Page 1

Manufacturers of

The World's Finest

Loading Equipment

SQUARE DEAL ‘B’

Instruction Manual

Version 4.5

illon

recision

Products, Inc.

Page 2

2

Stock # Description

11628 Bullet Seater Insert

11734 Crimp Insert

*12124 Seating Stem

12864 Carbide Sizer Insert

13028 Square Deal B Manual

13328 Shellplate Bolt

13355 Return Bracket

*13427 Powder Funnel

13429 Decap Pin Nut

13433 Ejector Wire

13437 Shaft

13444 Overtravel Block Bolt

13445 Square Deal Frame

13461 Index Bolt

13479 Spent Primer Track Cover

*13504 Shellplate

13594 Spent Primer Chute

13597 Over Travel Block

13621 Primer Cup – Large

13622 Crank Pin

13624 Indexer Spring (RL1000)

13644 Smaller Powder Bar Spacer

13651 Spent Primer Cup

13657 Primer Cup – Small

13659 Chute Bracket

13673 Primer Magazine – Large

13689 Primer Slide Roller

13690 Platform Base Disc

13691 Powder Measure Tube

13705 Indexer Pawl

13707 Follower Rod

13712 Toolhead Plate

13714 Indexer Lever

13718 Crank Pin Set Screw

13721 Delrin Die Lock/Friction Plate

13722 Primer Slide Bearing

13726 Return Spring Roll Pin

13739 Detent Spring

13754 Primer Slide

13756 Bin Box

13757 Primer Punch – Small

13764 Powder Die Clamp

13776 Pawl Pin

13789 Set Screw

13790 Primer Slide Return Pin

13793 Body Collar Roller

13797 Pivot Bushing

13798 Return Spring

13799 Blue Failsafe Strip Nut

13801 Tinnerman Insert

13809 Roller Bolt

13815 Toolhead Mount Screw

13818 Powder Bar Insert – Small

13822 Link Arm

13823 Primer Punch Set Screw

13828 Link Arm Washer

13843 Upper Decap Pin

13845 Collar Sleeve

13847 Overtravel Spring

13850 Handle Knob

13853 Powder Bar Insert – Large

13857 Battery Cover

Stock # Description

13860 Base Disc Screws

13864 Switch Lever

13865 Powder Die

13871 Bellcrank Cube

13879 Primer Magazine – Small

13882 Powder Measure Lid

13893 Powder Bar Post – Large

13895 Clamp Screw

13896 1/4-20 3/8 BH Screw

13908 Crimp Adjustment Screw

13921 Powder Measure Spacer Plug

13943 Powder Bar Adjustment Bolt

13944 Indexer Return Spring

13945 Pivot Bolt Wave Washer

13951 Powder Bar Post – Small

13957 Primer Shield Cap

13958 Powder Bar Washer

13961 Primer Adjustment Screw

13964 Spring Screw

13967 Primer Punch – Large

13976 Chute Bracket Screw

13979 Primer Return Pin Spring

13982 Primer Punch Spring

13986 Collar Clamp

13989 Feed Body Screw

13999 Pickup Tube Tip (yellow) - Small

14003 Magazine Orifice (red) - Large

14010 Pickup Tube Tip (green) - Large

14013 Roller Bracket Screw

14014 10-24x7/8 SHCS

14019 Detent Ball

14024 Magazine Orifice (blue) - Small

14033 Primer Cup Spring (RL550B)

14036 Powder Bar Spring

14037 Clamp/Bracket Screw

14040 Retaining Clip

14041 Bowed Washer

14051 Primer Retaining Pin

*14060 Locator Button (3)

14157 #10 Washer

14293 Indexer Lever Assembly

16523 Plastic Wave Bearing - 4 pack

16814 Failsafe Rod

17085 Dispensing Tip, Large

17086 Dispensing Tip, Small

18077 Brass Link Arm Bearing

18077 Brass Linkarm Bearing

18086 #10 Rod Washer

20059 Primer Pickup Tube – Small

20060 Primer Pickup Tube – Large

20114 Crank Handle

20117 Powder Bar – Large

20118 Powder Bar – Small

20261 Powder Measure Body

20302 Complete Early Warning System

20642 Body Collar Assembly

20900 Primer Feed Body

22200 Decap Stem w/ Cap & Pin

* Indicates a caliber/size specific part. See the caliber

conversion chart for the caliber you are loading for.

Square Deal B Parts List

Page 3

3

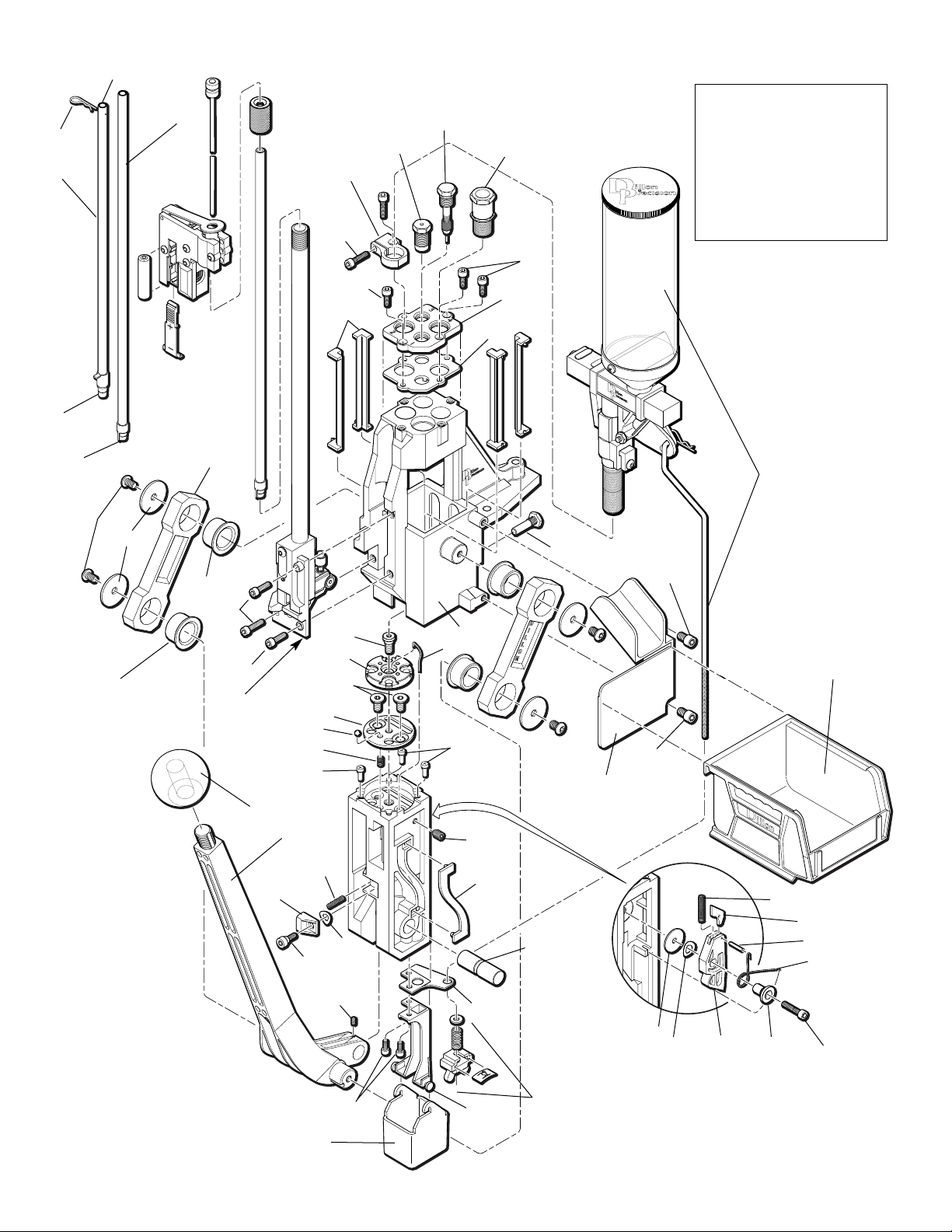

Square Deal B Schematic

22200

13908

13815

13712

13721

13815

16523 (4)

12124

13764

14040

*13879

*20059

*13999

*14003

14037 (2)

See page 5 for

more detail.

18077

13989

14037

13896

13828

13822

See page 4 for

more detail.

See

page 4

for more

detail.

Pre 1998 #13800 (old)

7/98 - Current #18077

13328

13504

13860

14019

13739

*14060

*14060

13690

13850

20114

13847

13597

13444

13718

14013

13651

13594

13622

14014

13797

13944

13776

13705

13624

13479

13659

13756

13976

13976

13445

13461

13433

13789

13355

14041

13714

13945

14157

See page 5 for

more detail.

17085, large

17086, small

IMPORTANT

The shellplate bolt

(#13328) and linkarm

bearings (#18077)

require occasional

lubrication.

Page 4

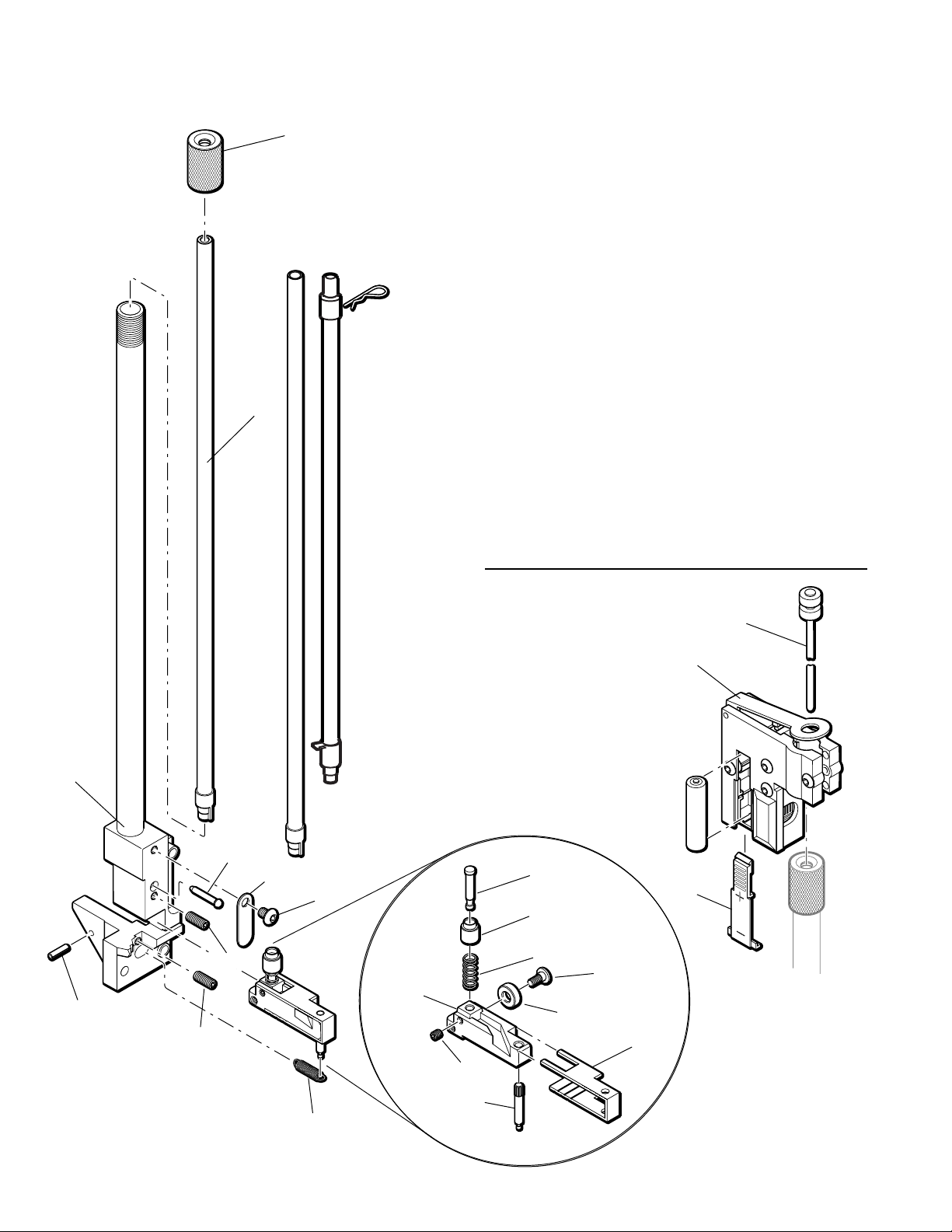

Automatic Primer System

13707

13957

13673

13864

AAA

battery

13857

20900

13964

14051

13979

13961b

13798

13621

13982

13809

13689

13754

13823

13790

13722

13967

13726

13961a

4

SDB Automatic Primer System

20253 Large – 20012 Small

13621 Primer Cup – Large

13657 Primer Cup – Small

13673 Primer Magazine – Large

13689 Primer Slide Roller

13722 Primer Slide Bearing

13726 Return Spring Roll Pin

13754 Primer Slide

13757 Primer Punch – Small

13790 Primer Slide Return Pin

13798 Return Spring

13809 Roller Bolt

13823 Primer Punch Set Screw

13957 Primer Shield Cap

13961a Primer Feed Adjustment Screw

13961b Slide Stop Adjustment Screw

13964 Spring Screw

13967 Primer Punch – Large

13979 Primer Return Pin Spring

13982 Primer Punch Spring

13989 Feed Body Screw

14037 Bracket Screw

14051 Primer Retaining Pin

20900 Primer Housing & Shield

20302 Early Warning

System (Complete)

13707 Follower Rod

13857 Battery Cover

13864 Switch Lever

See the machine schematic on

page 3 for mounting screw

positions – part #14037 & #13989

Page 5

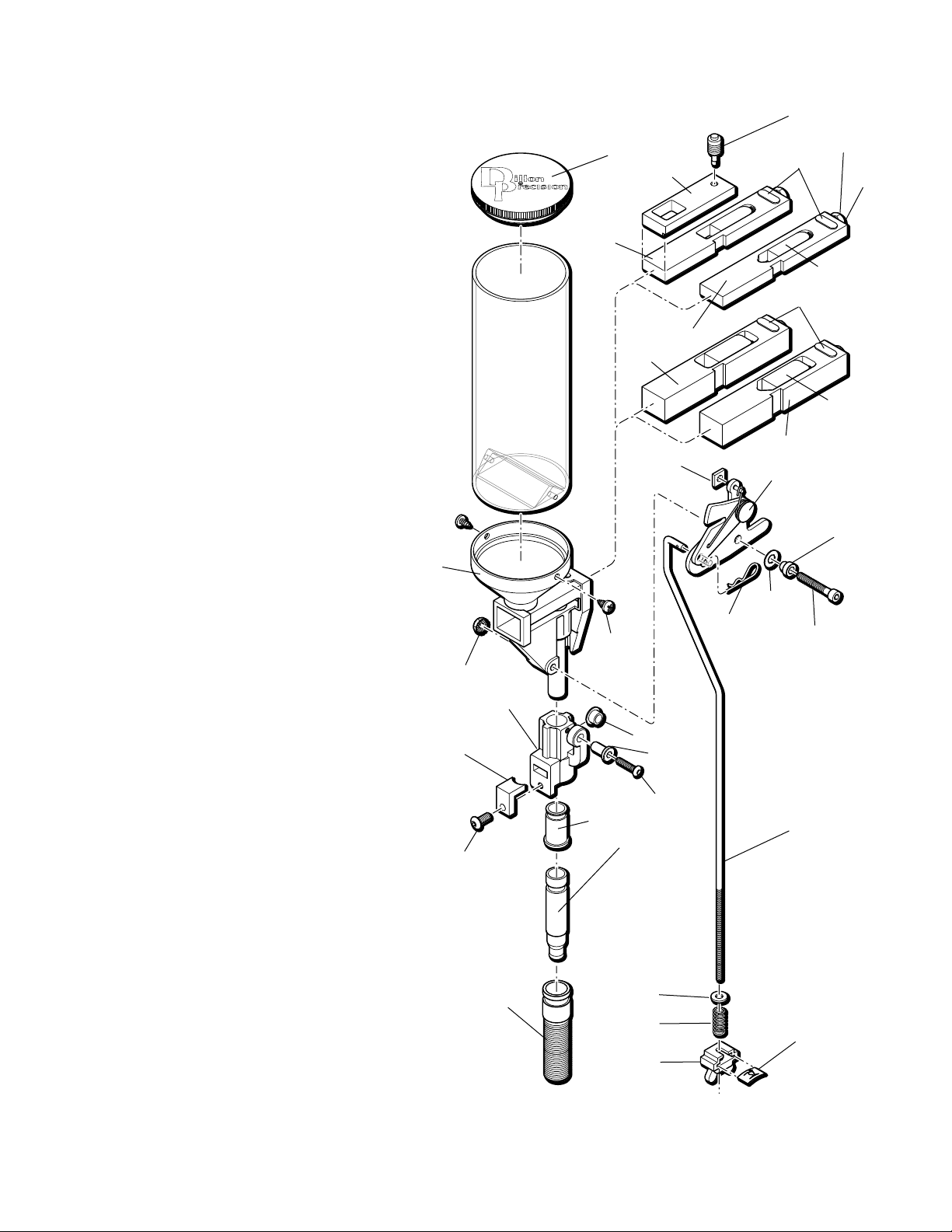

5

20001 SDB Automatic Powder System

13644 Powder Measure Spacer

13691 Powder Measure Tube

*13782 Powder Funnel – Pistol

13793 Powder Measure Roller

13799 Stripper Wing Nut

13801 Tinnerman Insert

13818 Powder Bar Insert – Small

13845 Collar Sleeve

13848 Bellcrank Bushing

13853 Powder Bar Insert – Large

13865 Powder Die

13871 Bellcrank Cube

13882 Powder Measure Lid

13893 Powder Bar Post – Large

13895 Collar Clamp Screw

13904 10-32x1 1/4 SHCS Bellcrank Bolt

13921 Powder Measure Spacer Plug

13943 Powder Bar Adjustment Screw

13951 Powder Bar Post – Small

13958 Powder Bar Washer

13986 Collar Clamp

14023 8-32x3/4 BH Screw

14033 Rod Spring

14036 Powder Bar Spring

14041 Bowed Washer

14202 Powder Measure Tube Screws

14808 Collar Roller Bushing

16340 Nylon Lock Nut

16814 Failsafe Rod

20063 Powder Bar – Large

20062 Powder Bar – Small

20642 SDB Body Collar - assembly

20780 Powder Bar Assembly – Extra Small

21353 Powder Bar Assembly – Extra Large

22273 Powder Measure Body

97034 Slotted Bellcrank & Cube

20304 Square Deal “B” Failsafe Kit

13355 Return Bracket

13799 Stripper Wing Nut

13801 Tinnerman Insert

13840 Throttle Clip

14033 Rod Spring

16814 Failsafe Return Rod

18086 Washer

Automatic Powder System

13882

22273

16340

14202

13793

20642

13986

13895

14808

14023

13691

13921

16814

13644

13871

97034

18086

14033

13801

13799

13840

14041

13845

13865

13951

13943

13958

13893

20062

20780

21353

13818

13853

*13782

13904

13848 - requires

lubrication

20063

Page 6

Okay, It’s Here; Now What?

First of all, the Square Deal “B” is a remarkably simple

machine and a little care and thought now while you’re

setting it up will save you time and give you thousands of

trouble free rounds.

Mandatory Safety Measures

Reloading ammunition involves the use of highly

explosive primers and powder. Handling these materials is

inherently dangerous. You should recognize this danger

and take certain minimum precautions to lessen your

exposure to injury.

Never operate the machine without ear and eye

protection on. Call our customer service department at (800)

223-4570 for information on the wide variety of

shooting/safety glasses and hearing protection that Dillon

has to offer.

• PAY ATTENTION: Load only when you can give your

complete attention to the loading process. Don’t watch

television or try to carry on a conversation and load at the

same time. Watch the automatic systems operate and make

sure they are functioning properly. If you are interrupted or

must leave and come back to your loading, always inspect

the cases at every station to insure that the proper operations

have been accomplished.

• SMOKING: Do not smoke while reloading or allow anyone

else to smoke in your reloading area. Do not allow open

flames in reloading area.

• SAFETY DEVICES: Do not remove any safety devices

from your machine or modify your machine in any way.

• LEAD WARNING: Be sure to have proper ventilation

while handling lead components or when shooting lead

bullets. Lead is known to cause birth defects, other

reproductive harm and cancer. Wash your hands thoroughly

after handling anything made of lead.

• LOADS AND LENGTHS: Avoid maximum loads and

pressures at all times. Use only recommended loads from

manuals and information supplied by reliable component

manufacturers and suppliers. Since Dillon Precision has no

control over the components which may be used on their

equipment, no responsibility is implied or assumed for

results obtained through the use of any such components.

Seat bullets as close to maximum cartridge length as

possible. Under some conditions, seating bullets excessively

deep can raise pressures to unsafe levels. Refer to a reliable

loading manual for overall length (OAL).

• QUALITY CHECKS: Every 50-100 rounds, perform

periodic quality control checks on the ammunition being

produced. Check the amount of powder being dropped and

primer supply.

• RELOADING AREA: Keep your components safely

stored. Clear your work area of loose powder, primers and

other flammables before loading.

• COMPONENTS: Never have more than one type of

powder in your reloading area at a time. The risk of a mix-up

is too great. Keep powder containers closed.

Be sure to inspect brass prior to reloading for flaws,

cracks, splits or defects. Throw these cases away.

Keep components and ammunition out of reach of

children.

• BLACK POWDER: Do not use black powder or black

powder substitutes in any Dillon powder measure. Loading

black powder cartridges requires specialized loading

equipment and techniques. Failure to do so can result in

severe injury or death.

• PRIMERS: Never force primers. If they get stuck in the

operation of the machine, disassemble it and gently remove

the obstruction.

Never attempt to clear primers that are stuck in either the

primer pickup tube or the primer magazine tube. Never,

under any circumstances, insert any type of rod to attempt to

force stuck primers out of these tubes. Trying to force

primers out of the tube will cause the primers to explode

causing serious injury or even death.

If primers get stuck in a primer magazine or pickup tube

flood the tube with a penetrating oil (WD-40), throw the tube

in the garbage and call us for a free replacement.

Never attempt to deprime live primers – eventually one

will go off. When it does it will detonate the others in the

spent primer cup. Depriming live primers is the single most

dangerous thing you can do in reloading and can cause

grave injury or death.

• LOADED AMMUNITION: Properly label all of your

loaded ammunition (Date, Type of Bullet, Primer, Powder,

Powder Charge, etc.).

• BE PATIENT: Our loading equipment is conservatively

rated and you should have no trouble achieving the

published rates with a smooth, steady hand. If something

doesn’t seem right, stop, look and listen. If the problem or

the solution isn’t obvious, call us. The reloading bench is no

place to get into a hurry.

We have done everything we know how to make your

machine as safe as possible. We cannot, however, guarantee

your complete safety. To minimize your risk, use common

sense when reloading and follow these basic rules.

• REMEMBER: If your machine does not perform to your

expectations, or if you are having technical difficulties, give

us a call.

Ready? Let’s Set Up

Carefully remove your new Square Deal “B” from its

packaging. Set the small parts aside.

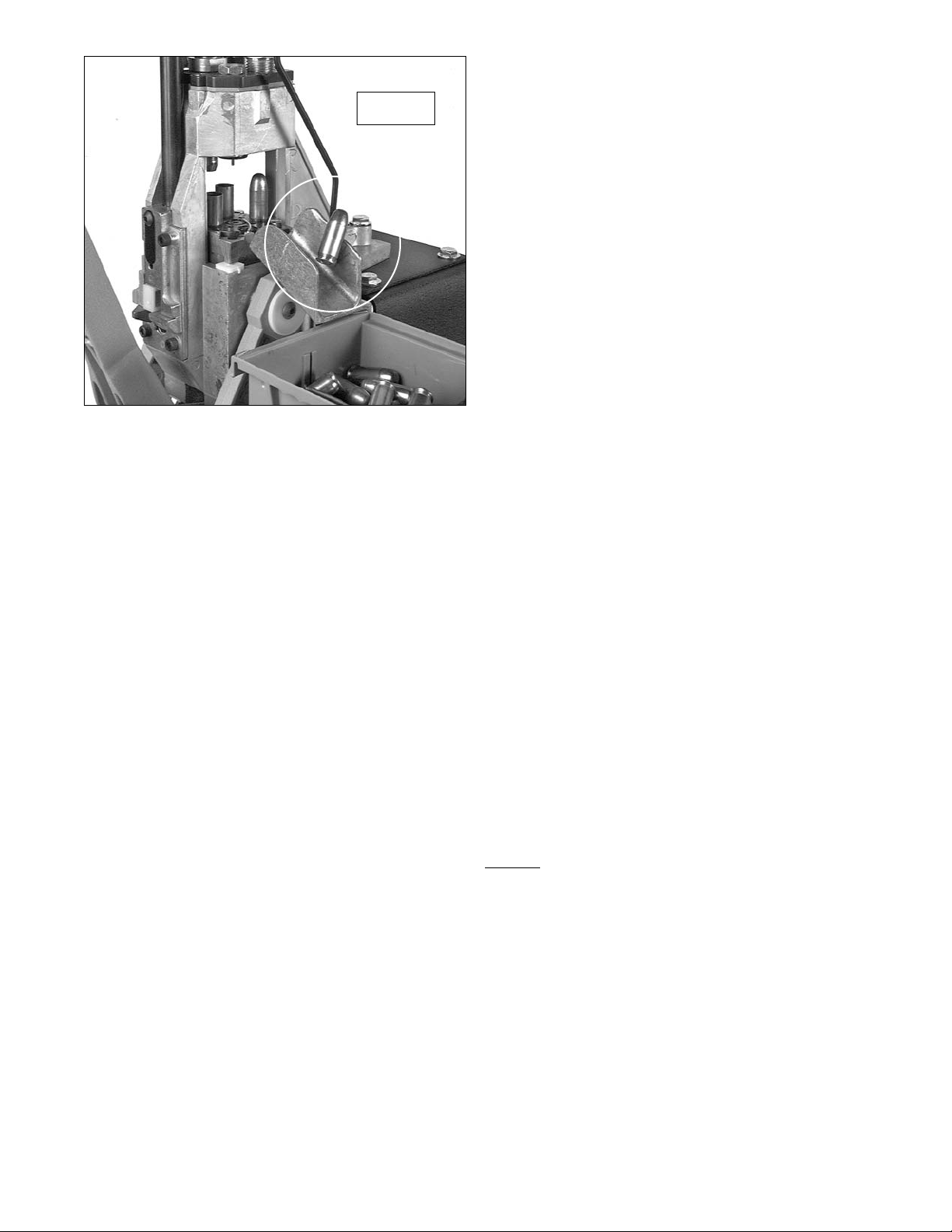

Fig. 1 – Install the ejected cartridge chute bracket

(#13659) with two large screws (#13976) from the parts

bag.

Fig. 1

6

Page 7

Fig. 2 – Using the machine itself as a template,

mark the three mounting holes. Allow about one

foot on both sides of your Square Deal “B” for

working room. Make sure your bench is sturdy and

does not shake, as this may disturb your powder

charge and primer system.

Fig. 3 – Drill the mounting holes and secure the

Square Deal “B” to your bench, using 1/4" bolts

(not supplied).

Fig. 4 – Install the return bracket (#13355)

between the bottom of the shaft (#13437) and the

spent primer chute (#13594). The spent primer cup

(#13651) simply hooks on the bottom of the chute.

Fig. 5 – Slide the cartridge collection box (#13756)

onto the chute bracket (#13659) as shown.

Fig. 6 – The locator buttons must be placed at

Stations 2, 3 and 4 to prevent the cartridge from

sliding off of the shellplate. The buttons can be

removed to access the case at these stations.

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

7

13355

13594

Page 8

Fig. 7 – Remove the cap from the top of the

powder die (#13865). The cap retains the

expander/powder funnel during shipping.

Fig. 8 – Make sure the expander/powder funnel

is free to move in the powder die and reinsert it as

shown.

Fig. 9 – With the cap removed and the

expander/powder funnel in position, you are now

ready to install the powder measure. Place the

powder measure on top of the powder die.

Fig. 10 – The powder measure is held in place by

the powder die clamp (#13986). Tighten in place, but

do not over tighten.

Fig. 7

Fig. 8

Fig. 9

Fig. 10

8

Page 9

Fig. 11 & 12 – Installation of the Powder Measure

Failsafe System.

To install the failsafe rod (#16814) remove the

blue stripper wingnut (#13799), rod spring

(#14033) and washer (#18086). (Note the order of

parts.) See Fig. 11

Insert the bottom end of the rod between the

bench and the Square Deal “B” through the hole in

the return bracket (#13355). Then, using your thumb

and index finger of your right hand, move the locklink (#17838) down to align the hole with the slot on

the Powder Measure bellcrank (#17839). Next, insert

the failsafe rod (#16814) through the two holes and

insert the failsafe rod clip (#13840).

Install the washer (#14033) and the wingnut

(#13799). With your left hand, move the operating

handle (#20114) to the priming position; press the

operating handle firmly forward and with your

right hand adjust the wingnut until the spring is

partially compressed. You are now ready to reload.

Refer to the rear view in Fig. 11 to assist in the rod

location and proper powder measure positioning.

Check It Out

Your assembly should now be complete, but

before you stock it with powder and primers let’s

run through the operation a few times.

Your Square Deal “B” has been adjusted at the

factory in the caliber of your choice and we’ve

enclosed the sample rounds that we used to obtain

those adjustments. One cartridge has a bullet seated

to illustrate the seating depth and the other round

was primed (the primer is inert).

Place the cartridge case without the bullet in

Station 1 and pump the operating handle. The

primer will be pushed out and dropped into the

spent primer cup (#13651). Continue to pump the

handle and observe the advancement of the

cartridge from station to station until it is ejected

into the cartridge collection box. Now take a new

primer and drop it (shiny side down) into the

primer magazine (#13673). Operate the handle and

the primer will appear at Station 2, press forward

on the handle, pick up the primer with your

fingers and put it back into the primer magazine.

The forward pressure on the handle is important

as it exerts the pressure necessary to seat the

primer in a cartridge.

Reinsert the case in Station 1, drop the primer in

the primer magazine and operate the handle. As the

case is moved to Station 2 press forward firmly but

gently and you will feel the primer being seated.

Cycle the machine and eject the primed round.

IMPORTANT: Let’s do it again but this time do

not put the primer in the magazine. Repeat the

sequence using an unprimed case. Notice how the

primer punch tends to stick in the cartridge when no

primer is present. This is the feeling you get when

your Square Deal “B” runs out of primers.

Fig. 11

Fig. 12

9

Page 10

Now that you’ve seen the Square Deal “B”

function, read the following description of what is

happening at each station.

Understanding the Machine

Station 1: When a cartridge is fired, it expands.

The carbide resizer returns it to factory dimensions.

The primer decap pin knocks out the old primer and

deposits it into the spent primer cup.

No adjustments are ever necessary at this station.

Station 2: As you recall, when you press forward

on the handle you will seat the primer, but that’s not

all that’s happening here. As the cartridge goes up

into the powder measure it encounters a powder

funnel that slightly “bells” the mouth of the

cartridge – this bell or flare enables you to start your

bullet easier at Station 3. As the powder funnel is

carried upward by the cartridge it will operate your

automatic powder measure and dispense the

amount of powder chosen.

Two adjustments are possible here. The amount

of bell has been adjusted at the factory; however,

you may increase or decrease the amount of bell by

simply screwing the powder die into or out of the

toolhead. (See Fig. 14.)

The second adjustment is the most important of

the entire loading sequence and must be approached

with a great deal of caution. You must adjust your

powder measure to meter the proper weight of

powder in grains for the load you’ve selected from a

powder manufacturer’s chart or reloading manual.

Cycle your empty cartridge into Station 2.

Turning the adjusting screw as shown on Fig. 13 will

open or close the powder insert. Fill the powder

measure with the powder of your choice. Cycle your

primed practice round into Station 2 to activate the

powder measure. Do this several times and then,

using a powder scale, weigh your charge. (See Fig.

15.) Then, by trial and error, continue adjusting until

the proper weight of powder is achieved. Run it six

more times just to be sure.

With the powder measure up and running let’s

get some primers.

Fill ‘er Up

Using the appropriately sized primer pick up tube,

pick up the primers, shiny side up as shown in Fig.

16. This tube will hold approximately 100 primers.

You will notice that the primer magazines and

Fig. 14

Fig. 15

Fig. 16

10

Fig. 13

Page 11

primer pick-up tubes have different colored tips.

They have been color coded to help you identify size

more easily.

The color code is as follows:

Blue Small Primer Magazine Orifice

Red Large Primer Magazine Orifice

Yellow Small Primer Pick-up Tube

Green Large Primer Pick-up Tube

Primers are much easier to pick up if you use a

primer flip tray. A quality metal tray is available

from Dillon Precision.

Never forget that primers are potentially

dangerous. Never hit them or attempt to force them.

Primer Early Warning System Installation

(See page 4 for assistance.) Install the battery and

the battery cover (#13857) in the system’s main

body. Slide the Early Warning System Assembly

down over the knurled cap on your primer

magazine and lightly tighten the clamp screw.

Pivot the switch lever (#13864) away from the

Early Warning System housing to fill the primer

magazine with primers.

Invert the primer pick up tube over the knurled

cap and pull the primer retaining clip (#14040 – See

Fig. 17.) The primers should now fall smoothly into

the magazine. Pivot the switch lever back over the

Early Warning System housing. Gently slide the

follower rod (#13707) down through the switch

lever, the knurled cap and into the primer magazine

tube until the follower rod touches the primers.

You are now ready to reload. When you are

nearly out of primers (approximately three

remaining) the follower rod will activate the

buzzer. Never attempt to remove the primer

magazine shield, it is there for your protection.

Your primer system should now be ready. Let’s

move on to Station 3.

Station 3: This is an easy one. All we do is seat

the bullet to its proper depth in the cartridge case.

This depth was adjusted at the factory for the bullet

type on the sample cartridge.

We give you a choice of bullet seating stems, use

the one closest to the type of bullet you are using.

The depth of bullet seating may be adjusted

simply by screwing the seating stem in or out. The

adjustment is held in place by a layer of Delrin

beneath the toolhead.

Station 4: Another easy one. This station removes

the bell and crimps the bullet in place. Once again

this adjustment has been performed by Dillon.

More or less crimp can be achieved simply by

screwing the crimp adjustment screw (#13908) in or

out. Check your reloading manual for crimp

dimensions.

Load ‘em up

Okay now that you understand the purpose of all

of the Square Deal “B” stations, we are ready to

reload. Begin as follows:

1.) Place a clean, empty case in Station 1 and

cycle the handle, don’t forget to press forward

firmly to seat the primer in Station 2. Work slowly.

2.) Place another empty case in Station 1, cycle

the handle. Work slowly and carefully, watch the

powder bar function and be sure it travels fully to

the left each time. If it doesn’t, turn the powder die

(#13865) 1/8 turn clockwise and try again.

3.) Carefully place a bullet on top of the cartridge

case at Station 3. Insert a new empty case at Station

1, cycle the handle.

Fig. 17

11

Page 12

4.) From this point on, place a bullet on the case at

Station 3 with your left hand. Insert a case at Station

1 with your right hand and cycle the handle. Each

time you cycle the machine a finished round will be

ejected into the cartridge collection bin. (See Fig. 18)

REMEMBER!

Press forward firmly on the handle to seat your

primers. Primer jams or misfeeds can be caused by

misadjustment of the set screw (#13961) in the

primer feed block. The most common case of primer

misfeeds or jams is the primer punch not seating

fully onto the primer slide. This will cause the

primer cup to strike the flexible orifice on the

bottom of the primer magazine tube.

Watch the powder bar function, make sure you’re

getting powder.

Set the bullet straight on the case at Station 3 so

that it enters the die correctly.

Watch your supply of powder and primers,

you’ll be using them faster than you think you are.

Take your time and learn the machine and its

function. The Square Deal “B” will deliver hundreds

of trouble free rounds in short order, just relax and

take your time in the beginning.

Keep it clean – primer residue, spilled powder

and just plain dirt can jam your machine. All

bearing surfaces are Delrin and require no

lubrication.

Clean your powder bar and underneath your

shellplate about every 500 rounds. Some powders

build up and will eventually stick the powder bar.

Paint or lacquer thinner works well to remove any

build up.

Friend at the Factory

We started this manual by saying if you have a

problem, call us. We mean it. Anyone can make a

mistake. There’s no such thing as a dumb question. If

something is giving you a problem, let us help you!

Technical Support & Order Line

1-800-223-4570 FAX (480) 998-2786

Square Deal “B” Conversion Instructions

Changing calibers on your SDB is a simple

procedure.

First, you must decide whether you need to

change the priming system that is now set up on

your machine. Small calibers use small pistol

primers and large calibers use large pistol primers.

Skip step one if there are no changes needed.

Step 1: Changing The Priming System

Remove Primer Early Warning System. Remove

three screws (#13989 – refer to schematic) to remove

the primer system from the front of the machine.

Remove the primer slide return spring from pin

(#13790) and remove the primer slide assembly from

the magazine system. Replace the correct size

primer slide in the same manner.

IMPORTANT Make sure the magazine is empty

of all primers by inverting the primer assembly.

Remove cap (#13957) and pull out the internal

magazine tube (#13673). Take the correct size

magazine tube and drop a primer, anvil side up, into

the top of the tube to make sure the primer drops

freely through the tube and orifice. Insert the

magazine tube (#13673) into the magazine shield with

the keyed side of the orifice pushed all the way down

into the notch or key way in the housing (#20900).

Replace the cap (#13957). Do not over tighten!

Now, insert a few primers, anvil side up, into the

magazine. Pull the handle, a full stroke, raise the

handle and a primer should appear at Station 2. If a

primer fails to appear, adjust the primer feed

adjustment screw (#13961a), located at the lower tip

of the flat spring (#13979) on the front of the

housing (#20900) as follows:

If changing from a large primer to a small primer

turn the primer feed adjustment scew (#13961a) in

1/8 turn increments clockwise. If changing from

small to large, turn in 1/8 turn increments

counter

clockwise.

Give the handle another full stroke and a primer

should appear. If the primer cup is not centered

under the shellplate or snaps into place when the

handle is raised it may be necessary to adjust the

primer slide travel by turning the slide stop

adjustment screw (#13961b) in 1/8 turn increments.

It is located between the primer slide and the coiled

spring (#13798) on the front on the housing. (See

pages 3 & 4.)

Step 2: Changing Shellplates

Lift out the ejector wire (#13433) and remove

the shellplate bolt (#13328). Carefully remove the

shellplate and be aware of a very small index ball

(#14019) that sits on a spring. Install the correct

shellplate.

12

Fig. 18

Page 13

The short end of the ejector wire fits behind the

shellplate bolt (#13328). Note: The correct

positioning of the ejector wire is important or serious

damage to the sizing die could result. See Fig. 14.

Step 3: Changing and Adjusting Dies

Use of Dillon’s Bench Wrench is suggested when

changing or adjusting dies.

Remove screw (#13895) and remove the powder

measure. Remove screws (#13815) and (#14037) and

remove the toolhead assembly. Lift out the three die

inserts (#12864, #11628, #11734) from the frame.

Note: The toolhead you just removed is adjusted for

those dies. Store these parts for when you set up this

caliber again.

Now, take the dies of the caliber that you are

converting to and insert them into the frame,

corresponding to the position reference number on

each die. 1, 3 & 4. If you choose to use the toolhead

you removed, be certain that you back out the

adjustment bolt (#13908) at Station 4 and remove the

seating stem at Station 3.

Reinstall the toolhead with screws (#13815).

Drop the correct powder funnel expander in

the die body (#13865) and mount the powder

measure just as you removed it. Loosen the clamp

screw (#13895).

To achieve proper adjustment of the die it is

important to understand that the adjustable powder

bar should reach the end of its travel at the same

time that the handle reaches the bottom of its stroke

against the frame stops.

To achieve this adjustment, the die body (#13865)

must be screwed up or down. A sized empty shell

case must be placed in the shellplate at Station 2 in

order to check this adjustment. No powder should

be in the measure during these adjustments.

Beware! If you pull the handle and the powder

bar reaches the end of its travel before the handle

reaches the bottom of its stroke, STOP! Raise the die

(#13865) several turns and try again. Once the

adjustment is correct but you want the case mouth

flared a little more, just screw die (#13865) down

1/4 turn or less.

The base of the bullet needs only to set within a

slightly flared case mouth.

Tighten screws (#14037) and (#13895).

Now, you can adjust the powder measure for the

charge your loading data tells you to use. Remember

that the powder charge adjustment screw (#13943)

turns counterclockwise to decrease the volume of

charge and clockwise to increase the charge.

Your conversion kit comes with the seating stems

to fit the most popular bullet styles; wadcutters,

semi-wadcutters and round nose. Choose one and

insert it in Station 3. Simply seat the bullet to a

desired depth. Consult your loading data!

Now, index your seated cartridge to Station 4.

Lower the handle all the way against the frame

stops. Turn the die adjustment bolt (#13908) down

until you feel a slight opposition. Raise the handle

and turn the adjustment bolt clockwise 1/4 to 1/2 a

turn. Insert this cartridge back into the shellplate at

Station 4 and give the handle a full stroke. The

crimping die is now adjusted and you’re ready to

start loading.

Reloading Tips:

If you’re using new unfired brass remove the

sizing die (#12864). Virgin brass usually does not

require full length sizing. (Optional)

Always give the handle a FULL STROKE or

remove all cases and start over, as operations may

be only partially completed.

Use cleaned brass or damage to dies may result.

Avoid the use of military brass with crimped primer

pockets. Crimps can easily be removed with a Dillon

SS-600.

Mount the machine on a sturdy work bench that

will not move while loading. Bench movement will

impair your ability to prime correctly. Suggestion:

Nail or screw your bench directly to your wall.

Keep your machine clean! Read this manual

carefully! If you have any questions please call us!

We’ll help. 1-800-223-4570

NOTICE!

THIS MACHINE IS DESIGNED SPECIFICALLY

TO BE A MANUALLY OPERATED

HANDLOADING MACHINE. ANY ATTEMPTS TO

MECHANIZE THIS PRODUCT WILL VOID ANY

AND ALL WARRANTIES OFFERED BY THE

COMPANY. WE SPECIFICALLY WARN AGAINST

CONVERTING THIS PRODUCT TO AUTOMATED

OR MOTORIZED OPERATION.

All Dillon machines are warranted for life from

defects in material or workmanship, plus a one year

100% warranty against normal wear. All

electrical/electronic components in Dillon

equipment are covered by a one year warranty.

13

Caliber Conversion Chart

Caliber Shellplate Locator Powder

Button Funnel

.45 ACP #1 #1 E

.38/.357 #2 #2 D

.380 Auto #3 #3 F

.44 Mag./Spcl. #4 #4 G

9mm/.38 Super #5 #3 F

.41 Mag. #6 #1 H

.45 LC #C #4 E

10mm #W #2 W

Page 14

Dillon Precision Products, Inc.

8009 E. Dillon’s Way

Scottsdale, AZ 85260

(480) 948-8009

FAX (480) 998-2786

www.dillonprecision.com

e-mail: dillon@dillonprecision.com

Technical Support & Customer Service

(800) 223-4570

#13028 Spot Manuals SDB Manual Folder SDB Manual. V 4.5 9/01 WJC

On the cover…

The Square Deal B is pictured with optional accessories:

SDB Strong Mount #22223

Low Powder Sensor #16306

Other accessories available for the Square Deal B include:

Bullet Tray #22214

Machine Cover #13795

Maintenance Kit & Spare Parts Kit #97015

The Blue Press, Dillon’s monthly catalog, has a complete listing

of accessories available for all machines.

Loading...

Loading...