Page 1

Installation Guide

Model

BF33STP/DXP

BF39STP/DXP

BF45DXP

IMPORTANT SAFETY INFORMATION: Always read this manual rst before attempting to install or use this replace. For your

safety, always comply with all warnings and safety instructions contained in this manual to prevent personal injury or property

damage.

To view the full line of Dimplex products, please visit

www.dimplex.com

7206350500R06

Page 2

Table of Contents

Listing and Code Approvals .................................................................3

Model Specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Step-by-Step Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section A: Installation information ...........................................................4

Framing Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section B: General Electrical Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Recommended Power Supply Wire Specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Voltage Selector Switch Location ............................................................5

Section C: Direct Power Wiring ..............................................................6

240V Installation .........................................................................6

120V Installation .........................................................................6

120V Installation - No Heat Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section D: Alternate Control Options ......................................................... 8

240V Main Power Wall Switch ..............................................................8

120V Main Power Wall Switch ..............................................................9

120V Main Power Wall Switch - No Heat .....................................................10

120V/240V Heater Wall Switch Control ...................................................... 11

120V/240V Wall Mounted Thermostat .......................................................12

120V/240V Wall Mounted Flame Override Switch .............................................. 13

Wall Remote - WRCPF-KIT ...............................................................14

Unit Internal Wiring Diagram ...............................................................14

!

NOTE: Procedures and techniques that are consid-

ered important enough to emphasize.

CAUTION: Procedures and techniques which, if not

carefully followed, will result in damage to the equipment.

WARNING: Procedures and techniques which, if not

carefully followed, will expose the user to the risk of

re, serious injury, or death.

2

www.dimplex.com

Page 3

LISTING AND CODE APPROVALS

The BF series replaces have been tested in accordance with the UL 2021 and CSA C22.2 No. 46 standards for xed and

location-dedicated electric room heaters.

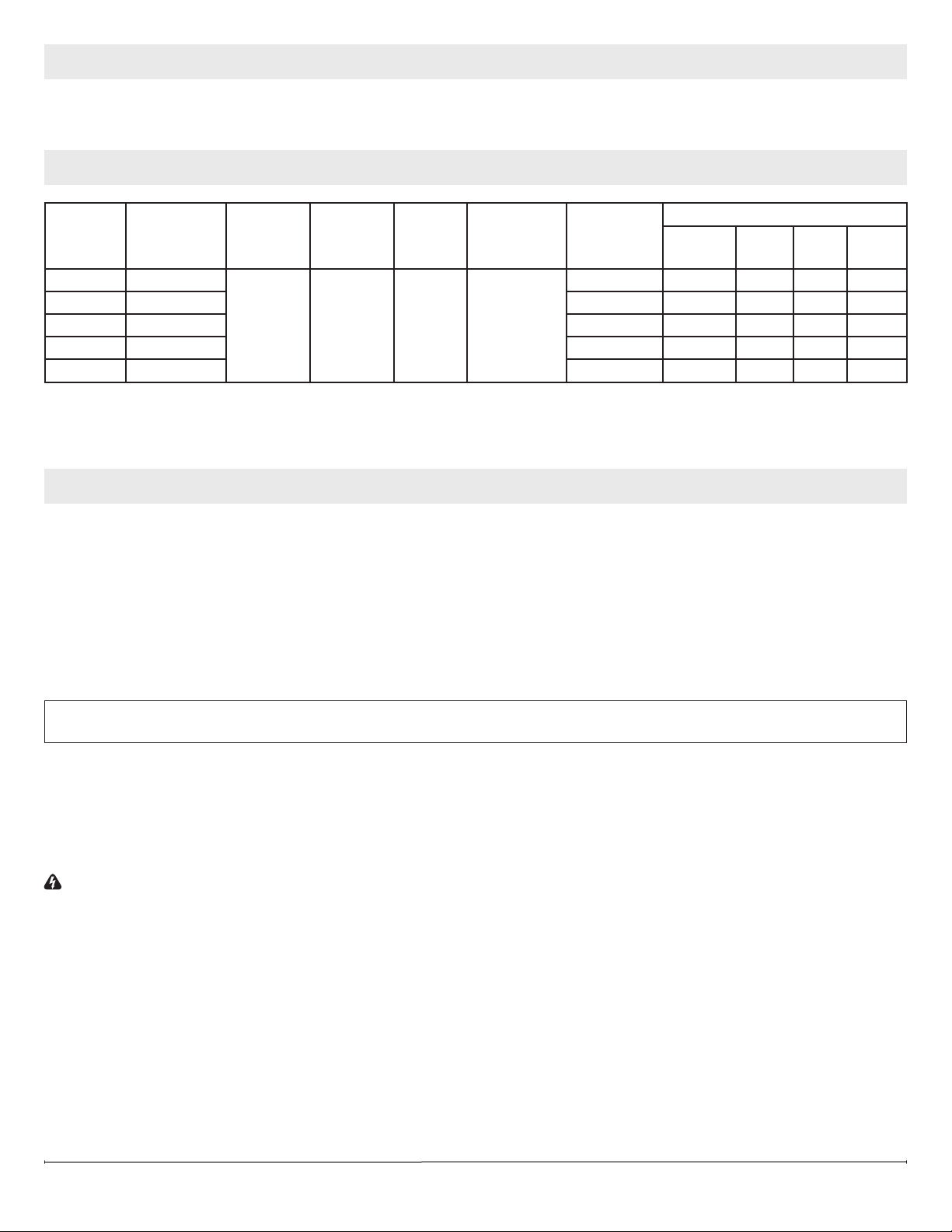

MODEL SPECIFICATIONS

Model

Number

BF45DXP 45” Deluxe

BF39DXP 39” Deluxe Included 2.0 12.0 10.10 11.25

BF39STP 39” Standard N/A 2.0 12.0 10.10 11.25

BF33DXP 33” Deluxe Included 2.0 12.0 10.10 11.25

BF33STP 33” Standard N/A 2.0 12.0 10.10 11.25

!

NOTE: Power ratings shown include the light bulbs and motors (275 watts)

The installation of the fireplace unit must comply with the applicable Local and/or National Electrical Codes and utility requirements. This installation should be entrusted to duly qualified personnel where required by law.

Description Voltage

120/120/

208/240

Rated

Power

(Watts)

245/1440/

2100/2700

Remote

Control

Optional Optional

Wall

Thermostat

Refractory

Brick Look

Included 2.0 12.0 10.10 11.25

Current Draw (Amps)

No Heat

120V

120V 208V 240V

STEP-BY-STEP INSTALLATION

!

NOTE: Please read all instructions before installing.

1. Rough in framing opening following the recommended dimensions located in Section A: Framing Dimensions.

2. Allow 8” (20.3 cm) of service cable for connecting power supply wire to junction box on replace when installing before

nishing wall. Allow up to 4’ (121.9 cm) of service cable for connecting power supply wire to junction box on replace

when installing after nishing wall. Remove the outer jacket and strip the individual conductors ½” (1.3 cm) from the end.

3. Loosen the screw securing the junction box cover and remove the cover.

4. Remove knockouts, if necessary, or use the provided cable clamp.

5. Place unit in position in the framed opening, level with shims if necessary and attach unit to frame using mounting anges

provided (Figure 2).

6. Unit is factory wired for 208/240V power supply. If 120V operation is required, slide the switch and recongure the wiring

(Section C). Wires L1, L2, N & G are attached to the rear of the junction box cable clamp for easy access.

!

NOTE: If wiring unit to operate with NO heat a dedicated circuit may not be required.

7. Wire a dedicated, properly fused circuit with a 15amp rating for the appropriate voltage (120V, 208/240V). See Section C

for factory setting wiring.

8. Make wall switch and or wall mounted thermostat connections as outlined in Section D.

9. Place all connectors inside the unit and secure the junction box cover to unit. Ensure that the cable clamp grips only the

jacket of service cable, thermostat and if applicable wall switch lines.

WARNING: Ensure method of installation does NOT obscure the air intake slots on bottom front of unit in any manner.

(See diagram in Section A)

3

Page 4

SECTION A: INSTALLATION INFORMATION

FRAMING DIMENSIONS

Model A B C D E F G H I J K L

BF45DXP

16.0”

(40.5cm)

45.5”

(115.6cm)

33.5”

(85.1cm)

30.1”

(76.5cm)

15.3”

(38.9cm)

42.0”

(106.7cm)

44.7”

(113.5cm)

22.8”

(57.9cm)

32.7”

(83.1cm)

60.0”

(152.4cm)

42.0”

(106.7cm)

42.0”

(106.7cm)

BF39STP/DXP

BF33STP/DXP

16.0”

(40.5cm)

15.0”

(38.1cm)

39.5”

(100.3cm)

33.5”

(85.1cm)

33.5”

(85.1cm)

29.5”

(75.0cm)

30.1”

(76.5cm)

25.7”

(65.3cm)

15.3”

(38.9cm)

14.3”

(36.3cm)

36.0”

(91.4cm)

29.6”

(75.2cm)

38.7”

(98.3cm)

32.8”

(83.3cm)

22.8”

(57.9cm)

18.8”

(47.8cm)

32.7”

(83.1cm)

28.5”

(72.4cm)

54.0”

(137.2cm)

48.0”

(121.9cm)

38.0”

(96.5cm)

34.0”

(86.4cm)

38.0”

(96.5cm)

34.0”

(86.4cm)

Figure 1

K

L

J

Air Intake Slots

Rough-In Framing Dimensions Firebox Dimensions Rough-In Corner Framing

This replace is a zero clearance design, with the exception of the top of the unit, where any insulation and vapor barrier

should be placed a minimum of 2” (5.1 cm) from the unit. No combustibles can be placed on the top surface of the replace.

CAUTION: Ensure installation does not allow replace to be in direct contact with building vapor barrier or insulation and

meets all local building code.

Four mounting anges on the sides of the unit are provided to facilitate installation.

MOUNTING FLANGES

Figure 2

Mounting

Flanges

There are two mounting anges located on each side of the replace insert.

From the inside of the unit, bend tabs outward and mount to the inside of the framing using suitable hardware.

4

www.dimplex.com

Page 5

SECTION B: GENERAL ELECTRICAL INFORMATION

RECOMMENDED POWER SUPPLY WIRE SPECIFICATIONS

For 120V installations use two conductor, non-metallic sheath cable with ground wire (3 wires total) for the incoming power

supply on replace inserts. Use the appropriate wire to meet local and national electrical codes for rated power consumption.

For 208V / 240V installations use three conductor, non-metallic sheath cable with ground wire (4 wires total) for the incoming power supply on replace inserts. Use the appropriate wire to meet local and national electrical codes for rated power

consumption.

Two conductor, non-metallic sheath cable with ground wire (3 wires total) is recommended for installation of a wall mounted

thermostat and/or wall switch for use on replace inserts. Use appropriate wire to meet local and national electrical codes for

rated power consumption. All wire gauges should match the recommended wire sizes shown below.

Voltage Wire Gauge Fuse Rating

120 Volts 12 Gauge 15 Amp

208 Volts 12 Gauge 15 Amp

240 Volts 12 Gauge 15 Amp

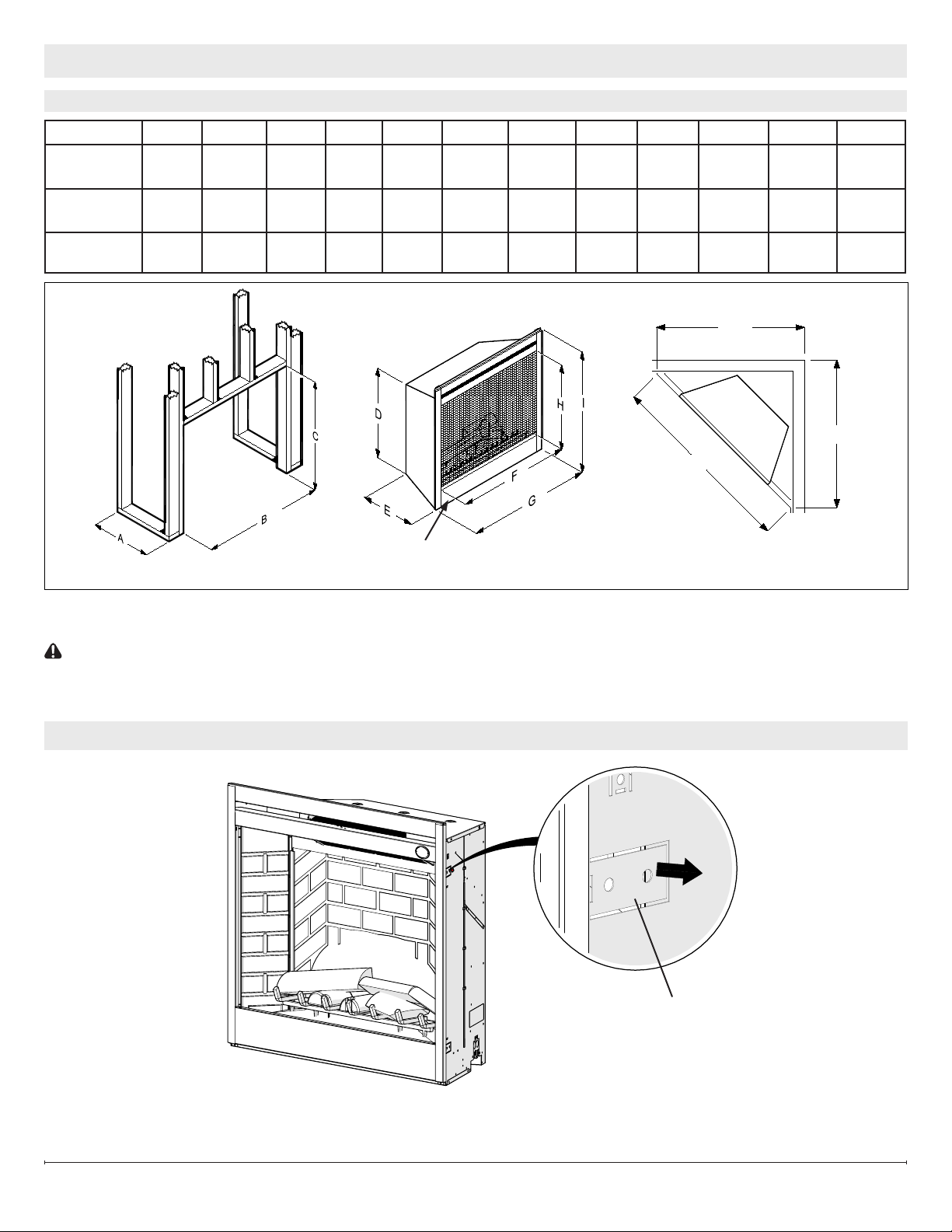

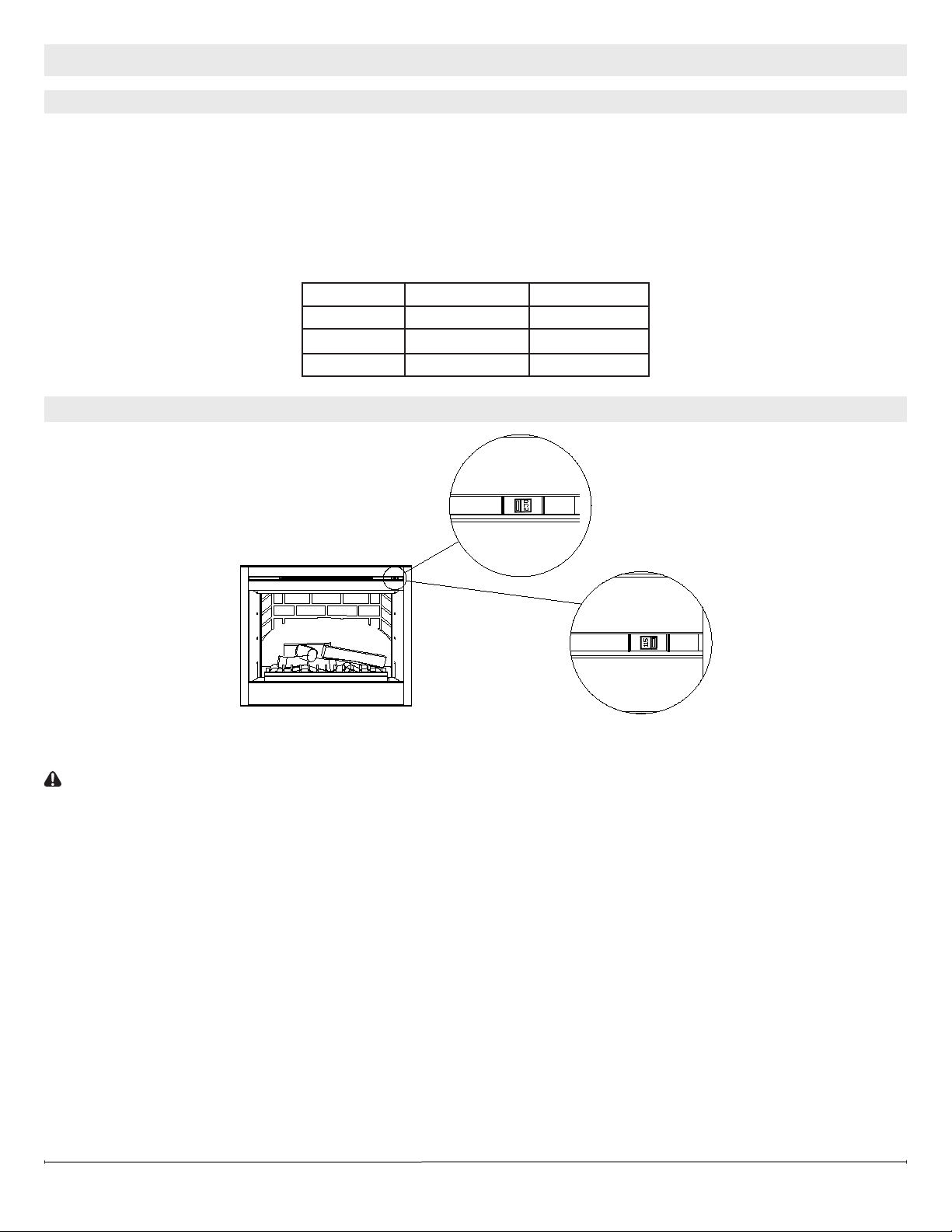

VOLTAGE SELECTOR SWITCH LOCATION

!

IMPORTANT: Ensure that the incoming power supply voltage matches the setting of the voltage selector switch.

!

NOTE: The voltage selector switch is located inside the exhaust panel on the top right hand corner.

CAUTION: When changing the voltage selector switch from 240V to 120V ensure that the power supply is turned off.

!

NOTE: Carefully insert a at headed screwdriver inside the exhaust panel to change the switch from 240V (230 position)

to 120V (115 position).

When wiring the unit for 208V / 240V the voltage selector switch should be in the 230V position.

When wiring the unit for 120V the voltage selector switch should be in the 115V position.

5

Page 6

PANEL)

FIREPLACE JUNCTION BOX

WHITE WIRE - N

RED WIRE – L2

BLACK WIRE – L1

GREEN WIRE - G

WHITE WIRE - N

RED WIRE – L2

BLACK WIRE – L1

GROUND WIRE - G

SECTION C: DIRECT POWER WIRING

FIREPLACE JUNCTION BOX

PANEL)

WHITE WIRE - N

RED WIRE – L2

BLACK WIRE – L1

WHITE WIRE - N

BLACK WIRE – L1

GROUND WIRE - G

240V INSTALLATION

240 V

POWER

SUPPLY

(BREAKER

!

IMPORTANT: The unit is factory congured for 208/240V operation.

!

NOTE: Use 3 conductor wires with ground (4 wires total) from the power supply (breaker panel) to the junction box on the

unit.

!

NOTE: All wiring must be completed prior to installing the unit.

!

NOTE: Ensure that the voltage selector switch is in the proper position for the required supply voltage prior to connecting

the unit to the power supply.

1. Locate the voltage selector switch inside the exhaust panel on the top right hand corner of the unit. Ensure that the

switch is in the 240V position. (230 is printed on switch)

2. Loosen the screw securing the junction box cover and remove the cover.

3. Remove the knockouts (if necessary) or use the provided cable clamp.

4. Pull out the four wires marked L1, L2, N, and G.

5. Connect L1 (black) from the unit to the L1 (black) from the power supply.

6. Connect L2 (red) from the unit to the L2 (red) from the power supply.

7. Connect N (white) from the unit to the to the Neutral (white) from the power supply.

8. Connect the ground wire (green) from the unit to the ground from the power supply.

9. Ensure that all connections are tight.

10. Insert all the wiring back into the unit and secure with a cable clamp.

120V INSTALLATION

120 V

POWER

SUPPLY

GREEN WIRE - G

!

IMPORTANT: The unit is factory congured for 208/240V operation.

!

NOTE: Use 2 conductor wires with ground (3 wires total) from the power supply (breaker panel) to the junction box on the

unit.

!

NOTE: All wiring must be completed prior to installing the unit.

!

NOTE: Ensure that the voltage selector switch is in the proper position for the required supply voltage prior to connecting

the unit to the power supply.

1. Locate the voltage selector switch inside the exhaust panel on the top right hand corner of the unit. Flip the switch from

240V to 120V conguration. (230 and 115 is printed on switch)

2. Loosen the screw securing the junction box cover and remove the cover.

(BREAKER

6

www.dimplex.com

Page 7

3. Remove the knockouts (if necessary) or use the provided cable clamp.

FIREPLACE JUNCTION BOX

WHITE WIRE - N

RED WIRE – L2

BLACK WIRE – L1

GREEN WIRE - G

WHITE WIRE - N

BLACK WIRE – L1

GROUND WIRE - G

RED - 1

RED - 2

WIRE NUTS

4. Pull out the four wires marked L1, L2, N, and G.

5. Connect L1 (black) wire from the unit to the L1 (black) from the power supply.

6. Connect L2 (red) and N (white) from the unit to the Neutral (white) from the power supply.

7. Connect the ground wire (green) from the unit to the ground from the power supply.

8. When the unit has been congured for the appropriate power supply voltage, ensure that all connections are tight.

9. Insert all the wiring back into the unit and secure with a cable clamp.

120V INSTALLATION - NO HEAT INSTALLATION

120 V

POWER

SUPPLY

(BREAKER

PANEL)

!

IMPORTANT: The unit is factory congured for 208/240V operation.

!

NOTE: Use 2 conductor wires with ground (3 wires total) from the power supply (breaker panel) to the junction box on the

unit.

!

NOTE: All wiring must be completed prior to installing the unit.

!

NOTE: Ensure that the voltage selector switch is in the proper position for the required supply voltage prior to connecting

the unit to the power supply.

!

NOTE: PurireTM will operate without heat in this application.

1. Locate the voltage selector switch inside the exhaust panel on the top right hand corner of the unit. Flip the switch from

240V to 120V conguration. (230 and 115 is printed on switch)

2. Loosen the screw securing the junction box cover and remove the cover.

3. Remove the knockouts (if necessary) or use the provided cable clamp.

4. Pull out the four wires marked L1, L2, N, and G.

5. Connect L1 (black) wire from the unit to the L1 (black) from the power supply.

6. Connect L2 (red) and N (white) from the unit to the Neutral (white) from the power supply.

7. Connect the ground wire (green) from the unit to the ground from the power supply.

8. Locate and separate, by installing a wire nut on the 1 (red) and 2 (red).

9. When the unit has been congured for the appropriate power supply voltage, ensure that all connections are tight.

10. Insert all the wiring back into the unit and secure with a cable clamp.

7

Page 8

SECTION D: ALTERNATE CONTROL OPTIONS

FIREPLACE JUNCTION BOX

WHITE - N

RED – L2

BLACK – L1

WHITE – N

BLACK – L1

GROUND - G

RED – L2

GROUND - G

240V MAIN POWER WALL SWITCH

240 V

(BREAKER

N

L2

L1

G

POWER

SUPPLY

PANEL)

G FROM

POWER SUPPLY

G FROM UNIT

L1 FROM

POWER SUPPLY

L2 FROM

POWER SUPPLY

NEUTRAL FROM

UNIT AND SUPPLY

L1 FROM UNIT

L2 FROM UNIT

G FROM UNIT

L1 FROM

POWER SUPPLY

L2 FROM

POWER SUPPLY

L1 FROM UNIT

3 CONDUCTOR WIRE

FROM POWER SUPPLY

3 CONDUCTOR WIRE

FROM MAIN SWITCH

POWER SUPPLY

WALL

SWITCH

!

NOTE: This option should not be used with the remote control kit.

!

NOTE: Before installing the unit have the following wires installed:

1. A 3 conductor wire with ground (4 wires total) from the power supply panel to the main switch wall box.

2. A 3 conductor wire with ground (4 wires total) from the main switch wall box to the junction box on the unit.

!

NOTE: Use a double pole, single throw (On/Off) wall switch that is rated for a minimum of 15 amps.

1. Locate the voltage selector switch inside the exhaust panel on the top right hand corner of the unit. Ensure that the

switch is in the 240V position. (230 is printed on switch)

2. Loosen the screw securing the junction box cover and remove the cover.

3. Remove the knockouts (if necessary) or use the provided cable clamp.

4. Pull out the four wires marked L1, L2, N, and G. (black, red, white and green)

5. Connect the L1 (black) wire from the unit to the L1 (black) wire from the main power wall switch by using a wire connector

(not supplied).

6. Connect other end of L1 (black) wire from the main power wall switch to the L1 terminal of the main power wall switch.

7. Connect the L2 (red) wire from the unit to the L2 (red) wire from the main power wall switch by using a wire connector

(not supplied).

8. Connect the other end of the L2 (red) wire from the main power wall switch to the L2 terminal of the main power wall

switch.

9. Connect the N (white) wire from the unit to the N

(white) wire from the main power wall switch by

using a wire connector (not supplied).

10. Connect the G (green) wire from the unit to the G

(green) wire from the main power wall switch by

using a wire connector (not supplied).

11. Connect the L1 wire from the power supply to the

L1 terminal of the main power wall switch.

12. Connect the L2 (black) wire from the power

supply to the L2 terminal of the main power wall

switch.

N

L2

L1

G

13. Connect the N (white) wire from the power supply

to the remaining N (white) wire from the unit by

using a wire connector.

14. Secure the 2 remaining G (green) wires with a

ground screw in the main switch wall box.

15. Ensure that all connections are tight.

16. Insert all the wiring of the main power wall switch

into the main switch wall box.

17. Insert all the wiring back into the unit and secure

with a cable clamp.

G FROM

L2 FROM UNIT

NEUTRAL FROM

UNIT AND SUPPLY

8

www.dimplex.com

Page 9

120V MAIN POWER WALL SWITCH

FIREPLACE JUNCTION BOX

WHITE - N

RED – L2

BLACK – L1

WHITE – N

BLACK – L1

GROUND - G

GROUND - G

120 V

WALL

SWITCH

!

NOTE: This option should not be used with the remote control kit.

!

NOTE: Before installing the unit have the following wires installed:

1. A 2 conductor wire with ground (3 wires total) from the power supply panel to the main switch wall box.

2. A 2 conductor wire with ground (3 wires total) from the main switch wall box to the junction box on the unit.

!

NOTE: Use a single pole, single throw (On/Off) wall switch that is rated for a minimum of 15 amps.

1. Locate the voltage selector switch inside the exhaust panel on the top right hand corner of the unit. Ensure that the

switch is in the 120V position. (115 is printed on switch)

2. Loosen the screw securing the junction box cover and remove the cover.

3. Remove the knockouts (if necessary) or use the provided cable clamp.

4. Pull out the four wires marked L1, L2, N, and G (black, red, white and green).

5. Connect L1 (black) from the unit to the L1 (black) from the main power wall switch using a wire connector (not supplied).

6. Connect the other end of L1 (black) to the L1 terminal of the main power wall switch.

7. Connect L2 (red) from the unit and N (white) from the unit to the Neutral wire (white) of the main power wall switch by using a wire connector (not supplied).

8. Connect the other end of the N (white) to the Neutral wire (white) from the power supply panel by using a wire connector

(not supplied).

9. Connect Ground (green) from the unit to the Ground (green) wire of the main power wall switch by using a wire connector

(not supplied).

10. Connect L1 (black) wire from the power supply to the L1 terminal of the main power wall switch.

11. Secure the 2 remaining Ground wires (green) with a ground screw in the main switch wall box.

12. Ensure that all connections are tight.

13. Insert all the wiring of the main power wall switch into the main switch wall box.

14. Insert all the wiring back into the unit and secure with a cable clamp.

POWER

SUPPLY

(BREAKER

PANEL)

G FROM

G FROM

POWER SUPPLY

G FROM UNIT

L1 FROM UNIT

NEUTRAL FROM

UNIT AND SUPPLY

L1 FROM

POWER SUPPLY

N

L2

L1

G

2 CONDUCTOR WIRE

FROM POWER SUPPLY

N

L2

L1

G

2 CONDUCTOR WIRE

FROM MAIN SWITCH

G FROM UNIT

L1 FROM UNIT

POWER SUPPLY

L1 FROM

POWER SUPPLY

NEUTRAL FROM

UNIT AND SUPPLY

9

Page 10

FIREPLACE JUNCTION BOX

WHITE - N

RED – L2

BLACK – L1

WHITE – N

BLACK – L1

GROUND - G

GROUND - G

RED – 1

RED – 2

WIRE

120V MAIN POWER WALL SWITCH - NO HEAT

120 V

WALL

SWITCH

!

NOTE: This option should not be used with the remote control kit.

!

NOTE: Before installing the unit have the following wires installed:

1. A 2 conductor wire with ground (3 wires total) from the power supply panel to the main switch wall box.

2. A 2 conductor wire with ground (3 wires total) from the main switch wall box to the junction box on the unit.

!

NOTE: Use a single pole, single throw (On/Off) wall switch that is rated for a minimum of 15 amps.

1. Locate the voltage selector switch inside the exhaust panel on the top right hand corner of the unit. Ensure that the

switch is in the 120V position. (115 is printed on switch)

2. Loosen the screw securing the junction box cover and remove the cover.

3. Remove the knockouts (if necessary) or use the provided cable clamp.

4. Pull out the four wires marked L1, L2, N, and G (black, red, white and green).

5. Connect L1 (black) from the unit to the L1 wire (black) from the main power wall switch using a wire connector (not supplied).

6. Connect the other end of the L1 wire (black) to the L1 terminal of the main power wall switch.

7. Connect L2 (red) from the unit and the N (white) from the unit to the Neutral wire (white) of the main power wall switch by

using a wire connector (not supplied).

8. Connect the other end of the Neutral wire (white) to the Neutral wire (white) from the power supply panel by using a wire

connector (not supplied).

9. Connect the Ground wire (green) from the unit to the Ground wire (green) of the main power wall switch by using a wire

connector (not supplied).

10. Connect L1 (black) from the power supply to the L1 terminal of the main power wall switch.

11. Locate and separate by wire nut the 1 (red) and 2 (red).

12. Secure the 2 remaining Ground wires (green)

with a ground screw in the main switch wall

box.

13. Ensure that all connections are tight.

14. Insert all the wiring of the main power wall

switch into the main switch wall box.

15. Insert all the wiring back into the unit and secure with a cable clamp.

POWER

SUPPLY

(BREAKER

PANEL)

G FROM

POWER SUPPLY

G FROM UNIT

L1 FROM UNIT

L1 FROM

POWER SUPPLY

G FROM

POWER SUPPLY

G FROM UNIT

NEUTRAL FROM

UNIT AND SUPPLY

L1 FROM UNIT

10

NEUTRAL FROM

N

L2

L1

G

2 CONDUCTOR WIRE

FROM POWER SUPPLY

N

1

L2

2

L1

G

2 CONDUCTOR WIRE

FROM MAIN SWITCH

L1 FROM

POWER SUPPLY

UNIT AND SUPPLY

www.dimplex.com

Page 11

120V/240V HEATER WALL SWITCH CONTROL

FIREPLACE JUNCTION BOX

RED – 2

RED – 1

GROUND - G

WALL

SWITCH

!

NOTE: Before installing the unit complete the following:

1. Install main power connection with appropriate wiring - directly to the main power or through a wall switch.

2. Install a 2 conductor wire with ground (3 wires total) from the heater switch wall box to the junction box on the

unit.

!

NOTE: Use a heater wall switch (On/Off) that is rated for a minimum of 15 amps.

1. Loosen the screw securing the junction box cover and remove the cover.

2. Remove the knockouts (if necessary) or use the provided cable clamp.

3. Pull out the three wires marked 1, 2, and G (red, red, and green).

4. Remove the wire connector and separate the wires marked 1 and 2.

5. Connect the 1 wire (red) from the unit to the L1 wire (black) from the heater wall switch by using a wire connector (not

supplied).

6. Connect the other end of L1 wire (black) from the heater wall switch to the L1 terminal of the heater wall switch.

7. Connect the 2 wire (red) from the unit to the Neutral wire (white) from the heater wall switch using a wire connector (not

supplied).

8. Connect the other end of the Neutral wire (white) from the heater wall switch to the L2 terminal of the heater wall switch.

9. Connect the Ground wire (green) from the unit to the Ground wire (green) from the heater wall switch using a wire connector (not supplied).

10. Secure the remaining Ground wire (green) with a ground screw in the heater switch wall box.

11. Ensure that all connections are tight.

12. Insert all the wiring of the heater wall switch into the heater switch wall box.

13. Insert all the wiring back into the unit and secure with a cable clamp.

G FROM

POWER SUPPLY

G FROM UNIT

L1 FROM UNIT

NEUTRAL FROM

UNIT AND SUPPLY

L1 FROM

POWER SUPPLY

1

2

G

2 CONDUCTOR WIRE

FROM HEATER SWITCH

2

1

!

G FROM UNIT

WIRE 2 FROM

UNIT

WIRE 1 FROM

UNIT

NOTE: This only illustrates

heater switch connection,

see previous sections for

G

main power connection

instructions.

11

Page 12

120V/240V WALL MOUNTED THERMOSTAT

FIREPLACE JUNCTION BOX

RED – 1

GROUND - G

RED – 2

WALL

THERMOSTAT

!

NOTE: Before installing the unit complete the following:

1. Install main power connection with appropriate wiring - directly to the main power or through a wall switch.

2. Install a 2 conductor wire with ground (3 wires total) from the thermostat wall box to the junction box on the unit.

!

NOTE: Wiring of the thermostat must be completed prior to installing the unit.

!

NOTE: The following installation instructions are for a single pole thermostat.

1. Loosen the screw securing the junction box and remove the cover.

2. Remove the knockouts (if necessary) or use the provided cable clamp.

3. Pull out the three wires marked 1, 2, and G (red, red, and green).

4. Remove the wire connector and separate the wires marked 1 & 2.

5. Connect the 1 wire (red) from the unit to the Neutral (white) wire from the wall thermostat box by using a wire connector

(not supplied).

6. Connect the other end of the Neutral (white) wire from the thermostat wall box to the red wire from the wall thermostat.

7. Connect the 2 wire (red) from the unit to the black wire from the thermostat wall box by using a wire connector (not supplied).

8. Connect the other end of the black wire from the thermostat wall box to the black wire from the wall thermostat.

9. Connect the Ground wire (green) from the unit to the Ground (green) wire from the thermostat wall box by using a wire

connector (not supplied).

10. Connect the other end of the Ground wire (green) to the thermostat wall box ground screw.

11. Ensure that all connections are tight.

12. Insert all the wiring of the wall mounted thermostat into the wall box.

13. Insert all the wiring back into the unit and secure with a cable clamp.

12

BLACK

RED

GROUND

1

2

GROUND

G

!

BLACK

BLACK WIRE

RED

WHITE WIRE

GROUND

SCREW

GROUND

NOTE: This only illustrates

thermostat connection, see

previous sections for main

1

2

GROUND

G

power connection instructions.

www.dimplex.com

Page 13

120V/240V WALL MOUNTED FLAME OVERRIDE SWITCH

FIREPLACE JUNCTION BOX

BLUE – 4

BLUE – 3

GROUND - G

WALL

SWITCH

DO NOT USE WITH NO HEAT INSTALLATIONS

!

NOTE: The replace can be wired to have a wall switch operate the ame independent of the heater.

!

NOTE: Before installing the unit complete the following:

1. Install main power connection with appropriate wiring - directly to the main power or through a wall switch.

2. Install a 2 conductor wire with ground (3 wires total) from the ame override switch wall box to the junction box

on the unit.

!

NOTE: Use a wall switch (On/Off) that is rated for a minimum of 15 amps.

1. Loosen the screw securing the junction box cover and remove the cover.

2. Remove the knockouts (if necessary) or use the provided cable clamp.

3. Pull out the three wires marked 3, 4, and G (blue, blue, and green).

4. Remove the wire connector and separate the wires marked 3 and 4.

5. Connect 3 wire (blue) from the unit to the L1 wire (black) from the ame override wall switch by using a wire connector

(not supplied).

6. Connect the other end of the L1 wire (black) from the ame override wall switch to the L1 terminal of the ame override

wall switch.

7. Connect 4 wire (blue) from the unit to the Neutral wire (white) from the ame override wall switch using a wire connector

(not supplied).

8. Connect the other end of the Neutral wire (white) from the ame override wall switch to the L2 terminal of the ame override wall switch.

9. Connect the Ground wire (green) from the unit to the Ground wire (green) from the ame override wall switch using a wire

connector (not supplied).

10. Secure the remaining Ground wire (green) with a ground screw in the ame override switch wall box.

11. Ensure that all connections are tight.

12. Insert all the wiring of the heater wall switch into the heater switch wall box.

13. Insert all the wiring back into the unit and secure with a cable clamp.

G FROM

POWER SUPPLY

G FROM UNIT

L1 FROM UNIT

NEUTRAL FROM

UNIT AND SUPPLY

L1 FROM

POWER SUPPLY

1

2

G

FROM FLAME OVERRIDE SWITCH

4

3

G FROM UNIT

WIRE 4 FROM

UNIT

WIRE 3 FROM

UNIT

2 CONDUCTOR WIRE

!

NOTE: This only illustrates

ame switch connection,

see previous sections for

G

main power connection

instructions.

13

Page 14

WALL REMOTE - WRCPF-KIT

• Can be used for 120V or 240V installations

• Battery or 24V powered

• 50’ (15m) control range

• Built in Thermostat

• Flame On/Off Control

• Heat On/Off Control

UNIT INTERNAL WIRING DIAGRAM

10

12

1. Room Temperature

6

5

8

4

14

7

1

2

9

11

13

3

2. Set Temperature

3. Flame Effect

4. Purire™

5. Heat Off Indicator

6. Function Lock Indicator

7. RF Code Function Indicator

8. Set Temperature Down

9. Set Temperature Up

10. Flame Off

11. Flame On

12. Purire™ Off

13. Purire™ On

14. Low Battery Indicator

Dimplex North America Limited

1367 Industrial Road, Cambridge, ON, Canada N3H 4W3

© 2016 Dimplex North America Limited

14

!

NOTE: Standard models

do not have a log driver

www.dimplex.com

Loading...

Loading...