Page 1

Quick Balance

Tension Meter

User Instructions

AWT 35-500545

Issue AB

Page 2

Dillon is part of Avery Weigh-Tronix. Avery Weigh-Tronix is a trademark of the Illinois Tool Works group of companies whose

ultimate parent company is Illinois Tool Works Inc (“Illinois Tool Works”). Copyright © 2017 Illinois Tool Works. All rights reserved.

No part of this publication may be reproduced by making a facsimile copy, by the making of a copy in three dimensions of a two-dimensional

work and the making of a copy in two dimensions of a three-dimensional work, stored in any medium by electronic means, or transmitted

in any form or by any means, including electronic, mechanical, broadcasting, recording or otherwise without the prior written consent of the

copyright owner, under license, or as permitted by law.

This publication was correct at the time of going to print, however Avery Weigh-Tronix reserves the right to alter without notice the

specification, design, price or conditions of supply of any product or service at any time.

QuickBalance_u_en_500545.book

Page 3

Table of Contents

page

Chapter 1 General information and warnings ......................................................................................... 5

About this manual ..............................................................................................................5

Text conventions ......................................................................................................... 5

Special messages ....................................................................................................... 5

Installation .......................................................................................................................... 6

Safe handling of equipment with batteries .................................................................. 6

Routine maintenance ......................................................................................................... 6

Cleaning the machine ........................................................................................................ 7

Training .............................................................................................................................. 7

Sharp objects ..................................................................................................................... 7

FCC and EMC declarations of compliance ........................................................................ 7

Chapter 2 Introduction .............................................................................................................................. 8

Unpacking .......................................................................................................................... 8

Description ......................................................................................................................... 8

Important features ............................................................................................................ 10

Chapter 3 Operation ................................................................................................................................ 11

Typical Operation ............................................................................................................. 11

Measurement Practices ................................................................................................... 12

Softkey Functions ............................................................................................................ 13

Top level softkeys ...................................................................................................... 13

Chapter 4 Configuration Mode ............................................................................................................... 18

Accessing the Configuration Mode .................................................................................. 18

Chapter 5 Changing Sheaves ................................................................................................................. 21

Chapter 6 Achieving Best Accuracy ...................................................................................................... 22

Accuracy .......................................................................................................................... 22

Calibration to Specific Wire Type ..................................................................................... 22

What Calibration Choice and Sheaves Should I Use? .............................................. 22

Loading Error ................................................................................................................... 23

Non-repeatability ..............................................................................................................23

Non-linearity ..................................................................................................................... 23

Wire Characteristics ......................................................................................................... 23

Chapter 7 Troubleshooting ..................................................................................................................... 24

Quick Balance User Instructions 3

Page 4

4 Quick Balance User Instructions

Page 5

1 General information and warnings

1.1 About this manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled as shown by the 1 and 1.1 headings shown above.

The names of the chapter and the next subsection level appear at the top of alternating

pages of the manual to remind you of where you are in the manual. The manual name

and page numbers appear at the bottom of the pages.

1.1.1 Text conventions

Key names are shown in bold and reflect the case of the key being described. This

applies to hard keys and onscreen or softkeys.

Displayed messages appear in bold italic type and reflect the case of the displayed

message.

1.1.2 Special messages

Examples of special messages you will see in this manual are defined below. The

signal words have specific meanings to alert you to additional information or the relative

level of hazard.

ELECTRICAL WARNING!

THIS IS AN ELECTRICAL WARNING SYMBOL.

ELECTRICAL WARNINGS MEAN THAT FAILURE TO FOLLOW

SPECIFIC PRACTICES OR PROCEDURES MAY RESULT IN

ELECTROCUTION, ARC BURNS, EXPLOSIONS OR OTHER HAZARDS

THAT MAY CAUSE INJURY OR DEATH.

CAUTION!

This is a Caution symbol.

Cautions give information about procedures that, if not observed, could result

in damage to equipment or corruption to and loss of data.

NOTE: This is a Note symbol. Notes give additional and important information, hints

and tips that help you to use your product.

Quick Balance User Instructions 5

Page 6

1.2 Installation

DANGER: RISK OF ELECTRICAL SHOCK. NO USER SERVICEABLE

PARTS. REFER TO QUALIFIED SERVICE PERSONNEL FOR SERVICE.

1.2.1 Safe handling of equipment with batteries

CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only

with the same or equivalent type recommended by the manufacturer. Dispose

of used batteries according to the manufacturer’s instructions.

ATTENTION: Il y a danger d'explosion s'il y a remplacement incorrect de la

batterie, remplacer uniquement avec une batterie du même type ou d'un type

équivalent recommandé par le constructeur. Mettre au rebut les batteries

usagées conformément aux instructions du fabricant.

1.3 Routine maintenance

IMPORTANT: This equipment must be routinely checked for proper operation

and calibration.

Application and usage will determine the frequency of calibration required for

safe operation.

Always turn off the machine and remove batteries before starting any routine

maintenance.

6 Quick Balance User Instructions

Page 7

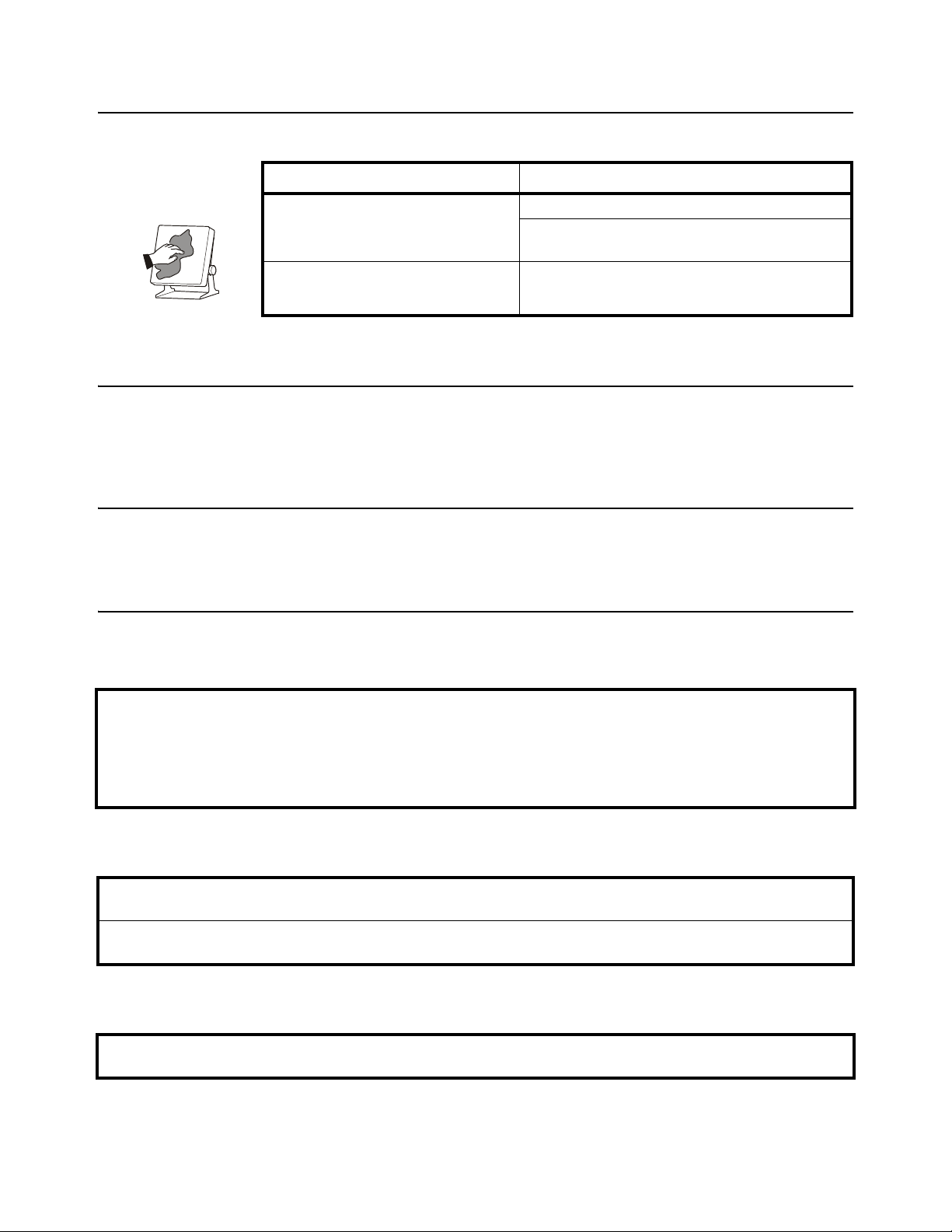

1.4 Cleaning the machine

Table 1.1 Cleaning DOs and DON’Ts

DO DO NOT

Wipe down the outside of standard products

with a clean cloth, moistened with water and

a small amount of mild detergent

Spray the cloth when using a proprietary

cleaning fluid

Attempt to clean the inside of the machine

Use harsh abrasives, solvents, scouring cleaners or

alkaline cleaning solutions

Spray any liquid directly on to the display windows

1.5 Training

Do not attempt to operate or complete any procedure on a machine unless you have

received the appropriate training or read the instruction books.

1.6 Sharp objects

Do not use sharp objects such as screwdrivers or long fingernails to operate the keys.

1.7 FCC and EMC declarations of compliance

United States

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Canada

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la Classe A prescrites dans le Règlement sur le brouillage radioélectrique edicté par le ministère des Communications du Canada.

European Countries

WARNING: This is a Class A product. In a domestic environment, this product may cause radio interference in which the user may be

required to take adequate measures.

Quick Balance User Instructions 7

Page 8

2 Introduction

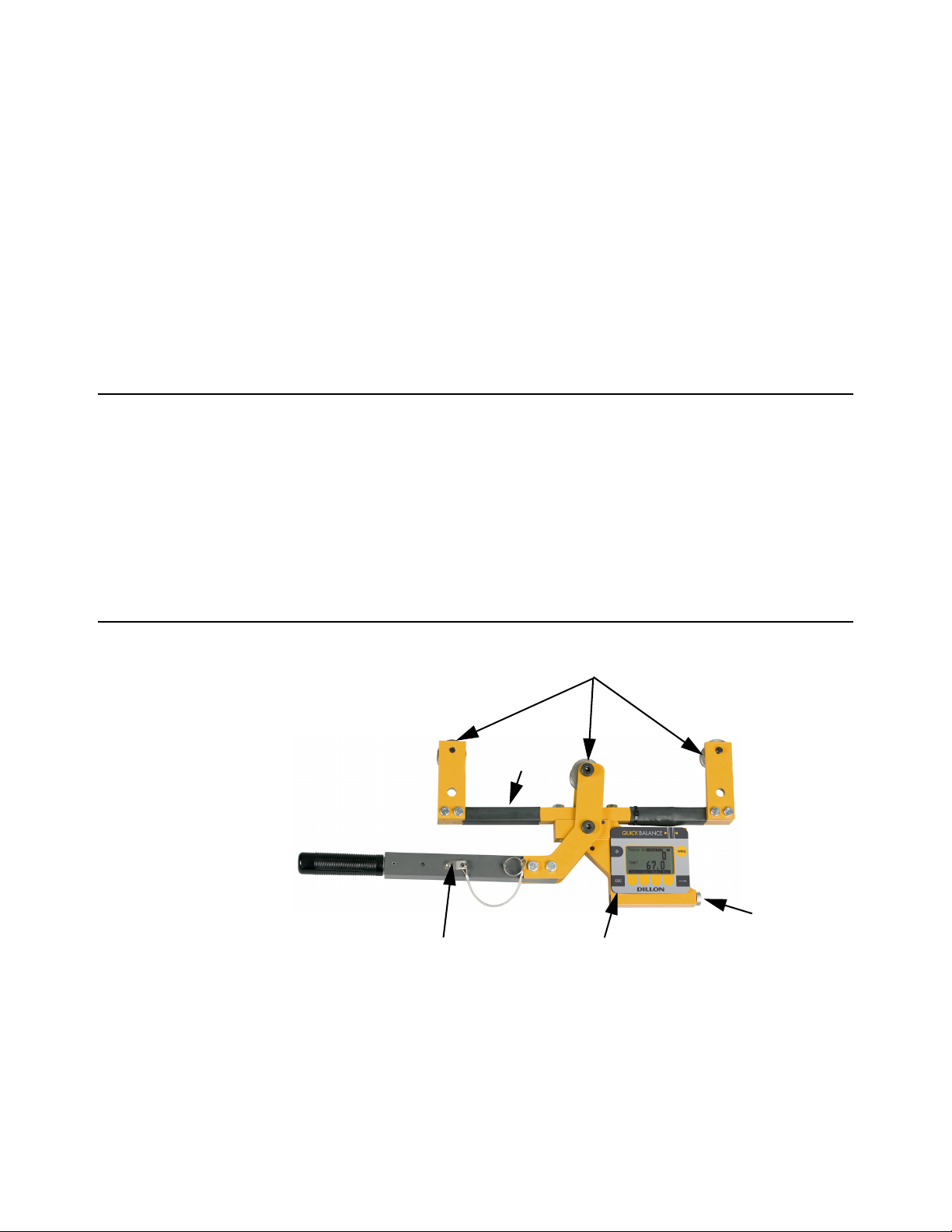

Sheaves

Lever arm

Front panel

Battery

compartment

Support

arm

This manual covers the setup and operation of the Quick Balance Tension Meter from

Dillon. The Quick Balance is a simple, accurate strand dynamometer. It can be

clamped onto a cable, accurately determine the wire tension and be removed in

seconds.

The Quick Balance can handle multiple wire diameters, it can display live tension, dual

live/peak tension, average tension captured from several tests, dual tension/

temperature display and a check-tensioning graphical display.

With its battery-powered electronic interface, setup and operation is made simple with

on-screen prompts.

2.1 Unpacking

When you receive your Quick Balance, unpack it and inspect the container and the

instrument for any damage. Report any problems to the shipping company immediately

and save the packing materials.

Insert 2 ‘C’ batteries into the battery compartment, shown in Figure 2.1. Your Quick

Balance probably comes from the factory with the proper sheave size installed and

calibrated for your application. If not, follow the setup directions in Configuration Mode

on page 18 and Changing Sheaves on page 21.

2.2 Description

The Quick Balance is shown in Figure 1 with the parts labeled.

Figure 2.1 Front Panel and Keys

8 Quick Balance User Instructions

Page 9

The front panel of the Quick Balance is shown in Figure 2.2.

Figure 2.2 Quick Balance front panel

Following are descriptions of the keys and their functions:

ON/OFF key. Press this key to power up and turn off the Quick Balance.

ESC key. Press this key to escape an area of the menu or to clear the field when

in data entry mode.

WIRE key. Press this key to change the wire diameter you are testing with the

Quick Balance. Choose from the listed selection and when the desired size is

highlighted, press the ENTER softkey. Three standard sizes included:

1/2” 8 x 19

9/16” 8 x 19

5/8” 8 x 19

Five additional sizes may be added.

Softkey. Softkey function changes as needed for different tasks. The softkey

labels appear above the keys themselves. You will use these for operation and

configuration.

Arrow key. Press this key to reveal more softkeys in a group of softkeys.

Quick Balance User Instructions 9

Page 10

2.3 Important features

Quick to use Attaches and removes from tensioned line in seconds.

Direct tension readings No more complicated lookup charts! Save time and

Portable & rugged Designed for outdoor use.

Accurate Employs Weigh Bar

Multiple wire size storage Three standard sizes included:

Quick readout for ultra fast line tensioning.

improve accuracy.

®

technology used for precise

weighing.

1/2” 8 x 19

9/16” 8 x 19

5/8” 8 x 19

Five additional sizes may be added.

10 Quick Balance User Instructions

Page 11

3 Operation

Typical operation of the Quick Balance is covered below, followed by explanations of

the various display modes, how to change wire size, how to change the unit of

measure, etc.

3.1 Typical Operation

Take readings at three different places along the cable, moving the tension meter at

least four inches for each reading. Take the average of the readings. The built-in

average function is ideal for this task.

The handle quick release pin should be used when the Quick Balance is attached to a

cable that will be de-tensioned and retensioned. The pin prevents the handle from

opening once the tension falls to a small level. The pin should also be used if the

Quick Balance will be installed for a prolonged period.

To perform a typical tension measurement, see the note above and follow these steps:

1. Turn the unit on by pressing the ON/OFF key…

The display shows DILLON briefly, then, in this example, the screen

shows the following:

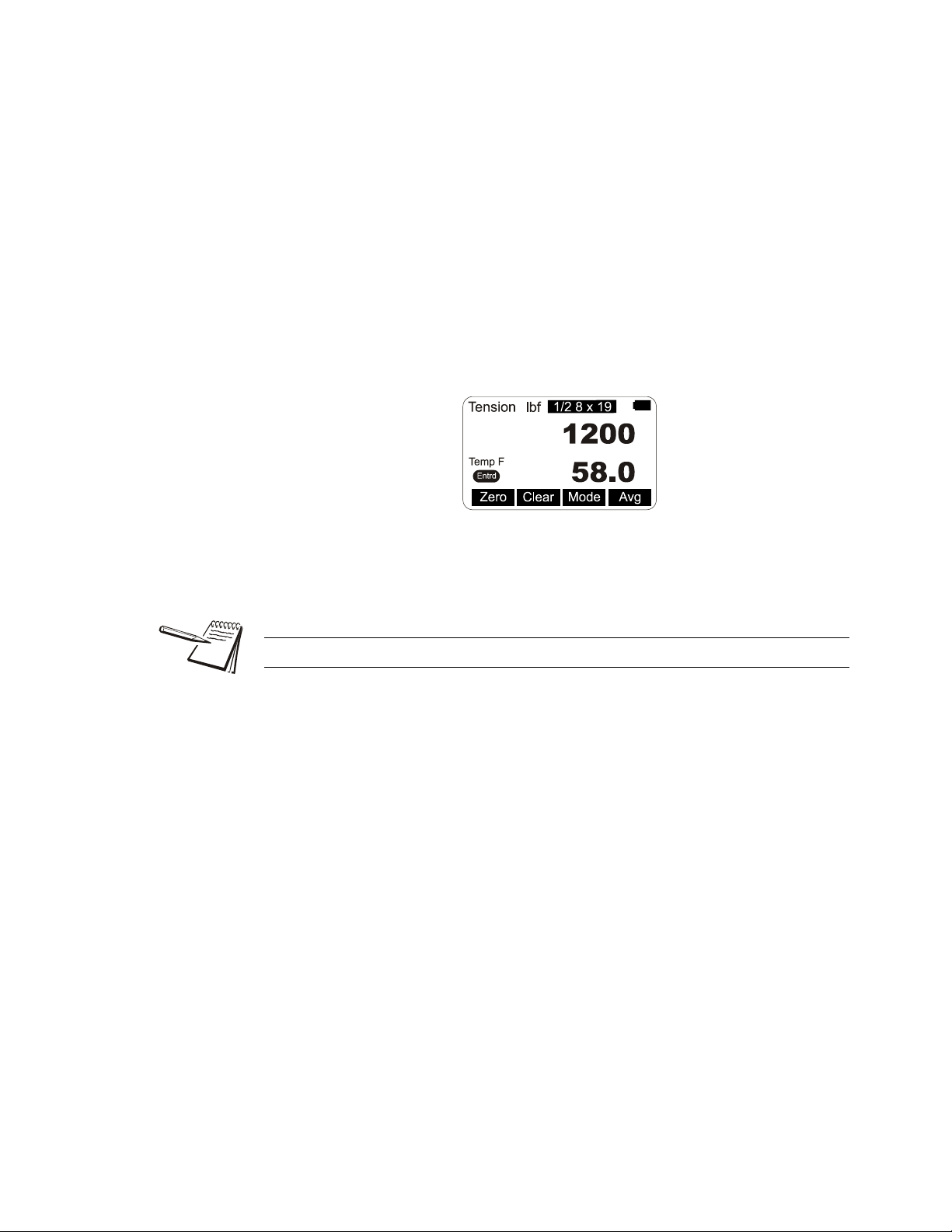

Figure 3.1 Sample display

Press the WIRE key to list the stored calibrations.

2. This example shows the wire is a 1/2”, 8 X 19 stranded cable and the unit of

measure is lbf. Place the Quick Balance so the two outside sheaves hang on

the wire. Insure that the wire rope is riding in the groove of all three sheaves.

See Figure 3.2. Press the Zero softkey to zero the display.

0 should be displayed.

3. Raise the lever arm until it locks in the upright position to apply tension to the

wire. Read the line tension on the display.

Quick Balance User Instructions 11

Page 12

4. Release the lever arm and you are ready to perform another measurement.

Figure 3.2 Quick Balance attached to cable

3.2 Measurement Practices

For best measurement, install the Quick Balance at least 2 feet (0.6 m) from

terminations, clamps or other hardware. Do not install over the top of wire wrappings.

Take readings at three different places along the cable, moving the tension meter at

least four inches for each reading. Take the average of the readings. The built-in

average function is ideal for this task.

Do not apply tension greater than rated capacity of the instrument or overload

damage to the sensor may result.

Do not use the Quick Balance with cable larger than indicated on the sheaves.

Overload and damage to the instrument may result.

Do not mix sheave sizes. This will result in inaccurate measurement and possible

overload.

Do not use the Quick Balance to measure tension for wires if both of the following are

true:

1. No wire calibrations are stored of the same diameter as the wire you are looking

to measure, and

2. You do not have sheaves of the same diameter.

If both of these conditions exist, contact your Dillon distributor.

Contact your Dillon distributor to improve accuracy for a specific wire type by calibrating

to it.

Insure that the wire rope is riding in the groove of all three sheaves.

12 Quick Balance User Instructions

Page 13

Insure sheaves installed agree with sheaves noted in the Wire calibration. Exception:

Sheaves match the wire diameter of the cable to be measured and alternate calibration

is selected as per section Calibration to Specific Wire Type on page 22.

The Quick Balance has an internal temperature sensor inside the electronics cavity.

Dramatic temperature changes (such as moving from a warm vehicle to cooler

outdoors) requires time for the sensor to reach the same temperature. Direct sunlight

will heat the electronics cavity and cause higher readings than actual ambient

temperature. In these cases, use a seperate thermometer to determine temperature.

Be certain to enter this temperature into the Quick Balance if using the quick-tensioning

mode with the temperature dependent acceptance window.

For best tension accuracy, use the exact temperature of the wire. This may be widely

different from the ambient temperature if the cable has been sitting in direct sunlight.

3.3 Softkey Functions

Now that you’ve seen a simple operation, we’ll explain the softkey functions. Figure 3.3

shows the softkeys available during normal operation.

3.3.1 Top level softkeys

Zero Press this softkey to zero the force display. Press this at the beginning of

Clear Press this softkey and you are prompted to clear the Peak reading or the

Mode Press the Mode key to scroll through the five display modes. These are

Figure 3.3 Normal mode softkeys

a series of tension tests. You do not need to do it for every test unless there

is some zero drift.

Average. Make your choice by pressing the appropriate softkey and that

value is cleared from memory.

explained below:

Live Tension Mode: This is the default mode and it displays the live

tension.

Peak Mode: While in this mode, Peak is displayed on the screen. The

display shows the live tension on the top display and the peak force

achieved on the bottom display. To clear the peak remove any force on the

Quick Balance, press the Clear softkey and follow the prompts.

Balance Mode: While in this mode, Bal is displayed on the screen. This

mode allows you to capture the tension on two through 16 cables and

compare the readings.

Quick Balance User Instructions 13

Page 14

Temperature Mode: This mode shows the live tension in the top display

Display when tension is below

the dotted, target box.

Display when tension falls

within the dotted, target box.

and the current temperature in the bottom display. Also shown is whether

the reading is in Fahrenheit or Centigrade and if the temp is one that was

Entrd (entered) manually.

You can enter the temperature in one of two ways; let the Quick Balance

determine the ambient temperature automatically or key in a temperature

manually. Instructions for entering the temperature are under the Temp

softkey description.

Upper and lower thresholds for the Check-tensioning mode, discussed below, are set

in the Configuration WIRE menu.

Check-tensioning Mode: Check-tensioning mode permits quick & easy

graphical view of the applied tension versus the desired tension. This

mode works well when you are repeatedly tensioning to the same tension

range. This mode displays a bar graph representation of the tension being

applied. See Figure 3.4. The black bar represents the range of the wire,

from zero to ultimate wire rating. The wide white band is the tolerance

window based on upper and lower thresholds you can enter. The live force

is represented by the arrow and the white line on the black bar. When the

force gets within ±5% of the acceptance window, a close-up of the

acceptance window is displayed. See bottom example in Figure 3.4.

The Quick Balance has automatic tension targeting with temperature.

Points may be entered from a linear Tension-Temperature supplied table

for a wire cable. If entered, the check-tensioning window will automatically

float according to the active temperature (manual or automatic). Use the

bottom and top entries from the table. Patent is pending on this feature.

Figure 3.4 Check-tension display

To exit the check-tension mode, press any softkey to display the softkey

labels, then press the Mode softkey to scroll to the next mode. The next

mode is the first mode that was described, live tension mode.

14 Quick Balance User Instructions

Bal Press the Bal softkey to add a displayed tension to the average of other

entered readings. Follow the onscreen prompts.

Press the Right Arrow key to move to the next set of softkeys:

Page 15

Units Press this key to set the Quick Balance for displaying:

Temperature Display Mode

l Force in lbf, kgf or N

l Size of wire in inches or millimeters

l Temperature in Fahrenheit or Centigrade

Temp Press this softkey to choose the source of the temperature reading, the

Quick Balance itself (Meter), outside input (Input) or None. If you choose

Input, you are prompted to enter the temperature. When finished, press

the Enter softkey to accept this value.

Next you are prompted to choose Fahrenheit or Centigrade as the

temperature unit. When your choice is highlighted, press the Enter

softkey.

An annunciator shows when temperature has been manually entered. See

example below:

Setup Press the Setup softkey and you will see these choices; Bal, Off, About,

Misc and Test. These are described below:

Auto-off can preserve battery life.

Bal Press this softkey to perform a cable balance operation. You will

be prompted for information regarding the load such as the total

system weight and the number of cables being used to suspend it.

Off Press this softkey to enable or disable the auto-shutdown function.

If you choose Yes, you are asked to set a period of time in minutes.

Next, press the Enter softkey to accept this value. You are then

asked to set the shutdown type; Fixed, No Load, or No Change.

These are described below;

Fixed - The unit will shutdown after the set number of

minutes no matter what happens.

No Load - The unit will shutdown after the set number of

minutes only if there is no load on the unit. This

prevents shutdown in the middle of a test.

No Change - The unit will shutdown if there has been no keypad

activity or change in tension after the set number of

minutes.

Quick Balance User Instructions 15

Page 16

About Press this softkey to see the following information:

Device - Press this softkey to show a list of information about

the Quick Balance, such as -- serial number,

capacity rating, hardware and software revision

levels. Press any key to return to the previous

softkey set.

Calib - Press this softkey to show Calibration Points and

the calibration information for the current wire size.

Follow the on-screen prompts.

O. Load - Press this softkey to show an audit count of the

number of times the unit has been overloaded

beyond 125% of capacity. Press any key to return

to the previous softkey set.

Zero - Press this softkey to show the deadload anaylsis of

the Quick Balance. Press any key to return to the

previous softkey set.

Misc Press this softkey to set the following:

Flash - Enables or disables the momentary blinking of the

display to acknowledge a key press.

Zero - Enables the use of the Zero softkey to clear a peak

tension value.

Contr - Press this key to adjust the contrast of the LCD

display. Press the Up softkey to lighten the contrast.

Press the Down softkey to darken the contrast.

There is a keypad shortcut for increasing and

decreasing contrast. While in normal display mode

press and hold the Arrow key, then press and hold

the 2nd softkey simultaneously to increase contrast.

Press and hold the Arrow key, then press and hold

the 1st softkey simultaneously to decrease contrast.

Blite - Choose Blite to change the backlight operation.

You can increase or decrease the intensity (Inten)

or choose to turn the backlight on or off (Mode).

Test Press this softkey and the following softkeys appear:

Batt - Press this softkey to test the battery level.

A-D - Press this softkey to display the A to D counts.

Disp. - Press this softkey to perform a test of the display

pixels.

Keys - Press this softkey to test the keypad.

16 Quick Balance User Instructions

Page 17

Config This is a password protected menu. See Configuration Mode on page 18.

Press the ESC key to return to the normal operating mode. If you made changes to the

configuration of the unit, you are prompted to save them or abort the changes. Do so

and the unit returns to normal operation mode.

Quick Balance User Instructions 17

Page 18

4 Configuration Mode

4.1 Accessing the Configuration Mode

You need to access the Configuration mode to perform certain tasks. Access to some

of these tasks may be restricted by a supervisor password.

The Num keys increment and decrement the displayed numbers. The Adv key

moves the cursor to the next digit position.

Default Configuration password is 0. If a new password is lost or forgotten, contact

your Dillon distributor.

To access Configuration mode:

1. From normal operating mode, press the Right Arrow softkey…

A new softkey set, shown below, appears:

2. Press the Config softkey…

The following is displayed:

3. Use the Num and Adv keys to enter the Config password. Default is 0. After

the number is displayed, press the Enter key…

The following is displayed:

18 Quick Balance User Instructions

Page 19

4. The unit is now in the Configuration mode. To see the rest of the softkeys

available in this mode, press the Right Arrow key. All the Config softkeys are

shown below.

The softkeys in the Configuration mode are Wire, Setup, Reso, Mode, Units, Power,

ChPwd, and Reset. These are described below:

Wire Press this softkey and the wire selection screen is displayed. Choose an

existing wire to change its defining characteristics.

You are given a choice of changing the Range, which is used to set the

check-tensioning function, or the Rating, which is the maximum rating of

the cable.

Range - Press the Range softkey to set the range parameters for the

check tensioning display and follow the prompts to set the

following:

Low Temperature This is the lowest temperature at which the

device is accurate.

High Temperature This is the hioghest temperature at which the

device is accurate.

Units Set temperature scale (F or C)

Tension at Low This is the lowest acceptable force

Tension at High This is the highest acceptable force

Units Unit of measure used in defining the tension

limit (lbf, N, or kgf)

+/- Tolerance - Set the tolerance value.

Units - Set the unit of measure for the tolerance value

(lbf, N, or kgf)

Rating - Press this softkey and you are prompted to set the ultimate

rating for the cable being used and the unit of measure for that

rating (lbf, N, or kgf).

Setup Press the Setup softkey to view the Setup softkeys. This is the same as

the Setup softkey described in Top level softkeys on page 13.

Reso Press the Reso softkey and you are prompted to enter a display, or count-

by, resolution. Choose from Low, Medium or High. Medium is the default

value.

Low resolution provides the best stability and makes the display easiest to

read. High resolution provides the finest graduations, but sees greater drift

from wire creep and non-repeatability. If the reading is decreasing over

time or differing between measurements on the same line, lowering the

resolution will reduce these effects.

Mode Press this softkey to set the display mode on power up. Choices are

Force, Last, Temp,

Check, Bal, and Peak. Use the Sel keys to scroll

through the choices and press Enter to accept the displayed choice.

Quick Balance User Instructions 19

Page 20

Units Press this softkey to set the following:

l Unit of measure on power up. Choices are Last*, C2, C1, N, kgf, and

lbf. Use the Sel keys to display your choice and press Enter to

accept it. C2 and C1 are custom units. If you choose to have custom

units, you are prompted to enter the number of pounds in each

custom unit. The Quick Balance will then automatically calculate

correct display for the applied force.

Custom units of measure are handy when working with multi-part lines.

l Enable lbf - Enable or disable the pound-force unit of measure.

l Enable kgf - Enable or disable the kilogram-force unit of measure.

l Enable N - Enable or disable the N unit of measure.

l Enable CUST1 - Enable or disable the Cust1 unit of measure.

l Enable CUST2 - Enable or disable the Cust2 unit of measure.

l Enable C - Enable or disable Centigrade temperature.

l Enable F - Enable or disable Fahrenheit temperature.

Power Press this softkey to enable or disable the auto-shutdown. If you enable

this function you are prompted to set a period of time in minutes. Next,

press the Enter softkey to accept this value. You are then asked to set the

shutdown type; Fixed, No Load, or No Change. These are described

below;

Fixed - The unit will shutdown after the set number of minutes no

matter what happens.

No Load - The unit will shutdown after the set number of minutes only

if there is no load on the unit. This prevents shutdown in the

middle of line tensioning.

No Change - The unit will shutdown if there has been no keypad activity

or change in tension after the set number of minutes.

ChPwd Press this key and you are prompted to enter a new password to access

the configuration menus. Use the softkeys to scroll in a new password and

press the Enter softkey to accept it.

Reset Press this key and you are asked if you wish to reset the system. Press the

Yes softkey only if you want to reset the unit to factory default

configuration. Press the No softkey to abort this and return to the previous

screen.

Default password is 0. If a new password is lost or forgotten, contact your Dillon

distributor.

20 Quick Balance User Instructions

Page 21

5 Changing Sheaves

Screws

Do not use the Quick Balance with cable larger than indicated on the sheaves.

Overload and damage to the instrument may result.

Do not mix sheave sizes. This will result in inaccurate measurement and possible

overload.

As you use the Quick Balance on different diameter cables you must change to the

correct sheave size. To change sheaves, remove the hex head screws pointed out in

Figure 5.1 below. Replace the sheaves with the correct letter sheave and reinsert the

screws and tighten.

Insure sheaves installed agree with sheaves noted in the Wire calibration. Exception:

Sheaves match the wire diameter of the cable to be measured and alternate calibration

is selected as per the instructions in Calibration to Specific Wire Type on page 22.

Insure that the wire rope is riding in the groove of all three sheaves.

Figure 5.1 Changing sheaves

Quick Balance User Instructions 21

Page 22

6 Achieving Best Accuracy

6.1 Accuracy

The Quick Balance is an instrument designed to give accuracy that typically exceeds

normal requirements for wire tensioning. You should have an understanding of what

factors affect tension measurement accuracy.

6.2 Calibration to Specific Wire Type

While it is best to have the instrument calibrated to the specific wire size(s) and type(s)

used, the Quick Balance can often work adequately in other situations. If the best

tension accuracy is required, Dillon recommends that a calibration be performed for

that specific wire size and type.

Contact your Dillon distributor for any additional calibrations you may need.

6.2.1 What Calibration Choice and Sheaves Should I Use?

Situation Wire calibration selection Sheave selection Accuracy

Exact wire size and type is

shown in wire list

Wire size is same, but type

is not identical

Wire size is not the same Closest diameter Sheaves matching the wire size

Description of exact match Sheaves noted in list Best

Description of same wire diameter Sheaves noted for that wire size Good

being measured

Do not use the Quick Balance to measure tension for wires if both of the following are

true:

1. No wire calibrations are stored of the same diameter as the wire you are looking

to measure, and

2. You do not have sheaves of the same diameter.

If both of these conditions exist, contact your Dillon distributor.

Contact your Dillon distributor to improve accuracy for a specific wire type by calibrating

to it.

Fair

22 Quick Balance User Instructions

Page 23

6.3 Loading Error

A tensiometer works by deflecting the cable, which makes the cable path longer than

when a tensiometer is not installed. When the tensiometer is removed, the wire tension

decreases as the cable length is restored. This effect is known as loading error. The

Quick Balance design elongates the cable by a mere 0.08 inch (2 mm), making loading

errors extremely small.

6.4 Non-repeatability

The Quick Balance’s sheave with bearing design provides the best mechanical

performance. It is also superior at detecting tension that is being added or removed.

6.5 Non-linearity

Most three-point tension meters employ only linear characterization and have large

errors at the midpoints (up to 15%). The Quick check uses multi-point segmenting to

correct for non-linearity, reducing it to less than 0.2%.

6.6 Wire Characteristics

Creep Every material including steel exhibits creep under load. It will neck down

over time, quite quickly over the first few seconds and much slower as

time progresses. A wire cable also sees creep from the wire spacing and

wind. This effect is seen as a display that drifts lower after it has been

clamped in line.

Variations Material that varies in diameter or shape will have different output at the

same tension

Strands The best cable assembly is one that is perfectly round, as it will not

change contact geometry with the wire twist. The closer the wire cable

cross section appears to be round, the better the measurement

performance will be.

Quick Balance User Instructions 23

Page 24

7 Troubleshooting

Problem Possible Cause Solution

Powers on momentarily and turns off Low battery Replace with high quality alkaline batteries

Does not power on Low battery Replace with high quality alkaline batteries

Batteries installed backwards or no

spring contact

Software reset Remove battery cap & reinstall after one

Display contrast too light Hold the Right Arrow key down while pressing

Display is completely dark Display contrast too dark Hold the Arrow key down while pressing the F1

Display drifts downward once installed Wire material is creeping and internal

friction between wires is relieved.

Temperature not accurate Instrument changed temperature

environments

Instrument exposed to sun Enter temp manually

Insure that positive terminals of both batteries

(nub) face inward – towards the black cap.

Check that spring is attached to the battery

cap.

minute. Attempt to turn power on again.

the F2 key several times to increase the

display contrast. If nothing occurs, release both

keys. Press the power button and try again.

key several times to decrease the display

contrast.

This is normal behavior of wire. Lower display

resolution to mask this effect.

Allow instrument to remain in environment until

temp stabilizes or enter temp manually

24 Quick Balance User Instructions

Page 25

Page 26

AUTHORIZED DISTRIBUTORS

Ask the experts. Dillon distributors offer complete

service capabilities from application assistance to

sales and product support. Their experienced

representatives are the most knowledgeable

experts that you will find in the force measurement

industry. We recommend that you consult these

capable specialists for all of your measuring needs.

Overload Protection and

Overhead Weighing Equipment

Fairmont, Minnesota U.S.A.

Toll-Free: (800) 368-2031

Phone: (507) 238-4461

Fax: (507) 238-8258

www.dillon-force.com

Loading...

Loading...