Page 1

AP3591

Document number: DS36906 Rev. 1 - 2

1 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

Description

The AP3591 is a synchronous adaptive on-time buck controller

providing high efficiency, excellent transient response and high DC

output accuracy for low voltage regulation in notebook application.

The constant-on-time PWM control scheme handles wide input/output

voltage ratios with ease and features small external component count

and fast transient response.

The operation mode is selectable by EN voltage. A Diode Emulation

Mode (DEM) is activated for increasing efficiency at light loads, while

PWM mode is activated only for low noise operation. The AP3591

also integrates internal Soft-start, UVLO, OVP, OTP, and

programmable OCP to protect the circuit. A Power Good signal is

employed to monitor the output voltage.

The AP3591 is available in U-QFN3535-14 package.

Features

Fixed Frequency Constant On-time Control; Resistor

Programmable Frequency Adjustable from 100kHz to 700kHz

Good Stability Independent of the Output Capacitor ESR

Quick Load Step Response

Input Voltage Range: 4.5V to 26V

Output Voltage Range: 0.75V to 5.5V

CCM/DEM Mode Selection

Integrated Bootstrap Diode

Resistor Programmable Current Limit by Low-side R

DS_ON

Sense

Integrated Negative Over Current Limit

Integrated OVP/UVP and Over Thermal Shutdown Function

Power Good Indicator

Internal Soft-start

Integrate Output Discharge (Soft-stop)

Safe Start-up into Pre-biased Loads

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

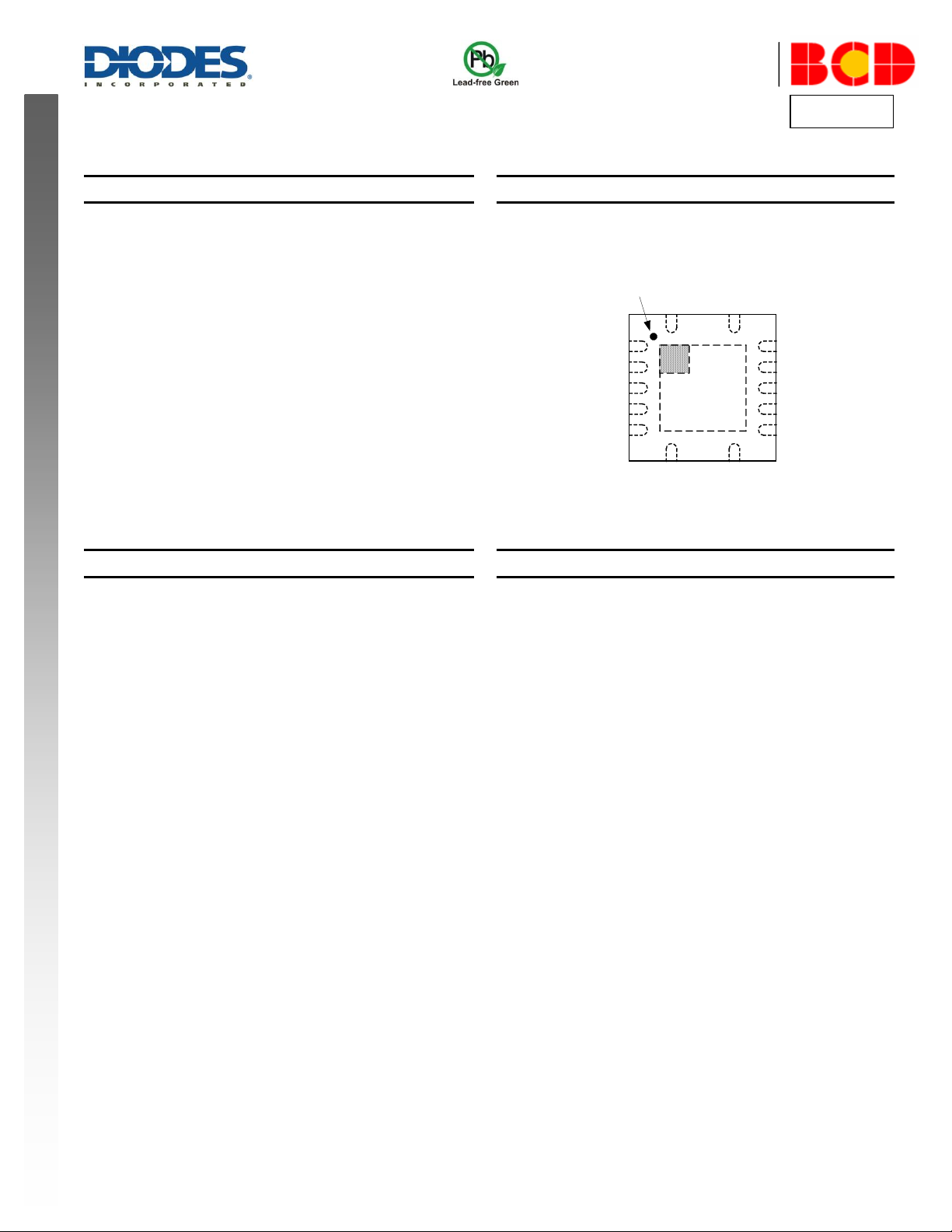

Pin Assignments

(Top View)

U-QFN3535-14

Applications

Notebook Computer, AIO PC

Low-voltage Distribute Power

I/O Supplies

VOUT

VDD

FB

PGOOD

GND

PGND

LGATE

EN/DEM

TON

BOOT

UGATE

PHASE

CS

VDDP

Pin 1 Mark

EP

1 14

2

3

4

5

6

7 8

9

10

11

12

13

SINGLE PHASE SYNCHRONOUS BUCK CONTROLLER

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen - and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

Page 2

AP3591

Document number: DS36906 Rev. 1 - 2

2 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

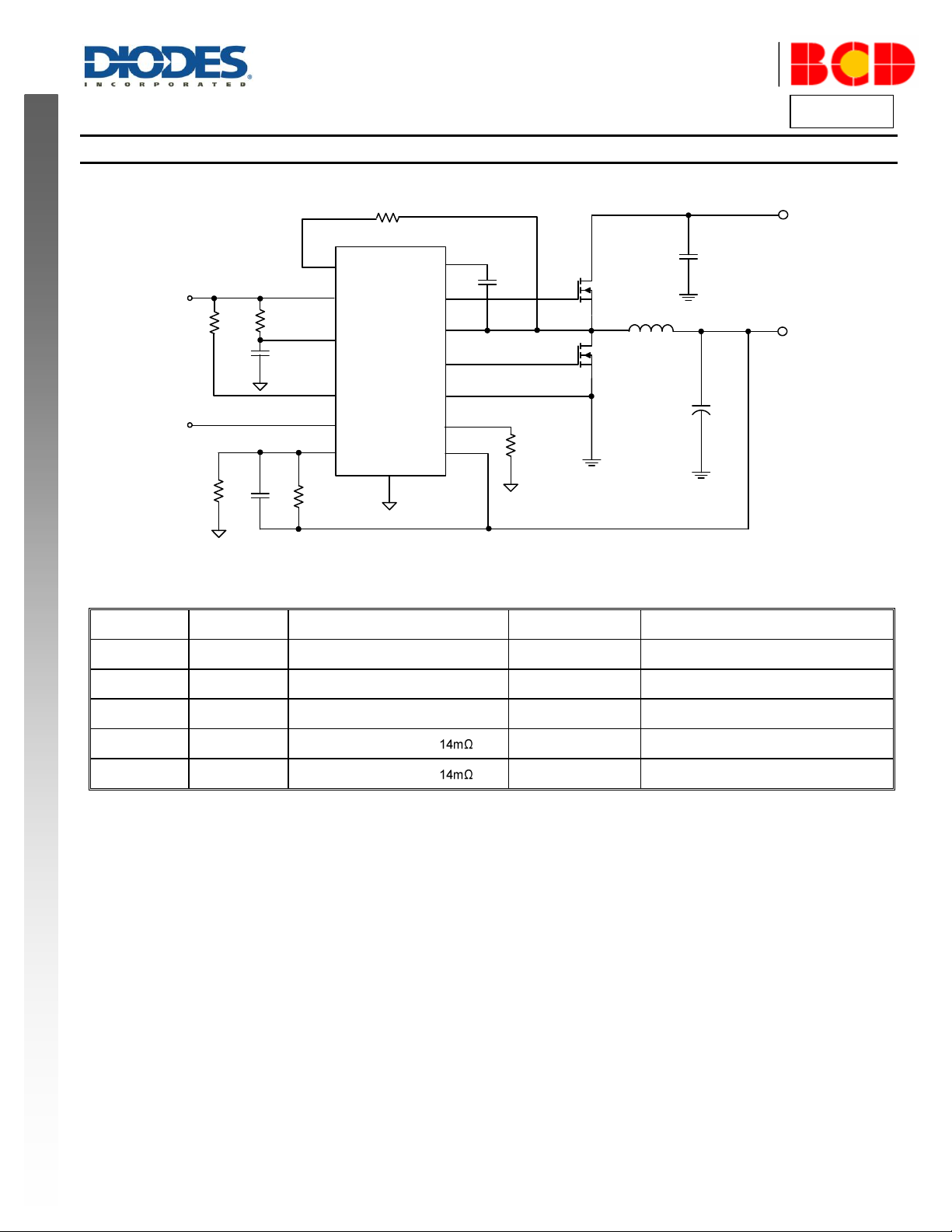

VDDP

BOOT

UGATE

LGATE

PHASE

VOUT

PGOOD

EN/DEM

FB

AP3591

13

14

12

9

5

4

GND

7

L

1.0

C

4

220

mF

R1

C2

C1

10

mF

TON

Q2

Q1

C3

0.1mF

R3

PGND

VDD

VDDP

CCM/ DEM

CS

mH

1

2

3

6

8

10

11

1

mF

C

Optional

10

R2

100K

250K

R4

18K

12K

R5

R6

30K

V

OUT

=1.05V

=12V

V

IN

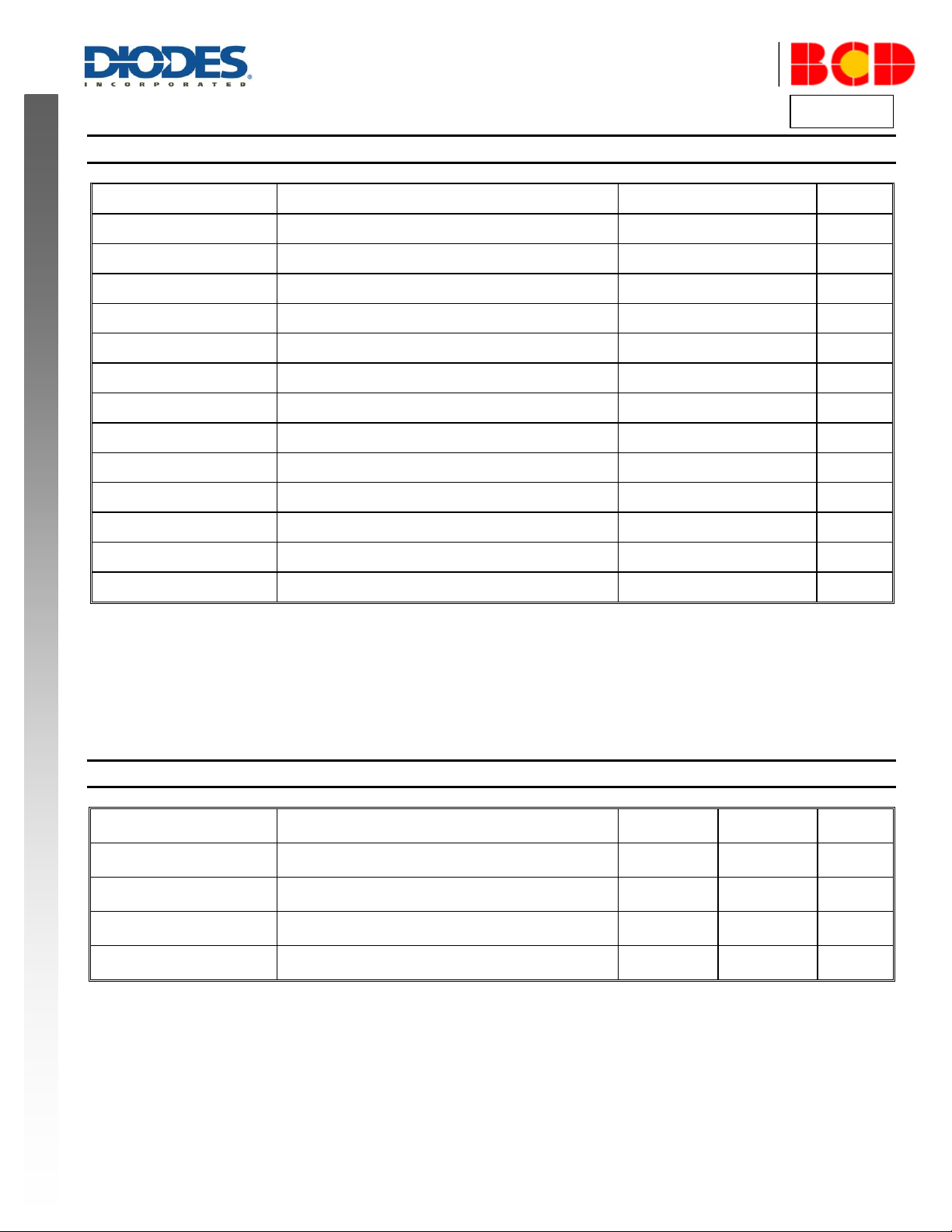

Symbol

Value

Description

Manufacturer

Part Number

C1

10µF/25V

ESR < 4mΩ @400kHz

Murata

GRM31CR61E106KA12

C4

220µF/6.3V

ESR < 9mΩ @300kHz

Sanyo

6SVPE220M

L

1.0µH

DCR < 4mΩ, I

MAX

= 24A

Vishay

IHLP5050CEER1R0M01

Q1

N-MOSFET

I

DMAX

= 30A, R

DS(ON)

=

Infineon

BSC119N03S

Q2

N-MOSFET

I

DMAX

= 30A, R

DS(ON)

=

Infineon

BSC119N03S

Typical Applications Circuit

BOM

Page 3

AP3591

Document number: DS36906 Rev. 1 - 2

3 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

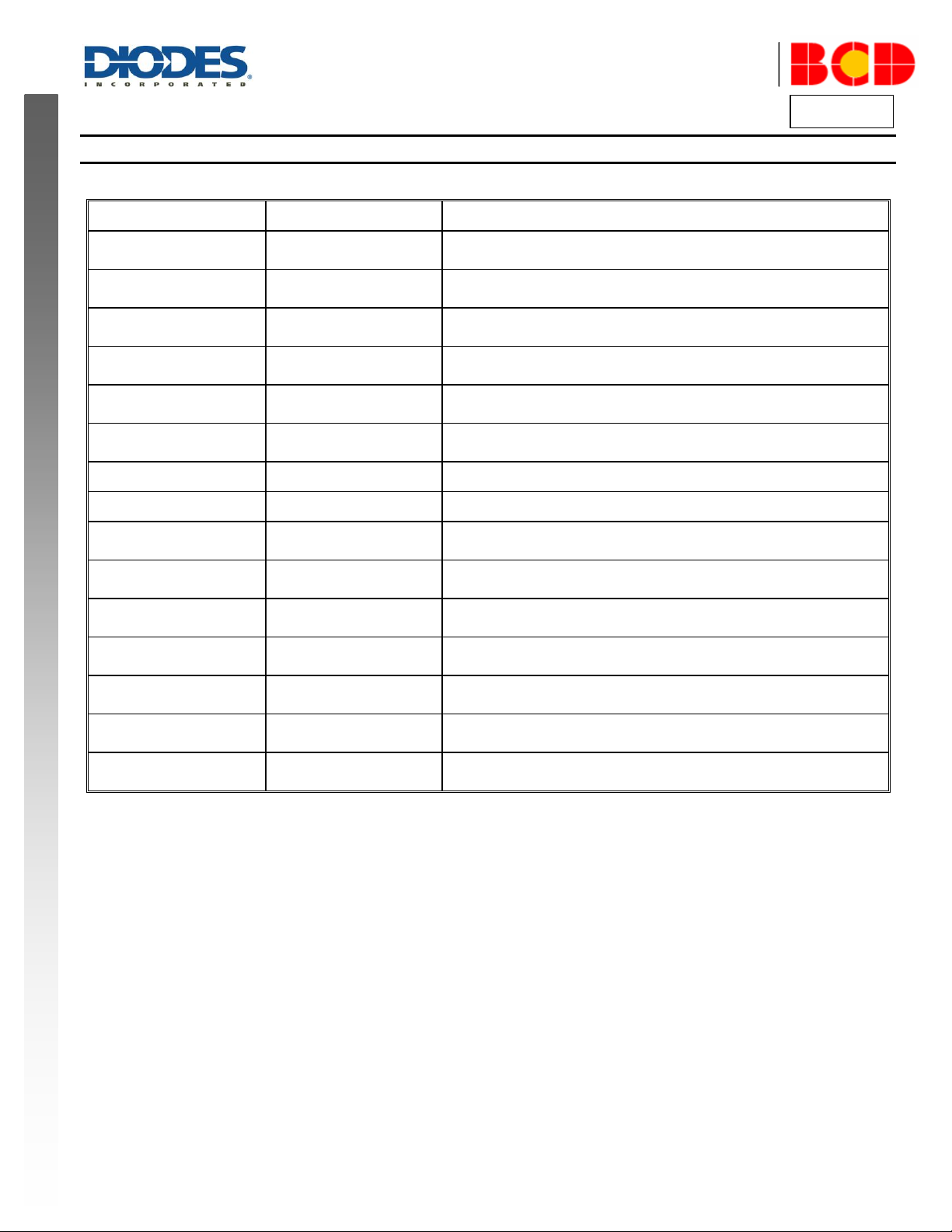

Pin Number

Pin Name

Function

1

EN/DEM

Enable/Diode Emulation Mode control input. Connect to VDD for DEM mode;

connect to GND for shutdown and float the pin for CCM mode

2

TON

On time/Frequency adjustment pin. Connect to PHASE through a resistor. TON

is an input for the PWM controller

3

VOUT

Output voltage pin. Connect to the output of PWM converter. VOUT is an input

for the PWM controller

4

VDD

Analog supply voltage input for the internal analog integrated circuit. Bypass to

GND with a 1µF ceramic capacitor

5

FB

Feedback input pin. Connect FB pin to a resistor voltage divider from VOUT to

GND to adjust V

OUT

from 0.75V to 3.3V

6

PGOOD

Power good signal open-drain output for PWM converter. This pin will be pulled

high when the output voltage is within the target range

7

GND

Analog Ground 8 PGND

Power Ground

9

LGATE

Low-side N-MOSFET gate driver output for the PWM converter. This pin swings

between PGND and VDDP

10

VDDP

VDDP is the gate driver supply for external MOSFETs. Bypass to GND with a

1µF ceramic capacitor

11

CS

Over current trip point set input. Connect a resistor from this pin to signal ground

to set threshold for both over current limit and negative over current limit

12

PHASE

The UGATE High-side gate driver return. Also serves as anode of over current

comparator

13

UGATE

High-side N-MOSFET floating gate driver output for the PWM converter. This pin

swings between PHASE and BOOT

14

BOOT

Bootstrap pin. A bootstrap capacitor is connected for PWM converter. Connect

to an external ceramic capacitor to PHASE

–

Exposed Pad

The exposed pad must be soldered to a large PCB and connected to GND for

maximum power dissipation

Pin Descriptions

Page 4

AP3591

Document number: DS36906 Rev. 1 - 2

4 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

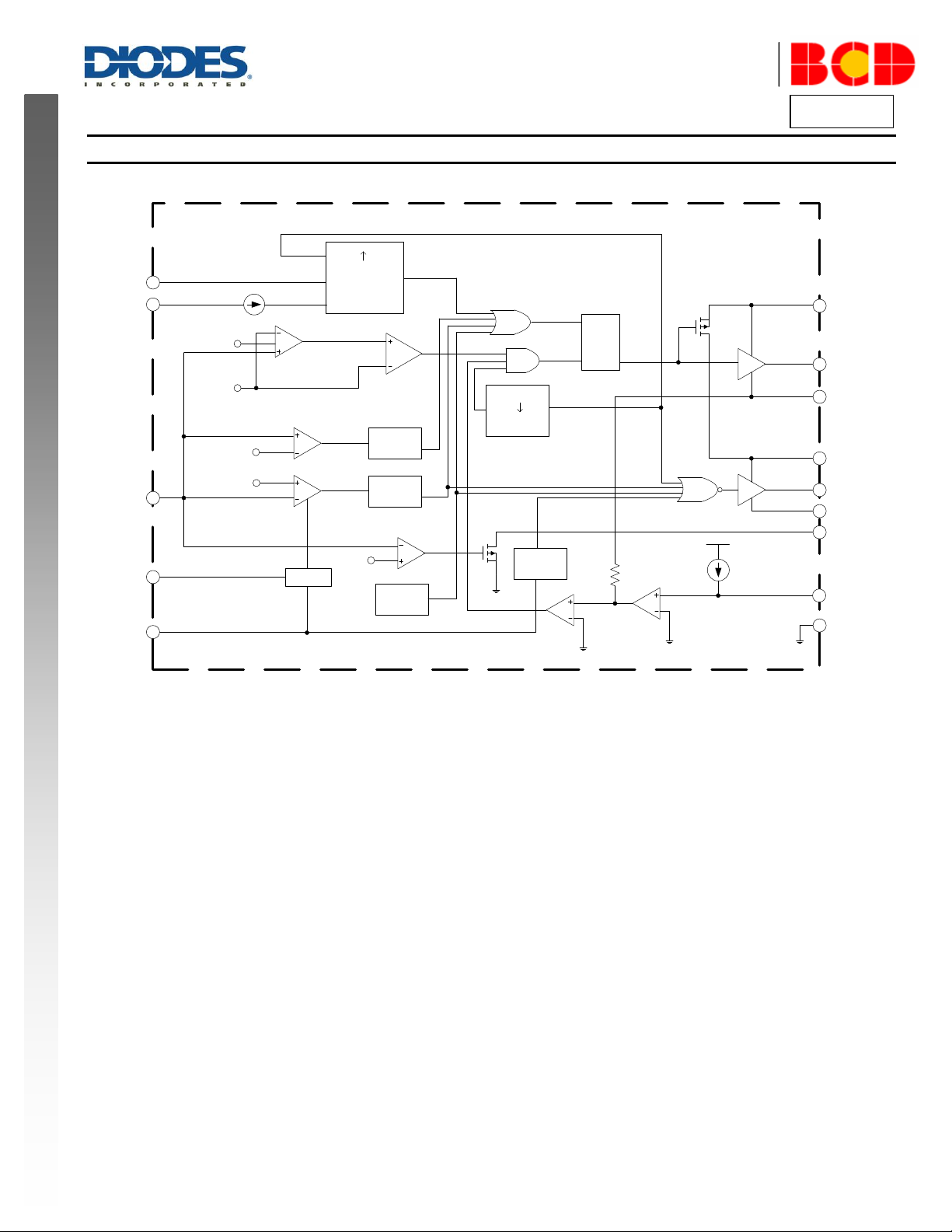

Min. t

OFF

1-SHOT

Q

S1

Latch

On-time

Compute

1-SHOT

TRIG

GM

V

REF

SS

(internal)

125% V

REF

70% V

REF

Q

S1

Latch

OV

UV

TRIG

Q

90% V

REF

SS Timer

Thermal

Shutdown

Diode

Emulation

Q

R

S

DRV

DRV

GM

5

2

3

4

1

7

6

8

9

10

12

13

14

11

10mA

VOUT

TON

FB

EN/DEM

GND

CS

PGOOD

PGND

LGATE

VDDP

PHASE

UGATE

BOOT

VDD

Functional Block Diagram

Page 5

AP3591

Document number: DS36906 Rev. 1 - 2

5 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

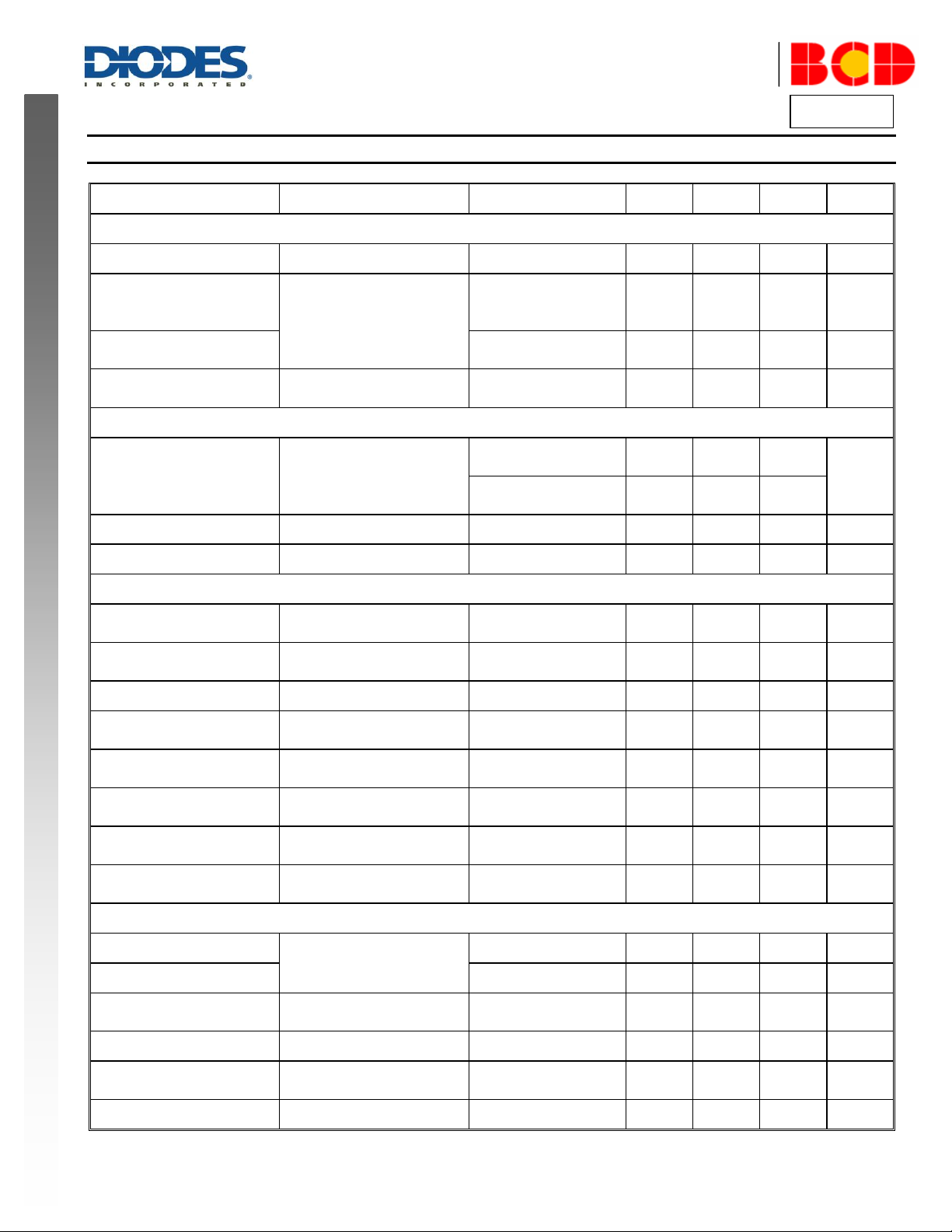

Symbol

Parameter

Rating

Unit

VDD, V

DDP

Supply Voltage

-0.3 to 6

V

VBS

BOOT Pin Voltage

-0.3 to V

PHASE

+6

V

V

UGATE

Voltage from UGATE to PHASE

-0.3 to 6

V

V

LGATE

Voltage from LGATE to GND

-0.3 to 6

V

V

PHASE

Voltage from PHASE to GND

-0.3 to 36

V

V

PGND

Voltage from PGND to GND

-0.3 to 0.3

V

–

Voltage from Other Pins to GND

-0.3 to 6

V

JA

Thermal Resistance (Junction to Ambient)

60

C/W

TJ

Operating Junction Temperature

+150

C

T

STG

Storage Temperature

-65 to +150

C

T

LEAD

Lead Temperature (Soldering, 10Secs)

+260

C

V

HBM

ESD (Human Body Model)

2000

V

VMM

ESD (Machine Model)

200

V

Symbol

Parameter

Min

Max

Unit

VDD, V

DDP

Supply Voltage

4.5

5.5

V

VIN

Input Voltage

4.5

26

V

V

OUT(MAX)

Maximum Output Voltage

–

5.5

V

TA

Operating Ambient Temperature

-40

+85

ºC

Absolute Maximum Ratings (Note 4)

Note 4: Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “Recommended Operating Conditions” is not implied.

Exposure to “Absolute Maximum Ratings” for extended periods may affect device reliability.

Recommended Operating Conditions

Page 6

AP3591

Document number: DS36906 Rev. 1 - 2

6 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

SUPPLY INPUT

VIN

Input Voltage

–

4.5 – 26

V

I

Q-CCM

Quiescent Current

VDD+VDDP current,

CCM, EN floating, V

FB

=

0.8V

–

500

800

µA

I

Q-DEM

VDD+V

DDP

current, DEM,

V

EN

= 5V, V

FB

= 0.8V

–

500

800

µA

I

SHDN

Shutdown Current

VDD+V

DDP

current, DEM,

V

EN

= 0V

– 1 10

µA

ON-TIME TIMER, OSCILLATOR FREQUENCY AND SOFT START

tON

On Time

V

PHASE

= 12V, V

OUT

=

2.5V, R

ON

= 200kΩ

510

630

750

ns

V

PHASE

= 12V, V

OUT

=

1.05V, R

ON

= 200kΩ

190

260

330

t

OFF-MIN

Min Off Time

–

250

400

580

ns

t

SS

Internal Soft Start Time

–

0.82

1.2

1.5

ms

PWM CONTROLLER GATE DRIVERS

R

U_PH

Upper Gate Pull-up Resistance

V

BOOT-VPHASE

= 5V,

50mA source current

–

3.3 7 Ω

R

U_GATE

Upper Gate Sink Resistance

V

BOOT-VPHASE

= 5V,

50mA sink current

– 1 3

Ω

R

L_PH

Lower Gate Pull-up Resistance

– – 1.8 4 Ω

R

L_GATE

Lower Gate Sink Resistance

V

BOOT-VPHASE

= 5V,

50mA source current

–

0.5 2 Ω

–

PHASE Falling to LGATE

Rising Delay

V

PHASE

< 1.2V to

V

LGATE

> 1.2V

–

30 – ns

–

LGATE Falling to UGATE

Rising Delay

V

LGATE

< 1.2V to

(V

UGATE-VPHASE

) > 1.2V

–

30 – ns

V

BOOT

Boot Diode Forward Voltage

V

DDP-VBOOT

, I

BOOT

=

10mA

0.5

0.83 1 V

I

BSLK

VBS Leakage Current

V

BOOT

= 34V, V

PHASE

=

28V

–

0.1 1 µA

POWER GOOD

–

PGOOD Threshold

PGOOD from low to high

92.5

95

97.5

%

–

PGOOD from high to low

102

105

107

%

–

PGOOD Lower Threshold

Hysteresis

– – ±5 – %

V

PG_L

PGOOD Low Voltage

– – –

0.4

V

I

PG_LEAK

PGOOD Output Leakage

Current

V

PGOOD

= 5V

– – 1

µA

t

DELAY

PGOOD Delay Time

Delay for PGOOD pin

16

22

36

µs

Electrical Characteristics (V

= 12V, V

IN

DD

= V

DDP

= 5V, V

= 1.05V, TA = +25oC, unless otherwise specified.)

OUT

Page 7

AP3591

Document number: DS36906 Rev. 1 - 2

7 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

VOUT AND REFERENCE VOLTAGE

V

OUT

Output Voltage

–

0.75 – 5.5

V

R

DISCHARGE

Output Discharge Resistance

V

EN

= 0V

–

20 – Ω

VFB

Feedback Voltage

V

DD

= 4.5V to 5.5V

0.742

0.75

0.758

V

IFB

Feedback Bias Current

V

FB

= 0.75V

-1 – 1

µA

PROTECTION

IOC

Current Limit Source Current

CS to GND

9

10

11

µA

–

IOC Temperature Coefficient

– – 4500

–

ppm/oC

V

ILIM_SET

Current Limit Setting Voltage

Range

CS to GND

30 – 200

mV

V

OCL_OFFSET

Over Current Limit Comparator

Offset Voltage

V

CS

= 60mV,

V

CS-GND-VPGND-PHASE

-10 0 10

mV

V

ZC_OFFSET

Zero Crossing Comparator

Offset Voltage

V

PHASE

to GND, V

EN

=

5V

-10 0 10

mV

V

UCL_OFFSET

Negative Over Current Limit

Comparator Offset Voltage

EN floating, V

CS

= 60mV,

V

CS-GND-VPHASE-PGND

-10 0 10

mV

V

FBOV

/VFB

Feedback Over Voltage

Threshold

–

120

125

130

%

t

FBOV_D

Feedback Over Voltage Delay

Time

– – 33 – µs

V

FBUV

/VFB

Feedback Under Voltage

Threshold

–

65

70

75

%

t

FBUV_D

Feedback Under Voltage

Protection Delay Time

– – 28 – µs

t

FBUV_EN_D

Feedback Under Voltage

Protection Enable Delay Time

–

1.3 2 3.1

ms

V

UVLO

VDD Under Voltage Lock

Threshold

VDD Rising

3.7

3.9

4.1

V

V

HYS

VDD Under Voltage Lock

Hysteresis

– – 300 – mV

T

OTSD

Thermal Shutdown

– – +160

– oC

T

HYS

Thermal Shutdown Hysteresis

– – +20

– oC

LOGIC THRESHOLD

V

ENH

EN Control Logic Input Voltage

Setting DEM mode

2.4

2.65

2.9

V

V

ENH-HYS

Hysteresis

–

25 – mV

V

EN_FT

Setting PWM-only mode

1.9

1.96 2 V

V

ENL

Shutdown Threshold

0.8

1.24

1.6

V

V

ENL-HYS

Hysteresis

–

65 – mV

I

EN_PH

EN Pull_up Current

V

EN

= 0V

– 1 –

µA

Electrical Characteristics (Cont. V

= 12V, V

IN

DD

= V

DDP

= 5V, V

= 1.05V, TA = +25oC, unless otherwise specified.)

OUT

Page 8

AP3591

Document number: DS36906 Rev. 1 - 2

8 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

0 2000 4000 6000 8000 10000 12000

0

20

40

60

80

100

Efficiency (%)

Load Current (mA)

VIN = 8V

VIN = 12V

VIN = 20V

0 2000 4000 6000 8000 10000 12000

0

20

40

60

80

100

Efficiency (%)

Load Current (mA)

VIN = 8V

VIN = 12V

VIN = 20V

0 2000 4000 6000 8000 10000 12000

0

20

40

60

80

100

Efficiency (%)

Load Current (mA)

DEM

CCM

0 100 200 300 400 500 600 700 800 900

0

100

200

300

400

500

600

700

800

900

1000

1100

Frequency (KHz)

RT ()

V

OUT

= 1.05V

V

OUT

= 2.5V

-2 0 2 4 6 8 10 12 14 16

100

150

200

250

300

350

400

Frequency (KHz)

Load Current (A)

VIN = 8V

VIN = 12V

VIN = 20V

5 10 15 20 25 30

100

150

200

250

300

350

400

Frequency (KHz)

VIN (V)

V

OUT

= 1.05V@0A

V

OUT

= 1.05V@10A

V

OUT

= 2.5V@0A

V

OUT

= 2.5V@10A

Performance Characteristics

Efficiency vs. Load Current @V

Efficiency vs. Load Current (CCM vs. DEM) Frequency vs. RT

= 1.05V Efficiency vs. Load Current @V

OUT

Frequency vs. Load Current Frequency vs. VIN

OUT

= 2.5V

Page 9

AP3591

Document number: DS36906 Rev. 1 - 2

9 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

6 8 10 12 14 16 18 20 22 24 26

0.0

0.5

1.0

1.5

2.0

Shutdown Current (

mA)

VIN (V)

-40 -20 0 20 40 60 80 100 120 140 160

7

8

9

10

11

12

13

14

15

I

CS

(mA)

Temperature (oC)

V

OUT

2V/div

V

PHASE

10V/div

VEN

1V/div

IL

2.5A/div

Time 2ms/div

V

OUT

2V/div

V

PHASE

10V/div

VEN

2V/div

IL

5A/div

Time 1ms/div

V

OUT

2V/div

V

PHASE

10V/div

VDD

1V/div

IL

5A/div

Time 1ms/div

V

OUT

2V/div

V

PHASE

10V/div

VDD

2V/div

IL

5A/div

Time 1ms/div

Performance Characteristics (Cont.)

Shutdown Current vs. V

Power ON from EN @CCM Power ON from EN @DEM

Power ON from VDD @CCM Power ON from VDD @DEM

IN ICS

vs. Temperature (C)

Page 10

AP3591

Document number: DS36906 Rev. 1 - 2

10 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

V

OUT

2V/div

VUG

5V/div

VLG

5V/div

V

FB

1V/div

Time 200µs/div

V

OUT

2V/div

VUG

5V/div

IL

10A/div

Time 20µs/div

V

OUT

2V/div

V

PHASE

10V/div

VEN

2V/div

Time 4ms/div

V

OUT

2V/div

V

PHASE

10V/div

VEN

2V/div

Time 4ms/div

V

OUT

100mV/div

I

L

10A/div

Time 1ms/div

V

OUT

100mV/div

I

L

10A/div

Time 1ms/div

VLG

10V/div

Performance Characteristics (Cont.)

OVP UVP

MODE Transition DEM to CCM MODE Transition CCM to DEM

Load Transient Response @ CCM Load Transient Response @ DEM

Page 11

AP3591

Document number: DS36906 Rev. 1 - 2

11 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

f

IN

OUT

ON

V

V

t

ON

t

2L

VV

I

OUTIN

LOAD

Application Information

1. Functional Description

The AP3591 is a synchronous step-down controller. Adaptive constant on time (COT) control is employed to provide fast transition response and

easy loop stabilization. AP3591 does not have a dedicated in board oscillator. It runs with a pseudo-constant frequency which is set by RON. The

output voltage variation is sensed by FB Pin. If VFB is below 0.75V, the error comparator will trigger the control logic and generate an ON-time

period, in which high side MOSFET is turned on and low side MOSFET is turned off. The ON-time period length is calculated using the following

equation:

V

is the output voltage, VIN is the input voltage, and f is the switching frequency.

OUT

The on-time is the time required for the voltage on this capacitor charging from zero volts to V

directly proportional to the output voltage and inversely proportional to the input voltage. The implementation results in a nearly constant switching

frequency without the need of a clock generator.

t

= 14.5p×R

ON

After an ON-time period, the AP3591 goes into the OFF-time period. The OFF-time period length depends on VFB in most case. It will end when

VFB decreases below 0.75V and then the ON-time period is triggered again. If the OFF-time period is less than the minimum OFF time, the

minimum OFF time will be applied, which is about 400ns typical.

2. Mode Selection Operation

AP3591 has two operation modes: Continuous Conduction Mode (CCM) and Diode Emulation Mode (DEM). When the EN/DEM pin voltage is

higher than 2.9V, AP3591 will operate in DEM mode for high efficiency; when the EN/DEM pin is floating, AP3591 will operate in forced CCM

mode to a certain frequency during a light load condition.

2.1 Diode Emulation Mode

If the DEM mode is selected, the AP3591 automatically reduces the switching frequency under a light load condition to get high efficiency. When

the output current decreases and heavy load condition is formed, the inductor current decreases as well, and eventually comes close to zero

current, which is the boundary between CCM and DEM. The low side MOSFET will turn off whenever the inductor current reaches zero level. The

load is provided only by the output capacitor. When FB voltage is lower than 0.75V, the next ON cycle is beginning. The ON-time is kept the same

as that in the heavy load condition. The switching frequency increases to keep V

load. The transition load point is calculated using the following equation:

TON

×(V

OUT

+0.1)/VIN+50ns

voltage when the output current increases from light to heavy

OUT

, thereby the ON-time of the high side switch is

OUT

tON is the on-time.

2.2 Continuous Conduction Mode

When AP3591 operates in CCM mode, the duty cycle V

inductor current decreases to reverse. The benefit of CCM is to keep the switching frequency fairly constant to avoid a certain frequency during a

light load condition.

3. Power On Reset and Soft-start

Power on reset occurs when VDD rises above approximately 3.9V: the IC will reset the fault latch and prepare the PWM for operation. When VDD is

below 3.6V, the VDD under voltage lockout (UVLO) circuitry inhibits switching by keeping UGATE and LGATE low. A built-in soft-start is used to

prevent surge current from power supply input VIN during turn on (referring to Functional Block Diagram). The error amplifier is a three-input device.

Reference voltage V

amplifier. VSS internally ramps up to 95% of 0.75V in 1.2ms for AP3591 after the soft-start cycle is initiated.

Figure 1 shows a typical start-up interval for AP3591 when the EN/DEM pin has been released from a grounded (system shutdown) state.

is not changed at light load condition. The low side MOSFET keeps on even when

OUT/VIN

or the internal soft-start voltage VSS whichever is smaller dominates the behavior of the non-inverting inputs of the error

REF

Page 12

AP3591

Document number: DS36906 Rev. 1 - 2

12 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

T0

T1

T2

V

OUT

Normal

V

OUT

Pre-Biased

V

OUT

Over-Charged

GND

V

OUT

1V/div

V

UGATE

20V/div

VEN

2V/div

V

PGOOD

5V/div

Time 400µs/div

Application Information (Cont.)

Power On from EN (DEM Mode)

Figure 1. Start-up Behavior of AP3591

4. Power Good Output

The AP3591 features power good output to monitor the output voltage. It is an open-drain output and should be connected to a 5V power supply

node through a resistor. The power good function is active after the soft start is finished. PGOOD signal becomes high if output voltage reaches

±5% of the target value after 64µs delay building into the PGOOD circuitry. It will become low immediately if the output voltage goes beyond ±10%

of the target value.

5. Soft Stop

The AP3591 has a built in soft-stop circuitry. The output is discharged with an internal 20Ω transistor when EN/DEM is low or the device is in a

fault condition including UVLO and OTP. The discharge time constant is determined by the output capacitance and resistance of the discharge

transistor.

6. Pre-biased Output

Figure 2 shows the normal V

to a voltage less than the expected value, as shown by the magenta curve, the AP3591 will detect that condition. Neither MOSFET will turn on

until the soft-start ramp voltage exceeds the output. V

expected value, as showed in the black curve, neither MOSFET will turn on until the output voltage is pulled down to the expected value through

external load. Any resistive load connected to the output will help pull down the voltage.

start-up curve in blue; Initialization begins at T0, and output ramps between T1 and T2. If the output is pre-biased

OUT

starts seamlessly ramping from there. If the output is pre-biased to a voltage above the

OUT

Figure 2. Start-up Behavior with Pre-biased Output Voltage

Page 13

AP3591

Document number: DS36906 Rev. 1 - 2

13 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

OC

COMPARATOR

CURRENT SENSE

Ioc

OPS

ROC-SET

Q1

Q2

REVERSE BUFFER

)(RA10)(V

SET-OCCS

KmV

m

IN

OUTOUTIN

PP

L

V

VVV

fL

V

I

V

)(

2

1

R

2R

I

DS(ON)

CS

)(

DS(ON)

CS

O_OCSET

Application Information (Cont.)

7. Over Current Protection (OCP)

Figure 3 shows the over current protection (OCP) scheme of AP3591. In each switching cycle, the inductor current is sensed by monitoring the

low-side MOSFET in the OFF period. When the voltage between PGND pin and PHASE pin is larger than the over current trip level, the OCP is

triggered and the controller keeps the OFF state. Because the R

temperature coefficient to compensate this temperature dependency of R

A resistor R

the OCP trip point I

The load current at over-current threshold (I

V

OUT

8. Negative Over Current Protection (NOCP)

The AP3591 supports cycle by cycle negative over current limiting in CCM mode. The over current limit value is the same absolute value as the

positive over current limit. If the inductor reverse current is larger than NOCP current at OFF time, the LMOSFET is turned off. The reverse current

will flows to VIN through the body diode of HMOSFET. After 400ns delay, LMOSFET is turned on again. If the NOCP is released, the HMOSFET

is turned on and the device resumes normal operation.

9. Under Voltage Protection (UVP)

The output voltage is also monitored for under voltage protection. When the output voltage is less than 70% of the setting voltage threshold, under

voltage protection is triggered after 28µs delay to prevent false transition. When UVP is triggered, UGATE and LGATE will get low, and the output

is discharged with the internal 20Ω transistor. UVP is a latched protection; it can only be released by VDD or EN/DEM power-on reset. The UVP

blanking time is 2ms during soft-start.

10. Under Voltage Lockout

The AP3591 provides an under voltage lockout circuit to prevent from undefined status at startup. The UVLO circuit shuts down the device when

VDD drops below 3.6V. The UVLO circuit has 300mV hysteresis, which means the device will start up again when VDD rises to 3.9V.

11. Over Voltage Protection (OVP)

The feedback voltage is continuously monitored for over voltage protection. When OVP is triggered, LGATE will go high and UGATE will go low to

discharge the output capacitor.

OC-SET

is the output voltage, ΔI

of MOSFET increases with the temperature, IOC has 4500ppm/ºC

DS(ON)

.

DS(ON)

Figure 3. Over Current Scheme

should be connected from CS pin to GND. An internal current source IOC (10µA typically), flowing through R

, which can be calculated using the following equation:

OCSET

), can be calculated using the following equation:

O_OCSET

is the inductor current ripple peak to peak value and f is the switching frequency.

L(PP)

OC-SET

determines

Page 14

AP3591

Document number: DS36906 Rev. 1 - 2

14 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

V

OUT

1V/div

V

LGATE

5V/div

Time 100µs/div

V

UGATE

20V/div

Application Information (Cont.)

The AP3591 provides full-time over voltage protection whenever soft-start completes or not. The typical OVP threshold is 125% of the internal

reference voltage V

built into the over voltage protection circuit to prevent false transitions.

. The AP3591 provides latched OVP and can only be released by VDD or EN/DEM power-on reset. There is 33µs delay

REF

Figure 4. Over Voltage Protection

12. Thermal Shutdown

If the junction temperature of the device reaches the thermal shutdown limit of +160ºC, the AP3591 shuts itself off. Both UGATE and LGATE are

driven low, turning off both MOSFETs. The output is discharged with the internal 20Ω transistor. When the junction temperature cools down to the

required level (+140°C nominal), the device initiates soft-start as during a normal power-up cycle.

Page 15

AP3591

Document number: DS36906 Rev. 1 - 2

15 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

PackingPackageProduct Name

TR : Tape & Reel

G1 : Green

AP3591 XX XX – XX

RoHS/Green

FN : U-QFN3535-14

Package

Temperature

Range

Part Number

Marking ID

Packing

U-QFN3535-14

-40 to +85C

AP3591FNTR-G1

BHA

5000/Tape & Reel

First Line: Logo and Marking ID

Second and Third Lines: Date Code

Y: Year

WW: Work Week of Molding

A: Assembly House Code

XX: 7th and 8th Digits of Batch No.

Ordering Information

Diodes IC’s Pb-free products with "G1" suffix in the part number, are RoHS compliant and green.

Marking Information

(1) U-QFN3535-14

(Top View)

Page 16

AP3591

Document number: DS36906 Rev. 1 - 2

16 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

3.400(0.134)

3.600(0.142)

3.400(0.134)

3.600(0.142)

1.900(0.075)

2.100(0.083)

1.500(0.059)

BSC

0.500(0.020)

BSC

0.350(0.014)

0.450(0.018)

0.200(0.008)

0.300(0.012)

0.750(0.030)

0.900(0.035)

0.000(0.000)

0.050(0.002)

A1

Pin 1 Mark

PIN #

1 IDENTIFICATION

See DETAIL A

1

DETAIL A

Pin 1 options

N1

N2

N6

N8

N13

N14

2

3

4

1

2

3

4

1

2

3

4

Symbol

A1

min(mm) max(mm) min(inch) max(inch)

Option1

Option2

0.203(REF)

0.150(REF)

0.008(REF)

0.006(REF)

1.900(0.075)

2.100(0.083)

Package Outline Dimensions (All dimensions in mm(inch).)

(1) Package Type: U-QFN3535-14

Page 17

AP3591

Document number: DS36906 Rev. 1 - 2

17 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

E2

X2

X1

Y1

Y2

E1

Y3

X3

X

Y

Dimensions

X=Y

(mm)/(inch)

X1=Y1

(mm)/(inch)

X2=Y2

(mm)/(inch)

X3=Y3

(mm)/(inch)

E1

(mm)/(inch)

E2

(mm)/(inch)

Value

3.800/0.150

2.100/0.083

0.650/0.026

0.300/0.012

0.500/0.020

1.500/0.059

Suggested Pad Layout

(1) Package Type: U-QFN3535-14

Page 18

AP3591

Document number: DS36906 Rev. 1 - 2

18 of 18

www.diodes.com

March 2014

© Diodes Incorporated

AP3591

NE W P R OD U CT

A Product Line of

Diodes Incorporated

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2014, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

Loading...

Loading...