Page 1

EDjunior Dynamometer

and Crane Scale

User Instructions

29810-0017 Issue AG Sept. 2012

Page 2

© Avery Weigh-Tronix, LLC 2012. All rights reserved.

No part of this publication may be reproduced, stored in an electronic retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording or otherwise without the prior written consent of

the copyright owner, or as permitted by law or under license. Full acknowledgment of the source must be given.

Avery Weigh-Tronix is a registered trade mark of the Avery Weigh-Tronix, LLC. This publication was correct at the

time of going to print however, Avery Weigh-Tronix, LLC reserves the right to alter without notice the specification,

design, price or conditions of supply of any product or service at any time.

All third party brands and product names used within this document are trademarks or registered trademarks of

their respective holders.

edjr_u_en_29810_0017.book

Page 3

Table of Contents

page

Chapter 1 General information and warnings ......................................................................................... 5

About this manual ..............................................................................................................5

Text conventions ......................................................................................................... 5

Special messages ....................................................................................................... 5

Installation .......................................................................................................................... 6

Safe handling of equipment with batteries .................................................................. 6

Safe Operation ................................................................................................................... 6

Routine maintenance ......................................................................................................... 8

Cleaning the machine ........................................................................................................ 8

Training .............................................................................................................................. 8

Sharp objects ..................................................................................................................... 8

Chapter 2 Introduction .............................................................................................................................. 9

Chapter 3 EDjr Description ..................................................................................................................... 10

EDjr Front Panel .............................................................................................................. 10

EDjr Keys .................................................................................................................. 11

Chapter 4 Power On and Annunciators ................................................................................................. 12

Chapter 5 EDjr Setup ...............................................................................................................................13

Setup>Misc ...................................................................................................................... 13

Setup>About ....................................................................................................................14

Setup>Test ...................................................................................................................... 14

Chapter 6 EDjr Operation ........................................................................................................................ 16

Display Modes ................................................................................................................. 16

Force Measurement ......................................................................................................... 16

Force Measurement Rezero ............................................................................................ 16

Displaying Peak Force ..................................................................................................... 17

Calculating Tension in a System ...................................................................................... 18

Chapter 7 Troubleshooting ..................................................................................................................... 19

Chapter 8 Weighing and Force Measurement Practice ........................................................................ 20

Load Centering ................................................................................................................ 20

Alignment ......................................................................................................................... 20

Proper Pin Fit ................................................................................................................... 20

Torque and Bending ........................................................................................................ 20

Certified Gear ................................................................................................................... 20

E1070 Indicator Service Manual 3

Page 4

4 E1070 Indicator Service Manual

Page 5

1 General information and warnings

1.1 About this manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled as shown by the 1 and 1.1 headings shown above.

The names of the chapter and the next subsection level appear at the top of alternating

pages of the manual to remind you of where you are in the manual. The manual name

and page numbers appear at the bottom of the pages.

1.1.1 Text conventions

Key names are shown in bold and reflect the case of the key being described. This

applies to hard keys and onscreen or soft keys.

Displayed messages appear in bold italic type and reflect the case of the displayed

message.

1.1.2 Special messages

Examples of special messages you will see in this manual are defined below. The

signal words have specific meanings to alert you to additional information or the relative

level of hazard.

DANGER!

THIS IS A DANGER SYMBOL.

DANGER MEANS THAT FAILURE TO FOLLOW SPECIFIC PRACTICES

OR PROCEDURES WILL CAUSE INJURY OR DEATH.

ELECTRICAL WARNING!

THIS IS AN ELECTRICAL WARNING SYMBOL.

ELECTRICAL WARNINGS MEAN THAT FAILURE TO FOLLOW

SPECIFIC PRACTICES OR PROCEDURES MAY RESULT IN

ELECTROCUTION, ARC BURNS, EXPLOSIONS OR OTHER HAZARDS

THAT MAY CAUSE INJURY OR DEATH.

WARNING!

This is a Warning symbol.

Warnings mean that failure to follow specific practices and procedures may

have major consequences such as injury or death.

CAUTION!

This is a Caution symbol.

Cautions give information about procedures that, if not observed, could result

in damage to equipment or corruption to and loss of data.

EDjunior Dynamometer User Instructions 5

Page 6

NOTE: This is a Note symbol. Notes give additional and important information, hints

and tips that help you to use your product.

1.2 Installation

DANGER: RISK OF ELECTRICAL SHOCK. NO USER SERVICEABLE

PARTS. REFER TO QUALIFIED SERVICE PERSONNEL FOR SERVICE.

1.2.1 Safe handling of equipment with batteries

CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only

with the same or equivalent type recommended by the manufacturer. Dispose

of used batteries according to the manufacturer’s instructions.

ATTENTION: Il y a danger d'explosion s'il y a remplacement incorrect de la

batterie, remplacer uniquement avec une batterie du même type ou d'un type

équivalent recommandé par le constructeur. Mettre au rebut les batteries

usagées conformément aux instructions du fabricant.

1.3 Safe Operation

Keep all the following in mind as you use the EDjr dynamometer.

DANGER: IF YOU OVERLOAD THIS DYNAMOMETER YOU COULD

SUFFER SEVERE INJURIES OR DEATH. THE TOTAL LOAD ON THE

DYNAMOMETER SHOULD NEVER EXCEED THE RATED CAPACITY.

The system capacity is equal to the rating of the dynamometers. The shackle rating

should not be used to determine lift capacity of the system.

Any zeroed deadload must be considered as part of the

ultimate load.

Although this instrument has a substantial overload protection rating, the instrument

should not be used above the rated capacity. Doing so can significantly impact fatigue

life of the instrument and cause premature and abrupt failure. If a higher capacity

reading is needed, Dillon insists that a larger instrument be used.

6 EDjunior Dynamometer User Instructions

Page 7

Safety is always a concern in overhead lifting and tensioning applications. To limit your

liability always insist upon factory supplied shackles and pins and factory tested and

certified safe optional equipment. All DILLON products are designed to meet the

published Safe Working Load (SWL) and Ultimate Safety Factor (USF) standards of the

United States Military.

Do not grind, stamp or deform the metal on the dynamometer body in any way.

Any significant damage or deformation to the loading element is cause for evaluation

by Dillon, particularly in the element side members to the right and left of the display.

Relieve all torsional and off axis loads.

Apply load in the center of the shackle bow with this instrument.

Off center loading results in substandard performance.

Instrument requires time to stabilize when changing temperatures.

Use only the hardware supplied with this instrument. If no hardware was supplied,

insure that the mating pin and shackle bow is equivalent to the hardware used at

calibration. Otherwise substandard performance can result.

Dillon recommends only using qualified rigging hardware and cannot be responsible

for unapproved hardware.

This instrument is not designed for the following:

l Applications that see rapid, dramatic temperature swings or thermal shock.

Wide variation in readings can occur.

l Environments with high electromagnetic fields such as cranes employing

electromagnets to lift metal. These induce trace voltages that are picked up

within the load cell lead wiring and appear as inaccurate loads.

l Intrinsically safe environments. This unit has not been Factory Mutual

tested.

EDjunior Dynamometer User Instructions 7

Page 8

1.4 Routine maintenance

IMPORTANT: This equipment must be routinely checked for proper operation

and calibration.

Application and usage will determine the frequency of calibration required for

safe operation.

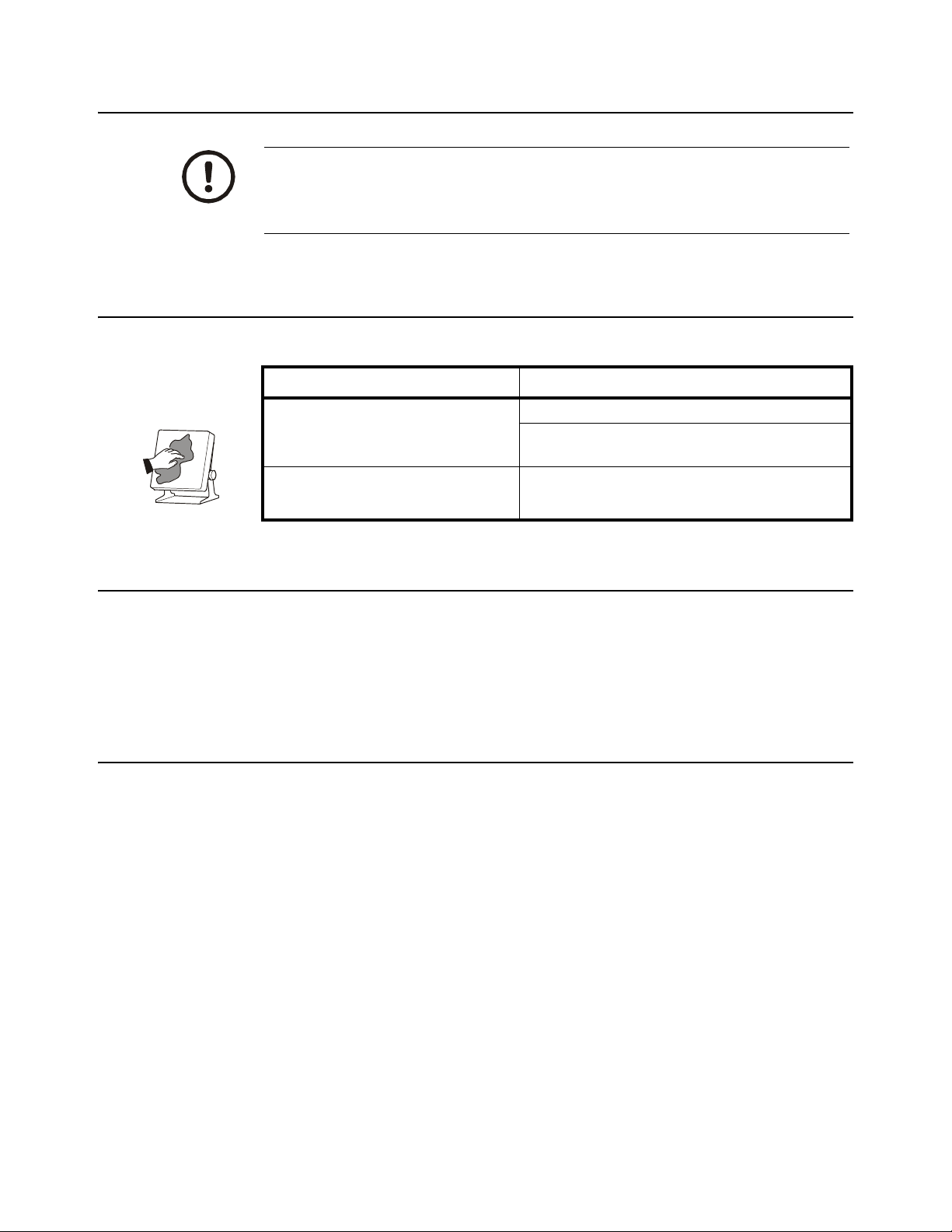

1.5 Cleaning the machine

Table 1.1 Cleaning DOs and DON’Ts

DO DO NOT

Wipe down the outside of standard products

with a clean cloth, moistened with water and

a small amount of mild detergent

Spray the cloth when using a proprietary

cleaning fluid

1.6 Training

Do not attempt to operate or complete any procedure on a machine unless you have

received the appropriate training or read the instruction books.

To avoid the risk of RSI (Repetitive Strain Injury), place the machine on a surface which

is ergonomically satisfactory to the user. Take frequent breaks during prolonged usage.

1.7 Sharp objects

Do not use sharp objects such as screwdrivers or long fingernails to operate the keys.

Attempt to clean the inside of the machine

Use harsh abrasives, solvents, scouring cleaners or

alkaline cleaning solutions

Spray any liquid directly on to the display windows

8 EDjunior Dynamometer User Instructions

Page 9

2 Introduction

The EDjuniorTM (EDjr) electronic dynamometer from Dillon is a force measurement

load sensor and digital readout in one instrument. The EDjr can be used to measure

tension or weight.

This manual covers the setup and operation of the EDjr. General information is covered

in the right column of each page with major sections separated by the black bar shown

above. Subheads appear in the left column along with any special notes, cautions or

warnings.

This manual covers the following:

l EDjr Description

l EDjr Setup

l EDjr Operation

l Troubleshooting

Be sure to read the safety precautions found in the Safe Operation section.

DANGER: IF YOU OVERLOAD THIS DYNAMOMETER YOU COULD

SUFFER SEVERE INJURIES OR DEATH. THE TOTAL LOAD ON THE

DYNAMOMETER SHOULD NEVER EXCEED THE RATED CAPACITY.

EDjunior Dynamometer User Instructions 9

Page 10

3 EDjr Description

ESC

3.1 EDjr Front Panel

The EDjr comes in several weight capacities. All have the same front panel, shown in

Figure 3.1.

Figure 3.1 EDjunior front panel

10 EDjunior Dynamometer User Instructions

Page 11

3.1.1 EDjr Keys

ESC

There are four “hard” keys and four “soft” keys. The hard keys are permanently labeled

and the soft keys are just below the display. The soft key functions change and the key

label appears above each key on the display. Sometimes the individual soft keys are

referred to as the F1, F2, F3 and F4 keys as numbered from left to right.

On/Off key Use this key to turn the unit on and off.

ZERO key Use this key to zero the force indicated on the display.

ESC key

Arrow key Use this key to access any available soft keys not currently viewed.

Use this key to escape from portions of the menu structure and

return to previous choices or displays.

EDjunior Dynamometer User Instructions 11

Page 12

4 Power On and Annunciators

Force

Force

lbf lbf

00

Clear

Mode ConfigSetupUnits

Arrow key

press

ESC key

press

P

When you power up the EDjr you will see a display similar to the example shown on

the left in Figure 4.1.

Figure 4.1 Initial displays

Depending on permission settings and/or revision of firmware, various soft keys may

be in a different location or not visible.

The display sample above shows several symbols you may see on your display but

usually not all at the same time.

Force This tells you that the display is showing live force measurement at the

moment. Will show Peak when viewing Peak Mode.

lbf Current unit of measure is lbf in this example. May also be kgf or N. See

note below.

~ Motion symbol. This appears when the force is in motion. This symbol

disappears when motion ceases.

Battery annunciator. This shows approximate remaining battery life.

Capture of a new peak value. This annunciator will remain lit for a few

seconds.

lbf and kgf are units of force, not weight.

12 EDjunior Dynamometer User Instructions

Page 13

5EDjr Setup

Setup

Misc

Flash Zero Contr

O.Load

Zero

Calib

About

Device

Software rev.

link info

Lists #

of overloads

List current

zero

compared

against

cal zero

Points

Display

calibration

points

Enable

keypad

display

flash

Clear

peaks

on Zero

press

Adjust

LCD

contrast

Te st

A-D

Tes t

A-D

Disp.

Te st

display

Keys

Te st

keys

Batt

Tes t

battery

One of the first things you should do to begin using the EDjr is to set it up to suit your

specific needs and equipment. You can access the Setup menu, shown in Figure 5.1,

using the soft keys. Press the appropriate soft key to accomplish the functions listed on

the following pages.

Figure 5.1 Operator setup menu

5.1 Setup>Misc

EDjunior Dynamometer User Instructions 13

Press the Misc key to access the following soft key set (refer to Figure 3):

Flash Press this soft key to enable or disable the “display flash” feedback. If

Zero Press this soft key to enable or disable the Zero key’s ability to also clear

Contr Press this key to adjust the contrast of the LCD display. Press the Down

enabled, the press of a key causes the display to momentarily flash to give

you a visual feedback that the key was activated.

the Peak force value. If you enable this function, press the Zero key to

clear the Peak force and zero the load. If you disable the function, the Zero

key will only zero the load. Peak force remains in effect and will only be

cleared with the Clear function during operation.

soft key to lighten the contrast. Press the Up soft key to darken the

contrast.

Page 14

Sometimes the individual soft keys are referred to as the F1, F2, F3 and F4 keys as

numbered from left to right.

5.2 Setup>About

The next soft key is About. The About menu shows an assortment of information about

your Dillon instrument. This can be handy for maintaining calibration, troubleshooting

or determining if the firmware can be upgraded. Press this and access the following soft

key set (refer to Figure 3):

Device Press this to see software revision and dynamometer information.

Dillon suggests that calibration data be recorded and saved.

There is a keypad shortcut for increasing and decreasing contrast. While

in normal display mode press Arrow key and F2 simultaneously to

increase contrast. Press Arrow key and F1 simultaneously to decrease

contrast.

Calib This soft key access the following soft key set:

5.3 Setup>Test

The Test functions can help service technicians remotely diagnose your Dillon

instrument by showing information on key internal functions. Typically these menus will

have significance only to trained technicians . You may look at these menus without

technical guidance, but the information may have little meaning, or an error may be

reported that may not exist.

Press this key to access several items described below (refer to Figure 5.1):

Batt Press this key to perform a battery test. This shows the battery level in A-

Points Press this key to display the calibration loading points.

O.Load Lists the number of overloads that have occurred since the unit was

manufactured.

Zero Lists the current zero point compared to the calibration zero point. If

the zero point has moved significantly, this may indicate a serious

overload has occurred and the instrument should be returned for

service.

D counts and approximate voltage. Voltage is not calibrated.

A-D Press this key to test the A-D section of the EDjr. You need to apply force

to change the counts and test the unit. The A-D is the electronics portion

that converts analog load cell signal to digital numbers.

Disp. Press this key to perform a display test. Stop the test by pressing the ESC

key.

14 EDjunior Dynamometer User Instructions

Page 15

Keys Press this key to perform key tests. Any key pressed will be reflected in the

display. Press to end the test.

EDjunior Dynamometer User Instructions 15

Page 16

6 EDjr Operation

6.1 Display Modes

The EDjr has two display modes accessible by pressing the Mode soft key. See Figure

6.1.

The first display mode when you power up is the live force measurement mode.

Press the Mode soft key and the display changes to peak measurement mode. This

mode shows the peak force applied to the EDjr since the last peak clearing action.

Delete the peak reading by pressing the Clear soft key.

Press the Mode soft key again and the display returns to the force measurement mode.

6.2 Force Measurement

Follow these steps to perform a gross force measurement.

1. Turn on the unit with the On/Off key.

2. Remove any weight from the EDjr.

3. Zero the EDjr by pressing the ZERO key.

4. Apply the force to the EDjr and read the gross force on the display.

You can change the units of measure of the display by pressing the Units soft key. Zero

reference is maintained after instrument power off and will be recalled with the next

power-on. Zero reference may be lost if battery power is removed.

6.3 Force Measurement Rezero

Rezeroing allows the weight or load of fixturing to be invisible to the measurement. The

zeroed load must always be considered as part of the maximum capacity.

1. Turn on the unit with the On/Off key.

2. Remove any weight from the EDjr.

3. Zero the EDjr by pressing the ZERO key.

4. Apply the tare force to the EDjr and press the ZERO key.

5. Apply the force to the EDjr and read the net force on the display.

Steps 2 and 3 are not required if the weight of the fixturing is not needed. This should

be maintained, however, to know cumulative loads.

16 EDjunior Dynamometer User Instructions

Page 17

6.4 Displaying Peak Force

Force

Peak Peak

Force

lbf

lbf lbf

lbf

0

0

0

0

Display #2Mode

Display Mode #1

Live force

reading

Peak force

reading

Arrow key

press

Mode key

press

Arrow key

press

Clear

Mode ConfigSetupUnits

Clear

Mode

Config

SetupUnits

ESC key

press

ESC key

press

The EDjr will store the peak force applied until that reading is cleared. To display the

peak force applied to an EDjr, from the force measurement mode, press the Mode soft

key. The display changes to display mode #2 shown in Figure 6.1 which is the peak

display mode. The peak force is displayed. You can clear this by pressing the Clear soft

key.

Peak force can only be reset to zero if live force is zero. Peak force will reset to match

live force.

Peak reading is maintained after instrument power off and will be recalled with the next

power-on. Peak reading may be lost if battery power is removed.

Figure 6.1 Display mode menu

EDjunior Dynamometer User Instructions 17

Press the Mode soft key until the desired display mode is reached.

Page 18

6.5 Calculating Tension in a System

Cable

T

T=

2 cos

F

F

2

Truck Winch

The setup shown above will give you an approximate tension reading. This can vary

from actual tension due to variables in equipment and environment.

18 EDjunior Dynamometer User Instructions

Page 19

7 Troubleshooting

Problem Possible Cause Solution

EDjr powers on momentarily

and turns off

EDjr does not power on Low battery

Display is completely dark Display contrast too dark Hold the Arrow key down while pressing the F1 key several times to

Low battery

Bad keypad

Bad keypad

Batteries installed backwards

or no spring contact

Software reset Remove battery cap & reinstall after one minute. Attempt to turn

Display contrast too light Hold the Arrow key down while pressing the F2 key several times to

Replace with high quality alkaline batteries

Have EDjr serviced

Replace with high quality alkaline batteries

Have EDjr serviced

Insure that positive terminals of both batteries (nub) face inward –

towards the black cap. Check that spring is attached to the battery

cap.

power on again.

increase the display contrast. If nothing occurs, release both keys.

Press the power button and try again.

decrease the display contrast.

EDjunior Dynamometer User Instructions 19

Page 20

8 Weighing and Force Measurement Practice

The basis for all electronic force measurement or weighing is measurement of stress

in a loadcell body. To obtain optimal results it is necessary to establish a few basic rules,

otherwise the effect may be a nonlinear or non-repeatable response. Read and follow

these tips and see the illustrations on the next page.

8.1 Load Centering

For accurate performance the force acting on the unit must be in line with the unit.

8.2 Alignment

Insure shackles are oriented parallel with the instrument. Apply load in the center of the

shackle bow.

8.3 Proper Pin Fit

A proper fitting pin is important in order to generate an even stress distribution and

avoid yield stresses. To achieve published accuracy you must use the shackle pins

provided by Dillon.

8.4 Torque and Bending

Torque and bending should be avoided. Use swivels on the lifting wire for anti-torque

and avoid side forces.

8.5 Certified Gear

Certified shackles and lifting gear should always be used in accordance to local laws

and federal legislation. Insure all hardware, fittings and line used to sustain the load are

properly sized and rated for the installation. Have the system evaluated by a qualified

engineer if any question or uncertainty exists.

20 EDjunior Dynamometer User Instructions

Page 21

Center the load

on the shackle pin.

Use spacers to

insure centering

where applicable.

Use only with

a pin of the

same diameter

and hardness

as the original

factory equipment.

Do not torque,

bend or

sideload.

Use hardware that allows

single point attachment

and freedom of alignment.

Do not use hardware that

is undersize or restricts

self-alignment. This results in

poor measurement

performance and possible

dangerous safety conditions.

Be sure fixturing does

not bind between the

body of the EDjr and

the shackle!

EDjunior Dynamometer User Instructions 21

Figure 8.1 Good force measurement practice

Page 22

22 EDjunior Dynamometer User Instructions

Page 23

Page 24

AUTHORIZED DISTRIBUTORS

Ask the experts. Dillon distributors offer complete

service capabilities from application assistance to

sales and product support. Their experienced

representatives are the most knowledgeable

experts that you will find in the force measurement

industry. We recommend that you consult these

capable specialists for all of your measuring needs.

Overload Protection and

Overhead Weighing Equipment

Fairmont, Minnesota U.S.A.

Toll-Free: (800) 368-2031

Phone: (507) 238-4461

Fax: (507) 238-8258

www.dillon-force.com

Loading...

Loading...