Dock Edge Mooring Whip User Manual

Premium & Ultimate

&

Mooring Whip Installation

Instructions

IMPORTANT

CAUTION

Warning: Failure to follow proper installation instructions voids warranty and may lead to product failure and/ or property damage.

Note: Some mooring areas may be too rough for any type of tie-up system.

IMPORTANTNOTESTO ENSURE A SAFE, SECURE INSTALLATION & WARRANT YOUR NEW MOORINGWHIPS

IMPORTANT: Ensure that you have purchased the appropriate DockEdge Mooring Whip for your application. Weight and water level variations are more critical factors than length in estimating your requirements.

3 YEAR Limited Warranty

against defects in materials and workmanship.

Premium & Ultimate

Premium & Ultimate Whips

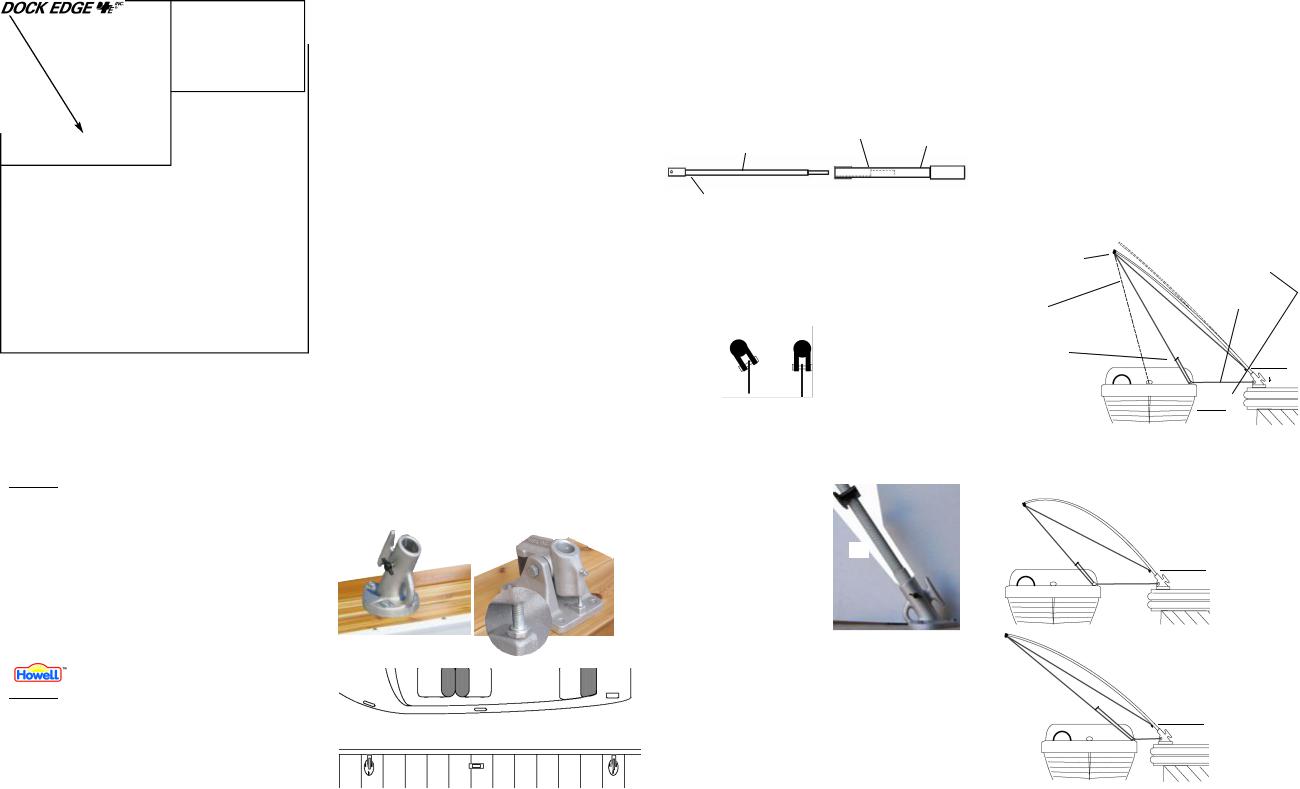

1- INSTALLING THE MOORING WHIP BASES

Mooring whips require a firm, secure footing for mounting.

-The recommended location for mooring whips is on the side of the dock which is most protected from winds. This is preferrable to cause the boat to stay clear of the dock rather than be forced towards it.

-Locate the cast aluminum bases 4-5” from the edge of the dock. Fig. #1a & 1b

-Align the whip bases with their respective cleats on the bow and stern of the boat making sure that the whips are perpendicular to the edge of the

dock. Fig. #1c

The general rule is that the span between the whips should be approximately 2/3 of the boats’ overall length. Install additional cleat(s) on the boat if necessary to retain the 2/3 rule. Space whip bases accordingly for such an application.

ATTENTION: Fig. #1b also illustrates the location of a bolt at the rear of the rocker base which is used to adjust the freeplay of a completed whip assembly. This bolt should be adjusted only enough to eliminate any freeplay between the rocker base arm and the rubber bushing.

NOTE: In applications where side cleats are unavailable a center bow or stern cleat of the boat may be used.

-Mark the location of the mounting holes for the bases and drill through the plank with a 1/8” drill bit. Lag down the whip bases with the lag bolts and washers supplied.

NOTE: Concrete docks will require lag bolts and masonry plug inserts. Softwood docks such as cedar should have a 3/8” hole drilled through the dock at each mounting hole location of the base and 3/8” bolts or “carriage” bolts and use washers, lockwashers and nuts or locking nuts in place of the 3/8” lag bolts sup - plied with your mooring whip kit.

Fig. 1a |

|

4 to 5” |

Fig. 1b |

|

|||

|

|

|

|

|

4 to |

5” |

|

|

FREEPLAY ADJUSTMENT |

|

|

|

Fig. 1c |

|

BOLT |

Align Bases with cleats to be used

2- WHIP ASSEMBLY (where applicable)

Models 3400, 3450, 3600, 3650, 3800 & 3850 are two part assemblies. Carefully follow the instructions for 2-part assemblies. (See Fig. #2) With a threading motion turn the top portion of the mooring whip into the base section until it is fully seated. Approximately 18 inches of the upper section should be retained inside the lower section of the whip assembly.

Fig. 2 |

Reinforcement Collar |

Lower Section |

|

|||||||||||

|

|

Upper Section |

|

18in. |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Whip Tip or roller |

|

|

Insert into |

|

Insert into |

||||||||

|

|

|

Lower Section |

|

||||||||||

|

|

|

|

Mounting Base |

||||||||||

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3- WHIP MOUNTING & PREPARATION

-Feed the whip lines over the line rollers at the tips. Ensure whip tip rollers are parallel to the dock surface. (Fig. #3)

-Insert the whip into the base, making sure the whip is fully seated in the base and so that the whip line is hanging straight down. OR for models incorporating a tip pulley, align the pulley so that it is perpendicular to the dock surface. (Fig. #3)

Fig. 3 |

Whip tip & roller pin assembly |

|||||

is ready for |

use. |

Optional |

||||

ROLLER |

||||||

wheel |

(not |

included |

with |

|||

TIP |

||||||

Howell |

models) |

may |

be |

|||

|

||||||

installed at the users discretion.

Once the tip has been aligned, tighten the thumb screw on the whip base only enough to prevent the whip from lifting out of the base. Overtightening may damage the fiberglass strand and integrity of the whip.

Pole Cleat - Attach the pole cleat no more than 14 inches from the whip base.

See Fig. #4.

The pole cleat can be used to wrap the boats’ whip line around for quick release and ease of manouvering the watercraft towards the dock when required.

Fig. 4

Cleat not included with Howell Whips

4- INSTALLATION OF WHIP LINES

-Tie off the dock side end of each whip line to the pole or base cleat, Fig. #4 making sure there is sufficient excess line at both ends to allow for tie-up of the boat with the tensioner, and release of line tension at the dock.

-To adjust for proper tension on the mooring whip lines slip the loops from the lines through the bow and stern cleats of the boat.

Using the sliding tension adjuster, place enough tension on the line to just pull the whip tip down.(See Fig. #5 & #6)

CAUTION: When adjusting whip and/ or spring line tensions Do Not over-torque the whip. Pull each whip tip down in inches, as the whip is in total length, ie. 8ft. - 8 inches, 12 ft. - 12 inches, 14 ft. - 14 inches, 16 ft. - 16 inches.

CAUTION: For installation of mooring whips on stationary docks in locations where water levels fluctuate more than 2 ft., mooring whips without a rocker base MUSTbe adjusted periodically to compensate for these variations. Failure to make adjustments to spring and whip line tension in such conditions may result in damage to the whips and void the manufacturers warranty, see Fig. #5 thru #9. Adjustments are seldom necessary on floating docks, as the dock and boat will rise and fall accordingly. Alternatively, Mooring whips with a rocker base (models 3450, 3650 & 3850) may be installed for such applications. The rocker base should adequately adjust for tidal variations that could exceed the abilities of whips with a rigid non-pivoting base.

Fig. 5 |

At Rest |

CORRECTINSTALLATION |

|

|

|

See Product Chart “A” regard - |

|

|

|

||

|

Under Load |

|

|

|

|

|

|

|

|

|

ing this dimension. |

Whip Line

Bow & Stern Bow Line (Keep as vertical as possible)

Tensioner

14 in.

Optional Bow Cleat

Usage if Bow or Stern Cleats See “A” Unavailable (See 6A)

INCORRECT INSTALLATIONS

Fig. 6a

14 in.

Fig. 6b

14 in.

Under no cir- c u m s t a n c e s should any mooring whip be installed with an excess of tension as shown in these- d i a g r a m s . Doing so will affect the mooring whips ability to protect your water craft and will void the manufacturers warranty.

Loading...

Loading...