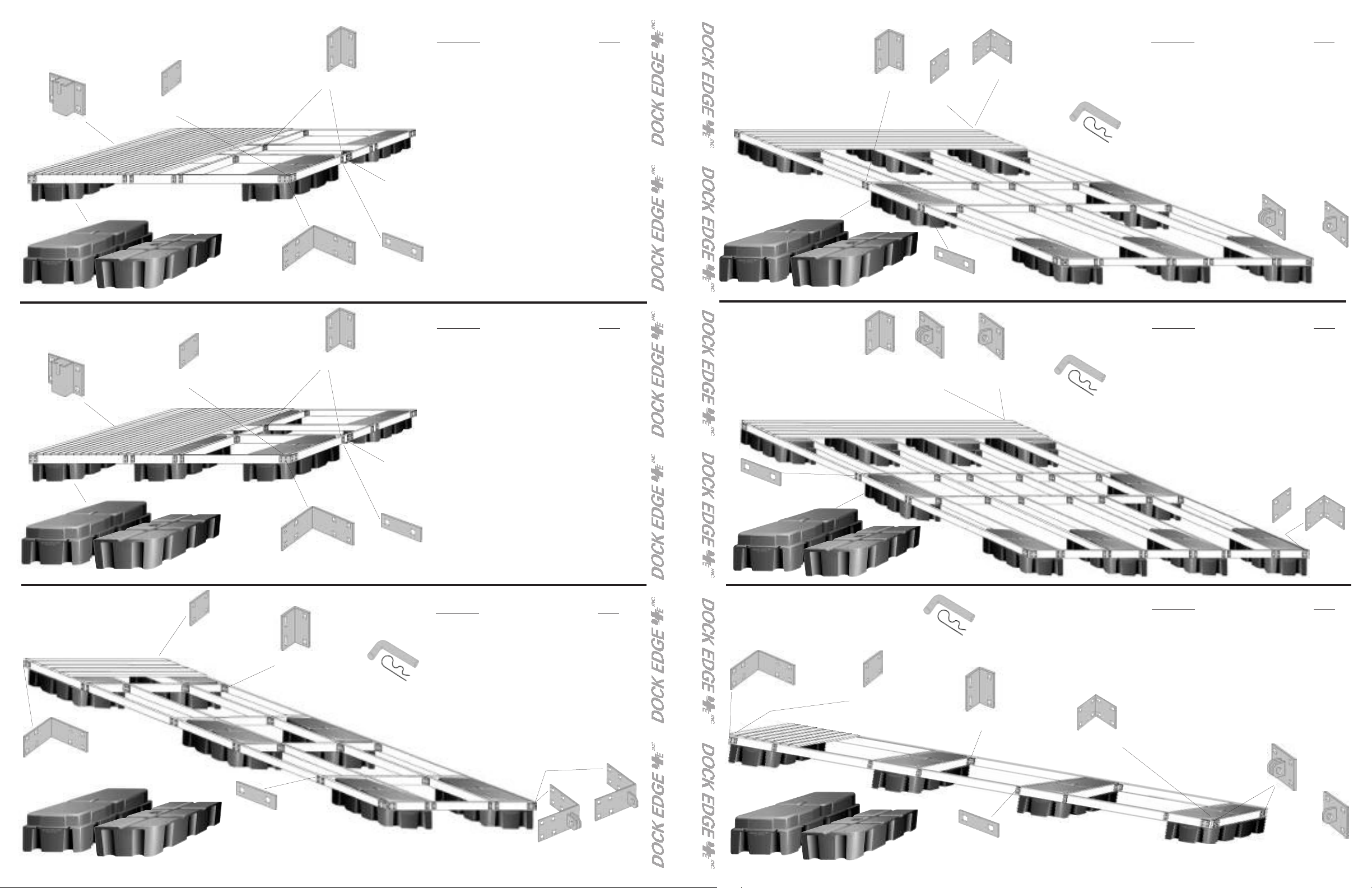

10 x 10

SWIM FLOAT

99-013-F

Chain

Retainer

Howell 550™

Howell 400™

12 x 12

SWIM FLOAT

99-013-F

Chain

Retainer

93-122-F

Backer Plate

93-122-F

Backer Plate

oist Corner

J

99-004-F

Outside

Corner

99-002-F

Joist Corner

99-002-F

99-013-F

Chain

Retainer

99-006-F

Washer Plate

99-013-F

Chain

Retainer

DOCK HARDWARE REQUIRED

Description QTY

99-004-F Outside Corner 4

99-002-F Joist Corner 24

99-006-F Washer Plate 16

99-013-F Chain Retainer 2

93-122-F Backer Plate 8

99-246-F Howell 550 Float 4

99-242-F Howell 400 Float 6

1/2” x 2 1/2” Carriage Bolts and nuts 116 each

3/8” x 2” Lag Bolts 32

Note: The Howell 550 has a recessed flange whereas the

Howell 400 has traditional top flange mount.

See rear cover for sample optional hardware placement for

corners and hinges and formulae for the recommended

number of floats to use for your dock project as well as an

IMPOR

OR

TANT note from DockEdge+.

DOCK HARDWARE REQUIRED

Description QTY

99-004-F Outside Corner 4

99-002-F Joist Corner 24

99-006-F Washer Plate 16

99-013-F Chain Retainer 2

93-122-F Backer Plate 8

99-246-F Howell 550 Float 6

99-242-F Howell 400 Float 8

1/2” x 2 1/2” Carriage Bolts and nuts 116 each

3/8” x 2” Lag Bolts 48

Note: The Howell 550 has a recessed flange whereas the

Howell 400 has traditional top flange mount.

See rear cover for sample optional hardware placement for

corners and hinges and formulae for the recommended

number of floats to use for your dock project as well as an

IMPORTANT note from DockEdge+.

OR

8 x 20

MAIN DOCK

99-002-F

Joist Corner

Howell 550™

Howell 400™

10 x 20

MAIN DOCK

99-002-F

oist Corner

J

See rear cover for sample optional hardware

placement for corners and hinges and formulae

for the recommended number of floats to use

for your dock project as well as an IMPORTANT note from DockEdge+

99-006-F

Washer Plate

3-122-F

9

Backer Plate

99-006-F

Washer Plate

99-011-F

Female T

onnector

C

92-104-F

Inside Corner

+

+

99-012-F

Male T

Connector

See rear cover for sample

optional hardware placement for

corners and hinges and formulae

for the recommended number of

floats to use for your dock project as well as an IMPORTANT

note from DockEdge+

96-111-F

Connector Pin

96-111-F

Connector

Pin

DOCK HARDWARE REQUIRED

Description QTY

99-012-F Male T Connector 1 or 2

99-011-F Female T Connector 1 or 2

96-111-F Connector Pin 2

92-104-F Inside Corner 4

93-122-F Backer Plate 6

99-002-F Joist Corner 56

99-006-F Washer Plate 24

99-246-F Howell 550 Float 8

99-242-F Howell 400 Float 10

1/2” x 2-1/2”” Carriage Bolts and nuts 168 each

3/8” x 2” Lag Bolts & Washers 60 each

Note: The Howell 550 has a recessed flange whereas the

Howell 400 has traditional top flange mount.

OR

1-F

99-01

Female T

Connector

+

+

99-012-F

Male T

Connector

DOCK HARDWARE REQUIRED

Description QTY

99-012-F Male T Connector 1 or 2

99-011-F Female T Connector 1 or 2

11-F Connector Pin 2

96-1

99-002-F Joist Corner 82

9-006-F Washer Plate 32

9

93-122-F Backer Plate 6

92-104-F Inside Corner 4

99-246-F Howell 550 Float 10

99-242-F Howell 400 Float 12

1/2” x 2-1/2” Carriage Bolts and nuts 224 each

3/8” x 2” Lag Bolts & Washers 72 each

Note: The Howell 550 has a recessed flange whereas the

Howell 400 has traditional top flange mount.

OR

93-122-F

Backer Plate

Howell 550™

Howell 400™

6 x 20

MAIN DOCK

99-004-F

Outside Corner

Howell 550™

Howell 400™

93-122-F

Backer Plate

99-004-F

Outside

Corner

99-006-F

asher Plate

W

DOCK HARDWARE REQUIRED

Description QTY

99-009-F Male Corner Hinge 1 or 2

99-010-F Female Corner Hinge 1 or 2

96-111-F Connector Pin 2

99-004-F Outside Corner 2

99-002-F

Joist Corner

96-111-F

Connector

Pin

99-006-F

Washer Plate

See rear cover for sample optional hardware placement for corners and hinges

and formulae for the recommended number of floats to use for your dock project

as well as an IMPORTANT note from DockEdge+.

93-122-F

99-002-F Joist Corner 56

99-006-F Washer Plate 24

99-246-F Howell 550 Float 6

99-242-F Howell 400 Float 8

1/2” x 2 1/2” Carriage Bolts and nuts 136 each

3/8” x 2” Lag Bolts & Washers 48 ea.

Note: The Howell 550 has a recessed flange whereas the

Howell 400 has traditional top flange mount.

Backer Plate

OR

99-010-F

Female Corner

Hinge

8

99-009-F

Male Corner

Hinge

Howell 550™

4 x 20

FINGER DOCK

99-004-F

Outside Corner

Howell 550™

93-122-F

Backer Plate

Howell 400™

Howell 400™

96-111-F

Connector

Pin

Washer Plate

99-002-F

Joist Corner

99-006-F

DOCK HARDWARE REQUIRED

Description QTY

99-011-F Female T Connector 1 or 2

99-012-F Male T Connector 1 or 2

96-111-F Connector Pin 2

99-002-F Joist Corner 12

99-006-F

92-104-F Inside Corner 2

99-004-F Outside Corner 2

93-122-F Backer Plate 6

99-246-F Howell 550 Float 4

99-242-F Howell 400 Float 6

1/2” x 2-1/2” Carriage Bolts and nuts 80 each

92-104-F

Inside Corner

See rear cover for sample optional hardware placement for corners and

hinges and formulae for the recommended number of floats to use for

your dock project as well as an IMPOR

3/8” x 2”

Note: The Howell 550 has a

recessed flange whereas the

Howell 400 has traditional top

flange mount.

TANT note from DockEdge+.

Washer Plate 24

OR

Lag Bolts & Washers 36 each

99-011-F

Female T

Connector

92-104-F

Inside Corner

+

+

99-012-F

Male T

Connector

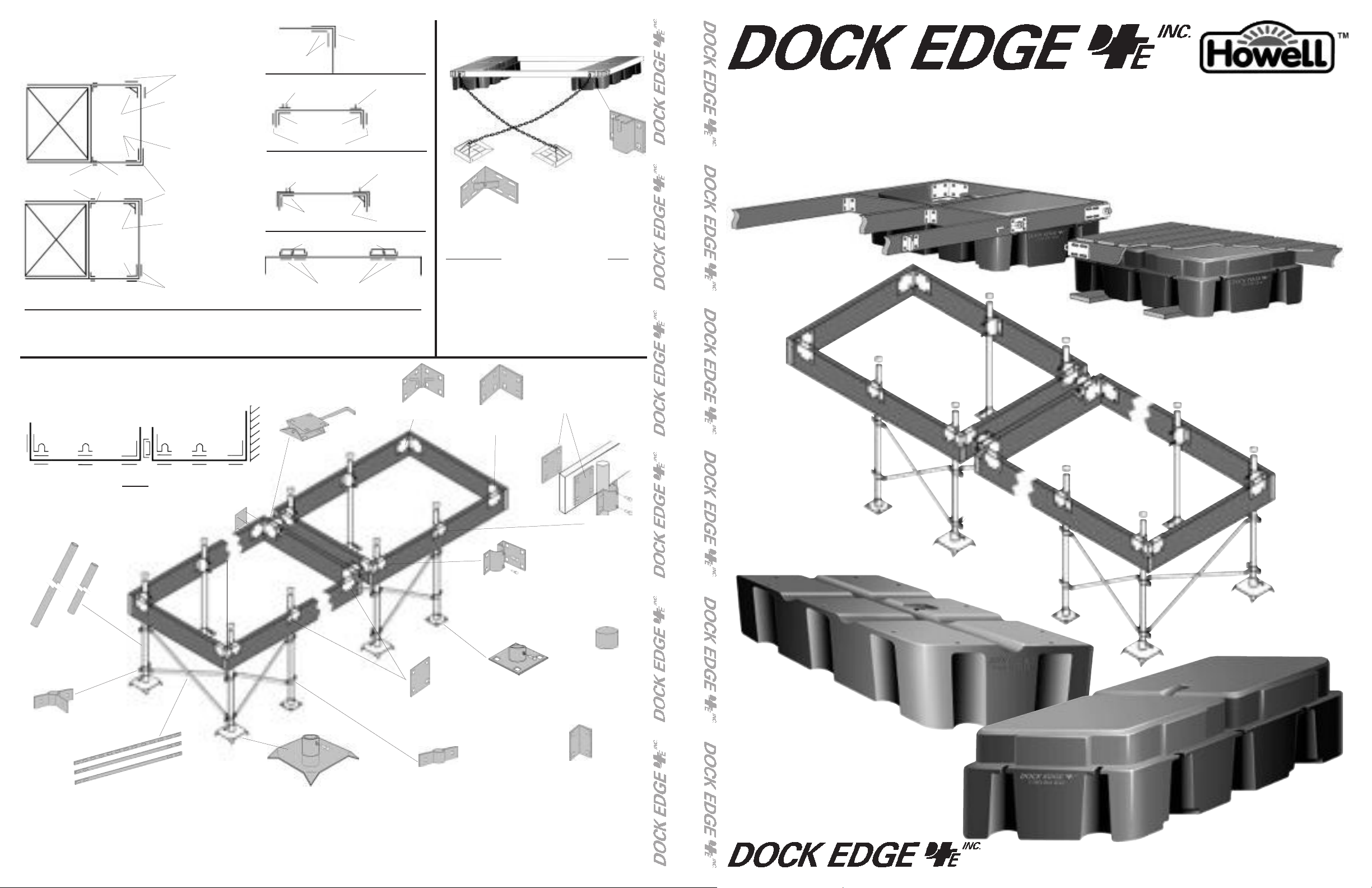

FLOATING DOCK HARDWARE

PLACEMENT for CORNERS &

HINGES

99-242-F

Howell 400™

Float

99-006-F

Washer Plate

99-242-F

Howell 400™

loat

F

99-002-F

Joist Corner

92-104-F

Inside

Corner

93-122-F

Backer Plate

99-001-F

HD Anchor Chain Corner

Backer Plate

Outside Corner

HD Anchor Chain Corner

Backer Plate

OR

92-116

Inside Anchor Corner

93-122-F

99-004-F

99-001-F

3-122-F

9

93-122-F

Backer Plate

99-011-F

emale T

F

Connector

92-104-F

Inside Corner

Backer Plate

99-010-F

orner Hinge

C

93-122-F

Backer Plate

HD Connector Hinge

93-122-F

Female

91-112-F

93-122-F

Backer Plate

99-004-F

Outside Corner

99-012-F

Male T

Connector

99-009-F

Male Corner

Hinge

99-001-F

HD Anchor

Chain Corner

FLOTATION CAPACITY FORMULAE, REQUIRED # OF FLOATS

Howell 550™: (Square Footage of Dock x 25 )/ 550= # of Floats

Howell 400™: (Square Footage of Dock x 25 )/ 400= # of Floats

Formulae based on average use of residential dock at 25lb/ ft.

2

FLOATING DOCK

ANCHORAGE

99-013-F

Chain

91-120-F

Dock Anchor

99-001-F

HD Anchor

Chain Corner (see placement guide)

Retainer

DOCK HARDWARE REQUIRED

Description QTY

99-013-F Chain Retainer 2

93-122-F

99-001-F HD Anchor Chain Corner 2

99-004-F Outside Corner 2

3/8” x 2-1/2” Carriage Bolts and nuts 16 each

1/2” x 2 1/2” Carriage Bolts and nuts 16 each

3/8” chain QTY to suit application

91-120-F Dock Anchor 2

Backer Plate 4

OR

OR

®

THE FINEST QUALITY DOCK HARDWARE AND MARINE ACCESSORIES

FLOATING AND STATIONARY DOCK

HARDWARE GUIDE

STATIONARY DOCK HARDWARE

Hardware Placement Guide

Correct Usage of Hardware with Backer Plates

Connector Hinge

(see placement guide)

87-122-F Backer Plate MUST be used On Opposite

Side Of All Fittings as shown in the Hardware

placement Guide above.

93-168-F &

93-110-F

Galvalume

Leg Pipe

87-107-F

Corner Leg

Brace Holder

86-103-F

91-116-F

Tie Down

Anchor

Corner

87-122-F

Backer Plate

(see placement guide)

86-104-F

Corner Plate

(see placement guide)

86-100-F

Corner Leg Holder

(see placement guide)

86-102-F

Base Plate

Proper hardware placement for 86-101 & 86-100

leg holders.

backer plates 87-122 as

shown.

Always use

86-101-F

Side Leg Holder

(see placement guide)

The Side Leg Holder

86-101-F may be

mounted inside the

dock framing or outside for convenient

adjustment if needed.

91-111-F

Plastic Leg Cap

Howell 400™

89-101-F

Adjustable Leg Brace Set

Max extension of 72”

94-102-F

Bottom Pad, 12”

93-105-F

Leg Brace Holder

95-122-F

Joist Corner Bracket

IMPORTANT: DockEdge+ Inc. assumes no responsibility or liability for the accuracy or representation of the graphic illustrations shown in this hardware guide. These graphic

illustrations are not intended to be architectural drawings, and are not to be substituted for engineered drawings. Each is intended as a guideline ONL

quantities and/ or bill of materials to be accurate in all uses and applications. Individual dock structures may vary by necessity, preference or design. It may be necessary to vary the amount

of materials listed in this guide depending on dock size, material usage, necessity and/ or the severity of the conditions to which the dock structure is subjected to.

All graphic illustrations are based on the use of conventional framework of 2” x 6” lumber and decking lumber. Freeboard may be adjusted by using 2”x8” or 2”x10” lumber. Substitutions in

lumber and hardware placement may effect floatation.

Y. DockEdge+ Inc. does not warrant the

Howell 550™

®

www

.dockedge.com

Loading...

Loading...