Page 1

AP3440

Document number: DS36691 Rev. 2 - 2

1 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

Description

The AP3440 is a current mode, PWM synchronous buck (step-down)

DC-DC converter, capable of driving a 4A load with high efficiency,

excellent line and load regulation.

The device integrates two N-channel power MOSFETs with low onresistance. Current mode control provides fast transient response and

cycle-by-cycle current limit.

The switching frequency of AP3440 can be programmable from

200kHz to 2MHz, which allows small-sized components, such as

capacitors and inductors. A standard series of inductors from several

different manufacturers are available. This feature greatly simplifies

the design of switch-mode power supplies.

Under voltage lockout is internally set at 2.6V, but can be increased

by programming the threshold with a resistor network on the enable

pin. The output voltage startup ramp is controlled by the soft-start pin.

An open drain power good signal indicates the output is within 93% to

107% of its nominal voltage.

The AP3440 is available in U-QFN3030-16 package.

Applications

Low-voltage, High-density Power Systems

Point of Load Regulation for High Performance DSPs, FPGAs,

ASICs and Microprocessors

Broadband, Networking and Optical Communications

Infrastructure

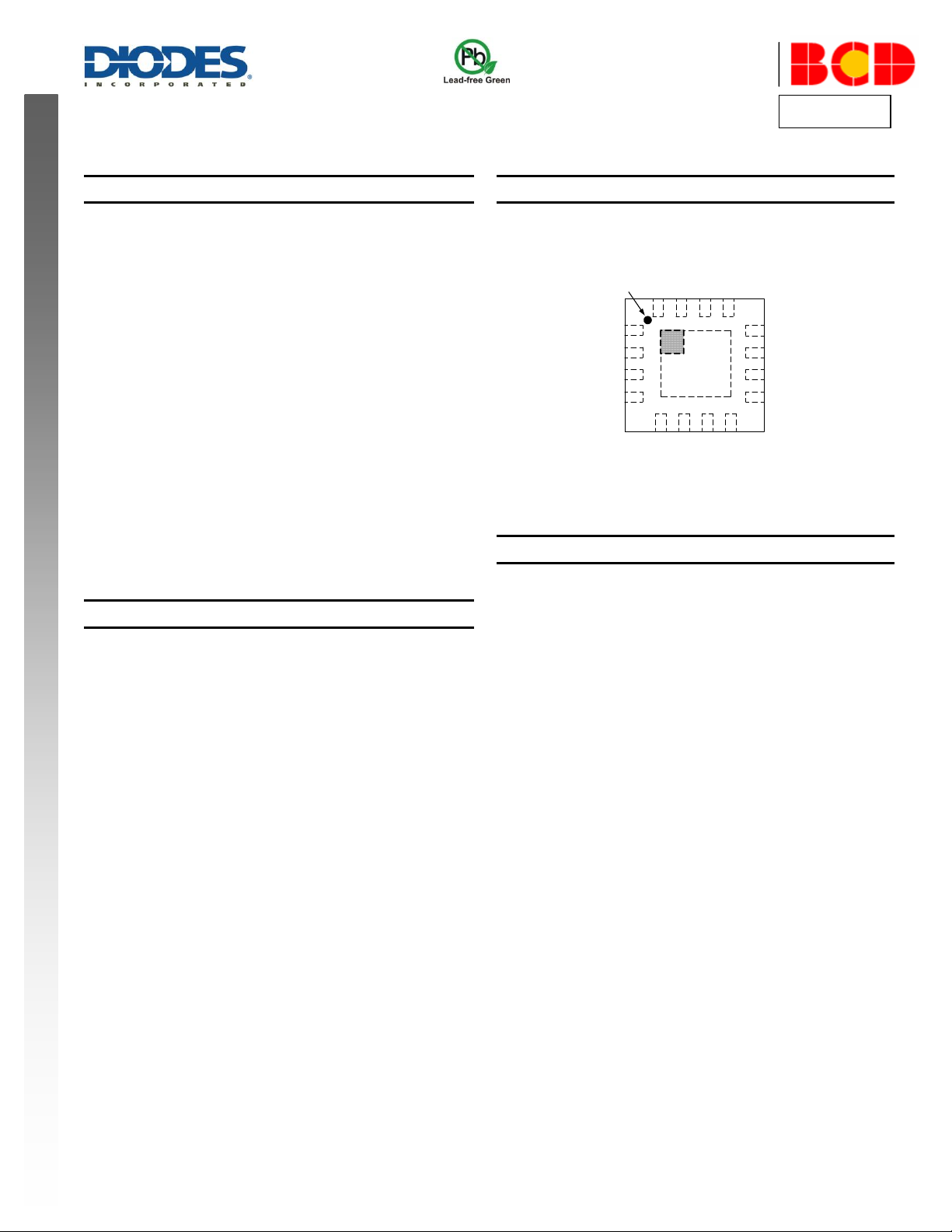

Pin Assignments

(Top View)

VIN

VIN

GND

GND

AGND

FB

COMP

RT/CLK

SS

SW

SW

SW

BOOT

PGD

EN

VIN

E P

5 6 7 8

1

2

3

4 9

12

Pin 1 Mark

11

10

13141516

U-QFN3030-16

Features

Input Voltage Range: 2.95V to 5.5V

0.8V Reference Voltage with ±3% Precision

Two 30m(Typical) MOSFETs for High Efficiency at 4A Load

High Efficiency: Up to 94%

Output Current: 4A

Programmable Frequency:200kHz to 2MHz

Current Mode Control

Synchronizes to External Clock

Adjustable Soft-start

Soft Start-up into Pre-biased Output

UV and OV Power Good Output

Built-in Over Current Protection

Built-in Thermal Shutdown Function

Programmable UVLO Function

Built-in Over Voltage Protection

Thermally Enhanced 3mm×3mm 16-pin U-QFN3030-16

Totally Lead-free & Fully RoHS Compliant (Note1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

4A, 2MHZ HIGH PERFORMANCE SYNCHRONOUS BUCK CONVERTER

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

Page 2

AP3440

Document number: DS36691 Rev. 2 - 2

2 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

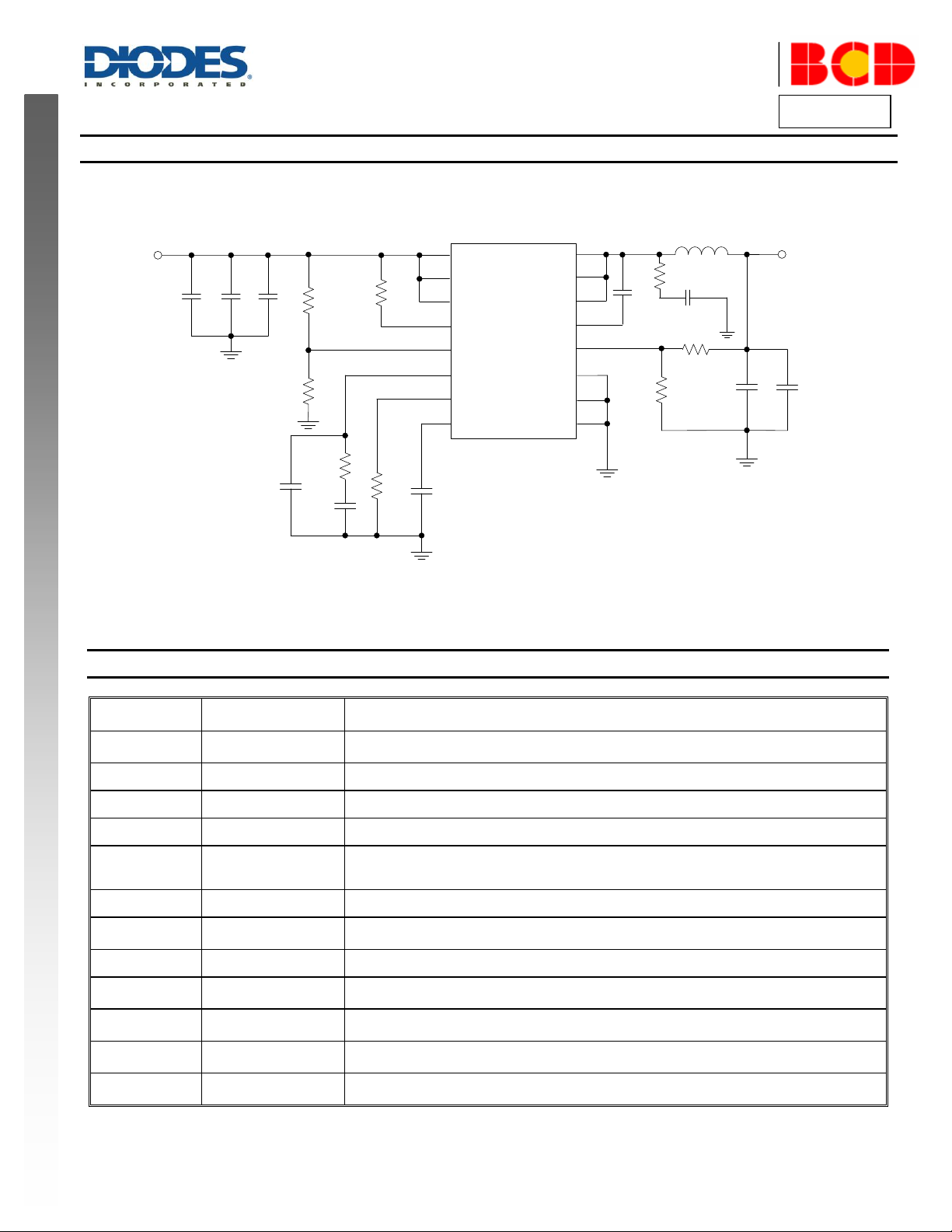

VIN

VIN

VIN

PGD

EN

COMP

SS

RT/CLK

SW

SW

SW

BOOT

FB

GND

GND

AGND

L1 1.5mH

V

OUT

=1.8V

R6 12.5kΩ

R7

10kΩ

VIN=5V

R4

100kΩ

16

1

2

14

15

7

8

9

10

11

12

13

6

4

5

3

C5

Optional

C2

C7

0.01mF

C4

2.7nF

R3

7.5kΩ

R5

180kΩ

R1

R2

AP3440

C3

C9

22mF

C1

10mF 0.1mF

C8

22mF

U1

C6

0.1mF

R8 2.2Ω

(Optional)

C10 2.2nF

(Optional)

Pin Number

Pin Name

Function

1,2,16

VIN

Supply input pin. A capacitor should be connected between the VIN and GND pin to keep the

DC input voltage constant

3,4

GND

Power ground. This pin should be electrically connected to the power pad under the IC

5

AGND

Analog ground. This pin should be electrically connected to GND close to the device

6

FB

Feedback pin. Inverting node of the transconductance error amplifier

7

COMP

Compensation pin. This pin is the output of the transconductance error amplifier and the input

to the current comparator. Connect external compensation elements to this pin to stabilize the

control loop

8

RT/CLK

Resistor timing or external clock input pin

9

SS

Soft-start pin. An external capacitor connected to this pin sets the output voltage rise time. This

pin can also be used for tracking

10,11,12

SW

Internal power switch output pin. This pin is connected to the inductor and bootstrap capacitor

13

BOOT

Bootstrap pin. A bootstrap capacitor is connected between the BOOT pin and SW pin. The

voltage across the bootstrap capacitor drives the internal high-side power MOSFET

14

PGD

Power good indicator output. Asserts low if output voltage is low due to thermal shutdown,

over-current, over/under-voltage or EN shut down

15

EN

Enable pin, internal pull-up current source. Pull below 1.2V to disable. Float to enable. Can be

used to set the on/off threshold (adjust UVLO) with two additional resistors

EP

Exposed Thermal Pad

Exposed Pad can be connected to GND, for best thermal performance thermal vias are

recommended under the package

Typical Applications Circuit

Pin Description

Page 3

AP3440

Document number: DS36691 Rev. 2 - 2

3 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

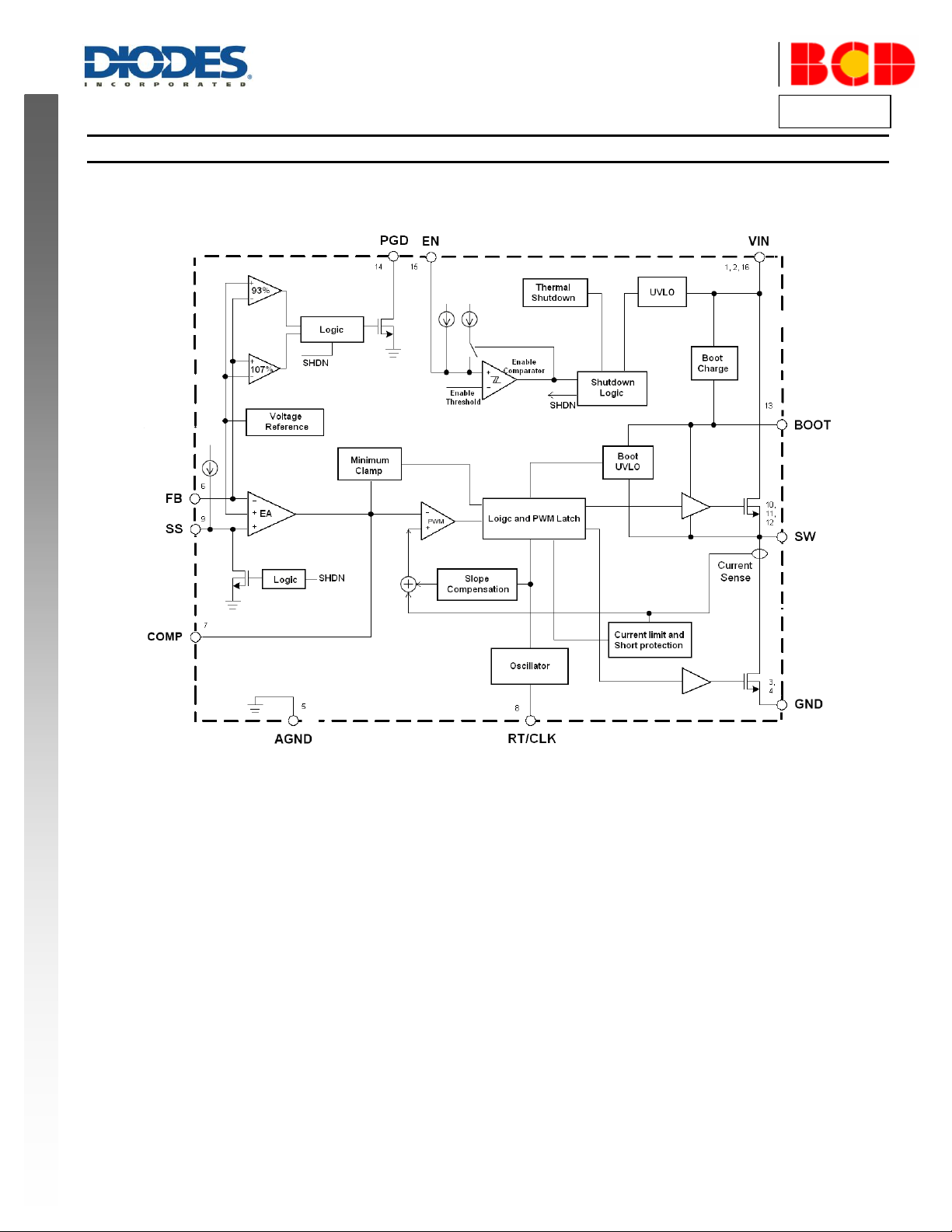

Functional Block Diagram

Page 4

AP3440

Document number: DS36691 Rev. 2 - 2

4 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

Symbol

Parameter

Rating

Unit

VIN

VIN Pin Voltage

-0.3 to 6.5

V

VEN

EN Pin Voltage

-0.3 to 6.5

V

VSW

SW Pin Voltage

-0.3 to VIN+0.3

V

VFB

FB Pin Voltage

-0.3 to 6.5

V

V

COMP

COMP Pin Voltage

-0.3 to 6.5

V

V

PGD

PGD Pin Voltage

-0.3 to 6.5

V

V

RT/CLK

RT/CLK Pin Voltage

-0.3 to 6.5

V

VSS

SS Pin Voltage

-0.3 to 6.5

V

JA

Thermal Resistance

70

ºC/W

TJ

Operating Junction Temperature

-40 to +125

ºC

T

STG

Storage Temperature

-65 to +150

ºC

T

LEAD

Lead Temperature (Soldering, 10sec)

+260

ºC

—

ESD(Machine Model)

200

V

—

ESD(Human Body Model)

2000

V

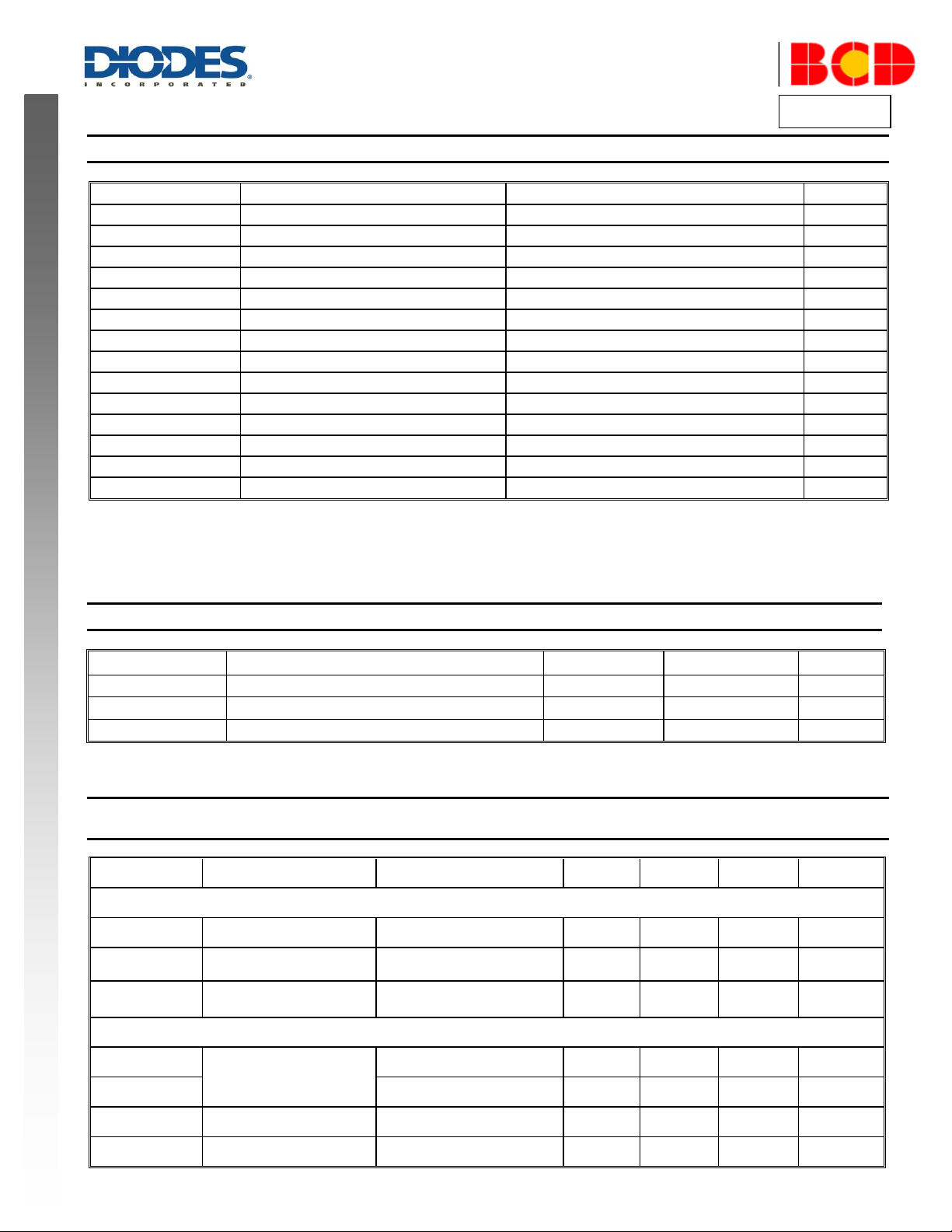

Symbol

Parameter

Min

Max

Unit

VIN

Input Voltage

2.95

5.5

V

I

OUT(MAX)

Maximum Output Current

4 — A

TA

Operating Ambient Temperature

-40

+85

ºC

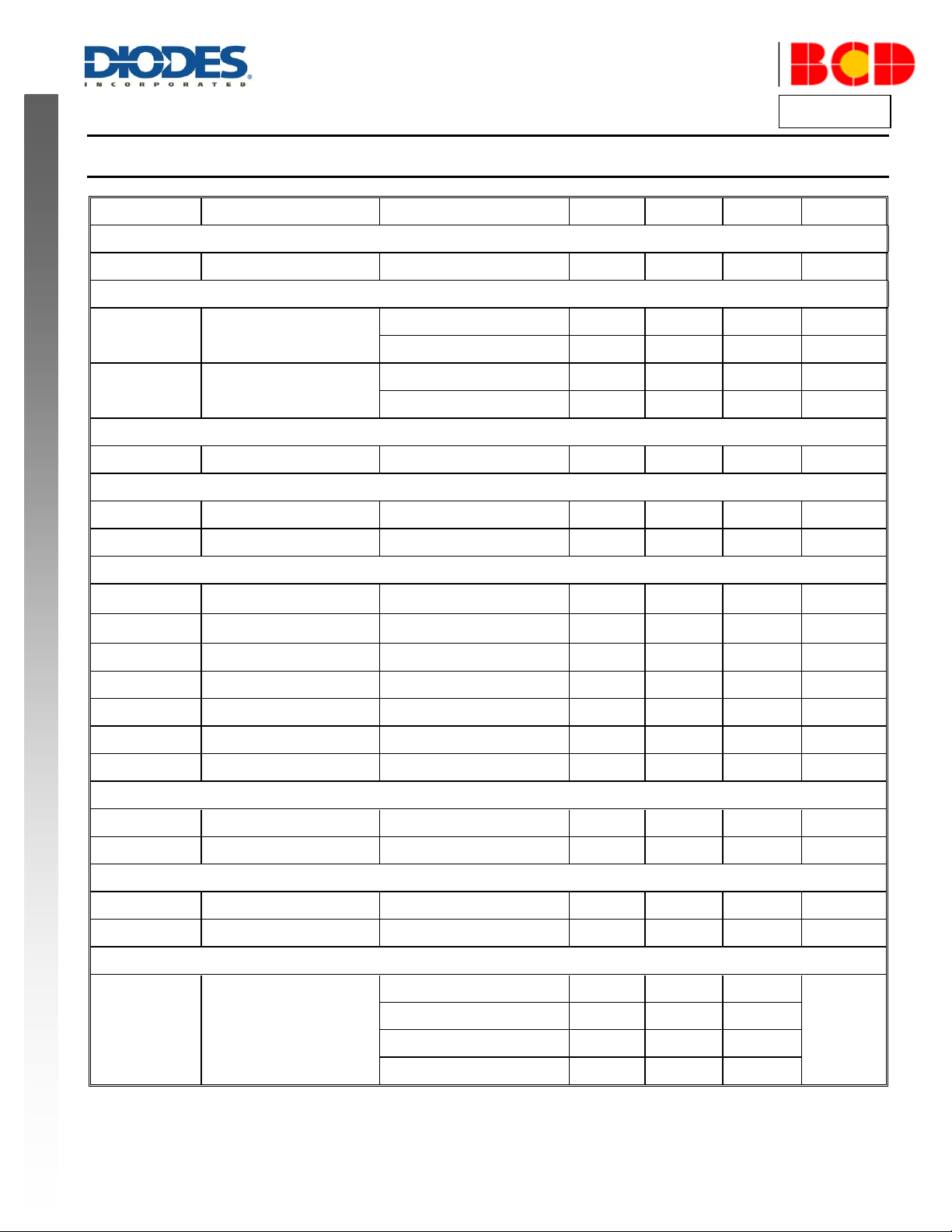

Symbol

Parameters

Conditions

Min

Typ

Max

Unit

SUPPLY VOLTAGE (VIN PIN)

VIN

Input Voltage

—

2.95 — 5.5

V

IQ

Quiescent Current

VFB=0.9V, VIN=5V,

TA=+25ºC, RT=400k

—

360

575

μA

I

SHDN

Shutdown Supply Current

VEN=0V,TA=+25C,

2.95V≤V

IN

≤5.5V

—

2 5 μA

ENABLE AND UVLO (EN PIN)

V

EN_H

Enable Threshold

Rising

1.16

1.25

1.37

V

V

EN_L

Falling — 1.18 — V

V

UVLO

Internal Under Voltage

Lockout Threshold

—

—

2.6

2.8

V

V

HYS

Internal Under Voltage

Hysteresis

—

—

150 — mV

Absolute Maximum Ratings (Note 4)

Note 4: Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “Recommended Operating Conditions” is not implied.

Exposure to “Absolute Maximum Ratings” for extended periods may affect device reliability.

Recommended Operating Conditions

Electrical Characteristics (@V

over full operating temperature range from -40 to +85ºC.)

=2.95 to 5.5V, TA=+25ºC, unless otherwise specified. Specifications with boldface type apply

IN

Page 5

AP3440

Document number: DS36691 Rev. 2 - 2

5 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

Symbol

Parameters

Conditions

Min

Typ

Max

Unit

VOLTAGE REFERENCE (FB PIN)

V

REF

Voltage Reference

2.95V≤V

IN

≤5.5V

0.779

0.803

0.827

V

MOSFET

R

ON_H

High Side Switch Onresistance

V

BOOT-SW

=5V

—

30

60

m

V

BOOT-SW

=2.95V

—

44

70

m

R

ON_L

Low Side Switch Onresistance

VIN=5V

—

30

60

m

VIN=2.95V

—

44

70

mΩ

CURRENT LIMIT

I

LIMIT

Current Limit Threshold

—

4.2

7.0 — A

THERMAL SHUTDOWN

T

TSD

Thermal Shutdown

—

—

140

—

C

—

Hysteresis

—

—

20

—

C

TIMING RESISTOR AND EXTERNAL CLOCK (RT/CLK PIN)

—

Switching Frequency Range

(RT Mode)

—

200 — 2000

kHz

—

Switching Frequency Range

(CLK Mode)

—

300 — 2000

kHz

fS

Switching Frequency

RT=400k

400

500

600

kHz

—

Minimum CLK Pulse Width

—

75

—

—

ns

—

RT/CLK Voltage

RT=400k

—

0.5 — V

—

RT/CLK High Threshold

—

—

1.6

2.2

V

—

RT/CLK Low Threshold

—

0.4

0.6 — V

BOOT (BOOT PIN)

R

BOOT

BOOT Charge Resistor

VIN=5V

—

16

— —

BOOT-SW UVLO

VIN=2.95V

—

2.2 — V

SOFT START (SS PIN)

ISS

Charge Current

VSS=0.4V

— 2 —

mA

VSS

SS to Reference Crossover

98% Nominal

—

1.1 — V

POWER GOOD (PGD PIN)

V

FB_TH

Feedback Threshold

VFB Falling (Fault)

—

91

—

%V

REF

VFB Rising (Good)

—

93

—

VFB Rising (Fault)

—

107

—

VFB Falling (Good)

—

105

—

Electrical Characteristics (Cont.) (@V

apply over full operating temperature range from -40 to +85ºC.)

=2.95 to 5.5V, TA=+25ºC, unless otherwise specified. Specifications with boldface type

IN

Page 6

AP3440

Document number: DS36691 Rev. 2 - 2

6 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

2.4 2.7 3.0 3.3 3.6 3.9 4.2 4.5 4.8 5.1 5.4 5.7

360

365

370

375

380

385

390

395

400

405

410

415

420

425

430

435

Supply Current (

mA)

Input Voltage (V)

-50 -25 0 25 50 75 100 125 150

390

395

400

405

410

415

420

425

430

435

440

445

450

455

460

Supply Current (

mA)

Temperature (oC)

-50 -25 0 25 50 75 100 125 150

2.10

2.15

2.20

2.25

2.30

2.35

2.40

2.45

2.50

2.55

2.60

UVLO Threshold (V)

Temperature (oC)

Start Switching

Stop Switching

-50 -25 0 25 50 75 100 125 150

1.14

1.15

1.16

1.17

1.18

1.19

1.20

1.21

1.22

1.23

1.24

1.25

1.26

1.27

1.28

EN Threshold (V)

Temperature (oC)

VIN=5V

Rising

Falling

0 300 600 900 1200 1500 1800 2100 2400 2700 3000 3300 3600 3900 4200

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

Efficiency (%)

Output Current (mA)

V

OUT

=1.8V

VIN=3.3V

VIN=5V

-50 -25 0 25 50 75 100 125 150

920

930

940

950

960

970

980

990

1000

1010

1020

RT=180k

Switching Frequency (kHz)

Temperature (oC)

Performance Characteristics

Supply Current vs. Input Voltage Supply Current vs. Temperature

UVLO Threshold vs. Temperature EN Threshold vs. Temperature

Efficiency vs. Output Current Switching Frequency vs. Temperature

Page 7

AP3440

Document number: DS36691 Rev. 2 - 2

7 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

V

OUT

1V/div

V

IN

2V/div

I

L

2A/div

VSS

2V/div

V

EN

2V/div

V

OUT

1V/div

VSS

2V/div

I

L

2A/div

V

OUT(AC)

200mV/div

I

OUT

2A/div

V

CLOCK

2V/div

VSW

2V/div

V

OUT

1V/div

VSS

2V/div

V

COMP

0.5V/div

I

L

2A/div

V

OUT

1V/div

VSS

2V/div

V

COMP

0.5V/div

I

L

2A/div

Performance Characteristics (Cont.)

Start Up from VIN (VIN=5V, V

OUT

=1.8V, I

=4A) Disable IC (VIN=5V, V

OUT

OUT

=1.8V, I

OUT

=4A)

Time 4ms/div Time 20ms/div

Load Transient Response (VIN=5V, V

OUT

=1.8V, I

=0 to 4A) Synchronizing to External Clock (f

OUT

CLOCK

=2MHz)

Time 200ms/div Time 400ns/div

Short Circuit Protection (VIN=5V, V

OUT

=1.8V, I

=4A) Short Circuit Recovery (VIN=5V, V

OUT

OUT

=1.8V, I

OUT

=4A)

Time 4ms/div Time 4ms/div

Page 8

AP3440

Document number: DS36691 Rev. 2 - 2

8 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

)(

)()(

)(

VV

AImst

nFC

REF

SSSS

SS

m

6

1059.2

944.0

1

STOPSTART

VV

R

6

102.3118.1

118.1

2

RV

R

R

STOP

AP3440

R1

R2

VIN

EN

2.55μA0.6μA

Application Note

Theory of Operation

The AP3440 consists of a reference voltage module, slope compensation circuit, error amplifier, PWM comparator, current limit circuit, two Nchannel MOSFETs etc. (Refer to the Functional Block Diagram on page 3 for detailed information)

Soft-start

The AP3440 integrates an internal soft start circuit to minimize inrush currents or provide power supply sequencing during power up. A capacitor

connected between SS pin and ground implements the soft-start time. The AP3440 has an internal pull-up current source of 2μA, which charges

the external slow start capacitor. Equation 1 calculates the required slow start capacitor, ISS is the internal slow start charging current of 2μA, and

V

is the internal voltage reference of 0.803V.

REF

………………….(1)

During normal operation, if the VIN goes below the UVLO, or the EN pin is pulled below 1.2V, or a thermal shutdown occurs, the AP3440 will stop

switching and the SS pin will be discharged to 40mV before reinitiating a powering up sequence.

Enable and Adjusting UVLO

The AP3440 are disabled when the VIN falls below 2.6V. If an application requires a higher under-voltage lockout (UVLO), use the EN pin as

shown in Figure 1 to adjust the input voltage UVLO by using two external resistors. The EN pin has an internal pull-up current source that provides

the default condition of the AP3440 operating when the EN pin floats. Once the EN pin voltage exceeds 1.25V, an additional 2.55μA of hysteresis

is added. When the EN pin is pulled below 1.18V, the 2.55μA hysteresis is removed. This additional current facilitates input voltage hysteresis.

For AP3440, the divider resistor R1 and R2 on the EN pin can be calculated according to equation 2 and 3.

…………………...(2)

………………(3)

Figure 1. Adjustable Under Voltage Lock Out

Adjusting Output Voltage

The output voltage is set with a resistor divider from the FB pin. It is recommended to use divider resistors with 1% tolerance or better. Start with a

10kΩ R2 resistor and use the equation 4 to calculate R1. To improve efficiency at very light loads consider using larger value resistors. If the

values are too high, the regulator is more susceptible to noise and voltage errors from the FB input current are noticeable.

Page 9

AP3440

Document number: DS36691 Rev. 2 - 2

9 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

1

803.0

21

OUT

V

RR

AP3440

R1

R2

V

OUT

FB

0.803V

SS

AP3440

R

T

RT/CLK

Clock

Source

Figure 3. Synchronizing to a System Clock

Figure 4. Synchronizing Waveform

0793.1

)(

311890

)(

kHzf

kR

SW

T

9393.0

)(

133870

)(

kR

kHzf

T

SW

Application Note (Cont.)

Resistor R1 can be calculated according to equation 4.

……………………….. (4)

Figure 2. Voltage Divider Circuit

Synchronize Using the RT/CLK Pin

The RT/CLK pin of AP3440 is used to synchronize the converter with an external system clock referring to Figure 3. To implement the

synchronization feature in a system, connect a square wave to the RT/CLK pin with an on-time of at least 75ns. When the clock is detected on the

RT/CLK pin, a mode change occurs and the pin becomes a synchronization input. The internal amplifier is disabled. If clocking edges stop, the

internal amplifier is re-enabled and the mode returns to the frequency set by the resistor. The low level of the square wave must be lower than

0.6V and the high level higher than 1.6V typically. The synchronization frequency range is from 300kHz to 2000kHz. The rising edge of the SW is

synchronized to the falling edge of RT/CLK pin. Figure 4 shows a typical synchronizing waveform, the clock frequency is 2MHz.

Constant Switching Frequency and Timing Resistor

The switching frequency of the AP3440 is adjustable over a wide range from 200kHz to 2000kHz by placing a resistor with maximum value of

1000kΩ and minimum of 85kΩ, respectively, on the RT/CLK pin. An internal amplifier holds this pin at a fixed voltage when connecting an external

resistor to ground to set the switching frequency. The V

use the equation 5.

To reduce the solution size one should typically set the switching frequency as high as possible, but tradeoffs of the efficiency, maximum input

voltage and minimum controllable on time should be considered.

……………………….(5)

………………………..(6)

is typically 0.5V. To determine the timing resistance for a given switching frequency,

RT/CLK

Page 10

AP3440

Document number: DS36691 Rev. 2 - 2

10 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

VIN

VIN

VIN

PGD

EN

COMP

SS

RT/CLK

SW

SW

SW

BOOT

FB

GND

GND

AGND

L1 1.5mH

V

OUT

=1.8V

R6 12.5kΩ

R7

10kΩ

VIN=5V

R4

100kΩ

16

1

2

14

15

7

8

9

10

11

12

13

6

4

5

3

C5

Optional

C2

C7

0.01mF

C4

2.7nF

R3

7.5kΩ

R5

180kΩ

R1

R2

AP3440

C3

C9

22mF

C1

Optional

10mF 0.1mF

C8

22mF

U1

C6

0.1mF

R8 2.2Ω

(Optional)

C10 2.2nF

(Optional)

IN

OUT

IN

OUT

OUT(MAX)CIN_RMS

V

V

1

V

V

II

Application Note (Cont.)

Over Current Protection

The AP3440 implements a cycle-by-cycle current limit. The high side switch current is detected during each cycle. During SCP conditions, V

pulled down and V

is drived to high, increasing the switch current. When the increased high side switch current is continuously detected to

COMP

trigger the current limit of high side switch 6 times, the high side and low side switches are turned off for about 2.5ms. Then both switches start

switching and they will not be turned off until the next 6 OCPs are triggered. The IC works with a hiccup mode during SCP conditions.

Power Good

The PGD pin output is an open drain MOSFET. The output is pulled low when the FB voltage enters the fault condition by falling below 91% or

rising above 107% of the nominal internal reference voltage. There is a 2% hysteresis on the threshold voltage, so when the FB voltage rises to

the good condition above 93% or falls below 105% of the internal voltage reference the PGD output MOSFET is turned off. It is recommended to

use a pull-up resistor between the values of 1kΩ Ω to a voltage source that is 5V or less. The PGD is in a valid state once the VIN input

voltage is greater than 1.2V.

Thermal Shutdown

The AP3440 implement an internal thermal shutdown to protect itself if the junction temperature exceeds +140°C. Switching is stopped when the

junction temperature exceeds the thermal trip threshold. Once the die temperature decreases below +120°C, the device reinitiates the soft start

operation. The thermal shutdown hysteresis is +20°C.

Component Selection

Typical application circuit of AP3440 is shown in Figure 5. For the major component selection please refer to the following section.

OUT

is

Input Capacitor

The AP3440 requires a high quality ceramic, type X5R or X7R, input decoupling capacitor of at least 4.7μF effective capacitance and in some

applications a bulk capacitor. The effective capacitance includes any DC bias effects. To ensure a stable operation, the input capacitor should be

placed as close to the VIN pin as possible, and its value varies according to different load and different characteristic of input impedance.

There are two important parameters of the input capacitor: the voltage rating and RMS current rating. The voltage rating of the input capacitor

should be at least 1.25 times larger than the maximum input voltage. The capacitor must also have a RMS current rating greater than the

maximum input current ripple of the AP3440. The RMS current of input capacitor can be expressed as:

Figure 5. Typical Application of AP3440

………..(7)

Page 11

AP3440

Document number: DS36691 Rev. 2 - 2

11 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

)

8

1

(

OUT

ESRLOUT

Cf

RIV

)(

kIVf

VV

VL

OUTIN

OUTIN

OUT

)

2

(

LVf

VV

VII

IN

OUTIN

OUTOUTPEAK

)(

)()(

)(

VV

AImst

nFC

REF

SSSS

SS

m

1

803.0

76

OUT

V

RR

Application Note (Cont.)

Output Capacitor

The output capacitor is the most critical component of a switching regulator. It is used for filtering output and keeping the loop stable. The typical

value is 44μF.

The primary parameters for output capacitor are the voltage rating and the equivalent series resistance (ESR). A low ESR capacitor is preferred to

keep the output voltage ripple low. The output ripple is calculated as the following:

……………..(8)

Where f is the switching frequency, C

Inductor

The inductor is used to supply smooth current to output when it is driven by a switching voltage. The higher the inductance, the lower the peak-topeak ripple current, as the higher inductance usually means the larger inductor size, so some trade-offs should be made when select an inductor.

The AP3440 is a synchronous buck converter. It always works on continuous current mode (CCM), and the inductor value can be selected as the

following:

is the output capacitance and △IL is the ripple current in the inductor.

OUT

…………………. ….(9)

Where V

to 40%. Another important parameter for the inductor is the current rating. Exceeding an inductor's maximum current rating may cause the

inductor to saturate and overheat. If inductor value has been selected, the peak inductor current can be calculated as the following:

It should be ensured that the current rating of the selected inductor is 1.5 times of the I

Slow Start Capacitor

The slow start capacitor determines the output voltage soft start time during power up.

The slow start capacitor value can be calculated using equation 11.

In AP3440, ISS is 2μA and V

Bootstrap Capacitor

A 0.1μF ceramic capacitor must be connected between the BOOT pin and the SW pin for normal operation. It is recommended to use a ceramic

capacitor with X5R or better grade dielectric.

Feedback Resistors

It is recommended to use divider resistors with 1% tolerance or better. Start with a 10kΩ for the R7 resistor and use the equation 12 to calculate

R6.

is the output voltage, VIN is the input voltage, I

OUT

…………..(10)

……………………… (11)

is 0.803V.

REF

…………………………………(12)

is the output current, k is the coefficient of ripple current, and its typical value is 20%

OUT

.

PEAK

Page 12

AP3440

Document number: DS36691 Rev. 2 - 2

12 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

OUTLOAD

P

CRf

2

1

1

OUTESR

Z

CRf

2

1

1

COMPEAOUT

P

CR

f

_

2

2

1

COMPCOMP

Z

CRf

2

1

2

Application Note (Cont.)

Compensation

The output capacitor and the load resistance largely determine where the error amplifier poles and zeros need to be placed for optimum transient

response and loop stability. The corner frequency of the pole and zero generated by output capacitor are:

………………………..(13)

………………………. .. (14)

Where R

The error amplifier provides most of the loop gain. After selecting the output capacitor, the control loop is compensated by tailoring the frequency

response of the error amplifier. The low frequency pole of the error amplifier is the dominant pole and is determined primarily by C

output resistance of the error amplifier as shown by:

is the load resistance, C

LOAD

is the output capacitance and R

OUT

…………………..(15)

is the capacitor ESR.

ESR

COMP

and the

Resistor R

Where R

A 7.5kΩ resistor and 2.7nF capacitor are used in typical application.

adds a zero to the frequency response to control gain in the mid frequency range. This zero frequency is:

COMP

……………………..(16)

COMP

and C

are compensation resistor and capacitor connected to COMP pin, R

COMP

is the output impedance of the error amplifier.

OUT_EA

Layout Consideration

PCB layout is very important to the performance of AP3440. The loop which switching current flows through should be kept as short as possible.

The external components (especially CIN) should be placed as close to the IC as possible.

The feedback trace should be routed far away from the inductor and noisy power traces, and it needs to be routed as direct as possible. Locate

the feedback divider resistor network near the feedback pin with short leads.

Since the SW connection is the switching node, the output inductor should be located very close to the SW pins, and the area of the PCB

conductor is minimized to prevent excessive capacitive coupling.

The boot capacitor must also be located close to the device. The sensitive analog ground connections for the feedback voltage divider,

compensation components, slow start capacitor and frequency set resistor should be connected to a separate analog ground trace.

The RT/CLK pin is sensitive to noise so the RT resistor should be located as close as possible to the IC and routed with minimal lengths of trace.

Figure 6. Top View of PCB Layout Figure 7. Bottom View of PCB Layout

Page 13

AP3440

Document number: DS36691 Rev. 2 - 2

13 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

AP3440 XX XX - XX

Packing

Package

TR : Tape & Reel

FN : U-QFN3030-16

G1 : Green

Product Name

RoHS/Green

Package

Temperature Range

Part Number

Marking ID

Packing

U-QFN3030-16

-40 to +85ºC

AP3440FNTR-G1

B2D

5000/Tape & Reel

B2D

YWW

MXX

: AAC Logo

B2D: Marking ID (Per Datasheet)

YWW: Year and Work Week of Mold Operation

M: Assembly Site Code

XX: The 7th & 8th Digits of Batch No.

· Pin 1 Mark

Ordering Information

Diodes IC’s Pb-free products with "G1" suffix in the part number, are RoHS compliant and green.

Marking Information

Page 14

AP3440

Document number: DS36691 Rev. 2 - 2

14 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

U-QFN3030-16

Type B

Dim

Min

Max

Typ

A

0.55

0.65

0.60

A1

0

0.05

0.02

A3

0.15

b

0.18

0.28

0.23

D

2.95

3.05

3.00

D2

1.40

1.60

1.50

E

2.95

3.05

3.00

E2

1.40

1.60

1.50

e

0.50

L

0.35

0.45

0.40

Z

0.625

All Dimensions in mm

Dimensions

Value

(in mm)

C

0.500

G

0.150

G1

0.150

X

0.350

X1

1.800

Y

0.600

Y1

1.800

Side View

A

A3

A1

Bottom View

D

D2

E

e

b (16x)

L (16x)

E2

(Pin #1 ID)

Z (8x)

0.450

R0.200

X (16x)

Y (16x)

C

Y1

X1

G1

G

Package Outline Dimensions

(1) Package Type: U-QFN3030-16

Suggested Pad Layout

(1) Package Type: U-QFN3030-16

Page 15

AP3440

Document number: DS36691 Rev. 2 - 2

15 of 15

www.diodes.com

March 2014

© Diodes Incorporated

AP3440

A Product Line of

Diodes Incorporated

NEW PRODUCT

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2014, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

Loading...

Loading...