Page 1

Model GL Force Gauge User’s Guide

Thank you for purchasing the Dillon Model GL Electronic Force Gauge. A force

gauge is designed to measure forces inline with its load cell stem. This instrument may be

used handheld, attached to a test stand or mounted to a fixture in order to measure force

reactions and/or weight.

Features:

9 Measures tension (pull) and compression (push) forces

9 Die cast metal enclosure

9 Handheld use or mount using four threaded holes provided

9 Rechargeable batteries

9 Backlight

9 Serial data output to PC

9 Includes everything needed for many common tests

The model GL is available in a variety of capacities from 10 to 500 N. All operate

identically. Only the maximum capacity and display graduations vary. Various power

adapters exist for different countries, however all operate identically once plugged in.

Discard any extra power supplies included that are not suitable for your location.

Register:

Register your Dillon products at www.dillonforce.com

Contents:

Model GL Electronic Force Gauge

AC Power adapter/charger

Five popular grip styles – Hook, plate, notch, inverted notch, cone point

Extension rod

Plastic carry case

User’s guide

Calibration sheet

Display:

Remove protective film from display for best viewing.

Batteries

Charge the battery for at least 12 hours before first use. Subsequent recharging time is

about 6 hours. The GL has a working time of about 10 hours on a charge at room

temperature.

LINE

kg

lb

N

Page 2

The GL Force Gauge can operate from its battery pack or while connected to the power

adapter/charger. When the battery is too low, appears. Connect to AC power

adaptor/charger. The indicator light is red when charging. The LED changes from red to

green when the battery is full.

Fully discharging the battery is not necessary or recommended. If not using the gauge for

long time, freshen the charge every three months.

OVER LOAD

Damages from overloads are not covered by warranty. Avoid loading above rated

capacity. If the applied force (either pull or push) exceeds rated gauge capacity, an alarm

will sound. Unload the force gauge to protect load cell.

If the applied force exceeds 120% of the capacity, the load cell may be damaged. Compare

versus a known weight in both tension and compression. Repairs should be directed

through your authorized Dillon distributor.

Overload damage is based on gross load, which may vary from displayed load. Always

take into account the load which has been zeroed off.

Impact loads should be avoided. Dropping the force gauge onto its load cell stem may

result in overload, particularly in small capacities.

Operation:

Always push or pull along the axis of the load cell stem. Exerting forces off-axis can

result in erroneous results and/or damage to the force gauge. The unit of measure

annuniator flickers when the load is changing.

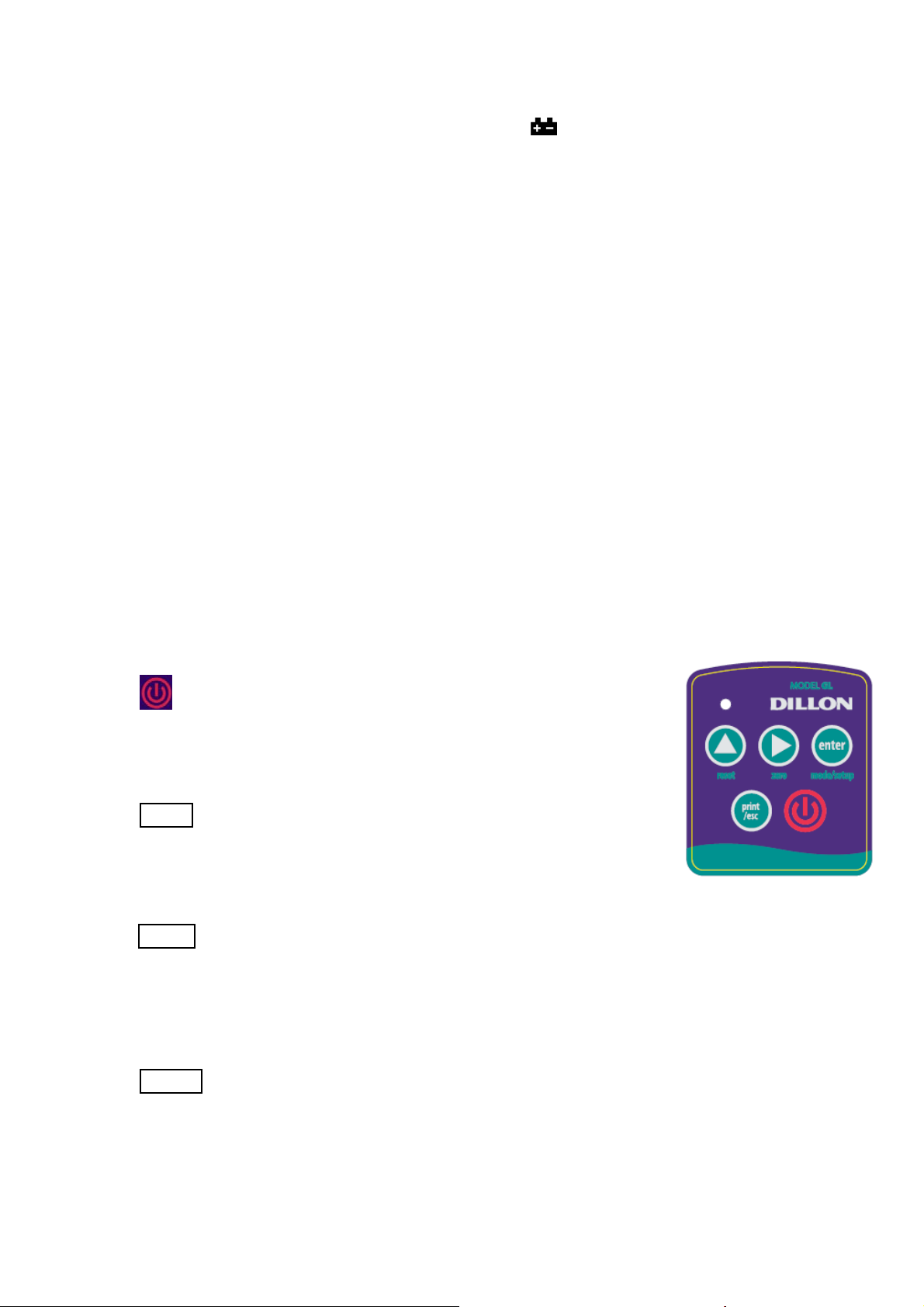

Power

Powers the instrument on. The gauge activates all display segments,

performs a self-test, and shows “0.0”, which indicates that the gauge

is ready for measurement. Press again to turn off the power.

zero

When pressed the display reads zero. The instrument shows

changes in force from this reference point. This function is handy to

tare weight from test fixtures.

print

The displayed reading is transferred through the serial port when the button is pressed.

Requires a serial cable. Baud rate is 9600, 7 data bits, 1 stop bit, no parity. One reading

per second maximum output rate.

mode

Toggles display between Live and Peak modes.

Live mode shows force/weight increases and decreases as they occur.

Peak mode keeps the highest number on the display. The Pull / Push annuciator shows

which direction it occurred. Press reset to clear this value.

Page 3

SETUP MODE

Pressing mode/setup for 3 seconds enters setup mode. Once in setup, use the navigation

markings for selection and entry (▲, ►).

Unit of measure:

Configures which unit of measure is shown. The GL force gauge has unit conversions

built-in.

Press and hold mode/setup for 3 seconds. When screen shows “Unit”, press ► . Press ▲_

to cycle displayed units of measure between kg—N—lb (or g-N-lb as appropriate for gauge capacity).

Press ► to accept and continue with setup procedure.

Factory setting: N

Automatic power off :

Configures the inactivity period before the gauge powers down. This lengthens time

between charges.

Press and hold mode/setup for 3 seconds. Press ▲ until “Auto” shows. Press ► . Press

▲ to increment the flashing digit. Press ► to advance to the next digit. Press ► after the

last digit to accept the new value and proceed with setup.

The auto-off time setting is 00-99 minutes. An entry of 00 disables the auto-off function.

Factory setting: 10 (10 minutes of gauge inactivity)

The gauge powers off automatically if none of the following occurs within the time period

in the setting:

• Key press

• Change is weight or load on the display

• Serial request input.

Local gravity constant:

The GL Force Gauge may be adjusted for use as a weighing scale in locations where

gravity varies significantly from typical. Adjusting this value is not common. It is not

recommended to change unless living in extreme altitudes

and the instrument is being used

to measure weight/mass.

Press and hold mode/setup for 3 seconds. Press ▲ until “Loc.n” appears. Press ► . Press

▲ to increment the flashing digit. Press ► to advance to the next digit. When the last digit is

complete, press ► to accept new value and proceed with setup.

Factory setting: 9.807 m/s2. To adjust the value without knowing your gravitational

constant, insure Loc.n is at 9.807. Attach the hook and zero instrument. Suspend a known

weight (near gauge capacity) and observe the load.

New Loc.n reading is = (Displayed weight / Known applied weight) * 9.807

Reverify after entry.

Reset factory defaults:

Press and hold mode/setup for 3 seconds. Press ▲ until “dEF” appears. Press

Page 4

► . Press ▲ to cycle between choices of YES and NO. YES will return to

factory default settings. Choosing NO will keep the current settings. Press ► to

accept choice and return to operating mode.

Recalibration:

Ensure the force gauge is meeting your accuracy requirements by recalibrating at

regular intervals. Your Dillon distributor can assist you with this practice and service.

Serial Inputs

Content Instruction

*

Response

Print

Zero gauge

Peak/live mode ‘T” Toggles between peak value & live value

Trouble shooting

Item Reason Solution

Gauge locks on beep

Gauge does not power on

Gauge powers off

Serial output not

recognized

Gauge does not read

accurately

“P”

“Z”

* One command per second maximum input rate.

Low battery Connect to charger

Low battery Connect to charger

Low battery Connect to charger

Auto-off function

configured

Improper parameters in

software program

Undesired loading such

as side load or torque

Local gravity constant

parameter configured

Overloaded or out of

calibration gauge

Adjust auto-off to longer interval or turn off

Align settings with gauge output settings. See

PRINT section.

Insure push or pull force acts through load cell.

Eliminate torque or off-axis loads.

Verify Loc.n parameter in setup.

Contact your authorized Dillon distributor

Returns reading output

Display goes to zero

an Avery Weigh-Tronix Brand

www.dillonforce.com

USA office

1000 Armstrong Drive

Fairmont, Minnesota 56031 USA

Sales +01 (507) 238-8796

Service +01 (507) 238-4461

UK office

P. O. Box 9533

Smethwick

West Midlands B66 2TE U.K.

Sales +44 870 444 6132

Service +44 870 901 4116

11/06

Loading...

Loading...