Page 1

RL 1050

Instruction Manual

Version 3.3

illon

recision

Products, Inc.

Manufacturers of

The World's Finest

Loading Equipment

Page 2

#13385 Spot Manuals RL1050 Man Folder RL1050 Manual V3.3 9/01 WJC

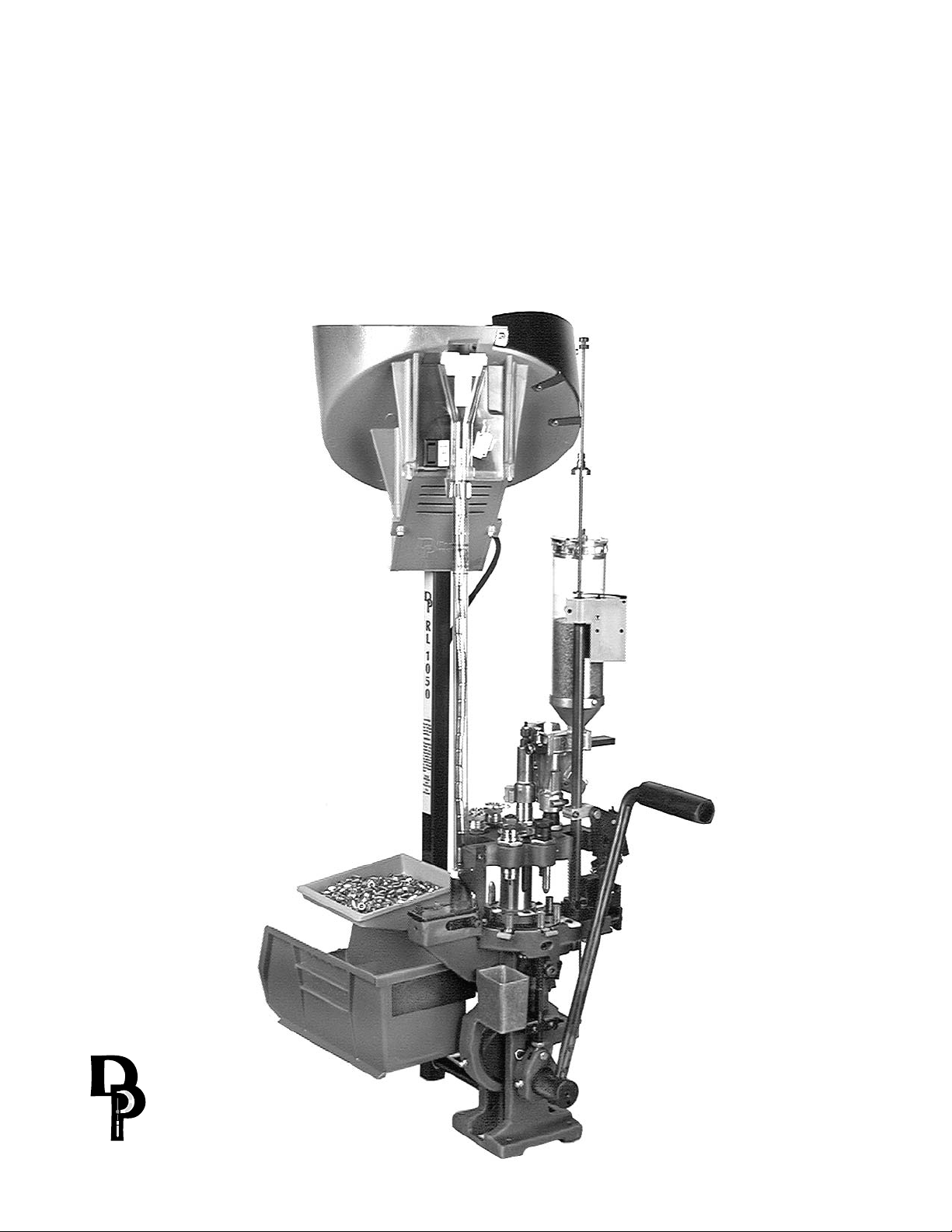

On the cover…

The RL 1050 is pictured with optional accessories:

Powdercheck System #21044

Low Powder Sensor #16306

Bullet Tray #22215

Other accessories available for the RL 1050 include:

Machine Cover #13239

Maintenance Kit & Spare Parts Kit #97018

The Blue Press, Dillon’s monthly catalog, has a complete listing

of accessories available for all machines.

Page 3

Table of Contents

Warranty Agreement 4

Mandatory Safety Measures 4

RL1050 Assembly 5

Powder Measure Adjustment 8

Primer Magazine 9

Electric Casefeeder 10

How the RL1050 Works – Stations 1 - 8 10

To Begin Reloading 11

Adjustments and Conversions: 11

Casefeeder 11

Handle 12

Swager 12

Swage Conversion & Adjustment 12

Primer System Change Over Instructions 12

Toolhead Removal 13

Shellplate Removal 14

Casefeed Plunger Conversion 14

Die Adjustments 14

Older Model Users 15

Trouble Shooting 16

Maintenance 17

Definitions 17

Caliber Conversion Chart 19

Parts List 20

Schematics 21 - 25

Page 4

4

Warranty Agreement

The Dillon RL1050 reloader has been designed as a

commercial machine. Our expectation is that its life

expectancy will be in excess of two million rounds of

loaded ammunition. All RL1050 machines are

warranted for life from defects in material or

workmanship, plus a one year 100% warranty against

normal wear. All electrical/electronic components in

Dillon equipment are covered by a one year warranty.

However, the RL1050 is a complex machine and we

need your cooperation. So there’s a hitch. All we ask is

that you take the time to read the following information

and fill out the warranty registration card stating that

you have done so.

Mandatory Safety Measures

The reloading of ammunition and the handling of

components (gun powder and primers) is inherently

dangerous, indeed shooting firearms is inherently

dangerous. Accidents can and do occur, sometimes with

disastrous results including, but not limited to, loss of

vision, hearing or life. These accidents are

nondiscriminatory, they occur with both the novice and

the experienced reloader.

Dillon Precision Products has consciously designed

the RL1050 with this in mind. We’ve shielded the primer

magazine and machined clearance holes for the

elimination of powder and primer residue. In short, we

have done everything we know how, to make the use of

our machine as safe as possible. We cannot however,

guarantee your complete safety. In order to minimize

your risk, use common sense when reloading and follow

these basic rules:

Never operate the machine without ear and eye

protection on. Call our customer service department at

(800) 223-4570 for information on the wide variety of

shooting/safety glasses and hearing protection that

Dillon has to offer.

• PAY ATTENTION: Load only when you can give your

complete attention to the loading process. Don’t watch

television or try to carry on a conversation and load at

the same time. Watch the automatic systems operate and

make sure they are functioning properly. If you are

interrupted or must leave and come back to your

loading, always inspect the cases at every station to

insure that the proper operations have been

accomplished.

• SMOKING: Do not smoke while reloading or allow

anyone else to smoke in your reloading area. Do not

allow open flames in reloading area.

• SAFETY DEVICES: Do not remove any safety devices

from your machine or modify your machine in any way.

• LEAD WARNING: Be sure to have proper ventilation

while handling lead components or when shooting lead

bullets. Lead is known to cause birth defects, other

reproductive harm and cancer. Wash your hands

thoroughly after handling anything made of lead.

• LOADS AND LENGTHS: Avoid maximum loads and

pressures at all times. Use only recommended loads

from manuals and information supplied by reliable

component manufacturers and suppliers. Since Dillon

Precision has no control over the components which

may be used on their equipment, no responsibility is

implied or assumed for results obtained through the use

of any such components.

Dillon Precision Products, Inc.

8009 E. Dillon’s Way

Scottsdale, AZ 85260

(480) 948-8009

FAX (480) 998-2786

Web Site: www.dillonprecision.com

E-mail: dillon@dillonprecision.com

Technical Support & Customer Service

(800) 223-4570

Page 5

5

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

Seat bullets as close to maximum cartridge length as

possible. Under some conditions, seating bullets

excessively deep can raise pressures to unsafe levels.

Refer to a reliable loading manual for overall length

(OAL).

• QUALITY CHECKS: Every 50-100 rounds, perform

periodic quality control checks on the ammunition being

produced. Check the amount of powder being dropped

and primer supply.

• RELOADING AREA: Keep your components safely

stored. Clear your work area of loose powder, primers

and other flammables before loading.

• COMPONENTS: Never have more than one type of

powder in your reloading area at a time. The risk of a

mix-up is too great. Keep powder containers closed.

Be sure to inspect brass prior to reloading for flaws,

cracks, splits or defects. Throw these cases away.

Keep components and ammunition out of reach of

children.

• BLACK POWDER: Do not use black powder or black

powder substitutes in any Dillon powder measure.

Loading black powder cartridges requires specialized

loading equipment and techniques. Failure to do so can

result in severe injury or death.

• PRIMERS: Never force primers. If they get stuck in

the operation of the machine, disassemble it and gently

remove the obstruction.

Never attempt to clear primers that are stuck in

either the primer pickup tube or the primer magazine

tube. Never, under any circumstances, insert any type of

rod to attempt to force stuck primers out of these tubes.

Trying to force primers out of the tube will cause the

primers to explode causing serious injury or even death.

If primers get stuck in a primer magazine or pickup

tube flood the tube with a penetrating oil (WD-40),

throw the tube in the garbage and call us for a free

replacement.

Never attempt to deprime live primers – eventually

one will go off. When it does it will detonate the others

in the spent primer cup. Depriming live primers is the

single most dangerous thing you can do in reloading

and can cause grave injury or death.

• LOADED AMMUNITION: Properly label all of your

loaded ammunition (Date, Type of Bullet, Primer,

Powder, Powder Charge, etc.).

• BE PATIENT: Our loading equipment is

conservatively rated and you should have no trouble

achieving the published rates with a smooth, steady

hand. If something doesn’t seem right, stop, look and

listen. If the problem or the solution isn’t obvious,

call us.

The reloading bench is no place to get into a hurry.

We have done everything we know how to make

your machine as safe as possible. We cannot, however,

guarantee your complete safety. To minimize your risk,

use common sense when reloading and follow these

basic rules.

• REMEMBER: If your machine does not perform to

your expectations, or if you are having technical

difficulties, give us a call. Technical Support (800) 223-

4570.

How the RL1050 Works

Stations 1 - 8 (counterclockwise)

Station 1: In this station the empty cases are

automatically inserted into the shellplate via the electric

casefeeder.

Station 2: Here the spent cartridge cases are resized

and deprimed.

Station 3: This station is totally unique. The case is

supported from the inside and slightly expanded (not

belled) while simultaneously a swager is driven into the

primer pocket to remove any crimp.

Station 4: In this station a new primer is installed.

The spring driven primer slide is extremely smooth. The

steel shrouded primer magazine is capped with an

electronic Early Warning Device to let you know when

you’re down to approximately three primers.

Station 5: Here the case is belled and powder is

dropped by the case activated powder measure. It is

extremely accurate and will not drop powder unless a

case is present. Dillon Precision offers an optional

accessory to be utilized with the automatic powder

measure at this station – Dillon’s Low Powder Sensor

provides an audible and visual reminder when it’s time

to refill the powder reservoir.

Station 6: This station is open to allow for case

inspection.

Station 7: In this station the bullet is seated to its

proper depth.

Station 8: In this station the bullet is crimped into

place. The cartridge is then automatically ejected into a

collection bin.

Your dies have been adjusted at the factory. Before

you change anything, try it the way it is, once you

thoroughly understand the machine’s operation, make

whatever adjustments to the dies you feel necessary.

Reminder: There may be some variation due to

components.

RL1050 Assembly

Your new RL1050 has been assembled at the factory.

All of the adjustments necessary to reload have already

been made, in fact we’ve even adjusted the dies to

reload the caliber you have chosen. However, before

you can reload you must do some minor assembly.

Due to variations in components, check all stations

for proper settings before loading ammunition. It is

absolutely necessary that you read the following

instructions.

Page 6

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

6

If you get stuck on something that you don’t

understand, call (800) 223-4570 for technical assistance.

Step 1: Mounting the RL1050

Select a clear area on your reloading bench. Be certain

your bench is free from vibration and is strong enough to

support your RL1050’s mass and operating force. If

possible attach your bench to the wall using screws.

Remove the RL1050 main frame from the packaging

and place it on your selected area. The crank extension

(#12901) should be to your right. Bring the machine to

the forward edge of your bench – be sure to allow

clearance for operation of the handle. Mark the four

mounting holes using the machine as a template.

Remove the machine and drill four 1/4” holes through

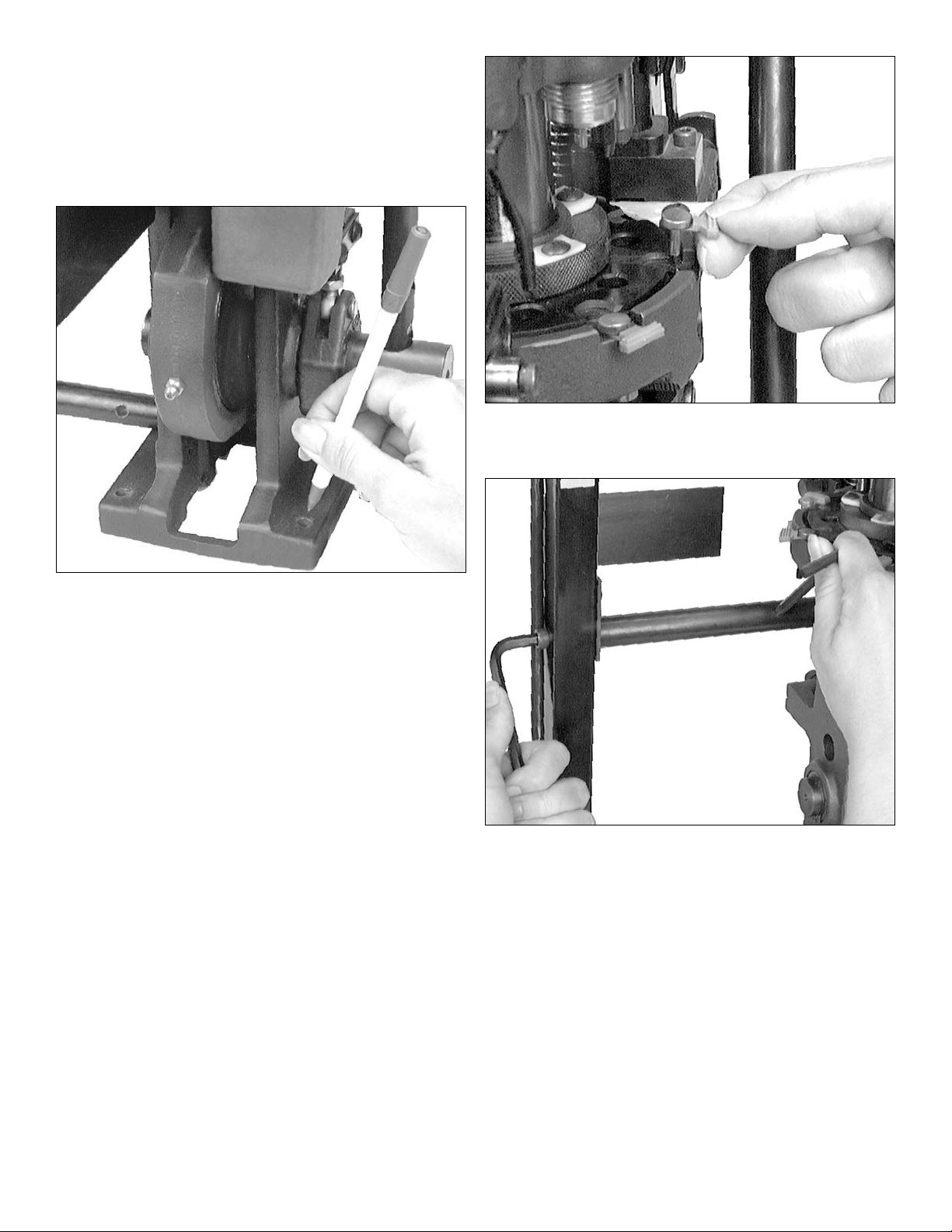

the bench. Replace the machine and bolt securely. Fig. 1

Install the handle (#12727) as indicated in the parts

schematic. Secure in place with the handle set screw

(#13432). You will note that there are three different

positions for mounting the operating handle. Choose

the one that feels best for you. The longer the handle is,

the less force is required but the stroke is longer.

The toolhead (#20420) is held down on the main

frame for shipping by the use of plastic ties. Remove the

ties while holding the handle.

Slowly move the handle up. This will move the

toolhead approximately three inches to its “up”

position. Note: If the handle is not moving freely,

carefully inspect for shipping damage.

Install the six brass locator buttons (#20637*) around

the shellplate (#12600*). Fig. 2

Step 2: Installing the Casefeed Assembly

Using the screw provided (#13377) install the

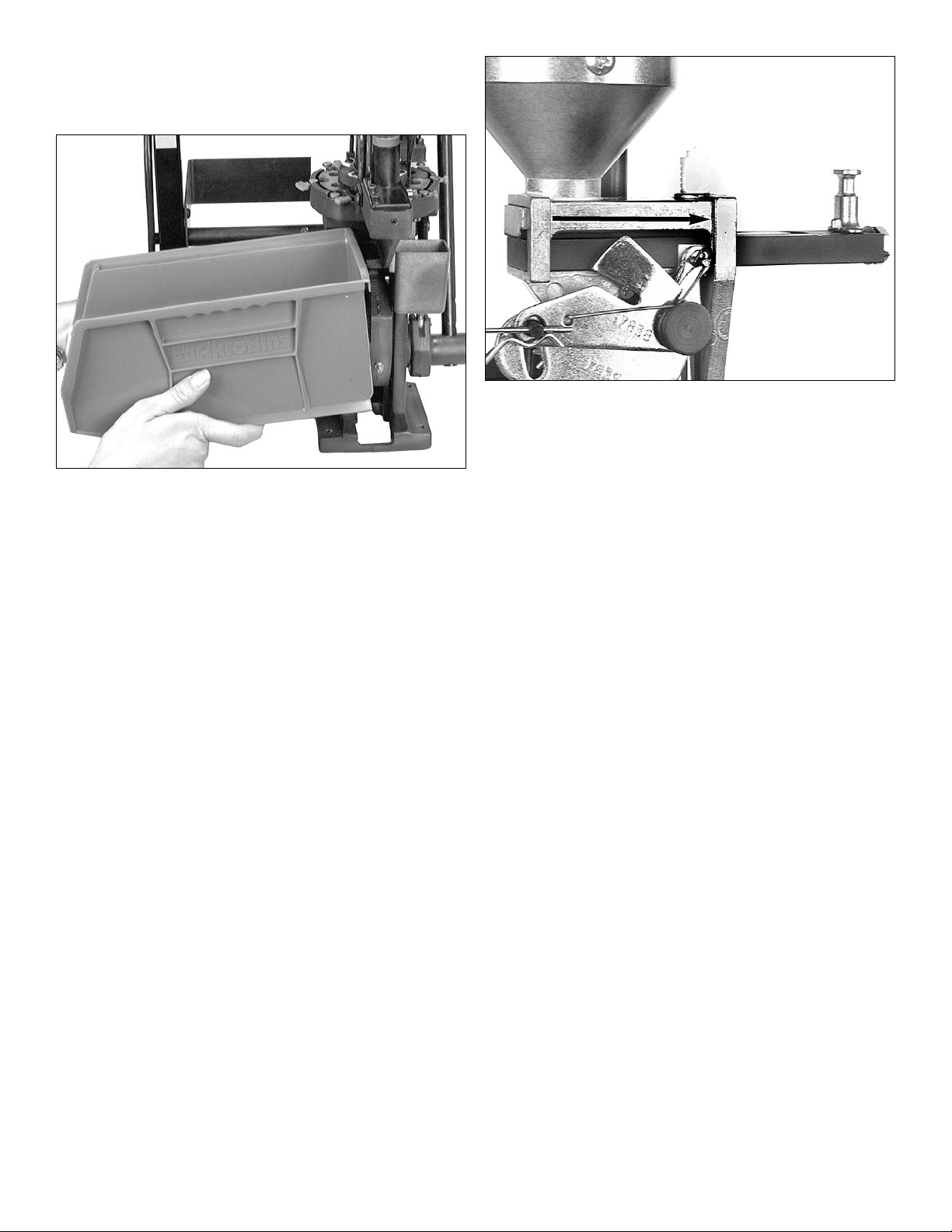

cartridge bin bracket (#13238) to the main frame. Fig. 3

Screw the casefeed post studs (#13271) to the main

frame (place the washer provided on the bottom post

only), tighten securely with an Allen wrench through

the cross hole provided. Fig. 3

Install the bullet bin bracket (#12144) to the casefeed

post (#20641) using the screw (#13685). See the

schematic on page 24.

The casefeed mounting post assembly (#20641) is

attached to the casefeed post studs (#13271) by the use

of two post bolts (#13205). Attach the power cable and

clamp as shown in the schematic on page 24.

Fig. 2: Locator button being inserted into its proper position.

Fig. 3: Place an Allen wrench into the cross hole and use it for

leverage to tighten the casefeed post studs.

Fig. 1: Be sure the machine is to the forward edge of the table or

bench when marking the four holes to be drilled.

Page 7

7

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

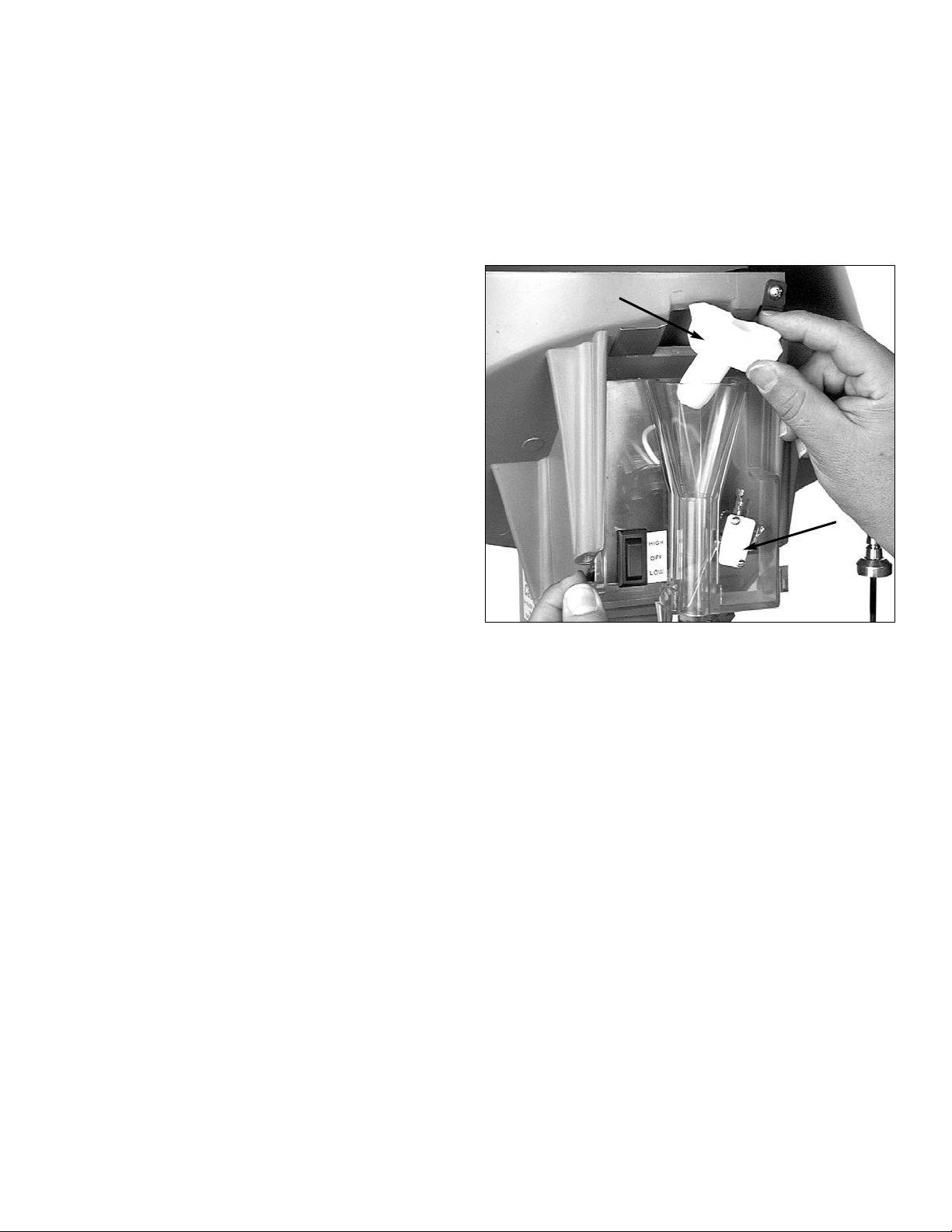

The casefeed bowl assembly needs to be placed on

the casefeed post with the Dillon logo and the on/off

switch facing you.

The casefeed tube (#13761) should now be inserted

into the casefeed adapter (#13654*) Fig. 4 Note that the

tube is marked “up” on one end. Press this end into the

tube clip (#13859) attached to the casefeeder motor

housing Fig. 5. This assembly is now complete.

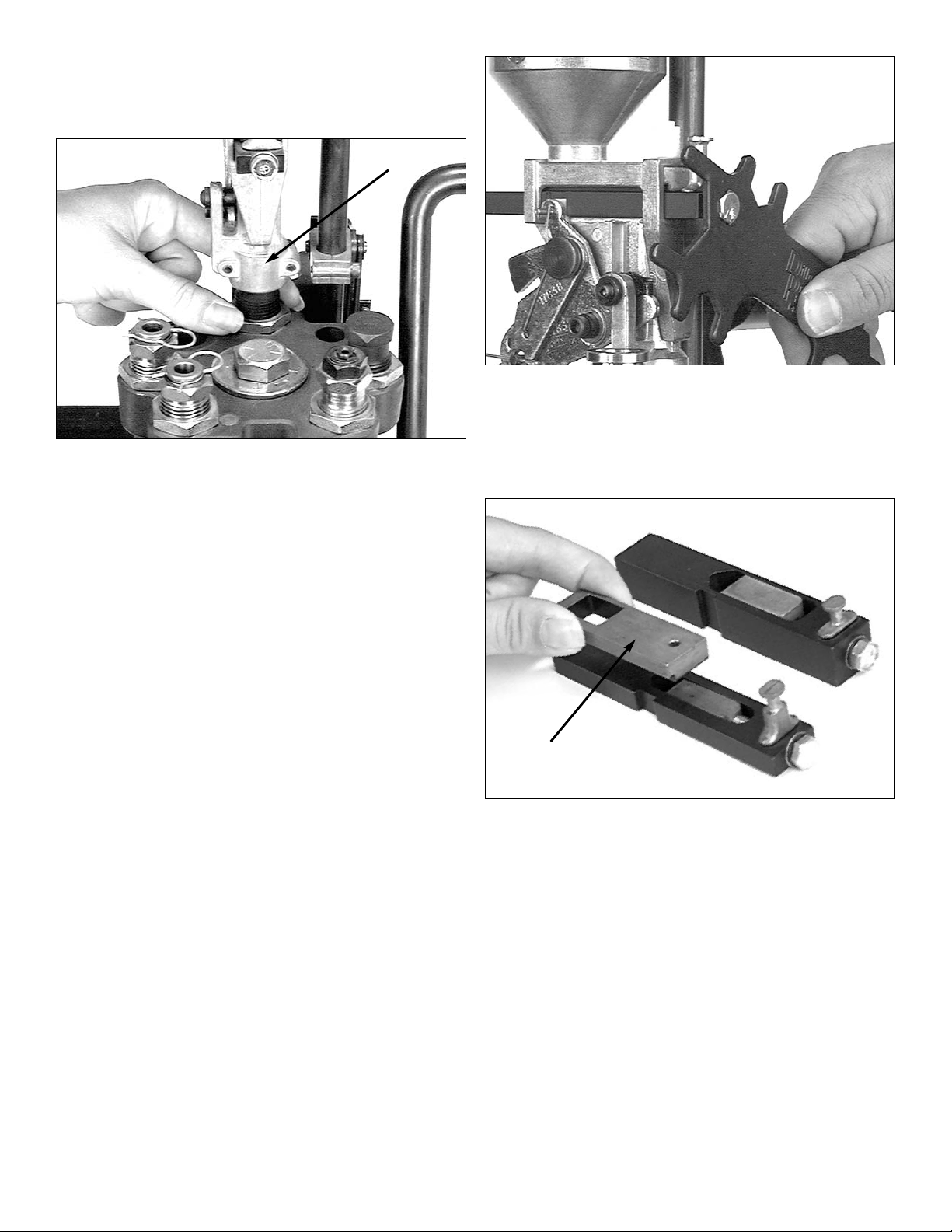

Step 3: Installing the Powder Measure

Remove the blue cap from the powder die (#20320)

and loosely clamp the powder measure in position.

Fig. 6 Install the powder measure return rod (#13960)

through the 3/8” eyebolt (#13089) mounted on the left

rear of the main frame. Fig. 7 Now attach the rod to the

powder measure bellcrank using the clip. Fig. 7 Install

Fig. 6: See arrow. A slight gap allows the powder die to be

adjusted without removing the powder measure.

Fig. 7: Note how the spring above the wingnut is slightly

compressed.

Clip

Spring

Fig. 4: The proper location and positioning of the casefeed tube

and adapter is as shown above.

Fig. 5: The end of the casefeed tube marked “up” snaps into the

clip at the base of the casefeeder motor housing.

Page 8

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

8

the spring (#14033) and wing nut (#13799) on the rod

and screw the wing nut up until you feel light tension

on the spring. Tighten the powder measure clamp

screws (#14037).

Step 4: Installing the Spent Primer Cup

and Bullet Bin

Install the spent primer cup (#13650) on the right

side as shown on the schematic on page 21.

Hook the bullet bin (#13756) and the loaded

cartridge collection box (#13484) on their respective

bracket. Fig. 8

Step 5: Cycling the Machine

At this point your assembly should be complete.

Gently pull the operating handle towards you, make a

full stroke to the bottom and up again. The shellplate

should be indexing and the primer slide (#20318*)

should function. The casefeed plunger (#13073*)

should travel forward to the shellplate. Make sure that

you repeat this several times to gain an understanding

of the various functions of the machine before you

start reloading.

Now plug in the casefeed motor and activate the

switch. The casefeed plate should turn smoothly within

the casefeed bowl.

Assuming that all is well, proceed with components.

Loading Components

Your RL1050 is equipped with a cartridge activated

powder measure that will dispense powder only when a

cartridge is in Station 5.

It is important to understand that the adjustable

powder bar should reach the end of its travel at the

same time that the handle reaches the bottom of its

stroke against the frame stop. Fig. 9 To achieve this

adjustment, the die body must be screwed up or down

as needed.

The powder die has already been adjusted at the

factory. An empty case must be placed in the shellplate

at Station 5 in order to check this adjustment. Note that

the case used to adjust the powder measure die must

already be sized.

NOTE: If you are adjusting for a straight wall case, start

your powder die adjustment with the die obviously too high

and work down. This will avoid over belling the case.

If you are adjusting a case with a shoulder, such as a .223,

do not turn the die down too far or the shoulder will buckle.

Use a reloading manual to determine how much

powder you need for a particular load and an accurate

powder scale to determine the weight. Caution: While

you do not have to use a Dillon Precision powder scale,

you should use a scale of equal quality. Do not use

scales with plastic frames or scales that do not have

jeweled pivot points versus “razor blade” pivots. Razor

blade pivots can dig into the frame of the scale and give

dangerously inaccurate readings.

Powder Measure Adjustments

In Station 5 we adjust the powder measure. It works

like this: first screw the powder die into the toolhead

and insert the pistol powder funnel expander or a rifle

powder funnel with the grooved end toward the top of

the powder die. The funnel should move freely in the

die, leaving a loose fit between the top of the die and the

powder measure collar. This will enable you to adjust

the die to give you a bell on the mouth of your pistol

cases making it easier to start the bullet.

On rifle cases, the die should be adjusted so that the

powder funnel will contact the mouth of the case and

then fully actuate the powder bar. These adjustments are

accomplished with a sized case in the shellplate and

Fig. 9: This photo shows the powder bar at the end of its travel.

Fig. 8: Shown is the proper location of the cartridge collection

bin. Note the bullet bin bracket in the background.

Page 9

9

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

alternately raising and lowing the operating handle

while adjusting the powder die.

When properly adjusted, the powder bar will be

moved to the end of its travel by the cartridge case Fig. 9.

When you have determined that your adjustments

are correct, tighten the lock ring (#14067) and locking

collar (#13939). Fig. 10

Failsafe Assembly

The purpose of the powder measure failsafe rod is to

return the powder bar to its closed position.

Remove the blue cap from the powder die (#20320)

and loosely clamp the powder measure in position.

To install the failsafe rod (#13960) remove the blue

wing nut (#13799) and rod spring (#14033) from the

rod, then insert the bottom end through the 3/8”

eyebolt (#13089) that’s mounted on the left rear of the

main frame.

Next, using your thumb and index finger of your left

hand, move the locklink down and align the hole with

the slot on the bellcrank. Then, insert the rod through

the two holes and insert the failsafe rod clip (#13929).

Install the spring (#14033) and wing nut (#13799) on

the rod and screw the wing nut up until you feel light

tension on the spring. Tighten the powder measure

clamp screws (#14037).

You will notice an adjusting bolt on the front of the

powder bar. Counterclockwise reduces the powder

charge, clockwise increases the charge. Fig. 11

Your machine comes with two powder bars. Fig. 12

One large (#20063) and one small (#20062). Rule of

thumb: Use the large bar whenever possible.

Index a sized and primed case under the measure

and operate the machine’s handle. Turning the powder

bar adjustment bolt clockwise increases the powder

charge – counterclockwise turns decreases the powder

charge. By trial and error, determine the correct weight

of your powder charge by using a powder scale. Fig. 11

When the correct powder charge had been set, cycle

several cases through the machine and check the load

with a scale.

Primer Magazine

Select the proper size primer pick-up tube and fill it

by placing the plastic tip over loose primers and

pressing down.

Fig. 10: Be sure to tighten the lock ring and locking collar when

adjustments are completed.

Collar

Fig. 12: Small powder bar (left), large powder bar (right).

Spacer

Fig. 11: Clockwise turns of the powder bar adjustment bolt will

increase the powder charge while counterclockwise turns will

decrease the powder charge.

Page 10

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

10

You will notice that the primer magazines and

primer pick-up tubes have different colored tips.

They have been color coded to help you identify size

more easily.

The color code is as follows:

Blue Small Primer Magazine Orifice

Red Large Primer Magazine Orifice

Yellow Small Primer Pick-up Tube

Green Large Primer Pick-up Tube

The shiny side of the primers should be facing up.

This is most easily accomplished by use of a primer flip

tray. Fig. 13

This quality cast metal flip tray is available from

Dillon Precision and is a better choice than the smaller

plastic trays which are difficult to use and have a

tendency to warp.

Once you’ve filled the pick-up tube, make sure the

little retaining clip is in place at the top of the tube.

Fig. 14 Pivot the switch lever (#13864) away from the

Early Warning System housing and invert the pick-up

tube over the primer shield cap (#13957). You will notice

the cap has a bevel to help you funnel the primers in.

Hold the tube in place as shown in Fig. 14, pull the

retaining pin and allow the primers to drop into the

magazine. Pivot the switch the lever back over the Early

Warning System housing. Gently slide the follower rod

down through the switch lever and into the primer

magazine tube. When you are nearly out of primers,

approximately three remaining, the follower will

activate the buzzer.

The Electric Casefeeder

Use only clean cartridge cases that have been

inspected for any potential problems; split cases, rocks

or smaller caliber cartridges that may be hidden in

larger caliber cartridges. Warning: Be sure that no

loaded rounds are mixed with your empty cases. It is

possible to feed a blunt nosed cartridge like a .38 WC

into the shellplate upside down and explode it when it

is hit by the decap pin.

Now fill the casefeed bowl with approximately 500

pistol cases or about 350 .223 cases.

Your RL1050 is now charged with components and

ready to go, but before you start reloading, read the

following explanation of the sequence of the eight

reloading stations and the processes that are done at

each station.

How the RL1050 Works

Stations 1 - 8 (counterclockwise)

Station 1: In this station the empty cases are

automatically inserted into the shellplate via the electric

casefeeder.

Station 2: Here the spent cartridge cases are resized

and deprimed.

Station 3: This station is totally unique. The case is

supported from the inside and slightly expanded (not

belled) while simultaneously a swager is driven into the

primer pocket to remove any crimp.

Station 4: In this station a new primer is installed.

The spring driven primer slide is extremely smooth. The

steel shrouded primer magazine is capped with an

electronic Early Warning Device to let you know when

you’re down to approximately three primers.

Station 5: Here the case is belled and powder is

dropped by the case activated powder measure. It is

extremely accurate and will not drop powder unless a

case is present. Dillon Precision offers an optional

accessory to be utilized with the automatic powder

measure at this station – Dillon’s Low Powder Sensor

provides an audible and visual reminder when it’s time

to refill the powder reservoir.

Station 6: This station is open to allow for case

inspection.

Station 7: In this station the bullet is seated to its

proper depth.

Station 8: In this station the bullet is crimped into

place. The cartridge is then automatically ejected into a

collection bin.

Fig. 14: When installing primers into the primer magazine, be sure

the pick-up tube centers itself before pulling the clip.

Fig. 13: All of the primers must be shiny side up.

Page 11

11

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

As stated earlier, your dies have been adjusted at

the factory. Before you change anything, try it the

way it is, once you thoroughly understand the

machine’s operation, make whatever adjustments to

the dies you feel necessary.

Reminder: There may be some variation due to

components.

To Begin Reloading

Turn on the switch on the front of the casefeed motor

housing. The casefeeder plate should begin to turn.

Cases will begin to dispense, base down, into the clear

plastic casefeed tube. The motor will continue to run

until the tube is full, at which point a micro switch will

temporarily stop the case flow.

From this point the casefeeder will automatically fill

the tube as you reload. If the casefeeder does not

function properly or the cases do not fall base down,

refer to the Trouble Shooting section of this manual.

Pull the operating handle smoothly to the bottom

stop, then raise the handle. Once again, strive to be

smooth in your operation.

The first case should be indexed to Station 2. Cycle

the handle again.

It is not necessary to apply any force on the upstroke

of the handle. All you are doing on the upstroke is

indexing the shellplate. Remember that priming is done

on the down stroke. A slow measured upstroke gives

you lots of time to pick up the next bullet and ready it

for seating. If you count one second down and one up

you’ll have a good pace.

The first case should now be in Station 3 with a case

in Station 2 as well. Cycle the handle again. The case

will be expanded when it comes out of Station 3.

Observe the swage operating part (#20314*), if the

swage is proper, proceed – if not see items 3 and 4 in the

Trouble Shooting section of this manual. Cycle the

handle again.

You should now have inserted a primer into the first

case in your sequence and it is now in Station 5. Remove

the locator button (#20637*) extract the round and check

the primer. If everything looks okay, replace the case

and button and proceed, if not, refer to the Trouble

Shooting sections regarding stations 3, 4, and 5.

Cycle the handle again, the automatic powder

measure will drop the charge you’ve selected. Pistol

casemouths will be belled at this time. Look through the

inspection hole in station 6 – you should be able to see

your powder charge in the case.

Cycle the handle again. Now, with your left hand

place a bullet on the powder charged case and cycle the

handle, your bullet will be seated to its proper depth, if

not a simple height adjustment to the seating stem may

be necessary. Refer to a loading manual for proper

loaded length (OAL). Add a bullet to the case at station

7, cycle again and check for crimp at station 8. Refer to

Trouble Shooting item 8 for adjustments if necessary.

Add a bullet, cycle again. Your first loaded round

should now be ejected into the collection bin.

If all has gone well to this point you’ve got it made.

Just keep adding bullets, watch your fingers so they

don’t get caught and don’t hurry. Just try to be smooth

in your operation. The speed will come naturally and

you’ll be doing a thousand rounds per hour before you

even realize it.

The following are some adjustment suggestions as

well as Trouble Shooting hints.

Adjustments and Conversions

Casefeeder

It may be necessary to readjust the microswitch for

different calibers. Cases may become lodged between

the microswitch and the tube wall. The other extreme is

the case failing to put enough pressure on the

microswitch to shut off the system causing it to continue

running and over flowing the tube. Fig. 15

The casefeed spacer (#13703) supplied in the

accessory package, is to be used when you are reloading

.41 mag, .44 mag, .37 mag, .30 Carbine, or .45 Long Colt.

Fig. 15: Shown is the microswitch that automatically shuts off

when a case is next to it. Also shown is an optional spacer for

certain calibers: .380 and 9mm.

Microswitch

Spacer

Page 12

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

Remove the two clutch screws (#13732), lock washers

(#13813) and upper clutch (#13632) and the casefeed

plate. Place the spacer on the shoulder of the lower

clutch and reassemble. The casefeed plate should now

be approximately 1/8” above the floor of the casefeed

bowl. Note: Make sure the casefeed plate is centered in

the bowl. Fig. 16

Handle

The operating handle is adjustable to three

different length settings. Choose the one most

comfortable for your operation. Loosen the set screw

(#13432) then retighten when the handle is in the

most comfortable position.

Swager

Swaging on the RL1050 is a simple process and is

necessary on all cartridge cases as a means of uniforming

the entrance of the primer pocket. The swage rod

(#20314 large or #20313 - small) is fully adjustable.

Swage Conversion and Adjustment

Conversion – See Fig. 17

Begin by removing the swage cover (#13064). Next

remove the hitch pin (#13840) and slide out the clevis

pin (#13522). Rotate the swage connecting rod a half

turn, this will allow you access to the swager. Pull the

swager down and out of the machine.

Insert the new swager and reassemble.

Swage Adjustments

Use ONLY an unswaged military case for these

adjustments.

With the handle in the down position, screw the

swage back up rod (#13017*) down until it makes contact

with the case bottom and holds it in place. Fig. 18

With the handle still in the down position, turn the

swage rod up until it makes contact with the case bottom.

Raise the handle half-way and rotate the swage rod a

quarter turn. Now, cycle the handle. Inspect the case and

when you achieve a completed swage of the primer

pocket, tighten the swage lock nut (#13682).

A properly swaged pocket will show a rounded edge

around the rim. Some military cases (.223 & .308) start

out with three small dents around the base of the

pocket, once properly swaged, the dents will no longer

be visible.

Primer System Change Over Instructions

The RL1050 has been shipped to you with either the

large or small primer system installed. To change the

system from large to small or vise versa, follow these

instructions:

Be sure all primers have been removed from the

primer system. Then remove the Early Warning System

and the knurled cap. Then remove the magazine

(#13673 - large or #13879 - small) and replace it with the

new size magazine. Be sure the key on the tip (#14003 large or #14024 - small) is in the slot and the magazine is

all the way down in place.

Pull the operating handle to its down position.

Fig. 18: A cut-a-way view of a .45 ACP with the swage rod and the

backup rod properly adjusted in the swaging position.

Fig. 16: Make sure the casefeed plate is centered in the bowl with

approximately 1/8” all the way around when using the disc spacer.

1/8”

Fig. 17: Shown is the swage rod from the right side of the machine.

12

Page 13

13

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

Loosen the lever arm bracket screw (#13732) and

slide the bracket assembly up four inches and lock it

in place.

Raise the operating handle, remove the two primer

feed body screws (#13363) and lift the primer feed body

assembly (#20773) off.

Remove the ratchet cam (#11686) from the toolhead

(#20420). Fig. 19

Remove the mechanical return rod (#13960) from the

powder measure bellcrank (#13871) by releasing the rod

clip (#13929). Fig. 20

Read complete toolhead and shellplate removal

instructions before proceeding.

Remove the casefeed tube (#13761) place it on your

bench and take the toolhead off. Now you can remove

the shellplate locknut (#20311) by loosening the four

lock ring screws about four complete turns. This will

allow you to remove, and replace, the primer slide

(#20318 - large or #20317 - small); bushing (#13031 large or #13222 - small); spring (#13858) and punch

(#12849 - large or #13307 - small) with the replacement

parts for your new primer size.

You should clean your machine at this time. Note

that there is a specially designed screwdriver supplied

for the bushing (found in your accessory bag). Prior to

installation, lube the base of the primer punch. Now

adjust your new punch (#12849 - large or #13307 small) so that it is flush with the bushing (#13031 - large

or #13222 - small) by turning set screw (#13226) up or

down. If the primer punch is too low, dirt will collect on

top of it leaving imprints on your primers. If it is too

high it will bind the slide. Note: You can use the slide for

a guide. Slide it back and forth over the bushing to

check your adjustments.

Toolhead Removal

Disconnect the mechanical return rod (#13960)

from the bellcrank (#20319) by releasing the return rod

clip (#13929). Fig. 20

Lower the handle and remove the toolhead ratchet

(#11686). Fig. 19

Remove the Primer Early Warning device.

Remove the primer slide lever assembly (#20488).

Obtain a 15/16” socket or wrench (not supplied) to

remove the toolhead bolt (#13342) and washer

(#13449). Fig. 21

Now remove the toolhead (#20420). Due to being

spring loaded, there will be some resistance. Wiggle the

toolhead up and off while holding the handle.

After removing the toolhead, carefully lower the

handle.

Fig. 21: Use a 15/16” socket wrench to remove the toolhead bolt.

Fig. 19: Remove the toolhead ratchet by first removing the bolt

(#12486). See the schematic on page 21

Fig. 20: After removing the clip and disconnecting the rod, replace

the clip in the rod for safe-keeping.

Page 14

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

14

When reinstalling the toolhead bolt (#13342) turn it

in only finger tight then cycle the handle up and down

to make sure everything is properly located. With the

handle in the down position, tighten the toolhead bolt

with the above mentioned wrench.

Shellplate Removal

Remove the ejector tab (#13189).

Loosen the four locator tab screws (#13895) about

two full turns.

Use a toothbrush to remove any powder that may be

in the threads before removing the lock ring.

Next remove the lock ring (#20311). Now push the

casefeed plunger back (#13073*) and lift the shellplate

(#11925) off. Be sure to lightly grease the bore of the

shellplate when reinstalling it. Rule of thumb: turn the

lock ring down until tight then back off one-eighth of a

turn. Then tighten the four locator tab screws (#13895).

Casefeed Plunger Conversion

When changing calibers it may be necessary to

replace the casefeed plunger (#13073*).

To do this, remove the clear casefeed tube (#13761)

and pull out the colored casefeed adapter (#13654*). The

adapter is taped for shipping purposes.

Remove the two housing screws (#13815) and the

casefeed adapter housing (#13534).

Place your hand on the plunger while removing

the roller bolt (#13333). This will prevent the

casefeed plunger and spring from jumping out of the

machine. Fig. 22

Thoroughly clean the track and casefeed parts with a

solvent. Now very lightly apply grease to the sides and

install the proper size casefeed plunger (#13073*).

Remember to grease the roller (#13498) and the roller

track and Loctite the threads on the roller bolt (#13333).

Install the casefeed housing and insert the proper

size adapter (#13654*). The casefeed tube (#13761)

should now be inserted into the casefeed adapter

(#13654*). Note that the tube is marked “up” on one

end. Press this end into the tube clip (#13859). See the

Trouble Shooting section for any adjustments.

Die Adjustments

Sizing Die Adjustments – Station 2

With the toolhead in the down position, screw the

sizing die down until the bottom of the die touches the

shellplate. Raise the toolhead and insert an empty case

into the shellplate. Now, lower the toolhead down all

the way over the case and tighten the die lock ring on

the sizing die. The process described above will insure

the die is centered correctly in the toolhead when it is

locked in place. A note of caution: Never attempt to

deprime a live primer. An explosion may occur.

Expander Die Adjustments – Station 3

Install the expander die (caliber specific) at station 3

of the shellplate. Place a case in station 2 and cycle the

operating handle once (sending the case to station 3).

Turn the expander die down until it makes contact with

the case and cycle the operating handle. Make

adjustments in one-quarter turn increments until the

desired bell is achieved. Tighten the die lock ring.

A properly belled case should show a slight flare at

the case mouth.

Seating Die Adjustments – Station 7

Screw the seating die into Station 7 with the

appropriate seating stem installed. Each die set will

include seating stems to fit the most common bullet

types. Use the nose of the bullet to see which seating

stem fits best.

Refer to a reloading manual for proper bullet seating

depth or over all length (OAL).

With the handle in the down position, screw the

seating die down until it makes contact with the

shellplate. Then turn the die counterclockwise four full

turns. Raise the handle and place one of the cases

charged with powder into Station 7. Place a bullet on the

mouth of the case and cycle the operating handle.

Inspect the bullet for seating depth (OAL) with a dial

caliper or case gage. To make the OAL longer, turn the

seating die counterclockwise in small increments. To

make the OAL shorter, turn the seating die clockwise in

small increments.

When the OAL is correct, tighten the die lock ring

with the operating handle in the down position.

Crimping Die Adjustments – Station 8

Screw the crimp die into Station 8. Screw it down

until it is flush with the bottom of the toolhead. This is a

good starting point for the crimp adjustment.

Place a cartridge with a properly seated bullet into

Station 8. Raise the platform and continue to screw the

die down until it touches the cartridge.

Fig. 22: Be sure to lightly grease the plunger and roller after

cleaning.

Page 15

15

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

Lower the platform and give the die an 1/8 turn

down, again raise the platform.

Lower the platform halfway and inspect the

cartridge. If the bell is still present, or the desired

amount of crimp has not been achieved, give the die a

1/8 turn down and try again. Continue making small

adjustments to your crimp die until the desired amount

of crimp has been achieved.

Once the adjustment is complete, place the case back

into Station 8 and raise the platform. Using a 1-1/8”

wrench to turn the lockring and a 7/8” wrench to hold

the die body, snug the lockring.

Note: See drawing (above). When adjusting the

crimp die it is important to know what to look for.

Check that the crimp: Looks OK, allows your firearm

to function consistently and the bullet feels tight in

the case.

The drawing of case #3 (above) is a depiction of a

case that has been over crimped by adjusting the

crimp die down (clockwise) too far. Note the defined

line below the mouth of the case and the bulge below

the line. This is not a proper crimp. This line is the

direct result of the cartridge being over crimped. A

line like this will only appear if the crimp die is

adjusted down too far. Warning: Over crimping

.45ACP, .38 Super, 9mm, etc., can actually cause the

bullet to be loose in the case.

Older Model RL1050 Users Section

The casefeed spring (#13526) when adjusted

correctly, will keep the cases from becoming lodged

between the casefeed plate and the casefeed port. When

adjusting, position the spring as close as possible to the

casefeed plate in a location favoring the left side of

center in relation to the port opening. Allow one case

diameter (in perspective to the caliber) for clearance

between the spring and the leading edge of the exit port.

Note that the spring becomes the wall the case will hit it

before falling down the funnel.

Adjustments

for calibers 9mm, .38 Spl, .45 ACP and for hot

loads that have been fired many times

Configuration 1

Place a military case (sized, decapped and

unswaged) into Station 3.

Screw the backup rod (#12749*) down two turns into

the toolhead (#20420). Pull the handle.

Using a wrench turn the backup rod (#12749*)

down until it hits the inside bottom of the case. Note:

Do not force the expander as this will damage the case

and the shellplate. Now secure the lock ring (#20006*).

Raise the handle.

Screw the eyebolt (#13245) all the way into the

swager. Grease the clevis pin (#13522) heavily.

Put the swager into position. Push the clevis pin

through the connecting rod and eyebolt and secure with

the hitch pin (#13840). Replace the swage cover (#13064).

With the military case still in Station 3, pull the

operating handle down with your left hand. Now turn

the swager upward with your right hand until it meets

resistance. Fig. 17 With your left hand raise the

operating handle about 10”. With your right hand turn

the swager up a quarter turn. Cycle the handle down.

Raise the handle just enough to remove the case and

inspect the primer pocket to see the amount of swaging

being done. The swager should leave a radiused

entrance on the primer pocket. Turn the swager in,

using one quarter turn increments until you achieve the

proper swage. Secure the jam nut (#13682). Note: Do not

over swage. This condition will cause damage to the

shellplate (#12600*). When your swager is properly

adjusted you will feel resistance during the final 1/2” to

1” of the downward stroke of the handle.

Adjustments

for .223 and 7.62x39 Russian

Configuration 2

Place a military case (sized, decapped and

unswaged) into Station 3.

Remove the backup rod (#12749*) from the backup

die (#12184).

With the operating handle in the down position,

screw the backup die into Station 3 until the die

comes into contact with the shellplate. Now back the

die out one full turn and secure it in place with the

lock ring (#14067).

Leave the handle in the down position. With a

wrench screw the backup rod into the backup die. Turn

the backup rod down until it touches the inside bottom

of the case. Fig. 18 Note: Do not force the expander as

this will damage the case and the shellplate. Now secure

the lock ring (#20006*). Raise the handle.

Screw the eyebolt (#13245) all the way into the

swager. Grease the clevis pin (#13522) heavily.

Put the swager into position. Push the clevis pin

through the connecting rod and eyebolt and secure with

the hitch pin (#13840). Replace the swage cover (#13064).

With the military case still in Station 3, pull the

operating handle down with your left hand. Now turn

the swager upward with your right hand until it meets

resistance. Fig. 17 With your left hand raise the

operating handle about 10”. With your right hand turn

123

Page 16

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

16

the swager up a quarter turn. Cycle the handle down.

Raise the handle just enough to remove the case and

inspect the primer pocket to see the amount of swaging

being done. The swager should leave a radiused

entrance on the primer pocket. Turn the swager in,

using one quarter turn increments until you achieve the

proper swage. Secure the jam nut (#13682). Note: Do not

over swage. This condition will cause damage to the

shellplate (#12600*). When your swager is properly

adjusted you will feel resistance during the final 1/2” to

1” of the downward stroke of the handle.

Adjustments

for all other calibers

Configuration 3

Use ONLY an unswaged military case for this

adjustment.

Adjust the swage die body (#12184) 1/16” above the

shellplate, now lock the die in place. Install the

expander (#12749*).

With the shellplate empty, place a case in Station 2.

Cycle the machine once (sending the case to station 3).

Using one quarter turn increments, adjust the expander

until you achieve the desired bell. Once the desired bell

is achieved, tighten the expander lock ring. (#20006*).

Using the same case in Station 3, cycle the handle

down. With the lock nut (#13419) off, rotate the swage

backup rod clockwise until the rod contacts the inside

web of the case. Now install the lock nut (#13419) and

lock it in place.

With the handle still in the down position, begin

rotating the swage rod (#20314*) counterclockwise. You

will begin to notice resistance, now raise the handle

half-way, rotate the swage rod a quarter turn and cycle

the handle. Inspect the case and when you achieve a

completed swage of the primer pocket, tighten the

swage lock nut (#13682).

Trouble Shooting

Hard or Incomplete Indexing

1.) Wrong size locator buttons (#20637*).

2.) Index pawl bent or worn (#13705).

3.) Shellplate lock ring adjusted too tightly (#20311).

4.) Dirt under the shellplate (#12600*).

5.) Bent or broken shellplate (#12600*).

Station 1: Case Insertion Problems

1.) Wrong size case insert plunger (#13073*).

2.) Wrong case insert adapter (#13654*).

3.) Shellplate lock ring not adjusted tight enough.

4.) Dirt in the shellplate (#12600*) pockets or

damaged shellplate.

5.) Handle being moved too rapidly on upstroke.

6.) Bent or broken roller bolt (#13333).

7.) Dirt or media in casefeed track.

Station 2: Resizing and Decapping Problems

1.) Crushed cases:

a.) Shellplate lock ring too loose or too tight.

b.) Not enough radius on the die. Use Dillon dies

whenever possible.

c.) Wrong size or missing locator buttons.

2.) Bending or breaking decapping pins:

a.) Wrong shellplate (#12600*).

b.) Slightly bent decapping assembly or pin.

c.) Berdan primed cases.

d.) Dirt in shellplate pockets .

e.) Handle being moved too rapidly on the

down stroke.

f.) Rocks or other foreign objects in cases.

Station 3: Primer Pocket Swaging Problems

1.) Primers smearing or crushing:

a.) Swage backup rod not down far enough

(#13332 or #13348).

b.) Swage rod not adjusted high enough (#20314 -

large or #20313 - small).

Station 4: Priming Problems

1.) Crushed primers:

a.) Swage rod (#20314 - large or #20313 - small)

not adjusted correctly, dirty or worn out.

b.) Dirt in the shellplate (#12600*).

c.) Ringed Primer. When a spent primer has been

pierced by the decapping pin leaving a ring of metal

from the primer in the pocket.

d.) Primer station locator button (#20637*) not

adjusted correctly.

e.) Chipped or worn primer punch (#12849).

f.) Bench that the machine is mounted on is not

rigid enough. This can be corrected by affixing a board

to both the wall and your casefeed bowl.

g.) Hot loaded ammo that has been fired several

times and the base of the case has been flattened out.

2.) High primers:

a.) Adjust the primer push rod (#12819).

b.) On .223 cases the swage backup rod (#13332) is

down too far, slightly collapsing the primer pocket and

not allowing the primer to seat fully.

c.) Loose shellplate (#12600*).

d.) Erratic handle motion.

e.) Do not remove the rubber piece on the

primer slide.

3.) Smeared primers: See Station 3: Primer Pocket

Swaging

4.) Locator tab:

a.) When adjusting the priming station locator tab,

it should be set as close to the case as possible without

touching it. Be sure the cases in the shellplate rotate

freely past the tab. Change primer magazine tips every

20,000 rounds. Note: Move the handle down, bringing

the toolhead down. Move the locator tab in to the case in

the priming station.

Station 5. Powder & Case Mouth Belling Problems

1.) Crushing cases:

a.) Wrong size or missing locator buttons.

2.) Spilling powder:

a.) Slamming or going too fast with the operating

handle (#12727).

b.) Stick or pencil lead type powders bridging on

the case mouth in the powder funnel (#13005). See

conversion chart.

Page 17

17

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

c.) Check powder bar adjustment.

3.) Erratic belling:

a.) Variation in case length. Divid cases by brand.

b.) Handle not moving all the way down on each

stroke. Note: Try setting a bullet on the case mouth in

Station 6.

4.) Erratic powder charges:

a.) Powder bar not moving full length of its travel.

Turn the powder die down until it does.

Station 7: Bullet Seating Problems

1.) Erratic seating depth of the bullet:

a.) Build up of lead shaving and/or lube in the

seater or crimp dies.

b.) Bullets having erratic dimension (length

and/or the ogive).

c.) Use the proper seating stem for the type of

bullet being used.

d.) Variations in case types and/or lots – sort brass.

e.) Refer to a loading manual for proper loaded

length (OAL) and additional information.

Station 8: Crimping Problems

1.) Erratic crimping:

a.) Length of cartridge cases erratic, probably due

to mixed brands of brass.

b.) Worn out or improperly made die, use Dillon

dies whenever possible.

2.) Loose bullet:

a.) Too much taper crimp. Note, this condition

also ruins accuracy.

b. Wrong expander (#12749*).

c.) Thin cases.

Maintenance

Loctite

Loctite should be used following adjustments to or

replacement of all threaded screws. Please note that

Loctite should be applied to threaded portions only

and should be of a non-permanent type. Blue Loctite

#242 is recommended.

Lubrication

Operating circumstances will dictate the frequency of

required lubrication. It is highly recommended that the

RL1050 be cleaned and lubed after every 10,000 rounds

of operation.

Use a high grade conventional wheel bearing grease

– do not use oil.

Lubrication Points:

Casefeed Plunger (#13073*)

Casefeed Plunger Roller (#13498) and Bolt (#13333)

Swage Connecting Rod (#13417) and Clevis Pin

(#13522)

Tappet (#12995)

Rocker Arm (#13058)

Pivot Bolt (#13296)

Primer Punch Base (#12849 - large or #13307 - small)

Alignment Pins (#12972 & #13515 located under

the toolhead)

Shellplate Locating Ring (#12600*)

Shellplate Lock ring (#20311 - contacting surface)

Indexing Lever Cam surface (#20312) and Pivot

Bolt (#13276)

Indexing Bolt (#13086)

Ratchet Restriction Tab (#13376)

Toolhead Bore (#20420 - lightly to avoid rusting

and/or freezing up)

Connecting Rod (#13324) using grease fittings Cam

Guide Bolt (#12486)

Lever Cam (#13413)

Main Shaft Lubrication – Use only 30 wt. motor oil.

DO NOT use a penetrating lubricant such as WD-40,

Breakfree, etc…

Swage

Clean the swage by pulling the operating handle

down and use a small brush to clean the tip. Every

10,000 rounds, remove the swage rod (#20314 - large or

#20313 - small). and clean, lightly grease and replace.

Note: Do not grease the tip of the swage where it

contacts the primer pocket.

Definitions

ANVIL: Contained in the primer. A fixed metallic point

against which the priming mixture is crushed and

thereby detonated by the action of the firing pin.

BEARING SURFACE: That portion of a bullets surface

that touches the bore when moving through the barrel.

BELL: To expand the mouth of the case slightly in order

to seat a bullet easily.

BERDAN PRIMER: Type of primer with no integral

anvil. The anvil is formed in the bottom of the primer

pocket. Common in Europe on military cartridges.

Difficult if not impossible to reload. Identify by viewing

the empty cartridge from the top. If you see two flash

holes, throw the case away.

BOXER PRIMER: The standard American type of

primer. When viewed from the top of an empty

cartridge case, one flash hole should be seen. This is the

one to reload.

BULLET: The missile only. Becomes a projectile in flight.

It may be of the jacketed or cast lead type.

BULLET SEATING: Inserting the bullet into the

cartridge case to the correct over all length (OAL) of the

completed cartridge.

CALIBER: Approximate bore or groove diameter

expressed in decimals or metric i.e.: .308 or 10mm.

CANNELURE: Groove around a bullet or cartridge

case. Used to hold lubricant, or to crimp case into.

CARTRIDGE: A compete unit of ammunition

assembled i.e.: Cartridge case, propellant powder,

primer, and bullet.

CASE TRIMMING: The trimming of a fired rifle case

back to its original over all length. Note that the

trimming of straight walled cases is unnecessary.

CHAMBER: The part of the bore, at the breach,

machined to accept and support the cartridge.

CHAMFER: To ream a taper on the inside of a case

mouth to assist in seating a bullet.

CRIMP (ROLL OR TAPER): The bending inward of the

mouth of a case in order to grip the bullet.

CRIMPED PRIMER: A forcing inward of the brass

Page 18

18

around the top of the primer pocket to prevent the

primer from backing out. Usually found in military

cartridges. Crimp must be removed to allow you to

insert a new primer.

DECAP: To push out a primer from the primer pocket

with the decapping pin in the sizing die.

EXPAND: To open rifle pistol cartridge casemouths to

the proper diameter needed to hold the bullet firmly.

Not to be confused with “belling”.

FLARING: See BELL.

FLASH HOLE: The hole leading from the primer pocket

into the cartridge case.

HEADSPACE: The distance from the bolt face to that

point in the barrel or chamber that stops the cartridge

from moving further forward into the chamber. Rifle;

cartridge rim, belt or shoulder. Handgun; cartridge

mouth of the case or rim.

LEADING: Lead deposited in the bore from shooting

swaged lead bullets. Hardcast bullets will not cause

leading in pistols.

NECK SIZE: To resize the neck on a rifle case. For rifle

cases only.

OVER ALL LENGTH (OAL): The distance from the tip

of the bullet to the base of the case.

OGIVE: The rounded portion of the bullet ahead of the

cylindrical section. Also the radius of the curve ahead of

the bearing surface.

OIL DENT: Dent in the case formed by having too

much oil or lubricant when sizing.

PRIMER POCKET: The portion of the cartridge case

that contains the primer. Note: It is not necessary to clean

primer pockets on modern ammunition. This practice is

a carry over from the old corrosive primer days.

RESIZE: To return a fired cartridge case to its original

dimensions by its insertion into a resizing die. Note:

resizing does not compensate for the stretching of a rifle

case when they’ve been fired. See CASE TRIMMING.

Page 19

19

20477 – .38/.357 Conversion

12704 #2 Shellplate

14062 #2 Locator Buttons (6)

13137 .38/.357 cal. Expander – D

13802 Adapter – Orange

13098 Casefeed Plunger – Medium

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13005 Powder Activator – Pistol

20478 – .41 Mag Conversion

11856 #6 Shellplate

13930 #1 Locator Buttons (6)

12882 .41 cal. Expander – H

13654 Adapter – Yellow

13073 Casefeed Plunger – Large

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13005 Powder Activator – Pistol

20479 – .44 Spl/Mag Conversion

12600 #4 Shellplate

14047 #4 Locator Buttons (6)

12628 .44 cal. Expander – G

13654 Adapter – Yellow

13073 Casefeed Plunger – Large

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13005 Powder Activator – Pistol

20480 – .45 ACP Conversion

12999 #1 Shellplate

13930 #1 Locator Buttons (6)

12749 .45 cal. Expander – E

13872 Adapter – Red

13073 Casefeed Plunger – Large

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13005 Powder Activator – Pistol

20481 – .45 LC Conversion

11235 #C Shellplate

14047 #4 Locator Buttons (6)

12749 .45 cal. Expander – E

13654 Adapter – Yellow

13073 Casefeed Plunger – Large

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13005 Powder Activator – Pistol

20482 – 9mm Conversion

12938 #5 Shellplate

14060 #3 Locator Buttons (6)

12833 9mm cal. Expander – F

13878 Adapter – Green

13306 Casefeed Plunger – Small

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13005 Powder Activator – Pistol

20483 – .380 Auto Conversion

12441 #3 Shellplate

14060 #3 Locator Buttons (6)

13285 .380 cal. Expander – F

13810 Adapter – White

12964 Casefeed Plunger – Small .380

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13419 1/4–28 Jam Nut

13017 Swage Back Up Rod – Large

12184 Swage Die

13483 9/16-18 Lock Nut

13005 Powder Activator – Pistol

20484 – .38 Super Conversion

12938 #5 Shellplate

14060 #3 Locator Buttons (6)

12833 9mm cal. Expander – F

13878 Adapter – Green

13306 Casefeed Plunger – Small

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13005 Powder Activator – Pistol

20788 – 10mm Auto Conversion

12940 #W Shellplate

14062 #2 Locator Buttons (6)

12912 10mm cal. Expander – W

13872 Adapter – Red

13098 Casefeed Plunger – Medium

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13005 Powder Activator – Pistol

20485 – .223 Conversion

12441 #3 Shellplate

14060 #3 Locator Buttons (6)

13332 Backup/Expander .223

13426 Powder Funnel – A

12146 Adapter (pinned) – White, Long

13306 Casefeed Plunger – Small

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

12184 Swage Die

13483 9/16-18 Lock Nut

20626 – .30 Carbine Conversion

12655 #8 Shellplate

14048 #8 Locator Buttons (6)

12748 .30M1 cal. Expander – C

13564 Powder Funnel C

12641 Adapter – White, Slotted

13306 Casefeed Plunger – Small

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

20631 – 7.62x39 Conversion

11925 #A Shellplate

14062 #2 Locator Buttons (6)

13348 Backup/Expander 7.62x39

13015 Powder Funnel AK

12943 Adapter

13098 Casefeed Plunger – Medium

13703 Casefeed Spacer

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

12184 Swage Die

13483 9/16-18 Lock Nut

14067 Die Lock Ring

20634 – .32 S&W Long/H&R

Magnum Conversion

12107 #D Shellplate

14060 #3 Locator Buttons (6)

12780 .32 cal. Expander – S

12845 Powder Funnel – S

13878 Adapter – Green

13306 Casefeed Plunger – Small

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

21525 – 9x25 Dillon Conversion

12940 #W Shellplate

14062 #2 Locator Buttons (6)

12833 9mm cal. Expander – F

13872 Adapter – Red

13098 Casefeed Plunger – Medium

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13005 Powder Activator – Pistol

20545 – .40 S&W Conversion

12940 #W Shellplate

14062 #2 Locator Buttons (6)

12912 10mm cal. Expander – W

13878 Adapter – Green

13098 Casefeed Plunger – Medium

17384 Blue Locator Tab – Short (1)

13569 Blue Locator Tab (5)

14067 Die Lock Ring

13005 Powder Activator – Pistol

Caliber Conversion Chart

Page 20

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

20

RL 1050 Parts Listing

Part # Description

11686 Toolhead Ratchet Cam 1050

12144 Bullet Bin Bracket

12184 Swage Die Body – Part

12260 1050 Box For Shipping

12486 Cam Guide Bolt 1/4x20

12819 Primer System Push Rod

12901 Crankshaft 1050

12930 Primer Station Retain Tab

12972 Toolhead Alignment Rod

12995 Primer System Tappet

13001 New Lever Arm Bracket

13042 Crankshaft Journal

13058 Primer System Rocker Arm

13064 Swage Cover 1050

13073 Casefeed Plunger – Large

13086 Index Roller Bolt 1050

13089 Failsafe Rod Eye Bolt

13091 Alignment Bushing – New

13098 Casefeed Plunger – Medium

13108 Primer Slide Stop “B”

13142 Mainshaft 1050

13161 Casefeed Cam1050

13189 1050 Ejector Tab

13205 Post Bolts

13226 Rocker Arm Set Screw

13238 Cartridge Bin Bracket

13244 Crank Retaining Ring

13245 Primer Swage Adjustment Bolt

13258 Mainshaft Pivot Pin

13262 7/32” Hex Wrench (Short)

13271 Post Stud

13276 Crank Hand Roller Bolt

13296 Primer System Rocker Bolt

13306 Casefeed Plunger – Small

13324 Connecting Rod 1050

13328 SD Shellplate Bolt

13333 Locator Tab Bolt

13335 Spring Bushing

13342 Toolhead Bolt

13363 Primer Magazine Socket Bolt

13365 Index Roller 1050

13376 Ratchet Restriction Tab

13377 Bin Bracket Mount Screw

13392 Crankshaft Bearing

13413 Slide Actuating Lever

13417 Swage Connecting Rod

13419 Swage Rod Locknut

13426 Powder Funnel A – Rifle

13432 Crank Handle Lock Screw

13435 1/4” Hex Wrench

13449 Toolhead Washer

13475 Journal Key 1050

13483 Old Style Jam Nut 9/16x18

13484 1050 Cartridge Bin

13495 Lower Cord Clamp

13498 Plunger Roller 1050

13502 Clamp Retaining Screw

Part # Description

13508 Index Ball 1050

13515 Slide Alignment Pin

13522 Clevis Pin

13525 Index Ball Spring 1050

13534 Casefeed Adapter Housing

13561 Lock Ring Insert

13567 Casefeed Plunger Spring

13572 Toolhead Spring

13581 Grease Zerts

13593 5/32” Hex Wrench

13607 Rocker Bolt Lock Washer

13611 Casefeed Post Warning Label

13624 Index Pawl Spring

13644 Small Powder Bar Spacer

13650 Spent Primer Cup

13655 5/16 Washer

13664 5/16-18 Nut

13682 Swage Lock Nut 1050

13685 1/4-20x1/2 Bracket Bolt

13696 3 Packing Foam Pieces

13701 Index Pawl Pin 3/8

13705 1050 Index Pawl

13728 1/8” Hex Wrench

13746 Actuating Lever Cotter Pin

13756 1050 Bullet Bin

13761 Casefeed Tube 1050

13793 Collar Roller

13799 Failsafe Strip Nut

13801 Tinnerman Insert

13813 Clutch Spring Washer

13815 Adapter Housing Screw

13818 Powder Bar Insert – Small

13827 3/16” Hex Wrench

13840 Hair Pin Cotter

13844 Short Lever Spring

13845 Body Collar Sleeve

13848 Bellcrank Bushing

13853 Powder Bar Insert – Large

13858 Primer Punch Spring 1050

13859 Casefeed Tube Clip

13871 Bellcrank Cube

13882 Powder Measure Lid

13886 3/32” Hex Wrench

13893 Powder Bar Post – Large

13895 10-24 x 3/8” BH Screw

13896 1/4-20 3/8 BH –

Ejector Tab Screw

13904 Bellcrank Bolt

13921 Powder Bar Spacer Plug

13929 Failsafe Rod Clip

13936 Tab/Spring Arm Spring

13939 Body Collar Clamp – Part

13943 Powder Bar Adjustment Screw

13944 Indexer Return Spring

13945 Pivot Bolt Waved Washer

13951 Powder Bar Post – Small

13955 Lower Plate Screw

Part # Description

13957 Magazine Shield Cap 1050

13958 Powder Bar Bolt Washer

13960 Failsafe Rod – Part

13972 3/16 Roll Pin

14003 Magazine Orifice –

Large – Red

14023 10-24 5/8 Buttonhead Screw

14024 Magazine Orifice –

Small – Blue

14033 Return Rod Spring

14036 Old Powder Bar Return Spring

14037 Collar Clamp Screw

14067 Die Lock ring

14202 Powder Measure Tube Screw

14517 Swage Station Bushing

14808 Collar Roller Bushing

14990 Slide Roll Pin Sleeve

17069 Snap Ring

17084 Irolox Retaining Ring

17110 Dowel Pins

17604 Bracket Pivot Pin

17808 Casefeed Bowl Insert

20062 Small Powder Bar Assembly

20063 Large Powder Bar Assembly

20311 1050 Lock Ring Assembly

20312 1050 Index Lever Assembly

20313 Swage Rod 1050 – Small

20314 Swage Rod 1050 – Large

20317 1050 Primer Slide – Small

20318 1050 Primer Slide – Large

20320 Powder Die

20322 Casefeed Assembly 1050 –

Large Pistol

20324 Casefeed Assembly 1050 –

Small Rifle

20341 1050 Bushing Driver

20419 1050 Primer System – Small

20420 1050 Toolhead Assembly

20421 Auto Powder System

20476 1050 Primer System – Large

20488 1050 Primer Arm/Cam –

Assembly

20635 Ratchet Detent Assembly

20641 Casefeed Mounting Post –

Assembly

20773 Primer Feed Body/Shield

20785 Powder Measure Body

21072 Casefeed Plate – Large Pistol

21073 Casefeed Plate – Small Pistol

21074 Casefeed Plate – Small Rifle

21079 Casefeed Assembly 1050 –

Small Pistol

21275 Body Collar – Complete

21530 Floating Decap Assembly

Page 21

21

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

;;;;;;;

;;;;;;;

;;;;;;;

RL 1050 Upper Machine Assembly

#17071 – Handle Assembly

17918

12727

12901

13432

17069

12901

#20420 – Toolhead Assembly

13342

13449

20420

13957

20773

20317 – small

20318 – large

13955

13108

13376

13328

13936

13276

13944

13205

13664

12930

13895

12974

13650

13896

13896

13189

13525

13508

13226

13089

13425

20635

13335

13572

13895

13142

13561

*20637

13896

13945

See page 23 for

more detail.

13342

12819

13005 - 13015

see caliber

conversion

chart on pg. 19

Expander

– see

caliber

conversion

chart on

pg. 19

20320

14067

Seating

Die

Sizing

Die

14067

13482

13142

13161

13896

11686

12486

20420

13449

Crimp

Die

20312

assembly

20311

assembly

Shellplate –

caliber specific,

see the caliber

conversion

chart on pg. 19

Page 22

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

22

13244

13392

12901

13475

13392

14517

20313 - small assembly

20314 -

large assembly

13064

13896

13682

13245

13417

13581

13840

13522

See item

#22216

below

See page 25 – Casefeed

Frame Assembly

See

Item A

below

RL 1050 Lower Machine Assembly

#22216 – Connecting Rod Assembly

Item A – Swage Rod Assembly

13142

13258

17084

13365

13086

13324

13581

17110

13581

17084

13042

Lower Machine Assembly

Part # Description

12901 Crankshaft 1050

13244 Crank Retaining Ring

13392 Crankshaft Bearing

13475 Journal Key 1050

#22216 – Connecting Rod

Assembly

Part # Description

13086 Index Roller Bolt 1050

13142 Mainshaft 1050

13258 Mainshaft Pivot Pin

13365 Index Roller 1050

22216 1050 Connecting Rod Assembly:

13042 Crankshaft Journal

13324 Connecting Rod 1050

13581 Grease Zerts

17084 Irolox Retaining Ring (2)

17110 Dowel Pins

Item A – Swage Rod Assembly

Part # Description

13064 Swage Cover 1050

13417 Swage Connecting Rod

13522 Clevis Pin

13581 Grease Zerts

13840 Hair Pin Cotter

13896 1/4-20 3/8 BH Ejector Tab Screw

14517 Swage Station Bushing

20313 Swage Rod Assembly – Small:

13127 Swage Rod (1050) – Small

13245 Primer Swage Adjmnt Bolt

13682 Swage Lock Nut 1050

20314 Swage Rod Assembly – Large:

13245 Primer Swage Adjmnt Bolt

13364 Swage Rod (1050) – Large

13682 Swage Lock Nut 1050

Page 23

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

Primer System Assembly - #20488

Upper Lower

13957

13840

14037

13001

20488

13413

17604

13844

13936

13746

20773

13363

13363

12995

13130 - large

13222 - small

13423

14990

13858

13058

13607

13296

12849 - large

13307 - small

20317 - small

20318 - large

22030 - small

22031 - large

Upper Assembly

Stock Description

13957 Magazine Shield Cap

20773 Primer Feed Body/Shield

22030 Primer Magazine Tube – Small

22031 Primer Magazine Tube – Large

20488 Primer Arm/Cam Assembly

13001 New Lever Arm Bracket

13413 Slide Actuating Lever

13746 Actuating Lever Cotter Pin

13840 Hair Pin Cotter

13844 Short Lever Spring

13936 Tab/Spring Arm Spring

14037 Clutch/Motor Bolt

17604 Bracket Pivot Pin

Lower Assembly

Stock Description

12849 1050 Primer Punch – Large

12995 Primer System Tappet

13058 Primer System Rocker Arm

13130 Primer Punch Bushing – Large

13222 Primer Punch Bushing – Small

13296 Primer System Rocker Bolt

13307 1050 Primer Punch – Small

13363 Primer Magazine Socket Bolt

13607 Rocker Bolt Lock Washer

13858 Primer Punch Spring 1050

20317 Primer Slide Assembly – Small

13423 Roll Pin – 1/8x5/8

14990 Slide Roll Pin Sleeve

20318 Primer Slide Assembly – Large

13423 Roll Pin – 1/8x5/8

14990 Slide Roll Pin Sleeve

23

Page 24

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

24

RL 1050 Casefeeder Assembly

HIGH

OFF

LO

13400

17808

13494

13859

13812

13540

13761

13756

20641

13539

13205

13484

13377

13685

12144

13655

13238

See

Page 25

Item A

13271

13655

13495

Stock # Description

12144 Bullet Bin Bracket

13205 Post Bolts

13238 Cartridge Bin Bracket

13271 Post Stud

13377 Bin Bracket Mount Screw

13400 Casefeed Bowl 1050

13473 Casefeed Motor – 4 RPM

(Not Shown)

13484 1050 Cartridge Bin

13494 Casefeed Funnel

13495 Lower Cord Clamp

13502 Clamp Retaining Screw

13539 Casefeed Cord Set

13540 Casefeed Motor Cover

13655 5/16 Washer

13688 Casefeed Funnel Baffle

(9mm/.380/.38 Sup. Not Shown)

13756 Bullet Bin

13761 Casefeed Tube 1050

13779 Micro Switch (Not Shown)

13812 Lighted Power Switch

13859 Casefeed Tube Clip

13895 10-24 BH Screw (Not Shown)

13954 Micro Switch Mount Screw

(Not Shown)

14022 Casefeed Motor Roll Pin

(Not Shown)

14023 10-24 5/8 Buttonhead Screw

(Not Shown)

14026 8-32x1/2 Bowl/Motor Screw

(Not Shown)

17808 Casefeed Bowl Insert

20322 Casefeed Assembly 1050

(Large Pistol)

20324 Casefeed Assembly 1050

(Small Rifle)

20641 Casefeed Mounting Post

Assembly

21079 Casefeed Assembly 1050

(Small Pistol)

Page 25

25

* Indicates a caliber specific part – see the caliber conversion

chart on page 19 for the caliber you are loading for.

RL 1050 Casefeed Sub Assemblies

#22221 – Powder Measure Assembly

Casefeeder Clutch

Assembly

Stock # Description

13632 Upper Clutch

13655 5/16 Washer

13703 Spacer (.41, .44, .45LC,

.357, .30 Carbine)

13732 Clutch/Motor Bolt

13736 Lower Clutch

13813 Clutch Spring Washer

21072 Casefeed Plate

(Large Pistol)

21073 Casefeed Plate

(Small Pistol)

21074 Casefeed Plate

(Small Rifle)

Item A – Casefeed

Frame Assembly

Stock # Description

13333 Bolt (Locator Tab)

13498 Plunger Roller

13534 Adapter Housing

13567 Casefeed Plunger Spring

13815 Adapter Housing Screw

13972 3/16 Roll Pin

Stock # Description

*13005 Powder Activator, Pistol

13089 Failsafe Rod Eye Bolt

*13426 Powder Funnel “A”, Rifle

13644 Small Powder Bar Spacer

13793 Collar Roller

13799 Blue Failsafe Strip Nut

13801 Tinnerman Insert