.ALL-TRANS.BY

T42 (C2)

T3 (C3)

T1 (C4)

T2 (C5)

Technical Service Information

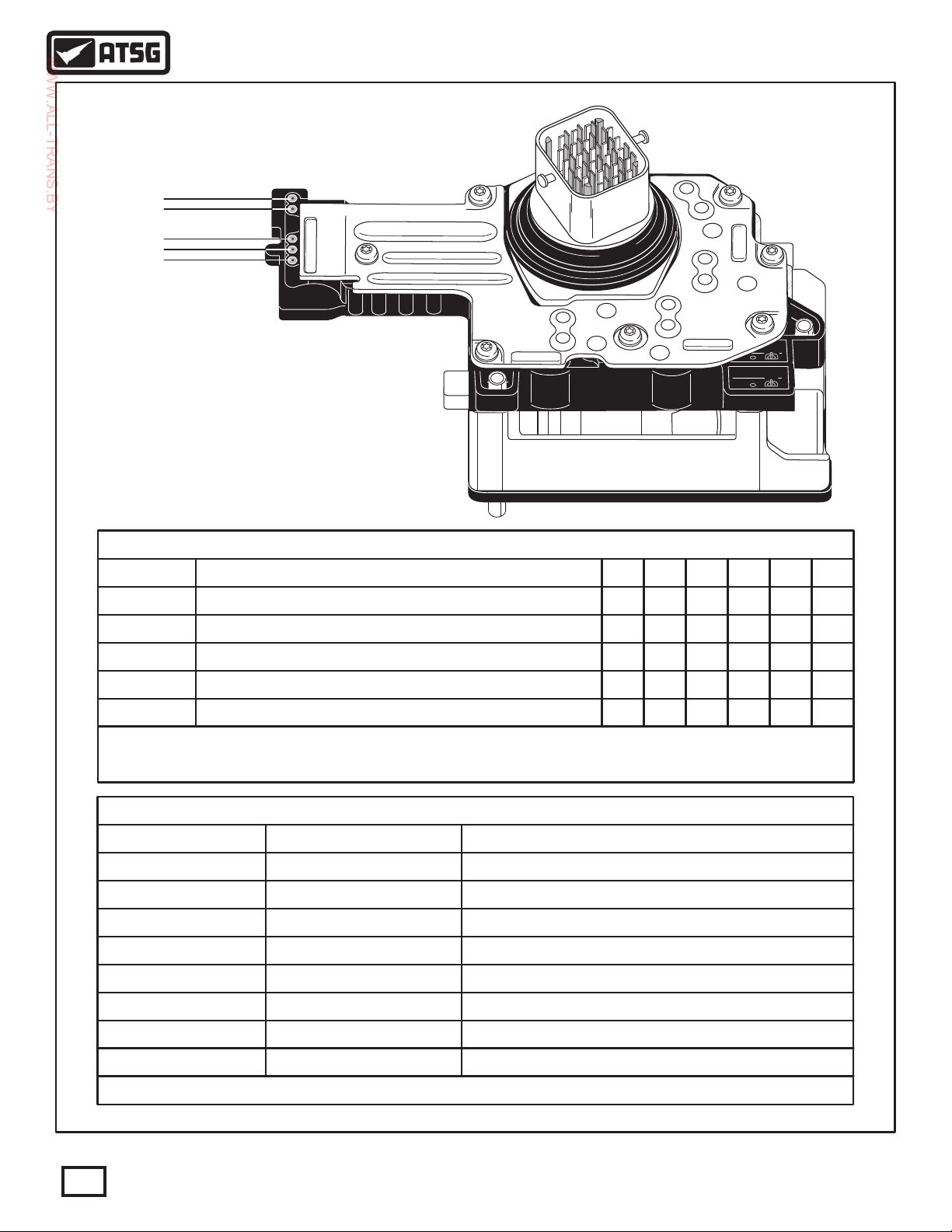

TRANSMISSION RANGE SENSOR/SOLENOID BODY TESTS

TRANSMISSION RANGE SENSOR CHART

CIRCUIT METER P R N OD 2* 1*

T41 & GRD OR CONNECTOR PIN 4 & GRD

T42 (C2)

T3 (C3)

T1 (C4)

T2 (C5)

* Vehicles equipped with Electronic Range Selector (ERS) do not have

"2" or "1" positions on the shift lever.

T42 & GRD OR CONNECTOR PIN 5 & GRD

T3 & GRD OR CONNECTOR PIN 8 & GRD

T1 & GRD OR CONNECTOR PIN 9 & GRD

T2 & GRD OR CONNECTOR PIN 13 & GRD

C

C

O O

O O

C

C = Closed O = Open

CO O

C C

O

CCC

O O

O O O

O OT41 (C1)

OOO

C

C

C C

SOLENOID RESISTANCE CHART

23-WAY CONN. PINS

LR/TCC 10 AND 2

OVERDRIVE

UNDERDRIVE

2ND CLUTCH

4TH CLUTCH

10 AND 7

10 AND 17

10 AND 20

10 AND 19

RESISTANCESOLENOID

1.9 W @ 72°F

1.9 W @ 72°F

1.9 W @ 72°F

1.9 W @ 72°F

1.9 W @ 72°F

MULTI-SELECT

LINE PRESSURE

TOT SENSOR

See Figure 20 For 23/Way Connector Pin Identification.

20

10 AND 21

10 AND 12

22 AND 23

1.9 W @ 72°F

4.3 W @ 72°F

9.37k W @ 72°F

Figure 19

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

Technical Service Information

WWW.ALL-TRANS.BY

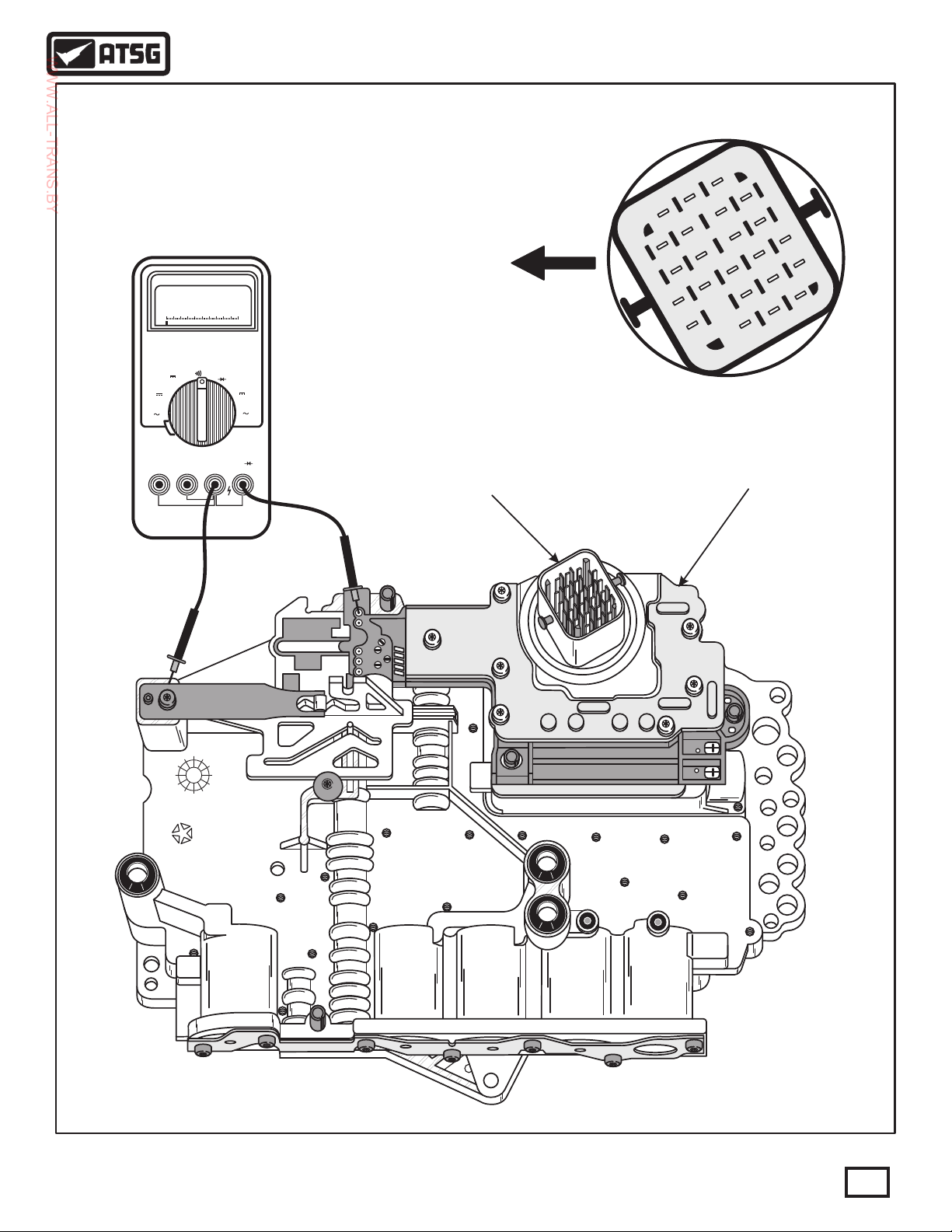

Meter shown at T41 (C1) Circuit and

should correspond with chart in

Figure 19. Solenoid tests "must" be

made thru case connector pins.

W

0.1

W

mV

V

RPM

V

OFF

mA

A

V

mA

A

W

RPMCOMmAA

23-WAY

CONNECTOR

"Front"

2122

17

23

20

16

12

81

19

15

7

13

14

1011

8

9

4

5

6

3

1

2

Transmission

Case Connector

TRANSMISSION RANGE SENSOR

AND SOLENOID BODY ASSEMBLY

97

4799591

Figure 20

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

21

DTC

WWW.ALL-TRANS.BY

Technical Service Information

68RFE DIAGNOSTIC TROUBLE CODES

DESCRIPTION

P0101

P0102

P0103

P0116

P0117

P0118

P0122

P0123

P0124

P0218

P0560

P0562

P0563

P0571

P0572

P0573

P0604

Mass Air Flow Sensor Circuit Performance

Mass Air Flow Sensor Circuit Low

Mass Air Flow Sensor Circuit High

Engine Coolant Sensor Circuit Performance

Engine Coolant Sensor Circuit Low

Engine Coolant Sensor Circuit High

TPS/APP Circuit Low

TPS/APP Circuit High

TPS/APP Circuit Intermittent

High Temperature Operation Activated

Battery System Voltage

Battery System Voltage Low

Battery System Voltage High

Brake Switch Performance

Brake Switch Stuck On

Brake Switch Stuck Off

Control Module, Internal RAM Error

P0605

P0613

P0700

P0702

P0706

P0707

P0708

P0711

P0712

P0713

P0714

P0715

P0717

P0721

P0722

Control Module, Internal ROM Error

Internal Transmission Control Module Error

Transmission Control System, MIL Request

Transmission Control System, Electrical

Transmission Range Sensor Rationallity

Transmission Range Sensor Circuit Low

Transmission Range Sensor Circuit High

Transmission Temperature Sensor Performance

Transmission Temperature Sensor Circuit Low

Transmission Temperature Sensor Circuit High

Transmission Temperature Sensor Circuit Intermittent

Input Speed Sensor Circuit Performance

Input Speed Sensor, No Signal

Output Speed Sensor Performance

Output Speed Sensor, No Signal

22

Continued on Page 23

Copyright © 2011 ATSG

Figure 21

AUTOMATIC TRANSMISSION SERVICE GROUP

DTC

WWW.ALL-TRANS.BY

Technical Service Information

68RFE DIAGNOSTIC TROUBLE CODES

DESCRIPTION

P0729

P0731

P0732

P0733

P0734

P0735

P0736

P0740

P0745

P0750

P0755

P0760

P0765

P0770

P0841

P0845

P0846

Sixth Gear Ratio Error

First Gear Ratio Error

Second Gear Ratio Error

Third Gear Ratio Error

Fourth Gear Ratio Error

Fifth Gear Ratio Error

Reverse Gear Ratio Error

Torque Converter Clutch Out Of Range (Slip Fault)

Line Pressure Solenoid Circuit

Low/Reverse Clutch Solenoid Circuit Fault

Second Clutch Solenoid Circuit Fault

Overdrive Clutch Solenoid Circuit Fault

Underdrive Clutch Solenoid Circuit Fault

Fourth Clutch Solenoid Circuit Fault

Low/Reverse Clutch Pressure Switch Rationallity

Second Clutch Pressure Switch, Pressure Test

Second Clutch Pressure Switch Rationallity

P0854

P0868

P0869

P0870

P0871

P0875

P0876

P0882

P0883

P0884

P0890

P0933

P0934

P0935

P0944

P0957

Overdrive Clutch Switch Circuit Low

Line Pressure Low

Line Pressure High

Overdrive Clutch Pressure, Pressure Test

Overdrive Clutch Pressure Switch Rationallity

Underdrive Clutch Pressure, Pressure Test

Underdrive Clutch Pressure Switch Rationallity

Transmission Control Module Power Input Low

Transmission Control Module Power Input High

Power Up At Speed

Switched Battery Fault

Line Pressure Sensor Performance

Line Pressure Sensor Circuit Low

Line Pressure Sensor Circuit High

Loss If Hydraulic Prime

Autostick Circuit Low (Electronic Range Select)

Continued on Page 24

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

Figure 22

23

DTC

WWW.ALL-TRANS.BY

Technical Service Information

68RFE DIAGNOSTIC TROUBLE CODES

DESCRIPTION

P0987

P0988

P1679

P1684

P1715

P1720

P1775

P1776

P1794

P2700

P2701

P2702

P2703

P2704

P2706

P2741

P2742

Fourth Clutch Pressure, Pressure Test

Fourth Clutch Pressure Switch Rationallity

Calibration Not Learned

Battery Was Disconnected

Restricted Manual Valve In T3 Range

Input Speed Sensor, No Signal

Solenoid Switch Valve, Latched In TCC position

Solenoid Switch Valve, Latched In LowReverse position

Speed Sensor, Ground Error

Inadequate Element Volume In Low/Reverse Clutch

Inadequate Element Volume In Second Clutch

Inadequate Element Volume In Overdrive Clutch

Inadequate Element Volume In Underdrive Clutch

Inadequate Element Volume In Fourth Clutch

Multi-Select Solenoid Circuit Fault

Transmission Fluid Temperature Sensor Performance

Transmission Fluid Temperature Sensor Low

P2743

P2757

P2806

Transmission Fluid Temperature Sensor High

TCC Pressure Control Solenoid, Control Circuit Performance

Transmission Range Sensor Alignment

24

Copyright © 2011 ATSG

Figure 23

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

WWW.ALL-TRANS.BY

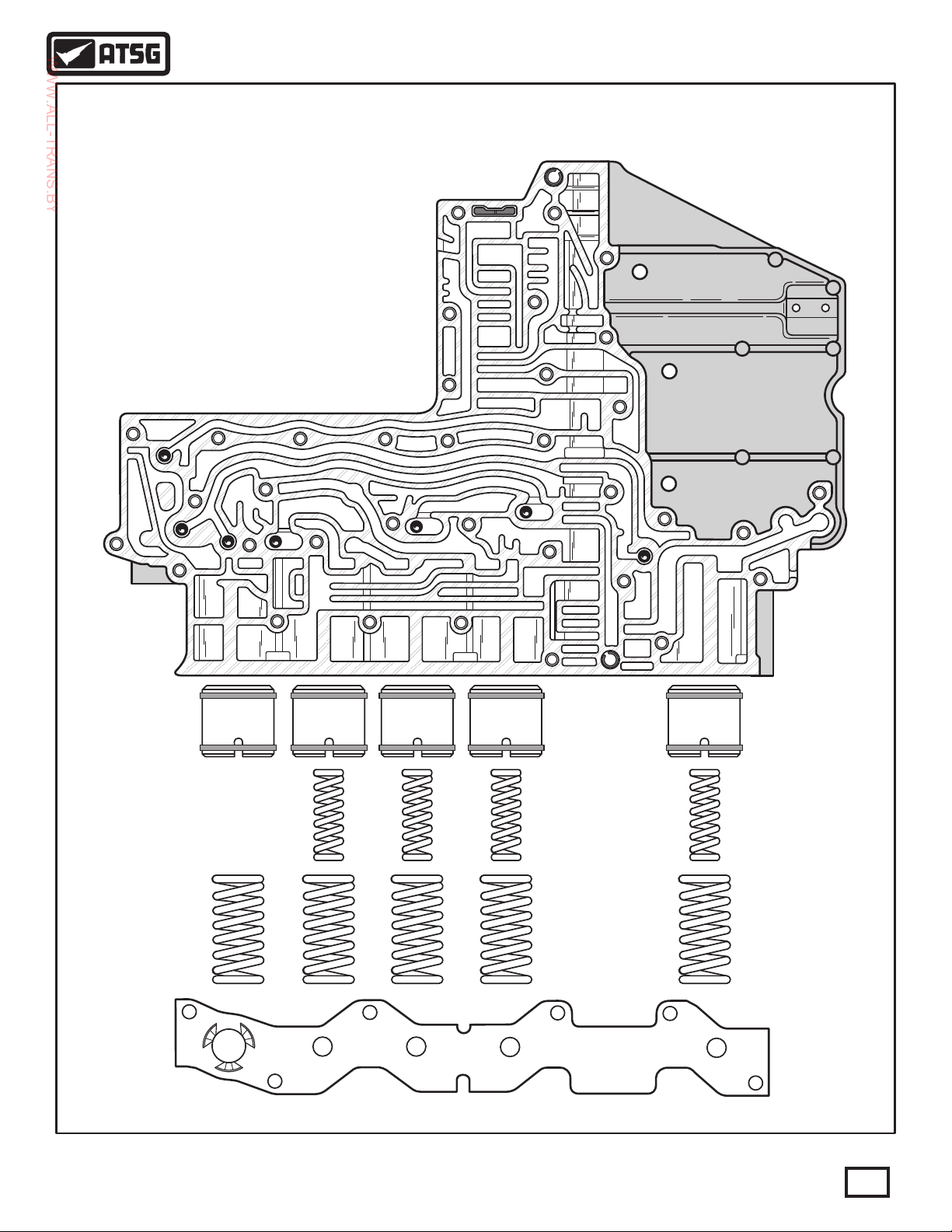

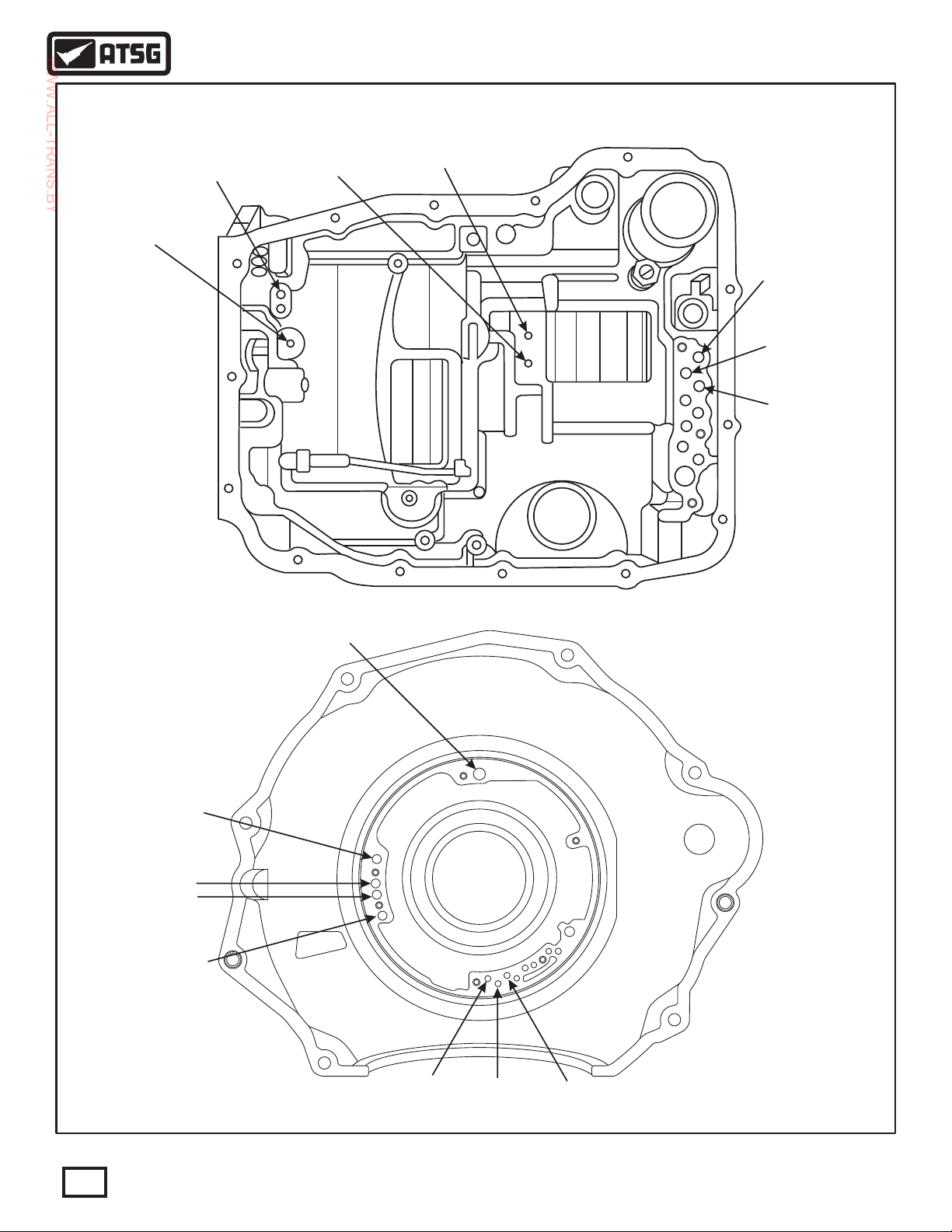

68RFE ACCUMULATOR AND CHECKBALL LOCATIONS

SEVEN CHECKBALL LOCATIONS

ARE SHOWN BELOW

OD

ACCUM

UD

ACCUM

4TH CLUT

ACCUM

2ND CLUT

ACCUM

Figure 24

LOW/REV

ACCUM

Copyright © 2011 ATSG

AUTOMATIC TRANSMISSION SERVICE GROUP

25

Technical Service Information

WWW.ALL-TRANS.BY

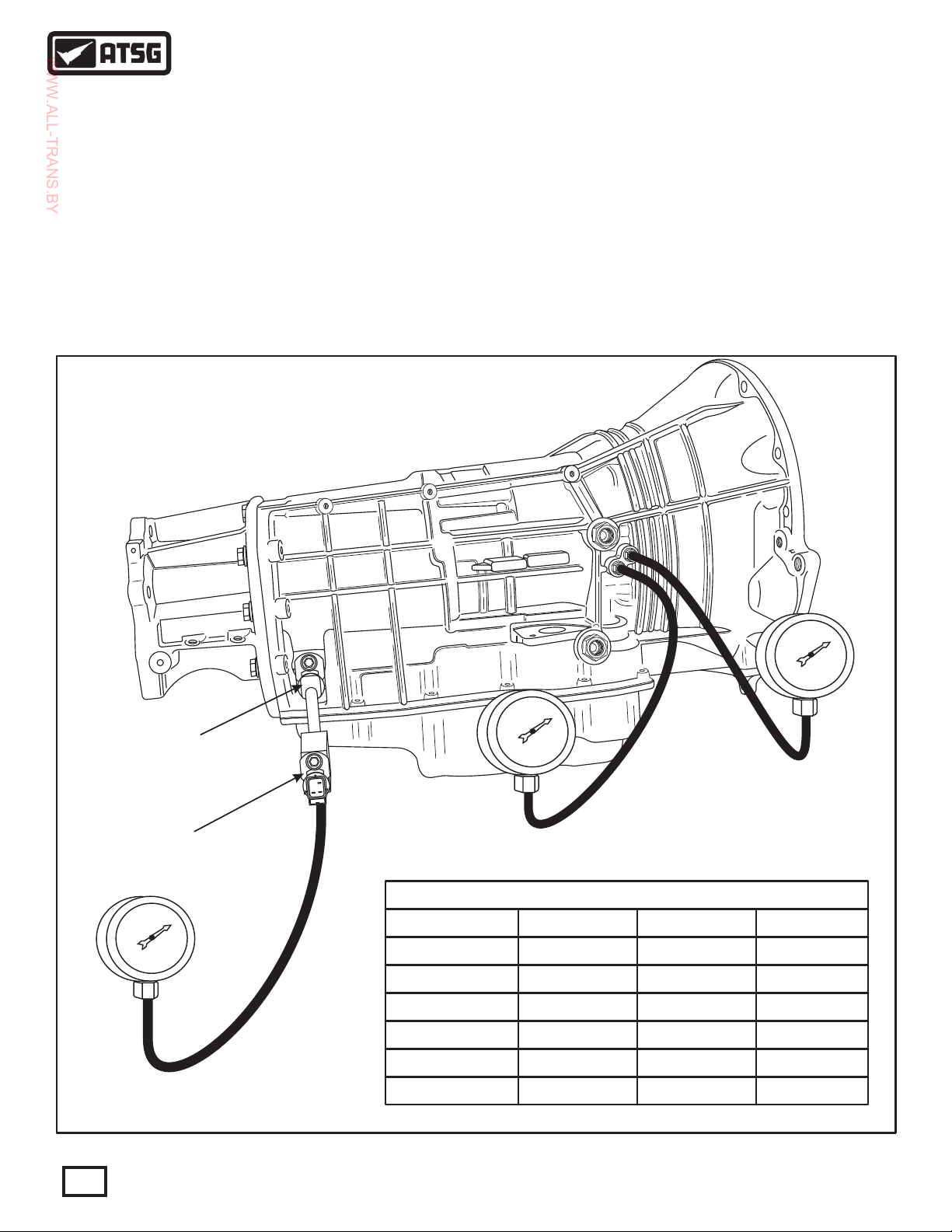

PRESSURE TEST LOCATIONS AND PROCEDURE

There are only 2 pressure taps supplied externally on

the case. The torque converter ON and torque

converter OFF taps are located on the right side of the

transmission case, shown in Figure 25.

There are two available methods to determine main

line pressure. The DRB Scan Tool can be used to read

main line pressure from the line pressure sensor. The

2nd method is to install Line Pressure Adapter 8259

into the transmission case, and re-install line pressure

sensor and the pressure gauge into the adapter, as

shown in Figure 25.

OIL PRESSURE TESTS

This will allow a comparison of the DRB readings

and the pressure gauge to determine the accuracy of

the feedback to the controller. Refer to the chart in

Figure 25 for proper pressure readings.

To access any of the other pressure tap locations, the

transmission oil pan must be removed, the pressure

taps removed from the valve body and the Valve Body

Pressure Tap Adapter 8258 installed. Refer to Figure

26. The extensions supplied with Adapter 8258 will

allow the installation of pressure gauges to the valve

body to test individual clutch pack pressures.

Tool No.8259

Line Pressure

Sensor

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

MAIN LINE

PRESSURE

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

LOCK-UP "OFF"

PRESSURE

LOCK-UP "ON"

PRESSURE

PRESSURE CHART

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

GEAR

PARK

REVERSE

NEUTRAL

OD-1ST

TCC OFF

TCC ON

LINE

35-165 35-118

45-250

35-165

35-165

35-165

35-165

TCC ON TCC OFF

15-80

40-11840-75

15-80

15-80

15-80

35-80

35-118

35-118

35-118

0

Copyright © 2011 ATSG

26

Figure 25

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

WWW.ALL-TRANS.BY

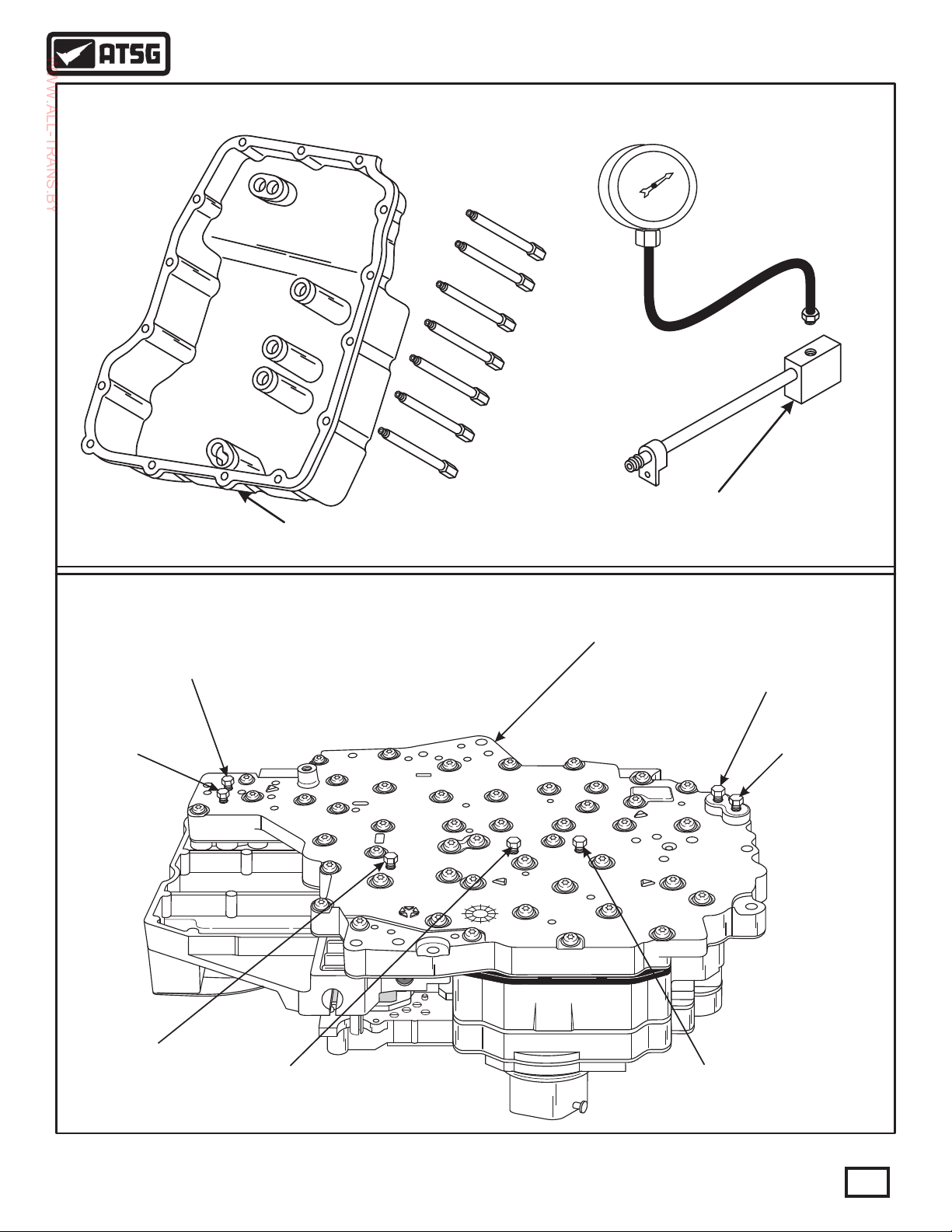

MANDATORY TOOLS NEEDED FOR CHECKING PRESSURES ON 68RFE

Pressure Tap Adapter Tool No. 8258, to check oil

pressures through the valve body taps.

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

Line Pressure Adapter Tool No. 8259, to install into the

line pressure sensor circuit, and then reinstall the

sensor and pressure gage.

Line Pressure

Low/Reverse

Clutch Pressure

Overdrive Clutch

Pressure

4th Clutch

Pressure

VALVE BODY

Underdrive Clutch

Pressure

Reverse Clutch

Pressure

05111

1

AK

4799655

98

2nd Clutch

Pressure

Figure 26

AUTOMATIC TRANSMISSION SERVICE GROUP

27

Technical Service Information

WWW.ALL-TRANS.BY

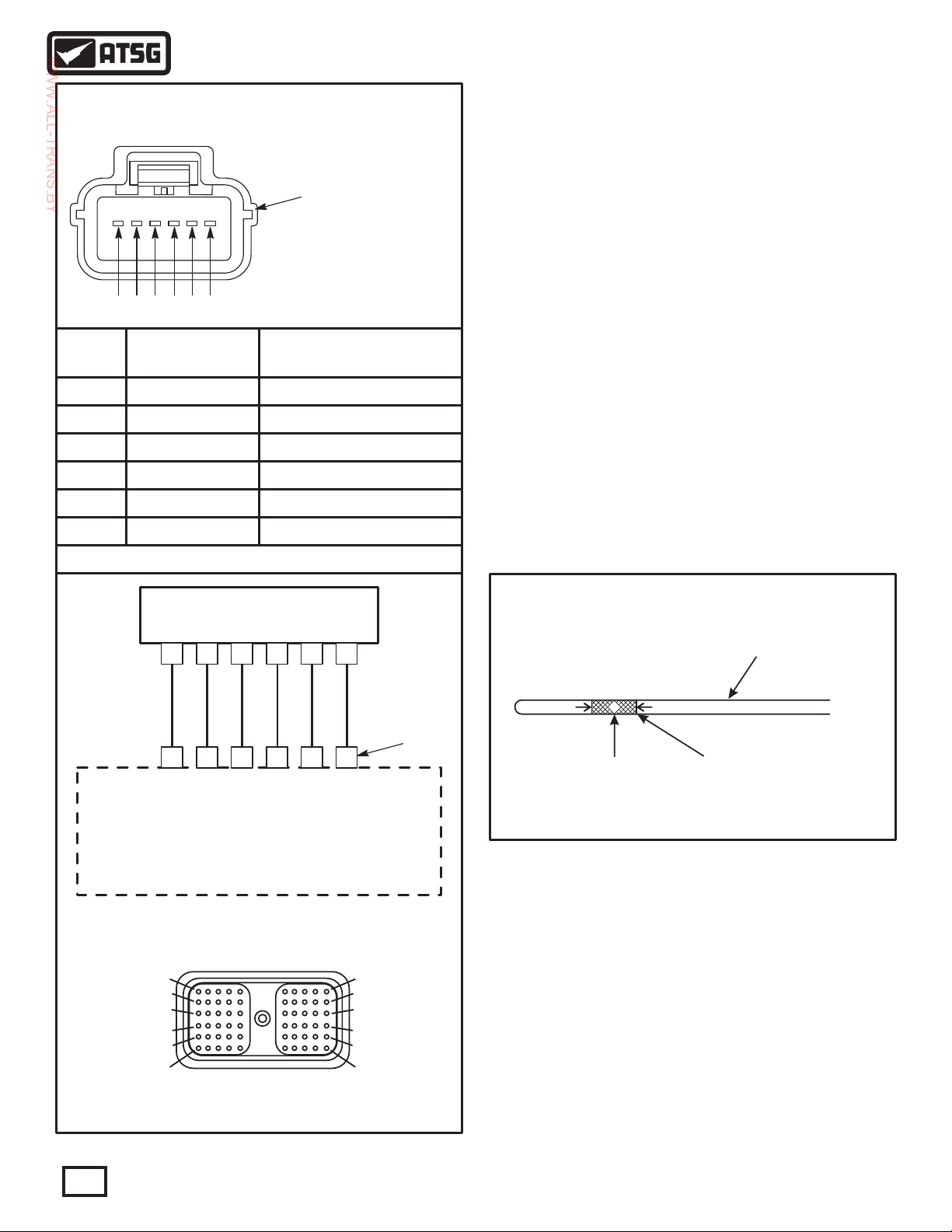

ACCELERATOR PEDAL POSITION SENSOR

6.7L DIESEL DIAGNOSTIC INFORMATION

APPS

Connector

Face View

123456

WIRE

CAVITY COLOR FUNCTION

1 Brown/Lt Blue

2

3

4

5

6

Brown/White

Brown/Yellow

Brown/Violet

White/Brown

Violet/Brown

5 Volt Supply

APPS No. 1 Signal

APPS No. 1 Return

APPS No. 2 Return

APPS No. 2 Signal

5 Volt Supply

FLUID LEVEL CHECK PROCEDURE

(1) Transmission fluid level must be checked

before performing the pressure tests and must

be at normal operating temperature for

accurate check. Drive vehicle if necessary to

bring fluid temperature up to normal operating

temperature of 82°C (180°F).

(2) Position vehicle on flat level surface.

(3) Start and run engine at curb idle speed.

(4) Apply Parking Brakes.

(5) Shift transmission through all gear ranges and

then back to the Neutral position.

(6) Remove dipstick and check fluid level.

(A) Correct level is in crosshatch area.

(B) Correct maximum level is to MAX arrow.

(C) Incorrect level is at or below MIN line.

(7) If fluid level is low, add only enough of the

Mopar® ATF Plus 4, to restore correct fluid

level. Do not overfill (See Figure 28).

Dexron II fluid is NOT recommended. Clutch

chatter can result from the use of improper fluid.

Engine

Control

Module

This Information Shared with TCM over CAN C Bus

Accelerator Pedal Position Sensor

2

3

4

5

6

Violet/Brown

26

5 VOLT SUPPLY

60-Way C2 Connector (Diesel)

10

20

30

40

50

60

Brown/Violet

White/Brown

22

24

APPS NO. 2 SIGNAL

APPS NO. 2 RETURN

Face View

Engine Control Module

Note: numbers are marked

on connector

Brown/White

Brown/Dk Green

35

28

APPS NO. 1 SIGNAL

APPS NO. 1 RETURN

1

Brown/Lt Blue

27

Engine

Control

Module

5 VOLT SUPPLY

1

11

21

31

41

51

ECM

C2

Conn

OK MAXMIN

ACCEPTABLE

FLUID LEVEL

TYPICAL

DIPSTICK

MAXIMUM CORRECT

FLUID LEVEL

Copyright © 2011 ATSG

Figure 28

28

Copyright © 2011 ATSG

Figure 27

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

WWW.ALL-TRANS.BY

CONVERTER CLUTCH OPERATION

The Torque Converter Clutch can be engaged in all

gear ranges except first, depending on the Tow/Haul

and ERS status. In normal operation, the converter

clutch will engage after the shift to fourth gear. If the

Tow/Haul mode is enabled, the converter clutch will

engage after the shift to third gear.

The TCM controls the torque converter clutch via the

duty cycle of the L/R-TCC Solenoid. There are four

different TCC operational modes.

No EMCC

Partial EMCC

Full EMCC

Gradual EMCC Release

This function, referred to as Electronically Modulated

Converter Clutch (EMCC), can occur at various times

depending on the following variables:

Shift Lever Position

Current Gear Range

Transmission Fluid Temperature

Engine Coolant Temperature

Input Speed

Throttle Angle

Engine Speed

Switch Valve Position

NO EMCC Under No EMCC conditions, the L/RTCC Solenoid is Off. There are several things that can

result in No EMCC operations. No EMCC can be

iniated due to a fault in the transmission or because the

TCM does not see the need for EMCC under current

driving conditions

PARTIAL EMCC Partial EMCC operation will

modulate the L/R-TCC Solenoid duty cycle to obtain

partial converter clutch application. Partial EMCC

operation is maintained ubtil Full EMCC is called for

and actuated. During Partial EMCC some slip does

occur. Partial EMCC will usually occur at low speeds,

low load and light throttle situations.

FULL EMCC During Full EMCC operation, the

TCM increases the L/R-TCC Solenoid duty cycle to full

On after Partial EMCC control brings the engine speed

within the desired slip range of transmission input

speed relative to engine RPM.

GRADUAL EMCC RELEASE This operation is to

soften the change from Full or Partial EMCC down to

No EMCC. This done at mid-throttle by slowly

decreasing the L/R-TCC Solenoid duty cycle.

Apply

Release

Figure 29

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2011 ATSG

29

Technical Service Information

WWW.ALL-TRANS.BY

68RFE CASE PASSAGE IDENTIFICATION

Low/Reverse

Clutch

Line

2nd Clutch

4th Clutch

Overdrive

Clutch

Underdrive

Clutch

Reverse

Clutch

Lock-Up Off

Lock-Up On

To

Cooler

From

Cooler

Vent

Overdrive

Clutch

Underdrive

Clutch

Reverse

Clutch

Copyright © 2011 ATSG

30

Figure 30

AUTOMATIC TRANSMISSION SERVICE GROUP

Loading...

Loading...