Page 1

GS Series User’s Manual

Page 2

Table of Contents

Table of Contents…………………………………………………………… 2

Introduction…………………………………………………………………… 3

Before Use…………………………………………………………… 3

Operation Overview…………………………………………… 3

Powering the GS………. ………………………………………………… 4

Using the GS…………. ……….…………………………………………… 5

Fitting Accessories……………………………………………… 5

Mounting to a Test Stand…………………………………… 5

Powering up………………………………………………………… 5

Basic Functions…………………………………………………… 6

Main Menus……………………………………… ………………… 10

AUTO-OFF………………………………………………… 10

PASS-FAIL………………………………………………… 11

MEMORY…………………………………………………… 12

CALIBRATION…………………………………………… 13

DIAGNOSTIC…………………………………………… 13

ABOUT……………………………………………………… 14

Measurement Practice………………………………………… 15

GS Specifications……….………………………………………………… 16

Conversion Factor…………………………………………………………… 17

GS series User’s Manual REV 2.1 22/01/12

2

Page 3

Introduction

Thank you for choosing the Dillon GS series instrument. With

correct use and regular re-calibration it will give many years of accurate

and reliable service.

The GS can measure tensile and compressive forces accurately,

while being simple to use by the operator. It may be used handheld or

mounted top a fixture or test stand.

Software and accessories are available to make your force gauge

even more versatile. Ask your distributor for additional information.

Before Use

Upon receiving the unit please check that no physical damage

has occurred to the packaging material, plastic case or the instrument

itself. If any damage is evident please notify Nextech immediately.

Operation Overview

The most commonly used features (such as displaying force,

peak hold, zero and changing of displayed units) can all be done by

pressing a single dedicated key identified on the font panel-see the Basic

Functions section.

You can press a menu key to access the gauge configuration- see

the Main Menu section.

3

GS series User’s Manual REV 2.1 22/01/12

Page 4

Powering the first time

The GS is supplied with a set of 4 Nickel Metal Hydride AA

rechargeable batteries. For safety reasons during transportation the

batteries are shipped discharged. To obtain maximum battery life we

recommend that you charge them with the charger/adaptor supplied for

at least 14-16 hours when you first receive the instrument.

Battery Indicator

Battery level > 5.0 V

5.0 V > Battery level > 4.9 V

4.9 V > Battery level > 4.8 V

4.8 V > Battery level > 4.7 V

Battery level < 4.7 V

If battery level is less than 4.6 V, The “ battery empty” message

will be displayed and the gauge will power down automatically.

Important: Only use the adaptor/charger supplied.

GS series User’s Manual REV 2.1 22/01/12

4

Page 5

Using the GS

Fitting Accessories

Couple fittings directly to the load cell stem or use an extension

rod. The threads are 5mm and have capacities up to 2500 N.

Ensure that fixturing does nor contact the force gauge case.

Ensure that anything coupled to the gauge is screwed finger-tight

only. Excessive torque can damage the load cell and is not covered by

warranty.

Mounting to a Fixture or Test Stand

Use the two 10-32 threaded holes. The distance between the

holes is 2.5 inch. Or fours 3mm thread holes on the rear of the gauge

can be used for mounting the gauge. A versatile stand mounting plate is

available to couple the force gauge to many brands of test stands.

Powering up

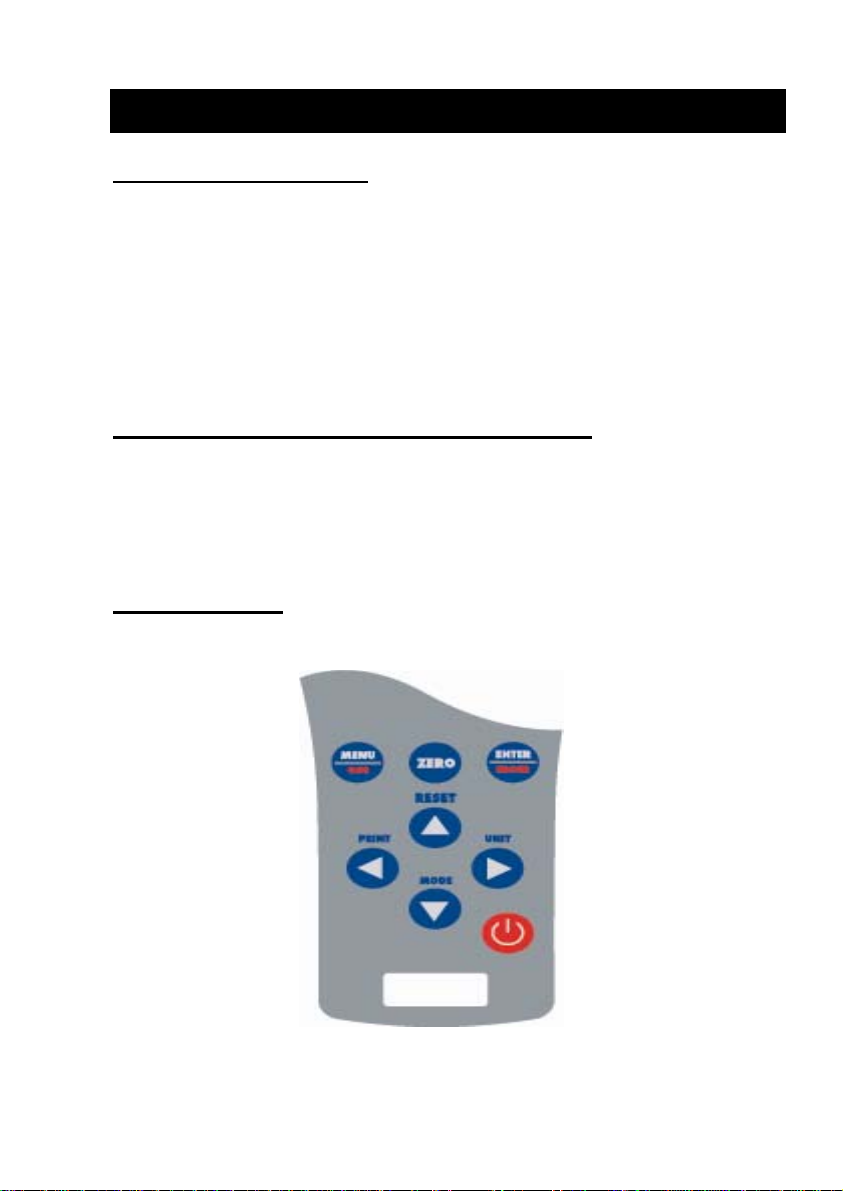

As show in Figure 1 the control panel has eight keys.

Figure 1 GS control panel

5

GS series User’s Manual REV 2.1 22/01/12

Page 6

To power up the gauge press the ON/OFF key. A short self-test

runs during which the display will show the capacity in Newton.

After the self test, providing no load has been applied to the

instrument, the display will show all zeroes. This is because the gauge

re-zeroes itself during the self-test routine.

*If a force is applied via the load cell probe (hole at bottom of

GS), the reading on display will register the applied force.

*Forces may not show zero if it is moved during the self test

routine. Once it is properly mounted and zeroed the reading will be

stable.

*Do not overload the load sensor. This will cause irreparable

damage. Forces greater than 120% of full-scale will produce an audibl e

beep and OL symbol will blink on the display until load is release and

RESET key is pressed.

To power down the gauge press the ON/OFF key.

*All the current settings are saved when the gauge is turned off

and the gauge will function in the same mode when powered up again.

Basic Functions

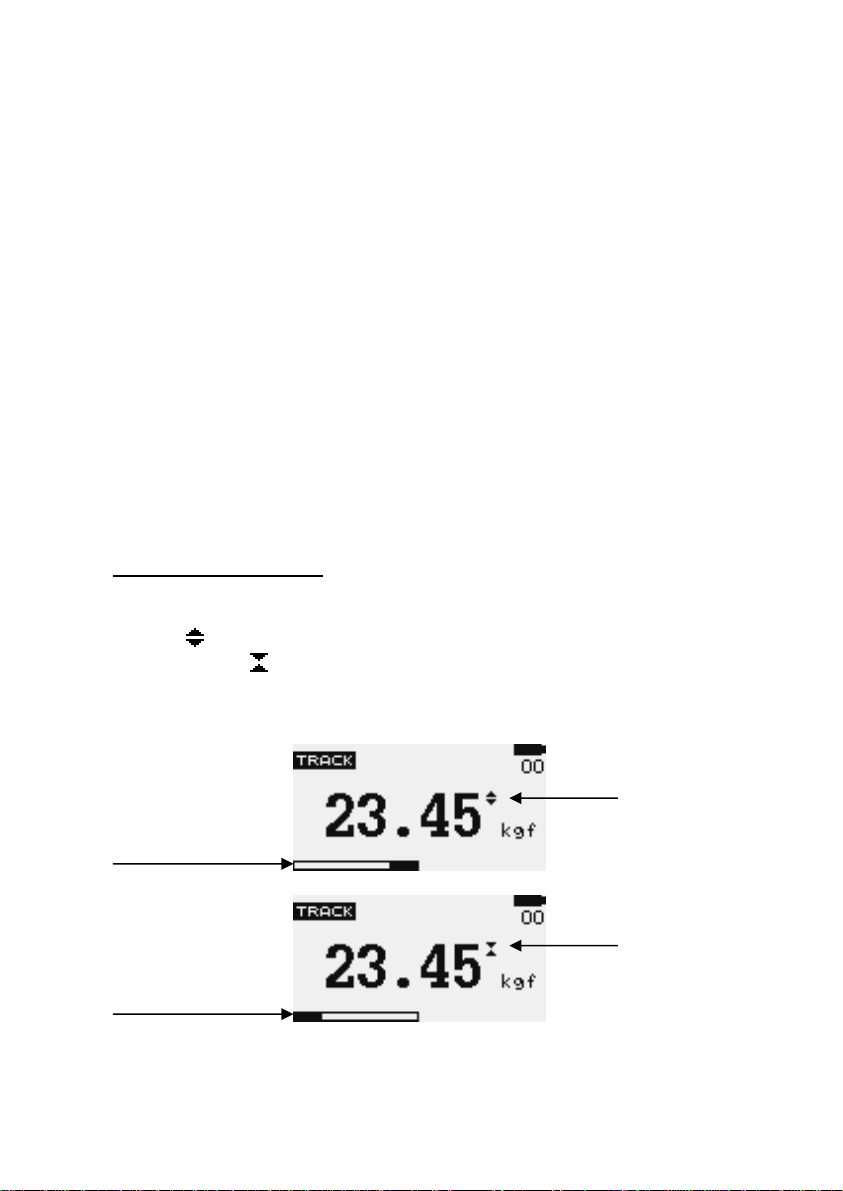

Tensile forces are displayed on the GS and recognized by the

symbol

by the symbol

Display of Tension/Compression

Tension

symbol

Load indicator

bar of tension

Compression

Load indicator symbol

bar of

compression

, Compressive forces are displayed on the GS and recognized

Figure 2 Tension and compression displays

GS series User’s Manual REV 2.1 22/01/12

6

Page 7

A load indicator bar alerts the operator to how much load has been

applied to the load sensor.

For tensile force the indicator bar is move from right to left. For

compressive forces the indicator bar is move from left to right.

Zeroing the gauge During the operation of the gauge it is often

necessary to zero the display – e.g. when you wish to tare out the weight

of a grip, so it does not become part of the measured reading. Press and

release the ZERO key.

Changing the unit of measure You can choose from the following

units of measure depending on the capacity of your gauge:

milliNewtons, kiloNewtons, Newtons, gram-force, kilogram-force, ounceforce or pound-force.

To change the display units press the UNITS key. Each

successive key press will select the next available units until the gauge

returns to its original setting. The GS automatically converts readings as

new unit of measure are selected.

*Note: All units may not be displayed depending on gauge capacity.

Changing the mode of measure You can choose from the following

modes of measure: Track, Peak-Tension, and Peak-Compression,

To change the display mode press MODE key. Each successive

key press will select the next available modes until the gauge returns to

its original setting.

Track mode Press MODE key until the

on the display. The display will now indicate forces applied in both

directions as they are applied to the load sensor and maintain the live

display. See Figure 3a

Track symbol

Figure 3a Track

7

GS series User’s Manual REV 2.1 22/01/12

appeared

Page 8

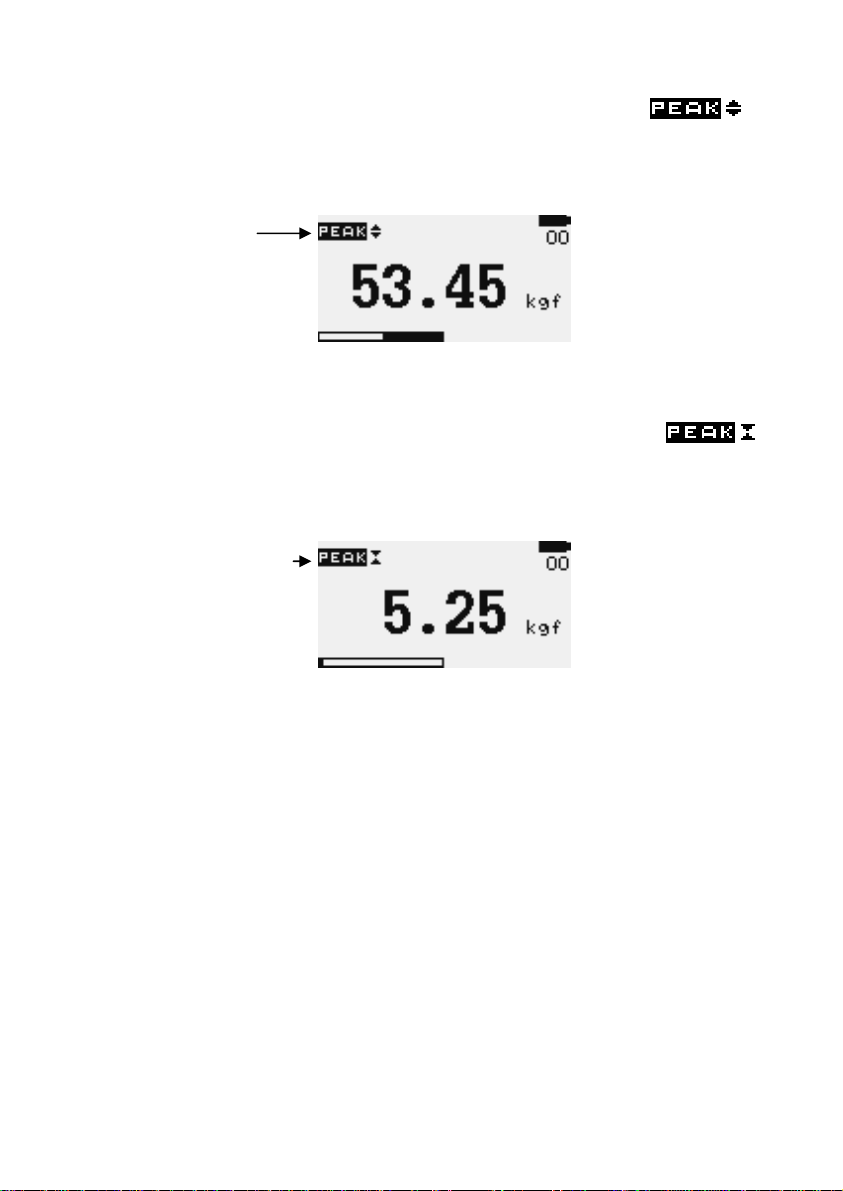

Peak-Tension mode Press MODE key until the

appeared on the display. The display will show the maximum tensile

force. See Figure 3b

Peak Tension

symbol

Figure 3b Peak Tension

Peak-Compression mode Press MODES key until

appeared on the display. The display will show the maximum

compressive force. See Figure 3c

Peak Compression

symbol

Figure 3c Peak Compression

Resetting the gauge Press RESET key to clear both maximum

registers and prepare for detecting the next maximum readings.

Backlit Display When you press any key or applied forces to load

sensor greater than 0.5 % of full scale the backlight will go on for 60

seconds.

Invert Display The display may be inverted or “reversed”, so that the

operator can read it more comfortably. Press and hold the MENU key

while powering up the GS to invert the display. This feature is

remembered after power down. Perform the same steps again to restore

the display to the opposite direction

GS series User’s Manual REV 2.1 22/01/12

8

Page 9

Saved reading to memory Any reading can be saved anytime by

press MEM/ENTER key. A total of 500 readings can be stored in the

database include the reading unit.

Computer Control of Force Gauge A computer can control the force

gauge by sending USB commands.

USB Command Action

“m” Changing measure mode.

“u” Changing measure unit.

“z” Zero the gauge.

“r” Reset the gauge.

RS232 output signal The displayed reading may be transmitted to PC

by pressing the PRINT key or sending request command from PC to the

gauge

USB command Action

“l” Send live reading value with unit.

“p” Send peak tension value with unit.

“c” Send peak compression valu e with unit.

“x” or pressing

PRINT key

“d” Send memory

“!” Send information of gauge (model, capacity,

Send live reading value with unit, if current

mode is track mode.

Send peak tension value with unit, If current

mode is peak tension mode.

Send peak compression value with unit. If

current mode is peak compression mode.

serial number, firmware revision, original

offset, current offset, overload count).

9

GS series User’s Manual REV 2.1 22/01/12

Page 10

Main Menu

Press MENU/ESC key to access the main menu. To move

between the option listed on the main menu page, press UP and DOWN

arrow keys to move the cursor. Press ENTER to select the sub-menus,

activate feature and enter values. Within sub-menus UP, DOWN, LEFT

and RIGHT arrow keys will also change numerical values. Press ESC to

return to the main menu page.

1) AUTO-OFF Press the MENU key, the display will show main menu

page and use UP and DOWN to move the cursor point to AUTO-OFF.

Press the ENTER key. The display will show the Auto-off menu page.

Press ESC key to return to the main menu page.

An Auto-off feature can be enabled to conserve bat tery power

where the gauge powers down after 5,10 and 15 minutes (depend on

Auto-off time) since the last key press. The AO will appear in the main

display if you activate this feature.

Use UP and DOWN key to move the cursor. Press the ENTER key

to select auto-off option and return to main menu page.

MAIN MENU

1) AUTO-OFF

2) PASS-FAIL

3) MEMORY

4) CALIBRATION

5) DIAGNOSTIC

6) ABOUT

Figure 4 Main Menu

AUTO-OFF MENU

1) OFF

2) 5 MINUTE

3) 10 MINUTE

4) 15 MINUTE

Figure 5 Auto-Off Menu

GS series User’s Manual REV 2.1 22/01/12

10

Page 11

2) PASS-FAIL the Pass-Fail feature used to set a defined acceptable

maximum and minimum forces gap for measuring. It activate by setting

the lower level and upper level forces limit If the forces value is within

the gap level, the display will show message PASS. Any reading values

outside this gap (higher or lower), the display will show message FAIL. If

you activate this feature the PF symbol will display on main display.

To access PASS-FAIL menu, Press UP and DOWN to move the

cursor point to PASS-FAIL and press the ENTER key the display will show

the Pass-Fail menu page. Press ESC key to return the main menu page.

PASS FAIL MENU

UPPER = 2.5 N

LOWER = 1.0 N

Press ‘Zero’ key to

Clear both value.

Figure 6 Pass-Fail Menu

Use LEFT ARROW keys to move cursor point to the desired value.

Use UP and DOWN keys to change the value, press and hold to scroll

values. Use RIGHT ARROW key to change the unit. Press ENTER to save

setting and return to main menu page.

*Pass-Fail feature will automatically disabled if you set LOWER

and UPPER = 0 N.

*LOWER must be less than the UPPER.

example LOWER LEVEL = 0 N, UPPER LEVEL = 20 N

Load

The “UPPER” LED will ON. Another LED OFF. Analog Out = 0V

Upper level

The “OK” LED will ON. Another LED OFF

Time

Figure 6a

11

GS series User’s Manual REV 2.1 22/01/12

Page 12

example LOWER LEVEL = 20 N, UPPER LEVEL = 0 N

Load

The “OK” LED will ON. Another LED OFF. Analog Out = 2V

Lower level

The “LOWER” LED will ON. Another LED OFF.

Time

Figure 6b

example LOWER LEVEL = 10 N, UPPER LEVEL = 20 N

Load

The “UPPER” LED will ON. Another LED OFF. Analog Out = 0V

Upper level

The “OK” LED will ON. Another LED OFF. Analog O ut = 2V

Lower level

The “LOWER” LED will ON. Another LED OFF. Analog Out = 0V

Time

Figure 6c

3) MEMORY This use to view the saved record, delete current record,

delete all record and print data of the saved record.

To access MEMORY menu, go to the main menu page press UP

and DOWN to move the cursor point to MEMORY and press ENTER key

the display will show the memory page. Press ESC key to return to main

menu page.

GS series User’s Manual REV 2.1 22/01/12

12

Page 13

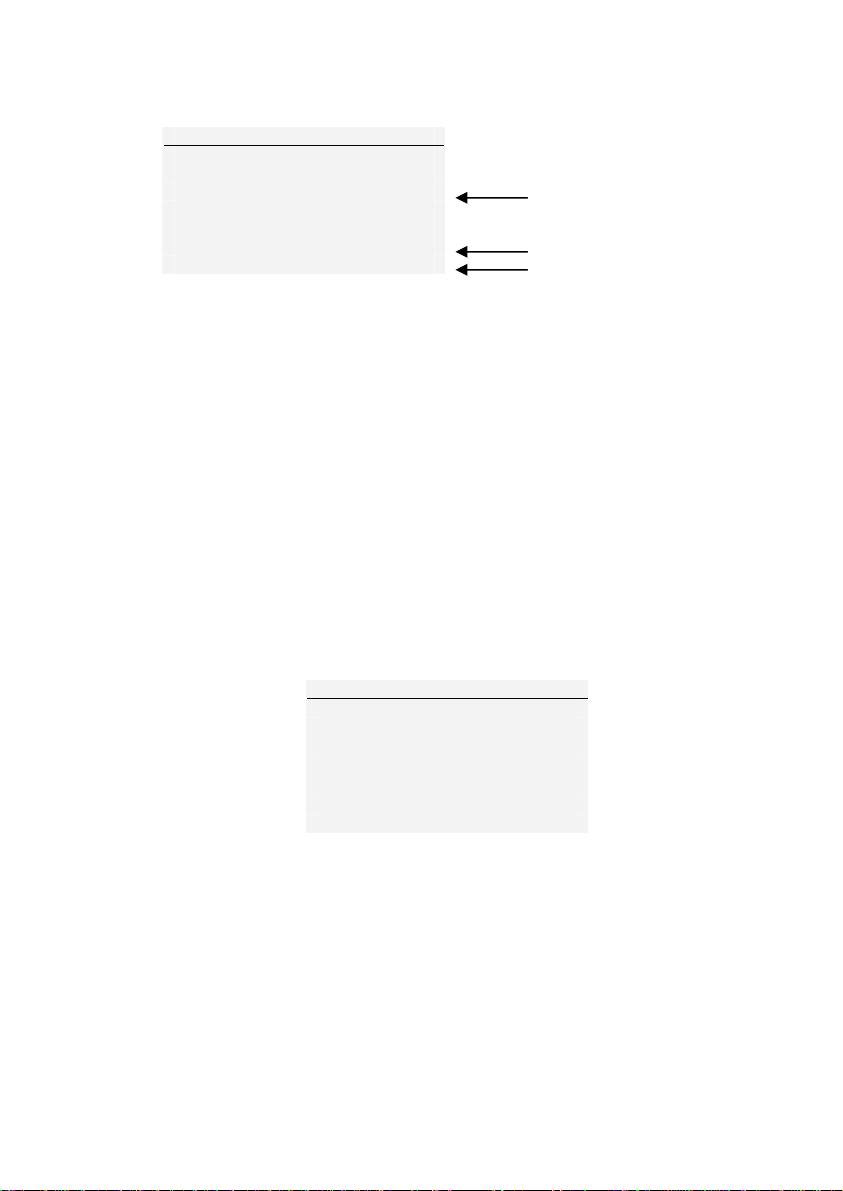

Figure 7a Memory Page

Press UP and DOWN to change memory page, press and hold to

scroll change memory page. Press PRINT key to print the memory to the

serial port. Press ZERO key to access the DELETE menu.

DELETE ?

1) NO

2) DELETE

3) DELETE ALL

Figure 7b Delete last Menu

Press UP and DOWN to select the delete option , If you selected

NO and press ENTER key the gauge will return to memory page. If you

selected DELETE and press ENTER key the gauge will delete current

saved record and return to memory page. If you selected DELETE ALL

and press ENTER key the gauge will delete all saved record and return to

memory page.

4) CALIBRATION This is used by service technicians when calibrating

the gauge. Contact your Nextech distributor for details.

5) DIAGNOSTIC This is used to check status of the load cell. If you

suspect that your load cell transducer has sustained an overload it is

possible to check the status of the load cell immediately.

Place the gauge horizontally on the flat level surface and go to

main menu page. Use UP and DOWN key to move the cursor point to

DIAGNOSTIC and press ENTER key the display will show Diagnostic menu

page. Press ESC to return to main menu page.

13

GS series User’s Manual REV 2.1 22/01/12

Page 14

DIAGNOSTIC

OVERLOAD COUNT: 2

ORG. OFFSET : +0.4 %

CUR. OFFSET : +0.4 %

A total of overload count

% offset of last calibrate

% current offset

Figure 8 Diagnostic Menu

If the % offset is between 5% - 10 % please contact your

supplier to arrange a recalibration of your gauge.

If the % offset is greater than 10% please contact your supplier

to arrange for load cell replacement.

These values are given as an indicator only – the need for

calibration/repair may vary according to the individual characteristics of

the load cell.

6) ABOUT This shows the information of your gauge (Firmware

revision, Model, Capacity, Serial number). To access ABOUT menu, go to

main menu page and press UP and DOWN to move the cursor point to

ABOUT and press ENTER key the display will show About menu page.

Press ESC key to return to main menu page.

ABOUT

FIRMWARE REV. : 1.00

MODEL: GS

CAPACITY: 100 N

S/N: 05130001

Figure 9 About Menu

GS series User’s Manual REV 2.1 22/01/12

14

Page 15

Measurement practice

For best measurement accuracy keep the compression/tension

forces in line with the force gauge. Alleviate bending loads and torque

loads applied to the load cell as these can adversely affect measurement

performance.

Always keep the gauge below the capacity limit shown on the

front of the gauge. If gauge is used above this capacity in either tension

or compression, even for a short time, permanent load cell damage can

result. Overload damage is not covered by warranty.

15

GS series User’s Manual REV 2.1 22/01/12

Page 16

GS Specifications

Capacity and Divisions

Capacity

(N)

5

10

25

50

100 -

250 -

500 -

1000 -

2500 -

mN N kN g-f kg-f oz-f lb-f

5000 x 2 5 x

10000

x 5

25000

x 10

50000

x 20

Accuracy: ± 0.2 % of rated capacity

Operating temperature: 60 ºF - 95 ºF (15 ºC - 35 ºC)

Temperature shift at zero load: ± 0.04 % of full-scale/ºC

Output

RS-232 and USB: 8 data bits, 1 Start bit, 1 Stop bit, no parity

Baud rate: 38400

Peak Capture Rate : 0.100 S

ADC Sampling Rate : 1,000 Hz

0.002

10 x

0.005

25 x

0.010

50 x

0.02

100 x

0.05

250 x

0.10

500 x

0.2

1000

x 0.5

2500

x 1.0

-

-

-

-

-

-

-

1 x

0.0005

2.5 x

0.0010

500 x

0.2

1000

x 0.5

2500

x 1.0

5000

x 2

10000

x 5

25000

x 10

50000

x 20

-

-

0.5 x

0.0002

1 x

0.0005

2.5 x

0.0010

5 x

0.002

10 x

0.005

25 x

0.010

50 x

0.02

100 x

0.05

250 x

0.10

17.5 x

0.010

35 x 0.02

87.5 x

0.05

175 x

0.10

350 x 0.2

875 x 0.5

1750 x

1.0

-

-

1.1 x

0.0005

2.2 x

0.0010

5.5 x

0.002

11 x

0.005

22 x

0.010

55 x

0.02

110 x

0.05

220 x

0.10

550 x

0.2

GS series User’s Manual REV 2.1 22/01/12

16

Page 17

Conversion Factor

Unit mN N kN g-f kg-f oz-f lb-f

mN

N

kN

g-f

Kg-f

oz-f

lb-f

1 0.001 1e-6 101.97e-3 101.97e-6 3.597e-3 224.81e-6

1000 1 0.001 101.97 101.97e-3 3.597 224.81e-3

1e6 1000 1 101.97e3 101.97 3597 224.81

9.807 9.807e-3 9.807e-6 1 0.001 35.28e-3 2.205e-3

9807 9.807 9.807e-3 1000 1 35.28 2.205

278.01 0.27801 278.01e-6 28.345 28.345e-3 1 0.0625

4448.2 4.4482 4.4482e-3 453.5 0.4535 16 1

17

GS series User’s Manual REV 2.1 22/01/12

Page 18

Dillon, a Weigh-Tronix Brand

1000 Armstrong drive

Fairmont, Minnesota 56031

Sales (507) 238-8796

Service (507) 238-4461

www.dillonforce.com

Made in Thailand

GS series User’s Manual REV 2.1 22/01/12

18

Loading...

Loading...