Page 1

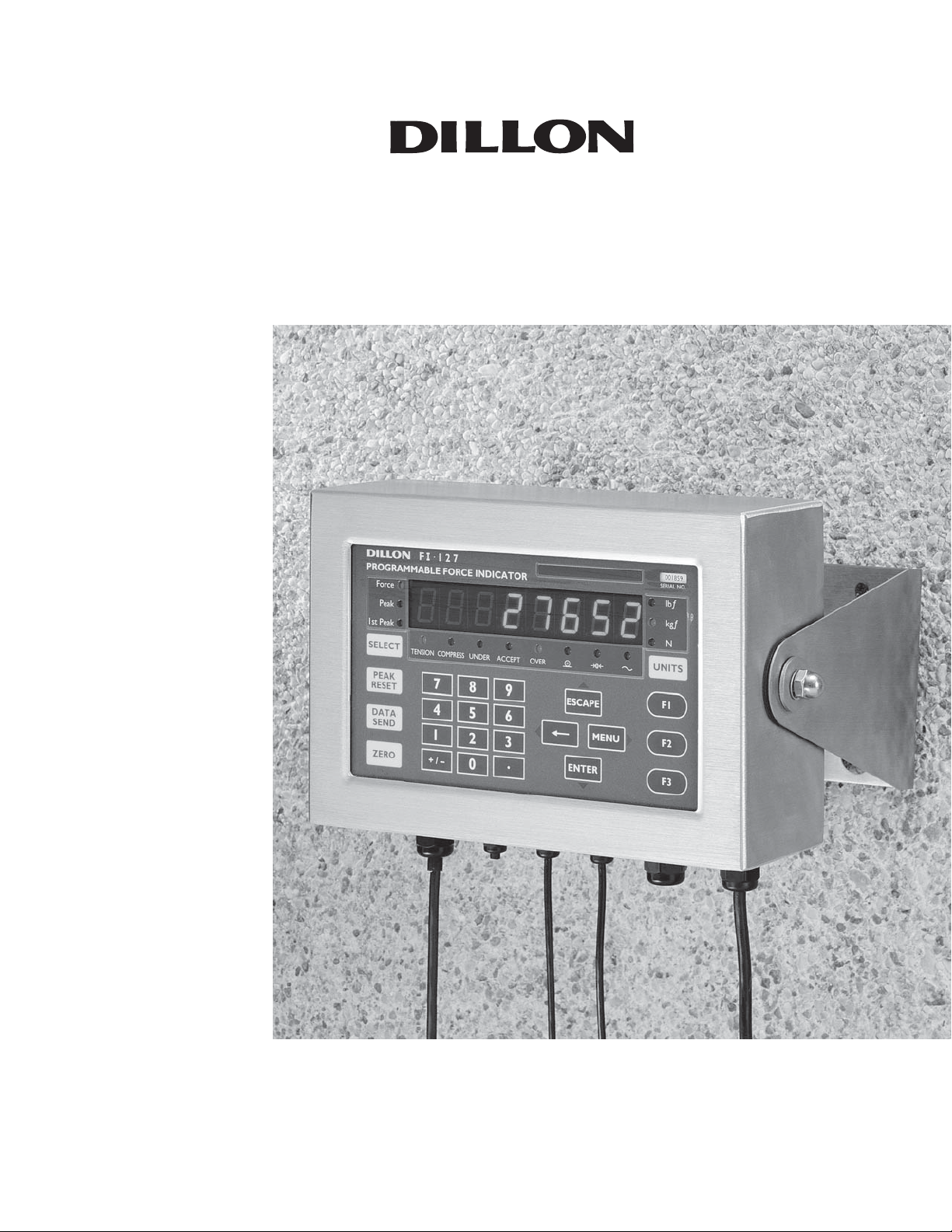

FI-127 Force Indicator

User’s Manual

Page 2

CAUTION

Risk of electrical shock. Do not remove cover. No user serviceable

parts inside. Refer servicing to qualified service personnel.

Weigh-Tronix reserves the right to change

specifications at any time.

06/30/98 FI127USE.P65 PN 29653-0017B Printed in USA

2

Page 3

Table of Contents

Introduction ............................................................................................................................................................................... 5

Operating Modes ...................................................................................................................................................................... 5

Front Panel ................................................................................................................................................................................. 6

Keys6

Standard Instrument Keys ................................................................................................................................... 6

Function Keys ......................................................................................................................................................... 6

Keypad Keys ............................................................................................................................................................ 7

Directional Keys ..................................................................................................................................................... 7

Annunciators .................................................................................................................................................................... 7

Error Messages ......................................................................................................................................................................... 8

Using Your FI-127 .................................................................................................................................................................... 9

Setting Up Your FI-127 .................................................................................................................................................. 9

Performing a Force Measurement .............................................................................................................................. 9

Using the Function Keys.............................................................................................................................................. 10

F1 Key ..................................................................................................................................................................... 10

F2 Key ..................................................................................................................................................................... 11

F3 Key ..................................................................................................................................................................... 11

Using the User Menu ............................................................................................................................................................ 12

The User Menu.............................................................................................................................................................. 12

Capture .................................................................................................................................................................. 12

Hour ........................................................................................................................................................................ 14

Day .......................................................................................................................................................................... 14

Database ................................................................................................................................................................. 15

Loadcell ................................................................................................................................................................... 16

Bounds .................................................................................................................................................................... 17

Using the Service Menu ........................................................................................................................................................ 18

About Menu ................................................................................................................................................................... 18

Audit Menu ..................................................................................................................................................................... 19

Abuse Menu .................................................................................................................................................................... 20

Zero Menu ...................................................................................................................................................................... 20

Test Menu ....................................................................................................................................................................... 21

Setup Menu ..................................................................................................................................................................... 24

Units submenu ...................................................................................................................................................... 24

Loadcells submenu ............................................................................................................................................... 26

Options submenu ................................................................................................................................................ 32

Serial submenu...................................................................................................................................................... 41

B.C.D. Out submenu .......................................................................................................................................... 42

Analog submenu ................................................................................................................................................... 42

Outputs submenu ................................................................................................................................................ 43

Inputs submenu .................................................................................................................................................... 44

Seal submenu ........................................................................................................................................................ 44

Reset Menu / Master Clear ................................................................................................................................................ 47

Adding and Calibrating a Loadcell ...................................................................................................................................... 48

Adding a Loadcell .......................................................................................................................................................... 48

Calibrating a Loadcell ................................................................................................................................................... 49

Step by Step Instructions...................................................................................................................................................... 52

Strings .............................................................................................................................................................................. 52

Layouts ............................................................................................................................................................................. 54

Groups ............................................................................................................................................................................. 56

Freeze Force Function .......................................................................................................................................................... 58

Control ............................................................................................................................................................................ 58

Display.............................................................................................................................................................................. 58

Keypad ............................................................................................................................................................................. 58

Outputs ........................................................................................................................................................................... 58

Data Capture ........................................................................................................................................................................... 59

Control ............................................................................................................................................................................ 59

Display.............................................................................................................................................................................. 59

Keypad ............................................................................................................................................................................. 59

Outputs ........................................................................................................................................................................... 59

Notes ............................................................................................................................................................................... 59

Appendix A: ASCII Control Codes ................................................................................................................................. 60

Appendix B: Default Layouts and Examples ................................................................................................................. 61

Appendix C: Tips on Setting Up and Using the Harmonizer®................................................................................. 63

Appendix D: Cable Pinouts ............................................................................................................................................... 64

3

Page 4

FI-127 Specifications

Power requirements:

115 Volts AC, +10% to -15% @ 0.3Amp maximum

230 Volts AC, +10% to -15% @ 0.15 AMP maximum

50 /60 Hz

Excitation: 10 Volts DC

Supports up to twelve 350-ohm weight sensors

Operational keys:

Five yellow standard keys: Select, Peak Reset, Data Send,

Zero, Units

Three function keys: F1, F2, F3

Numeric keys: 0-9

Operational annunciators:

Tension, Compression, Under, Accept, Over, Print, Zero,

and Motion

Three units of measure

Display: Eight digit, seven segment, 0. 8-inch high LED

Display rate: Selectable (1, 2, 5, 10)

Analog to digital conversion rate: 60 times per second

Calibration Memory: Six loadcell calibration memory

Unit of measure:

Three, independently programmable:

Pounds force, kilograms force, grams force, ounces force,

ton force, tonne force, custom, Off

Standard outputs:

Three outputs, open collector design

Relay power supply, 24 VDC at 150mA

5 VDC at 200 mA for scanner power source

Bidirectional serial port (RS-232 or RS-422/485 or

20mA current loop)

Self diagnostics:

Display, keys, inputs, outputs, serial port,

A to D converter, loadcell output display, voltages

Circuitry protection: RFI, EMI, and ESD protection

Options:

Two additional serial ports

BCD parallel

10 cutoffs

Analog output

0-5, 0-10 volts

1-5, 4-20, 10-50 mA

Operating temperature:

-40 to 140° F (-40 to 60° C)

100% relative humidity including washdown

Enclosure: NEMA 4X stainless steel enclosure

Dimensions:

12" W x 8" H x 4" D (without mounting bracket)

12.3" W x 11.0" H x 5.3" D (with mounting bracket)

Capacity selections:

999,999 with decimal located from zero to five places

Incremental selections:

Multiples and submultiples of 1, 2, 5

Programmable selections:

Zero range, motion detection, five-point linearization.

Time and date / RAM:

Battery backed up real time clock and RAM are standard

Internal resolution: 6,291,456 counts per mV/V per sec.

HarmonizerTM digital filtering:

Fully programmable to ignore noise and vibration

Standard inputs:

Seven logic level inputs for functions such as foot switch

inputs, freeze reading inputs, PLC control, etc.

Weight: 12.5 lb, 5.7 kg

Agencies:

CUL pending

Warranty: 2 year

4

Page 5

Introduction

Major sections of this manual are

separated by the large black bars as

seen above and below. Subsections

are titled in this lefthand column.

Notes, definitions, and other

information also appear in this

column

The model FI-127 is a versatile, full-featured indicator housed in a stainless steel

enclosure. Its user interface includes an 8-digit, 7-segment LED display, fourteen

LED annunciators, and 24 keys.

This manual is divided into the following major sections:

• Introduction

• Operating Modes

• Front Panel

• Error Messages

• Using Your FI-127

• Using the User Menu

• Using the Service Menu

• Reset Menu/Master Clear

• Adding and Calibrating a Loadcell

• Step by Step Instructions

• Freeze Force Function

• Data Capture

Operating Modes

There are three modes of operation for the FI-127—Display mode, User Menu

mode and Service Menu mode.

In Display mode you perform all normal force measurement operations.

The User and Service menus give you access to testing modes, configuration of

your system, database and system information. This manual explains how to use

these different modes of operation.

5

Page 6

Front Panel

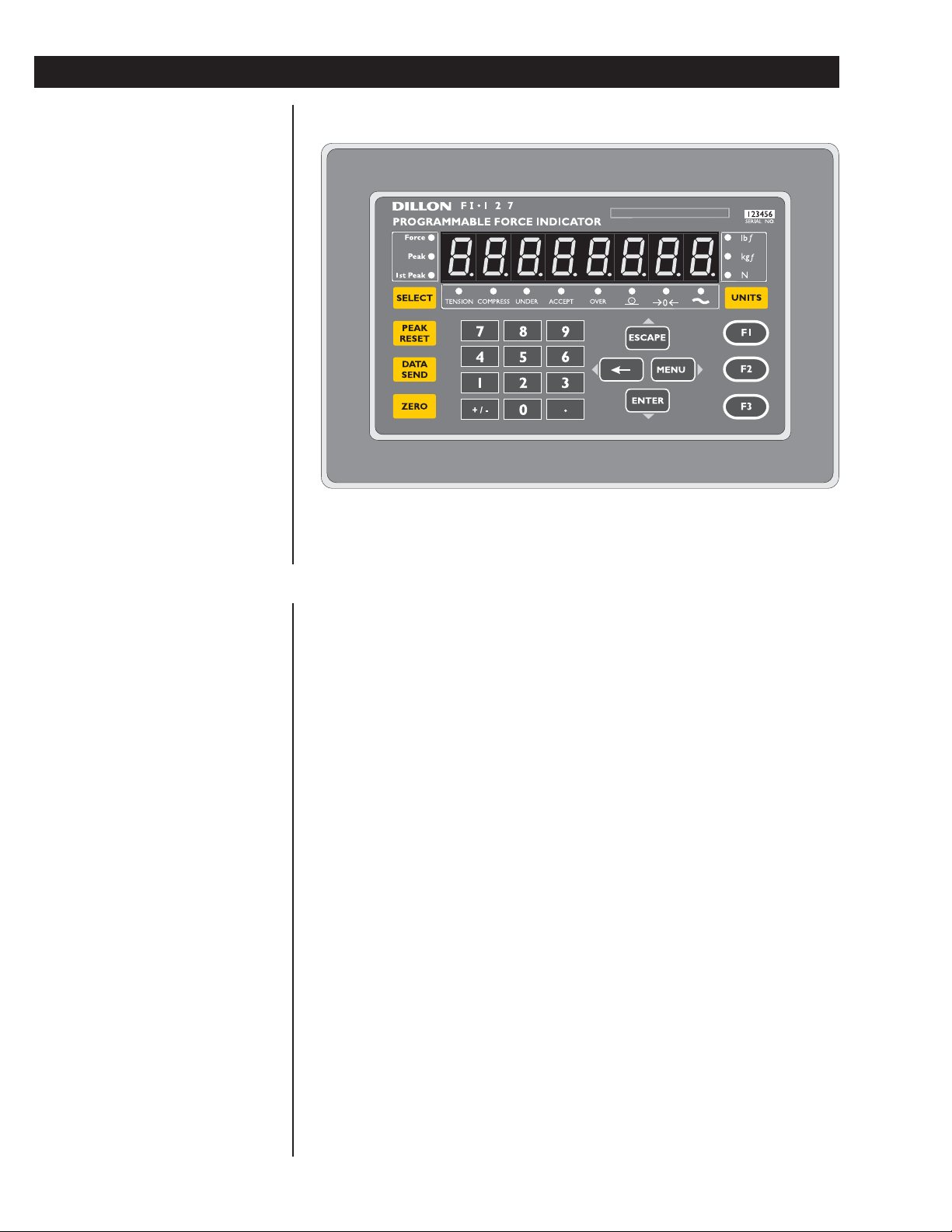

The FI-127's front panel consists of 24 keys and fourteen annunciators.

Keys

Standard Instrument Keys

Function Keys

Figure 1

FI-127 Front Panel

The FI-127's keys are divided into four primary groups:

Standard Instrument Keys These yellow keys are common to a majority of

applications and include SELECT, PEAK RESET, DATA SEND, ZERO, and UNITS.

The SELECT and UNITS keys are placed next to the annunciators they affect.

SELECT Use to switch between force, peak ad first peak display modes.

SELECT can also be used to accept a current selection and

return to weigh mode from within any menu.

PEAK RESET Use to reset all peak and first peak values. This key may also be

used to capture the current measurement as an entered value

during data entry.

DATA SEND Use to initiate one or more serial outputs.

ZERO Zeros the scale in the display mode. Also clears values in

numeric entry.

UNITS Switches the units of measure in the display mode. Up to three

units of measure are selectable.

Function Keys These oval keys along the right side of the display face are

configurable and are labeled F1, F2, and F3. The default configurations for these

keys are:

F1 Allows load cell selection

F2 Allows entry of ID number

F3 Allows access to cutoff registers.

6

Page 7

Keypad Keys

Keypad Keys These are the twelve square keys which support numeric entry.

The keyboard keys are labelled 0-9, plus/minus (+/-), and decimal point (.) and are

located near the center of the display face.

+/- This key is used to change the sign of a numeric entry, enter a dash in ID

entry, and insert when editing lists. This key also initiates numeric entry,

except in display mode where it serves to toggle between tension and

compression for bidirectional cells. Toggling between tension and compression resets peak, first peak and break detect; unfreezes the force display; and

halts data capture.

Directional Keys

Directional Keys The directional keys are used to navigate through the FI-127's

menus. These keys are labeled ESCAPE (up), ENTER (down),

MENU (right) and are positioned in a compass-like cluster on the display face.

These directional keys are denoted by the small transparent arrows located next

to them. ESCAPE, ENTER, and

ESCAPE Exits a menu parameter without saving any changes. This key moves

up within a menu. In display mode, ESCAPE "unfreezes" the force

display.

ENTER Used to end digit entry, accept a change made, or select an item

from a function list. ENTER moves down within a menu. When in

display mode, ENTER "unfreezes" the force display.

ÅÅ

Å Backspaces (deletes the last digit or punctuation mark entered)

ÅÅ

while in numeric entry and moves left within a menu.

MENU Accesses user menus and moves right within a menu.

←←

← also support numeric entry.

←←

←←

← (left), and

←←

Annunciators

The FI-127 has fourteen annunciators.

Force Illuminates when indicator is in force display mode.

Peak Illuminates when indicator is in peak display mode.

1st Peak Illuminates when indicator is in first peak display mode.

lbf, kgf, N Illuminates the active unit of measure in weighing mode.

Data Send: Illuminates when the indicator is transmitting data.

Does not illuminate when a host connection is communicating

with the indicator or with continuous send.

Zero: Illuminates when the scale is within the configured center

of zero.

Motion: Illuminates when the scale detects motion (within

configured motion window).

Under, Accept, Over Specific application annunciators.

Tension Indicates the type of force being measured.

Compression Indicates the type of force being measured.

7

Page 8

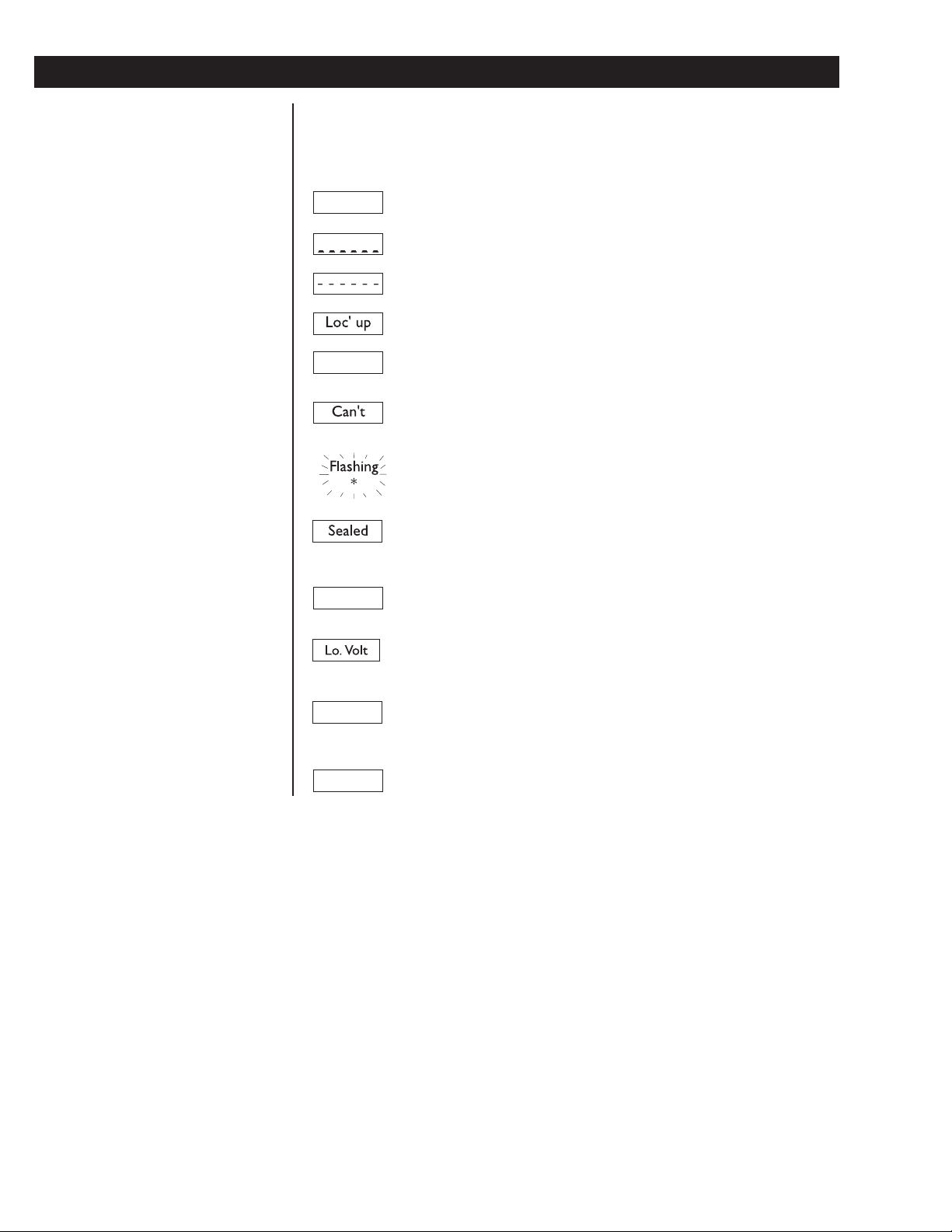

Error Messages

The following are displays you may see if problems occur or if invalid operations

are attempted with your FI-127:

Display Description

O. LoAd

L.C. Error

Auto. 0

Overrange force.

Underrange force.

Recovering from lock-up or out of range condition.

A-D converter is not functioning.

A-D converter subjected to an input signal beyond ±5.00000 mV/V

The unit cannot perform a function. Displayed only while key is held

down.

Corrupted data in the reset menus. See the Service Manual.

(* = RESET, SETUP, or CAL)

Displayed while a key is pressed when attempting to modify a sealed

selection without edit privileges.

Displayed while waiting for a stable, valid weight to use as a zero

reference on power-up.

Displayed when input voltage to excitation regulator drops below

10.5 VDC. Will clear when input voltage rises above 11.5 VDC.

1 Busy

Ouch

Displayed when the ready/busy handshake has exceeded its time out

limit. Default is 2 seconds. This can also apply to optional 2nd and

3rd serial ports.

Displayed when the force applied to the load cell has exceeded the

level considered to be abusive to the load cell.

8

Page 9

Using Your FI-127

Setting Up Your FI-127

Performing a Force

Measurement

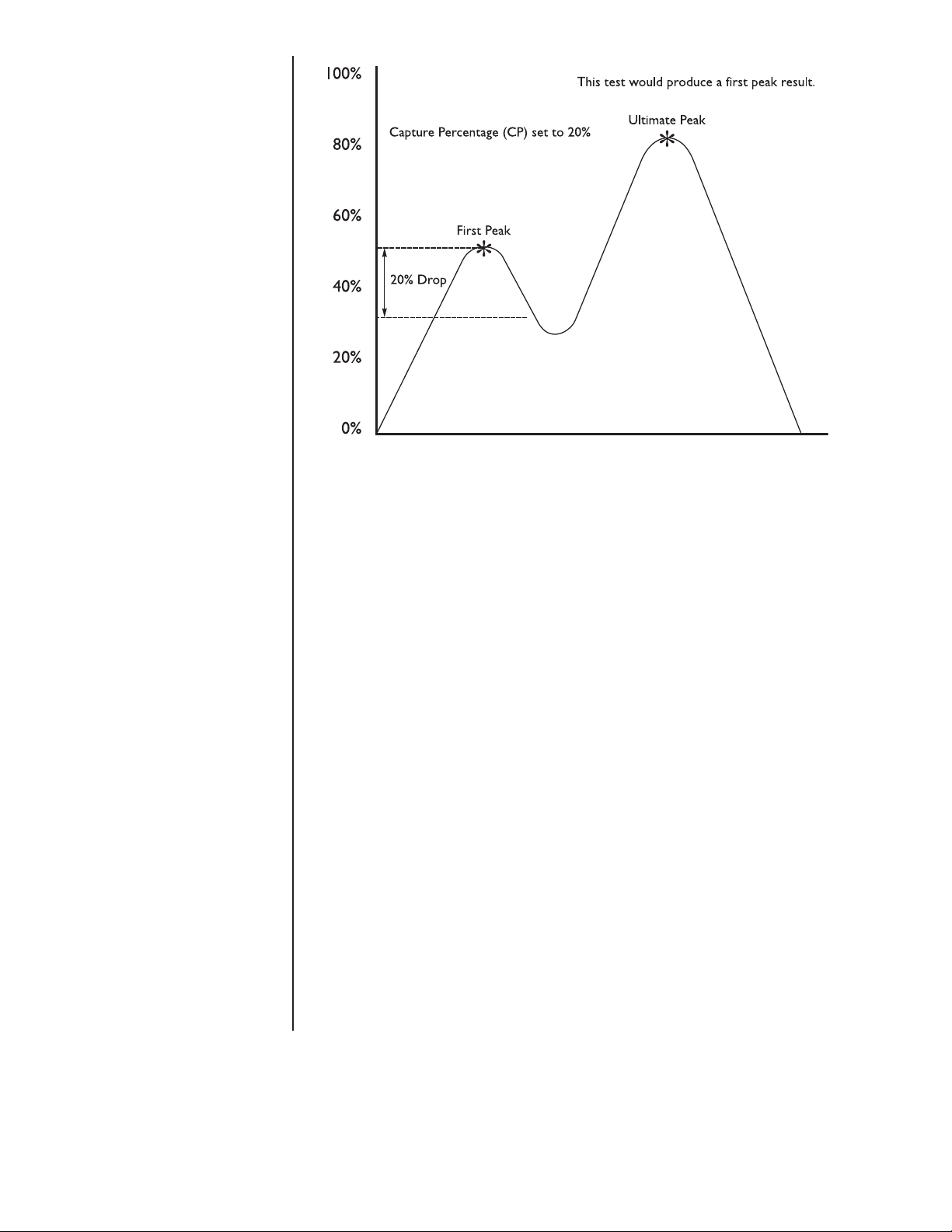

First Peak

First peak is defined as an applied

force, followed by a drop in force of

at least x% of full capacity followed

by an ultimate peak in force. x is

called the capture percentage. You

can set this percentage via the front

panel. Instructions can be found in

the section Using the Service

Menu. See the graphed example in

Figure 2.

Your FI-127 will probably be ready to use when you receive it from your Dillon

distributor. Connect the loadcell to the 7-pin connector on the back of the unit.

Connect your RS-232 communication equipment to the other connector on back

of the FI-127. Power up your peripheral equipment and plug in the FI-127 to an

appropriate grounded power source.

The indicator will power up in Display mode with annunciators lit for your

application. From the factory, the default annunciators which are lit are Force,

Tension and lb F. The center of zero (COZ) annunciator should also be lit. If the

display does not show 0 or the COZ annunciator is not lit, press the ZERO key.

Your unit is now ready for use in your force measurement application. If you want

to add a loadcell, see the section Adding a Loadcell later in this manual.

1. With the indicator powered up,

select the unit of measure you

want to use by pressing the

UNITS key. . . The proper annunciator will light.

2. Press the ZERO key if the display

does not show 0 and apply force

to the loadcell. . . The force will be displayed in the unit

of measure you have chosen. The type

of force, tension or compression, will

be indicated by the annunciators under

the display. The motion annunciator

will be lit while the indicator detects

motion.

3. If you are running a test where

First Peak and Peak readings are

important to you, you can see

those values by pressing the

SELECT key. The value on the

display will correspond to the

annunciated item on the left side

of the display panel. See the First

Peak definition at left.

4. After you have seen the peak

values, you can reset them by

removing the force from the loadcell and pressing the PEAK

RESET key.

5. Repeat steps 2-4 for the other

force measurements you want to

make.

9

Page 10

Full Scale Capacity of Loadcell

First peak illustration

Time➔

Figure 2

Using the Function Keys

F1 Key

The function keys are used for

• F1 Loadcell selection

• F2 ID number entry

• F3 Viewing or entering data in cutoff registers

1. Press F1 key. . . The display shows the current cell

number and a letter showing if the cell

type is F for force or T for torque.

2. Press the ENTER key. . . The capacity of the current cell is

displayed.

3. Press the MENU key. . . The division size for the current cell is

displayed.

4. Press the ENTER key to return to

Display mode or press

the ESCAPE key to return to the

display from step 1.

10

Page 11

F2 Key

1. Press the F2 key. . . The current ID number is displayed.

2. Press any of the following keys to

return to Display mode:

ÅÅ

F2,

Å, MENU, ESCAPE,

ÅÅ

SELECT

or

press a number key to start

entering a new ID number. When

you are finished, press the ENTER

key. . . The new number will become the

active ID number.

F3 Key

Cutoff Register

A cutoff register is a force value you

enter into memory (register) which

the indicator uses to control outputs.

There are 10 cutoff registers in the

FI-127. You can set ten different

force values which the indicator will

use to trigger outputs.

When activated (force on the

loadcell is less than the force in the

cutoff registers), these cutoffs are all

on at the same time. Each cutoff will

deactivate as soon as the force on

the loadcell matches the value in

each cutoff register.

When the force is equal to or

greater than positive register values,

or more negative than negative

register values, the corresponding

output is disabled.

When the force is less than the

positive register values, or less

negative than negative register

values, the corresponding output is

enabled.

The F3 key is used to view and change cutoff registers. You can view cutoff

registers by two methods:

Method A:

1. Press the F3 key. . . 1 xx is displayed. The number 1

stands for cutoff register #1 and xx is

the current value in register 1.

2. Continue pressing F3 or MENU

to scroll forward or

backward through the remaining

cutoff registers.

Method B:

1. If you know which cutoff register

you wish to view, press the

number of that register, then press

F3. That particular cutoff register is

displayed.

To change a cutoff value, display the register you want to change then:

1. Key in a new value with the

numeric keypad. Use the +/- key to

change the sign of the value.

Press the ENTER key to accept

the new value and return to

Display mode

or

press the F3 key to accept the new

value and move to the next register.

ÅÅ

Å to scroll

ÅÅ

2. To deactivate or clear a cutoff

value, set the value to zero.

11

Page 12

Using the User Menu

Use these keys to navigate

through the menus:

ESCAPE =up

ENTER = down

ÅÅ

Å = left

ÅÅ

MENU = right

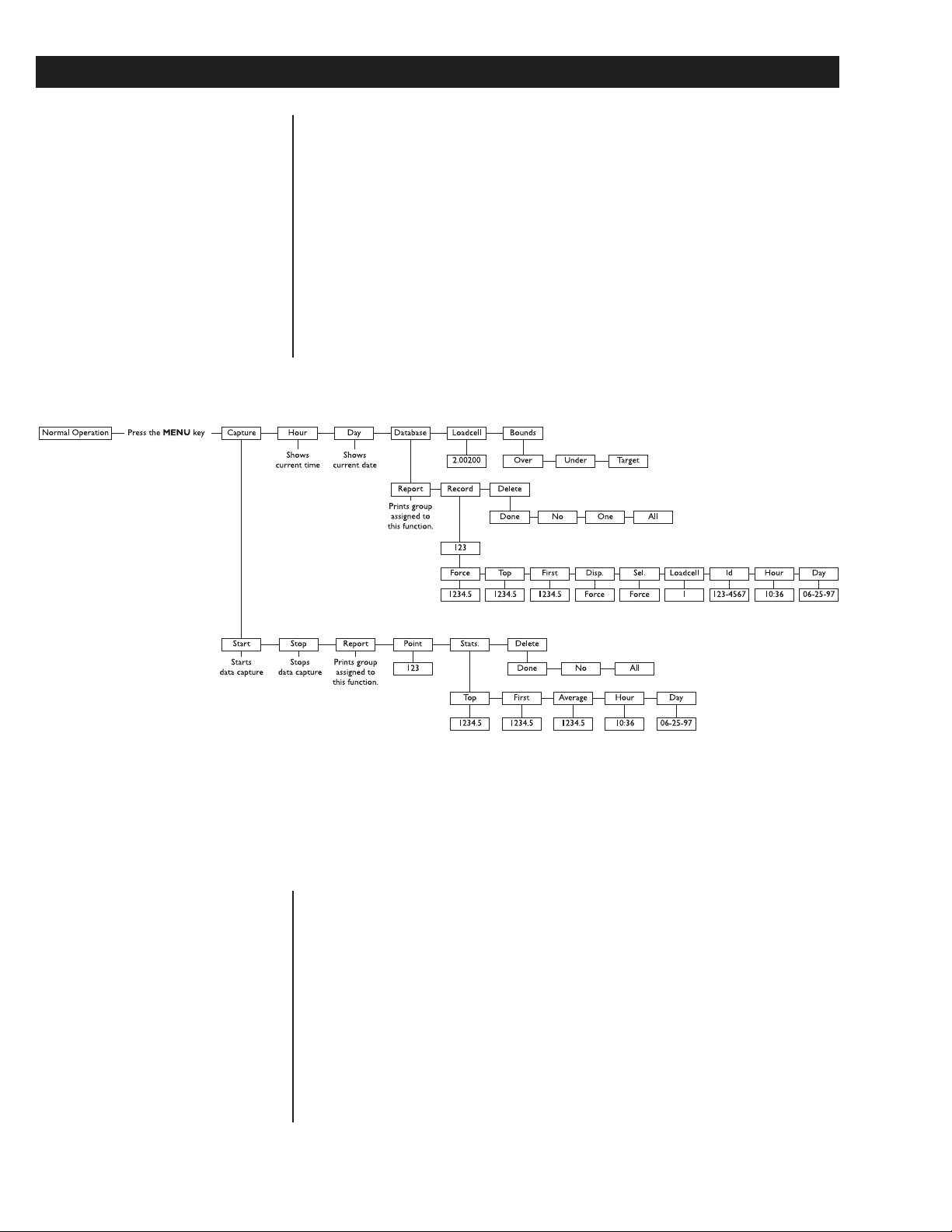

The FI-127 has two menus—the user menu and the service menu. The service

menu is covered later in this manual. You use it to configure the operation of your

indicator. The user menu, shown in Figure 3, allows you to do the following things:

• Capture and view data points

• Print a report on data points

• View statistics about captured data points

• Delete captured data points

• View the current time and date

• View and delete database records

• See live display of loadcell output in counts or mV/V

• Set Target, Under, and Over values

The User Menu

Capture

This manual assumes that all

functions are enabled. Your indicator

may not show some of the items in

the user menu because your

configuration does not enable them.

See the Using the Service Menu

section to reconfigure your system.

12

Figure 3

User menu

Following are instructions for accessing and using the user menu. Refer to Figure 3

as you go through these instructions.

1. Press the MENU key. . . CAPturE is displayed. This is the first

menu item. Use this to start and stop

capturing data points, view captured

points, see statistics on captured points

and to delete the points.

2. Press the ENTER key. . . StArt or StoP is displayed depending

on if you are currently capturing data

points or not.

Page 13

3. Press the ENTER key to start or

stop capturing data points. . . The indicator will start or stop captur-

ing data points.

4. Press the MENU key to move to

the next menu item. . . rEPOrt is displayed. Use this to print a

report on the data capture information.

5. Press the ENTER key with this

displayed if you want a

preconfigured set of information

to be sent through the serial port.

6. Press the MENU key to move to

the next menu item. . . Point is displayed. Use this to see any

captured data point.

7. Press the ENTER key to view the

current point number. Press

MENU to scroll to other points.

With the point you want displayed,

press the ENTER key to see the

value of that data point. . . The captured point will be displayed as

ÅÅ

Å or

ÅÅ

well as the unit of measure and tension/

compression annunciators.

Remember to use the direction keys

to navigate among the levels and

choices in the menu structure.

Press SELECT to accept the

current selection and return to the

Display mode from anywhere in the

menus.

8. Press the MENU key to move to

the next menu item. . . StAtS. is displayed. Under this item you

can see statistics on the captured data

points.

9. Press ENTER to see the first item

in the list of statistics. Press the

or MENU to move to other stat.

items and press ENTER to see the

value for the displayed statistic.

Following are the statistics and

what they show you:

Top Peak value for the currently captured points.

First Shows the first peak value for the currently captured points.

Average Shows the mean value of the currently captured points. Does

not include those points which are below the data capture

threshold set in the Ave. Over parameter of the setup menu.

See the Service Manual.

Hour Time at which the data was captured.

ÅÅ

Å

ÅÅ

Day Date on which the data was captured.

13

Page 14

Use these keys to navigate

through the menus:

ESCAPE =up

ENTER = down

ÅÅ

Å = left

ÅÅ

MENU = right

10. After viewing the statistics, press

the ESCAPE key until StAtS. is

displayed, then press MENU to

see the next menu item. . . dELEtE is displayed. Use this to delete

all captured data points.

11. Press the ENTER key. . . donE is displayed if there are no data

point to delete. All is displayed if there

are data points to delete.

12. If there are data points to delete

and you want to delete them, press

ENTER while All is displayed. . . The data points are deleted from

memory and donE is displayed.

Hour

13. Press ESCAPE twice to return to

the CAPturE display. Press MENU

to move to the next user menu

item. . . Hour is displayed.

14. Press ENTER to see the currently

set time. . . Time is displayed as HH:MM:SS (24

hour clock) or HH:MM:SS AM (12

hour clock). You may toggle between

the two formats by pressing the

UNITS key.

15. Press ENTER or ESCAPE to

leave the time and format

unchanged or enter a new time

using the numeric keys.

16. After changes have been made to

the time, press the ENTER key to

accept them and start the clock. . . Display shows Hour.

14

Day

17. Press the MENU key to go to the

next menu item. . . dAY is displayed.

18. Press ENTER to see the currently

set date. . . The date is displayed as MM/DD/YY.

19. Press ENTER to accept this date

or key in a new date and press

ENTER to accept it. . . dAY is displayed.

Page 15

Database

20. Press the MENU key to go to the

next menu item. . . dAtAbASE is displayed. Under this

menu item you can send a

preconfigured report of database items

to a serial port, look at individual

records in the database and delete one

or all of the records.

21. Press the ENTER key. . . rEPOrt is displayed. Use this to send a

report to a serial port. The information

sent depends on the configuration of

your system. See the Service Manual for

instructions.

22. Press the ENTER key to send the

database information to the serial

port. . . The print annunciator will light then the

display will show dAtAbASE again.

23. Press ENTER then MENU to go

to the next menu item under

dAtAbASE. . . rEcord is displayed.

24. Press the ENTER key to access

the current record. . . A record number is displayed.

25. You can view this record's data by

pressing the ENTER key

or

you can access other record

numbers by pressing the

MENU key, then press the

ENTER key. . . The first item in the database record is

26. Use the

through the list of items, then

press the ENTER key to view the

value for each item,

ÅÅ

Å or MENU key to scroll

ÅÅ

ÅÅ

Å or

ÅÅ

displayed. What this item is depends on

the configuration of your database.

15

Page 16

Use these keys to navigate

through the menus:

ESCAPE =up

ENTER = down

ÅÅ

Å = left

ÅÅ

MENU = right

Below is a full list of items in default order:

Force A stored force measurement. Displayed with unit of measure and

tension/compression annunciators.

Top A stored peak value. Displayed with unit of measure and tension/

compression annunciators.

First A stored first peak value. Displayed with unit of measure and

tension/compression annunciators.

Disp. A stored measurement. May be Force, Top or First depending on

configuration. Press the ENTER key again to see the value. Displayed as F 1234.5 if the stored value is a frozen force. Displayed

with unit of measure and tension/compression annunciators.

Sel. A stored measurement. May be Force, Top or First depending on

configuration. Press the ENTER key again to see the value. Displayed with unit of measure and tension/compression annunciators.

Loadcell A stored loadcell number.

Id A stored ID number.

Hour Time the record was stored.

Loadcell

Day Date the record was stored.

27. Press ESCAPE until rEcord is

displayed, then press the MENU

key to move to the next item in

the database submenu. . . dELEtE is displayed. Use the items

under this to delete one or all the

records.

28, If you choose to delete one record

you can scroll through the records

using the

press the ENTER key to delete

that one record. . . dELEtE is displayed.

29. With dELEtE displayed, press the

ESCAPE key. . . dATAbASE is displayed.

30. Press the MENU key to move to

the next user menu item. . . LOAdCELL is displayed.

ÅÅ

Å or MENU keys then

ÅÅ

16

31. Press the ENTER key to see a live

display of loadcell output in either

mV/V or counts. Toggle between

the two views using the UNITS

key.

Page 17

Bounds

32. Press the ESCAPE key to return

to the LOAdCELL display, then

press MENU to move to the last

user menu item. . . boundS is displayed. Use this item to

set target, over and under values. See

example at left.

Target, Over, Under Example

Target value = 350

Under value = -10

Over value = 20

With these settings the ACCEPT

annunciator will be lit when force is

340 to 370. The UNDER annunciator will be lit when force is less than

340. The OVER annunciator will be

lit when force is greater than 370.

33. Press the ENTER key. . . OVEr is displayed.

34. Press ENTER to see the current

value. Key in a positive value then

press ENTER to accept it. . . OVEr is displayed.

35. Press MENU to display UndEr.

Press ENTER to see the current

value. Key in a negative value then

press ENTER to accept it. . . UndEr is displayed.

36. Press MENU to display tArGEt.

Press ENTER to see the current

value. Key in a value then press

ENTER to accept it. . . tArGEt is displayed.

37. This is the last item in the user

menu. Press ESCAPE repeatedly

or SELECT to return to

Display mode.

17

Page 18

Using the Service Menu

Be sure to key in the password '127'

before pressing and holding the

ESCAPE key if you want to

change items in the service menu,

otherwise you will only be able to

view them.

You use the service menu to see information about your indicator, to test its

various functions and to configure how you want the system to work. Figures 4

through 19 show the service menu structure in the FI-127. Following each figure

are explanations for each of the service menu items. Use the same methods to get

around in the menu structure as you used in Using The User Menu section of this

manual. To edit items in this menu you must key in '127' before pressing

and holding the ESCAPE key.

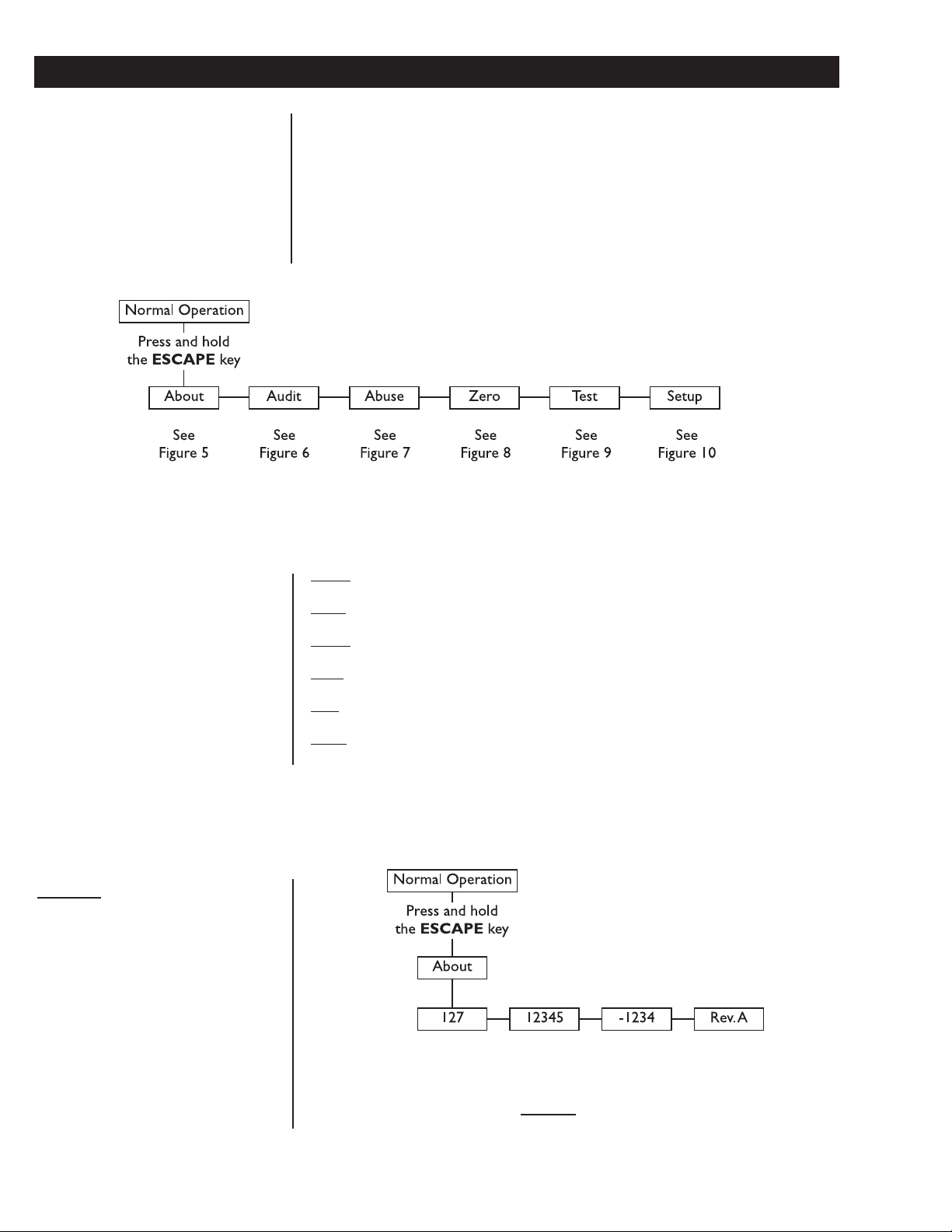

Figure 4

Top level of the Service menu

About Menu Information about the software

About Menu

Audit Menu Audit counters for calibration and configuration

Abuse Menu Loadcell overload counters

Zero Menu Zero balance information and reset

Test Menu For testing the hardware of the indicator

Setup Menu For configuration of the indicator

18

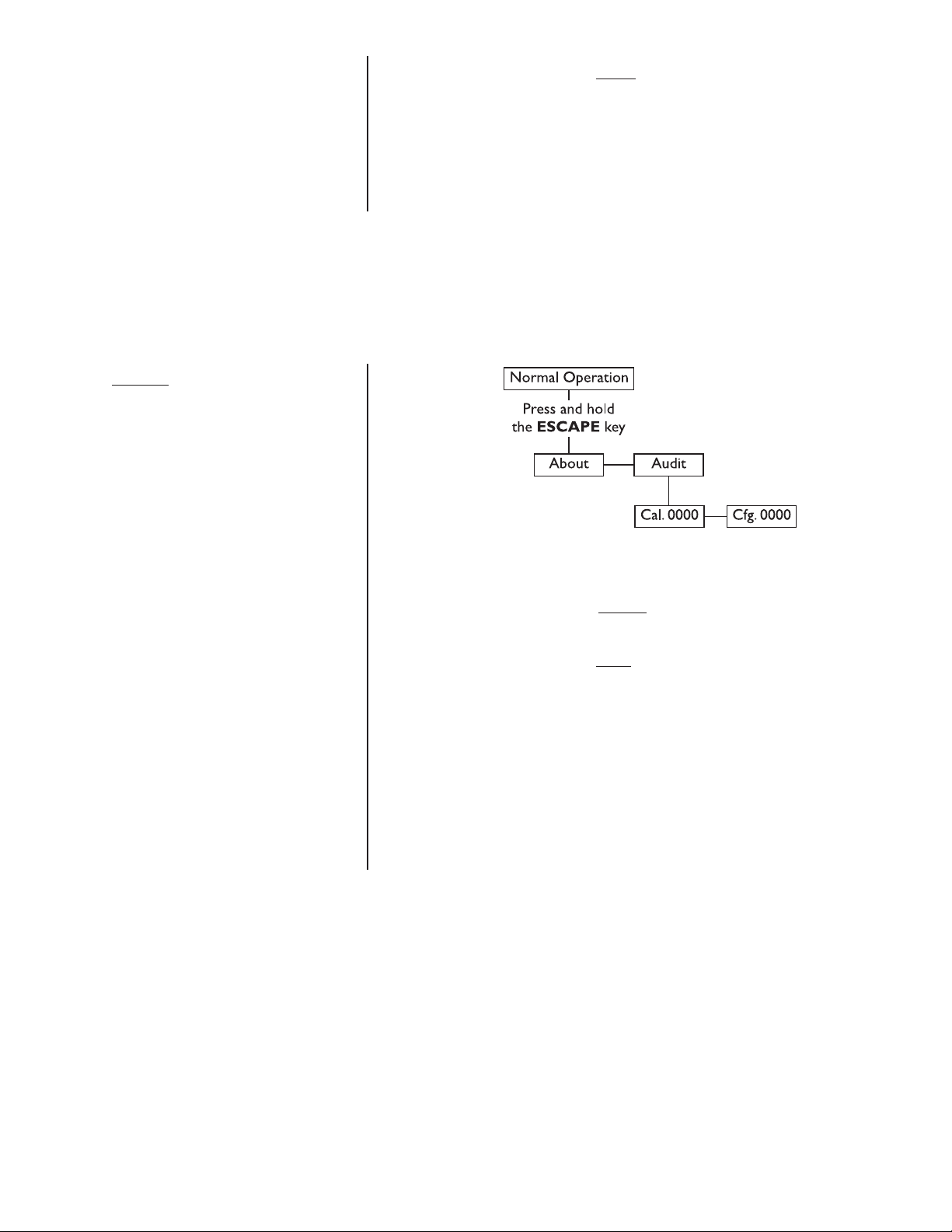

Figure 5

About menu

Page 19

Audit Menu

These are the items listed in the

127 The unit designation.

12345 Parent part number of the software.

-1234 The dash portion of the software part number.

Rev. A The revision level of the software.

About menu:

Figure 6

Audit menu

These are the items listed in the Audit menu:

Cal. 0000 This is an example of how the calibration audit trail counter will

appear. The actual value will be between 0000 and 9999. It is

nonresettable and may not be edited.

Cfg. 0000 This is an example of how the configuration audit trail counter

will appear. The actual value will be between 0000 and 9999. It is

nonresettable and may not be edited. The counter is

incremented each time a metrological item is modified in the

setup menus and saved and so may be used as a control audit.

19

Page 20

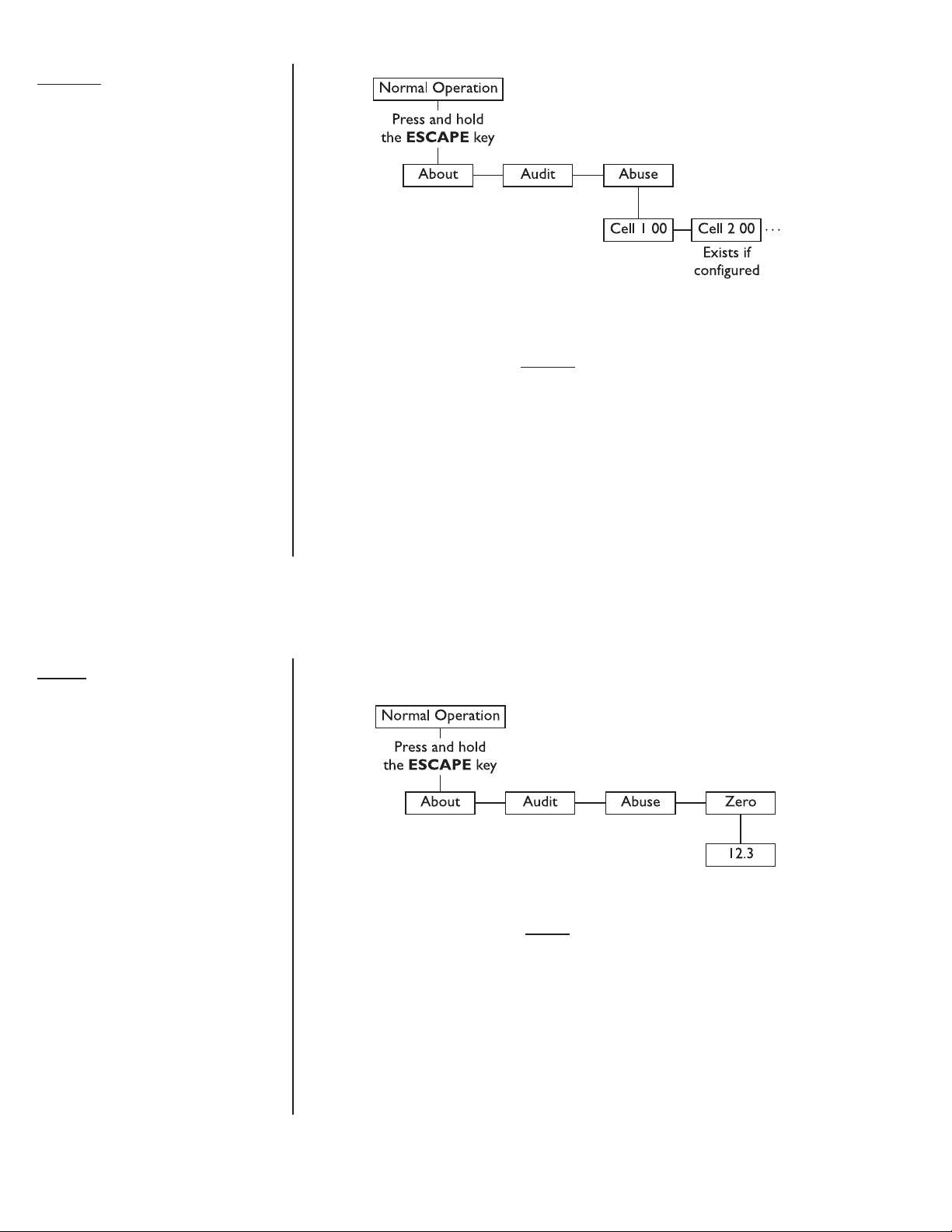

Abuse Menu

Be sure to key in the password '127'

before pressing and holding the

ESCAPE key if you want to

change items in the service menu,

otherwise you will only be able to

view them.

Figure 7

Abuse menu

Cell 1 00 This is an example of how a loadcell overload counter appears.

Use the

have. The counter shows up to 99 overloads. An overload is

defined as an applied force beyond the threshold configured

under Abused in the loadcell configuration section of the

service menu. The overload counter can only be reset at the

factory.

ÅÅ

Å or MENU keys to view other loadcells you may

ÅÅ

Zero Menu

This menu provides access to zero balance information and reset.

Figure 8

Zero menu

12.3 This is an example of the offset between the current zero

balance and the zero balance value established in calibration.

Displayed offset = Calibration zero - Current zero

When you press the ZERO key the current balance is reset to

calibration zero and resets the peak and 1st peak. The force

display is also unfrozen.

20

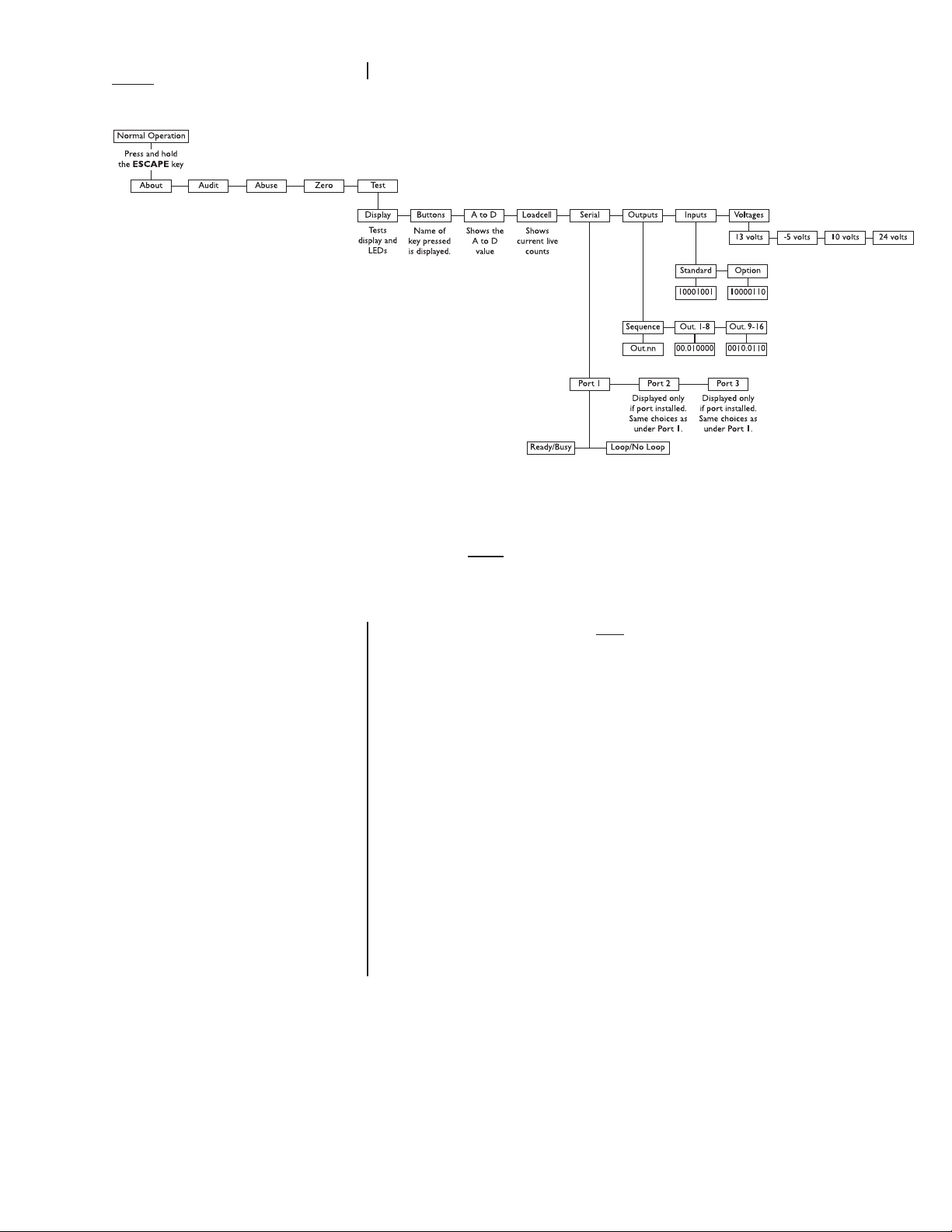

Page 21

Test Menu

The test menu, shown below, gives you access to diagnostic tests.

Figure 9

Test menu

These are the items listed in the Test menu from left to right:

Display Press ENTER to start and stop a continuous display test. With

the test stopped press the

or forward one step at a time. Press ENTER again to resume

the automatic test or press ESCAPE to stop the test and

return to diSPLAy.

Buttons This provides a test of the keypad. The name of the key that is

pressed appears on the display. If no key is pressed, nOnE is

displayed. Press MENU to return to buttonS.

A to D Press this key to see the current A to D value. The displayed

resolution is 1 part in 20,000 per mV/V. This test exists so that

the offset and gain of the electronics can be checked. The offset

is initially set to the nominal offset of the electronics, but you can

press the ZERO key to establish the actual offset, allowing the

gain to be evaluated.

ÅÅ

Å or MENU key to move backward

ÅÅ

21

Page 22

With motors connected to external

circuits, this is a good way to test

your hardware.

☞

Loadcell With LOAdCELL displayed, press the ENTER key to see a live

display of the current counts coming from the A-D converter.

400400 is an example of how this might appear. Press the

UNITS key to toggle between the counts display mode and the

mV/V display, which appears in this format: 2.00200. This stands

for 2.002 mV/V. The decimal indicates you are looking at mV/V

and not current counts.

Serial This item accesses the internal port serial tests. With SEriAL

displayed, press the ENTER key. Port 1 is displayed. This is

always the internal serial port. When the optional serial boards

are installed in the same stack, port two is always on the bottom.

When installed in different stacks (side by side), port two is

always closest to the power supply. Press the

to select the port you wish to test.

Ready/

Busy With the port you want to test displayed, press the ENTER

key. rEAdy or bUSy is displayed telling you if the hardware

input line is ready or busy. This is useful in tracking down serial

output problems.

Loop/

No Loop Press the MENU key to see the Loop - No Loop test. Connect

the transmit line to the receive line at some point in the cabling.

The FI-127 checks if it receives the same characters that it

transmits. If it can, LOOP is displayed. If it cannot, no LOOP is

displayed. This is useful in isolating serial output problems to the

FI-127, cable, or connected device by looping back at the

corresponding points.

Outputs This test allows you to check the operation of the onboard and

optional outputs. The onboard outputs are copies of the first

three outputs on the optional I/O board when it is installed.

ÅÅ

Å or MENU key

ÅÅ

To exit back to Display mode, press

the SELECT key and save changes

as needed by pressing ENTER with

SAVE? displayed.

22

Sequence This is the first item in the Outputs submenu. Press the ENTER

key to test the outputs. Each output is turned on and off

sequentially. The display will show Out. nn. The nn being the

number of the output being tested. The outputs will sequence

every half second. Press the ENTER or ESCAPE key to end

the test and return to the SEqUEnCE display.

Out 1-3 (or 1-16 with optional boards)

This is the second item in the Outputs submenu. This allows you

to activate or deactivate any of the outputs 1-3 (1-16 if the

optional boards are installed). Press the ENTER key to see the

display of the outputs status.

The screen has 0s and 1s displayed in this format: 00.010000. In

this example, output #4 is active. The zeros and ones represent

the status of each output. A 1 means it is activated and a 0

means it is deactivated. The left digit is output #1 or #9.

To change the status of an output, press the

to move the decimal point to the right of the output you want to

change. Press the ENTER key to toggle the output from one

status to the other.

ÅÅ

Å or MENU key

ÅÅ

Page 23

This allows you to test your remote

push button switches (ie. remote

zero, print, etc.)

☞

Press the ESCAPE key to exit the test. The outputs remain as

selected until you exit the Test menu. Returning to Display

mode returns the control of the outputs to the cutoff values.

Inputs This test allows you to check the operation of the onboard and

optional inputs. Press the ENTER key to access the submenu.

Standard This submenu item lets you check the status of the onboard

inputs. In this example, 1000100, inputs #1 and #5 are active.

The inputs are ordered 1-8 from left to right. A 1 means

activated and a 0 means deactivated.

As you view the inputs, #8 is actually a flag that is dependent on

the states of inputs 6 and 7. Input 6 resets flag #8 to a false 0.

Input 7 sets flag #8 to a true 1. Input 8 does not terminate at a

connector.

Option This menu item is available only if the option board is installed. It

works the same way as the Standard example above.

Voltages The submenu under VoltAgES lets you see the power supply

voltages. The voltage readings are updated 2 times per second.

13 volts This test displays the unregulated weight sensor excitation

power supply voltage. If the voltage drops below 10.5 the display

will show Lo. Volt. The error condition will not clear until

voltage reaches 11.5.

- 5 volts This test displays the -5 volt excitation voltage.

10 volts This test displays the unregulated 5 volt logic supply voltage.

24 volts This test display shows the relay supply voltage. If this voltage

drops too far it may not be possible to activate certain relays.

Nominal level for this power supply voltage is 22.8.

23

Page 24

Setup Menu

Be sure to key in the password '127'

before pressing and holding the

ESCAPE key if you want to

change items in the service menu,

otherwise you will only be able to

view them.

The setup menu allows you to configure your indicator to your specific application. Each item in this menu is described in the order presented in Figure 10.

Figure 10

Setup menu

Units submenu

The first submenu under Setup is Units. This submenu lets you select what unit of

measure will be assigned to the three annunciators on the front panel.

24

Figure 11

Units submenu

Page 25

Units

Unit 1 The unit of measure you choose for this item will be assigned to

the annunciator labeled “lb f” on the front panel. You can also

choose a length unit of measure for torque loadcells. Following is

the list of units of measure:

* = default value

To exit back to Display mode, press

the SELECT key and save changes

as needed by pressing ENTER or

SELECT with SAVE? displayed.

To exit without saving changes, press

ÅÅ

Å or MENU until No Save

ÅÅ

appears then press ENTER or

SELECT.

Pounds F* = pounds force

1000g F = kilograms force

N = Newtons

1000 N = 1000 Newtons

g F = grams force

OZ F = ounces force

Ton F = tons force

Tonne F = tonnes (metric tons) force

Other = Allows you to define a custom unit of force. Choose

what unit of force you want it based on, a multiplier upon which

the custom unit is based and an ASCII label to be used in serial

output. See the example at the bottom of this page.

None = no unit of measure is assigned.

Following is the list of length units of measure you can choose:

foot* = foot

inch = inch

m = meter

cm = centimeter

other = Allows you to define a custom length unit. Choose what

unit of length you want it based on, a multiplier upon which the

custom unit is based and an ASCII label to be used in serial

output.

Unit 2 The unit of measure you choose for this item will be assigned to

the annunciator labeled “kg f” on the front panel. You have the

same choices as shown in Unit 1 above. 1000g F is the default

setting.

Unit 3 The unit of measure you choose for this item will be assigned to

the annunciator labeled “N” on the front panel. You have the

same choices as shown in Unit 1 above. N is the default setting.

Custom Unit Example:

If you want a unit of measure called PLUTOs that is equal to 3.5 pounds of

force you need to enter the ASCII codes for P, L, U, T, and O. (See Appendix A). Enter pounds as the unit of measure the custom unit is based on and

enter 3.5 as the multiplier so that 1 PLUTO will equal 3.5 pounds.

25

Page 26

Loadcells submenu

The next Setup submenu is Loadcells. Use this menu, shown in Figure 12 to

linearize and configure each loadcell in your system.

Cell 1 This is the first loadcell in a list of loadcells. Cell 2, Cell 3, etc. are

available by pressing the MENU key if they are configured. To

add loadcells to the system, press the +/- key while End is

displayed. To delete the last loadcell from the list, press ZERO

while that Cell # is displayed. The FI-127 supports up to six

loadcells.

Below are the descriptions of the items available under each

configured loadcell.

Cell Type Choose which type of loadcell you are using: Force or Torque.

Polarity Select the direction of positive measurement:

Regular - selects tension for force and clockwise for torque.

Counter - selects compression for force and counter clockwise

(CCW) for torque.

Bi-dir. - specifies that the loadcell is bidirectional and is used for

measuring force in both tension and compression, or torque in

both CW and CCW directions. This selection enables the +/- key

to change measurement direction while in the display mode.

Calibration is part of the Linear-

ize process. See the section

titled Adding and Calibrating a

Loadcell for more detailed

instructions on calibrating your

loadcell.

☞

Linearize

Points Use this submenu to view, edit, add, or delete calibration

points in a list. You may have 2-10 points per loadcell with

a maximum of 35 points among all six available cells.

A 0

A 5000

Examples of the two default calibration points. The

indicator will automatically order the list by increasing

count values. The first point will show A 0. The A stands

for Applied load and the 0 for zero force. Access other

existing points by using the

The FI-127 comes from the factory with two calibration

points: 0 and 5000 lbs f. (These force values may differ

depending on your unit of measure.)

Cal.

Counts

Points may be calibrated in two ways: 1) by standard force

calibration or 2) by entering count values. Counts are

calibrated to 5000 lbf at 1 mV/V signal from the factory.

Existing points may be reviewed and modified via the

keyboard.

Delete

You can delete a calibration point using this item.

ÅÅ

Å or MENU key.

ÅÅ

26

Deadload Lets you view the count value for the current deadload.

Press the UNITS key to change the display to mV/V.

Display Shows the weight display without having to exit the menus.

An example of what is shown—d 5000. The d indicates a

live display of weight and reminds you that the unit is in

calibration. The value you see depends on the selected unit

of measure, the calibration and the weight applied. The

UNITS key works in this mode

.

Page 27

Figure 12

Loadcell submenu

Use these keys to navigate

through the menus:

ESCAPE =up

ENTER = down

←←

← = left

←←

MENU = right

27

Page 28

Printing the calibration values will

allow both a record of your calibration and a means of restoring a

calibration if the indicator fails or is

damaged.

Reset Use this item to reset the calibration points to factory

default values. If you choose yES the values are set to 0

lbs f at 0 mV/V and 5000 lbs f at 1 mV/V.

Print Lets you print the calibration values for a selected loadcell.

See note at left. Choose from No or Yes. If you choose

Yes, the information is output to port 1. Below is an

example of the output format:

07-04-97 10:36 AM

Loadcell 1 T

lbf mV/V

-------- --------

-20000 -0.20055

0 0.00101

10000 0.10203

20000 0.20301

30000 0.30512

40000 0.40333

100000 1.01234

Serial No. _______

If you change capacity or division

size in any unit of measure, this

automatically changes all the other

enabled units of measure as well.

If you want leading zeroes in your

printouts or broadcast and autosend

information, key in leading zeroes

when setting division size.

The T after Loadcell stands for tension. This string

corresponds to the Cell Type.

Config. This submenu contains force measurement related parameters.

Capacity Use this to see or edit the capacity. The UNITS key

works during this display. 5000 lb f is the default value.

Division This selection allows you to view and edit the division size

of the enabled units of measure. You can enter any

division size. The indicator will use the closest division size

for each enabled unit of measure.

You can view the division in other units of measure by

pressing the UNITS key. The number is stored in the

resolution you enter but is displayed in the closest valid

division size. Any additional resolution is used in calculating division size in the other units of measure.

Zero Use this menu item to set zero related options. Zero

range is specified as a percent of capacity referenced from

the deadload. There are two items in the submenu:

-Range and Range.

-Range - Use this to set the negative range (below

reference zero) within which the unit may be zeroed. 2%

is the default value.

28

Range - Use this to set the positive range (above reference zero) within which the unit may be zeroed. 2% is the

default value.

Page 29

Bust Use this to enter a break percentage. Break percentage is

the drop in force which the indicator will interpret as a

break detection. This is entered as percentage of full

capacity. 10% is the default value. The output signal is

asserted when a break is detected and switches to the

inactive state whenever you perform a zero or peak reset.

Capture Use this to enter a capture percentage. Capture percent-

age is drop in force occurring before a rebound in force to

an ultimate peak of force. This capture percentage is given

as a percentage of full capacity. See Figure 2 for an

illustration.

Stable Use this menu item to set the motion detection param-

eters. There are three items in the submenu: Range,

Delay and Display.

Range Use this to specify the number of ±divisions for

the motion window. Default is 1.0 division.

Delay Use this to specify the number of seconds

during which the weight must be within range (described

above) before a no-motion condition is displayed. Default

value is 0.4 seconds.

Display Choose ON to if you want the display on while

the indicator senses scale motion. Choose OFF to blank

the display while there is scale motion. Default is ON.

Update Use this to set the display update rate from these choices:

1 One update per second.

2 Two updates per second

5 Five updates per second

10 Ten updates per second.

29

Page 30

Average Use this to configure the number of intervals to average

for each force display. This can be entered in one of two

methods: x disp. or x a-ds. Press the UNITS key to

switch back and forth between the two choices.

The suggested method of setting the average is by picking

a value for x disp. Doing this insures that a multiple of the

display rate is always being averaged. This results in a

steadier weight display.

Use x a-ds if you need an exact number of A-D conversions for your particular situation.

Changing the update rate changes

the x disp. or x a-ds value based on

the new update rate.

Harmonizer® filter is used only if the

average value will not filter out the

vibration by itself. See Tips on

setting up and using the

Harmonizer filtering in Appendix

C.

Throughout the calibration process

values will change as you press the

UNITS key to change the unit of

measure.

☞

x disp. - 1 disp. is the default display when you access this

item. x is the number of display interval(s) over which the

data is internally averaged prior to being displayed.

The number of A-Ds averaged is based on the display

update rate you set under the Update menu item. Default

is 1 disp.

x a-ds - x is the number of a-d conversions to average for

each display.

The A-D weight conversion happens 60 times per second

in this indicator. Average is the number of conversions

you want to average for the weight that is displayed.

Default is 12 a-ds when Update is at default of 5 and x

disp. is at default value of 1.

Filter Use this menu item to configure the Harmonizer filter

settings. Constant and Threshld are the two items you

can configure in this submenu.

Constant - This number represents the amount of

filtering. Choose a setting between 1 and 10. Choose 1 for

the least amount of filtering but the fastest response.

Choose 10 for the most filtering but the slowest response. Choose Off to disable the Harmonizer functions

and default to the lowest filtering.

Threshld - This is the window, in the current unit of

measure, within which weight changes are altered according to the constant. 0.0 is the default value. You should set

the threshold value between 130 and 150% of the total

weight oscillations that need to be suppressed. If weight

changes are +20 lbs and -10 lbs, set this value to 130 to

150% of 30 lbs.

30

Page 31

When using overload or over

capacity alone, set the other menu

item to its maximum value to disable

any conflicts.

Over This submenu lets you setup the overload and capacity

setting which cause the O. load error message.

Overload - This value is expressed as a percent of

capacity referenced from the deadload determined by

calibration. Overload is restricted to 200% or lower. 105%

is the default value.

Over Cap. - This value expressed as a number of divisions

over the capacity referenced from the zero value. A value

of 9 satisfies UK requirements. Configurable from 0 to

999999 divisions. Default is 9 divisions.

Abuse Use this to set the percent of capacity at which an abuse

count will be incremented.

Clone Use this to initialize a the currently selected loadcell with

the same values of another loadcell. Select the number

loadcell you want to clone. If an invalid value for a loadcell

is selected, Error is displayed.

31

Page 32

Options submenu

The next Setup menu item is Options. Use this to configure the way your FI-127

works. Below is the entire menu structure located under this item. See the

following pages for descriptions of these menu items.

32

Figure 13

Options submenu

Page 33

33

Page 34

Buttons Use this to enable or disable the following front panel keys:

Select - Choose Yes or No to enable or disable the SELECT

key.

Units - Choose Yes or No to enable or disable the UNITS

key.

Reset - Choose Yes or No to enable or disable the PEAK

RESET key.

Send - You have two items to configure in this submenu.

PB Send - Use this to determine which layouts are sent

to which ports for pushbutton data send. You

can choose a Group number to send a

preconfigured layout, disable the pushbutton

data send, or save the information to the

database rather than outputting to the serial

port. If you choose the Save option and the

database is full, the display will show Full

when you press the DATA SEND key.

n Send - Use this to enable or disable the ability to key

in a group number then press the DATA

SEND key to send that group data to a serial

port.

Zero - Choose Yes or No to enable or disable the ZERO key.

Menu - Choose Yes or No to enable or disable the MENU key.

F1 - Choose Yes or No to enable or disable the F1 key.

F2 - Choose Yes or No to enable or disable the F2 key.

F3 - Choose Yes or No to enable or disable the F3 key.

Display The Display submenu allows you to customize the order in

which the FI-127 cycles through its weight display modes and

units of measure.

Select Customize the list of weight display modes here. The default list

is: ForceÆTopÆPeak. Repeatedly pressing SELECT while in

the Display mode will cycle through the list in that order. You

may customize the list by inserting and/or deleting items in the

list. The list can contain a maximum of four items.

To add an item: Determine where in the list you wish to insert

an item. Display the item which will immediately follow the one

you are inserting. Press +/-. The ACCEPT annunciator illuminates. Cycle through the options by pressing the

keys until the item you wish to insert is displayed, then press

ENTER. That item is now included in the list.

To delete an item: With that item displayed, press ZERO. That

item is deleted from the list.

Units Customize the list of units of measure here. The default list is:

Unit 1ÆUnit 2ÆUnit 3. Repeatedly pressing UNITS while

displaying a weight in the weight display mode will cycle through

the list in that order. You may customize the list by inserting

and/or deleting items in the list. The list can contain a maximum

of four items.

ÅÅ

Å or MENU

ÅÅ

34

Page 35

To add an item: Determine where in the list you wish to insert

an item. Display the item which will immediately follow the one

you are inserting. Press +/-. The ACCEPT annunciator illuminates. Cycle through the options by pressing the

keys until the item you wish to insert is displayed, then press

ENTER. That item is now included in the list.

To delete an item: With that item displayed, press ZERO. That

item is deleted from the list.

Define The Define submenu allows you to customize printouts, build

ASCII strings, create groups, enable continuous send, assign input

characters to specific actions for each port, enable database

reports, define database records, and configure data capture.

ASCII Under this menu item are Labels and Strings. Following

the explanation of these two items are instructions for

customizing the labels and strings.

Labels are short ASCII strings predefined at the factory.

When information is sent to a serial port and the layout

calls for one of the preset labels, the associated ASCII

string is sent. Following is a list of the label names and the

character called out by the associated ASCII string:

ÅÅ

Å or MENU

ÅÅ

Force = F

Top = P (for Peak)

First = I (for Initial)

Tension = T

'Press = C (for Compression)

C.W. = CW (for Clockwise)

C.C.W. = CCW (for Counter ClockWise)

Id = ID

Strings are groups of ASCII characters. You configure the

indicator to call for these strings in the Layout portion of

the menu. There are five predefined strings and ten other

strings you can modify to suit your needs. The five default

strings are:

Ascii 1: Dillon FI-127<cr><lf><End>

Ascii 2: Loadcell <End>

Ascii 3: Peak: <End>

Ascii 4: 1st Peak: <End>

Ascii 5: Average: <End>

35

Page 36

Instructions for working with strings:

An ASCII character is any number between 0 and 255,

inclusive. See Appendix A for a complete list of ASCII

characters used with the FI-127. To repeat any ASCII

character without entering it multiple times, enter the

number then a decimal, then the number of repetitions

you want. For example, an entry of 32.5 specifies that a

space character is to be transmitted five times. If no

decimal is entered, the indicator will send one character.

To insert a character at the end of the string, just press

ENTER while the indicator displays End. To insert a

character before the current character, press the +/- key.

To move back and forth along the string press the

MENU keys. To delete the current character press

ZERO.

Layouts The FI-127 has 14 default print layouts (max. 15) (see

Appendix B: Default Layouts and Examples). The display

shows LAy. nn, with nn being the identifying number of

that layout.

Each layout consists of one or more of the print items in

Table 1 below. Some items have a selectable variable. To

see this variable, press the ENTER key twice while the

item is displayed, key in a value or press the

keys to scroll through a list. Press ENTER to accept the

variable.

ÅÅ

Å or

ÅÅ

ÅÅ

Å or MENU

ÅÅ

* - denotes items that require

detailed information. For example: if

“LABEL” is inserted within a layout,

you must specify the label to be

printed; if “SP” is inserted, you must

specify the number of spaces to be

transmitted.

See the section Step by Step Instructions for some extra

help.

Table 1: Layout Print Items

*ASCII Select an ASCII string number defined in the ASCII menu.

*Ch. Outputs an ASCII character you enter.

*Spaces Displayed as nn SP where nn is the number of spaces to be

transmitted. (0 through 255)

*Crs Displayed as nn Cr. where nn is the number of carriage

returns transmitted.

*LFS Displayed as nn LF where nn is the number of line feeds to be

transmitted.

FF Transmits a form feed control character.

Force Transmits the Force value.

Top Transmits the peak force.

First Transmits the 1st peak value.

Display Transmits the currently displayed force (force, peak, 1st peak,

frozen force). This means that if a frozen force is displayed,

that is what will be transmitted.

36

Selected Transmits currently selected display. This means that if you

have Force selected but a frozen force is displayed, the live

force will be transmitted.

Page 37

* - denotes items that require

detailed information. For example: if

“LABEL” is inserted within a layout,

you must specify the label to be

printed; if “SP” is inserted, you must

specify the number of spaces to be

transmitted.

Hour Transmits time in 12 hour or 24 hour format, depending on

current setting.

Day Transmits the date in mm/dd/yy format.

Status Transmits the current status.

Transmitted as a single character. The bits appear as follows:

011LEBM, where L is set to logic 1 when a Low voltage

condition exists; logic 0 otherwise. E is set to 1 when an a-d

Error condition exists; 0 otherwise. B is 1 when the measurement is Beyond displayable range (over- or under-capacity); 0

otherwise. And M is set to logic 1 when an in-motion condition exists; set to logic 0 when the measurement is stable.

The upper four bits are set to 0011 to cause the value to be

printed as a digit or symbol in row 3 of the ASCII character

set.

*Label Transmits the chosen label. Choose from Force, Top, First,

Display and Id.

Units Transmits the unit of measure label.

Loadcell Outputs the currently selected loadcell number.

Cell Type Outputs the label for the type of loadcell; tension, compres-

sion, clockwise, counterclockwise and mode for bidirectional

cells.

*Layout Allows you to embed another layout within the current

layout. Displayed as Use n. Choose the layout number, n, you

want to print as part of the current layout.

*Delay Use this to specify a time delay in seconds from 0-255.

Record Transmits the currently selected record number.

Db. Force Transmits the force value stored in the currently selected

database record.

Db. Top Transmits the peak value stored in the currently selected

database record.

Db. First Transmits the 1st peak value stored in the currently selected

database record.

Db. Disp. Transmits the displayed value stored in the currently selected

database record.

Db. Sel. Transmits the selected value stored in the currently selected

database record.

Db. Label Transmits the Force, Peak, or 1st Peak label stored in the

currently selected database record.

Db. Cell Transmits the loadcell number stored in the currently selected

database record.

Db. Type Transmits the cell type label stored in the currently selected

database record.

Db. Units Transmits the unit of measure stored in the currently selected

37

Page 38

database record.

Db. Id Transmits the Id value stored in the currently selected

database record.

Db. Hour Transmits the time stored in the currently selected database

record.

Db. Day Transmits the date stored in the currently selected database

record.

nn by DB. Specifies that Layout nn is to be used once for every record in

the database, in ascending order. This allows you to generate

database reports. As Layout nn is used for each record, that

record is considered to be the currently selected record for

the purpose of serial output. The actual current record is not

modified by the generation of a report.

Point - Transmits the currently selected data capture point. If

no points exist, blanks are output. During data capture, no

points are considered to exist.

D.C. Force Transmits the force value of the currently selected data point.

D.C. Top Transmits the peak value of the currently selected data point.

D.C. First Transmits the 1st peak value of the currently selected data

point.

D.C. Ave. Transmits the mean value of the stored points.

D.C. Int. Transmits the data capture interval in nnnn format, right

justified with leading zero suppression.

D.C. Hour Transmits the data capture start time.

D.C. Day Transmits the data capture start date.

nn By D.C. Specifies that Layout nn is to be used for every point captured,

in ascending order. This allows you to generate data capture

reports.

End Specifies the end of the layout. Does not transmit anything.

* denotes items that require detailed information. For example: if “LABEL” is

inserted within a layout, you must specify the label to be printed; if “SP” is

inserted, you must specify the number of spaces to be transmitted.

Groups A group defines which ports will print which layouts. A

total of nine groups is available. Six are set up with

defaults. See the list below. Within each group, up to

three ports can output layouts. Port 1 is standard; ports 2

& 3 are offered only if additional serial boards are installed.

Each port is then assigned a layout to print.

38

You can also choose to inhibit the output while a motion

condition or other invalid condition exists. Choose Yes to

inhibit output and No to allow output during motion.

Page 39

Default Groups

Group # Port 1 Port 2 Port 3 Inhibit

1 Layout 5 None None Yes

2 Layout 6 None None Yes

3 Layout 7 None None Yes

4 Layout 8 None None Yes

5 Layout 10 None None No

6 Layout 14 None None No

Broadcast Enables or disables continuous send. To enable continuous

send, a group number must be entered under GrouP. This

number defines the group to be activated at each display

update.

Autosend Enables or disables autosend. To enable auto send, a

group number must be entered under GrouP. This

number defines the group to be printed each time weight

stabilizes above 1% capacity. The weight must fall below

1% capacity for the indicator to initiate another print.

Choose Save so information is saved in the database

rather than outputting to the serial port. If the database is

full, the data cannot be stored and the autosend trigger is

ignored.

Except for Reply and Save, the

actions at right can only be executed

if the character is received while the

indicator is in the Display mode.

Reply and Save can be executed

when the indicator is in Display

mode and also in the User Menu.

Protocol A protocol is defined as the set of input characters

assigned to specific actions for each port. Under this item

you choose a port, choose an input number, assign an

ASCII character to the action, and choose the associated

action from the following list (see note at left):

Units - Switches indicator to the next available unit of

measure.

Unit 1 - Switches indicator to Unit 1, if available.

Unit 2 - Switches indicator to Unit 2, if available.

Unit 3 - Switches indicator to Unit 3, if available.

Select - Switches indicator to next available display

mode.

Force - Switches display to the Force mode.

Top - Switches display to the Peak mode.

First - Switches display to the 1st Peak mode.

Reset - Causes a Peak Reset.

Send - Causes a Data Send to occur. Use Group to

specify which group to output.

Reply - Specifies that a specified group is to be output.

Use Group to specify which group to output.

Save - Causes information selected by the record

definition is to be stored in the database. If the

database is full this command is ignored.

Zero - Performs a Zero function.

39

Page 40

Freeze - Causes the Force display to be frozen. See the

section Freeze Force Function.

Unfreeze- Causes a frozen force to be unfrozen. See the

section Freeze Force Function

Capture - Starts the data capture process.

Database - Use this item to enable or disable database report output

and specify which group to use. Choose a group number

under Report to enable the function and choose No to

disable it.

Under Record, you define the database record format.

Any of the following items can be included in any order

but only once. If one of the force measurement items is

included, the unit of measure, identification (force, peak,

1st peak), and tension/compression are also saved for that

record within the database.

Force - Force measurement

Top - Peak value

First - 1st peak

Display - Force, Frozen force, Peak or 1st Peak, depend-

ing on display mode.

See detailed notes on data capture

in the section Data Capture later in

this manual

Selected - Force, Peak or 1st Peak, depending on display

mode.

Loadcell - Currently selected loadcell number.

Id - Id value.

Hour - Current time.

Day - Current date.

End - End of the list. Insertions and deletions may be

performed with the +/- and ZERO keys

anywhere within this list.

Capture - This is the last item in the Define submenu. Use this item

to configure data capture.

Under Report, enable the data capture function by

choosing which group to use. Disable it by choosing No.

Under Interval, set the time, in seconds, between

captured points. If you set a value of 0, the data capture

function is disabled.

Under Points, set the number of data points to be

captured. Can be 0-4000. Entering 0 disables data capture.

Default value is 3600 which is equal to one minute of data

if capture rate is 60 Hz.

40

Under Ave. Over, set the data capture threshold for

computing the average. The value is expressed as a

percent of full capacity referenced from the current zero

balance. 10% is the default setting. Can be as high as 100%.

Page 41

Serial submenu

The next setup menu item is Serial. See Figure 14. Use this configure your serial

communications.

Figure 14

Serial submenu

Choose which port you are going to configure. The choices for all three ports are

the same as those shown in the Figure 14 under Port 1.

Port n - Under Busy, select whether ready/busy input is respected.

Choose No to disable ready/busy input. Choose Yes to

enable ready/busy input. If you choose Yes, you may enter

a busy time-out period. This sets how long a port can be

busy before the indicator displays a port busy message.

Baud - Select the baud rate from these choices: 300,

600, 1200, 2400, 4800, 9600, 19200

Data - Set the number of data bits: 7 or 8

Parity - Set the parity. No is default. Other choices are

Even, Odd, Clear and Set.