Page 1

DWS773

DWS774

Final Page size: A5 (172mm x 240mm)

Page 2

2

3

4

5

6

7

8

11

13

16

18

21

22

Dansk (oversat fra original brugsvejledning) 22

Deutsch (übersetzt von den originalanweisungen) 29

English (original instructions) 37

Español (traducido de las instrucciones originales) 44

Français (traduction de la notice d’instructions originale) 51

Italiano (tradotto dalle istruzioni originali) 59

Nederlands (vertaald vanuit de originele instructies) 66

Norsk (oversatt fra de originale instruksjonene) 74

Português (traduzido das instruções originais) 81

Suomi (käännetty alkuperäisestä käyttöohjeesta) 88

Svenska (översatt från de ursprungliga instruktionerna) 95

Türkçe (orijinal talimatlardan çevrilmiştir) 102

Ελληνικά (μετάφραση από τις πρωτότυπες οδηγίες) 109

Page 3

3

DWS773

DWS774

250 – 300 Lux

Page 4

4

DWS773

DWS774

x 2

6 mm

XXXX-XX-XX

Page 5

5

>15 mm

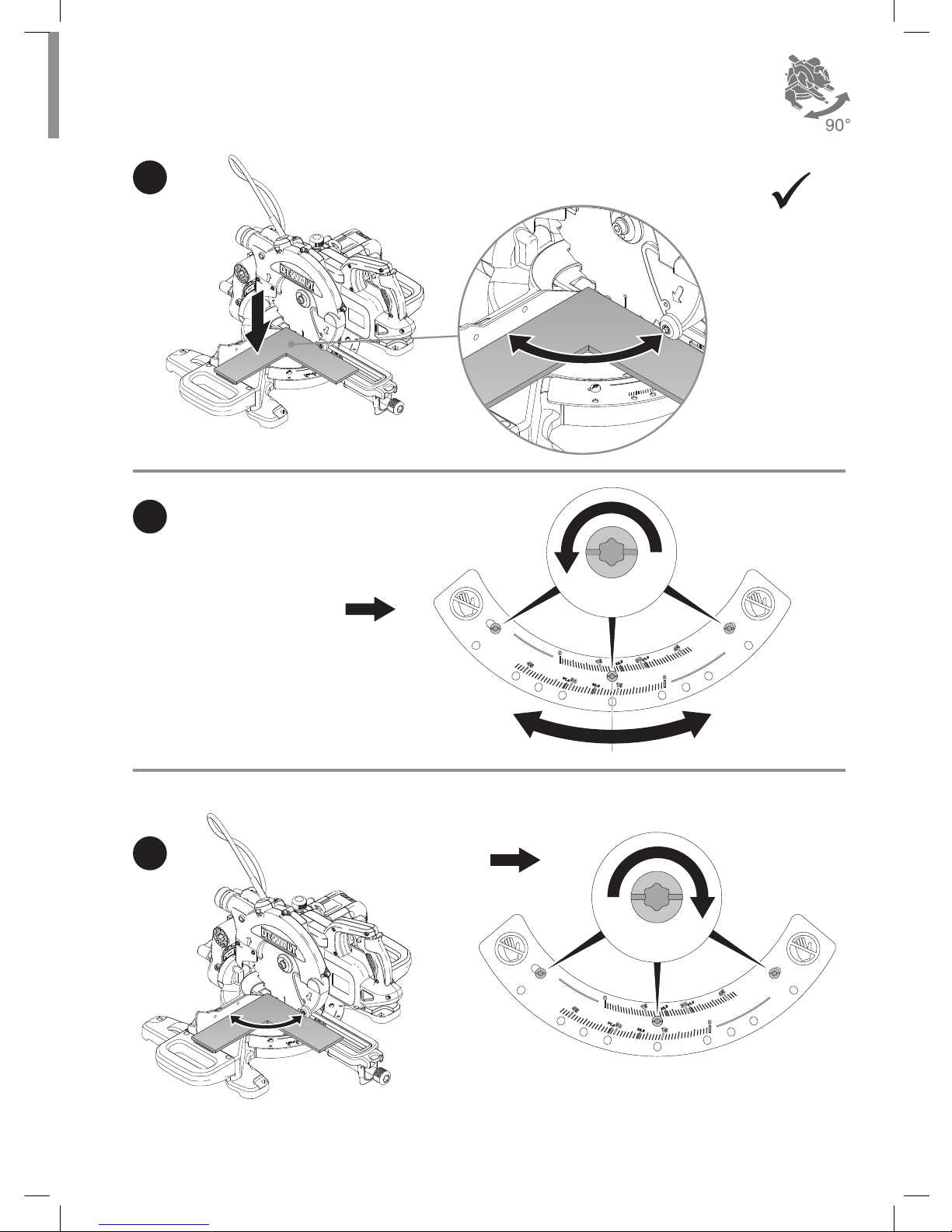

1

2

> 8 mm

Page 6

6

1

2

3

B

A

Page 7

7

1

2

A

B

Page 8

8

1

2

A

B

0°

0°

Page 9

9

α

3

4

5

A

A

A

B

α =⁄ 90°

α = 90°

α

α = 90°

B

B

α = 90°

Page 10

10

A

B

Page 11

11

1

2

A

B

α

3

α = 90°

Page 12

12

4

5

α = 45°

α = 45°

α = 48°

Page 13

13

1

2

3

A

A

A

B

B

B

C

Page 14

14

4

5

>10 cm

A

A

B

B

C

DWS774

XPS

Page 15

15

Page 16

16

1

2

3

A

B

45°

A

C

B

Page 17

17

4

5

A

B

C

Page 18

18

α

β

γ

γ

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

5

10

15

20

25

30

35

40

45

50

5

5

60

65

70

75

80

85

α

0

5

10

15

20

25

30

35

40

45

β

0510 15 20 25 30 35 40 45

Page 19

19

α

1

2

3

A

A

B

B

Page 20

20

1

2

β

Page 21

21

Page 22

22

CROSS CUT MITRE SAW

DWS773, DWS774

TECHNICAL DATA

DWS773 DWS774

Voltage:

Europe V 230 230

U.K. & Ireland V 230/115 230/115

Fuses:

Europe

230 V

A

10

(mains)

10

(mains)

U.K. & Ireland

230 V

A

13

(in plugs)

13

(in plugs)

U.K. & Ireland

115 V

A

16

(mains)

16

(mains)

Type 1 1

Power input W 1300 1400

Blade diameter mm 216 216

Blade bore mm 30 30

Blade speed, max. min-14600/4500 4600/4500

Mitre positions, max.

left

right

48°

48°

48°

48°

Bevel position, max. left 48° 48°

Compound mitre

bevel

mitre

45°

45°

45°

45°

Capacities:

cross-cut 90° (max height) mm 70 x 20 70 x 20

cross-cut 90° mm 60 x 250 60 x 250

mitre 45° mm 60 x 170 60 x 170

mitre 48° mm 60 x 160 60 x 160

bevel 45° mm 48 x 250 48 x 250

bevel 48° mm 45 x 250 45 x 250

Overall dimensions(with table extensions) mm 625 x 425 x 355 625 x 425 x 355

Dimensions(without table extensions) mm 445 x 425 x 355 445 x 425 x 355

Weight kg 11.5 11.5

LPA (sound pressure) dB(A) 92 92

LWA (acoustic power) dB(A) 98 98

K (acoustic power uncertainty) dB(A) 0,3 0,3

Vibration total values (triax vector sum) determined according to EN 61029:

ah (vibration emission value) m/s

2

2,7 2,7

K (uncertainty) m/s

2

1.5 1.5

XPS No Yes

Vibration Emission

The vibration emission level given in this information sheet has been

measured in accordance with a standardised test given in EN 62841-3-9

and may be used to compare one tool with another. It may be used for a

preliminary assessment of exposure.

The declared vibration emission level represents the main applications

of the tool. However if the tool is used for different applications, with

different accessories or poorly maintained, the vibration emission may

differ. This may significantly increase the exposure level over the total

working period.

An estimation of the level of exposure to vibration should also take into

account the times when the tool is switched off or when it is running but

not actually doing the job. This may significantly reduce the exposure

level over the total working period.

Identify additional safety measures to protect the operator from the

effects of vibration such as: maintain the tool and the accessories, keep

the hands warm, organisation of work patterns.

Electrical Power Source

This device is intended for the connection to a power supply system

with maximum permissible system impedance Zmax of 0,39 Ohm at the

interface point (power service box) of user’s supply.

The user has to ensure that this device is connected only to a power

system which fulfils the requirement above. If necessary, the user can

ask the public power supply company for the system impedance at the

interface point.

EC-Declaration of Conformity

In accordance with

Machinery Directive 2006/42/EC

Product: Cross-cut Mitre Saw

Types: DWS773, DWS774

DEWALT declares that these products described under Technical Data

are in compliance with the harmonized standards: EN 62841-1:2015 and

EN 62841-3-9:2015. These products also comply with Directive 2014/30/

EU and 2011/65/EC.

For more information, please contact DEWALT at the following address

or refer to the back of the manual.

The undersigned is responsible for compilation of the technical file and

makes this declaration on behalf of DEWALT.

Markus Rompel

Director Engineering

DeWALT

, Richard-Klinger-Straße 11,

D-65510, Idstein, Germany

30.11.2015

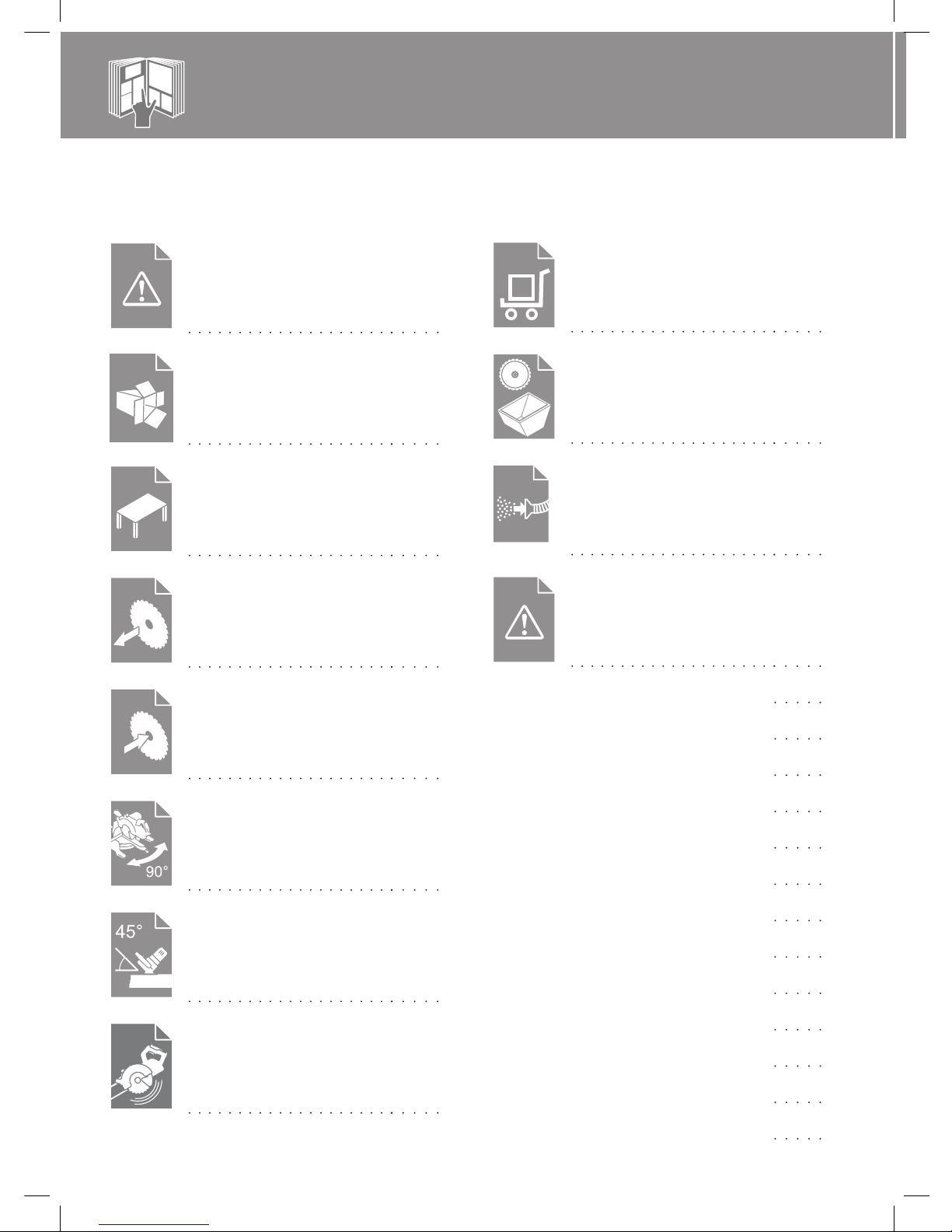

GENERAL SAFETY NOTES

Read the safety manual carefully before use in order to

ensure asafe and proper operation of the device. Retain

the instruction manual until the product is disposed of.

Intended Use

The Cross-Cut Mitre Saw has to be used in accordance with the

specifications of this safety manual and the operational manual. Mitre

Saw are not “toys” and require prudent, responsible and careful handling.

The Mitre Saw has been designed for professional cutting wood, wood

products and plastics. It performs the sawing operations of cross-cutting,

bevelling and mitring easily, accurately and safety.

The Mitre Saw is designed for use with a nominal blade diameter

216mm carbide tip blade.

Responsibilities of the employer, for example:

• Complying with the deadlines for periodic inspections as well as

ordering repair measures to be performed by by an authorized

DeWALT

repair agent.

• Safe storage of the Mitre Saw out of reach of children.

• Provisioning and ensuring the usage of protective equipment, see

chapter 1.3 “Personal Protective Equipment”.

ENGLISH

Page 23

23

The Mitre Saw may only be used by persons over 18 years of age or

apprentices/trainees over 16 years of age (while in the presence of

aresponsible supervisor) who are not under the influence of fatigue,

alcohol, medication or drugs.

Misapplications, misuse or “fooling around” may cause lethal injuries and

serious property damage.

For example:

• Overriding of safety mechanisms

• Cutting tree limbs or logs

• Cutting steel or other hard material

• Cutting light alloy, especially magnesium

Modifications to the device, additions to the device or conversions as

well as maintenance operations and repairs performed by yourself can

impair the safety, reliability and proper functioning of the device to

asignificant extent and void any warranty claims.

DWS774: A failure of XPS, has no effect on the intended operation.

UK only

The attention of UK users is drawn to the “woodworking machines

regulations 1974” and any subsequent amendments.

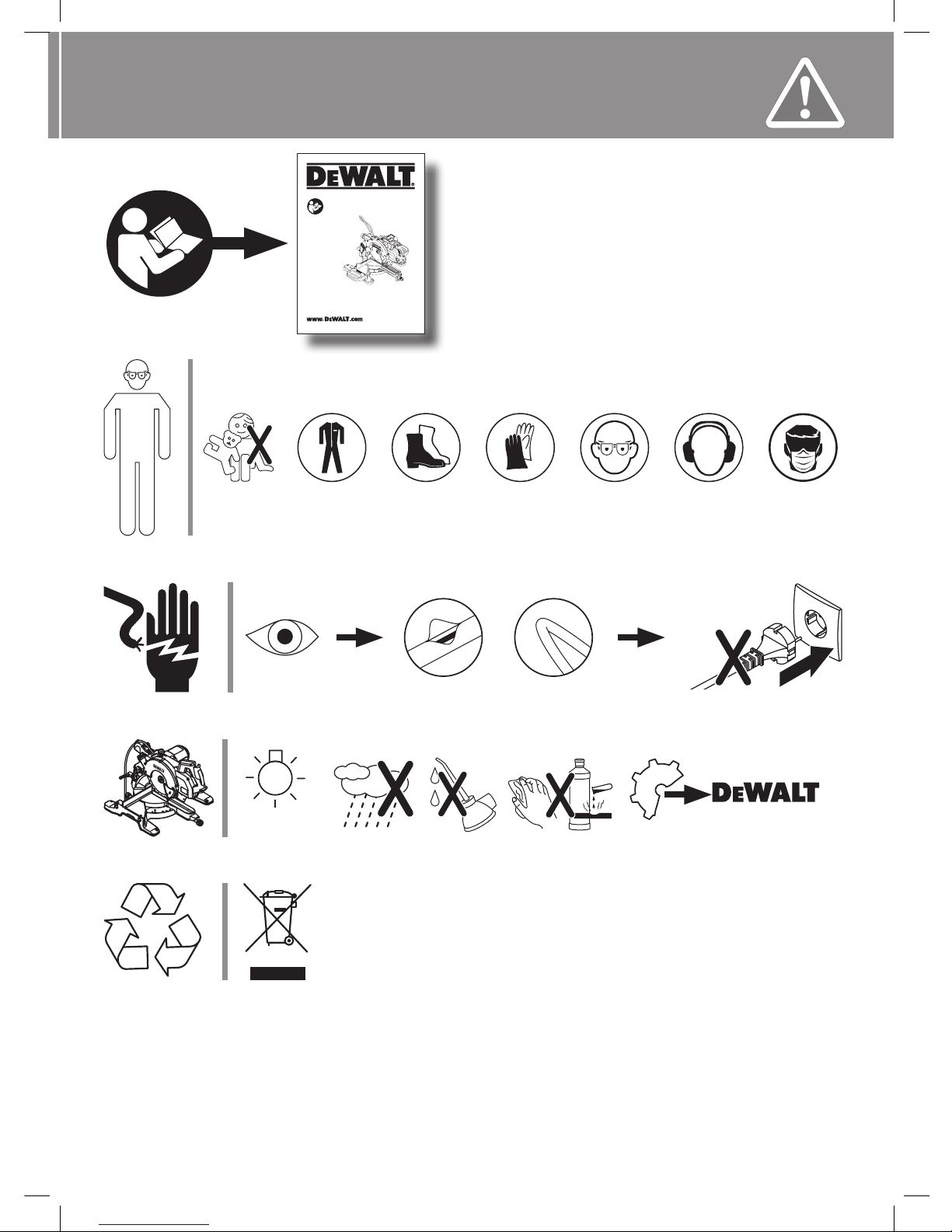

Product code

The product code, which also includes the year of manufacture, is

printed into the housing. (See page 4.)

Example:

2016 XX XX

Year of Manufacture

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word.

Please read the manual and pay attention to thesesymbols.

DANGER: Indicates an imminently hazardous situation which, if

not avoided, will result in death or seriousinjury.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or seriousinjury.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderateinjury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in propertydamage.

Denotes risk of electricshock.

Denotes risk offire.

General Power Tool Safety Warnings

WARNING: Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric

shock, fire and/or seriousinjury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) powertool.

1) Work area safety

a ) Keep work area clean and well lit. Cluttered or dark areas

inviteaccidents.

b ) Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust orfumes.

c ) Keep children and bystanders away while operating a power

tool. Distractions can cause you to losecontrol.

2) Electrical safety

a ) Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching outlets

will reduce risk of electricshock.

b ) Avoid body contact with earthed or grounded surfaces such

as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is earthed orgrounded.

c ) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electricshock.

d ) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away from

heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electricshock.

e ) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for outdoor

use reduces the risk of electricshock.

f ) If operating a power tool in a damp location is unavoidable,

use a residual current device (RCD) protected supply. Use of an

RCD reduces the risk of electricshock.

3) Personal safety

a ) Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while

you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power tools

may result in serious personalinjury.

b ) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personalinjuries.

c ) Prevent unintentional starting. Ensure the switch is in the off

position before connecting to power source and/or battery

pack, picking up or carrying the tool. Carrying power tools with

your finger on the switch or energising power tools that have the

switch on invitesaccidents.

d ) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating part of

the power tool may result in personalinjury.

e ) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpectedsituations.

f ) Dress properly. Do not wear loose clothing or jewellery. Keep

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in movingparts.

g ) If devices are provided for the connection of dust extraction

and collection facilities, ensure these are connected

and properly used. Use of dust collection can reduce dust-

relatedhazards.

h ) Do not let familiarity gained from frequent use of tools allow

you to become complacent and ignore tool safety principles.

A careless action can cause severe injury within a fraction of a

second.

Page 24

24

4) Power tool use and care

a ) Do not force the power tool. Use the correct power tool for

your application. The correct power tool will do the job better and

safer at the rate for which it wasdesigned.

b ) Do not use the power tool if the switch does not turn it on

and off. Any power tool that cannot be controlled with the switch

is dangerous and must berepaired.

c ) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the

power toolaccidentally.

d ) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrainedusers.

e ) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other condition

that may affect the power tool’s operation. If damaged, have

the power tool repaired before use. Many accidents are caused

by poorly maintained powertools.

f ) Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier

tocontrol.

g ) Use the power tool, accessories and tool bits etc., in

accordance with these instructions taking into account the

working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result

in a hazardoussituation.

h ) Keep handles and grasping surfaces dry, clean and free

from oil and grease. Slippery handles and grasping surfaces do

not allow for safe handling and control of the tool in unexpected

situations.

5) Service

a ) Have your power tool serviced by a qualified repair person

using only identical replacement parts. This will ensure that the

safety of the power tool ismaintained.

Safety Rules for Mitre Saws

a ) Mitre saws are intended to cut wood or wood-like products,

they cannot be usedwith abrasive cut-off wheels for cutting

ferrous material such as bars, rods, studs,etc. Abrasive dust

causes moving parts such as the lower guard to jam. Sparks

fromabrasive cutting will burn the lower guard, the kerf insert and

other plastic parts.

b ) Use clamps to support the workpiece whenever possible. If

supporting theworkpiece by hand, you must always keep

your hand at least 100 mm from eitherside of the saw blade.

Do not use this saw to cut pieces that are too small to besecurely

clamped or held by hand. If your hand is placed too close to the saw

blade,there is an increased risk of injury from blade contact.

c ) The workpiece must be stationary and clamped or held

against both the fence and the table. Do not feed the workpiece

into the blade or cut “freehand” in any way. Unrestrained or moving

workpieces could be thrown at high speeds, causing injury.

d ) Push the saw through the workpiece. Do not pull the saw

through the workpiece. To make a cut, raise the saw head and

pull it out over the workpiece without cutting, start the motor, press

the saw head down and push the saw through the workpiece.

Cutting on the pull stroke is likely to cause the saw blade to climb

on top of the workpiece and violently throw the blade assembly

towards the operator.

e ) Never cross your hand over the intended line of cutting either

in front or behind the saw blade. Supporting the workpiece

“cross handed” i.e. holding the workpiece to the right of the saw

blade with your left hand or vice versa is very dangerous.

f ) Do not reach behind the fence with either hand closer than

100 mm from either side of the saw blade, to remove wood

scraps, or for any other reason while the blade is spinning.

The proximity of the spinning saw blade to your hand may not be

obvious and you may be seriously injured.

g ) Inspect your workpiece before cutting. If the workpiece is

bowed or warped, clamp it with the outside bowed face

toward the fence. Always make certain that there is no gap

between the workpiece, fence and table along the line of the

cut. Bent or warped workpieces can twist or shift and may cause

binding on the spinning saw blade while cutting. There should be

no nails or foreign objects in the workpiece.

h ) Do not use the saw until the table is clear of all tools, wood

scraps, etc., except for the workpiece. Small debris or loose

pieces of wood or other objects that contact the revolving blade can

be thrown with high speed.

i ) Cut only one workpiece at a time. Stacked multiple

workpieces cannot be adequately clamped or braced and

may bind on the blade or shift during cutting.

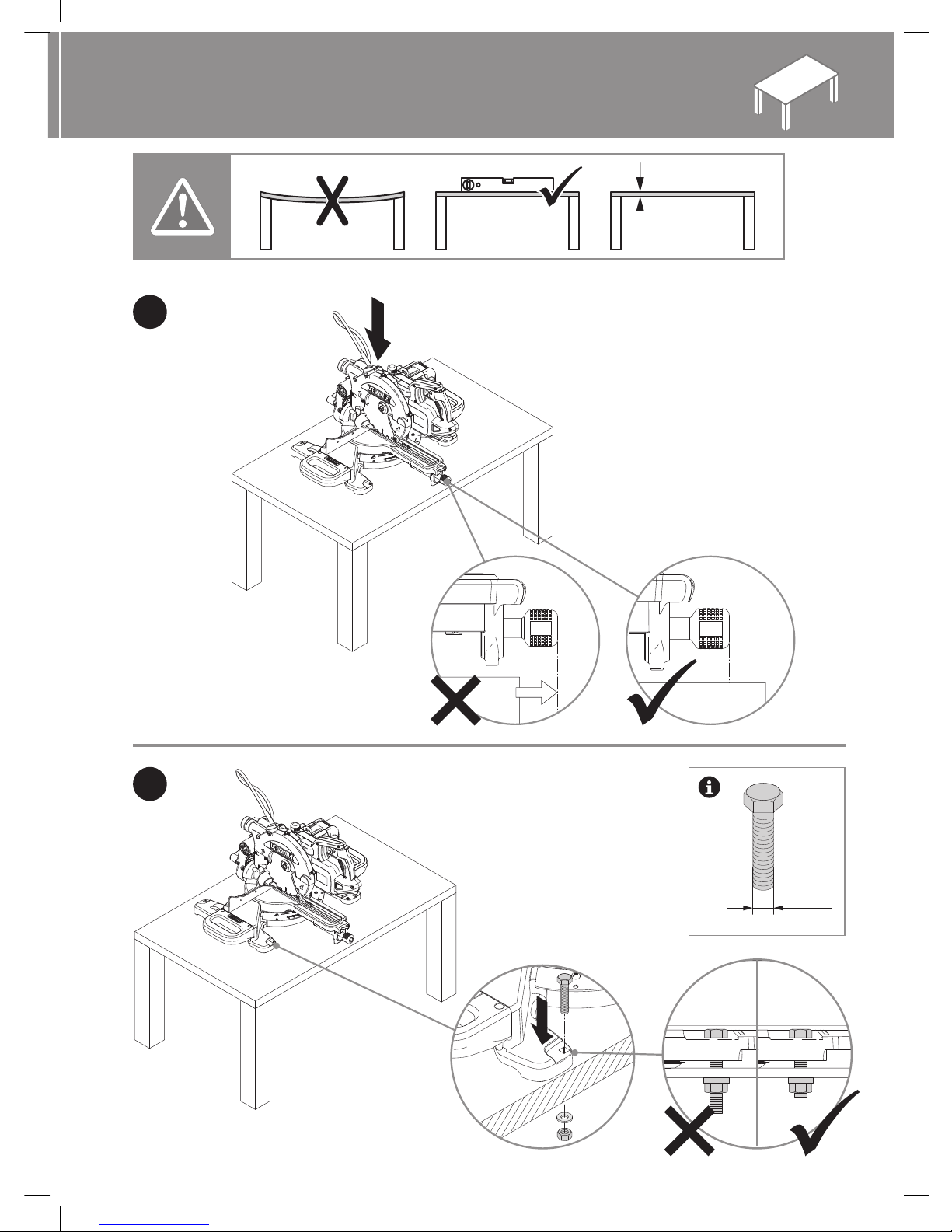

j ) Ensure the mitre saw is mounted or placed on a level, firm

work surface before use. A level and firm work surface reduces

the risk of the mitre saw becoming unstable.

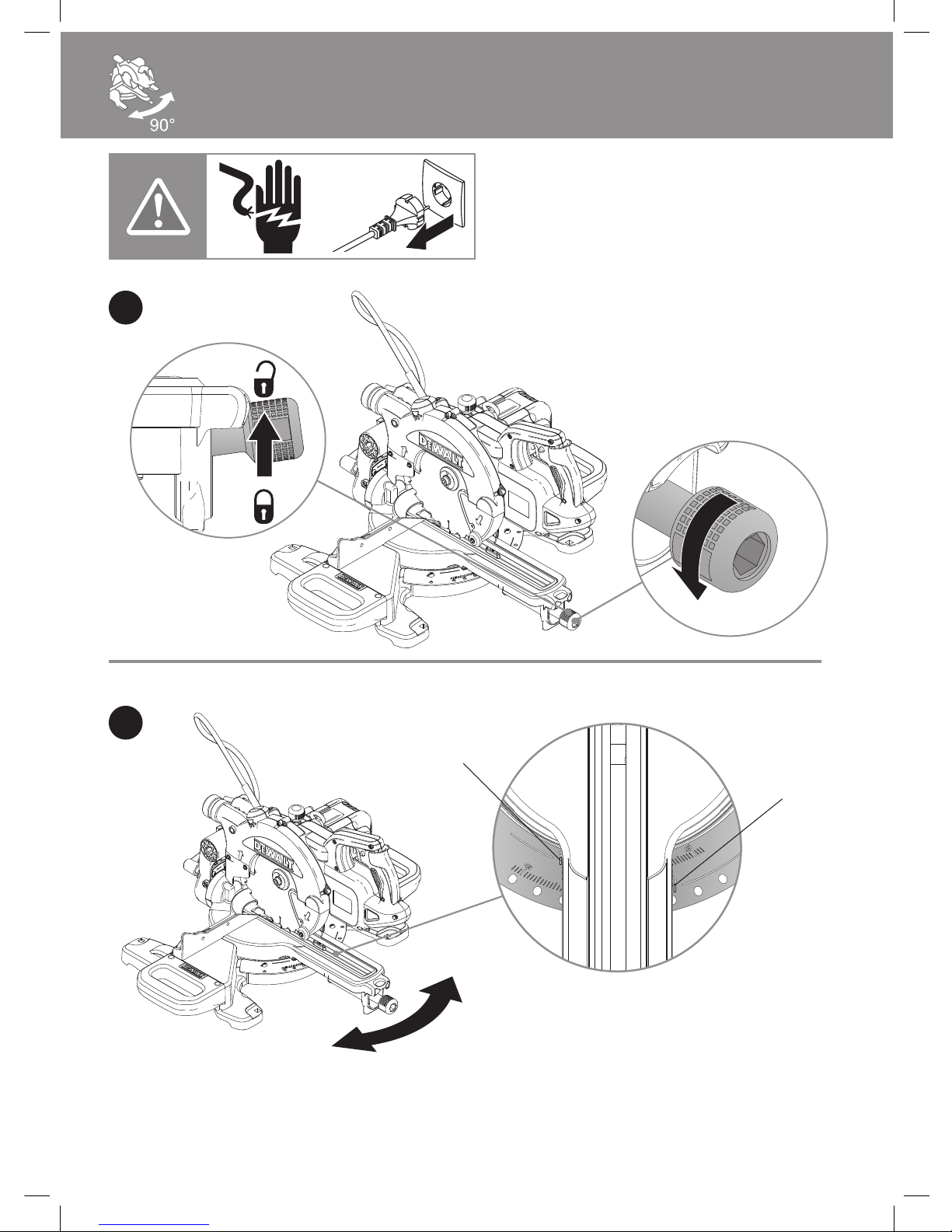

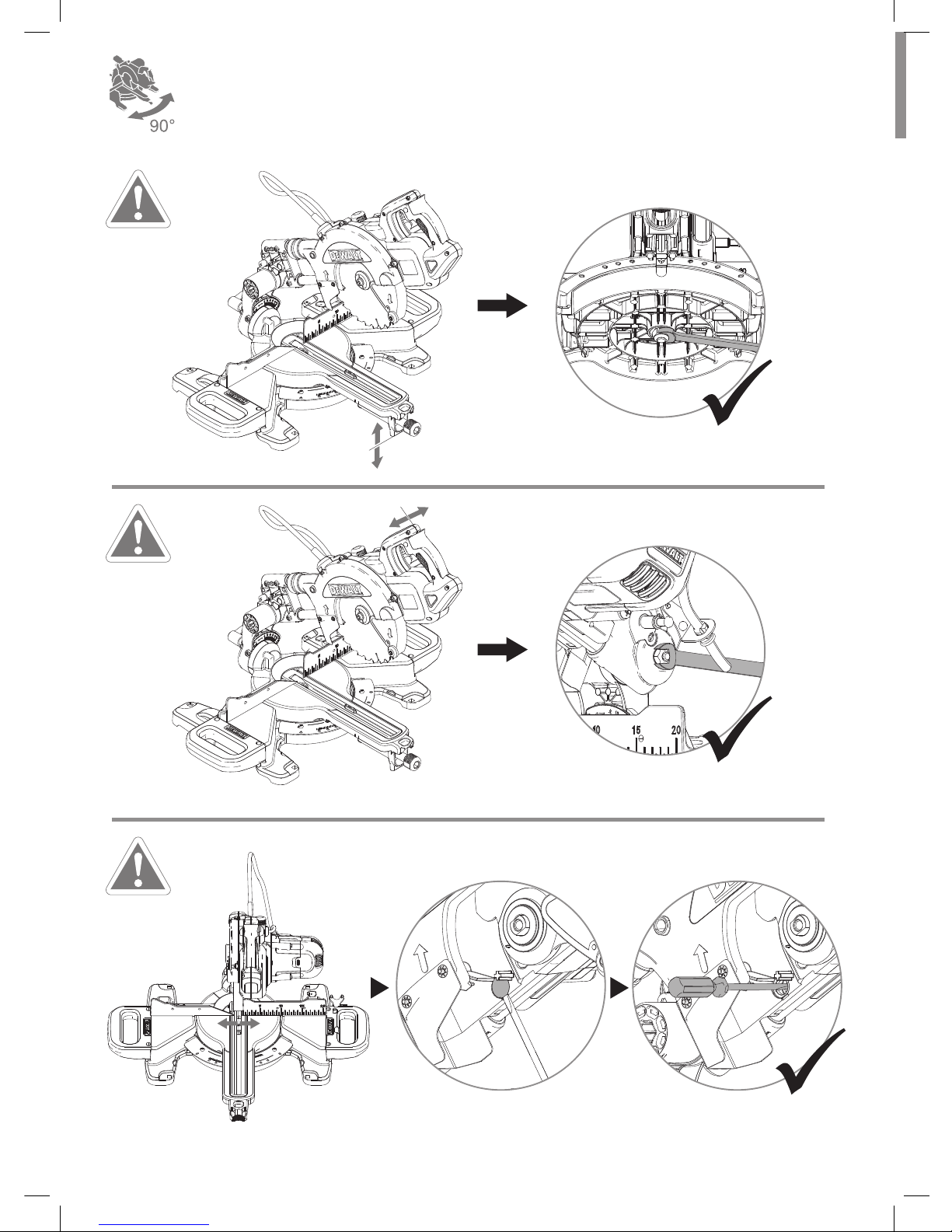

k ) Plan your work. Every time you change the bevel or mitre

angle setting, make sure the adjustable fence is set correctly

to support the workpiece and will not interfere with the blade

or the guarding system. Without turning the tool “ON” and with

no workpiece on the table, move the saw blade through a complete

simulated cut to assure there will be no interference or danger of

cutting the fence.

l ) Provide adequate support such as table extensions, saw

horses, etc. for a workpiece that is wider or longer than the

table top. Workpieces longer or wider than the mitre saw table can

tip if not securely supported. If the cut-off piece or workpiece tips, it

can lift the lower guard or be thrown by the spinning blade.

m ) Do not use another person as a substitute for a table

extension or as additional support. Unstable support for the

workpiece can cause the blade to bind or the workpiece to shift

during the cutting operation pulling you and the helper into the

spinning blade.

n ) The cut-off piece must not be jammed or pressed by any

means against the spinning saw blade. If confined, i.e. using

length stops, the cut-off piece could get wedged against the blade

and thrown violently.

o ) Always use a clamp or a fixture designed to properly support

round material such as rods or tubing. Rods have a tendency

to roll while being cut, causing the blade to “bite” and pull the work

with your hand into the blade.

p ) Let the blade reach full speed before contacting the

workpiece. This will reduce the risk of the workpiece being thrown.

q ) If the workpiece or blade becomes jammed, turn the mitre

saw off. Wait for all moving parts to stop and disconnect the

Page 25

25

plug from the power source and/or remove the battery pack.

Then work to free the jammed material. Continued sawing with a

jammed workpiece could cause loss of control or damage to the

mitre saw.

r ) After finishing the cut, release the switch, hold the saw head

down and wait for the blade to stop before removing the

cut-off piece. Reaching with your hand near the coasting blade is

dangerous.

s ) Hold the handle firmly when making an incomplete cut or

when releasing the switch before the saw head is completely

in the down position. The braking action of the saw may cause

the saw head to be suddenly pulled downward, causing a risk of

injury.

Additional Safety Rules for Mitre Saws

• Do not use the saw to cut other materials than those recommended by

the manufacturer.

• Do not operate the machine without guards in position, or if guards do

not function or are not maintained properly.

• Select the correct blade for the material to be cut.

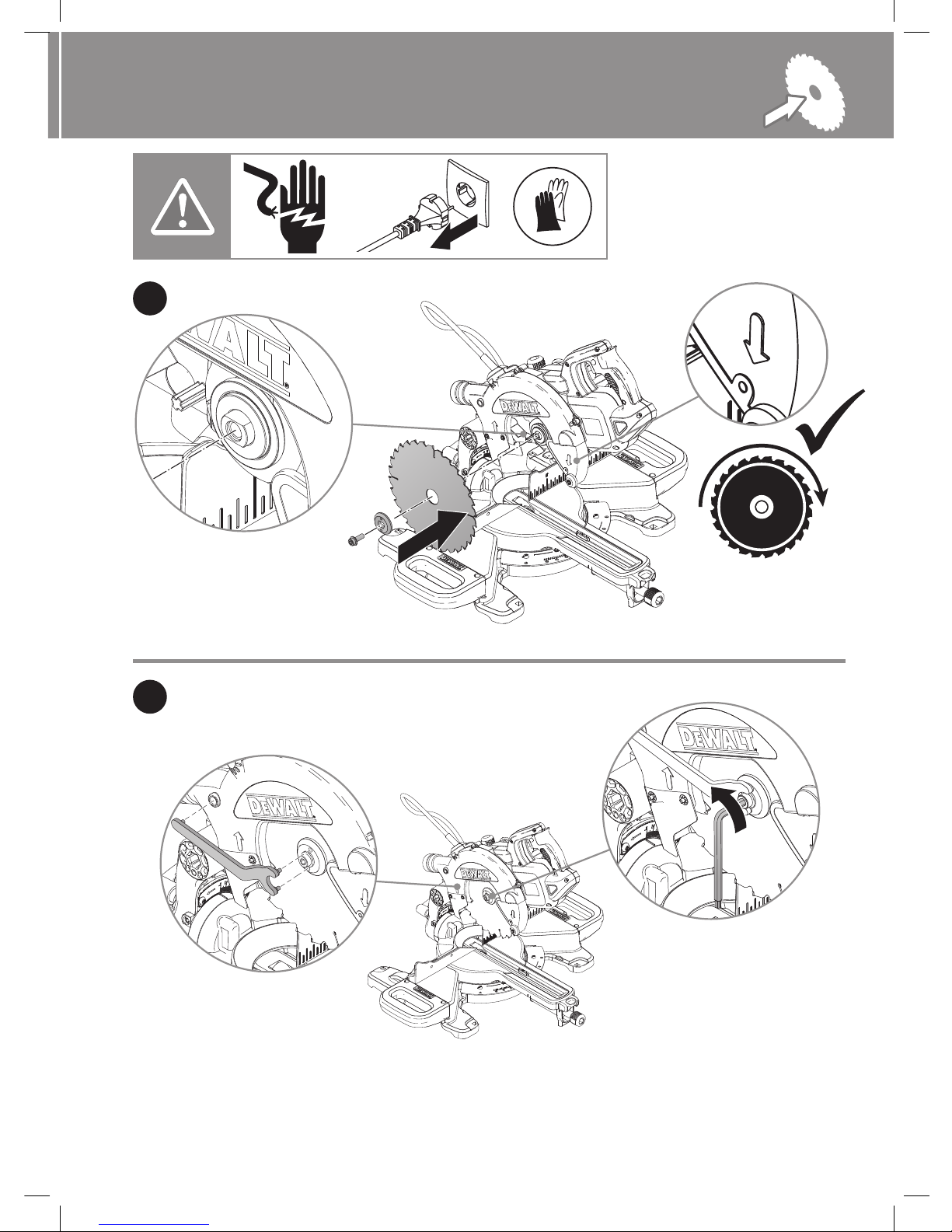

• Use correctly sharpened saw blades.

• Make sure that the blade rotates in the correct direction.

• USE ONLY CROSSCUT SAW BLADES recommended for mitre saws. Do not

use carbide tipped blades with hook angles in excess of 7 degrees. Do not

use blades with deep gullets. These can deflect and contact the guard,

and can cause damage to the machine and/or serious injury.

• Never attempt to stop a machine in motion rapidly by jamming a tool or

other means against the blade; serious accidents can occur.

• Before using any accessory consult the instruction manual.

The improper use of an accessory can cause damage.

• Ensure that the saw blade is mounted correctly before use.

• Do not use blades of larger or smaller diameter than recommended. For

the proper blade rating refer to the technical data. Use only the blades

specified in this manual, complying with EN 847-1.

• Do not use HIGH SPEED STEEL blades.

• Do not use cracked or damaged saw blades.

• Do not use any abrasive or diamond discs.

• Use only saw blades where the marked speed is at least equal to the

speed marked on the saw.

• Do not wedge anything against the fan to hold the motor shaft.

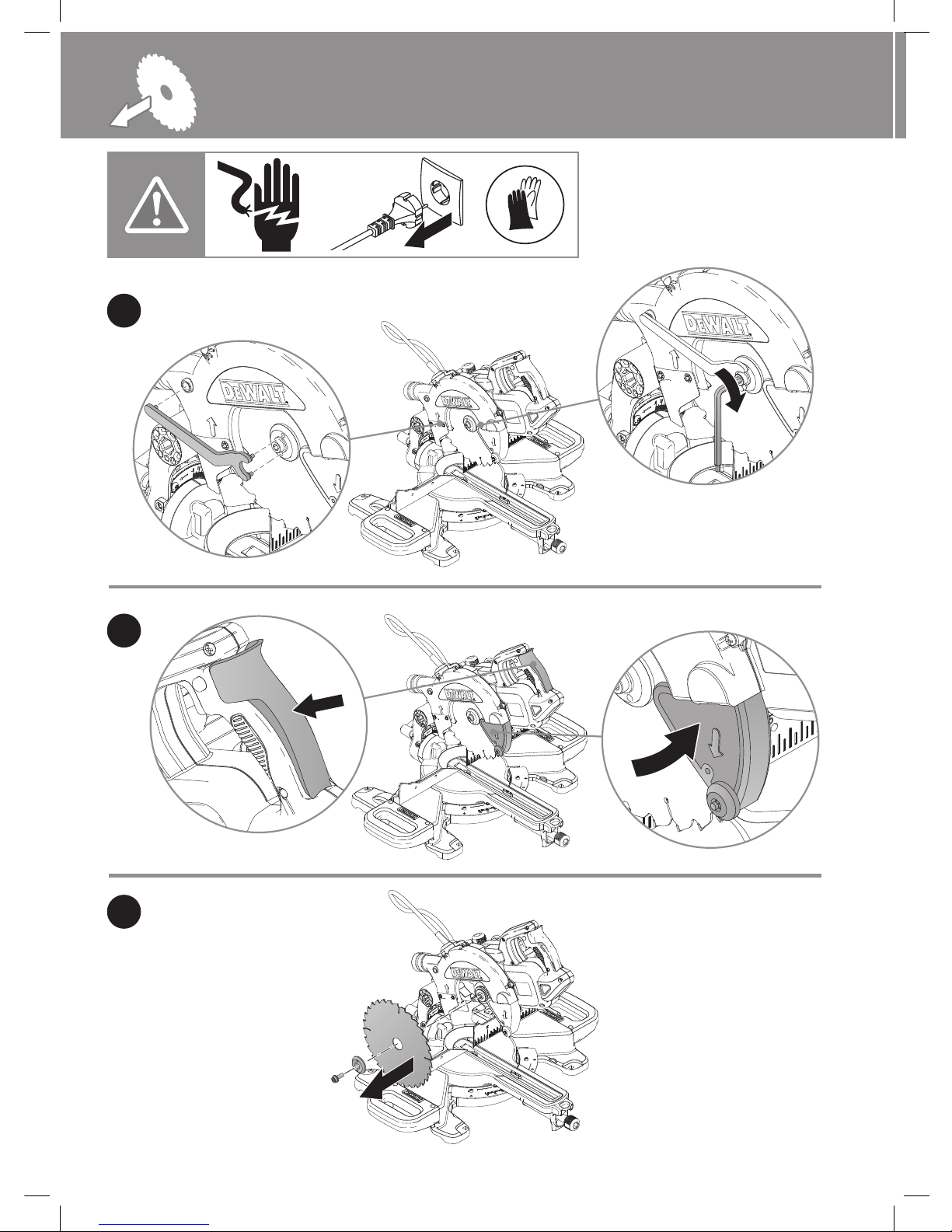

• Never raise the blade guard manually unless the saw is switched off. The

guard can be raised by hand when installing or removing saw blades or

for inspection of the saw.

• Check periodically that the motor air slots are clean and free of chips.

• Please be aware of the following factors influencing exposure

to noise:

ʵ use saw blades designed to reduce the emitted noise;

ʵ use only well sharpened saw blades;

• Machine maintenance shall be conducted periodically;

• In case of an accident or machine failure, immediately turn the machine

off and disconnect machine from the power source.

• Report the failure and mark the machine in suitable form to prevent

other people from using the defective machine.

• When sawing plastic melting of the material is to be avoided.

Personal Protective Equipment

Loose clothes, jewellery, noise and similar hazards may present adanger

to persons. Persons that will be using the device and have to reside

in the vicinity of the device, must wear suitable personal protective

equipment.

Protective clothing protects the skin against mechanical

effects, e.g. cuts

Safety boots protect the feet against falling objects and the

entry of protruding nails

Safety gloves protect the hands against mechanical effects,

e.g. cuts

Marked on tool: Safety goggles: protects the eyes against

flying objects, such as splinters and dust

Marked on tool: Ear protection: protects the ears against

excessive noise

Marked on tool: Wear a dust respirator.

Young children and the infirm. This machine is not intended

for use by young children or infirm persons without

supervision.

Warning Signs and Labels

The device may only be used if all safety labels on the Mitre Saw are both

complete and legible.

The safety alert symbol is used to alert you

to potential physical injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

Read the manual before using the device.

Risk of electrical hazard

Examples of cable damages

Do not connect the power cable with the power

supply.

Danger of cuts

Page 26

26

Keep your hand at least 100 mm from either side

of the saw blade

This product must not be disposed of with

normal household waste

Keep away from children

Do not use the tool in damp or wet conditions

Do not use solvents or other harsh chemicals for

cleaning

The Mitre Saw requires no additional lubrication

250 – 300 Lux

Well lightning of work area (250 - 300 Lux)

While using the worklight do not stare at the

light. Serious eye injury could result

Marked on Tool: Carrying points

Repair by

DeWALT

or by an authorized

DeWALT

repair agent

OPERATIONAL SAFETY NOTES

WARNING: Mitre Saws can cause serious injuries if improperly

handled.

Electrical Safety

The Mitre Saw is double insulated in accordance with EN 62841;

therefore no earth wire is required.

• The electric motor has been designed for one voltage only. Always

check that the power supply corresponds to the voltage on the

rating plate.

• Do not expose the tool to rain. Do not use the tool in damp or wet

conditions.

• Avoid body contact with earthed surfaces (e.g., pipes, radiators,

cookers and refrigerators).

• Outdoor use: Electric safety can be improved by inserting an isolating

transformer or a (FI) earth-leakage circuit-breaker.

WARNING: Do not abuse the power cable.

• Never yank the power cable to disconnect it from the socket.

• Keep the power cable away from heat, oil and sharp edges.

Extension cables

• If an extension cable is required, use an approved 3–core extension

cable suitable for the power input of this tool (see Technical Data).

The minimum conductor size is 1.5mm2; the maximum length is

30m.

• When using a cable reel, always unwind the cable completely.

• Before use: check the extension cable and replace if damaged.

• When the tool is used outdoors, use only extension cables intended

for outdoor use and marked accordingly.

Mains Plug and Cord Replacement

In case of cord or plug replacement the tool must only be repaired by an

authorized service agent or by qualified electrician.

The following cords are mandatory:

DWS773, DWS774: 230V

DWS773, DWS774: 115V

H05RN-F, 2 x 1.0 mm2

H05RR-F, 2 x 1.5 mm2

Mains plug replacement (UK & Ireland only)

If a new mains plug needs to be fitted:

• No connection is to be made to the earth terminal.

• Connect the brown lead to the live terminal in the plug.

• Connect the blue lead to the neutral terminal.

• Safely dispose of the old plug.

• Fitting a mains plug to 115 V Units: The plug fitted should be comply

with BS EN 60309 (BS4343), 16 Amps, earthing contact position 4h.

TASKS RELATED WARNINGS

Unpacking, Transport, Storage

Unpacking

NOTICE:

• Check for damage to the tool, parts or accessories which

may have occurred during transport.

• Check the content for completeness.

Transport

CAUTION: Improper transport can cause bruises.

• Do not carry the tool with a finger on the switch. Be sure that the

tool is in the “off” position.

• Do not use guards to lift or transport the mitre saw.

Storage

NOTICE: The mitre saw must be stored in a dry place and locked up

securely, out of reach of children.

Bench Mounting

Ergonomic requirements

Ensure the tool is placed to satisfy your ergonomic conditions in terms

of table height and stability. The machine site shall be chosen so that

the operator has a good overview and enough free surrounding space

around the machine that allows handling of the workpiece without any

restrictions.

Page 27

27

Adjustments and Replacements

The Mitre Saw was accurately adjusted at the factory. Due to shipping

and handling or any other reason a readjustment can be required.

WARNING: Electrical shock can cause serious injuries or dead

• Before work: Disconnect the power cable from the power supply.

NOTICE:

• Ensure that the arm is securely fixed when performing bevel cuts.

• Check that the blade does not touch the table at the rear of the slot or at

the front of the rotating arm at 90° vertical and 45° bevel positions.

• If the saw blade is worn, replace it with a new sharp blade.

• Check the technical data of the new blade: Use 216 mm saw blades with

30 mm arbor holes to obtain the desired cutting capacities.

• Replace the kerf plate when worn. If the kerf plate becomes worn or

damaged take saw to an authorised service centre.

Operating

General

• Use the optional roller tables for large and long pieces of wood.

• Use the optional dust extraction.

• Never use your saw without the kerf plate.

Before use

• Check for damage to the tool and the power cable. Take care that

the power supply cord is not placed in the cutting area

• Check the upper blade guard, movable lower blade guard as well as

the dust extraction tube to determine that it will operate properly.

• Check the lower blade guard , it is designed to close quickly when

the lever is released. If it does not close within 1 second, have the

saw serviced by an authorized

DeWALT

repair agent.

• Ensure that chips, dust or workpiece particle cannot lead to blockage

of one of the functions.

• In case of workpiece fragments jammed between saw blade and

guards disconnect the tool from the power supply. Remove the

jammed parts and reassembling the saw blade.

• Allow the blade to cut freely. Do not force.

• Always make dry runs (without power) before finish cuts so that you

can check the path of the blade.

• Allow the motor to reach full speed before cutting.

• Make sure all locking knobs and clamp handles are tight.

WARNING: Improper use can cause serious harm.

• Be sure that the tool is in the “off” position before plugging in.

• Do not let persons, especially children, not involved in the work,

touch the tool or the extension cord and keep them away from

the work area.

Body and hand position

• Never place your hands closer than 100 mm from the blade.

• Never cross your hands.

• As you move the saw arm left and right, follow it and stand

slightly to the side of the saw blade.

Cutting

• Always let the blade come to a full stop before raising the arm.

If small fibres of wood still split out at the rear of the workpiece,

stick a piece of masking tape on the wood where the cut will be

made. Saw through the tape and carefully remove tape when

finished.

• Hold the workpiece tightly to the table and the fence when

cutting. Keep your hands in position until the switch has been

released and the blade has completely stopped.

• When mitring the end of a piece of wood with a small off-cut,

position the wood to ensure that the off-cut is to the side of the

blade with the greater angle to the fence, i.e:

- left mitre, off-cut to the right

- right mitre, off-cut to the left

After use

• Disconnect the power cable from the power supply.

• Store the Mitre Saw in a dry place and locked up securely, out of

reach of children.

Dust Extraction

WARNING: Risk of dust inhalation. To reduce the risk of personal

injury ALWAYS wear approved dust mask.

WARNING: ALWAYS use a vacuum extractor designed in

complaince with the applicable directives regarding dust emission

when sawing wood.

• Certain dusts, such as oak or beech dust, are considered as

carcinogenic.

• Observe the relevant regulations in your country for the materials to

be worked.

NOTICE:

• Connect the saw to a dust collection device when sawing wood. Always

consider factors which influence exposure of dust such as:

ʵ good ventilation of the working place;

ʵ sharpness of the saw blade;

ʵ correct adjustment of the saw blade,

ʵ Push the saw through the workpiece. Do not pull the saw through

the workpiece.

Cleaning and Maintenance

The Mitre Saw requires no additional lubrication and has been designed

to operate over a long period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon proper tool care and

regular cleaning.

WARNING: Electrical shock can cause serious injuries or death.

• Before cleaning: Disconnect the power cable from the power

supply.

NOTICE:

• Use a cloth dampened only with water and mild soap.

• Never let any liquid get inside the tool; never immerse any part of the

tool into a liquid.

Page 28

28

• The guide grooves can become clogged with sawdust. Use suitable dust

extraction or some low pressure air to clear the guide grooves.

• Disconnect the machine from the mains before carrying out any

maintenance work or when changing the blade.

• Never perform any cleaning or maintenance work when the machine is

still running and the head is not in the rest position.

Disposal

Protecting the environment!

Separate collection. Products and batteries marked

with this symbol must not be disposed of with normal

household waste.

Products and batteries contain materials that can be

recovered or recycled reducing the demand for raw

materials. Please recycle electrical products and batteries

according to local provisions. Further information is

available at www.2helpU.com.

Page 29

Page 30

Page 31

Page 32

Belgique et

Luxembourg België

en Luxemburg

DeWA LT

- Belgium BVBA

Egide Walschaertsstraat 16

2800 Mechelen

Tel: NL 32 15 47 37 63

Tel: FR 32 15 47 37 64

Fax: 32 15 47 37 99

www.dewalt.be

enduser.BE@SBDinc.com

Danmark

DeWA LT

Roskildevej 22

2620 Albertslund

Tel: 70 20 15 10

Fax: 70 22 49 10

www.dewalt.dk

kundeservice.dk@sbdinc.com

Deutschland

DeWA LT

Richard Klinger Str. 11

65510 Idstein

Tel: 06126-21-1

Fax: 06126-21-2770

www.dewalt.de

infodwge@sbdinc.com

Ελλάς

DeWA LT

(Ελλάς) Α.Ε.

EΔΡΑ-ΓΡΑΦΕΙΑ : Στράβωνος 7

& Λ. Βουλιαγμένης, Γλυφάδα 166 74, Αθήνα

SERVICE : Ημερος Τόπος 2 (Χάνι Αδάμ) – 193 00

Ασπρόπυργος

Τηλ: 00302108981616

Φαξ: 00302108983570

www.dewalt.gr

Greece.Service@sbdinc.com

España

DeWA LT

Ibérica, S.C.A.

Parc de Negocios “Mas Blau”

Edificio Muntadas, c/Bergadá, 1, Of. A6

08820 El Prat de Llobregat (Barcelona)

Tel: 934 797 400

Fax: 934 797 419

www.dewalt.es

respuesta.postventa@sbdinc.com

France

DeWA LT

5, allée des Hêtres

BP 30084, 69579 Limonest Cedex

Tel: 04 72 20 39 20

Fax: 04 72 20 39 00

www.dewalt.fr

scufr@sbdinc.com

Schweiz

Suisse

Svizzera

DeWA LT

In der Luberzen 42

8902 Urdorf

Tel: 044 - 755 60 70

Fax: 044 - 730 70 67

www.dewalt.ch

service@rofoag.ch

Ireland

DeWA LT

Calpe House Rock Hill

Black Rock, Co. Dublin

Tel: 00353-2781800

Fax: 00353-2781811

www.dewalt.ie

Italia

DeWA LT

via Energypark

20871 Vimercate (MB), IT

Tel: 800-014353

39 039 9590200

Fax: 39 039 9590313

www.dewalt.it

Nederlands

DeWA LT

Netherlands BV

Holtum Noordweg 35

6121 RE BORN, Postbus 83, 6120 AB BORN

Tel: 31 164 283 063

Fax: 31 164 283 200

www.dewalt.nl

Norge

DeWA LT

Postboks 4613, Nydalen

0405 Oslo

Tel: 45 25 13 00

Fax: 45 25 08 00

www.dewalt.no

kundeservice.no@sbdinc.com

Österreich

DeWA LT

Werkzeug Vertriebsges m.b.H

Oberlaaerstrasse 248, A-1230 Wien

Tel: 01 - 66116 - 0

Fax: 01 - 66116 - 614

www.dewalt.at

service.austria@sbdinc.com

Portugal

DeWA LT

Limited, SARL

Centro de Escritórios de Sintra Avenida

Almirante Gago Coutinho, 132/134, Edifício 14

2710-418 Sintra

Tel: 214 66 75 00

Fax: 214 66 75 80

www.dewalt.pt

resposta.posvenda@sbdinc.com

Suomi

DeWA LT

PL 47

00521 Helsinki

Puh: 010 400 4333

Faksi: 0800 411 340

www.dewalt.fi

asiakaspalvelu.fi@sbdinc.com

Sverige

DeWA LT

Box 94

431 22 Mölndal

Tel: 031 68 61 60

Fax: 031 68 60 08

www.dewalt.se

kundservice.se@sbdinc.com

Türkiye KALE Hırdavat ve Makina A.Ş.

Defterdar Mah. Savaklar Cad. No:15

Edirnekapı / Eyüp / İSTANBUL 34050 TÜRKİYE

Tel: 0212 533 52 55

Faks: 0212 533 10 05

www.dewalt.com.tr

United Kingdom

DeWA LT

, 210 Bath Road;

Slough, Berks SL1 3YD

Tel: 01753-567055

Fax: 01753-572112

www.dewalt.co.uk

emeaservice@sbdinc.com

Australia

DeWA LT

82 Taryn Drive, Epping

VIC 3076 Australia

Tel: Aust 1800 338 002

Tel: NZ 0800 339 258

www.dewalt.com.au

www.dewalt.co.nz

Middle East Africa

DeWA LT

P.O. Box - 17164,

Jebel Ali Free Zone (South), Dubai, UAE

Tel: 971 4 812 7400

Fax: 971 4 2822765

www.dewalt.ae

Service.MEA@sbdinc.com

N470602

06/16

Loading...

Loading...