Page 1

DWE7491-XE

HEAVY-DUTY 254 MM (10") JOB SITE TABLE SAW

INSTRUCTION MANUAL

Questions? See us on the World Wide Web at www.dewalt.com

Page 2

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the manual and pay

attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

NOTICE: indicates a practice not related to personal injury which, if not avoided, may result in property

damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL, CALL US AT: 1800 338 002

(Aust) or 0800 339 258 (NZ).

DWE7491

Voltage V 230

Motor power (input) W 2000

Motor power (output) W 970

No load speed min

-1

3800

Blade diameter mm 254

Blade bore mm 16

Blade body thickness mm 1.75

Riving knife thickness mm 2.2

Depth of cut at 90° mm 79

Depth of cut at 45° mm 57

Ripping capacity mm 825

Overall dimensions mm 710 x 650 x 450

Weight kg 28.1

L

PA

(sound pressure) dB(A) 95.0

K

PA

(sound pressure uncertainty) dB(A) 3.0

L

WA

(sound power) dB(A) 106.0

K

WA

(sound power uncertainty) dB(A) 3.0

SAFETY INSTRUCTIONS

When using power tools, always observe the safety regulationsapplicable in your country to reduce the risk of fire,

electric shockand personal injury. Read the following safety instructions beforeattempting to operate this product.

KEEP THESE INSTRUCTIONS IN A SAFE PLACE!

General

1. Keep work area clean.

Cluttered areas and benches can cause accidents.

2. Consider work area environment.

Do not expose the tool to rain. Do not use the tool in damp or wet conditions. Keep the work area well lit

(250 - 300 Lux). Do not use the tool where there is a risk of causing fire or explosion, e.g., in the presence of

flammable liquids and gases.

3. Guard against electric shock.

Avoid body contact with ear thed surfaces (e.g., pipes, radiators, cookers and refrigerators). When using the

tool under extreme conditions (e.g., high humidity, when metal swarf is being produced, etc.), electric safety

can be improved by inserting an isolating transformer or a (FI) ear th-leakage circuit-breaker.

4. Keep other persons away.

Do not let persons, especially children, not involved in the work, touch the tool or the extension cord and keep

them away from the work area.

5. Extension cords for outdoor use.

When the tool is used outdoors, always use extension cords intended for outdoor use and marked

accordingly.

6. Store idle tools.

When not in use, power tools must be stored in a dr y place and locked up securely, out of reach of children.

7. Do not force the tool.

It will do the job better and safer at the rate to which it was intended.

8. Use the right tool.

The intended use is described in this instruction manual. Do not force small tools to do the job of a heavy duty

tool. Do not use tools for purposes not intended; for example do not use circular saws to cut tree limbs or logs.

WARNING! The use of any accessory or attachment or performance of any operation with this tool, other than

those recommended in this instruction manual may present a risk of personal injury.

9. Dress properly.

Do not wear loose clothing or jeweller y. They can be caught in moving parts. Preferably wear rubber gloves

and non-slip footwear when working outdoors. Wear protective hair covering to keep long hair out of the way.

10. Use protective equipment.

Always use safety glasses. Use a face or dust mask if working operations create dust or flying par ticles. If

these particles might be considerably hot, also wear a heat-resistant apron. Wear ear protection at all times.

Wear a safety helmet at all times.

11. Do not abuse the cord.

Never yank the cord to disconnect it from the socket. Keep the cord away from heat, oil and sharp edges.

Never carry the tool by its cord.

12. Secure work.

Where possible use clamps or a vice to hold the work. It is safer than using your hand and it frees both hands

to operate the tool.

13. Beware of maximum sound pressure.

Take appropriate measures for the protection of hearing if the sound pressure of 85 dB(A) is exceeded.

14. Do not overreach.

Keep proper footing and balance at all times.

15. Maintain tools with care.

Keep cutting tools sharp and clean for better and safer per formance. Follow instructions for lubricating and

changing accessories. Inspect tools periodically and if damaged have them repaired by an authorised service

facility. Keep handles and switches dry, clean and free from oil and grease.

16. Disconnect tool.

When not in use, before servicing and when changing accessories such as blades, bits and cutters,

disconnect tools from the power supply.

17. Avoid unintentional starting.

Be sure that the tool is in the “off ” position before plugging in.

18. Use outdoor extension leads.

Before use, inspect the extension cable and replace if damaged. When the tool is used outdoors, use only

extension cords intended for outdoor use and marked accordingly.

18. Stay alert.

Watch what you are doing. Use common sense. Do not operate the tool when you are tired or under the

influence of drugs or alcohol.

19. Remove adjusting keys and wrenches.

Always check that adjusting keys and wrenches are removed from the tool before operating the tool.

20. Check for damaged parts.

Before use, carefully check the tool and mains cable to determine that it will operate properly and perform its

intended function. Check for alignment of moving parts, binding of moving par ts, breakage of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should be

properly repaired or replaced by an authorised service centre unless otherwise indicated in this instruction

manual. Have defective switches replaced by an authorised service centre. Do not use the tool if the switch

does not turn it on and off. Never attempt any repairs yourself.

2

Page 3

21. Always use blades with correct size and shape (diamond versus round) of arbour holes. Blades that do

not match the mounting hardware of the saw will run eccentrically, causing loss of control.

22. Never use damaged or incorrect blade washers or bolt. The blade washers and bolt were specially

designed for your saw, for optimum performance and safety of operation.

23. Do not reach underneath the workpiece. The guard cannot protect you from the blade below the workpiece.

24. Adjust the cutting depth to the thickness of the workpiece. Less than a full tooth of the blade teeth should

be visible below the workpiece.

WARNING: The use of any accessory or attachment or performance of any operation with this tool other

than those recommended in this instruction manual may present a risk of personal injury.

25. Have your tool repaired by an authorized DEWALT repair agent.

This power tool is in accordance with the relevant safety regulations. To avoid danger, electric appliances

must only be repaired by qualified technicians.

Additional Safety instructions for Table Saw

WARNING: The use of any accessory or attachment, other than recom mended in this instruction manual, may

present a risk of personal injury.

• Do not use saw blades which are damaged or deformed.

• Do not use saw blades made from high speed steel.

• Do not use saw blades which do not comply with the characteristics specified within this manual.

• Do not stop the saw with lateral pressure on the blade.

• Do not lock the moveable guard in the open position.

• Ensure the moveable guard operates freely without jammrng.

• Always remove the plug of the saw from the mains supply before making any adjustments or maintenance to

the saw.

• Replace the table insert when worn.

• Use only saw blades recommended by the manufacturer which confirms to EN 847-1, with warning that the

riving knife shall not be thicker than the width of the groove cut by the saw blade and not thinner than the

body of the saw blade.

• Take care that the selection of the saw blade depends on the material to be cut.

• Use a push-stick to feed the workpiece past the saw blade The push-stick or push block should always be

stored with the machine when not in use.

• Connect your table saw to a dust collecting device when sawing.

• Use and correct adjustment of the riving knife.

• Use and correct adjustment of the upper saw blade guard.

• Wear ear protection.

• Take care when slotting.

• Not for cutting metal, timber or round log.

• NEVER attempt to cut a stack of loose pieces of material which could cause loss of control or kickback.

Support all materials securely.

SAW BENCHES

• Do not use saw blades with a body thickness greater or a width of tooth smaller than the thickness of the

splitter.

• Make sure that the blade rotates in the correct direction and that the teeth are pointing to the front of the saw

bench.

• Be sure all clamp handles are tight before starting any operation.

• Be sure all blade and flanges are clean and the recessed sides of the collar are against the blade. Tighten the

arbor nut securely.

• Keep the saw blade sharp and properly set.

• Make sure that the splitter is adjusted to the correct distance from the blade - maximum 5 mm.

• Never operate the saw without the upper and lower guards in place.

• Do not have any part of your body in line with the blade. Personal injury may occur. Stand to either side of the

blade.

• Disconnect the saw from the mains supply before changing blades or carrying out maintenance.

• Use a push stick to feed the workpiece at all times, and ensure that you do not place hands closer than 150

mm from the saw blade while cutting.

• Do not attempt to operate on anything but the designated voltage.

• Do not apply lubricants to the blade when it is running.

• Do not reach around behind the saw blade.

• Always keep the push stick in its store place when not in use.

• Do not stand on top of the unit.

• During transportation make sure that the upper part of the saw blade is covered, e.g. by the guard.

• Do not use the guard for handling or transportation.

WARNING: This machine is equipped with a specially configured power supply cord (type Y attachment). If

the power supply cord is damaged or otherwise defective, it must only be replaced by the manufacturer or by

an authorised repair agent.

• Immediately replace the table insert (throat plate) when worn or damaged.

• Check that the workpiece is properly supported. Always provide additional support for long workpieces.

• Do not exert side pressure on the saw blade.

• Never cut light alloy. The machine is not designed for this application.

• Do not use abrasive disc or diamond cutting wheels

• Rabbeting, slotting or grooving is not allowed.

• In case of an accident or machine failure, immediately switch the machine off and pull the plug. Report the

failure and mark the machine in suitable form which prevents that other persons use the defective machine.

• When the saw blade is blocked due to abnormal feed force during cutting, ALWAYS switch the machine off

and disconnect from power supply. Remove the workpiece and ensure that the saw blade runs free. Turn the

machine on and start a new cutting operation with reduced feed force.

SAW BLADES

• When sawing wood always connect the machine with suitable dust extractor.

• The max. allowable speed of the saw blade must always be equal to or greater than the no-load speed of the

tool specified on the nameplate.

• Do not use saw blades that do not conform to the dimensions stated in the Technical Data. Do not use any

spacers to make a blade fit onto the spindle. Use only the blades specified in this manual, complying with

EN 847-1.

• Consider applying specially designed noise-reduction blades.

• Do not use high steel (HS) saw blades.

• Do not use cracked or damaged saw blades.

• Ensure that the chosen saw blade is suitable for the material to be cut.

• Always wear gloves for handling saw blades and rough material. Saw blades should be carried in a holder

wherever practicable.

Residual Risks

The following risks are inherent to the use of saws:

- injuries caused by touching the rotating par ts

In spite of the application of the relevant safety regulations and the implementation of safety devices, certain

residual risks cannot be avoided. These are:

- Impairment of hearing.

- Risk of accidents caused by the uncovered par ts of the rotating saw blade.

- Risk of injur y when changing the saw blade with unprotected hands.

- Risk of squeezing fingers when opening the guards.

- Health hazards caused by breathing dust developed when sawing wood, especially oak, beech and MDF.

The following factors are of influence to noise production:

- the material to be cut

- the type of saw blade

- the feed force

- machine maintenance

The following factors are of influence to dust exposure:

- worn saw blade

- dust extractor with air velocity less than 20 m/s

- workpiece not exactly guided

3

Page 4

Package Contents

The package contains:

1 Partly assembled machine

1 Rip fence

1 Mitre gauge

1 Saw blade

1 Upper blade guard assembly

1 Throat plate

2 Blade wrenches

1 Dust extraction adapter

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or accessories which may have occurred during transpor t.

• Take the time to thoroughly read and understand this manual prior to operation.

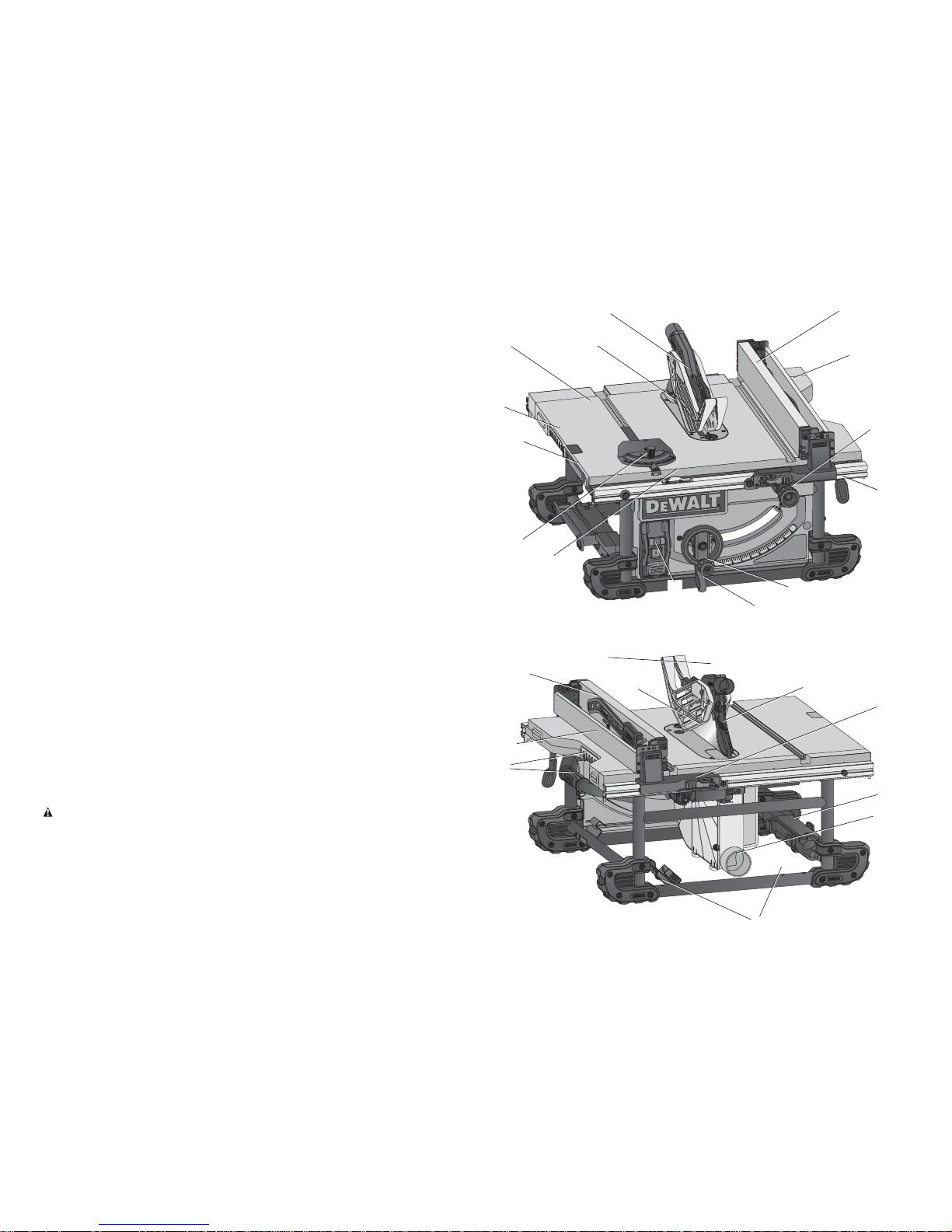

Description (fig. 2, 3)

Your DWE7491-XE jobsite table saw has been designed to per form the four main sawing operations of ripping,

cross-cutting, bevelling and mitring easily, accurately and safely in wood, wood products and plastics. This unit is

designed for use with a 254 mm carbide-tipped blade.

A. Table

B. Blade

C. Rip scale indicator

D. Fine adjust knob

E. Rail lock lever

F. Blade height adjustment wheel

G. Bevel lock lever

H. ON/OFF switch

I. Mounting holes

J. Miter gauge

K. Blade guard assembly

L. Blade guard release lever

M. Splitter

N. Dust exhaust port

O. Guard dust exhaust port

P. Throat plate

Q. Rip fence

R. Rip fence latch

S. Work support/narrrow rip fence (shown in stored

position)

T. Blade wrenches

U. Push stick (shown in stored position)

ELECTRICAL SAFETY

The electric motor has been designed for one voltage only. Always check that the power supply corresponds

to the voltage on the rating plate. 230 V AC means your tool will operate on alternating current. As little as 10%

lower voltage can cause loss of power and can result in overheating. All DEWALT tools are factor y tested; if this

tool does not operate, check the power supply. Your DEWALT tool is double insulated, therefore no earth wire is

required.

• Young children and the infirm. This appliance is not intended for use by young children or infirm persons

without supervision. Young children should be supervised to ensure that they do not play with this appliance.

• Replacement of the supply cord. If the supply cord is damaged, it must be replaced by the manufacturer or

an authorised DEWALT Service Centre in order

to avoid a hazard.

Extension Cords

CAUTION: Use only extension cords that are approved by the country’s Electrical Authority. Before using extension cords, inspect them for loose or exposed wires, damaged insulation and defective fittings. Replace the cord if

necessary.

FIGURE 1

FIGURE 2

A

P

K

E

F

D

G

L

SS

S

Q

H

C

J

O

T

S

SS

R

I

U

B

N

M

4

Page 5

FIG. 3

X

V

T

B

W

1. Raise the saw blade arbor to its maximum height by turning the blade height adjustment wheel (F) clockwise.

2. Remove the throat plate (P). Refer to Mounting the throat plate.

3. Using wrenches, loosen and remove the arbor nut (V) and flange (X) from the saw arbor by turning anticlockwise.

4. Place the saw blade on to the spindle (W) making sure the teeth of the blade (B) point down at the front of

the table. Assemble the washers and arbor nut to the spindle and tighten arbor nut (V) as far as possible by

hand, making sure that the saw blade is against the inner washer and the outer flange (X) is against the blade.

Ensure the largest diameter of the flange is against the blade. Ensure the spindle and washers are free from

dust and debris.

5. To keep the spindle from rotating when tightening the arbor nut, use the open end of the blade wrench (T) to

secure the spindle.

6. Using the arbor wrench, tighten the arbor nut (V) by turning it clockwise.

7. Replace the throat plate.

WARNING: Always check the rip fence pointer and the blade guard assembly after having changed the blade.

Mounting the Blade Guard Assembly (Fig. 1, 4)

WARNING: Use the guard assembly for all through cuttting.

1. Raise the saw blade arbor to its maximum height.

2. Install blade guard assembly by pulling the guard release lever (L) and inser ting splitter (M) until it bottoms

out.

3. Release lever, make sure clamp plates are fully closed and clamp the splitter securely.

FIG. 4

M

B

K

L

WARNING: Before connecting the table saw to the power source or operating the saw, always inspect the blade

guard assembly for proper alignment and clearance with saw blade. Check alignment after each change of bevel

angle.

WARNING: To reduce the risk of serious personal injury, DO NOT operate saw if blade assembly is not securley

clamped in place.

When properly aligned, the splitter (M) will be in line with the blade at both table top level, and at the top of the

blade. Using a straight edge, ensure that the blade (B) is aligned with the splitter (M). With power disconnected,

operate the blade tilt and height adjustments through the extremes of travel and insure the blade guard assembly

clears the blade in all operations.

WARNING: Correct mounting and alignment of the blade guard assembly is essential to safe operation!

MINIMUM GAUGE FOR CORD SETS

For Cable length (m): 7.5 15 25 30 45 60

Use Cable with minimum rating (Amperes)

Tool Amperes

0 - 3.4 7.5 7.5 7.5 7.5 7.5 7.5

3.5 - 5.0 7.5 7.5 7.5 7.5 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 –

WARNING: We recommend the use of a residual current device with a residual current rating of 30mA or less.

WARNING: ALWAYS wear approved protective safety equipment complying with the following standards:

• Eye protection: AS/NZS1337 Eye Protectors for Industrial Applications;

• Hearing protection: AS/NZS1270 Acoustics – Hearing Protection;

• Respiratory protection: AS/NZS1716 Respiratory Protective Devices.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction

activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into

your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and permanent

respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust

exposure. Direct particles away from face and body.

WARNING: Always wear proper personal hearing protection that conforms to AS/NZS1270 during use.

Under some conditions and duration of use, noise from this product may contribute to hearing loss.

ASSEMBLY

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from power source before

installing and removing accessories, before adjusting or changing set-ups or when making repairs. Be sure

the ON/OFF switch is in the OFF position. An accidental start-up can cause injury.

Unpacking

• Remove the saw from the packaging material carefully.

• The machine is fully assembled except for the rip fence and blade guard assembly.

• Finalise the assembly following the instructions as described below.

WARNING: Always keep the push stick in its place when not in use.

Mounting the Saw Blade (Fig. 1, 3)

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from power source before

installing and removing accessories, before adjusting or changing set-ups or when making repairs. Be sure

the trigger switch is in the OFF position. An accidental start-up can cause injury.

WARNING:The teeth of a new blade are very sharp and can be dangerous.

WARNING:The saw blade MUST be replaced as described in this section. ONLY use saw blades as specified

under Technical Data. We suggest DT4226. NEVER fit other saw blades.

NOTE: This tool has blade installed from factory.

5

Page 6

TO REMOVE THE BLADE GUARD ASSEMBLY (FIG. 4)

1. Pull the guard release lever (L).

2. Lift up on blade guard assembly (K).

Mounting the Throat Plate (Fig. 5)

1. Align the throat plate (P) as shown in Figure 8, and

insert the tabs on the back of the throat plate into the

holes on the back of the table opening.

2. Rotate cam counterclockwise until the front of throat

plate drops into place. Secure by rotating cam lock

knob (Y) clockwise 1/4 turn (when cam lock is under

the table holding the throat plate in place).

3. The throat plate includes four adjustment screws which

raise or lower the throat plate. When properly adjusted,

the front of the throat plate should be flush or slightly below the surface of the table top and secured in place.

The rear of the throat plate should be flush or slightly above the table top.

WARNING: Never use the machine without the throat plate. Immediately replace the throat plate when worn or

damaged.

TO REMOVE THE THROAT PLATE

1. Remove the throat plate (P) by turning the cam lock knob (Y) 1/4 turn counterclockwise

2. Using finger hole (Z) on the plate, pull throat plate up and forward to expose the inside of the saw. DO NOT

operate the saw without the throat plate. If using dado blade, use proper dado throat plate (sold seperately).

Fitting the Rip Fence (Fig. 6)

The rip fence can be installed in two positions on the right (Position 1 for 0 mm to 62 cm [24.5”] ripping, and

Position 2 for 20.3 cm [8”] to 82.5 cm [32.5”] ripping) and one position on the left of your table saw.

1. Unlock the rip fence latches (R).

2. Holding the fence at an angle, align the locator pins (front and back) (CC) on the fence rails with the fence

head slots (DD).

3. Slide the head slots onto the pins and rotate the fence down untill it rests on the rails.

4. Lock the fence in place by closing the front and back latches (R) onto the rails.

FIG. 6

R

CC

DD

Bench Mounting (Fig. 1)

WARNING: To reduce the risk of personal injury, make sure table saw is firmly mounted to a stable surface

before use.

WARNING:Ensure that the surface is stable enough that large pieces of material will not cause it to tip over

during use.

The table saw must be mounted firmly. Four holes (I) are provided in the tool’s base for mounting. We strongly

recommend that these holes be used to anchor the table saw to your workbench or other stationary rigid frame.

1. Center the saw on a square piece of 12.7 mm (1/2”) plywood.

2. Mark the positions of the two rear mounting holes (spaced 220 mm (8-5/8”) apar t) in the frame of the saw

with a pencil. Then measure forward 498.5 mm (19-5/8”) the two front holes.

3. Remove the saw and drill 9 mm (11/32”) holes in the places you have just marked.

4. Position the saw over the four holes you drilled in the plywood and inser t four 8 mm (5/16”) machine screws

FROM THE BOTTOM. Install washers and 8 mm (5/16”) nuts on the top. Tighten securely.

FIG. 5

Y

Z

P

5. In order to prevent the screw heads from marring the sur face to which you clamp the saw, attach two strips

of scrap wood to the bottom of the plywood base. These strips can be attached with wood screws installed

from the top side as long as they don’t protrude through the bottom of the strip.

6. Use a “C” clamp to secure the plywood base to your workbench whenever you use the saw.

ADJUSTMENTS

Blade Adjustment (Fig. 7)

BLADE ALIGNMENT (PARALLEL TO MITER SLOT)

WARNING:Cut Hazard. Check the blade at 0˚ and 45˚ to make sure blade does not hit the throat plate, causing

personal injury.

If the blade appears to be out of alignment with the mitre slot on the table top, it will require calibration for

alignment. To realign the blade and mitre slot, use the following procedure:

WARNING:To reduce the risk of injury, turn unit off and disconnect machine from power source before

installing and removing accessories, before adjusting or changing set-ups or when making repairs. An

accidental start-up can cause injury.

1. Using a 5 mm hex wrench, loosen rear pivot bracket

fasteners (FF), located on the underside of the table, just

enough to allow the bracket to move side-to-side.

2. Adjust the bracket until the blade is parallel to the mitre gauge

slot.

3. Tighten the rear pivot bracket fasteners to 110–120

in-lbs (12.5–13.6 Nm).

BLADE HEIGHT ADJUSTMENT (FIG. 1)

The blade can be raised and lowered by turning the blade height

adjustment wheel (F).

Make sure the top three teeth of the blade are just breaking through

the upper surface of the workpiece when sawing. This will ensure

that the maximum number of teeth are removing material at any

given time, thus giving optimum performance.

Aligning Guard Assembly/Splitter to Blade (Fig. 8)

1. Remove the throat plate. Refer to Remove Throat Plate.

2. Raise the blade to full depth of cut and 0° bevel angle.

3. Locate the three small set screws (LL) adjacent to the guard assembly

lock knob (MM). These screws will be used to adjust the guard

assembly position.

5. Lay a straight edge on the table against two blade tips. The splitter (M)

should not touch the straight edge. If needed, loosen the two larger

lock screws (NN).

6. Adjust the small set screws (LL) to move the splitter according to the

position noted in step 5. Lay the straight edge on the opposite side of

the blade and repeat adjustments as needed.

7. Lightly tighten the two larger lock screws (NN).

8. Place a square flat against the splitter to the verify splitter is ver tical and in-line with the blade.

9. If needed, use the set screws to bring the splitter ver tical with the square.

10. Repeat steps 5 and 6 to verify position of splitter.

11. Fully tighten the two larger lock screws (NN).

Parallel Adjustment (Fig. 1, 9, 15)

For optimum performance, the blade must be parallel to the rip fence. This adjustment has been made at the

factory. To re-adjust:

FIG. 7

FF

FIG. 8

LL

MM

NN

6

Page 7

FIG. 9

POSITION 1

POSITION 2

CC

POSITION 1 FENCE ALIGNMENT

1. Install the fence in position 1 and unlock the rail lock lever (E). Locate both locator pins (CC) that suppor t the

fence on the front and rear rails.

2. Loosen the rear locator pin screw and adjust the allignment

of the fence in the groove until the fence face is parallel to the

blade. Make sure you measure from the fence face to the front

and back of the blade to ensure alignment.

3. Tighten the locator screw and repeat on the left side of the

blade.

4. Check rip scale pointer adjustment. Refer to figure 11.

POSITION 2 FENCE ALIGNMENT

1. To align position 2 fence locator pins (CC), ensure position 1

pins have been aligned, refer to Position 1 Fence Alignment.

2. Loosen the position 2 pins, then using the blade wrench holes

as a guide for positioning, align the pins (fig. 10).

3. Tighten the locator pins (front and rear).

Adjusting the Rip Scale (Fig. 11)

1. Unlock the rail lock lever (E).

2. Set the blade at 0° bevel and move the fence in until it touches the blade.

3. Lock the rail lock lever.

4. Loosen the rip scale indicator screws (EE) and set the rip scale indicator

to read zero (0). Retighten the rip scale indicator screws. The yellow rip

scale (top) reads correctly only when the fence is mounted on the right

side of the blade and is in position 1 (for zero to 62 cm [24.5”] ripping)

not the 82.5 cm (32.5”) rip position. The white scale (bottom) reads

correctly only when the fence is mounted on the right side of the blade

and in position 2 (for 20.3 cm [8”] to 82.5 cm [32.5”] ripping).

The rip scale reads correctly only when the fence is mounted to the right of the blade.

Rail Lock Adjustment (Fig. 1, 12)

The rail lock has been factory-set. If you need to re-adjust,

proceed as follows:

1. Lock the rail lock lever (E).

2. On the underside of the saw, loosen the jam nut (GG).

3. Tighten the hex rod (HH) until the spring on the locking

system is compressed creating the desired tension on the

rail lock lever. Retighten the jam nut against the hex rod.

4. Flip the saw over and check that the fence does not move

when the lock lever is engaged. If the fence is still loose,

tighten the spring further.

FIG. 10

CC

T

FIG. 11

151413 1817 20 21916

765109 12 1118

EE

HH

GG

FIG. 12

Bevel stop and pointer adjustment (Fig. 13)

1. Raise the blade fully by rotating the blade height

adjustment wheel (F) clockwise until it stops.

2. Unlock the bevel lock lever (G) by pushing it up and to the

right. Loosen the bevel stop screw (JJ).

3. Place a square flat against the table top and against the

blade between teeth. Ensure the bevel lock lever is in its

unlocked, or up, position.

4. Using the bevel lock lever, adjust the bevel angle until it is

flat against the square.

5. Tighten the bevel lock lever by pushing it down.

6. Turn the bevel stop cam (II) until it firmly contacts the

bearing block. Tighten the bevel stop screw (JJ).

7. Check the bevel angle scale. If the pointer does not read

0°, loosen pointer screw (KK) and move the pointer so it

reads correctly. Retighten the pointer screw.

8. Repeat at 45°, but do not adjust pointer.

Mitre Gauge Adjustment (Fig. 1)

To adjust mitre gauge (J) loosen knob, set to desired angle and tighten knob.

Body and Hand Position

Proper positioning of your body and hands when operating the table saw will make cutting easier, more accurate

and safer.

WARNING:

• Never place your hands near the cutting area.

• Place your hands no closer than 150 mm from the blade.

• Do not cross your hands.

• Keep both feet firmly on the floor and maintain proper balance.

Prior to Operation

WARNING:

• Install the appropriate saw blade. Do not use excessively worn blades.The maximum rotation speed of the

tool must not exceed that of the saw blade.

• Do not attempt to cut excessively small pieces.

• Allow the blade to cut freely. Do not force.

• Allow the motor to reach full speed before cutting.

OPERATION

Instructions for Use

WARNING:Always observe the safety instructions and applicable regulations.

WARNING:To reduce the risk of injury, turn unit off and disconnect machine from power source before

installing and removing accessories, before adjusting or changing set-ups or when making repairs. Be sure

the trigger switch is in the OFF position. An accidental start-up can cause injury.

The attention of UK users is drawn to the “woodworking machines regulations 1974” and any subsequent

amendments.

Ensure the machine is placed to satisfy your ergonomic conditions in terms of table height and stability. The

machine site shall be chosen so that the operator has a good overview and enough free surrounding space around

the machine that allows handling of the workpiece without any restrictions.

To reduce effects of increased vibration, make sure the environment is not too cold, the machine and accessory

are well maintained and the workpiece size is suitable for this machine.

F

KK

JJ

G

II

FIG. 13

7

Page 8

WARNING:

• Always observe the safety instructions and applicable regulations.

• Ensure the machine is placed to satisfy ergonomic conditions in terms of table height and stability. The

machine site shall be chosen so that the operator has a good overview and enough free surrounding space

around the machine that allow handling of the workpiece without any restrictions.

• Install the appropriate saw blade. Do not use excessively worn blades. The maximum rotation speed of the

tool must not exceed that of the saw blade.

• Do not attempt to cut excessively small pieces.

• Allow the blade to cut freely. Do not force.

• Allow the motor to reach full speed before cutting.

• Make sure all locking knobs and clamp handles are tight.

• Never place either hand in the blade area when the saw is connected to the electrical power source.

• Never use your saw for freehand cuts!

• Do not saw warped, bowed or cupped workpieces. There must be at least one straight, smooth side to go

against the rip fence or mitre fence.

• Always support long workpieces to prevent kickback.

• Do not remove any cut-offs from the blade area while the blade is running.

Switching On and Off (Fig. 14)

The on/off switch (H) of your saw bench offers multiple advantages:

• No-volt release function: should the power be shut off for any reason, the

switch has to be deliberately reactivated.

• To switch the machine on, press the green star t button.

• To switch the machine off, press the red stop button.

Rip Fence Operation (Fig. 15–17)

RAIL LOCK LEVER

The rail lock lever (E) locks the fence in place preventing movement during cutting. To lock the rail lever, push it

down and toward the rear of the saw. To unlock, pull it up and toward the front of the saw.

NOTE: When ripping, always lock the rail lock lever.

FIG. 15

AA

BB

WORK SUPPORT EXTENSION /NARROW RIPPING FENCE

Your table saw is equipped with a work support extension to support

work that extends beyond the saw table.

To use the narrow ripping fence in the work support position, rotate

it from its stored position as shown in Figure 15, and slide the pins

into the lower sets of slots (aa) on both ends of the fence.

To use the narrow ripping fence in the narrow ripping position, snap

the pins into the upper sets of slots (bb) on both ends of the fence.

This feature will allow 51 mm (2”) of extra clearance to the blade.

Refer to Figure 16.

NOTE: Retract the work support extension or adjust to narrow rip fence position whenever working over the table.

FINE ADJUSTMENT KNOB

The fine adjustment knob (D) allows smaller adjustments when setting the fence. Before adjusting, be sure the rail

lock lever is in its up or unlocked, position.

FIG. 14

H

FIG. 16

FIG. 17

D

E

RIP SCALE POINTER

The rip scale pointer will need to be adjusted for proper performance of the rip fence if the user switches between

thick and thin kerf blades. The rip scale pointer only reads correctly for position 1 (zero to 61 cm), however for

position 1 with narrow rip fence in use add 5.08 cm. See Adjusting the Rip Scale under Assembly.

BASIC SAW CUTS

Ripping (Fig. 1, 2, 18 & 19)

WARNING: Sharp edges.

1. Set the blade to 0°.

2. Lock the rip fence latch (R) (fig. 1).

3. Raise the blade until it is about 3 mm higher than the top of the workpiece. Adjust the height of the upper

blade guard as necessary.

4. Adjust the position of the fence, refer to Rip Fence Operation.

5. Hold the workpiece flat on the table and against the fence. Keep the workpiece away from the blade.

6. Keep both hands away from the path of the blade (fig. 18).

7. Switch the machine on and allow the blade to reach full speed.

8. Slowly feed the workpiece underneath the guard, keeping it firmly pressed against the rip fence. Allow the

teeth to cut, and do not force the workpiece through the blade. The blade speed should be kept constant.

9. Always use a push stick (U) when working close to the blade (fig. 19).

10. After completing the cut, switch the machine off, allow the blade to stop and remove the workpiece.

FIG. 18 FIG. 19

u

WARNING:

• Never push or hold the “free” or cut-off-side of the workpiece.

• Do not cut excessively small workpieces.

• Always use a push stick when ripping small workpieces.

Bevel Cuts (Fig 1)

1. Set the required bevel angle, by rotating lever (g) by pushing it up and to the right.

2. Set to desired angle, rotate lever by pushing down and to the left to lock in place.

3. Proceed as for ripping.

8

Page 9

Cross-Cutting and Bevel Crosscutting

1. Remove the rip fence and install the mitre gauge in the desired slot.

2. Lock the mitre gauge at 0°.

3. Proceed as for ripping.

Mitre Cuts (fig. 1)

1. Set the mitre gauge (J) to the required angle.

NOTE: Always hold the workpiece tightly against the face of the mitre gauge.

2. Proceed as for ripping.

Compound mitre

This cut is a combination of a mitre and a bevel cut.Set the bevel to the angle required and proceed as for a crosscut mitre.

Support for long pieces

• Always support long pieces.

• Support long workpieces using any convenient means such as saw-horses or similar devices to keep the

ends from dropping.

Dust extraction (Fig. 1)

The machine is provided with a dust exhaust port (N) at the rear of the machine suitable for use with dust

extraction equipment featuring 57/65 mm nozzles. Supplied with the machine is a reducer port for use of dust

extraction nozzles of 34-40 mm diameter.

The blade guard assembly also features a dust exhaust port for 35 mm nozzles.

• During all operations, connect a dust extraction device designed in accordance with the relevant regulations

regarding dust emission.

• Ensure that the dust extraction hose in use is suitable for the application and material being cut. Ensure proper

hose management.

• Be aware that man-made materials such as chipboard or MDF produce more dust particles during cutting

than natural timber.

Storage (Fig. 20–22)

1. Attach push stick (U) to fence.

2. Remove blade guard assembly. See To Remove Blade Guard Assembly. Hook front of blade guard assembly

onto bracket and slide the rear of the assembly into holder as shown, then turn lever anti-clockwise to lock.

3. Slide blade wrenches (T) into pocket until yellow button aligns with hole to secure in place, refer to figure 22.

4. Inser t guide bar of mitre gauge into pocket, then pivot and snap in place. Position the mitre gage extension

upwards to avoid interference.

5. Wrap cord in this location (OO).

6. To store fence, snap work support in stored position. Remove fence from rails. Reattach fence upside down on

left side of saw, refer to figure 21. DO NOT hook locator slots on left side fence locator screws. These screws

will align with clearance pocket on fence as shown. Close the rip fence latches (R) to secure.

FIG. 20

J

K

U

OO

FIG. 21

FIG. 22

R

T

Transporting (Fig. 1, 2)

• Always carry the machine using the designated handles (SS), refer to figures 1 and 2.

WARNING: Always transport the machine with the upper blade guard fitted.

MAINTENANCE

Your DEWALT machine has been designed to operate over a long period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon proper tool care and regular cleaning.

Lubrication (Fig. 23)

The motor and bearings require no additional lubrication. If raising and lowering the

blade becomes difficult, clean and grease the height adjustment screws:

1. Unplug the saw from power source.

2. Turn the saw on its side.

3. Clean and lubricate the height adjustment screw threads (pp) on the underside of

this saw as shown in figure 24. Use general purpose grease.

Cleaning (Fig. 1, 24)

WARNING: To reduce the risk of serious personal injury, turn unit off and

disconnect machine from power source before cleaning. An accidental start-up can

cause injury.

WARNING: Blow dirt and dust out of all air vents with clean,

dry air at least once a week. To minimize the risk of eye injury,

always wear AS/NZS1337 approved eye protection when performing this.

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

WARNING: To reduce the risk of injury, regularly clean the

table top.

WARNING: To reduce the risk of injury, regularly clean the dust collection system.

The blade guard assembly (K) and throat plate must be placed in position before operating the saw.

Before use,carefully inspect upper and lower blade guards as well as the dust extraction tube to determine that

it will operate properly. Ensure that chips, dust or work piece particles cannot lead to blockage of one of the

functions.

In case workpiece fragments are jammed between saw blade and guards, disconnect the machine from the power

supply and follow the instructions given in section Mounting the saw blade. Remove the jammed parts and

reassemble the saw blade.

Keep the ventilation slots clear and regularly clean the housing with a soft cloth.

Regularly clean the dust collection system:

1. Unplug the saw.

2. Turn the saw on its side, so the bottom, open part of the unit is accessible.

3. Open the dust access door (QQ) shown in figure 19 loosening the two screws and then by pressing the side

clips (RR). Clean out the excess dust, and re-secure by pushing the side clips completely into place then

tightening the lock screws.

PP

FIG. 23

QQ

RR

FIG. 24

9

Page 10

Optional Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested with this product, use

of such accessories with this tool could be hazardous. To reduce the risk of injury, only DEWALT, recommended

accessories should be used with this product.

Replace blade guard when worn. Contact your local DEWALT service centre for details on a blade guard

replacment.

SAW BLADES: ALWAYS USE 254 mm noise reduced saw blade with appropriate sized clamp washer for blade

hole and 16 mm saw arbour. Blade speed rating must be at least 5000 RPM. Never use a small diameter blade.

Never use a smaller diameter blade. It will not be guarded properly.

BLADE DESCRIPTIONS

APPLICATION DIAMETER TEETH

Construction Saw Blades (fast rip)

General Purpose 254 mm 24

Fine Crosscuts 254 mm 40

Woodworking Saw Blades (provide smooth, clean cuts)

Fine crosscuts 254 mm 60

Consult your dealer for further information on the appropriate accessories.

WARNING: Since accessories, other than those offered by DEWALT, have not been tested with this product, use

of such accessories with this tool could be hazardous. To reduce the risk of injury, only DEWALT recommended

accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local service center. If you

need any assistance in locating any accessory, please contact Stanley Black & Decker, 82 Taryn Drive, Epping,

VIC 3076 Australia or call 1800 338 002 or (NZ) 0800 339 258.

WARNING: Sharp edges.

Unwanted Tools and the Environment

Take your tool to an authorized DEWALT repair agent where it will bedisposed of in an environmentally safe way.

Service Information

Please have the following information available for all service calls:

Model Number _________________ Serial Number _________________

Date and Place of Purchase ____________________________________

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and

replacement) should be performed by cer tified service centers or other qualified service organizations, always

using identical replacement parts.

10

Page 11

11

Page 12

Stanley Black & Decker

82 Taryn Drive, Epping, VIC 3076 Australia • 1800 338 002 (Aust) or 0800 339 258 (NZ)

www.dewalt.com.au • www.dewalt.co.nz

(MAR14) Part No. N393535 DWE7491-XE Copyright © 2013, 2014 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped

humps on the surface of the tool.

Loading...

Loading...