Page 1

Before returning this product call

1-800-4-DEWAL T

Questions? Visit us at www.dewalt.com

Des questions ? Rendez nous visite à www.dewalt.com

¿Tiene preguntas? Visítenos en www.dewalt.com

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR DEWALT PURCHASE,

CALL 1-800-4-DEWALT

IN MOST CASES, A DEWALT REPRESENTATIVE CAN RESOLVE

YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL.

YOUR FEEDBACK IS VITAL TO THE SUCCESS OF D

IMPROVEMENT PROGRAM.

E

WALT’S QUALITY

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

DWE7490, DWE7491

Heavy-Duty 10" (254 mm) Job Site Table Saw

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

Scie de table industrielle de chantier de 254mm (10po)

Sierra de banco para el lugar de trabajo de 254 mm (10 pulg.) de alta resistencia

Page 2

Page 3

Defi nitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided,

may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-D

WARNING: To reduce the risk of injury, read the instruction manual.

EWALT (1-800-433-9258).

General Safety Rules

WARNING: Read all instructions before operating product. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS

WARNING: FOLLOW ALL WIRING CODES and recommended electrical connections to

prevent shock or electrocution.

Double Insulation

If saw is of double-insulated construction, read the following instructions.

This symbol

constructed throughout with two separate layers of electrical insulation or one double

thickness of insulation between you and the tool’s electrical system. Tools built with this

insulation system are not intended to be grounded. As a result, your tool is equipped with a

two prong plug which permits you to use extension cords without concern for maintaining a

ground connection. Repair or replace damaged or worn cord immediately.

NOTE: Double insulation does not take the place of normal safety precautions when

operating this tool. The insulation system is for added protection against injury resulting from

a possible electrical insulation failure within the tool.

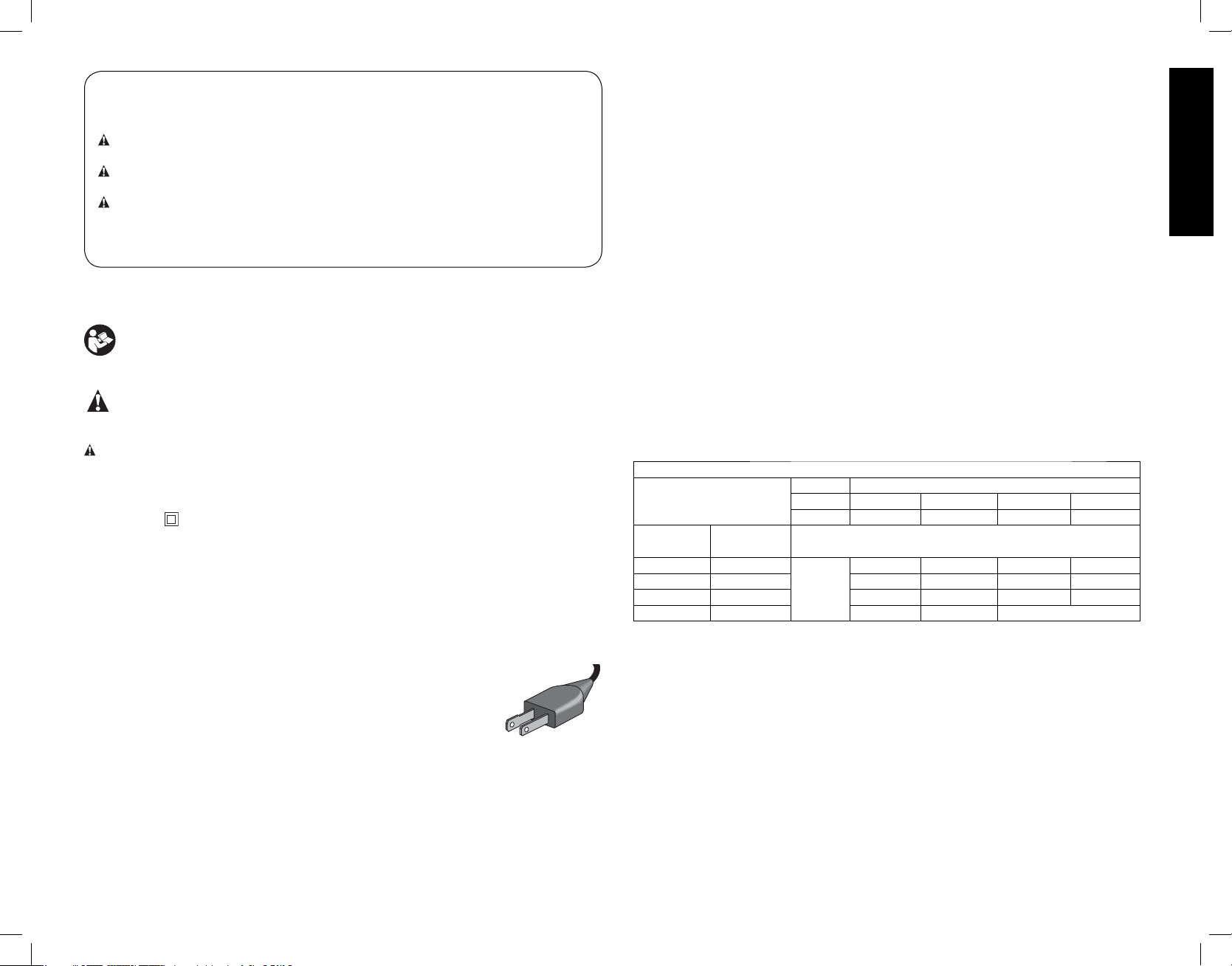

POLARIZED PLUGS

To reduce the risk of electric shock, this equipment has a polarized plug

(one blade is wider than the other). This plug will fit in a polarized outlet

only one way. If the plug does not fit fully into the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician to install the proper

outlet. Do not change the plug in any way.

represents double insulated construction. Double insulated tools are

Important Safety Instructions

• TO REDUCE THE RISK OF KICKBACK AND OTHER INJURIES, use all components

of the guarding system (blade guard assembly, riving knife and anti-kickback) for every

operation for which they can be used including all thru-cutting.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from spindle before turning tool on. Tools, scrap

pieces, and other debris can be thrown at high speed, causing injury.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

• DO NOT USE THE MACHINE IN A DANGEROUS ENVIRONMENT. The use of power

tools in damp or wet locations or in rain can cause shock or electrocution. Keep your work

area well-lit to avoid tripping or placing arms, hands, and fingers in danger.

• KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from work area.

Your shop is a potentially dangerous environment.

• MAKE WORKSHOP CHILDPROOF with padlocks, master switches, or by removing

starter keys. The unauthorized start-up of a machine by a child or visitor may result in

injury.

• DO NOT FORCE TOOL. It will do the job better and be safer at the rate for which it was

designed.

• USE THE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not

designed. Using the incorrect tool or attachment may result in personal injury.

• DO NOT OVERREACH. Keep proper footing and balance at all times. Loss of balance

may cause personal injury. Do not attempt to retrieve materials near the blade on the saw

table while the blade is spinning.

• MAINTAIN TOOLS WITH CARE. Keep blades sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories. Poorly

maintained blades and machines can further damage the blade or machine and/or

cause injury.

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating.The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 Not Recommended

• WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get caught in moving parts. Nonslip footwear is

recommended. Wear protective hair covering to contain long hair.

• ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation

is dusty. Everyday eyeglasses only have impact resistant lenses, they are NOT safety

glasses.

• SECURE WORK. Use clamps to hold work when practical (such as when using a zero

clearance insert/throat plate). It's safer than using your hand and it frees both hands to

operate tool.

• TURN THE MACHINE “OFF”, AND DISCONNECT THE MACHINE FROM THE

POWER SOURCE before installing or removing accessories, before adjusting or

changing set-ups, when making repairs or changing locations. Do not touch the plug’s

metal prongs when unplugging or plugging in the cord. An accidental start-up can cause

injury.

Not More

Than

120 V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240 V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

English

1

Page 4

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure that the switch is in

the “OFF” position before plugging in the power cord. In the event of a power failure, move

the switch to the “OFF” position. An accidental start-up can cause injury.

• Do not plug into or unplug from power source with wet hands.

• USE RECOMMENDED ACCESSORIES. Use only accessories that are recommended

by the manufacturer for your model. Accessories that may be suitable for one tool may be

hazardous when used on another tool. Consult the instruction manual for recommended

English

accessories. The use of improper accessories may cause risk of injury to persons.

• Magnetic accessories will not work on this saw.

• NEVER STAND OR SIT ON TOOL. Serious injury could occur if the tool is tipped or if the

cutting tool is unintentionally contacted.

• CHECK FOR DAMAGED PARTS. Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate properly and

perform its intended function—check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or replaced. Do not use

tool if switch does not turn it on and off. Damaged parts can cause further damage to the

machine and/or personal injury.

• DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation

of the blade or cutter only. No cove cutting or freehand cuts.

• Check for adequate outfeed distance behind the saw to be sure materials can pass

unobstructed through the cut. Work support tables should be placed in proper locations

to fully support the material.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave

tool until it comes to a complete stop. Serious injury can result.

• DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN

GASEOUS OR EXPLOSIVE ATMOSPHERES. Motors and switches in these tools may

spark and ignite fumes.

• STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE COMMON SENSE. DO

NOT USE THE MACHINE WHEN YOU ARE TIRED OR UNDER THE INFLUENCE

OF DRUGS, ALCOHOL, OR MEDICATION. A moment of inattention while operating

power tools may result in serious injury.

• DO NOT ALLOW FAMILIARITY (gained from frequent use of this saw) TO

REPLACE SAFETY RULES. Always remember that a careless fraction of a second is

sufficient to inflict severe injury. Use extra caution and stay alert when making repetitive

cuts. Turn off saw frequently to clean up saw dust and check adjustments to reduce

monotony.

Additional Safety Rules for Table Saws

• AVOID AWKWARD POSITIONS, where a sudden slip could cause a hand to move into

a saw blade.

• Do not attempt to retrieve materials near the blade on the saw table while the blade is

spinning.

• NEVER REACH IN BACK OF, OR AROUND, THE CUTTING TOOL with either hand

to hold down the workpiece.

• KEEP ARMS, HANDS AND FINGERS AWAY from the blade to prevent serious injury.

• USE A PUSH STICK THAT IS APPROPRIATE TO THE APPLICATION TO PUSH

WORKPIECES THROUGH THE SAW. A push stick is a wooden or plastic stick, often

homemade, that should be used whenever the size or shape of the workpiece would

cause you to place your hands within 6" (152mm) of the blade.

• USE HOLD-DOWNS, JIGS, FIXTURES OR FEATHER BOARDS TO HELP GUIDE

AND CONTROL THE WORKPIECE. Accessories for use with your tool are available

at extra cost from your local dealer or authorized service center. Instructions for making a

push stick, a narrow rip auxiliary fence, a push block and feather boards are included in

this manual.

• DO NOT PERFORM RIPPING, CROSSCUTTING OR ANY OTHER OPERATION

FREEHAND.

• NEVER reach around or over saw blade.

• STABILITY. Make sure the table saw is firmly mounted to a secure surface before use and

does not move.

• NEVER CUT METALS, CEMENT BOARD OR MASONRY. Certain man-made

materials have special instructions for cutting on table saws. Follow the manufacturer’s

recommendations at all times. Damage to the saw and personal injury may result.

• THE PROPER THROAT PLATE MUST BE LOCKED IN PLACE AT ALL TIMES to

reduce the risk of a thrown workpiece and possible injury.

• USE THE CORRECT SAW BLADE FOR THE INTENDED OPERATION. The blade

must rotate toward the front of the saw. Always tighten the blade arbor nut securely. Before

use, inspect the blade for cracks or missing teeth. Do not use a damaged or dull blade.

• NEVER ATTEMPT TO FREE A STALLED SAW BLADE WITHOUT FIRST TURNING

THE MACHINE OFF AND DISCONNECTING THE SAW FROM THE POWER

SOURCE. If a workpiece or cut-off piece becomes trapped inside the blade guard

assembly, turn saw off and wait for blade to stop before lifting the blade guard assembly

and removing the piece.

• NEVER START THE MACHINE with the workpiece against the blade to reduce the risk

of a thrown workpiece and personal injury.

• DO NOT HAVE ANY PART OF YOUR BODY IN LINE WITH THE BLADE. Personal

injury may occur. Stand to either side of the blade.

• NEVER PERFORM LAYOUT, ASSEMBLY OR SET-UP WORK on the table/work area

when the machine is running. A sudden slip could cause a hand to move into the blade.

Severe injury can result.

• CLEAN THE TABLE/WORK AREA BEFORE LEAVING THE MACHINE. Lock

the switch in the “OFF” position and disconnect from the power source to prevent

unauthorized use.

• ALWAYS lock the fence and bevel adjustment before cutting.

• DO NOT leave a long board (or other workpiece) unsupported so the spring of the

board causes it to shift on the table resulting in loss of control and possible injury.

Provide proper support for the workpiece, based on its size and the type of operation to

be performed. Hold the work firmly against the fence and down against the table surface.

• IF THIS SAW makes an unfamiliar noise or if it vibrates excessively, cease operating

immediately, turn unit off and disconnect from power source until the problem has been

located and corrected. Contact a D

service center or other qualified service personnel if the problem can not be found.

• DO NOT OPERATE THIS MACHINE until it is completely assembled and installed

according to the instructions. A machine incorrectly assembled can cause serious injury.

• ADDITIONAL INFORMATION regarding the safe and proper operation of power tools

(i.e., a safety video) is available from the Power Tool Institute, 1300 Sumner Avenue,

Cleveland, OH 44115-2851 (www.powertoolinstitute.com). Information is also available

from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201. Please

refer to the U.S. Department of Labor OSHA 1910.213 Regulations.

EWALT factory service center, a DEWALT authorized

2

Page 5

TERMS: THE FOLLOWING TERMS WILL BE USED THROUGHOUT THE MANUAL

AND YOU SHOULD BECOME FAMILIAR WITH THEM.

• Thru-sawing refers to any cut that completely cuts through the workpiece.

• Non thru-sawing refers to any cut that does not completely cut through the workpiece.

• Push Stick refers to a wooden or plastic stick, usually homemade, that is used to push

small workpiece through the saw and keeps the operator’s hands clear of the blade.

• Kickback occurs when the saw blade binds in the cut and violently thrusts the workpiece

back toward the operator.

• Freehand refers to cutting without the use of a miter gauge or rip fence or any other

means of guiding or holding the workpiece other than the operator’s hands.

WARNING: Never perform freehand cutting with this saw.

• Plunge cutting refers to cutting where the workpiece is either lowered down onto the

blade with the workpiece controlled by the user's hands or the workpiece is supported

by the user's hands on the table surface and the blade is then raised up through the

workpiece.

WARNING: Never perform plunge cutting with this saw.

• Resawing - Flipping material to make a cut the saw is not capable of making in one pass.

WARNING: Resawing IS NOT recommended.

• Outfeed - The distance behind the saw required to pass the material all the way through

the cut.

SAW BLADE GUARD ASSEMBLY, ANTI-KICKBACK ASSEMBLY AND RIVING KNIFE

This table saw is equipped with a blade guard assembly with splitter and anti-kickback

assembly that covers the blade and reduces the possibility of accidental blade contact. A

non thru-sawing riving knife is also provided when making non thru-cuts. The riving knife and

splitter are flat plates that fit into the cut made by the saw blade and effectively fights kickback

by lessening the tendency of the blade to bind in the cut. The blade guard assembly and

anti-kickback assembly can only be used when making thru-cuts that sever the

wood. When making rabbets and other cuts that make non thru-cuts, the blade

guard assembly and anti-kickback assembly must be removed and then install the

non thru-sawing riving knife provided. Two anti-kickback pawls are located on the sides

of the riving knife that allow the wood to pass through the blade in the cutting direction but

reduce the possibility of the material being thrown backwards toward the operator.

Use all components of the guarding system (blade guard assembly, riving knife and antikickback assembly) for every operation for which they can be used including all thru-cutting.

If you elect not to use any of these components for a particular application exercise additional

caution regarding control of the workpiece, the use of push sticks, the position of your hands

relative to the blade, the use of safety glasses, the means to avoid kickback and all other

warnings contained in this manual and on the saw itself. Replace the guarding systems

as soon as you return to thru-cutting operations. Keep the guard assembly in working

order.

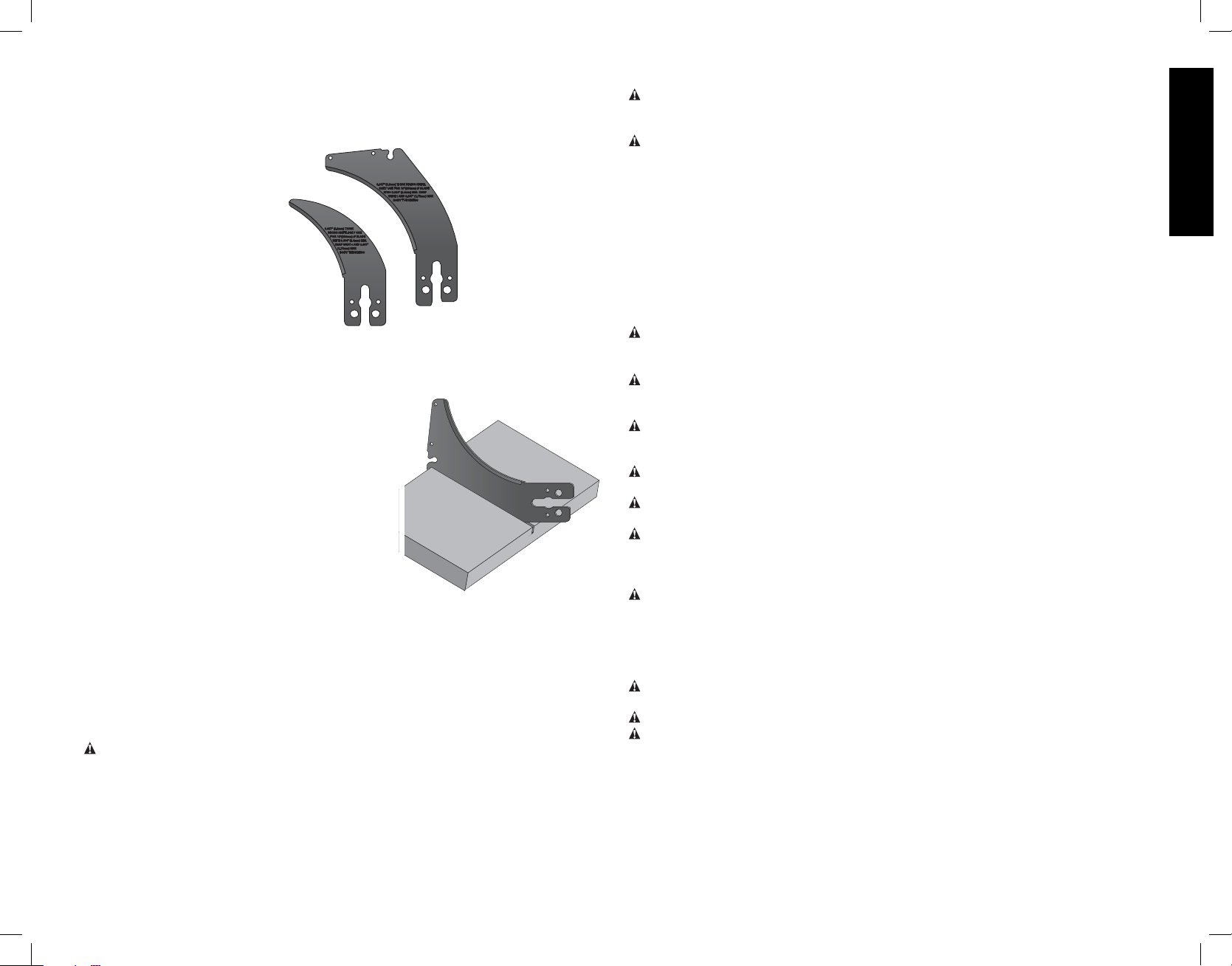

MAKING A PUSH STICK (Inside Back Cover)

• In order to operate this table saw safely you must use a push stick whenever the size or

shape of the workpiece would cause your hands to be within 6" (152mm) of the saw blade

or other cutter. A push stick is included with this saw.

• No special wood is needed to make additional push-sticks as long as it’s sturdy and long

enough. A length of 15.7" (400mm) is recommended with a notch that fits against the

edge of the workpiece to prevent slipping. It’s a good idea to have several push sticks

of the same length (15.7" [400mm] ) with different size notches for different workpiece

thicknesses.

• See the inside back cover for a picture of a push stick. The shape can vary to suit your

own needs as long as it performs its intended function of keeping your hands away from

the blade.

KICKBACKS

Kickbacks can cause serious injury. A kickback occurs when a part of the workpiece binds

between the saw blade and the rip fence, or other fixed object, and rises from the table

and is thrown toward the operator. Kickbacks can be avoided by attention to the following

conditions.

How to Avoid Them and Protect Yourself from Possible Injury

a. Use the blade guard with splitter, or use the riving knife whenever possible.

b. Be certain that the rip fence is parallel to the saw blade.

c. Do not rip by applying the feed force to the section of the workpiece that will become

the cut-off (free) piece. Feed force when ripping should always be applied between the

saw blade and the fence; use a push stick for narrow work, 6" (152mm) wide or less.

d. Keep saw blade guard assembly, riving knife and anti-kickback assembly in place and

operating properly. If anti-kickback assembly is not operational, return your unit to

the nearest authorized D

must be in alignment with the saw blade and the anti-kickback assembly must stop a

kickback once it has started. Check their action before ripping by pushing the wood

under the anti-kickback assembly. The teeth must prevent the wood from being pulled

toward the front of the saw.

e. Plastic and composite (like laminate flooring) materials may be cut on this saw.

However, since these are usually quite hard and slippery, the anti-kickback pawls may

not stop a kickback. Therefore, be especially attentive to following proper set up and

cutting procedures for ripping.

f. Use saw blade guard assembly, anti-kickback assembly and riving knife for every

operation for which it can be used, including all thru-sawing.

g. Push the workpiece past the saw blade prior to release.

h. NEVER rip a workpiece that is twisted or warped, or does not have a straight edge to

guide along the fence.

i. NEVER saw a large workpiece that cannot be controlled.

j. NEVER use the fence as a guide or length stop when crosscutting.

k. NEVER saw a workpiece with loose knots, flaws, nails or other foreign objects.

l. NEVER rip a workpiece shorter than 10" (254mm).

m. NEVER use a dull blade – replace or have resharpened.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses.

Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

EWALT service center for repair. The splitter and riving knife

English

3

Page 6

WARNING: Use of this tool can generate and/or disperse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

Specifi cations

Amperes 15 A

English

Table Size 21-7/8" (556 mm) X 26-3/8" (669 mm)

Miter Angle 30° L&R

Bevel Angle 0° to 45°L

Blade Size 10" (254mm)

Max. Cut Depth, 0° Bevel 3-1/8" (79mm)

Max. Cut Depth, 45° Bevel 2-1/4" (57mm)

RPM, no load 4800

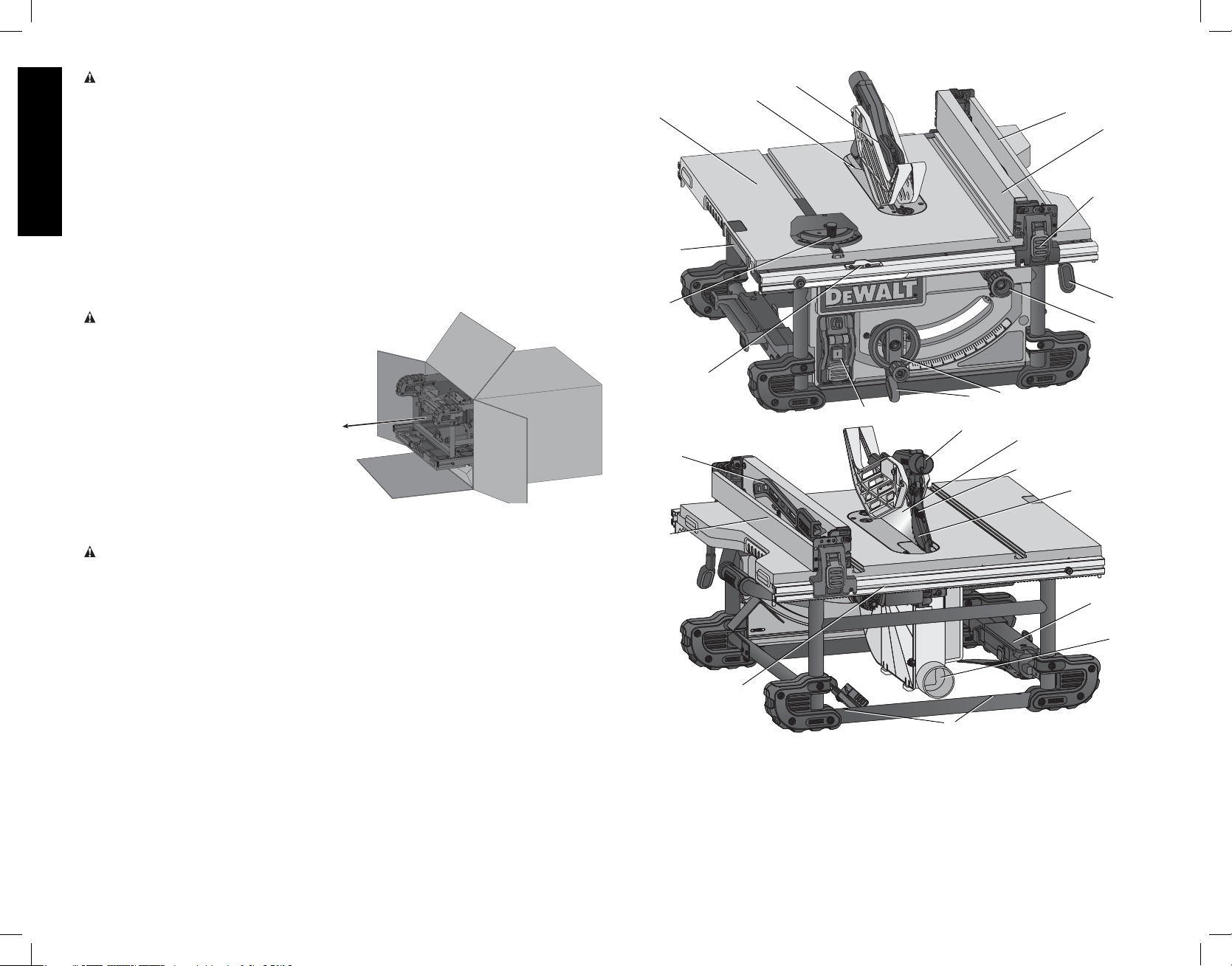

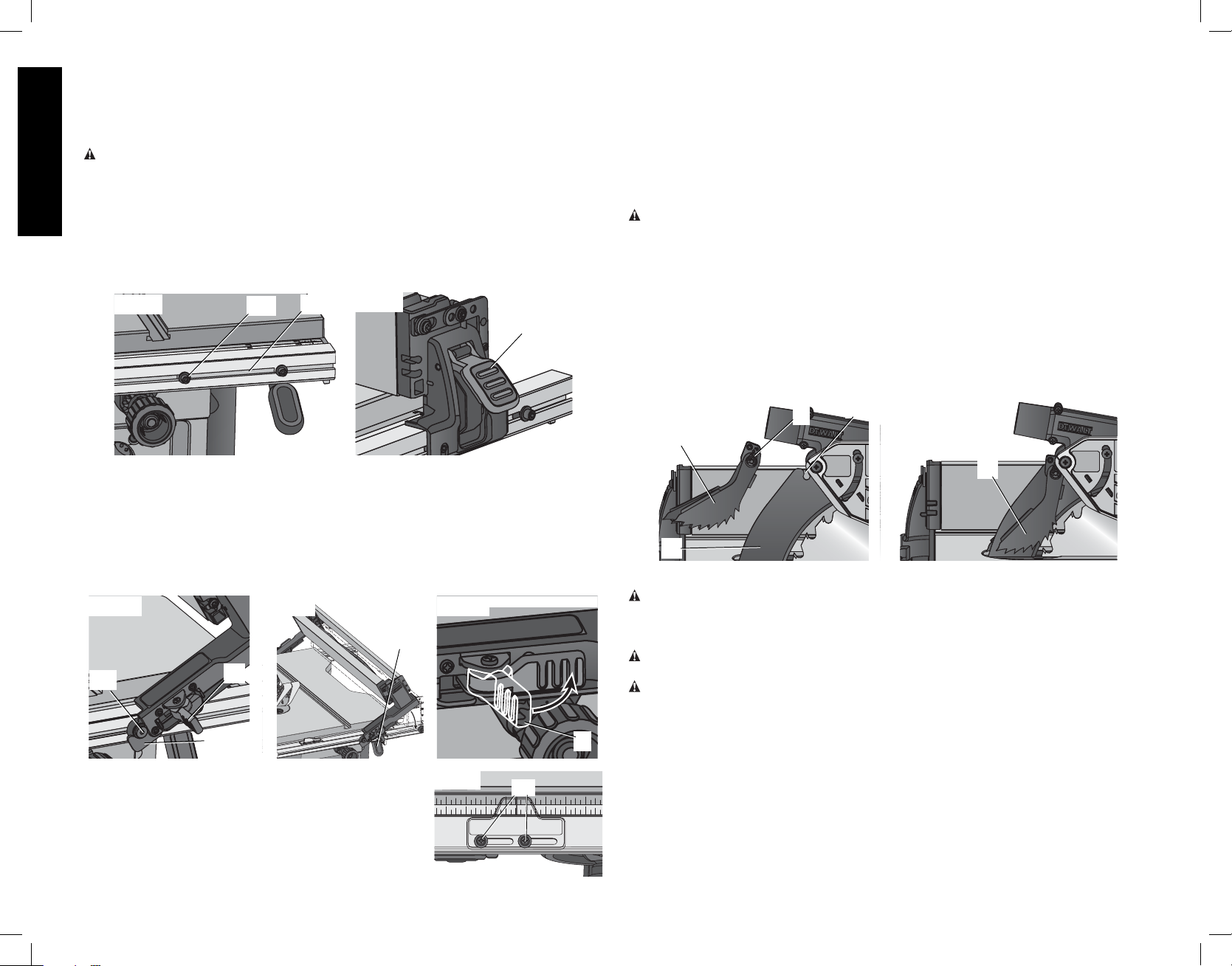

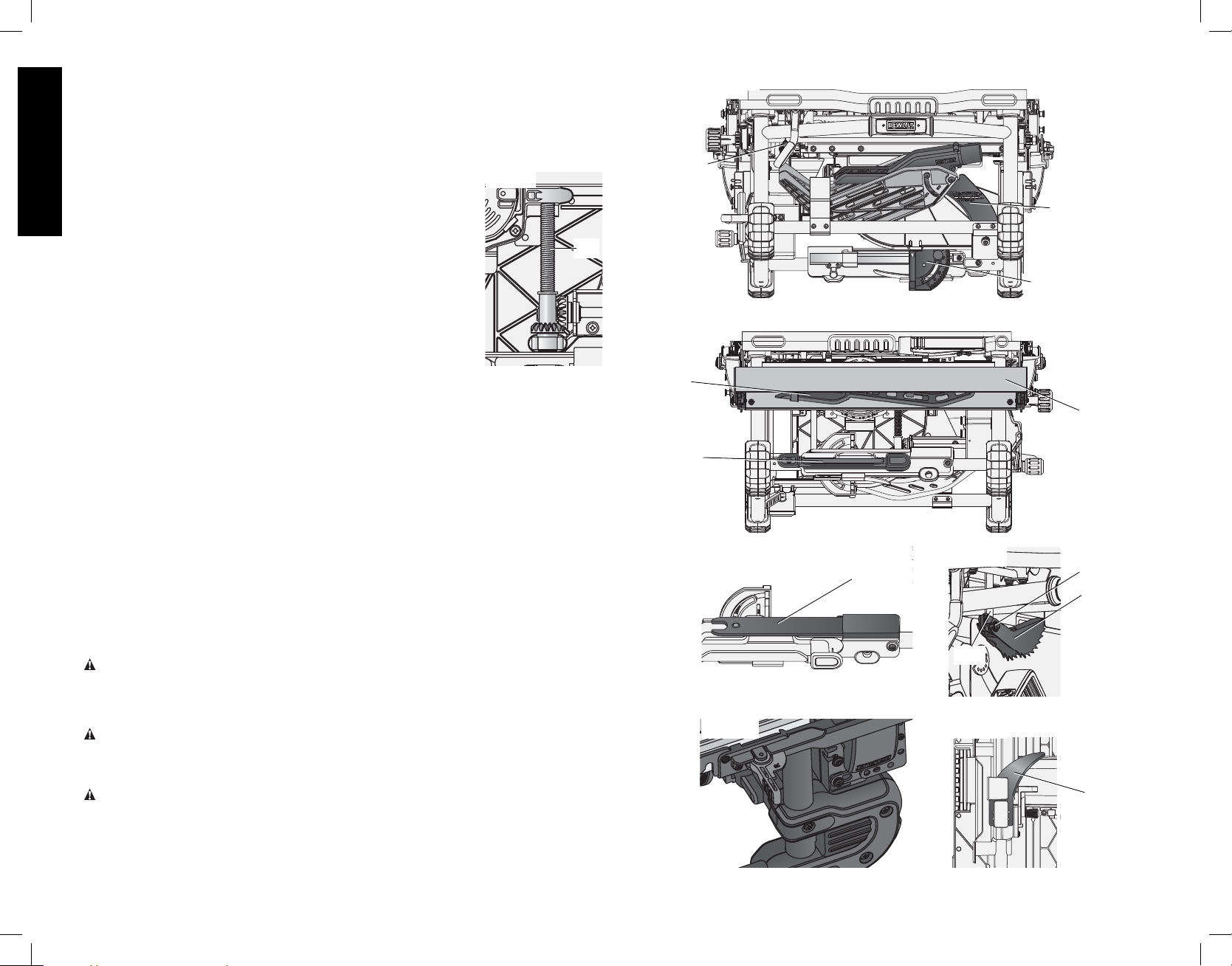

Unpacking (Fig. 1)

WARNING: To reduce the risk of injury,

FIG. 1

DO NOT connect the machine to the

power source until the table saw is

completely assembled and you have read

the entire instruction manual.

Open the box and slide the saw out, as

shown in Figure 1.

Carefully unpack the table saw and all

loose items from the carton. Examine all

parts to make sure that parts have not

been damaged during shipping. If any parts

are missing or damaged, contact your

dealer to replace them before attempting

to assemble the tool.

FEATURES (Fig. 2, 3)

WARNING: Never modify the power tool or any part of it. Damage or personal injury could

result.

Examine Figures 2 and 3 to become familiar with the saw and its various parts. The following

sections on assembly and adjustments will refer to these terms and you must know what and

where the parts are.

A. Table

B. Blade

C. Rip scale indicator

D. Fine adjust knob

E. Rail lock lever

F. Blade height adjustment wheel

G. Bevel lock lever

H. ON/OFF switch

I. Mounting holes

J. Miter gauge

K. Blade guard assembly

L. Riving knife/blade guard release lever

M. Splitter

N. Anti-kickback assembly

O. Dust collection port

P. Guard dust collection port

Q. Throat plate

R. Rip fence

S. Rip fence latch

T. Work support/narrrow rip fence (shown

in stored position)

U. Blade wrenches (stored position)

V. Push stick (stored position)

W. Riving knife (non thru sawing) (FIG. 27)

FIG. 2

A

L

J

C

FIG. 3

V

T

S

K

Q

F

G

H

P

I

B

M

T

R

S

E

D

N

U

O

INTENDED USE

This table saw is designed for professional ripping, crosscutting, mitering, beveling and non

thru-cutting applications, such as dadoing, with various materials.

DO NOT use for cutting metal, cement board, or masonry.

DO NOT use under wet conditions or in presence of flammable liquids or gases.

DO NOT let children come into contact with the tool. Supervision is required when

inexperienced operators use this tool.

4

Page 7

ASSEMBLY

WARNING: Shock Hazard. To reduce the risk of serious personal injury, turn unit

off and disconnect machine from power source before attempting to move it, change

accessories or make any adjustments. An accidental start-up can cause injury.

THIS SAW SHOULD BE ASSEMBLED IN THE FOLLOWING ORDER: (FIG, 2, 4)

1. Make sure blade is installed correctly and arbor nut is tight. Use wrenches (U) stored on

the tool. Refer to Figure 3.

2. Install and lock throat plate (Q). (NOTE: Adjust leveling screws before proceeding. Refer

to To Assemble the Throat Plate.)

3. Attach the rip fence (R). (NOTE: Adjust rip scale before proceeding. Refer to Adjusting

Rip Scale.)

4. Position the blade guard assembly.

5. Attach anti-kickback assembly to the guard assembly.

NOTE: To attach this table saw to a stand, please follow the instructions included with the

stand assembly.

Tools needed for assembly include the wrenches included with this saw.

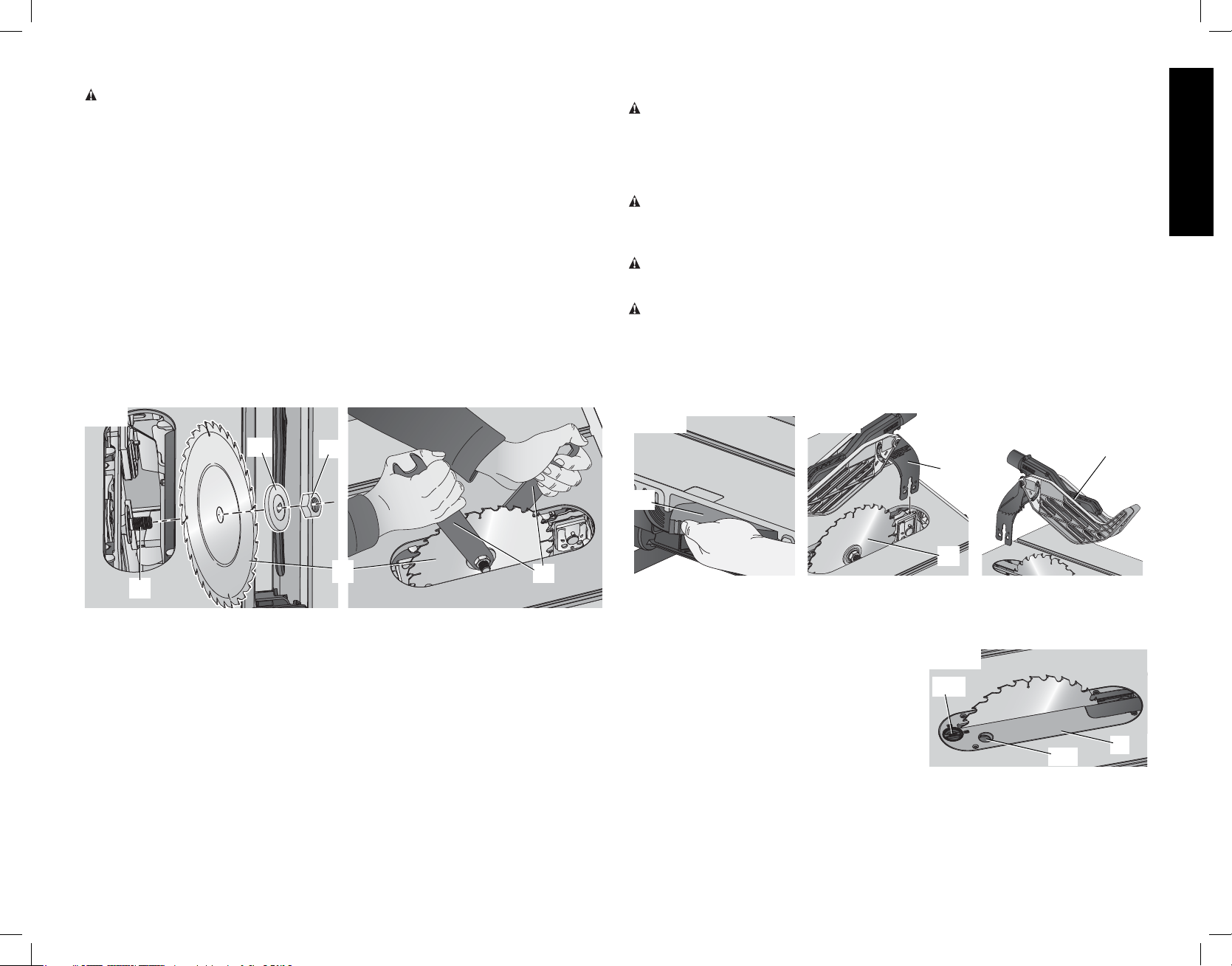

ATTACHING/REPLACING THE BLADE (FIG. 2, 4)

1. Raise the saw blade arbor to its maximum height by turning the blade height adjustment

wheel (F) clockwise.

2. Remove the arbor nut (X) and flange (AA) from the saw arbor by turning counterclockwise.

FIG. 4

AA

X

POSITIONING THE BLADE GUARD ASSEMBLY/RIVING KNIFE (FIG. 5, 6)

To position the blade guard assembly:

WARNING: Use the blade guard assembly for all thru-sawing.

1. Raise the saw blade arbor to its maximum height.

2. Install blade guard assembly by pulling the riving knife/guard release lever (L) and inserting

splitter (M) until it bottoms out.

3. Release lever, make sure clamp plates are fully closed and the splitter is clamped securely.

NOTE: Pull on the blade guard assembly/riving knife to ensure it has locked into place.

WARNING: Use the riving knife for non thru-sawing when blade guard assembly cannot

be used.

NOTE: Follow steps 1–3 to install the riving knife (W) in the same manner as the blade guard

assembly, Refer to figure 24.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the blade guard assembly and riving knife for proper alignment and clearance

with saw blade. Check alignment after each change of bevel angle.

WARNING: To reduce the risk of serious personal injury, DO NOT operate saw if riving knife

or blade guard assembly is not securely clamped in place.

When properly aligned, the blade guard assembly/riving knife will be in line with the blade at

both table top level, and at the top of the blade. Using a straight edge, ensure that the blade

(B) is aligned with the riving knife (W) or the splitter (M). With power disconnected, operate the

blade tilt and height adjustments through the extremes of travel and ensure the blade guard

assembly clears the blade in all operations and that the anti-kickback assembly is functioning.

FIG. 5

FIG. 6

FIG. 7

K

M

L

English

B

Y

U

3. Place the saw blade on to the spindle (Y) making sure the teeth of the blade (B) point down

at the front of the table. Assemble the flange and arbor nut to the spindle and tighten arbor

nut (X) as far as possible by hand, making sure that the saw blade is against the inner washer

and the flange (AA) is against the blade. Ensure the largest diameter of the flange is against

the blade. Ensure the spindle and flange are free from dust and debris.

4. To keep the spindle from rotating when tightening the arbor nut, use the open end of the

wrench (U) to secure the spindle.

5. Using the arbor wrench, tighten the arbor nut (X) by turning it clockwise.

6. NOTE: Different types of blades make different kerfs (width of cuts). Therefore, it is

necessary to check adjustment of rip scale when changing blades. Replacement blade

MUST not exceed the thickness stated on the riving knife. The riving knife provided with

the saw is 2.2mm thick.

B

To remove the blade guard assembly/riving knife (FIG. 5, 7)

1. Pull the riving knife/guard release lever (L).

2. Lift up on blade guard assembly(K)/riving knife (W).

TO ASSEMBLE THE THROAT PLATE (FIG. 8)

1. Align the throat plate (Q) as shown in Figure 8,

FIG. 8

and insert the tabs on the back of the throat

plate into the holes on the back of the table

BB

opening.

2. Rotate cam counterclockwise until the front

of throat plate drops into place. Secure

by rotating cam lock knob (BB) clockwise

1/4 turn (when cam lock is under the table

CC

holding the throat plate in place).

3. The throat plate includes four adjustment screws which raise or lower the throat plate.

When properly adjusted, the front of the throat plate should be flush or slightly below the

surface of the table top and secured in place. The rear of the throat plate should be flush

or slightly above the table top.

5

Q

Page 8

TO REMOVE THE THROAT PLATE

151413 1817 20 21916

76510912 1118

1. Remove the throat plate (Q) by turning the cam lock knob (BB) 1/4 turn counterclockwise

2. Using finger hole (CC) on the plate, pull throat plate up and forward to expose the inside

of the saw. DO NOT operate the saw without the throat plate. If using dado blade, use

proper dado throat plate (sold seperately).

WARNING: To reduce the risk of serious personal injury, the throat plate must be locked in

place at all times.

English

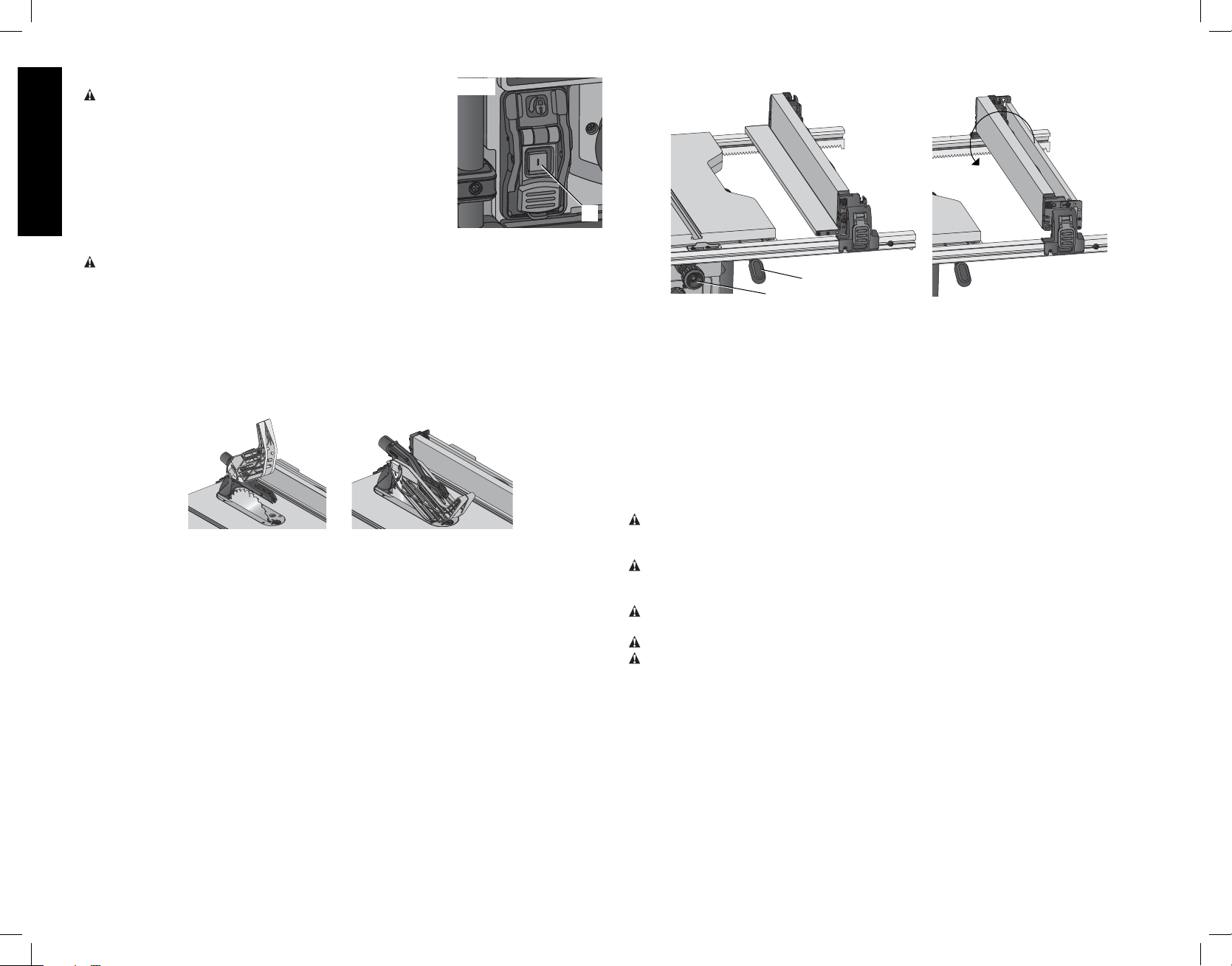

DWE7490 - ASSEMBLING THE RIP FENCE (FIG. 9, 10)

The rip fence can be installed in two positions on the right (position 1 for 0" to 24.5" ripping,

and position 2 for 4" to 28.5" ripping) and one position on the left of your table saw.

1. Align the locator pin (DD) on the fence rail with the fence head slot and align the latch (S)

with the opening (EE).

2. Secure the rip fence by snapping the latches onto the rails as shown in Figure 9. Be sure

to snap both front and rear latches (S) in place.

FIG. 9

DD

EE

FIG. 10

S

4. Loosen the rip scale indicator screws (GG) and set the rip scale indicator to read zero (0).

Retighten the rip scale indicator screws. The yellow rip scale (top) reads correctly only

when the fence is mounted on the right side of the blade and is in position 1 (for 0 to 24.5"

ripping) [not the 32" rip position]. The white scale (bottom) reads correctly only when the

fence is mounted on the right side of the blade and in position 2 (for 4" to 32.5" ripping).

NOTE: For the DWE7491 the white scale (bottom) reads correctly only when the fence is

mounted on the right side of the blade and in position 2 (for 8" to 28.5" ripping)

A metric scale is available at an additional cost, refer to Accessories for details.

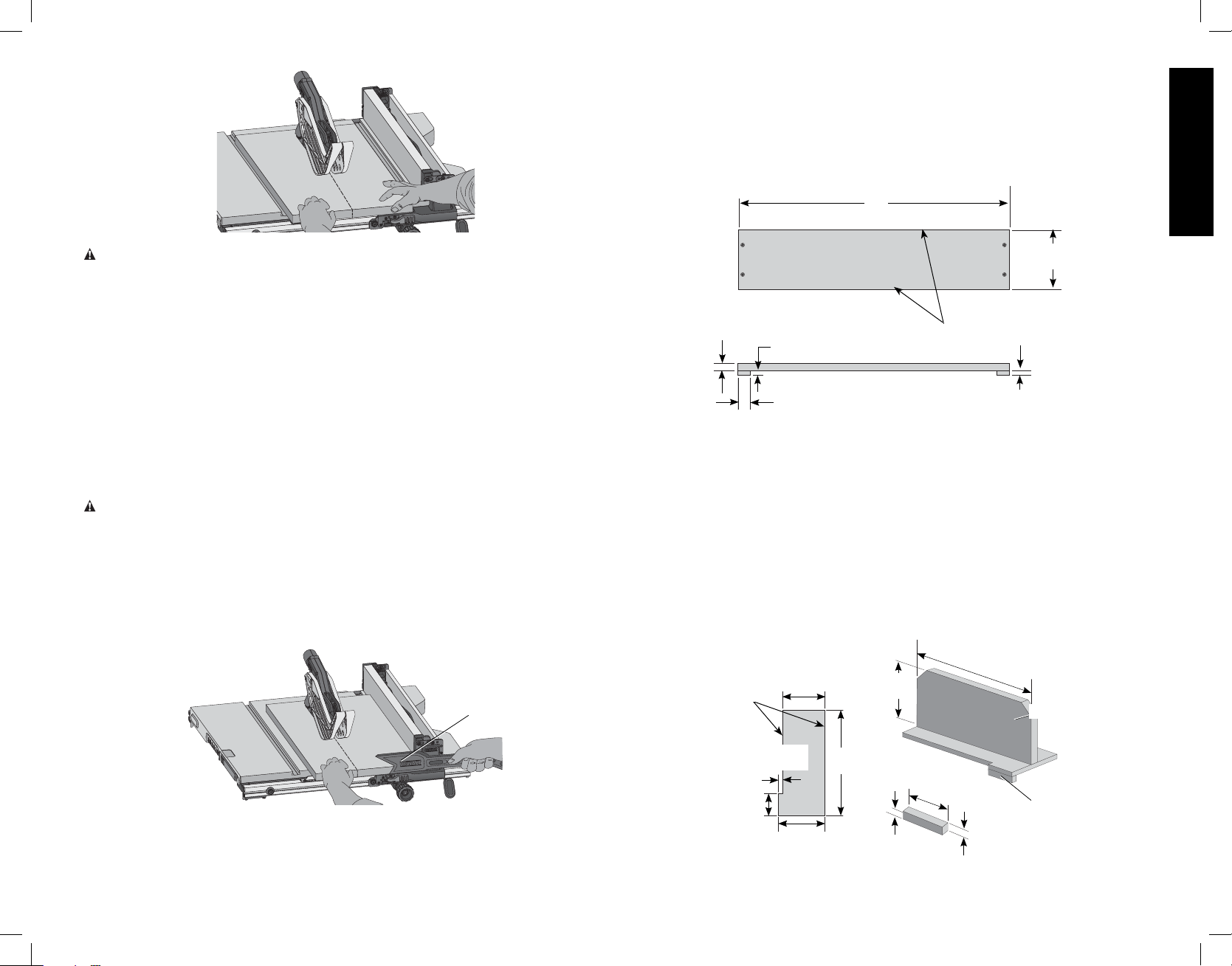

ANTI-KICKBACK ASSEMBLY (FIG. 15, 16)

WARNING: To reduce the risk of serious personal injury, the anti-kickback assembly must

be in place for all possible cuts.

1. Remove the anti-kickback assembly (N) from the storage position. Refer to Storage.

2. Locate the anti-kickback mounting slot (HH) at the top of the splitter (M).

3. Align the stem (II) with the mounting slot. Depress the stem (II) and push down on the

anti-kickback assembly (N) until it snaps and locks into place. NOTE: Pull on the antikickback assembly to ensure it has locked into place.

4. To remove the anti-kickback assembly, depress the stem and pull up and out of the

mounting slot.

With power disconnected, operate the blade tilt and height adjustments through the extremes

of travel and ensure the blade guard assembly clears the blade in all operations and that the

anti-kickback assembly is functioning.

FIG. 15

II

HH

FIG. 16

N

DWE7491 - ASSEMBLING THE RIP FENCE (FIG. 11–13)

The rip fence can be installed in two positions on the right (Position 1 for 0" to 24.5" ripping, and

Position 2 for 8" to 32.5" ripping) and one position on the left of this saw.

1. Unlock the fence latches (S).

2. Holding the fence at an angle, align the locator pins (front and back) (DD) on the fence

rails with the fence head slots (FF) as shown in Figure 11.

3. Slide the head slots onto the pins and rotate the fence down untill it rests on the rails.

4. Lock the fence in place by closing the front and back latches (S) onto the rails.

FIG. 11

FIG. 12

FIG. 13

E

DD

S

FF

ADJUSTING THE RIP SCALE (FIG. 12, 14)

1. Unlock the rail lock lever (E).

FIG. 14

GG

2. Set the blade at 0° bevel and move the fence in until it

touches the blade.

3. Lock the rail lock lever.

N

M

Bench Mounting

WARNING: Before mounting to a bench or a stand, to reduce the risk of serious

personal injury, turn unit off and disconnect machine from power source before

attempting to move it, change accessories or make any adjustments. An accidental

start-up can cause injury.

CAUTION: To reduce the risk of personal injury, make sure table saw is firmly mounted to

a stable surface or stand provided before use.

CAUTION: Ensure that the surface is stable enough that large pieces of material will not

cause it to tip over during use.

The table saw must be mounted firmly. The mounting surface must have a 15" by 15" (38

S

x 38cm) opening to allow dust to escape.

Four holes (I) are provided in the tool’s base for mounting. We strongly recommend that these

holes be used to anchor the table saw to your workbench or other stationary rigid frame.

1. Center the saw on a square piece of 1/2" (12.7mm) plywood. The plywood must have a

15" x 15" (38 x 38 cm) opening to allow dust to escape.

2. Mark the positions of the two rear mounting holes (spaced 8-5/8" [220 mm] apart) in the

frame of the saw with a pencil. Then measure forward 19-5/8" (498.5 mm) the two front

holes.

3. Remove the saw and drill 5/16" (7.9 mm) holes in the places you have just marked.

6

Page 9

4. Position the saw over the four holes you drilled in the plywood and insert four 1/4"

(6.4mm) machine screws FROM THE BOTTOM. Install washers and 5/16" (7.9 mm) nuts

on the top. Tighten securely.

5. In order to prevent the screw heads from marring the surface to which you clamp the saw,

attach two strips of scrap wood to the bottom of the plywood base. These strips can

be attached with wood screws installed from the top side as long as they don’t protrude

through the bottom of the strip.

6. Use a “C” clamp to secure the plywood base to your workbench whenever you use the

saw.

Connecting Saw to Power Source

WARNING: To reduce the risk of injury, before connecting saw to power source, make

sure the switch is in the OFF position.

Be sure your power supply agrees with the name plate marking. AC ONLY means that this

saw will operate on alternating current only. A voltage decrease of 10 percent or more will

cause a loss of power and overheating. All D

EWALT tools are factory tested. If this tool does

not operate, check the power supply.

ADJUSTMENTS

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or changing set-

ups or when making repairs. An accidental start-up can cause injury.

NOTE: This saw is fully and accurately adjusted at the factory at the time of manufacture. If

readjustment due to shipping and handling or any other reason is required, follow the sections

below to adjust this saw.

Once made, these adjustments should remain accurate. Take a little time now to follow these

directions carefully to maintain the accuracy of which this saw is capable.

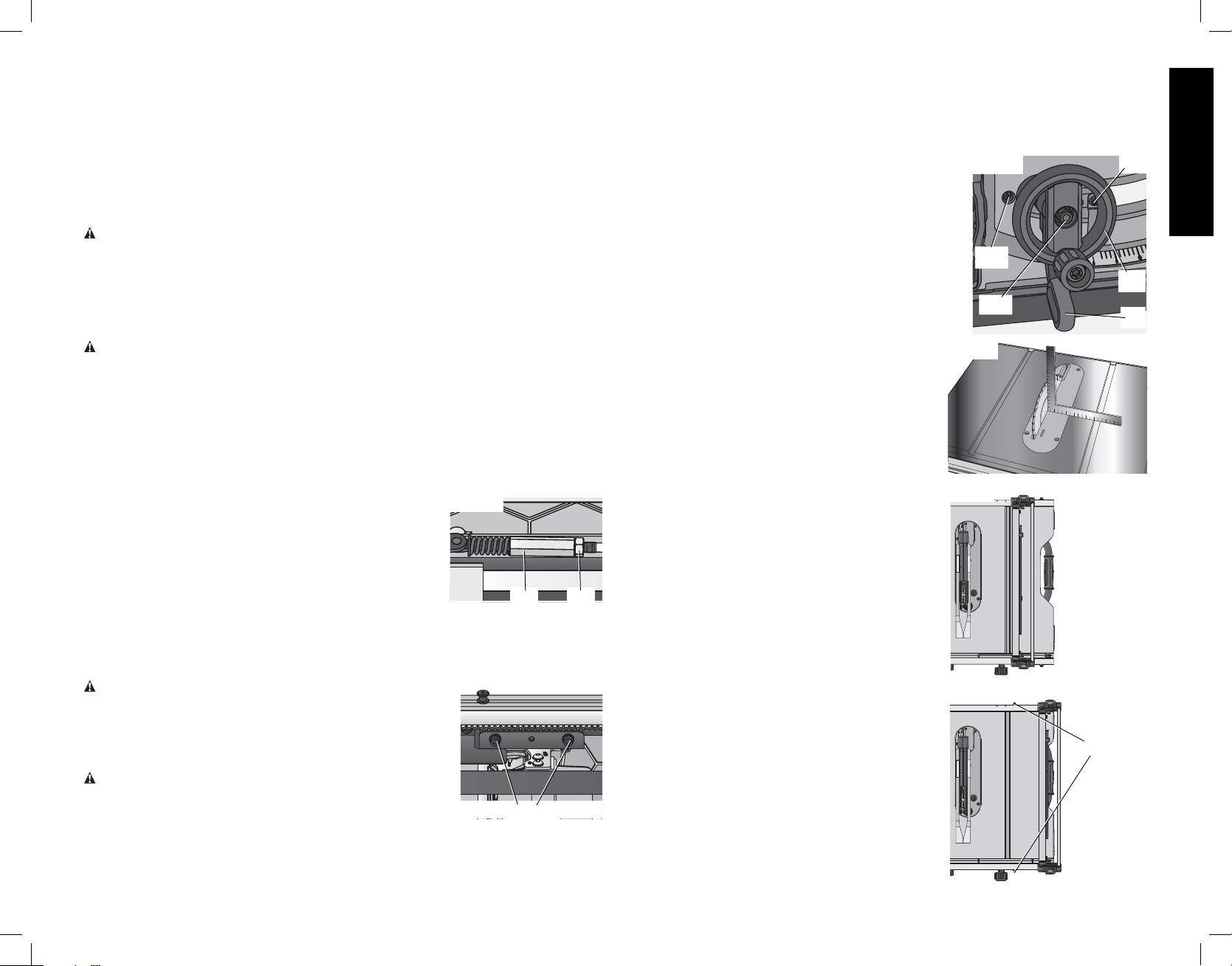

RAIL LOCK ADJUSTMENT (FIG. 2, 17)

(Tightening Fence Clamping System)

1. Lock the rail lock lever (E).

2. On the underside of the saw, loosen the jam nut (JJ).

3. Tighten the hex rod (KK) until the spring on the locking

system is compressed creating the desired tension on the

rail lock lever. Retighten the jam nut against the hex rod.

4. Check that the fence does not move when the lock lever is

engaged. If the fence is still loose, tighten the spring further.

RIP SCALE ADJUSTMENT

See Adjusting the Rip Scale under Assembly.

BLADE ALIGNMENT ADJUSTMENT (FIG. 18)

(Blade Parallel to Miter Slot)

WARNING: Cut Hazard. Check the blade at 0˚ and 45˚ to

make sure blade does not hit the throat plate, causing personal

injury.

If the blade appears to be out of alignment with the miter slot on

the table top, it will require calibration for alignment. To realign the

blade and miter slot, use the following procedure:

WARNING: To reduce the risk of injury, turn unit off and

disconnect machine from power source before installing and

removing accessories, before adjusting or changing set-ups or

when making repairs. An accidental start-up can cause injury.

FIG. 17

FIG. 18

KK

JJ

LL

1. Using a 6mm hex wrench, loosen rear pivot bracket fasteners (LL) just enough to allow

the bracket to move side-to-side.

2. Adjust the bracket until the blade is parallel to the miter gauge slot.

3. Tighten the rear pivot bracket fasteners to 110–120 in-lbs (12.5–13.6 Nm).

BEVEL STOP AND POINTER ADJUSTMENT (FIG. 19, 20)

1. Raise the blade fully by rotating the blade height

adjustment wheel (F) clockwise until it stops.

FIG. 19

OO

2. Unlock the bevel lock lever (G) by pushing it up and to

the right. Loosen the bevel stop screw (NN).

3. Place a square flat against the table top and against the

blade between teeth, as shown in Figure 20. Ensure the

bevel lock lever is in its unlocked, or up, position.

4. Using the bevel lock lever, adjust the bevel angle until it

is flat against the square.

5. Tighten the bevel lock lever by pushing it down.

6. Turn the bevel stop cam (MM) until it firmly contacts the

bearing block. Tighten the bevel stop screw (NN).

7. Check the bevel angle scale. If the pointer does not

read 0°, loosen pointer screw (OO) and move the

NN

F

MM

G

FIG. 20

pointer so it reads correctly. Retighten the pointer

screw.

8. Repeat at 45°, but do not adjust pointer.

MITER GAUGE ADJUSTMENT (FIG. 2)

To adjust miter gauge (J) loosen knob, set to desired

angle and tighten knob.

FENCE ALIGNMENT ADJUSTMENT (FIG. 2, 21)

(Blade Parallel to Fence)

If you experience fence alignment problems and want

FIG. 21

to correct an out of parallel alignment between the

fence and the blade, be sure to check the alignment

of the blade to the miter slot first. After confirming that

those elements are aligned, proceed with alignment of

the blade to the fence using the following procedure:

POSITION 1

POSITION 1 FENCE ALIGNMENT (FIG. 21)

1. Install the fence in position 1 (Fig. 21) and unlock

the rail lock lever (E). Locate both locator pins (DD)

that support the fence on the front and rear rails.

2. Loosen the rear locator pin screw and adjust the

allignment of the fence in the groove until the

fence face is parallel to the blade. Make sure you

measure from the fence face to the front and back

FIG. 22

of the blade to ensure alignment.

3. Tighten the locator pin screw and repeat on the

left side of the blade.

DD

4. Check rip scale pointer adjustment.

POSITION 2

English

7

Page 10

POSITION 2 FENCE ALIGNMENT

(FIG. 22, 23)

1. To align position 2 fence locator pins, ensure position 1 pins have been aligned, refer to

Position 1 Fence Alignment.

2. Loosen the position 2 locator pins, then using the blade wrench holes as a guide for

positioning, align the pins (Fig. 23).

3. Tighten the locator pins (front and rear).

English

FIG. 23

DD

U

ALIGNING RIVING KNIFE TO BLADE (FIG. 24)

1. Remove the throat plate. Refer to Remove Throat

Plate under Assembly.

FIG. 24

2. Raise the blade to full depth of cut and 0° bevel

angle.

3. Locate the three small set screws (PP) adjacent to

the riving knife lock knob (QQ). These screws will

be used to adjust the riving knife position.

4. Lay a straight edge on the table against two blade

tips. The riving knife should not touch the straight

QQ

edge. If needed, loosen the two larger lock screws

(RR).

5. Adjust the small set screws (PP) to move the riving

knife according to the position noted in step 5. Lay

RR

the straight edge on the opposite side of the blade

and repeat adjustments as needed.

6. Lightly tighten the two larger lock screws (RR).

7. Place a square flat against the riving knife to verify the riving knife is vertical and in-line with

the blade.

8. If needed, use the set screws to bring the riving knife vertical with the square.

9. Repeat steps 5 and 6 to verify position of riving knife.

10. Fully tighten the two larger lock screws (RR).

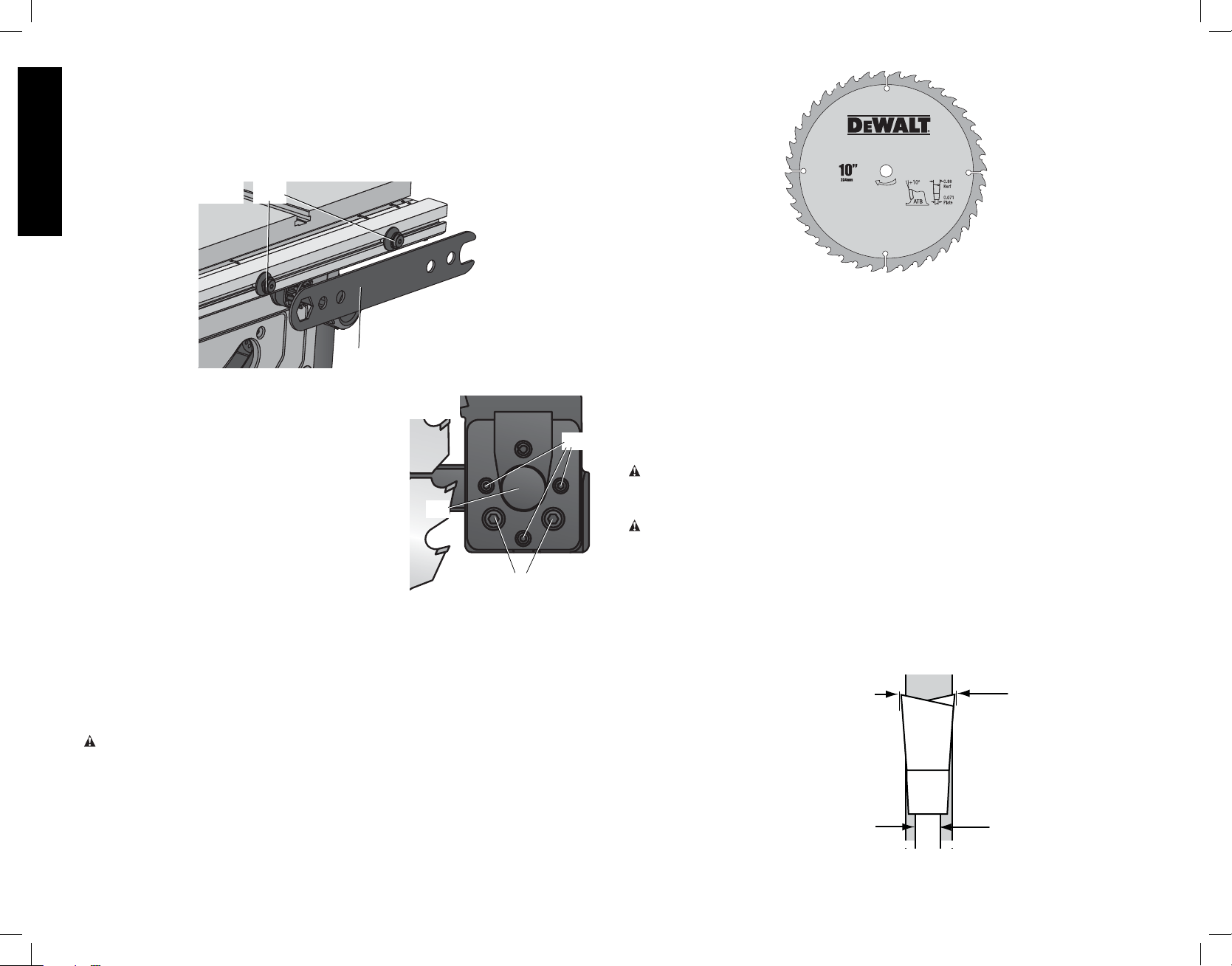

Saw Blades (Fig. 25)

WARNING: Riving knives must be matched to saw blade dimensions in order to function

effectively. Refer to Riving Knife Selection.

NOTE: THIS SAW IS INTENDED FOR USE ONLY WITH SAW BLADES 10" (254 mm) IN

DIAMETER.

PP

FIG. 25

• The saw blade furnished with your new saw is a 10" (254mm) combination blade, used

for crosscutting (across the grain) and ripping (with the grain) through the material. The

center hole to fit on the arbor is 5/8" (16mm) diameter. This blade will produce a good

quality cut for most applications.

• There are many types of blades available to do specific and special jobs such as cross

cut only, rip only, hollow ground, thin plywood, paneling, etc.

• Use only saw blades designed for maximum safe operating speeds of 5,000 RPM or

greater.

• Saw blades should always be kept sharp. It is recommended that you locate a

reputable sharpening service to sharpen your blades when needed.

• Never stack blades on top of one another to store. Place material such as cardboard

between them to keep the blades from coming in contact with one another.

CAUTION: To reduce the risk of injury, abrasive wheels or blades (including diamond)

should not be used on this saw.

Splitter and Riving Knife Selection (Fig. 26–28)

WARNING: To minimize the risk of kickback and to ensure proper cutting, the splitter and

riving knife must be the proper thickness for the blade used.

The splitter and riving knife supplied with this table saw is the correct size for the blade

supplied with the saw.

If a different blade is used, check the blade body (plate) thickness and the blade kerf (cutting)

width marked on the blade or on the blade packaging. The splitter and riving knife thickness

must be greater than the body thickness and less than the kerf width as shown in Figure 26.

FIG. 26

KERF WIDTH

(WIDTH OF CUT

MADE BY THE

BLADE)

BODY (OR PLATE)

THICKNESS OF THE

BLADE

RIVING KNIFE

THICKNESS

8

Page 11

The riving knife provided with this saw is marked as follows (Fig. 27):

0.087" (2.2mm) THICK RIVING KNIFE. ONLY USE FOR 10" (254mm) Ø BLADE WITH

0.094" (2.4 mm) MIN. KERF WIDTH AND 0.067" (1.75mm) MAX. BODY THICKNESS.

FIG. 27

All DEWALT blade body thickness and kerf widths are provided at www.dewalt.com.

If a different blade is used and the body thickness

and kerf width dimensions are not provided, use the

following procedure to determine the correct riving

knife thickness:

1. Measure the body thickness of the blade.

2. Make a shallow cut in scrap material and measure

the kerf width.

3. Select the riving knife (Fig. 28).

4. Slide the riving knife through the shallow cut

made in step 2 to confirm the correct riving knife

has been selected. The riving knife should not

bind or drag through the cut (Fig. 28).

IMPORTANT: If any dragging or binding of the

material is encountered as it reaches the riving knife,

turn unit off and disconnect machine from power

source. Repeat steps 1–4 to make the proper riving

knife selection before attempting another cut.

FIG. 28

Kickback

Kickback is a dangerous condition! It is caused by the workpiece binding against the blade.

The result is that the workpiece can move rapidly in a direction opposite to the feed direction.

During kickback, the workpiece could be thrown back at the operator. It can also drag

the operator’s hand back into the blade if the operator’s hand is at the rear of the blade. If

kickback occurs, turn the saw OFF and verify the proper functioning of the riving knife, antikickback assembly and blade guard assembly before resuming work.

WARNING: See Additional Safety Rules for Table Saws and follow all warnings

provided regarding KICKBACK.

OPERATION

WARNING: To reduce the risk of injury, turn unit off and disconnect machine

from power source before installing and removing accessories, before adjusting or

changing set-ups or when making repairs. An accidental start-up can cause injury.

WARNING: Before using the saw, verify the following each and every time:

• ALWAYS wear proper eye, hearing and respiratory equipment.

• Blade is tight.

• Bevel angle and height lock knobs are tight.

• If ripping, ensure fence lock lever is tight and fence is parallel to the blade.

• If crosscutting, miter gauge knob is tight.

• The blade guard assembly is properly attached and the anti-kickback assembly is

functioning.

• ALWAYS inspect the blade guard assembly and riving knife for proper alignment, operation

and clearance with saw blade.

• ALWAYS make sure both guards are in the down position in contact with the table before

operating.

WARNING: To reduce the risk of serious personal injury, have push stick ready to use

before starting cut.

Failure to adhere to these common safety rules can greatly increase the likelihood of injury.

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or changing set-

ups or when making repairs. An accidental start-up can cause injury.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the blade guard assembly and riving knife for proper operation alignment and

clearance with saw blade. Personal injury may result.

WARNING: Ripping or crosscutting may cause saw to tip over while operating. Make sure

saw is securely mounted to a stable surface.

WARNING: Never use the fence and miter gauge together. This may cause a kickback

condition and injure the operator.

CAUTION: If this saw makes an unfamiliar noise or if it vibrates excessively, cease

operating immediately, turn unit off and disconnect from power source until the problem has

been located and corrected. Contact a D

service center or other qualified service personnel if the problem cannot be found.

CAUTION: The proper throat plate must be in place at all times to reduce the risk of a

thrown workpiece and possible injury.

There are two basic types of cutting with table saws: ripping and crosscutting. Regardless

of material, man made or natural wood, the distinction between ripping and crosscutting

is as follows: Ripping is cutting to a different width (usually with the grain) and crosscutting

describes cutting material across the shorter dimension (usually against the grain).

WARNING: When ripping, always use the fence to provide a guide for the material and

blade guard assembly to protect against a kickback situation.

WARNING: Never perform any cutting operation free hand. Never perform plunge cutting.

CAUTION: When crosscutting, always use the miter gauge.

EWALT factory service center, a DEWALT authorized

English

9

Page 12

On-Off Switch (Fig. 29)

WARNING: To reduce the risk of injury, be sure the switch

is in the OFF position before plugging machine in.

Push green button (H) in to turn this saw on and push down the

red paddle to turn this saw off.

LOCK OFF FEATURE INSTRUCTIONS

A cover above the switch folds down for insertion of a padlock

English

to lock the saw off. A padlock with a maximum diameter of

1/4" (6.35 mm) and minimum clearance of 3" (76.2 mm) is

recommended.

FIG. 29

Guard Operating Feature (Fig. 30)

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or changing set-

ups or when making repairs. An accidental start-up can cause injury.

1. The guard(s) will lock in place when in the raised position.

2. This feature increases visability when measuring the blade to fence distance.

3. Push down on guard(s) and they will release to the operating position.

NOTE: Pull on the anti-kickback assembly to ensure it is locked in place.

ALWAYS make sure both guards are in the down position in contact with the table before

operating.

FIG. 30

RAISED

POSITION

OPERATING

POSITION

Rip Fence Operation (Fig. 31, 32)

RAIL LOCK LEVER (FIG. 31)

The rail lock lever (E) locks the fence in place preventing movement during cutting. To lock

the rail lever, push it down and toward the rear of the saw. To unlock, pull it up and toward

the front of the saw.

NOTE: When ripping, always lock the rail lock lever.

WORK SUPPORT EXTENSION/NARROW RIPPING FENCE

The table saw is equipped with a narrow ripping fence that also supports work that extends

beyond the saw table.

To use the narrow ripping fence in the work support position, rotate it from its stored position

as shown in Figure 32, and slide the pins into the lower sets of slots on both ends of the fence.

To use the narrow ripping fence in the narrow ripping position, snap the pins into the upper

sets of slots on both ends of the fence.

This feature will allow 2" (51 mm) of extra clearance to the blade. If more clearance is

necessary, follow directions for making an auxiliary fence under Narrow Rip Auxiliary Fence

in the Operation section.

NOTE: When not in use, the narrow ripping fence should be placed in its stored position.

FIG. 31

H

E

D

NOTE: This fence will allow the guard to remain on the saw when completing narrow ripping.

This fence will provide ample space for a push stick. If you prefer more clearance for push

blocks or push sticks, refer to Narrow Rip Auxiliary Fence.

FINE ADJUSTMENT KNOB (FIG. 31)

The fine adjustment knob (D) allows smaller adjustments when setting the fence. Before

adjusting, be sure the rail lock lever is in its up or unlocked position.

RIP SCALE POINTER

The rip scale pointer will need to be adjusted for proper performance of the rip fence if the

user switches between thick and thin kerf blades. The rip scale pointer only reads correctly

for position 1 (0 to 24.5"), however for position 1 with narrow rip fence in use add 2" (50 mm).

See Adjusting the Rip Scale under Assembly.

FIG. 32

Ripping (Fig. 33)

WARNING: Never touch the “free end” of the workpiece or a “free piece” that is cut off,

while the power is ON and/or the saw blade is rotating. Piece may contact the blade resulting

in a thrown workpiece and possible injury.

WARNING: A rip fence should ALWAYS be used for ripping operations to prevent loss of

control and personal injury. NEVER perform a ripping operation freehand. ALWAYS lock the

fence to the rail.

WARNING: When bevel ripping and whenever possible, place the fence on the side of the

blade so that the blade is tilted away from the fence and hands.

WARNING: Keep hands clear of the blade.

WARNING: Use a push stick to feed the workpiece if there is 2–6" (51–152mm) between

the fence and the blade. Use a narrow ripping fence feature and push block to feed the

workpiece if there is 2" (51mm) or narrower between the fence and the blade.

1. Lock the rip fence by pressing the rail lock lever down. Remove the miter gauge.

2. Raise the blade so it is about 1/8" (3.2mm) higher than the top of the workpiece.

3. Hold the workpiece flat on the table and against the fence. Keep the workpiece about 1"

(25.4mm) away from the blade.

10

Page 13

FIG. 33

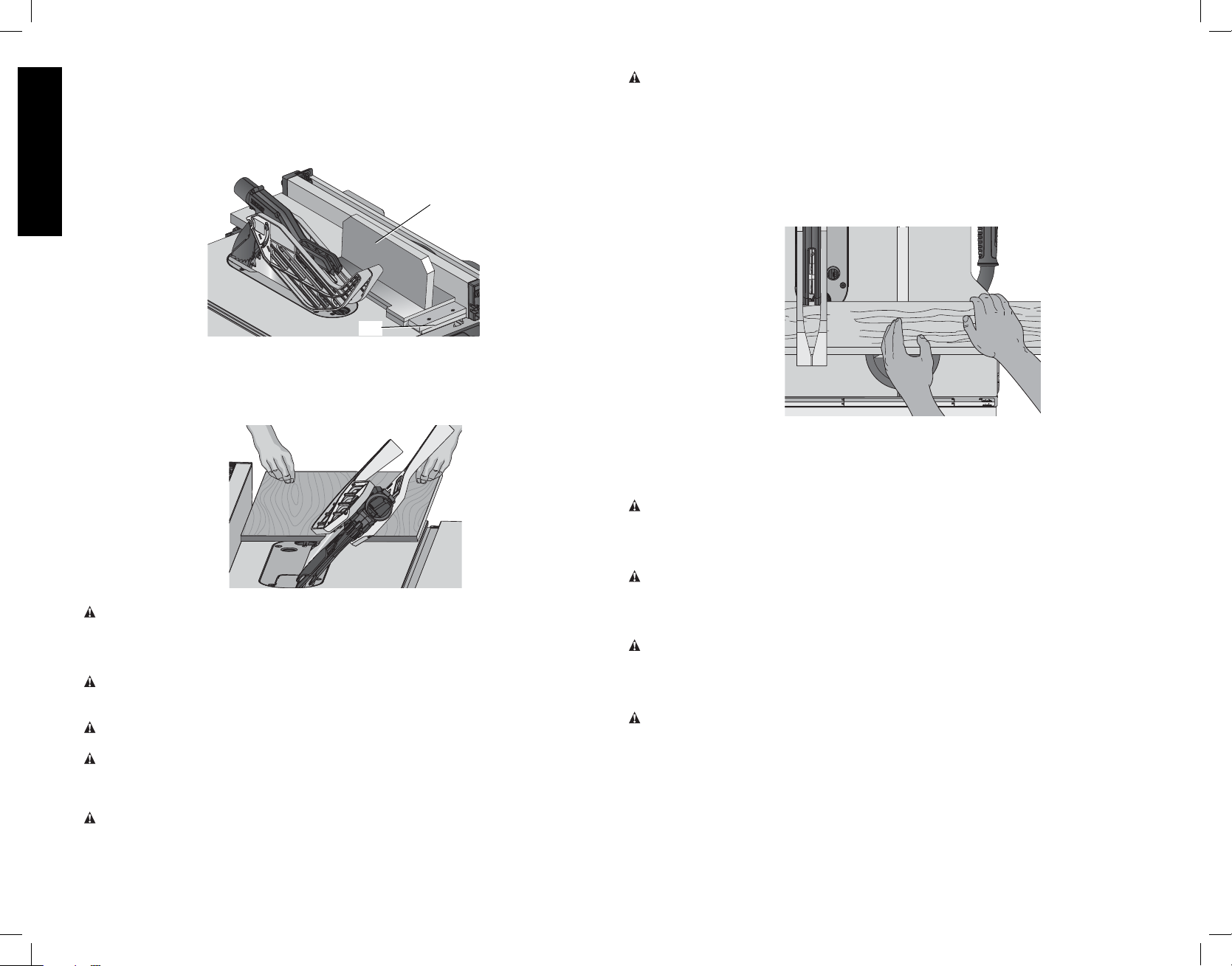

Narrow Rip Auxiliary Fence (Fig. 35, 36)

The narrow rip auxiliary fence should be used for a rip measuring 2" (51mm) or narrower. This

fence will allow the guard to remain on the saw when completing narrow ripping. This fence

will provide ample space for proper use of a push block (TT, see Push Block).

1. Follow the diagram in Fig. 35 to construct the narrow rip auxiliary fence (SS).

NOTE: The length should be cut to fit the length of the saw table top and sides (TT) must be

parallel.

FIG. 35

SS

English

CAUTION: The workpiece must have a straight edge against the fence and must not be

warped, twisted or bowed. Keep both hands away from the blade and away from the path of the

blade. See proper hand position in Figure 33.

4. Turn the saw on and allow the blade to come up to speed. Both hands can be used in

starting the cut. When there is approximately 12" (305mm) left to be ripped, use only one

hand, with your thumb pushing the material, your index and second finger holding the

material down and your other fingers hooked over the fence. Always keep your thumb

along side your first two fingers and near the fence.

5. Keeping the workpiece against the table and fence, slowly feed the workpiece rearward

all the way through the saw blade. Continue pushing the workpiece until it is clear of the

blade guard assembly and it falls off the rear of the table. Do not overload the motor.

6. Never try to pull the workpiece back with the blade turning. Turn the switch off, allow the

blade to stop, raise the anti-kickback teeth on each side of the riving knife if necessary

and slide the workpiece out.

7. When sawing a long piece of material or a panel, always use a work support. A sawhorse,

rollers, or out feed assembly provides adequate support for this purpose. The work

support must be at the same height or slightly lower than the saw table.

CAUTION: Never push or hold onto the free or cut-off side of the workpiece if it is between

the blade and the fence.

Ripping Small Pieces (Fig. 34)

It is unsafe to rip small pieces. It is not safe to put your hands close to the blade. Instead, rip

a larger piece to obtain the desired piece. When a small width is to be ripped and the hand

cannot be safely put between the blade and the rip fence, use one or more push sticks. A

pattern is included at the end of this manual to make push sticks. A push stick (V) is included

with this saw, attached to the rip fence. Use the push stick(s) to hold the workpiece against

the table and fence, and push the workpiece fully past the blade.

FIG. 34

V

4-3/4"

(121 mm)

1/2"

(12.7 mm)

3/8"

(9.5 mm)

1"

(25 mm)

TT

3/8"

(9.5mm)

2. After the narrow rip auxiliary fence is constructed, slip it over the saw table top and place

it flush to the fence as shown in Figure 37.

3. Feed the workpiece through until the edge of the material reaches the front edge of the

saw table top.

4. Continue feeding the material using the push block (UU) until the cut is complete.

Push Block (Fig. 36, 37)

IMPORTANT: Only use the push block (UU) with the narrow rip auxiliary fence, refer to

Narrow Rip Auxiliary Fence. The push block should be used once the material being cut

reaches the saw table top.

1. Construct a push block using the diagram in Figure 36.

NOTE: Edges (V V) must be the same size.

IMPORTANT: The over hanging edge (V V, Fig. 36) MUST be square. An uneven lip could

cause the push block to slip or push the material away from the fence.

FIG. 36

V V

4-3/4"

(121 mm)

5"

(127 mm)

12

"

(305mm)

UU

11

2-1/2"

(64 mm)

1/2"

(12.7 mm)

5-1/4"

(133 mm)

12"

(305 mm)

2-1/2" (64mm)

1/2"

(12.7 mm)

WW

1/2"

(12.7 mm)

Page 14

2. Place the push block (UU, Fig. 37) behind the material and ensure the lip of the block is

flush to the narrow rip auxiliary fence (SS).

3. Once the push block is in place, continue feeding the material until the cut is complete

making sure the push block remains flush to the narrow rip auxiliary fence at all times.

IMPORTANT: The narrow rip auxiliary fence and the over hanging edge (W W, Fig. 36) should

both be the same thickness.

FIG. 37

English

UU

SS

Bevel Ripping

This operation is the same as ripping except the bevel angle is set to an angle other than zero

degrees. For proper hand position, Refer to figure 38.

FIG. 38

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the blade guard assembly and riving knife for proper alignment and clearance

with saw blade. Check alignment after each change of bevel angle.

Crosscutting

WARNING: NEVER touch the “free end” of the workpiece or a “free piece” that is cut off,

while the power is ON and/or the saw blade is rotating. Piece may contact the blade resulting

in a thrown workpiece and possible injury.

WARNING: To reduce the risk of injury, NEVER use the fence as a guide or length stop

when crosscutting.

WARNING: NEVER use a length stop on the free end of the workpiece when crosscutting.

In short, the cut-off piece in any thru-sawing (cutting completely through the workpiece)

operation must never be confined — it must be allowed to move away from saw blade to

prevent contact with blade resulting in a thrown workpiece and possibly injury.

WARNING: Use caution when starting the cut to prevent binding of the blade guard

assembly against the workpiece resulting in damage to saw and possible injury.

CAUTION: When using a block as a cut-off gauge, the block must be at least 3/4" (19mm)

thick and is very important that the rear end of the block be positioned so the workpiece is

clear of the block before it enters the blade to prevent contact with blade resulting in a thrown

workpiece and possibly injury.

1. Remove the rip fence and place the miter gauge in the desired slot.

2. Adjust the blade height so that the blade is about 1/8" (3.2mm) higher than the top of the

workpiece.

3. Hold the workpiece firmly against the miter gauge with the path of the blade in line with

the desired cut location. Keep the workpiece an inch or so in front of the blade. KEEP

BOTH HANDS AWAY FROM THE BLADE AND THE PATH OF THE BLADE (Fig. 39).

FIG. 39

4. Start the saw motor and allow the blade to come up to speed.

5. While using both hands to keep the workpiece against the face of the miter gauge, and

holding the workpiece flat against the table, slowly push the workpiece through the blade.

6. Never try to pull the workpiece with the blade turning. Turn the switch off, allow the blade

to stop, and carefully slide the workpiece out.

CAUTION: Never touch or hold onto the free or cut-off end of the workpiece.

Bevel Crosscutting

This operation is the same as crosscutting except that the bevel angle is set to an angle other

than 0°.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the blade guard assembly and riving knife for proper alignment and

clearance with saw blade. Check alignment after each change of bevel angle.

Mitering (Fig. 40)

WARNING: Miter angles greater than 45˚ may force the blade guard assembly into the saw

blade causing damage to the blade guard assembly and personal injury. Before starting the

motor, test the operation by feeding the workpiece into the blade guard assembly. If the blade

guard assembly contacts the blade, place the workpiece under the blade guard assembly, not

touching the blade, before starting the motor.

CAUTION: Certain workpiece shapes, such as molding may not lift the blade guard

assembly properly. Feed the workpiece slowly to start the cut. If the blade guard assembly

contacts the blade, place the workpiece under the blade guard assembly, not touching the

blade, before starting the motor.

This operation is the same as crosscutting except the miter gauge is locked at an angle other

than 0°. Hold the workpiece FIRMLY against the miter gauge (J) and feed the workpiece

slowly into the blade (to prevent the workpiece from moving).

12

Page 15

FIG. 40

J

Miter Gauge Operation

To set your miter gauge:

1. Loosen the miter gauge lock handle.

2. Move the miter gauge to the desired angle.

3. Tighten the miter gauge lock handle.

COMPOUND MITERING

This is a combination of bevel crosscutting and mitering. Follow the instructions for both bevel

crosscutting and mitering.

Dado Cutting

CAUTION: Do not attempt to stack dado blades thicker than 13/16" (20mm). Do not use

dado blades larger than 8" (200mm) diameter.

Since dado cuts are not thru-cuts, the cuts must be performed with the blade guard

assembly removed. To remove the blade guard assembly, pull riving knife/blade

guard release lever and pull up on the guard or riving knife to remove.

When using the dado, the special dado insert (also sold as an accessory) must be used.

Anytime a cut is required that is considerably wider than the saw kerf, a dado is used. A dado

cut is commonly used to add support and line up a shelf for a cabinet, bookcase or some

such project. When using the dado, the blade guard assembly must be removed. Use

EXTREME care when using the dado without the blade guard assembly and riving

knife. If a deep cut is required, use several successive passes rather than attempting to make

it with one pass. Maximum dado width on this saw is 13/16" (20mm). DO NOT USE WIDER

COMBINATIONS.

CAUTION: Always check dado blade clearance before plugging in the saw.

Be sure to place the blade guard assembly and standard throat plate back in

position and check adjustments when the dado cuts are complete. Reinstall blade

guard assembly, anti-kickback assembly and riving knife.

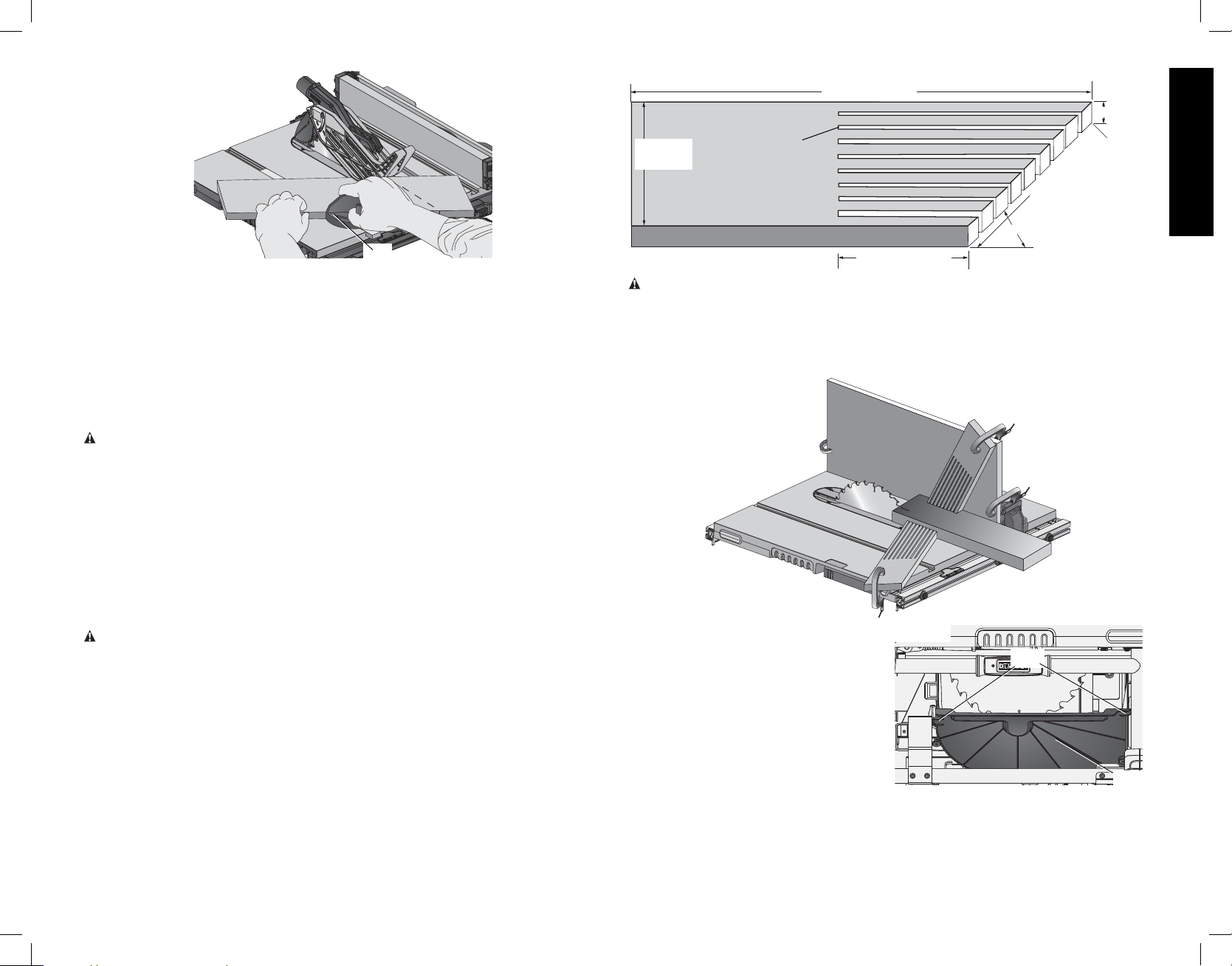

Featherboard Construction (Fig. 41, 42)

Featherboards are used to keep the work in contact with the fence and table, and help

prevent kickbacks. Dimensions for making a typical featherboard are shown in Figure 41.

Make the featherboard from a straight piece of wood that is free of knots and cracks. Clamp

the featherboard to the fence and table so that the leading edge of the featherboard will

support the workpiece until the cut is complete (Fig. 42). An 8" (203mm) high flat board can

be clamped to the rip fence and the featherboard can be clamped to the 8" (203mm) high

board.

FIG. 41

4"

(102mm)

THE KERF

SHOULD BE

ABOUT 1/4"

(6.4mm) APART

24" (610mm)

3/4"

(20mm)

60º

5" (127mm)

WARNING: Use featherboards for all non thru-sawing operations where the blade guard

assembly, anti-kickback assembly and riving knife cannot be used. Always replace the

blade guard assembly, anti-kickback assembly and riving knife when the non thrusawing operation is complete. Make sure the featherboard presses only on the portion of

the workpiece in front of the blade.

FIG. 42

Dust Collection (Fig. 43)

This table saw is equipped with a dustshroud

and dust collection port. For best results,

FIG. 43

YY

connect a vacuum to the port at the rear of

the saw and on the guard using a Y connector.

After extended use, the saw’s dust collection

system may become clogged. To clear the

dust collection system:

1. Unplug the saw.

2. Turn the saw on its side, so the bottom,

open part of the unit is accessible.

XX

3. Open the dust access door (XX) shown in Figure 43 by pressing the the side clips (YY).

Clean out the excess dust, and re-secure by pushing the side clips completely into place.

English

13

Page 16

Motor Overload and Power Loss Reset Switch

If power is interrupted by a circuit breaker trip, or power is lost, the saw contains a power loss

reset switch feature that will automatically reset to OFF position.

Circuit breaker overload is often the result of a dull blade. Change your blade on a regular

basis to avoid tripping your breaker. Disconnect the saw from power source and check your

blade before re-setting the circuit breaker and continuing to saw.

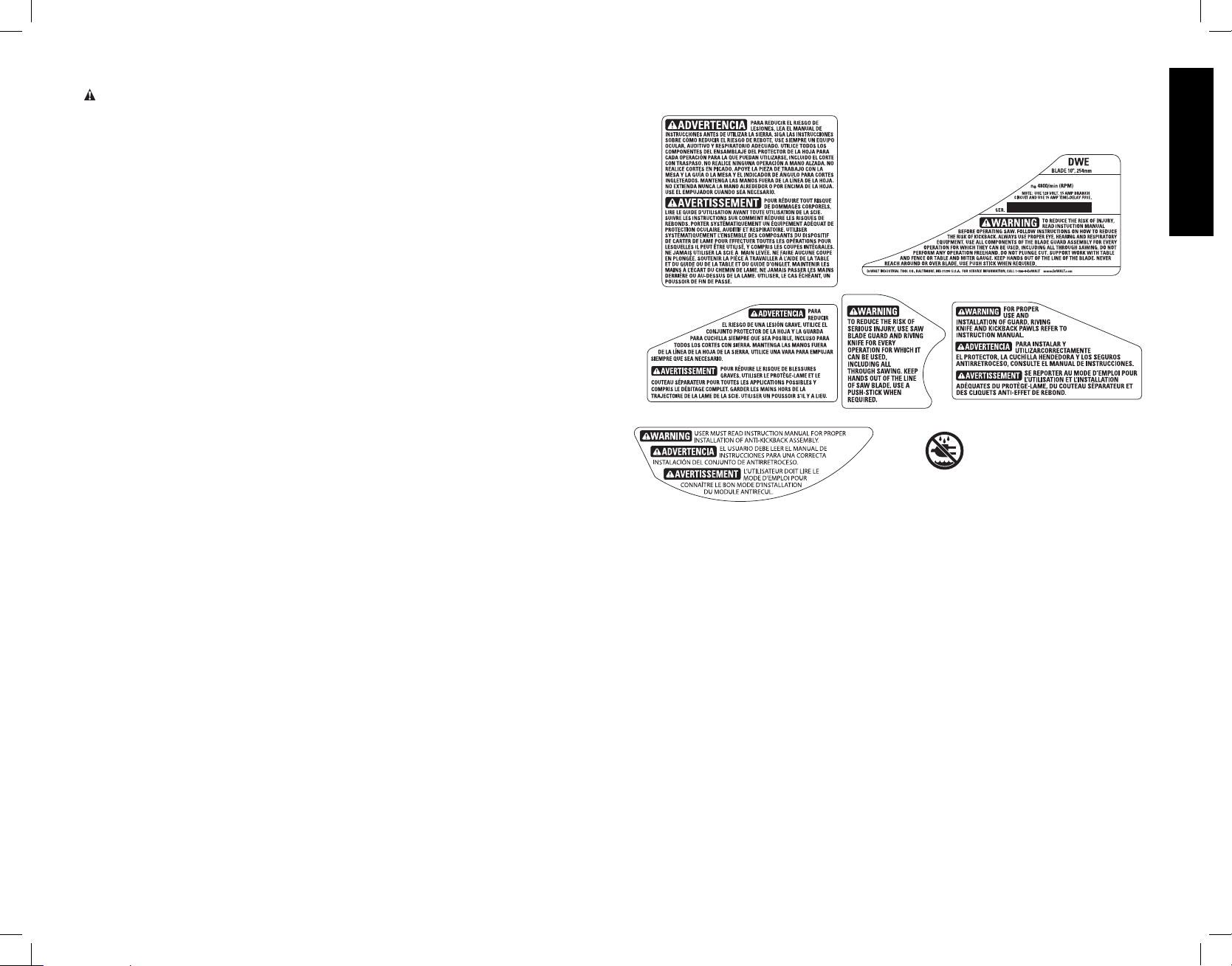

Lubrication (Fig. 44)

English

FIG. 44

1. All motor bearings are permanently lubricated at the factory and

no additional lubrication is needed.

2. The height adjustment screw may require periodic cleaning and

lubrication. If you have difficulty raising or lowering the blade:

a) Unplug the saw.

b) Turn the saw on its side, so the bottom, open part of the unit

is accessible.

c) Clean and lubricate the height adjustment screw threads (ZZ)

on the underside of this saw with general purpose grease.

Refer to Figure 44.

STORAGE (Fig. 45–50)

1. Attach push stick (V) to fence.

2. Remove blade guard assembly (K). See Remove Blade Guard Assembly. Slide blade

guard assembly into holder as shown, then turn lever counterclockwise to lock.

3. Depress the stem on the anti-kickback assembly (N) to allow the assembly to slide from the

riving knife slot.

4. Position anti-kickback assembly into the storage hole as shown. While depressing stem (II)

slide the anti-kickback assembly across the storage bracket (A1) and release pin to lock into

place.

5. Slide blade wrenches (U) into pocket until yellow button aligns with hole to secure in place,

refer to Figure 47.

6. Insert guide bar of miter guage (J) into pocket, then pivot and snap in place (Fig. 45).

7. Wrap cord in this location (A2, Fig. 46).

8. Non thru-sawing riving knife (W) slides in place underneath the saw, below the cord wrap.

Refer to Figure 50.

9. To store fence (K), snap work support in stored position. Remove fence from rails. Reattach

fence upside down on left side of saw. Refer to Figure 46. DO NOT hook locator pins on left

side fence locator screws. These screws will align with clearance pocket on fence as shown.

Pivot fence lock latches to secure.

MAINTENANCE

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or

changing set-ups or when making repairs. An accidental start-up can cause injury.

Cleaning

WARNING: Blowing dust and chips out of the motor housing using clean, dry compressed

air is a necessary regular maintenance procedure. Dust and chips containing metal particles

often accumulate on interior surfaces and could create an electrical shock or electrocution if

not frequently cleaned out. ALWAYS WEAR SAFETY GLASSES.

CAUTION: When cleaning, use only a damp cloth on plastic parts. Many household

cleaners contain chemicals which could seriously damage plastic. Also, do not use gasoline,

turpentine, lacquer or paint thinner, dry cleaning fluids or similar products which may seriously

damage plastic parts. Never let any liquid get inside the tool; never immerse any part of the

tool into a liquid.

ZZ

FIG. 45

N

K

J

FIG. 46

V

R

A2

FIG. 47

U

FIG. 48

FIG. 49

II

N

A1

FIG. 50

W

14

Page 17

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the

risk of injury, only D

EWALT recommended accessories should be used with this product.

Recommended accessories, such as a metric rip scale, for use with your tool are available at

extra cost from your local dealer or authorized service center. If you need assistance in locating

any accessory, please contact D

MD 21286, call 1-800-4-D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

EWALT (1-800-433-9258) or visit our website: www.dewalt.com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including

brush inspection and replacement) should be performed by a D

a D

EWALT authorized service center or other qualified service personnel. Always use identical

EWALT factory service center,

replacement parts.

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you obtain more efficient

warranty service in case there is a problem with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance loss, such as fire, flood or

theft, your registration of ownership will serve as your proof of purchase.

• FOR YOUR SAFETY: Registering your product will allow us to contact you in the unlikely

event a safety notification is required under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-D

apply to accessories or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have other rights which vary

in certain states or provinces.

In addition to the warranty, D

D

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

EWALT tools are covered by our:

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your D

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained in the

packaging, call the local company or see website for warranty information.

EWALT (1-800-433-9258). This warranty does not

1 YEAR FREE SERVICE

EWALT Power Tool, Laser, or

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-D

EWALT (1-800-433-9258) for a free replacement.

XXX

English

15

Page 18

Défi nitions: lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour chaque mot-indicateur

employé. Lire le mode d’emploi et porter une attention particulière à ces symboles.

DANGER: indique une situation dangereuse imminente qui, si elle n’est pas évitée,

entraînera la mort ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, pourrait entraîner la mort ou des blessures graves.

ATTENTION: indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourrait entraîner des blessures légères ou modérées.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais

qui par contre, si rien n’est fait pour l’éviter, pourrait poser des risques de dommages

matériels.

POUR TOUT COMMENTAIRE OU QUESTION RELATIF À CET OUTIL OU TOUT AUTRE

OUTIL D

EWALT, COMPOSEZ GRATUITEMENT LE: 1-800-4-DEWALT (1-800-433-9258).

AVERTISSEMENT : afin de réduire le risque de blessures, lire le mode d’emploi de

l’outil.

Règles de sécurité – Généralités

AVERTISSEMENT: lire ces directives avant toute utilisation. Tout manquement aux

directives suivantes pose des risques de choc électrique, d’incendie et/ou de blessure

grave.

CONSERVER CES CONSIGNES

AVERTISSEMENT: SE CONFORMER AUX NORMES DU CODE EN MATIÈRE DE

Français

CÂBLAGE et connexions électriques pour prévenir tout risque de décharge électrique ou

d’électrocution.

Double isolation

Si la scie a été conçue d’usine avec une double isolation, lire les consignes suivantes.

Ce symbole

les décharges électriques, les outils à double isolation sont complètement recouverts de deux

couches distinctes d’isolant électrique ou d’une double épaisseur de matière isolante. Les

outils possédant ce type d’isolation ne sont pas destinés à être mis à la terre. Par conséquent,

ils sont munis d’une fiche à deux broches permettant d’utiliser une rallonge ne nécessitant

aucune prise à la terre. Réparer ou remplacer immédiatement tout cordon endommagé ou

usé.

REMARQUE : le fait que cet outil soit muni d’une double isolation ne signifie pas que

l’utilisateur peut cesser de respecter les consignes de sécurité qui s’imposent. L’isolation offre

une protection supplémentaire contre les blessures causées par toute défaillance électrique

des systèmes d’isolation internes.

FICHES POLARISÉES

Pour réduire tout risque de choc électrique, cet outil est muni d’une fiche

polarisée (l’une des lames est plus large que l’autre), laquelle ne peut être

raccordée qu’à une prise polarisée et ce, dans un seul sens. Si la fiche ne

rentrait pas complètement dans la prise, inverser le sens de la fiche. Si la

fiche ne s’adapte toujours pas, faire appel à un électricien qualifié pour qu’il

installe la prise appropriée. Ne jamais modifier la fiche en aucune façon.

atteste d’une fabrication à double isolation. Afin de protéger l’utilisateur contre

Consignes de sécurité importantes

• POUR RÉDUIRE TOUT RISQUE DE DOMMAGES CORPORELS, utiliser

systématiquement l’ensemble des composants du dispositif de protection (dispositif de

carter de lame, couteau diviseur et dispositif anti-rebonds) au cours des opérations pour

lesquelles ils ont été conçus, et ce, pendant toute la durée de coupe.

• RETIRER TOUTE CLÉ ET TOUT OUTIL DE RÉGLAGE. Vérifier systématiquement que

toute clé ou outil de réglage a été retiré de la broche avant de mettre l’outil en marche.

Outils, chutes, ou autres débris pourraient être projetés brusquement, et causer des

dommages corporels.

• MAINTENIR L’AIRE DE TRAVAIL PROPRE. Les établis et locaux encombrés sont

propices aux accidents.

• NE PAS UTILISER LA MACHINE DANS UN ENVIRONNEMENT DANGEREUX. Ne

pas utiliser d’outils électriques dans des endroits trempés ou humides, ou sous la pluie,