Page 1

Model X Mechanical Force Gauge

User Instructions

16949-0018

Issue AH

Page 2

© Avery Weigh-Tronix, LLC 2012. All rights reserved.

No part of this publication may be reproduced, stored in an electronic retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording or otherwise without the prior written consent of

the copyright owner, or as permitted by law or under license. Full acknowledgment of the source must be given.

Avery Weigh-Tronix is a registered trade mark of the Avery Weigh-Tronix, LLC. This publication was correct at the

time of going to print however, Avery Weigh-Tronix, LLC reserves the right to alter without notice the specification,

design, price or conditions of supply of any product or service at any time.

All third party brands and product names used within this document are trademarks or registered trademarks of

their respective holders.

xforce_gauge_u_en_16949_0018.book

Page 3

Table of Contents

page

Chapter 1 General information and warnings ......................................................................................... 5

About this manual ..............................................................................................................5

Special messages .............................................................................................................. 5

Safe Operation ................................................................................................................... 5

Routine maintenance ......................................................................................................... 6

Cleaning the force gauge ................................................................................................... 7

Declaration of conformity ................................................................................................... 8

Chapter 2 Introduction .............................................................................................................................. 9

General description ............................................................................................................9

Description of parts ............................................................................................................ 9

Klaxon alarm option ......................................................................................................... 11

Operational data .............................................................................................................. 12

Helpful pointers ................................................................................................................ 12

Tensile Model ................................................................................................................... 14

Push-Pull model ............................................................................................................... 15

Maintenance and handling ............................................................................................... 15

Model X Mechanical Force Gauge User Instructions 3

Page 4

4 Model X Mechanical Force Gauge User Instructions

Page 5

1 General information and warnings

1.1 About this manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled as shown by the 1.1 and 1.1.1 headings. The

names of the chapter and the next subsection level appear at the top of alternating

pages of the manual to remind you of where you are in the manual. The manual name

and page numbers appear at the bottom of the pages.

1.2 Special messages

Examples of special messages you will see in this manual are defined below. The

signal words have specific meanings to alert you to additional information or the relative

level of hazard.

WARNING! This is a Warning symbol. Warnings mean that failure to follow

specific practices and procedures may have major consequences such as

injury or death.

1.1 About this manual

CAUTION! This is a Caution symbol. Cautions give information about

procedures that, if not observed, could result in damage to equipment or

corruption to and loss of data.

NOTE: This is a Note symbol. Notes give additional and important information, hints

and tips that help you to use your product.

1.3 Safe Operation

WARNING: If you overload this force gauge you could suffer severe injuries or

death. The total load on the force gauge should NEVER exceed the rated

capacity.

Keep all the following in mind as you use the force gauge.

The system capacity is equal to the rating of the force gauges. The shackle rating

should not be used to determine lift capacity of the system.

The shackles are rated in metric tons. Thus the 12-ton shackles are rated to 26,450 lbf

and are suitable for use on the 25,000 lbf force gauge.

Any zeroed deadload must be considered as part of the ultimate load.

Model X Mechanical Force Gauge User Instructions 5

Page 6

General information and warnings

Although this instrument has a substantial overload protection rating, the instrument

should not be used above the rated capacity. Doing so can significantly impact fatigue

life of the instrument and cause premature and abrupt failure. If a higher capacity

reading is needed, Dillon insists that a larger instrument be used.

Safety is always a concern in overhead lifting and tensioning applications. To limit your

liability always insist upon factory supplied shackles and pins and factory tested and

certified safe optional equipment. All DILLON products are designed to meet the

published Safe Working Load (SWL) and Ultimate Safety Factor (USF) standards of the

United States Military.

Do not grind, stamp, drill or deform the metal on the force gauge body in any way.

Protect the instrument from impact in use and storage.

Any significant damage or deformation to the loading element is cause for evaluation

by Dillon.

Relieve all torsional and off axis loads.

Apply load in the center of the shackle bow with this instrument.

Off center loading results in substandard performance.

Instrument requires time to stabilize when changing temperatures.

Use only the hardware supplied with this instrument. If no hardware was supplied,

insure that the mating pin and shackle bow is equivalent to the hardware used at

calibration. Otherwise substandard performance or failure can result.

Dillon recommends only using qualified rigging hardware and cannot be responsible for

unapproved hardware.

This instrument is not designed for applications that see rapid, dramatic temperature

swings or thermal shock. Wide variation in readings can occur.

1.4 Routine maintenance

IMPORTANT: This equipment must be routinely checked for proper operation

and calibration.

Application and usage will determine the frequency of calibration required for

safe operation.

6 Model X Mechanical Force Gauge User Instructions

Page 7

1.5 Cleaning the force gauge

Cleaning DOs and DON’Ts

l DO - Wipe down the outside of standard products with a clean cloth,

moistened with water and a small amount of mild detergent

l DO NOT - Attempt to clean the inside of the machine

l DO NOT - Use harsh abrasives, solvents, scouring cleaners or alkaline

cleaning solutions

Training

Do not attempt to operate or complete any procedure on a machine unless you have

received the appropriate training or read the instructions.

1.5 Cleaning the force gauge

Model X Mechanical Force Gauge User Instructions 7

Page 8

General information and warnings

Only the 5,000kg Force Gauge with Klaxon alarm is CE approved.

1.6 Declaration of conformity

8 Model X Mechanical Force Gauge User Instructions

Page 9

2 Introduction

2.1 General description

The Model X mechanical force gauges measure tension, compression or push/pull. A

D-shaped deflection beam is the heart of the Model X force gauge. Machined to close

tolerances, beams are heat treated to develop optimum strength and spring

characteristics.

A precision dial indicator is mounted on the deflection beam. The indicator plunger

rests against a slanted anvil at the open end of the beam. Under compression loads,

the two halves of the beam tend to close. Tension force causes them to move apart.

This action pushes the plunger inward, as determined by the slant of the anvil.

Readings produced on the dial are in direct relation to applied load. The pointer

revolves 360° clockwise under compression or tension forces.

Push-pull gauges read half scale (180°) clockwise in compression, and

counterclockwise, 180° from center zero under tension loads.

2.1 General description

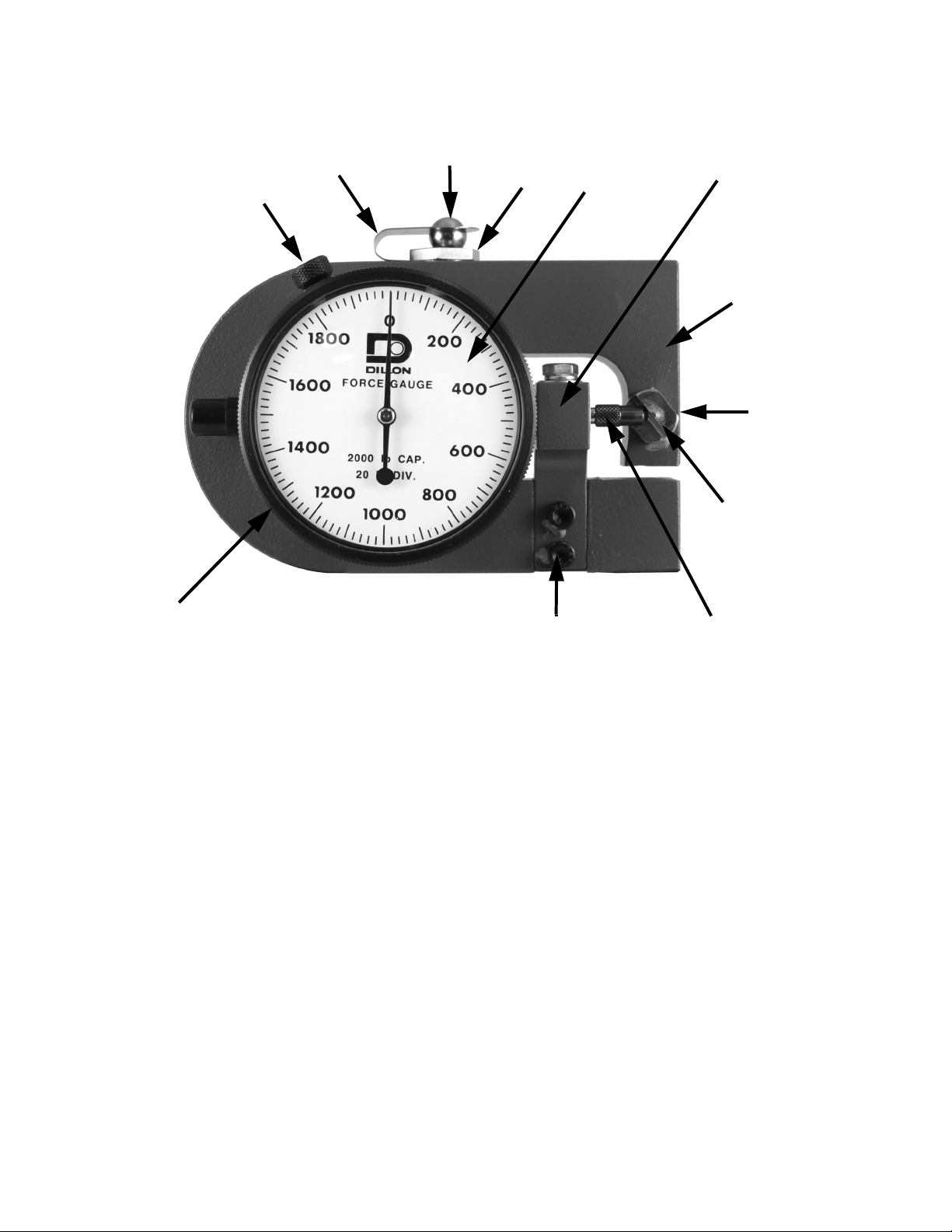

2.2 Description of parts

Figure 2.1 shows you the parts of the force gauge. If you have questions about your

force gauge, contact your Dillon service provider and refer to this illustration. A photo

or rough sketch of your particular setup will be helpful.

1 “U” shaped deflection beam

2 Dial indicator

3 Bezel (For zero adjustment purposes)

4 Pressure button

5Anvil

6 Dial indicator gauge movement plunger

7 Anvil set screw

8 Dial indicator mounting bracket

9 Mounting bracket screws

10 Bezel locking screw

11 Loading ball

12 Spring retainer clip

Model X Mechanical Force Gauge User Instructions 9

Page 10

Introduction

1

7

5

6

9

3

10

12

11

4

2

8

*An optional Maximum Pointer is available but not shown

Figure 2.1 Force gauge parts

10 Model X Mechanical Force Gauge User Instructions

Page 11

2.3 Klaxon alarm option

Test Button:

Press to test horn function

Front View

Rear View

Force Gauge with

optional klaxon alarm

Alarm switch

adjustment screw

Only the 5,000kg Force Gauge with Klaxon alarm is CE approved. All other

models are not CE approved.

The force gauge can be attached to an optional klaxon alarm. See Figure 2.2.

2.3 Klaxon alarm option

Model X Mechanical Force Gauge User Instructions 11

The klaxon alarm is rated at 80db(A) @ 0.6 meters (2 feet).

The klaxon alarm is set off when the adjustment screw shown in Figure 2.2 contacts

the switch as the force gauge is compressed. There can be up to four switches

installed. This allows you to control up to four different operations as the gauge is

compressed. See your Dillon representative for information on these options.

Figure 2.2 Force gauge with optional klaxon alarm

Page 12

Introduction

2.4 Operational data

WARNING: Never pick up the force gauge by the dial indicator. This will cause

loss of calibration accuracy, loss of operation or non-warranty damage.

Your Dillon Force Gauge is ready to go to work for you without any special assembly.

Upon removing it from the storage case, it is only necessary to check the zero setting.

1. Place the unit on a flat table with the pressure button, #4, at the top.

2. The dial bezel, #3, is locked lightly by a knurled thumb screw, #10. Loosen the

knurled screw and turn the bezel in either direction, depending upon which

way zero may be off. Revolving the bezel causes the dial to follow.

3. With zero positioned directly under the pointer tip, tighten the locking screw

(see CAUTION below) and the instrument is ready to use.

CAUTION: When adjusting bezel locking screw, #10, only tighten as much as is

necessary to hold bezel in proper position. DO NOT OVERTIGHTEN, as this will

distort the thin housing of the dial indicator gauge and affect the smooth action

of the movement and produce false readings!

Because of the sensitivity of the Dillon Gauge, zero should always be set with the unit

resting on the lower or thicker portion of the deflection beam as illustrated. This is the

same position it occupies during calibration. Ordinarily, zero will be retained indefinitely.

However, under repeated stress or through accidental banging around, it may go off

slightly. Thus, it is a good plan to check zero occasionally.

CAUTION: The small anvil, #6, against which the dial indicator plunger rides,

should never be altered except by factory technicians. This anvil has nothing to

do with zero setting. By careful adjustment, it has been positioned in such a

way that, for full load application within the range of the instrument, the pointer

will revolve 360°. TAMPERING WITH THE SETTING OF THIS ANVIL

AUTOMATICALLY VOIDS THE ACCURACY GUARANTEE. If the anvil should be

accidently thrown out of position by dropping or striking against another

object, the entire gauge should be returned to the factory for resetting and

calibration check.

2.5 Helpful pointers

l Occasionally test the tightness of the hardened dial indicator plunger, #6.

This part is screwed into a finely threaded seat and may sometimes work

loose. This would cause the gauge to read high and might be mistaken for

an off zero condition. Be sure not to force the plunger tip too tightly when

screwing it down since, as explained, the threads are fairly delicate and

might break off.

12 Model X Mechanical Force Gauge User Instructions

Page 13

2.5 Helpful pointers

l Note that threaded mounting holes have been provided in opposite faces of

the “U” shaped deflection beam, #1. In the upper mounting hole, a

spherically recessed pressure button, #4, is screwed. This button is

hardened and plated. It receives the loading ball, #11. Force should be

applied directly against this ball. In operation, the deflection beam bends

inward slightly, and the ball revolves, tending to keep the line of force

vertical. A drop of light oil on the ball assists this action.

l Never fasten the “U” shaped deflection beam in such a way that the free

movement of the upper portion will be restricted. The lower or thicker “leg”,

however, may be tightened as securely as desired, using a stud or bolt

through the threaded mounting hole.

l Since the deflection beam is hardened, it is not possible nor would it be

recommended, to drill and tap it once it is in the field. If special mounting

holes are desired, these can be provided during early stages of

manufacture, but must be specified at that time.

l If a particular test calls for load application through a pulley, roller or chuck,

etc., due care should be taken to see that the load is applied in a true vertical

line through the center of the top mounting hole #4. Off-center loading would

introduce leverage, thereby increasing or decreasing readings from their

true value. Universal joints or hinged fittings should be carefully machined to

obviate side slop or play. If in doubt about the best method of applying load

for specific arrangement, don’t hesitate to consult our Engineering

Department. Remember, a rough pencil sketch or snapshot will aid

tremendously in understanding your problem. Never oil the dial indicator at

any point. It is unnecessary. If oil or other fluids should get on the unit, wipe

off gently, but well. Foreign matter lodging on the plunger, #6 will retard its

free action, resulting in inaccurate readings.

l If accidental overload is anticipated, a solid steel rod about 3/4 inch in

diameter can be inserted at the center point of the Gauge between the “U”

shaped bar. Length of this rod should be figured so that the upper, flexible

half of beam will bottom against it, once the full capacity of the instrument

has been reached. Further load will then pass through this solid path without

harm to the Force Gauge. Note the method of mounting the dial indicator to

the supporting bracket on the reverse side of the case. Allen screws are

used. Be sure to check these screws at intervals, making sure that they are

always tight. Vibration may in time loosen them slightly, and it is best to take

this precaution.

Model X Mechanical Force Gauge User Instructions 13

Page 14

Introduction

2.6 Tensile Model

Generally speaking, the same requirements and suggestions applying to the

compression model force gauge also apply to the tensile unit, shown in Figure 2.3. The

main exception, of course, is that on the tensile model, load is applied through the use

of special end rod bearings.

Figure 2.3 Tensile model with adapters and shackles

These bearings are available for all tensile models as standard equipment. They are a

perfect fit and without any side play. Bearing pins can be machined from drill rod to suit

your particular test plan. Remember that if you require a special adapter of some kind

in place of these bearings, be sure that such adapters are self-aligning so that applied

force is always able to assume a vertical line.

CAUTION: Because there is the possibility that in service the ball-socket

connectors can become unscrewed from the beam, the operator should check

these parts at intervals to make sure that some of the threaded shank is

ALWAYS showing on the inside of the “U” shaped beam. If it is not showing, no

further loads should be applied until the connector is screwed down to its

normal position.

14 Model X Mechanical Force Gauge User Instructions

Page 15

Do not attempt to weld, cotter pin, or otherwise make tensile connectors a solid part of

the bar since every requirement is different as to the length of the shank that has to be

used.

Dillon will not be liable for any incident that might result from accidental or

intentional screw-out or break-away of the ball-socket connectors. For your own

protection, keep these parts properly seated at all time.

Tare settings cannot be made on the Force Gauge without a slightly resultant loss in

accuracy. This is due to the fact that the dial layout is not 100% linear. Each unit is

individually machined and thus must be individually calibrated. While this makes for

split-hair accuracy, division marks are not equidistant and hence do not lend

themselves to tare adjustment. Instead, any tare weight encountered in a typical test

should simply be deducted.

2.7 Push-Pull model

There is one more type of force gauge, a push-pull model, shown in Figure 2.4.

2.7 Push-Pull model

Figure 2.4 Push-pull model force gauge

This model can be used for both tension and compression situations. As you can see

the dial can go in two directions.

2.8 Maintenance and handling

The Dillon force gauge is a precision instrument and will provide many years of

dependable service if given reasonable care and suitable protection. Many firms make

it a regular practice to return force gauges to their distributors at 6 to 8 month intervals

(depending upon how much they are used) to have accuracy recertified. We

recommend this at least once a year. Consult with your Dillon distributor concerning

any questions you may have about recalibration intervals. Your area may require

periodic proof testing. Consult your local regulations.

Transport and store the force gauge in the supplied storage case when not in use.

Model X Mechanical Force Gauge User Instructions 15

Page 16

Introduction

16 Model X Mechanical Force Gauge User Instructions

Page 17

Page 18

AUTHORIZED DISTRIBUTORS

Ask the experts. Dillon distributors offer complete

service capabilities from application assistance to

sales and product support. Their experienced

representatives are the most knowledgeable

experts that you will find in the force measurement

industry. We recommend that you consult these

capable specialists for all of your measuring needs.

Overload Protection and

Overhead Weighing Equipment

1000 Armstrong Drive

Fairmont, Minnesota U.S.A. 56031

Toll-Free: (800) 368-2031

Phone: (507) 238-4461

Fax: (507) 238-8258

Foundry Lane, Smethwick

West Midlands B66 2LP

Tel: +44 (0) 845 246 6717

Fax: +44 (0) 845 246 6718

www.dillon-force.com

Dillon is a brand of Avery Weigh-Tronix

Loading...

Loading...