Page 1

Dillon FI-90 Force Indicator

Users Manual

Page 2

CAUTION

Risk of electrical shock. Do not remove cover. No user service-

able parts inside. Refer servicing to qualified service personnel.

Weigh-Tronix reserves the right to change

specifications at any time.

12/19/03 FI90_U.P65 PN 29527-0011E e2 Printed in USA

2

Page 3

Table of Contents

Table of Contents ................................................................................................. 3

FI-90 Specifications.............................................................................................. 4

Features and Options ........................................................................................... 6

Introduction .......................................................................................................... 7

Keyboard .............................................................................................................. 7

Annunciators ........................................................................................................ 8

Display Messages .............................................................................................. 8

Powering Up......................................................................................................... 9

Getting Around in the Operations Menu ............................................................. 10

Measuring Gross Force ...................................................................................... 11

Measuring Peak Force ....................................................................................... 11

Entering or Viewing an ID Number..................................................................... 12

Entering Data with Arrow Keys .......................................................................... 13

Introduction ........................................................................................... 13

ID Number as an Example ................................................................................. 13

Viewing and Entering Setpoints (Cutoffs) ........................................................... 14

Cutoff Connections ................................................................................ 17

Viewing and Setting Time ................................................................................... 17

Viewing and Setting the Date ............................................................................. 18

Transmitting Data ............................................................................................... 19

Analog Output Option ......................................................................................... 20

Using Test Mode for Indicator Diagnostics ......................................................... 21

Main Displays Viewed in the Test Mode Menu ...................................... 22

Pages are numbered consecutively beginning with the cover page.

3

Page 4

FI-90 Specifications

Display: 7-segment LCD, 6-1/2 digits plus sign, .5 inch high, movable decimal, with

7 annunciators

Display Update Rate: Two times per second

Analog-to-Digital

Conversion Rate: 60 times per second

Resolution: Up to 10,000 divisions standard

Controls: Pushbutton zero; pushbutton peak-hold; pound-, kilogram-, Newton-scroll selection;

PRINT, MENU, and SELECT keys for configuration; ON / OFF switch (optional: used

only on alkaline battery option); BATT / AC switch (optional: used on rechargeable

battery / AC versions)

Peak Detection Rate: 60 times per second

Peak Detection: Threshold 1% of capacity setting

Accuracy : Span: ±5.0 ppm/C Zero: ±.066 uV/C (-10 to 40°C)

Linearity: ±0.005% of capacity, maximum

Repeatability: ±0.005% of capacity, maximum

Hysteresis: 0.005% of capacity, maximum

Power: Std - 117VAC +10/-15% 50/60Hz 5 watt

Opt - 230VAC +10/-15% 50/60Hz 5 watt

Opt - 12VDC +10/-15% 130mA max.

Load Cell Drive Capacity: Up to four 350-ohm load cells. Up to twelve 1000-ohm load cells.

(+5VDC load cell excitation voltage)

Environment: -10 to 40°C (14 to 104°F)

10 to 90% relative humidity

Calibration

and Programming: All calibration and programming is done through the front panel with data stored in

non-volatile memory.

Analog Range: -0.14 to +3.5 mV/V

Scale Capacities: .00001 to 999999, programmable to any number between these limits

Scale Division Sizes: .0001 to 20000, programmable to any division size between these limits

Pushbutton-Zero Range: 0 to ±100% of capacity; programmable in any percentage of indicator capacity;

independent positive and negative limits; unit will not allow zeroing beyond capacity.

Overrange Capacity: The indicator displays force measurements up to and including full-scale capacity

4

Page 5

Automatic Zero Tracking: Window programmable from 0 to 999999 divisions; decimal entries accepted.

Tracking in peak-view mode may be enabled or disabled..

AZT (Auto-Zero

Tracking) Rate: 0.1 division per second; starting delay of 2 seconds

Annunciators: Center of zero, pounds, kilograms, newtons, peak, gross, battery status

Standard Enclosure: ABS grey plastic case with RFI coating

Enclosure Dimensions: 2.65"H x 8.36"W x 9.11"D

RFI Rejection: Operates in the presence of moderate RFI

RS232 / 20mA Output: Data is transmitted when PRINT button is pressed. Host computer may solicit data by

sending an ENQ character. Auto print and broadcast data are also options. Format

programmable.

Baud rate options - 300, 600, 1200, 2400, 4800

Parity bit options - even, odd, logic 1, logic 0

Word length - 8 data bits, including parity

Stop bit options - one or two

Analog Output: Dip-switch selectable, isolated outputs: 1 to 5mA, 4 to 20mA, 10 to 50mA,

0 to +5 volts, 0 to +10 volts

5

Page 6

Features and Options

Standard AC Version

Options: RS232 / 20mA current loop serial I/O with real-time clock

Dual cutoffs with one programmable input

Analog output

230VAC

Panel mount

AC / Lead-Acid Battery Version

Options: RS232 / 20mA current loop serial I/O with real-time clock

Panel Mount

Features: Rechargeable 6V lead-acid battery

Operates on AC or internal battery

Sleep mode to conserve battery power

26-32 hours between recharge (1 load cell, continuous)

14-16 hours between recharge (4 load cells, continuous)

Alkaline Battery Version

Options: RS232 serial I/O with real-time clock

Panel mount

Features: Long battery life - 5 weeks @ 40 hrs / week for one load cell

Sleep mode to conserve battery power

12VDC Version

Options: RS232 / 20mA current loop serial I/O with real-time clock

Panel mount

6

Page 7

Introduction

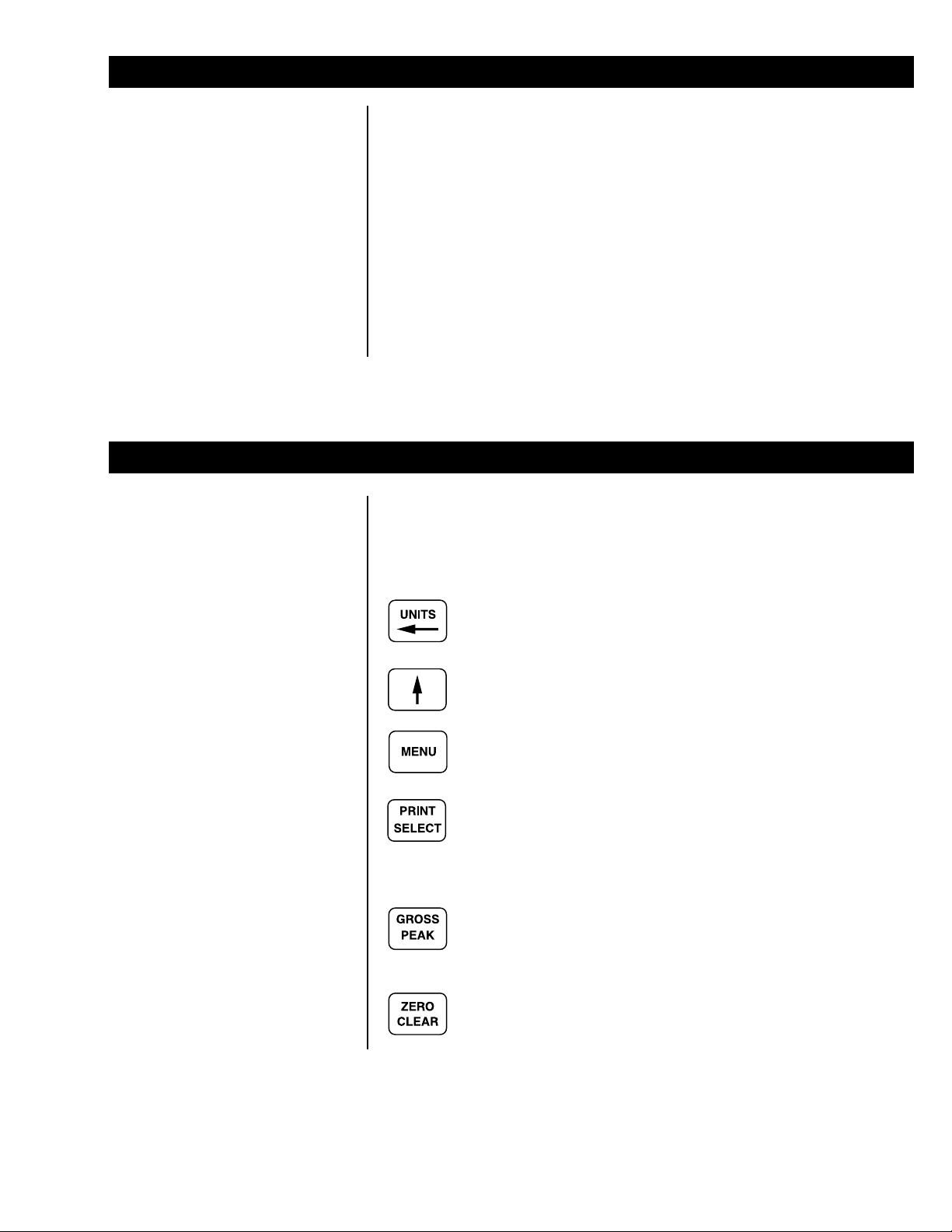

Keyboard

The FI-90, a full-function force indicator, is available in four versions:

1) the standard AC powered version

2) an AC lead-acid, rechargeable battery version

3) an alkaline battery version

4) a 12 volt DC version

Operations mode provides gross force and peak force readings and allows

viewing and configuration of one or more of these parameters:

ID number

up to two cutoff registers

time

date

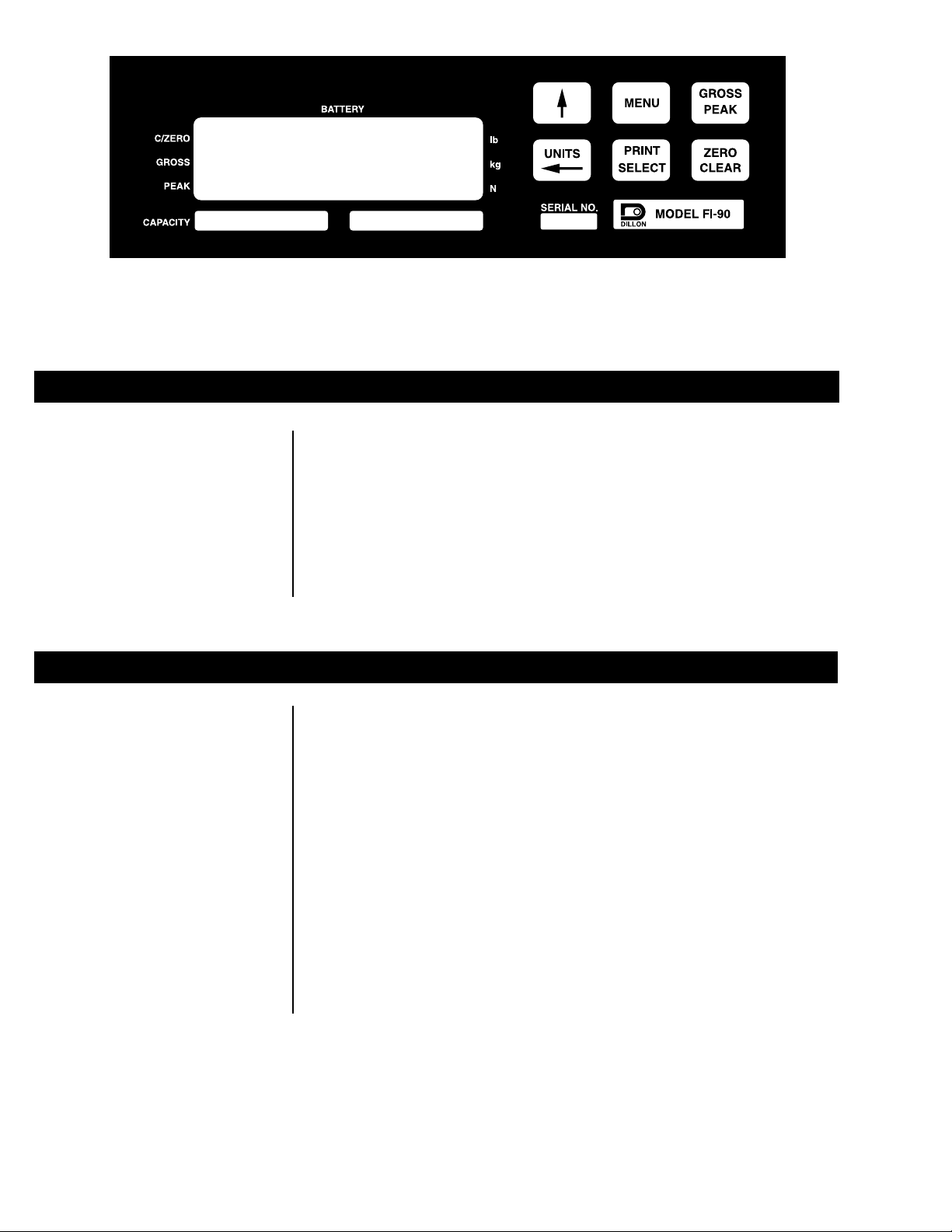

The key board consists of six keys that control all gross and peak force

measuring functions and provide access to configuration and system-test

information. See Figure 1.

A dual function key: UNITS selects the operational unit of

measure; LEFT ARROW enters data.

Enters data.

Selects menu topics.

A dual-function key: PRINT transmits displayed data to a printer,

computer, or programmable controller; SELECT accepts dis-

played data in configuration and helps you move around in the

configuration hierarchy.

A dual-function key toggles between gross mode and peak-view

mode and displays gross force or peak force.

A dual-function key: In gross mode, ZERO established a zero

reference; In peak-view mode, CLEAR clears the retained peak

value and displays the current gross load input.

7

Page 8

ON

FI-90 Front-Panel Keyboard, Annunciators, and Display

Annunciators

Figure 1

Gross Illuminates when the indicator is in gross mode.

Peak Illuminates when the indicator is in peak-view mode.

lb, kg, N Illuminates to show the active unit of measure.

Battery Illuminates when the battery voltage is low. "D" cells should be

replaced or a lead acid battery recharged.

C/Zero Illuminates when the indicator is within ±1/4 division of zero or the

force at which the indicator was zeroed.

Display Messages

- - - - - - -

[

[

- - - - - - -

[8888888] Appears briefly at the time of power on. The indicator is

[ Loc'd ] The A-D converter is locked up. Applied force is too high

[ASLEEP] The indicator has gone to sleep to conserve on battery

] The indicator is in a state of over capacity.

] The indicator is in a state of under capacity.

being initialized.

or too low.

power. Make it operational again by pressing any key.

8

Page 9

Powering Up

The method of powering up depends on the type of power supply your

indicator uses. Look at the back panel of your indicator and the four back

panel illustrations below and identify the one that matches your indicator.

Then follow the appropriate power-up instructions on the next page.

Figure 2

Back Panel of Standard AC-Powered Version

Figure 3:

Back Panel of AC / Lead-Acid, Rechargeable-Battery Version

Figure 4

Back Panel of Alkaline-Battery Version

Figure 5

Back Panel of Twelve-Volt-DC Version

9

Page 10

For the standard AC version (See Figure 2): Plug the power cord into the

back of the indicator and connect the cord with an external AC power source.

The FI-90 indicator powers up

in the same mode it was in

when power was removed.

For the AC / lead-acid battery version (See Figure 3): The power switch

controls your choice of AC power or internal lead-acid battery power. To use

external AC power, depress the bottom portion of the power switch, and plug

the power cord from an AC power source into the AC receptacle. To use the

internal lead-acid battery, depress the top portion of the power switch.

For the alkaline battery version (See Figure 4): Press the power switch to

the ON position (lower portion depressed).

For the 12-volt DC version (See Figure 5: Press the power switch to the ON

position (lower portion depressed).

Getting Around in the Operations Menu

Your unit is configured to display gross force or peak force. It may also be

configured to display one or more of the following functions: ID number, one or

two cutoff registers, time, and date. This manual assumes the unit is config-

ured to allow full access to all functions. The following flowchart and instruction procedure explains how to move around in and use the operations menu.

10

Figure 6

Operations Menu

Press MENU to à

Press SELECT to go á or â

Press and hold MENU to go ß

Press SELECT to select new choice and go á

Page 11

Measuring Gross Force

1. Power up the indicator. . . The FI-90 powers up in the same

2. Access the gross mode. If the

3. Zero the FI-90 by pressing

4. Select unit of measure by

mode it was in when power was

removed.

gross annunciator is not

illuminated, press

GROSS / PEAK once. . . The gross annunciator illuminates

(See Figure 2).

ZERO / CLEAR (Any stable

applied force up to full-rated

capacity may be zeroed off). . . 0 is displayed. Any small changes

in force are zero tracked automatically and the displayed zero is

maintained.

pressing UNITS. . . The units annunciator indicates your

selected unit of measure.

5. Apply force . . . The applied gross force is displayed.

Measuring Peak Force

This procedure allows the FI-90 to monitor a varying force and hold the peak

value.

1. With the indicator powered up in

2. Press GROSS / PEAK to access

3. Remove force, or await removal of

In peak load applications,

removal of force occurs when

maximum tension or compression strength of the material or

product is met.

the gross mode, zero by pressing

ZER0 / CLEAR and apply force. . . Gross displayed value increases to

reflect increasing live force.

peak-view mode. . . The peak annunciator comes on.

Displayed is the incrementing peak

value. It reflects the live gross force

continuing to increase.

force. . . The force now displayed is the

retained peak value. Retained peak

is measured precisely at the maximum load sensed by the indicator

before force is reduced. Retained

peak value stays displayed while the

live gross force drops.

11

Page 12

4. View and, if necessary, record the

retained peak value. Press

PRINT / SELECT to transmit data

to a peripheral deviceprinter,

chart recorder, or computer or

other programmable controllerif

interfaced via the RS232 or 20mA

option.

5. Clear the last retained peak value

by pressing ZERO / CLEAR, and

re-apply force. . . The retained peak value is released

and 0 is momentarily displayed. The

display increments in the peak-view

mode, reflecting increasing live gross

force.

6. You may view increasing force in

the gross mode by pressing

GROSS / PEAK. . . The gross annunciator comes on and

gross force is displayed. Important:

The next peak captured (see step 8)

will not be displayed with the FI-90

toggled to gross mode, but the peak

will continue to be tracked and can

only be viewed in the peak-view

mode.

7. As desired, you may again view

your last retained peak (displayed

by step 4) by toggling

GROSS/PEAK. This key allows

you to toggle between peak-view

mode and gross mode.

8. Repeat steps 3, 4, and 5 for each

peak force measurement

needed. . . The indicator will capture the new

Entering or Viewing an ID Number

You may enter an identification number of up to seven digits.

1. While in gross weighing mode,

press MENU repeatedly until. . . ID. is displayed.

retained peak when force goes above

the last retained peak, even if it is

not displayed, and you can toggle to

the peak-view mode to view it as

desired.

12

2. Press PRINT / SELECT. . . The current identification number is

displayed.

Page 13

3. You now have two choices, A or B:

A. Accept the displayed ID by

pressing either GROSS /

PEAK or PRINT / SELECT. . . GROSS / PEAK takes you directly

Or

B. Enter a new ID of up to seven

digits. Use the data entry

procedure shown in the

section, Entering Data with

Arrow Keys. Then press

PRINT / SELECT. . . The new ID number is accepted and

Entering Data with Arrow Keys

out to the gross mode. PRINT /

SELECT displays ID.

ID is displayed.

Introduction

ID Number as an

Example

If at any time you enter an

incorrect character, press

ZERO / CLEAR to backspace

and delete the wrong character,

then re-key.

The arrow keys are used to enter data for the ID number, cutoff numbers,

time, and date. Refer to this section whenever the manual instructs you to

enter data for one of those parameters.

Entering data is all done through a single edit character position on the

display. The UP ARROW key increments the digit displayed in the edit-

character position up to the value needed, and the LEFT ARROW key moves

the configured digits to the left, out of the way, and brings up a new zero digit

in the edit-character position. The FI-90 allows you to enter up to seven

character positions of data.

To teach the procedure, we'll show you how to enter the three-digit ID number, 603. The same keying principles generically apply to your entry of ID,

cutoffs, time, and date.

1. Starting from a display of the

current identification number (the

outcome of step 2 under Entering

or Viewing an ID Number), press

the UP ARROW key. . . First, a zero is displayed

in the edit character

position, indicated here by

an arrow. Only in the edit-

character position can

you edit the numeric value of a digit

upward or downward.

13

Page 14

2. Start with the left-most digit (in

our example, a 6 ). Pressing UP

ARROW one depression for each

whole number, increment the

displayed number up to the

desired value. . .

3. Then press LEFT ARROW to

bump the 6 a single space to the

left and display a 0 in the

edit-character position. . .

4. The 0 in the edit-character position

is acceptable for our example's

second digit, so no depressions of

UP ARROW are required for it.

Instead, press LEFT ARROW

again to bump the 60 a single space

to the left and again display a 0 in

the edit-character position. . .

A data field of more than the

three digits entered in our

example ID number would

require one additional combination of LEFT ARROW and UP

ARROW keyings for each

additional digit.

5. Press UP ARROW, as necessary,

to increment the edit character to

the desired value, a 3 in our 603

example. . . Entry of ID #603 is complete.

14

Page 15

Viewing and Entering Setpoints (Cutoffs)

A setpoint cutoff is a force-load value at which an internal electrical connection is broken, causing an external relay to de-energize. Additional relay

configurations can turn on or shut off another electrical device.

You may configure the FI-90 to accept either one of two types of cutoff: (1) a

gross-based setpoint or (2) an increment-based setpoint. A gross-based

setpoint is called, simply, a setpoint. With this type of setpoint, activation of

a cutoff is signaled by a specified gross applied force. You specify, through

the front-panel keypad, the gross force-load setpoint that will activate each

cutoff. For example, suppose your first cutoff requires 100 pounds of force,

and your second cutoff requires 200 pounds of force; you would set the first

setpoint at 100 pounds of force and the second setpoint at 300 pounds of

force, because those values will represent gross force load when the cutoffs

activate.

With the increment-based setpoint, activation of a cutoff is signaled by a

specified amount of net force. You tell the indicator the net amount of force

required to activate each of the cutoffs. Suppose your first cutoff requires 100

pounds of force, and your second cutoff requires 100 pounds of force; you

would enter 100 for setpoint #0 and 100 for setpoint #1.

You can view the type of setpoint that has been configured in your indicator

by looking at the cutoff display in the operations menu. A decimal point

following the word cutoff indicates configuration of gross-based setpoints. If

no decimal point appears after cutoff, the FI-90 is configured for incrementbased setpoints.

The two setpoint registers are

numbered #0 and #1.

1. Starting from either gross mode or

peak-view mode, press MENU

twice to access. . . CutOFF.0 The decimal after CutOFF

says this is a gross-based setpoint.

Then press PRINT / SELECT. . . nn.n is displayed. The n 's represent

the current value in register 0 .

15

Page 16

2. Enter a new setpoint value in

register #0, using the procedure

presented in the section, Entering

Data with Arrow Keys. Before you

enter any numeric values, specify

a negative setpoint, if appropriate

for your application. To display a

negative sign, "-", use

UP ARROW to scroll through all

digits and characters until the

sign is displayed. Then press

LEFT ARROW to place a new

edit character in the edit position.

To display a decimal point in your

setpoint, scroll similarly through

all digits until the decimal is

displayed. Use the arrow keys to

enter all digits of the new

setpoint. When the correct

setpoint is displayed, press

PRINT / SELECT to accept the

value and redisplay. . . CutOFF.0

then press MENU to move to the

next register (register #1). . . CutOFF.1 is displayed (if the

second setpoint has been configured;

if not, you now see the time display).

The 1 now displayed stands for

setpoint register #1.

3. Press PRINT / SELECT. . . nn.n is the current value in register

#1.

4. Enter a new setpoint in cutoff

register #1 (See #2 and Entering

Data with Arrow Keys).

5. Press PRINT / SELECT to

accept the value and redisplay. . . CutOFF.1

then press MENU to see the

clock or GROSS / PEAK to go

back to gross or peak-view mode.

16

Page 17

Cutoff Connections

The cutoff connector located on the bottom of the indicator is a nine-pin

female connector. Figure 7 shows the pin assignments.

Signal Name Pin Number

+12v (on 12v units) #9

+ Relay voltage #6

Cutoff 0 #1

Cutoff 1 #2

Logic ground #5

Shield #7

Remote input #4

Figure 7

Cutoff Connection Pin Assignments

Viewing and Setting Time

1. From gross or peak-view mode,

press MENU repeatedly until

Hour is displayed, then press

PRINT / SELECT. . . A 12-hour clock displays time in

2. Set the clock by entering data in

the desired format, as shown in

the outcome to step 1 (12- or

24-hour time), using the data

entry procedure documented

under Entering Data with Arrow

If you enter an incorrect

character, press ZERO /

CLEAR to backspace and

delete the wrong character,

then rekey.

Keys. Start by changing AM to

PM or vice versa, if necessary:

use UP ARROW to scroll through

numbers to this display, . .- A or . .- P

then press LEFT ARROW to

change A to P or P to A. . . . 0 P or . 0 A. Zero is now in the

hours and minutes, plus A for

A.M. or P for P.M: 09 40 A . A 24-

hour clock displays hours, minutes, and seconds: 09 40 38.

edit-character position, ready for

the leftmost digit of the time data

string to be entered.

17

Page 18

3. After the clock is set, you may

press PRINT / SELECT to start

the clock and return to operations

mode menu,. . . Hour is displayed and the clock

or

press GROSS / PEAK to return

to gross or peak-view mode. . . The clock starts at the new time

Viewing and Setting the Date

1. From gross or peak-view mode,

press MENU repeatedly until

dAY is displayed, then press

PRINT / SELECT. . . Depending on the configuration of

If you enter an incorrect digit,

press ZERO / CLEAR key to

clear the display one digit at a

time.

2. To change the date, start by

pressing UP ARROW to bring a

0 into the edit-character position,

and continue using the procedure

explained in the section, Entering

Data with Arrow Keys. Use the

same date format that you saw

when you displayed the date in

step 1.

begins.

setting.

your indicator you will see the date

displayed in one of three ways:

day-month-year31.12.92

month-day-year12.31.92

year-month-day92.12.31

18

3. Press PRINT / SELECT to return

to the operations mode menu,. . . The date is accepted and dAY is

displayed.

or

press GROSS / PEAK to return

to gross or peak-view mode. . . The date is accepted and the display

returns to gross or peak-view mode.

Page 19

Transmitting Data

Your indicator requires an RS-232 / 20mA output for data transmission. The

RS-232 / 20mA connector is located on the bottom of the indicator and is a 9pin male connector. Connect a printer following the pin assignments listed in

Figure 8.

RS-232

Pin

Signal Name Number

Transmit to printer #3

Receive from printer #2

CTS (BUSY) from printer #8

DTR (READY) to printer #4

Logic ground #5

Shield #9

Signal Name Pin Number

TTY REC + #8

TTY XMT - #3

TTY REC - #2

TTY XMT + #7

Logic ground #5

Shield #9

20mA

Figure 8

RS-232 Connector Pin Assignments

If your indicator is configured to allow

printing, from the gross or peak-view

mode, press PRINT / SELECT. . . Data is transmitted and the data

configured to be printed will be output

to the printer. See Figure 9 for a

sample printout.

Figure 9

Sample FI-90 Printout

The default settings for serial output are:

Busy Disabled

Baud 1200

Parity Clear

Stops 1

19

Page 20

Analog Output Option

An optional, isolated analog output provides dip-switch selectable output: 15mA, 4-20mA, 10-50mA, 0-5VDC, 0-10VDC. The analog output can be used

with programmable controllers, chart recorders, etc. It uses a nine-pin female

connector as shown in Figure 10.

Signal Name Pin Number

Current return #1

Voltage out #4

Voltage return #5

Current out #6

Chassis ground #9

Figure 10

Analog Output Pin Assignments

20

Page 21

Using Test Mode for Indicator Diagnostics

Test mode allows you to test various functions of the FI-90. A flowchart of the

test mode menu is shown in Figure 11, followed by instructions for getting

around in the test mode and executing tests.

Figure 11

Flowchart of the Test Mode Menu

1. Enter the test mode from gross or peak-view mode by pressing and

holding MENU until tESt is displayed. SEAL or unSEAL is displayed

briefly while you hold the key.

2. Move to the right through the menu selections by briefly pressing MENU.

Move to the left through the menu selections by pressing MENU for one

second. Scroll continuously to the left by pressing and holding MENU.

3. Move down a level in the test mode hierarchy by pressing PRINT /

SELECT. Move up a level in the hierarchy: from any display in the

hierarchy, by pressing and holding PRINT / SELECT for approximately

1.5 seconds; or from the End display, by pressing PRINT / SELECT.

4. Press MENU to toggle between the options under any test parameter,

such as the ready and busy options under the serial test parameter.

5. Press GROSS / PEAK to return to gross or peak-view mode at any time.

Descriptions and instructions follow for the tests and parameters you see in

the test mode flowchart.

21

Page 22

Main Displays Viewed

in the Test Mode Menu

VERSION version - Under version are the Weigh-Tronix part number for

the FI-90 force indicator, and the revision number for

the software found in your unit. Weigh-Tronix part

numbers are divided into two parts: a five-digit prefix

and a four-digit dash number.

dISPLAY display - From this display: dISPLAY, press PRINT / SE-

LECT and the top row of annunciators turns on.

Press PRINT / SELECT again and a dynamic test is

run. Press MENU to stop the dynamic test or

consecutively press MENU to step through the

display test routine. Press PRINT / SELECT when

the dynamic test is active to return the display to

dISPLAY.

buttonS buttons - With bUttOnS displayed, press PRINT / SELECT

and an underscore will appear on the screen. Press

any key except MENU to check for proper key

functioning. After testing the keys, press MENU to

return the display to bUttonS.

OutPutS outputs - These tests allow you to turn the cutoffs on and off

automatically in sequence, under CYCLE, or individually, under CUTOFF 1 and CUTOFF 2. When

you exit the outputs test, the cutoffs revert to their

proper condition according to the applied gross force.

input input - This test tells you how the remote control input is

configured. It may be off, or it may be configured as

a remote PRINT key control, a remote GROSS /

PEAK key control, or a remote ZERO / CLEAR key

control. With input displayed, press PRINT /

SELECT and an underscore will appear. Activate the

external remote switch, and the display will print the

name of the key to which the remote input is dedicated, verifying proper functioning of the connection.

VoltAgE voltage - The input power voltage is displayed in tenths of a

volt. In the battery versions, the BATTERY annunciator comes on when the voltage reaches approximately 5.4 volts.

A to d A to D - Displays the analog-to-digital counts. The span is

normally 20,000 counts per millivolt per volt. With a

calibrator at zero millivolts per volt, the displayed

value should be between -200 and +200.

SEriAL serial - Tells you if the serial output is ready or busy. A

jumper connecting pins 4 and 8 of the serial port will

cause READY to be displayed.

22

Page 23

23

Page 24

Dillon

A division of Weigh-Tronix Inc.

1000 Armstrong Dr.

Fairmont, MN 56031 USA

Telephone: 507-238-4461

Facsimile: 507-238-8258

e-mail: dillon@weigh-tronix.com

www.dillon-force.com

Force Measurement Products & Systems

Loading...

Loading...