Disney md20080 schematic

MD20080

SERVICE MANUAL

COLOR TELEVISION RECEIVER

ORIGINAL

CHASSIS CODE B

Design and specifications are subject to change without notice.

SERVICING NOTICES ON CHECKING

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an

electric shock while the electric current is

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

PUT PARTS AND WIRES IN THE

4.

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

5. TAKE CARE TO DEAL WITH THE

CATHODE-RAY TUBE

In the condition that an explosion-proof cathoderay tube is set in this equipment, safety is

secured against implosion. However, when

removing it or serving from backward, it is

dangerous to give a shock. Take enough care to

deal with it.

6. AVOID AN X-RAY1. KEEP THE NOTICES

Safety is secured against an X-ray by considering about the cathode-ray tube and the high

voltage peripheral circuit, etc.

Therefore, when repairing the high voltage peripheral circuit, use the designated parts and

make sure not modify the circuit.

Repairing except indicates causes rising of high

voltage, and it emits an X-ray from the cathoderay tube.

7.PERFORM A SAFETY CHECK AFTER

SERVICING

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

1.

Unplug the plug from the AC outlet.

2.

Remove the antenna terminal on TV and turn

on the TV.

3.

Insulation resistance between the cord plug

terminals and the eternal exposure metal

[Note 2] should be more than 1M ohm by

using the 500V insulation resistance meter

[Note 1].

4.

If the insulation resistance is less than 1M

ohm, the inspection repair should be

required.

[Note 1]

If you have not the 500V insulation

resistance meter, use a Tester.

[Note 2]

External exposure metal: Antenna terminal

Earphone jack

HOW TO ORDER PARTS

Please include the following informations when you order parts. (Particularly the CHASSIS CODE.)

1. MODEL NUMBER and CHASSIS CODE

You canfind it in the back of your unit.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

IMPORTANT

Inferior silicon grease can damage IC's and transistors.

When replacing an IC's or transistors, use only specified silicon grease (YG6260M).

Remove all old silicon before applying new silicon.

A1-1

ABOUT LEAD FREE SOLDER (PbF)

Distinction of PbF PCB:

PCBs (manufactured) using lead free solder will have a PbF printing on the PCB.

(Please refer to figures.)

Caution:

Pb free solder has a higher melting point than standard solder;

•

Typically the melting point is 50°F~70°F(30°C~40°C) higher.

Please use a soldering iron with temperature control and adjust it to 650°F ± 20°F (350°C ± 10°C).

In case of using high temperature soldering iron, please be carefull not to heat too long.

Pb free solder will tend to splash when heated too high (about 1100°F/ 600°C).

•

All products with the printed circuit board with PbF printing must be serviced with lead free solder.

•

When soldering or unsoldering, completely remove all of the solder from the pins or solder area,

and be sure to heat the soldering points with the lead free solder until it melts sufficiently.

Recommendations

Recommended lead free solder composition is Sn-3.0Ag-0.5Cu.

A1-2

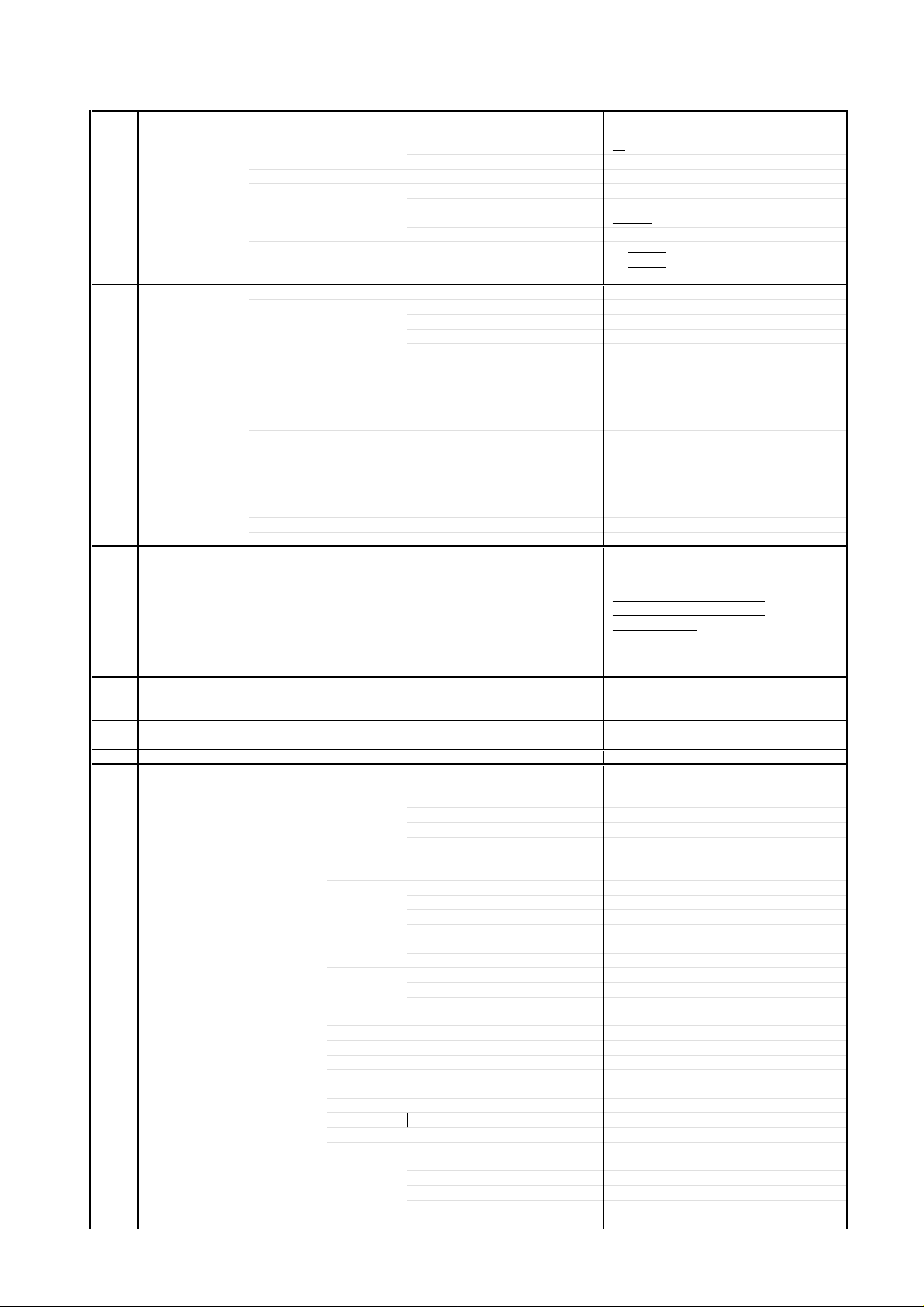

CONTENTS

SERVICING NOTICES ON CHECKING..........................................................................................................

HOW TO ORDER PARTS ...............................................................................................................................

IMPORTANT....................................................................................................................................................

ABOUT LEAD FREE SOLDER (PbF).............................................................................................................

CONTENTS .....................................................................................................................................................

GENERAL SPECIFICATIONS ........................................................................................................................

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF ANODE CAP .................................................................................................................

2. REMOVAL AND INSTALLATION OF FLAT PACKAGE IC ...................................................................

SERVICE MODE LIST.....................................................................................................................................

CONFIRMATION OF HOURS USED ..............................................................................................................

WHEN REPLACING EEPROM (MEMORY) IC ...............................................................................................

ELECTRICAL ADJUSTMENTS .......................................................................................................................

BLOCK DIAGRAM ...........................................................................................................................................

PRINTED CIRCUIT BOARDS

MAIN/CRT/OPERATION/FRONT JACK/POWER SW/RELAY....................................................................

MAIN/CRT/OPERATION/FRONT JACK ......................................................................................................

SCHEMATIC DIAGRAMS

MICON/TUNER............................................................................................................................................

CHROMA/SIF/VIF/21PIN .............................................................................................................................

SOUND/AV ..................................................................................................................................................

DEFLECTION/CRT ......................................................................................................................................

TV POWER ..................................................................................................................................................

WAVEFORMS ..................................................................................................................................................

MECHANICAL EXPLODED VIEW ...................................................................................................................

MECHANICAL REPLACEMENT PARTS LIST ...............................................................................................

ELECTRICAL REPLACEMENT PARTS LIST .................................................................................................

A1-1

A1-1

A1-1

A1-2

A2-1

A3-1~A3-4

B1-1

B2-1, B2-2

C-1

C-1

C-1

D-1~D-5

E-1, E-2

F-1, F-2

F-3, F-4

G-1, G-2

G-3, G-4

G-5, G-6

G-7, G-8

G-9, G-10

H-1~H-3

I-1

J1-1

J2-1, J2-2

A2-1

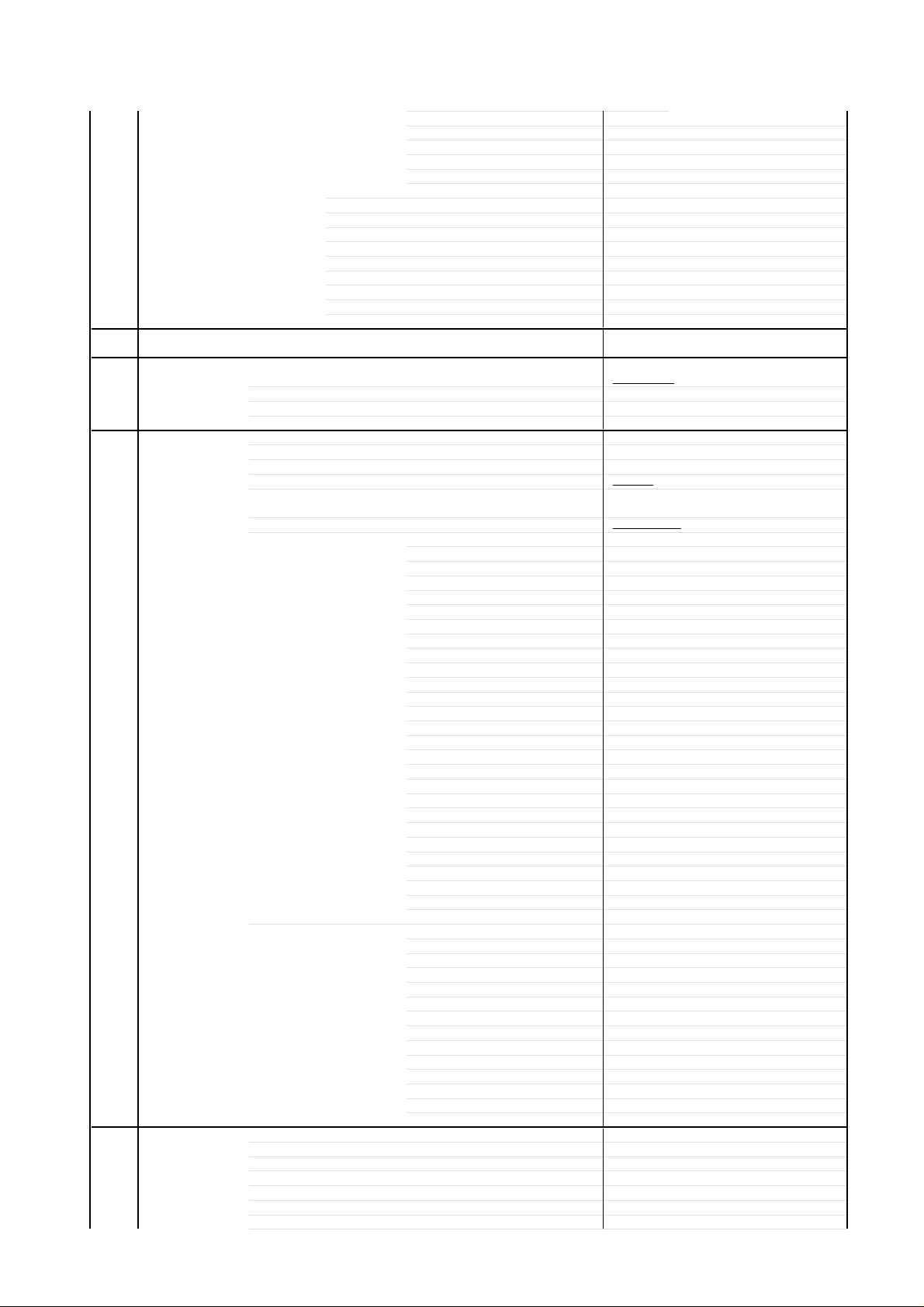

GENERAL SPECIFICATIONS

5oC

0oC

0oC

60oC

G-1 TV CRT CRT Size / Visual Size 14 inch / 335.4mmV

G-2 Tuning Broadcasting System FRANCE+CCIR System B/G L

G-3 Power Power Source AC 230V AC 50Hz

G-4 Regulation Safety CE

G-5 Temperature Operation

G-6 Operating Humidity Less than 80% RH

G-7 On Screen Menu Yes

System CRT Type Normal

Color System PAL / SECAM / MESECAM

Speaker 2 Speaker

Sound Output MAX 0.5+0.5 W

PAL60Hz Yes

System Tuner and System 1Tuner

Receive CH Destination CCIR (W/HYPER), FRENCH CATV

Intermediate PAL,SECAM(U&VH),SECAM(VL)

Frequency Picture(FP) 38.9,38.9,34.4MHz

Auto Tuning Method All Band (Not CCIR CH Plan)

Preset CH 80

StereoTV Sound (Ext Audio Input Only) Yes

Tuner Sound Muting Yes

Power Consumption at AC

Protector Power Fuse Yes

Display Menu Type Disney Character

Picture Yes

Audio No

CH Tuning Yes

Language Yes

Clock Set No

On/Off Timer Set No

Pin Code Registration No

Nicam Auto Off No

Colour System No

Sound System No

AV2 Output Source No

Control Level Yes

Deflection 90 degree

Magnetic Field BV/BH +0.45G/0.18G

Position Ext

Size 3 Inch

Impedance 8 ohm

10%(Typical) -- W

Tuning System F-Synth

Input Impedance VHF/UHF 75 ohm

CH Coverage PAL:

Sound(FS) 33.4,32.4,40.9MHz

FP-FS 5.5,6.5,6.5MHZ

DC -

Stand by (at AC) 5 W at AC 230 V 50 Hz

Per Year -- kWh/Year

Safety Circuit Yes

IC Protector(Micro Fuse) No

Radiation CE

X-Radiation PTB

Storage

Contrast Yes

Brightness Yes

Color Yes

Tint No

Sharpness Yes

Bass No

Treble No

Balance No

BBE On/Off No

Stable Sound On/Off No

Manual Yes

Auto Yes

CH Allocation Yes

Volume Yes

Brightness Yes

Contrast Yes

Color Yes

Tint (NTSC Only) No

E2 - E4, X - Z+2, S1 - S10, E5 - E12,

S11 - S41, E21 - E69

SECAM:

F2-F4, FB-FQ,F21-F69

44 W at AC 230 V 50 Hz

+

~ +4

-2

~ +

A3-1

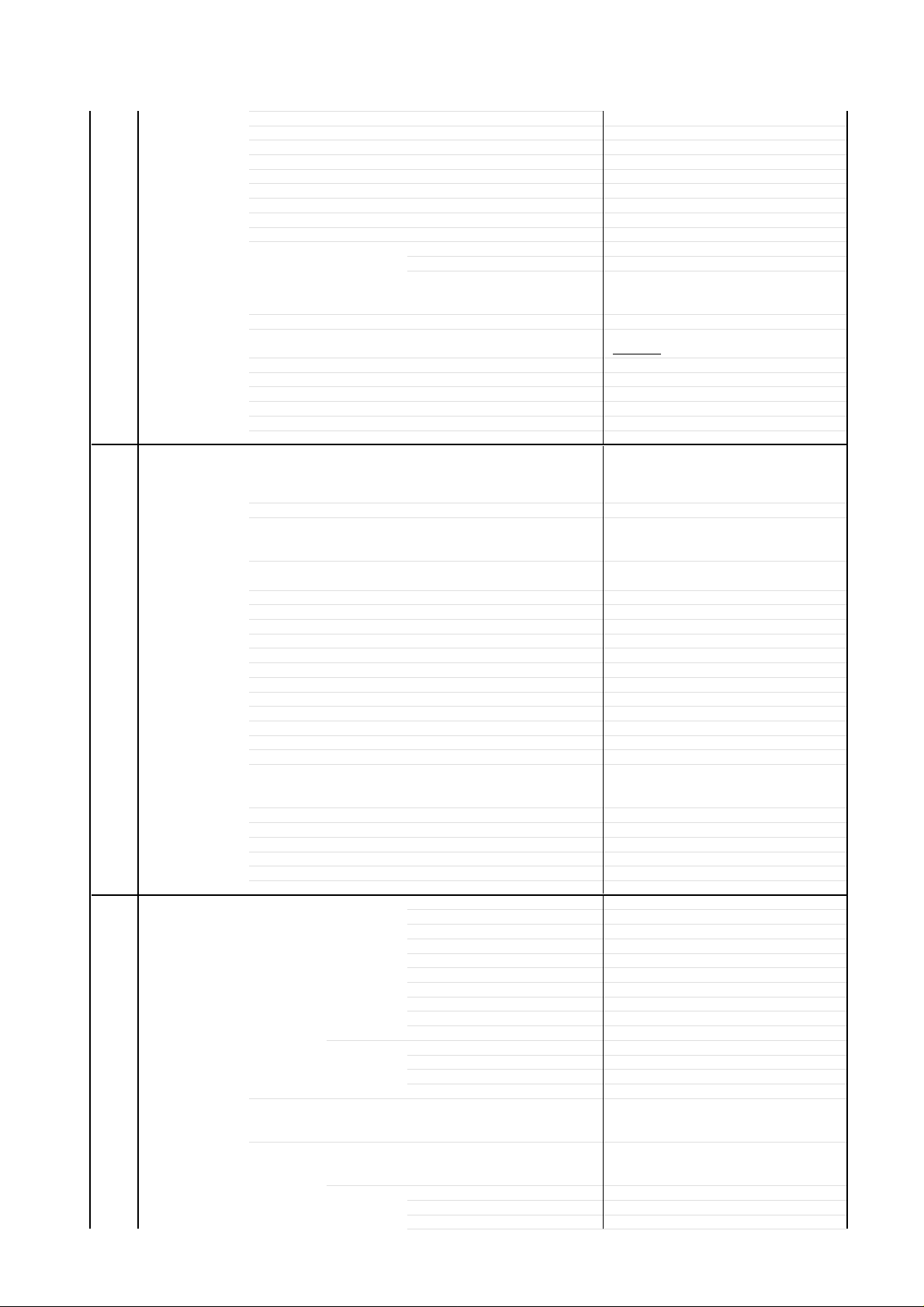

GENERAL SPECIFICATIONS

Sharpness Yes

Tuning Yes

Bass No

Treble No

Balance No

Nicam ST No

Tone 1/2 No

Pin Code No

AV Yes

Skip Yes

Channel Yes

Hotel Lock No

Sleep Timer Yes

Sound Mute Yes

G-8 OSD Language English French Spanish

G-9 Clock and Sleep Timer Max Time 120 Min

Timer Step 10 Min

On/Off Timer Program(On Timer / Off Timer) No

Wake Up Timer No

Timer Back-up (at Power Off Mode) more than -- Min Sec

G-10 Remote Unit RC-JP

Control Glow in Dark Remocon No

Format NEC

Custom Code 80-63 h

Power Source Voltage(D.C) 3V

Total Keys 24 Keys

Keys Power(Stand By) Yes

T'TEXT Keys TEXT / MIX / TV No

G-11 Features Auto Degauss Yes

Auto Shut Off Yes

Canal+ Yes

CATV Yes

Anti-theft No

Memory(Last CH) Yes

Memory(Last Volume) Yes

Back Light No

German Italian

UM size x pcs UM-4 x 2 pcs

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

0 Yes

TV/AV Yes

CH Up Yes

CH Down Yes

Volume Up / + Yes

Volume Down / - Yes

Quick View Yes

Sleep Yes

Info(CH Call) Yes

Normal No

Menu Yes

Enter No

Mute Yes

Fine Tuning + Yes

Fine Tuning - Yes

Skip Yes

Tone 1/2 No

CH Up / Page Up No

CH Down / Page Down No

Red No

Green No

Yellow / Fine Tuning - No

Cyan / Fine Tuning + No

F/T/B(Expand) / Normal No

Reveal / Skip No

Display Cancel No

Reset No

Reset / Tone 1/2 No

Hold / Status No

Sub Page / Quick View No

A3-2

GENERAL SPECIFICATIONS

BBE No

Auto Search Yes

CH Allocation Yes

Channel Lock No

Just Clock Function No

Game Position No

CH Label No

VM Circuit No

Full OSD No

T'Text No

Premiere No

Comb Filter No

Auto CH Memory Yes

Auto Set Up No

Stable Sound No

FBT Leak Test Protect No

Hotel Lock No

Power On Memory Yes

G-12 Accessories Owner's Manual Language Einglish/Germany/French/Spanish

Remote Control Unit Yes

Rod Antenna

Loop Antenna

U/V Mixer

DC Car Cord (Center+)

Guarantee Card Yes

Warning Sheet

Circuit Diagram

Antenna Change Plug

Service Facility List

Important Safeguard

Dew/AHC Caution Sheet

AC Plug Adapter

Short Instbook (Spa/Por/IT/Dutch/Fin/Swe/Dan/Nor)

Quick Set-up Sheet

Battery Yes

AC Cord

AV Cord (2Pin-1Pin)

Registration Card

Safety Strap

Printed Matter for Disney

300 ohm to 75 ohm Antenna Adapter

G-13 Interface Switch Front Power No

Rear AC/DC No

Indicator Power No

Terminals Front Video Input RCA x1

Rear Video Input(Rear1)

Text type Text Language -

Lines

Portuguese/Italian/Dutch/Finnish

w/Guarantee Card

Poles Terminal -

Terminal -

UM size x pcs UM-4 x 2 pcs

OEM Brand

System Select No

Main Power SW Yes

Sub Power No

Channel Up Yes

Channel Down Yes

Volume Up Yes

Volume Down Yes

Menu Yes

TV/AV Yes

TV/CATV Selector No

Degauss No

Main Power SW No

Stand-by Yes

On Timer No

Audio Input RCA x2

Other Terminal

Video Input(Rear2)

Audio Input(Rear1)

Swedish/Danish/Norwegian

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

Head Phone

No

No

No

A3-3

GENERAL SPECIFICATIONS

s

Audio Input(Rear2)

Video Output

Audio Output

Euro Scart(21Pin) Yes ( x1 )

Component Input

Diversity No

Ext Speaker No

DC Jack 12V(Center +) No

VHF/UHF Antenna Input

AC Outlet No

G-14 Set Size Approx. W x D x H (mm) 401.5 x 371 x 465.5

w/o Speaker,Legs Approx. W x D x H (mm)

G-15 Weight Net (Approx.) 11.0kg

Net w/o Speaker,Legs Approx. 9.5 kg

Gross (Approx.) 13.5kg

G-16 Carton Master Carton

Content ---Material --

Dimensions W x D x H(mm) -- x -- x --

Description of Origin

Gift Box Yes

Material Double/Full Color

Dimensions W x D x H(mm) 493 x 423 x 465

Design As per Buyer's

Description of Origin

Drop Test

Height (cm) 62

Container Stuffing

G-17 Material Cabinet Cabinet Front PS 94HB

Cabinet Rear PS 94HB

Cover Yes

PCB Non-Halogen Demand

Eyelet Demand

G-18 Environment Environmental

Pb-free Phase3 (Phase3A)

WEEE Yes

Din Type

401.5 x 371 x 350

Natural Dropping At 1 Corner / 3 Edges / 6

640

Green procurement of ORION

No

No

No

No

( 24.3lbs)

( 20.9lbs )

( 29.8lbs)

No

Sets

/--

No

No

Surfaces

Sets/40' container

No

No

A3-4

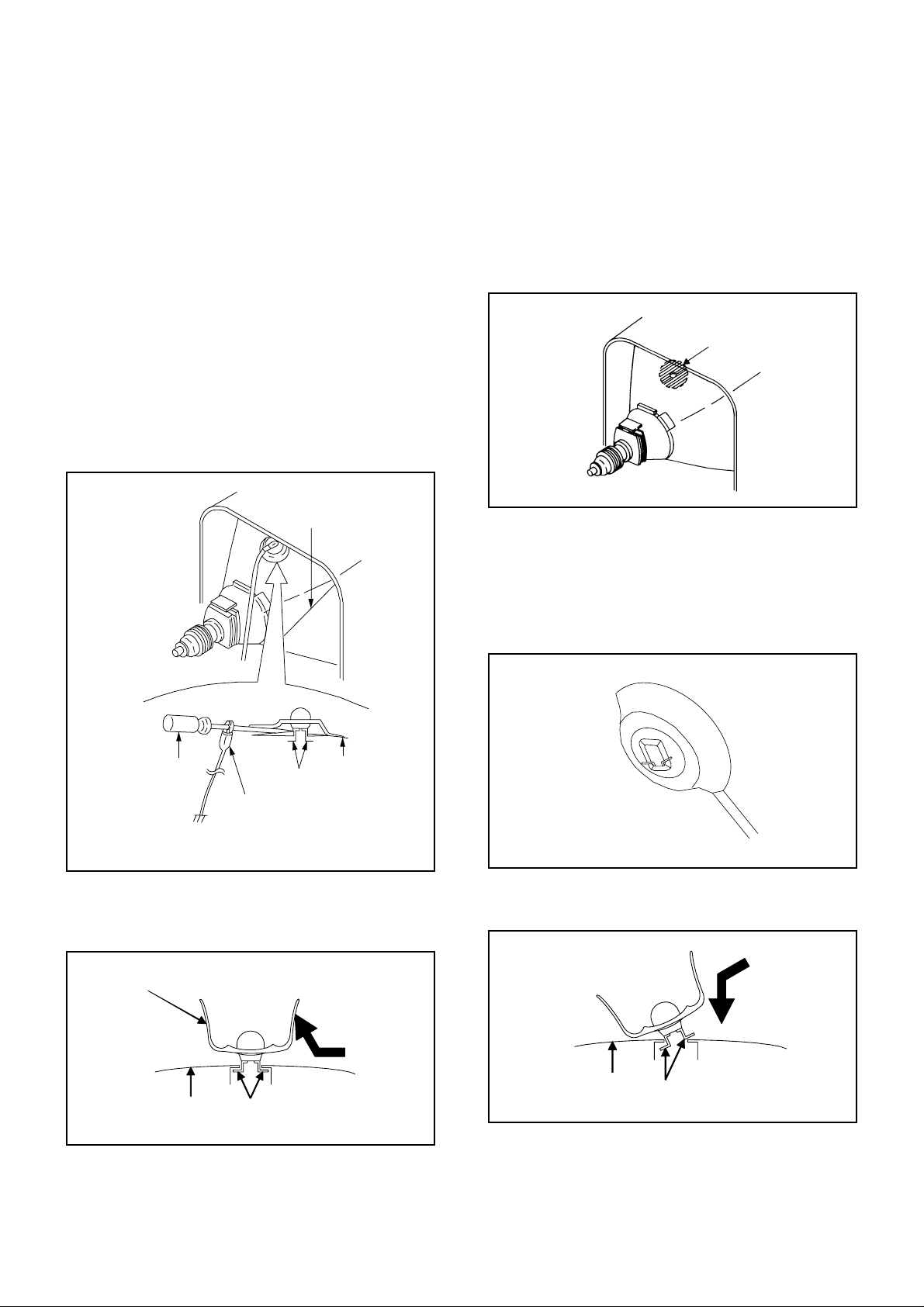

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF ANODE CAP

Read the following NOTED items before starting work.

After turning the power off there might still be a potential

*

voltage that is very dangerous. When removing the

Anode Cap, make sure to discharge the Anode Cap's

potential voltage.

Do not use pliers to loosen or tighten the Anode Cap

*

terminal, this may cause the spring to be damaged.

REMOVAL

1. Follow the steps as follows to discharge the Anode Cap.

(Refer to Fig. 1-1.)

Connect one end of an Alligator Clip to the metal part of

a flat-blade screwdriver and the other end to ground.

While holding the plastic part of the insulated screwdriver,

touch the support of the Anode with the tip of the

screwdriver.

A cracking noise will be heard as the voltage is discharged.

GND on the CRT

3. After one side is removed, pull in the opposite direction to

remove the other.

NOTE

Take care not to damage the Rubber Cap.

INSTALLATION

1. Clean the spot where the cap was located with a small

amount of alcohol. (Refer to Fig. 1-3.)

Location of Anode Cap

Fig. 1-3

NOTE

Confirm that there is no dirt, dust, etc. at the spot where

the cap was located.

2.3.Arrange the wire of the Anode Cap and make sure the

wire is not twisted.

Turn over the Rubber Cap. (Refer to Fig. 1-4.)

Screwdriver

Alligator Clip

GND on the CRT

Flip up the sides of the Rubber Cap in the direction of the

2.

arrow and remove one side of the support.

(Refer to Fig. 1-2.)

Rubber Cap

CRT

Support

Support

CRT

Fig. 1-1

Fig. 1-2

Fig. 1-4

4. Insert one end of the Anode Support into the anode button,

then the other as shown in Fig. 1-5.

CRT

Support

Fig. 1-5

5.6.Confirm that the Support is securely connected.

Put on the Rubber Cap without moving any parts.

B1-1

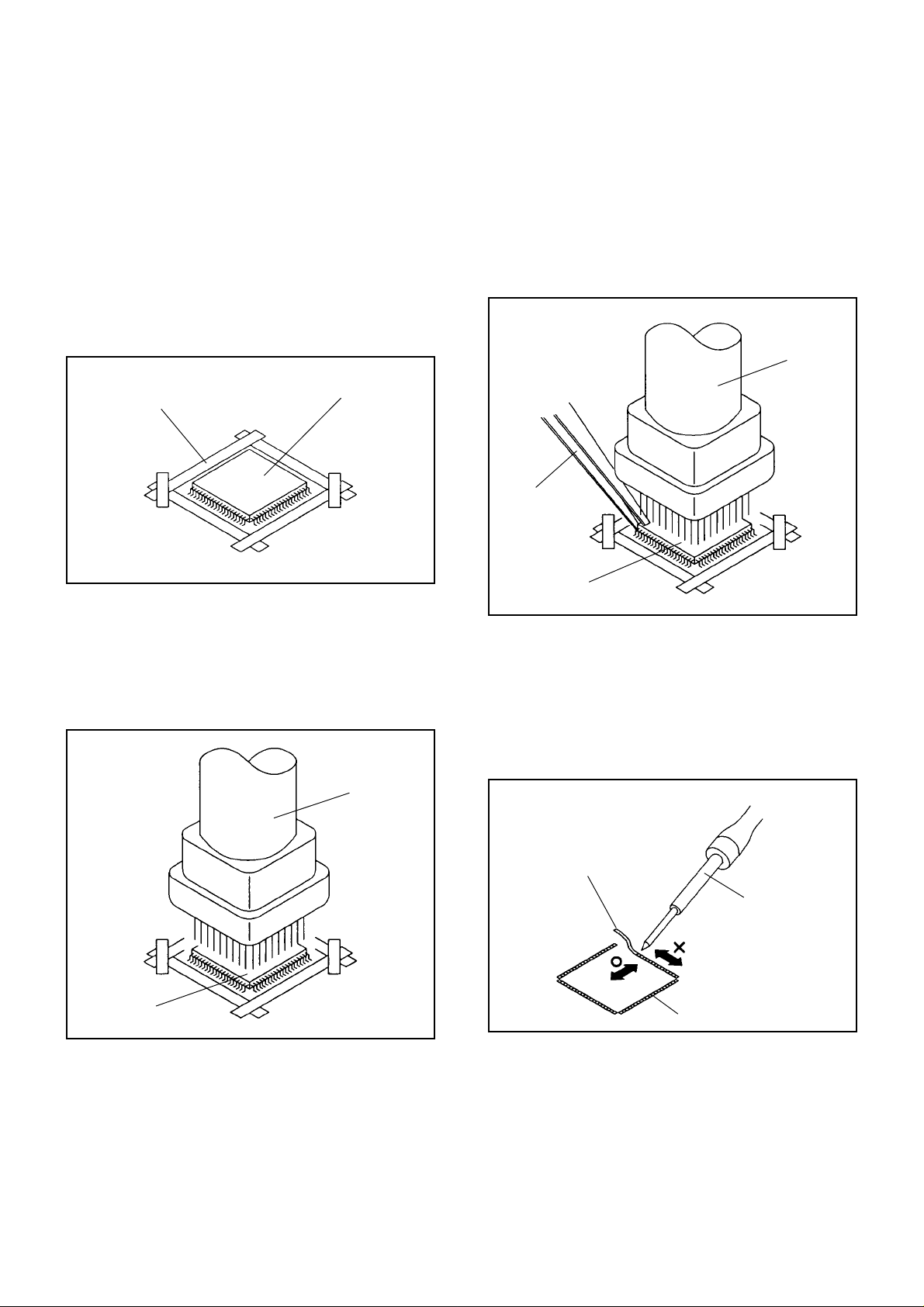

DISASSEMBLY INSTRUCTIONS

2.

REMOVAL AND INSTALLATION OF

FLAT PACKAGE IC

REMOVAL

Put Masking Tape (cotton tape) around the Flat Package

1.

IC to protect other parts from any damage.

(Refer to Fig. 2-1.)

NOTE

Masking is carried out on all the parts located within

10 mm distance from IC leads.

When IC starts moving back and forth easily after

3.

desoldering completely, pickup the corner of the IC using

a tweezers and remove the IC by moving with the IC

desoldering machine. (Refer to Fig. 2-3.)

NOTE

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

leads or solder lands under the IC when removing it.

Blower type IC

desoldering

machine

Masking Tape

(Cotton Tape)

Heat the IC leads using a blower type IC desoldering

2.

IC

machine. (Refer to Fig. 2-2.)

NOTE

Do not rotate or move the IC back forth until IC can

move back and forth easily after desoldering the

leads completely.

Blower type IC

desoldering machine

Fig. 2-1

Tweezers

IC

Peel off the Masking Tape.4.

Absorb the solder left on the pattern using the Braided

5.

Shield Wire. (Refer to Fig. 2-4.)

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Fig. 2-3

Braided Shield Wire

Soldering Iron

IC

Fig. 2-2

IC pattern

Fig. 2-4

B2-1

Loading...

Loading...