Page 1

Dillon’s New Dynamic Pistol Dies

& Three-Die Rifle Die Sets

Instruction Manual, May 2007

illon

recision

Products, Inc.

8009 E. Dillon’s Way

Scottsdale, AZ 85260

Technical Support • (800) 223-4570

(480) 948-8009 • FAX (480) 998-2786

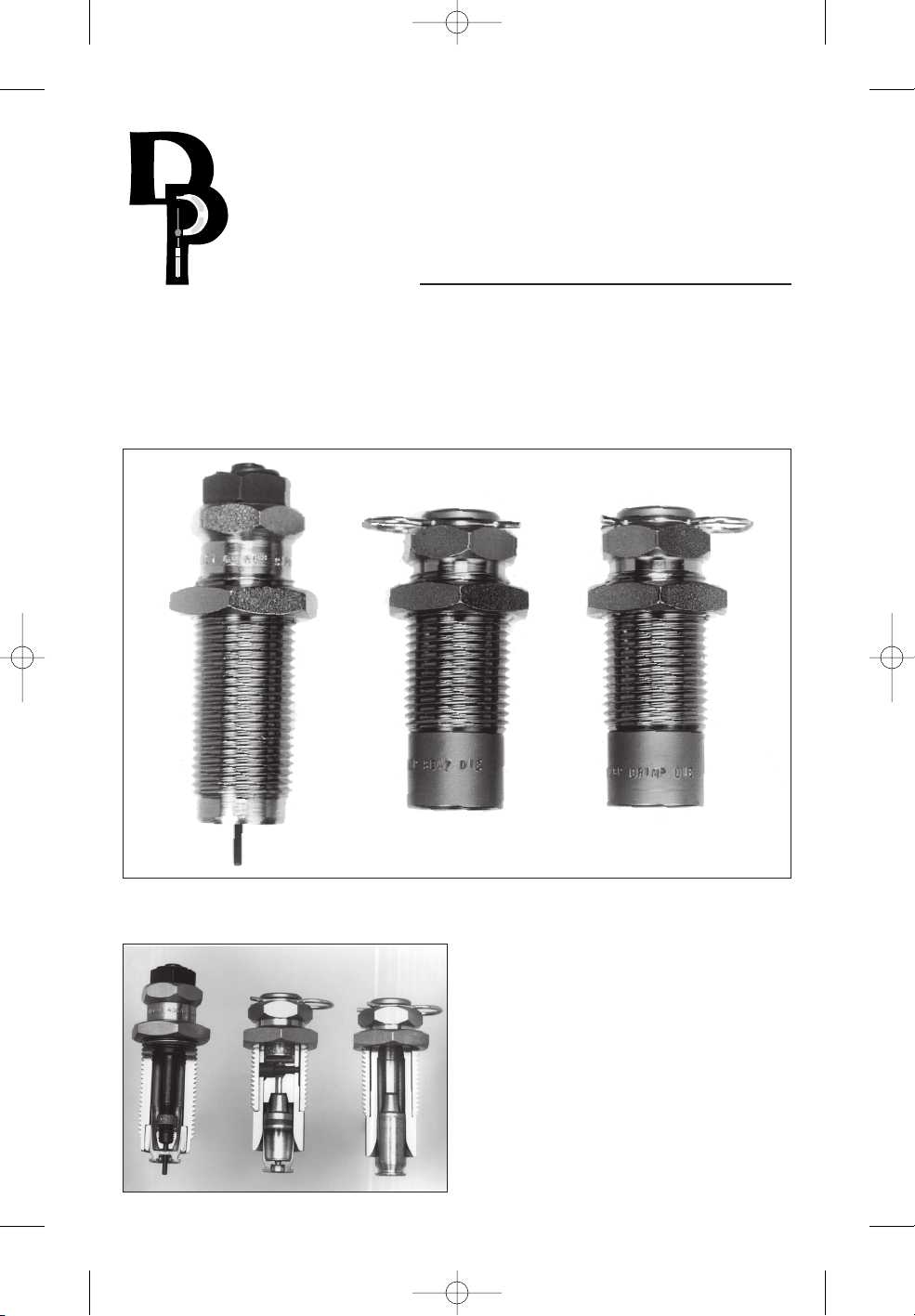

Fig 1. Dillon’s New Dynamic Die Set, cut

a

w

a

y so that y

ou can see how they look and

how they operate. From left to right they

are: Full length sizing and decapping die,

seating die (with the double ended seating

stem) and the crimp die. Note that the seat

die and the crimp die have clips on the top

to allo

w the insert to be remo

ved without

affecting the critical die adjustments.

Adjust the sizing die by screwing the die

bod

y do

wn until it contacts the shellplate and

snug the loc

k ring.

T

he decap assembly should

be screwed fully into the die at all times.

Dillon’s “New Dynamic” Pistol Die Sets

Fig 1

Dillon Die Instructions, May 2007 5/22/07 1:47 PM Page 1

Page 2

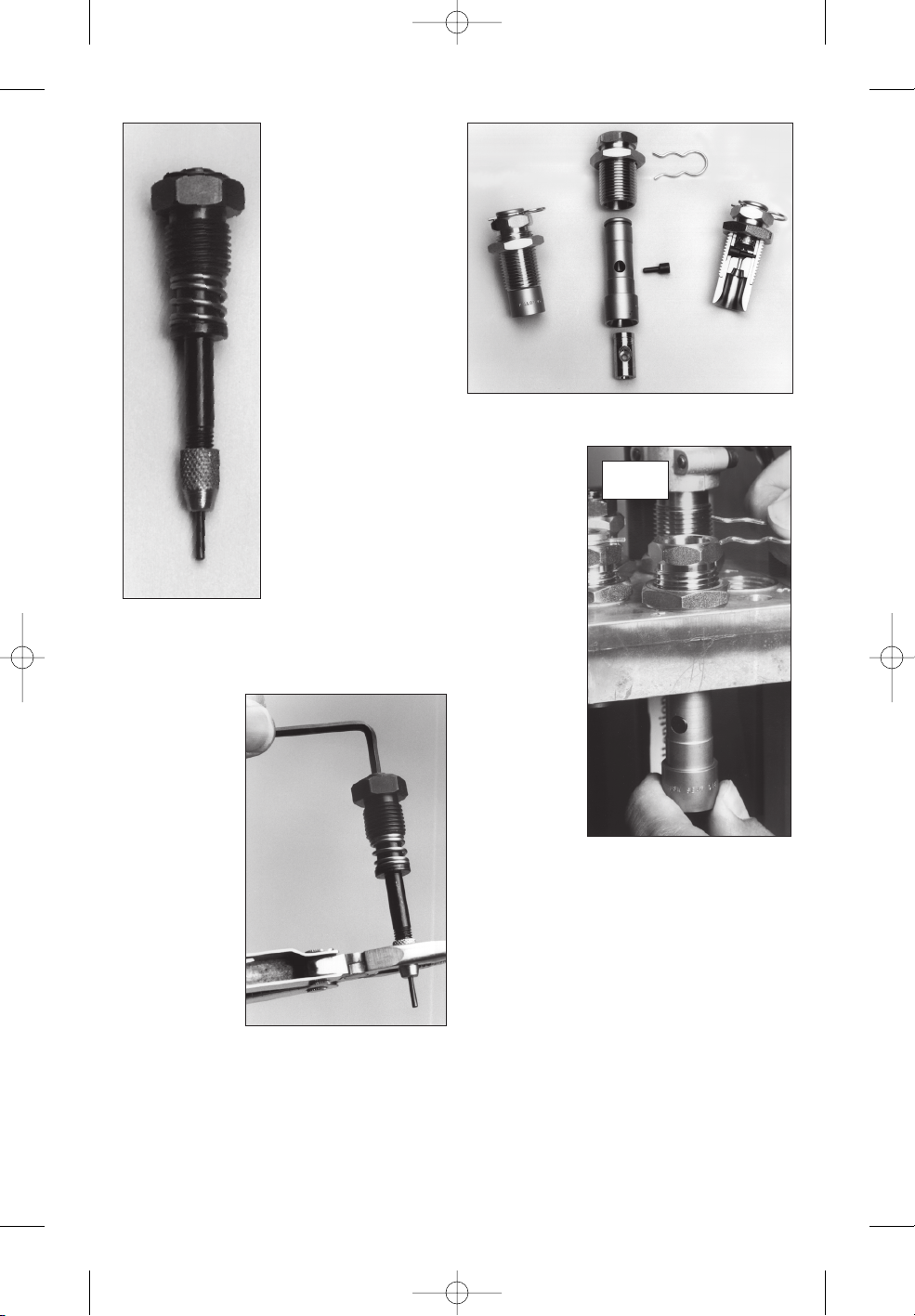

Fig 2. Your New

Dynamic Dies are

equipped with Dillon’s

unique “snap spring”

decap assembly. The

s

pring on this unit

compresses as the

decap pin pushes

against the spent

primer. As the spent

primer clears the

primer pocket, the

spring snaps the pin

downward, throwing

the spent primer off the

pin. This prevents the

spent primer from

being drawn back into

the primer pocket and

jamming the machine.

The problem of primer

“draw back” often

occurs when decapping military brass. This

exclusive feature is

unique to Dillon dies

and at no extra charge. Fig 2 also shows the

three main pieces of the decapping stem:

A. Decapping shaft. B. Retaining cap. C.

Decapping pin.

Fig 3. To

remove the

decap pin, use

a 1/8” Allen

wrench to

hold the decap

stem while

loosening the

retaining cap

with a pair of

pliers. Use a

small amount

of 242 (blue)

Loctite and

tighten securely on reassem

-

bly.

Fig 4. Your Dillon Dynamic seating die is

a snap-together assembly.

Fig 5. The

seating die

can be disassembled by

simply removing the snap

ring at the top

and pulling

the seat die

insert out of

the bottom of

the seat die

body. This

allows you to

take the die

apart for

cleaning without tools and

without disturbing your

seating adjustment.

Fig 5

Fig 4

Fig 2

A

C

B

Fig 3

Dillon Die Instructions, May 2007 5/22/07 1:47 PM Page 2

Page 3

Fig 6. The

double-ended

seating stem

can then be

removed for

cleaning or

changing by

pushing out

the black cross

pin. Note that

the seat stem

is doubled

ended and can

be reversed to

match the

shape of your

bullet.

Figs 7 & 8.

Choose the

seating stem

which best fits

your bullet.

Fig 7 is the round

nose seating stem

and Fig 8 is the

semi-wadcutter

seating stem.

When the

desired configuration is found

push the stem

back into the

insert and

replace the cross

pin. Reinsert the

seating insert

into the die

body. Replace

the clip and proceed.

Adjustment.

Place a sized

and belled case

into the seating

station of the

shellplate.

Next place a bullet on the mouth of the

case and cycle the handle do

wn. Screw the

die do

wn until it makes contact with the

bullet. Raise the handle a small amount and

screw the die down 1/2 turn. Cycle the handle down and raise it to the top. Remove the

case with the partially seated bullet and

measure the overall length with dial

calipers.

Compare the length to that suggested in

y

our loading manual. If the OAL is too long

turn the seating die down in 1/8 turn increments and cycle the handle again.

Repeat the above process until the proper

seating depth is achieved.

Note: One full turn of the die is approximately 0.070 of an inch. As you get closer

to your desired length do not turn the die

down in more than 1/8 turn increments.

When the desired OAL has been achieved

snug the lock ring while the cartridge is in

the die.

Crimp adjustment. Place a belled case

with a seated bullet into the crimping station

of the shellplate and, with the die out of the

toolhead, cycle the handle down. Leave the

handle down and start the die into the toolhead. Screw the die down until it contacts

the case.

Now, raise the handle (to pull the cartridge part way out of the die), screw the die

down 1/8 of a turn and then lower the handle again. Remove the case from the die and

check for the proper crimp. (Note: refer to a

loading manual for proper crimp dimension.)

If your case is not crimped enough,

place the cartridge back into the shellplate

and repeat your adjustments in 1/8 turn

increments until you achieve the proper

crimp.

F

ig 9. Crimp die assembly

. On the left the

completed assembly is sho

wn before screw-

ing it into the toolhead.

IMPORTANT Now is the time to try this

round to see that it fits the barrel or cylinder

of your gun. Also, if you’re loading for a

semi-auto, it’s a good idea to load 10-20

rounds and fire them. It’s depressing to load

a thousand rounds and then find out they

w

on’t function the action of your gun.

Fig 6

Fig 7

Fig 8

Fig 9

Dillon Die Instructions, May 2007 5/22/07 1:47 PM Page 3

Page 4

Dillon Three-Die Rifle Die Sets Include:

1- Full-Length Size die, nut, priming assem-

bly with carbide expander

1- Seat die, nut, seat stem with nut

1- Crimp die, nut and 1- Spare decap pin

Sizing/Depriming Die

The sizing/depriming die is a full-length

sizing die, manufactured to minimum tolerances. We

strongly suggest that a headspace case gage be used to correctly adjust

the size die. Always clean and lube your

rifle cases before attempting to process the

cases (thru the size die).

1. Move the handle down to raise the plat-

form.

2. Screw the sizing/depriming die into sta-

tion one of your reloader.

3. When the die contacts the shellplate,

back the die off 1/2 turn.

4. Use one lubed rifle case to test your siz-

ing and headspace. Readjust the die as

needed to achieve proper headspace.

5.

W

ith a case in the die, snug the loc

k ring.

The depriming assembly includes a car-

bide expander ball for “squeak free,” effort

less neck expansion. In the event of a stuck

case, the design of the depriming assembly

allows it to function as a stuck-case

remover. Simply remove the silver clip,

loosen the stem lock nut and then spin it up

to the top of the stem.

W

ith a wrench, turn

the depriming assembly into the die.

“Clockwise” turns will loosen the stuck

case. Use pliers to remo

v

e the case from the

depriming assembly.

Bullet Seating Die

Our bullet seating die is

internally designed to keep the

b

ullet straight throughout the

seating process.

1. Move the handle down, to

raise the platform.

2. Screw the bullet seating die

into the bullet seating station

on your reloader.

3. Put a sized, empty case into

the shellplate under the seating

die. Pull the handle down.

Screw the seat die body down

until it stops, then back it up

1/8 of a turn.

4. Refer to your rifle loading

manual for proper overall

length (O.A.L.) information.

5. Use only resized, deprimed cases when

setting this die. Move the case to the bullet seating station on your reloader

6. Place a bullet on the case and make one

complete stroke of the handle.

7. Check the overall length (O.A.L) of the

test case and bullet using a quality dial

caliper. Adjust the die up or down as

needed.

8. With the case and bullet in the die, snug

the lock ring.

Taper Crimp Die

The taper crimp die is configured to cen-

ter both the case neck and case body, thereby aligning the entire cartridge for a more

uniform crimp.

1. Place the test case/bullet you have into

the crimp station on your reloader.

2. Move the handle down to raise the platform.

3. Screw the taper crimp die into the crimp

station on your reloader.

4. When the die contacts the test case/bullet

move the handle up to lower the platform

5. Turn the die 1/4 to a 1/2 turn “clockwise”

and try crimping your test case/bullet

6. Use a quality dial caliper to measure the

case mouth diameter. Usually, a .002

change is noticed between the neck

diameter and the case mouth diameter.

Adjust as needed.

7. With the test case/bullet in the die, snug

the lock ring.

Refer to the machine operating manual

for any further instructions.

Hex adjustments

for wrench

Stuck Case

Remover

Solid,

1-Piece

Decapping

Pin

Radiused

Mouth

Precise,

Uniform

Taper Crimp

Size Die

Polished

to a High

Micro-Finish

Standard

7/8 x 14

Threads

Carbide

Expander

Ball

Dillon Three-Die Rifle Die Sets

Dillon Die Instructions, May 2007 5/22/07 1:47 PM Page 4

Loading...

Loading...