Page 1

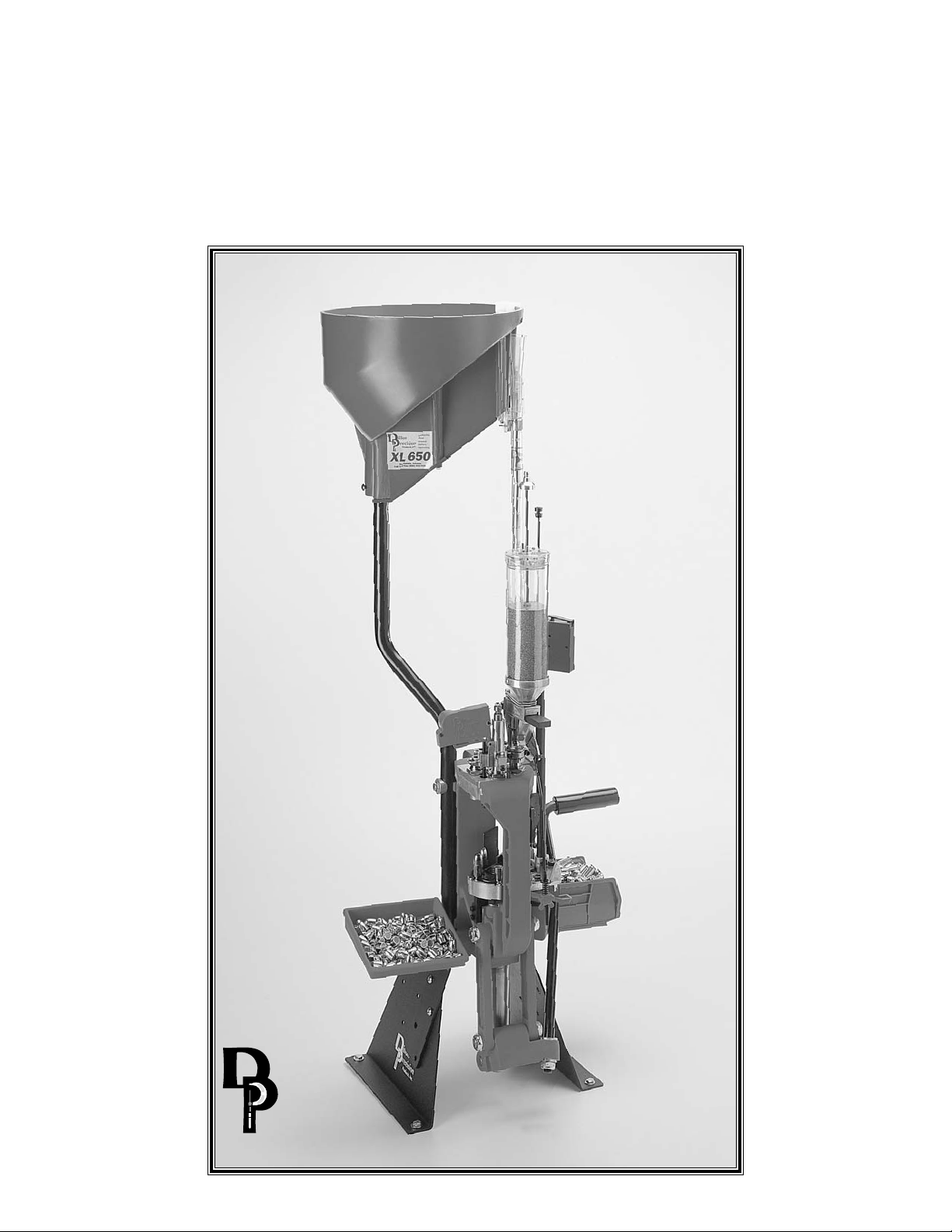

Manufacturers of

The World's Finest

Loading Equipment

XL 650

Instruction Manual

Version 6.1

illon

recision

Products, Inc.

Page 2

Dillon Precision Products, Inc.

8009 E. Dillon’s Way

Scottsdale, AZ 85260

(480) 948-8009

FAX (480) 998-2786

Web Site: www.dillonprecision.com

E-mail: dillon@dillonprecision.com

Technical Support & Customer Service

(800) 223-4570

On the cover…

The XL 650 is pictured with optional accessories:

Strong Mount (550/650) #22051

Strong Mount (650 only) #22052

Aluminum Roller Handle #17950

Low Powder Sensor #16306

Bullet Tray #22214

Powdercheck System #21044

Electric Casefeeder (four sizes available)

Other accessories available for the XL 650 include:

Video Instruction Manual #15064

Machine Cover #10443

Maintenance Kit & Spare Parts Kit #97017

The Blue Press, Dillon’s monthly catalog, has a complete listing

of accessories available for all machines.

Part #13524 Spot Manuals XL 650 Folder XL 650 Man. 6.1 9/01 WJC

Page 3

Page #

Mandatory Safety Measures 5

Getting Started 6

1. Unboxing your machine 6

2. Mounting your XL 650 7

3. Initial Set-Up 7

A. Installation of Handle 7

B. Installation of the Spent Primer Cup and Cartridge Bin 8

C. Installation of the Casefeed Post 8

D. Installation of the Casefeed Tube Bracket 8

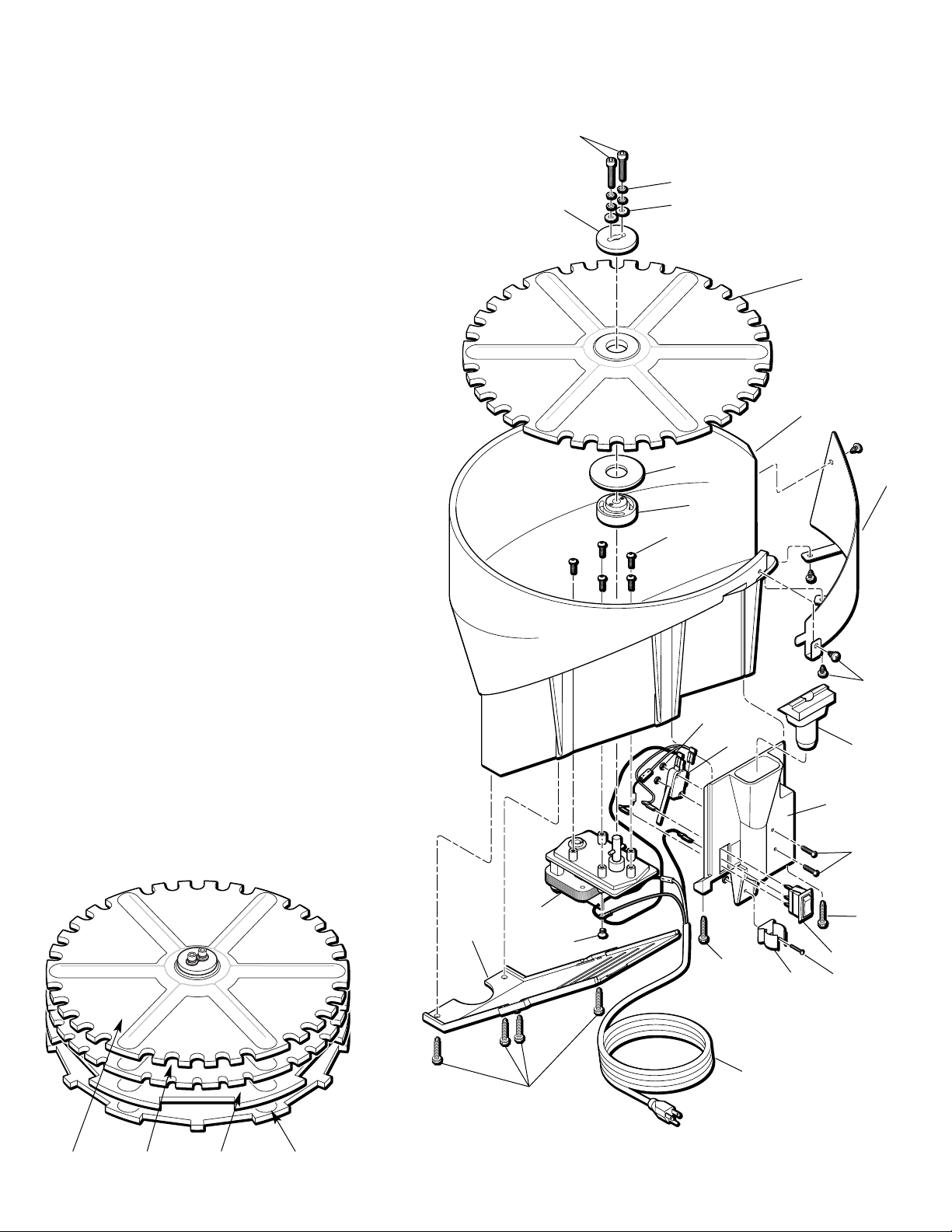

E. Installation of the Optional Casefeeder 9

4. Toolhead Overview 11

Lubricating Brass 11

Pistol Section – Toolhead Set Up 12

A. Station One – Installation of the Sizing/Decapping Die 12

B. Station One – The Decapping assembly 12

C. Station Two – Installation of the Powder Measure Assembly 12

D. Station Two – About Powder Bars 13

E. Station Two – Adjustment of the Powder Die/Powder Funnel 14

F. Station Two – Installation of the Failsafe Rod Assembly 15

G. Station Three – Installation of the Powder Check System 16

H. Station Four – General Information on Bullet Seating 17

I. Station Four – Seating Stems 18

J. Station Four – Installation and Adjustment of the Seating Die 18

K. Station Five – Installation and Adjustment of the Crimp Die 18

Rifle Section – Toolhead Set Up 20

A. Station One – About the Case Gage 20

B. How to Use the Case Gage 20

C. Station One – Installation of the Sizing/Decapping Die 21

D. Station One – The Decapping assembly 22

E. Station Two – Installation of the Powder Measure Assembly 22

F. Station Two – About Powder Bars 23

G. Station Two – Adjustment of the Powder Die/Powder Funnel 23

H. Station Two – Installation of the Failsafe Rod Assembly 25

I. Station Three – Installation of the Powder Check System 25

J. Station Four – How to Determine the Proper Seating Depth 26

K. Station Four – Seating Stems 27

L. Station Four – Installation and Adjustment of the Seating Die 27

M. Station Five – Installation and Adjustment of the Crimp Die 28

Final Assembly 29

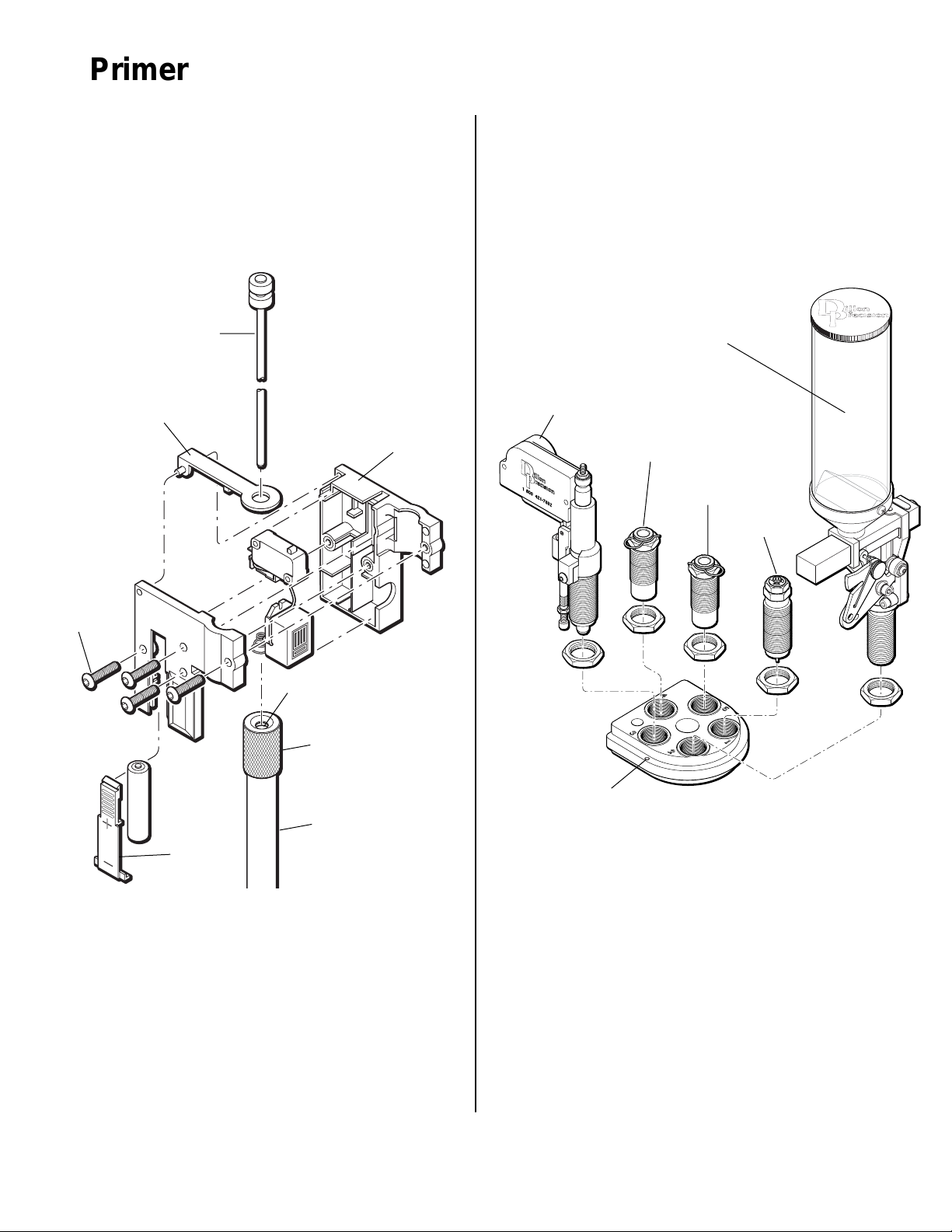

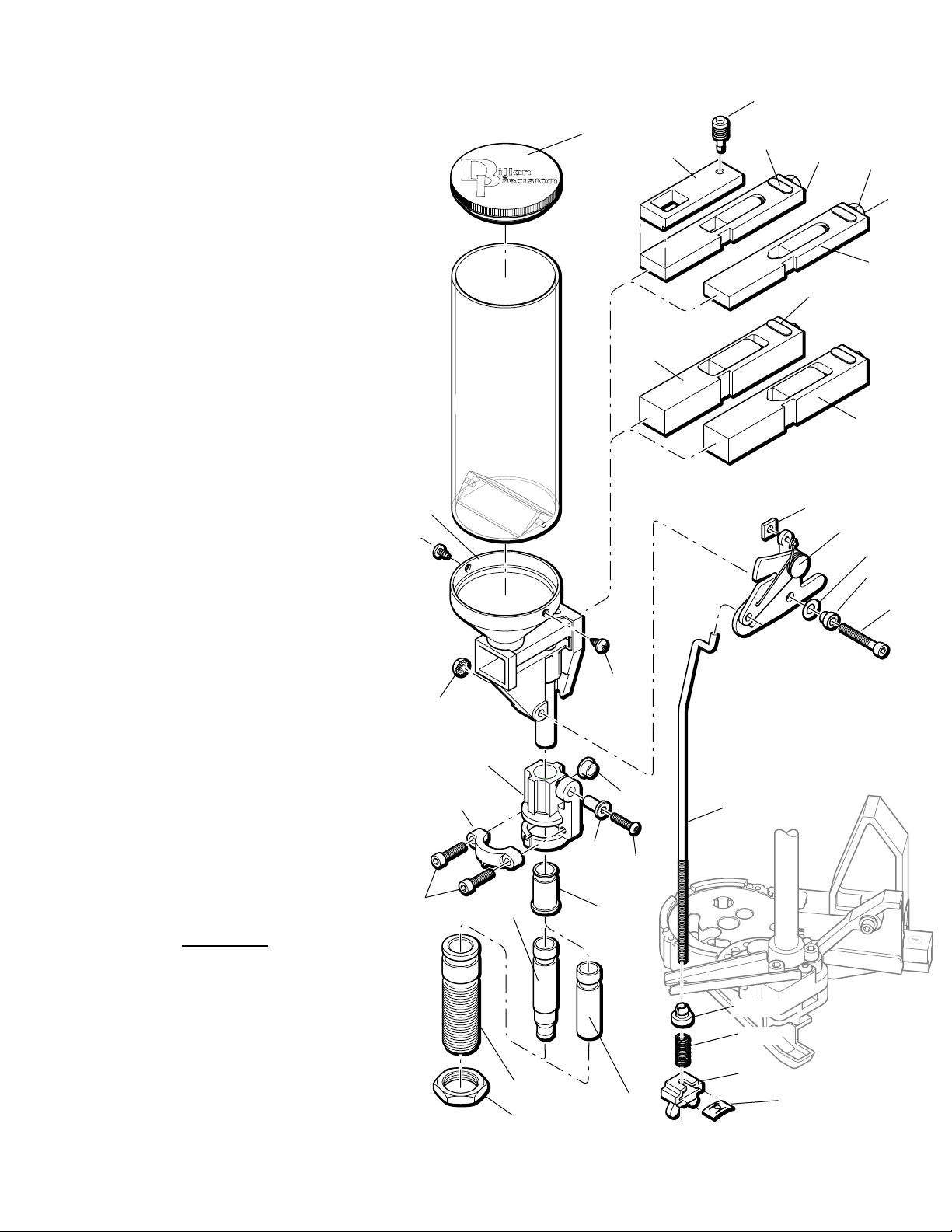

1. The Primer Magazine 29

2. Installation of the Primer Early Warning System 29

3. Installation of the Locator Buttons 30

Loading Components Section

1. Primer System Overview (how it works) 30

2. Powder Bar Adjustment 30

3. Powder Check System Adjustment 31

A. Installation and Adjustment of the Powder Check Rods 31

B. Powder Check System demonstration 32

4. Filling the Primer System 32

Station Orientation and Loading Funtions 34

Caliber Conversion Section 35-42

Trouble Shooting 43-45

Caliber Conversion Chart 46-48

Schematics 49-58

Table of Contents

Page 4

Reloading small arms ammunition involves the use of highly

explosive primers and powder.

Handling these materials is inherently dangerous. You should recognize this danger and take certain

minimum precautions to lessen

your exposure to injury.

Never operate the machine

without ear and eye protection on.

Call our customer service department at (800) 223-4570 for information on the wide variety of shooting/safety glasses and hearing

protection that Dillon has to offer.

• PAY ATTENTION: Load only

when you can give your complete attention to the loading

process. Don’t watch television

or try to carry on a conversation

and load at the same time. Watch

the automatic systems operate

and make sure they are functioning properly. If you are interrupted or must leave and come back

to your loading, always inspect

the cases at every station to

insure that the proper operations

have been accomplished.

• SMOKING: Do not smoke

while reloading or allow anyone

else to smoke in your reloading

area. Do not allow open flames

in reloading area.

• SAFETY DEVICES: Do not

remove any safety devices from

your machine or modify your

machine in any way.

• LEAD WARNING: Be sure to

have proper ventilation while handling lead components or when

shooting lead bullets. Lead is

known to cause birth defects, other

reproductive harm and cancer.

Wash your hands thoroughly after

handling anything made of lead.

• LOADS AND LENGTHS:

Avoid maximum loads and pressures at all times. Use only recommended loads from manuals

and information supplied by reliable component manufacturers

and suppliers. Since Dillon

Precision has no control over the

components which may be used

on their equipment, no responsibility is implied or assumed for

results obtained through the use

of any such components.

Seat bullets as close to maximum cartridge length as possible.

Under some conditions, seating

bullets excessively deep can raise

pressures to unsafe levels. Refer to

a reliable loading manual for overall length (OAL).

• QUALITY CHECKS: Every 50100 rounds, perform periodic quality control checks on the ammunition being produced. Check the

amount of powder being dropped

and primer supply.

• RELOADING AREA: Keep your

components safely stored. Clear

your work area of loose powder,

primers and other flammables

before loading.

• COMPONENTS: Never have

more than one type of powder in

your reloading area at a time. The

risk of a mix-up is too great. Keep

powder containers closed.

Be sure to inspect brass prior to

reloading for flaws, cracks, splits

or defects. Throw these cases away.

Keep components and ammunition out of reach of children.

• BLACK POWDER: Do not use

black powder or black powder

substitutes in any Dillon powder

measure. Loading black powder

cartridges requires specialized

loading equipment and techniques. Failure to do so can result

in severe injury or death.

• PRIMERS: Never force primers.

If they get stuck in the operation of

the machine, disassemble it and

gently remove the obstruction.

Never attempt to clear primers

that are stuck in either the primer

pickup tube or the primer magazine tube. Never, under any circumstances, insert any type of rod

to attempt to force stuck primers

out of these tubes. Trying to force

primers out of the tube will cause

the primers to explode causing

serious injury or even death.

If primers get stuck in a primer

magazine or pickup tube flood the

tube with a penetrating oil (WD-

40), throw the tube in the garbage

and call us for a free replacement.

Never attempt to deprime live

primers – eventually one will go

off. When it does it will detonate

the others in the spent primer cup.

Depriming live primers is the single most dangerous thing you can

do in reloading and can cause

grave injury or death.

• LOADED AMMUNITION:

Properly label all of your loaded

ammunition (Date, Type of

Bullet, Primer, Powder, Powder

Charge, etc.).

• BE PATIENT: Our loading

equipment is conservatively rated

and you should have no trouble

achieving the published rates with

a smooth, steady hand. If something doesn’t seem right, stop,

look and listen. If the problem or

the solution isn’t obvious, call us.

The reloading bench is no place

to get into a hurry.

We have done everything we

know how to make your machine

as safe as possible. We cannot,

however, guarantee your complete

safety. To minimize your risk, use

common sense when reloading

and follow these basic rules.

• REMEMBER: If your machine

does not perform to your expectations, or if you are having technical

difficulties, give us a call.

Technical Support (800) 223-4570

A

LL ELECTRICAL/ELECTRONIC COM-

PONENTS IN DILLON EQUIPMENT ARE

COVERED BY A ONE

-YEAR WARRANTY.

5

MANDATORY SAFETY MEASURES

Page 5

6

GETTING STARTED

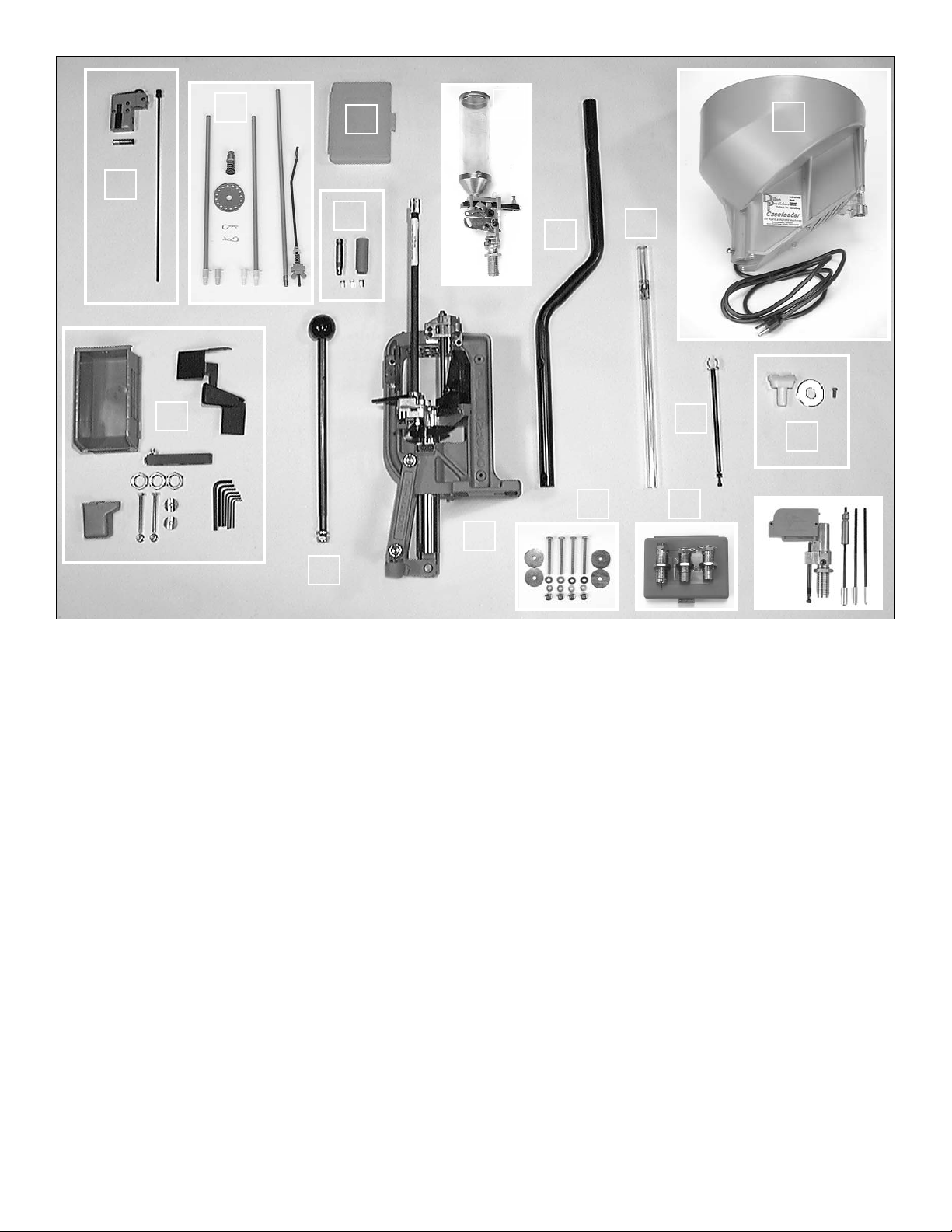

1.Unboxing Your

Machine:

After opening the box, check the contents against the list below. If any items are

missing or damaged, call us right away so

we can send out a replacement at no

charge.

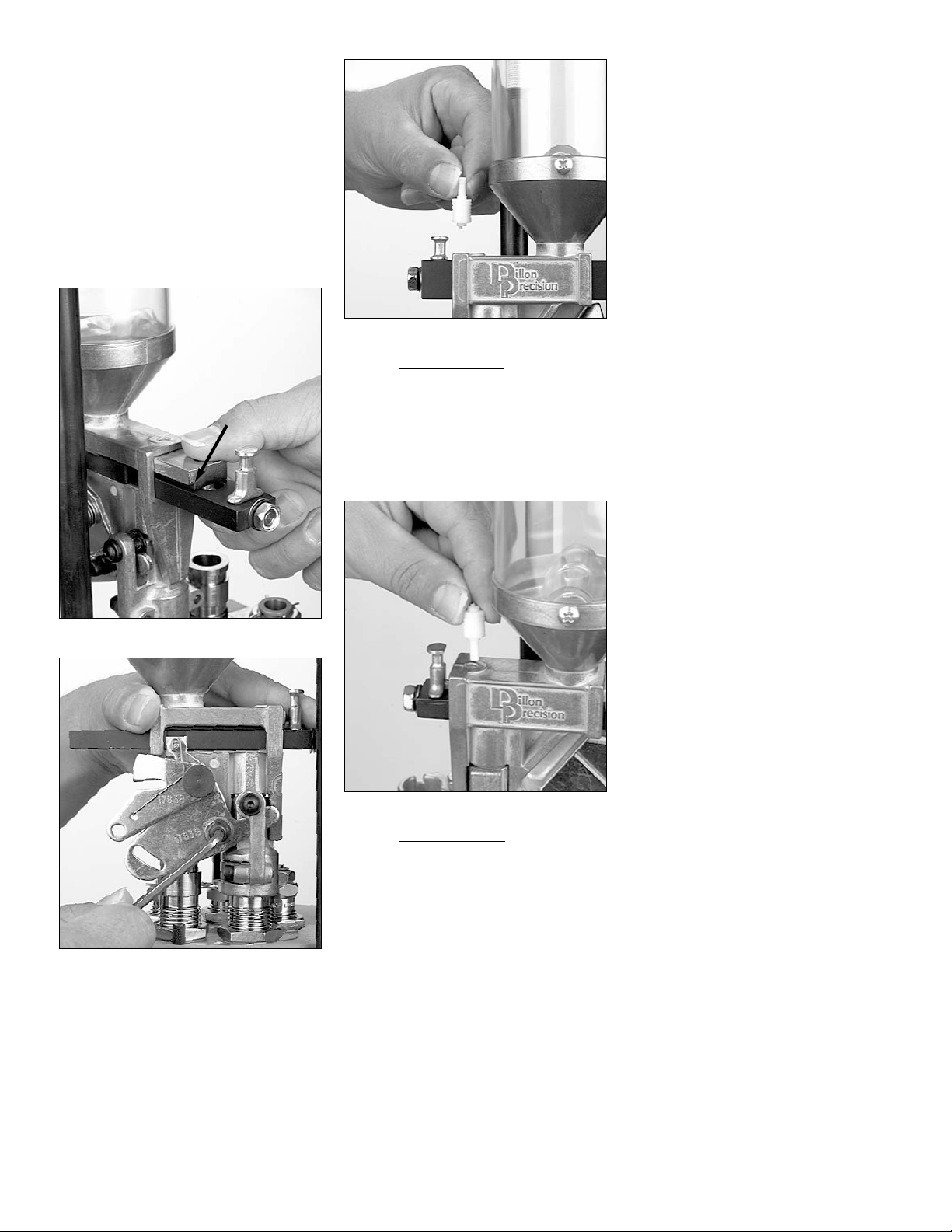

You should have the following:

1. Machine with toolhead and toolhead

retaining pins installed

2. Operating handle assembly with washer

and lock nut

3. Casefeed mounting post

4. Casefeed tube

5. Casefeed support bracket

6. Primer Early Warning System bag

containing:

a. Primer Early Warning System (with

AAA battery included)

b. Primer follower rod (16” black plastic

rod)

7. Primer system parts bag containing:

a. Powder Measure Failsafe assem-

bly (10” black metal rod w/ hardware)

b. One small and one large primer pickup

tube – 12” aluminum tube each with

plastic tip - green tip (large), yellow tip

(small)

c. One large and one small plastic tip,

(spares)

d. Primer feed disk (2” diameter metal

disk w/16 small holes)

e. Primer magazine (15” aluminum tube

w/ brass tip)

f. Primer punch assembly. (metal

w/spring, approximately 2 x 1/2”)

g. Two steel hitchpins

8. Conversion kit box (empty)

9. Conversion kit includes caliber specific:

a. Powder funnel

b. Casefeed adapter

c. Three locator buttons

d. Shellplate (installed)

e. Station 1 locator (installed)

f. Casefeed arm bushing (installed)

g. Body bushing (installed)

10. Powder system with powder die

11. Accessory box containing:

a. Cartridge bin (blue plastic,

approximately 3 x 4 x7”)

b. Ejected cartridge chute (black

metal, wrapped in bubble pack)

c. Two 1/4” x 20 x 3”: hex bolts and two

1/4” x 20 nuts

d. Two Aluminum tube clamps

e. Spent primer cup (blue plastic)

f. Extra powder bar

g. Three die lockrings (7/8 x 14” thread)

h. Seven Allen wrenches (1/4”, 3/16”,

5/32”, 9/64”, 1/8”, 3/32”, 5/64”)

12. Casefeed assembly (optional)

13. Casefeed accessory bag containing:

a. Casefeed funnel adapter (white)

b. Spacer washer

c. Casefeed mounting post set screw

14. Mounting hardware kit (optional)

15. Three die set (optional)

16. Powder check system (optional)

11

1

16

4

5

3

8

6

7

2

9

13

14 15

12

10

Page 6

7

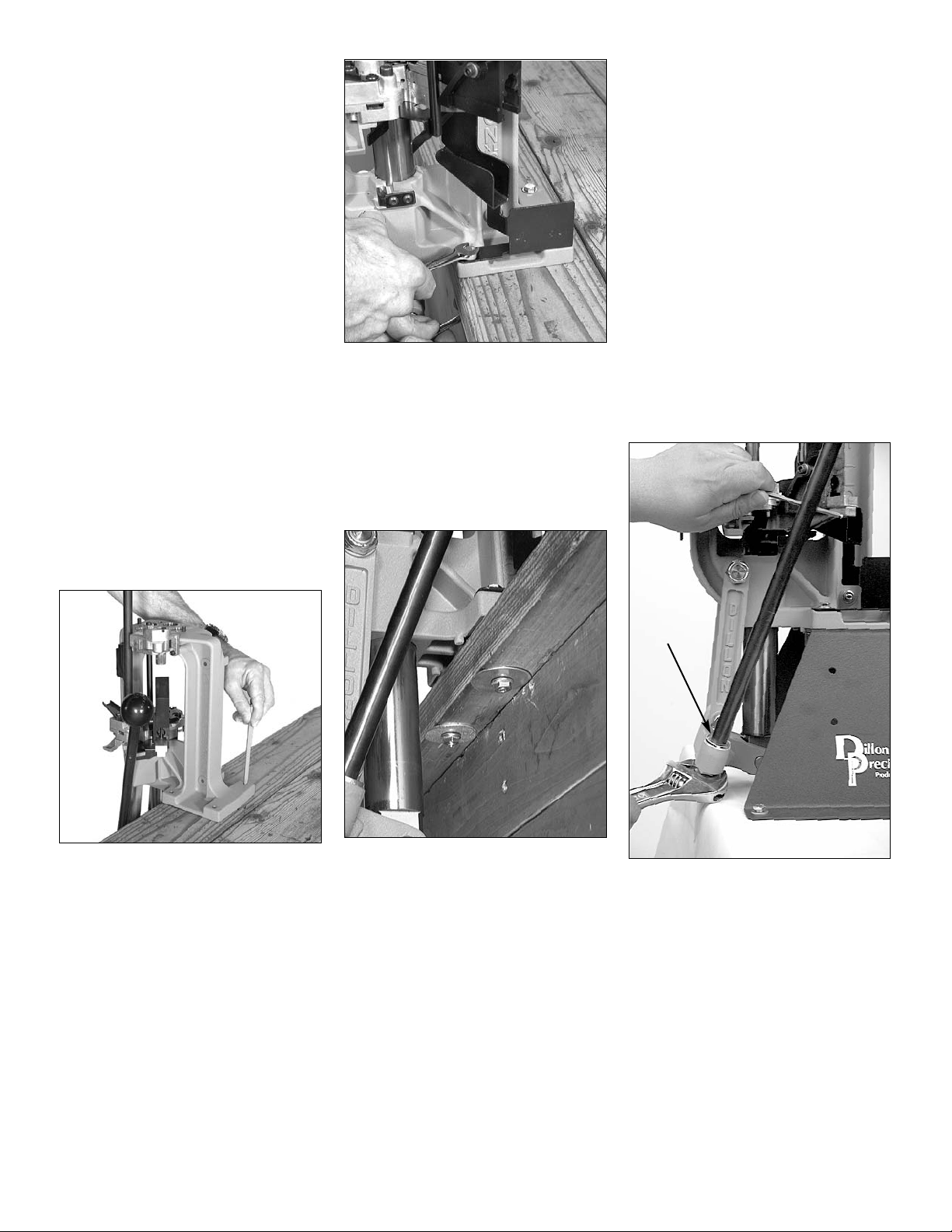

2.Mounting your XL 650:

A. Locate a sturdy bench at least

24” wide and 14” deep, with 44” of

overhead clearance. We suggest a

minimum of 1” plywood or equivalent,

secured to the back wall. The workbench should be tall enough to place

your eye level about 18” above the

bench.

Note: It is important that the leading edge

of the bench has an overhang of at

least 3/4”. If the overhang is less

than 3/4”, the crank will interfere

with the front of the bench when the

operating handle is lowered. Unless

you have Strong Mounts, then none

of this is necessary.

B. Tools Needed:

You will need the following to mount and

set up your machine:

1. Electric drill

2. 17/64” drill bit preferred, 1/4” – 9/32” OK

3. Mounting Hardware Kit (#14355) or

four 1/4” through bolts with nuts and

washers

Note: The bolts should be at least 1 1/2”

longer than the thickness of the

mounting surface.

4. Two 7/16” wrenches if using kit

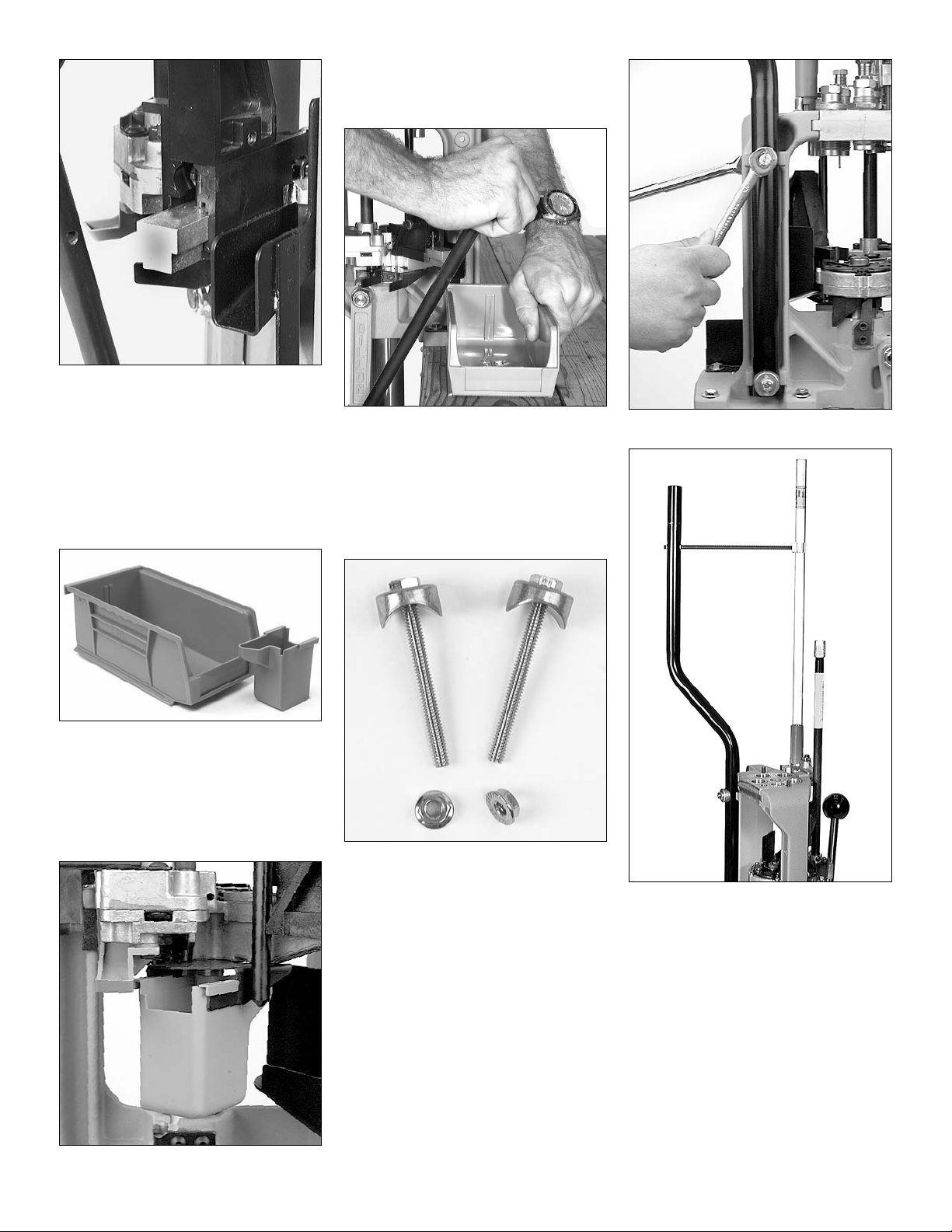

FIG 1

C. Drill the mounting holes FIG 1:

1. Using the machine as a template, mark

the four holes.

2. Using a 1/4” bit, drill the holes.

FIG 2

D. Bolting the machine to the

bench FIG 2:

Note: If you do not have a Mounting Hard-

ware Kit, ensure that you use 1/4”

or equivalent through bolts (with

large area washers if mounting to

wood). Do not use lag bolts or wood

screws!

FIG 3

1. Mount the left side of the machine with

the small washers on top and the large

washers on the bottom FIG 3. Run

the two left side nuts down finger tight.

2. Place the chute/bin bracket FIG 2 on

the right side of the machine. As

before, place the small washer on top

and the large washers on the bottom

and thread the nuts.

Note: The chute/bin mount goes under

the two right hand mounting bolts so

it must be installed as you are

mounting the machine FIG 2.

Check the fit of the chute/bin

mount. The chute/bin mount

should rest snugly against the

frame. Also, make sure that the

walls of the chute are parallel and

have not been bent during shipping or installation.

3. Using two 7/16” wrenches, tighten all

four bolts down.

3.Initial Set Up

If you ordered your XL 650 for a specific

caliber, it comes factory adjusted for that

caliber (minus dies) with the appropriate

“caliber specific” parts included. In fact, a

Dillon technician runs casings and primers

through the machine to check its function.

Note: As you assemble your machine,

we recommend that you cross

check caliber specific parts, included with your machine, with those

specified in the caliber conversion

chart (pages 42-44). The

point being – if we sent you the

wrong part, you’ll want to know it

before getting started. Reference

page 35 for instructions on how to

use the caliber conversion chart.

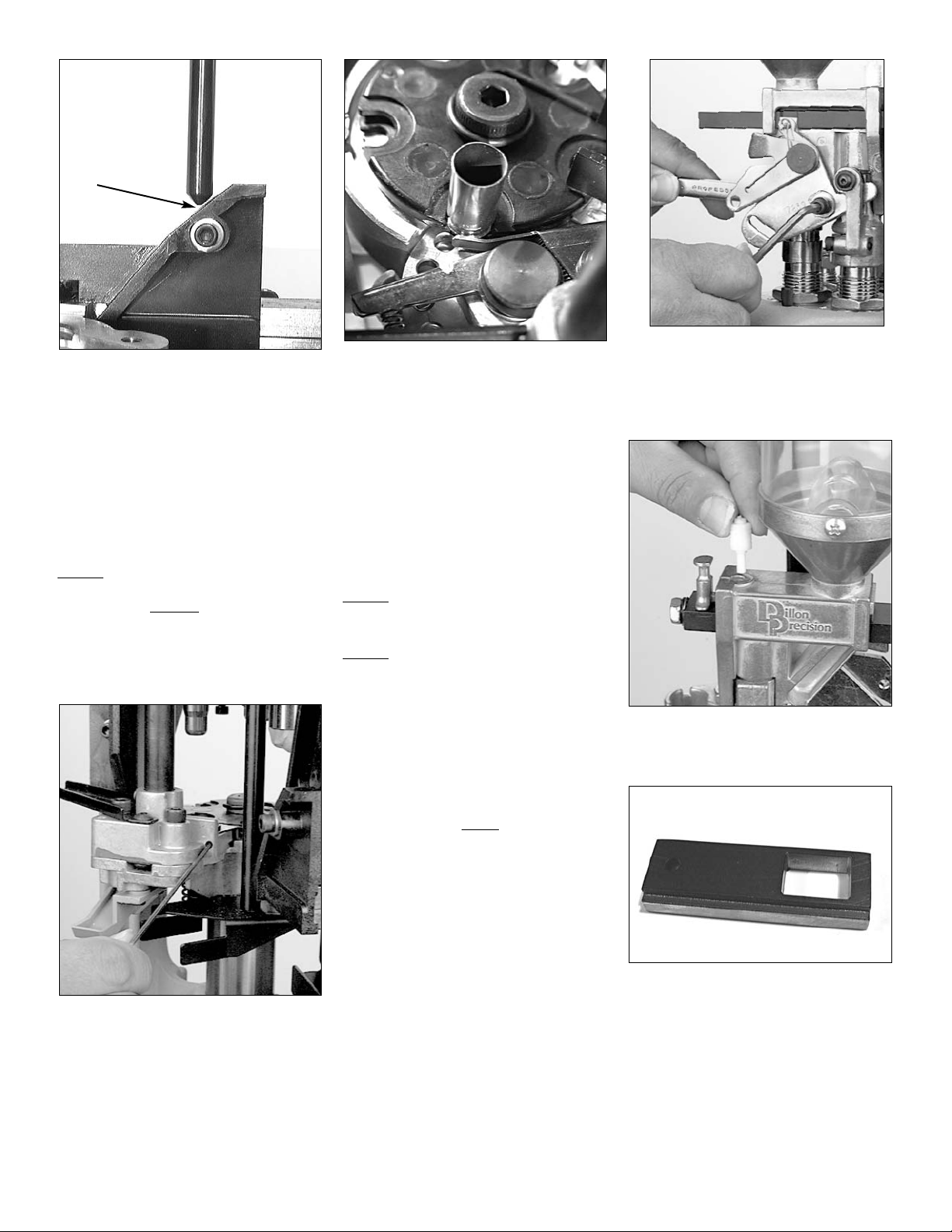

FIG 4

A. Installation of the handle FIG 4:

1. Hold the washer (see arrow FIG 4)

over the hole on the right side of the

crank and insert the handle.

2. Place a 5/32” Allen wrench or screw

driver through the hole in the handle to

help your grip.

3. Tighten the nut using a 7/8” wrench.

Page 7

FIG 5

Operate the handle slowly to ensure that

the machine operates smoothly. Make sure

that the handle and the crank completely

clear the bench. Contact with the bench may

hinder its range of movement. Observe the

movement of the shellplate platform and verify that there is no interference or contact of

the case insert slide and the chute/bin mount

FIG 5.

FIG 6

B. Installation of the Spent

Primer Cup FIG 7 and

Cartridge Bin FIG 6:

1. Raise the platform (i.e., lower the

handle all the way).

FIG 7

2. Slide the spent primer cup onto the

rails as shown. Make sure when

installing the cup that it is on both

rails.

FIG 8

3. Place the cartridge bin on the

chute/bin bracket. Push the handle aft

FIG 8 while sliding the bin toward

the handle as shown. With the handle

pushed to its full aft position, there

should be a space between the handle and bin.

FIG 9

C. Installation of the Casefeed

Post

1. Remove the bolts, nuts and clamp

from the spacer kit and assemble

them as shown in FIG 9.

FIG 10

FIG 11

2. Install the casefeed post as shown in

FIG 10. Make sure the bend in the

post is facing away from you FIG 11.

3. Using two 7/16” wrenches, tighten

the bolts.

D. Installation of the Casefeed

Tube Bracket FIG 11.

Install as shown in FIG11.

Note: If you ordered your machine with

the optional casefeed assembly,

you won’t need to use the casefeed

tube bracket. This is because the

upper end of the casefeed tube is

supported by the casefeed bowl.

8

Page 8

9

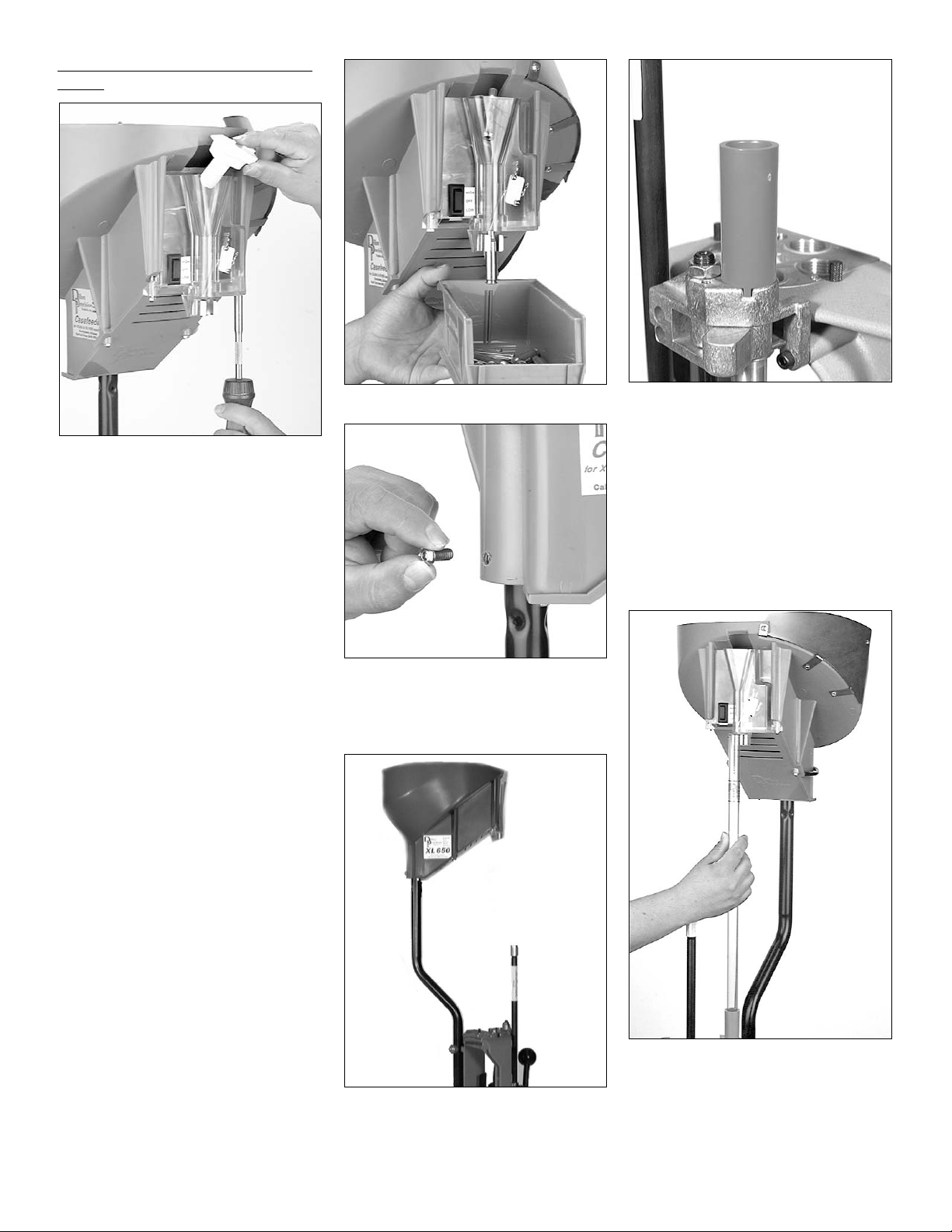

E. Installation of the Optional

Casefeeder FIG 12:

FIG 12

1. Remove the casefeed parts bag

from the casefeed bowl and remove

the casefeed assembly from the box

FIG 12.

FIG 13

a. Spacer Washer FIG 13: (see casefeed-

er schematic page 57)

Some calibers call for a spacer washer to

be used under the casefeed plate.

Installation of this washer raises the plate up

a bit to make the feeder function properly

with longer pistol cases (such as .357

Magnum, .44 Magnum and .30 M1 – this

listing of calibers requiring the spacer is

repeated in the caliber conversion chart on

pages 46-48 of this manual).

Note: The spacer washer does not come

factory installed.

FIG 14

To Install the Spacer Washer:

a.1. FIG 14 Remove the casefeed plate.

a.2. With the casefeed plate removed, dis-

assemble the clutch drive. To do so

unscrew the two clutch screws.

a.3. Install the spacer washer as illustrated

in the casefeed schematic (page 57).

IMPORTANT: The spacer washer goes

between the lower clutch and the casefeed plate.

a.4. Reassemble the clutch drive and rein-

stall the casefeed plate. (Note how the

clutch drive engages the drive pin).

FIG 15

b. Clutch Adjustment FIG 15:

Note: The clutch comes factory adjusted

(if you don’t have to install the

spacer washer you shouldn’t have

to adjust the clutch drive).

The two socket-head machine screws (pt#

13732) should be just tight enough for the

clutch to drive the casefeed plate under a

normal load of brass. To check this, place

the casefeed assembly in front of you on the

bench. With the switch off, plug the casefeeder in. Turn the switch to the down (low)

position and observe the movement of the

plate. You should be able to cause the

clutch to slip, using moderate finger pres-

sure, without stalling the motor. Alternately

tighten and loosen the two machine screws

evenly, observing the effect on the holding

power of the clutch. The correct setting

will stall the plate before stalling the motor,

yet not slip when the casefeed bowl is

about half full of brass.

Note: The casefeed bowl is not designed

to be completely filled with brass. If

it is fully loaded it will not function

reliably. The rated capacity of the

casefeeder is about 1/2 of the

bowl’s physical capacity.

FIG 16

c. Casefeed Funnel Adapter FIG 16:

Some calibers call for the white plastic

funnel adapter to be used, located in the

casefeed accessory bag FIG 16. It is used

for feeding 9mm, .38 Super, .32 H&R, and

.380 ACP. (This listing of calibers is repeated in the caliber conversion chart on pages

46-48). Without this funnel adapter these

calibers will occasionally hang up in the

clear plastic funnel FIG 17 at the top of the

casefeed tube.

FIG 17

Note: The casefeed funnel adapter does

not come factory installed.

Page 9

10

To Install the casefeed funnel adapter

FIG 18:

FIG 18

Remove the screws that attach the clear

casefeed funnel. Slide the front cover down

a bit, and slip the white plastic funnel

adapter into the funnel FIG 18. Reassemble.

Note: Do not loosen the two screws that

are holding the microswitch (pt#

13779).

Note: Occasional jams will occur. To

keep them to a minimum, be sure

to use the spacer washer FIG 13

or white casefeed funnel adapter

FIG 16 when called for. Use the

low setting if it will keep up with

your loading pace, and do not overload the casefeed bowl. The rated

capacity of the casefeeder is about

1/2 of the bowl’s physical capacity.

Before placing the casefeed bowl on the

casefeed post, take a moment to look over

and understand the casefeed assembly and

how it works. If you like, you can run the

casefeeder before placing it on top of the

casefeed post. This will allow you to get a

better idea of how it works. To do so, plug

in the casefeeder and fill it with about 50

cases. Hold the casefeeder FIG 19 so the

funnel is vertical. Place the cartridge bin

under the funnel and turn it on. Experi-ment

using both the high and low settings.

FIG 19

FIG 20

2. Remove the set screw from the acces-

sory bag and thread it into the casefeed assembly FIG 20.

FIG 21

3. Place the casefeed bowl onto the

casefeed post FIG 21.

FIG 22

4. Place the casefeed adapter on the case-

feed body FIG 22. Note how the key

fits into the notch on the casefeed

body.

Note: Casefeed adapters are caliber spe-

cific. Crosscheck your casefeed

adapter with the one listed in the

caliber conversion chart (for the caliber you’re loading) to ensure that

you have the correct one installed in

your machine.

FIG 23

5. Align the casefeed bowl so the spring

clamp is directly over the casefeed

adapter. Place the casefeed tube into

the casefeed adapter then snap the

tube into the clamp FIG 23.

Page 10

11

Note: One end of the casefeed tube is

beveled and one end is squared off.

Insert the squared end of the tube

(down) into the top of the casefeed

adapter.

FIG 24

6. Using A 5/32” Allen wrench, snug

the machine screw against the casefeed mounting post FIG 24 to prevent the casefeed bowl from rotating.

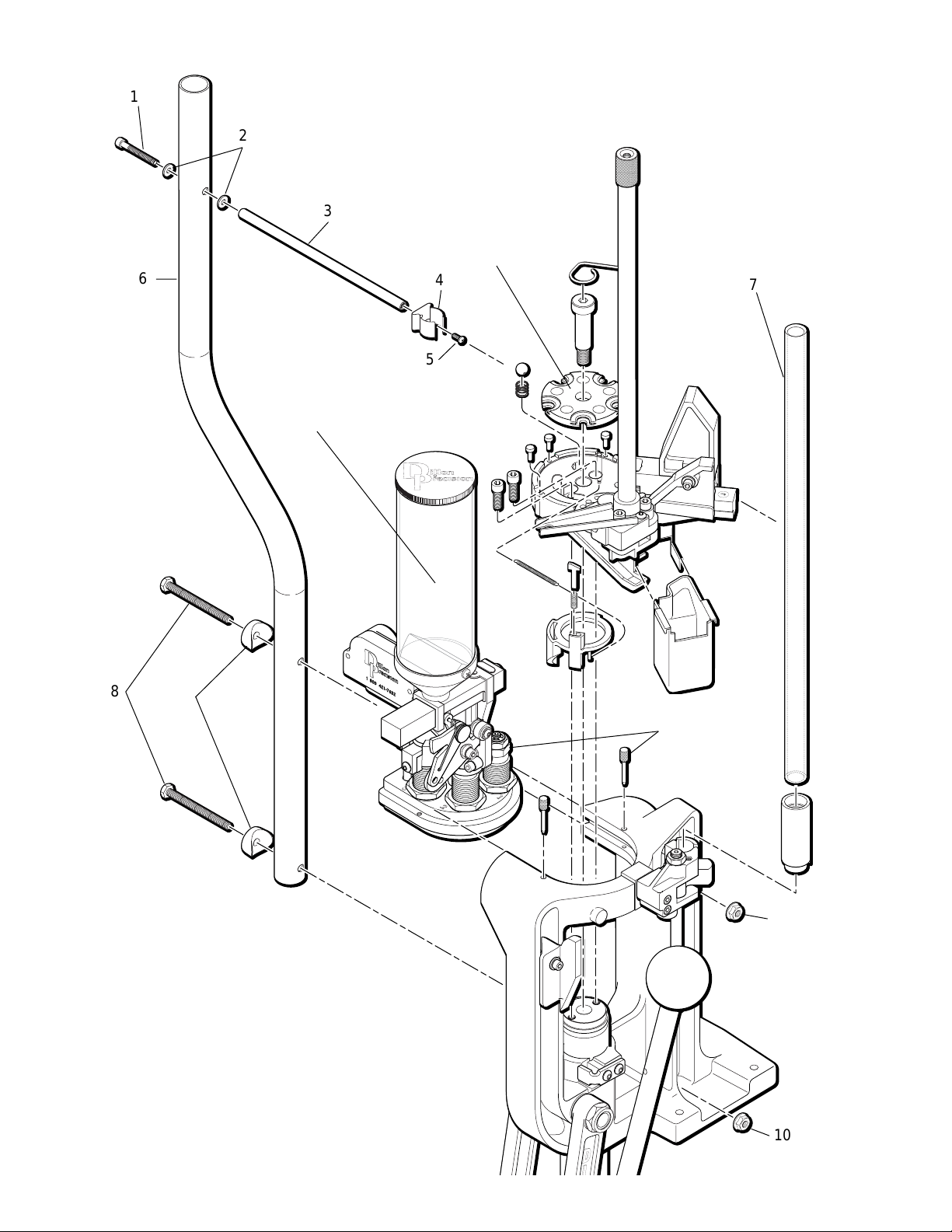

4.Toolhead Overview

You’re now ready to install the toolhead

and adjust the dies. But first, we’ll give a

brief overview of the location and function

of each station, we’ll then follow up with a

detailed illustration.

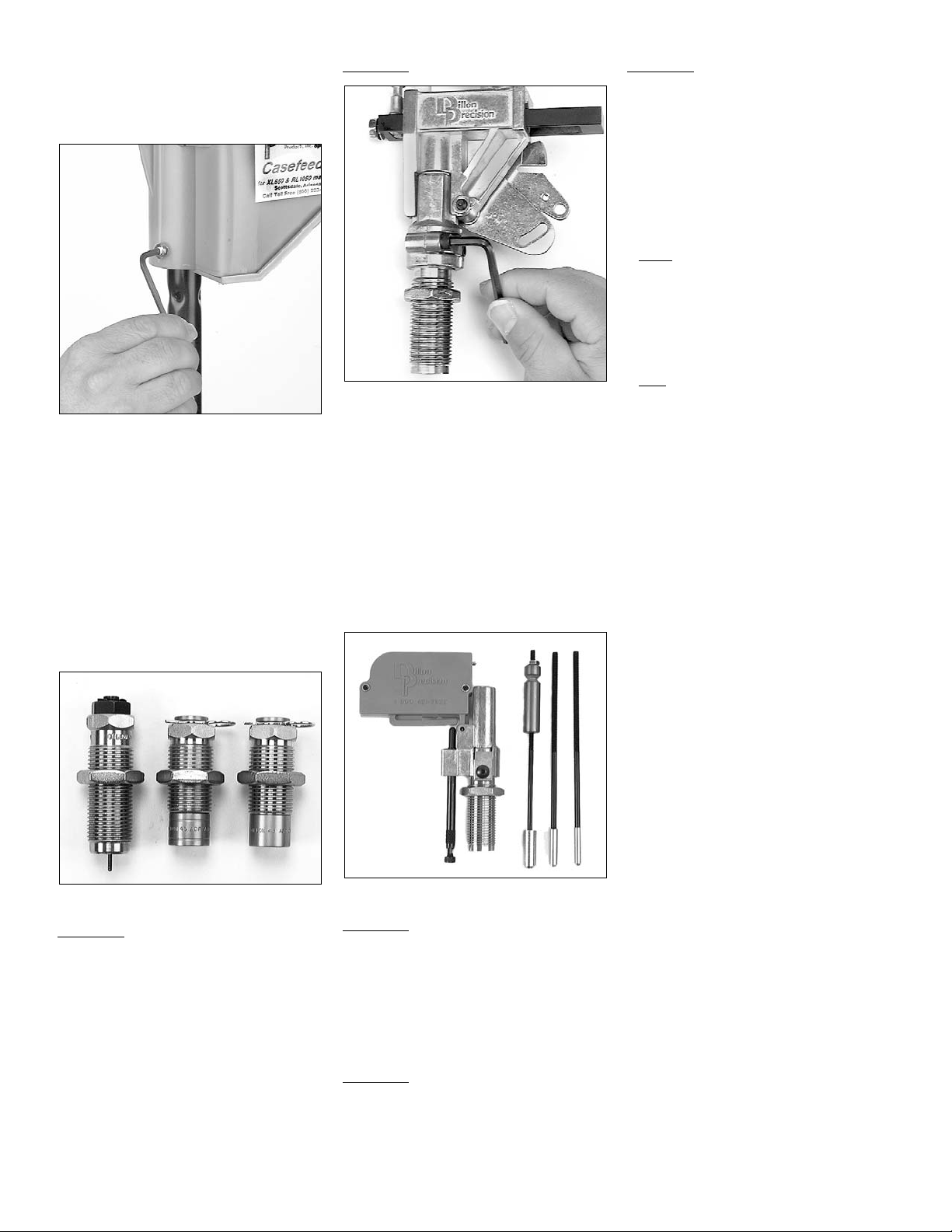

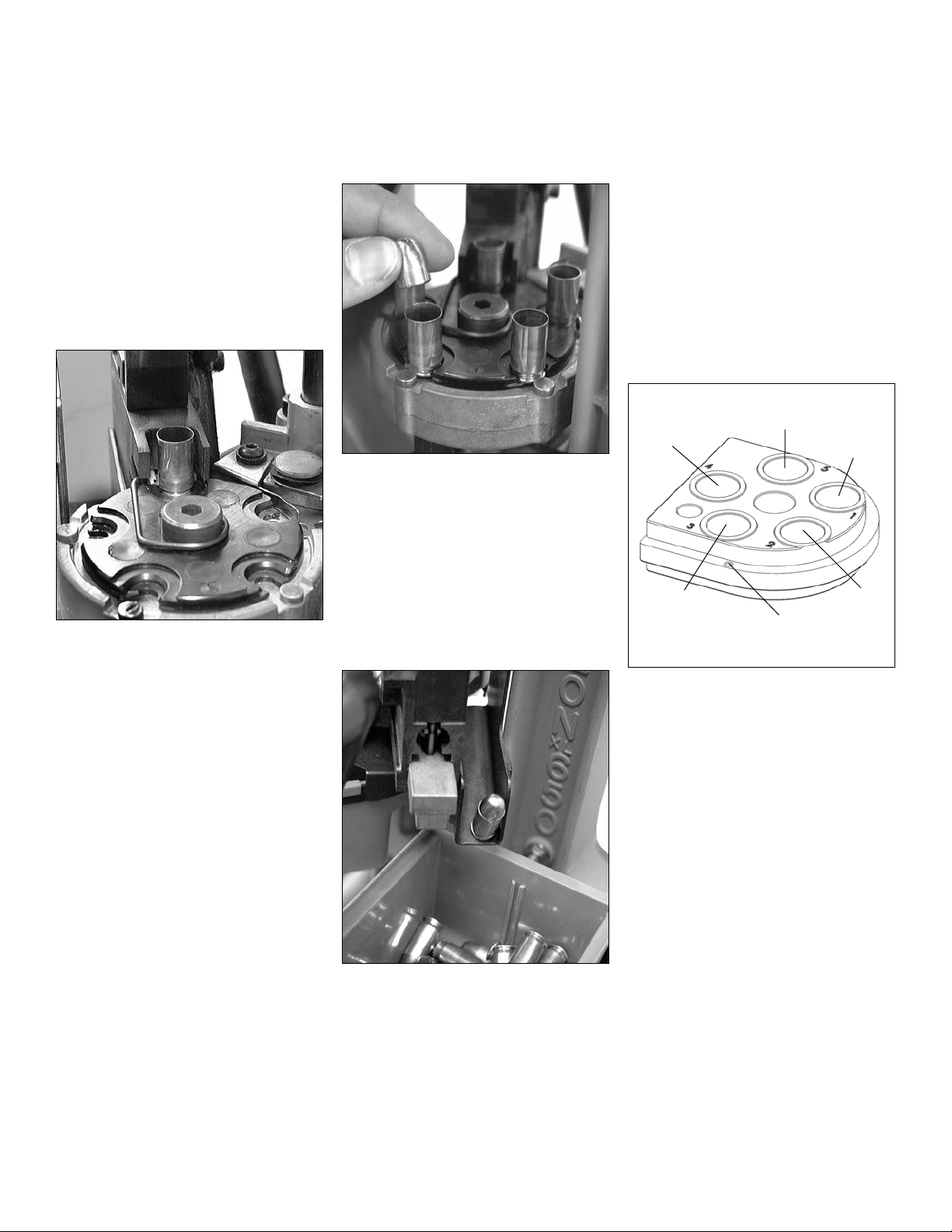

FIG 25

Station 1

- Sizing/Decapping

The stations on the toolhead are numbered 1-5. Station 1 is for the sizing/decapping die FIG 25. This die can be easily

identified by the decapping pin sticking out

the bottom as well as by its label. This die

removes or “decaps” the old primer and

resizes the case.

Warning: Never decap live primers! (See

mandatory safety procedures.)

Station 2 - Powder Measure

FIG 26

Station 2 is for the powder die, which

comes attached to the powder measure

FIG 26. Here several operations are conducted. The case is primed, straightwalled

pistol cases are belled, and powder is

dropped. The purpose of the bell at the

mouth of the case is simply to help align

the bullet and to keep the case from shaving lead during the seating process. Note:

Only straight-walled cases receive a bell,

bottle-necked cases (rifle cartridges) are

not belled.

FIG 27

Station 3

- Powder Check

Station 3 is used for the optional powder

check system FIG 27. This system is located

in a separate package and can be identified

by the blue warning buzzer attached to a

die. This system is designed to detect gross

deviations in the powder charge, i.e. a double charge of powder or no powder at all.

Station 4

- Bullet Seating

Station 4 is for the seating die FIG 25.

This is where the bullet is pushed into the

case.

Station 5 - Crimp

Station 5 is for the crimp die FIG 25. This

die not only removes the bell created at

Station 2, but rolls the mouth of the case

inward to insure proper feeding and to

secure the bullet.

LUBRICATING BRASS

To lubricate brass, use “Dillon Case

Lubricant” (item# 13733).

Pistol

– If you’re using a carbide sizing

die, you will not need to lubricate your

cases (before sizing) when loading straightwalled cases. If you’re not using a carbide

sizing die, you must lube the brass before

sizing. We do, however, recommend lubricating all brass.

Rifle

– Lubricate all bottle-necked cases,

even if you’re using a carbide sizing die.

To lubricate your cases, start by ensuring that they are clean. Place your clean

brass in a shallow box so the cases are laying on their side. Pump a couple of sprays

of Dillon Case Lubricant over the cases.

Shake the box so the cases will tumble and

roll. Repeat this process again making sure

that the lubricant is well distributed over the

cases.

Note: When loading rifle cartridges, if your

sizing die doesn’t have a carbide

case mouth expander, you may

want to allow a little bit of lube to get

inside the case mouth.

Note: When loading bottle-necked

cartridges, if you get an excessive

amount of lube on the shoulder of

the case, it will leave oil dents.

Regardless of whether you’re lubri

cating pistol or rifle cases – do not

drench the cases in lubricant. A light

film of lubricant is sufficient.

Toolhead Head Setup:

Pistol – go to page 12

Rifle – go to page 20

Page 11

12

PISTOL SECTION –

Toolhead Set Up

To set up the toolhead you’ll need to have

empty brass, bullets, primers and powder

on hand. (For your convenience Dillon

Precision offers a wide variety of new

primed and unprimed brass, bullets, primers

and powder.) For easy access, place your

brass in an open container. Dillon Precision

also offers a variety of blue bin boxes which

come in handy for this purpose.

A. Station 1 – To install the

size/decap die FIG 25:

Warning: Never attempt to de-prime live

primers, an explosion may result in

serious injury or even death.

1. Raise the platform, by lowering the

handle all the way down.

2. Screw the sizing die into Station 1.

Continue to screw the die down until

it just touches the shellplate. Tighten

the die lockring finger tight Now

lower the platform by raising the handle to its upright position.

3. Place a case in the casefeed funnel.

Here, the case drops to the casefeed

arm bushing.

4. Raise the platform. The inserter cam

pushes the feed arm bushing over the

body, dropping the case onto the

Station 1 locator.

5. Lower the platform. The case is inserted into Station 1.

FIG 28

Note: After raising the handle, insure that

you push the handle against its full aft

stop FIG 28. This will insure

that the case is fully inserted into

Station 1.

Note: Also, when priming, pushing the

handle against its full aft stop, FIG

28, will insure that the primer is

fully seated.

6. Again, raise the platform. The case is

now sized. If the case has a spent

primer, it will be deprimed. Leave

the platform in the raised position

with the case fully inserted in the

die. This will ensure that the die

remains in alignment when tightening the lockring.

FIG 29

7. Using a 1-1/8” wrench to turn the

lockring and a 7/8” wrench to hold

the die body, tighten the lockring

FIG 29.

FIG 30

B. Station 1 – The decap-

ping assembly FIG 30:

Dillon decapping assemblies are made

with replaceable decap pins. One extra pin

is included with each sizing die. To replace

a bent or broken pin, simply:

1. Unscrew the decapping assembly

from the top of the die FIG 30.

FIG 31

2. Unscrew the knurled retaining nut,

see “A” FIG 31, remove the old pin

and replace it with a new one, see

“B” FIG 31.

3. Screw the decapping assembly back

into the sizing die.

Note: The decapping assembly can be

removed from the sizing die without

affecting the adjustment of the sizing die or sizing operation.

Note: The decapping assembly must be

removed when loading primed

cases. (Tip: Check prices of

components. You can often purchase primed cases for the price

of the primers and new empty

cases. Obviously, this is a good

deal since you pay the same price

and save time.)

FIG 32

C. Station 2 – Installation of

powder measure assembly

FIG 32:

A

B

Page 12

13

FIG 33

FIG 34

1. Use a 5/32” Allen wrench to loosen

the two collar clamp screws and

remove the powder die FIG 33 & 34.

FIG 35

2. Screw the powder die into Station 2.

Stop when the die is flush with the

bottom of the toolhead FIG 35.

FIG 36

3. Remove the powder funnel FIG 36

from the bag containing the locator

buttons.

FIG 37

FIG 38

About Powder Funnels:

In FIG 37 are two examples of the many

powder funnels available for the XL 650.

On the left is a typical pistol caliber funnel. On the right, a rifle or bottle-necked

type. The bottom of the rifle-style funnel

fits snugly over the neck of the case,

allowing powder to drop in without

spilling (the rifle-style powder funnel does

not bell the mouth of the case). The bottom of the pistol funnel, on the other hand,

fits inside and actually expands and bells

as it guides the powder into the case.

Powder funnels are caliber specific, so be

sure you have the correct funnel by referring to the caliber conversion chart.

4. Insert the funnel into the die FIG 38.

Make sure that you insert the funnel

into the die with the grooved end up.

The funnel should move up and

down freely.

FIG 39

5. Remove the lid and the protective

cardboard tube from the powder

measure and place it onto the powder die FIG 39. Turn down the two

clamp screws until they are snug.

Then loosen them slightly. The measure should move freely atop the die.

D. Station 2: About Powder

Bars

Dillon Precision manufactures four types

of powder bars for the XL 650:

1. Extra Small – use for dropping less

than 3 grains of powder.

2. Small – use for dropping 3 to 20

grains of powder.

3. Large – use for dropping 20 to approx.

45-50 grains of powder.

4. Magnum – use for dropping more

than approx. 45-50 grains of powder.

The extra small powder bar is used when

loading .32 Auto, .32 S&W and .32 SWL.

Both the extra small powder bar and the

magnum powder bar are non-standard

items and are ordered separately. The large

and small powder bar, on the other hand,

Page 13

14

are standard equipment and are included

with every XL 650. If you ordered your

machine set up for a specific caliber, the

proper size powder bar should already be

installed. If you need to change the powder bar – refer to “Powder Bar Adjust-

ment” in the Caliber Conversion Section

on page 30.

E. Station 2 – Adjustment

of Powder Die & Powder

Funnel:

Note: Adjusting the powder die for a

straight wall case is not the same

as adjusting a powder die for a

bottle-necked case. This is

because straight wall cases are

given a bell and bottle-necked

cases are not given a bell.

Adjusting the powder die for a

bottle-necked case is covered in

the rifle section.

FIG 40

For the powder bar to properly dispense a

measured powder charge the powder bar

must travel its full distance. To travel its full

distance, the white cube must contact the

powder measure body (see arrow FIG 40).

FIG 41

Also the belling process does not begin until

after the powder bar has traveled its full distance. The angled portion on the bottom of

the powder funnel (see arrow FIG 41) is

what bells the cartridge. Once the white

cube has contacted the powder measure

body the case is forced upward against the

tapered portion of the powder funnel producing a bell. The more the powder die is

adjusted down (clockwise) the more the

case will be belled.

Note: If the powder die is not adjusted

down far enough to cause the

powder bar to travel its full distance the powder charge will be

erratic and the case will not

receive enough bell.

To adjust the powder die/powder

funnel:

1. Drop a case into the casefeed funnel

and cycle the handle. The case

should now be in the shellplate at

Station 1.

2. Raise the platform. Notice the resistance at the end of the downstroke.

This is the resistance of the case in

the sizing die. Lower the platform.

The case will index to Station 2.

3. Raise the platform. Check to see

how far the powder bar has traveled

FIG 40.

FIG 42

4. If the white cube has not traveled its

full distance, lower the platform just

enough to pull the case off of the

powder funnel (this will prevent the

shellplate from indexing while you

adjust the powder die). While holding

the powder measure, turn the die

down 1/8 of a turn FIG 42. Again

raise the platform and observe the

travel of the powder bar.

5. Repeat step four until the powder bar

travels its full distance FIG 40.

FIG 43

Once the powder bar travels fully across

you should continue to adjust the powder

die for the desired amount of bell (turn the

powder die 1/8 of a turn at a time). The

desired amount bell is just enough to allow

the bullet to sit on the case mouth without

falling off and to keep the case from shaving

lead during the seating process (see “A”

FIG 43).

Note: If you screw the die down too far,

the case will look like example “C”

FIG 43. You must then discard

this case, back the powder die off,

by turning it counter-clockwise, and

continue with a new sized case.

You’ll soon learn to judge the correct

amount of bell by simply looking at it. In

the meantime, you might want to use your

dial calipers to check it. Twenty thousandths of an inch greater (at the mouth of

the case) than its original diameter, should

about do it.

A

Correct amount of

bell.

B

Not enough bell.

C

Too much bell.

Page 14

15

FIG 44

6. Once you’ve achieved the desired

amount of bell – with the case in

Station 2, raise the platform. Run the

lockring down hand tight FIG 44.

FIG 45

FIG 46

7. Insure the bellcrank and the failsafe

bracket FIG 45 are aligned. Using a

5/32” Allen wrench, snug the collar

clamp screws FIG 46.

FIG 47

8. While holding the powder mea-

sure, snug the lockring using a 1

1/8 wrench FIG 47. Now lower the

platform.

FIG 48

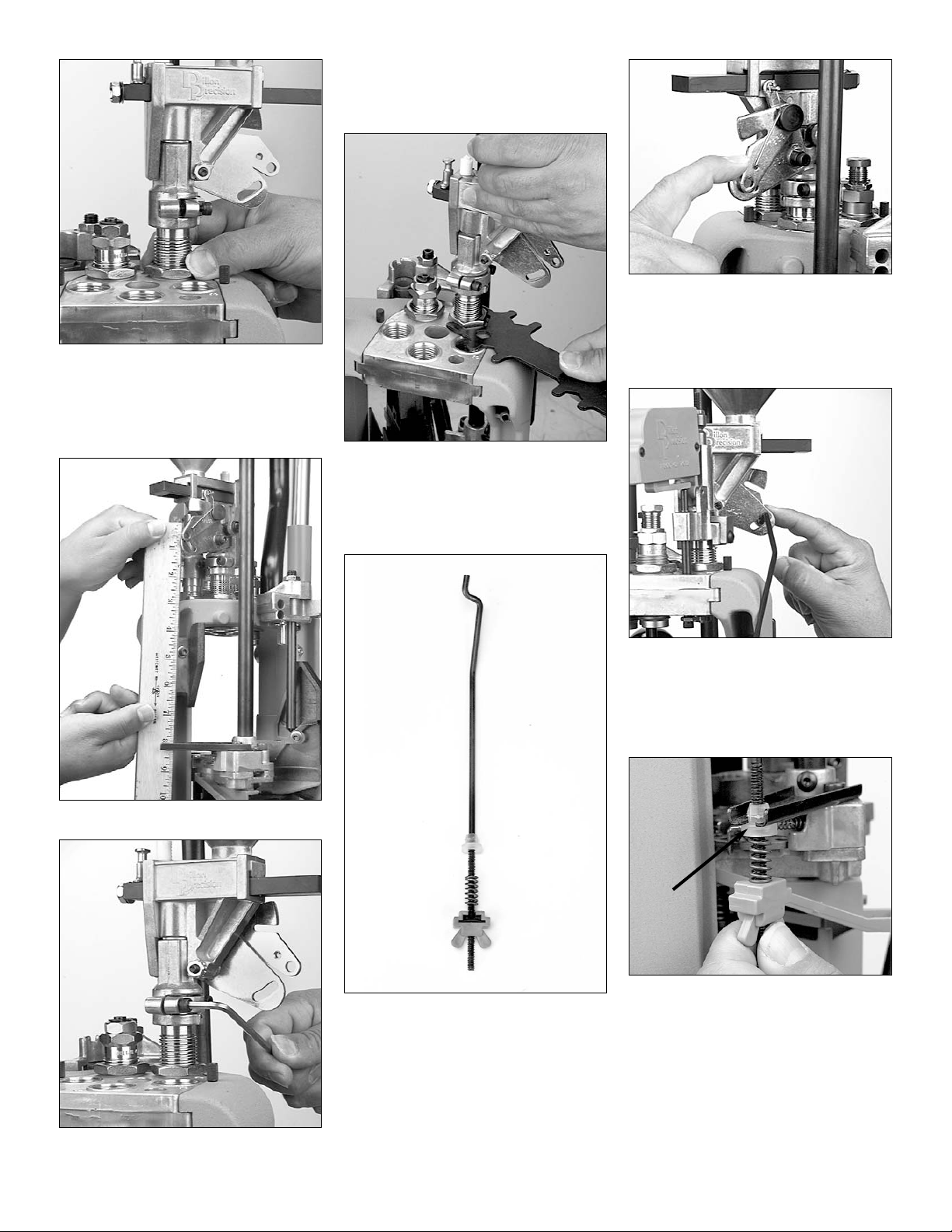

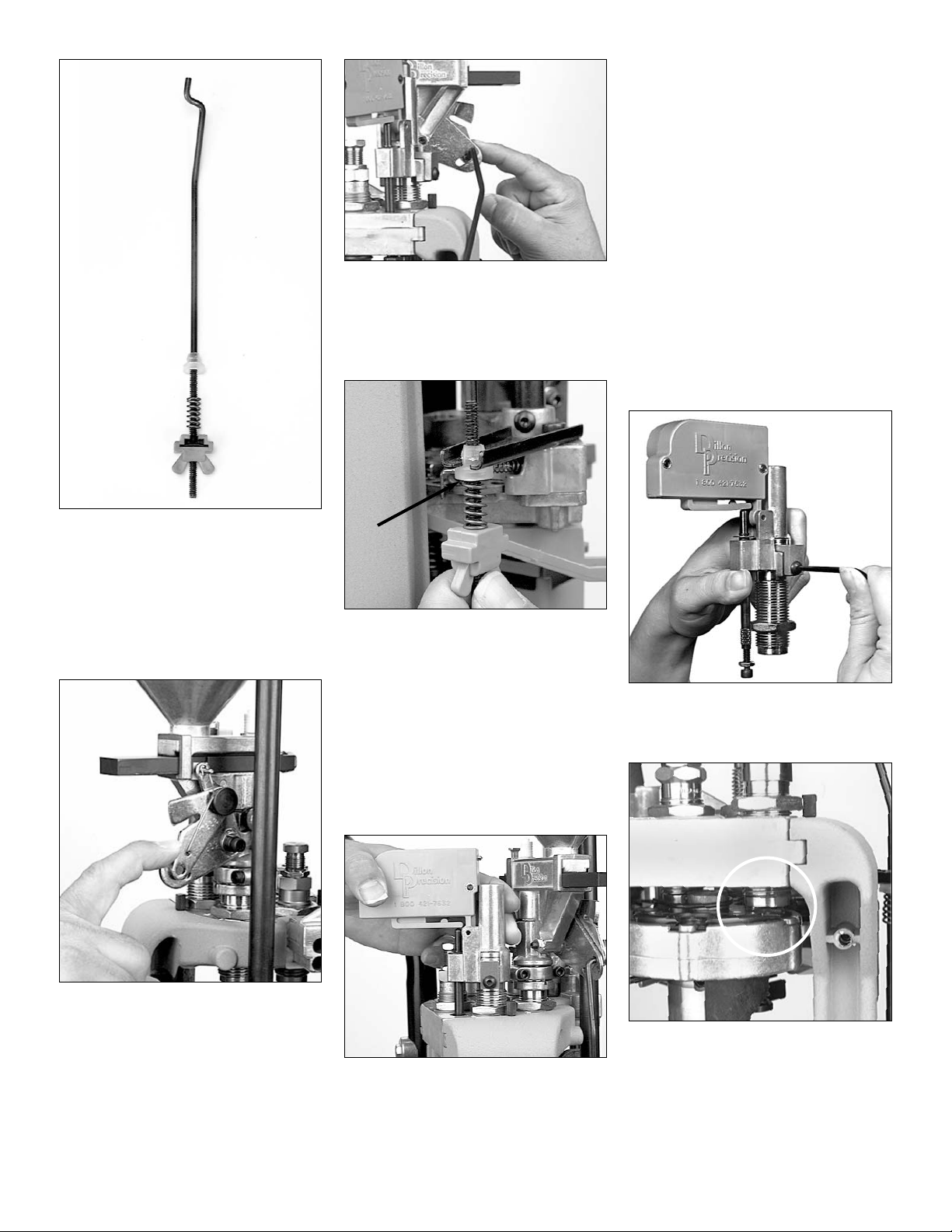

F. Station 2 – Installation of

the failsafe rod assembly

FIG 48:

The purpose of the powder measure failsafe rod is to return the powder bar to its recharge position.

FIG 49

1. Using your forefinger, move the lock-

link (#17838) down to align the hole

with the slot on the Powder Measure

bellcrank (#97034) FIG 49.

FIG 50

2. Insert the rod (#13629) through the

holes FIG 50.

3. Loosen the blue plastic wing nut

(#13799).

FIG 51

4. Slide the failsafe rod into the failsafe

return bracket. Push the shoulder

washer up into place (see arrow FIG

51) and tighten the blue plastic wing

nut until the spring just touches the

underside of the bracket.

Note: Do not fill the powder measure or

adjust the powder bar until the rest

of the dies are installed and adjusted.

Page 15

16

FIG 52

G. Station 3 – Installation of

the Powder Check System

FIG 52:

Note: The powder check system does not

guarantee the accuracy of the powder charge. It is designed to warn

you if the powder charge is grossly

out of tolerance, i.e., no powder or a

double charge.

Warning: A double-charged round (a

loaded round with twice as much

powder as it should have) can damage your gun as well as cause bodily injury.

Warning: A round loaded without powder

can also damage your gun as well

as cause bodily injury. If a round

without powder is fired in your gun,

the detonation of the primer will

push the bullet part way down the

barrel. If the lodged bullet is not

removed before another round is

fired, the gun will be damaged

and bodily injury may occur.

FIG 53

1. Loosen the die clamp screw FIG 53

and remove the die.

FIG 54

2. Raise the platform and screw the pow-

der check die into Station 3. There

should be a 1/8 to 1/4 inch space

between the shellplate and the bottom

of the die FIG 54.

FIG 55

3. Run the lockring down. Using a

1 1/8” wrench snug the lockring

FIG 55.

FIG 56

FIG 57

4. Remove the 10-24 screw and nut

from the black push rod FIG 56 and

place the powder check system on

the powder check die FIG 57.

Center the black push rod (see arrow

FIG 57) in the hole that is to the left

of the die.

FIG 58

5. Reinstall and snug the die clamp screw

FIG 58.

FIG 59

Page 16

17

FIG 60

6. FIG 59 Screw the 10-24 screw and

nut fully into the rod. Raise the platform. Unscrew the 10-24 screw until

it contacts the edge of the platform

FIG 59. Lower the platform part way

and unscrew the screw (counterclockwise) until raising the platform

causes the buzzer housing to gently

rock into the side of the die collar

FIG 60.

FIG 61

7. Secure the jam nut by holding the

black push rod while tightening it

using a 3/8” wrench FIG 61.

Note: Once you’ve adjusted the powder

bar for the desired powder charge,

adjustment of the powder check

system can be completed.

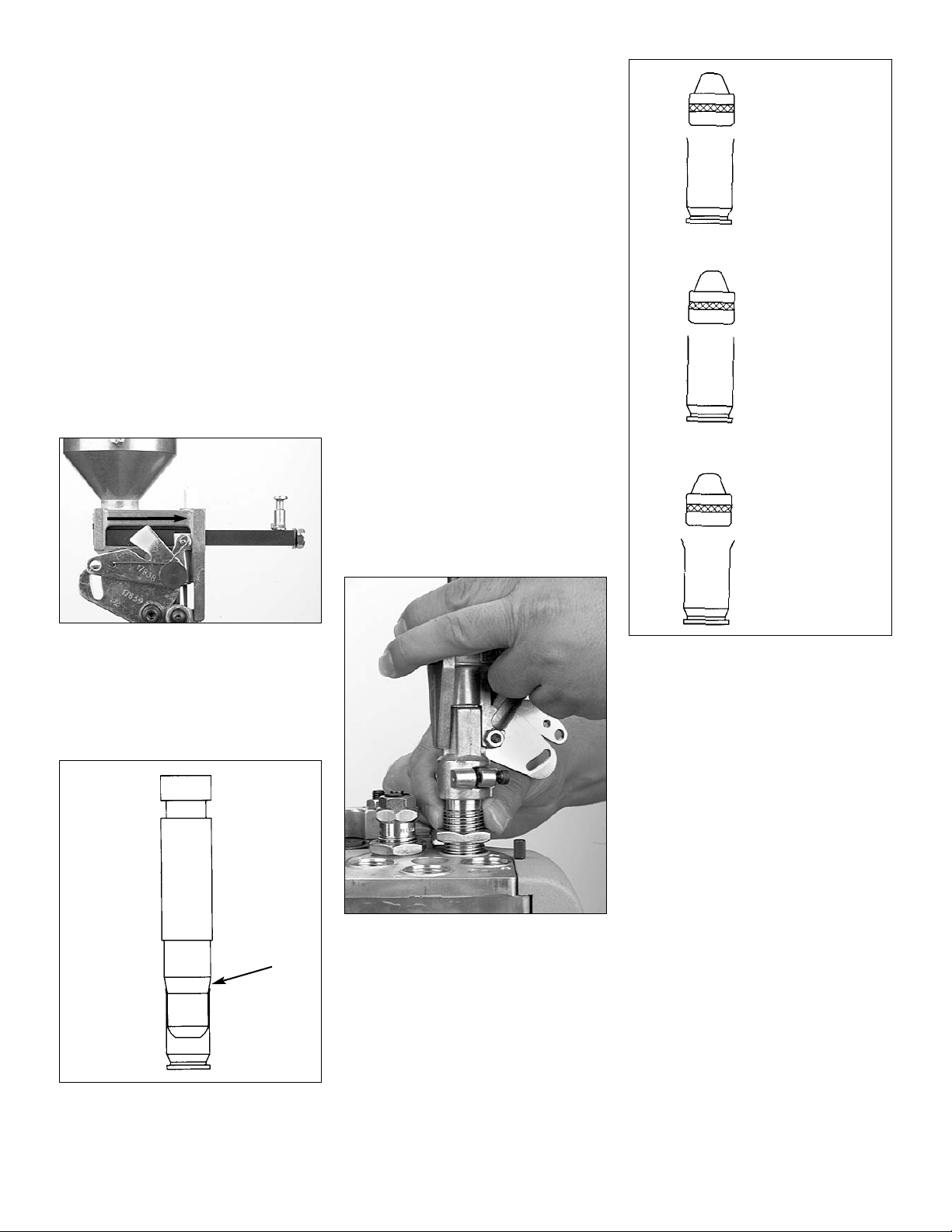

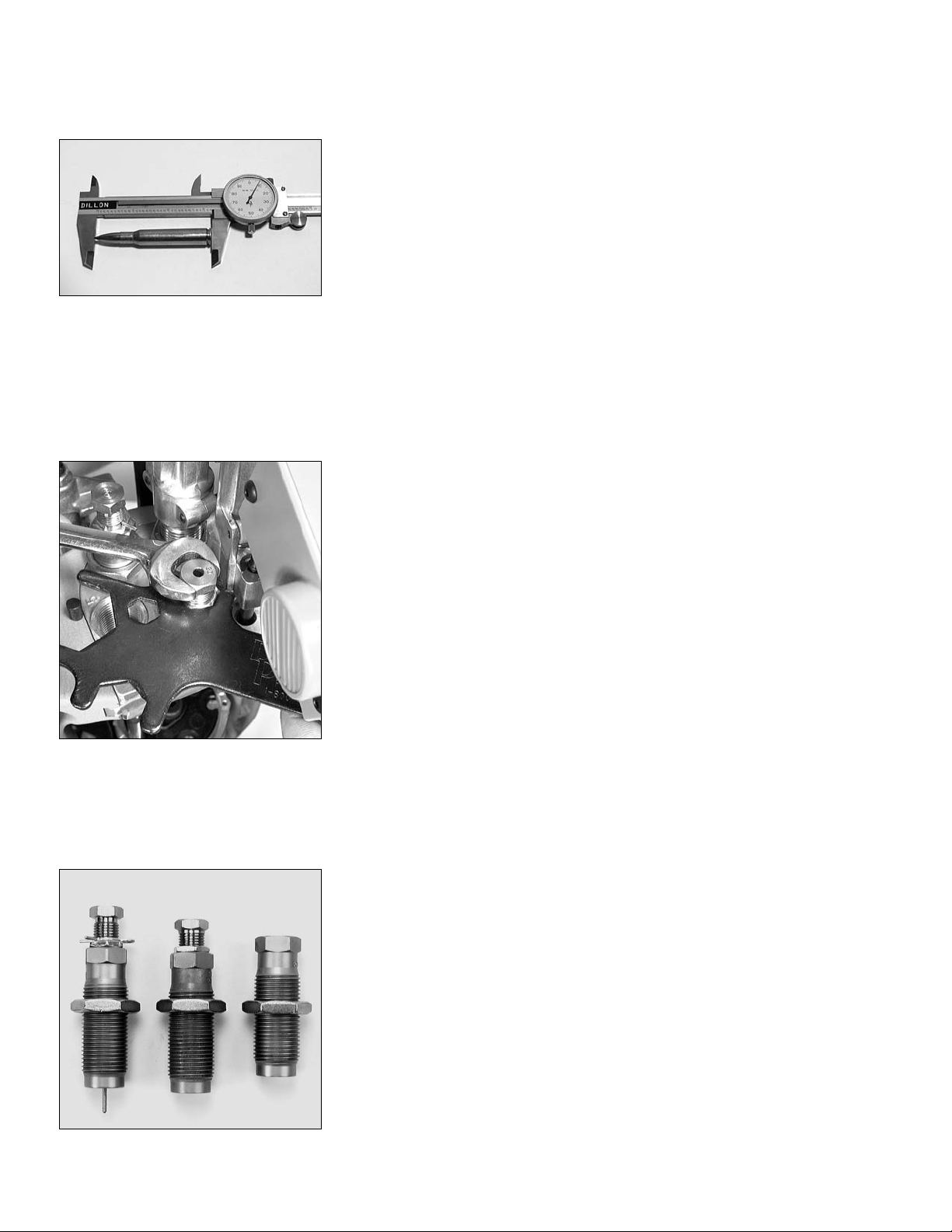

H. Station 4 – General

Information on Bullet

Seating

FIG 62

FIG 63

FIG 64

The purpose of the seating die FIG 62 is

to insert the bullet into the case and to push

it down into the case the proper amount.

How far the bullet is pushed into the case

will determine the overall length (OAL).

Several factors go into determining the

proper OAL – such as, the maximum recommended OAL, listed in the reloading

manual, and the type of bullet being

loaded. The type of bullet can determine

the OAL in one of two ways. If the bullet

has what is called a cannelure, or crimping

groove (items A&B in FIG 63), this will

determine the proper OAL. If the bullet

you’re using doesn’t have a cannelure or a

crimping groove (item C in FIG 63), then

you’ll need to refer to your reloading manual for the suggested OAL. The purpose of

the cannelure and crimping groove is to

secure the bullet by giving the mouth of the

case a place to go (without deforming the

bullet) when being crimped. When the bullet is properly seated, the mouth of the cartridge case should be near the top of the

cannelure/crimping groove FIG 64.

Refer to your reloading manual. Under

the section specified for the caliber you’re

loading, you’ll find a schematic of the cartridge. For example, .38 Special lists a maximum OAL of 1.55” (Lyman Reloading

Handbook). If you’re seating the bullet to

the cannelure/crimping groove, the OAL

should be well within the maximum OAL

listed, however, use a set of dial calipers to

check it. (Dial calipers are available from

Dillon Precision). If the bullet you’re using

doesn’t have a cannelure/crimping groove,

refer to the specific type of bullet you’re

using in the reloading manual. For example

– if you’re loading a 158gr 38sp JHP and it

doesn’t have a cannelure/ crimping groove,

use the suggested OAL of 1.480 (Lyman

Reloading Handbook).

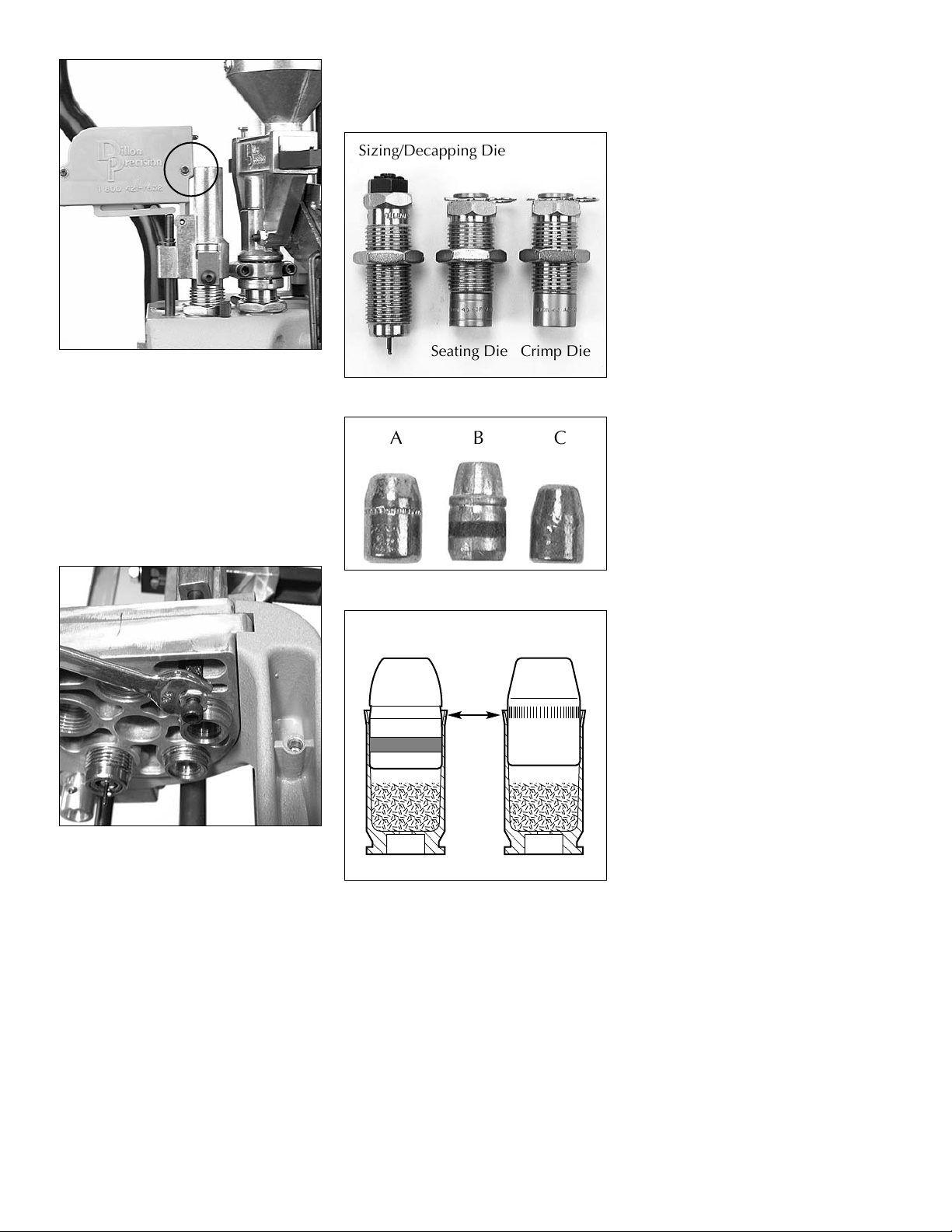

A

Sizing/Decapping Die

Seating Die Crimp Die

BC

Page 17

18

FIG 65

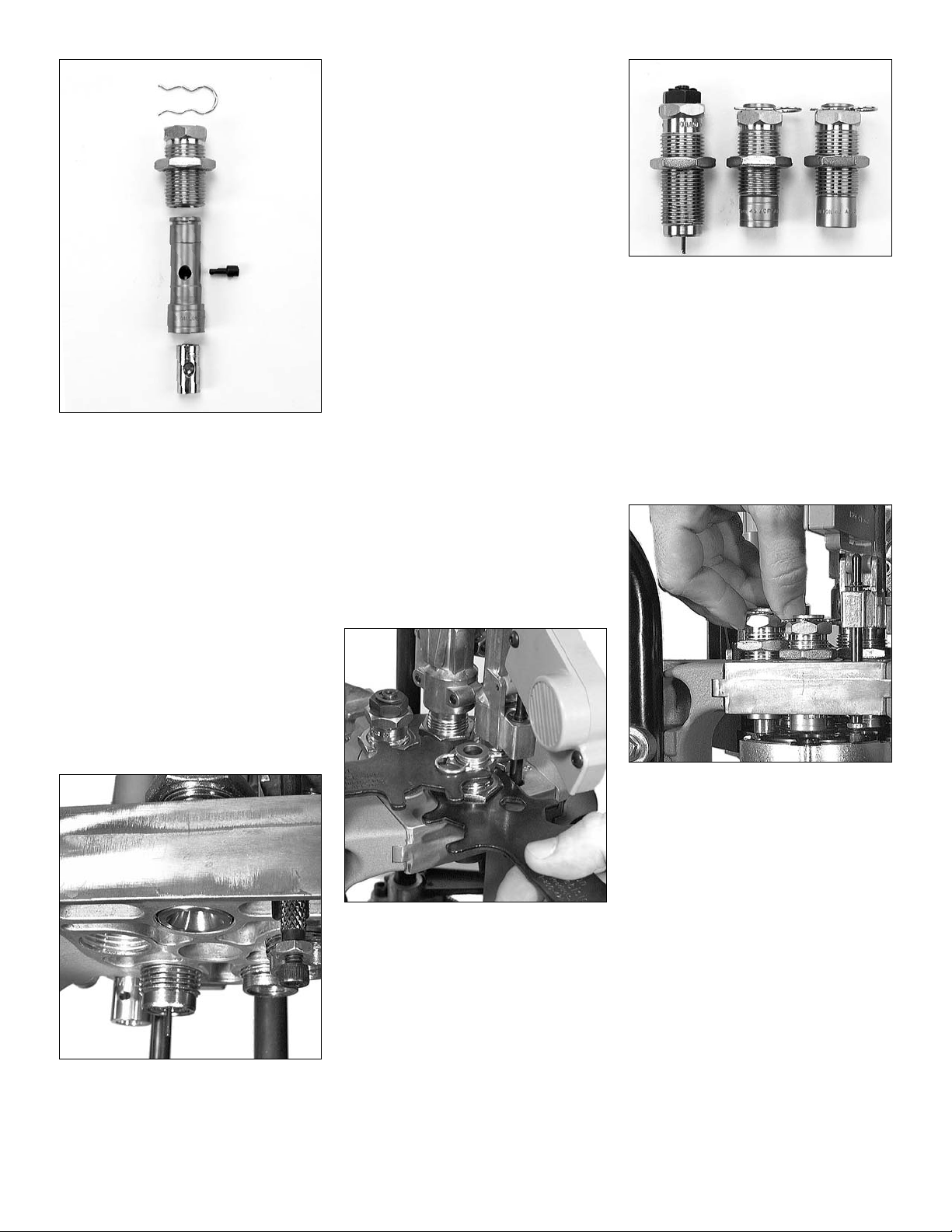

I. Station 4 – Seating Stems

for pistol FIG 65

All pistol seating dies come with interchangeable seating stems. The seating stem

you should use will depend on the shape of

the bullet you’re loading. Three different

types of seating stems may be available –

wadcutter, semi-wadcutter and round nose.

Check to make sure that the seating stem

installed in your seating die matches the

bullet you are loading.

Dillon seating dies, which are being used

in this manual, are easily disassembled.

Simply remove the hitch pin from the top

and slide the seating stem out FIG 65.

Replace the seating stem and reassemble

the die.

FIG 66

J. Station 4 – Installation and

Adjustment of the

Seating Die:

1. Take the seating die from the die box

and screw it into Station 4. Screw

the die down until the bottom of the

die is flush with the bottom of the

toolhead FIG 66. Note: At this point

the die will not be screwed down far

enough to begin seating the bullet,

but it will give you a place to start.

2. Place a case (with a belled case

mouth) into Station 4.

3. Place a bullet on the belled case

mouth and raise the platform. Then,

lower the platform just enough to

inspect the bullet without indexing the

shellplate. If the bullet is not seated

deep enough, screw the seating die

down 1/2 turn at a time. As a guide,

one full turn moves the die down

about 70 thousandths of an inch,

about the thickness of a nickel.

Again, cycle the machine and inspect

the seating depth. Repeat these steps

as necessary until the correct overall

length is achieved. Use a dial caliper

or equivalent to measure the overall

length of the cartridge. Check the

overall length of the round against the

information in your reloading manual.

FIG 67

4. Once you have obtained the proper

OAL, replace the cartridge into

Station 4 and raise the platform.

Using a 1-1/8” wrench to turn the

lockring and a 7/8” wrench to hold

the die body, snug the lockring

FIG 67.

Note: If you should happen to seat the

bullet too deep, you can use a

Dillon bullet puller to reclaim your

components.

FIG 68

K. Station 5 – Installation and

adjustment of the Crimp

Die FIG 68:

1. Screw the crimp die into Station 5.

Screw it down until it is flush with the

bottom of the toolhead. This is a good

starting point for the crimp adjustment.

2. Place a cartridge with a properly seated bullet into Station 5.

FIG 69

3. Raise the platform and continue to

screw the die down until it touches

the cartridge FIG 69.

4. Lower the platform and give the die

an 1/8 turn down, again raise the

platform.

5. Lower the platform halfway and

inspect the cartridge. If the bell is still

present, or the desired amount of

crimp has not been achieved, give

the die a 1/8 turn down and try again.

Continue making small adjustments

to your crimp die until the desired

amount of crimp has been achieved.

6. Once the adjustment is complete,

place the case back into Station 5 and

raise the platform. Using a 1-1/8”

wrench to turn the lockring and a

7/8” wrench to hold the die body,

snug the lockring.

Sizing/Decapping Die

Seating Die Crimp Die

Page 18

FIG 70

Note: FIG 70 When adjusting the crimp

die it is important to know what to

look for. Check that the crimp: Looks

OK, allows your firearm to function

consistently and the bullet feels tight

in the case.

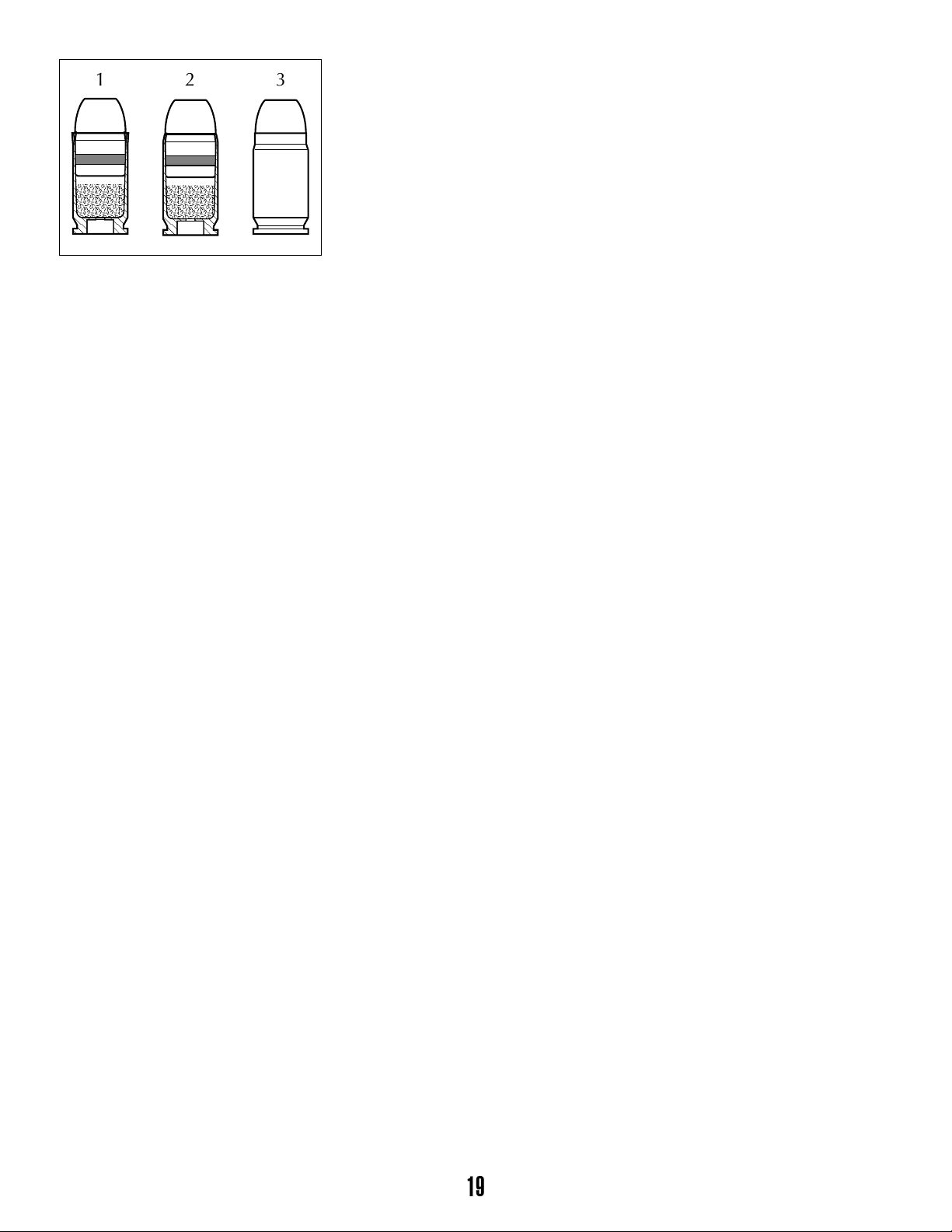

The drawing of case #3 FIG 70 is a

depiction of a case that has been over

crimped by adjusting the crimp die down

(clockwise) too far. Note the defined line

below the mouth of the case and the bulge

below the line. This is not a proper crimp.

This line is the direct result of the cartridge

being over crimped. A line like this will

only appear if the crimp die is adjusted

down too far. Warning: Over crimping

.45ACP, .38 Super, 9mm, etc., can actually

cause the bullet to be loose in the case.

Go to Loading Components

Section – Page 30

19

123

Page 19

RIFLE SECTION –

Toolhead Set Up

To set up the toolhead you’ll need to

have your empty brass on hand. For your

convenience Dillon Precision offers a wide

variety of new primed and unprimed brass.

For easy access, place your brass in an

open container. Dillon Precision also offers

a variety of blue bin boxes which come in

handy for things like this.

FIG 71

A. Station 1 – About the Case

Gage FIG 71:

To install and adjust a sizing/decapping

die you must have a case gage and know

how to use it. The sizing die shapes the

case. If the case doesn’t have the proper

shape it won’t fit properly in the chamber of

the rifle. The purpose of the case gage is to

determine whether or not the case has the

proper shape, which in turn will tell you if

your sizing die is properly adjusted.

Note: Case gages are caliber specific.

B. Station 1 – How to use the

Case Gage:

The way the case gage works is this:

Once you’ve made a preliminary adjustment to your sizing die drop the sized case

all the way into the case gage FIG 72. Look

at the base of the case.

FIG 72

FIG 73

FIG 74

FIG 75

If the base of the case is below the high step

(see “B” FIG 73) and above the low step

(see “A” FIG 73) then the sizing die is prop-

erly adjusted. If the base of the case is

above the high step FIG 74 then you will

need to adjust the sizing die down by turning it clockwise.

FIG 76

FIG 77

If the base at the case is below low step

FIG 75 then the sizing die is adjusted

down too far and needs to be backed out

by turning it counter-clockwise (Note: this

case should be thrown away). Once the

sizing die is properly adjusted, drop the

properly sized case back into the case

gage and look at the mouth of the case FIG

76. If the case mouth is below the high

step (see “C” FIG 76) and above the low

step (see “D” FIG 76) then the case is the

proper length and will not need to be

trimmed. If the case mouth is above the

high step FIG 77 then the case mouth

needs to be trimmed in order to reduce the

overall length of the case. If you find that

your cases need to be trimmed, Dillon

Precision offers two types of case trimmers.

3

20

A

Low Step

B

High Step

C

Low Step

D

High Step

AB

AB

C

D

AB

C

D

7

Page 20

FIG 78

FIG 79

C. Station 1 – Installation

and adjustment of the sizing/decapping die FIG 78:

Warning: Never attempt to de-prime a live

primer, an explosion may result

causing serious injury or even

death.

Note: Whenever sizing a bottle-necked

case you must lubricate the case

first, otherwise you will stick the

case inside the sizing die. For

more information refer to the section

“Lubricating Your Brass” (page 11).

1. Raise the platform, by lowering the

handle all the way.

2. Install the sizing die by screwing it

into Station 1 FIG 79. Continue to

screw the die down until the mouth

of the die is about the thickness of a

dime away from the shellplate. Lower

the platform by raising the handle to

its upright position.

FIG 80

3. Drop a lubricated case into the case-

feed funnel FIG 80. Here the case

drops to the casefeed arm bushing.

4. Raise the platform. The inserter cam

pushes the feed arm bushing over the

body, dropping the case onto the

Station 1 locator.

5. Lower the platform. The case is

inserted into Station 1.

FIG 81

Note: After raising the handle, insure that

you push the handle against its full

aft stop FIG 81. This will insure

that the case is fully inserted into

Station 1.

Note: When priming, pushing the handle

against its full aft stop will insure

that the primer is fully seated.

6. Again raise the platform. The case is

now sized. If the case has a spent

primer, it will be deprimed. Notice

the resistance at the end of the

downstroke. This is the resistance of

the case in the sizing die. Lower the

platform. The case will index to

Station 2.

7. Remove the case from Station 2 and

place it in the case gage. From this

point – follow the instructions provided under “Rifle Section B. Station 1 –

How to use the Case Gage.”

8. Once the sizing die is properly

adjusted, replace the case into Station

1 and raise the platform. Leave the

platform in the raised position with

the case fully inserted in the die. This

will ensure that the die remains in

position when tightening the lockring.

FIG 82

9. Run the lockring down until it con-

tacts the toolhead. Using a 1 1/8”

wrench to turn the lockring and a

3/4” wrench to hold the die body,

snug the lockring FIG 82.

21

Sizing/Decapping Die

Seating Die

Crimp Die

Page 21

D. Station 1 – The decapping

assembly FIG 78:

Dillon decapping assemblies are made

with replaceable decap pins. One extra pin

is included with each sizing die. To replace

a bent or broken pin, simply:

FIG 83

1. Unscrew the decapping assembly

from the top of the die FIG 83.

FIG 84

2. Unscrew the decapping pin (see

arrow FIG 84), and replace it with a

new one.

3. Screw the decapping assembly back

into the sizing die.

Note: The decapping assembly can be

removed from the sizing die without

affecting the adjustment of the sizing die or sizing operation.

Note: The decapping assembly must be

removed when loading primed

cases.

FIG 85

FIG 86

FIG 87

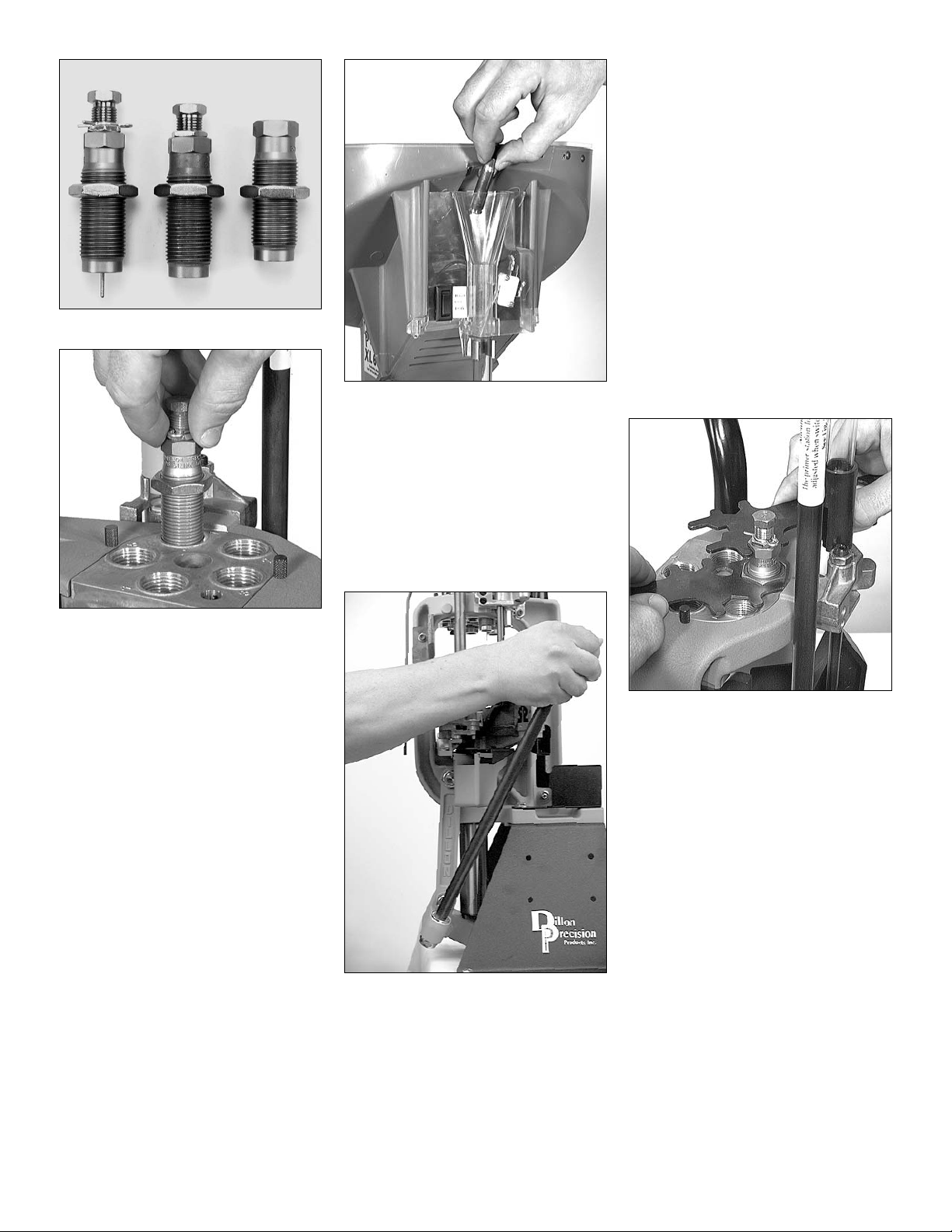

E. Station 2 – Installation

of powder measure assembly FIG 85:

1. Using a 5/32” Allen wrench, loosen

the two collar clamp screws and

remove the powder die FIG 86 & 87.

FIG 88

2. Thread the powder die into Station 2.

Screw it down about halfway FIG 88.

FIG 89

3. Remove the powder funnel from the

bag containing the brass locator buttons FIG 89.

22

Page 22

FIG 90

In FIG 90 are two examples of the many

powder funnels available for the XL 650.

On the left is a typical pistol caliber funnel. On the right, a rifle or bottle-necked

type. The bottom of the rifle style funnel

fits snugly over the neck of the case allowing powder to drop in without spilling (the

rifle style powder funnel does not bell the

mouth of the case). The bottom of the pistol funnel, on the other hand, fits inside

and actually expands the case mouth as it

guides the powder into the case (the

expansion of the case mouth is where the

mouth of the case gets its bell). Powder

funnels are caliber specific so be sure you

have the correct funnel by referring to the

caliber conversion chart.

FIG 91

4. Insert the funnel into the die FIG 91.

Regardless of whether you’re using a

rifle or pistol powder funnel, make

sure that you insert the funnel into the

die with the grooved end up. It

should move up and down freely.

FIG 92

5. Remove the lid and the protective

cardboard tube from the powder measure and place it onto the powder die

FIG 92. Turn down the two clamp

screws until they are snug. Then

loosen them slightly. The measure

should move freely atop the die.

F. Station 2 – About powder

bars:

Dillon Precision manufactures four types

of powder bars for the XL 650:

1. Extra Small – use for dropping less

than 3 grains of powder.

2. Small – use for dropping 3 to 10

grains of powder.

3. Large – use for dropping 10 to

approx. 45-50 grains of powder.

4. Magnum – use for dropping more

than approx. 45-50 grains of powder.

The extra small powder bar is used when

loading .32 Auto, .32 S&W and .32 SWL.

Both the extra small powder bar and the

magnum powder bar are non-standard

items and are ordered separately. The large

and small powder bar, on the other hand,

are standard equipment and are included

with every XL 650. If you ordered your

machine set up for a specific caliber, the

proper size powder bar should already be

installed. If you need to change out the

powder bar – refer to “Powder Bar

Adjustment” in the Caliber Conversion

Section on page 30.

G. Station 2 – Adjustment

of Powder Die/Powder

Funnel

Important: Adjusting the powder die for a

bottle-necked case is not the same

as adjusting the powder die for

straight-walled cases. This is

because bottle-necked cartridges

are not given a bell – straightwalled cases are given a bell. For

straight-walled cartridges refer to

the pistol section.

FIG 93

For the powder bar to properly dispense a

measured powder charge, the powder bar

must travel its full distance. To travel its full

distance, the white cube must contact the

powder measure body (see arrow FIG 93).

When adjusting the powder die for a

bottle-necked cartridge, the objective is to

adjust the powder die so that the powder

bar just travels the full distance and no

further (see arrow FIG 93). If you try to

apply the procedures used for belling a

straight walled case, as when loading pistol cartridges, you will crush the bottlenecked case and possibly damage the

powder measure.

Note: If the powder die is not adjusted

down far enough to cause the powder bar to travel its full distance the

powder charge will be erratic.

Note: Whenever sizing a bottle-necked

case you must lubricate the case

first, otherwise you will stick the

case inside the sizing die. For

more information refer to the section

“Lubricating Your Brass” (page 11).

23

Page 23

FIG 94

To adjust the powder die/powder

funnel:

1. Drop a lubricated case into the case-

feed funnel and cycle the handle. The

case should now be in the shellplate

at Station 1.

2. Raise the platform. Notice the resistance at the end of the downstroke.

This is the resistance of the case in

the sizing die. Lower the platform.

The case will index to Station 2.

3. Raise the platform. Check to see

how far the powder bar has traveled

FIG 94.

FIG 95

4. If the white cube has not traveled its

full distance, lower the platform just

enough to pull the case off of the

powder funnel (this will prevent the

shellplate from indexing while you

adjust the powder die). While holding

the powder measure, turn the die

down 1/8 of a turn FIG 95. Again

raise the platform and observe the

travel of the powder bar.

5. Repeat step four until the powder bar

travels its full distance FIG 94.

Note: If you screw the powder die down

too far, the powder bar will travel its

full distance before the handle is all

the way down. If this happens – DO

NOT FORCE THE HANDLE

DOWN. Instead lower the platform

and back the powder die out by

turning it counter-clockwise. If you

force the handle, you will crush the

case and possibly damage the powder measure.

FIG 96

6. Once the powder bar is traveling its

full distance – with the case in Station

2 – raise the platform. Run the lockring down hand tight FIG 96.

FIG 97

FIG 98

7. Insure the bellcrank and the failsafe

bracket are aligned, FIG 97. Using a

5/32” Allen wrench snug the collar

clamp screws, FIG 98.

FIG 99

8. While holding the powder measure,

snug the lockring using a 1 1/8”

wrench FIG 99. Now lower the platform.

24

Page 24

FIG 100

H. Station 2 – Installation of

the failsafe rod assembly

FIG 100:

The purpose of the powder measure failsafe rod is to return the powder bar to its recharge position.

FIG 101

1. Using your forefinger, move the lock-

link down to align the hole with the

slot on the Powder Measure bellcrank

FIG 101.

FIG 102

2. Insert the rod (#13629) through the

holes FIG 102.

3. Loosen the blue plastic wing nut

(#13799) FIG 102.

FIG 103

4. Slide the failsafe rod into the failsafe

return bracket. Push the shoulder

washer up into place (see arrow FIG

103) and tighten the blue plastic wing

nut until the spring just touches the

underside of the bracket.

Note: The powder measure is filled and

the powder bar is adjusted after

installing and adjusting the rest of

the dies.

FIG 104

I. Station 3 – Installation of

the Powder Check System

FIG 104:

Note: The powder check system does not

guarantee the accuracy of the powder charge. It is designed to warn

you if the powder charge is grossly

out of tolerance, i.e., no powder or a

double charge.

Warning: A double-charged round (a

loaded round with twice as much

powder as it should have) can damage your gun as well as cause bodily injury.

Warning: A round loaded without powder

can also damage your gun as well

as cause bodily injury. If a round

without powder is fired in your gun,

the detonation of the primer will

push the bullet part way down the

barrel. If the lodged bullet is not

removed before another round is

fired, the gun will be damaged.

FIG 105

1. Loosen the die clamp screw FIG 105

and remove the die.

FIG 106

2. Raise the platform and screw the

powder check die into Station 3 and

raise the platform. There should be a

1/8 to 1/4 inch space between the

shellplate and the bottom of the die

FIG 106.

25

Page 25

3. Run the lockring down. Using a 11/8” wrench snug the lockring.

FIG 107

FIG 108

4. Remove the 10-24 screw and nut

from the black push rod FIG 107 and

place the powder check system on

the powder check die FIG 108.

Center the black push rod (see arrow

FIG 108) in the hole that is to the left

of the die.

FIG 109

5. Reinstall and snug the die clamp

screw FIG 109.

FIG 110

FIG 111

6. FIG 110 Screw the 10-24 screw and

nut fully into the rod. Raise the platform. Unscrew the 10-24 screw

until it contacts the edge of the platform FIG 110. Lower the platform

part way and unscrew the screw

(counter-clockwise) until raising the

platform causes the buzzer housing

to rock into the side of the die collar

FIG 111.

FIG 112

7. Secure the jam nut by holding the

black push rod while tightening it

using a 3/8” wrench FIG 112.

Note: Once you’ve adjusted the powder

bar for the desired powder charge –

installation and adjustment of the

powder check system can be completed.

J. Station 4 – How to determine the proper seating

depth:

Before installing and adjusting the seating

die you’ll need to know how to determine

the proper seating depth. How far the bullet

is seated into the case will determine the

overall length (OAL). Several factors go into

determining the proper OAL – such as, the

maximum recommended OAL, listed in the

reloading manual, and the type of bullet

being loaded. The type of bullet can determine the OAL by one of two ways. If the

bullet has what is called a cannelure, FIG

113, this will determine the proper OAL.

FIG 113

26

Page 26

FIG 114

If the bullet you’re using doesn’t have a

cannelure, then you’ll need to refer to

your reloading manual for the suggested

OAL. The purpose of the cannelure is to

secure the bullet by giving the mouth of

the case something to dig into when being

crimped. When the bullet is properly

seated, the mouth of the cartridge case

should be in the middle of the cannelure,

see arrow FIG 114.

Refer to your reloading manual. Under

the section specified for the caliber you’re

loading, you’ll find a schematic of the cartridge. For example, .30-06 lists a maximum

OAL of 3.340” (Lyman Reloading

Handbook). If you’re seating the bullet to

the cannelure, the OAL should be well

within the maximum OAL listed, however,

use a set of dial calipers to check it. (Dial

calipers are available from Dillon

Precision). If the bullet you’re using doesn’t

have a cannelure, refer to its specific type in

the reloading manual. For example – if

you’re loading a .30-06 180 gr. JHPBT, and

it doesn’t have a cannelure, use the suggested OAL of 3.280 (Lyman Reloading

Handbook).

FIG 115

K. Station 4 – Seating Stem

for rifle FIG 115:

Unlike pistol seating dies, rifle seating dies

come with only one type of seating stem.

Dillon seating dies, which are being

used in this manual, are easily disassembled. Should you need to disassemble the

rifle seating die – simply unscrew the seating stem from the top of the seating die

FIG 115.

L. Station 4 – Installation and

Adjustment of the

Seating Die

1. Place a lubricated sized case into

Station 4 and raise the platform.

FIG 116

2. Thread the seating die into Station 4.

Continue to screw it down until it

contacts the case FIG 116. Once the

die is in contact with the case back

the die off (counter-clockwise) 1/4 of

a turn. Using a 1 1/8” wrench snug

the lockring on the seating die.

FIG 117

FIG 118

3. Lower the platform.

4. FIG 117 Back the seating stem all the

way out of the seating die. Now

screw the seating stem back into the

seating die two full turns FIG 118.

5. Place a bullet on the case mouth and

raise the platform – then lower the

platform just enough to inspect the

bullet without indexing the shellplate.

a. If the bullet is not pushed down far

enough – go to step 6.

b. If the bullet is pushed down too far:

b.1. Pull the bullet from the case

using a Dillon bullet puller.

b.2. Back the seating stem out by

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

27

Page 27

turning it counter clockwise and try

again.

6. Screw the seating stem down 1/2 turn

at a time FIG 118.

FIG 119

7. Repeat as necessary until the correct

overall length is achieved. Use a dial

caliper or equivalent to measure the

overall length of the cartridge FIG

119. Check the overall length of the

round against the information in your

reloading manual.

FIG 120

8. Once you have obtained the proper

OAL, replace the cartridge into

Station 4, raise the platform and

snug the lockring on the seating stem

FIG 120.

FIG 121

M.Station 5 – Installation and

adjustment of the Crimp

Die FIG 121:

1. Screw the crimp die into Station 5.

Screw it down until it is flush with the

bottom of the toolhead. This is a good

starting point for the crimp adjustment.

2. Place a lubricated cartridge with a

properly seated bullet into Station 5.

3. Raise the platform and continue to

screw the die down until it stops.

4. Lower the platform and give the die a

half turn down; again, raise the platform.

5. Lower the platform halfway and

inspect the cartridge. If the desired

amount of crimp has not been

achieved, give the die a 1/4 turn

down and try again. Continue making

small adjustments to your crimp die

until the desired amount of crimp has

been achieved.

6. Once the adjustment is complete,

place the case back into Station 5 and

raise the platform. Using a 1 1/8”

wrench to turn the lockring and a

7/8” wrench to hold the die body,

snug the lockring.

Go to Loading Components

Section - Page 30

28

Sizing/Decapping Die

Seating Die

Crimp Die

Page 28

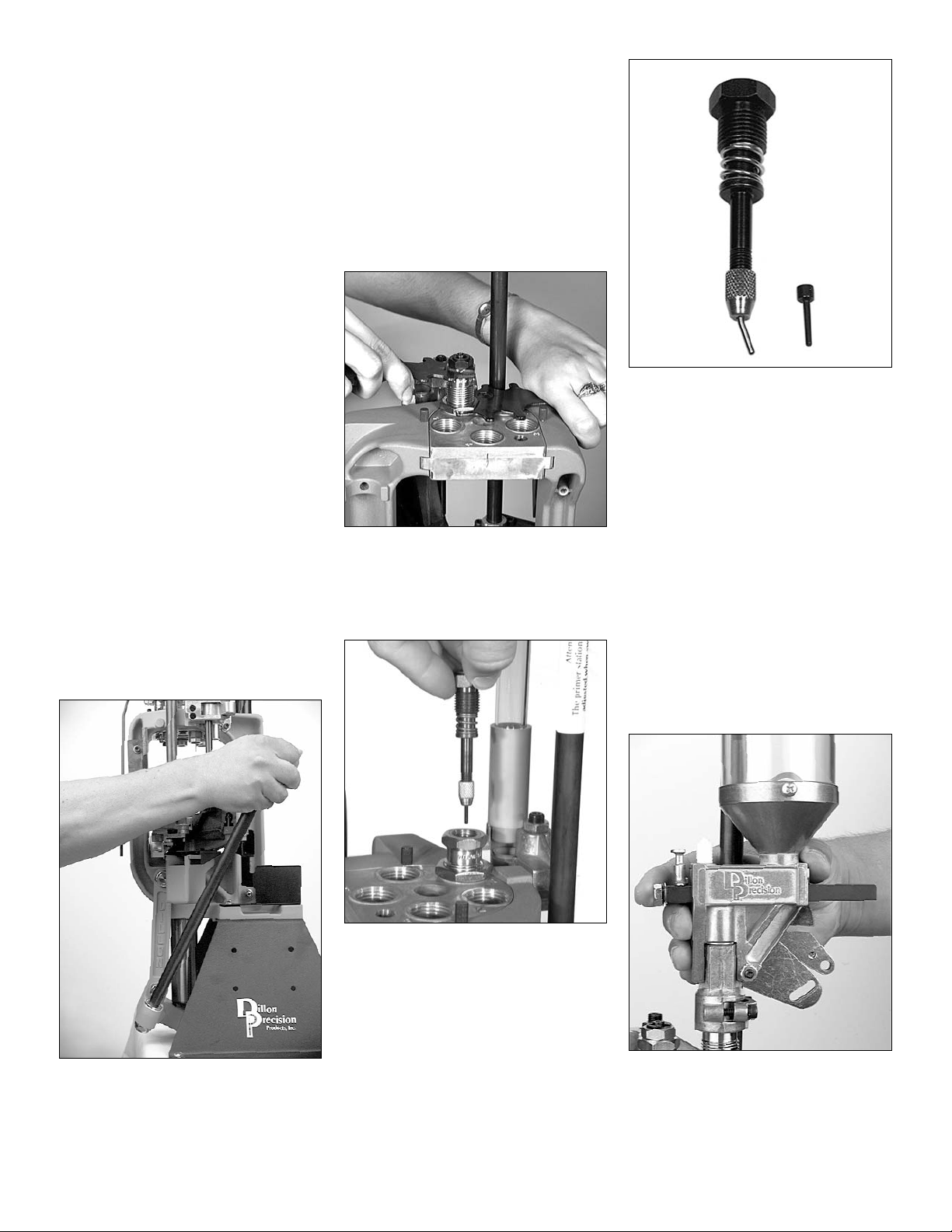

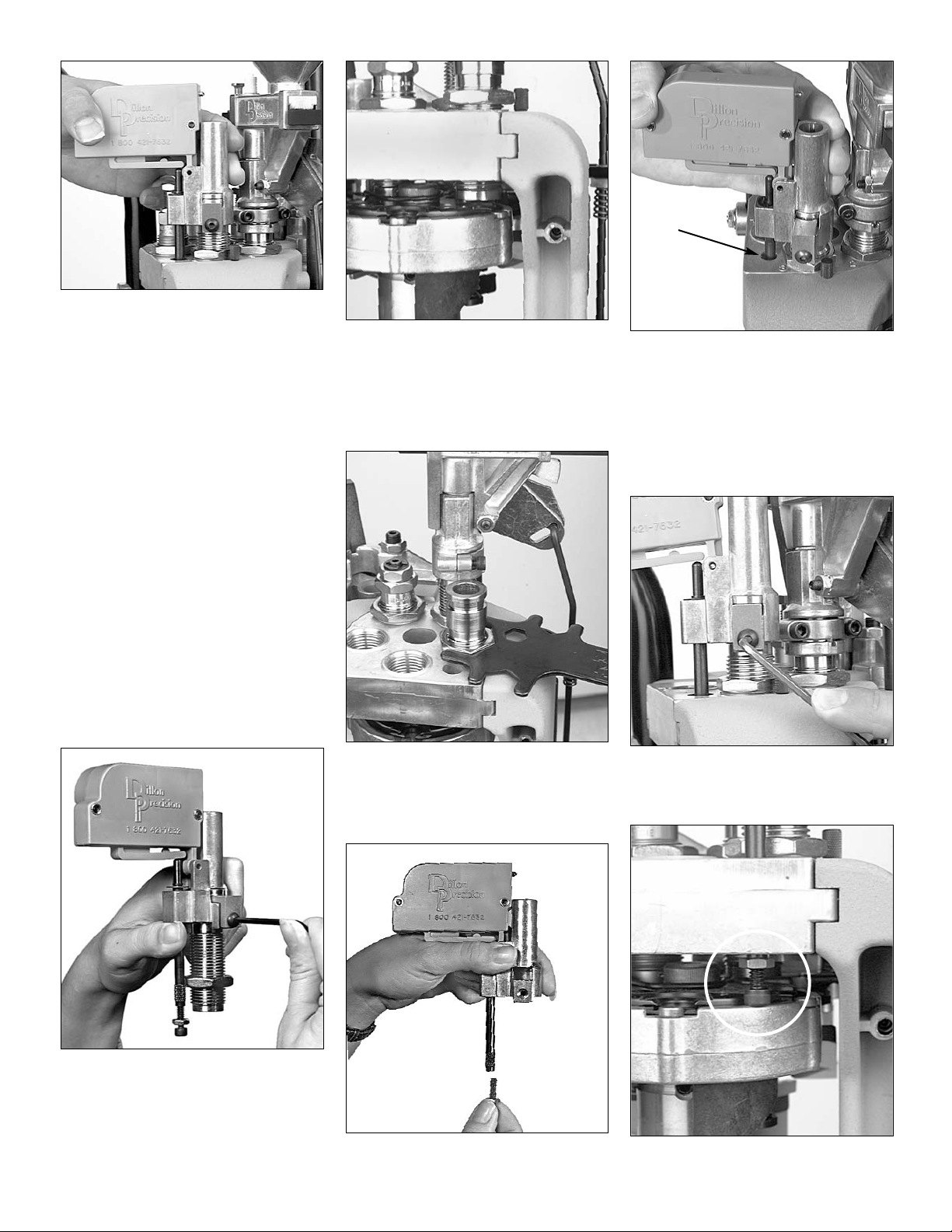

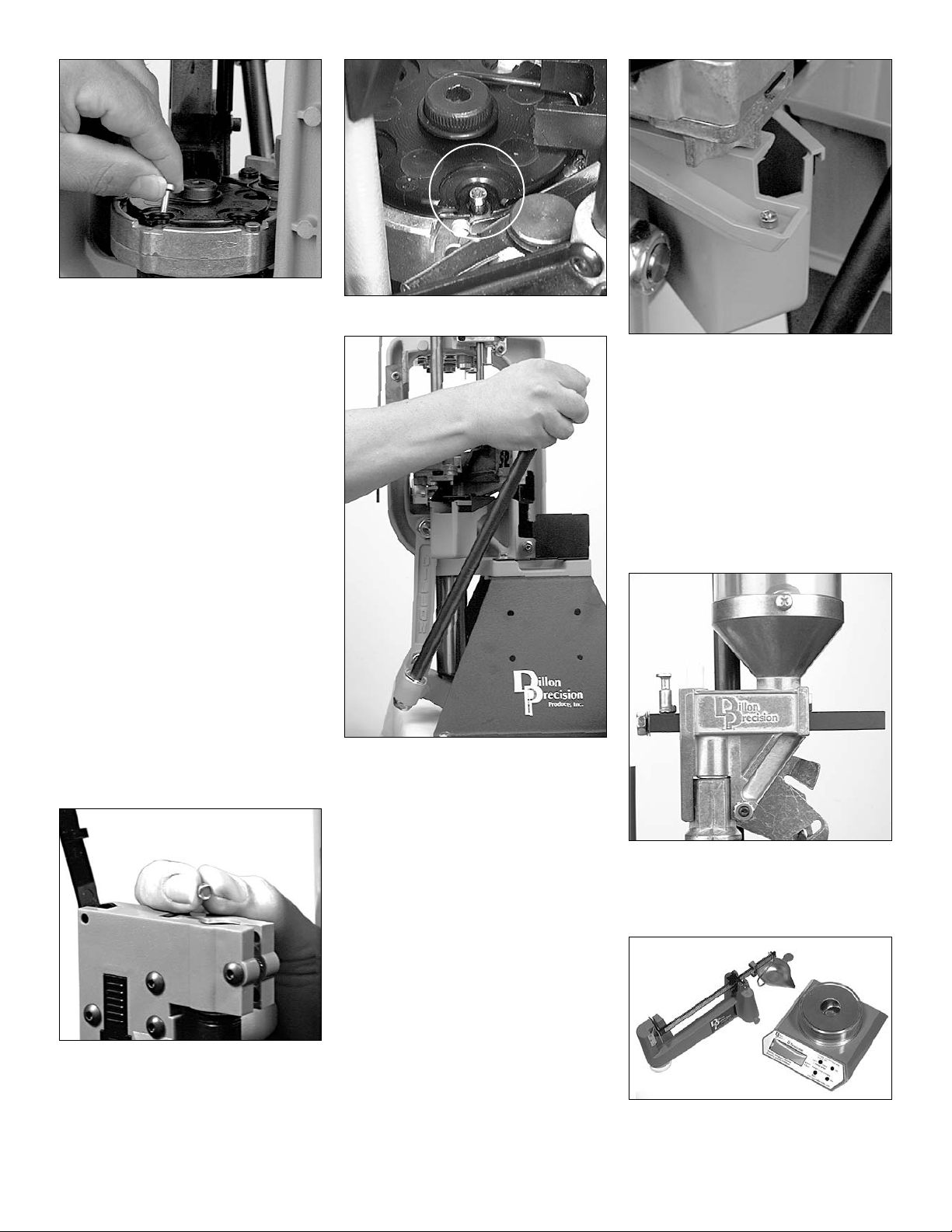

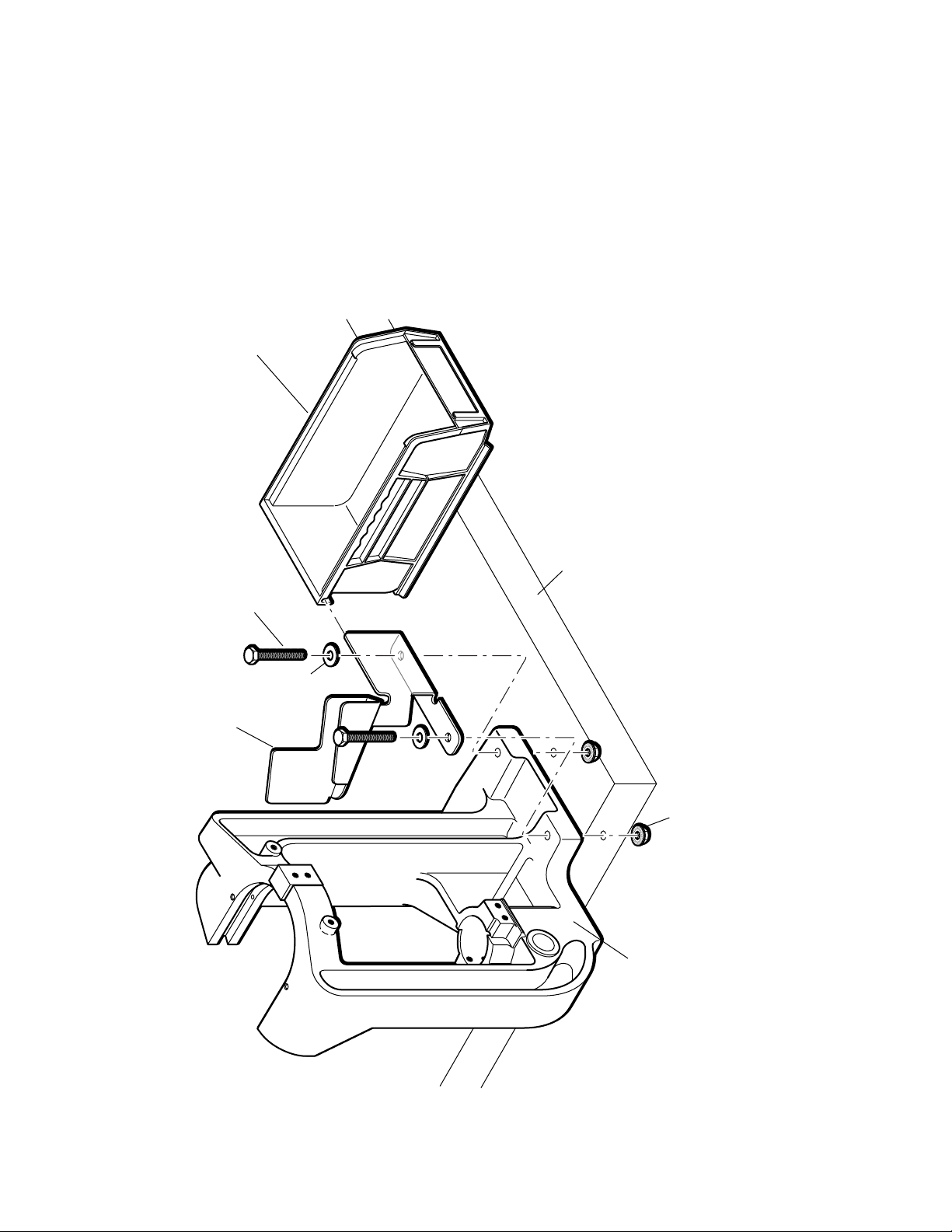

Final Assembly

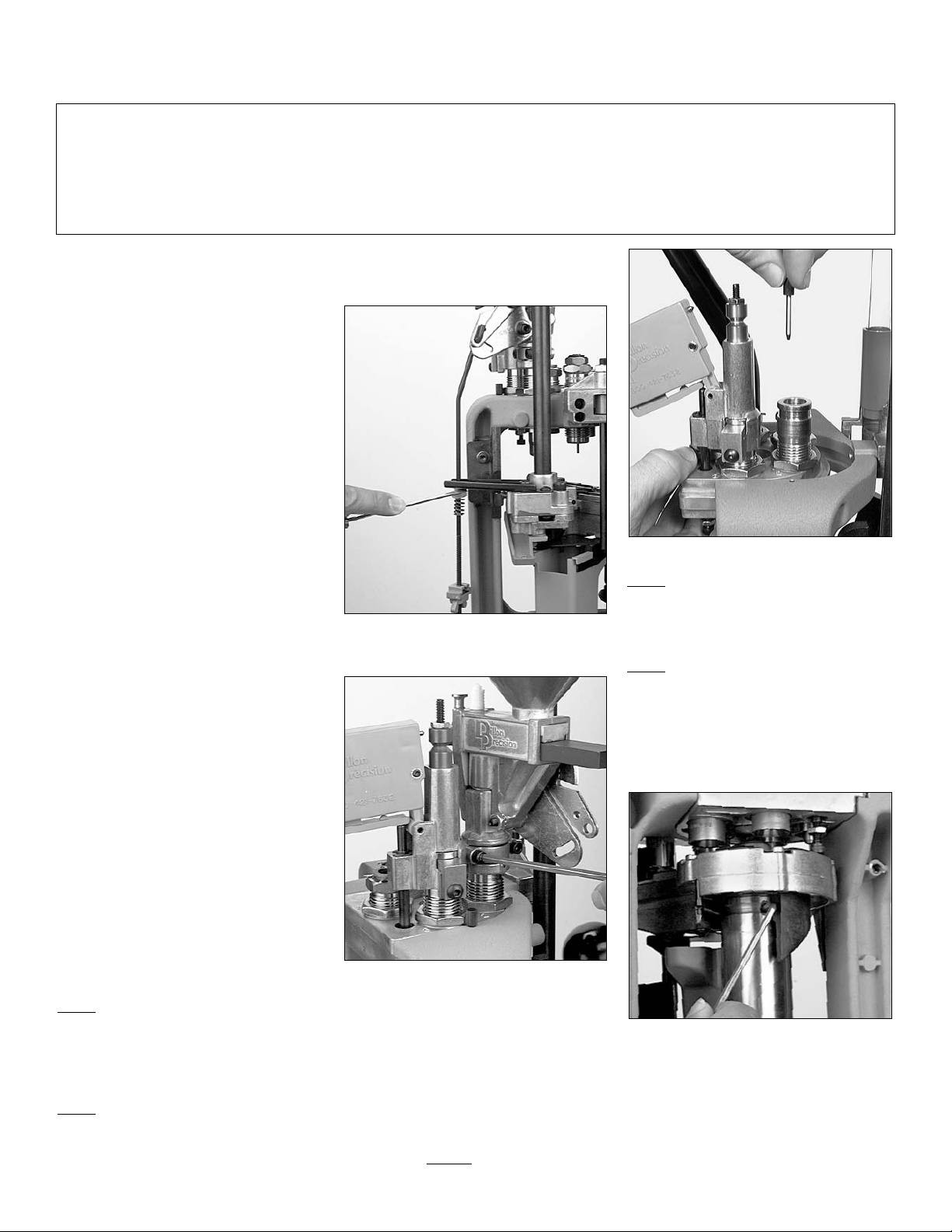

FIG 122

FIG 123

1. The Primer Magazine

The XL 650 comes equipped with an

automatic primer system.The XL 650’s automatic primer system is protected by a steel

shield which is permanently secured to the

primer feed body and must never be

removed. The primer magazine is located

inside of a steel shield FIG 122. Primer

magazines come in two different sizes –

large and small FIG 123. Your machine

comes with both. One comes installed in

the machine, the other is located in the

primer accessory package. If you ordered

your machine set up in a particular caliber,

the magazine installed should be the proper

one for the caliber you selected. However,

you should check to make sure. By comparing the two magazines FIG 123 you will be

able to determine which is large and which

is small.

FIG 124

To change the primer magazine:

1. Remove the primer shield cap FIG

124.

2. Remove the primer magazine by

pulling it straight up FIG 122.

3. Insert the new primer magazine FIG

125 and replace the primer shield

cap.

FIG 125

FIG 126

2. Installation of the Primer

Early Warning System:

FIG 126 The purpose of the Primer Early

Warning system is to warn you when the

primer magazine is low on primers. When

you hear the buzzer, it’s time to reload the

primer magazine tube.

FIG 127

1. Insert the battery into its receptacle

FIG 127 and push the black switch

lever to insure the device is working

properly.

2. Install the Primer Early Warning sys-

tem on top of the primer magazine

shield FIG 126. Lightly tighten the

clamp screw with a 3/32” Allen

wrench.

29

Page 29

FIG 128

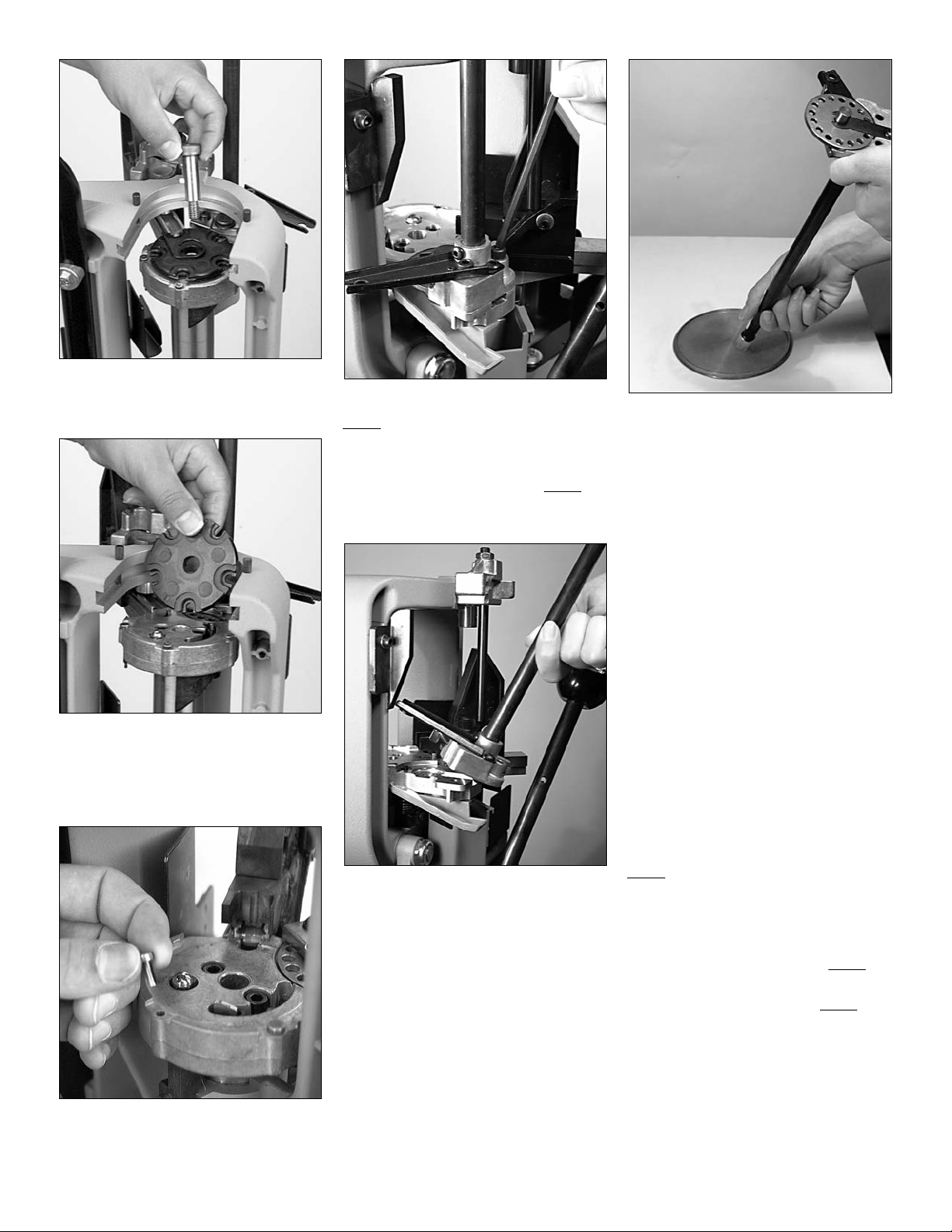

3. Installation of the Locator

Buttons FIG 128:

Install the three brass locator pins in the

shell platform at stations 3, 4 and 5. These

pins retain the cases during loading while

providing an easy way to remove a case

from the shellplate at any stage without disturbing the other rounds. Note: The locator

buttons are caliber specific and can be

properly identified by referencing the caliber conversion chart on pages 42-44.

LOADING COMPONENTS

SECTION

1. The Rotary Primer System

(how it works):

Warning: Wear safety glasses whenever

working with live primers. Safety

glasses are available from Dillon

Precision Products.

Observe how the rotary primer system

works, how to charge it and how to seat a

primer. To do so:

1. Put on your safety glasses.

FIG 129

2. Place five or six primers into the

primer magazine shiny side down

FIG 129.

3. Cycle the machine until a primer

appears in Station 2.

FIG 130

FIG 131

When you cycle the machine, the rotary

primer disc rotates one notch, advancing

another primer into position. When the

handle is pushed to its full aft stop FIG 131,

the primer seating punch pushes the primer

up through the rotary primer disc FIG 130,

fully inserting it onto the primer pocket of

the case. If there is no case in Station 2 to

receive the primer, the primer will return to

the rotary disc and continue around until

being dropped down a chute FIG 132

where it can be retrieved.

FIG 132

4. Drop an unprimed case into the casefeed funnel and cycle the machine

twice. As the case is rotated into

Station 2, complete the downstroke of

the platform by firmly pushing the

handle to its full aft stop FIG 131 –

this will ensure that the primer is fully

seated.

5. Set aside the primed case, it will be

used later for adjusting the powder

measure.

FIG 133

2. Powder Bar Adjustment

FIG 133:

FIG 134

Note: Although a scale is not included with

the machine, you’ll need one to

30

Page 30

31

properly adjust the powder bar.

Dillon Precision Products offers two

types of scales FIG 134. On the

right, and electronic scale, and on

the left, a balance beam scale.

FIG 135

You are now ready to fill the powder

measure FIG 135, but first you’ll need to

refer to your reloading handbook. Under

the section specified for the caliber you’re

loading you’ll see a number of suitable

powders. Also given are “suggested starting

loads” and “maximum loads” (Lyman

Reloading Handbook).

Note: We do not recommend using IMR

stick powders (looks like pencil

lead) when loading a caliber size

less than 25 caliber. We do not

recommend using maximum loads

of powder.

Warning: Wear safety glasses whenever

working with live primers. Safety

glasses are available from Dillon

Precision Products.

Note: Insure that you have the proper

powder bar installed. To do so refer

to “About Powder Bars” on page 13.

For instructions on how to change

the powder bar, refer to Step 19 in

the Caliber Conversion Section,

page 41.

1. Put on your safety glasses.

FIG 136

2. Fill the powder measure and replace

the cap on both the powder measure

and the powder container FIG 136.

3. Place a primed case into Station 2.

Note: Using a case with a primer in it will

keep the powder from leaking out

through the primer flash hole.

FIG 137

4. Cycle the machine to charge the

case. Using your powder scale, weigh

the powder charge FIG 137. (From

this initial measurement, you will be

able to determine whether you’ll

need to increase or decrease the

powder charge.)

FIG 138

5. Using a 7/16” wrench, give the powder bar bolt a quarter of a turn clockwise or counter-clockwise as necessary to adjust the powder charge FIG

138. Clockwise will increase the

powder charge and vice versa.

Warning: As always, be sure to replace

the lid on the powder measure.

6. IMPORTANT! Before measuring the

next load, charge the case then empty

the powder back into the powder

measure. This will allow the powder

in the newly adjusted powder bar to

settle and give an accurate reading.

7. Replace the cartridge into Station 2

and charge the case. Continue this

process until the charge is reading

correctly. Once you have achieved

the desired powder charge weigh two

more charges to insure the powder

bar is throwing a consistent charge.

3. Powder Check System

Adjustment:

Once the powder bar is throwing the

desired charge, the powder check rod can

be installed and adjusted.

Warning: A double-charged round (a

loaded round with twice as much

powder as it should have) can damage your gun as well as cause bodily injury.

Warning: A round loaded without powder

can also damage your gun as well

as cause bodily injury. If a round

without powder is fired in your gun,

the detonation of the primer will

push the bullet part way down the

barrel. If the lodged bullet is not

removed before another round is

fired, the gun will be damaged.

Page 31

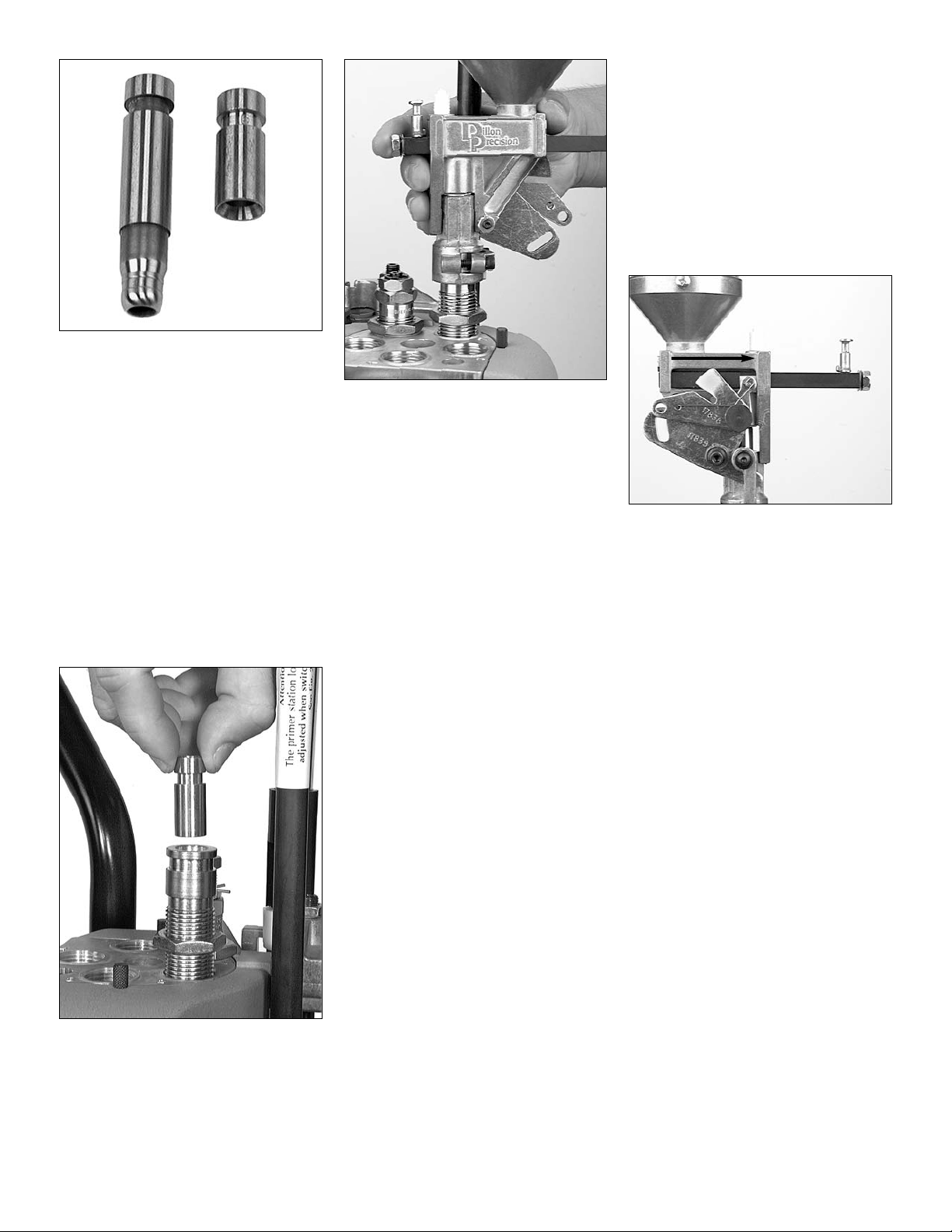

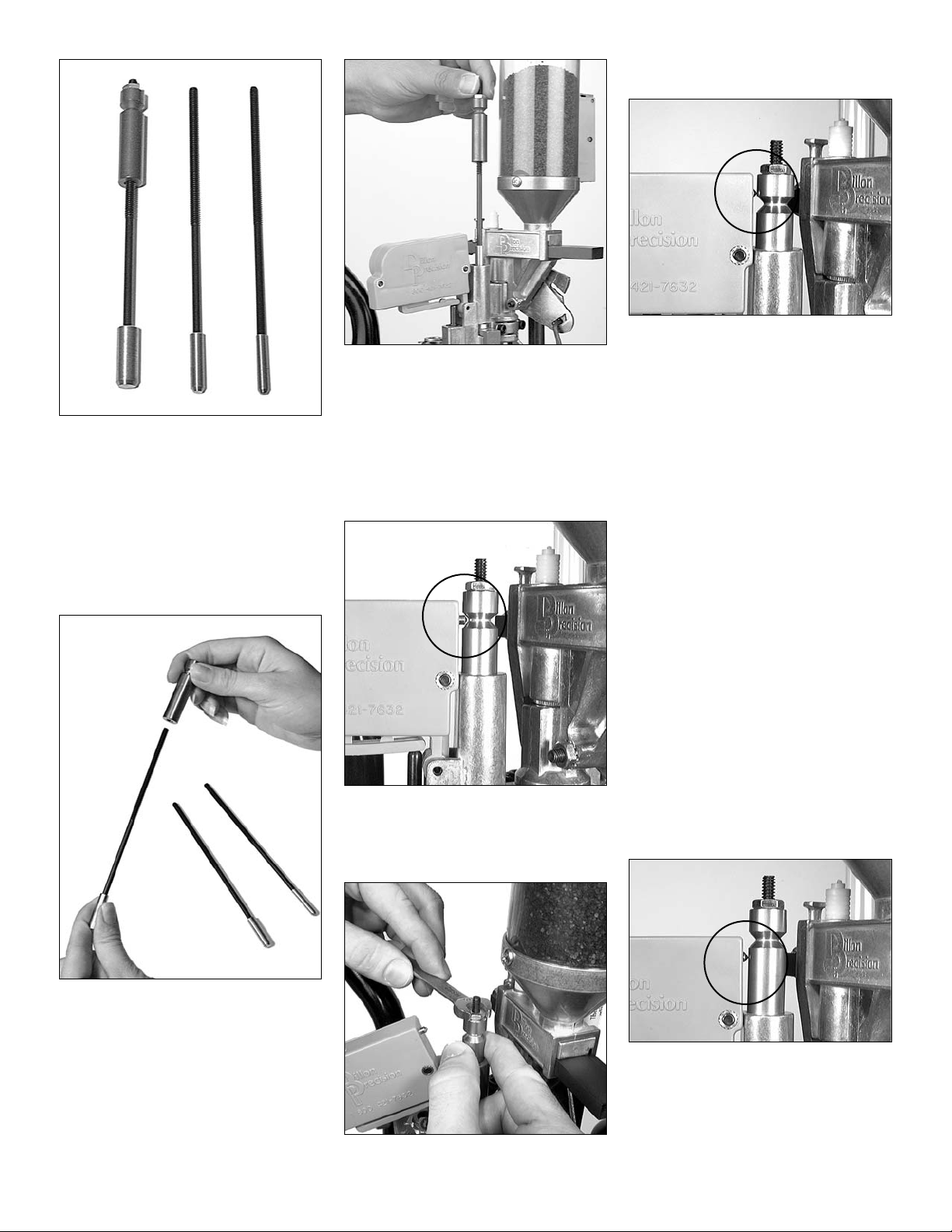

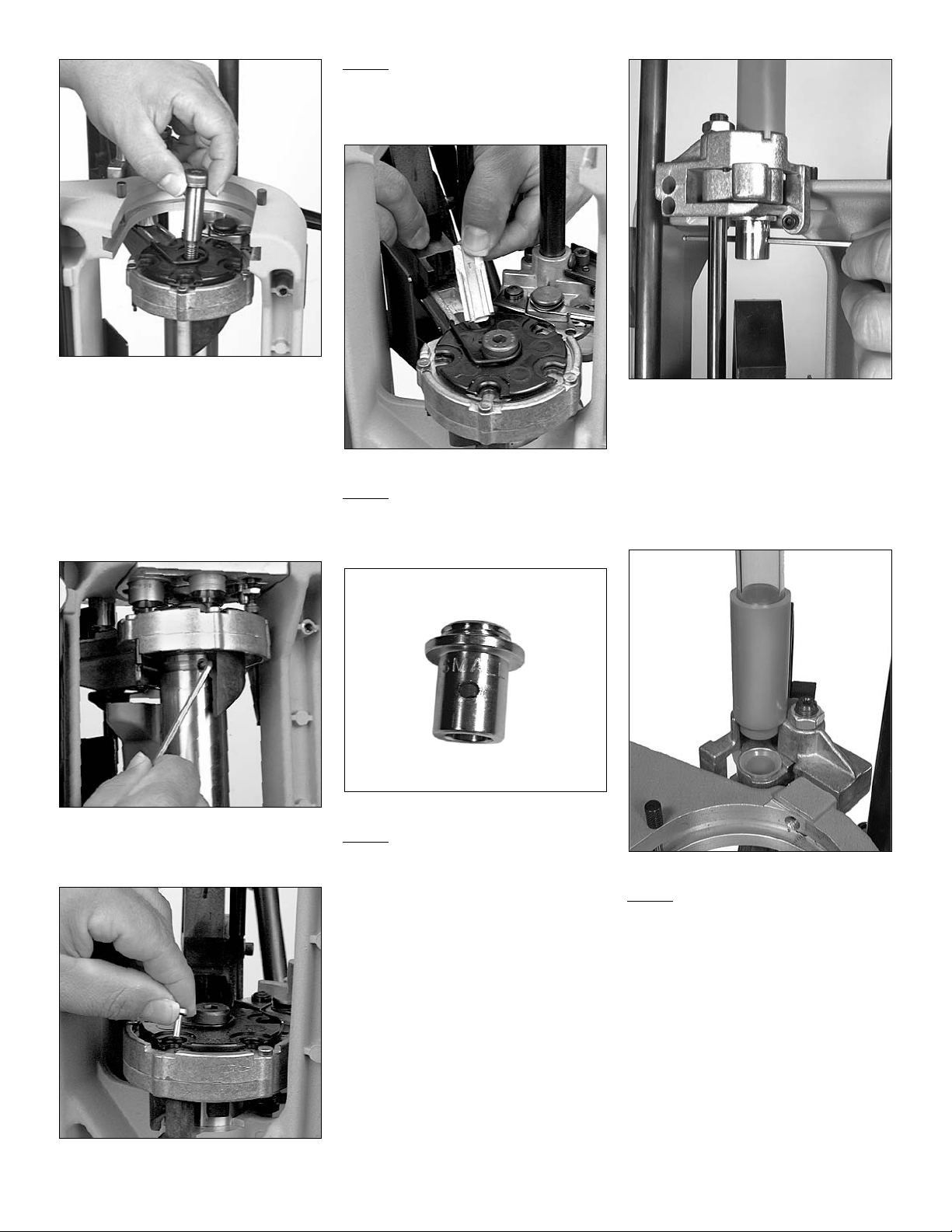

FIG 139

A. Installation and adjustment of

the powder check rods

FIG 139:

1. Remove the powder check rods from

the bag FIG 139. The three rods fit

different calibers. On the left .44-.45

caliber, center .30-.41 caliber and on

the right .22-.29 caliber.

FIG 140

2. Choose the correct rod for the caliber

you’re loading. For example – if

you’re loading .38 Spl. you would

use the .30-.41 caliber rod. If the rod

you’re using doesn’t have the

grooved sleeve on it, remove the

grooved sleeve from the one you’re

not using and thread it onto the correct rod FIG 140.

FIG 141

3. Insert the rod into the powder check

die FIG 141.

4. Put on your safety glasses.

5. Place a case with the proper powder

charge into Station 3 and raise the

platform. Leave the platform in the

raised position.

FIG 142

6. Thread the grooved sleeve down so

that the contact pin fits inside the

groove as seen in FIG 142.

FIG 143

7. Snug the lock nut with a 3/8” wrench

FIG 143.

FIG 144

B. Powder Check System

Demonstration:

1. Place a primed but empty case (case

with no powder) into Station 3 and

raise the platform. The contact pin is

above the groove FIG 144 (the alarm

sounds) indicating that the case has a

low or no charge.

2. Lower the platform. Remove the

empty case from Station 4 and place

it in Station 2.

3. With the empty case in Station 2 give

it a double charge.

To do so:

a. Raise the platform all the way to

charge the case.

b. Lower the platform halfway (enough

for the powder bar to return to its starting point without indexing the case to

Station 3 and releasing the locklink).

c. Again, raise the platform to give the

case a second charge of powder.

d. Index the case to Station 3 by lowering the platform all the way. (The case

is now double charged and ready to be

checked by the Powder Check System.)

FIG 145

4. Raise the platform FIG 145. The contact pin is below the groove (the

alarm sounds) indicating that the

powder charge is double or more.

32

Page 32

Note: If the buzzer to the powder check

system goes off, stop loading and

check the powders weight with the

scale. The primer warning buzzer

and the powder check system have

different pitch buzzers to distinguish

the two. The primer system is a

deep buzz and the powder check is

a high pitched tone.

4. Filling the Primer System:

Warning: Wear safety glasses whenever

working with live primers. Safety

glasses are available from Dillon

Precision Products.

FIG 146

Now it’s time to fill the primer magazine. To begin, you’ll need the proper size

primer pickup tube. Primer pickup tubes

come in either large or small. In FIG 146

are the two primer pickup tubes included

with your XL 650.

FIG 147

FIG 148

On the left is the large pickup tube (with

a green tip), on the right is the small pickup

tube (with a yellow tip). Make sure the

retaining clip FIG 147 is always in place

before using either tube. You’ll need the

proper size primers and we suggest using this

optional Dillon Primer Flip Tray FIG 148. It

will make this task quite a bit easier.

1. Put on your safety glasses.