Page 1

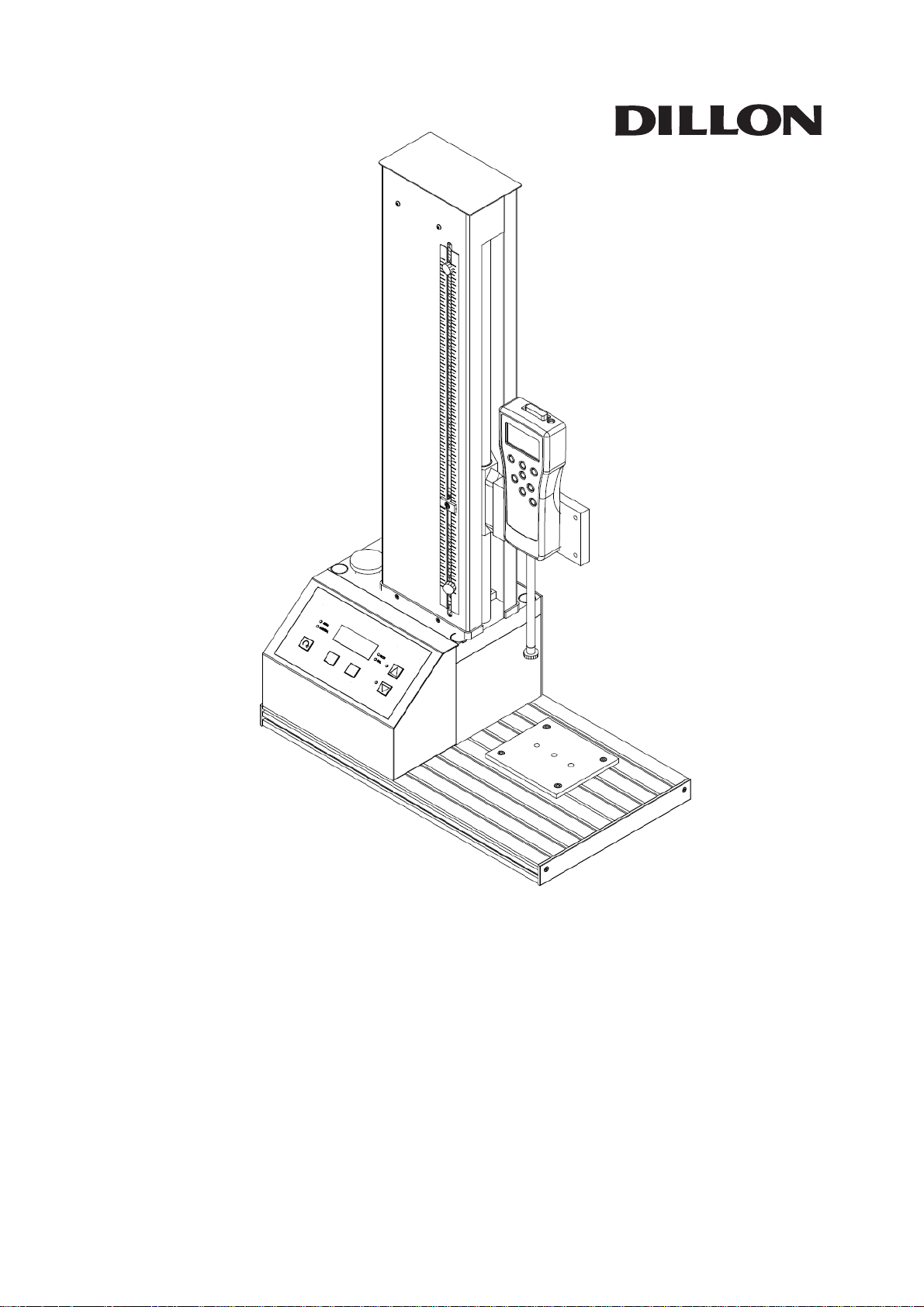

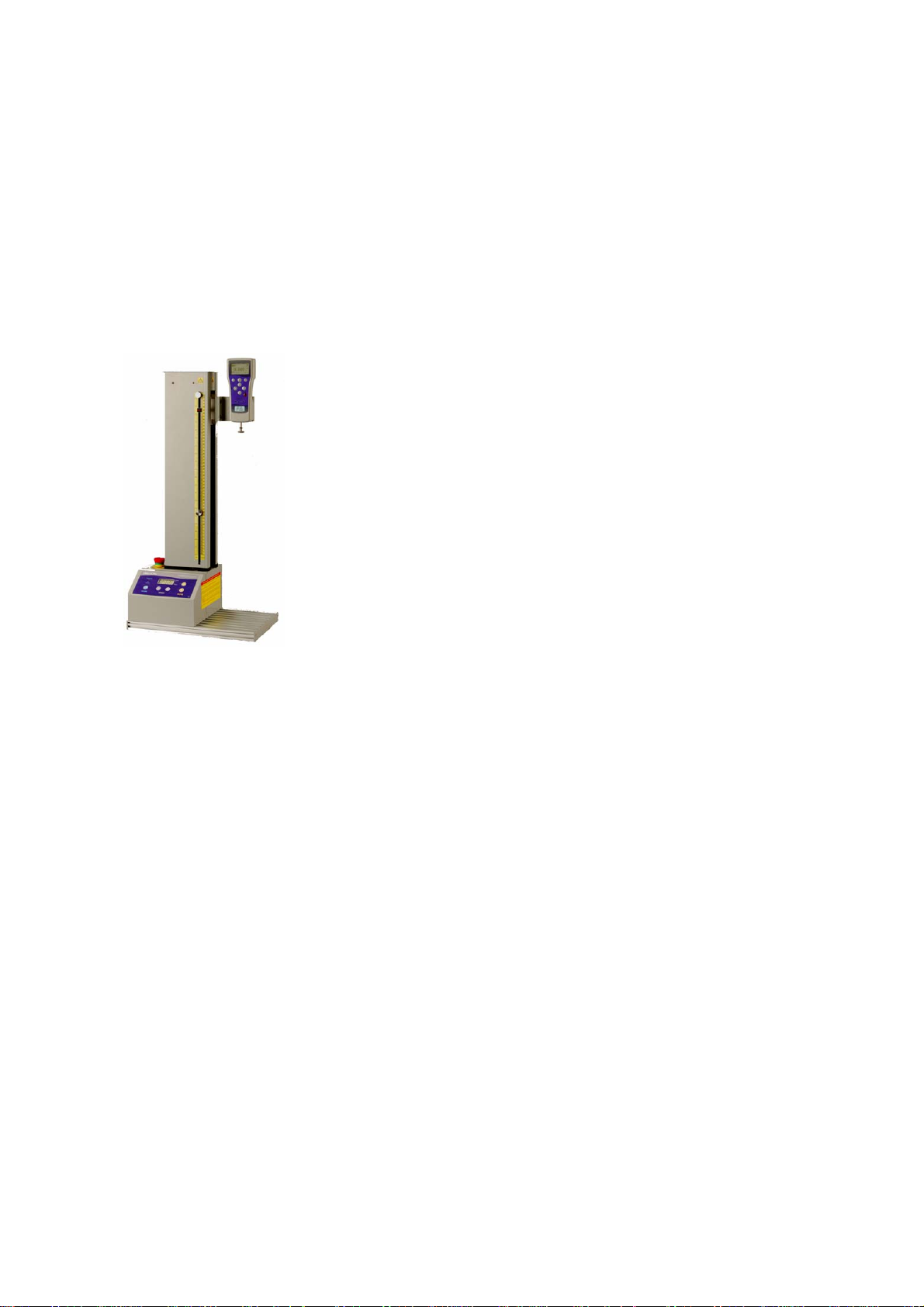

GTS-1000 Digital Control

Motorized Test Stand

Operator’s Manual

Page 2

TABLE OF CONTENTS

Introduction................................................................................................................................3

Safety and Equipment Precautions....................................................................................4

Set-up and First Configuration............................................................................................6

Register....................................................................................................................................6

Unpacking................................................................................................................................6

Setting up for your supply voltage.................................................................................6

Connect to power .................................................................................................................7

Selecting units-of-measure for speed...........................................................................7

Alignment ................................................................................................................................7

Mounting the force gauge.................................................................................................8

Getting Familiar with the GTS-1000 Testing Capabilities.........................................9

Working area..........................................................................................................................9

Column......................................................................................................................................9

Crosshead..............................................................................................................................10

Connectors ............................................................................................................................10

Operation...................................................................................................................................10

Front console........................................................................................................................10

Emergency stop button....................................................................................................12

Travel limits..........................................................................................................................12

Power switch........................................................................................................................13

Accessories................................................................................................................................13

Performing a Test...................................................................................................................14

Troubleshooting......................................................................................................................15

Specifications...........................................................................................................................16

2

3/07 Rev B

Page 3

INTRODUCTION

The motorized test stand is a tool to improve the quality of force testing results. It

helps attain the best testing repeatability by pulling or pushing at extremely consistent

speed in a direction in-line with the measuring device, such as a force gauge.

Motorized stands also improve ergonomics and testing throughput.

The Dillon GTS-1000 is a ball-screw driven digital test frame with capacity up to 1000 N

(220 lbf / 100 kg). The dimensions, speed range and capacity have been carefully

optimized to cover the test procedures and specimen sizes most often needed by

quality departments within many sectors of R&D and production

industry. Complemented by a Dillon force gauge, grips and

accessories, it constitutes a key component in force

measurement systems to accurately test a wide range of

products.

This tester may be used for tensile and compression tests of

many types (e.g. break, peel, flexural, top-load and many more).

The digital controls make testing speed more accurate and the

stand more intuitive to operate.

The crosshead features

the side-mounted controls and large working area, it can test large samples.

he Dillon GTX and GS force gauges are recommended for use with the GTS-1000 Test

T

Stand. It can accommodate other gauges with proper fixturing and alignment.

ith correct use your GTS-1000 will give many years of reliable service.

W

Please re

ad this operating manual thoroughly before attempting to operate

an adjustable generous 5 inch (127 mm) throat. Combined with

your GTS-1000 force tester.

3

Page 4

SAFETY & EQUIPMENT PRECAUTIONS

Read the instruction manual completely before attempting to use the

GTS-1000 Test Stand. By following the instructions contained in this manual, the

optimum accuracy and performance can be attained in the safest manner.

RISK OF PERSONAL INJURY! Samples under test can store large amounts of energy

which can be suddenly released upon sample failure. Sample failures can occur without

warning. Be certain the operator is protected from flying/ whipping parts from potential

high energy failures with some type of barrier.

Exercise extreme caution during testing or whenever the crosshead is moving.

ALWAYS Wear eye and face protection when testing.

NEVER place fingers inside the column!

NEVER place hands in vicinity of moving parts.

NEVER place hands near sample when subjected to load.

NEVER operate the GTS-1000 with the cover off.

RISK OF ELECTRICAL SHOCK! Do not remove cover. No user serviceable parts

inside. Refer servicing to qualified service personnel.

RISK OF ELECTRICAL SHOCK! Do not allow fluid to run into the T-slots. This can

reach the electrical circuitry. Tests with potential for running fluids should have a larger

plate secured to the T-slot work surface. Always unplug the stand immediately if fluid

runs into the T-slot and do not reconnect until all fluid is cleaned.

Verify Input Power Source BEFORE operation. The GTS-1000 may operate with

110V or 220V provided the Power Input Module is in the proper setting corresponding

to the source power. Always make sure that the supply power matches the setting on

the Power Input Module before connecting the power cord. Failure to do so will cause

serious damage to the tester.

Use Dillon GS/GTX force gauges. The GTS-1000 is designed to be used safely with

the Dillon GS/GTX force gauges.

Prevent overloads. Do not exceed capacity of the force gauge or stand (whichever is

lower). Stand capacity is dependent upon gauge attachment position. See rear of

crosshead. Damage from overload is not covered by warranty.

Watch for accidental contact. Loadcells and force gauges are delicate pieces of

equipment and can easily be damaged irreparably. Damage commonly results from the

4

Page 5

crosshead traveling downwards and running fixtures together. Take precaution to

minimize this situation.

Verify alignment. Be sure to align any lower fixture location in line with the attached

force gauge stem. The force must be applied in line for tests to be accurate and to

avoid gauge damage.

Understand all aspects of testing equipment operation before operating! See users

manual or contact your Dillon dealer with any questions.

5

Page 6

SET-UP & FIRST CONFIGURATION

Register:

Register your Dillon products at www.dillonforce.com.

Unpacking the GTS-1000

Upon receiving the unit please check for obvious physical damage to the packaging

material and the instrument itself. Be sure you have adequate equipment available to

safely lift the test frame from the packaging. Once removed from the packaging, place

the test frame on a stable, flat and level work surface. Inspect the machine for any

signs of obvious transit damage. If any damage is evident, or if any of the items listed

below are missing, please notify your Dillon distributor immediately.

GTS-1000 test stand with feet and two limit switch knobs

Tension plate and 10-32 short stud

This User’s Manual

Appropriate power cable

Allen key for side plates

Allen key for tension plate hardware

Two screws to mount gauge

If any damage is discovered do not go any further with installation and do not connect

the unit to a power supply under any circumstances.

We recommend you keep all packaging for future shipping requirements.

Setting up for your supply voltage

The GTS-1000 Power Module has two settings:

-110-120 VAC

-220-240 VAC

The GTS-1000 requires a stable, regulated AC power source.

Confirm your AC supply power matches the setting on the power supply module. Read

the voltage range at the bottom, next to the twin arrows –

see circled items on image. If this does not match, the power

supply module must be reversed. Carefully apply torque to

the slot located under the main connector jack with a flathead

screwdriver to open the power module. Pull out, flip over and

reinsert fully. You may need to lift a closing gate Make sure

the correct label is displayed at the bottom of the power entry

module and that the module is fully seated.

6

Page 7

CAUTION – Before connecting power:

1. Insure voltage setting on the stand agrees with

your supply voltage.

2. Insure the AC power is regulated.

Non-warrantable stand damage can result if not

followed.

If in question about your supply voltage or the stand voltage configuration,

contact your Dillon distributor before connecting to power!

Connect to power

After all the above points have been checked and confirmed to be correct, connect your

power cord and power the GTS-1000 on. The power switch is at the rear of the stand

right above the power cord. The console will illuminate indicating the machine is ready

for use.

WARNING

The power supply for the test frame must have a

third-wire earth ground. Connecting the test frame to

an outlet without an earth ground produces potential

for dangerous electrical shocks.

Selecting units-of-measure for speed

The GTS-1000 displays speed in inches per minute or millimeters per minute as shown

by the LED annunciator. To toggle the units, press and speed keys simultaneously.

Although easily changed, this parameter is generally set only once by most users.

Alignment

Proper alignment is important for testing accuracy and to prevent damage to the stand,

gauge and fixtures.

1. Load cell alignment with the stand structural columns. The GTS-1000

has a wide range of force gauges it can accommodate. However adapter plates

and other hardware must be designed to insure the load cell stem extends no

more than 28 mm in front of the crosshead. This is essential to prevent twisting

loads to the frame, which can cause irreparable stand damage. See “Mounting

the force gauge”.

2. Load cell stem alignment with lower fixture (tension tests). This is key

for accuracy and to prevent damage to the gauge. Adjust lower tension plate

hardware/fixturing to bring into alignment with load cell stem.

7

Page 8

Mounting the force gauge

For long stand life, the gauge must be mounted so the load cell stem is in-line with the

center of the internal columns. The standard GTS-1000 crosshead accommodates

gauges that measure between 8 – 28 mm from the back of the gauge to the load cell

stem center AND have 57 mm twin vertical hole spacing.

ll GS/GTX Series gauges mount directly to the GTS-1000 tester in perfect alignment

A

with the tester columns. Use included screws to secure.

another force gauge will be mounted, discuss mounting with your Dillon dealer.

If

CAUTION

When using a force than a Dillon GS or gauge other

GTX, it is the installer’s responsibility to ensure:

1 . strength of all connections and insure hardware

mounting depth falls within gauge manufacturer

requirements, and

2. load cell stem columns within is centered on the

GTS-1000 specifications.

Choose the gauge mounting position on the crosshead noting the maximum rated stand

capacity at that position. Secure with two screws insuring maximum depth for gauge is

not exceeded.

8

Page 9

GETTING FAMILIAR WITH THE GTS-1000 CAPABILITIES

Working area

The GTS-1000 Series features a large working area ideal for testing large samples up to

10.2 inches (260 mm) wide. The versatile T-slots can secure unusual shaped fixtures

or parts in tension. T-nuts and screws may be used to secure other fixturing.

Do not allow fluid to run into the T-slots. Tests with potential for running fluids should

secure The Dillon oversized plate accessory (available separately) to the T-slot work

surface and remove the side T-slot cover plates. Always unplug the stand immediately

if fluid runs into the T-slot and do not reconnect until all fluid is cleared and dried.

The GTS-1000 includes a handy tension base plate for in-line tension

grips as well. To remove or install, remove one cover plate side

screw and loosen the other. Rotate cover 90 degrees. Slide tension

plate with T-nuts loosely attached in or out as desired. Rotate cover

back and retighten screws.

Column

The GTS-1000 Series is a single column stand designed for vertical use. Maximum

crosshead travel is 18.7 inches (475 mm).

The GTS offers exceptional working headroom of 22.8 inches (580 mm) with the GTX or

Do not allow fluid to run into the T-slots. This can

produce an electrocution hazard. Always unplug the

stand immediately if fluid runs into the T-slot and do

not reconnect until all fluid is dried.

WARNING

GS force gauge. Over 5 inches (125 mm) of extra headroom reduces travel loss impact

due to fixturing. Extension rods may be required for short samples with low profile

fixturing. In compression, blocks may be used to elevate the sample as needed.

9

Page 10

Crosshead

The crosshead has six mounting holes for attaching a gauge with twin 2.25 inch (57

mm) hole spacing. The maximum stand capacity is dependent upon which position the

force gauge is mounted to.

Gauge mounting position Throat opening Maximum stand capacity

A (closest to column) 2.64 inch / 67 mm 1000 N / 220 lbf / 100 kgf

B (middle) 3.82 inch / 97 mm 750 N / 165 lbf / 75 kgf

C (furthest from column) 5.00 inch / 127 mm 500 N / 110 lbf / 50 kgf

Connectors

Three 15-pin connectors are on the rear of the stand.

Position Use

Top (n/c) No connection. Factory and dealer use only.

Middle (GTX) Connect to a Dillon GTX force gauge for stand reverse/stop control

on sample break or compression overload.

Bottom (PC) Sends the GTX serial information to a computer when the stand

reverse/stop cable above is used.

expansion boxes required by other brands.

OPERATION

Overview of controls

The GTS-1000 front console has three basic

sections:

#1 Operating mode

#2 Test speed

#3 Move

Additional controls include:

- Emergency stop button (above console)

- Crosshead travel limit switches (on column)

- On/off power switch (at rear of stand)

The PC port eliminates Y-cables or

10

Page 11

#1 Operating MODE

The GTS-1000 has two operating modes, marked by an LED on the console. Press to

cycle between:

1. Manual. Once UP or DOWN is depressed, the crosshead moves until any of the

following occurs:

a. Either MOVE key is pressed

b. A limit switch is tripped (in the appropriate direction)

c. The emergency stop button is pressed

2. Auto-reverse. This mode can speed up your repetitive batch testing. It runs at

test speed until it reaches the travel limit and then automatically reverses,

traveling at wide open throttle back to the other limit switch. You can stop the

stand at any time by pressing the UP or DOWN key or Emergency Stop button.

CAUTION

Auto-reverse mode is not suitable for tensile testing

when the sample must be removed before lowering,

such as ductile metal parts.

The Dillon GTX force gauge offers increased stand control.

- In Manual mode, the GTX can stop the stand upon sample break detection.

- In Auto-reverse, it can reverse the stand upon sample break detection.

The GTX also interrupts downward travel when gauge capacity is exceeded to reduce

potential for overload.

See accessories for the GTX stand reverse cable.

CAUTION

The overload detection within the GTX is intended as

a backup approach to help reduce accidental

overloads under slow speeds. The GTX must NOT be

the primary method to prevent overload.

#2 Test SPEED

The GTS-1000 features speed selection keys and a speed display. The and keys

adjust the crosshead speed shown on the LED display. The speed adjustment is slow

initially, but then increases the rate when held down.

Speed may be adjusted while stopped or while moving. Full speed return in autoreverse mode is not adjustable.

WARNING

Take care when adjusting speed up while crosshead

is moving. Speed may rapidly increase.

11

Page 12

The speed unit of measure is shown by an LED at right of window, either in/min or

mm/min. To toggle between the units, press and keys at the same time.

#3 MOVE Crosshead

The GTS-1000 crosshead travel is controlled by the MOVE Keys.

To begin the crosshead in an UPWARD direction, depress ×.

To begin the crosshead in a DOWNWARD direction, depress Ø.

The corresponding LED is lit while the stand is moving.

The crosshead will not move in a given direction if it is against a limit switch stop.

CAUTION

The GTS-1000 is an extremely quiet stand in

operation and others may not be aware when the

stand is moving. The operator must remain

monitoring when crosshead is in motion.

PRECAUTION

To avoid accidental crosshead movement, power off

the stand or engage the emergency stop when

unattended.

To stop a moving crosshead press either × or Ø key or the emergency stop button.

Emergency stop button

The GTS-1000 Series features an emergency stop button conveniently located at the

top of the console. This can be used as a panic switch whenever conditions are

becoming a concern. Engaging the emergency stop is also a good precaution to avoid

inadvertent crosshead movement when the stand is unattended.

When emergency stop button is depressed, motor control is removed from the tester.

The crosshead will stop, all annunciators light and “Stop” is displayed in the speed

window. To activate, press firmly downward. The stop button will latch and lock into

position.

To release the emergency stop button, gently turn in a clockwise direction. This will

disengage the lock and return the stop button to its normal position. You will see a

green band below the red stop button and the speed will return to normal display. The

stand will remain stopped until × or Ø is depressed.

Travel limits

The GTS-1000 Series has two adjustable mechanical travel limits that restrict the

working travel range of the stand.

12

Page 13

- Travel limits help protect your stand and force gauge from overloads by

preventing fixturing from contacting when the crosshead is moving.

- Limits improve testing convenience by stopping at convenient test start and stop

points.

The crosshead will stop moving (or automatically reverse) when the crosshead comes in

contact with a travel limit. You need to adjust these limits to your equipment and test

to attain the benefits.

To adjust, turn knob counterclockwise ½ to 1 turn. Gently lift or lower limit switch to

the desired stopping point. (TIP: keep the knob face as plumb as possible for easiest

sliding.) Snug the knob clockwise to lock and confirm proper stopping point by slowly

moving the crosshead and checking where it stops.

On/Off switch

The GTS-1000 Power On/Off switch is located at the power entry module at the rear of

the stand. When turning the machine OFF, it may take about 15 seconds for the speed

indicator display to extinguish while the internal capacitor self-discharges. Do not turn

power back on until the front panel lights have extinguished.

The console lights require about 15 seconds to completely

discharge when the power is turned OFF.

NOTICE

ACCESSORIES

Force gauges – many styles and capacities available from Dillon.

Software – provides more information about tests and eliminates entry

errors.

Adapter plate – accommodate other gauges with different hole spacing.

GTX stand reverse cable – offers additional stand control with the GTX

force gauge.

Extension rods – for short/thin sample testing without using blocks.

Oversize working plate – increases depth for large samples and/or increases

protection when fluid leakage may occur during testing.

Quick-couplers and adapters – change grips in seconds. Can also

join two differently threaded items quickly and affordably.

13

Page 14

PERFORMING A TEST

Force testing is fairly easy and consistent with a little experience. It generally consists

of:

a) Attach the appropriate testing fixtures to the gauge.

b) Attach the appropriate testing fixtures to the base.

c) Ensure fixtures are in alignment.

d) Position lower travel limit switch so fixtures cannot contact each other.

e) Start software package such as Q-Graph or Q-Data.

f) Secure your sample to the fixture on the gauge.

g) Zero and reset the force gauge peaks.

h) Lower the crosshead and secure sample to the lower fixture.

i) Add barrier if projectile pieces may fly.

j) Reposition lower travel limit at convenient test starting point.

k) Note the starting crosshead measurement on the ruler.

l) Adjust test speed.

m) Check manual or auto-reverse mode.

n) Start test with × or Ø key.

o) Note crosshead measurement at point of interest.

p) Save/print Q-Graph report or send peak gauge reading to Q-Data.

q) Crosshead Return for new sample – start again at step f.

Some steps are optional depending upon test type and the information being sought.

Most force gauges will retain the peak force for the test, which is generally considered

strength or effort to break the item.

The GTX Series break detection function will send a stop /reverse signal to the stand

upon sample break detection. Requires a cable connection between the GTX and GTS-

1000. Be certain to press RESET after each test to clear the peak values and ready the

gauge for the next test.

14

Page 15

TROUBLESHOOTING

Behavior Problem Action

No lights on front panel Power switch off Turn on power switch on

rear of stand

Power not connected Insure cord is secure at

both ends and has supply

power

Power setting Verify supply power and

power module setting

Stand does not move Limit switch Attempt movement in other

direction.

Release limit switch.

Emergency stop Release emergency stop

button.

Stand moving at wrong

speed

Stand does not reverse at

limit

No reverse upon sample

break with GTX

GTX configuration Set break detect and verify

Gauge not in alignment

with fixture

Grinding noise

Non smooth movement

Struggling motor

Console lights remain on

after power down.

Incorrect speed unit-ofmeasure (in/min or

mm/min)

Manual mode selected Change mode to auto-

Prior test peaks not cleared Press RESET on the GTX

Alignment adjustments See ‘Alignment’ section of

Stand may have been

overloaded or other

problem

Normal Allow 20 seconds for

Press and together at

the same time to change

units of speed

reverse

prior to starting each test

peak reading is larger

manual

Contact your Dillon dealer

capacitor to discharge and

lamps to extinguish.

Contact your Dillon dealer if these troubleshooting steps do not take care of the

condition.

15

Page 16

Specifications

Gauge mounting position Throat opening Maximum stand capacity

A (closest to column) 2.64 inch / 67 mm 1000 N / 220 lbf / 100 kgf

B (middle) 3.82 inch / 97 mm 750 N / 165 lbf / 75 kgf

C (furthest from column) 5.00 inch / 127 mm 500 N / 110 lbf / 50 kgf

Power consumption: 150 watts maximum

Stand weight: 54 lb / 25kg

Travel range: 18.7in / 475 mm

Maximum headroom: 22.8 in / 580 mm

Working area: 10.2 x 10.2 in / 255 x 255 mm

Tension plate: Three 10-32 UNF holes

Speed range: 0.2 – 40.0 in/min ; 5 – 1000 mm/min

Speed display: Digital LED

Direction of travel indicated on stand: Yes

Operating modes: Manual and auto-reverse

Reverse on sample break: Yes, with GTX and cable

Reverse on compression gauge overload: Yes, with GTX and cable

16

Loading...

Loading...