Page 1

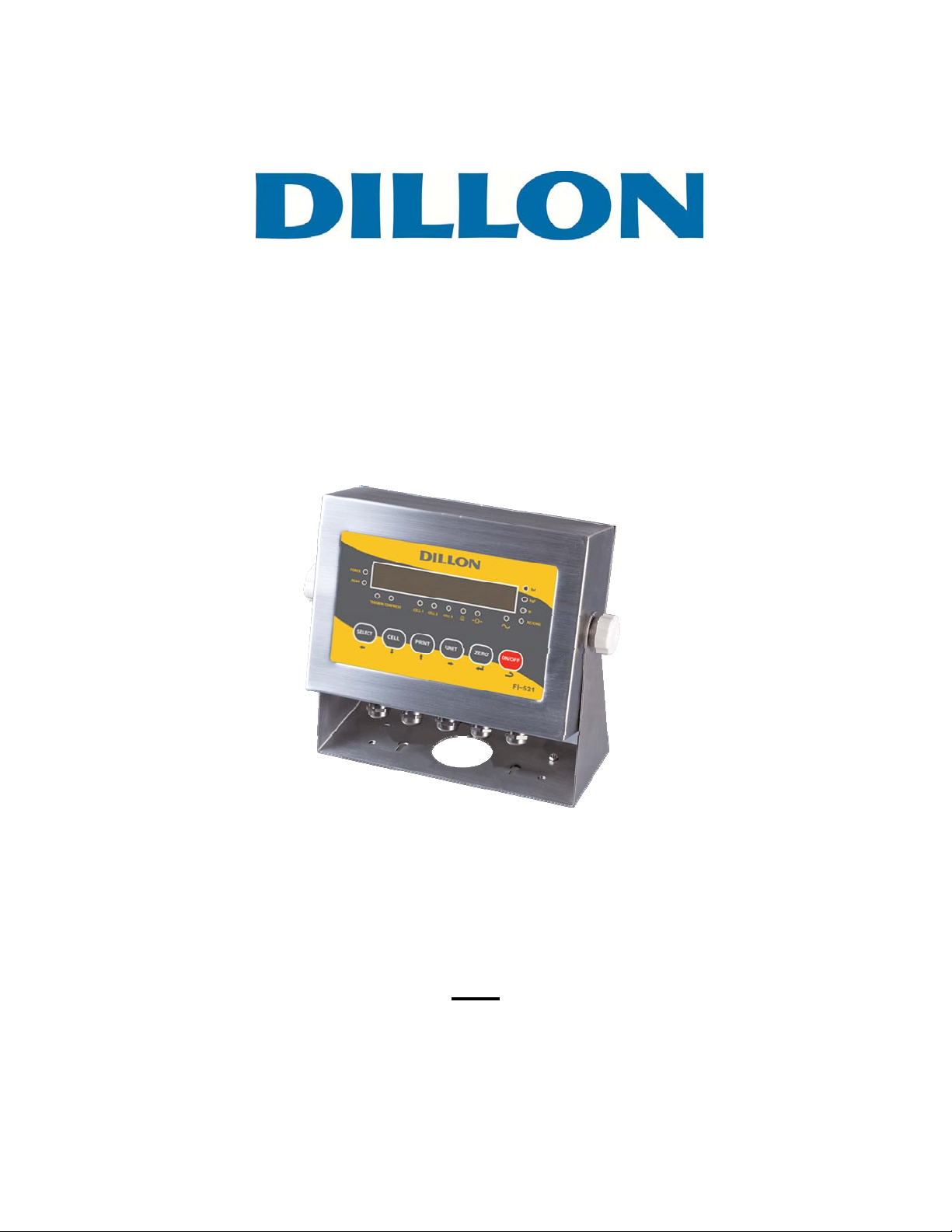

FI-521 Indicator

Operation & Service Manual

V1.1

Contents Subject to Change without Notice

Page 2

FI-521 Indicator Operation & Service Manual

────────────────────────────────────────────────────────

2

Page 3

FI-521 Indicator Operation & Service Manual

CONTENT

1. General information and warnings........................................................ 4

2. Specification ............................................................................................ 7

3. Faceplate .................................................................................................. 9

4. Summary of Key function ..................................................................... 10

5. Operation Menu Structure .................................................................... 11

6. Normal Force Measure mode ............................................................... 22

7. Calibration .............................................................................................. 24

8. Force Fine-tune ...................................................................................... 25

9. View ADC output Code .......................................................................... 25

10. View and Set Time ............................................................................... 26

11. View and Set Date ................................................................................ 26

12. View Firmware Version ........................................................................ 26

13. View COM2’s Type ............................................................................... 26

14. View the Times of Load Cell was Abused ......................................... 27

15. View Zero Offset .................................................................................. 27

16. Display Test .......................................................................................... 27

17. Keyboard and Buzzer Test .................................................................. 27

18. Input Test .............................................................................................. 27

19. Output Test ........................................................................................... 27

20. Serial Port1/2 (COM1/2) Receiving Test ............................................. 27

21. Serial Port1/2(COM1/2) Transmitting Test ......................................... 28

22. Remote Input Function Selection ....................................................... 28

23. Output Setting ...................................................................................... 28

24. Analog Voltage Output Setup ............................................................. 29

25. Details about Serial Communication ................................................. 29

26. Sockets and Jumpers .......................................................................... 33

27 Meaning of Some Symbols and Troubleshooting ............................. 40

28. Display Character ................................................................................ 42

29. Packing List ......................................................................................... 42

────────────────────────────────────────────────────────

3

Page 4

FI-521 Indicator Operation & Service Manual

1. General information and warnings

1.1 About this manual

This manual is divided into chapters1,2.3.... Subsections are labeled as shown by the 1.1 and

1.1.1 headings. The manual name appear at the top of the pages and page numbers appear at

the bottom of the pages.

1.1.1 Text conventions

Key names are shown in bold and reflect the case of the key being described. This applies to

hard keys and onscreen or soft keys.

1.1.2 Special messages

Examples of special messages you will see in this manual are defined below. The heading

words have specific meanings to alert you to additional information or the relative level of

hazard.

DANGER!

THIS IS A DANGER SYMBOL.

DANGER MEANS THA T FAILURE TO FOLLOW SPECIFIC PRACTICES OR PROCEDURES

WILL CAUSE INJURY OR DEATH.

ELECTRICAL WARNING!

THIS IS AN ELECTRICAL WARNING SYMBOL.

ELECTRICAL WARNINGS MEAN THAT FAILURE TO FOLLOW SPECIFIC PRACTICES OR

PROCEDURES MAY REAULT IN ELECTROCUTION, ARC BURNS, EXPLOSIONS OR

OTHER HAZARDS THAT MAY CAUSE INJURY OR DEATH.

WARNING!

This is a Warning symbol.

Warnings mean that failure to follow specific practices and procedures may have major

consequences such as injury or death.

CAUTION!

This is a Caution symbol.

Cautions give information about procedures that, if not observed, could result in

damage to equipment or corruption to and loss of data.

NOTE: This is a Note symbol. Notes give additional and important information, hints and tips

that help you to use your product.

1.2 Installation

DANGER: RISK OF ELECTRICAL SHOCK. NO USER SERVICEABLE PARTS. REFER TO

QUALIFIED SERVICE PERSONNEL FOR SERVICE.

────────────────────────────────────────────────────────

4

Page 5

FI-521 Indicator Operation & Service Manual

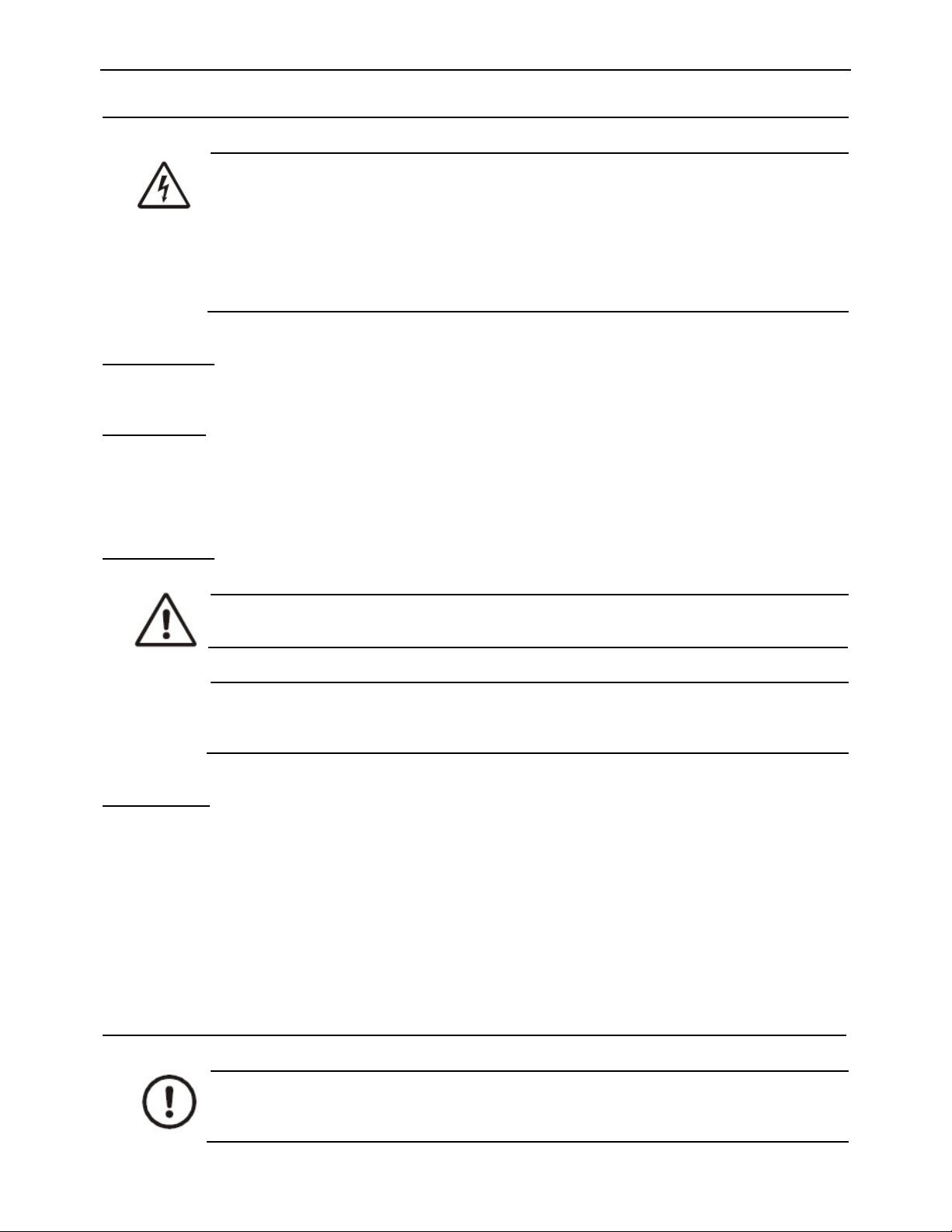

1.3 Electrical installation

ELECTRICAL WARNING: The power cable must be connected to an earth-grounded

electrical outlet. The electrical supply must have a circuit breaker with an appropriate

rating to protect from over-current conditions.

For your protection, all electrical (110V or 230V) equipment used out of doors or in wet

or damp conditions should be supplied from a correctly fused power source and

protected by an approved ground fault protection device (RCD, GFCI etc.)

IF IN DOUBT SEEK ADVICE FROM A QUALIFIED ELECTRICIAN.

1.3.1 Pluggable equipment

Pluggable equipment must be installed near an easily accessible socket outlet.

1.3.2 Permanently wired equipment - Isolator requirements

Permanently connected equipment must have a readily accessible disconnect device

incorporated in the fixed wiring such as an isolator or circuit breaker with at least 3mm contact

separation.

The isolator MUST NOT be installed into the flexible power cable supplied with the unit.

1.3.3 Safe handling of equipment with batteries

WARNING: Danger of explosion if battery is incorrectly replaced. Replace only with the

same or equivalent type recommended by the manufacturer. Dispose of used batteries

according to the manufacturer’s instructions.

ATTENTION: Il y a danger d'explosion s'il y a remplacement incorrect de la batterie,

remplacer uniquement avec une batterie du meme type ou d'un type equivalent

recommande par le constructeur. Mettre au rebut les batteries usagees conformement

aux instructions du fabricant.

1.3.4 Wet conditions

Under wet conditions, the plug must be connected to the final branch circuit via an appropriate

socket / receptacle designed for washdown use.

Installations within the USA should use a cover that meets NEMA 3R specifications as

required by the National Electrical Code under section 410-57. This allows the unit to be

plugged in with a rain tight cover fitted over the plug.

Installations within Europe must use a socket which provides a minimum of IP56 protection

to the plug / cable assembly. Care must be taken to make sure that the degree of protection

provided by the socket is suitable for the environment.

1.4 Routine maintenance

IMPORTANT: This equipment must be routinely checked for proper operation and

calibration.

Application and usage will determine the frequency of calibration required for safe

operation.

────────────────────────────────────────────────────────

5

Page 6

FI-521 Indicator Operation & Service Manual

Always turn off the machine and isolate from the power supply before starting any routine

maintenance to avoid the possibility of electric shock.

Make sure that it is placed securely on a flat and level surface.

1.5 Cleaning the machine

1.6 Training

Do not attempt to operate or complete any procedure on a machine unless you have received

the appropriate training or read the instruction books.

To avoid the risk of RSI (Repetitive Strain Injury), place the machine on a surface which is

ergonomically satisfactory to the user. Take frequent breaks during prolonged usage.

1.7 Sharp objects

Do not use sharp objects such as screwdrivers or long fingernails to operate the keys.

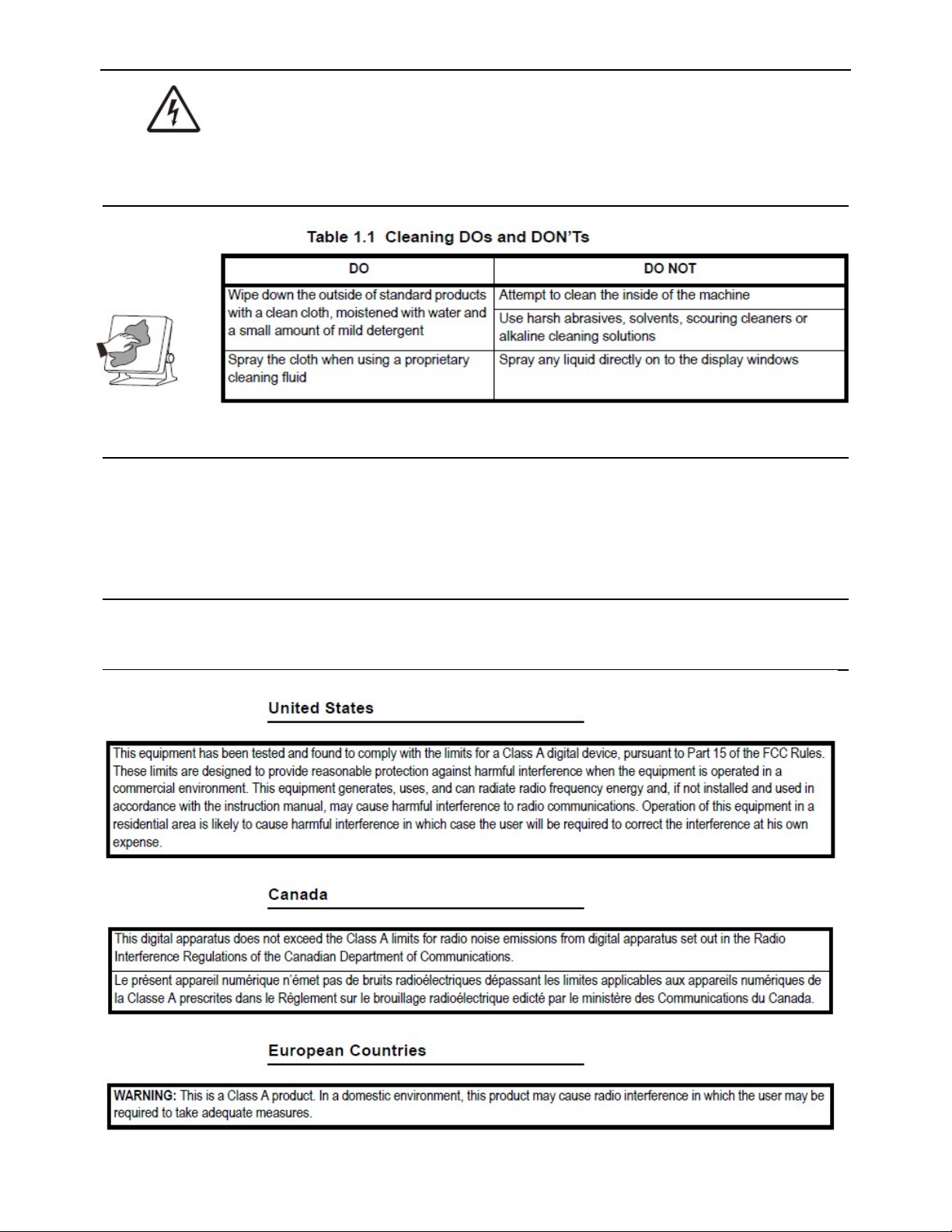

1.8 FCC and EMC declarations of compliance

────────────────────────────────────────────────────────

6

Page 7

FI-521 Indicator Operation & Service Manual

2. Specification

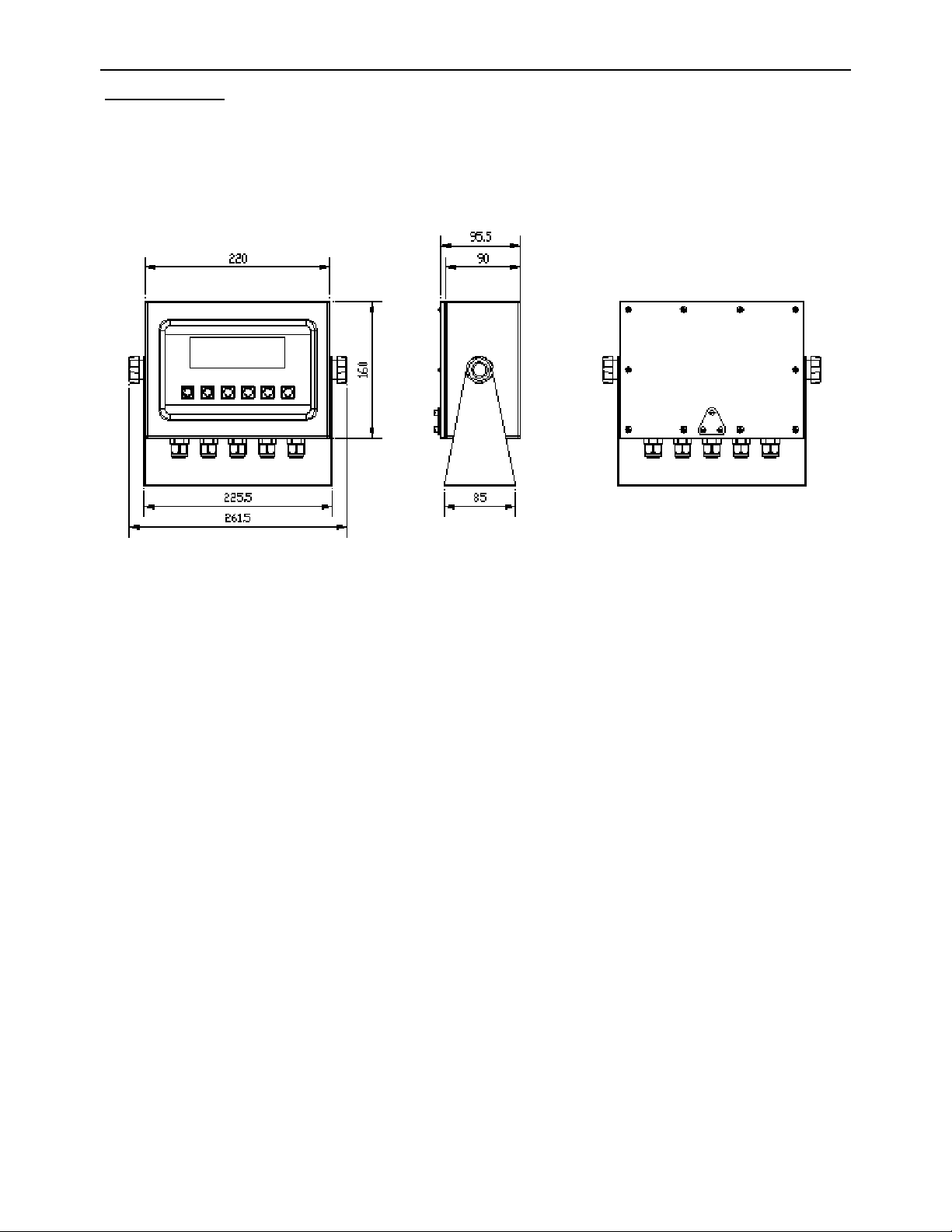

2.1 Housing and Outline Dimension:

1.2.1 IP65 wash-down stainless steel housing with adjustable bracket

1.2.2 Outline Dimension:

With bracket: 10.3" x 8.5" x 3.8" (262mm x 215mm x 96mm)

Without bracket: 8.9" x 6.3" x 3.8" (225mm x 160mm x 96mm)

Front View Side View Back View

2.2 Power Supply:

2.2.1 12 Vdc / min.500mA output AC adapter

2.3 Display:

2.3.1 FI-521: 7-digits,7-segment, 0.7’’(17mm) ultra brightness LEDs with 14 annunciators.

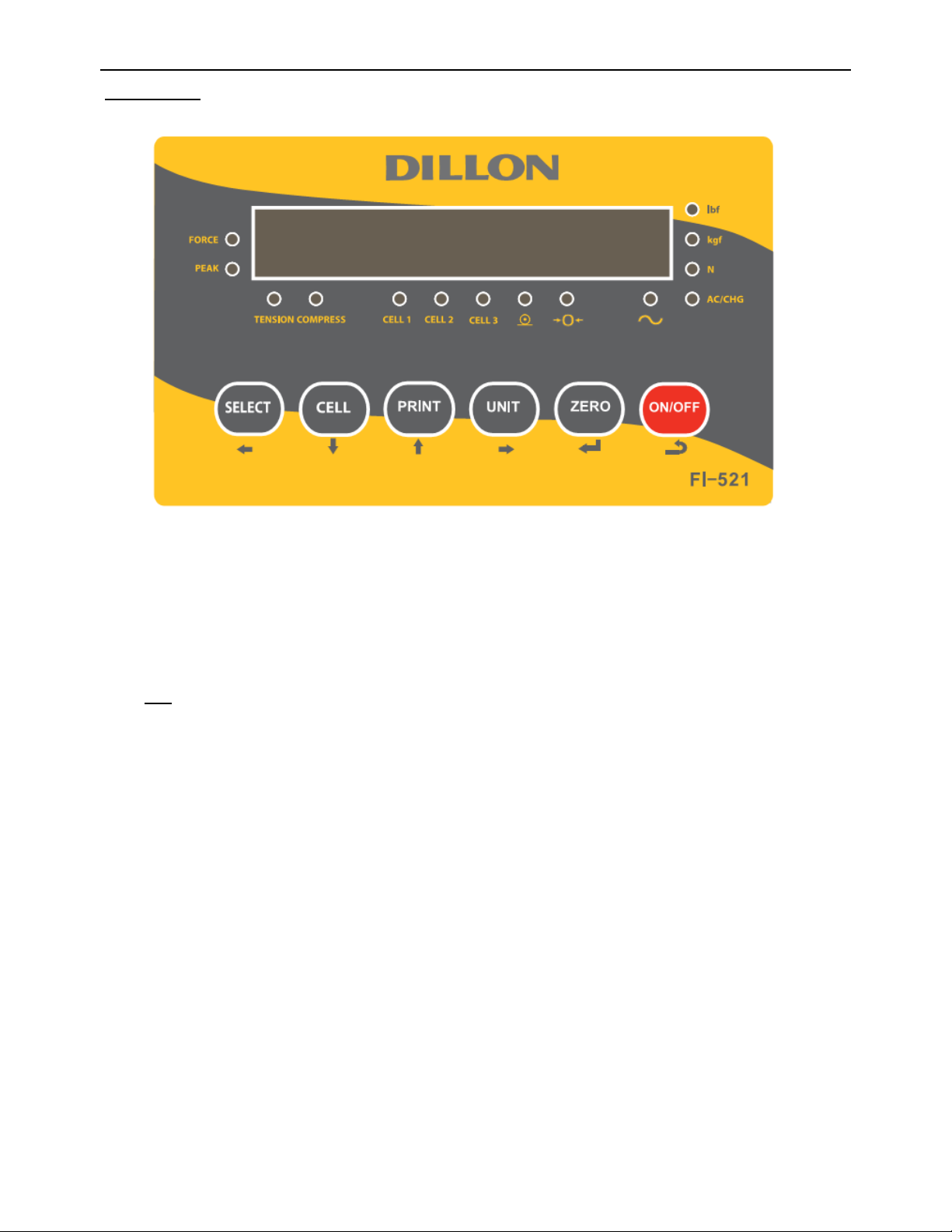

2.4 Keypad: 6 push buttons of SELECT, CELL, PRINT, UNIT, ZERO, ON/OFF

2.5 Environment:

2.5.1 Working temperature: -10°C to 40°C

2.5.2 Storage temperature: -20°C to 70°C

2.5.3 Humidity: 10 to 90% RH without condensation

2.5.5 Protection: IP65

2.6 Load cell Excitation:

2.6.1 Voltage: 5Vdc

2.6.2 Max. Current: 120mA (can power 8-350 ohm bridge)

2.6.3 Signal connection: 4 or 6 lead with sense leads

2.6.4 Max Sensitivity: -3mV/V to +3mV/V

2.7 Communication:

2.7.1 Serial port1: Full-duplex RS232

2.7.2 Serial port2: Full-duplex RS232 or half-duplex RS485

2.7.3 Baud Rate: Selectable: 1200-2400-4800-9600-19200-22800/38400-57600 bps

2.7.4 Data Output Format: 8N1, 7O1, 7E1

2.7.5 Protocol: selectable

2.8 Analog Circuit characters:

2.8.1 24-bit A/D converter

2.8.2 Conversion Speed: 80Hz

────────────────────────────────────────────────────────

7

Page 8

FI-521 Indicator Operation & Service Manual

2.8.3 Peak Capture Rate: 80 Hz

2.8.4 Input range: -15mV to +15mV

2.8.5 Output code: 1mV input between S+ and S- of load cell connector will output about 100,000 raw

Counts.

2.8.6 With Hardware low pass filter and 2 programmable digital low pass filters

2.9 Capacity and Division: Programmable

2.9.1 Max display range: -999,999 to 999,999

2.9.2 Max number range of all units = 100-100,000

2.9.3 Recommended Display Sensitivity: >0.5uV/ display division

2.10 Accuracy: ≤0.01%

2.11 Calibration Method:

2.11.1 Software calibration with long-term storage in EEPROM

2.11.2 Provides smooth curve fit through linearization points.

2.11.3 Calibration can be done under kgf or lbf weight unit with 10% -100%FS standard weight

2.12 Real Clock: built-in nonvolatile real time & date

2.13 Remote Digital Input:

2.13.1 There are four external inputs

2.13.2 Function: each input can be defined to HOLD, ZERO, TARE, PRNT, UNIT, OFF or NONE

2.14 Digital Output (Set point Output):

2.14.1 There are two configurable outputs

2.14.2 Each digital output combined with a digital comparator: if current force is over or less than the set

force point, the corresponding output will change its output electronic state according to the

pre-configuration.

2.15 Analog Voltage Output:

2.15.1 The output voltage is 0-2.5V, the output current should be limited 5mA by external circuit.

2.15.2 The accuracy of this analog voltage is 0.01% after calibration

2.16 Other Main Function:

2.16.1 Programmable Zero Range

2.16.2 Programmable automatic zero point tracking

2.16.3 Programmable motion detection window

2.16.4 Programmable auto-power off time, adjustable LED brightness

2.16.5 Available Measure Unit: kgf, lbf, Newton

2.16.6 Programmable serial output content

────────────────────────────────────────────────────────

8

Page 9

FI-521 Indicator Operation & Service Manual

3. Faceplate

3.1 Meaning of symbol on faceplate:

3.1.1 FORCE--------Illuminates when indicator is in force display mode.

3.1.2 PEAK----------Illuminates when indicator is in peak display mode. When it’s flashing, the displayed

number is live force, when it’s steady, the number is peak force.

3.1.3 lbf,kgf,N------Illuminates the active unit of measure .

3.1.4 ----------Data Send: Illuminates when the indicator is transmitting data.

3.1.5 →0← ----------Zero: Illuminates when the indicator is within the configured center of zero.

3.1.6 ~ ----------Motion: Illuminates when the indicator detects motion (out of configured motion window).

3.1.7 TENSION, COMPRESS-----Indicates the type of force being measured.

3.1.8 CELL1, CELL2, CELL3------Show which Load Cell that is being used

3.3.9 AC/CHG

---Red when battery is being charged, Green when it’s full or not installed

────────────────────────────────────────────────────────

9

Page 10

FI-521 Indicator Operation & Service Manual

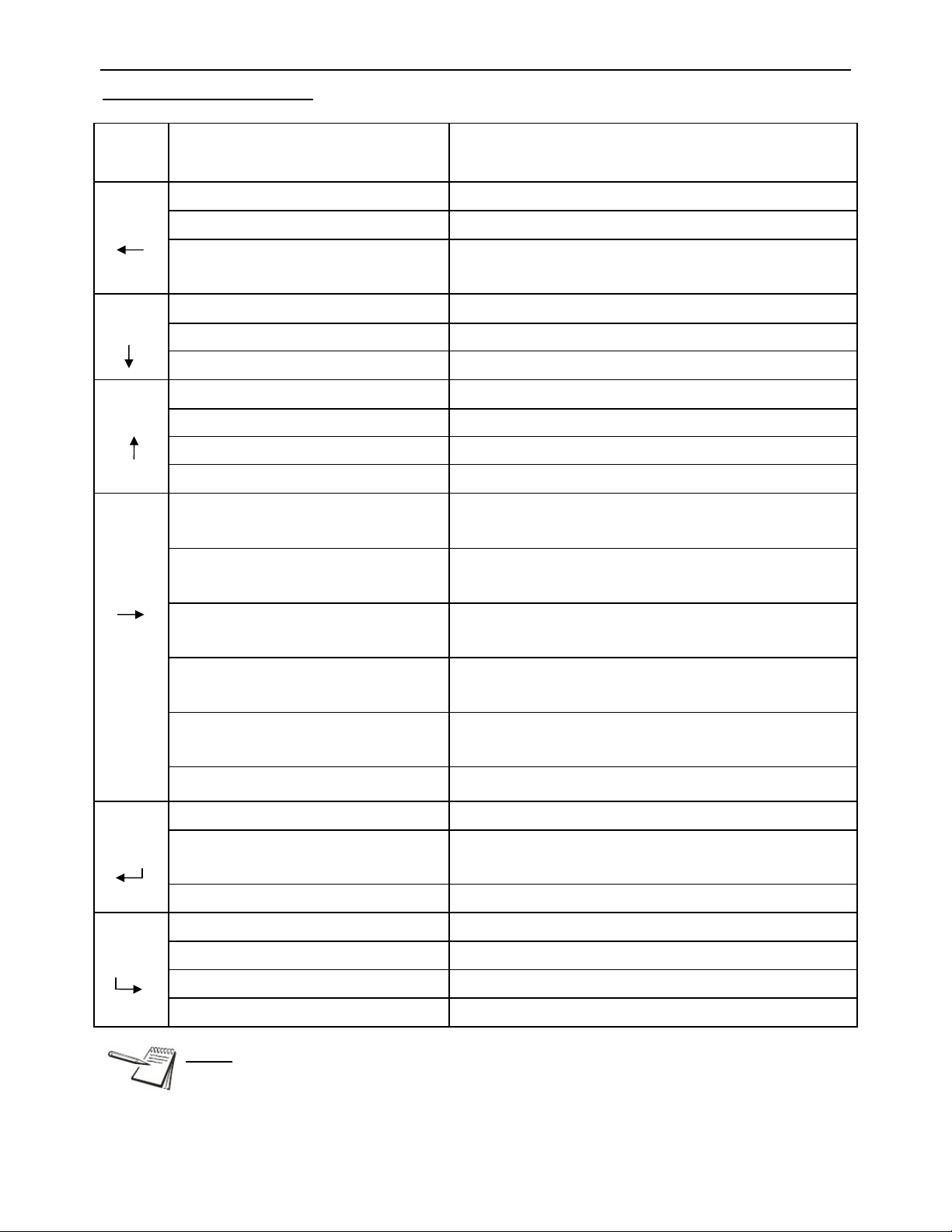

4. Summary of Key function

Key Condition Function

SELECT

CELL

PRINT

UNIT

Weighing: press less than 3 seconds To select displayed content type: Force↔Peak

Weighing: press 3 seconds or more To enter CONFIG mode

Input data mode or

Return to last sub-menu

Menu selection mode

Weighing: press less than 3 seconds To select Cell1→Cell2→Cell3→Cell1

Input data mode The digit on flashed position subtract 1

Menu selection mode To Next item of current menu

Weighing mode Output data to serial communication port

Input data mode the digit on flashed position add 1

Menu selection mode To last item of current menu

Display ADC code mode Select displaying ADC code from no-filter, filter1, filter2

Weighing mode, press less than 3

Change weighing units: lbf->kgf->N->lbf

seconds

Display date or time mode,

To set current date or time

press 3 seconds or more

Display voltage mode, press 3 seconds

To calibrate input voltage value

or more

ZERO

ON/OFF

Display ADC code, press less than 3

second

Select displaying ADC code or displaying input signal in

mV/V

Display ADC code, press 3 seconds or

To calibrate input signal in mV/V

more

Input data mode Rotate the flashed position from left to right

Weighing: press less than 3 seconds Zero function

input data mode or

Menu selection mode

To confirm input data or current item selection, and go to

next item of current menu, or next operation

Display ADC code Set or clear reference “Zero” code

Power off mode Power on

Weighing: press 3 seconds or more Power off

Input data mode ignore modification

Menu selection mode Prepare to exit from current working mode

Note:

Normally, the second function of one key is by pressing and holding down more than 3 seconds.

────────────────────────────────────────────────────────

10

Page 11

FI-521 Indicator Operation & Service Manual

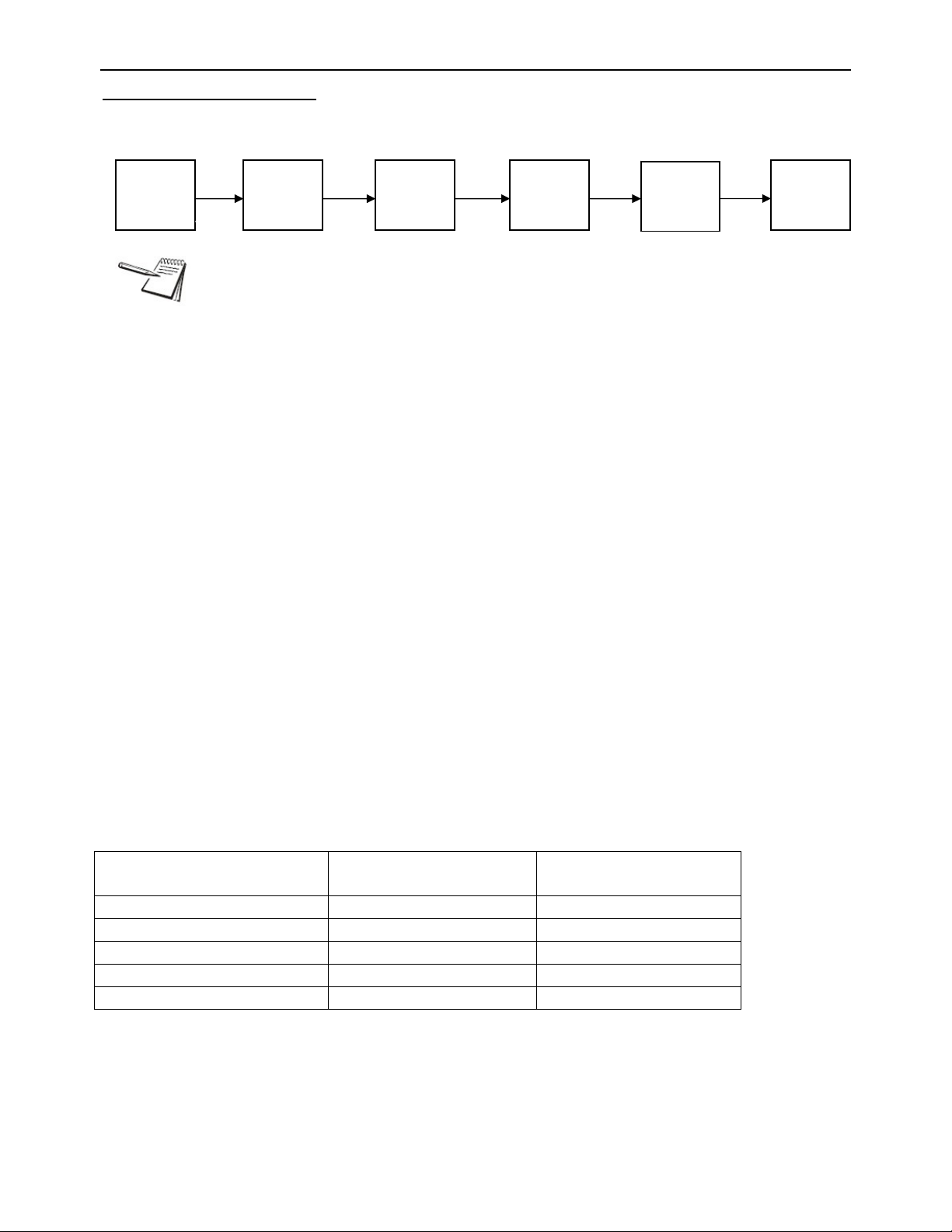

5. Operation Menu Structure

5.1 Main menu:

(Cell) (Cell) (Cell) (Cell) (Cell)

CONFIG

USER

CAL

IN.OUT

MISC

TEST

NOTE:

(1) Each LOAD CELL has its own CONFIG, CAL, IN.OUT parameters, so, before you enter

this main menu select, which load cell will be configured with the CELL key!

(2) The parameters of USER, MISC, and TEST are the same for all load cells

(3) When “Lo.VoL” or “Lo.BAT” is displayed (the voltage to PCB is low), CONFIG, USER,

CAL, IN.OUT menu can not be entered and edited .

5.2 CONFIG Submenu:

5.2.1 Access the set up mode by pressing and holding the SELECT key for 3 seconds, until display shows

CONFIG.

5.2.2 Press the ZERO key once (ZERO key is your Enter key)

5.2.3 Display will show CFG.ON or CFG.OFF

a. If it shows CFG.OFF, then you will need to move the switch in the back of the indicator,

through the CAL. Switch cover. Cycle power of the indicator and start at step #1 again.

5.2.4 Press the ZERO key once. Display shows RESET

5.2.5 Pres the CELL key until display shows CELL.TY

5.2.6 Press ZERO key once. Display shows TS.CP

5.2.7 Press ZERO key once. Display shows CELL.TY

5.2.8 Press CELL key once. Display shows DSP.POL

5.2.9 Press ZERO key once. (Select NEG or POS)

5.2.10 Press ZERO to accept

5.2.11 Press CELL key to PRIM.N

5.2.12 Press ZERO key. Display shows 10,000

a. This is number of Divisions. Use the chart below as a reference

CAPACITY is based on RESOLUTION

Capacity & Count by

Required (LBS)

PRIM.N PRIM.D

500 X 0.1 5,000 .1

2,000 X 0.5 4,000 .5

5,000 X 1 10,000 .5

10,000, X 2 10,000 1

50,000 X 10 5,000 10

** Take your Capacity and divide by your desired count-by (PRIM.D) will give you your PRIM.N number

** Example = 5,000 lb load cell divided by .5 lbs will give you 10,000

5.2.13 Press UNIT key to change to the desired number you want to change. Stop when your digit is flashing.

5.2.14 Press CELL key or PRINT key to change a number

5.2.15 Once you have set your DIVISION press ZERO to accept. Display shows PRIN.N

────────────────────────────────────────────────────────

11

Page 12

FI-521 Indicator Operation & Service Manual

5.2.16 Press CELL key. Display shows PRIM.D

5.2.17 Press ZERO key once. Display shows 1

5.2.18 Press CELL key or PRINT key to change the digit

a. Once you make a choice press ZERO key to accept

5.2.19 Press CELL key. Display shows PRIN.

5.2.20 Press ZERO key. Display shows LbF

a. Press CELL key to toggle between kgF or LbF

5.2.21 Press ZERO key to accept

5.2.22 Press ON/OFF key twice

5.2.23 Display will cycle software version, then capacity, then go to normal weighing mode.

5.2.24 Move CAL. Switch back to CFG.OFF (if you want to lock calibration)

CONFIG

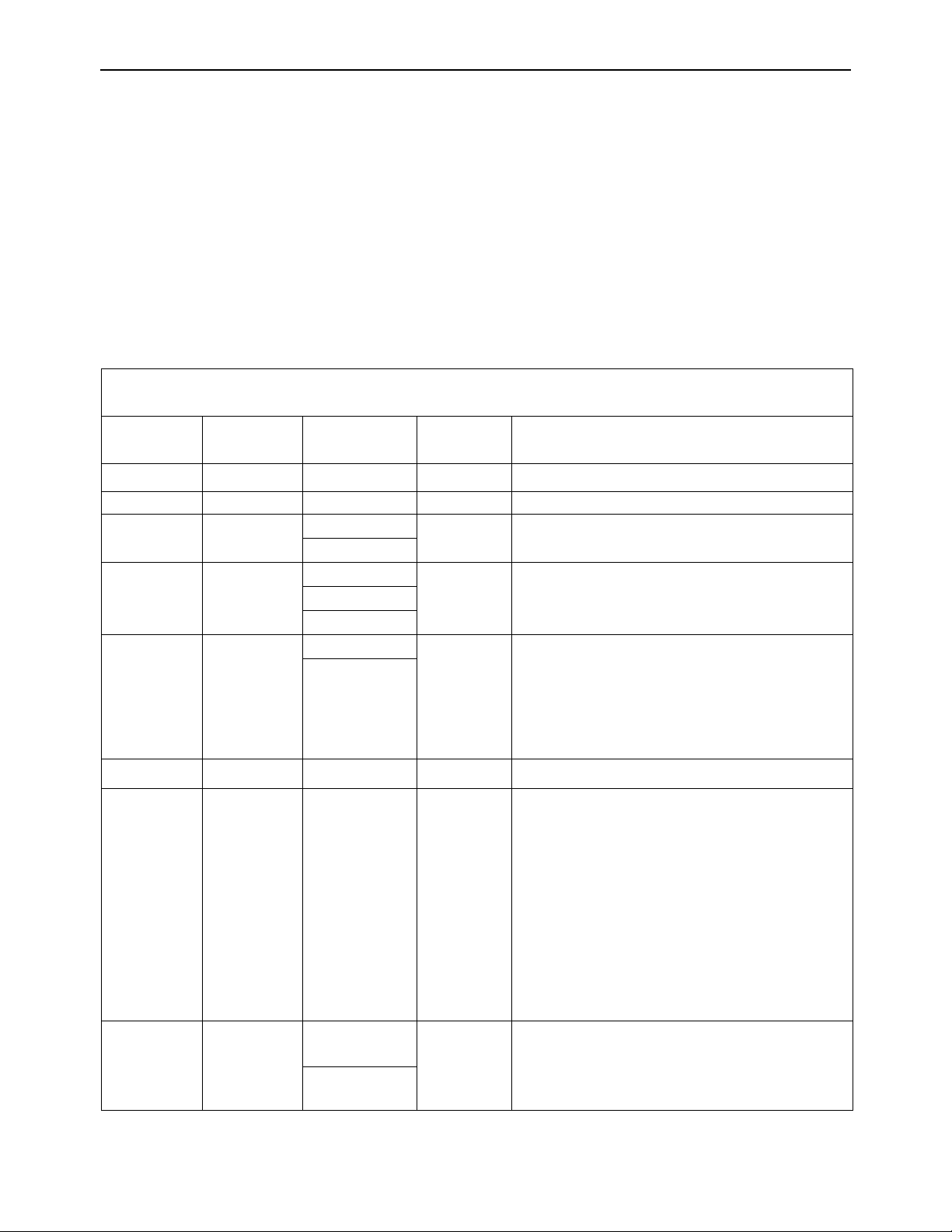

SubMenu1 SubMenu2 Option Default Remark

CFG.ON seal switch is on

CFG.OFF

RESET

Seal switch is off

NO

YES

NO reset configure parameters to default setting

Tension

CELL.TY

Compres

Tension

Select the connected load cell is used for

tension or compression force

TS.CP

Pos

Select the display polarity sign of positive or

negative for the connected load cell. When

CELL.TY = TS.CP, “DSP.POL=POS” indicates

DSP.POL

Neg

Pos

that the inner code increased direction is

tension direction; “DSP.POL=Neg” indicates

that inner code decreased direction is tension

direction.

PRIM.N 100 – 100,000 10,000 the division number under primary unit

PRIM.D

0.0001,

0.0002,

0.0005,

0.001,

0.002,

0.005,

0.01,

0.02,

1

The division value under primary unit; the

division value under second unit is

automatically determined by indicator according

to the division value under primary unit.

0.05,

0.1, 0.2, 0.5,

1, 2, 5,

10, 20, 50

PRIM.Ut

KGF

LBF

LBF

────────────────────────────────────────────────────────

Select the primary unit from kg or lb, the second

unit is the lb if kg selected as primary unit or kg

if lb selected as primary unit; the calibration

standard weight must be in primary unit!

12

Page 13

FI-521 Indicator Operation & Service Manual

SECOND.N 100-125,000 10,000

NEWTON.N 100 – 125,000 10,000

the division number under second unit ,the max

is 1.25*(PRIM.N),

the division number under the NEWTON

unit ,the max is 1.25*(PRIM.N),

units that can use UNIT key to select:

UNITS 0-6 6

0=kgf, 1=lbf, 2=N(Newton), 3= kgf,lbf,

4=kgf,N, 5=lbf,N, 6=kgf,lbf,N

refer to section5.12 for some limitation

MOTION 1-255 4 Check motion window: 1-255=±0.25d *(1-255)

over load display limitation:

OVER.LD 0-100 0

0=FS+9d,

1-100=101%FS to 200%FS

FS+(0%FS to 255%FS), If the force has exceed

ABUSE 0-255 20%

this level, it’s considered to be abusive to the

load cell

ZRO.PNT

P.IZSM 0-100 10

Initial zero(power on zero) point range:

0=no limitation,

1-100= (calibration zero point) + 1%FS to

(calibration zero point) +100%FS

Initial zero(power on zero) point range:

N.IZSM 0-100 10

0=no limitation,

1-100= (calibration zero point) - 1%FS to

(calibration zero point) -100%FS

IN.IZSM

FORCE

Which force will works as initial zero point when

force is in IZSM range:

CAL.ZRO

FORCE

FORCE= current force ;

CAL.ZRO= calibration zero;

LAST.ZRO

LAST.ZRO=switch-off zero force

OV.IZSM

DSP.OVR

Choose which force will works as initial zero

FORCE

DSP.OVR

CAL.ZRO

point when force is over IZSM range:

DSP.OVR=display initial zero point is over;

FORCE= current force;

CAL.ZRO= calibration zero;

LAST.ZRO=switch-off zero force

LAST.ZRO

Zero key range:

SAZSM 0-100 2

0=no limitation,

1-100= (initial zero point) ±1%FS to (initial

zero point) ±100%FS

Zero tracking window:

AZSM 0-255 2

0=0d, no tracking;

1-255=±0.25d*(1-255)

────────────────────────────────────────────────────────

13

Page 14

FI-521 Indicator Operation & Service Manual

FILTER

FLT1.TH 0-255 40

FLT1.ST 1-64 8

FLT2.TH 0-255 20

FLT2.ST 0-255 160 Digital filter2 intensity: 0-255=weak to strong

FUNC F.ADJ

PEAK Threshd

Enter digital filter1 threshold:

0=no filter1;

1-254=filter1 be used only when vibration in

±0.5d*(1-254) ;

255= filter1 be always used

Digital filter1 intensity: 1-64 ADC’s data will be

averaged

Enter digital filter2 threshold: 0=no filter2;

1-254=filter2 be used only when vibration in

±0.5d*(1-254) ; 255= filter2 be always used

YES

NO

NO

Enable or disable fine-adjust force number in

normal force measure mode

5-65535d, When reverse varying(Threshold) of

5-65535 10

force is over this value, one peak is occurred

and will be captured

────────────────────────────────────────────────────────

14

Page 15

FI-521 Indicator Operation & Service Manual

5.3 USER Submenu:

To enter this parameter, press and hold the SELECT key for 3 seconds until display shows CONFIG. Press

CELL key to USER. Press ZERO key to RESET and press CELL key to COM1.

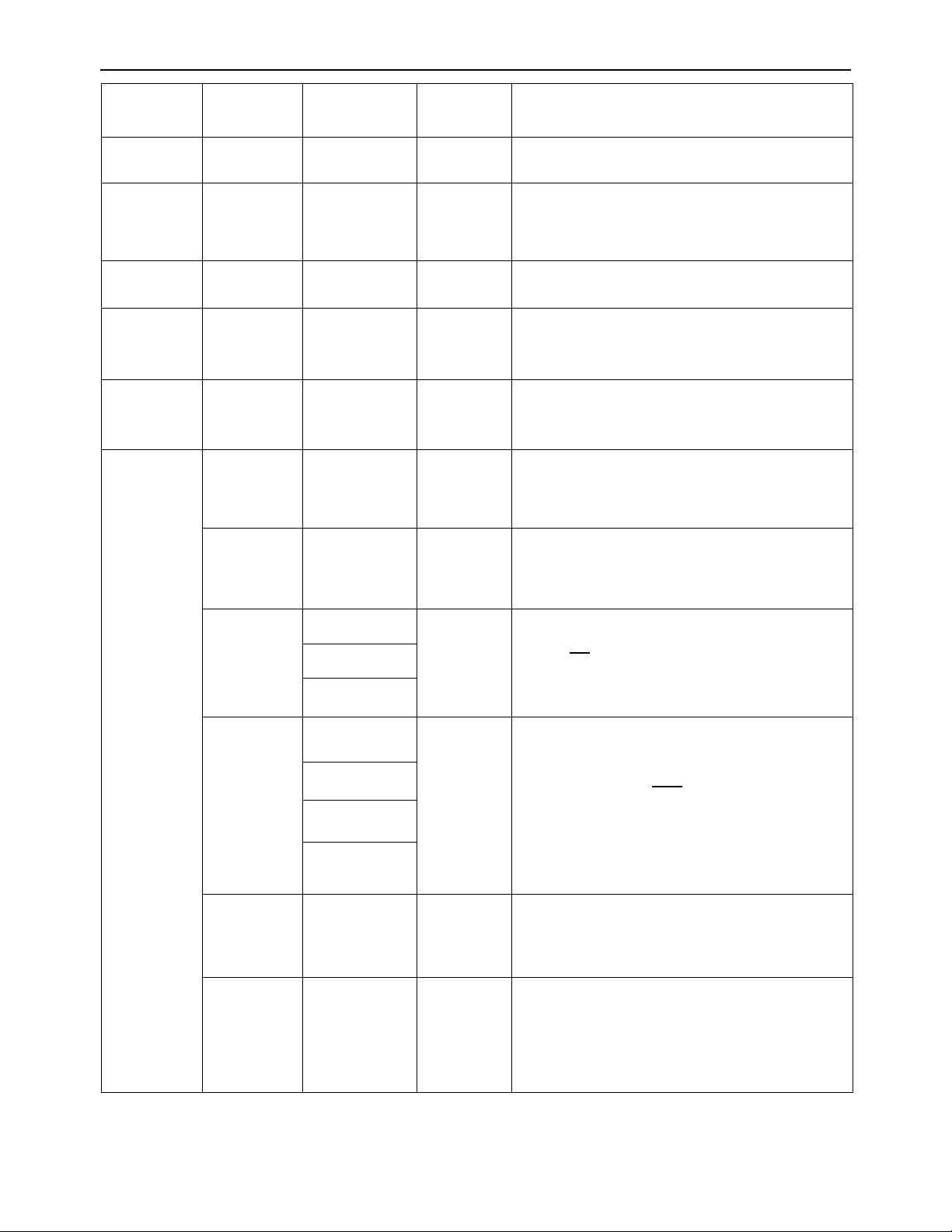

USER

Sub-

Menu1

SubMenu2 Option Default

RESET NO

YES

NO reset user parameters to default setting

Remark

COM1 BAUD.RT 1200

2400

4800

9600

9600 selection of com1's baud rate

19200

38400

57600

BYT.FMT

8N1

7O1

8N1

7E1

selection of com2's byte format:

(1) 8N1=8 data bits, No parity check bit, 1 stop bit;

(2) 7O1=7 data bits,1Odd parity check bit, 1 stop

bit;

(3)7E1=7 data bits, 1 Even parity check bit, 1 stop

bit;

OUT.MOD

NONE

CONT

Selection com1 output mode:

(1)NONE= COM1 disabled;

(2)CONT=continuously output;

(3)PRINT=output after PRINT key pressed;

PRINT

CMD

PRT.CMD

(4)CMD=output after a request command is

received;

(5)PRT.CMD= output after PRINT key pressed or

request command received;

PRT.CMD

(6)STABLE=output after indicator is stable;

STABLE

LAYOUT

MULTPL

MULTPL

SINGLE

Note: use PRINT or CMD to output data, the

indicator must be stable.

com1 output content and format set:

(1)MULTPL= the following selected item in OUT1

will be output use defined format;

(2)SINGLE= only displayed content and current

status will be output, it’s compatible with

NCI-SCP01

OUT1 TITLE

IND.ID

CELL.No

CELL.TYP

DSP.POL

FORCE

PEK.VLY

────────────────────────────────────────────────────────

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO

NO

NO

NO

NO

YES

NO

Yes/No=enable/disable output prompt of every

output line

Yes/No=enable/disable output indicator's ID

number, Prompt is “IND. ID”

Yes/No=enable/disable output load cell’s ID

number, Prompt is “CELL No.”

Yes/No=enable/disable output load cell’s type,

Prompt is “CELL TYPE”

Yes/No=enable/disable output load cell’s measure

type, Prompt is “DSP.POL”

Yes/No=enable/disable output gross force.

Prompt is “FORCE”

YES/NO=enable/disable output current captured

peak value and valley value; prompt is “PEAK”

and “VALLEY”

15

Page 16

FI-521 Indicator Operation & Service Manual

OUT1

MAX.MIN

DATE YES

TIME

AD.CODE

IN. mV/V YES

BAT.VOL

STATUS YES

B.LINE

COM2 BAUD.RT

BYT.FMT

OUT.MOD

LAYOUT

LC.ADDR

EN.ADDR

YES

NO

NO

YES

NO

YES

NO

NO

YES

NO

NO

NONE,

LINE1 –9

NO

NO

NO

NO

NO

NO

NO

LINE1

YES/NO=enable/disable output max peak and

valley value, prompt is “Max.”/ “Min.”

Yes/No=enable/disable output date. Prompt is

“DATE”

Yes/No=enable/disable output time. Prompt is

“TIME”

Yes/No=enable/disable output ADC's code.

Prompt is “A/D CODE”

Yes/No=enable/disable output input signal in

mV/V unit, Prompt is “INPUT”

Yes/No=enable/disable output voltage of battery.

Prompt is “VOLTAGE”

Yes/No=enable/disable output indicator's status.

Prompt is “STATUS”

How many blank lines after strings output:

None,LINE1-9=there're 0 - 9 blank lines after

strings

1200

2400

4800

9600

9600 selection of com2's baud rate

19200

28800

57600

8N1

7O1

8N1

selection of com2's byte format:

1)8N1=8 data bits, No parity check bit, 1 stop bit;

2)7O1=7 data bits,1Odd parity check bit,1stop bit;

3)7E1=7 data bits, 1Even parity check bit, 1stop

7E1

NONE

bit

Selection com2 output mode:

(1)NONE= COM2 disabled;

CONT

(2)CONT=continuously output;

(3)PRINT=output after PRINT key pressed;

PRINT

PRT.CMD

CMD

(4)CMD=output after a request command is

received;

(5)PRT.CMD= output after PRINT key pressed or

request command received;

PRT.CMD

STABLE=output after indicator is stable;

Note: use PRINT or CMD to output data, the

STABLE

indicator must be stable.

com2 output content and format set:

MULTPL

MULTPL

SINGLE

(1)MULTPL= the following selected item in OUT2

will be output use defined format;

(2)SINGLE= only displayed content and current

status will be output, it’s compatible with

NCI-SCP01

01-99 01 Local address for COM2, “00” is broadcast addr.

NO

NO

YES

Yes/No=enable/disable using com2 local address

in output or input strings

────────────────────────────────────────────────────────

16

Page 17

FI-521 Indicator Operation & Service Manual

OUT2 TITLE

IND.ID

CELL. No

CELL.TYP

DSP.POL

FORCE

PEK-VLY

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO

NO

NO

NO

NO

YES

NO

Yes/No=enable/disable output prompt of every

output line

Yes/No=enable/disable output indicator's ID

number, Prompt is “IND. ID”

Yes/No=enable/disable output load cell’s ID

number, Prompt is “CELL No.”

Yes/No=enable/disable output load cell’s type,

Prompt is “CELL TYPE”

Yes/No=enable/disable output load cell’s measure

type, Prompt is “DSP.POL”

Yes/No=enable/disable output gross force.

Prompt is “FORCE”

YES/NO=enable/disable output current captured

peak and valley value; prompt is “PEAK” and

“VALLEY”

MAX.MIN

DATE

TIME

AD.CODE

IN. mV/V

BAT.VOL

STATUS

B.LINE

BEEP KEY

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NONE,

LINE1 –

LINE9

YES

NO

NO

NO

NO

NO

NO

NO

NO

LINE1

YES

YES/NO=enable/disable output max peak and

valley value, prompt is “Max.” and “Min.”

Yes/No=enable/disable output date. Prompt is

“DATE”

Yes/No=enable/disable output time. Prompt is

“TIME”

Yes/No=enable/disable output ADC's code.

Prompt is “A/D CODE”

Yes/No=enable/disable output input signal in

mV/V unit, Prompt is “INPUT”

Yes/No=enable/disable output voltage of battery.

Prompt is “VOLTAGE”

Yes/No=enable/disable output indicator's status.

Prompt is “STATUS”

How many blank lines after strings output:

NONE,LINE1 – LINE9=there're none,1 - 9 blank

lines after strings

Yes/No=enable/disable beep after a key pressed

down

MAX

MIN

PEAK Display

PEAK

MAX

VALLEY

────────────────────────────────────────────────────────

Select what is displayed In peak display mode:

MAX=Max. Force value;

MIN=Min. Force value;

PEAK=current captured peak value;

VALLEY=current captured valley value;

17

Page 18

FI-521 Indicator Operation & Service Manual

OTHER

NLD.RNG 1-255 10

CMD.SRC

NONE

COM1

COM1

COM2

COM1-2

A.OFF.T 0-255 0

OFF.MOD

OFF

DSP.TIM

DSP.DAT

OFF

AC.TIME

AC.DATE

1-255=the range of force is ±1-255d; when

current force is less than this value, the load cell

can be regarded as no load on it. It must be bigger

than (CONFIG.MOTION).

Source of the executed command selection:

NONE=no command will be executed;

COM1= command from COM1 will be executed;

COM2= command from COM2 will be executed;

COM1-2= command from COM1 or COM2 will be

executed;

Auto off time:

0=not auto power off;

1-255=auto power off after 1-255 minutes, in this

period, it should be no operation or no weight

changing

Auto off mode:

(1)OFF=turn off instrument;

(2)DSP.TIM= display time;

(3)DSP.DAT=display date;

(4)AC.TIME=turn off when only battery is used,

display time when AC adaptor is used;

(5)AC.DATE=turn off when only battery is used,

display date when AC adaptor is used;

LED brightness level set:

BRT1-BRT2-BRT3-BRT4-BRT5=low - middle high; only available on LED version

LED.BRT

IND.ID

BRT1-2-3-4-

5

000000 -

999999

BRT4

123456 Indicator’s ID number: 000000-999999

────────────────────────────────────────────────────────

18

Page 19

FI-521 Indicator Operation & Service Manual

5.4 CAL Submenu:

To enter this parameter, press and hold the SELECT key for 3 seconds until display shows CONFIG. Press

CELL key (2x) to CAL. Press ZERO key to enter Cal Menu.

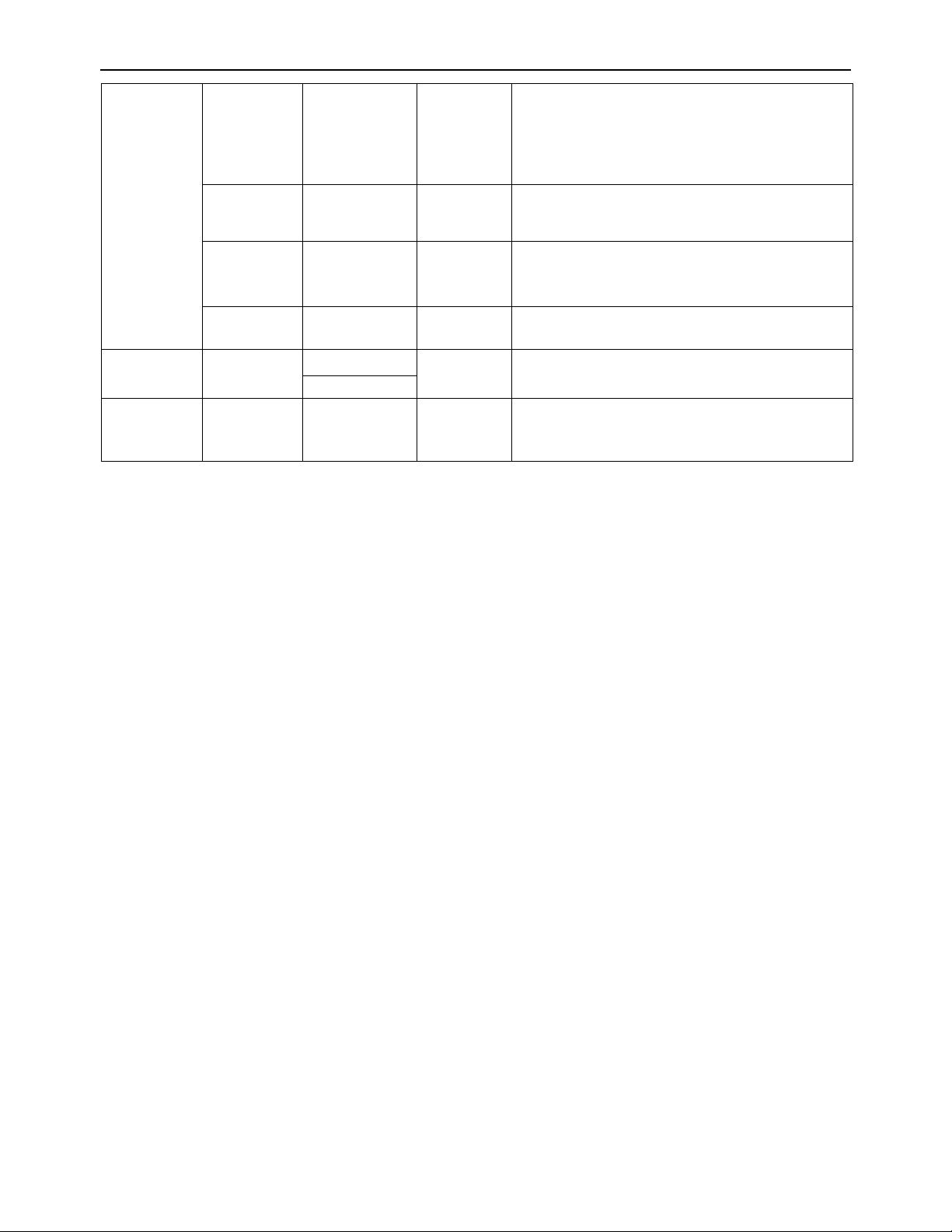

CAL

SUBMENU1 SUBMENU2 OPTION REMARK

CAL.ON Seal switch is on

CAL.OFF

ZERO

Seal switch is off

LINE CAL.P0

CAL.P1

END.Y

CAL.P2

END.Y

CAL.P3

END.Y

CAL.P4

END.Y

CAL.P5

INPUT

CAL.END

Only do zero point calibration, then go to CAL.END to

end. (Only needed when a zero shift has occurred.)

Line calibration point0: do zero point calibration,

this point can't be omitted.

Line calibration point1: do first weight point

calibration, this point can't be omitted and standard

weight must be over 10%FS.

YES

NO

End calibration? YES=go to CAL.END to end; NO=go

to do next point calibration

Line calibration point2: do second weight point

calibration, standard weight must be over 10%FS and

be larger than it in CAL.P1, this point can be omitted.

YES

NO

End calibration? YES=go to CAL.END to end; NO=go

to do next point calibration

Line calibration point3: do third weight point

calibration, standard weight must be over 10%FS and

be larger than it in CAL.P2, this point can be omitted.

YES

NO

End calibration? YES=go to CAL.END to end; NO=go

to do next point calibration

Line calibration point4: do forth weight point

calibration, standard weight must be over 10%FS and

be larger than it in CAL.P3, this point can be omitted.

YES

NO

End calibration? YES=go to CAL.END to end; NO=go

to do next point calibration

Line calibration point5: do fifth weight point

calibration, standard weight must be over 10%FS and

be larger than it in CAL.P4, this point can be omitted.

Input or view calibration parameters value that is got

before

Calibration end and restart

NOTE:

The details can be referred in section “7.CALIBRATION”

────────────────────────────────────────────────────────

19

Page 20

FI-521 Indicator Operation & Service Manual

5.5 IN.OUT Submenu:

IN.OUT

SUB-

MENU1

INPUT INx. yyyy

SUB-

MENU2

MODE OUTx.yz

OUTPUT

SPF1 0kgf

SPF2 0kgf

OFF

MODE

ON

2.5V-F 3000kgf

AVOUT

SUB-

MENU3

DEFAULT REMARK

IN1.SELE

IN2.CELL

IN3.UNIT

IN4.ZEO

Select function(yyy) of each remote input(x)

X=1-4; yyyy=SELE(select)/ CELL(cell)/ PRNT(print)/

UNIT(unit)/ ZERO(zero)/ OFF/ NONE(none); normally,

one remote input is low (0), that means one external

switch is closed

OUT1.00

OUT2.00

Select output(x) level after power on(y) and after an event

trigger(z); x=1-2, y=0-1, z=0-1; Normally, y/z=0 will make

external relay closed, and y/z=1 make the relay open

Select the force unit of OUTPUT1 referred:

→lbf→N→kgf

kgf

; and Input the force number of

OUTPUT1 referred: 0 to FS

Select the force unit of OUTPUT2 referred:

→lbf→N→kgf

kgf

; and

Input the force number of OUTPUT2 referred: 0 to FS

OFF OFF/ON=analog voltage output is off/on

Select the controlling force unit: kgf→lbf→N→kgf

Input the force value or capacity that you want to the

2.5VDC reference: 10%FS to 120%FS. Default is 10,000.

0.0000 V

CAL.VO

1.2500 V

------------

To set and check the output voltage of

0.0000/1.2500/2.5000VDC

2.5000 V

4.6 MISC Submenu:

MISC

SUBMENU1 REMARK

CODE

VOL

display ADC's code, this code can be after no-filter, filter1 or filter2; or display input

signal in mV/V; details refer to section8

display voltage; calibrate voltage; set full charged voltage and low battery voltage;

details refer to section9

────────────────────────────────────────────────────────

20

Page 21

FI-521 Indicator Operation & Service Manual

DATE display date and set date; details refer to section11

TIME display time and set time; details refer to section10

VER display firmware version; details refer to section12

COM2.TY Display type of COM2; details refer to section13

ABUS.CNT View times of occurred abuse on selected cell; details refer to section14

ZERO.OFS ZERO OFFSET: Current zero - Calibration zero; details refer to section15

5.7 TEST Submenu:

TEST

SUBMENU1 REMARK

DISP.tst test LCD or LED; details refer to section17

COM1.rd test COM1 receiving; details refer to section20

COM1.td test COM1 transmitting; details refer to section21

COM2.rd test COM2 receiving; details refer to section20

COM2.td test COM2 transmitting; details refer to section21

KEY.tst test keys and buzzer; details refer to section17

INPUT To view the level of input lines; details refer to section18

OUTPUT To set and check output level of output lines ; details refer to section19

────────────────────────────────────────────────────────

21

Page 22

FI-521 Indicator Operation & Service Manual

6. Normal Force Measure mode

6.1 During key operation, please note to use the second function of a key, press the key down over 3 seconds;

to input data or select menu, use to process.

6.2 Power on indicator: when indicator is off, short press ON/OFF key to turn on;

Power off indicator: when indicator is on, long press ON/OFF key to turn off the indicator.

6.3 To select which load cell is connected to this indicator: press and release CELL key; after this, the indicator

will display new load cell capacity and related configuration parameters will be called and used in later

operations.

6.4 To send data out through RS232 or RS485: press PRINT key when system is stable

6.5 To zero display, presses ZERO key to set new zero point when the system is stable and within the zero

range. Please refer its range in COFIG-ZRO.PNT-SAZSM

6.6 To change measure unit: Short press UNIT key to select lbf, kgf or Newton unit. Note: under some

condition, some measure units are not available. Please refer the following Tables.

6.7 To set configuration parameters, set user parameters, set current date or time, set other parameters, or do

calibration mode, or test some hardware… Press SELECT key more than 3s to enter SETUP mode.

After entering setup mode, the MAIN MENU item CONFIG will be shown first, and then you can use

keys to select wanted submenu and wanted menu item,

select wanted choice, set wanted number, confirm and save data, or exit this mode. Please refer the

“4.Operation Menu Structure”.

6.8 To display FORCE or Captured PEAK data: press SELECT key. In PEAK display mode, what peak will be

displayed is determined by setting of USER-PEAK-DISPLAY. Pleas refer following Fig.

Force

0

Max.

CONFIG-PEAK-THRESHOLD

Valley

Peak

Valley Min

Peak

Peak

Current

Captured

Peak

Current

Captured

Valley

Time

CONFIG-PEAK-THRESHOLD

────────────────────────────────────────────────────────

22

Page 23

FI-521 Indicator Operation & Service Manual

Table1: use Kgf as primary unit:

Calibration division value

Display division value in different weight unit that can be used

Kgf Lbf Newton

0.0001kgf 0.0001 0.0002 0.001

0.001kgf 0.001 0.002 0.01

0.01kgf 0.01 0.02 0.1

0.1kgf 0.1 0.2 1

1kgf 1 2 10

10kgf 10 20 Not available

0.0002kgf 0.0002 0.0005 0.002

0.002kgf 0.002 0.005 0.02

0.02kgf 0.02 0.05 0.2

0.2kgf 0.2 0.5 2

2kgf 2 5 20

20kgf 20 50 Not available

0.0005kgf 0.0005 0.001 0.005

0.005kgf 0.005 0.01 0.05

0.05kgf 0.05 0.1 0.5

0.5kgf 0.5 1 5

5kgf 5 10 50

50kgf 50 Not available Not available

Table2: use lbf as primary unit:

Calibration division value

Display division value in different weight unit that can be used

kgf lbf Newton

0.0001lbf Not available 0.0001 Not available

0.001 lbf 0.0005 0.001 0.005

0.01 lbf 0.005 0.01 0.05

0.1 lbf 0.05 0.1 0.5

1 lbf 0.5 1 5

10 lbf 5 10 50

0.0002 lbf 0.0001 0.0002 0.001

0.002 lbf 0.001 0.002 0.01

0.02 lbf 0.01 0.02 0.1

0.2 lbf 0.1 0.2 1

2 lbf 1 2 10

20 lbf 10 20 Not available

0.0005 lbf 0.0002 0.0005 0.002

0.005 lbf 0.002 0.005 0.02

0.05 lbf 0.02 0.05 0.2

0.5 lbf 0.2 0.5 2

5 lbf 2 5 20

50 lbf 20 50 Not available

────────────────────────────────────────────────────────

23

Page 24

FI-521 Indicator Operation & Service Manual

7. Calibration

7.1 Select the load cell (1-3) for recalibration with the cell key. If the load cell has not been configured; you will

have to access the CONFIG submenu and select the load cell parameters

Access the calibration mode by pressing theSELECT key for 3 seconds or more, until you see Config

displayed.

7.2 Press theCELL key to select the Cal menu

7.3 Press the ZERO key to enter the calibration menu.

a. After entering this mode, the history of calibrations will be shown first. This number will be

increment one digit after every calibration and calibration data saved.

b. After the counter number above was displayed, it will show “CAL.OFF” or “CAL.ON” which

depends on whether the sealed calibration switch is OFF or ON. If CAL OFF is displayed, you

can still do calibration but the result will not be saved. To turn CAL ON, power down the unit and

flip the switch located on the back of the indicator under the triangle stainless steel plate, and

power back on and follow the step above.

7.4 Press the ZERO key to go to next step.

7.5 Press theCELL key to scroll to LINE

7.6 When LINE is displayed, press theZERO key to enter linearity calibration.

7.7 CAL.PO will be displayed with a zero value. Remove all weight on the scale and then press theZEROkey

to confirm zero point calibration. The zero weight will flash while capturing the zero point. After getting

the zero-point data, the zero weight will become steady and proceed to the next step.

7.8 When first default standard weight is display after CAL.P1being shown. The default standard weight is

100% of full scale. Using the SELECT, PRINT, CELL, UNIT keys to input the value of the loaded weight.

Minimum test weight value 10% of full scale.

7.9 Put corresponding weight onto the scale

7.10 Press theZERO key to confirm the calibration.

7.11 If calibration was successful, display will show END.Yand the Y is flashing. It is waiting for a command

to go onto the next calibration point or exit the calibration mode. Use the CELLorPRINTkey to select

End.y for yesor End.n for no.

a. If yes is selected, the calibration will be saved and exit to the force mode when the load is

removed.

b. If no is selected, it will go to the next step, requiring a higher calibration or linearization point.

7.12 Press the ZEROkey to confirm.

7.13 The first default standard weight is displayed after Cal.P2being shown. The default standard weight is

100 % of full scale. Use the SELECT, PRINT, CELL, UNIT keys to input the value of the loaded weight.

(More than 10% of full scale weight, and larger than the weight used on CAL.P1) onto scale.

7.14 If calibration was successful, display will show END.Yand the Y is flashing. It is waiting for a command

to go onto the next calibration point or exit the calibration mode. Use the CELLorPRINTkey to select

End.y for yes or End.n for no.

────────────────────────────────────────────────────────

24

Page 25

FI-521 Indicator Operation & Service Manual

a. If yes is selected, the calibration will be saved and exit to the force mode when the load is

removed.

b. If no is selected, it will go to the next step.

7.15 Press the ZERO key to confirm

7.16 The first default standard weight is displayed after Cal.P3being shown. The default standard weight is

100 % of full scale. Use the SELECT, PRINT, CELL, UNIT keys to input the value of the loaded weight.

(more than 10% of full scale weight, and larger than the weight used on CAL.P2) onto scale

7.17 Press the ZERO key to confirm

7.18 When calibration is complete CAL.ENDwill be displayed. The indicator will restart, remove the load

from the scale and the indicator will go back to the normal force mode.

8. Force Fine-tune

With this function, the user can adjust displayed force a little, and no need standard weight. But please

note:

(1)The indicator must have been calibrated before this

(2)The range of adjustment is “(current displayed force) x (0.9-1.1)”. it means the range is about ±10%

(3)The “CONFIG-F.ADJ=YES” must be set.

(4) The current unit should be the unit in PRIM.U, and the tare weight is 0.

8.1 To enter this mode, turn on indicator, after indicator displaying 0 force, put a load (suppose: its correct force

is 1230.0lb) onto load cell, then indicator will display the load’s force, say “1234.5 lb”. Press down

ON/OFF and ZERO at same time until first digit flashes, this means indicator has entered into “force

fine-tune” mode.

8.2 Use to input correct force (1230.0). Press the ZERO key, the active correct force will be

displayed and Display will stop flashing. After this, displayed force will be adjusted by this ratio

(1230.0/1234.5) and this ratio will be active until next modification on it.

8.3 To remove the effect of this ratio, there’re two ways: “8.3.1 way” and “8.3.2 way”

8.3.1 Do standard calibration, like in “6.CALIBRATION”

8.3.2 Remove all weight on scale, Press ZERO to make 0 displayed, Put a load onto load cell, a number

will be displayed, suppose it’s 1230.0lb ; Press down ON/OFF and ZERO at same time until first

digit flashes, this means indicator has entered into “force fine-tune” mode.

Press key, the displayed weight will be restored to 1234.5, and then press key to

confirm and exit to normal weighing mode.

9. View ADC output Code

9.1 In this mode, you can examine the stability of weighing system, the increment value of ADC output code

corresponding to the loaded weight.

Note:

The increment of ADC code for FS weight must be larger or equal to 10 times of selected

display division; otherwise, the calibration cannot be properly completed. e.g. The display

division is 0.1kg. Load 100kg standard weight on the platform, the increment of ADC code

should be at least more than 10x100kg/0.1kg= 10x1000=10000. In this case, the indicator can

be calibrated. Otherwise, smaller division needs to be Chosen.

The variation of ADC code should be small; otherwise, the calibration cannot properly complete

also.

────────────────────────────────────────────────────────

25

Page 26

FI-521 Indicator Operation & Service Manual

9.2 To go to this working mode, press down SETLECT until CONFIG is shown, using CELL, PRINT and ZERO

key to go to MISC - Code item, press ZERO to enter this mode and display ADC output raw code.

9.3 In this mode, first press ZERO key can set current code as a reference zero, and then to display net code,

press ZERO again to clear this reference and display gross code.

9.4 In this mode, press PRINT key to select displaying code that has been filtered by no-filter, filter1 or filter1

and filter2, and corresponding announciator N, kgf, lbf will be lighted.

9.5 In this mode, press UNIT key to select displaying ADC’s code or input signal in x.xxxxx mV/V unit. When

display in mV/V unit, all announciator of N, kgf, lbf will be lighted.

9.6 When in display signal in x.xxxxx mV/V mode, press down UNIT key to calibration input signal in mV/V.

After enter this mode, “0mV/V” will be flashed, input 0mV/V signal to load cell connector, then press ZERO

to confirm. When “1mV/V” or “2mV/V” is displayed, use UNIT key select “2mV/V” or “1mV/V”, then input

corresponding signal to load cell connector, then press ZERO to confirm. After calibration done, it backs to

display signal in x.xxxx mV/V. In above steps, press CELL or PRINT key will also back to display signal in

x.xxxxx mode. The end customer normally no need to do this calibration, it has been done in factory.

9.7 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

10. View and Set Time

10.1 After entering MAIN MENU mode (by press down SELECT key more than 3s), using PRINT or CELL key

to select MISC-TIME item, press ZERO to display current time.

Time display Format is: txx.xx.xx(hh-mm-ss) for LED Version, 24h format

Press down UNIT more than 3s to enter modification time mode. Using PRINT, CELL, UNIT, ZERO keys

to modify current time. If time of no operation s more than 5s, it will automatically exit modification mode.

Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

11. View and Set Date

11.1 After entering MENU mode (by press down SELECT key more than 3s), using PRINT or CELL key to

select MISC-DATE item, press ZERO to enter MISC menu.

11.2 Date display Format is: dxx.xx.xx(yy-mm-dd) for LED Version

11.3 Press down UNIT more than 3s to enter modification date mode. Using SETLECT, PRINT, CELL, UNIT,

ZERO keys to modify current date. If time of no operation is more than 5s, it will automatically exit

modification mode.

11.4 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

12. View Firmware Version

12.1 Press down SELECT until CONFIG is shown, using PRINT or CELL key to select MISC-VER item, press

ZERO to display current Version.

12.2 Firmware Version display Format is: Vxx.yy, xx is hardware version, yy is software version

12.3 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

13. View COM2’s Type

13.1 Press down SELECT until CONFIG is shown, using PRINT or CELL key to select MISC-COM2.TY item,

────────────────────────────────────────────────────────

26

Page 27

FI-521 Indicator Operation & Service Manual

press ZERO to display COM2’s type (485, 232, None)

13.2 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

14. View the Times of Load Cell was Abused

14.1 Press down SELECT until CONFIG is shown, using PRINT or CELL key to select MISC-ABUS.CNT item,

press ZERO to show the times of selected load cell had been abused (CLx.yyy). x=1,2,3; yyy=000-999

14.2 When the indicator is not sealed and press ZERO key more than 3s, this counter can be reset to 000.

14.3 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

15. View Zero Offset

15.1 Press down SELECT until CONFIG is shown, using PRINT or CELL key to select MISC-ZERO.OFS item,

press ZERO to view the offset of current zero point and calibration zero point.

15.2 Use UNIT key to view this offset in code (xxxxxxx) or in x.xxxxx mV/V format

15.3 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

16. Display Test

16.1 Press down SELECT more than 3s to enter MAIN MENU mode, using PRINT or CELL key to select

TEST-DISP item, press ZERO to enter test display mode and all segments will be lighted first.

16.2 In this mode, every pressing of CELL key will light next segment, every pressing of UNIT will light next

digit, press ZERO will automatically light all segments and all digits.

16.3 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

17. Keyboard and Buzzer Test

17.1 Press down SELECT more than 3s to enter MAIN MENU mode, using PRINT or CELL key to select

TEST-key item, press ZERO to enter test keypad mode, and key. -- will be displayed.

17.2 In this mode, press a key, the value of this key will be displayed on - - position and buzzer will beep..

17.3 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

18. Input Test

18.1 Press down SELECT until CONFIG is shown, using PRINT or CELL key to select MISC-INPUT item,

press ZERO to show level (0/1) of input line1. “INP1.0/1” will be shown

18.2 Use CELL, PRINT to view the level of input line1,2,3,4

18.3 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

19. Output Test

19.1 Press down SELECT until CONFIG is shown, using PRINT or CELL key to select MISC-OUTPUT item,

press ZERO to output 0/1 on output line1. “OUT1.0/1” will be displayed

19.2 Use CELL key to select output 0 or 1 on output line. Use PRINT key to select test output line1 or line2.

19.3 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

20. Serial Port1/2 (COM1/2) Receiving Test

────────────────────────────────────────────────────────

27

Page 28

FI-521 Indicator Operation & Service Manual

20.1 Before test the receiving function of COM1 or COM2, a cable is need to connect a PC and this indicator,

and a software that is similar with Super Terminal of Windows is also need to run on PC to send bytes to

this indicator. Please note: testing uses USER-COM1/2-BAUD.RT setting baud rate and 8N1 byte format,

Hex data.

20.2 Press down SELECT more than 3s to enter MAIN MENU mode, using PRINT or CELL key to select

TEST-COM1.RD or TEST-COM2.RD item, press ZERO to enter test COM1/2 receiving function, and

rd1.-- or rd2.--will be displayed first.

20.3 In this mode, received hex data (0x00 – 0xff) will be displayed on -- position.

20.4 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

21. Serial Port1/2(COM1/2) Transmitting Test

21.1 Before test the transmitting function of COM1 or COM2, a cable is need to connect a PC and this

instrument, and a software that is similar with Hyper Terminal of Windows is also need to run on PC to

receive bytes from this instrument. Please note: testing uses USER-COM1/2-BAUD.RT setting baud rate

and 8N1 byte format, Hex data.

21.2 Press down SELECT more than 3s to enter SELECT mode, using PRINT or CELL key to select

TEST-COM1.TD or TEST-COM2.TD item, press ZERO to enter test COM1/2 transmitting function, and

td1.-- or td2.-- will be displayed first.

21.3 In this mode, transmitted hex data (0x00 – 0xff) will be displayed on -- position, and PRINT, CELL, UNIT,

ZERO keys can be used to modify transmitted data.

21.4 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

22. Remote Input Function Selection

22.1 Press down SELECT until CONFIG is shown, using PRINT or CELL key to select IN.OUT-INPUT item,

press ZERO to display original function of input line1.It is displayed in “Inx.yyyy) format. X(=1,2,3,4) is the

number of input line, yyyy(=NONE, SELE, CELL, PRNT, UNIT, ZERO, OFF) is the function of input line x.

Every input function can be defined to SELECT,CELL,PRINT,UNIT,ZERO, or OFF.

22.2 Use CELL key to change input line; Use PRINT key to select the function of this line, Use ZERO key to

confirm and save.

22.3 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

23. Output Setting

23.1 Press down SELECT until CONFIG is shown, using PRINT or CELL key to select IN.OUT-OUTPUT item,

press ZERO to enter setting mode.

23.2 Use CELL or PRINT key to select MODE (setting output mode) or SPF1 or SPF2 (“Set Point Force”,

setting the corresponding data of output). Use ZERO to confirm.

23.3 When “OUTx.yz” is shown, Use CELL key to change output line number(x), Use PRINT key to change

level after power on (y) and after an event trigger(z); x=1-2, y=0-1, z=0-1; Normally, y/z=0 will make

external relay closed, and y/z=1 make the relay open. y=0/1 means after the indicator power on, the

output level is 0/1, z=0/1 means if current display force is over the setting data (SPF1/2), the output level is

0/1. Use ZERO to confirm.

────────────────────────────────────────────────────────

28

Page 29

FI-521 Indicator Operation & Service Manual

23.4 When “SPF1/2” is shown, use ZERO to enter set set-point1/2 data mode. When “UNIT.kgf/lbf/n” is shown,

use CELL, PRINT, or UNIT key to select unit of input force number. After this, use CELL, PRINT, UNIT

key to input force number, and then use ZERO to confirm and save them.

23.5 In normal force measure mode, if SPF1 or SPF2 is set bigger than 0, the electronic level on output line will

change according to the setting of OUTx.yz.

23.6 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

24. Analog Voltage Output Setup

Note:

The current draw from analog voltage output should be less than 2.5mA, that means the resistor

M

added on this output connector should more than 1K

!

24.1 Press down SELECT until CONFIG is shown, using PRINT or CELL key to select IN.OUT-AVOUT item,

press ZERO to enter this mode.

24.2 Use CELL or PRINT key to select MODE (set analog voltage output is enable or disable) or 2.5V-F (set

the force number of 2.5V output) or CAL.VO (calibrate the output analog voltage). Use ZERO to confirm.

24.3 After enter MODE item, use CELL and PRINT to enable or disable output analog voltage, Use ZERO to

confirm.

24.4 After enter 2.5V-F item, “UNIT.kgf/lbf/n” will be shown, use CELL, PRINT, or UNIT key to select unit of

input force number, then use CELL, PRINT, UNIT to input force number that is corresponding to the 2.5V

analog voltage output, Use ZERO to confirm.

24.5 When CAL.VO is shown, it means calibrate output voltage. Before this, a high accuracy voltage meter is

need. After enter this calibration mode by pressing ZERO key, “0.0000V” will be shown, that means output

0.0000V is ready to be calibrated. if the reading on voltage meter is not 0.0000V, use CELL or PRINT to

adjust the reading to 0.0000V, then use ZERO key to finish 0.0000V output calibration. Similarly, do

calibration on 1.2500V and 2.5000V. When adjust the output voltage, the output code to DAC (Digit to

Analog Converter) will be displayed temporally and then back to display output voltage.

24.6 Press SELECT key to return to last menu item, press ON/OFF key to prepare to exit this mode

25. Details about Serial Communication

25.1 COM1 is RS232, communication wires come from RS232 connector, and TXD1, RXD1 and GND are

used.

25.2 COM2 can be RS232 or RS485, if used as RS232, communication wires come from RS232 connector,

and TXD2, RXD2 and GND are used, if used as RS485, communication wires come from RS485

connector, and A and B are used (if need GND or +5VCC1 can be used).

Please refer to section 26.2, 26.3.4-5, 26.3.7-9 for jumper connector details.

25.3 The baud rate and byte format is set by USER-COM1/2-BAUD.RT and USER-COM1/2-BYT.FMT.

Responses to serial commands will be immediate, or within one force measure cycle of the indicator. One

second should be adequate for use as a time-out value by remote (controlling) device.

25.4 The length of each item in a transition string:

25.4.1 Reading data --- 6bytes

Data polarity ----1byte: “-” for negative, and followed the first digit; “ ” for positive.

Decimal point ---1byte: “.”

────────────────────────────────────────────────────────

29

Page 30

FI-521 Indicator Operation & Service Manual

Measure unit ----1-3bytes:“ lbf”,“ kgf”, “N”, left aligned

Current status-- 4bytes

25.4.2 If the force is overcapacity, the indicator will return eight “^” characters (the field of polarity, decimal

point, force data is filled by “^”).

25.4.3 If the force is under capacity, it will return eight “_” characters (the field of polarity, decimal point, and

force data is filled by “_”).

25.4.4 If the zero point is error, it will return eight “-“ characters (the field of polarity, decimal point, and force

data is filled by “-”).

25.4.5 Useless leading 0 before digits is suppressed. Reading weight is right aligned.

25.5 Key to symbols used

<LF> Line Feed character (hex 0AH)

<CR> Carriage Return character (hex 0DH)

<ETX> End of Text character (hex 03H)

<SP> Space (hex 20H)

H

1H2H3 H4

Four current status bytes

<P> Polarity character: “-” or “ ”

W

---W

1

6

Reading data

<DP> Decimal point

U

1U2 U3

Measure units, kgf, lbf, N

<Add> Address of indicator

<Prompt> Prompt of output content

The bit definition of H

1H2H3 H4

:

Bit Byte 1 (H1) Byte 2 (H2) Byte 3 (H3) Byte 4 (H4)

0=stable 0= not under capacity

0

1= not stable 1= under capacity

0= not at zero point 0= not over capacity

1

1= at zero point 1= over capacity

0=RAM ok 0=ROM ok 0= force mode

2

1= RAM error 1=ROM error 1= peak mode

0= eeprom OK

3

1= eeprom error

0=calibration ok 0=initial zero ok 0=input4’s level is low

1=calibration error 1=initial zero error 1=input4’s level is high

0=output1 is set low 0=input1’s level is low

1=output1 is set high 1=input1’s level is high

0=output2 is set low 0=input2’s level is low

1=output2 is set high 1=input2’s level is high

0=input3’s level is low

1=input3’s level is high

4 always 1 always 1 always 1 always 1

5 always 1 always 1 always 1 always 1

6 always 0 always 1 always 1 always 0

7 parity Parity parity Parity

25.6 Communication when USER-COM1/2-LAYOUT is set to SINGLE:

25.6.1 Commands and response

25.6.1.1 Command: W<CR> (57h 0dh), request current reading

────────────────────────────────────────────────────────

30

Page 31

FI-521 Indicator Operation & Service Manual

Response:

<LF>^^^^^^^^U

<LF>_ _ _ _ _ _ _ _ U

<LF> - - - - - - - - U

Note: U

1U2 U3

<CR><LF> H1H2H3 H4<CR><ETX>---over capacity

1U2 U3

<CR><LF> H1H2H3 H4<CR><ETX>---under capacity

1U2 U3

<CR><LF> H1H2H3 H4<CR><ETX>---zero-point error

1U2 U3

is 1or 3 bytes according to current unit: kgf, lbf, N

<LF><P>W

1W2W3W4W5

<DP>W6 U1U2 U3 <CR><LF> H1H2H3 H4 <CR><ETX>---normal data

Note: The decimal point position is determined by CONFIG-PRIM.D

25.6.1.2 Command: S<CR> (53h 0dh) , request current status

Response: <LF> H

1H2H3 H4

<CR><ETX>

25.6.1.3 Command: Z<CR> (5ah 0dh)

Response: Zero function is activated (simulate ZERO key) and it returns to current indicator status.

<LF> H

1H2H3H4

<CR><ETX>

If ZERO function cannot be activated, it will return to current indicator status.

25.6.1.4 Command: U<CR> (55h 0dh)

Response: Changes units of measure (simulate UNIT key) and return indicator status with new units,

The new measure unit should be allowed to use

<LF> U

<CR><LF> H1H2H3 H4<CR><ETX>

1U2 U3

25.6.1.5 Command: L<CR> (4ch 0dh)

Response: Select next load cell to work (simulate CELL key), and returns indicator status.

<LF> H

1H2H3H4

<CR><ETX>

25.6.1.6 Command: X<CR> (58h 0dh)

Response: power off the indicator, just like press down the ON/OFF key to turn off the indicator.

25.6.1.7 Command: all others

Response: Unrecognized command <LF>? <CR><ETX>

25.6.2 Summary of Command and Response:

Command

Response

ASCII HEX

Read scale weight:

<CR><LF> H1H2H3 H4<CR><ETX>---over capacity

1U2 U3

<CR><LF> H1H2H3 H4<CR><ETX>---under capacity

1U2U3

<CR><LF> H1H2H3 H4<CR><ETX>---zero-point error

<dp>W6U1U2U3<CR><LF>H1H2H3H4<CR><ETX>---norm

W<CR> 57 0d

<LF>^^^^^^^^U

<LF>________U

<LF>-------- U

<LF><p>W

1U2 U3

1W2W3W4W5

al data

S<CR> 53 0d <LF> H1H2H3H4<CR><ETX>; read indicator status

Z<CR> 5a 0d <LF> H1H2H3H4<CR><ETX> ; simulate ZERO key

U<CR> 55 0d <LF> U1U2 U3 <CR><LF> H1H2H3H4<CR><ETX>; simulate UNIT key

L<CR> 4c 0d <LF> H1H2H3H4<CR><ETX>; simulate SELECT key

────────────────────────────────────────────────────────

31

Page 32

FI-521 Indicator Operation & Service Manual

X<CR> 58 0d power off the indicator, simulate OFF key

others

<LF>? <CR><ETX>

25.7 Communication whe n USER-COM1/2-LAYOUT is set to MULTIPLE:

25.7.1 Output string frame:

<LF><Add><Prompt><p>W

1W2W3W4W5

<Dp>W6 U1U2 U3 <CR>

…… ---- Line number and content are determined by setting of USER-OUT1/2-xxxx

<LF><Add><Prompt>H

1H2H3 H4

<CR> ---- USER-OUT1/2-STATUS is set to YES

……

<LF><Add><CR> --- USER-OUT1/2-LINE is set to LINE1…9

…… The number of blank lines is determined by USER-OUT1/2-LINE setting

<ETX> --- Last byte of string frame

25.7.2 Caution:

(1)The decimal point position is determined by CONFIG-PRIM.D

(2)The unit position and bytes is determined by which current unit is used.

(3)The details of <Prompt> refer to the content in 4.3USER Submenu.

(4)If USER-COM2-EN.ADDR is set to NO, no <Add> will be output.

(5)In continues output mode, if USER-COM1/2-LAYOUT is set to MULTIPLE, and many contents are

selected to output, the output contents from COM1 or COM2 may not catch up with the data processed

in indicator, So, if you want to watch “real time” data, you need to select fewer output contents and set

higher baud rate for COM1 or 2.

25.7.3 Examples of some layout when USER-OUT1-xxxx is set to YES:

IND. ID: 123456

CELL No. : 1

CELL TYPE: COMPRESS

DSP.POL: POSITIVE

FORCE: 123.34 lbf

PEAK: 150.60 lbf

VALLEY: 10.78lbf

Max: 192.24lbf

Min: 1.56lbf

DATE: 2012-02-12

TIME: 12:34:56

A/D CODE: 982463

INPUT: 1.23034 mV/V

VOLTAGE: 6.7V

STATUS: bpq2

────────────────────────────────────────────────────────

32

Page 33

FI-521 Indicator Operation & Service Manual

26. Sockets and Jumpers

26.1 Back View of Indicator:

With back cover without back cover

26.2 Sockets and Jumpers on Main Board

26.2.1 Without Analog Voltage Output Board:

────────────────────────────────────────────────────────

33

Page 34

FI-521 Indicator Operation & Service Manual

26.2.2 With Analog Voltage Output Board:

26.3 Definition of Sockets and Jumpers: (make sure the no.1 pin position, refer to 22.2)

26.3.1 ADP---adapter power input connector

PIN # DEFINITION IN/OUT/POWER ELECTRICAL LEVEL

1 Adapter input voltage + Power input 12Vdc(10.5-15Vdc,≥0.5A)

2 Adapter input voltage – (GND) Power ground 0Vdc

3 Shell Earth

26.3.2 BAT---Battery power input connector

PIN # DEFINITION IN/OUT/POWER ELECTRICAL LEVEL

1 Battery input voltage + Power input 5.6-7.2Vdc (6V lead acid

battery)

2 Battery input voltage – (GND) Power ground 0Vdc

26.3.3 LOADCELL Connector:

PIN # DEFINITION IN/OUT/POWER ELECTRICAL LEVEL

1 Excitation + Power output 5±0.3 Vdc (≤0.12A)

2 Sense + Power input 5±0.3 Vdc

3 Excitation- Power ground ≤0.5 Vdc

4 Sense - Power input 0Vdc

5 Signal + Signal Input 2.5±0.3 Vdc

6 Signal - Signal Input 2.5±0.3 Vdc

7 Shield - -

────────────────────────────────────────────────────────

34

Page 35

FI-521 Indicator Operation & Service Manual

If a pigtail (an around 30cm cable with a 7-pin female connector) is used for loadcell interface,the cable

pinouts are:

A: Signal -

B: Excitation +

C: Signal +

D: Excitation -

E: Sense -

F: Sense +

G: Ground

26.3.4 RS232 Connector:

PIN # DEFINITION IN/OUT/POWER ELECTRICAL LEVEL

1 COM1 Receive Input -12 to +12Vdc

2 COM1 Transmit Output -12 to +12Vdc

3 GND Power ground 0Vdc

4 GND Power ground 0Vdc

5 COM2 Receive Input -12 to +12Vdc

6 COM2 Transmit Output -12 to +12Vdc

26.3.5 RS485 Connector:

PIN # DEFINITION IN/OUT/POWER ELECTRICAL LEVEL

1 RS485 signal A Input/output 0Vdc

2 RS485 signal B Input/output 0-5Vdc

3 GND Power ground 0-5Vdc

26.3.6 CAL Jumper set:

CONNECTED PINS FUNCTION

1-2 Calibration Enabled

2-3 Calibration Disabled

26.3.7 JP4 Jumper set:

CONNECTED PINS FUNCTION

1-2 RS485 terminal 120ohm resistor on board is disabled

2-3 RS485 terminal 120ohm resistor on board is enabled

────────────────────────────────────────────────────────

35

Page 36

FI-521 Indicator Operation & Service Manual

26.3.8 JP8 Jumper Connector:

CONNECTED PINS FUNCTION

COM2 is used as RS232

COM2 is used as RS485

COM2 is not used

COM2 is not used

26.3.9 RXD2 and TXD2 Jumper Connector:

CONNECTED PINS

TXD2 RXD2

26.3.10 JP3 Jumper Connector:

CONNECTED PINS FUNCTION

FUNCTION

COM2 is not used

COM2 is used as RS232

COM2 is used as RS485

JP3-2,3 pin connected:

4 wires Load cell is used

JP3-1,2 pin connected:

6 wires load cell is used

────────────────────────────────────────────────────────

36

Page 37

FI-521 Indicator Operation & Service Manual

R

26.3.11 AVOUT Connect on Analog Voltage Output Sub-Board:

CONNECTED PINS FUNCTION

1 Analog Voltage Output +

2 Analog Voltage Output – (Internal Power GND)

Note:

The current draw from 1-2 connector should be less than 2.5mA, that means the resistor added

between 1-2 connector should more than 1K

M

!

26.3.12 XIN (Remote Input) Connector:

26.3.12.1 Pin Definition

PIN # DEFINITION IN/OUT/POWE

ELECTRICAL LEVEL

1 Internal Power output + Power output 5 - 8Vdc (≤0.1A)

2 Input1+ input 5-24Vdc

3 Input1- input 0Vdc

4 Input2+ input 5-24Vdc

5 Input2- input 0Vdc

6 Input3+ input 5-24Vdc

7 Input3- input 0Vdc

8 Input4+ input 5-24Vdc

9 Input4- input 0Vdc

10 Internal Power output - Power GND 0 Vdc

26.3.12.2 Connection Example When External Power Supply:

The remote keys RK1-RK4 also can be transistor, and the remote keys connection is isolated to internal circuit.

────────────────────────────────────────────────────────

37

Page 38

FI-521 Indicator Operation & Service Manual

26.3.12.3 Connection Example When Internal Power Supply (not recommended):

The remote keys RK1-RK4 also can be transistor, and the remote keys connection is not isolated to internal

circuit.

26.3.13 XOUT (Output) Connector:

26.3.13.1 Pin Definition

PIN # DEFINITION IN/OUT/POWER ELECTRICAL LEVEL

1 Internal Power output - Power GND 0 Vdc

2 Output driver COM /

Emitter of Output NPN Transistor 1 and 2

External Power input -

3 Output driver 1 Output, open NPN Transistor Collector 1 Sink 0.5A Max.

4 Output driver 2 Output, open NPN Transistor Collector 2 Sink 0.5A Max.

5 External Power input + Power input 5 – 24 Vdc

6 Internal Power output + Power output 5 - 8 Vdc (≤0.1A)

26.3.13.2 Connection Example When External Power Supply:

The external power is isolated by optocoupler to internal circuit in this situation. The Max. voltage of external

power should not be over than 24VDC, and should to keep the Max. current of output1 or output2 less than

0.5A .

────────────────────────────────────────────────────────

38

Page 39

FI-521 Indicator Operation & Service Manual

25.3.13.3 Connection Example When Internal Power Supply (not recommended):

When use internal power is used, the total current of output1 and output 2 draw (sink) must be less than

0.1A, that means heavy extra load should not be added on internal power! As above drawing, only light

load can be used in this condition.

────────────────────────────────────────────────────────

39

Page 40

FI-521 Indicator Operation & Service Manual

27 Meaning of Some Symbols and Troubleshooting

27.1 Meaning of Symbols:

27.1.1 0﹉﹉﹉﹉ ------ Zero is over the setting range

27.1.2 0﹍﹍﹍﹍ ------ Zero point is below the setting range

27.1.3 Ad﹉﹉﹉ ------ Signal to ADC is over max. range)

27.1.4 Ad﹍﹍﹍ ------ Signal to ADC is below min. range

27.1.5 ﹉﹉﹉﹉ ------ Force is over upper limitation, or display data is over limitation

27.1.6 ﹍﹍﹍﹍ ------ Force is below lower limitation

27.1.7 EEP.E1 ------ CONFIG or CAL parameters are not correctly set

27.1.8 EEP.E2 ------ USER parameter is not correctly set

27.1.9 Lo.bAt ------ Battery voltage is lower than setting.

27.1.10 CAP.- - - ---- Next displaying content is Capacity

27.1.11 CAP.ER ----- Setting Capacity is over display range

27.1.12 CAL.Px ----- Calibration on point(x)

27.1.13 CAL.OFF ----- Calibration Seal Switch is on OFF position

27.1.14 CAL.ON ----- Calibration Seal Switch is on ON position

27.1.15 CAL.Er ----- Calibration error, maybe input data or applied load is incorrect, unstable, un-linear

27.1.16 CAL.End ------- Calibration is end

27.1.17 OFF ------ Power OFF the indicator

────────────────────────────────────────────────────────

40

Page 41

FI-521 Indicator Operation & Service Manual

27.2 Troubleshooting

SYMPTOM PROBABLE CAUSE REMEDY

Ad﹉﹉﹉

Ad﹍﹍﹍

Load cell wires to indicator are

incorrectly connected, or shorted, or

opened; or ADC, load cell are damaged

Weight reading exceeds Power On Zero

Make sure wires are ok and correctly

connected. Replace load cell or ADC

chip, Service required.

Make sure cell platform is empty.

0﹉﹉﹉﹉

limit.

Weight reading below Power On Zero

Perform zero calibration.

Install platform on cell. Perform zero

0﹍﹍﹍﹍

limit.

calibration.

Reduce load on cell until force value

Weight reading exceeds Overload limit,

can be displayed. Use a more

or The weight value cannot be displayed

﹉﹉﹉﹉

appropriate unit of measure. Re-set

in the current unit of measure because it

some parameters of CONFIG or

exceeds 6 digits..

UAER.

Install platform on load cell.

﹍﹍﹍﹍ Weight reading below Under load limit.

Perform zero calibration

CONFIG or CAL parameters are not

Re-set items in CONFIG, do

EEP.E1

correctly set

calibration

EEP.E2 USER parameter is not correctly set Re-set items in USER

CAP.ER Setting Capacity is over display range

CAL.Er

Not turn on.

Cannot zero the display

or will not zero when

turned on.

Cannot display weight in

desired weighing unit.

Battery symbol is empty

or Lo.bAt is shown

Calibration error, maybe input data or

loaded weight is too small, too big,

unstable, un-linear

Power cord not plugged in or properly

connected. Power outlet not supplying

electricity. Battery discharged. Other

failure.

Load on cell exceeds allowable limits.

Load on cell is not stable.

Load cell damaged.

Unit not set to enable Enable unit in CONFIG-UNITS

Batteries are discharged. Charge batteries

Decrease PRIM.N or PRIM.d to

make sure capacity not more than 6

digit(ignore decimal point)

Input correct data, load correct

weight onto platform, Service

required

Check power cord connections.

Make sure power cord is plugged

into the power outlet. Check power

source. Replace batteries. Service

required.

Remove load on cell.

Wait for cell become stable.

Service required.

────────────────────────────────────────────────────────

41

Page 42

FI-521 Indicator Operation & Service Manual

28. Display Character

Alpha LCD/LED Show Alpha LCD/LED Show

A

N

B O

C P

D Q

E R

F S

G T

H U

I

J W

K X

L Y

M Z

29. Packing List

V

No. CONTENT QTY

1 Indicator 1

2 User manual 1

3 Swivel bracket 1

4 6V2.8AH lead-acid battery (optional) 1

────────────────────────────────────────────────────────

42

Page 43

FI-521 Indicator Operation & Service Manual

────────────────────────────────────────────────────────

43

Page 44

FI-521 Indicator Operation & Service Manual

Model FI-521 Made in China