Page 1

RL 550B

Instruction Manual

Version 7.8

illon

recision

Products, Inc.

Manufacturers of

The World's Finest

Loading Equipment

Page 2

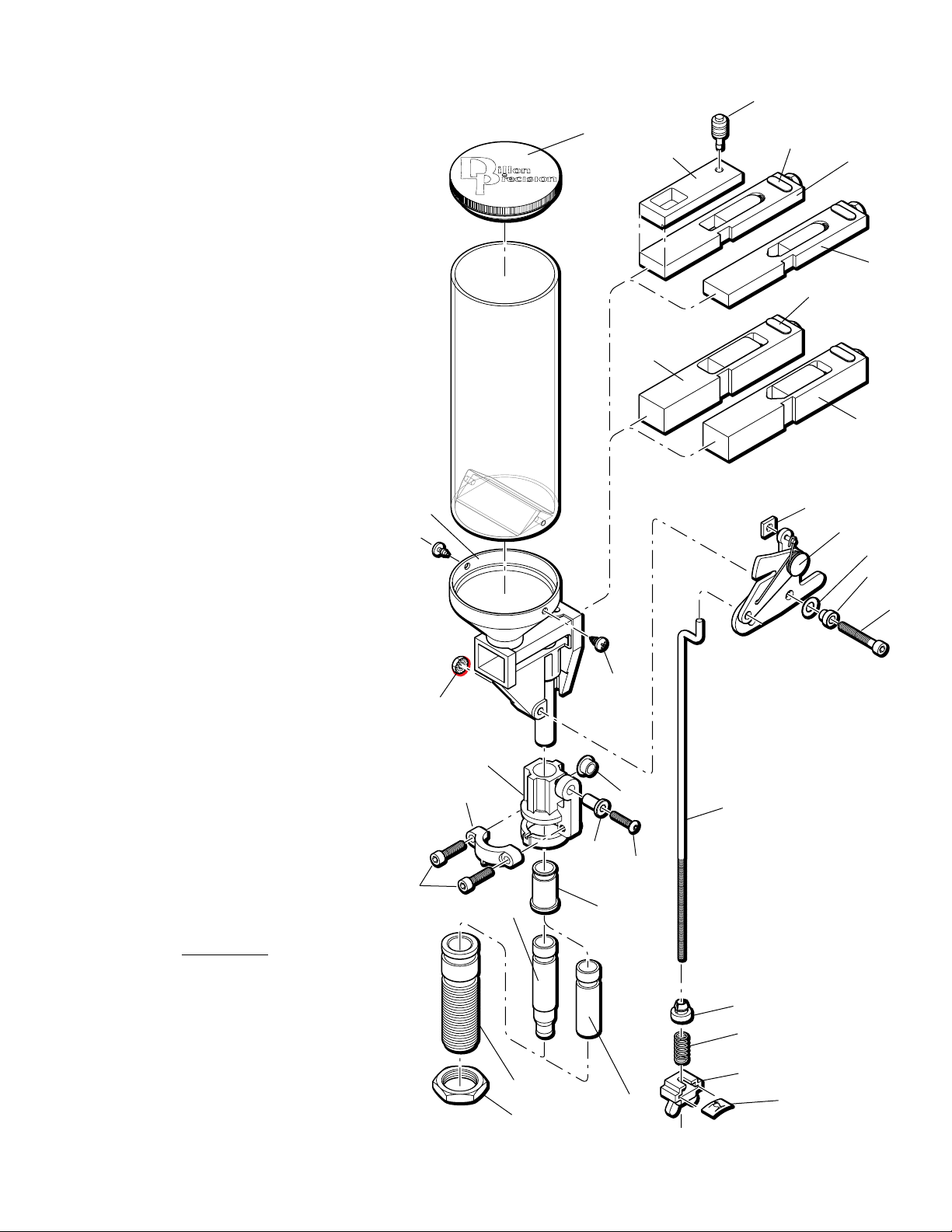

RL 550B Parts List

Part # Description

13149 Manual

13409 Crank

13573 Machine Box

13583 Link Arm, Left

13644 Powder Bar Spacer

13650 Spent Primer Cup

13673 Primer Magazine, Red, Large

13691 Powder Measure Tube

13700 Link Arm Pin

13704 Handle Washer

13707 Follower Rod

13719 Cartridge Spring Retainer Screw

13720 Index Sprocket

13734 Parts Box

13747 Link Arm, Right w/Hook

13757 Primer Seating Punch, Small

13765 Roller

13775 Main Shaft

13781 Shellplate Platform

13789 1/4-2/8 Set Screw

13793 Roller

13794 Shellplate Bolt

13795 Machine Cover

13799 Stripper Wing Nut

13801 Tinnerman Nut Insert

13803 Ejected Cartridge Chute Bracket

13824 Primer Seating Cup, Large

13825 Primer Seating Cup, Small

13830 Main Shaft Pivot Pin

13834 Solid Link Arm Pin, Left

13839 Cartridge Collection Bin

13841 Nylock Nut

13845 Collar Sleeve

13848 Bellcrank Bushing

13850 Operating Handle Knob

13857 Battery Cover

13864 Switch Lever

13869 Operating Rod

13871 Bellcrank Cube

13879 Primer Magazine, Blue, Small

13881 Hollow Link Arm Pin, Right

13882 Powder Measure Lid

13885 Return Bracket

13887 Operating Rod Bracket

13889 Primer Slide Roller

13890 Spring Washer

13891 Index Ball

13893 Powder Bar Post, Large

13898 Primer Slide Stop Nut

13899 Spent Primer Catcher Chute

13904 Bellcrank Bolt, New Style

13909 Toolhead

13917 Roller Clip

13919 Slide Roller Post

13920 Primer Slide

13921 Powder Bar Spacer Plug

13923 Brass Tip Set Screw

13924 Slide Post

13925 Ejector Wire

13926 Cartridge Spring

13928 Primer Slide Return Spring

Part # Description

* 13930 Locator Buttons (3)

13939 Body Collar Clamp

13940 Body Collar - Part

13943 Powder Bar Bolt

13951 Powder Bar Post, Small

13957 Magazine Shield Cap

13958 Powder Bar Bolt Washer

13961 Slide Pickup Adjustment Screw

13964 Retain Spring Screw

13966 Shellplate Platform Bolt

13967 Primer Seating Punch, Large

13979 Primer Retain Pin Spring

13996 Primer Punch Set Screw

13997 Index Ball Spring

13998 Spent Primer Catcher Pin

13999 Primer Pickup Tip, Yellow, Small

14001 Roller Pin

14003 Flexible Orifice, Red, Large

14008 Toolhead Pin

14010 Primer Pickup Tip, Green, Large

14013 Roller Bracket Screw

14014 Primer Housing Screw

14015 Primer Track Bearing

14023 8-32x3/4 BH Screw

14024 Flexible Orifice, Blue, Small

14025 Primer Slide Return Spring Retainer

14033 Spring

14037 Clamp/Bracket Screw

14040 Retaining Clip

14051 Primer Retaining Pin

14067 Die Lock Ring

14202 Powder Measure Tube Screw

14280 Roller Bracket Shell Platform

14281 Primer Slide Assembly, Large

14282 Primer Slide Assembly, Small

17085 Dispensing Tip, Large

17086 Dispensing Tip, Small

18086 Shoulder Washer

20048 Spare Parts Kit

20059 Primer Pickup Tube, Yellow, Small

20060 Primer Pickup Tube, Green, Large

20062 Powder Bar Assembly, Small

20063 Powder Bar Assembly, Large

20064 Powder Die

* 20093 Shellplate

20094 Frame

20263 Primer Feed Body w/ Shield

20302 Primer Early Warning System

20303 Powder Measure Failsafe Kit

20339 Bellcrank

20636 Operating Handle Assembly

20782 Powder Measure System

21275 Connector Body Collar

22038 Crank Assembly

22273 Powder Body w/ Drop Tube

97000 Rod

* Indicates caliber specific parts. See the caliber conversion

chart for the correct part number for the caliber you are

loading for.

Some items listed are not shown in schematic illustration.

Part #13149 Spot Manuals RL550B Manual Folder 550B Manual.V7.8 9/01 WJC

Page 3

14040

20059

13673

13707

13794

13720

20093

13966

13925

14015

13881

14025

13928

14014

13923

13747

13650

13775

13890

13409

13700

13789

13830

13890

13583

13841

13803

13839

13834

20094

13909

14067

13841

20636

Assembly

13781

13885

14008

13891

13997

13930

20302

See page 5 for

more detail.

14280

See page 5 for

more detail.

See page 4 for

more detail.

See page 5 for

more detail.

13801

97000

18086

14033

13799

3

RL 550B Schematic

17085 (large)

or

17086 (small)

Page 4

13882

22273

13691

13793

14808

13940

13845

13871

97034

14041

13904

13939

14037

18086

14033

13801

13799

14067

20064

*13782

*13426

16340

14202

97000

13848

13893

20062

21353

20063

13426 * Powder Funnel, .45 cal Pistol

13644 Powder Bar Spacer

13691 Powder Measure Tube Only

13782 * Powder Funnel, .22 cal Rifle

13793 Roller

13845 Collar Sleeve

13848 Bellcrank Bushing

13871 Bellcrank Cube

13882 Powder Measure Lid

13893 Powder Bar Post, Large

13904 Bellcrank Screw

13921 Plastic Plug

13939 Body Collar Clamp

13940 Body Collar - Part

13943 Powder Bar Bolt

13951 Powder Bar Post, Small

13958 Powder Bar Bolt Washer

(not pictured)

14023 8-32x3/4 BH Screw

14037 Clamp/Bracket Screw

14041 Bowed Washer

14067 Die Lock Ring

14202 Powder Measure Tube Screws

14808 Collar Roller Bushing

16340 10-32 Nylon Lock Nut

20062 Powder Bar Assembly, Small

20063 Powder Bar Assembly, Large

20064 Powder Die

20780 Powder Bar Assembly, Extra Small

21275 Connector Body Collar - Complete

21353 Powder Bar Assembly, Extra Large

22273 Powder Measure, Part

97034 Slotted Bellcrank

20303 Powder Measure Failsafe Kit

13799 Stripper Wing Nut

13801 Tinnerman Nut Insert

13885 Return Bracket

(not pictured– see the main

schematic to identify part)

14033 Rod Spring

18086 Shoulder Washer

97000 Failsafe Rod

NOTE: * Indicates caliber specific parts –

see the caliber conversion chart for the

correct part number for the caliber you are

loading for.

W

ARNING

This powder measure drops a full charge of

powder each time the operating handle is

cycled. If, for any reason, you believe that

more than a single measure of powder was

dropped or you think that you may have

cycled the handle more than once on a

single case, you need to empty the case and

start over.

A double charged case can result in bodily

injury or a damaged firearm.

14202

13951

20780

13644

RL 550B Automatic Powder System

13921

14023

4

Page 5

13757 Primer Seating Punch, Small

13824 Primer Seating Cup, Large

13825 Primer Seating Cup, Small

13869 Operating Rod

13887 Operating Rod Bracket

13889 Large Roller

13898 Primer Slide Stop Nut

13917 Roller Clip

13919 Roller Pin

13920 Primer Slide

13924 Primer Slide Return Spring Post

13957 Primer Shield Cap

13961 Slide Pickup Adjustment Screw

13964 Primer Feed Stop Spring Screw

13967 Primer Seating Punch, Large

13979 Primer Feed Stop Spring

13996 Primer Punch Set Screw

14003 Flexible Orifice Large (small 14024)

14010 Pickup Tube Tip Large (small 13999)

14033 Primer Seating Cup Spring

14037 Clamp/Bracket Screw

14040 Retaining Clip

14051 Primer Feed Stop Pin

17085 Dispensing Tip, Large

17086 Dispensing Tip, Small

20263 Primer Housing and Shield

22028 Primer Pickup Tube, Small

22029 Primer Pickup Tube, Large

22030 Primer Magazine, Small

22031 Primer Magazine, Large

20302 Primer Early Warning System

13707 Follower Rod

13857 Battery Cover

13864 Switch Lever

14280 Roller Bracket Assembly

13719 Cartridge Spring Retaining Screw

13765 Roller

13899 Spent Primer Catcher Chute

13926 Cartridge Spring

13998 Spent Primer Catcher Pin

14001 Roller Pin

14530 Roller Bracket Screw(s)

Complete Primer Slide Assemblies

14281 Primer Slide Assembly, Large

14282 Primer Slide Assembly, Small

5

13707

13864

20302

13957

14040

17085 (large)

or

17086 (small)

20060

14010

14003

20263

13967

13887

22031

13869

13857

13964

14051

13979

13961

13898

13924

13919

13917

14280

14530

13899

13765

13719

13889

13996

14033

13824

14037

14037

13998

14001

13920

RL 550B Automatic Primer System

13926

Page 6

Introduction

First of all, the Dillon RL 550B is a remarkably simple

machine–a little care and thought while setting up will

save you time and give you thousands of trouble free

rounds.

Suggested Minimum Equipment:

1) Loading Manual 2) Powder Scale

3) Safety Glasses 4) Primer Flip Tray *

5) Dial Caliper * (* Indicates items that are not

absolutely essential, but are pretty darned handy!)

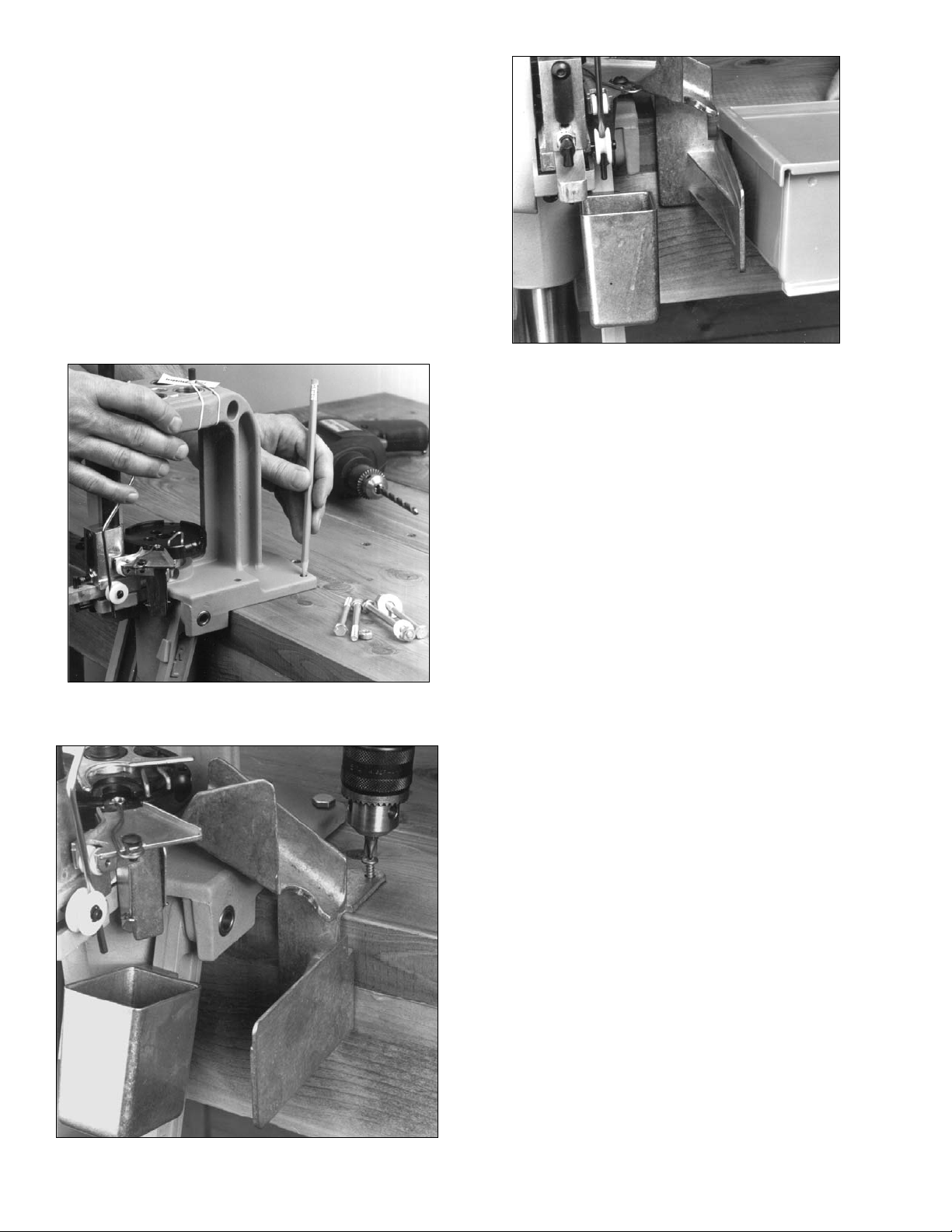

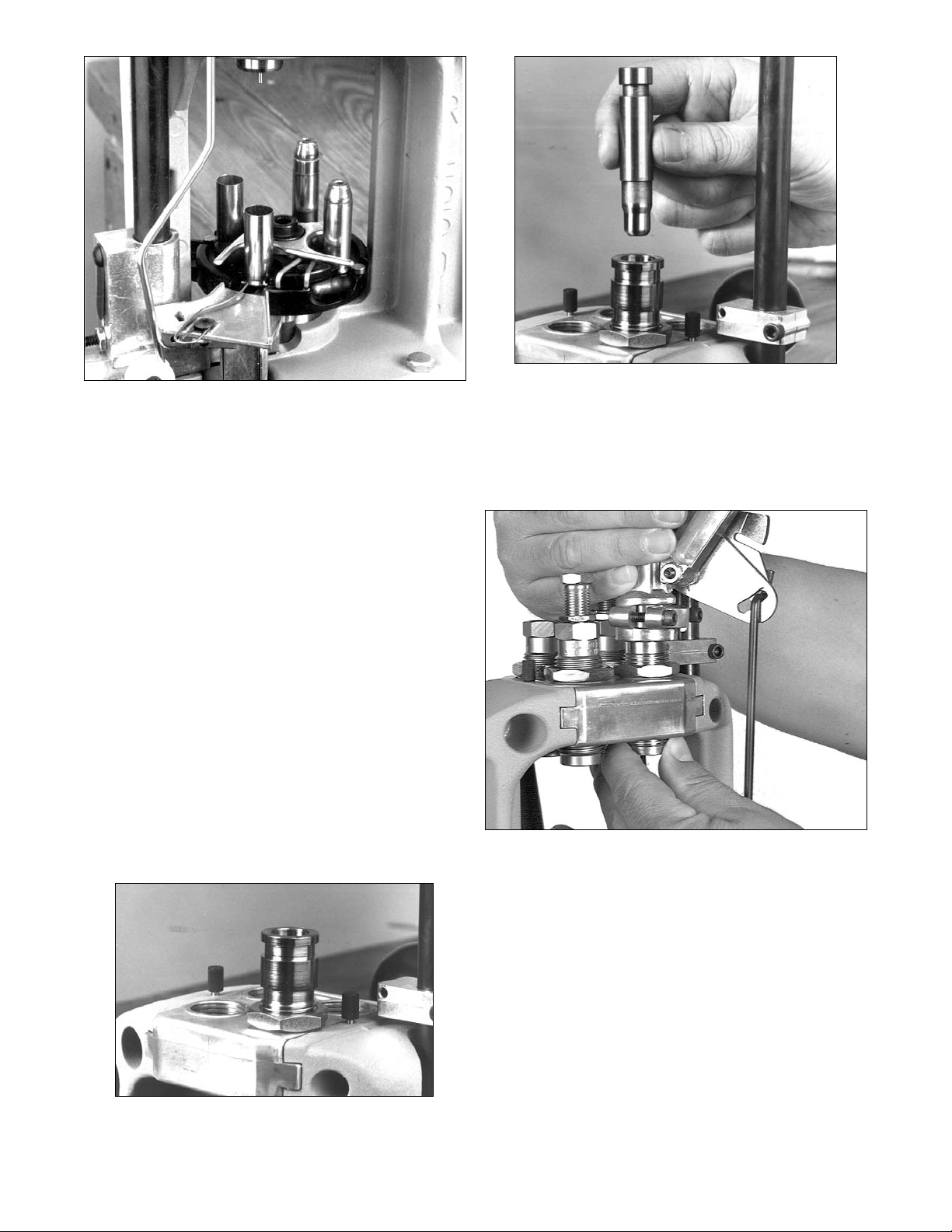

Mounting the RL 550B to your bench.

Place your RL 550B on the edge of sturdy bench or table.

Give yourself about 12 inches of work space on each side of

the machine to allow room for components.

Using the machine itself as a template, mark and drill

four one-quarter inch holes in your bench and bolt your RL

550B securely to it, Fig. 1. Next, mount the cartridge

collection bin bracket (#13803) onto your bench, Fig. 2,

allowing approximately one-eighth inch clearance between

the platform (#13781) and the ejected cartridge chute.

Using two screws or bolts, secure the bracket to your

bench. The cartridge collection bin (#13839) simply slides

on the bracket, Fig. 3, and will be in the proper position to

catch ejected loaded rounds. Bolt the operating handle in

place as shown in the schematic.

Safety Points to Know Before you Begin

Reloading ammunition involves the use of highly

explosive primers and powder. Handling these materials is

inherently dangerous. You should recognize this danger

and take certain minimum precautions to lessen your

exposure to injury.

Never operate the machine without ear and eye

protection on. Call our customer service department at

(800) 223-4570 for information on the wide variety of

shooting/safety glasses and hearing protection that Dillon

has to offer.

• PAY ATTENTION: Load only when you can give your

complete attention to the loading process. Don’t watch

television or try to carry on a conversation and load at the

same time. Watch the automatic systems operate and make

sure they are functioning properly. If you are interrupted

or must leave and come back to your loading, always

inspect the cases at every station to insure that the proper

operations have been accomplished.

• SMOKING: Do not smoke while reloading or allow

anyone else to smoke in your reloading area. Do not allow

open flames in reloading area.

• SAFETY DEVICES: Do not remove any safety devices

from your machine or modify your machine in any way.

• LEAD WARNING: Be sure to have proper ventilation

while handling lead components or when shooting lead

bullets. Lead is known to cause birth defects, other

reproductive harm and cancer. Wash your hands

thoroughly after handling anything made of lead.

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

Fig. 2 - This photograph shows the correct mounting

position of the cartridge collection bin bracket in relation

to the machine.

Fig. 1 - Using the machine as a template, mark and drill

four 1/4 inch holes allowing 12 inches on each side for

your work area.

Fig. 3 - The cartridge collection bin (#13839) simply slides

onto the bracket and will be in the proper position.

6

Page 7

• LOADS AND LENGTHS: Avoid maximum loads and

pressures at all times. Use only recommended loads from

manuals and information supplied by reliable component

manufacturers and suppliers. Since Dillon Precision has no

control over the components which may be used on their

equipment, no responsibility is implied or assumed for

results obtained through the use of any such components.

Seat bullets as close to maximum cartridge length as

possible. Under some conditions, seating bullets

excessively deep can raise pressures to unsafe levels. Refer

to a reliable loading manual for overall length (OAL).

• QUALITY CHECKS: Every 50-100 rounds, perform

periodic quality control checks on the ammunition being

produced. Check the amount of powder being dropped

and primer supply.

• RELOADING AREA: Keep your components safely

stored. Clear your work area of loose powder, primers and

other flammables before loading.

• COMPONENTS: Never have more than one type of

powder in your reloading area at a time. The risk of a mixup is too great. Keep powder containers closed.

Be sure to inspect brass prior to reloading for flaws,

cracks, splits or defects. Throw these cases away.

Keep components and ammunition out of reach of

children.

• BLACK POWDER: Do not use black powder or black

powder substitutes in any Dillon powder measure.

Loading black powder cartridges requires specialized

loading equipment and techniques. Failure to do so can

result in severe injury or death.

• PRIMERS: Never force primers. If they get stuck in the

operation of the machine, disassemble it and gently

remove the obstruction.

Never attempt to clear primers that are stuck in either

the primer pickup tube or the primer magazine tube.

Never, under any circumstances, insert any type of rod to

attempt to force stuck primers out of these tubes. Trying to

force primers out of the tube will cause the primers to

explode causing serious injury or even death.

If primers get stuck in a primer magazine or pickup

tube flood the tube with a penetrating oil (WD-40), throw

the tube in the garbage and call us for a free replacement.

Never attempt to deprime live primers – eventually one

will go off. When it does it will detonate the others in the

spent primer cup. Depriming live primers is the single

most dangerous thing you can do in reloading and can

cause grave injury or death.

• LOADED AMMUNITION: Properly label all of your

loaded ammunition (Date, Type of Bullet, Primer, Powder,

Powder Charge, etc.).

• BE PATIENT: Our loading equipment is conservatively

rated and you should have no trouble achieving the

published rates with a smooth, steady hand. If something

doesn’t seem right, stop, look and listen. If the problem or

the solution isn’t obvious, call us. The reloading bench is

no place to get into a hurry.

We have done everything we know how to make your

machine as safe as possible. We cannot, however, guarantee

your complete safety. To minimize your risk, use common

sense when reloading and follow these basic rules.

• REMEMBER: If your machine does not perform to your

expectations, or if you are having technical difficulties, give

us a call.

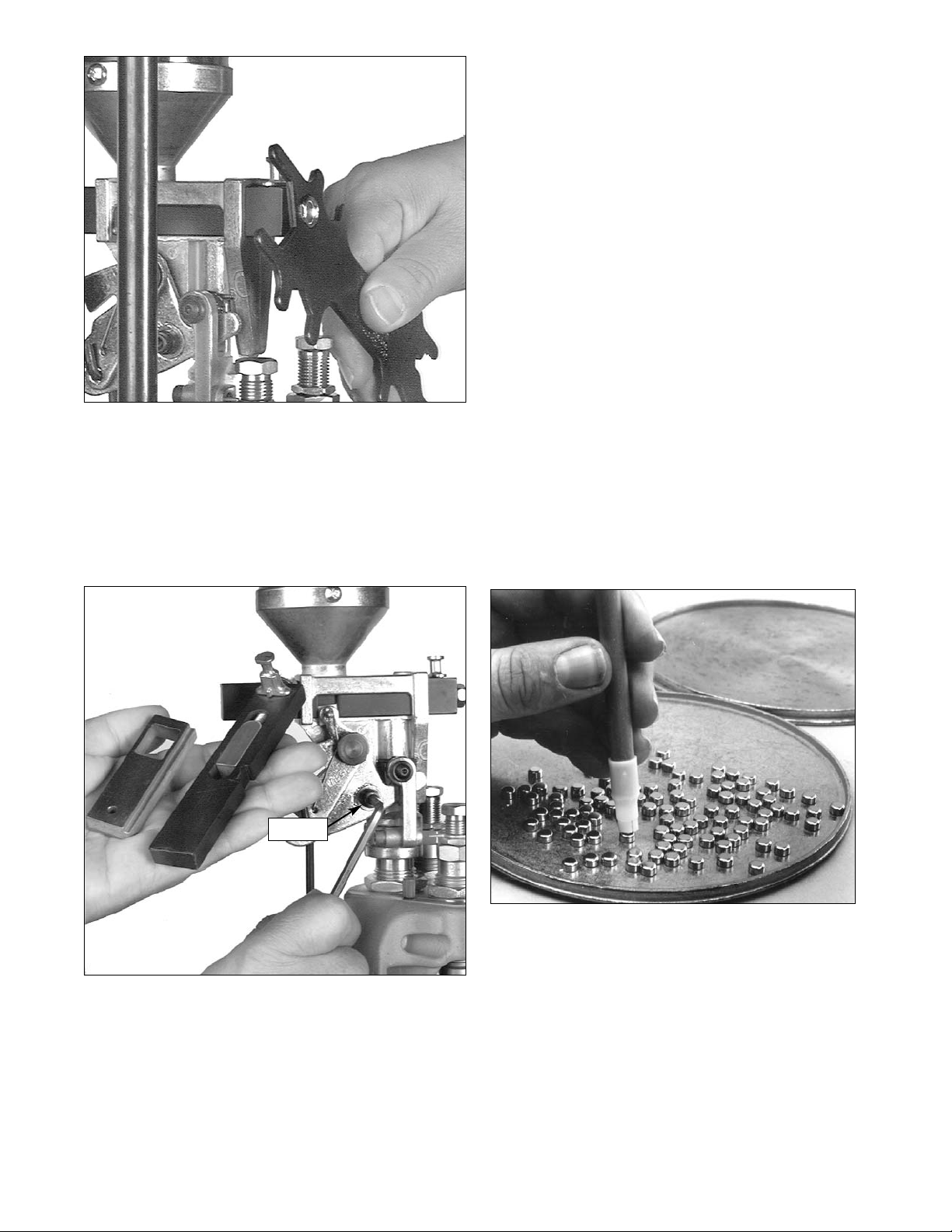

TO BEGIN LOADING

Now that everything is bolted down and you

understand the safety precautions, you can proceed.

First, decide what caliber you want to reload and take

the shellplate (*#20079) from the caliber conversion box,

Fig. 4. Now, in your parts box, find a bag containing; index

ball (#13891), shellplate bolt (#13794), index ball spring

(#13997), set screw (#13923), and index sprocket (#13720).

Insert the index ball spring (#13781) in the platform as

shown in Fig. 5. Next set the index ball on top of the index

ball spring. Now place the shellplate (number up) over the

index ball spring and index ball, Fig. 6.

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

Fig. 4 - This photo shows a complete caliber conversion;

the powder funnel, shellplate and locator buttons.

Fig. 5 - This photo shows the index ball spring and index

ball being placed in the platform.

7

Page 8

Place the index sprocket on top of the shellplate

(making sure the locator posts go into the

corresponding holes in the shellplate, see Fig. 7).

Next, insert the shellplate bolt through the

sprocket and plate and into the center hole of the

platform, Fig. 8. Tighten with the supplied Allen

wrench to the point where you are unable to turn the

sprocket by hand. Now, back off the bolt slightly,

allowing you to push the sprocket easily with your

thumb, Fig. 9. There should be no looseness or slop at

this point and when you rotate the plate, you should

be able to feel and hear the index ball “click” into

place under the shellplate.

Fig. 8 - Inserting the shellplate bolt, first through the index

sprocket then the shellplate.

Fig. 7 - This photo shows the index star in its proper

position: the locating tabs centered in the shellplate.

8

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

Fig. 6 - Showing the shellplate in its proper position:

under the ejector wire with the shellplate number up.

Fig. 9 - This photo shows the proper method of

indexing the shellplate and the proper installation of

the locator buttons.

Page 9

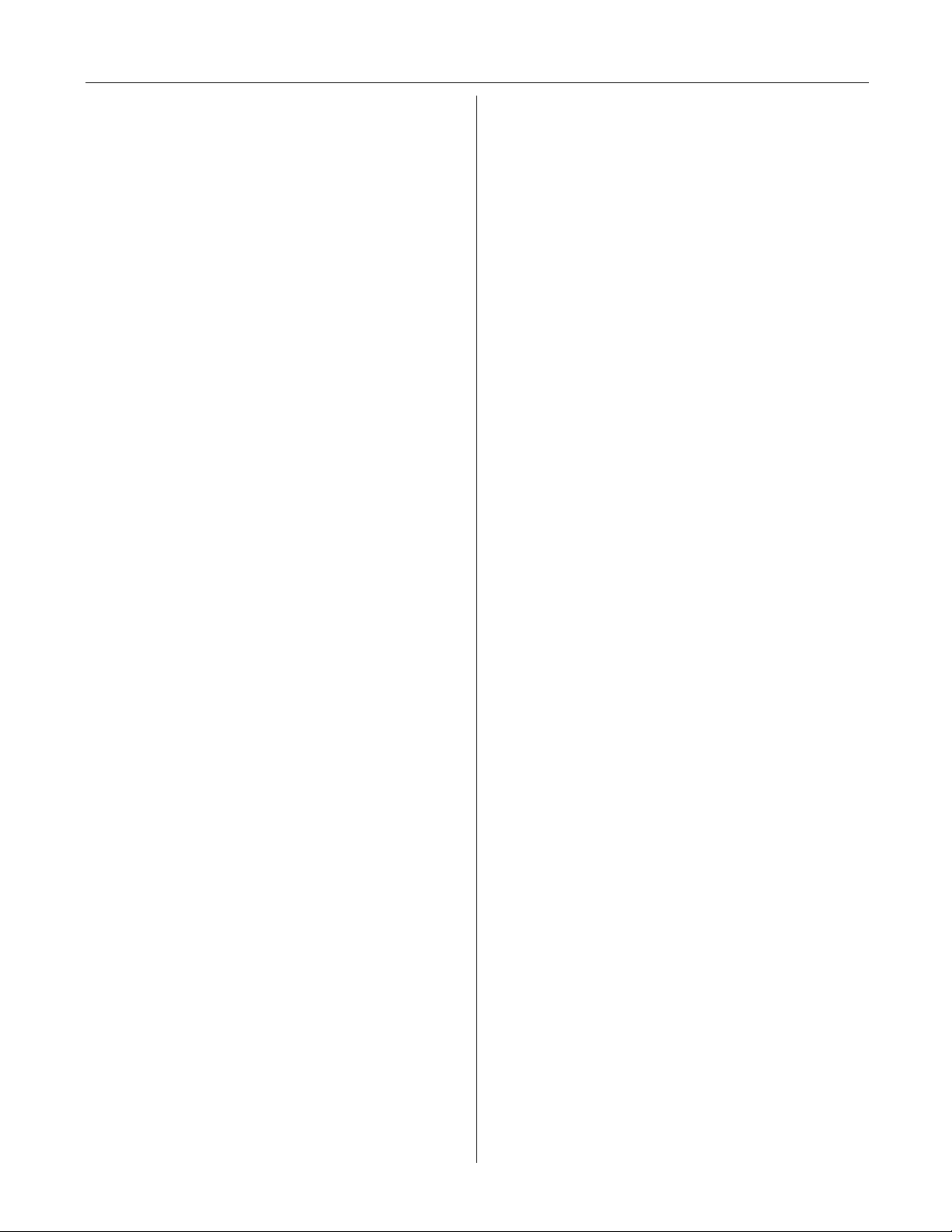

Take the brass tipped set screw (#13923) insert

and tighten securely in the tapped hole beneath the

platform on the left side of the main shaft, Fig. 10.

This will keep the shellplate from tightening as you

use the machine. This screw must be loosened when

changing calibers, something that is often forgotten

as it’s out of sight.

In your caliber conversion box, you will find three

brass locator buttons. These simply drop into the three

remaining holes in the platform, Fig. 9. These

“buttons” hold the cases securely in place while you

are reloading, but by removing them, allow you to take

out a troublesome case, should that occur in your

reloading process.

What Primer Size?

Your RL 550B has been shipped to you with the

primer system installed and correctly adjusted to feed

large primers. If the caliber you have selected to start

with requires small primers, you must change to the

small primer slide bar.

Observe carefully how the factory-adjusted bar fits,

Fig. 11. Raise and lower the platform and notice the

alignment of the primer seating cup (*#13824) as it

enters the platform. This adjustment is made by

turning the cap screw (#14037) on the primer feed

body, Fig. 12. Now remove the two screws from

beneath the frame under the primer feed body, Fig. 13.

Unhook the spring and remove the primer slide. To

replace, reverse this procedure.

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

Fig. 11 - This is the proper alignment of the operating rod

and the position of the primer slide fully forward with the

primer seating cup in the lowered platform.

Fig. 12 - The operating rod has moved the primer slide

into the primer feed body where it will automatically

pick up a primer.

Fig. 10 - Insert the brass tipped set screw (#13923) and

tighten securely.

Fig. 13 - Removing the primer feed body to change primer

slides. Caution do not over tighten these bolts (#14014).

9

This set screw (#13961) adjusts

the outward travel of the primer

slide to align the primer seating

cup with the primer magazine.

Page 10

The operating rod (#13869) must be installed

between the two white rollers before the operation of

the primer slide. Refer to Fig. 12 for the proper

placement of the rod. Unscrew the knurled cap

(#13957) and remove the large primer magazine and

replace with the small primer magazine tube, Fig. 14;

the plastic tip should look like the one you just took

out. Replace the knurled cap.

Wait until you’ve finished assembly before actually

placing primers in the magazine.

You will notice that the primer magazine tube tips

are different colors and have an indexing ridge on the

tip. The magazine tips and the primer pick-up tube tips

are color coded to help identify their size, see page 13

for more information. The indexing ridge is to help

you place the magazine in its proper position in the

primer feed body.

The Toolhead

Your new RL 550B has been shipped to you with

one removable toolhead. Additional toolheads are

available from the factory.

The advantage of this system is simple, once your

dies have been adjusted just the way you want them,

they can stay that way. Plus, changing to another

caliber becomes a simple matter of pulling two pins

and sliding the toolhead out, Fig. 15.

Choose Your Dies

Your RL 550B will perform well with any

manufacturer’s standard 7/8 x 14 die. However, for

ease of use in your RL 550B, the dies should have a

radius on the lead-in portion of the die; that is to say

a taper or funnel effect to assist the entrance of the

case into the die. This is especially recommended on

the sizing die.

We also recommend the use of separate bullet

seating and crimp dies for pistol cases. Simultaneous

seating and taper crimping of semi-auto cases is not

recommended. Why?

Two reasons. First, in a combination seating and

crimping die, we have two forces that are opposed to

one another. That is, forcing the bullet into the case

while trying to simultaneously crimp it in place.

A better idea is to seat the bullet in one die and then

crimp it in place in another. With semi-auto cases

(9mm & .45 ACP) you must use a separate taper crimp

die to get reliable ammunition and function from your

semi-automatic pistol. This type of crimp is necessary

to maintain the square shoulder effect where the brass

edge of the case meets the bullet. It is on this tiny

shoulder that the functioning of your semi-auto pistol

depends. If this shoulder is rounded or roll-crimped,

the cartridge may enter too far into your pistol’s

chamber and jams will result. On revolver

ammunition, where the cartridge headspaces on the

rim of the case, this type of crimp is not as important,

but once again, by using a separate crimp die, you will

obtain better and more uniform bullet seating.

Carbide Dies?

All Dillon pistol resizing dies are manufactured

with a carbide insert. Carbide is one of the world’s

hardest materials and will last the average reloader a

lifetime. It also takes a high polish and being more

dense is smoother than a steel die. Besides its

longevity, it has another advantage. All steel dies

require lubrication of your brass before resizing, but

with a carbide pistol resizing die this is not absolutely

necessary. Lubrication will make sizing easier, but

with a carbide pistol die, it is not required.

However, when using carbide rifle dies, your cases

must always be lubricated.

The advantage of carbide rifle dies is their long life

and scratch resistant qualities. If you are a commercial

reloader, you may want to consider them.

Setting your Pistol Dies

If you’re setting up rifle dies, use the separate

instruction booklet supplied with the dies.

Before you begin, make sure that the toolhead is

secured by the toolhead pins (#14008).

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

Fig. 15 - A complete, removable toolhead with all of the

dies adjusted. Toolhead stand is optional.

Fig. 14 - The machine comes with two primer pickup tubes

(#20060 Lg, #20059 Sm) and two primer magazine tubes

(#22031 Lg, #22030 Sm). Each has a large and small. They are

color coded for easier identification. See page 13 for color

coding information. The large ones should be used together

and the small ones should be used together. You will notice

that the primer magazine tips have an indexing ridge to

assist in their placement in the primer feed system.

10

Page 11

Station One

In the first station, Fig. 16, brass is resized,

deprimed, and then reprimed.

Using the die lock rings provided, screw the sizing

die into the toolhead. Raise the platform and screw the

die down until it touches the shellplate. Then back it

off one-half turn. Lower the platform and insert an

empty case into Station One and cycle the operating

handle. Now check it for sizing and depriming.

If it looks good, raise the platform so the case is in

the die, tighten the lock ring on the die and tighten the

decapping stem. This will keep everything centered.

A note of caution, never attempt to deprime a live

primer. An explosion may result.

Station Two

In the second station, the powder is dropped and

the mouth of the case is belled. This is where the

Automatic Powder System is installed.

First, screw the powder die (#20064) into the

toolhead, Fig. 17. Now insert the pistol powder funnel

(*#13782) or a rifle powder funnel (*#13426) with the

tapered end down, Fig. 18. The funnel should move

freely in the die.

Set the powder measure assembly onto the powder

die, Fig. 19. The powder measure clamp (#13939)

should fit loosely around the die, tighten the screws

just a little. This will enable you make adjustments to

the die easily, Fig. 19.

Fig. 16 - A fully loaded shellplate, directly below the

proper dies. Clockwise from Station One, the cartridge at

this station is resized, deprimed and reprimed. Notice the

cartridge retaining spring holding the case in place.

Station Two bells the case mouth (pistol only) and

dispenses the powder. Station Three seats the bullet.

Station Four crimps the bullet.

Fig. 17 - This photo shows the powder die in its correct

position (Station Two) in the toolhead. The powder die

may be higher or lower depending on the caliber it is being

adjusted for

.

Fig. 18 - Drop the powder funnel into the powder die

tapered end first. The funnel should move freely in the die.

Fig. 19 - The powder die can be easily adjusted by turning

the die beneath the toolhead while holding the powder

measure securely from above.

11

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

Page 12

On rifle cases, the die should be adjusted so that the

powder funnel will contact the mouth of the case and

then fully actuate the powder bar, Fig. 20 & 21. These

adjustments are accomplished with a case in the

shellplate and alternately raising and lowering the

operating handle, while adjusting the powder die, Fig.

19. When properly adjusted, the powder bar will be

moved to its full rearward position by the case, Fig. 20

& 21. When you have determined that your

adjustments are correct, tighten the lock ring and the

locking collar.

Next, attach the powder measure fail safe rod

assembly to the bellcrank (#17839). Using your thumb

and index finger of your right hand, move the locklink down to align the hole with the slot on the

Powder Measure bellcrank (#17839). Then insert the

rod (#97000) through the two holes, Fig. 20. Next,

lower the operating handle (#20636). Insert the powder

measure rod into the slot in the return bracket (#13885)

press the shoulder washer into the slot from the

bottom. Move the operating handle to the priming

position, press the operating handle firmly forward.

Tighten the blue wingnut (#13799) until the top of the

spring (#14033) just touches the underside of the

return bracket (#13885). We’ll come back to filling the

measure with powder and adjusting the bar. The

purpose of the powder measure failsafe rod (#97000) is

to return the powder bar to its closed position.

Station Three

In this station the bullet is seated to its proper

depth. You need to refer to a loading manual for

overall length of the completed round.

Put a case into the shellplate at Station Three. Raise

the platform up and screw the die down until it just

touches the shellplate and back it out two turns. Now,

back your seating stem out.

Place a bullet on the case and operate the handle.

Using a dial caliper or case gage, check for overall

length. Keep screwing the seating stem down in small

increments until the correct overall length is achieved.

Once you are satisfied with the overall length, tighten

the lock ring.

Station Four

The crimping operation is performed at this station.

Insert the crimp die and place an empty case in

Station Four. Raise the platform and screw the

crimping die down until it touches the rim of the case.

Now lower the platform and screw the die down an

additional one-quarter of a turn. Place a round in

Station Four with a seated bullet and cycle the

operating handle.

You will need to refer to a loading manual to get

proper crimp dimensions for the caliber you are

loading. A dial caliper is required to take accurate

measurements from your crimped round.

If more crimp is needed, screw the crimp die down

in small increments until you get the desired crimp,

now tighten the lock ring.

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

12

Fig. 20 - This photo shows the large powder bar in its

closed position. (Primer system removed for clarity.)

Fig. 21 - This photo shows the large powder bar in its fully

open position. (Primer system removed for clarity.)

Page 13

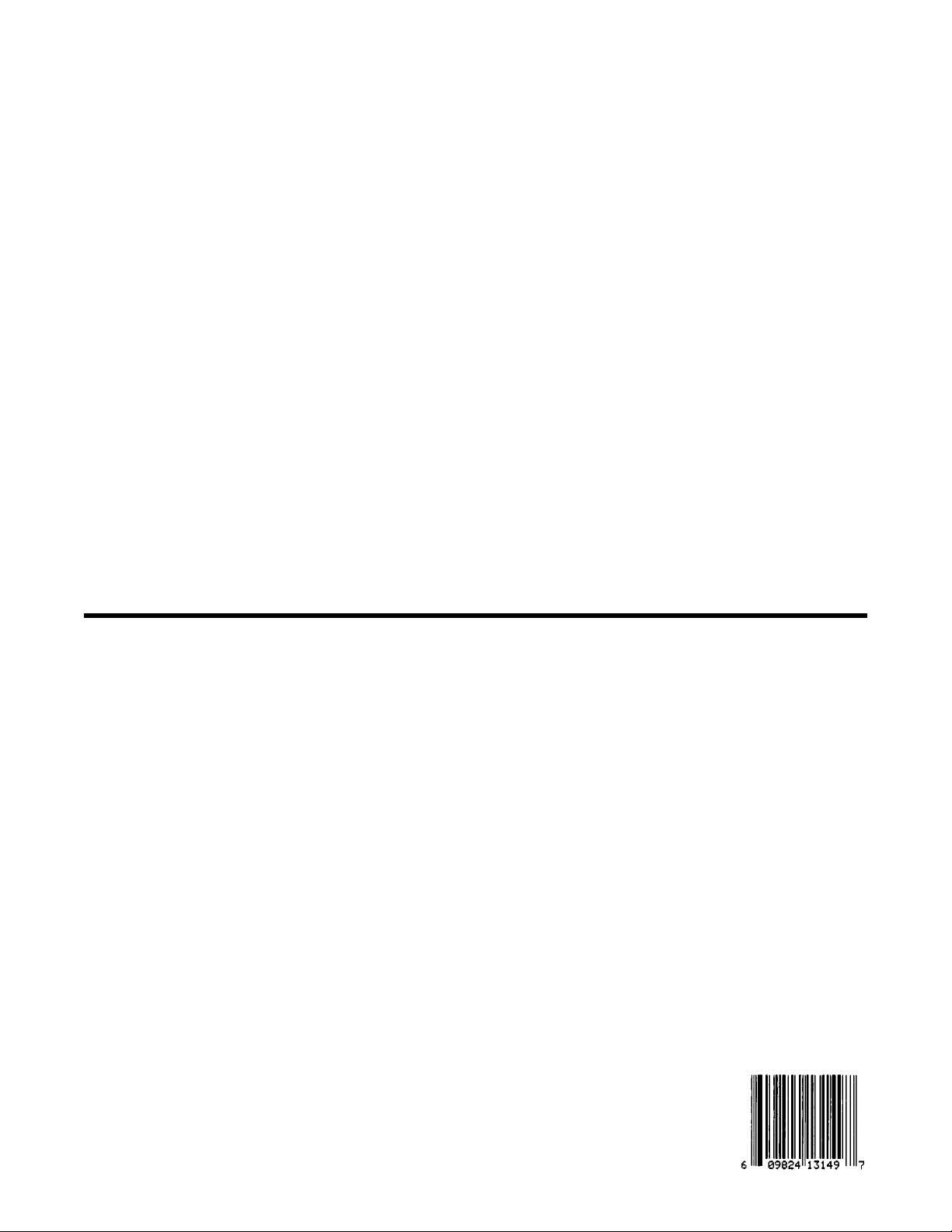

Adjusting the Powder Charge

You will notice an adjusting bolt on the back of the

powder bar, Fig. 22.. Turning the bolt counterclockwise reduces your powder charge, clockwise

increases the charge. Your machine comes with two

powder bars – one large and one small.

Rule of thumb: Use the large bar whenever

possible. These bars are easily changed, Fig. 23. Use a

reloading manual to determine how much powder

you need for a particular load and an accurate

powder scale to determine the weight. A high quality

precision powder scale is available from Dillon. You

should now fill the powder measure with your

chosen powder. Place an empty case under the

measure and operate the machine's handle. Then, by

trial and error adjustments, determine the correct

weight of your powder charge. You are now ready to

fill the primer magazine.

Primer Early Warning System Installation

(See item #20302 on page five for assistance.)

Remove the follower rod (#13707) from the

assembly bag and set it aside. Install the battery and

the battery cover (#13857) in the system’s main body.

Slide the Early Warning System assembly down over

the knurled cap on your primer magazine (#13957) and

lightly tighten the clamp screw.

Primer Magazine

You will notice that the primer magazines and

primer pick-up tubes have different colored tips.

They have been color coded to help you identify

size more easily.

The color code is as follows:

Blue Small Primer Magazine Orifice

Red Large Primer Magazine Orifice

Yellow Small Primer Pick-up Tube

Green Large Primer Pick-up Tube

Select the proper size pick-up tube and fill it by

placing the plastic expandable tip over loose primers

and pressing down. The shiny sides of the primers

need to be facing up, Fig. 24.

This is most easily accomplished by using a primer

flip tray, which will arrange them all for you, Fig. 24. A

quality cast metal flip tray is available from Dillon and

is a better choice than the smaller plastic trays which

are difficult to use and have a tendency to warp.

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

Fig. 24 - Use of the primer pickup tube and the Dillon

Primer flip tray.

Fig. 22 - Turning the bolt counter- clockwise reduces

your powder charge, clockwise increases the charge.

Fig. 23 - After emptying the powder measure, loosen the

bellcrank screw (#13904) sufficiently to allow you to

remove the powder bar. Insert the new powder bar and

reverse this procedure.

13

#13904

Page 14

Once you’ve filled the pick-up tube, make sure the

little retaining clip is in place at the top of the tube.

Pivot the switch lever (#13864) away from the Early

Warning System housing. Invert the pick-up tube over

the knurled cap (#13957) of the primer magazine, Fig.

25. You will notice the cap has a bevel to help you

funnel the primers in. Hold the tube in place, pull the

retaining clip and allow the primers to drop into the

magazine. Pivot the switch lever back over the Early

Warning System housing. Gently slide the follower rod

down into the primer magazine tube until the follower

rod touches the primers.

When you are nearly out of primers (about three

left) the follower rod (#13707) will activate the buzzer.

A word of caution: primers are easily detonated,

sometimes by a remarkably light blow. Treat them as if

they are as fragile as eggs. Never force them.

At Last

If you’ve followed instructions, you are now ready

to load.

Many reloaders develop their own style when

using the RL 550B. But, let me explain the most

efficient method. Try it and later, if you want to make

changes in your technique, go ahead.

Place your bullets in a box to the left of the RL 550B

and the empty cases in a box to the right. A few extra

cartridge collection bins (#13839) are ideal for this.

You will notice an adjustable retaining spring at

Station One. This spring should be adjusted to almost

contact the case when it’s placed in the shellplate.

Now, with your right hand, place a case in Station

One and smoothly pull the operating handle. This

resizes and decaps this case, at the same time your

primer slide should be automatically carried back to

the primer magazine, where it will pick up a primer.

Now, raise the handle smoothly. The primer slide

(#13920) will come forward with a primer and place it

under the deprimed case. If you are using the handle

gently, you will feel the primer contact the primer

pocket. Press forward firmly until the handle stops.

Your primer will now be seated.

Advance the case to the second Station by pressing

on the index sprocket (#13720) with your left thumb.

Place another empty case into Station One and pull the

operating handle. Station One will repeat as before.

Station number two will bell the case mouth and

dispense the powder. Again, raise the handle, index

with your thumb and place a bullet on the powder

charged case at Station Three with your left hand, Fig.

7. With your right hand, install a new case at Station

One and pull the handle. Stations one and two will

repeat as before.

Station Three will seat the bullet. Index with your

left thumb and put in a bullet. Put an empty case into

Station One with your right and operate the handle.

Stations one, two and three will repeat: Station Four

will have crimped the bullet. Index again and your first

completed round will tumble into the cartridge

collection bin. Now just add a bullet and a case. Each

time you operate the handle you’ll get a loaded round.

Works good, right? If not, go back over the procedure.

If it’s not right you need to do some...

Trouble Shooting

Use 30 weight motor oil on the main shaft and

bearing grease on the pivot pins. Do not use spray type

penetrating lube such as WD40 or Break Free as you

run the risk of contaminating powder and primers.

Problem One. Primers are not seated deeply

enough.

A. Shellplate too loose.

B. Shellplate upside down. You should be able to

see a stamped shellplate number facing up.

C. The crimp in the primer pockets of military brass

will cause this problem. Crimps can be easily removed

by use of a Dillon Primer Pocket Swage.

Problem Two. Erratic powder bar operation:

A. Turn the powder die (#20064) clockwise in oneeighth turn increments. This will insure complete

powder bar activation.

B. Extruded pencil type powders will not flow

smoothly through smaller sized powder funnels

because of their length. Another problem with

extruded powders is getting them into small necked

cases. Many times these powders will “bridge” across

the case mouth and cause spillage and erratic charges,

There is no fast way of dispensing these powders and

if you insist on using them in small mouthed cases it

is best to weigh every charge by hand. Modern ball

type powders will do for most reloading situations.

These powders will do everything the pencil powders

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

14

Fig. 25 - Drop the primers into the primer magazine.

Page 15

15

will do, but without this problem. Warning: Do not

use I.M.R. pencil lead type powder in cases smaller

than .30 caliber.

Problem 3. Primer jams or misfeeds.

A. Primer misfeeds can be caused by

misadjustment of the set screw (#13961) in the primer

feed block, Fig. 12.

B. The most common cause of primer misfeeds or

jams is the primer punch not seated fully into the

primer slide. This will cause the primer seating cup to

strike the flexible orifice on the bottom of the primer

magazine tube.

Warning: If the primers are jammed and will not

feed from the bottom of the primer magazine, Do Not

Attempt to force the primers or the primer slide. An

explosion resulting in injury may occur.

C. Another common problem is that the primer

slide fails to return fully forward with the new primer.

Periodically wipe the primer slide with rubbing

alcohol. This removes the spent primer residue that

causes the slide to drag.

Problem 4. Crushing cases:

A. If your dies do not have a radiused lead-in you

must guide the cases into the die. The best solution is

to replace the offending dies with dies having the

proper radius.

B. Always tighten your die lock rings with a case in

the die. This will assure you of proper alignment

between the die and the shellplate. Adjust your

depriming stem in the same manner and it will always

be on center.

REMEMBER

Be sure to use the necessary precautions when

loading lead bullets or when casting lead bullets.

Exposure to lead can cause cancer, birth defects, and

reproductive problems. Be sure to wash your hands

thoroughly after handling lead. When firing lead

bullets, be sure that you have adequate ventilation.

Keep any lead items out of reach of children.

Press forward firmly on the handle once it is at the

aft position to seat your primers fully.

Watch the powder bar function to make sure you’re

getting powder.

Set the bullet straight on the case at Station Three so

that it enters the die correctly.

Watch your supply of powder, you’ll be using it

faster than you think you are.

Take your time and learn the machine and its

function. The RL 550B will deliver hundreds of trouble

free rounds in short order, just relax and take your

time in the beginning.

Keep it clean – primer residue, spilled powder and

just plain dirt can jam your machine.

Clean your powder bar about every 500 rounds.

Some powders build up and will eventually stick the

powder bar. Paint thinner, acetone or lacquer thinner

works well to remove any build up.

NOTICE

This machine is designed specifically to be a

manually operated handloading machine. Any

attempts to automate this product will void any and all

warranties offered by the company. We specifically

warn against converting this product to automated or

motorized operation.

All Dillon machines are warranted for life from

defects in material or workmanship, plus a one year

100% warranty against normal wear. All

electrical/electronic components in Dillon equipment

are covered by a one year warranty.

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

Page 16

16

Conversion Powder Shellplate Locator

Handgun Calibers Kit Funnel Button

.30 Luger #20175 C - #13564 5 - #13743 3

.30 Mauser #20174 C - #13564 5 - #13743 3

.32 ACP - 7.65mm #20160 S - #12845 8 - #13135 8

.32 S&W Long #20146 S - #12845 D - #13092 3

.32 Short Colt #20160 S - #12845 8 - #13135 8

.380 ACP #20133 F - #13806 3 - #13684 3

9x18 #21656 9 - #14980 5 - #13743 3

9mm Luger #20127 F - #13806 5 - #13743 3

9x25 Dillon/.357 Sig. #21526 F - #13806 5 - #13743 2

.38 S&W #20159 F - #13806 U - #12944 2

.38 AMU #20278 F - #13806 O - #12013 3

.38 Super #20127 F - #13806 5 - #13743 3

.38 Sp.-.357 Mag./Max. #20132 D - #13599 2 - #13751 2

10mm/.40 S&W #20179 W - #13600 5 - #13743 2

.41 AE #20277 AE - #13180 5 - #13743 3

.41 Mag. #20135 H - #13240 6 - #13120 1

.44 Sp. - Mag. #20136 G - #13427 4 - #13610 4

.45 ACP #20126 E - #13782 1 - #13692 1

.45 Auto Rim #20158 E - #13782 H - #13010 4

.45 Colt #20137 E - #13782 C - #13334 4

.45 Win. Mag. #20221 E - #13782 L - #12703 1

.454 Casull #20137 E - #13782 C - #13334 4

.50 AE #21428 50AE - #14465 50 - #13147 4

Rifle Calibers

.17 Rem. #20203 O - #12921 3 - #13684 3

.218 Bee #20151 A - #13426 O - #12013 3

.219 Zipper/Donaldson #20180 A - #13426 7 - #12501 4

.220 Swift #20154 A - #13426 L - #12703 1

.221 Rem. Fire Ball #20128 A - #13426 3 - #13684 3

.222 Rem. - Rem. Mag. #20128 A - #13426 3 - #13684 3

.22-250 #20145 A - #13426 1 - #13692 1

.223 - 5.56 mm #20128 A - #13426 3 - #13684 3

.224 Wby. Mag. #20235 A - #13426 A - #13211 2

.225 Win. #20181 A - #13426 L - #12703 1

.22 Hornet - K Hornet #20150 A - #13426 E - #12957 8

.22 Rem. Jet #20165 A - #13426 2 - #13751 2

.22 Savage Hi Power #20180 A - #13426 7 - #12501 4

.240 Wby. Mag. #20192 I - #13305 1 - #13692 1

.243 Win. #20192 I - #13305 1 - #13692 1

.250 Savage-.250/3000 #20147 K - #13216 1 - #13692 1

.25-06 #20147 K - #13216 1 - #13692 1

.25-20 Win. #20176 543R - #13243 O - #12013 3

.25-35 Win. #20197 K - #13216 7 - #12501 4

.256 Win. Mag. #20215 543R - #13243 2 - #13751 2

.257 Ack. Imp #20147 K - #13216 1 - #13692 1

.257 Roberts #20147 K - #13216 1 - #13692 1

.257 Wby. Mag. #20199 K - #13216 B - #13347 4

.25 Rem. #20233 K - #13216 R - #13497 2

.264 Win. Mag. #20210 Y - #12870 B - #13347 4

.270 Wby. Mag. #20196 J - #13456 B - #13347 4

.270 Win. #20142 J - #13456 1 - #13692 1

.284 Win. #20142 J - #13456 1 - #13692 1

.30 M1 Carbine #20131 C - #13564 8 - #13135 8

.300 Win. Mag. #20188 B - #13587 B - #13347 4

.30-06 #20138 B - #13587 1 - #13692 1

.300 H&H Mag. #20188 B - #13587 B - #13347 4

.300 Savage #20190 B - #13587 1 - #13692 1

.300 Wby. Mag. #20188 B - #13587 B - #13347 4

.303 British #20183 B - #13587 4 - #13610 4

.30-30 Win. #20139 B - #13587 7 - #12501 4

.30-338 Win. Mag. #20188 B - #13587 B - #13347 4

Conversion Powder Shellplate Locator

Rifle Calibers cont... Kit Funnel Button

.30-40 Krag #20185 B - #13587 P - #13134 4

.307 Win. #20237 B - #13587 L - #12703 1

.308 - 7.62 Nato #20130 B - #13587 1 - #13692 1

.308 Norma Mag. #20188 B - #13587 B - #13347 4

.30 Herret #20214 AK - #13015 7 - #12501 4

.30 Merrill #20231 AK - #13015 L - #12703 1

.30 Rem. -32 Rem. #20184 B - #13587 R - #13497 2

.32-20 Win. #20177 S - #12845 O - #12013 3

.32-40 Win. #20139 B - #13587 7 - #12501 4

.32 H&R Mag. #20146 S - #12845 D - #13092 3

.32 Win. Sp. #20139 B - #13587 7 - #12501 4

.33 Win. #20202 Q - #13406 G - #13313 7

.338 Win. Mag. #20156 Q - #13406 B - #13347 4

.340 Wby. Mag. #20156 Q - #13406 B - #13347 4

.348 Win. #20217 P - #13187 T - #12808 7

.350 Rem. Mag. #20167 P - #13187 B - #13347 4

.356 Win. #20238 P - #13187 L - #12703 1

.357 Herrett #20172 D - #13599 7 - #12501 4

.358 Win. #20170 P - #13187 1 - #13692 1

.358 Norma Mag. #20167 P - #13187 B - #13347 4

.35 Rem. #20166 P - #13187 M - #13230 2

.35 Whelen #20170 P - #13187 1 - #13692 1

.35 Win. #20168 P - #13187 P - #13134 4

.375 H&H/Wby Mag. #20204 544R - #13531 B - #13347 4

.375 Super Mag. #20226 543V - #13344 7 - #12501 4

.378 Wby. Mag. #21665 544378 - #15010 G - #13313 7

.38-40 Win. #20178 W - #13600 N - #10004 4

.38-55 Win. Ballard #20226 543V - #13344 7 - #12501 4

.444 Marlin #20164 543X - #12920 N - #10004 4

.44-40 Win. #20206 G - #13427 N - #10004 4

.45-70 Gov’t #20143 543T - #13407 G - #13313 7

.416 Rem. Mag. #20771 544RM - #13415 B - #13347 4

.455 Webley #20137 E - #13782 C - #13334 4

.458 Win. Mag. #20161 543T - #13407 B - #13347 4

.460 Wby. Mag. #21664 544460 - #15009 G - #13313 7

6.5-06 #20207 Y - #12870 1 - #13692 1

6.5 x 52 Carcano #20208 Y - #12870 M - #13230 2

6.5 mm x 54 Mann-Scho #20208 Y - #12870 M - #13230 2

6.5 x 55 Swed Mauser #20207 Y - #12870 1 - #13692 1

6.5 Japanese Arisaka #20209 Y - #12870 L - #12703 1

6.5mm Rem. Mag. #20210 Y - #12870 B - #13347 4

6mm Rem.- .244 #20192 I - #13305 1 - #13692 1

7mm-08 Rem. #20142 J - #13456 1 - #13692 1

7.62 x 39 Russian #20213 AK - #13015 A - #13211 2

7.62 x 54 Russian #20346 B - #13587 G - #13313 7

7x 57 Mauser #20142 J - #13456 1 - #13692 1

7 x 64 Brenneke #20142 J - #13456 1 - #13692 1

7.7 Japanese Arisaka #20130 B - #13587 1 - #13692 1

7mm BR #20216 N - #13014 1 - #13692 1

7mm Ex - 280 Rem. #20142 J - #13456 1 - #13692 1

7mm Rem. Mag. #20140 J - #13456 B - #13347 4

7mm Merrill #20230 N - #13014 L - #12703 1

7mm Int’l Rimmed #20223 N - #13014 7 - #12501 4

7mm TCU #20141 N - #13014 3 - #13684 3

7mm Wby. Mag. #20196 J - #13456 B - #13347 4

7-30 Waters #20223 J - #13456 7 - #12501 4

7.5 x 55 Swiss #20130 B - #13587 1 - #13692 1

7.65 Bel-Arg #20130 B - #13587 1 - #13692 1

8mm Mauser #20201 M - #12963 1 - #13692 1

8mm Rem. Mag. #20155 M - #12963 B - #13347 4

RL 450 & RL 550B Caliber Conversion Chart

Kits include shellplate, locator buttons and flow thru powder funnel.

Page 17

Shellplate 1 Locator Button 1

Powder Funnel

.22-250 A - #13426

.30-06 B - #13587

.300 Savage AK - #13015

.308 - 7.62 Nato B - #13587

7.7 Japanese Arisaka B - #13587

7.5 x 55 Swiss B - #13587

7.65 Bel-Arg B - #13587

.45 ACP E - #13782

.240 Wby. Mag. I - #13305

.243 Win. I - #13305

6mm Rem.- .244 I - #13305

.270 Win. J - #13456

.284 Win. J - #13456

7mm-08 Rem. J - #13456

7x 57 Mauser J - #13456

7 x 64 Brenneke J - #13456

7mm Ex - 280 Rem. J - #13456

.250 Savage-.250/3000 K - #13216

.25-06 K - #13216

.257 Ack. Imp K - #13216

.257 Roberts K - #13216

8mm Mauser M - #12963

7mm BR N - #13014

7mm Int’l N - #13014

.358 Win. P - #13187

.35 Whelen P - #13187

6.5-06 Y - #12870

6.5 x 55 Swed Mauser Y - #12870

Shellplate 2 Locator Button 2

.256 Win. Mag. 543R - #13243

.22 Rem. Jet A - #13426

.38 Sp.-.357 Mag./Max. D - #13599

Shellplate 3 Locator Button 3

.221 Rem. Fire Ball A - #13426

.222 Rem. - Rem. Mag. A - #13426

.223 - 5.56 mm A - #13426

.380 ACP F - #13806

7mm TCU N - #13014

.17 Rem. O - #12921

Shellplate 4 Locator Button 4

.303 British B - #13587

.44 Sp. - Mag. G - #13427

Shellplate 5 Locator Button 2

9x25 Dillon/.357 Sig. F - #13806

10mm/.40 S&W W - #13600

Shellplate 5 Locator Button 3

9x18 9 - #14980

.41 AE AE - #13180

.30 Luger C - #13564

.30 Mauser C - #13564

9mm Luger F - #13806

.38 Super F - #13806

Shellplate 6 Locator Button 1

.41 Mag. H - #13240

Shellplate 7 Locator Button 4

Powder Funnel

.375 Super Mag. 543V - #13344

.38-55 Win. Ballard 543V - #13344

.219 Zipper A - #13426

.219 Donaldson A - #13426

.22 Savage Hi Power A - #13426

.30 Herret AK - #13015

.30-30 Win. B - #13587

.32-40 Win. B - #13587

.32 Win. Sp. B - #13587

.357 Herrett D - #13599

7-30 Waters N - #13014

.25-35 Win. K - #13216

7mm Int’l Rimmed N - #13014

Shellplate 8 Locator Button 8

.30 M1 Carbine C - #13564

.32 ACP - 7.65mm S - #12845

.32 Short Colt S - #12845

Shellplate 50 Locator Button 4

.50 AE 50AE - #14465

Shellplate A Locator Button 2

.224 Wby. Mag. A - #13426

7.62 x 39 Russian AK - #13015

Shellplate B Locator Button 4

.458 Win. Mag. 543T - #13407

.375 H&H 544R - #13531

.375 Wby Mag. 544R - #13531

.416 Rem. Mag. 544RM - #13415

.300 Win. Mag. B - #13587

.300 H&H Mag. B - #13587

.300 Wby. Mag. B - #13587

.30-338 Win. Mag. B - #13587

.308 Norma Mag. B - #13587

.270 Wby. Mag. J - #13456

7mm Rem. Mag. J - #13456

7mm Wby. Mag. J - #13456

.257 Wby. Mag. K - #13216

8mm Rem. Mag. M - #12963

.350 Rem. Mag. P - #13187

.358 Norma Mag. P - #13187

.338 Win. Mag. Q - #13406

.340 Wby. Mag. Q - #13406

.264 Win. Mag. Y - #12870

6.5mm Rem. Mag. Y - #12870

Shellplate C Locator Button 4

.45 Colt E - #13782

.454 Casull E - #13782

.455 Webley E - #13782

Shellplate D Locator Button 3

.32 S&W Long S - #12845

.32 H&R Mag. S - #12845

Shellplate E Locator Button 8

.22 Hornet - K Hornet A - #13426

Shellplate G Locator Button 7

Powder Funnel

.45-70 Gov’t 543T - #13407

.378 Wby. Mag. 544378 - #15010

7.62 x 54 Russian B - #13587

.33 Win. Q - #13406

.460 Wby. Mag. 544460 - #15009

Shellplate H Locator Button 4

.45 Auto Rim E - #13782

Shellplate L Locator Button 1

.220 Swift A - #13426

.225 Win. A - #13426

.30 Merrill AK - #13015

.307 Win. B - #13587

.45 Win. Mag. E - #13782

7mm Merrill N - #13014

.356 Win. P - #13187

6.5 Japanese Arisaka Y - #12870

Shellplate M Locator Button 2

.35 Rem. P - #13187

6.5 x 52 Carcano Y - #12870

6.5 mm x 54 Mann-Scho Y - #12870

Shellplate N Locator Button 4

.444 Marlin 543X - #12920

.44-40 Win. G - #13427

.38-40 Win. W - #13600

Shellplate O Locator Button 3

.25-20 Win. 543R - #13243

.218 Bee A - #13426

.38 AMU F - #13806

.32-20 Win. S - #12845

Shellplate P Locator Button 4

.30-40 Krag B - #13587

.35 Win. P - #13187

Shellplate R Locator Button 2

.30 Rem. -32 Rem. B - #13587

.25 Rem. K - #13216

Shellplate T Locator Button 7

.348 Win. P - #13187

Shellplate U Locator Button 2

.38 S&W F - #13806

RL 450 & RL 550B Caliber Cross Reference Chart

17

Page 18

Dillon Precision Products, Inc.

8009 E. Dillon’s Way

Scottsdale, AZ 85260

(480) 948-8009

FAX (480) 998-2786

Web Site: www.dillonprecision.com

E-mail: dillon@dillonprecision.com

Technical Support & Customer Service

(800) 223-4570

On the cover…

The RL 550B is pictured with optional accessories:

Strong Mount #22051

Aluminum Roller Handle #17950

Low Powder Sensor #16306

Bullet Tray #22214

Other accessories available for the RL 550B include:

Video Instruction Manual #14621

Machine Cover #13795

Maintenance Kit & Spare Parts Kit #97016

The Blue Press, Dillon’s monthly catalog, has a complete listing

of accessories available for all machines.

Loading...

Loading...