Page 1

FI-80 LCD / FI-80 LED

Indicators

User’s Manual

Contents subject to change without notice.

Dillon division of Avery Weigh-Tronix

1000 Armstrong Drive

Fairmont, MN 56031 USA

Sales (507) 238-8796

Service (507) 238-4461

Register your Dillon product, get manuals and see other quality force measurement products at:

www.dillonforce.com

Page 2

TABLE OF CONTENTS

Page

Introduction to the FI-80 Series Indicator........................................................................................ 3

Installation .......................................................................................................................................... 3

Operation ............................................................................................................................................ 4

S etup / Configuration......................................................................................................................... 8

Appendix A: Specifications.............................................................................................................. A-1

Appendix B: Serial Port Information................................................................................................ B-1

Appendix C: Displayed Error Codes ............................................................................................... C-1

Page 3

INTRODUCTION TO THE FI-80 SERIES DIGITAL INDICATORS

The FI-80 Series Digital Indicator is a general purpose, industrial grade force indicator. Two models are

available with different display types and power supply.

MODEL DISPLAY TYPE POWER SOURCE

FI-80 LED Light Emitting Diode (LED) 110/220 VAC, 50/60 Hz

FI-80 LCD Liquid Crystal Display (LCD) Internal 6V battery with 12 VDC 800 ma charger

The LCD model contains a 6V rechargeable battery as the primary power source. The external power

supply with these units functions as a charger for the rechargeable battery and may also be used as the

main power supply.

The FI-80 is commonly outfitted at the factory with a load cell, hardware accessories and serial cable to fit

your specific requirements. It is calibrated and is ready for installation into your application. Alternatively,

your reselling distributor may have equipped this indicator for use with a particular load cell and calibrated

the system together. Confirm that a certificate of calibration is on hand for the FI-80 Indicator and load

cell combination. Prior to installation, you should view and record the calibration values in your FI-80.

This is found at the end of the SETUP section.

Please read this manual carefully and completely prior to using the indicator. Store the manual in a safe

and convenient place so it will be available if you have questions concerning the operation of your

system.

INSTALLATION

INSTALLING THE LOAD CELL

Install the load cell according to your specific equipment and application. Set-up will vary

between systems. Some things to keep in mind for best measurement performance

1. Insert the load cell fully in-line with the tensile or compressive force axis. Off center

loading may result in measurement errors.

2. Allow for movement and relief of undesired loads.

a. Compression load cells typically have one load cell end fixed in all directions

and the other end uses a load button or ball bearing to apply a single point load

that is free of undesired bending and torque loads.

b. Tension load cells are often not rigidly affixed to surfaces. In this arrangement it

becomes self aligning under load. Two convex surfaces contacting each other

offers good immunity from undesired bending loads and a limited range of

torque loads. An example is a lifting eye suspended from a shackle bolt.

CONNECTING THE POWER SUPPLY

The FI-80 LED indicator includes a hardwired AC line cord. Simply plug the unit into a

standard wall outlet.

The FI-80 LCD indicators ship with the rechargeable battery pre-installed. The external

power supply (included) can also be used to power the indicator. The adapter acts as the

battery charger and the FI-80 LCD must use a 12 VDC, 800 mA adapter.

1. Simply plug the AC adapter into the indicator’s DC Power Jack first, and then plug into a

standard wall outlet. Make sure that the AC voltage appearing at the wall outlet

3

Page 4

matches the input voltage marked on the AC adapter.

OPERATION

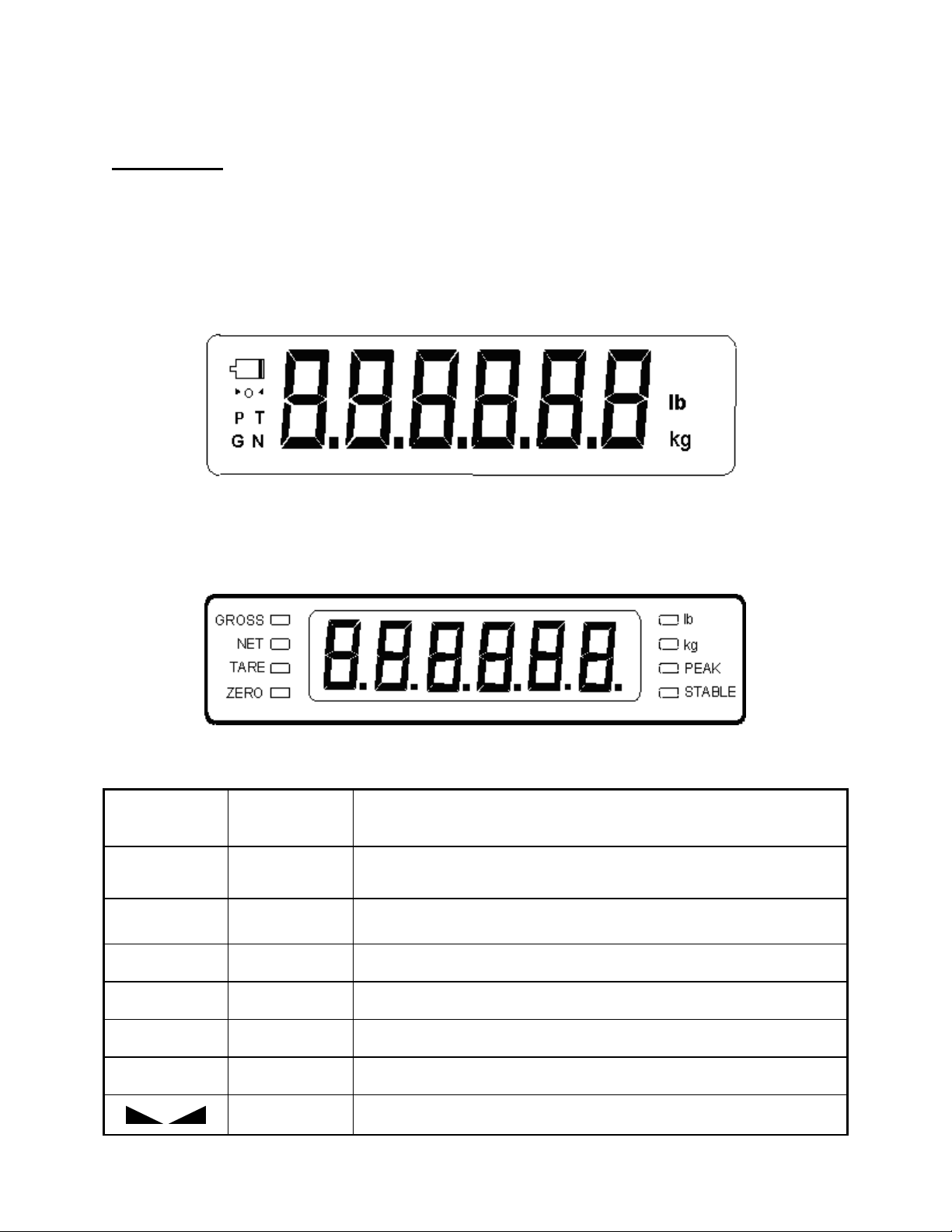

D ISPLAY

The two display types are 6 digit LCD (Liquid Crystal Display) and 6-digit LED (Light Emitting Diode)

display. Typically, LCD’s are used for outdoor applications while LED’s are used indoors where

brightness is needed. Table 7-1 summarizes both types of display annunciators.

LIQUID CRYSTAL DISPLAY (LCD)

LIGHT EMITTING DIODE (LED) DISPLAY

FI-80 LCD Detail

LCD

Annunciator

LED

Annunciator

0 ZERO

N NET

G GROSS

P PEAK

T TARE

lb, kg lb, kg

STABLE

TABLE 7-1: FI-80 Series Annunciator Definitions

FI-80 LED Display Detail

MEANING

Better known as the “Center of Zero” annunciator, this light is active

whenever the displayed load is within ± 0.25 divisions of true zero.

The FI-80 is displaying net load.

The FI-80 is displaying gross load.

The FI-80 is displaying peak load.

A tare load has been saved.

The active unit of measure.

Appears whenever the load is stable.

Page 5

FRONT PANELS

FUNCTION KEYS

PEAK – Toggles the indicator between normal live display mode and peak hold mode (Setup

ZERO - Sets the FI-80 to display “0” provided the following conditions are met:

1. The FI-80 is displaying Gross load.

2. The displayed load is within the zero reset range (F4 in setup).

3. The load is not in motion (F5 in setup).

4 . The FI-80 is not in overload (see Appendix D for error codes).

LED version front panel

LCD version front panel

5 must be set at “0” on the LCD version). A

NET/GROSS - Toggles the indicator between Gross load and Net load only if a Tare has

een established. b

TARE - Establishes a Tare provided the following conditions are met:

1. The reading is not at or below Gross zero.

2. The load is not in motion.

Page 6

3. The FI-80 is not in overload (see Appendix D for error codes).

PRINT - Sends display reading through the serial port when the following conditions are met:

1. The display is not changing.

2. The FI-80 is not in overload (see Appendix D for error codes).

See Appendix B for connection and print format details.

UNITS – (LCD model only) Toggles the indicator between lb and kg if enabled (A5 at “1”)

and peak hold is not configured (A11 at “0”). In any other conditions, the FI-80 LCD will

isplay only the default unit of measure. d

O FF – (LCD model only) When held for five seconds, shuts the unit off.

ON – (LCD model only) Turns the FI-80 on.

GENERAL OPERATION

DISPLAYING LOAD

TARING AN ITEM

PEAK HOLD

1. Select the desired unit by pressing the lb/kg key until that unit is indicated on the display.

2. Press the ZERO key to obtain a load reading of zero when necessary,.

3. Place the object to be weighed on the scale’s platter and allow the load indication to

stabilize. If the item load exceeds the load cell capacity, it displays “SSSSSS”.

4. Read the load shown on the display.

To weigh an item in a container, the weight of that container must first be subtracted from

the overall weight to obtain an accurate weight reading. This is known as taring.

1. Select the desired weighing unit by pressing the lb/kg key until that unit is indicated on

the display.

2. If necessary, press the ZERO key to obtain a weight reading of zero.

3. Place the empty container on the scale’s platter and allow the weight indication to

stabilize.

4. Press the TARE key. The display shows zero weight and turns the NET annunciator on.

5. Place the material to be weighed in the container and allow the weight indication to

stabilize.

6. Read the weight shown on the display.

7. You may toggle between the gross weight and the net weight by pressing the

NET/GROSS key.

Overview

1. The indicator has two modes of operation: NORMAL OPERATING mode and PEAK-HOLD mode.

2. Press the PEAK key to toggle the indicator back and forth between NORMAL OPERATING mode

and PEAK-HOLD mode. (Peak Hold mode must be enabled in the FI-80 LCD – see

Normal Operating Mode

Page 7

1. All keys perform as described in the manual while in this mode.

Peak-Hold Operation

In Peak-Hold mode, the display updates as the load increases, but not as the load decreases.

LCD version

1. Press PEAK to enter peak hold mode. The “P” annunciator appears on the left side of the display

when PEAK HOLD mode is engaged and the value on screen is the peak value.

2. The ZERO key clears the previously stored peak value and zeroes the indicator. Hint: To clear

the peak without rezeroing, press the PEAK key twice.

3. The PRINT key operates as it does in the NORMAL OPERATING mode.

LED version

1. Press PEAK to enter peak hold mode. The PEAK LED is lit when PEAK HOLD mode is engaged

and the value on screen is the peak value.

2. The ZERO key clears the previously stored peak value but does not zero the indicator. Hint: If

rezero is required, enter Live display mode, zero and return to Peak display

3. The NET/GROSS and TARE keys are locked out function in this mode.

Page 8

SETUP

SETUP OVERVIEW

The indicator contains two main setup menus:

1. The “F” menu items configure the indicator to the attached load cell and is known as

“Configuration” settings. Most of these are entered by a qualified instrumentation

technician.

2. The “A” menu items configure the serial communication port and general user options.

In setup mode the front panel keys become directional navigators to move around in the menus and to save

the selections.

ENTERING THE SETUP MENU

1. Power off the indicator.

2. Locate the slide switch on the rear cover and move it to the right.

NOTE: A metal plate held on by two drilled-head screws may conceal the slide switch.

The back cover may have a seal to keep unauthozed personnel from making changes

to the indicator.

3. Power on the indicator. The indicator shows ” F 1” to indicate that you are in Setup

Menu mode.

NAVIGATING IN THE SETUP MENU

Use the directional keys shown in Figure 3-1 to move around in the Setup Menu Chart

shown in Figure 3-2 on the following page.

1. Press and keys to move left and right to advance to the next or previous “F/A”

setup heading.

2. Press the key once. The current saved setting is shown.

3. Press and keys to scroll through selections for the current setup heading.

4. press the Set key to save the new selection. Press the key to escape without saving

and return to the current heading,.

5. Repeat Steps 1 through 4 until the desired Setup & Configuration changes are made.

SET

Figure 3-1: Setup Menu Key Assignments

8

Page 9

EXITING THE SETUP MENU

1. Power off the indicator.

2. Move the slide switch on the rear cover back to the left.

3. Power on the indicator. The display will go through a digit check, then settle into Normal

Operating mode. All front panel keys will now return to their normal mode of operation.

SETUP MENU DESCRIPTIONS

List and detailed descriptions of the items within the setup screens. Factory-s et defaults are s hown in

bold with a checkmark (√).

Note: Most “F” menu items configure the indicator to the attached load cell and are entered by a

qualified instrumentation technician. These parameters do not appear in this manual. Do not

change these parameters, or the indicator may not function properly or may report highly

inaccurate readings!

NAME/CODE DESCRIPTION CODE/VALUE

F1

F2

F3

F4

Zero Range

F5

Motion Band

This item is for configuration by a qualified load cell indicator

technician. Do not change this value or the instrument readings may

be in error.

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument readings may be

in error.

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument may respond

unpredictably.

Selects the range within which the scale may be zeroed. Note that the

indicator must be in standstill to zero the scale.

Defines ‘motion’ in number of divisions of change between the

present display update and the previous display. If motion has been

detected within the prior two seconds, the Print and Zero commands

are disabled.

If a stable reading is not needed for printing or zeroing in your

application, set this value at its highest number.

500 1,000

1,500 2,000

2,500 3,000

4,000 5,000√

6,000 8,000

10,000 12,000

20,000 30,000

40,000 50,000

25 50

75√ 100

150 200

0d

0.5d√

1d

3d

5d

100%√

1.9%

FI-80 LCD extras:

2%

20%

1d√

3d

5d

10d

FI-80 LCD extras:

0.25d 15d

20d 30d

40d 50d

Page 10

F6

Digital Filter

Averages load readings to produce higher stability. The higher the

filter setting, the greater the stability but the slower the indicator’s

response time. Choose 8 unless a very fast response is needed.

1 2

4 8√

FI-80 LCD extras

16 32

64 128

:

F7

F8

F9

F10

F12 (LCD

version only

F16

F17

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument may respond

unpredictably.

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument readings may be

in error.

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument readings may be

in error.

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument readings may be

in error.

Not presently used. Keep parameter on 10. 5

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument readings may be

in error.

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument readings may be

in error.

FS

FS + 2%√

FS + 1d

FS + 9d

1√

2

1√

2

5

0√ 0.0

0.00 0.000

0.0000 00

10√

20

50

75

100

Do not press

key

Do not press

key

F18

View Calibration

F19

F20

F21

Factory Reset

F23 (LED

version only

F24 (LED

version only)

Shows both the zero and span calibration value.

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument readings may be

in error.

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument readings may be

in error.

This sub-menu will reset all parameters in the “F” and “A” menus to

the default settings. USE WITH CAUTION!

Not presently used. Arbitrary value

Not presently used. Keep parameter on 0.

Press

key to

begin sequence

Do not press

key

Do not press

key

Press the

twice to execute.

0√

1

key

Page 11

A1

Baud Rate

Baud rate for data transmission through the serial port. 1200 2400

4800 9600√

19200

A2

Data Bits and

Parity

A3

Mode of Serial

Transmission

A4

Display Check

A5

Disable the

UNITS key

A6

Serial Port

Mode

A7

ID No. Enable

Number of data bits and parity of serial transmission.

"8n" = 8 data bits with no parity bit and one stop bit

"7O" = 7 data bits with odd parity bit and one stop bit

"7E" = 7 data bits with even parity bit and one stop bit

"7n" = 7 data bits with no parity bit and two stop bits

Data send mode:

"C" = Continuous mode; send data continuously

"d" = Demand mode; send data when a PRINT command is issued

from the printer, computer, or indicator.

Illuminates all digit segments, decimal points, and LCD annunciators

in a test sequence.

Disables the UNITS key so the operator does not inadvertently

change the displayed units.

"0" = Disable the lb/kg key "1" = Enable the lb/kg key

This function is only relevant on the FI-80 LCD when A11 peak hold

functionality is disabled.

RS-232 serial port mode:

"0" = Full Duplex Mode

"1" = Print Ticket Mode

Refer to Appendix B for more information.

Include ID number in the Print Ticket mode. Valid only when A6 is set

to “1”.

"0" = Disable the ID No. "1" = Enable the ID No.

8n√

7O

7E

7n

C

d√

Press

key to

begin sequence

0

1√

0

1√

0√

1

A8

ID No. Entry

A9

No. of Line

Feeds

LED version only (see below for LCD version)

A10

(LED version)

Handshaking

Enable

A11

(LED version)

LCD version only

A10

(LCD version)

Auto Power Off

Period

Change ID Number printed on ticket. Valid only when A6 is set to “1”.

Number of line feeds printed on ticket. Valid only when A6 is set to

“1”.

Enables hardware handshaking for Print Ticket Mode. Valid only

when A6 is set to “1”.

"0" = Disable Handshaking "1" = Enable Handshaking

Not presently used. Keep parameter on 0.

Selects the auto off time period in minutes:

“Off” = Disabled (Always ON)

Auto-off occurs when display does not change or buttons are not

pressed within the timescale.

0 - 999999

123456√

0 – 99

8√

0√

1

0√

1

Off

1, 2, 3, 5√, 8,

10, 15, 20, 30

Page 12

A11

(LCD version)

Peak-Hold

Mode

Enables “Peak Hold” mode. The display will only increment upward

and the peak reading is retained. Press PEAK key to enter and exit

the mode once active.

“0” = Peak Hold disabled, “3” = Peak Hold enabled

Note: UNITS are locked in default when A11 is enabled.

0√

3

A12

(LCD version)

Handshaking

A13

(LCD version)

Enables hardware handshaking for Print Ticket Mode. Valid only

when A6 is set to “1”.

"0" = Disable Handshaking "1" = Enable Handshaking

Not presently used. Keep parameter on 0.

USER MENU PROCEDURES

This section provides instructions for some parameters.

ID Number Entry (A8)

1. Scroll to "A 8" and press the key.

2. The display will momentarily show "ID NO", followed by a value with one flashing

digit. This value will be the current ID number value.

3. Use the four directional keys to adjust the displayed value to the actual ID Number

value. Increase and decrease the flashing digit by pressing or . Decrease

the flashing digit by pressing the ZERO key. The and keys will change the

position of the flashing digit.

4. After entering the exact value, press the Set key to save the ID Number value. The

display will show "SET" momentarily and revert back to A8.

0√

1

0√

1

LF (Line Feeds) Number Entry (A9)

1. Scroll to "A 9" and press the key.

2. The display will momentarily show "LF", followed by the current line feeds value.

3. Use the four directional keys to adjust the displayed value to the actual ID Number

value. Increase and decrease the flashing digit by pressing or . Decrease

the flashing digit by pressing the ZERO key. The and keys will change the

position of the flashing digit.

4. After setting the exact value, press the Set key to save the line feeds value. The

display will show "SET" momentarily and revert back to A9.

Page 13

VIEW CALIBRATION VALUES (F18)

1. While in the Setup mode, scroll to "F 18", then scroll down once using the key to enter View

Calibration menu.

2. The display will momentarily show "CAL 0" followed by a value. This value is the zero

calibration value and should be recorded in the table below. Press any key to continue.

3. The display will momentarily show "CAL 1" followed by another value. This value is the span

calibration value and should also be recorded in the table below. Press any key to return to

upper level (F18).

SERIAL NUMBERS

*

ZERO CALIBRATION

SPAN CALIBRATION VALUE

VALUE

FI-80:

CAL 0: CAL 1:

Load cell 1:

List any additional cells connected:

Table 6-1: Calibration Value Table

* Calibration is only valid for exact system calibrated. If any items are changed or removed, the

system must be recalibrated together or significant errors may result.

* Record the new values after each recalibration.

Page 14

APPENDIX A: SPECIFICATIONS

ANALOG SPECIFICATIONS

Excitation Voltage +10 VDC (LED), +5 VDC (LCD)

No load input 0.00 mV/V

Load cell output level up to + 3 mV/V

Sensitivity

Internal Resolution Approximately 150,000 counts

Display Resolution 50,000 display division max

Measurement Rate 10 Measurements /sec, nominal

System Linearity Within 0.02% of FS

Calibration Method Software Calibration, with long term storage in EEPROM

Maximum load cell support

0.4 μV / grad

4 x 350Ω load cells

OPERATOR INTERFACE

Display – LED Indicators 0.56" (14 mm) 7-segment, LED, 6 Digit

Display – LCD Indicators 0.8" (20 mm) 7-segment, Liquid Crystal, 6 Digit

Additional Symbols Net, Gross, Stable, Tare, lb, kg, Zero, Peak

Keyboard 5-key flat membrane panel

POWER

Rechargeable Battery – FI-80 LCD 6 VDC, 3.0 Ah lead acid with 12 VDC,

800mA charger

DC Power Consumption - FI-80 LCD

DC Power Consumption - FI-80 LED

55mA + 15mA/350Ω Load Cell

200mA + 30mA/350Ω Load Cell

ENVIRONMENTAL

Operating Temperature

Storage Temperature

14° to +104° F (-10° to +40° C)

-13° to +158° F (-25° to +70° C)

MECHANICAL

Overall Dimensions (L x W x H) 10.4" x 3.1" x 7.7" (265mm x 80mm x 195mm)

Appendix A

Page 15

p

p

APPENDIX B: SERIAL PORT INFORMATION

B.1 SERIAL PORT MODES

B.1.1 FULL DUPLEX MODE

The Full Duplex Mode provides a Demand serial transmission mode and is selected by

setting A3 to “d” and A6 to “0”. The Demand mode allows control from a host device, usually

a PC, and can be activated by pressing the PRINT key on the indicator’s front panel. Figure

B-1 shows a suggested cable diagram for interface to a PC. Figure B-2 shows the serial

data format for the Demand Mode.

INDICATOR PC

TXD 3

S. GND 5

2 RXDRXD 2

3 TXD

5 S. GND

4 DTR

6 DSR

8 CTS

DSUB9 DSUB9

FIGURE B-1. Cable Diagram for Indicator to IBM PC

<STX> <POL> xxxxx.xx <LB/KG> <GR/NT> <CR> <LF>

Start

Transmission

Polarity:

<SP> = Positive

"–" = Negative

Weight Data

<SP> <SP>

SpaceSpace

Units:

lb = pound

kg = kilogram

c = pieces

cs = pieces*

Gross/Net:

GR = Gross

NT = Net

Carriage

Return

Line

Feed

FIGURE B-2. Consolidated Controls Demand Mode

Appendix B

Page 16

B.1.1.1 RECOGNIZED HOST COMMANDS

“P” - This command is sent to the indicator to print the indicated display. The

indicator will not respond if the scale is in motion, positive overload or

negative overload.

“Z” - This command is sent to the indicator to zero the scale. The indicator will not

respond if the scale is in motion, positive overload or negative overload. The

indicator will also not respond if it is not in gross mode or within the zero

range specified in F4 of the Setup Menu.

“T” - This command is sent to the indicator to tare the scale. The indicator will not

respond if the scale is in motion, positive overload or negative overload. The

indicator will also not respond if it displaying a negative gross value.

“G” - This command is sent to the indicator to revert to gross mode. The indicator

will not respond if the scale is in motion, positive overload or negative

overload. The indicator will also not respond if it is not in net mode.

“N” - This command is sent to the indicator to revert to net. The indicator will not

respond if the scale is in motion, positive overload or negative overload. The

indicator will also not respond if it is not in gross mode or a tare has yet to be

established.

“C” - This command is sent to the indicator to toggle among the configured units.

B.1.2 PRINT TICKET MODE

The Print Ticket Mode is designed specifically for a serial printer and is selected by setting

A6 to “1”. Figure B-3 shows the fixed format of the print ticket.

For printers with limited buffers, this mode supports DTR pin handshaking. The DTR pin

from the serial printer is wired to the indicator’s RXD pin which then functions as a CTS pin.

Figure B-4 shows a suggested cable diagram for interfacing to a serial printer. Refer to the

printer’s user manual to confirm which pin is the DTR pin.

NOTES:

1. The TARE and NET fields are not printed unless a tare has been established in the

system.

2. The ID number field is not printed if it is disabled in A7 of the User Menu.

ID. NO. 123456

GROSS 25.00 LB

TARE 1.48 LB

NET 23.52 LB

INDICATOR PRINTER

TXD 3

. GND 5

3 RXDCTS 2

20 DTR

7 S. GND

DSUB9 DSUB25

FIGURE B-3. Print Ticket FIGURE B-4.

Cable Diagram for Indicator to Printer

Appendix B

Page 17

B.1.3 SIMPLEX MODE

The Simplex Mode provides a continuous serial transmission mode and is selected by

setting A3 to “C” and A6 to “0”. The Continuous mode is used to interface to computers,

scoreboards, and other remote devices requiring constant data updating. The

transmission occurs at the end of each display update. Figure B-5 shows the serial data

format for Continuous Mode.

<STX> <POL> xxxxx.xx <L/K> <G/N> <STAT> <CR> <LF>

Start

Transmission

Polarity:

<SP> = Positive

"–" = Negative

Weight Data

Units:

L = pound

K = kilogram

P = pieces

PCS = pieces*

C = custom units

Gross/Net:

G = Gross

N = Net

Carriage

Return

Line

Feed

Status:

<SP> = Valid

M = Motion

O = Over/under range

FIGURE B-5. Consolidated Controls Continuous Mode

Page 18

APPENDIX C: DISPLAYED ERROR CODES

CODE MEANING / POSSIBLE SOLUTION

Err 0

Err 1

Err 2

Err 3

Err 4

Err 5

Err 7

Err 9

Gross Overload. A load greater than the rated capacity has been applied

to the scale. Remove the load and verify operation. Contact your Dillon

distributor with any problems.

Should not appear in normal operation. Contact your Dillon distributor.

Should not appear in normal operation. Contact your Dillon distributor.

Should not appear in normal operation. Contact your Dillon distributor.

Non-volatile memory read error. One or more setup parameters have

been lost. Contact your Dillon distributor.

Non-volatile memory write error. Contact your Dillon distributor.

Should not appear in normal operation. Contact your Dillon distributor.

ADC reading error. Contact your Dillon distributor.

Calibration value read error. Contact your Dillon distributor.

Indicates that the battery voltage is too low for normal operation.

Recharge the battery.

Page 19

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his/her own expense.

Loading...

Loading...