Page 1

Dynaswitch & Cranegard

User’s Manual

Page 2

2

Page 3

Table of Contents

Section 1 Dynaswitch General Information........................................................ 5

1-1 Introduction ............................................................................................ 5

1-2 General Description ............................................................................... 5

1-3 Safety ..................................................................................................... 5

1-4 Compression Models ............................................................................. 5

1-5 Tension Models...................................................................................... 5

1-6 Key Specifications and Options ............................................................. 6

1-7 Microswitches ........................................................................................ 7

1-8 Attachment Fittings ................................................................................ 8

Secton 2 Installation .......................................................................................... 9

2-1 Mounting Positions Tension Models ...................................................... 9

2-2 Mounting Positions Compression Models .............................................. 9

2-3 Dynaswitches & Reeving Setups ......................................................... 10

2-4 Other Installation Possibilities .............................................................. 11

2-5 Dynaswitch Selection ........................................................................... 12

2-6 Dynaswitch Field Installation Procedures ............................................ 12

2-6-A Wiring the Compression Model Dynaswitch .............................. 12

2-6-B Wiring the Tension Model Dynaswitch ....................................... 12

2-6-C Setting the Set Points ................................................................ 13

Section 3 Operation ......................................................................................... 15

3-1 Safety Shutdown Function ................................................................... 15

3-2 Decreasing Load Operation ................................................................. 15

3-3 Automation Operation .......................................................................... 15

Section 4 Maintenance .................................................................................... 15

4-1 General Instructions ............................................................................. 15

4-2 Service Instructions.............................................................................. 15

4-3 Authorized Replacement ...................................................................... 16

4-4 Troubleshooting ................................................................................... 16

Section 5 Cranegard Load Limit Switch ........................................................... 17

5-1 Introduction .......................................................................................... 17

5-2 General Description ............................................................................. 17

5-3 Safety Factor........................................................................................ 17

5-4 Microswitches ...................................................................................... 17

5-5 Key Specifications................................................................................ 17

Section 6 Installation ....................................................................................... 18

6-1 Mounting Positions ............................................................................... 18

6-2 Selection .............................................................................................. 18

6-3 Cranegard Field Installation Procedures .............................................. 19

6-4 Electrical Wiring ................................................................................... 19

Section 7 Maintenance .................................................................................... 20

7-1 General Instruction............................................................................... 20

7-2 Mechanical Inspection ......................................................................... 20

7-3 Electrical Inspection ............................................................................. 20

7-4 Switch Setting ...................................................................................... 20

7-5 Authorized Parts Replacement ............................................................ 20

7-6 Troubleshooting ................................................................................... 20

Pages are numbered consecutively beginning with the cover page.

3

Page 4

4

Page 5

Section 1: Dynaswitch General Information

1-1

Introduction

1-2

General Description

The primary purpose of Model DS Dynaswitches® is to protect cranes,

hoists and other lifting machinery against weight or force overload damages. They can also be used to perform control functions proportional to

weight such as shutting down a pump when a tank is filled. As many as

four standard microswitches can be installed on the Dillon Dynaswitch to

perform multiple automated functions. The Dynaswitch is intended for

applications with gradually applied loads and should not be installed where

it may encounter severe dynamic or impact loads.

Dillon Dynaswitches are designed to work with either a tension or compression load. All Dynaswitches consist of a U-shaped force beam, a

microswitch (or microswitches), and attachment fittings for applying load at

mounting points. The force beam bends as force is applied and causes the

microswitches to open or close electrical circuits. Illustrations on pages 7

and 8 show various microswitches and attachment fittings. Dynaswitch

capacity should be selected based on maxiumum forces it may encounter,

including load-increasing factors such as acceleration of mass and static

arrangement of cables.

1-3

Safety

1-4

Compression Models

1-5

Tension Models

All Dynaswitch force beams and attachment fittings have a safety factor of

5:1. In addition, all models have an overload stop, set slightly in excess of

rated capacity to prevent damage to measuring capability.

When loads are applied to compression models, the force beam legs tend

to come closer together. Paragraph 2-6-A explains how to hook up safety

overload circuits and auxiliary circuits of compression models’ microswitches. Compression models contain threaded holes on the bottom

leg for mounting to machinery and a spherical bearing on the top leg to

concentrate the applied load at one point. The stops for measuring capability protection are adjustable bolts in all capacities except 25K and 50K,

where this stop is integral with the force beam.

When loads are applied to tension models, the force beam legs tend to

spread apart. Paragraph 2-6-B explains how to hook up safety overload

circuits and auxiliary circuits to tension models’ microswitches. Tension

model attachment fittings include spherical rod end connectors, shackles,

lifting eyes, non-swivel hooks and threadstuds. Attachment fittings are

mounted on opposite legs and are in-line axially so the applied load will not

cause rotation of the beam. The stops for measuring capability protection

are adjustable bolts in all capacities.

5

Page 6

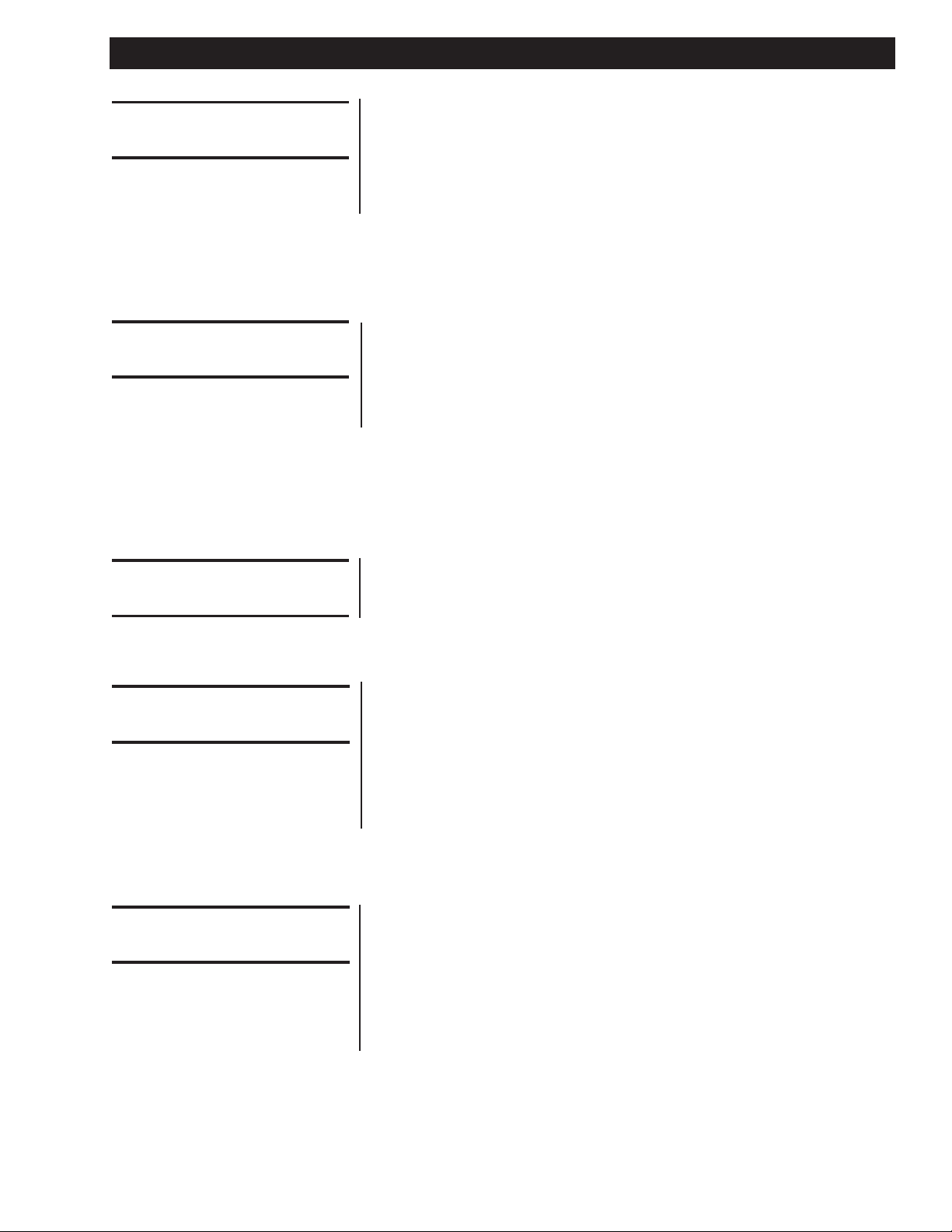

1-6

Table 1-1, below, contains key specifications and options available.

Key Specifications

and Options

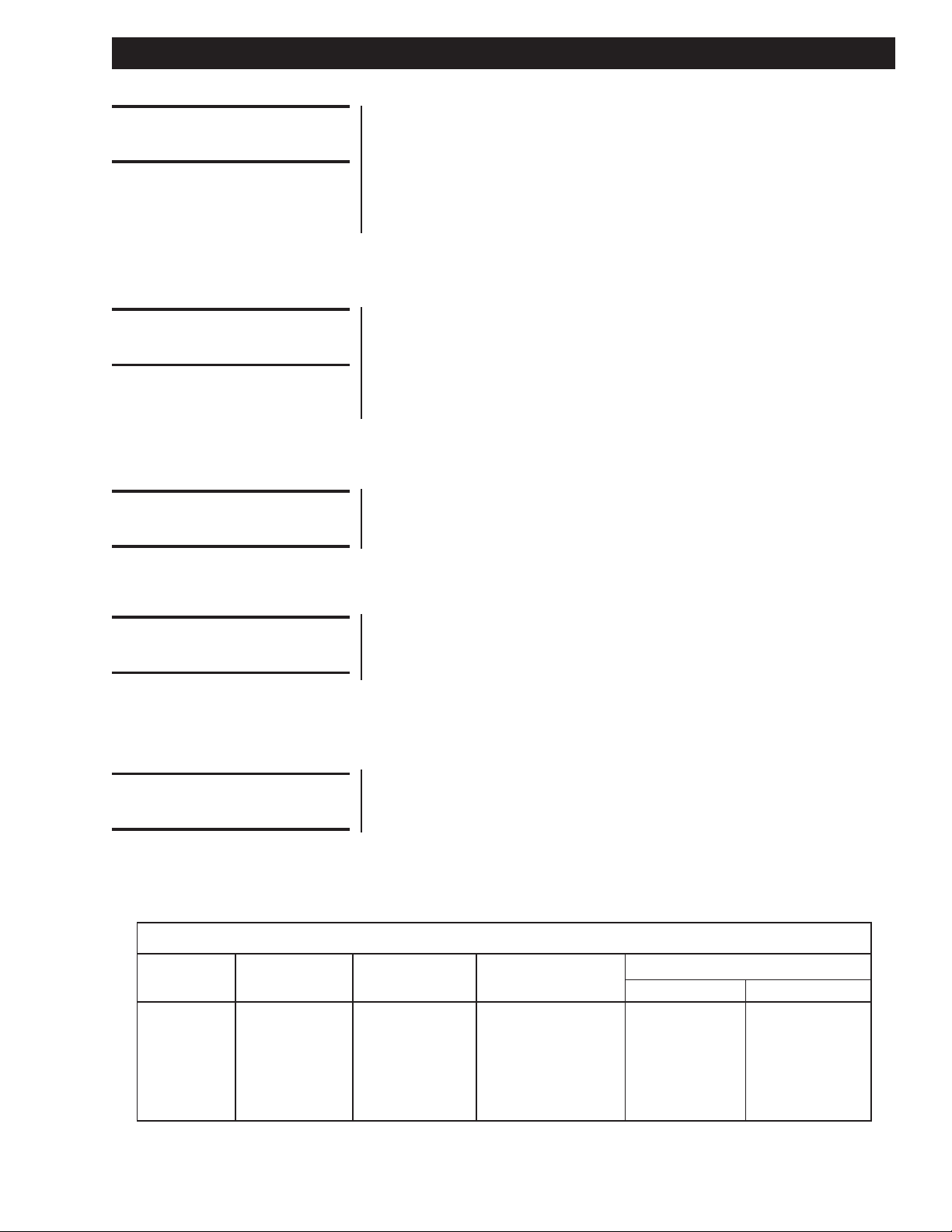

Table 1-1

Basic Beam DSW-1 DSW-2 DSW-3 DSW-4 DSW-5 DSW-6 DSW-7

Part Number

Rated

Capacity 100 1000 2000 5000 10000 25000 50000

pounds

Minimum 15 100 200 500 1000 1250 2500

Set point*

Repeatability ±3 ±30 ±60 ±150 ±300 ±750 ±1500

pounds

Nomi--l full

Cap. beam 0.02 0.03 0.05 0.05 0.05 0.06 0.06

deflection

in inches

Option A Avail. Avail. -- Avail. -- -- --

Option J Avail. Avail. -- Avail. -- -- --

Option B -- -- Avail. -- Avail. Avail. Avail.

Option C -- -- Avail. -- Avail. Avail. Avail.

Option D Avail. Avail. -- -- -- -- --

Option E Avail. Avail. Avail. Avail. Avail. Avail. Avail.

Option F -- -- Avail. -- Avail. -- --

Option G -- -- Avail. Avail. Avail. Avail. Avail.

Hardware Switch

Option H -- -- Avail. -- Avail. -- --

Option S Avail. Avail. Avail. Avail. Avail. Avail. --

Option A .001" differential travel switch; small size. P/N 26419-0026

Type 11SM401-T. Maximum 4 per unit.

Option J .004" differential travel switch; weatherproof, small size.

26420-0015 . Type 1SE1. Maximum 4 per unit.

Option B .002" differential travel switch; weatherproof. P/N 17891-0048

Type BZG1-2RN. Maximum 4 per unit.

Option C Explosion proof switch. 26424-0029. Type EXA-0. Maximum 2

per unit.

Option D Spherical rod end connector (one).

Option K Compression loading spherical ball fitting assembly (one).

Optioa F Lifting eye (one)

Option G Adapter, shackle & pin (one set).

Option H Non-swivel hook (one).

Option S Stud for tension loading (one).

6

Page 7

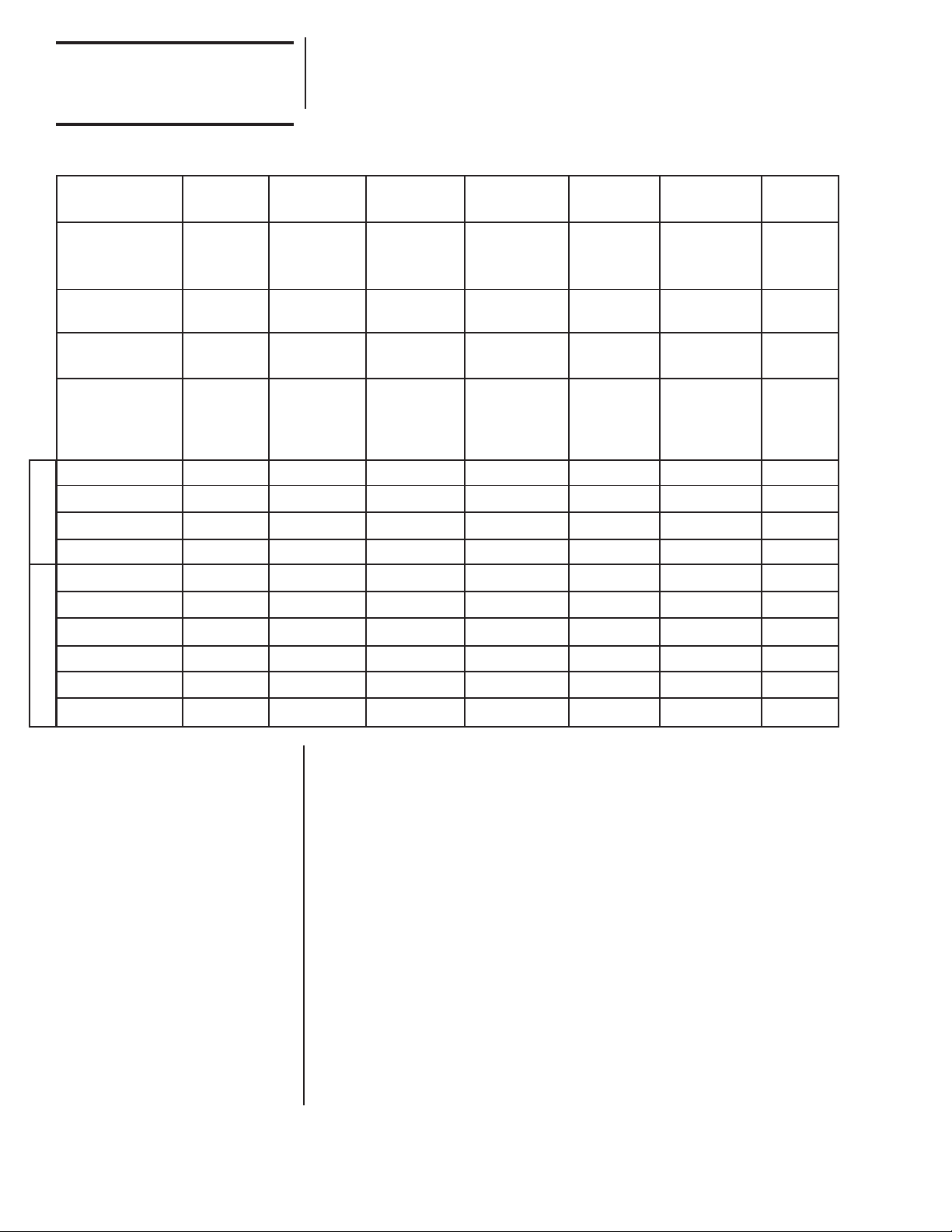

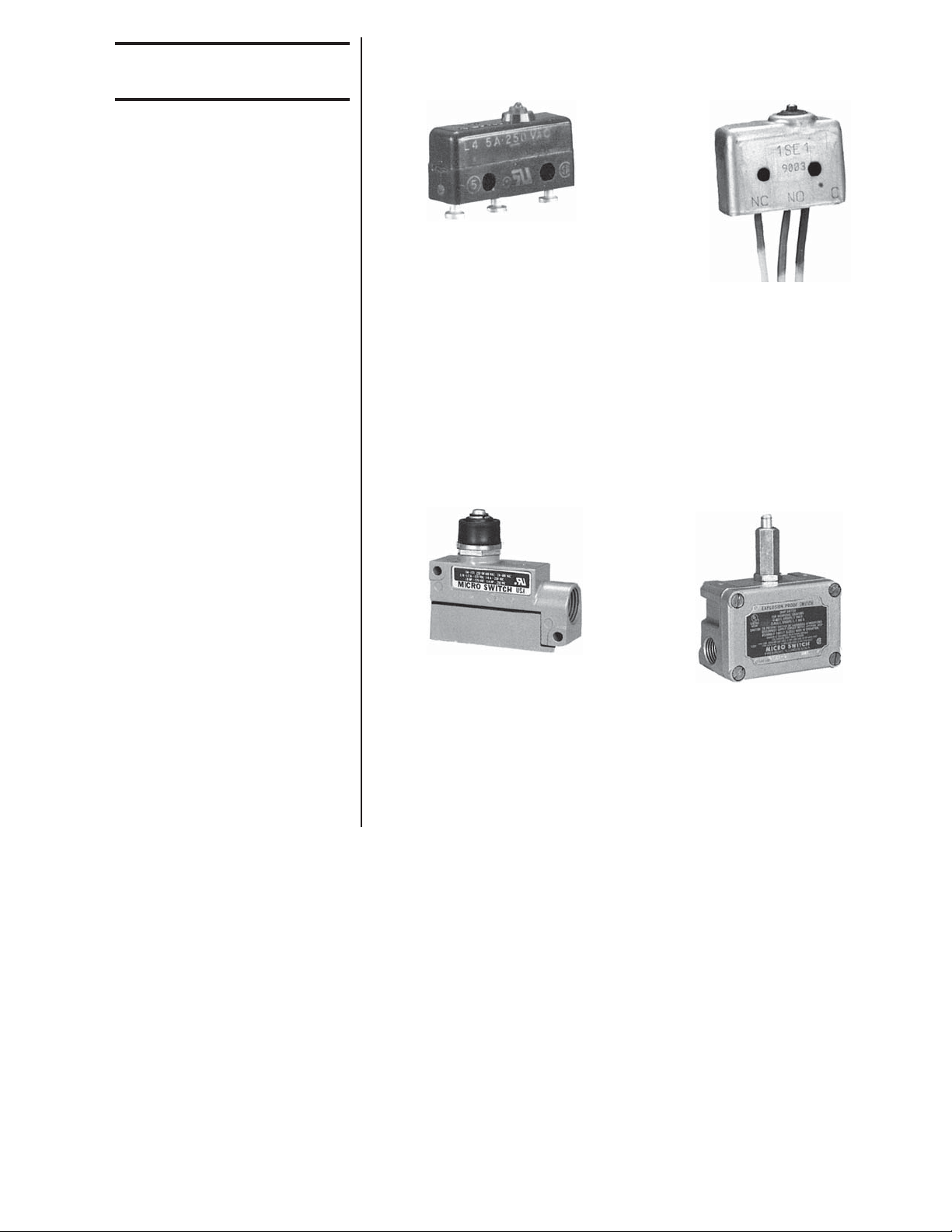

1-7

Microswitches

Below are the four microswitches available and their specifications.

Option A:

0.001” differential travel switch.

Small size

Dillon PN 26419-0026

(Cat. #11SM401-T.) S.P.D.T.

5 amps. resistive at 28VDC or

250VAC

Option J:

0.004” differential travel switch

Small size

Weatherproof

Dillon PN 26420-0015

(Cat. #1SE1.) S.P.D.T.

5 amps. resistive at 28VDC, 125 or

250VAC

Option B:

0.002” differential travel switch

Weatherproof

Dillon PN 17891-0048

(Cat. #BZG1-2RN.) S.P.D.T.

15 amps. resistive at 125, 250 or

480VAC. ½ amp. at 125VDC.

Option C:

0.060” differential travel switch

Explosion proof

Dillon PN 26424-0029

(Cat. #EXA-Q.) S.P.D.T.

20 amps. resistive at 125, 250 or

480VAC. ½ amp. at 125VDC.

7

Page 8

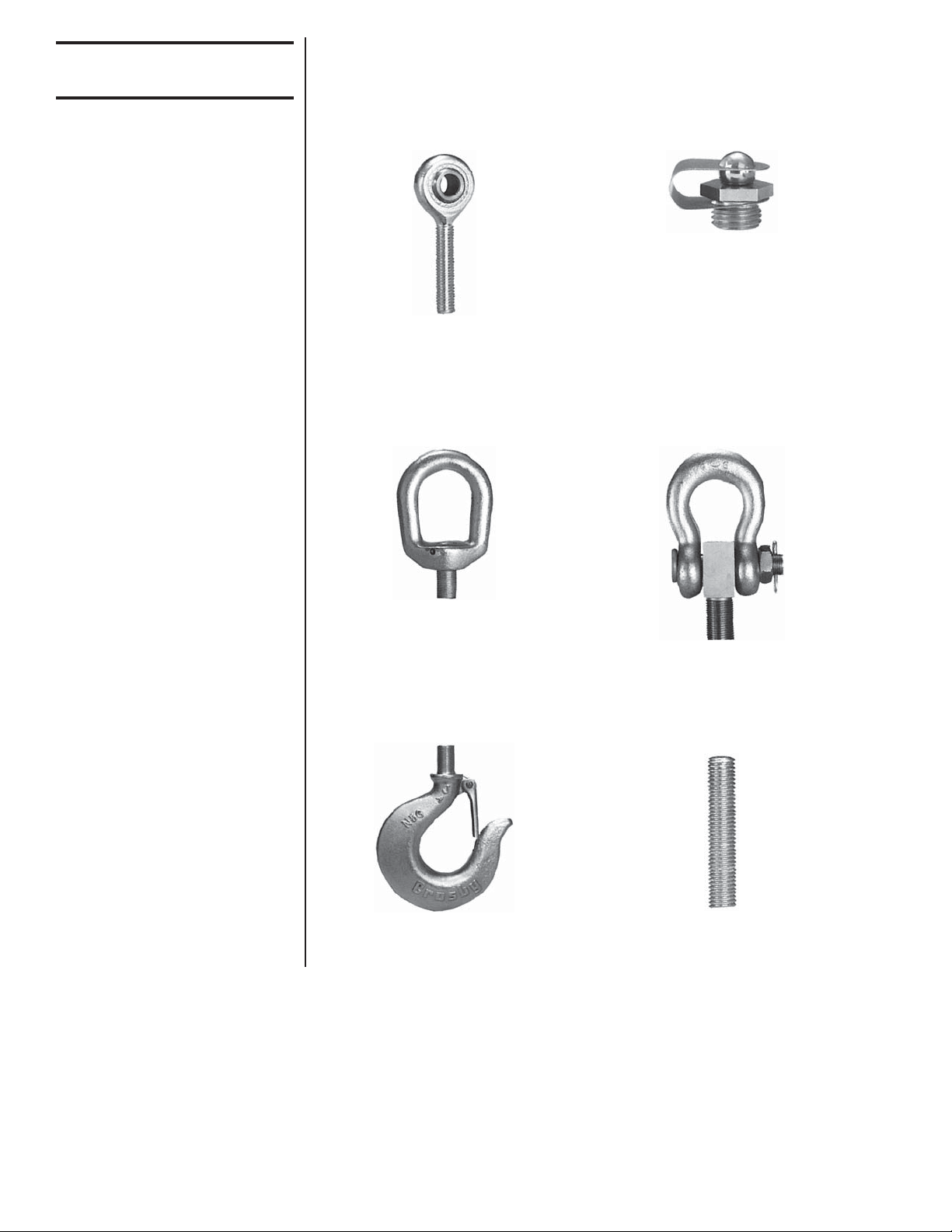

1-8

Attachment Fittings

Attachment fittings for tension and compression models are shown below.

Illustrations are not to scale.

Option E:

Compression loading spherical ball

fitting assembly

Option D:

Spherical rod end connector

Option F: Lifting eye

Option H:

Nonswivel hook

Option G:

Adapter, shackle and pin (one set)

Option S:

Threaded stud

8

Page 9

Section 2 Installation

2-1

Mounting Positions

Tension Models

2-2

Mounting Positions

Compression Models

Some compression models

have flat-top balls; rest the

applied load on the flat

surface of the flat-top ball.

The best mounting position for a tension model is on the dead end of the

line or on a crane anchor point. This mounting minimizes the effects of the

machinery’s motion on the Dynaswitch. It keeps the switch in one relative

position which reduces the possibility of wire tangling and connector

damage.

Position the Dynaswitch so that all of the supported load is transmitted

through the compression ball fitting. Bolt the bottom leg to the loading

machinery or the facility foundation. Make sure the load contacts the

Dynaswitch only at the top of the steel ball and nowhere else! If the load

rests on the upper leg as well as on the ball, the microswitches will not

actuate at the proper load setting. Do not restrict free motion of the upper

leg since this too could cause the Dynaswitch to activate improperly.

9

Page 10

2-3

Dynaswitches &

Reeving Setups

Below are some examples of hoist and reeving setups which use the

Dynaswitch for control and/or safety purposes.

Figure 2-A

2 ropes, 2 part single

reeving

Figure 2-B

As shown at right, Dynaswitch is

installed in series with rope to the

dead end. The microswitch is set

for ¼ capacity of the crane because

there are four parts of line to the

hook.

With two parts of line to the hook,

the Dynaswitch should be installed

in series between wire rope and its

dead end point. Microswitch is set

for ½ maximum capacity of the

hoist.

Frictional reactions within the

sheaves may prevent all parts

of the lines from having identical tension. While generally

suitable for overload protection,

it may give unsatisfactory

results for weighing or batch

control.

10

Figure 2-C

4 ropes, 4 part single

reeving

Figure 2-D

The Dynaswitch may also be placed

between hoist and trolley with

microswitch set for maximum

capacity of the hoist and trolley.

Page 11

2-4

Other Installation

Possibilities

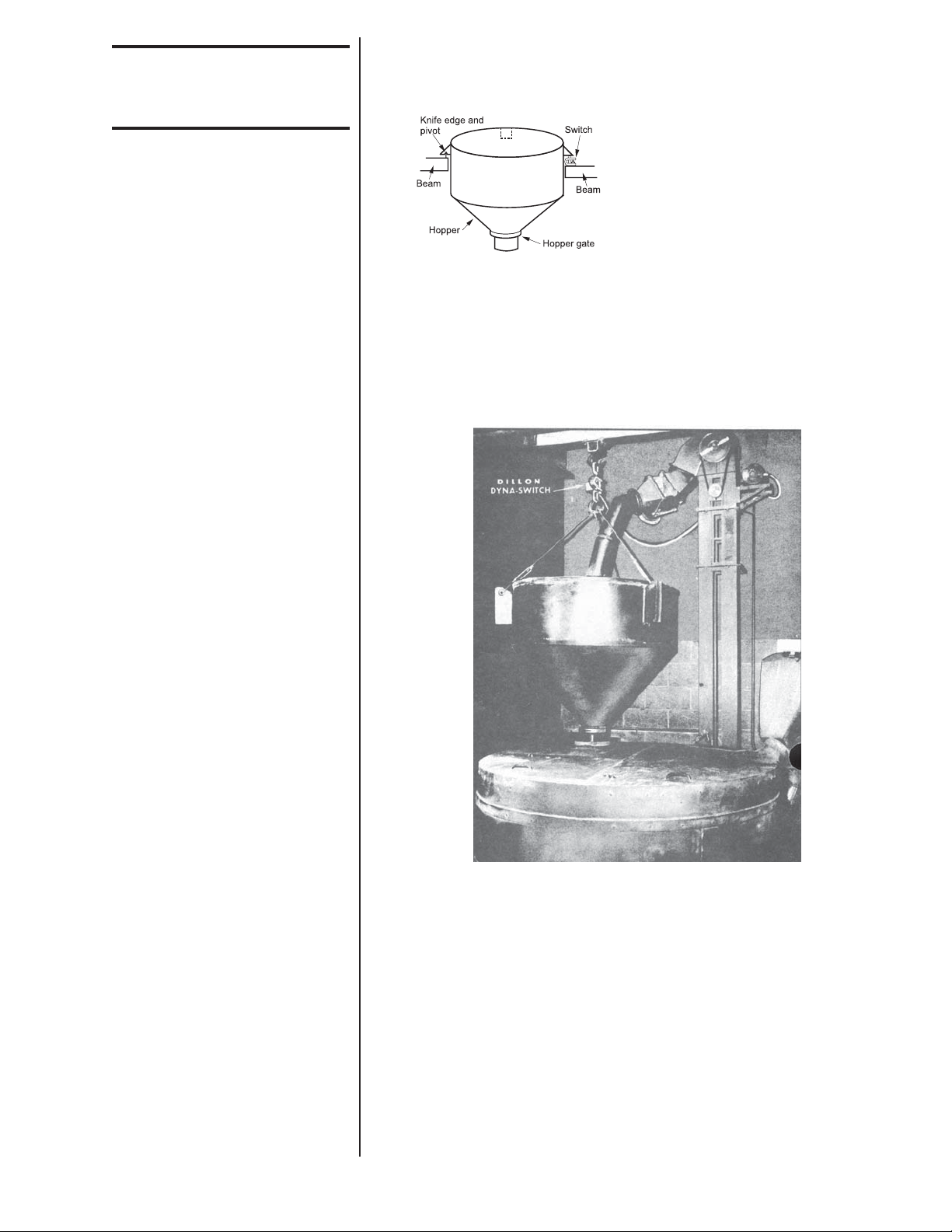

Figure 2-E and 2-F show other uses for the Dynaswitch when either

tension or compressions loads are present.

Batching operations at preset load

points are greatly simplified by

means of economical Dillon

Dynaswitches. Figure 2-E shows a

typical hopper with 3 point suspension. Dynaswitch under one suspension point is set for 1/3 maximum load. It opens hopper gate

automatically at this point. Contents

Figure 2-E

of tank should preferably be liquid,

since solid materials tend to pile

and cause erroneous results.

Figure 2-F

Figure 2-F shows an example of using the Dynaswitch in an automatic

control function. Sand used in foundry operations is brought up from the

floor below by conveyor. It falls into the chute and then spills into the

hopper. The hopper itself is suspended from the Dynaswitch at upper left.

The Dynaswitch is set to open the conveyor motor circuit at 1000 pounds

which represents a full hopper. At the same instant, a trap in the bottom of

the hopper also opens permitting contents to flow out into a mixer below. A

time delay switch on the hopper trap holds it open until all sand has been

discharged at which time the reduced load on the Dynaswitch causes it to

again close the conveyor motor circuit and repeat the cycle endlessly.

The Dynaswitch is also acting as a precision scale since it is set to function at a specific load point. Any form of batching operation can be easily

automated by this simple arrangement.

11

Page 12

2-5

Dynaswitch Selection

To pick the proper sized Dynaswitch for the job, do the following:

1. Determine the mounting position.

2. Calculate the load to be applied to the Dynaswitch.

3. Refer to Table 1-1 to select a Dynaswitch with the proper capacity and

minimum/maximum set point range.

2-6

Dynaswitch Field

Installation Procedures

2-6-A

Wiring the Compression

Model Dynaswitch

2-6-B

Wiring the Tension Model

Dynaswitch

You can put together a test

assembly consisting of an

indicator light or horn, a power

source and two leads with

alligator clips to simulate the

machinery’s control circuit.

Loads applied to compression Dynaswitches cause the force beam legs to

deflect and come closer together. Loads applied to tension units cause the

force beam legs to deflect outward and spread apart. Microswitches are

S.P.D.T. and have three contact terminals. One is normally open, one

normally closed, and one is common. Therefore they can be wired to

make or break a circuit at specific set point(s).

To make a circuit:

1. on increasing compression load, use common and normally open

contacts.

2. on decreasing compression load, use common and normally closed

contacts.

To break a circuit:

1. on increasing compression load, use common and normally closed

contacts.

2. on decreasing compression load, use common and normally open

contacts.

To make a circuit:

1. on increasing tension load, use common and normally closed contacts.

2. on decreasing tension load, use common and normally open contacts.

To break a circuit:

1. on increasing tension load, use common and normally open contacts.

2. on decreasing tension load, use common and normally closed

contacts.

Any time the Dynaswitch is

removed from the machinery and reinstalled, you

must check the switch

operation. Failure to do so

could result in inaccurate

actuation as the calibration

could change.

12

Page 13

2-6-C

Setting the Set Points

1. Figure the desired set point, in pounds, for each microswitch. In

setting two, three or four switches, set the highest set point first, then

work down according to weight. Any other sequence will cause a

shutdown during the adjusting process.

2. Turn the adjustment screw: In compression models, back the

adjustment screw as far as it will go

away from the switch plunger.

In tension models, turn the adjustment screw as far as it will go into the

switch plunger without damaging the

switch.

3. Apply a load on the unit equal to the desired setting. You must apply

an accurately measured load because the set point accuracy will be

no better than the known accuracy of the measured load.

4. Slowly turn the adjustment screw:

In compression, turn the screw until it

is just low enough to actuate the

switch. Then tighten the jam nut to

hold the adjustment.

In tension, turn the screw until it is just

high enough to actuate the switch

plunger. Then tighten the jam nut to

hold the adjustment.

5. Remove, then reapply the load to check the set point. It is properly set

if the machinery, or the test assembly, functions as planned within

desired tolerances.

6. Repeat steps 1-5 as many times as required to obtain correct settings.

Your Dynaswitch is now ready to use. It is recommended that you double

check your installation before beginning operation.

13

Page 14

Low Differential Travel Switch

(For 100, 1,000 and 5,000 lb beams only)

Circuitry

Single pole

Double throw

Electrical Data

UL Rating:

5 AMPS, 125 or 250VAC

Weatherproof Low Differential Travel Switch

(For 2,000, 10,000, 25,000 and 50,000 lb beams only)

Electrical DataCircuitry

UL Rating: L 74

15 AMPS, 125, 250 or 480 VAC;

2 AMPS, 600 VAC;

Single pole

Double throw

1/8 HP, 125 VAC; 1/4 HP, 250 VAC;

.5 AMPS, 125 VDC; .25 AMP 250 VDC.

Explosion-Proof Switch

(For 2,000, 10,000, 25,000 and 50,000 lb beams only)

Electrical DataCircuitry

UL Rating: L 23

20 AMPS, 125, 250 or 480 VAC;

10 AMPS, 125 VAC “L”;

Single pole

Double throw

1 HP, 125 VAC; 2 HP, 250 VAC;

.5 AMPS , 125 VDC; .25 AMP 250 VDC.

Weatherproof Low Differential Travel Switch

(For 100, 1,000 and 5,000 lb beams only)

Electrical DataCircuitry

5 AMPS Res., 3 AMPS Ind., (Sea level),

4 AMPS Res., 2 AMPS Ind., (50,000 feet)

28 VDC

Single pole

Double throw

5 AMPS Res. or Ind. 115 VAC, 60 Hz.

UL/CSA Rating: 5 AMPS, 250 VAC.

14

Page 15

Section 3 Operation

3-1

Safety Shutdown

Function

3-2

Decreasing Load

Operation

3-3

Automation Operation

DO NOT override the safety shutdown circuit. This can result in injury to

workers and damage to equipment.

Ensure that the Dynaswitch triggers both the increasing and decreasing

load function as planned. Stop the machinery and adjust the switch or

setup if a problem exists.

Ensure the automated machinery setup is working properly. If it is not, stop

the machinery and adjust either the Dynaswitch or the other components

of the setup until it does work properly.

Section 4 Maintenance

4-1

General Instructions

4-2

Service Instructions

Service the Dynaswitch at least once every six months (more often if it is

exposed to extreme climate or working conditions) according to paragraph

4-2, below. In addition, check the accuracy of the microswitch at least

once every six months (more often if it is part of a setup which receives

frequent use) and reset the microswitch as required. Switch setting

procedures are outlined in paragraph 2-6.

A. Attachment Fittings - Check for unusual wear, deformation, looseness

B. Micro-Switches - Replace if wires are frayed or if the connection

C. Overload Stop - Make sure no foreign material is present in overload

D. Adjustment screws, overload devices, switch and screw mounting

and corrosion. Replace if damaged or loose. Clean off corrosion; oil

compression steel ball fitting as required.

plunger or housing is damaged in any way.

stop gap, since this could cause errors.

brackets - Replace the component if it is damaged or deformed

enough not to work as designed.

E. Force Beams - Cleaning corrosion and painting are the only authorized

services. If the force beam has suffered damage or permanent

deformation, replace the entire Dynaswitch.

15

Page 16

4-3

Authorized

Replacement

A. Attachment Fittings - The customer is authorized to replace only

shackle and pin attachment fittings at their facility. Customers desiring

replacement of any other attachment fitting must return the

Dynaswitch to Dillon or a factory authorized distributor for attachment

fitting replacement. The reason for this is that all attachment fittings

other than shackles and pins are pinned to the force beam after

assembly.

B. Microswitches - Addition and replacement of microswitches, as well as

conversion from one type to another is authorized as long as the user

orders the proper Dillon microswitches. Microswitch mounting brackets and adjustment screw mounting brackets are available for all

authorized configurations. Switch calibration is required after such

service.

C. Other Parts - The replacement of parts other than shackle and pin

attachment fittings, authorized microswitches and microswitch mounting hardware is not authorized. Attempting to make unauthorized

repairs on the Dynaswitch automatically voids the Dillon warranty.

4-4

Troubleshooting

Problems are generally limited to the Dynaswitch actuating too soon, too

late or not at all.

Recommended troubleshooting procedure:

A. Ensure there is power to the circuits involved.

B. Reset the microswitches.

C. Check the microswitch and the circuit for continuity.

D. Check the functions of the machinery setup (for items that would

cause improper actuation).

Most problems will be found in one of these areas.

Excessive wear in attachment fittings is caused by excessive loading,

improper installation or abnormal machinery travel. Replace damaged

fittings and correct the machinery installation or loading problem.

16

Page 17

Section 5 Cranegard® Load Limit Switch

5-1

Introduction

5-2

General Description

5-3

Safety Factor

The Dillon Cranegard Load Limit Switch is used to protect cranes and

hoists against overloading where it is impossible or inconvenient to use a

Dillon Dynaswitch. This unit can be applied to wire rope without cutting or

removing the dead end from its existing mount. It may also be used on

machinery such as elevators to provide a switch action at a given load.

The Cranegard is intended for applications with gradually applied tensions

and not dynamic or impact loads.

The Dillon Cranegard Load Limit Switch is designed to clamp directly onto

typical hoist or crane rope. It consists of two side plates. Two steel

sheaves which are equipped with precision bearings, a rope clamp and

center support which in turn is attached to a flexure. Arm(s) on the flexure

can actuate as many as four microswitches at preset load points. Adjustment screws for the switches are located under a sealed cover.

The Dillon Cranegard Load Limit Switch flexure beam has a safety factor

of 2:l. Ultimate safety factor is a function of wire rope condition. In the

interest of safety, damaged or worn wire rope should be replaced.

5-4

Micro-Switches

The microswitch is type BZG1-2RN, weatherproof, Dillon P/N 17981-0048

(paragraph 1-7). As many as four switches can be installed on one

Cranegard unit.

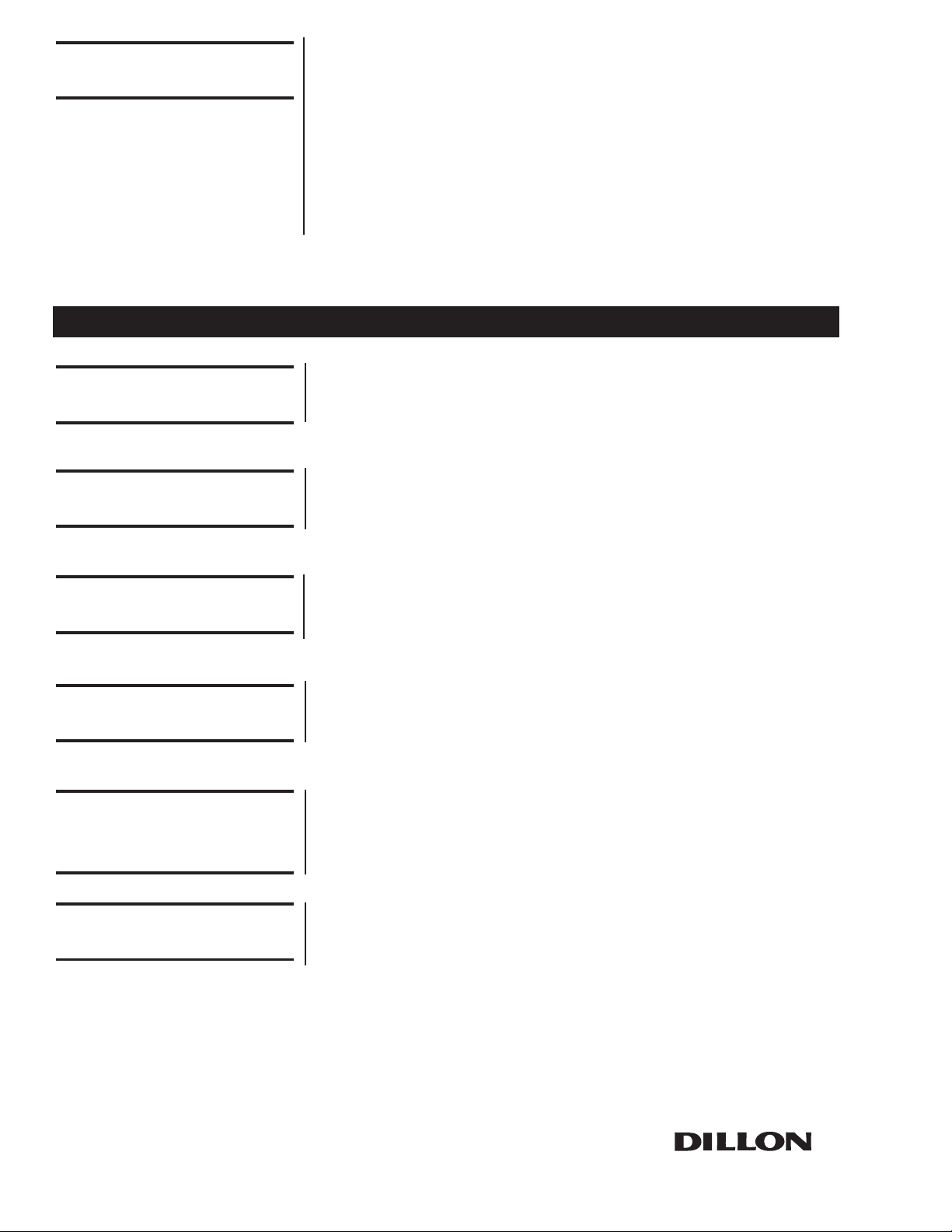

Table 5-1, below, indicates capacities and other specifications.

5-5

Key Specifications

Table 5-1

Part Capacity Min. Set Repeatability Rope Diameter Inches

Number Pounds Point Lb Pounds

CGS-1 2500 100 75 3/16 1/2

CGS-2 5000 200 150 3/8 7/8

Minimum Maximum

CGS-3 10000 400 300 7/16 7/8

CGS-4 20000 800 400 5/8 1 1/4

17

Page 18

Section 6 Installation

6-1

Mounting Positions

The best mounting position for the Cranegard Load Limit Switch is adjacent to the wire rope dead end point. It also could be installed adjacent to

the equalizer sheave where wire rope movement is small (a few inches).

The amount of wire rope movement around the equalizer sheave should

be measured by marking the wire rope, noting the amount of movement,

and allowing enough clearance for such movement when mounting the

Cranegard unit.

6-2

Selection

18

Figure 6-A

To pick the proper size Cranegard Load Limit Switch for the job, do the

following:

A. Measure the diameter of the rope on which the Cranegard Load Limit

Switch is to be installed.

B. Calculate the maximum load to be applied to the Cranegard Load Limit

Switch, using capacity of the hoist or crane and number of parts of line

to the hook (refer to 2-3).

C. Choose the number of switches and set point.

D. Refer to table 5-1 for proper selection.

Page 19

6-3

Cranegard Field

Installation Procedures

A. The Cranegard is designed to be mounted on a slack line. If line is not

slack, methods should be employed to shunt load in the cable area

where Cranegard will be installed. Often wire grips and portable

winches are used to accomplish this.

B. Position the Cranegard at the desired location on wire and loosely attch

the clamp wit the included screws. Tighten the screws so that the

cable is loosely gripped between the top and the bottom of the clamp.

Insure the same gap exists between the upper and lower clamps on

both sides.

C. Check switch operation using a voltmeter or other method for monitor-

ing open/closing of switch contacts. If specific loads were indicated at

the time of order, Dillon will calibrate to these values at the factory

prior to shipment. Once installed, there may be diffrences between

calibration and actual trigger values. Differences in rope type &

diameter, temperature, and external mechanisms (such as sheaves)

can affect the switch activation points. If more precise calibration is

required, it should be calibrated under the conditions used.

D. If field calibration is required, follow the additional instructions below.

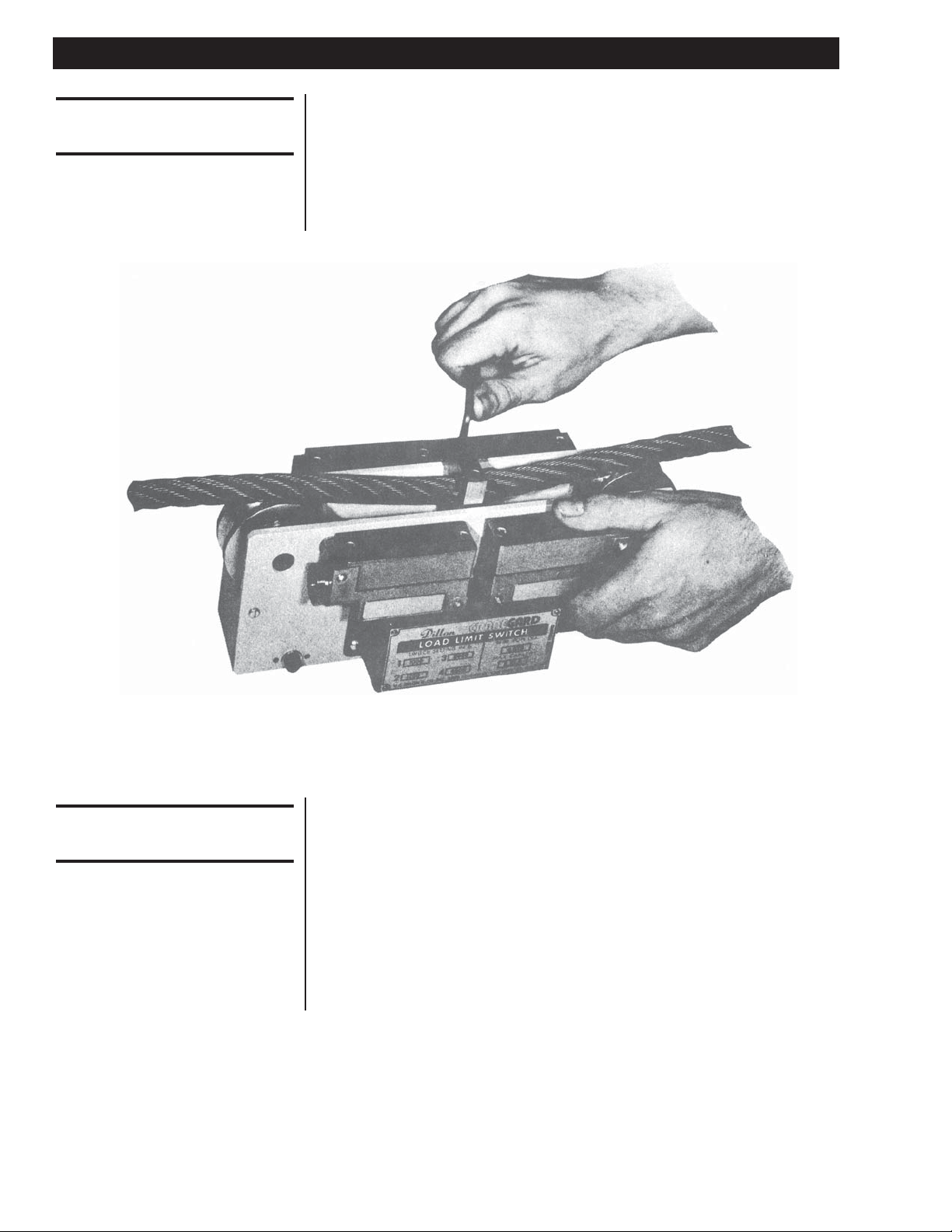

E. Remove the protective cover to expose adjustment screws.

F. Refer to Paragraph 2-6, Notes 1 and 2, for information on construction

of a test assembly for switch adjustment.

G. Figure the desired set point for each microswitch. In setting two, three

or four switches, set the highest set point first, then work down according to weight. Any other sequence will cause a shutdown during the

adjusting process.

H Turn the adjustment screw(s) counterclockwise, away from the

microswitch plunger(s) as far as possible.

I. Apply the trigger load, insuring that the cutoff load is approached from

the desired direction. For increasing loads, such as overload detection,

gradually apply the load. For decreasing loads, such as slack-line

detection, apply at least 5% more load (of Cranegard capacity) than is

desired for switch trigger, then gradually reduce the load until trigger

load is reached.

J. Slowly turn the adjustment screw until it contacts the microswitch

plunger and the switch actuates. Then tighten the jam nut to hold the

adjustment.

K. Remove, then reapply the load to check the set point. It is properly set

if the machinery (or the test assembly) functions as planned within

desired tolerances.

L. Repeat steps G through K as many times as required to obtain correct

settings.

Figure 6-B

19

Page 20

6-4

Electrical Wiring

Micro-switch(es) are S.P.D.T. and have three contacts. One is normally

open, one normally closed, and one is common. Therefore they can make

or break a circuit (start or stop an operation) at a specific set point(s).

Any time the Dynaswitch is

removed from the machinery and reinstalled, you

must check the switch

operation. Failure to do so

could result in inaccurate

actuation as the calibration

could change.

To BREAK a circuit at a set point as load increases, select normally closed

and common switch terminals. To MAKE a circuit as load increases, wire

to normally open and common terminals.

To BREAK a circuit at a set point as load decreases, wire to common and

normally open terminals. To MAKE a circuit as load decreases, wire to

common and normally closed terminals.

Section 7 Maintenance

7-1

General Instruction

7-2

Mechanical Inspection

Depending on environmental and working conditions, Cranegard Load

Limit Switches should be inspected periodically, at least every six months.

Cranegard Load Limit Switches should be free from any contact friction of

adjacent wire rope.

7-3

Electrical Inspection

7-4

Switch Setting

7-5

Authorized Parts

Replacement

7-6

Troubleshooting

Check for frayed wires, damage to the microswitch housing and protective

cover.

Check established operating setting(s). If necessary, the switches should

be reset.

Type BZG1-2RN microswitches are the only authorized parts replacements for Cranegard Load Limit Switches. Attempting to make unauthorized repairs to the Cranegard Load Limit Switch automatically voids the

Dillon warranty.

Follow the procedure for the Dynaswitch in section 4-4.

Dillon

A division of Weigh-Tronix Inc.

1000 Armstrong Dr.

Fairmont, MN 56031 USA

Telephone: 507-238-4461

Facsimile: 507-238-8258

e-mail: dillon@weigh-tronix.com

www.dillon-force.com

Weigh Bar® is a registered trademark of Weigh-Tronix Inc.

11/06/03 DS&CG_U.P65 PN 16947-0010G e2 Printed in USA

Force Measurement Products & Systems

Loading...

Loading...