Page 1

AP3595

Document number: DS36749 Rev. 1 - 2

1 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

Description

The AP3595 is a compact dual phase synchronous rectified buck

controller specifically designed to deliver high quality output voltage.

This device operates at adjustable operation frequency and is

capable of delivering up to 60A output current.

This controller integrates internal MOSFET drivers that support

12V+12V bootstrapped voltage for high efficiency power conversion.

The bootstrap diode is built-in to simplify the circuit design and

minimize external part count.

The AP3595 features configurable gate driving voltage for maximum

efficiency and optimal performance. The built-in bootstrap diode

simplifies the circuit design and reduces external part count and PCB

space. The output voltage is precisely regulated to the reference input

that is dynamically adjustable by external voltage divider.

Other features include adjustable soft start, adjustable operation

frequency, and quick response to step-load transient. With aforementioned functions, the IC provides customers a compact, high

efficiency, well-protected and cost-effective solution.

This IC is available in U-QFN4040-24 package.

Features

Operate with Single Supply Voltage

Simple Single Loop Voltage Mode Control

12V+12V Bootstrapped Drivers with Internal Bootstrap Diode

Adjustable Over Current Protection by DCR

Current Sensing

Adjustable Current Balancing by R

DS(ON)

Current Sensing

Adjustable Operation Frequency from 50kHz to 1MHz Per Phase

External Compensation

Dynamic Output Voltage Adjustment

Adjustable Soft Start

U-QFN4040-24 Package

RoHS Compliant and 100% Lead (Pb)-free

Totally Lead-free & Fully RoHS Compliant (Note1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

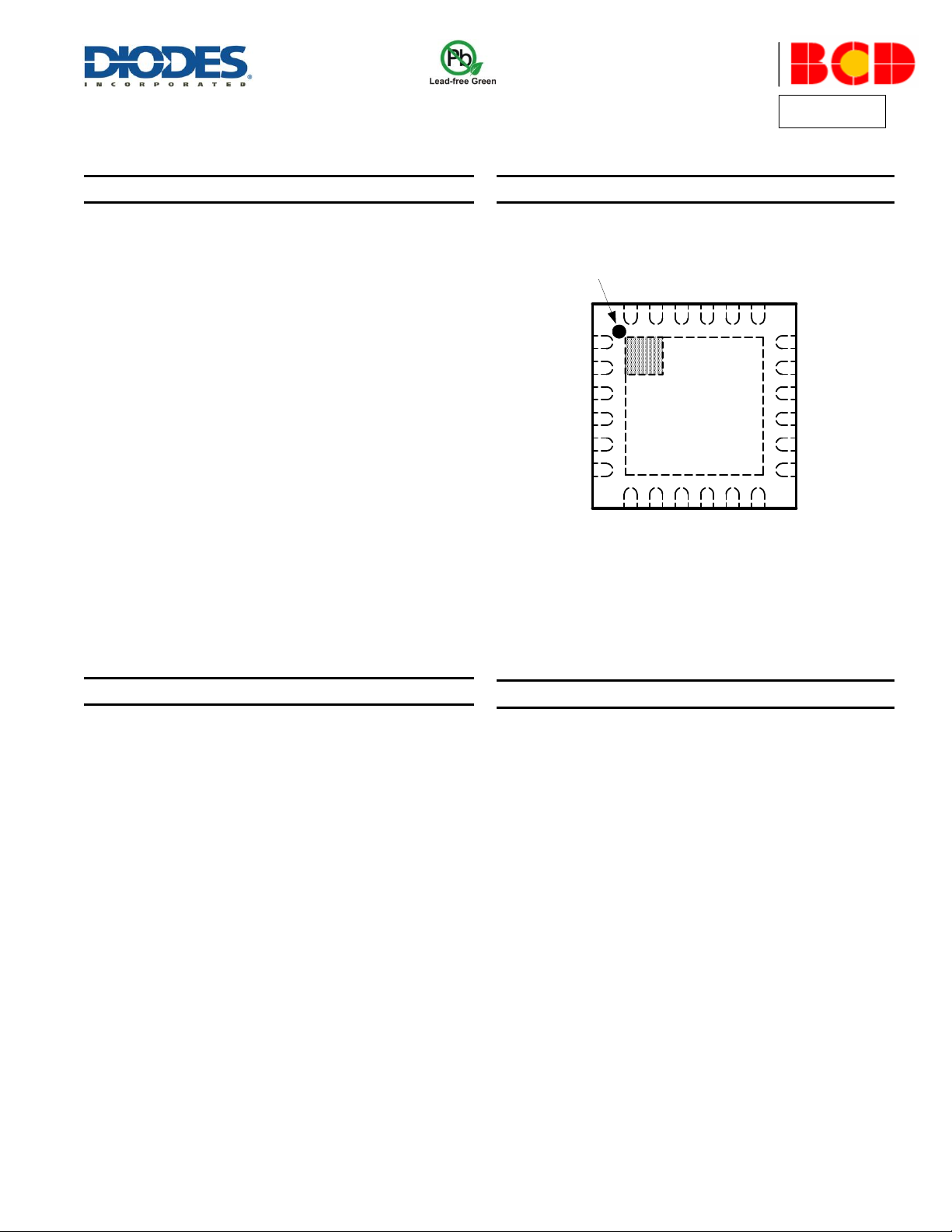

Pin Assignments

(Top View)

LG2

PHASE2

HG2

BOOT2

VID

RSET

PSI

CSP

CSN

SS

EAP

FBRTN

FB

COMP

IOFS

RT/EN

VREF

REFIN

VCC

PVCC

LG1

PHASE1

HG1

BOOT1

Pin 1 Mark

EP

1

10

2

3

4

5

6

7 8 9 11 12

13

14

15

16

17

18

192021222324

U-QFN4040-24 (FN Package)

Applications

Middle-High End GPU Core Power

High End Desktop PC Memory Core Power

Low Output Voltage, High Power Density

DC-DC Converters

Voltage Regulator Modules

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

DUAL PHASE SYNCHRONOUS RECTIFIED BUCK CONTROLLER

Page 2

AP3595

Document number: DS36749 Rev. 1 - 2

2 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

AP3595

BOOT1

HG1

PHASE1

LG1

VCC

V

OUT

V

IN

BOOT2

HG2

PHASE2

LG2

FBRTN

FB

COMP

RT/EN

GND

VID

EAP

RSET

SS

REFIN

VREF

IOFS

PSI

PVCC

CSP

FBRTN

CSN

PHASE2

PHASE1

V

OUT

17

11

10

12

4

2

1

24

9

8

23

3

5

6

7

19

20

21

22

16

15

14

13

18

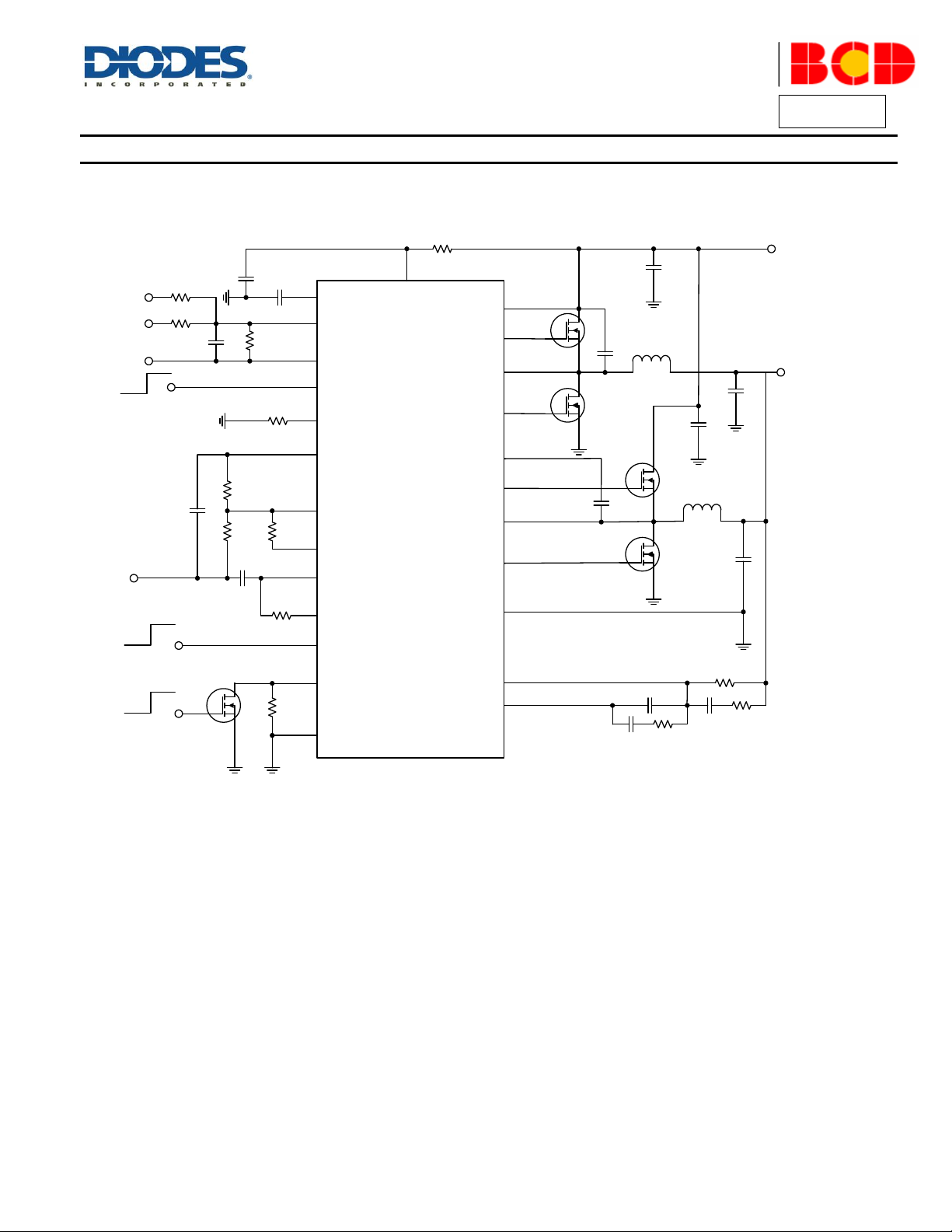

Typical Applications Circuit

Page 3

AP3595

Document number: DS36749 Rev. 1 - 2

3 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

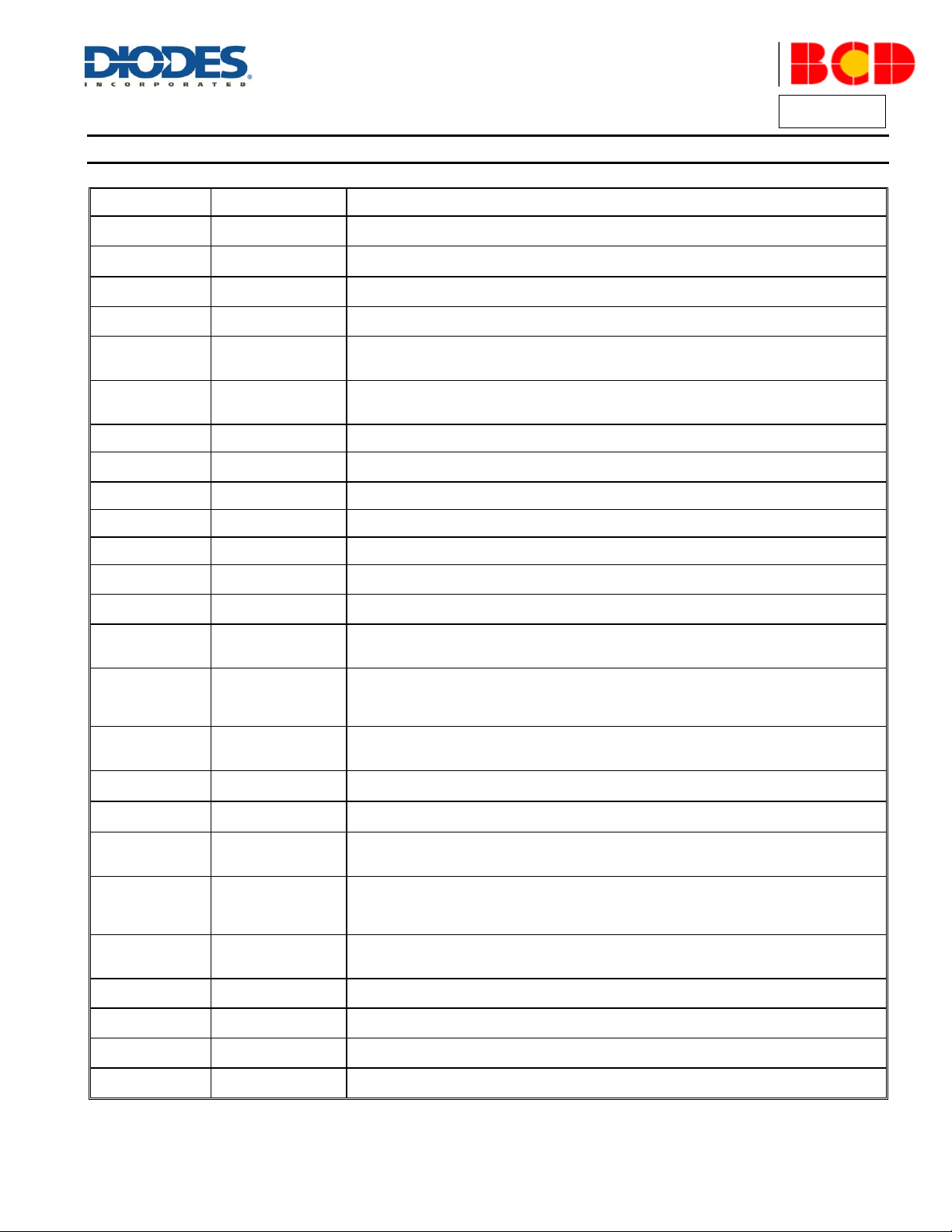

Pin Number

Pin Name

Function

1

REFIN

External Reference Input. This is the input pin of external reference voltage. Connect a voltage

divider from VREF to REFIN and FBRTN to set the reference voltage

2

VREF

Output for Reference Voltage. This is the output pin of high precision 2V reference voltage.

Bypass this pin with a 1F ceramic capacitor to FBRTN

3

RT/EN

Operation Frequency Setting. Connecting a resistor between this pin and GND to set the

operation frequency. Pull this pin to ground to shut down the AP3595

4

IOFS

Current Balance Adjustment. Connect a resistor from this pin to VREF or GND to adjust the

current sharing

5

COMP

Error Amplifier Output. This is the output of the error amplifier (EA) and the non-inverting input

of the PWM comparators. Use this pin in combination with the FB pin to compensate the

voltage control feedback loop of the converter

6

FB

Feedback Voltage. This pin is the inverting input to the error amplifier. Use this pin in

combination with the COMP pin to compensate the voltage control feedback loop of the

converter

7

FBRTN

Feedback Return. Connect this pin to the ground where the output voltage is to be regulated

8

EAP

Non-inverting Input of Error Amplifier. Connect a resistor from this pin to SS pin to set the

droop slope

9

SS

Soft Start Output. Connect a capacitor to FBRTN to set the soft start interval

10

CSN

Negative Input for Current Sensing Amplifier

11

CSP

Positive Input for Current Sensing Amplifier

12

PSI

Power Saving Mode. Connect this pin to VREF for always two phase operation. Short this pin

to ground for always single phase operation

13

BOOT1

Bootstrap Supply for the Floating Upper Gate Driver of Channel 1. Connect a bootstrap

capacitor between BOOT1 pin and the PHASE1 pin to form a bootstrap circuit

14

HG1

Upper Gate Driver Output for Channel 1. Connect this pin to the gate of upper MOSFET. This

pin is monitored by the adaptive shoot-through protection circuitry to determine when the upper

MOSFET has turned off

15

PHASE1

Switch Node for Channel 1. Connect this pin to the source of the upper MOSFET and the drain

of the lower MOSFET. This pin is used as the sink for the Upper GATE driver. It is also

monitored by the adaptive shoot-through protection circuitry to determine when the upper

MOSFET has turned off

16

LG1

Lower Gate Driver Output for Channel 1. Connect this pin to the gate of lower MOSFET. This

pin is monitored by the adaptive shoot-through protection circuitry to determine when the lower

MOSFET has turned off

17

PVCC

Supply Voltage for Gate Driver. This pin is the output of internal 9V LDO. This pin provides

current for gate drivers. Bypass this pin with a minimum 1F ceramic capacitor

18

VCC

Supply Voltage. This pin provides current for internal control circuit and 9V LDO. Bypass this

pin with a minimum 1F ceramic capacitor next to the IC

19

LG2

Lower Gate Driver Output for Channel 2. Connect this pin to the gate of lower MOSFET. This

pin is monitored by the adaptive shoot-through protection circuitry to determine when the lower

MOSFET has turned off

20

PHASE2

Switch Node for Channel 2. Connect this pin to the source of the upper MOSFET and the drain

of the lower MOSFET. This pin is used as the sink for the HG2 driver. It is also monitored by

the adaptive shoot-through protection circuitry to determine when the upper MOSFET has

turned off

21

HG2

Upper Gate Driver Output for Channel 2. Connect this pin to the gate of upper MOSFET. This

pin is monitored by the adaptive shoot-through protection circuitry to determine when the upper

MOSFET has turned off

22

BOOT2

Bootstrap Supply for the Floating Upper Gate Driver of Channel 2. Connect a bootstrap

capacitor between BOOT2 pin and the PHASE2 pin to form a bootstrap circuit

23

VID

VID Input. This pin is used to adjust the reference voltage. Logic high enables the internal

MOSFET connected to RSET pin

24

RSET

Reference Voltage Setting. This pin is an open drain output that is pulled low when VID sets to

high. Connect a resistor from this pin to REFIN pin to set the reference voltage

Exposed Pad

GND

Power Ground. Tie this pin to the ground island/plane through the lowest available impedance

connection

Pin Descriptions

Page 4

AP3595

Document number: DS36749 Rev. 1 - 2

4 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

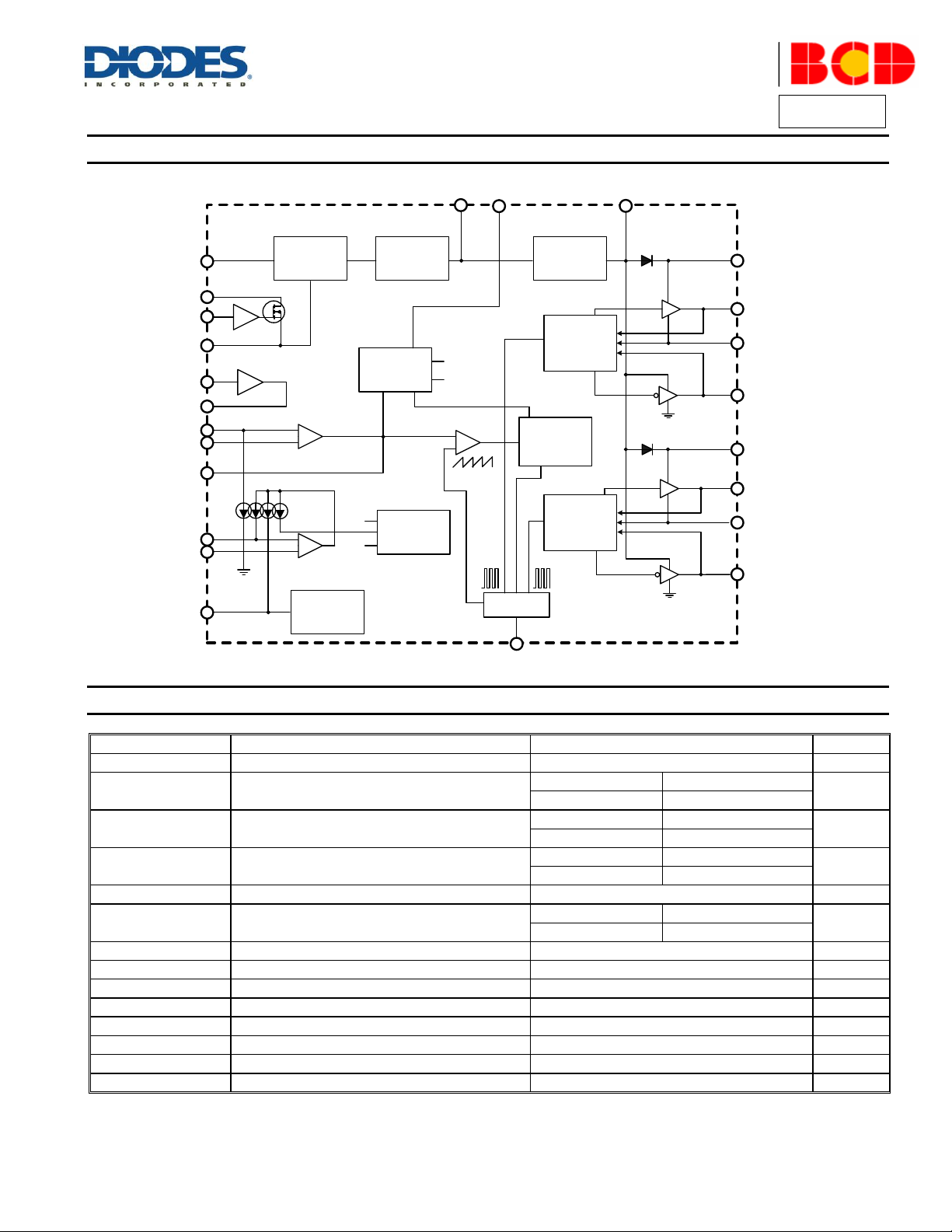

Reference

Voltage

POR

Internal

Regulator

Gate

Control

Logic

DUAL PHASE

Control

Gate

Control

Logic

OCP

OVP

UVP

Power Saving

Setting

Oscillator

+

-

BOOT1

HG1

PHASE1

LG1

BOOT2

HG2

LG2

PVCC

+

-

PWM

Current

Balance

RT/EN

PHASE1

PHASE2

IOFS

VREF

RSET

VID

FBRTN

REFIN

SS

EAP

FB

Error

Amplifier

COMP

+

-

CSN

CSP

PSI

FB

SS

VCC

2

24

23

1

9

8

6

5

10

11

12

3

19

20

15

21

22

16

14

13

17

4

18

PHASE2

7

Symbol

Parameter

Rating

Unit

VCC

Supply Input Voltage

-0.3 to 15

V

V

PHASE

PHASE to GND Voltage

DC

-0.3 to 15

V

<200ns

-5 to 30

VHG

HG to PHASE Voltage

DC

-0.3 to V

BOOT-PHASE

+0.3

V

<200ns

-5 to V

BOOT-PHASE

+5

VLG

LG to GND Voltage

DC

-0.3 to VCC+0.3

V

<200ns

-5 to VCC+5

–

BOOT to PHASE Voltage

15

V

V

BOOT

BOOT to GND Voltage

DC

-0.3 to V

PHASE

+15

V

<200ns

-0.3 to 42

Input, Output or I/O Voltage

-0.3 to 6

V

PD

Power Dissipation

2.5

W

JA

Thermal Resistance (Junction to Ambient)

40

°C/W

T

STG

Storage Temperature Range

-65 to +150

ºC

TJ

Junction Temperature

+150

ºC

T

LEAD

Lead Temperature (Soldering, 10sec)

+260

ºC

V

HBM

ESD (Human Body Model)

2000

V

V

MM

ESD (Machine Model)

200

V

Functional Block Diagram

Absolute Maximum Ratings(Note 4)

Note 4: Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “Recommended Operating Conditions” is not implied.

Exposure to “Absolute Maximum Ratings” for extended periods may affect device reliability.

Page 5

AP3595

Document number: DS36749 Rev. 1 - 2

5 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

Symbol

Parameter

Min

Max

Unit

VCC

Supply Input Voltage

10.8

13.2

V

TA

Operating Ambient Temperature

-40

+85

°C

TJ

Operating Junction Temperature

-40

+125

°C

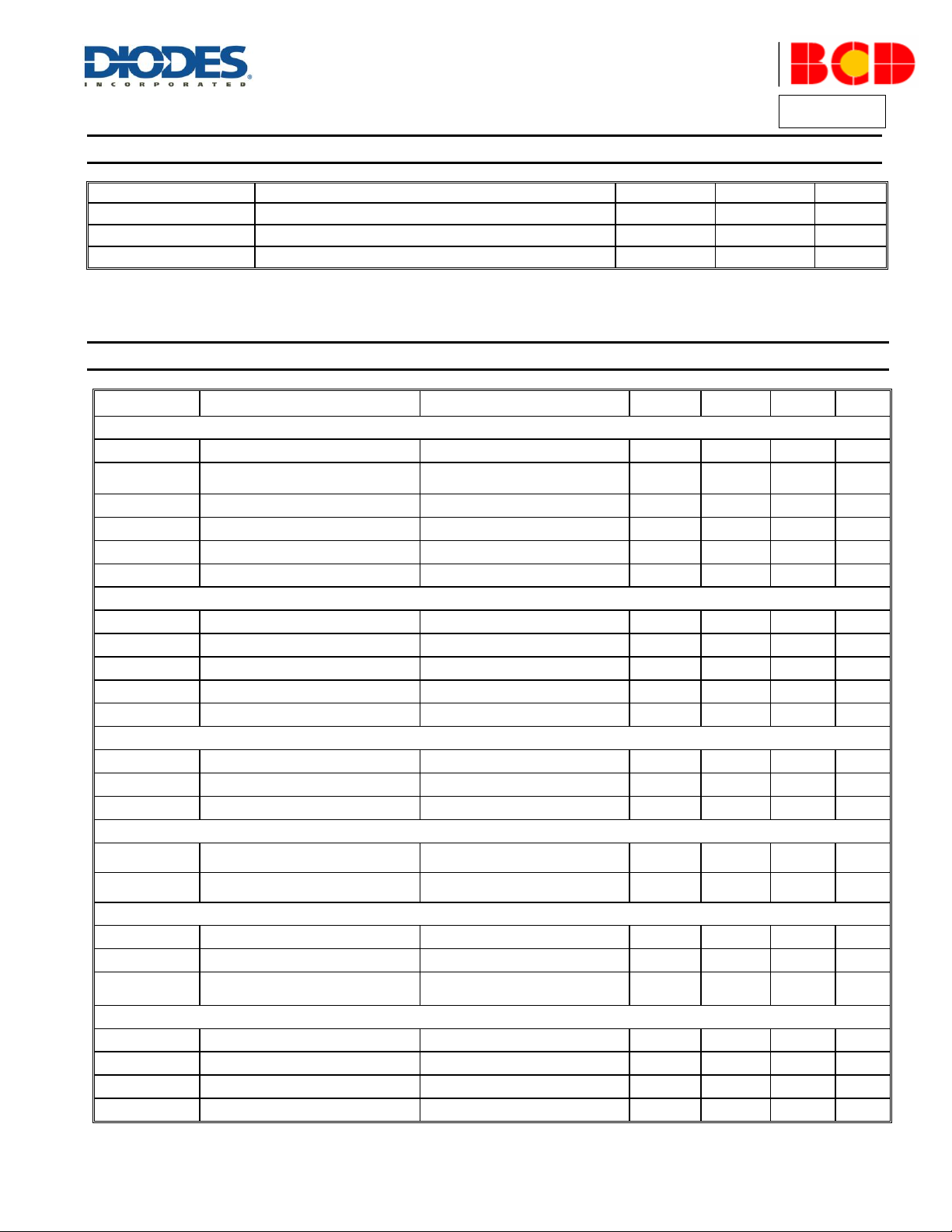

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

SUPPLY INPUT

VCC

Supply Input Voltage

–

10.8

–

13.2

V

ICC

Supply Current

HG and LG Open, VCC=12V,

Switching

– 5 –

mA

IQ

Quiescent Current

No Switching, I

PCC

=0mA

– 4 –

mA

V

PCC

Regulated Supply Voltage

RT/EN=0V, I

PCC

=0mA

8 9 10

V

V

RTH

POR Threshold

–

8 9 10

V

V

HYS

POR Hysteresis

–

– 1 –

V

CHIP ENABLE/FREQUENCY SETTING

I

RT/EN

RT/EN Sourcing Current

V

RT/EN

=GND

100

150

200

A

V

RT/EN

RT/EN Voltage

RRT=33kΩ

– 1 – V –

Switching Frequency Setting Range

–

50 – 1000

kHz

f

OSC

Free Run Switching Frequency

RRT=33kΩ

270

300

330

kHz

△f

OSC

Switching Frequency Accuracy

f

OSC

=200kHz to 500kHz

-15 – 15

%

OSCILLATOR

–

Maximum Duty Cycle

–

–

40 – %

–

Minimum Duty Cycle

–

– 0 –

%

V

OSC

Ramp Amplitude

VCC=12V

–

3.5 – V

POWER SAVING MODE

V

PSI_H

Threshold Voltage for Entering Dual

Phase

V

PSI

rising

1.2 – –

V

V

PSI_L

Threshold Voltage for Entering

Single Phase

V

PSI

falling

– – 0.4

V

REFERENCE VOLTAGE

V

REF

Reference Voltage Accuracy

I

REF

=100A

1.98

2.0

2.02

V

△V

REF

Reference Voltage Load Regulation

I

REF

=0 to 2mA

-5 – 5

mV

△V

FB

Output Voltage Accuracy

|V

REFIN-VFB

|, VCC=12V, No Load,

R

DRP

=0, V

REFIN

=0.8V to 1.6V

– – 5

mV

ERROR AMPLIFIER

AO

Open Loop DC Gain

Guaranteed by design

70

80 – dB

GBW

Gain Bandwidth Product

C

LOAD

=5pF, Guaranteed by design

–

20 – MHz

SR

Slew Rate

Guaranteed by design

15

20

–

V/s

I

COMP

Maximum Current (Sink and Source)

V

COMP

=1.6V

1.5

2.0 – mA

Recommended Operating Conditions

Electrical Characteristics (@V

=12V, TA=+25C, unless otherwise specified.)

CC

Page 6

AP3595

Document number: DS36749 Rev. 1 - 2

6 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

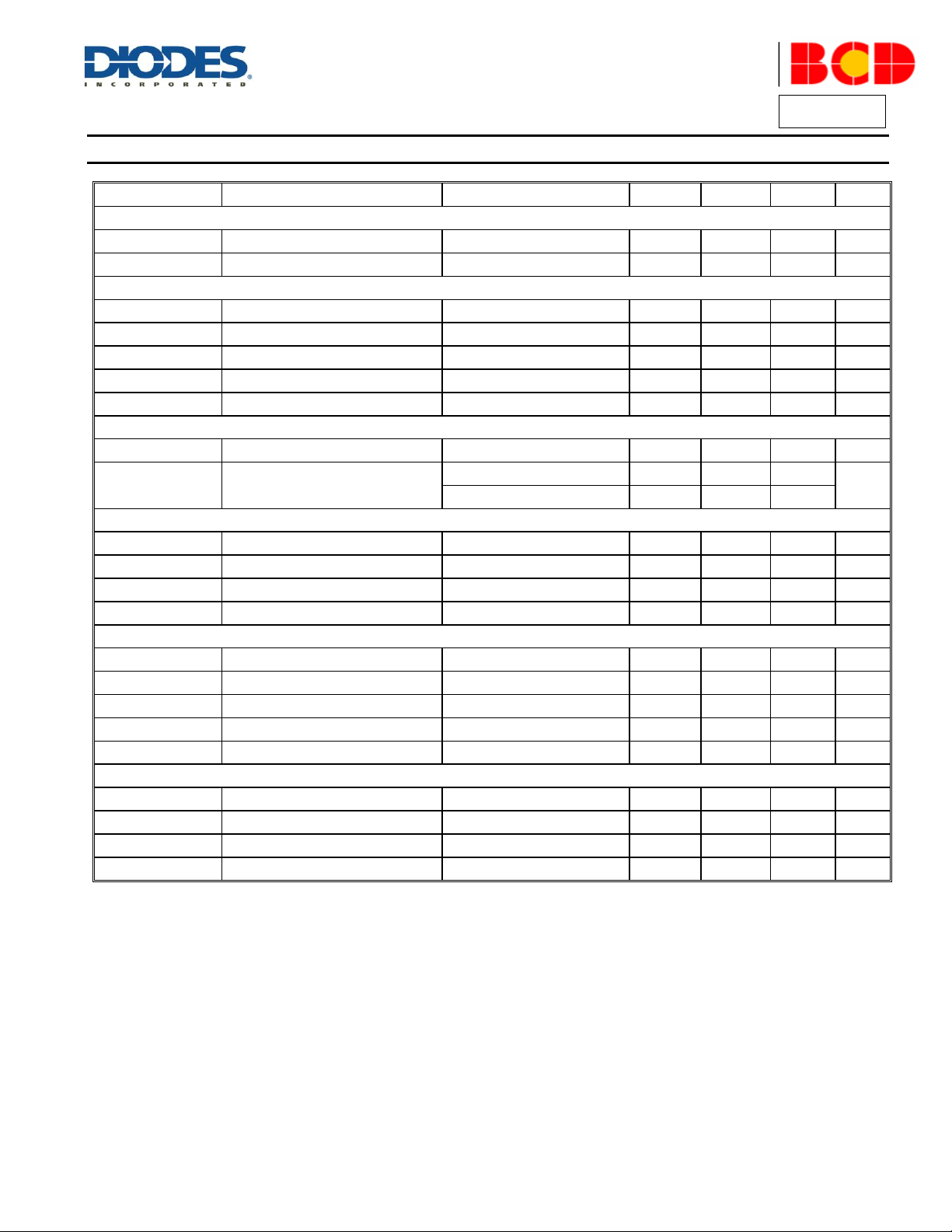

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

SOFT START

ISS

Soft Start Current

During soft start

–

22

–

A

I

SS_CC

Supply Current

After soft start end

–

200

–

A

TOTAL CURRENT SENSE

I

CSN_MAX

Maximum Sourcing Current

–

100 – –

A

–

GM Amplifier Offset Voltage

–

-5 0 5

mV

I

CSN_OCP

Over Current Protection Threshold

–

–

60

–

A

I

DRP/ICSN

Droop Accuracy

–

90

100

110

%

I

PSI/ICSN

PSI Accuracy

–

90

100

110

%

PHASE CURRENT SENSE

–

Trans-conductance

–

–

1.0 – mS

V

OFS

IOFS Voltage

100kfrom IOFS to VREF

–

1.5

–

V

100kfrom IOFS to GND

–

0.5

–

VID CONTROL INPUT

VIH

Logic High Threshold Level

–

1.2 – –

V

VIL

Logic Low Threshold Level

–

– – 0.4

V

R

RSET

On Resistance of RSET MOSFET

VID=High

–

20

–

I

RSET

Leakage Current of RSET Pin

V

RSET

=2V, VID=0V

– – 0.1

A

GATE DRIVER

I

HG_SRC

Upper Gate Sourcing Current

V

BOOT-VPHASE

=6V

–

1.2 – A

R

HG_SNK

Upper Gate Sinking Resistance

IHG=100mA sinking

–

1.5

3

I

LG_SRC

Lower Gate Sourcing Current

V

PCC-VLG

=6V

–

1.2 – A

R

LG_SNK

Lower Gate Sinking Resistance

ILG=100mA sinking

– 1 2

tDT

Dead Time

–

–

50 – ns

PROTECTION

VFB-VSS

Over Voltage Protection

–

–

300 – mV

VFB-VSS

Under Voltage Protection

–

–

-300

–

mV

–

Over Temperature Protection

–

–

+150

–

°C

–

Over Temperature Hysteresis

–

–

+20 – °C

Electrical Characteristics (Cont.) (@V

=12V, TA=+25C, unless otherwise specified.)

CC

Page 7

AP3595

Document number: DS36749 Rev. 1 - 2

7 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

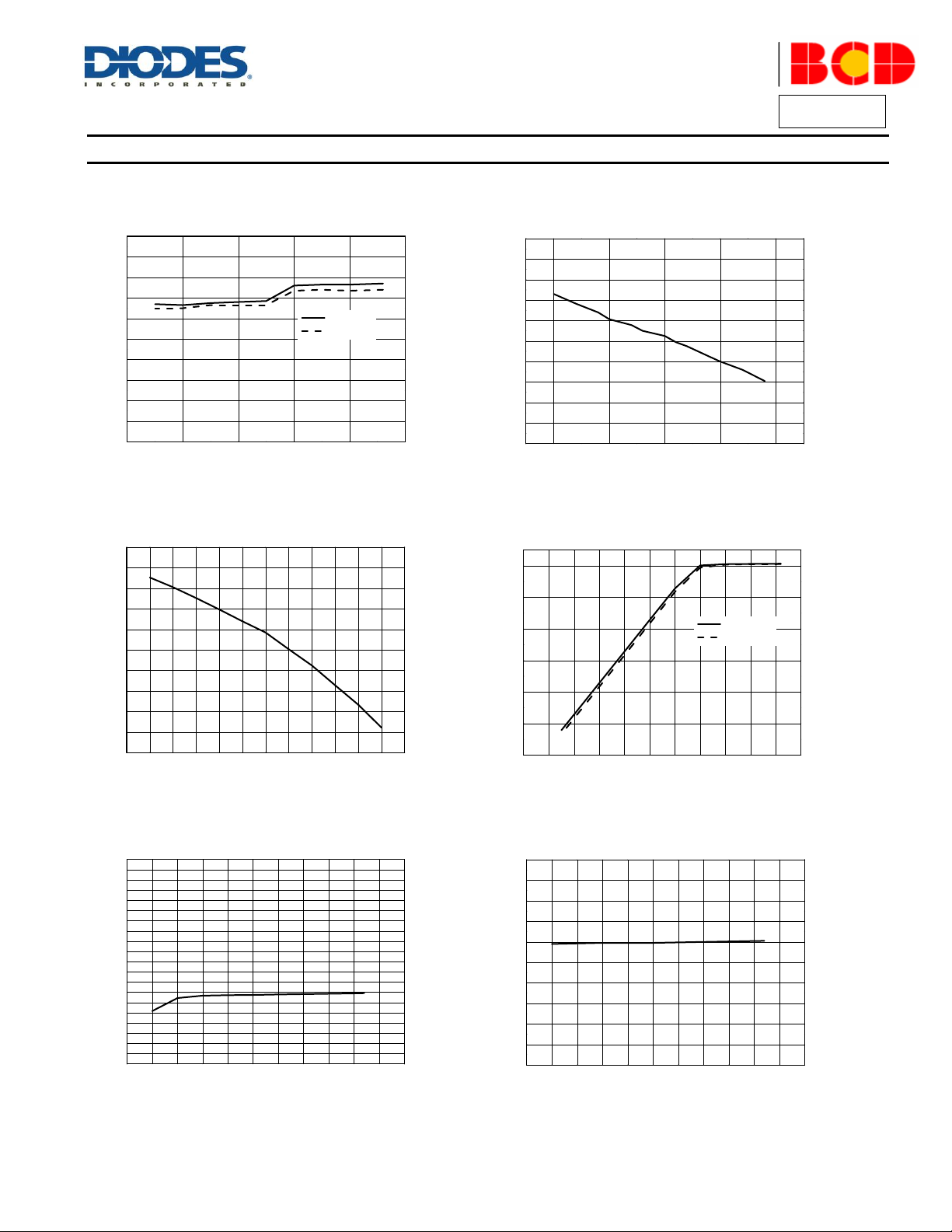

4 6 8 10 12 14

1.980

1.982

1.984

1.986

1.988

1.990

1.992

1.994

1.996

1.998

2.000

V

REF

(V)

VCC (V)

I

LOAD

=0mA

I

LOAD

=2mA

0 5 10 15 20

1.980

1.982

1.984

1.986

1.988

1.990

1.992

1.994

1.996

1.998

2.000

V

REF

(V)

I

LOAD

(mA)

0 20 40 60 80 100

8.85

8.90

8.95

9.00

9.05

9.10

V

PCC

(V)

I

LOAD

(mA)

4 6 8 10 12 14

3

4

5

6

7

8

9

V

PCC

(V)

VIN (V)

I

LOAD

=0mA

I

LOAD

=10mA

9 10 11 12 13 14

4.6

4.8

5.0

5.2

5.4

5.6

5.8

6.0

6.2

6.4

I

CC

(mA)

VIN (V)

9 10 11 12 13 14

290

292

294

296

298

300

302

304

306

308

310

f

OSC

(kHz)

VIN (V)

Performance Characteristics

V

V

Line Regulation V

REF

Load Regulation V

PCC

ICC vs.V

IN

f

Load Regulation

REF

Line Regulation

PCC

vs.V

OSC

IN

Page 8

AP3595

Document number: DS36749 Rev. 1 - 2

8 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

10 100

10

100

1000

f

OSC

(kHz)

RRT (k)

-40 -20 0 20 40 60 80 100 120 140

8.96

8.98

9.00

9.02

9.04

9.06

9.08

9.10

V

PCC

(V)

Temperature (oC)

I

LOAD

=0mA

I

LOAD

=10mA

-40 -20 0 20 40 60 80 100 120 140

1.980

1.982

1.984

1.986

1.988

1.990

1.992

1.994

1.996

1.998

2.000

V

REF

(V)

Temperature (oC)

-40 -20 0 20 40 60 80 100 120 140

290

292

294

296

298

300

302

304

306

308

310

f

OSC

(kHz)

Temperature (oC)

Time 200s/div

V

PHASE1

10V/div

V

RT/EN

1V/div

V

OUT

1V/div

V

SS

1V/div

V

PHASE1

10V/div

V

RT/EN

1V/div

V

OUT

1V/div

V

SS

1V/div

Time 4ms/div

Performance Characteristics (Cont.)

f

OSC

vs. R

V

RT

V

vs. Temperature f

REF

Power On Waveforms Power Off Waveforms

vs. Temperature

PCC

vs. Temperature

OSC

Page 9

AP3595

Document number: DS36749 Rev. 1 - 2

9 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

Time 200s/div

V

PHASE1

10V/div

V

RT/EN

1V/div

V

OUT

1V/div

V

SS

500mV/div

V

PHASE1

10V/div

V

RT/EN

1V/div

V

OUT

1V/div

V

SS

500mV/div

Time 1ms/div

Time 40ns/div

V

HG

5V/div

V

PHASE

5V/div

V

LG

5V/div

V

HG

5V/div

V

LG

5V/div

Time 40ns/div

V

PHASE

5V/div

V

HG VLG

V

HG VLG

V

PHASE

V

PHASE

Time 2ms/div

V

PSI

2V/div

V

PHASE1

10V/div

V

PHASE2

10V/div

VFB

1V/div

V

HG1

5V/div

V

LG1

5V/div

Time 4s/div

Performance Characteristics (Cont.)

EN On Waveform EN Off Waveform

Dead Time 1 Dead Time 2

OVP Function PSI Function

Page 10

AP3595

Document number: DS36749 Rev. 1 - 2

10 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

V

ID

5V/div

Time 2ms/div

V

OUT

200mV/div

Performance Characteristics (Cont.)

VID Change

Application Information

1. Overview

AP3595 is a dual-phase synchronous-rectified buck controller designed to deliver high quality output voltage for high power applications. It is

capable of delivering up to 60A output current with embedded bootstrapped drivers that support 12V+12V driver capability. The built-in bootstrap

diode simplifies the circuit design and reduces external part count and PCB space.

The output voltage is precisely regulated to the reference input that is dynamically adjustable by external voltage divider. The adjustable current

balance is achieved by R

AP3595 features comprehensive protection functions including over current protection, input/output under voltage protection, over voltage

protection and over temperature protection.

Other features include adjustable soft start, adjustable operation frequency, and quick response to step load transient. With aforementioned

functions, the IC provides customer a compact, high efficiency, well-protected and cost effective solution.

2. Power on Reset

A Power On Reset (POR) circuitry continuously monitors the supply voltage at VCC. Once the rising POR threshold is exceeded, the AP3595 sets

itself to active state and is ready to accept chip enable command. The rising POR threshold is typically 9V.

3. Soft Start

The AP3595 initiates its soft start cycle when the RT/EN pin is released from ground once the POR is granted as shown in Figure 1.

current sensing technique.

DS(ON)

Figure 1. Soft Start Cycle (R

DRP

=0)

Page 11

AP3595

Document number: DS36749 Rev. 1 - 2

11 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

)(

)(

10000

kHz

kR

f

FS

OSC

A1210RII

3

)ON(DSLXCSX

SS

FBEAP

SS

C

A

dt

dV

dt

dV

dt

dV

22

SS

FBEAP

SS

C

A

dt

dV

dt

dV

dt

dV

200

R

FS

(k)

Sample

&Hold

Current

Balance

I

CS1

I

CS2

_

+

Reference

Voltage

+

_

PHASE

Application Information (Cont.)

As mentioned in the above section, the slew rate of voltage transition at SS pin and V

capacitor connected to the SS pin. This reduces inrush current to charge/discharge the large output capacitors during soft start and VID changing,

and prevents OCP, OVP/UVP false trigger. The SS buffer sinking/sourcing capability is limited to 22A during soft start and 200A after soft start

end. Therefore, the slew rate of voltage ramping up/down at SS, EAP and FB pin during soft start or VID changing is calculated as:

During Soft Start

After Soft Start

4. Pre-Bias Function

AP3595 features pre-bias start-up capability. If the output voltage is pre-biased with a voltage V

reference voltage ramping V

output low until the ramping V

. The error amplifier keeps V

EAP

catches up the feedback voltage. The IC keeps both upper and lower MOSFETs off until the first pulse takes

EAP

lower than the valley of the saw tooth waveform and makes PWM comparators

COMP

place.

5. Chip Oscillator Frequency Programming

A resistor RFS connected to RT/EN pin programs the oscillator frequency as:

during soft start and V

OUT

BIAS

jumping is controlled by the

REFIN

, that accordingly makes VFB higher than

Figure 2 shows the relationship between oscillation frequency and RFS.

Figure 2. Switching Frequency vs. R

When released, the RT/EN pin voltage is regulated at 1V. Pulling the RT/EN pin to ground shuts down the IC.

6. Current Balance

AP3595 extracts phase currents for current balance by parasitic on-resistance of the lower switches when turned on as shown in Figure 3.

The GM amplifier senses the voltage drop across the lower switch and converts it into current signal when it turns on. The sampled and held

current is expressed as:

Figure 3. R

Current Sensing Scheme

DS(ON)

FS

Page 12

AP3595

Document number: DS36749 Rev. 1 - 2

12 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

2/

DCOUTCS

RIV

CSCSPDC

CRRL /2

CSCSNCSN

VRI

CSN

DCOUT

CSN

R

RI

I

2

+

_

+

_

PWM1

PWM2

COMP

I

CS2

I

CS1

+

_

+

RAMP1

RAMP2

AP3595

+

-

CSP

CSN

R

CSN

R

CSP

C

CS

R

DC

R

DC

L

L

R

CSP

PHASE1

PHASE2

V

OUT

GM

Amplifier

I

CSN

I

DRPIPSIIOCP

Application Information (Cont.)

Where ILX is the phase x current in Ampere, R

offset voltage of the current sensing circuit.

AP3595 tunes the duty cycle of each channel for current balance according to the sensed inductor current signals as shown in Figure 4. If the

current of channel 1 is smaller than the current of channel 2, the IC increases the duty cycle of the corresponding phase to increase its phase

current accordingly, vice versa.

7. Power Saving Interface (PSI)

The AP3595 supports dual phase or single phase which is controlled by V

AP3595 will operate in single phase mode. There is 2ms delay at the transient from dual phase to single phase, and no delay time from single

phase to dual phase.

8. Current Sense by DCR

The above figure shows the output current sensing block of AP3595. The voltage VCS across the current sensing capacitor C

as

If the following condition is true:

Where L is the output inductor of the buck converter, RDC is the parasitic resistance of the inductor, R

current sensing.

The GM amplifier will source a current I

Therefore the output current signal I

The output current signal I

,

is used to droop tuning and output over current protection.

CSN

is the on-resistance of low side MOSFET, 12A is a constant current to compensate the

DS(ON)

Figure 4. Current Balance Scheme of AP3595

. If V

PSI

Figure 5. Output Current Sensing Block

to the CSN pin to let its inputs virtually short circuit.

CSN

can be expressed as:

CSN

>1.2V, AP3595 will operate in dual phase mode. If V

PSI

can be expressed

CS

and CCS are the external RC network for

CSP

PSI

<0.4V,

Page 13

AP3595

Document number: DS36749 Rev. 1 - 2

13 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

A

m

kA

I

OCP

120

2

2602

DRPDRPSSFB

RIVV

CSN

DRPOUT

SSDRPDRPSSFB

R

RDCRI

VRIVV

2

1

OFS

IOFS

RVI /5.0

OFS

IOFS

RVVI /)5.12(

1)2/1(

1

2

OUTESROUT

OUTESR

LC

CRsCLs

CRs

Gain

Application Information (Cont.)

9. Short Circuit Protection (SCP)

The AP3595 has over current protection (OCP) and output under voltage protection (UVP) functions.

9.1 OCP Function

The sensed current signals are monitored for over current protection. If I

Take the above case for example, the OCP level is calculated as:

The OCP is of latch-off type and can be reset by toggling RT/EN or VCC POR.

9.2 UVP Function

The output feedback voltage VFB is also monitored for under voltage protection after soft start. The UV threshold is set as VFB-VSS<-0.3V. The

under voltage protection has 30s triggered delay. When UVP is triggered, both high side and low side are shutdown immediately.

OCP and UVP are latched functions. The IC can power off, and then power on or use RT/EN reset to restart again.

10. Over Voltage Protection (OVP)

The output voltage VFB is continuously monitored for over voltage protection. When it is 300mV higher than setting, the OVP function is triggered.

The over voltage protection has 30s triggered delay. When OVP is triggered, the LGATE will go high and the HGATE will go low to discharge the

output capacitor.

11. Droop Setting

In some high current applications, a requirement on precisely controlled output impedance is imposed. This dependence of output voltage on load

current is often termed droop regulation. The droop control block generates a voltage through external resistor R

EAP) and then sets the droop voltage. The droop voltage, V

I

CSN

and I

, please refer to the current sense section). As shown in the following equation:

DRP

, is proportional to the total current in two channels (For more information about the

DRP

is higher than 60A, the over current protection OCP is activated.

CSN

(Which is between SS and

DRP

Where I

12. Offset Current Setting

The AP3595 integrated IOFS allows the offset current to adjust phase current. The IOFS pin voltage is nominal 0.5V when connecting a resistor to

GND and 1.5V when connecting a resistor to VREF. Connecting a resistor from IOFS pin to GND generates a current source as:

This current is added to phase1 current signal I

Connecting a resistor from IOFS pin to VREF pin generates a current source as:

This current is added to phase2 current signal I

13. PWM Compensation

The output LC filter of a step down converter introduces a double pole, which contributes with -40dB/decade gain slope and 180 degrees phase

shift in the control loop. A compensation network among COMP, FB, and V

The output LC filters consist of the output inductors and output capacitors. For two-phase convertor, when assuming that V

the transfer function of the LC filter is given by:

is the droop current which is mirrored from I

DRP

. The output voltage also can be described as:

CSN

for current balance. Consequently, phase2 will share more percentage of output current.

SEN1

for current balance. Consequently, phase1 will share more percentage of output current.

SEN2

should be added. The compensation network is shown in Figure 9.

OUT

IN1=VIN2=VIN

, L1=L2=L,

Page 14

AP3595

Document number: DS36749 Rev. 1 - 2

14 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

OUT

LC

CL

f

)2/1(2

1

OUTESR

ESR

CR

f

2

1

V

PHASE1

V

PHASE2

V

OUT

C

OUT

R

ESR

L1=L

L2=L

OSC

IN

PW M

V

V

Gain

+

-

PWM

Comparator

OSC

ΔV

OSC

V

IN

Driver

Driver

PHASE

Output of Error

Amplifier

Application Information (Cont.)

The poles and zero of the transfer functions are:

The fLC is the double-pole frequency of the two-phase LC filters, and f

capacitors.

is the frequency of the zero introduced by the ESR of the output

ESR

Figure 6. The Output LC Filter

Figure 7. .Frequency Response of the LC Filters

The PWM modulator is shown in Figure 8. The input is the output of the error amplifier and the output is the PHASE node. The transfer function of

the PWM modulator is given by:

Figure 8.The PWM Modulator

Page 15

AP3595

Document number: DS36749 Rev. 1 - 2

15 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

)

33

1

()

212

21

(

}

3)31(

1

{)

22

1

(

131

31

)

3

1

3//(1

)

2

1

2//(

1

1

CR

s

CCR

CC

ss

CRR

s

CR

s

CRR

RR

sC

RR

sC

R

sC

V

V

Gain

OUT

COMP

AMP

222

1

1

CR

f

Z

3)31(2

1

2

CRR

f

Z

)

21

21

(22

1

1

CC

CC

R

f

P

332

1

2

CR

f

P

R3

V

OUT

+

-

V

REF

V

COMP

C3

C1

R2

C2

R1

FB

AMPPWMLC

GainGainGain

SWO

ff )10/1~5/1(

12 R

f

f

V

V

R

LC

O

IN

OSC

LCZ

ff 75.0

1

Application Information (Cont.)

The compensation network is shown in Figure 9. It provides a close loop transfer function with the highest zero cross over frequency and sufficient

phase margin. The transfer function of error amplifier is given by:

The pole and zero frequencies of the transfer function are:

Figure 9.Compensation Network

The closed loop gain of the converter can be written as:

Figure 10 shows the asymptotic plot of the closed loop converter gain, and the following guidelines will help to design the compensation network.

Using the below guidelines will give a compensation similar to the curve plotted. A stable closed loop has a-20dB/decade slope and a phase

margin greater than 45 degree.

1. Choose a value for R1, usually between 1k and 5k.

2. Select the desired zero crossover frequency.

Use the following equation to calculate R2:

3. Place the first zero fZ1 before the output LC filter double pole frequency fLC.

Page 16

AP3595

Document number: DS36749 Rev. 1 - 2

16 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

75.022

1

2

LC

fR

C

ESRP

ff

1

1222

2

1

ESR

fCR

C

C

LCZ

SWP

ff

ff

2

2

5.0

1

2

1

3

LC

SW

f

f

R

R

SW

fR

C

3

1

3

INOUT

VVD /

IN

OUT

SW

OUTIN

PP

V

V

Lf

VV

I

2

Application Information (Cont.)

Calculate the C2 by the equation:

4. Set the pole at the ESR zero frequency f

Calculate the C1 by the following equation:

5. Set the second pole fP2 at the half of the switching frequency and also set the second zero fZ2 at the output LC filter double pole fLC. The

compensation gain should not exceed the error amplifier open loop gain. Check the compensation gain at fP2 with the capabilities of the error

amplifier.

ESR

:

Combine the two equations will get the following component calculations:

Figure 10.Converter Gain and Frequency

14. Output Inductor Selection

The duty cycle (D) of a buck converter is the function of the input voltage and output voltage. Once an output voltage is fixed, it can be written as:

For two-phase converter, the inductor value (L) determines the sum of the two inductor ripple current, ΔI

response. Higher inductor value reduces the output capacitors’ ripple current and induces lower output ripple voltage. The ripple current can be

approximated by:

, and affects the load transient

P-P

Where fSW is the switching frequency of the regulator.

Page 17

AP3595

Document number: DS36749 Rev. 1 - 2

17 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

SWOUT

PP

COUT

fC

I

V

8

ESRPPESR

RIV

)21(2

2

DD

I

I

OUT

RMS

Application Information (Cont.)

Although the inductor value and frequency are increased and the ripple current and voltage are reduced, a tradeoff exists between the inductor’s

ripple current and the regulator load transient response time. A smaller inductor will give the regulator a faster load transient response at the

expense of higher ripple current. Increasing the switching frequency (fSW) also reduces the ripple current and voltage, but it will increase the

switching loss of the MOSFETs and the power dissipation of the converter. The maximum ripple current occurs at the maximum input voltage. A

good starting point is to choose the ripple current to be approximately 30% of the maximum output current. Once the inductance value has been

chosen, select an inductor that is capable of carrying the required peak current without going into saturation. In some types of inductors, especially

core that is made of ferrite, the ripple current will increase abruptly when it saturates. This results in a larger output ripple voltage.

15. Output Capacitor Selection

Output voltage ripple and the transient voltage deviation are factors that have to be taken into consideration when selecting output capacitors.

Higher capacitor value and lower ESR reduce the output ripple and the load transient drop. Therefore, selecting high performance low ESR

capacitors is recommended for switching regulator applications. In addition to high frequency noise related to MOSFET turn-on and turn-off, the

output voltage ripple includes the capacitance voltage drop ΔV

inductor’s current. The ripple voltage of output capacitors can be represented by:

and ESR voltage drop ΔV

COUT

caused by the AC peak-to-peak sum of the

ESR

These two components constitute a large portion of the total output voltage ripple. In some applications, multiple capacitors have to be paralleled

to achieve the desired ESR value. If the output of the converter has to support another load with high pulsating current, more capacitors are

needed in order to reduce the equivalent ESR and suppress the voltage ripple to a tolerable level. As mall decoupling capacitor in parallel for by

passing the noise is also recommended, and the voltage rating of the output capacitors must be considered too.

To support a load transient that is faster than the switching frequency, more capacitors are needed for reducing the voltage excursion during load

step change.

For getting same load transient response, the output capacitance of two-phase converter only needs to be around half of output capacitance of

single-phase converter.

Another aspect of the capacitor selection is that the total AC current going through the capacitors has to be less than the rated RMS current

specified on the capacitors in order to prevent the capacitor from overheating.

16. Input Capacitor Selection

Use small ceramic capacitors for high frequency decoupling and bulk capacitors to supply the surge current needed each time high-side MOSFET

turns on. Place the small ceramic capacitors physically close to the MOSFETs and between the drain of high-side MOSFET and the source of lowside MOSFET.

The important parameters for the bulk input capacitor are the voltage rating and the RMS current rating. For reliable operation, select the bulk

capacitor with voltage and current ratings above the maximum input voltage and largest RMS current required by the circuit. The capacitor voltage

rating should be at least 1.25 times greater than the maximum input voltage and a voltage rating of 1.5 times is a conservative guideline. For twophase converter, the RMS current of the bulk input capacitor is roughly calculated as the following equation:

For a through hole design, several electrolytic capacitors may be needed. For surface mount design, solid tantalum capacitors can be used, but

caution must be exercised with regard to the capacitor surge current rating.

17. MOSFET Selection

The AP3595 requires two N-Channel power MOSFETs on each phase. These should be selected based upon R

and thermal management requirements.

In high current applications, the MOSFET power dissipation, package selection, and heat sink are the dominant design factors. The power

dissipation includes two loss components: conduction loss and switching loss.

, gate supply requirements

DS(ON)

Page 18

AP3595

Document number: DS36749 Rev. 1 - 2

18 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

Application Information (Cont.)

The conduction losses are the largest component of power dissipation for both the high-side and the low-side MOSFETs. These losses are

distributed between the two MOSFETs according to duty factor (see the equations below). Only the high-side MOSFET has switching losses since

the low-side MOSFETs body diode or an external Schottky rectifier across the lower MOSFET clamps the switching node before the synchronous

rectifier turns on. These equations assume linear voltage current transitions and do not adequately model power loss due to the reverse-recovery

of the low-side MOSFET body diode. The gate-charge losses are dissipated by AP3595 and don’t heat the MOSFETs. However, large gate-

charge increases the switching interval tSW, which increases the high-side MOSFET switching losses. Ensure that all MOSFETs are within their

maximum junction temperature at high ambient temperature by calculating the temperature rise according to package thermal resistance

specifications. A separate heat sink may be necessary depending upon MOSFET power, package type, ambient temperature and air flow.

For the high-side and low-side MOSFETs, the losses are approximately given by the following equations:

P

HIGH-SIDE=IOUT

P

LOW-SIDE=IOUT

Where I

duty cycle.

Note that both MOSFETs have conduction losses while the high-side MOSFET includes an additional transition loss. The switching interval, tSW, is

the function of the reverse transfer capacitance C

extracted from the “R

18. Layout Consideration

In any high switching frequency converter, a correct layout is important to ensure proper operation of the regulator.

With power devices switching at higher frequency, the resulting current transient will cause voltage spike across the interconnecting impedance

and parasitic circuit elements. As an example, consider the turn-off transition of the PWM MOSFET. Before turn-off condition, the MOSFET is

carrying the full load current. During turn-off, current stops flowing in the MOSFET and is freewheeling by the low side MOSFET and parasitic

diode. Any parasitic inductance of the circuit generates a large voltage spike during the switching interval. In general, using short and wide printed

circuit traces should minimize interconnecting impedances and the magnitude of voltage spike.

Besides, signal and power grounds are to be kept separating and finally combined using ground plane construction or single point grounding. The

best tie-point between the signal ground and the power ground is at the negative side of the output capacitor on each channel, where there is less

noise. Noisy traces beneath the IC are not recommended. Figure 11 illustrates the layout, with bold lines indicating high current paths; these

traces must be short and wide. Components along the bold lines should be placed close together. Below is a checklist for your layout:

1. Keep the switching nodes (HGx, LGx, BOOTx, and PHASEx) away from sensitive small signal nodes since these nodes are fast moving signals.

Therefore keep traces to these nodes as short as possible and there should be no other weak signal traces in parallel with theses traces on any

layer.

2. The signals going through theses traces have both high dv/dt and high dI/dt with high peak charging and discharging current. The traces from

the gate drivers to the MOSFETs (HGx and LGx) should be short and wide.

3. Place the source of the high-side MOSFET and the drain of the low-side MOSFET as close as possible. Minimizing the impedance with wide

layout plane between the two pads reduces the voltage bounce of the node. In addition, the large layout plane between the drain of the MOSFETs

(VIN and PHASEx nodes) can get better heat sinking.

4. For experiment result of accurate current sensing, the current sensing components are suggested to place close to the inductor part. To avoid

the noise interference, the current sensing trace should be away from the noisy switching nodes.

5. Decoupling capacitors, the resistor-divider, and the boot capacitor should be close to their pins. (For example, place the decoupling ceramic

capacitor as close as possible to the drain of the high-side MOSFET).The input bulk capacitors should be close to the drain of the high-side

MOSFET, and the output bulk capacitors should be close to the loads.

6. The input capacitor’s ground should be close to the grounds of the output capacitors and the low-side MOSFET.

2

×(1+TC) ×R

2

×(1+TC)×(R

is the load current, TC is the temperature dependency of R

OUT

DS(ON)

×D+0.5×I

DS(ON)

DS(ON)

)×(1-D)

OUT×VIN×tSW×fSW

. The (1+TC) term is a factor in the temperature dependency of the R

RSS

vs. Temperature” curve of the power MOSFET.

, fSW is the switching frequency, tSW is the switching interval, D is the

DS(ON)

DS(ON)

and can be

Page 19

AP3595

Document number: DS36749 Rev. 1 - 2

19 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

HG1

HG2

Application Information (Cont.)

7. Locate the resistor-divider close to the FB pin to minimize the high impedance trace. In addition, FB pin traces can’t be close to the switching

signal traces (HGx, LGx, BOOTx, and PHASEx).

Figure 11.The Layout of AP3595

Page 20

AP3595

Document number: DS36749 Rev. 1 - 2

20 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

AP3595 XX XX - XX

Packing

Package

TR : Tape & Reel

FN: U-QFN4040-24

G1 : Green

Product Name

RoHS/Green

Package

Temperature Range

Part Number

Marking ID

Packing

U-QFN4040-24

-40°C to +85°C

AP3595FNTR-G1

B3D

5000/Tape & Reel

First Line: Logo and Marking ID

Second and Third Lines: Date Code

Y: Year

WW: Work Week of Molding

M: Assembly House Code

XX: 7th and 8th Digits of Batch No.

Ordering Information

Diodes IC’s Pb-free products with "G1" suffix in the part number, are RoHS compliant and green.

Marking Information

Page 21

AP3595

Document number: DS36749 Rev. 1 - 2

21 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

3.900(0.154)

4.100(0.161)

3.900(0.154)

4.

100

(0.161)

0.200(0.008)

MIN

0.500(0.020)

BSC

0.300(0.012)

0.500(0.020)

0.180(0.007)

0.300(0.012)

0.000(0.000)

0.050(0.002)

N1

N7

N13

N19

N24

Pin 1 Mark

Pin 1 Options

DETAIL A

1

2

3

2422 23

1

2

3

2422 23

1

2

3

2422 23

PIN #1 IDENTIFICATION

See DETAIL A

.

Symbol

D=E

A

min(mm) max(mm) max(mm)min(mm)min(inch) min(inch)max(inch) max(inch)

Option1

Option2

2.600

2.350

2.800

2.550

0.102 0.110

0.093 0.100

0.850

0.850

0.700

0.700

0.028

0.028

0.033

0.033

D

E

A3

max(mm)min(mm) min(inch) max(inch)

0.253

0.253

0.153

0.153

0.006

0.006

0.010

0.010

Option3 2.600 2.800 0.102 0.110 0.6500.550 0.022 0.026

0.1750.125 0.005 0.007

A

A3

Package Outline Dimensions (All dimensions in mm(inch).)

(1) Package Type: U-QFN4040-24

Page 22

AP3595

Document number: DS36749 Rev. 1 - 2

22 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

E

Y1

Y2

X1

E

X2

Y

X

X3

Y3

Dimensions

X=Y

(mm)/(inch)

X1=Y2

(mm)/(inch)

Y1=X2

(mm)/(inch)

X3=Y3

(mm)/(inch)

E

(mm)/(inch)

Value

4.400/0.173

0.300/0.012

0.650/0.026

2.800/0.110

0.500/0.020

Suggested Pad Layout

(1) Package Type: U-QFN4040-24

Page 23

AP3595

Document number: DS36749 Rev. 1 - 2

23 of 23

www.diodes.com

January 2014

© Diodes Incorporated

AP3595

A Product Line of

Diodes Incorporated

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2013, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

Loading...

Loading...