Page 1

illon

AT 500

Instruction Manual

Version 3.3

recision

Products, Inc.

Page 2

2

Table of Contents

Subject Page #

AT 500 Parts List 2

AT 500 Machine Schematic 3

Minimum Equipment to Begin Reloading 4

Reloading Safety 4

Parts List 4

Mounting the AT 500 to Your Bench 5

Configuring the AT 500 5

Changing Shellplate Position 5

Caliber Conversion Chart 6

Changing Primer Size 7

The Toolhead 7

Setting Up to Load Rifle Ammunition 8

Setting Up to Load Pistol Ammunition 11

The Reloading Process 13

AT 500 Upgrades and Accessories 15

Dillon Precision Products, Inc.

8009 E. Dillon’s Way

Scottsdale, AZ 85260

(480) 948-8009

(480) 998-2786 FAX

For Technical Assistance

or to place an order call: (800) 223-4570

For an issue of the Blue Press: call:

(800) 762-3844

For additional product information,

see our web site at:

www.dillonprecision.com

#16618 Spot Manuals AT500 Folder AT500 Manual. V 3.3 9/01 WJC

AT 500 Parts List

Part # Description

13409 Crank

13435 1/4” Hex Wrench

13583 Link Arm, Left

13593 5/32” Hex Wrench

13650 Spent Primer Cup

13700 Link Arm Pin

13728 1/8” Hex Wrench

13738 Rod Washer, #10

13747 Link Arm w/ Hook, Right

13757 Seating Punch, Small

13775 Main Shaft

13781 Platform

13789 Main Shaft Pin Set Screw

13794 Shellplate Bolt

13817 10-32 Kep Nut

13824 Primer Cup, Large

13825 Primer Cup, Small

13830 Main Shaft Pivot Pin

13834 Solid Link Arm Pin, Left

13841 Nylock Nut

13881 Hollow Link Arm Pin, Right

13886 3/32” Hex Wrench

13890 Spring Washer

13891 Index Ball

13904 Bellcrank Bolt

13909 Toolhead

13923 Brass Tip Set Screw

13966 Platform Mount Bolt

13967 Seating Punch, Large

13996 10-32 x 3/16 Set Screw

13997 Index Ball Spring

14008 Toolhead Pin

14013 Roller Bracket Screw

14033 Primer Cup Spring

14280 Roller Bracket Assembly

13719 Cartridge Spring Screw

13926 Cartridge Spring

16609 Conversion Kit

16610 Universal Shellplate

16611 Shellplate Cover

16612 Primer Punch Holder

16617 Plastic Funnel

16629 Powder Die

20094 Frame

20636 Handle, Knob & Nut Assembly

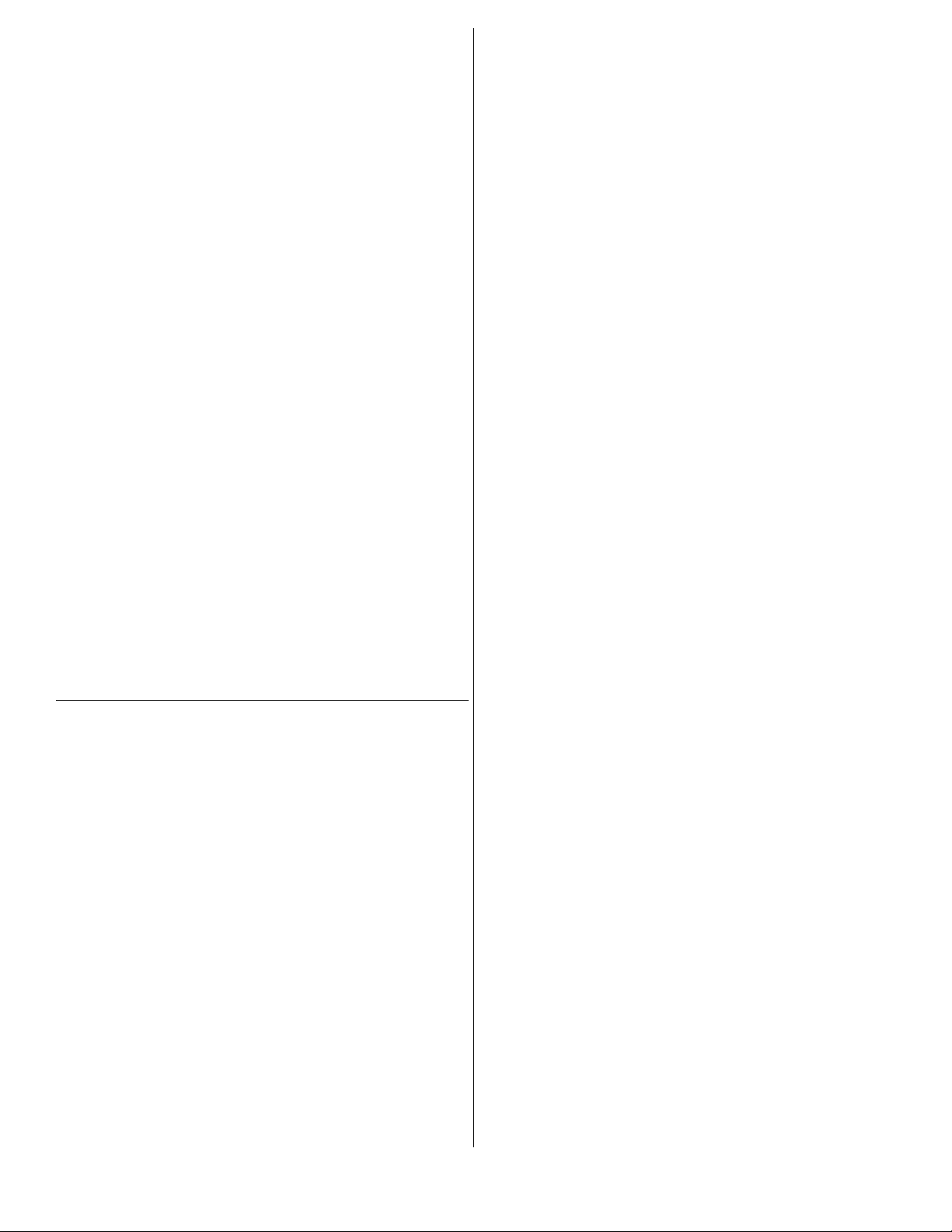

Not all items are shown in schematic illustration.

2

Page 3

13794

16611

16610

13966

13781

14033

16612

13996

13757 (Small)

13967 (Large)

13825 (Small)

13824 (Large)

14280

assembly

14013

13881

20094

13891

13997

Locator

Buttons

14008

16617

16629

13996

13909

13904

13738

See box above

for more detail.

13834

13817

13923

13747

13650

20636

Assembly

13775

13890

13841

13409

13789

13830

13700

13890

13841

13583

AT 500 Schematic

3

Page 4

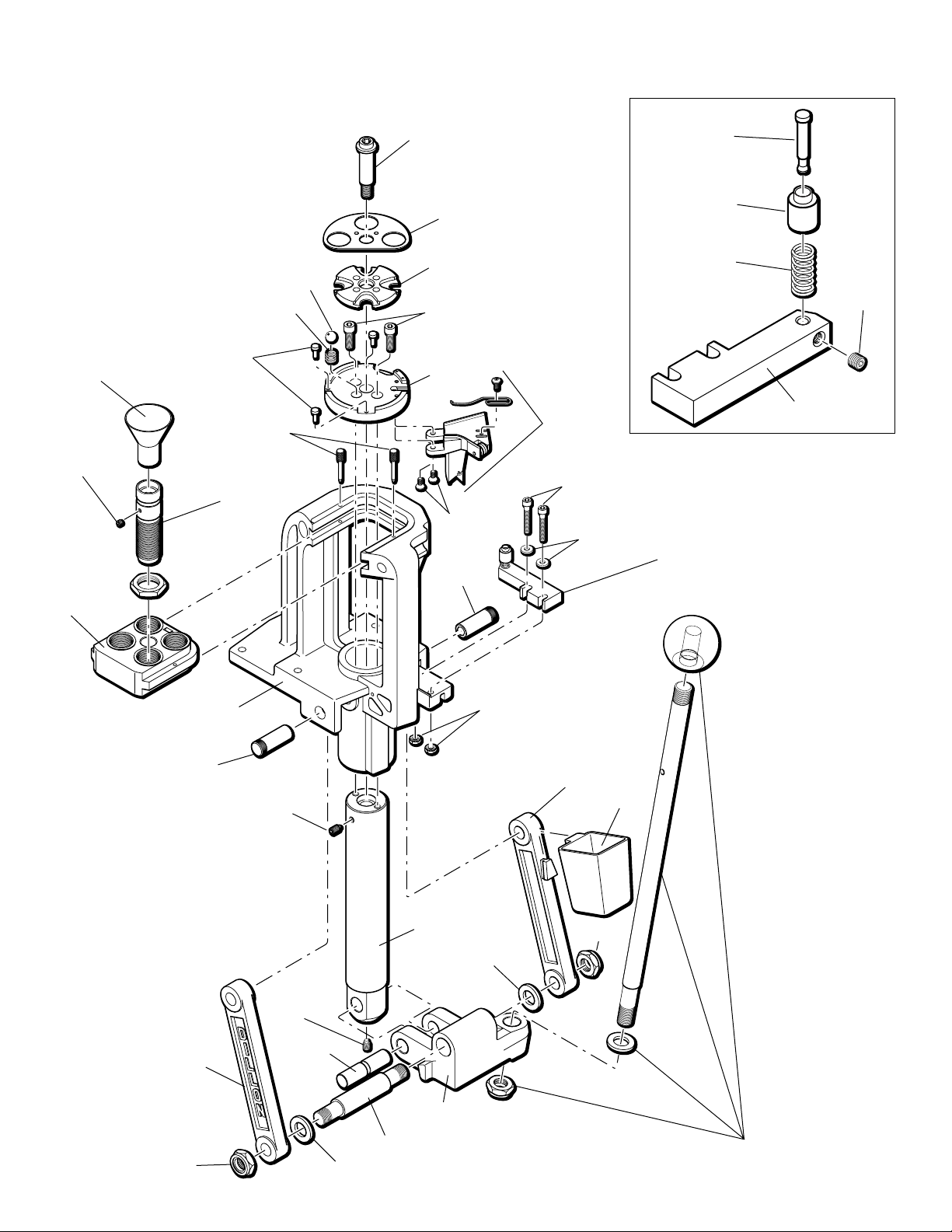

Suggested Minimum Equipment

to Begin Reloading

(Figure 1)

1) Powder scale

2) Dies

3) Loading manual

4) Case lubricant (for bottlenecked cases)

5) Safety glasses

6) Primer flip tray*

7) Dial calipers*

(*Not absolutely essential, but pretty handy.)

Figure 1– Minimum equipment needed to begin reloading.

Reloading Safety

At this point you’re anxious to finish your assembly

and start cranking out rounds. But for your own safety,

stop now and read the following:

Reloading small arms ammunition involves the use of

highly explosive primers and powder. Handling these

materials is inherently dangerous. You should recognize

this danger and take certain minimum precautions to

lessen your exposure to injury.

Never operate the machine without ear and eye protection on. Call our customer service department at (800) 2234570 for information on the wide variety of shooting/safety glasses and hearing protection that Dillon has to offer.

• PAY ATTENTION: Load only when you can give your

complete attention to the loading process. Don’t watch

television or try to carry on a conversation and load at the

same time. Watch the automatic systems operate and make

sure they are functioning properly. If you are interrupted

or must leave and come back to your loading, always

inspect the cases at every station to insure that the proper

operations have been accomplished.

• SMOKING: Do not smoke while reloading or allow anyone else to smoke in your reloading area. Do not allow

open flames in reloading area.

• SAFETY DEVICES: Do not remove any safety devices

from your machine or modify your machine in any way.

• LEAD WARNING: Be sure to have proper ventilation

while handling lead components or when shooting lead

bullets. Lead is known to cause birth defects, other reproductive harm and cancer. Wash your hands thoroughly

after handling anything made of lead.

• LOADS AND LENGTHS: Avoid maximum loads and

pressures at all times. Use only recommended loads from

manuals and information supplied by reliable component

manufacturers and suppliers. Since Dillon Precision has no

control over the components which may be used on their

equipment, no responsibility is implied or assumed for

results obtained through the use of any such components.

Seat bullets as close to maximum cartridge length as

possible. Under some conditions, seating bullets excessively deep can raise pressures to unsafe levels. Refer to a reliable loading manual for overall length (OAL).

• QUALITY CHECKS: Every 50-100 rounds, perform periodic quality control checks on the ammunition being produced. Check the amount of powder being dropped and

primer supply.

• RELOADING AREA: Keep your components safely

stored. Clear your work area of loose powder, primers and

other flammables before loading.

• COMPONENTS: Never have more than one type of

powder in your reloading area at a time. The risk of a mixup is too great. Keep powder containers closed.

Be sure to inspect brass prior to reloading for flaws,

cracks, splits or defects. Throw these cases away.

Keep components and ammunition out of reach of

children.

• BLACK POWDER: Do not use black powder or black

powder substitutes in any Dillon powder measure.

Loading black powder cartridges requires specialized loading equipment and techniques. Failure to do so can result

in severe injury or death.

• PRIMERS: Never force primers. If they get stuck in the

operation of the machine, disassemble it and gently

remove the obstruction.

Never attempt to clear primers that are stuck in either

the primer pickup tube or the primer magazine tube.

Never, under any circumstances, insert any type of rod to

attempt to force stuck primers out of these tubes. Trying to

force primers out of the tube will cause the primers to

explode causing serious injury or even death.

If primers get stuck in a primer magazine or pickup

tube flood the tube with a penetrating oil (WD-40), throw

the tube in the garbage and call us for a free replacement.

Never attempt to deprime live primers – eventually one

will go off. When it does it will detonate the others in the

spent primer cup. Depriming live primers is the single

most dangerous thing you can do in reloading and can

cause grave injury or death.

• LOADED AMMUNITION: Properly label all of your

loaded ammunition (Date, Type of Bullet, Primer, Powder,

Powder Charge, etc.).

4

Page 5

5

• BE PATIENT: Our loading equipment is conservatively

rated and you should have no trouble achieving the published rates with a smooth, steady hand. If something

doesn’t seem right, stop, look and listen. If the problem or

the solution isn’t obvious, call us. The reloading bench is

no place to get into a hurry.

We have done everything we know how to make your

machine as safe as possible. We cannot, however, guarantee your complete safety. To minimize your risk, use common sense when reloading and follow these basic rules.

• REMEMBER: If your machine does not perform to your

expectations, or if you are having technical difficulties,

give us a call. Technical Support (800) 223-4570

All electrical/electronic components in Dillon equipment are covered by a one-year warranty.

Your AT 500 comes complete with:

• AT 500 Machine

• Operating Handle Assembly including:

Handle Shaft

Handle Knob

Nylock Nut and Washer

• Accessory Bag including: (Figure 2)

Small Primer Cup and Pin

Note: The Large Primer Assembly comes installed in

the machine.

Plastic Funnel

Spent Primer Cup

Hex Wrenches: 1/8”, 1/4”, 5/32” and 3/32”

Powder Die with Lock Ring

• Conversion Kit including: (Figure 2)

Powder Funnels: A, B and K for Rifle – W, E, D

and F for Pistol calibers

Locator Pins: #1, #2 and #3

Double-check now to make sure all the parts needed

are present. (Figure 2)

Figure 2– A) Spent Primer Cup B) Plastic Funnel C) Hex

Wrenches D) Powder Die with Lock Ring E) Powder

Funnels F) Small Primer Cup and Pin G) Locator Buttons

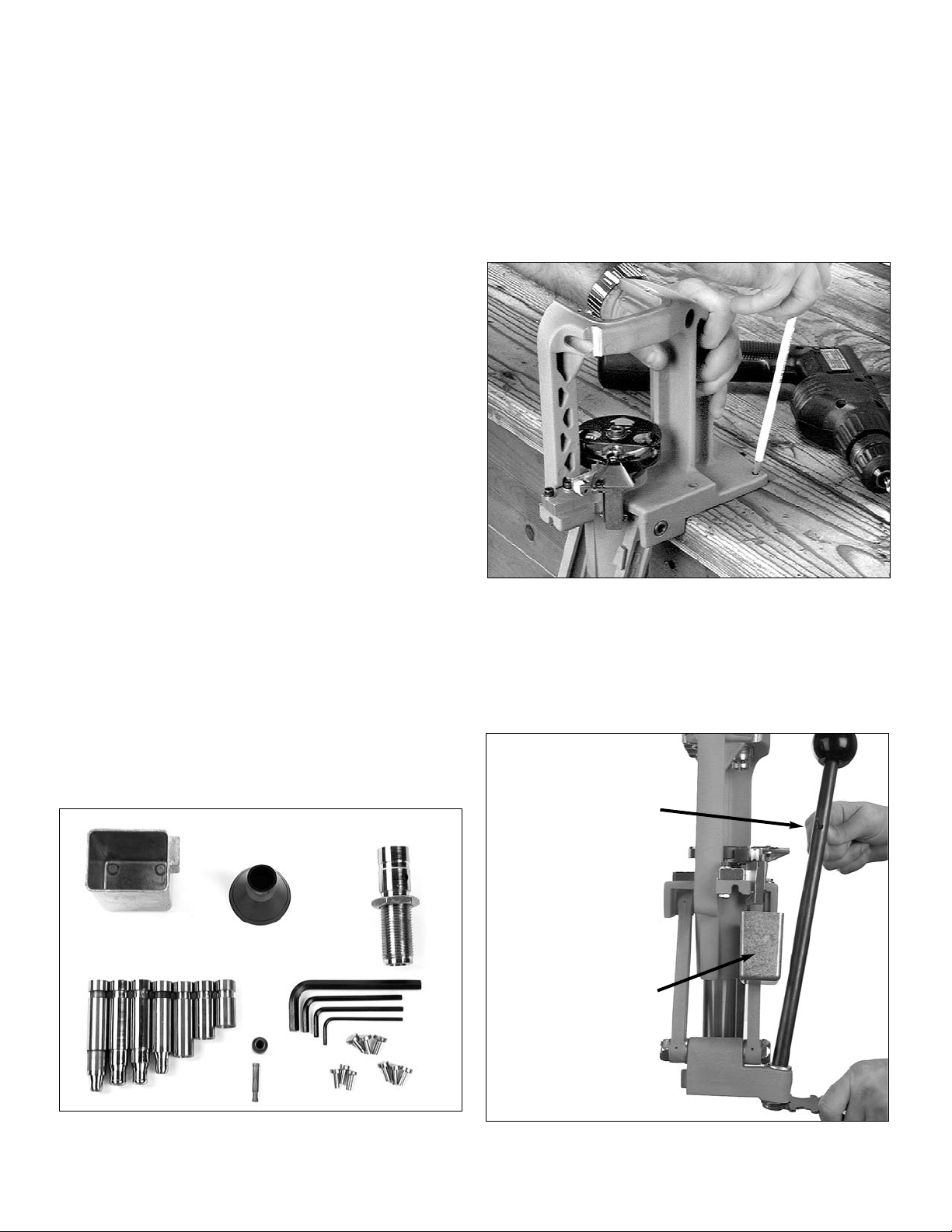

MOUNTING THE AT 500

TO YOUR BENCH

Place your AT 500 on the edge of a sturdy bench or

table where you plan to mount it. Give yourself about 12

inches of work space on each side of the machine to allow

room for components.

Using the machine itself as a template, mark and drill

four 1/4” holes in your bench and bolt your AT 500

securely to it. (Figure 3)

Figure 3 – Using the reloader as a template to mark your bench.

Avoid using wood or lag screws to mount your

reloader to the bench. These types of screws can loosen

over time.

CONFIGURING THE AT 500

Install the handle and spent primer cup. (Figure 4)

Figure 4 – Installation of the handle and spent primer cup.

A

B

C

D

E

F

G

Spent

Primer

Cup

Use hole in handle

for leverage while

tightening nut.

Page 6

6

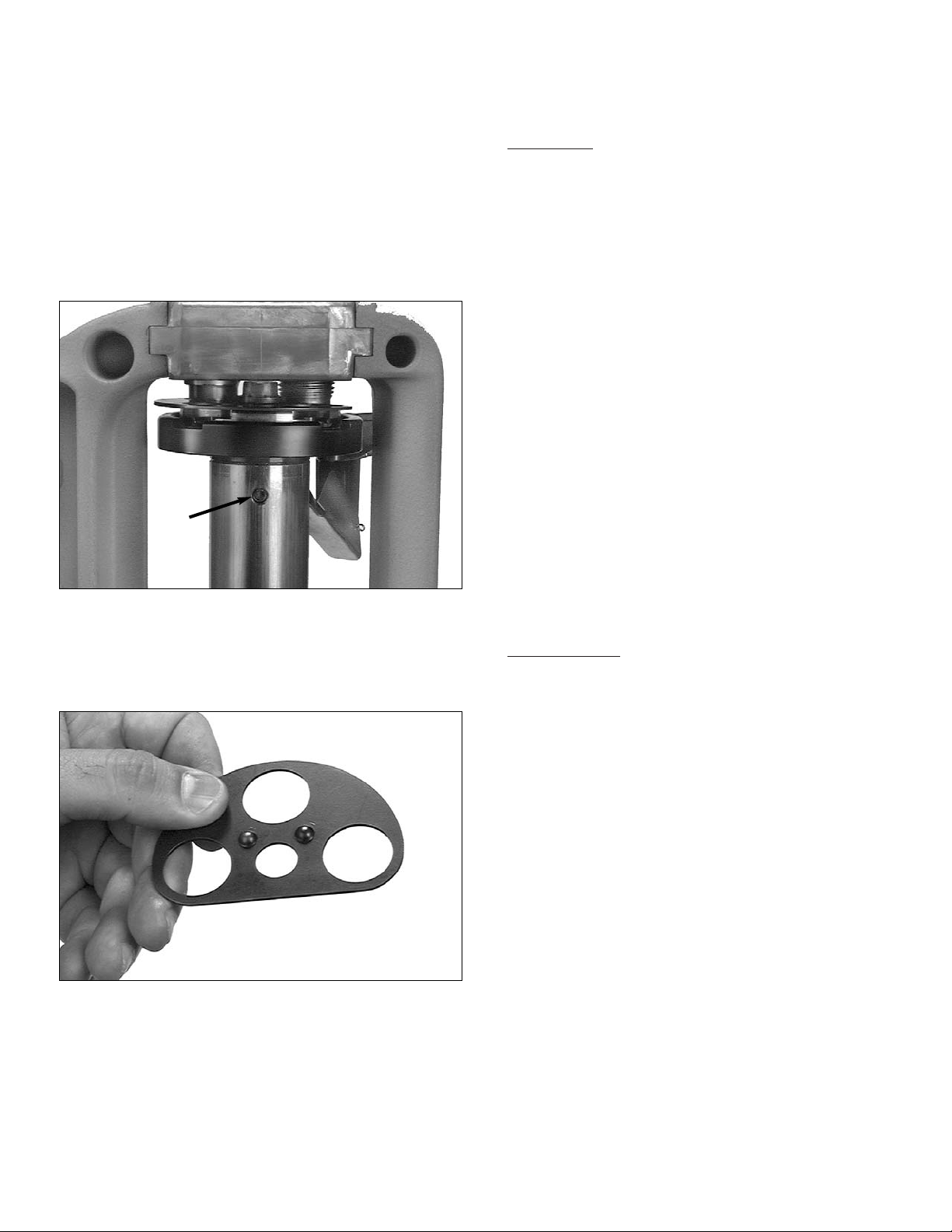

Changing Shellplate Position

Your AT 500 is shipped with the “universal” shellplate

installed. The “universal” shellplate has four shellholder

slots: #1, #2, #3 and #5. This allows you to reload a wide

variety of calibers.

All AT 500 reloaders are shipped with the #1 slot visible. If the caliber you wish to load requires one of the

other slots on the shellplate (see the caliber conversion

chart on page 3 to be sure), you may change this by first

loosening the brass-tipped set screw (Figure 5) at the top

left side of the shaft, just below the shellplate platform,

with the supplied 1/8” hex wrench.

Figure 5 – Location of the shellplate bolt set screw.

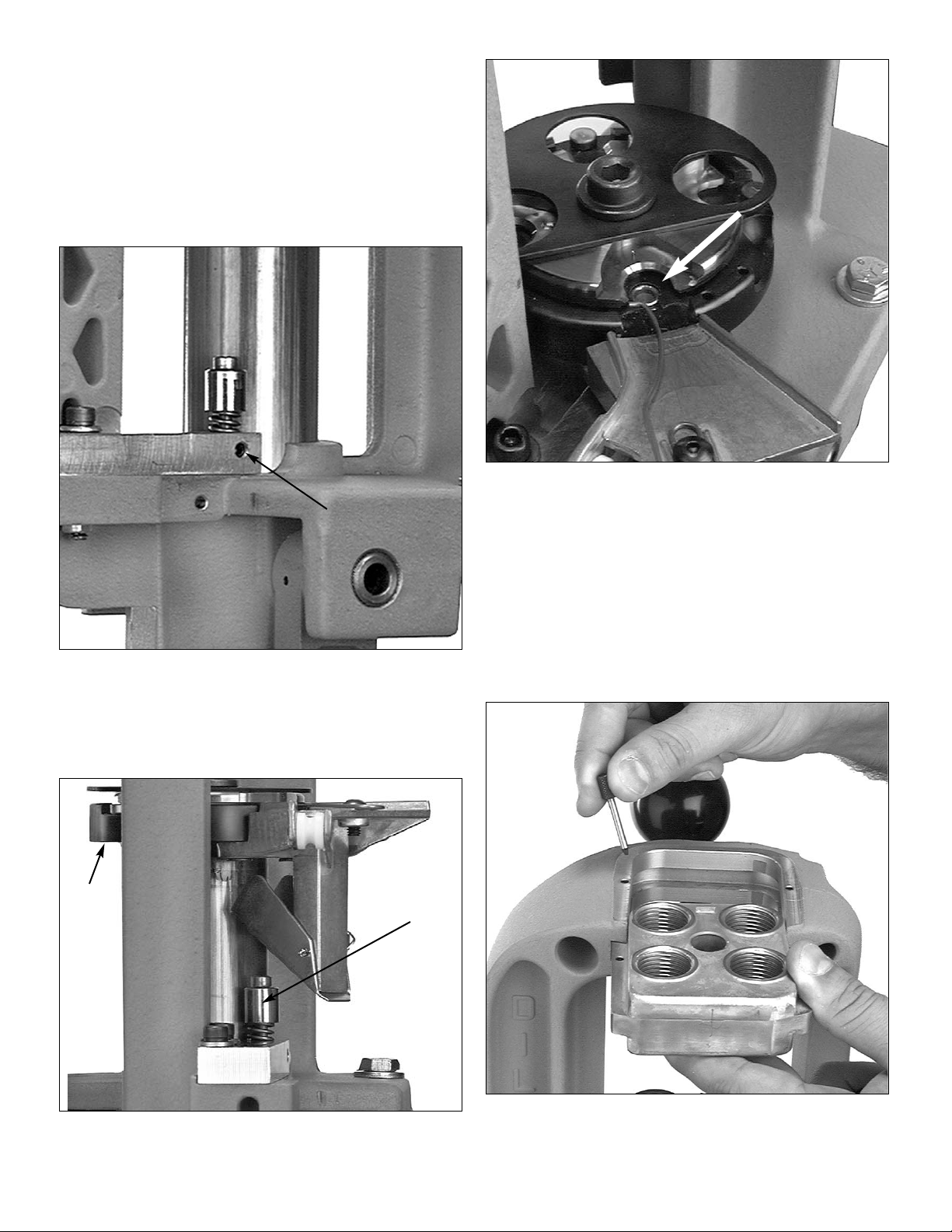

Next, loosen the shellplate bolt with the 1/4” hex

wrench. Then reposition the shellplate cover to display the

slot you desire to use. The shellplate cover has two dimples (Figure 6) to help you align it with the shellplate.

Figure 6 – Locator “dimples” on the AT 500 shellplate cover.

Tighten the shellplate bolt with the hex wrench – then

back the shellplate bolt out about 1/4 turn so that you can

rotate the shellplate easily. There should be no looseness or

“slop” at this point. When you rotate the shellplate, you

should be able to feel and hear the shellplate “click” into

place. Re-tighten the brass-tipped set screw under the

shellplate platform to prevent the shellplate bolt from

rotating as the shellplate is indexed.

Caliber Conversion Chart

Caliber Shellplate Powder Locator

Slot Funnel Button

Rifle Calibers

.222 Rem. 3 A 3

.22-250 1 A 1

.223 Rem. 3 A 3

.240 Wby. Mag. 1 K 1

.243 Win. 1 K 1

.250 Savage 1 K 1

.25-06 1 K 1

.257 Roberts 1 K 1

.257 Ackley Imp. 1 K 1

.270 Win. 1 K 1

.284 Win. 1 K 1

.30-06 1 B 1

.308 1 B 1

.358 Win. 1 B 1

.35 Whelen 1 B 1

6mm Rem. 1 K 1

6.5-06 1 K 1

6.5x55 1 K 1

7mm-08 1 K 1

7.65x53 1 B 1

7x57 1 K 1

7.7 Arisaka 1 B 1

7mm B.R. 1 K 1

7mm Exp./280 Rem. 1 K 1

7mm Int’l Rim 1 K 1

7.5x55 Swiss 1 B 1

8x57 1 B 1

Handgun Calibers

.22 Rem. Jet 2 A 2

.221 Rem. Fireball 3 A A

.380 ACP 3 F 3

.38 Super 5 F 3

.38/.357 Mag./Max. 2 D 2

.357 SIG 5 F 2

.45 ACP 1 E 1

7 TCU 3 K 3

9mm 5 F 3

9x25 5 F 2

9x21 5 F 3

10mm/.40 S&W 5 W 2

Page 7

7

Changing Primer Size

Your AT 500 has been shipped to you with the large

primer bar installed and correctly adjusted to feed large

primers. If the caliber you have selected requires small

primers, you must change to the small primer cup and

pin. Do this by loosening the set screw and removing the

large primer cup and pin from the primer bar. Install the

small primer cup and pin. (Figure 7) Do not tighten the

set screw yet.

Figure 7 – To change the primer cup and pin, loosen this set

screw. See arrow.

This set screw needs to be loose in order to align the

primer cup with the platform. Lower the platform onto the

primer cup (Figure 8), then tighten the set screw while the

cup is in the platform. (Figure 9)

Figure 8 – Lowering the platform onto the primer cup.

Figure 9 – The primer cup, showing through the platform.

The Toolhead

Your new AT 500 is equipped with a removable toolhead. Additional toolheads are available from the factory

or your local Dillon dealer.

The advantage of this system is simple. Once you have

adjusted your dies just the way you want them, they can

stay that way. Plus, changing to another caliber becomes a

simple matter of pulling two pins and sliding the toolhead

out. (Figure 10)

Figure 10 – Removing the toolhead.

Before you begin loading, make sure that the toolhead

is secured by the toolhead pins.

Platform

Primer Cup

Page 8

8

Figure 11 – Toolhead/die station orientation.

SETTING UP THE AT 500 TO LOAD

RIFLE AMMUNITION

We are using the .30-06 cartridge as an example in this

section. The AT 500 machine comes to you with the

shellplate (with the #1 slot ready for use) and large primer

bar installed.

Station #1 – Install the sizing/decapping die here.

Figure 12 – Installing the sizing/decapping die in Station #1.

Move the handle down (which will raise the platform)

and thread the sizing/decapping die completely into the

toolhead until the die comes in contact with the shellplate.

Return the handle to its rest position (up).

Wipe a small amount of case lube on the body and neck

of an empty .30-06 cartridge case, then place the case into

the #1 slot. (Figure 13)

Figure 13 – Placing the cartridge case in the shellplate.

Move the handle down to resize and deprime the case.

Return the handle to its rest position.

Examine the case you just resized and deprimed. If a

case gage is available, insert the case into the gage to

(Figure 14) assure yourself that the case has been resized

properly. (The bottom of the case should be flush with the

bottom of the gage.)

Figure 14 – Inserting a case in a case gage.

Rotate the sizing/decapping die in or out as needed to

reach the proper case-to-gage fit. After the die is adjusted,

tighten the die lock ring to hold it in place. Advance the

case to Station #2.

Station #2 – Install the powder die and powder funnel here (We are using powder funnel “B” for the

.30-06 cartridge – See Figure 15)

11

11

22

22

33

33

44

44

Page 9

9

Figure 15 –Installing rifle powder funnel into the powder die.

Slide the funnel into the powder die and tighten the set

screw, assuring yourself that it has entered the groove in

the funnel. (Figure 16)

Figure 16 – The groove in the rifle powder funnel.

With the resized case in Station #2, move the handle

down and thread the powder die into the toolhead until

the funnel comes in contact with the case. Tighten the die

lock ring. Advance the case to Station #3.

Station #3 – Install the bullet seating die here.

Place a bullet on the empty case and move the handle

down. Thread the bullet seating die into the toolhead until

it comes in contact with the case/bullet. (Figure 17)

Figure 17 – Installing the bullet seating die in Station #3.

In 1/4 turn increments, thread the bullet seating die

clockwise while you move the handle up and down, until

the proper loaded length is reached. (Always use a loading

manual for loaded length information.) Tighten the die

lock ring and the lock ring on the seating stem. (Figure 18)

Figure 18 – Tightening the lock ring on the seating stem.

Examine the cartridge you’ve just assembled, checking

the overall length. Advance the cartridge to Station #4.

Page 10

10

Station #4 – Install the taper crimp die (if you’re

using a separate taper crimp die) here.

Figure 19 – Installing a taper crimp die in Station #4.

Move the handle down. Thread the taper crimp die into

the toolhead until it comes in contact with the cartridge. In

1/4 turn increments, thread the taper crimp die clockwise

while you move the handle up and down, until a crimp

appears on the mouth of the case. An average crimp

should be approximately .002 smaller than the case diameter. (Figure 20) Tighten the die lock ring.

Figure 20 – A properly crimped rifle cartridge.

Once you’ve installed all the dies in the toolhead, place

the black plastic funnel onto the powder die. Install the

three #1 (.30-06) brass locator buttons, included in the

parts bag, on the platform. (For other calibers, see caliber

conversion chart on page 3.) (Figure 21)

Figure 21 – Installing a brass locator button at Station #2.

The above example used a Dillon three-die set for

reloading the .30-06 rifle cartridges. Some die companies

offer two die-sets for some rifle calibers. With these sets,

the bullet seating die must be adjusted as follows:

Place a resized rifle case in Station #3. Install your

bullet seating die here. Remove the seating stem from

the seating die. Move the handle down and thread the

die into the toolhead until it comes in contact with the

case. Tighten the die lock ring. Return the handle to its

rest position.

Reinstall the seating stem approximately five turns.

Place a bullet on the empty case and move the handle

down. In 1/4 turn increments, thread the bullet seating

stem clockwise while you move the handle up and

down until the proper loaded length is reached. (Figure

22 – Always use a loading manual for loaded length

information.)

Tighten the lock ring on the stem.

Figure 22 – Using a dial caliper to check overall length.

Measure crimp here.

Page 11

11

SETTING UP THE AT 500 TO LOAD

PISTOL AMMUNITION

We are using the .45 ACP cartridge as an example in

this section. The AT 500 machine comes to you with the

shellplate (with the #1 shellplate slot ready for use) and

large primer bar installed.

Station #1 – Install the sizing/decapping die here.

Figure 23 – Installing a sizing/decapping die in Station #1.

Move the handle down (which will raise the platform)

and thread the die completely into the toolhead until the

die comes in contact with the shellplate. Tighten the die

lock ring. Return the handle to its rest position and insert

an empty cartridge case into the #1 slot. (Figure 24)

Figure 24 – Inserting an empty cartridge case in Station #1.

Move the handle down to resize and deprime the case.

Return the handle to its rest position. Advance the case to

Station #2.

Station #2 – Install the powder die and powder funnel “E” for the .45 ACP cartridge here.

Figure 25 – Insert a pistol powder funnel into the powder die.

Slide the funnel into the powder die and tighten the set

screw, assuring yourself that it has entered the groove in

the funnel. (Figure 26)

Figure 26 – The groove in the pistol powder funnel.

With the resized case in Station #2, move the handle

down and thread the powder die into the toolhead until

the funnel comes in contact with the case. In 1/4 turn

increments, thread the powder die clockwise while you

move the handle up and down until you begin to see a

minor bell shape appear on the mouth of the case.

Page 12

12

Figure 27 – A properly belled pistol case.

Tighten the die lock ring. Advance the case to Station #3.

Station #3 – Install the bullet seating die here.

Figure 28 – Installing the bullet seating die in Station #3.

Inspect the inside seating stem. Assure yourself that the

shape of the seating stem matches the bullets you will be

loading (i.e. round-nose, semi-wadcutter, etc.).

Place a bullet on the empty case and move the handle

down. Thread the bullet seating die into the toolhead until

it comes in contact with the case/bullet. In 1/4 turn increments, thread the bullet seating die clockwise while you

move the handle up and down, until the proper loaded

length is reached.

Figure 29 – Using a dial caliper to check overall length.

(Always use a loading manual for loaded length information.) Tighten the die lock ring. Examine the cartridge

you’ve just assembled. Advance the case to Station #4.

Station #4 – Install the taper crimp die here.

Figure 30 – Installing a taper crimp die in Station #4.

Move the handle down. Thread the taper crimp die into

the toolhead until it comes in contact with case/bullet. In

1/4 turn increments, thread the taper crimp die clockwise

while you move the handle up and down, until a crimp

appears on the mouth of the case. An average crimp is

approximately .002 smaller than the body diameter.

(Figure 30) Tighten the die lock ring to hold it in place.

Page 13

13

Figure 31 – A properly crimped pistol cartridge.

Once you’ve installed all the dies in the toolhead, place

the black plastic funnel onto the powder die. Install the

three #1 (for .45 ACP) brass locator buttons, included in

the parts bag, on the platform. (Figure 32)

Figure 32 – Installing a brass locator button in Station #2.

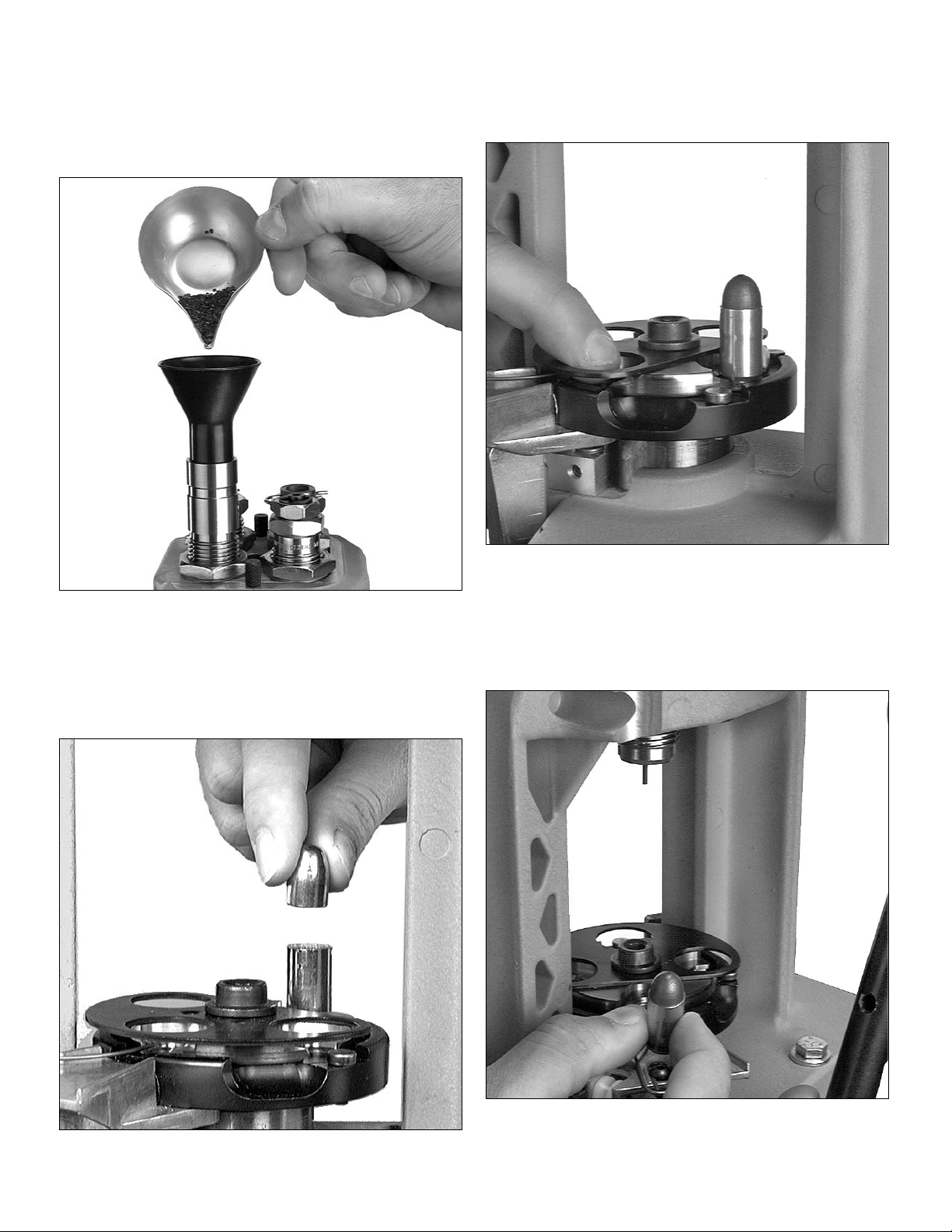

THE RELOADING PROCESS

The following is a list of items you will need before

you begin. (Figure 33)

1) Empty brass casings

2) Primers

3) Powder scale

4) Loading manual

5) Powder (see manual)

6) Bullets (see manual)

7) Dial calipers

8) Safety glasses

Figure 33 – What you will need to start loading.

To begin, place an empty case in Station #1 and move

the handle down. While the handle is in the down position, place a new primer in the primer cup. (Figure 34)

Return the handle to its rest position and insert the new

primer into the case by pushing the handle forward.

Figure 34 – Placing a primer in the primer cup at Station #1.

Measure crimp here.

Page 14

14

Place your left thumb on the shellplate cover and

advance the shellplate to Station #2. Move the handle

down. While the handle is in the down position, charge

the cartridge case by dispensing a properly weighed

amount of powder into the black plastic funnel. (Figure 35)

Return the handle to its rest position.

Figure 35 – Charging the case with powder at Station #2.

Place your right index finger on the shellplate cover

and advance the shellplate to Station #3. Place a bullet

on the case (Figure 36) and move the handle down, this

will seat the bullet into the case. Return the handle to its

rest position.

Figure 36 – Placing a bullet on the cartridge case at Station #3.

Place your right index finger on the shellplate cover

and advance the shellplate to Station #4. (Figure 37) Move

the handle down, this crimps the case around the bullet.

Return the handle to its rest position.

Figure 37 – Advancing the shellplate to Station #4.

Finally, grasp the finished cartridge with your right

hand while you advance the shellplate to Station #1 again.

Remove the completed cartridge from the machine. (Figure

38) Place the finished cartridge into a Dillon ammo box

and repeat the above steps.

Figure 38 – Removing the completed cartridge.

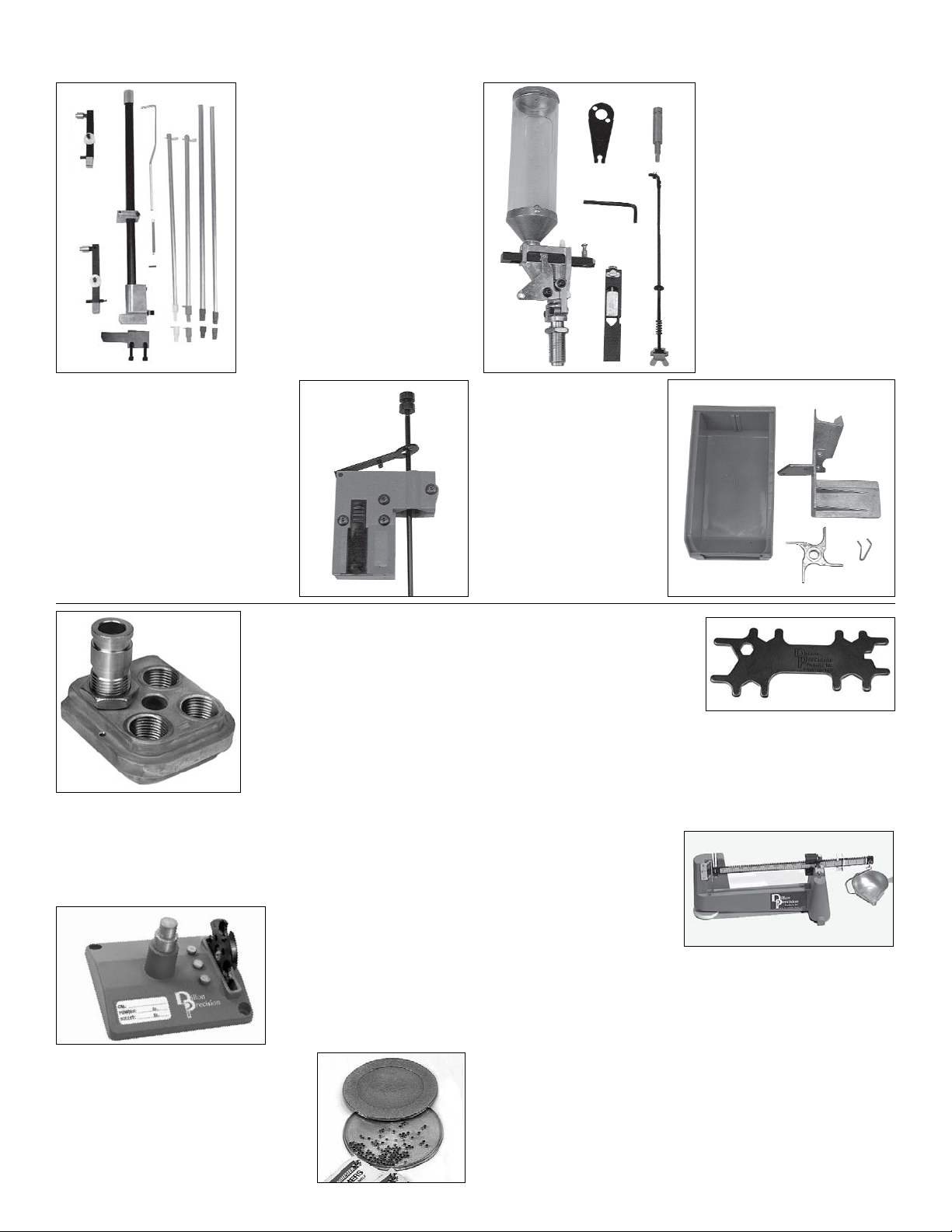

Page 15

J. ‘ELIMINATOR’ LOADING SCALE

This precision instrument eliminates the

guesswork by a simple

triple-poise balance

beam. Easy to use for the

novice; precision accuracy for the professional.

#13480

D. UPGRADE #4 –

AUTO EJECT SYSTEM

Greatly increases

your ammo production

capabilities and adds a

Cartridge

Chute/Bracket and a

Cartridge Bin to your

reloader.

#22120

B. UPGRADE #2 –

PRIMER EARLY WARNING KIT

The device sounds when you

have approximately three

primers left in the primer magazine. Allows you to focus on

loading instead of worrying

about failing to seat a primer,

and is an easy slip-on attachment to the auto prime system.

#20302

C. UPGRADE #3 –

AUTO POWDER SYSTEM

Accurate to within 0.1

grain, our Automatic

Powder Measure is

world-renowned for its

charge-to-charge

consistency.

#20251

OPTIONAL MAGNUM

RIFLE POWDER BAR

#21353

A. UPGRADE #1–

AUTO PRIME SYSTEM

Includes:

Primer Housing /Shield

Primer Slides, Lg./Sm.

Pickup Tubes, Lg./Sm.

Pickup Tube Tips, Lg./Sm.

Magazine Tubes, Lg./Sm.

Mag. Orifices, Lg./Sm.

Operating Rod

Primer Track Bearing

Housing Screws

Ret. Spring Retaining Pin

#16627

I. BENCH WRENCH

The Dillon Universal

Bench Wrench is like the old

bicycle or skate wrench.

This handy device has all

the correct sizes for Dillon

dies, powder systems, Square Deal “B”, RL 550B and

RL 1050 adjustments, etc.

Single, #13770 2 pak, #20486

H. PRIMER FLIP TRAY

Guns & Ammo magazine calls

this “the Cadillac of flip trays.”

A heavy, high-quality tray large

enough for the new Federal

primer package.

#13606

H.

J.

I.

AT 500 Upgrades & Accessories

E. POWDER DIES

Extra powder dies are a

must, allowing you to move

your powder measure from

toolhead to toolhead without changing the critical

“belling” adjustment.

Single, #20064

3 pak, #20057

G. TOOLHEAD STANDS

The ultimate in convenience for keeping your

reloading bench clean

and uncluttered.

Single, #22055

3 pak, #22050

F. TOOLHEADS

Don’t adjust dies when switching calibers. These

precision tool holders hold your dies in perfect alignment, making caliber changes a snap.

Single, #13909 3 pak, #20058

E.

F.

G.

15

Page 16

Loading...

Loading...