Page 1

Service Manual

Model

BLF3451

UL Part Number

6909590100

IMPORTANT SAFETY INFORMATION: Always read this manual rst before attempting to service this replace. For your

safety, always comply with all warnings and safety instructions contained in this manual to prevent personal injury or property damage.

Dimplex North America Limited

1367 Industrial Road Cambridge ON Canada N3H 4W3

1-888-346-7539 www.dimplex.com

In keeping with our policy of continuous product development, we reserve the right to make changes without notice.

© 2016 Dimplex North America Limited

REV PCN DATE

00 - 6-JAN-16

7400890000R00

Page 2

TABLE OF CONTENTS

Operation ...........................................................3

Maintenance .........................................................4

Exploded Parts Diagram ...............................................5

Wiring Diagram ......................................................6

Preparation for service ................................................7

Instructions for removing from wall .....................................7

Surface Mount .............................................................. 7

Recessed Mount - Partial In-wall ............................................... 8

Flush Mount – Complete In-wall ............................................... 8

Switchboard Replacement .............................................9

Relay Board Replacement ............................................10

AD/DC Adapter Replacement ..........................................10

Display / Control Board Replacement ...................................11

Flicker Motor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Flicker Motor/ Flicker Rod Replacement .................................12

LED Light Strips Replacement .........................................12

High Temperature Cutout Replacement .................................13

Element Replacement ................................................13

Blower/fan Replacement ..............................................14

Thermistor Replacement .............................................14

Troubleshooting Guide ...............................................16

Always use a qualied technician or service agency to repair this replace.

!

NOTE: Procedures and techniques that are considered important enough to emphasize.

CAUTION: Procedures and techniques which, if not carefully followed, will result in damage to the equipment.

WARNING: Procedures and techniques which, if not carefully followed, will expose the user to the risk of re, serious

injury, or death.

2 www.dimplex.com

Page 3

OPERATION

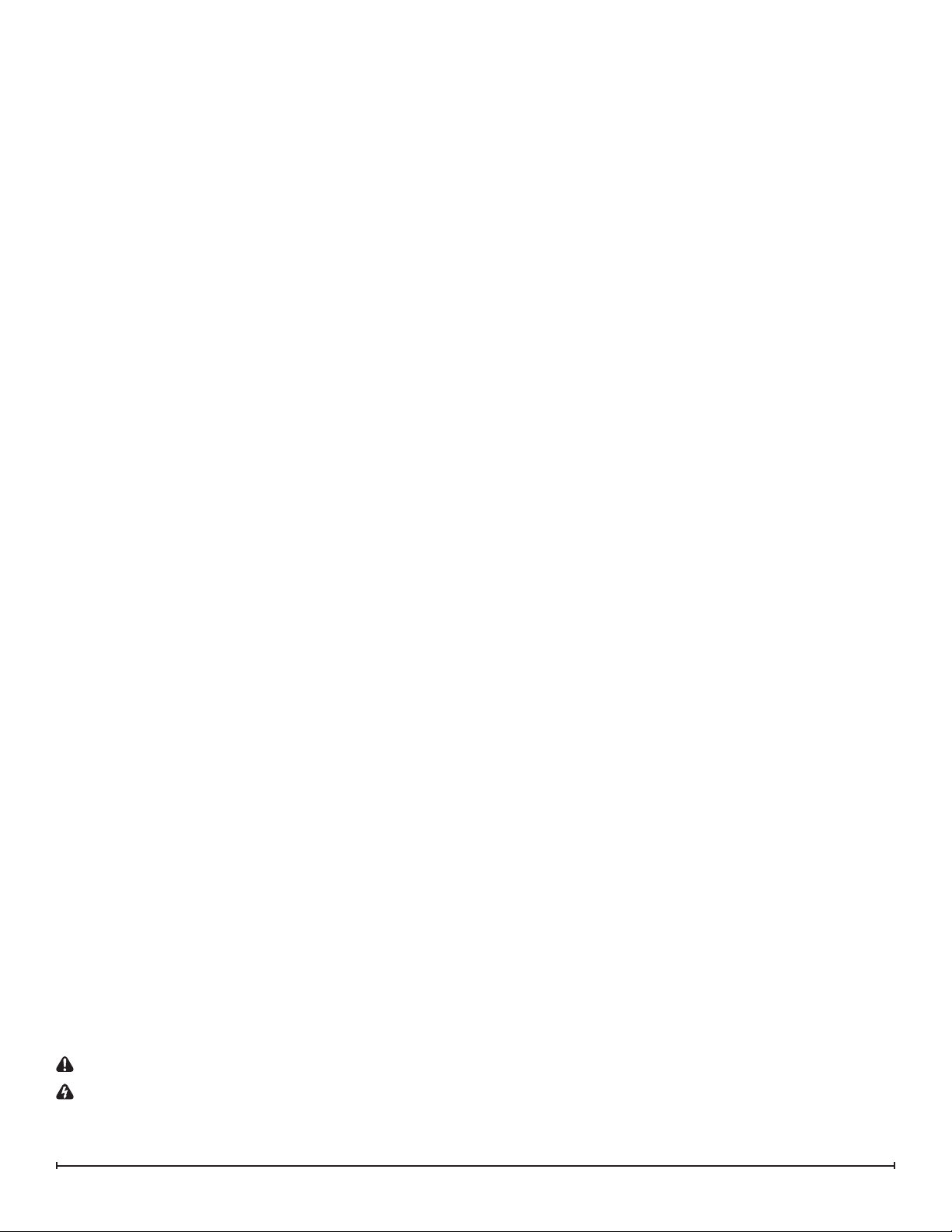

Figure 1

A C D E

Floating

Display

WARNING: This electric rebox must be properly installed

before it is used.

The unit can be controlled by either the manual controls which are

located on the upper right of the replace or the remote (Figure 13

& 14).

The replace is supplied with an IR multifunction remote control.

!

NOTE: To operate correctly, the remote control must be point-

ed towards the Floating DisplayTM.

A. Standby

Turns the unit On and Off.

→ Activated by pressing the Standby button on the remote or the

unit.

• The unit will turn on with the same functions that it was set to

when it was turned Off and the intake temperature will be indi-

cated on the Floating DisplayTM.

!

NOTE: When any button is pressed the intake temperature will

be displayed on the Floating DisplayTM for 5 seconds.

B. Flame Effects

Turns the ame effect On and Off.

→ Activated by pressing the button on the remote.

C. Heat ON/OFF

Turns the heater On and Off.

→ Activated by pressing the button on the unit or the remote.

• Indicated by the icon and the intake temperature being

displayed on the Floating DisplayTM, for 5 seconds before turn-

ing off.

!

NOTE: After the heater is switched off, there is a 60 second

fan delay, where the fan will continue running before turning off.

!

NOTE: The unit can be operated in Heat Only Mode. When

the unit is only running with the heater, the icon will continu-

ously be displayed on the Floating DisplayTM.

!

NOTE: The heater may emit a slight, harmless odor when rst

used. This odor is a normal condition caused by initial heating of

internal heater parts and will not occur again.

D & E. Thermostat Controls

Adjusts the temperature set point to your individual requirements.

Once the desired set temperature is reached the heater will turn

off. The heater will cycle on and off to maintain the desired set

temperature. The default temperature setting is 72°F (22°C).

F

TM

to increase the set point on the unit or the remote.

• The Floating DisplayTM will indicate the temperature set point as

it is adjusted.

!

NOTE: Holding the and the

seconds, on the unit, will change the temperature from °C to °F, or

vice versa.

buttons down for two

Disable Heat

If desired, depending on the season, the heater on the unit can be

disabled. The unit will operate in the same fashion, with remainder

of the controls.

Pressing the and buttons on the unit at the same time

and holding for 2 seconds will disable and enable the heater.

!

NOTE: When the heater has been disabled and either the

or the is pressed the Floating DisplayTM will indicate “--”.

F. Color Themes

Different presets of ambient lighting color combinations contained

in the unit.

→ Changed by repeatedly pressing the corresponding button on

the remote or the unit.

• Cycles through the different preset ambient lighting settings of

the unit, this includes different combinations of colours of the

ame base and media lighting.

!

NOTE: The last theme of the cycle is a prism where the unit

cycles through a variety of colours. Pressing the button stops

the cycling and holds the unit on the preferred color, indicated by

a “U” - Unfreeze or a “F” - Freeze on the display.

G.

Changes the brightness of the lights in the unit.

→ Adjusted by repeatedly pressing the corresponding button on

• Indicated by the second digit on the Floating Display™

Brightness

the remote.

changing to show: “H” (high), and “L” (low).

H. Sleep Timer

The Sleep Timer can be set to automatically shut off the replace

after a preset time (from 30 minutes to 8 hours).

→ To set the timer press the timer button on the remote, repeat-

edly, until the desired time is displayed.

• The Floating DisplayTM will display the different times as it is ad-

justed. Once the timer has begun, pressing the button will

display the time remaining before the unit turns Off.

!

NOTE: The Sleep Timer can be cancelled at any time by

pressing the button repeatedly until the sleep timer displays

nothing.

Resetting the Temperature Cutoff Switch

Should the heater overheat, an automatic cut out will turn the

whole unit off and it will not come back on without being reset. It

can be reset by turning the power to the unit and waiting 5 minutes before turning the unit back on.

CAUTION: If you need to continuously reset the heater, un-

plug the unit and call technical support at 1-888-346-7539.

→ Adjusted by pressing the

to decrease the set point and the

3

Page 4

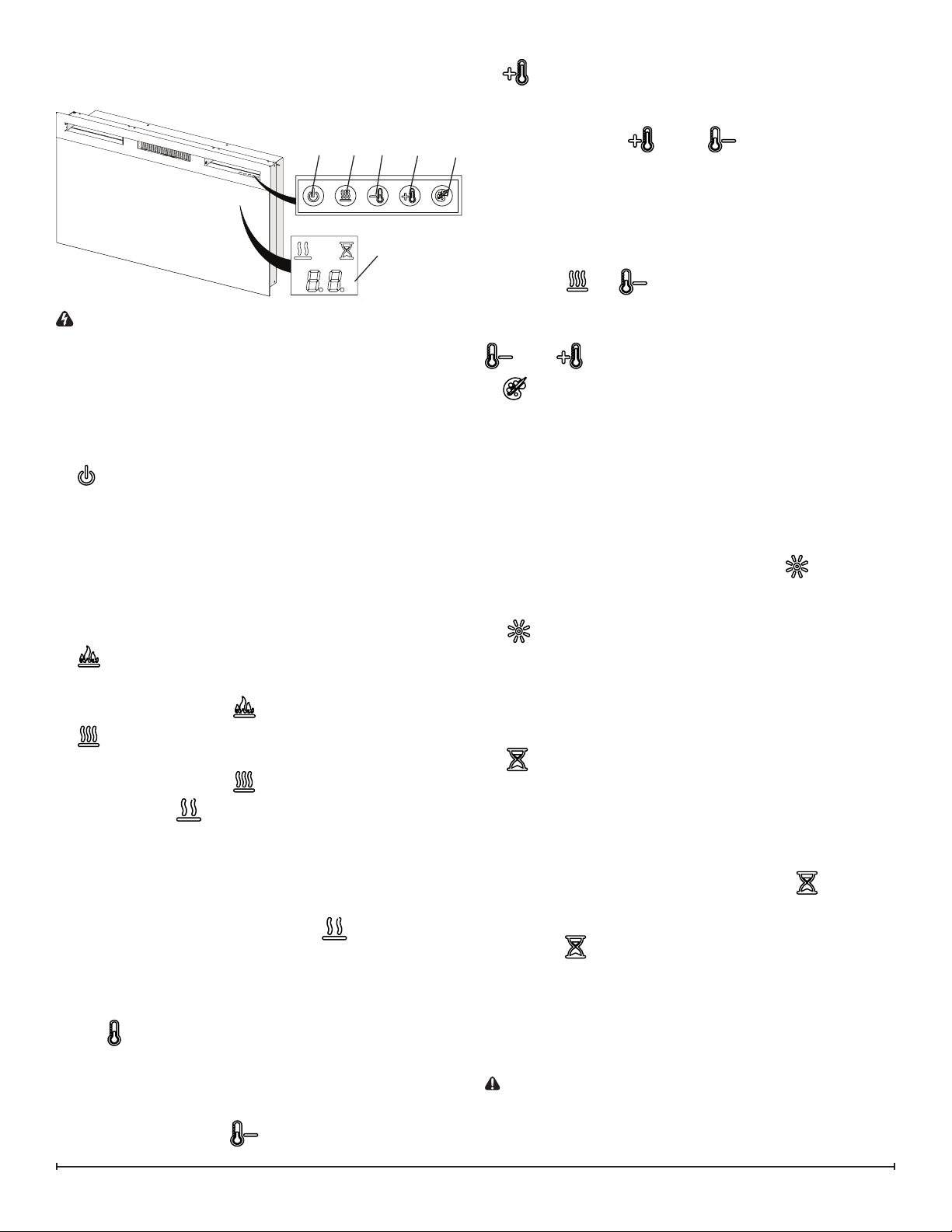

Remote Control Battery Replacement

To replace the battery:

1. Slide battery cover open on the remote control.

2. Correctly install one 3 Volt (CR2032 [longer life] or CR2025)

battery in the battery holder.

3. Close the battery cover.

Battery must be recycled or disposed of properly. Check

with your Local Authority or Retailer for recycling advice in

your area

Figure 2

A

B

D

F

C

E

G

H

MAINTENANCE

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of re, electric shock or damage to persons.

!

NOTE: The replace should not be operated with an ac-

cumulation of dust or dirt on or in the unit, as this can cause

a build up of heat and eventual damage. For this reason

the heater must be inspected regularly, depending upon

conditions and at least at yearly intervals.

Partially Reective Glass Cleaning

The partially reective glass is cleaned in the factory during the assembly operation. During shipment, installation,

handling, etc., the partially reective glass may collect dust

particles; these can be removed by dusting lightly with a

clean dry cloth.

To remove ngerprints or other marks, the partially reective glass can be cleaned with a damp cloth. The partially

reective glass should be completely dried with a lint free

cloth to prevent water spots. To prevent scratching, do not

use abrasive cleaners.

Fireplace Surface Cleaning

Use only a damp cloth to clean painted surfaces of the

replace. Do not use abrasive cleaners.

Servicing

Except for installation and cleaning described in this manual, an authorized service representative should perform any

other servicing.

4 www.dimplex.com

Page 5

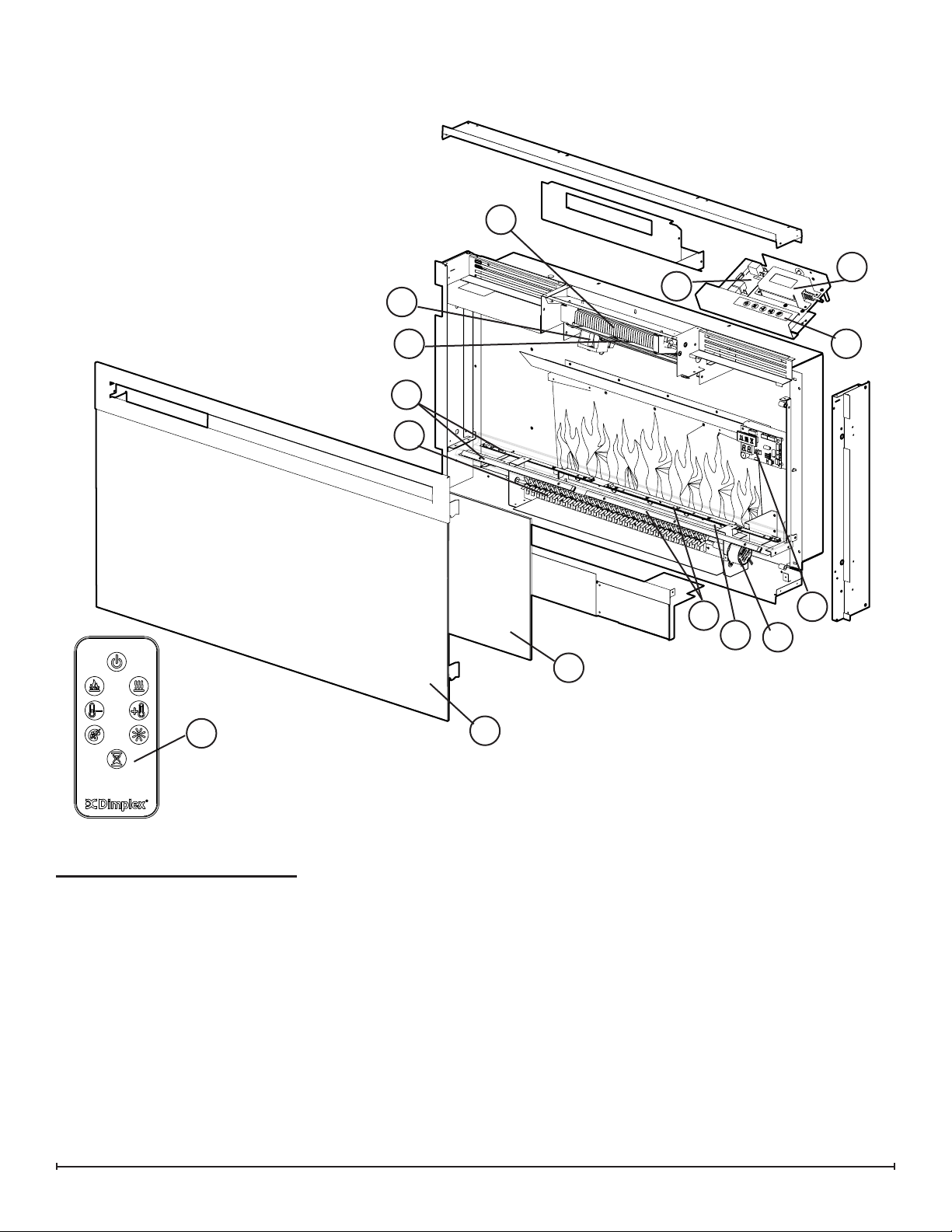

EXPLODED PARTS DIAGRAM

1

18

16

3

12

14

8

7

13

9

6

2

4

10

11

Replacement Parts List

1. Element. . . . . . . . . . . . . . . . . . . . . . . . .2200510300RP

2. Partially Reective Glass ...........5902700100RP

3. Blower . . . . . . . . . . . . . . . . . . . . . . . . . . 5300170300RP

4. Front Glass . . . . . . . . . . . . . . . . . . . . . .6909140100RP

5. Power Cord . . . . . . . . . . . . . . . . . . . . . . 4100190300RP

6. Flicker Motor . . . . . . . . . . . . . . . . . . . . . 2000500100RP

7. Flicker Assembly .................5902720100RP

8. Cutout . . . . . . . . . . . . . . . . . . . . . . . . . .2300201500RP

9. Flame LED Light Strip (Amber) .......3001420200RP

10. Switch Board . . . . . . . . . . . . . . . . . . . . . 3001520100RP

11. Display/ Control Board .............3001640100RP

12. Remote Control ...................6700520200RP

13. LED Light Strip (6) (RGB) (2 per unit) 3001570100RP

14. LED Light Strip (4) (RGB) (2 per unit) 3001570400RP

15. Thermistor .......................3001560300RP

16. Relay Board .....................3001630100RP

17. Mounting Kit .....................9600770100RP

18. AC/DC Adapter ...................2100250100RP

Accessories

River Rocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DFS1314

Driftwood Accessory Kit. . . . . . . . . . . . . . . . LF34DWS-KIT

5

Page 6

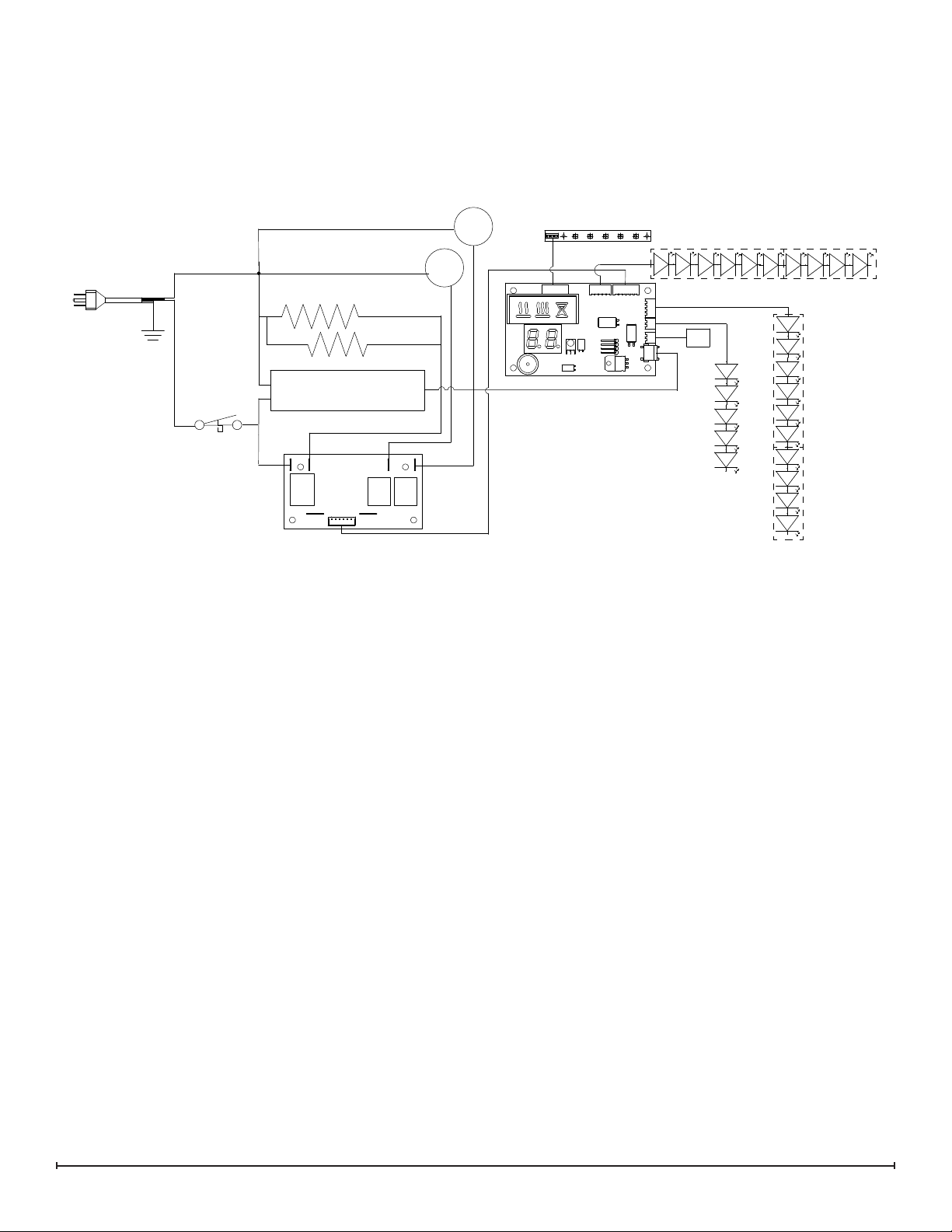

WIRING DIAGRAM

LINE

NEUTRAL

THERMAL

CUTOUT

ELEMENT

ELEMENT

AC/DC ADAPTER

HTR

FLICKER MOTOR

BLOWER MOTOR

RELAY BOARD

M

M

SWITCH BOARD

LED STRIPS (RGB) - MEDIA

LED STRIPS (RGB) - FLAME

FLAME LED STRIP (AMBER)

THERMISTOR

DISPLAY / CONTROL BOARD

6 www.dimplex.com

Page 7

PREPARATION FOR SERVICE

!

NOTE: All components are replaceable from the front of

the replace while the unit is mounted on the wall, with the

exception of replacement of the power cord.

!

NOTE: If the power cord needs replacing or if the unit

needs to be removed from the wall for any other reason

please begin service by following the “PREPARATION FOR

SERVICE” instructions, then move on to the section “IN-

STRUCTIONS FOR REMOVING FROM WALL”.

Tools Required: Phillips head screwdriver

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

1. Disconnect power source.

• Unplug the replace from the outlet.

• If unit has been hard wired for power or outlet is

not accessible from the front, turn the breaker off at

the electrical panel.

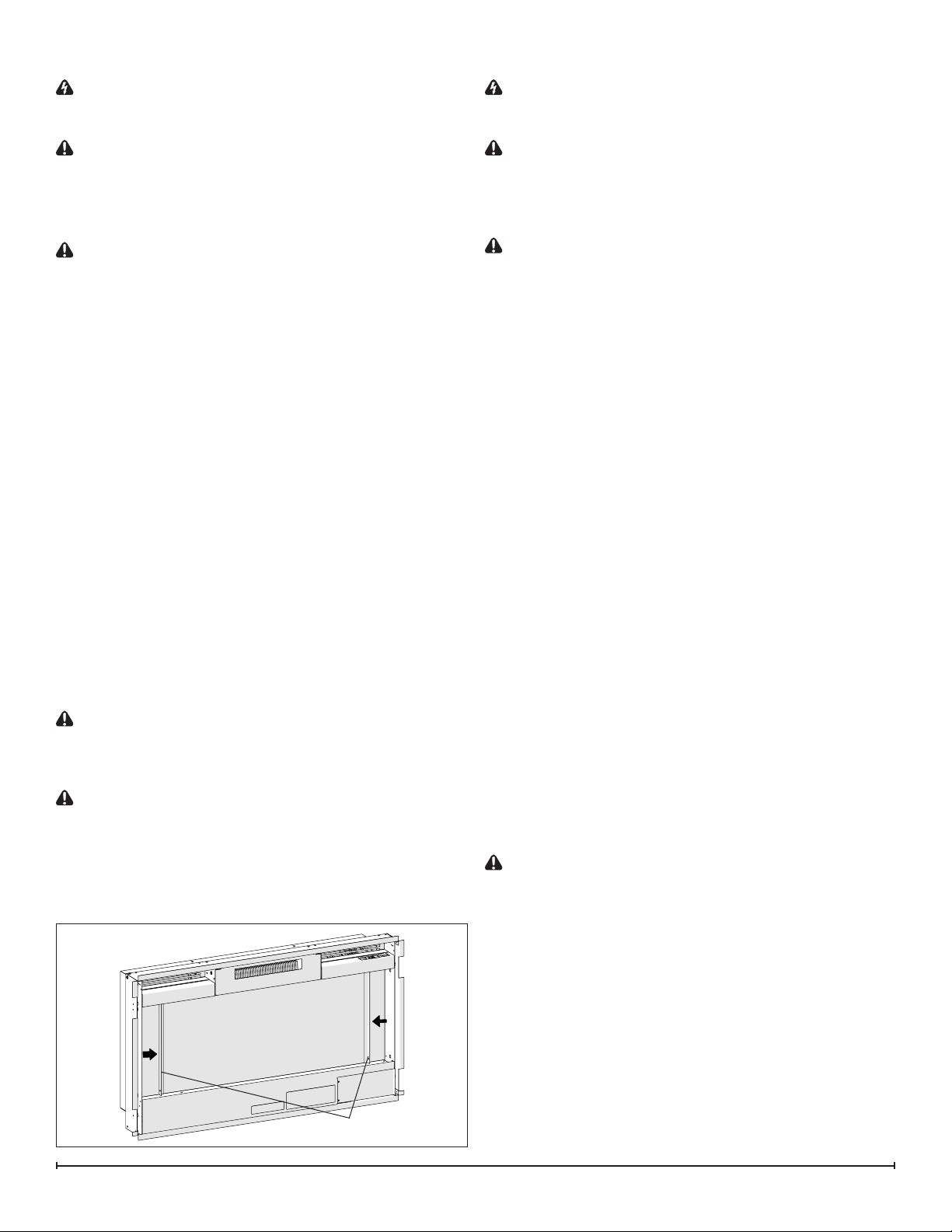

2. Remove the front glass assembly by removing the 2

screws (1 on the left and 1 on the right side). These

screws secure the front glass panel to the inside of the

replace. (Figure 4)

3. Lift the front glass assembly off of the 4 mounts located

between the outer and inner casing of the replace: 2

on the left and 2 on the right. (Figure 3) Carefully place

the glass assembly aside in a safe location.

4. Proceed to the instructions within this manual relating

to the repair being performed - see Table of Contents

for page number.

INSTRUCTIONS FOR REMOVING FROM WALL

!

NOTE: Only required for replacement of the

power cord or removal from service.

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

Mounting - The replace may be mounted in one of 3 methods:

• Surface Mount

• Recess Mount - Partial In-Wall

• Flush Mount (completely in the wall)

Identify the type of mounting and follow the appropriate

instructions in the following pages.

CAUTION: To prevent injury or damage, turn off the

breaker in your electrical panel prior to attempting to re-

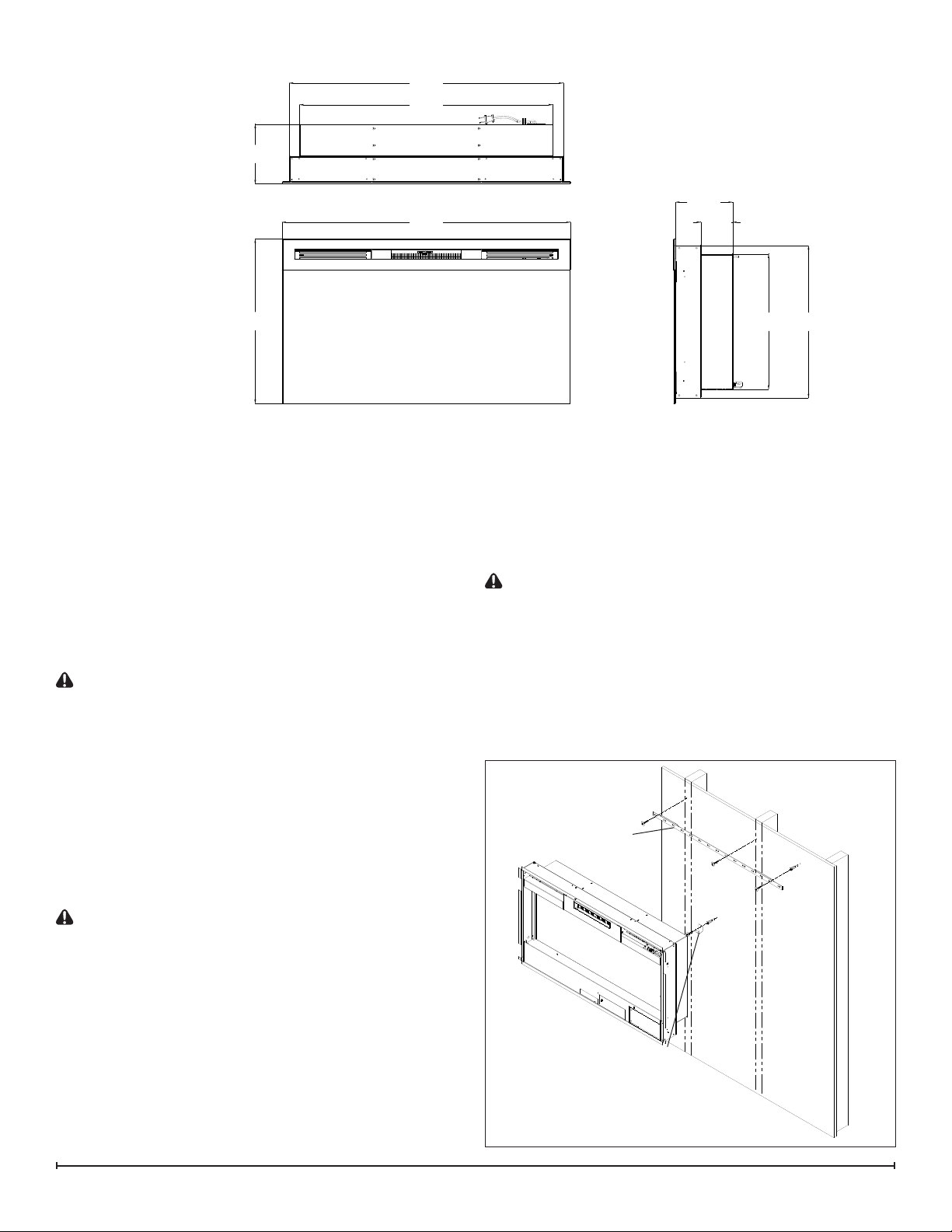

Figure 3

Front tray

Front glass

assembly

Figure 4

move this unit off the wall.

!

NOTE: If replace is hard wired directly to the electrical

panel, and there is not enough slack in the wires within the

wall to reach your work area, remove the electrical junction

box cover located on the bottom right by removing the 2

screws on the front of the cover. Lift the cover off and set

aside. Disconnect the 3 wire connectors connected to the

power source, taking note of their original conguration

• Line: Red wire from unit to the line wire power source

• Neutral: Thin white wire and thick blue wire to neutral

wire from power source

• Thin black wire and thick white wire are left connected and not changed.

Mounts (4)

Hooks (4)

Tab

Surface Mount

(Figure 6)

Tools Required: Phillips head screwdriver

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interi-

or Partially Reective Glass. A medium sized container

such as a bucket or a box will be needed to keep the

acrylic ember-bed pieces together.

2. On the bottom of the unit remove the securing screw

from the L-bracket. (Figure 5)

3. Lift the unit up and off of the wall.

4. Carefully lay the unit down on a solid at surface with

the front of the unit facing up.

7

Page 8

Figure 5

7.0 in.

(179 mm)

32.4 in.

(823 mm)

30.0 in.

(761 mm)

34.1 in.

(867 mm)

6.8 in.

(172 mm)

3.8 in.

(95 mm)

19.4 in.

(494 mm)

!

NOTE: If the surface you are using as a work area on is

a nished surface that is prone to scratches (i.e. hardwood

ooring), it is recommended that a protective barrier be

used underneath, (i.e. cloth, cardboard, thick plastic).

5. Proceed to the instructions within this manual relating

to the repair being performed - see Table of Contents

for page number.

6. Once repair is complete, reassemble in the reverse

order as above.

Recessed Mount - Partial In-wall

(Figure 7)

Tools Required: Phillips head screwdriver

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interior Partially Reective Glass. A medium sized container such as a bucket or a box will be needed to keep

the acrylic ember-bed pieces together.

2. Locate and remove the 4 mounting screws located

approximately 3 inches deep in the space between the

outer and inner casing on the left and right hand side.

There are 2 screws per side, upper and lower going

into a stud. (Figure 7)

CAUTION: The replace should be supported while

removing the screws to prevent the unit from falling.

3. Remove the replace out of the opening by slightly lifting and pulling forward.

4. Carefully lay the unit down on a solid at surface with

the front of the unit facing up.

!

NOTE: If the surface you are using as a work area is a

nished surface that is prone to scratches (i.e. hardwood

ooring), it is recommended that a protective barrier be

used underneath, (i.e. cloth, cardboard, thick plastic).

5. Proceed to the instructions within this manual relating

16.0 in.

18.0 in.

(406 mm)

(457 mm)

to the repair being performed - see Table of Contents

for page number.

6. Once repair is complete, reassemble in the reverse

order as above.

Flush Mount – Complete In-wall

(Figure 8)

Tools Required: Phillips head screwdriver

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interi-

or Partially Reective Glass. A medium sized container

such as a bucket or a box will be needed to keep the

acrylic ember-bed pieces together.

2. Locate and remove the 4 mounting screws inside the

unit located on left and right side towards the front.

Figure 6

Wall Mounting

Bracket

Bottom Support

Bracket

8 www.dimplex.com

Page 9

There are 2 screws per side, going from the side panels out into the side of the wall stud that frames the

replace. (Figure 8)

CAUTION: The unit should be supported while remov-

ing the screws to prevent the unit from falling.

3. Remove the replace out of the opening by slightly lifting and pulling forward.

4. Carefully lay the unit down on a solid at surface with

the front of the unit facing up.

!

NOTE: If the surface you are using as a work area is a

nished surface that is prone to scratches (i.e. hardwood

ooring), it is recommended that a protective barrier be

used underneath, (i.e. cloth, cardboard, thick plastic).

5. Proceed to the instructions within this manual relating

to the repair being performed - see Table of Contents

for page number.

6. Once repair is complete, reassemble in the reverse

order as above.

Figure 7

Mounting

holes

Mounting hole

SWITCHBOARD REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver.

Small adjustable wrench

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the 2 screws, that secure the controls assem-

bly (Figure 9), located at the top of the mirror on the

right side of the unit.

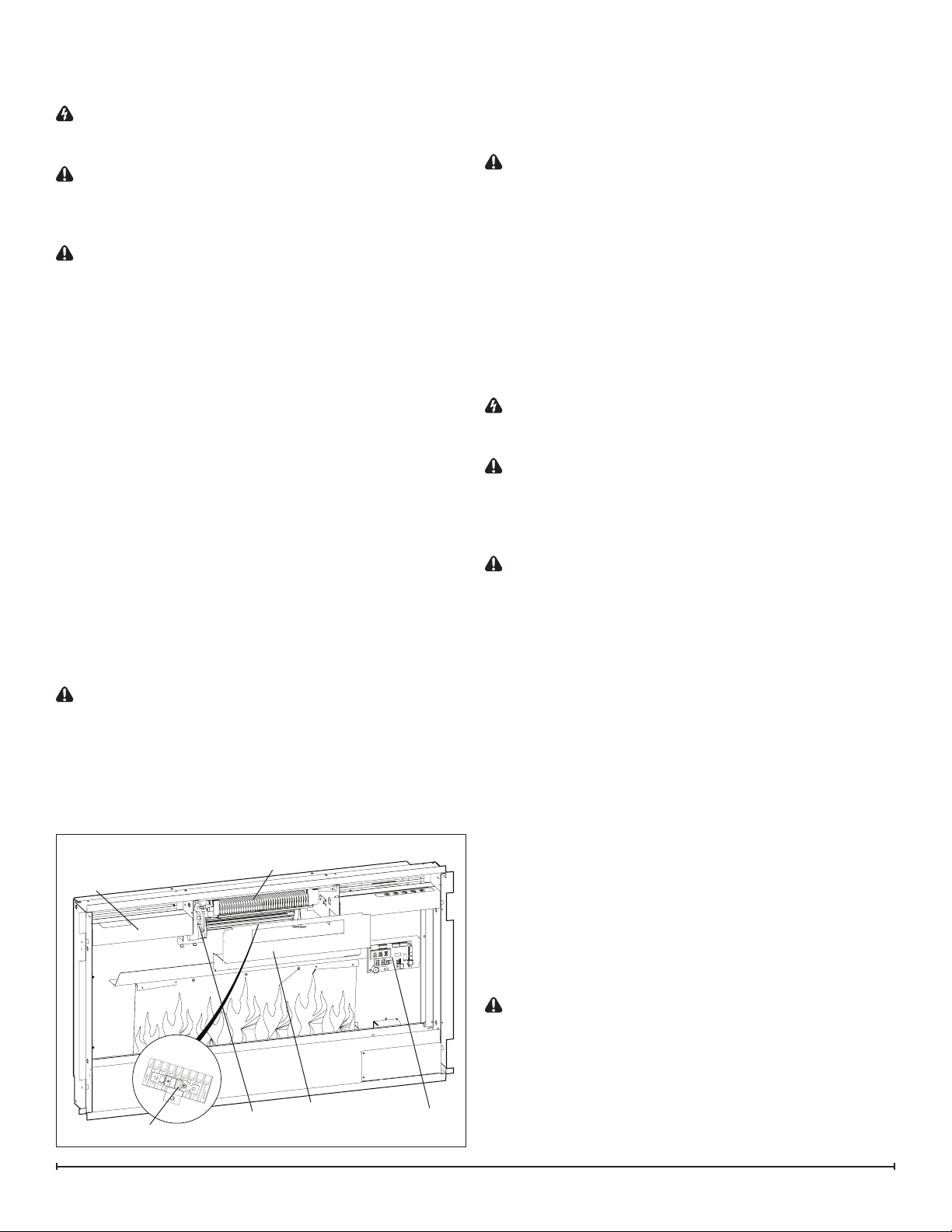

Figure 9

Controls Assembly

Figure 8

Wall Surface

Mounting Hole

Retaining Screws

Figure 10

Relay Board

AC/DC

Adapter

Switch

Board

9

Page 10

2. Slide the controls assembly out toward the front of the

unit.

CAUTION: Ensure that the assembly is removed care-

fully, ensuring that no wires are caught or over strained.

3. Locate the switchboard (Figure 10).

4. Disconnect the wiring harness from the switchboard.

5. Remove the switchboard by loosening the nuts on the

spacer stands.

6. Install the new switchboard on the space stands.

7. Reconnect the wire harness onto the back of the

switchboard in its original conguration.

8. Reassemble in the reverse order as above.

CAUTION: When re-installing, be sure the wires are

guided and tucked into the proper openings along the right

side so they are not pinched and allows enough space to

reinstall the panel.

RELAY BOARD REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver

Needle nosed pliers

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the 2 screws, that secure the controls assem-

bly (Figure 9), located at the top of the mirror on the

right side of the unit.

2. Slide the controls assembly out toward the front of the

unit.

CAUTION: Ensure that the assembly is removed carefully, ensuring that no wires are caught or over strained.

3. Locate the relay board (Figure 10).

4. Transfer the wiring connections from the existing board

to the new board.

!

NOTE: Using a at head screwdriver gently pry between

the end of the connectors and the board to release the

wires.

5. Remove the relay board off the plastic mounts by

pinching the plastic mounting tabs with needle nose

pliers. Pull the old board off.

6. Line up the holes on the board and gently press the

new board onto the mounts. Make sure the board is

secure.

7. Reassemble in the reverse order as above.

CAUTION: When re-installing, be sure the wires are

guided and tucked into the proper openings along the right

side so they are not pinched and allows enough space to

reinstall the panel.

AD/DC ADAPTER REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

Tools required: Phillips head screwdriver

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interior Partially Reective Glass. A medium sized container such as a bucket or a box will be needed to keep

the acrylic ember-bed pieces together.

2. Remove the 2 screws, that secure the controls assem-

bly (Figure 9), located at the top of the mirror on the

right side of the unit.

3. Remove the Partially Reective Glass retaining brack-

ets by removing the 3 screws on each brackets; (3

brackets in total), located on the left and right side of

the Partially Reective Glass. (Figure 13)

4. Remove the Partially Reective Glass. Carefully place

the glass assembly aside in a safe location.

5. Slide the controls assembly out toward the front of the

unit.

CAUTION: Ensure that the assembly is removed carefully, ensuring that no wires are caught or over strained.

6. Locate the defective AC/DC adapter (Figure 10).

7. Disconnect wires going to the wire connectors and the

wires that are attached to the display / control board.

(Figure 14)

!

NOTE: Using a at head screwdriver gently pry between

the end of the connectors and the board to release the

wires.

8. Remove the four screws that secure the AC/DC

adapter bracket to the controls assembly.

9. Install the new AC/DC adapter and install all wiring con-

nections.

10. Reassemble in the reverse order as above.

CAUTION: When re-installing, be sure the wires are

guided and tucked into the proper openings along the right

side so they are not pinched and allows enough space to

reinstall the panel.

10 www.dimplex.com

Page 11

DISPLAY / CONTROL BOARD REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

Tools required: Phillips head screwdriver

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interior Partially Reective Glass. A medium sized container such as a bucket or a box will be needed to keep

the acrylic ember-bed pieces together.

2. Remove the Partially Reective Glass retaining brack-

ets by removing the 3 screws on each brackets; (3

brackets in total), located on the left and right side of

the Partially Reective Glass. (Figure 13)

3. Remove the Partially Reective Glass. Carefully place

the glass assembly aside in a safe location.

4. Locate the defective display / control board (Figure 10).

5. Disconnect wires from old board and transfer to new

board. (Figure 14)

!

NOTE: Using a at head screwdriver gently pry between

the end of the connectors and the board to release the

wires.

6. Remove the relay board off the plastic mounts by

pinching the plastic mounting tabs with needle nose

pliers. Pull the old board off.

7. Line up the holes on the board and gently press the

new board onto the mounts. Make sure the board is

secure.

8. Reassemble in the reverse order as above.

CAUTION: When re-installing, be sure the wires are

guided and tucked into the proper openings along the right

side so they are not pinched and allows enough space to

reinstall the panel.

FLICKER MOTOR REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver

Short handled Phillips head screwdriver

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. In the bottom right hand of the unit, remove both of the

access covers. (Figure 11)

2. Remove the 2 screws holding the icker motor to the

bracket.

3. Holding the rubber gasket on the shaft, carefully re-

move the entire assembly.

4. Disconnect the wiring connections from the wire con-

nectors noting their original locations and install the

new motor similarly.

5. Properly orient the new icker motor onto the bracket

and re-attach with the 2 mounting screws.

6. Reassemble in the reverse order as above.

CAUTION: When removing and replacing the icker

motor try to keep any slight bending of the icker rod

minimal so as to not damage it. If icker rod is damaged, it

should be replaced to ensure proper operation.

CAUTION: When re-installing, be sure the wires are

guided and tucked into the proper openings along the right

side so they are not pinched and allows enough space to

reinstall the panels.

Figure 12

Media

Tray

Figure 11

Front

Panel

Rubber

Gasket

Attachment

Screws

Access Covers

Flicker

Motor

11

Page 12

FLICKER ROD REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver

Short handled Phillips head screwdriver

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interior Partially Reective Glass. A medium sized container such as a bucket or a box will be needed to keep

the acrylic ember-bed pieces together.

2. Remove the Partially Reective Glass retaining brack-

ets by removing the 3 screws on each brackets; (3

brackets in total), located on the left and right side of

the Partially Reective Glass. (Figure 13)

3. Remove the Partially Reective Glass. Carefully place

the glass assembly aside in a safe location.

4. In the bottom right hand of the unit, remove the two

screws and the front access cover. (Figure 11)

5. In the media tray, remove the two screws on either end

and the one on the side wall, to remove the clear media

tray and the front panel. (Figure 12)

!

NOTE: Tip the front panel forward then lift out of the unit.

6. Remove the icker rod by holding the gasket and slid-

ing it to the left. This will disengage it from the motor.

It will then be possible to remove it out of the opening.

7. Reassemble in the reverse order as above.

CAUTION: When removing and replacing the icker

motor try to keep any slight bending of the icker rod

minimal so as to not damage it. If icker rod is damaged, it

should be replaced to ensure proper operation.

CAUTION: When re-installing, be sure the wires are

guided and tucked into the proper openings along the right

side so they are not pinched and allows enough space to

reinstall the panels.

Figure 13

LED LIGHT STRIPS REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver

Wire Snips

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interior Partially Reective Glass. A medium sized container such as a bucket or a box will be needed to keep

the acrylic ember-bed pieces together.

2. Remove the Partially Reective Glass retaining brack-

ets by removing the 3 screws on each brackets; (3

brackets in total), located on the left and right side of

the Partially Reective Glass. (Figure 13)

3. Remove the Partially Reective Glass. Carefully place

the glass assembly aside in a safe location.

4. In the bottom right hand of the unit, remove the two

screws and the front access cover. (Figure 11)

5. In the media tray, remove the two screws on either end

and the one on the side wall, to remove the clear media

tray and the front panel. (Figure 12)

6. Remove the icker rod. This can be done by sliding it

to the left which will disengage it from the icker motor.

7. Locate the LED strip that needs to be replaced.

8. Disconnect the wire from the board by pulling gently on

the connector at the end.

9. Remove the board from the mounting bracket by press-

ing in the center of the standoffs to release them.

10. Line up the holes on the board and gently press the

new board onto the mounts. Make sure the board is

secure.

11. Reconnect the wire.

12. Reassemble in the reverse order as above.

CAUTION: When removing and replacing the icker

motor try to keep any slight bending of the icker rod

minimal so as to not damage it. If icker rod is damaged, it

should be replaced to ensure proper operation.

Retaining Brackets

12 www.dimplex.com

Page 13

HIGH TEMPERATURE CUTOUT REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interi-

or Partially Reective Glass. A medium sized container

such as a bucket or a box will be needed to keep the

acrylic ember-bed pieces together.

!

NOTE: Try to ensure the pieces do not get pushed or

wedged underneath the Partially Reective Glass. They

may obstruct the ease of removing the Partially Reective

Glass from the replace.

2. Remove the Partially Reective Glass retaining brack-

ets by removing the 3 screws on each brackets; (3

brackets in total), located on the left and right side of

the Partially Reective Glass. (Figure 14)

3. Remove the Partially Reective Glass. Carefully place

the glass assembly aside in a safe location.

4. Remove the remaining screw, that secures the controls

assembly (Figure 9), located at the top of the mirror on

the right side of the unit.

5. Slide the controls assembly out toward the front of the

unit.

CAUTION: Ensure that the assembly is removed carefully, ensuring that no wires are caught or over strained.

6. Remove the heating cover by removing the 4 screws: 2

on the left and 2 on the right of the tray. (Figure 14)

7. Locate the high temperature cutout and remove the

mounting screw.

Figure 14

Cover Panel

Cutout

Heating

Elements

Blower

Assembly

Heating

Cover

Display/Control

Board

8. Remove the 2 screws, that secure the controls assem-

bly (Figure 9), located at the top of the mirror on the

right side of the unit.

9. Slide the controls assembly out toward the front of the

unit.

CAUTION: Ensure that the assembly is removed care-

fully, ensuring that no wires are caught or over strained.

10. Disconnect the wiring connections noting their original

locations.

!

NOTE: Using a at head screwdriver gently pry between

the end of the connectors and the board to release the

wires.

11. Properly orient the new high temperature cutout and

connect all of the wiring connections.

12. Reassemble in the reverse order as above.

ELEMENT REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver.

Needle nosed pliers.

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interi-

or Partially Reective Glass. A medium sized container

such as a bucket or a box will be needed to keep the

acrylic ember-bed pieces together.

!

NOTE: Try to ensure the pieces do not get pushed or

wedged underneath the Partially Reective Glass. They

may obstruct the ease of removing the Partially Reective

Glass from the replace.

2. Remove the Partially Reective Glass retaining brack-

ets by removing the 3 screws on each brackets; (3

brackets in total), located on the left and right side of

the Partially Reective Glass. (Figure 14)

3. Remove the Partially Reective Glass. Carefully place

the glass assembly aside in a safe location.

4. Remove the remaining screw, that secures the controls

assembly (Figure 9), located at the top of the mirror on

the right side of the unit.

5. Slide the controls assembly out toward the front of the

unit.

CAUTION: Ensure that the assembly is removed carefully, ensuring that no wires are caught or over strained.

6. Remove the heating cover by removing the 4 screws: 2

on the left and 2 on the right of the tray. (Figure 14)

7. From the top panel of the heating assembly housing,

remove the 4 screws that hold the element cover to the

housing panel.

13

Page 14

Figure 15

Mounting Screws

8. Disconnect wires from the ends of the elements noting

their original locations.

!

NOTE: Using a at head screwdriver gently pry between

the end of the connectors and the element to release the

wires.

!

NOTE: Some of the wires may have a “piggy-back”

connector that allows a second wire to connect to the same

prong as the rst wire. Try and keep the “piggy-back” connection together when pulling the wires off the element.

9. Reassemble in the reverse order as above.

CAUTION: When re-installing covers and panels, be

sure the wires are guided and tucked into the proper openings along the right side so they are not pinched and allows

enough space to reinstall panel.

BLOWER/FAN REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver.

Needle nosed pliers.

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interi-

or Partially Reective Glass. A medium sized container

such as a bucket or a box will be needed to keep the

acrylic ember-bed pieces together.

!

NOTE: Try to ensure the pieces do not get pushed or

wedged underneath the Partially Reective Glass. They

may obstruct the ease of removing the Partially Reective

Glass from the replace.

2. Remove the Partially Reective Glass retaining brack-

ets by removing the 3 screws on each brackets; (3

brackets in total), located on the left and right side of

the Partially Reective Glass. (Figure 14)

3. Remove the Partially Reective Glass. Carefully place

the glass assembly aside in a safe location.

4. Remove the remaining screw, that secures the controls

assembly (Figure 9), located at the top of the mirror on

the right side of the unit.

5. Slide the controls assembly out toward the front of the

unit.

CAUTION: Ensure that the assembly is removed care-

fully, ensuring that no wires are caught or over strained.

6. Remove the heating cover by removing the 4 screws: 2

on the left and 2 on the right of the tray. (Figure 14)

7. Remove the 2 screws, that secure the controls assem-

bly (Figure 9), located at the top of the mirror on the

right side of the unit.

8. Slide the controls assembly out toward the front of the

unit.

CAUTION: Ensure that the assembly is removed care-

fully, ensuring that no wires are caught or over strained.

9. Remove the 2 screws, that secure the cover panel

(Figure 14), located at the top of the mirror on the left

side of the unit.

10. Remove the three screws on either side of the heater/

blower assembly and gently lower the assembly so that

the top can be viewed.

CAUTION: When removing the blower assembly

mounting screws, support the assembly to prevent any

damage to the unit.

11. Remove the 6 screws (3 sets) that secure the blower to

the assembly (Figure 15).

12. Disconnect the wiring connections noting their original

locations.

!

NOTE: Using a at head screwdriver gently pry between

the end of the connectors and the blower/fan to release the

wires.

13. Properly orient the new blower/fan assembly and con-

nect all of the wiring connections.

14. Reassemble in the reverse order as above.

THERMISTOR REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver.

Needle nosed pliers.

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the interi-

or Partially Reective Glass. A medium sized container

such as a bucket or a box will be needed to keep the

acrylic ember-bed pieces together.

!

NOTE: Try to ensure the pieces do not get pushed or

wedged underneath the Partially Reective Glass. They

14 www.dimplex.com

Page 15

may obstruct the ease of removing the Partially Reective

Glass from the replace.

2. Remove the Partially Reective Glass retaining brackets by removing the 3 screws on each brackets; (3

brackets in total), located on the left and right side of

the Partially Reective Glass. (Figure 14)

3. Remove the Partially Reective Glass. Carefully place

the glass assembly aside in a safe location.

4. Remove the remaining screw, that secures the controls

assembly (Figure 9), located at the top of the mirror on

the right side of the unit.

5. Slide the controls assembly out toward the front of the

unit.

CAUTION: Ensure that the assembly is removed care-

fully, ensuring that no wires are caught or over strained.

6. Remove the heating cover by removing the 4 screws: 2

on the left and 2 on the right of the tray. (Figure 14)

7. Remove the 2 screws, that secure the controls assem-

bly (Figure 9), located at the top of the mirror on the

right side of the unit.

8. Slide the controls assembly out toward the front of the

unit.

CAUTION: Ensure that the assembly is removed care-

fully, ensuring that no wires are caught or over strained.

9. Remove the 2 screws, that secure the cover panel

(Figure 14), located at the top of the mirror on the left

side of the unit.

10. Remove the three screws on either side of the heater/

blower assembly and gently lower the assembly so that

the top can be viewed.

CAUTION: When removing the blower assembly

mounting screws, support the assembly to prevent any

damage to the unit.

11. Locate the thermistor, carefully cut the tie wrap attach-

ing the thermistor to the standoff.

12. Disconnect the wiring connections on the display /

control board.

13. Install the new thermistor and secure it with a new tie

wrap and connect all of the wiring connections.

14. Reassemble in the reverse order as above.

15

Page 16

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

General

Circuit breaker trips or fuse

blows when unit is turned on

Lights dim in room while the

unit is on

Power cord gets warm Normal Operation The power cord may get slightly warm to

Appearance

Fireplace does not turn on

with the manual controls

Fireplace does not turn on

with the Remote Control

Flame Frozen Loose wiring Check wiring connections

Flame is not visible Loose wiring Check wiring connections

Flame Shudder Defective Flicker Motor Replace Flicker Motor 2000500100RP

Media bed does not light up

consistently

Media bed does not light up Loose wiring Check wiring connections

Media bed lighting comes

on by itself

Short in unit wiring. Trace wiring in unit.

Improper circuit current rating Additional appliances may exceed the

current rating of the circuit breaker or fuse.

Plug unit into another outlet or install unit on

a dedicated 15 amp circuit.

Unit is drawing close to circuit

current rating

Defective power cord Replace power cord if cord gets hot to the

Improper operation Refer to Operation Section

No incoming voltage from the

electrical wall socket

Loose wiring Check wiring connections

Defective switchboard Replace the switchboard assembly 3001520100RP

Defective AC/DC Adapter Replace the AC/DC Adapter 2100250100RP

Improper operation Refer to Operation Section

The batteries in the remote control are dead.

Defective remote control Replace the remote control 6700520200RP

Defective display/control board

assembly

Defective Flicker Motor Replace Flicker Motor 2000500100RP

Defective display/control board

assembly

Flame LED light assembly is not

working

Defective display/control board

assembly

Build up of static electricity in unit Unplug the unit for 1 minute then plug the

Media LED light assembly or log

set is not working

Defective display/control board Replace the display/control board 3001640100RP

Defective display/control board Replace the display/control board

Move the unit to another outlet or install unit

on a dedicated 15 amp circuit

the touch when the heater is on

touch.

Check Fuse/Breaker Panel

Install new battery into the remote control.

Replace the display/control assembly

Replace the display/control assembly

Replace ame LED light assembly

Replace the display/control assembly

unit back in.

Replace media LED light assembly or log

set

PART NUMBER

4100190300RP

3001640100RP

3001640100RP

3001420200RP

3001640100RP

6 LED - 3001570100RP

4 LED - 3001570400RP

3001640100RP

16 www.dimplex.com

Page 17

PROBLEM CAUSE SOLUTION

Heater

Heater is not turning on, but

ame effect is still functioning

Heater is turning off after a

couple of minutes of operation

Heater emits an odor Normal Operation Normal operation is when the heater emits

Heater fan turns On but

heater lacks heat

Heating element is glowing

red

Heater fan runs continuously

Noise

Excessive noise with the

heater on

Grinding or excessive noise

with the heater off

Improper operation Refer to Operation Section

Loose wiring Trace wiring in unit

Defective display/control board Replace the display/control board 3001640100RP

Defective Heating Element Replace Heating Element 2200510300RP

Improper operation Refer to Operation Section

Build up of dirt/dust in Heater

Assembly

Defective Heating Element Replace Heating Element 2200510300RP

Defective Heating Element Replace Heating Element 2200510300RP

Improper operation Refer to Operation Section

Loose wiring Trace wiring in unit

Defective Heating Element Replace Heating Element 2200510300RP

Normal Operation Small glowing sections of the element are

Defective Heating Element If larger glowing sections are causing the

Loose wiring Trace wiring in unit

Defective switchboard Replace the switchboard assembly 3001520100RP

Defective Blower/Fan Replace Blower/Fan 5300170300RP

Dirty Heater Assembly Ensure that exterior intake louvers and

Defective Blower/Fan Replace Blower/Fan 5300170300RP

Flicker rod hitting or rubbing

against internal components

Defective Flicker Motor Replace Flicker Motor 2000500100RP

Ensure that exterior intake louvers and

rebox cavity are free of dirt/dust.

an odor for a brief period after the heater is

initially turned on. The heater is burning off

any dust accumulated during manufacturing

or operation.

considered normal.

heater to trip the thermal cutout, unplug

unit, discontinue use and replace the heating element

rebox cavity are free of dirt/dust.

Ensure rod is straight and mounted properly

in the bracket, spinning freely away from

other components. Replace if necessary.

PART NUMBER

2200510300RP

17

Loading...

Loading...