Page 1

DWE7470

10" (254 mm) Table Saw

Page 2

2

English

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

NOTICE: indicates a practice not related to personal injury which, if not avoided, may

result in property damage.

General Safety Rules

WARNING: Read all instructions before operating product. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS

WARNING: FOLLOW ALL WIRING CODES and recommended electrical connections to

prevent shock or electrocution.

Grounding Instructions

If saw is of grounded construction, read the following instructions.

DANGER: SHOCK HAZARD. THIS MACHINE MUST BE GROUNDED WHILE IN USE.

SERIOUS INJURY COULD RESULT.

ALL GROUNDED, CORD-CONNECTED MACHINES

In the event of a malfunction or breakdown, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock. This machine is equipped with

an electric cord having an equipment-grounding conductor and a grounding plug. The

plug must be plugged into a matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances. Do not modify the plug provided - if it

will not fit the outlet, have the proper outlet installed by a qualified electrician. Improper

connection of the equipment-grounding conductor can result in risk of electric shock.

The conductor with insulation having an outer surface that is green with or without yellow

stripes is the equipment-grounding conductor. If repair or replacement of the electric cord

or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the machine is properly grounded. Use

only three-wire extension cords that have three-prong grounding type plugs and matching

three-conductor receptacles that accept the machine’s plug, as shown in Figure A. Repair

or replace damaged or worn cord immediately.

Important Safety Instructions

• TO REDUCE THE RISK OF KICKBACK AND OTHER INJURIES, use all components

of the guarding system (blade guard assembly, riving knife and anti-kickback) for every

operation for which they can be used including all through cutting.

• To change the cord set, contact your local dealer or authorized service center.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from spindle before turning tool on. Tools, scrap

pieces, and other debris can be thrown at high speed, causing injury.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

• DO NOT USE THE MACHINE IN A DANGEROUS ENVIRONMENT. The use of power

tools in damp or wet locations or in rain can cause shock or electrocution. Keep your work

area well-lit to avoid tripping or placing arms, hands, and fingers in danger.

• KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from work area.

Your shop is a potentially dangerous environment.

• MAKE WORKSHOP CHILDPROOF with padlocks, master switches, or by removing

starter keys. The unauthorized start-up of a machine by a child or visitor may result in injury.

• DO NOT FORCE TOOL. It will do the job better and be safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not

designed. Using the incorrect tool or attachment may result in personal injury.

– Do not use the saw blades if damaged or deformed;

– Use only manufacturer's recommended saw blades;

– Verify that the selection of the saw blade matches the material to be cut.

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition.

If your product is equipped with a cord set, use only three-wire extension cords that have

three-prong grounding-type plugs and three-pole receptacles that accept the tool’s plug.

When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The following table shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

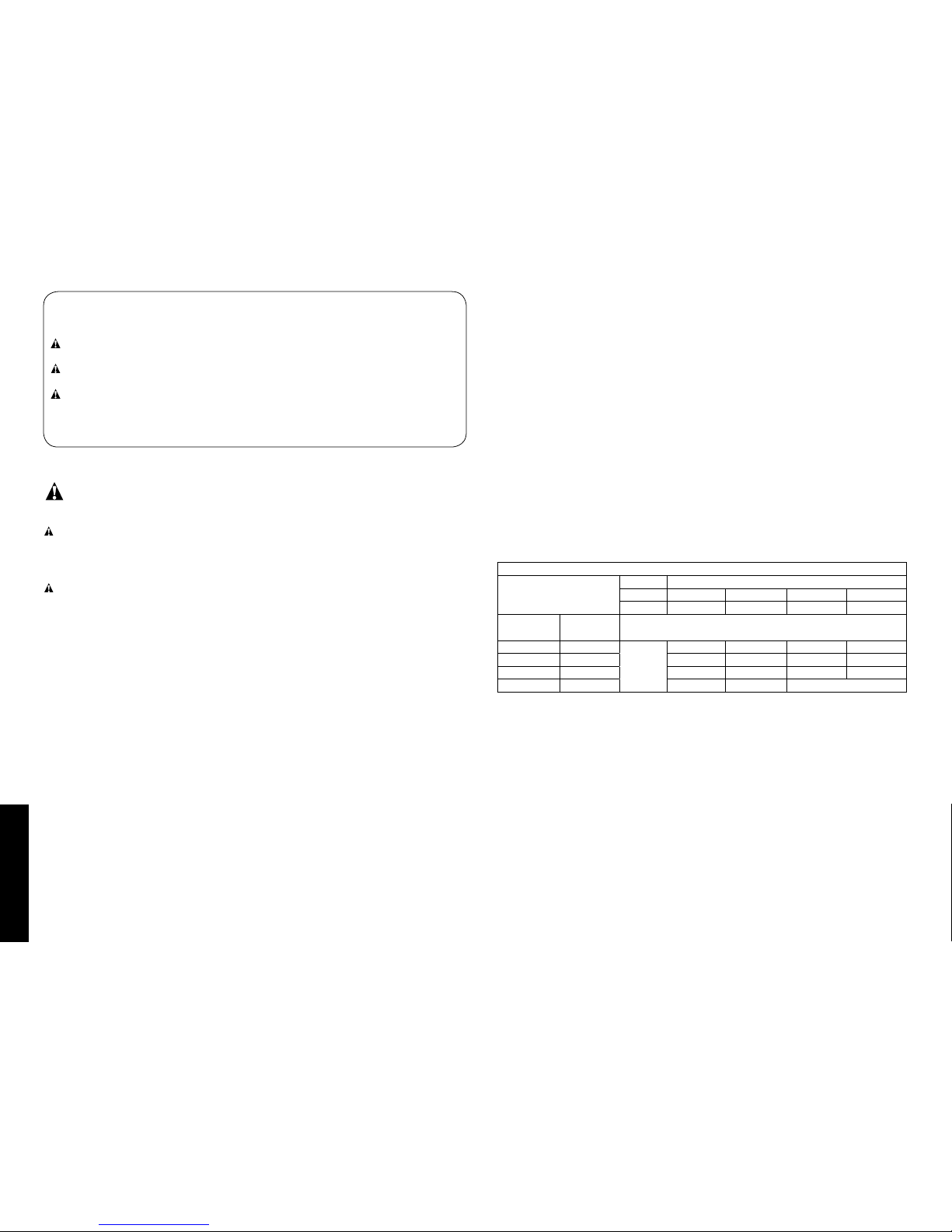

Minimum Gauge for Cord Sets

Ampere Rating

Volts Total Length of Cord in Feet (meters)

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

More

Than

Not More

Than

AWG

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

• WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or other

jewelry to get caught in moving parts. Non-slip footwear is recommended. Wear protective

hair covering to contain long hair. Air vents may cover moving parts and should also be

avoided.

• ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses. Also

use face or dust mask if cutting operation is dusty. All users and bystanders MUST

ALWAYS wear certified safety equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

• DO NOT OVERREACH. Keep proper footing and balance at all times. Loss of balance

may cause personal injury.

• MAINTAIN TOOLS WITH CARE. Keep blades sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories. Poorly

maintained blades and machines can further damage the blade or machine and/or cause

injury.

• TURN THE MACHINE “OFF”, AND DISCONNECT THE MACHINE FROM THE

POWER SOURCE before installing or removing accessories, before adjusting or

changing set-ups, when making repairs or changing locations. Do not touch the plug’s metal

prongs when unplugging or plugging in the cord. An accidental start-up can cause injury.

Page 3

3

English

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure that the switch is in

the “OFF” position before plugging in the power cord. In the event of a power failure, move

the switch to the “OFF” position. An accidental start-up can cause injury.

• USE RECOMMENDED ACCESSORIES. Use only accessories that are recommended

by the manufacturer for your model. Accessories that may be suitable for one tool may be

hazardous when used on another tool. Consult the instruction manual for recommended

accessories. The use of improper accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting

tool is unintentionally contacted.

• CHECK FOR DAMAGED PARTS. Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate properly and

perform its intended function—check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or replaced. Do not use

tool if switch does not turn it on and off. Damaged parts can cause further damage to the

machine and/or personal injury.

• DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation

of the blade or cutter only.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave

tool until it comes to a complete stop. Serious injury can result.

• DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN

GASEOUS OR EXPLOSIVE ATMOSPHERES. Motors and switches in these tools may

spark and ignite fumes.

• STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE COMMON SENSE. DO

NOT USE THE MACHINE WHEN YOU ARE TIRED OR UNDER THE INFLUENCE OF

DRUGS, ALCOHOL, OR MEDICATION. A moment of inattention while operating power

tools may result in serious injury.

• DO NOT ALLOW FAMILIARITY (gained from frequent use of your saw) TO

REPLACE SAFETY RULES. Always remember that a careless fraction of a second is

sufficient to inflict severe injury.

Additional Safety Rules for Table Saws

WARNING: ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty. All users and bystanders

MUST ALWAYS wear certified safety equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Do not expose to rain or use in damp locations.

• AVOID AWKWARD POSITIONS, where a sudden slip could cause a hand to move into

a saw blade.

• NEVER REACH IN BACK OF, OR AROUND, THE CUTTING TOOL with either hand to

hold down the workpiece.

• KEEP ARMS, HANDS AND FINGERS AWAY from the blade to prevent serious injury.

• USE A PUSH STICK THAT IS APPROPRIATE TO THE APPLICATION TO PUSH

WORKPIECES THROUGH THE SAW. A push stick is a wooden or plastic stick, usually

homemade, that should be used whenever the size or shape of the workpiece would cause

you to place your hands within 6" (152mm) of the blade.

• USE HOLD-DOWNS, JIGS, FIXTURES OR FEATHER BOARDS TO HELP GUIDE

AND CONTROL THE WORKPIECE. Accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. Instructions for making a

push stick, a narrow rip auxiliary fence, a push block and feather boards are included in this

manual.

• DO NOT PERFORM RIPPING, CROSSCUTTING OR ANY OTHER OPERATION

FREEHAND.

• NEVER reach around or over saw blade.

• STABILITY. Make sure the table saw is firmly mounted to a secure surface before use and

does not move.

• NEVER CUT METALS, CEMENT BOARD OR MASONRY. Certain man-made

materials have special instructions for cutting on table saws. Follow the manufacturer’s

recommendations at all times. Damage to the saw and personal injury may result.

• THE PROPER THROAT PLATE MUST BE LOCKED IN PLACE AT ALL TIMES to

reduce the risk of a thrown workpiece and possible injury.

• USE THE CORRECT SAW BLADE FOR THE INTENDED OPERATION. The blade

must rotate toward the front of the saw. Always tighten the blade arbor nut securely. Before

use, inspect the blade for cracks or missing teeth. Do not use a damaged or dull blade.

• NEVER ATTEMPT TO FREE A STALLED SAW BLADE WITHOUT FIRST TURNING

THE MACHINE OFF AND DISCONNECTING THE SAW FROM THE POWER

SOURCE. If a workpiece or cut-off piece becomes trapped inside the blade guard

assembly, turn saw off and wait for blade to stop before lifting the blade guard assembly

and removing the piece.

• NEVER START THE MACHINE with the workpiece against the blade to reduce the risk

of a thrown workpiece and personal injury.

• NEVER have any part of your body in line with the path of the saw blade. Personal

injury may occur.

• NEVER PERFORM LAYOUT, ASSEMBLY OR SET-UP WORK on the table/work area

when the machine is running. A sudden slip could cause a hand to move into the blade.

Severe injury can result.

• CLEAN THE TABLE/WORK AREA BEFORE LEAVING THE MACHINE. Lock

the switch in the “OFF” position and disconnect from the power source to prevent

unauthorized use.

• DO NOT leave a long board (or other workpiece) unsupported so the spring of the

board causes it to shift on the table resulting in loss of control and possible injury.

Provide proper support for the workpiece, based on its size and the type of operation to be

performed. Hold the work firmly against the fence and down against the table surface.

• IF YOUR SAW makes an unfamiliar noise or if it vibrates excessively, cease operating

immediately, turn unit off and disconnect from power source until the problem has been

located and corrected. Contact a

DeWALT factory service center, a DeWALT authorized

service center or other qualified service personnel if the problem can not be found.

• KEEP OUT of the line of saw blade. Stand to the side whenever possible.

• USE RECOMMENDED ACCESSORIES. The use of improper accessories may cause

risk of personal injury.

• DO NOT OPERATE THIS MACHINE until it is completely assembled and installed

according to the instructions. A machine incorrectly assembled can cause serious injury.

• OBTAIN ADVICE from your supervisor, instructor, or another qualified person if you are

not thoroughly familiar with the operation of this machine. Knowledge is safety.

TERMS: THE FOLLOWING TERMS WILL BE USED THROUGHOUT THE MANUAL

AND YOU SHOULD BECOME FAMILIAR WITH THEM.

• Thru sawing refers to any cut that completely cuts through the workpiece.

• Non-thru sawing refers to any cut that does not completely cut through the workpiece.

• Push Stick refers to a wooden or plastic stick, usually homemade, that is used to push

small workpiece through the saw and keeps the operator’s hands clear of the blade.

• Kickback occurs when the saw blade binds in the cut and violently thrusts the workpiece

back toward the operator.

Page 4

4

English

• Freehand refers to cutting without the use of a miter gauge or rip fence or any

other means of guiding or holding the workpiece other than the operator’s hand.

WARNING: Never perform freehand cutting with this saw.

• Plunge cutting refers to blind cuts in the workpiece made by either raising the blade

through the workpiece or lowering the workpiece down to the blade.

WARNING: Never perform plunge cutting with this saw.

• Resawing - Flipping material to make a cut the saw is not capable of making in one pass.

WARNING: Resawing IS NOT recommended.

SAW BLADE GUARD ASSEMBLY, ANTI-KICKBACK ASSEMBLY AND RIVING KNIFE

Your table saw is equipped with a blade guard assembly, anti-kickback assembly and riving

knife that covers the blade and reduces the possibility of accidental blade contact. The riving

knife is a flat plate that fits into the cut made by the saw blade and effectively fights kickback by

lessening the tendency of the blade to bind in the cut. The blade guard assembly and anti-

kickback assembly can only be used when making through cuts that sever the wood.

When making rabbets and other cuts that make non through cuts, the blade guard

assembly and anti-kickback assembly must be removed and riving knife lowered to

the non through cut position marked on the riving knife. Two anti-kickback pawls are

located on the sides of the riving knife that allow the wood to pass through the blade in the

cutting direction but reduce the possibility of the material being thrown backwards toward the

operator.

Use all components of the guarding system (blade guard assembly, riving knife and antikickback assembly) for every operation for which they can be used including all through

cutting. If you elect not to use any of these components for a particular application exercise

additional caution regarding control of the workpiece, the use of push sticks, the position of

your hands relative to the blade, the use of safety glasses, the means to avoid kickback and

all other warnings contained in this manual and on the saw itself. Replace the guarding

systems as soon as you return to thru-cutting operations. Keep the guard assembly in

working order.

MAKING A PUSH STICK (Inside Back Cover)

• In order to operate your table saw safely you must use a push stick whenever the size or

shape of the workpiece would cause your hands to be within 6" (152mm) of the saw blade

or other cutter. A push stick is included with this saw.

• No special wood is needed to make additional push-sticks as long as it’s sturdy and long

enough. A length of 15.7" (400 mm) is recommended with a notch that fits against the

edge of the workpiece to prevent slipping. It’s a good idea to have several push sticks

of the same length [15.7" (400 mm)] with different size notches for different workpiece

thicknesses.

• See the inside back cover for a picture of a push stick. The shape can vary to suit your own

needs as long as it performs its intended function of keeping your hands away from the

blade.

KICKBACKS

KICKBACKS: Kickbacks can cause serious injury. A kickback occurs when a part of the

workpiece binds between the saw blade and the rip fence, or other fixed object, and rises

from the table and is thrown toward the operator. Kickbacks can be avoided by attention to

the following conditions.

How to Avoid Them and Protect Yourself from Possible Injury

a. Be certain that the rip fence is parallel to the saw blade.

b. Do not rip by applying the feed force to the section of the workpiece that will become

the cut-off (free) piece. Feed force when ripping should always be applied between the

saw blade and the fence; use a push stick for narrow work, 6" (152mm) wide or less.

c. Keep saw blade guard assembly, riving knife and anti-kickback assembly in place and

operating properly. If anti-kickback assembly is not operational, return your unit to

the nearest authorized

DeWALT service center for repair. The riving knife must be in

alignment with the saw blade and the anti-kickback assembly must stop a kickback

once it has started. Check their action before ripping by pushing the wood under the

anti-kickback assembly. The teeth must prevent the wood from being pulled toward the

front of the saw.

d. Plastic and composite (like hardboard) materials may be cut on your saw. However,

since these are usually quite hard and slippery, the anti-kickback pawls may not stop

a kickback. Therefore, be especially attentive to following proper set up and cutting

procedures for ripping.

e. Use saw blade guard assembly, anti-kickback assembly and riving knife for every

operation for which it can be used, including all through-sawing.

f. Push the workpiece past the saw blade prior to release.

g. NEVER rip a workpiece that is twisted or warped, or does not have a straight edge to

guide along the fence.

h. NEVER saw a large workpiece that cannot be controlled.

i. NEVER use the fence as a guide or length stop when crosscutting.

j. NEVER saw a workpiece with loose knots, flaws, nails or other foreign objects.

k. NEVER rip a workpiece shorter than 10" (254mm).

l. NEVER use a dull blade – replace or have resharpened.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your mouth, eyes or lay on the skin

may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause

serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved

respiratory protection appropriate for the dust exposure. Direct particles away from face and

body. Always operate tool in well-ventilated area and provide for proper dust removal. Use

dust collection system wherever possible.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Specifications

Miter Angle 45° L and R

Bevel Angle 0° to 45° L

Blade Size 10" (254 mm)

Max. Cut Depth 90° Bevel 3" (76 mm)

Max. Cut Depth 45° Bevel 2-1/2" (64 mm)

Max. Dado Cut Width 1/2" (12.7mm)

Max. Dado Blade Diameter 6" (152.4mm)

RPM, no load 5000

Page 5

5

English

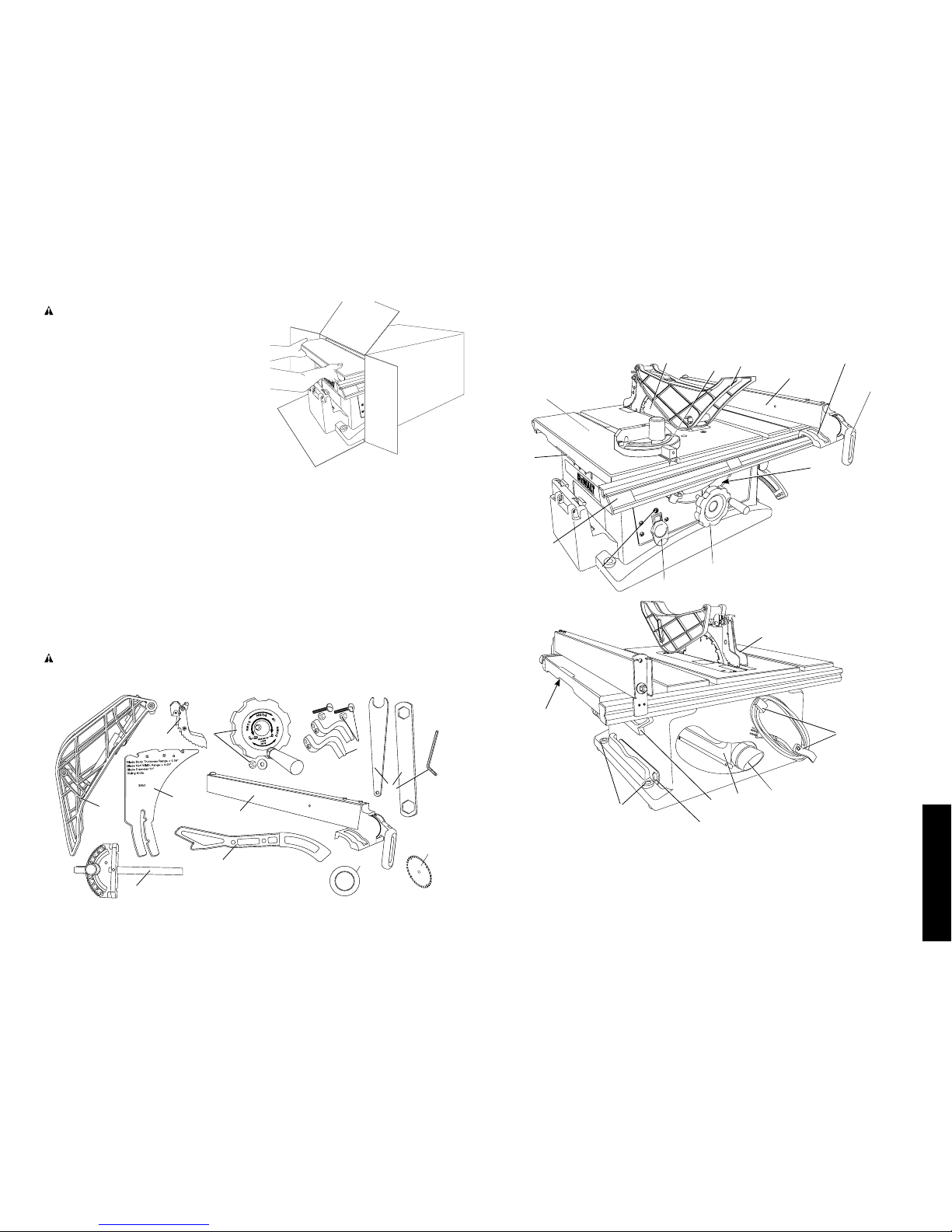

Unpacking

WARNING: To reduce the risk of injury, DO

FIG. 1

NOT connect the machine to the power source

until the table saw is completely assembled and

you read the entire instruction manual.

Open the box and slide the saw out, as shown

in Figure 1. Carefully unpack the table saw and

all loose items from the carton. Examine all

parts to make sure that parts have not been

damaged during shipping. If any parts are

missing or damaged, contact your dealer to

replace them before attempting to assemble

the tool.

Refer to Figure 2 for the loose items and

hardware included with the saw:

1. Rip fence

2. Arbor wrench, spindle wrench and hex wrench

3. Cord wrap brackets and hardware

4. Height/bevel adjustment wheel and hardware

5. Riving knife

6. Anti-kickback assembly

7. Push stick

8. Miter gauge

9. Blade guard assembly

10. Blade

11. Blade adaptor

NOTE: A portable table saw stand is designed for use with this saw and is available at a local

DeWALT dealer or service center at extra cost.

WARNING: To reduce the risk of serious personal injury, have push stick ready to use

before starting cut.

10

11

FIG. 2

3

5

6

9

7

8

1

2

4

FEATURES (Fig. 3, 4)

Examine Figures 3 and 4 to become familiar with the saw and its various parts. The following

sections on assembly and adjustments will refer to these terms and you must know what and

where the parts are.

FIG. 3

A

B

D

E

F

G

I

J

K

L

N

O

M

C

FIG. 4

S

R

U

Q

H

P

T

Page 6

6

English

FIGURE 3

A. Table H. Overload relay button

B. Miter gauge I. Blade height/bevel adjustment wheel

C. Blade J. Bevel lock lever

D. Blade guard assembly K. ON/OFF switch

E. Rip fence L. Rip fence indicator

F. Rip fence rails M. Handle for transport

G. Rip fence front latch

FIGURE 4

N. Mounting holes R. Arbor wrench, spindle wrench

O. Cord wrap S. Dust collection port

P. Cam lock lever T. Dust shroud

Q. Anti-kickback assembly U. Push stick

ASSEMBLY

WARNING: Shock Hazard. To reduce the risk of serious personal injury, turn unit

off and disconnect machine from power source before attempting to move it, change

accessories or make any adjustments.

ASSEMBLE YOUR SAW IN THE FOLLOWING ORDER

1. Blade height/bevel adjustment wheel

2. Cord wrap

3. Ensure blade is installed correctly and arbor nut is tight. Use wrenches supplied.

4. Postion the riving knife.

5. Install the throat plate. (NOTE: Adjust leveling screws before proceeding. Refer to To

Replace Throat Plate.)

6. Rip fence (NOTE: Adjust rip fence indicator before proceeding; refer to Rip Fence

Indicator Adjustment under Adjustment.)

7. Anti-kickback assembly

8. Blade guard assembly

9. Miter gauge (if required for application)

NOTE: Tools needed for assembly include the wrenches included with this saw.

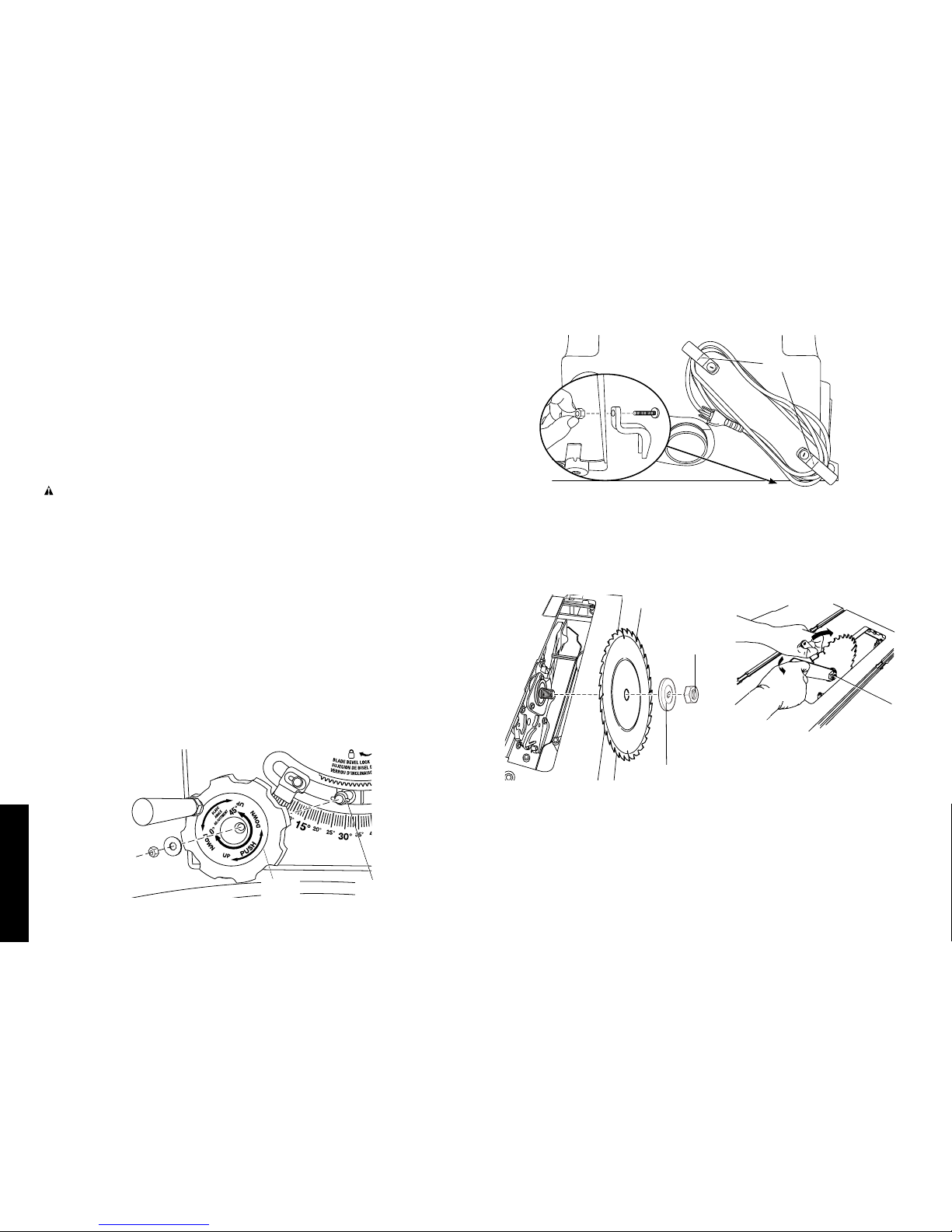

Blade Height/Bevel Adjustment Wheel (Fig. 5)

Slide blade height/bevel adjustment wheel (I) onto shaft. Ensure the slots on the hub align with

the pins (A2) on the shaft. Secure with washer and nut supplied. Tighten securely.

FIG. 5

A2

I

Cord Wrap (Fig. 6)

Attach the cord wrap brackets (O) to rear of saw using the hardware supplied. Tighten securely.

FIG. 6

O

Blade (Fig. 3, 7, 8)

1. Remove the throat plate. Refer to To Remove Throat Plate.

2. Raise the saw blade arbor to its maximum height by turning the blade height/bevel

adjustment wheel (I) clockwise.

3. Remove the arbor nut (Y) and outer washer (Z) and set aside.

4. Place the blade (C) onto the blade adaptor making sure the teeth of the blade point

downward and toward the front of the saw.(B1,A9 version no need adaptor)

FIG. 8

Y

FIG. 7

C

Y

Z

5. Place the outer washer (Z) against the blade, raised side out and tighten the arbor nut

against the washer as far as possible by hand. Ensure that the outer washer and arbor nut

are free of dust and debris before installing.

6. To further tighten the arbor nut (Y), use the open ended spindle wrench (supplied) to keep

the spindle from rotating.

7. Use the arbor wrench (supplied) to hold the nut and tighten it by turning it clockwise.

Reposition the wrench on the arbor nut and repeat as necessary until the nut and washer

are securely fastened against the blade.

NOTE: Different types of blades make different kerfs (width of cuts). Therefore, it is necessary

to check adjustment of rip scale when changing blades. Replacement blade MUST not exceed

the thickness stated on the riving knife. The riving knife provided with the saw is 0.09" (2.3mm)

thick.

Page 7

7

English

To Remove Throat Plate (Fig. 9)

Using finger hole (W) on the plate, pull throat plate (X) up and forward to expose the inside of

the saw.

FIG. 9

X

W

Positioning The Riving Knife (Fig. 3, 10, 11)

1. Loosen the bevel lock lever (J), turn and move the blade height/bevel adjustment wheel (I)

to 45° on the bevel scale, and then tighten the bevel lock lever (J).

2. Loosen the riving knife locking knob (YY) counterclockwise.

YY

FIG. 10

A3

A4

FIG. 11

FF

C

YY

A1

ZZ

A3

A4

3. Insert the riving knife (FF) into the space between the mounting bracket (A4) and the set

plate (A3) located behind the saw blade (C). Ensure the lock pin of the riving knife locking

knob (YY) engages with one of the slots (A1, ZZ) on the riving knife (FF).

4. Tighten riving knife locking knob (YY) clockwise.

NOTE: The riving knife has two positions, the high position for all through cuts and the lower

position for all non-through cuts. DO NOT operate saw if riving knife is not locked in the

through-cut slot (ZZ) or non through-cut position slot (A1), refer to Aligning The Riving Knife

Assembly under Adjustments.

5. Loosen the bevel lock lever (J) and return the blade to 0° and lock.

WARNING: To reduce the risk of serious personal injury. Place the locking knob (YY) in the

down position after tightening the riving knife to prevent it from interfering with the throat plate.

The locking knob (YY) can be pulled out and placed in the down position without loosening

the riving knife.

REMOVING THE RIVING KNIFE ASSEMBLY

NOTE: The throat plate should be removed and the blade raised to its highest position before

proceeding.

1. Remove the throat plate. Refer to To Remove Throat Plate.

2. Raise the saw blade arbor to its maximum height by turning the blade height/bevel

adjustment wheel (I) clockwise.

3. Loosen the bevel lock lever (J), turn and move the blade height/bevel adjustment wheel (I)

to 45° on the bevel scale, and then tighten the bevel lock lever (J).

4. Loosen riving knife locking knob (YY) 2–3 turns counterclockwise and push the set plate

(A3) back.

5. Remove the riving knife (FF) along the mounting bracket (A4).

6. Loosen the bevel lock lever (J) and return the blade to 0° and lock.

7. Replace throat plate. Refer to To Replace Throat Plate.

To Replace Throat Plate (Fig. 9)

1. Align the throat plate and insert the tabs on the back of the throat plate into the holes on

the back of the table opening.

2. The throat plate includes two adjustment screws which raise or lower the throat plate.

When properly adjusted, the front of the throat plate should be flush or slightly below the

surface of the table top and secured in place. The rear of the throat plate should be flush

or slightly above the table top.

Anti-Kickback Assembly (Fig. 12)

WARNING: To reduce the risk of serious personal injury, the anti-kickback assembly must

be in place for all possible cuts.

1. Locate the anti-kickback mounting hole and slot (EE) at the top of the riving knife (FF).

2. Slide anti-kickback locking tab (GG) up and hold while placing the front of the anti-kickback

assembly into slot (EE).

3. Push down to engage assembly into slot, continue pushing down on the anti-kickback

assembly until it snaps into place.

4. Release anti-kickback locking tab (GG) to lock the assembly in place.

NOTE: Pull up on the anti-kickback assembly to ensure it has locked into place.

FIG. 12

FF

Q

GG

GG

EE

TO REMOVE ANTI-KICKBACK ASSEMBLY

Slide anti-kickback locking tab (GG) up to release anti-back assembly and lift anti-kickback

assembly from riving knife slot.

Page 8

8

English

Blade Guard Assembly (Fig. 13)

TO ATTACH BLADE GUARD ASSEMBLY

WARNING: To reduce the risk of serious personal injury, the blade guard assembly must

be in place for all possible cuts.

1. While holding the blade guard assembly (D) slide the locating pin (HH) into the riving knife slot

(II) centering the riving knife within the v-shaped notch in the guard.

2. Slide and hold the blade guard lock lever (W W) up and press the blade guard assembly down

until the entire assembly is flat on the riving knife. Release the blade guard lock lever.

3. Ensure the guard is locked onto the riving knife. If the guard is not locked, repeat steps 1

and2.

FIG. 13

II

D

HH

W W

W W

TO REMOVE THE BLADE GUARD ASSEMBLY

Slide the blade guard lock lever (WW) up and remove blade guard assembly from riving knife

slot.

Rip Fence

The rip fence can be installed on the left or right side of your table saw.

RIP FENCE ASSEMBLY (FIG. 14)

1. Lift up the rip fence latch (G) to release the holding clamp (AA).

2. Hook the holding clamp (AA) onto the rear fence rail (F) and lower the front of the fence

onto the front fence rail.

3. Push down the rip fence latch (G) to lock the rip fence in place. Ensure the fence is secure.

G

FIG.14

AA

F

Miter Gauge (Fig. 15)

NOTE: A large auxiliary miter gauge face may be used.

TO ATTACH THE MITER GAUGE

The DWE7470 includes a miter gauge

FIG. 15

JJ

for crosscutting materials. The miter

gauge can be used by insertion into

one of the two miter gauge slots (JJ) in

the table top.

NOTE: See Crosscutting and Bevel

Crosscutting instructions under

Adjustments before performing these

operations on the table saw.

To Bench Mount Saw

(Fig. 4)

NOTE: A portable table saw stand is

designed for use with this saw and is

available at a local

DeWALT dealer or

service center at extra cost.

WARNING: To reduce the risk of serious personal injury, turn unit off and

disconnect machine from power source before attempting to move it, change

accessories or make any adjustments. An accidental start-up can cause injury.

CAUTION: To reduce the risk of personal injury, make sure table saw is firmly mounted

before use.

The table saw must be mounted firmly. Four mounting holes (N, Fig. 4) are provided in the

metal frame for mounting. We strongly recommend that these holes be used to anchor the

table saw to your workbench or other rigid, stationary work support.

CAUTION: Ensure that the surface is stable enough that large pieces of material will not

cause it to tip over during use.

1. Center the saw on the desired, stable work surface.

2. Drive four 3-1/2" (88.9 mm) long screws through the holes in the metal frame. Make sure

the screws extend through the frame and securely attach to the supporting work surface.

If marring the supporting work surface is a concern, the DWE7470 can be mounted to scrap

wood which can then be clamped onto the desired work surface.

1. Cut a piece of 3/4" (19 mm) plywood to fit beneath the footprint of the saw.

2. Screw the saw to the plywood and clamp the overhang of the plywood to the work

surface. If the screws protrude through the plywood base, set it on two scrap pieces of

material of equal thickness and attach them to the edges of the plywood to hold the saw

further off of the work surface and prevent the screws from marring the surface.

Connecting Saw to Power Source

WARNING: To reduce the risk of injury, before connecting saw to power source, make

sure the switch is in the OFF position.

Be sure your power supply agrees with the nameplate marking. AC Only means that your saw

will operate on alternating current only. A voltage decrease of 10 percent or more will cause

a loss of power and overheating. All

DeWALT tools are factory tested. If this tool does not

operate, check the power supply.

Page 9

9

English

On-Off Switch (Fig. 16)

WARNING: To reduce the risk of injury, be sure switch is in the OFF position before

plugging machine in.

WARNING: ALWAYS lock the switch OFF when the

FIG. 16

K

KK

T

saw is not in use. Remove the key (KK) and keep it in a

safe place. In the event of a power failure, blown fuse or

tripped circuit breaker, turn the switch OFF and remove

the key, preventing an accidental startup when power is

resumed.

The ON/OFF switch (K) has a removable safety key (KK).

With the key removed from the switch, unauthorized and

hazardous use by children and others is minimized and

the saw will not turn on.

1. To turn the saw ON, insert the key (KK) into the slot

of the switch (K), and move the switch upward to the

ON position.

2. To turn the saw OFF, move the switch downward.

3. To lock the switch in the OFF position, grasp the sides of the safety switch key (KK), and

pull it out.

4. With the switch key removed, the switch will not operate to power the saw on.

5. If the switch key is removed while the saw is running, it can be turned OFF but cannot be

restarted without inserting the switch key.

Motor Overload Protection (Fig. 16)

This saw has an overload relay button (T) that resets the motor after it shuts off due to

overloading or low voltage. If the motor stops during operation:

1. Place the ON/OFF switch (K) in the OFF position.

2. Unplug the saw and wait five minutes for the motor to cool.

3. Plug in the saw.

4. Push in the overload relay button (T) and place the ON/OFF switch in the ON position.

Circuit breaker overload is often the result of a dull blade. Change your blade on a regular basis

to avoid tripping your breaker. Disconnect the saw from power source and check your blade

before re-setting the circuit breaker and continuing to saw.

Rip Fence Operation

LOCKING FENCE (FIG. 3)

Lift up the rip fence latch (G) and slide the fence to the desired location on the rip fence rail (F).

Push down the rip fence latch to lock fence in place.

NOTE: When ripping, always lock the fence in place.

The rip fence will need to be adjusted for proper performance. Refer to Rip Fence Adjustment

under Adjustments for alignment instructions.

Table Extension Operation (Fig. 17)

NOTE: Use the scale on the front rail for rip cuts up to 10-1/2" (266.7 mm). For rip cuts

10-1/2" (266.7 mm) to 17-1/2" (444.5 mm), follow the below instructions.

1. Move the rip fence (E) to the 10-1/2" (266.7 mm) mark on the right side of scale (this is

marked with a red line on the scale) and lock down the fence.

2. Unlock the table extension by releasing the cam lock lever (P).

3. Slide the table extension with the fence to the desired location using the scale (XX) located

on the rear rail.

4. Lock the fence into position by pressing down the cam lock lever (P).

FIG. 17

E

P

XX

Blade Height/Bevel Wheel Operation (Fig. 3)

Turn blade height/bevel adjustment wheel (I) to lower and raise the blade.

Unlock the bevel lock lever (J), push in and turn the blade height/bevel adjustment wheel (I)

to bevel blade.

ADJUSTMENTS

WARNING: To reduce the risk of injury, turn unit off and disconnect machine

from power source before installing and removing accessories, before adjusting or

changing set-ups or when making repairs. An accidental start-up can cause injury.

NOTE: Your saw is fully and accurately adjusted at the factory at the time of manufacture. If

readjustment due to shipping and handling or any other reason is required, follow the steps

below to adjust your saw.

Once made, these adjustments should remain accurate. Take a little time now to follow these

directions carefully to maintain the accuracy of which your saw is capable.

RIP FENCE ADJUSTMENT (FIG. 18)

To check alignment

1. Position the rip fence on the right side of the table along one edge of a miter gauge slot

(JJ). When locked in place the rip fence should be parallel with the miter gauge slots.

If adjustment is needed:

a. Loosen the two screws (BB) and lift up the rip fence latch (G).

b. Hold the rip fence indicator (L) firmly against the table and move the rip fence until it is

parallel with the miter gauge slots (JJ).

c. Tighten screws (BB) and push down the rip fence latch.

2. The fence may become loose when locked into place.

To adjust:

a. Lift up the rip fence latch (G) and turn the adjusting nut (DD) clockwise to tighten rear

clamp.

NOTE: DO NOT turn the adjusting screw more than 1/4 of a turn at a time.

Overtightening will cause the fence to come out of alignment.

Page 10

10

English

FIG. 18

F

CC

DD

BB

L

G

JJ

RIP FENCE INDICATOR ADJUSTMENT (Calibrating Rip Scale) (FIG. 18)

NOTE: The rip fence indicator (L) points to the scale on the front of the table saw. Measurement

shown by the indicator will provide the user with accuracy up to 1/16 inch (1.6 mm ).

1. Measure the distance from the blade to the side of the fence closest to the blade. If there

is a difference between the measurement and the indicator reading, adjust the indicator.

2. Loosen the rip fence indicator screw (CC). Slide the rip fence indicator (L) to the correct

measurement position on the scale, then retighten the screw (CC).

TABLE EXTENSION SCALE POINTER (FIG. 19)

The table extension scale pointer (MM) should be at 10-1/2" (266.7 mm) on the scale when

the extension is in the closed position. If not, loosen the holding screw (LL), position the pointer

over 10-1/2" (266.7 mm) and re-tighten the screw.

ADJUSTING CAM LOCKING LEVER (FIG. 3, 20)

If the extension table moves when it is open and locked, then the cam locking lever (P) may

be loose and need adjustment, therefore, adjustment to the cam locking lever is necessary.

To adjust the locking lever tension, turn the bar (NN) with a 10 mm wrench until it is tightened,

but do not over tighten.

FIG. 19

MM

LL

FIG. 20

NN

ADJUSTING THE 90° AND 45° POSITIVE STOPS (FIG. 3, 21, 22)

This saw has positive stops that will quickly position the saw blade at 90° and 45° to the table.

Make adjustments only if necessary.

90° Stop

1. Raise the saw blade arbor to its maximum height by turning the blade height/bevel

adjustment wheel (I) clockwise.

2. Unlock the bevel lock lever (J), push in and turn blade height/bevel adjustment wheel (I) to

move the blade (C) to the maximum vertical position. Lock the bevel lock lever (J).

QQ

PP

FIG. 21

OO

C

FIG. 22

3. Place a combination square (OO) on the table and against the blade (C) to determine if the

blade is 90° to the table.

4. If the blade is not 90° to the table, loosen or tighten (depending on whether you are

increasing or decreasing the degrees) the hex bolt (PP) with a 5mm hex wrench until you

achieve 90°.

5. Unlock the bevel lock lever (J), push in and turn blade height/bevel adjustment wheel (I) to

move the blade (C) to the maximum vertical position. Lock the bevel lock lever (J).

6. Recheck the blade to ensure it is 90° to the table. If not, repeat step 4.

7. Ensure the blade bevel pointer reads 90°. If the pointer does not read 90°, refer to Blade

Bevel Pointer paragraph.

45° Stop

1. Raise the saw blade arbor to its maximum height by turning the blade height/bevel

adjustment wheel (I) clockwise.

2. Unlock the bevel lock lever (J), push in and turn blade height/bevel adjustment wheel (I) to

move the blade to the maximum bevel (45°) angle.

3. Place a combination square (OO) on the table and against the blade (C) to determine if the

blade is 45° to the table.

4. If the blade is not 45° to the table, loosen or tighten (depending on whether you are

increasing or decreasing the degrees) the hex bolt (QQ) with a 5mm hex wrench until you

achieve 45°.

5. Unlock the bevel lock lever (J), push in and turn blade height/bevel adjustment wheel (I) to

move the blade to the maximum bevel (45°) angle.

6. Recheck the blade to ensure it is 45° to the table. If not, repeat step 4.

Page 11

11

English

BLADE BEVEL POINTER (FIG. 23)

1. When the blade is positioned at 90°, adjust the blade

FIG. 23

V

bevel pointer to read 0° on the scale.

2. Loosen the mounting screw (V) and position pointer

over 0°. Tighten the screw.

BLADE PARALLEL TO THE MITER GAUGE SLOT

(FIG. 24, 25)

WARNING: This adjustment must be correct or

accurate cuts can not be made. Also inaccurate adjustment can result in kickback and serious

personal injury.

1. Remove the blade guard assembly from the saw. After adjustment reinstall blade guard

assembly.

2. Raise the blade to the highest position and set at the 0° angle (90° straight up).

3. Select and mark, with a felt tip maker, a blade tooth having a “right set” and rotate the

blade so the marked tooth is 1/2" (12.7 mm) above the table.

4. Place the combination square base (OO) into the right side miter gauge slot (JJ).

5. Adjust the rule so it touches the front marked tooth and lock ruler so it holds its position in

the square assembly.

6. Rotate the blade bringing the marked tooth to the rear and about 1/2" (12.7 mm) above

the table.

7. Carefully slide the combination square to the rear until the ruler touches the marked tooth.

8. If the ruler touches the marked tooth at the front and rear position, no adjustment is

needed at this time.

If not or the base of the rule is no longer parallel with the edge of the miter gauge slot,

perform the Additional Blade Adjustment in this section.

SS

FIG. 25

JJ

FIG. 24

OO

RR

UU

ADDITIONAL BLADE ADJUSTMENTS (FIG. 3, 25)

NOTE: The adjusting mechanism is located above the blade height/bevel adjustment wheel

(I) under the tabletop.

If the blade is partial to right side:

1. Turn the left adjustment screw (SS) counterclockwise and adjust the right side adjustment

screw (RR) clockwise.

2. Check adjustment as described in steps 4 to 8 in the Blade Parallel to the Miter Gauge

Slot section.

3. When alignment is achieved, turn the left adjustment screw (SS) until it touches the pivot

rod (UU).

If the blade is partial to left side:

1. Turn the right adjustment screw (RR) counterclockwise and adjust the left side adjustment

screw (SS) clockwise.

2. Check adjustment as described in steps 4 to 8 in the Blade Parallel to the Miter Gauge

Slot section.

3. When alignment is achieved, turn the right adjustment screw (RR) until it touches the pivot

rod (UU).

MITER GAUGE ADJUSTMENT (FIG. 26) (Calibrating Miter Gauge Pointer)

Your miter gauge features adjustable stops at 90° and 45° left and right.

To adjust miter gauge loosen knob (TT), set to desired angle and tighten knob.

TT

FIG. 26

ALIGNING THE RIVING KNIFE (FIG. 3, 27)

WARNING: To minimize the risk of kickback and to insure proper cutting, the riving knife

must be the proper thickness for the blade used. Refer to Riving Knife Selection to select

the correct riving knife.

1. Remove the throat plate. Refer to To

FIG. 27

FF

C

Remove Throat Plate under Assembly.

2. Raise the blade to the highest position.

2. Remove the blade guard and anti-kickback

pawl assembly. Refer to To Remove The

Blade Guard Assembly under Blade

Guard Assembly and To Remove Anti-

Kickback Assembly under Anti-Kickback

Assembly.

3. Loosen the bevel lock lever (J), turn and

move the blade height/bevel adjustment

wheel (I) to 0° on the bevel scale, and then

tighten the bevel lock lever (J).

4. To check if the blade (C) and riving knife (FF)

are correctly aligned, lay a straight edge on the table against two blade tips. The riving knife

should not touch the straight edge.

5. Bevel the blade to the 45° position and check the 45° alignment.

6. Check the riving knife and blade alignment again at both 0° and 45°.

7. Replace the throat plate, blade guard assembly and anti-kickback assembly.

Page 12

12

English

Saw Blades (Fig. 28)

WARNING: Riving knifes must be matched to saw blade dimensions in order to function

effectively. See Riving Knife Selection.

NOTE: THIS SAW IS INTENDED FOR USE

FIG. 28

ONLY WITH SAW BLADES 10" (254mm) IN

DIAMETER. See Fig. 28.

NOTE: This saw is not intended for use with

dado blades and molding cutters. Personal

injury may occur.

1. The saw blade furnished with your new

saw is a 10" (254 mm) combination blade,

used for crosscutting (across the grain)

and ripping (with the grain) through the

material. The center hole to fit on the arbor is

5/8" (16 mm) diameter (.625"). This blade

will produce a good quality cut for most

applications.

2. There are many types of blades available

to do specific and special jobs such as

cross cut only, rip only, hollow ground,

thin plywood, paneling, etc.

3. Use only saw blades designed for maximum safe operating speeds of 5,000 RPM or

greater.

4. Saw blades should always be kept sharp. It is recommended that you locate a reputable

sharpening service to sharpen your blades when needed.

CAUTION: Abrasive wheels or blades (including diamond) should not be used on this saw.

Riving Knife Selection (Fig. 29, 30)

WARNING: To minimize the risk of kickback and to insure proper cutting, the riving knife

must be the proper thickness for the blade used.

The riving knife supplied with this table saw is the correct size for the blade supplied with the

saw.

If a different blade is used, check the blade body, or plate, thickness and the blade kerf, or

cutting, width marked on the blade or on the blade packaging. The riving knife thickness must

be greater than the body thickness and less than the kerf width as shown in Figure 29. If it is

not, the riving knife MUST be replaced with one that has the correct thickness.

FIG. 30

RIVING KNIFE

THICKNESS

KERF WIDTH

(WIDTH OF CUT

MADE BY THE

BLADE)

BODY (OR PLATE)

THICKNESS OF

THE BLADE

FIG. 29

The riving knife provided with this saw is marked as follows (Fig.30):

0.09" (2.3mm) THICK RIVING KNIFE. ONLY USE FOR 10" (254mm) Ø BLADE WITH

0.09" (2.3mm) MIN. KERF WIDTH AND 0.067" (1.75mm) MAX. BODY THICKNESS.

DeWALT blade body thickness and kerf widths are provided at www.DeWALT.com.

If a different blade is used and the body thickness and kerf width dimensions are not provided,

use the following procedure to determine the correct riving knife thickness:

1. Measure the body thickness of the blade.

2. Make a shallow cut in scrap material and

FIG. 31

measure the kerf width.

3. Select the riving knife as shown in Figure 31.

4. Slide the riving knife through the shallow cut

made in step 2 to confirm the correct riving

knife has been selected. The riving knife

should not bind or drag through the cut.

IMPORTANT: If any dragging or binding of the

material is encountered as it reaches the riving

knife, turn unit off and disconnect machine from

power source. Repeat steps 1–4 to make the

proper riving knife selection before attempting

another cut.

KICKBACK

Kickback is a dangerous condition! It is caused by the workpiece binding against the blade.

The result is that the workpiece can move rapidly in a direction opposite to the feed direction.

During kickback, the workpiece could be thrown back at the operator. It can also drag the

operator’s hand back into the blade if the operator’s hand is at the rear of the blade. If kickback

occurs, turn the saw OFF and verify the proper functioning of the riving knife, anti-kickback

assembly and blade guard assembly before resuming work.

WARNING: See Additional Safety Rules for Table Saws and follow all warnings

provided regarding KICKBACK.

OPERATION

WARNING: Before using the saw, verify the following each and every time:

1. ALWAYS wear proper eye, hearing and respiratory equipment.

2. Blade is tight.

3. Bevel angle and height lock knobs are tight.

4. If ripping, ensure fence lock lever is tight and fence is parallel to the blade.

5. If crosscutting, miter gauge knob is tight.

6. The blade guard assembly is properly attached and the anti-kickback assembly is

functioning.

7. ALWAYS inspect the blade guard assembly and riving knife for proper alignment,

operation and clearance with saw blade.

8. ALWAYS make sure both guards are in the down position in contact with the table

before operating.

Failure to adhere to these common safety rules can greatly increase the likelihood of injury.

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or changing set-

ups or when making repairs. An accidental start-up can cause injury.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the blade guard assembly and riving knife for proper operation alignment and

clearance with saw blade. Personal injury may result.

Page 13

13

English

WARNING: Ripping or crosscutting may cause saw to tip over while operating. Make sure

saw is securely mounted to a stable surface.

WARNING: Never use the fence and miter gauge together. This may cause a kickback

condition and injure the operator.

CAUTION: If your saw makes an unfamiliar noise or if it vibrates excessively, cease

operating immediately, turn unit off and disconnect from power source until the problem has

been located and corrected. Contact a

DeWALT factory service center, a DeWALT authorized

service center or other qualified service personnel if the problem can not be found.

CAUTION: The proper throat plate must be in place at all times to reduce the risk of a

thrown workpiece and possible injury.

There are two basic types of cutting with table saws: ripping and crosscutting. Cutting

with the grain is ripping and cutting against the grain is crosscutting. With man made

materials, the distinction is made such that ripping is cutting to a different width and

crosscutting describes cutting material across the shorter dimension.

WARNING: When ripping, always use the fence to provide a guide for the material and

blade guard assembly against a kickback situation.

WARNING: Never perform any cutting operation free hand. Never perform plunge cutting.

CAUTION: When crosscutting, always use the miter gauge.

Ripping (Fig. 32)

WARNING: Never touch the “free end” of the workpiece or a “free piece” that is cut off, while

the power is ON and/or the saw blade is rotating. Piece may contact the blade resulting in a

thrown workpiece and possible injury.

WARNING: A rip fence should ALWAYS be used for ripping operations to prevent loss of

control and personal injury. NEVER perform a ripping operation freehand. ALWAYS lock the

fence to the rail.

WARNING: When bevel ripping and whenever possible, place the fence on the side of the

blade so that the blade is tilted away from the fence and hands. Keep hands clear of the blade

and use a push stick to feed the workpiece if there is less than 6" (152 mm) between the fence

and the blade.

1. Lock the rip fence by pressing the rail lock lever down. Remove the miter gauge.

2. Raise the blade so it is about 1/8" (3.2 mm) higher than the top of the workpiece.

3. Hold the workpiece flat on the table and against the fence. Keep the workpiece about 1"

(25.4 mm) away from the blade.

CAUTION: The workpiece must have

FIG. 32

a straight edge against the fence and

must not be warped, twisted or bowed.

Keep both hands away from the blade

and away from the path of the blade.

See proper hand position in Figure 32.

4. Turn the saw on and allow the

blade to come up to speed. Both

hands can be used in starting the

cut. When there is approximately

12" (305 mm) left to be ripped, use

only one hand, with your thumb

pushing the material, your index and second finger holding the material down and your

other fingers hooked over the fence. Always keep your thumb along side your first two

fingers and near the fence.

5. Keeping the workpiece against the table and fence, slowly feed the workpiece rearward

all the way through the saw blade. Continue pushing the workpiece until it is clear of the

blade guard assembly and it falls off the rear of the table. Do not overload the motor.

6. Never try to pull the workpiece back with the blade turning. Turn the switch off, allow the

blade to stop, raise the anti-kickback teeth on each side of the riving knife if necessary and

slide the workpiece out.

7. When sawing a long piece of material or a panel, always use a work support. A sawhorse,

rollers, or out feed assembly provides adequate support for this purpose. The work

support must be at the same height as the saw table.

CAUTION: Never push or hold onto the “free” or “cut off” side of the workpiece.

Ripping Small Pieces (Fig. 33)

It is unsafe to rip small pieces.

FIG. 33

U

It is not safe to put your hands

close to the blade. Instead, rip

a larger piece to obtain the

desired piece. When a small

width is to be ripped and the

hand cannot be safely put

between the blade and the rip

fence, use one or more push

sticks. A pattern is included at

the end of this manual to make

push sticks. A push stick (U) is

included with this saw,

attached to the rip fence. Use

the push stick(s) to hold the

workpiece against the table and fence, and push the workpiece fully past the blade. See

Figure33.

Narrow Rip Auxiliary Fence (Fig. 34–36)

The narrow rip auxiliary fence should be used for a rip measuring 2" (50.8mm) or narrower.

This fence will allow the guard to remain on the saw when completing narrow ripping. This

fence will provide ample space for proper use of a push block (A12, see Push Block).

1. Follow the diagram in Figure 34 to construct the narrow rip auxiliary fence (A13, Fig. 36).

NOTE: A11 should be cut to fit the length of the saw table top and sides (A14) must be

parallel.

3/8"

(9.5 mm)

1"

(25 mm)

1/2"

(12.7 mm)

FIG. 34

A14

A11

4-3/4"

(121 mm)

3/8"

(9.5mm)

2. After the narrow rip auxiliary fence is constructed, slip it over the saw table top and place

it flush to the fence as shown in Figure 36.

Page 14

14

English

3. Feed the workpiece through until the edge of the material reaches the front edge of the

saw table top.

4. Continue feeding the material using the push block (A12) until the cut is complete.

Push Block (Fig. 35, 36)

IMPORTANT: Only use the push block (A12) with the narrow rip auxiliary fence, see Narrow

Rip Auxiliary Fence. The push block should be used once the material being cut reaches

the saw table top.

1. Construct a push block using the diagram in Figure 35.

NOTE: Edges (A15) must be the same size.

IMPORTANT: The over hanging edge (A16, Fig. 35) MUST be square. An uneven lip

could cause the push block to slip or push the material away from the fence.

12

"

(305mm)

A12

A15

FIG. 35

A16

2-1/2" (64mm)

5"

(127 mm)

1/2"

(12.7 mm)

4-3/4"

(121 mm)

12"

(305 mm)

1/2"

(12.7 mm)

5-1/4"

(133 mm)

2-1/2"

(64 mm)

1/2"

(12.7 mm)

2. Place the push block (A12, Fig. 36) behind the material and ensure the lip of the block is

flush to the narrow rip auxiliary fence (A13).

3. Once the push block is in place, continue feeding the material until the cut is complete

making sure the push block remains flush to the narrow rip auxiliary fence at all times.

IMPORTANT: The narrow rip auxiliary fence and the over hanging edge (A16, Fig. 35) should

both be the same thickness.

FIG. 36

A12

A13

Bevel Ripping (Fig. 37)

This operation is the same as ripping

FIG. 37

except the bevel angle is set to an

angle other than zero degrees.

WARNING: Before connecting the

table saw to the power source or

operating the saw, always inspect the

blade guard assembly and riving knife

for proper alignment and clearance

with saw blade. Check alignment after

each change of bevel angle.

Crosscutting (Fig. 38)

WARNING: NEVER touch the “free

end” of the workpiece or a “free piece” that is cut off, while the power is ON and/or the saw

blade is rotating. Piece may contact the blade resulting in a thrown workpiece and possible

injury.

WARNING: To reduce the risk of injury, NEVER use the fence as a guide or length stop

when crosscutting.

WARNING: NEVER use a length stop on the free end of the workpiece when crosscutting.

In short, the cut-off piece in any through-sawing (cutting completely through the workpiece)

operation must never be confined — it must be allowed to move away from saw blade to

prevent contact with blade resulting in a thrown workpiece and possibly injury.

WARNING: Use caution when starting the cut to prevent binding of the guard against the

workpiece resulting in damage to saw and possible injury.

CAUTION: When using a block as a cut-off gauge, the block must be at least 3/4"

(19 mm) thick and is very important that the rear end of the block be positioned so the

workpiece is clear of the block before it enters the blade to prevent contact with blade resulting

in a thrown workpiece and possibly injury.

1. Remove the rip fence and place the miter

FIG. 38

gauge in the desired slot.

2. Adjust the blade height so that the blade

is about 1/8" (3.2 mm) higher than the

top of the workpiece.

3. Hold the workpiece firmly against the

miter gauge with the path of the blade in

line with the desired cut location. Keep

the workpiece an inch or so in front of

the blade. KEEP BOTH HANDS AWAY

FROM THE BLADE AND THE PATH OF

THE BLADE (Fig. 38).

4. Start the saw motor and allow the blade

to come up to speed.

5. While using both hands to keep the workpiece against the face of the miter gauge, and

holding the workpiece flat against the table, slowly push the workpiece through the blade.

See Figure 38.

6. Never try to pull the workpiece with the blade turning. Turn the switch off, allow the blade

to stop, and carefully slide the workpiece out.

CAUTION: Never touch or hold onto the “free” or “cut off” end of the workpiece.

Page 15

15

English

Bevel Crosscutting (Fig. 37)

This operation is the same as crosscutting except that the bevel angle is set to an angle other

than 0°. For proper hand position, refer to Figure37.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the blade guard assembly and riving knife for proper alignment and clearance

with saw blade. Check alignment after each change of bevel angle.

Mitering (Fig. 39)

WARNING: Miter angles greater than

FIG. 39

45˚ may force the blade guard assembly

into the saw blade causing damage to

the blade guard assembly and personal

injury. Before starting the motor, test the

operation by feeding the workpiece into

the blade guard assembly. If the blade

guard assembly contacts the blade,

place the workpiece under the blade

guard assembly, not touching the blade,

before starting the motor.

CAUTION: Certain workpiece

shapes, such as molding may not lift the

blade guard assembly properly. Feed

the workpiece slowly to start the cut. If the blade guard assembly contacts the blade, place

the workpiece under the blade guard assembly, not touching the blade, before starting the

motor.

This operation is the same as crosscutting except the miter gauge is locked at an angle other

than 0°. Hold the workpiece FIRMLY against the miter gauge and feed the workpiece slowly

into the blade (to prevent the workpiece from moving). See Figure 39.

Miter Gauge Operation

To set your miter gauge, loosen the lock handle and move the miter gauge to the desired

angle.

Compound Mitering

This is a combination of bevel crosscutting and mitering. Follow the instructions for both

bevel crosscutting and mitering.

Featherboard Construction (Fig. 40, 41)

Featherboards are used to keep the work in contact with the fence and table, and help

prevent kickbacks. Dimensions for making a typical featherboard are shown in Fig. 40. Make

the featherboard from a straight piece of wood that is free of knots and cracks. Clamp the

featherboard to the fence and table so that the leading edge of the featherboard will support

the workpiece until the cut is complete (Fig. 41). An 8" (203 mm) high flat board can be

clamped to the rip fence and the featherboard can be clamped to the 8" (203mm) high board.

WARNING: Use featherboards for all non-thru-sawing operations where the blade guard

assembly, anti-kickback assembly and riving knife cannot be used. Always replace the

blade guard assembly, anti-kickback assembly and riving knife when the non-thrusawing operation is complete. Make sure the featherboard presses only on the portion of

the workpiece in front of the blade.

60º

FIG. 40

24" (610mm)

5" (127mm)

3/4"

(20mm)

THE KERF

SHOULD BE

ABOUT 1/4"

(6.4mm) APART

4"

(102mm)

FIG. 41

Dado Cutting

CAUTION: Do not attempt to stack dado blades thicker than 13/16" (20mm). Do NOT use

adjustable or wobble type dadoes. Do not use dado blades larger than 6" (152.4 mm)

diameter. The maximum dado cut width is 1/2" (12.7mm).

Since dado cuts are not through cuts, the cuts must be performed with the blade

guard assembly removed. To remove the blade guard assembly, refer to Remove

Blade Guard Assembly under Assembly.

When using the dado, the special dado insert (also sold as an accessory) must be used.

Anytime a cut is required that is considerably wider than the saw kerf, a dado is used. A dado

cut is commonly used to add support and line up a shelf for a cabinet, bookcase or some

such project. When using the dado, the blade guard assembly must be removed. Use

EXTREME care when using the dado without the blade guard assembly and riving

knife. If a deep cut is required. Use several successive passes rather than attempting to make

it with one pass. Maximum dado width on this saw is 1/2" (12.7mm). DO NOT USE WIDER

COMBINATIONS.

Page 16

16

English

CAUTION: Always check dado blade clearance before plugging in the saw.

Be sure to place the blade guard assembly and standard throat plate back in position

and check adjustments when the dado cuts are complete. Reinstall blade guard

assembly, anti-kickback assembly and riving knife.

Dust Collection (Fig. 42)

S

FIG. 42

VV

A5

T

Your table saw is equipped with a dust shroud

(T) and dust collection port (S). For best results,

connect a vacuum to the port at the rear of

the saw.

After extended use, the saw’s dust collection

system may become clogged. To clear the dust

collection system:

1. Unplug the saw.

2. Turn the saw on its side, so the bottom,

open part of the unit is accessible.

3. Open the dust access door A5) shown in

Figure 42 by removing the screws (V V).

Clean out the excess dust, and re-secure

the access door with the screws.

Storage (Fig. 4, 43)

1. Place blade wrenches (R). into storage slot.

2. Place push stick (U) into storage bracket as

shown.

3. Slide rip fence (E) into storage bracket

4. Mitre gauge (B) is stored in slot on fence

storage bracket.

5. Wrap power cord onto cord wrap (O) and

secure in place.

FIG. 43

U

R

E

B

MAINTENANCE

WARNING: To reduce the risk of injury, turn unit off and disconnect tool from

power source before installing and removing accessories, before making any

adjustments or removing/installing attachments or accessories. An accidental start-up

can cause injury.

Your D

eWALT power tool has been designed to operate over a long period of time with a

minimum of maintenance. Continuous satisfactory operation depends upon proper tool care

and regular cleaning.

Cleaning

WARNING: When cleaning, use only mild soap and a damp cloth on plastic parts. Many

household cleaners contain chemicals which could seriously damage plastic. Also, do not use

gasoline, turpentine, lacquer or paint thinner, dry cleaning fluids or similar products which may

seriously damage plastic parts. Never let any liquid get inside the tool; never immerse any part

of the tool into a liquid.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including

brush inspection and replacement) should be performed by authorized service centers or other

qualified service personnel, always using identical replacement parts.

Lubrication

1. All motor bearings are permanently lubricated at the factory and no additional lubrication

is needed.

2. The height adjustment gear may require periodic cleaning and lubrication. If you have

difficulty raising or lowering the blade, contact a

DeWALT authorized service center.

Accessories

WARNING: Since accessories, other than those offered by DeWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the

risk of injury, only D

eWALT, recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center.

Protecting the Environment

Separate collection. This product must not be disposed of with normal household

waste.

Should you find one day that your

DeWALT product s replacement, or if it is of no further use

to you, do not dispose of it with household waste.

Separate collection of used products and packaging allows materials to be recycled

and used again. Re-use of recycled materials helps prevent environmental pollution

and reduces the demand for raw materials.

Local regulations may provide for separate collection of electrical products from the household,

at municipal waste sites or by the retailer when you purchase a new product.

DeWALT provides a facility for the collection and recycling of DeWALT products once they

have reached the end of their working life. To take advantage of this service please return your

product to any authorized service center that will collect them on our behalf.

You can check the location of your nearest authorized service center by contacting your

local

DeWALT office. Alternatively, a service center listing is included in the packaging of this

product.

SPECIFICATIONS

DWE7470-B1

Voltage: 220-240 V ~

Frequency: 50/60 Hz

Current Rating: 1800 W

RPM without load: 5 000/min

N441911 07/2015

Page 17

Loading...

Loading...